Move your dry granular materials gently, reliably and with significant reductions in product degradation and/or system wear.

Dynamic Air dense phase pneumatic conveying systems have been proven in over 15,000 installations worldwide. They handle a wide range of materials and bulk densities at rates from less than a hundred kilograms per hour to 400 tonnes per hour, over distances exceeding 1500 metres.

Each Dynamic Air system is custom designed from one of our sixteen different conveying concepts. So you get a conveying solution that fits your process perfectly, without compromises.

Our high material-to-air ratios reduce energy and compressed air requirements. Our low conveying velocities provide significant process savings in both operation and maintenance. Initial cost is surprisingly affordable too, thanks to our modular design concept and ease of installation.

Dynamic Air Ltd. Milton Keynes United Kingdom

Phone: +44 (0) 1908 622344 E-mail: sales@dynamicair.co.uk www.dynamicair.com

Sales Director: James Scrivens Production: Sarah Daviner Accounts Manager: Avery Hudson Office Manager: Katie Brehm

BULK SOLIDS TODAY is published 6 times a year by Abbey Publishing Ltd

Please contact us at: Tel: 01933 316931 Email: editorial@bulksolidstoday.co.uk advertising@bulksolidstoday. co.uk Web: www.bulksolidstoday.co.uk Twitter: www.twitter.com/ BulkSolidsToday

To receive a copy free of charge, please send your details to subs@bulksolidstoday.co.uk

No part of this publication may be reproduced by any means without prior permission from the publishers. The publishers do not accept any responsibility for, or necessarily agree with, any views expressed in articles, letters or supplied advertisements.

ISSN: 1365/7119

All contents © Abbey Publishing Ltd 2017

www.bulksolidstoday.co.uk

Roger Bullivant Limited is a renowned name in foundation engineering, specialising in the design and construction of foundations for all types of buildings and structures in a range of different ground conditions. As part of the company’s continuous work to provide its customers with the best solutions available, Roger Bullivant Limited has chosen National Pile Croppers to supply its leading range of pile cropping solutions.

As a specialist in its field, Roger Bullivant Limited is an industry acknowledged expert in the design and construction of foundations for all types of buildings and structures for a range of different ground condition. The company offers a wide range of services ranging from foundations, piling, restricted access, and ground improvement. With a long history of industry experience, its clients have chosen to work with the company due to its unrivalled in-house capabilities, which includes a state-of-the-art manufacturing plant, in-house geotechnical drawings, patented solutions,

all designed and developed by the acclaimed research and design division in order to provide leading economical and sustainable solutions. The company undertakes projects within the commercial, residential, infrastructure, and rail sectors, with clients including national government, local authorities, transport bodies, hospitals, universities, housing providers, utilities, and private/public companies in every sector.

Roger Bullivant Limited ethos is to work in collaboration with its clients, from start to finish. This allows the company to provide an integrated service from enquiry through to construction. This operating philosophy also extends to its relationship with its suppliers of equally industry leading solutions. Reinforcing this ethos, Roger Bullivant Limited has recently launched a video showing its work throughout the UK. The video features extensively another acknowledged industry expert, National Pile Croppers, whose pile cropping solutions are now used by Roger Bullivant Limited on numerous projects.

Simon Price, managing director of National Pile Croppers comments: “We’ve worked with Roger Bullivant Limited on numerous projects for many years, but we were highly flattered to have our leading pile cropping solutions featured in the

company’s new video outlining its services and solutions. We worked closely with them to show how our pile croppers can provide unrivalled levels of productivity, efficiency and safety, working on piles of any kind.

“To be chosen by a company of Roger Bullivant Limited standing as a partner company reaffirms National Pile Croppers’ position as a leader in the manufacture, supply and design of pile croppers. We know that Roger Bullivant Limited only uses the best, and by choosing to work with us, we know we’ve made the grade.”

With a management team with over 100 years of experience in the piling industry, an innovative in-house developed and manufactured product line and with a focus on personal service, National Pile Croppers has been one of the construction industry’s best kept secrets. From its base in the heart of England, the company has gone from strength to strength developing, manufacturing and supplying its own line of patented customer focused pile cropping solutions to a wide variety of customers globally.

NATIONAL PILE CROPPERS

Website: www. nationalpilecroppers.com Facebook: www.facebook. com/nationalpilecroppers LinkedIn: www.linkedin.com/ company/national-pile-croppersltd/ Twitter: twitter.com/ NatPileCropper

