6 minute read

Innovations at work during COVID-19 crisis

INNOVATIONS AT WORK DURING COVID-19 CRISIS FLEXIBLE MEDICAL GAS PIPING SPEEDS UP DEPLOYMENT OF MEDICAL GASES

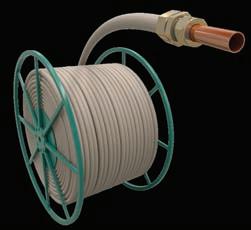

As part of the nationwide response to the COVID-19 situation, Healthcare Engineers, Contractors and Medical Gas Installers are under extreme pressure to construct temporary hospitals in record time. As the majority of these temporary hospitals require an oxygen pipeline infrastructure which although temporary must still adhere to national and international standards engineering teams are utilising a revolutionary flexible medical gas tubing product, comprising of a pliable corrugated stainless steel or copper alloy tube with an external polyethylene cover, supplied on easy to handle disposable drums in long continuous lengths. The flexibility, long lengths and the ability to bend the product by hand to a tight radius allow the piping to be quickly installed within temporary hospitals from external supply tanks or manifold directly to a patient’s bedside. Unlike typical rigid copper gas pipe, installers were able to simply unreel and pull the piping through the facility, around corners, up floors and down corridors, until the final connection. Thanks to its quick assembly fittings, the piping was attached using only basic hand tools and with little to no brazing. This was an invaluable asset to the medical gas installers on site and who’s remit was to install a medical gas piping network from bulk tanks to bedhead quickly and safely in a matter of days rather than weeks.

The flexible medical gas piping was used in Cleveland Clinic in Ohio, and in New York City’s Javits Convention Centre and Central Park temporary field hospital. The field hospital, Javits Centre and Cleveland Clinic sites were rapidly constructed to support the on-going pandemic and relieve other area hospitals of patient overflows. Although a relatively new product to the US market, MediTrac flexible medical gas piping has been installed within hospitals in Europe since 2005 and more recently within hospitals in Africa.

Central Park Temporary Field Hospital Cleveland Clinic Temporary Hospital (Hope Hospital)

The Cleveland Clinic facility, to be called Hope Hospital, will initially include 327 patient beds for lowacuity COVID-19 patients. The four

Introducing the world’s first Flexible Medical Gas Piping System.

MediTrac ® comes in long, continuous, bendable lengths resulting in up to 70% fewer fittings, up to 100% less hot work, and up to 5 times faster installation—mitigating the risk of contamination without closing your facility. It’s the inside track for up to 55% cost savings, less risk, and more time for patients.

MediTrac has been specially designed to conform to HTM 02 01