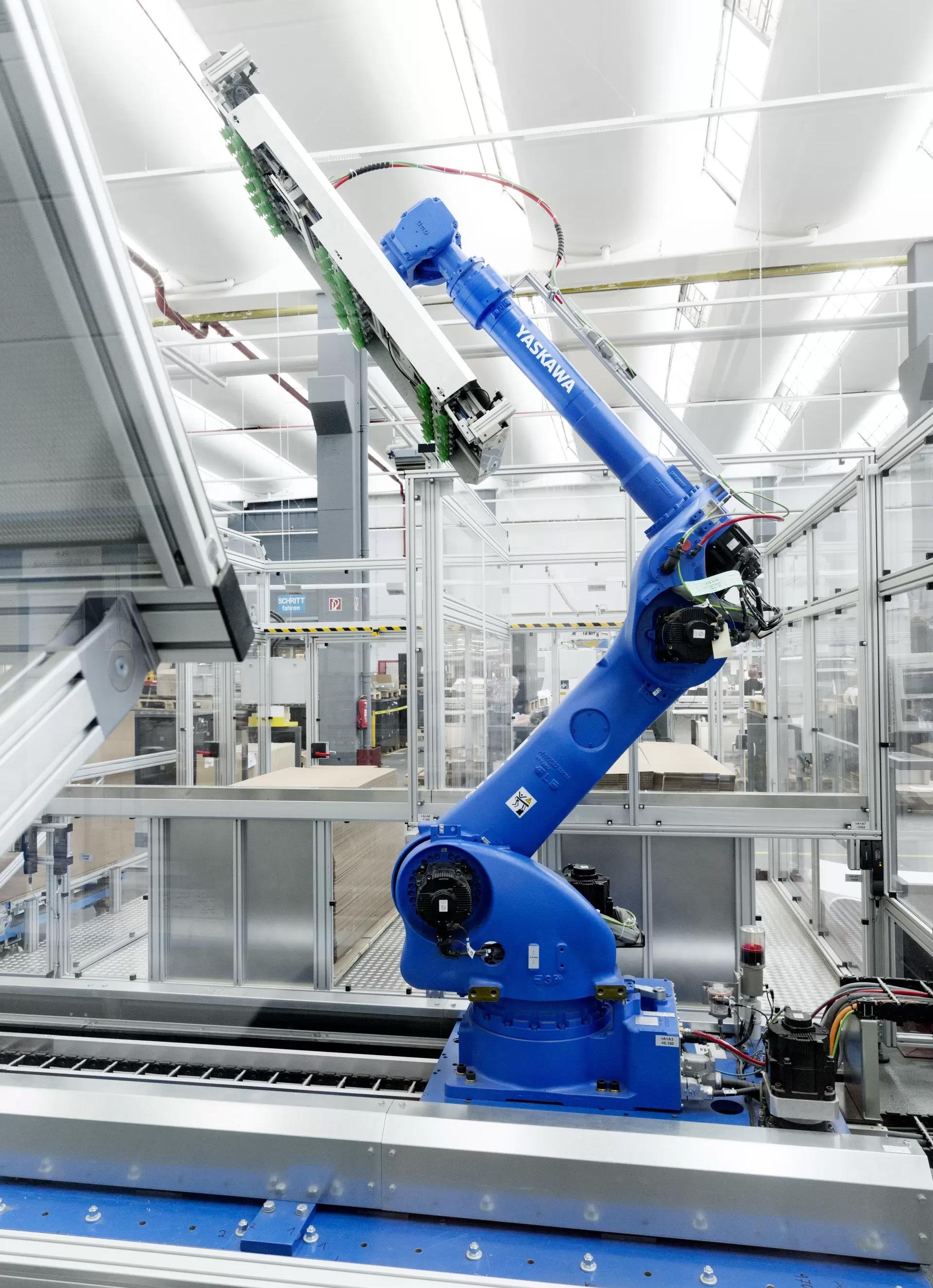

Reducing energy consumption in today’s highly competitive industrial environment is likely to be higher on most, if not all of today’s manufacturers’ agendas, especially due to current higher energy costs. With automation playing an increasingly important role in many applications maximising the efficiency of robots will be of significant interest across all manufacturing sectors.

Features such as regenerative braking can make a big difference to the efficiency of robots,

recovering braking energy and feeding it back into the power grid without the need for additional hardware. Motion control and Robotics specialists YASKAWA has developed an important solution for the recovery of robot braking energy and offers this feature as standard on its larger Motoman robot’s with a payload upwards of 50kg. Their latest YRC1000 robot controls are able to convert kinetic energy from the down and sideways movements directly into

400V AC at 50 Hz and feed in back into the grid. Depending on the movement pattern of the application, the robot’s energy requirements can be significantly reduced.

In applications such as handling, palletising, joining and processing, industrial robots make many down or sideway movements during which the servomotors dissipate energy thereby potentially generating electricity. Up until now, in older or other robot models on the market, the resulting energy has been converted to waste heat by control technology through electrical resistance and lost to the environment. In the Yaskawa solution the electric energy is fed back into the operator network – without the need for additional hardware so it can be re-used.

The extent of savings obviously depends on the specific application and the robots individual movement patterns, although realistically savings ranging from 8 to 25% can be anticipated which may result in annual feed-ins of about 2,800 kWh, equivalent to around 1600 kg CO2 and £1200.

This regenerative braking feature represents a unique technical solution with Yaskawa applying its experience as a leading global manufacturer of drive technology including servo drives and control packages which can be specifically tailored to industrial robots. In addition, the slim and compact design of Motoman robots with low moving masses and fast application of brakes during movement intervals enables the active position control to be switched off when not in use which increase the potential for greater efficiency.

More at: https://www. yaskawa.eu.com/header-meta/ news-events/article/yaskawarobots-with-regenerative-braking_ n18865.

Want to optimize your manufacturing processes with the best components? Or accommodate a new formulation or new application while boosting production?

Let the Alfa Laval Fluid Handling Application & Innovation Centre conduct trials under near-actual operating conditions to determine how to achieve the best outcomes.

Faced with a tight construction time frame, a leading soft drink manufacturer asked Alfa Laval to select equipment for a new mixing processing line. After analyzing the shear-sensitive syrup formulation and testing mixing equipment under actual operating conditions, our experts found the Alfa Laval Rotary Jet Mixer delivered superior performance compared with conventional agitators.

Installing the right equipment ensures more uptime, higher productivity and yields, and sustainable cost savings. The Application & Innovation Centre determined the Rotary Jet Mixer reduced mixing time from 20 minutes using their conventional agitators to just two minutes while ensuring the formulation’s structural ingrity.

“Using the right equipment and components boosts productivity, reduces costs and enhances your sustainability profile,” says Murat Boztepe, Global Beverage Industry Manager, Alfa Laval.

• Get proof of performance with validated test results

• Raise process efficiency and yield by choosing the right components from the start

• Reduce costs for capital investment, utilities and cleaning media

• Enhance product safety

Advice from experts at the Alfa Laval Application & Innovation Centre helps you quickly pivot and adapt to increased demand or changing needs – regardless of application or industry.

Sign up for a free trial to enhance process performance while safeguarding product safety and quality.

Unlike other valves that seal with friction, Posi-flate’s unique butterfly valve uses an inflatable seat to seal with air pressure. Thus it requires less torque and a smaller actuator, resulting in lower cost. Plus, the seat automatically compensates for wear, providing longer life. Some users have reported over six million cycles and the valves are still going strong.

Tel: +44 (0) 1908 622366 www.posiflate.com

At Bauma, Doosan demonstrated ‘TeleOperation’ of the company‘s new DX225LC7X ‘Smart’ crawler excavator working in the Demo Area on the stand.

Doosan defines TeleOperation as the operation of construction equipment from a remote station. At the last Bauma, Doosan created one of the highlights of the show, when the company provided the first demonstration of 5G technology for worldwide TeleOperation of construction machines. This entailed operating a Doosan DX380LC-5 40 tonne crawler excavator located over 8500 km away in South Korea, from an operator’s booth on the Bauma stand in Munich.

One of the reasons for the huge distance between the machine and operator at Bauma 2019 was the lack of availability

of 5G technology at the time in Europe. Three years on, 5G is now fully implemented in Europe so at this year’s show, visitors were able to see all of the parts of the operatlon live on the stand, with the DX225LC7X being teleoperated by an operator in a booth in the Innovation Center.

As Doosan’s first Smart crawler excavator, the DX225LC-7X is designed to help operators work faster and more efficiently. The DX225LC7X offers a number of exciting features as standard, including Full Electric Hydraulic (FEH) technology. As well as the FEH system, other standard features of the DX225LC-7X include integrated 2D machine guidance and machine control systems, as

well as an e-Fence Virtual Wall. In the latest development, the DX225LC-7X is now 3D Trimbleready and Engcon ready as standard from the factory. Once the machine has been delivered to the customer, they can simply contact their local Trimble dealer for a 3D extension, as well as their local Engcon dealer to install a tiltrotator.

The integrated machine guidance system on the DX225LC-7X uses sensors mounted on the front and body to recognize the location of each working device and inform/guide it for the operator. Feedback to the operator is provided through audio and visual displays which allow improved control of the machine in relation to the intended or

designed direction of travel.

There are three major Machine Control functions, and they can be activated by pushing the appropriate function button:

• Grade Assist

• Lift Assist and Weighing system

• Virtual e-fence – to limit the excavator with the maximum height/depth/reach and swing angle in both directions.

Full Electric Hydraulic (FEH) technology is similar to the D-ECOPOWER VBO (virtual bleed off) system now incorporated on the standard DX225LC-7 model and all Doosan crawler excavators from the DX300LC-7 and above. In effect, the FEH is a VBO system without pilot pressure lines. The joysticks and pedals are fully

electric, but give the operator the same feeling as hydraulic joysticks.

In the FEH system, an electric signal is sent to the central controller and as such is more precise and provides faster information. Back pressure and energy loss are therefore eliminated, by delivering the exact amount of oil needed. As the system does not utilise pilot pressure, energy is saved and there is a resultant fuel saving.

In fact, the FEH system offers a significant 8% less fuel burn compared to the D-ECOPOWER VBO system. This is on top of the

7% decrease in fuel consumption already achieved in the standard DX225LC-7, compared to the previous DX225LC-5 model.

For more on Doosan construction equipment, please visit the website: www. eu.doosanequipment.com

Kansas Governor Laura Kelly announced that Vortex Companies has received the highest honor a business can receive in the State of Kansas, The Governor’s Award of Excellence. The announcement was made Thursday, October 20, at the To the Stars Banquet in Topeka, which honored 237 businesses, including 181 Merit Award winners, 56 regional award winners, and nine state-wide award winners.

“Vortex Companies exemplify what Kansas has become – a state where innovation thrives and businesses can grow and succeed,” Governor Laura Kelly said. “All of the To the Stars award-winners deserve credit for their significant contributions to Kansas’ recordbreaking economy.”

Nominees were reviewed and scored for various criteria such as business expansion, employee recruitment and retention practices, training and educational programs, capital investments, and support of local community events.

The 2022 Governor’s Award of Excellence winner, Vortex Companies, was founded in 1977 in Salina, Kansas. Vortex specializes in the design and manufacture of components for the transport and flow control of dry bulk solids. With a global service network that spans more than 120 countries, Vortex delivers global solutions through localized relationships to more than 20,000 companies.

“On behalf of our entire team and Vortex Companies, it is an incredible honor to receive this award. There are many great companies in this State, and it is humbling to be considered one of the best. The dry bulk material processing industry is strong in Kansas, not only from an industry point-of-view, but from an educational one

as well. Vortex is proud to be a representative of that economic aspect of our State,” Vortex President and CEO Travis Young said.

Dry bulk solids handling was first introduced as a concept in the 1940s, primarily focused on flour. The city of Salina has a rich history in the industry dating back to the 1950s when the Heath Holsom Bakery began testing pneumatic conveying of flour. In 1961, Neil Peterson, founder of Vortex Global, began developing formulars for conveying materials other than flour.

Peterson developed a process to test conveying products with just a quart size sample. In 1977, Peterson and Lee Young, chairman of the board, founded Salina Vortex Corporation. Over the next four decades, Vortex would grow to become a global company handling dry bulk solid materials across a variety of industries.

This is the third Governor award that Vortex has received. Travis Young also received the Welcome Back Award this year. The Welcome Back Award recognizes entrepreneurs who left Kansas but have returned to make their mark in the Sunflower State. Young moved to the United Kingdom in 2008 to establish a European office for Vortex. After successfully launching the office and hiring key employees, Young and his family returned to Kansas in 2017.

Vortex has also won the Governor’s Exporter of the Year Award in 2008. The Governor’s Exporter of the Year award is presented annually to a single Kansas company that has demonstrated excellence in export sales and international marketing. The award recognized Vortex as a company committed to expanding sales in international markets and showcased it as a role model to other Kansas companies seeking similar success.

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our websitewww.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/ Distribution, Recycling & Waste Management and more. www.bulksolidstoday.co.uk bst@abbeypublishing.co.uk

Tuf-Lok ring grip pipe and tube couplings are rugged, heavy duty, self-aligning and self-grounded couplings with a high end pull. They can be used for almost any application where pipe or tube ends need to be connected. The Tuf-Lok self-aligning couplings install quickly and easily with little effort.

Features

Self-grounding

High pressure rated

Full vacuum rated

Stainless or mild steel

Usable on thin or thick wall pipe or tube

Low cost

Reusable

Absorbs vibration

Externally leakproof

Tuf-Lok (UK) Tel: +44 (0) 1706 822512 Email: sales@tuflok.co.uk • www.tuflok.com

In the ongoing battle against cyber criminals, a high level of data protection from malicious activities is crucial for engineering businesses and their customers. In the last couple of years, the UK has suffered the third-highest number of ransomware attacks globally, and manufacturing/engineering was one of the most likely sectors to be affected.

More than 40 per cent of businesses targeted opted to pay the ransom, but that doesn’t guarantee immunity from attack. The best course of action is always preventative – and that was the challenge set and met by cloud and data specialist PeaSoup for global engineering supplier Guttridge Ltd (a Mitchells Company).

Guttridge, which provides bulk materials handling solutions for a wide range of industry sectors, was keen to upgrade and future-proof its data protection so selected PeaSoup to implement Veeam Cloud Connect, cloud backup and recovery, for up to 10 of its core servers. The Veeam Cloud Connect service protects against natural and technological disasters, malicious deletion and ransomware.

Guttridge had a high expectation for data protection and therefore the backup and recovery service had to be fully encrypted, include WAN accelerator in case of low bandwidth, and supported by 24/7 monitoring. Additionally, the replica backup needed to be stored in UK tier-3 data centres for data sovereignty.

After an initial consultation, the PeaSoup tech team deployed Veeam Cloud Connect, quickly helping Guttridge to achieve comprehensive data protection for all workloads. This solution included licensing and no ingress or egress bandwidth charges, thus avoiding the costs of a secondary site or dedicated additional bandwidth.

Backups from the production premises (onsite) are then further backed up to a hosted cloud repository (offsite) through a secure SSL connection. The encrypted separation between the production site and the cloud helps to safeguard against ransomware and other cyber threats.

Veeam Cloud Connect service enables Guttridge to prohibit the deletion of data through immutability with Insider Protection, protecting the data from loss as a result of cyber-attacks, malware activity or any other malicious actions. Insider Protection is a standard free-of-charge feature provided by PeaSoup, ensuring that cloud backups are not deleted accidentally or intentionally for seven days. What’s more, this feature doesn’t affect backup storage size (quotas), keeping the costs down.

Encryption keys are held by Guttridge with an extra seven-day protection policy to stop attacks where all

data can be completely deleted, yet still recovered by PeaSoup’s technical support which is available 24/7/365.

Steven Shearer, IT manager at Guttridge, said: “From the initial consultation and understanding of our needs, we have in place the onboarding process, flexibility and fast deployment. PeaSoup provided us with a robust cloud backup which has become part of Guttridge’s continuity planning.”

PeaSoup Head of Marketing, Art Malinowski, added: “We’re delighted that PeaSoup has become a trusted partner for Guttridge with our Backup & Recovery as a Service offering powered by Veeam. Our onboarding actions, preferential charges and technical support helped us to complete implementation quickly and avoid non-conformity. We also increased Guttridge’s storage quotas to now exceed 10TB so they are in a very good place for the foreseeable future.”

Data is the most valuable asset a company has and safeguarding it should be the highest priority. Companies targeted with malware that pay the ransom are usually classified as an “easy target” by cyber criminals. Even if they pay up, there is no guarantee of getting their data back and no guarantee that they won’t be attacked again. Furthermore, compromised company data can result in weighty fines from the Information Commissioner’s Office (ICO).

Art Malinowski concluded: “Succumbing to a malicious attack to the extent that systems go offline can seriously tarnish a company’s image. Guttridge protected its reputation as well as its data assets by combining both local and cloud-based backups to significantly reduce the risk of breaches. Other engineering and manufacturing companies would do well to follow their lead.”

For further information visit https://peasoup. cloud/

The Posi-flate double dump valve assembly is a low cost, low maintenance alternative to the traditional rotary airlock feeder. The air-operated seat inflates to provide a long-lasting high integrity positive seal that that can accommodate either full vacuum or pressure up to 100 PSIG. The Posiflate double dump valve assembly can easily handle high cycling of dry granular or fine powdered materials. The seat automatically compensates for wear when it inflates against the disc, extending valve life considerably. The Posi-flate double dump valve assembly is available in carbon steel and stainless steel in sizes from 2-inch (50mm) to 30-inch (750mm) diameter and in any length desired. Other materials of construction are available upon request.

www.posiflate.com

Posi-flate

Milton Keynes, United Kingdom +44-1908-622366

E-mail: sales@posiflate.co.uk

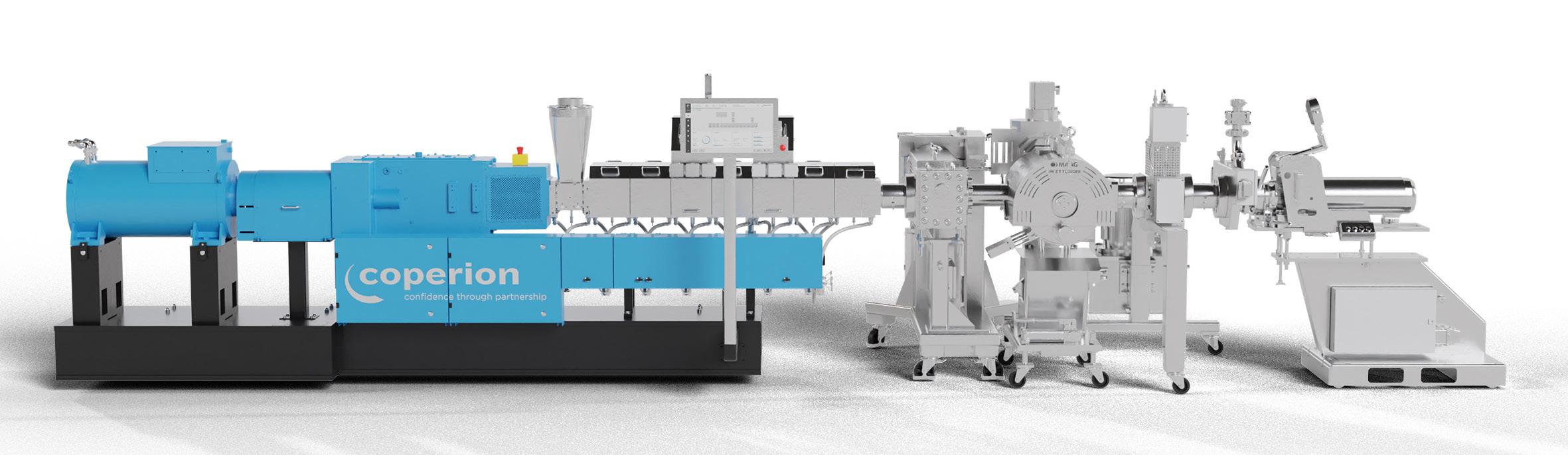

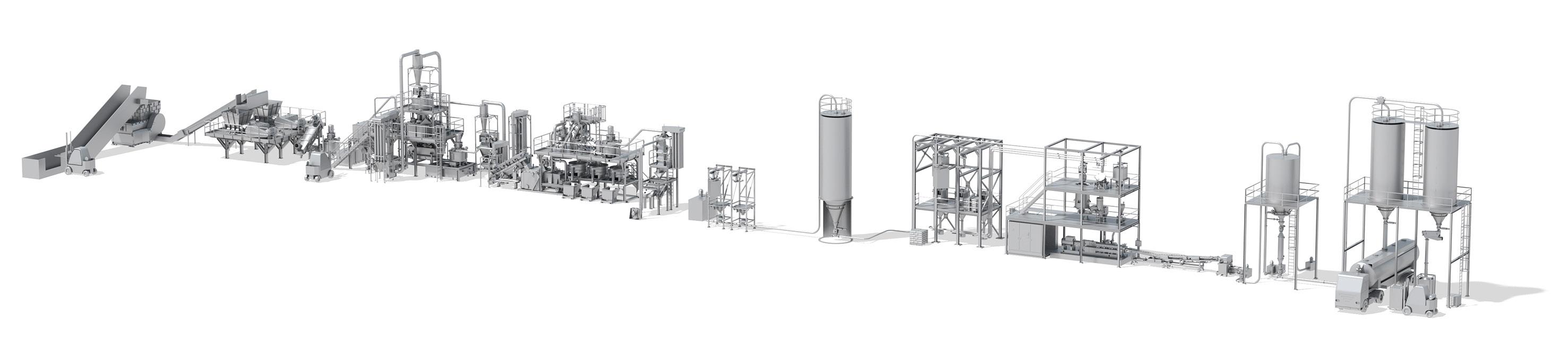

Stuttgart, October 2022 – Complete systems for industrial-scale plastics recycling from a single source – the recently completed merger between Coperion and machine manufacturer Herbold Meckesheim makes it possible. Coperion, technology leader in extrusion and compounding, bulk material handling and feeding systems, brings its own expertise in the field of recycling together with that of Herbold Meckesheim, specialist in the mechanical recycling of plastic and plastic waste, forming a new Recycling Business Unit. This new Business Unit makes innovative process solutions possible that represent a new benchmark in the efforts towards a circular economy in the plastics industry. Coperion is providing a first look at its integrated recycling solutions at K 2022 (19-26 October 2022, Dusseldorf) at its booth 14/B19, at its Recycling Pavilion in the open-air fairgrounds (CE09), and at Herbold Meckesheim’s booth 9/B34.

The newly created Recycling Business Unit is able to offer modular system and plant solutions that combine the complementary technologies of Coperion and Herbold Meckesheim to benefit customers. From mechanical processing – shredding, washing, separating, drying and agglomerating of plastics – to bulk material handling as well as feeding and extrusion all the way to compounding and pelletizing, the systems that both companies have developed together cover the entire process chain for reclaiming plastics. Moreover, the plastics industry will profit from this cumulative expertise thanks to their combined global sales and service network.

PET recycling is one example that illustrates how Coperion will be able to implement a complete system for plastics recycling in the future. As the plastics industry makes advances towards a circular economy, PET plays an ever more important role due to its

increasing use in disposable and reusable bottles and its recovery through deposit systems, along with other factors. This material possesses outstanding recycling properties, regardless of whether it is to be recycled in bottle-to-bottle, bottle-to-film/sheet, or bottle-to-fiber processes, or whether it comes from other product streams.

Complete PET recycling solutions from Coperion offer throughput performance of up to ten tons per hour. The quality of PET recyclate manufactured using Coperion recycling technology and decontaminated in an SSP (Solid State Polycondensation) reactor is so high that it is approved by the U.S. Food and Drug Administration (FDA) for direct contact with food.

One unique feature is that virgin material and various recyclates – such as regrind, agglomerates, or flakes – can be processed together, even if they exhibit different IV (Intrinsic Viscosity) values. Compared to conventional PET recycling procedures, Coperion’s solutions save on operation and energy costs and create less logistic efforts. Visitors to K can see and experience key components of this process at the Recycling Pavilion CE09/open-air fairgrounds and at Herbold Meckesheim’s booth 9/B34.

•

This is a granulator used for crushing PET bottles and is suitable for wet operation. One unique feature that it offers is horizontal force feeding using screw feeders. The granulator allows for space-saving installation and easy material feeding. Up to two tons of polyolefins or more than one ton of film per hour is processed.

•

This mechanical dryer is suitable for various materials such as film, regrind, and mixed and rigid plastics. Thanks to its optimized design and the position of the exchangeable, wear-resistant paddles, it achieves up to 50% higher drying performance than its predecessor.

•

The high-performance HV 70 Plastcompactor from

Herbold Meckesheim processes material in continuous operation between one rotating and one fixed compactor disk, each equipped with screwed-on and easily replaceable kneading bars. Since the material leaves the compactor zone within a fraction of a section, the thermal impact upon the plastic is very low. The process is regulated using two parameters – the screw speed and the distance between the disks.

The FLUIDLIFT ecodry® process dries the regrind while it is being conveyed to the extruder. A flash dryer specially modified for recycling regrind removes the moisture remaining after the washing process. Moisture content is significantly reduced which optimizes the energy consumption of the downstream process and leads to improved end product quality.

For feeding flakes and fiber, a Smart Weigh Belt (SWB) feeder is used. This low-headroom gravimetric feeder can feed large quantities of bulk material into the extrusion process at high accuracy, even at low and variable bulk densities.

Coperion ZSK twin screw extruders are the heart of the plastics recycling process. With their high-performance processing properties and high devolatilization performance, ZSK twin screw extruders are suited to energy-efficient recovery of plastics of all sorts. The ZSK extruder features high end product quality with gentle product handling, short residence time, intensive devolatilization, and outstanding dispersion with concurrently high throughput performance. In the Recycling Pavilion CE09/ open-air fairgrounds, Coperion is showing a ZSK 58 Mc18 twin screw extruder with a 58 mm screw diameter together with a melt pump, screen pack changer, and an underwater pelletizer.

• Product Discharge Diverters, melt pumps, and screen pack changers

follow the extrusion step. Depending upon whether pellets, fiber or film are to be manufactured from the PET, Coperion provides water baths and underwater pelletizers, fiber spinning pumps or film stretching lines as part of their complete solutions.

The start of construction on the state-of-the-art Recycling Innovation Center in June of this year demonstrates the importance of the topic of plastics recycling for the market leader in extrusion and compounding technology. This new test center for recycling applications is located in immediate proximity to Coperion’s existing test center for bulk material handling at its Niederbiegen/Weingarten production facility in Germany. In the future, every major step of the plastics recycling process can be tested under production conditions and results can be examined by customers down to the smallest detail prior to making an investment.

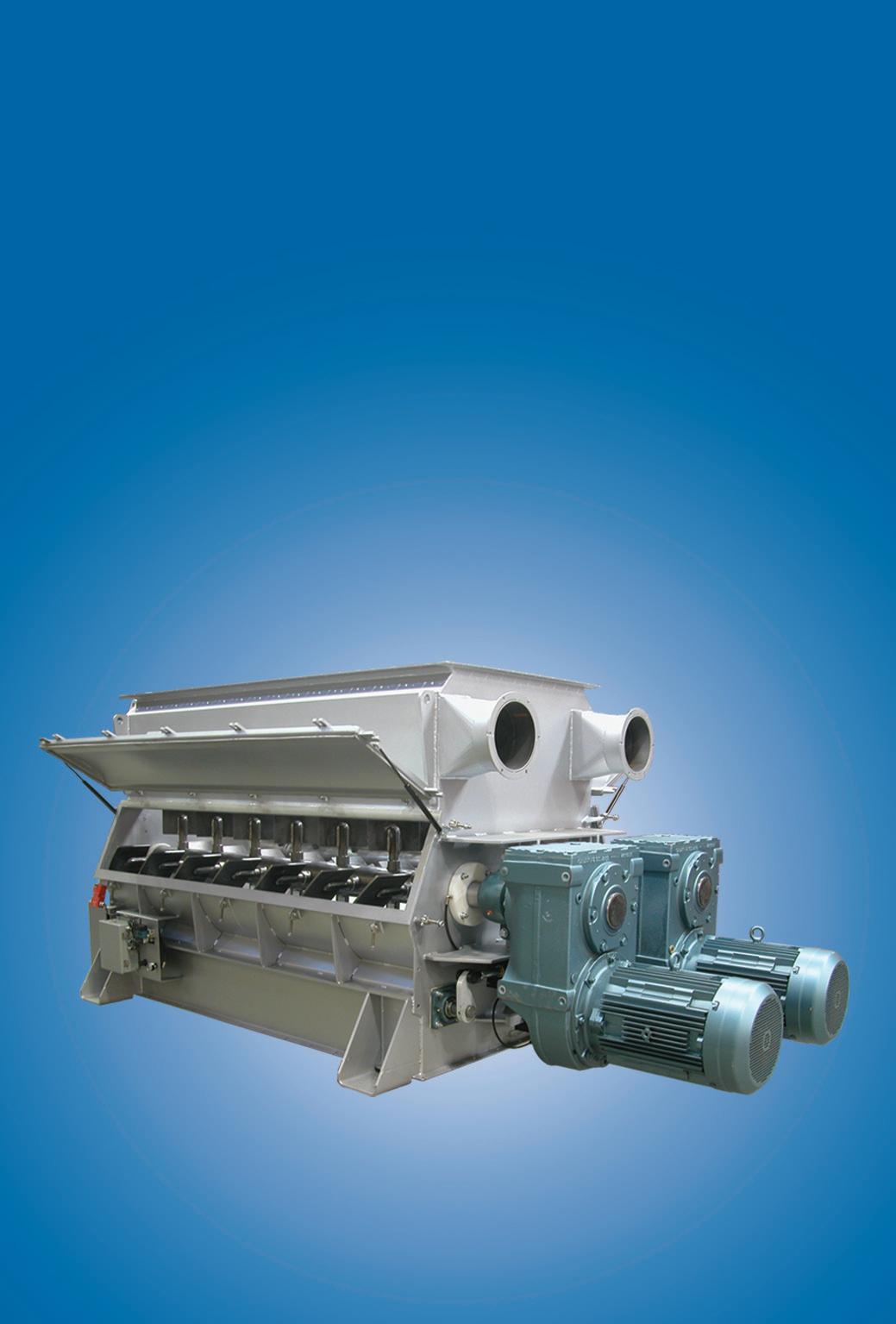

The Bella fluidized zone mixer by Dynamic Air features an original design that achieves fast, high capacity, thorough mixing of dry bulk solids or liquids with solids. Regardless of particle size, shape or density, materials are mixed with a fast, efficient, and gentle action. A weightless zone created by low-speed counter rotating paddles generates very low friction without shear. This makes it ideal for abrasive products and fragile products that cannot tolerate rough handling. Even flakes or spray-dried bodies remain intact.

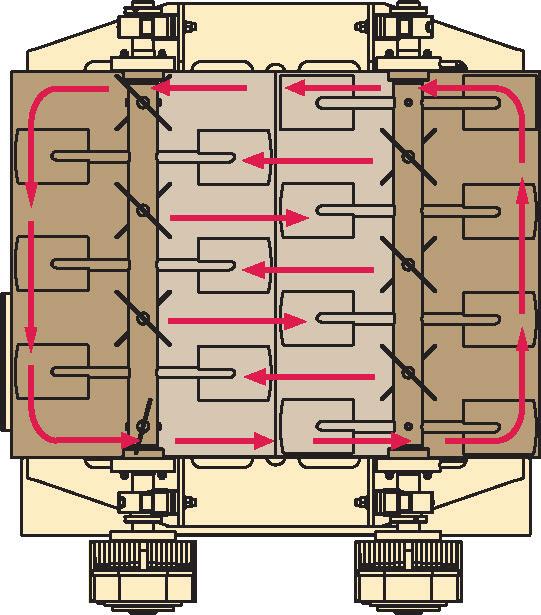

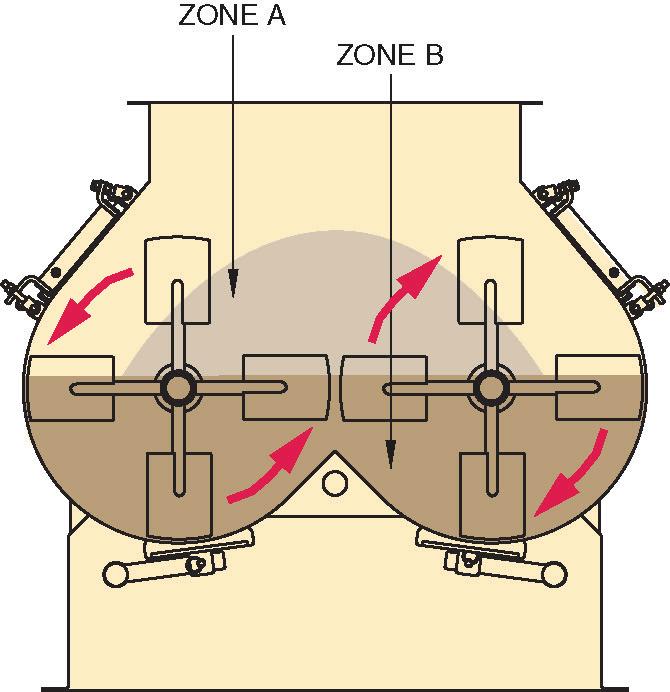

The Bella mixer consists of twin drums which have two counter-rotating agitators with specifically angled paddles. The paddles sweep the entire bottom of both mixer drums and yet allow the mixer to be started under full load (figure 1). The material in the mixer moves in a horizontal counterclockwise direction at the perimeter while simultaneously moving both left and right in the center (figure 2). The material in Zone B (figure 1) is in its normal gravimetric state as it is being moved and disbursed. In Zone A, a weightless zone is created that effectively lifts the ingredients to an almost weightless state allowing them to move freely and randomly, regardless of particle size and density. Thus, the two zones’ interaction becomes highly efficient as every particle moves rapidly to a highly homogenous mix, the key to the

Figure 1

Bella mixing technology for fast, precise mixing. The Bella mixer is available in stainless steel for food applications. Custom sizes, finishes and materials of construction are available upon request. www.dynamicair.com Dynamic Air Ltd Milton Keynes, United Kingdom +44-1908-622344

E-mail: sales@dynamicair.co.uk

Figure 2

A new laboratory-sized Vee Cone Blender from Munson Machinery, model VB-.25-SSXHDI, achieves uniform blends of dry bulk solids, evacuates fully and cleans rapidly.

Two inclined cylinders mounted on pillow block bearings rotate end-over-end at 30 RPM, causing bulk material to fall, converge and divide with each rotation, achieving consistent blends in 15 to 30 minutes typical.

Smooth interior surfaces allow unobstructed material flow, as well as complete discharge for thorough cleaning between changeovers.

The specialized model can blend materials having bulk densities up to 1.6 g/cm3 in capacities up to 7.65 l, and is equipped with an independently powered Intensifier Bar that breaks up soft agglomerates and improves diffusion of materials. Also available is a Dispersion Bar that sprays liquid additions onto the moving materials, minimising cycle times required to achieve batch uniformity.

Housed in a safety-interlocked polycarbonate

enclosure with lifting handles, the unit is constructed of carbon steel with stainless steel material contact surfaces finished to industrial standards. Also offered are all-stainless-steel, sanitary units finished to USDA, 3-A and pharmaceutical standards. Larger Vee Cone Blenders and Double Cone Blenders are available in capacities from 28 to 5,663 l. Other blending equipment offered by the company includes Rotary Batch Mixers, Ribbon/Paddle/Plow Blenders, Fluidised Bed Mixers, Rotary Continuous Mixers and Variable Intensity Blenders. Size reduction machinery includes Pin Mills, Screen Classifying Cutters, Attrition Mills, Lump Breakers, Rotary Knife Cutters, Hammer Mills and Shredders.

For information contact Munson Machinery Company, Inc., +1-315-797-0090, sales@ munsonmachinery.com, www.munsonmachinery. com

Bobcat has expanded the company’s attachment range with the launch of two new BrushcatTM rotary cutter models and a new log grapple attachment for the company’s range of small articulated loaders (SALs).

The new Brushcat attachments offer cutting widths of 1118 and 1372 mm, respectively, and are the smallest models in the full line-up of Brushcat rotary cutters, which offers larger models with cutting widths of 1676, 1829 or 2032 mm.

Like the new smaller Brushcat attachments, the log grapple is compatible with both the Bobcat L23 and L28 SAL models. The log grapple meets the challenging demands of landscaping and site clearing jobs and is ideal for customers seeking maximum productivity by increasing the versatility of their machines. The log grapple can also be used on the new MT100 mini track loader.

Like the larger models, the two new smaller Brushcat attachments deliver powerful cutting and

mulching action in areas of untamed growth and can pass through gates and other narrow entrances to work in areas that are inaccessible to larger machines. They are designed to handle tough brush

clearing jobs in a wide variety of applications, such as agriculture, forestry, landscaping, municipalities, parks and recreation areas. The light weight, short deck and superior oscillation of these attachments enable the brush cutter to follow ground contours in order to maintain a clean cut, even on slopes.

The new Brushcat attachments feature a highefficiency, direct-drive motor that maximizes hydraulic horsepower for optimal cutting and mulching of tall, thick vegetation in one pass. The high cutting speed and heavy-duty blades maximize momentum to cut and mulch vegetation up to 5 cm in diameter.

The new log grapple is the perfect attachment for any landscaping project, as it can easily clean up after cutting or trimming trees and bushes. Overall, the log grapple brings the best out of Bobcat SALs, increasing their versatility and providing savings in both time and money. From cleaning and recycling to discarding or collecting branches and logs, with its heavy-duty teeth there is no job the new log grapple cannot tackle.

The log grapple attachment also has reinforced tines, which with the heavy-duty teeth provides outstanding grip when managing unwieldy logs and brush. Rope bollards provide an additional anchor point, assisting in stability while at work. For increased operator control, the log grapple comes with an integrated tree pusher, ensuring material falls in the intended direction, allowing the operator to accomplish multiple tasks with the same attachment.

Operators will also appreciate the efficiency offered by the log grapple’s 143 cm wide opening and 360° rotation for increased productivity and ease of use. The open sides allow for easy clamping of logs and piles of brush, clearing areas - even in confined spaces - more quickly.

The Bobcat L23 and L28 SALs offer high lift capacities in confined spaces, ease-of-use with simple intuitive controls and low ground disturbance for working on any terrain. Designed and built by Bobcat at the company’s North American facilities, the new SALs offer impressive stability and tipping loads of up to 1.39 tonne. The machines’ compact size, with a width of just over one metre combined with a tight turning radius, allow Bobcat SALs to work easily even in tricky and hard to reach areas. Despite their robust construction, the SALs are also built to be light enough for easy transportation.

To ensure the new SALs are truly multi-purpose machines, Bobcat has utilised the company’s

unmatched expertise in attachments, to develop a special version of the proprietary Bob-Tach® attachment mounting system allowing the use of both S70/MT55 and S100/S450 approved attachments.

For more information about Bobcat and Bobcat products, visit the website www.bobcat.com

The Bella dryer/cooler offers thermal efficiencies to 80 percent or better because air flows around material while it is suspended in the weightless zone. The result is a more consistent material.

The eDAILY was put through its paces by the media at its European Launch in Italy.

Top journalists, influencers and content creators gathered at the IVECO Industrial Village in Turin from all over Europe to be amongst the very first to sample the new class-leading all-electric LCV: the eDAILY.

The eDAILY is more than an electric vehicle and that’s why it was presented by delving into the different facets of the ecosystem of which it is the centerpiece. Media were brought into an immersive event to experience firsthand the customer journey conceived for eDAILY clients. This path through a world of services enabled by connectivity and

digital technology smoothly propels the customers into eMobility and supports them in finding their way to the energy transition.

Thanks to the innovative modular chassis platform, eDAILY is the only eLCV in the market able to cover any application. It is offered with an extensive line-up including van, cab, crew cab, chassis cowl and minibus from 3.5 to 7.2 GVW. Its versatile chassis paves the way to electrification for conversions and makes eDAILY the best choice for bodybuilders.

The eDAILY Experience event allowed media to be amongst the first in the world appreciate the same performance and drivability of the diesel

model, just electric. They also had the chance to see converted vehicles in real-life operation covering a range of missions: from refrigerated body to tipper, last mile and mid mile delivery to refuse collection versions. Additionally, the gamechanging 15kW ePTO enables the vehicle to power a wide range of equipment, while tractionboosting rear-wheel drive makes eDAILY the only light commercial vehicle capable of towing 3.5 tonnes.

A fully modular battery set means that operators can tailor their eDAILY based on their mission. Offered with one, two, or three 37kWh battery packs, eDAILYs can cover up to 248 miles* on a single charge. Rapid charging at 80kW will see this model gain 62 miles of range in just 30 minutes. Peace of mind comes as standard with an eight-year 100,000-mile warranty for vehicles with one battery, or 155,000-miles with two or three batteries. A three-year or 100,000-mile chassis warranty accompanies the 2XL Repair and Maintenance package included for all models.

IVECO UK Light Business Line Director, Mike Cutts said “The eDAILY is a highly versatile vehicle that doesn’t compromise its effectiveness by being an EV. It leads the eLCV class in many respects and we can’t wait to get them into the hands of operators and our partner bodybuilders.”

The all-electric IVECO LCV is now on sale and

can be ordered from IVECO’s nation-wide dealer network.

To discover more about the e-mobility experience powered by IVECO and its connectivity advance features please visit https://edaily.iveco. com/en/

*Range quoted is that of an IVECO eDAILY 42S 3 battery model on the urban cycle fully laden.

If you are interested in submitting editorial to Bulk Solids Today magazine, please send your submission through to editorial@bulksolidstoday.co.uk

To subscribe to Bulk Solids Today magazine or for more information, please feel free to visit www.bulksolidstoday.co.uk

refurbished IT equipment and being an Approved Authorised Treatment Facility (AATF). From their recycling facility in Wetherby, UK, the company provided services for data destruction and disposal, recycling and refining. Continued expansion and growth resulted in the business being renamed Zixtel in 2019.

Bunting is one of the world’s leading designers and manufacturers of magnetic separators, eddy current separators, metal detectors and electrostatic separators. The Bunting European manufacturing facilities are in Redditch, just outside Birmingham, and Berkhamsted, both in the United Kingdom.

Zixtel Ltd, under the name of Advanced Digital Dynamics, was founded in 1997 to deliver IT and recycling solutions for businesses of all kinds, both locally and globally. This included buying and selling

The difficulties arising from the pandemic inspired Zixtel’s management team to focus on their recycling capabilities. The company’s objective was to recycle WEEE and other company’s waste products, and eliminate or, where no further processing was possible, minimize the amount of waste for landfill. End markets were identified for all recovered materials, including metals and plastic.

Zixtel’s engineering team designed and built a recycling plant, which included a Metal Separation Module from Bunting. The Module included a high-intensity Drum Magnet for separating weakly magnetic materials and an Eddy Current Separator to recover non-ferrous metals.

Early in the plant design process, Zixtel identified the necessity of tight particle size control for optimum separation. In the plant, material initially passes

The Zixtel evolution began in the midst of the global pandemic in 2020, when the company changed their focus to recycling and purchased the Bunting Metal Separation Module. Zixtel Ltd have since developed a reputation for metals recovery from a wide range of waste electrical and electronic equipment (WEEE) and waste discarded by other recycling companies.

through Untha shredders to liberate recoverable materials. The shredded material then passes up a conveyor and under a Bunting Permanent Overband Magnet, positioned in-line over the head pulley. Larger ferrous metal is lifted from the conveyor and discarded into a designated collection area. The remaining mix of non-ferrous metal and non-metallics feeds via a conveyor onto the primary Vibratory Feeder of the Metal Separation Module.

The Vibratory Feeder spreads the product mix across the whole one-metre width and onto the rotating shell of a high-intensity Rare Earth Drum Magnet. Small and weakly magnetic metals are removed leaving a mix of non-ferrous metals and non-metallics to fall onto a second Vibratory Feeder, which evenly delivers the material onto the belt of an Eddy Current Separator.

The Eddy Current Separator is a conveyor system with a head pulley which has a high-strength magnetic rotor spinning at high speeds within a nonmetallic shell. As the belt conveys material into the changing magnetic field, non-ferrous metals become charged with eddy currents causing a reaction that propels the particle out of the product stream. This enables the recovery of valuable aluminium, copper, zinc and other such non-ferrous metals. The non-ferrous metal fraction is further processed for concentration into individual metal fractions.

Presently, Zixtel is processing between 4 and 6 tonnes per hour of material through the Metal Separation Module, with the aim of increasing to 10 tonnes per hour.

With the existing process, Zixtel presently handles in excess of fifty different product streams. The material output of the plant is 70% metal, 25% printed circuit boards and plastics, 5% destined for an energy-to-waste plant, and 0% to landfill.

Since 2020 the recycling plant has evolved with additional particle size reduction and separation stages included granulators, air separators, and optical sorting. There are plans for additional process plants to recycle specific waste materials.

“The Zixtel plant is a great example of British recycling innovation excellence,” said Tom Higginbottom, Bunting’s Sales Engineer. “We [Bunting] have been fortunate enough to be part of the development of an incredible recycling success story. Zixtel continually push the separation capabilities of our Eddy Current Separator to the maximum and we continue to work with them by testing new waste fractions on our metal separators at our Recycling Test Centre in Redditch.”

For further information, please contact us on press@buntingmagnetics.com or visit our website: Bunting-Redditch – www.bunting-redditch.com

One of the important features of the Doosan stand at Bauma is the dedicated Innovation Center, where the company will unveil the new generation XiteCloud ‘All-in-One Platform’ for Smart Construction under the company’s ‘Powered by Innovation’ banner.

In 2019 in South Korea, Doosan introduced Concept-X, the world’s first unmanned automated and integrated control solution for construction, quarrying and mining sites. XiteCloud is the first stage in commercialising Concept-X.

Doosan is committed to producing innovative products and services for its customers and delivering added value through innovation. Visitors to Bauma will be able to see the latest developments in the XiteCloud system, as the company further expands its business portfolio into the field of construction site management, to complement its existing operations in manufacturing and sales of construction equipment.

With XiteCloud, a customer can manage multiple

tasks such as surveys, terrain analysis, machine purchases, equipment operation and construction management on a single platform, thereby reducing construction costs and saving time, while increasing work accuracy, which in turn raises productivity. XiteCloud also allows customers to manage multiple projects on a single platform, accumulating and managing data that can be utilized for future decision making/business.

At Bauma 2022, visitors to the Innovation Center on the Doosan stand will be able to see the new All-in-One Platform for smart construction, based around the Xitecloud system. The All-in-One Platform introduces a range of new solutions that form part of the XiteCloud system all of which will be demonstrated at Bauma, covering many aspects of construction management, including:

XiteCore

XiteFleet

XiteAnalyst

XiteSIM

XiteSafety

XiteAuto

As suggested by its name, XiteCore is a Cloud-based open integrated dashboard system that connects all of the XiteCloud solutions, providing the information needed to carry out a construction project and enables easy project management and control at a glance.

This system provides opportunities for collaboration/communication among project participants with an open platform that adopts an applied card-type interface that allows the user to set the dashboard flexibly according to the particular characteristics of the project (card type, location, size, etc.) It also incorporates realtime monitoring of weather, manpower, equipment, instruments, CCTV and other aspects, together with connection to the other solutions within XiteCloud such as XiteFleet, XiteAnalyst and so on.

In addition to several contracts awarded in South Korea and elsewhere around the world, XiteCloud has gone through an exhaustive technology

verification process at multiple international construction, mining and quarrying sites. Having successfully implemented XiteCloud in its home market and beyond, Doosan is using Bauma 2022 as an important springboard to continue the international launch of the XiteCloud system.

For more on Doosan construction equipment, please visit the website: www.eu.doosanequipment. com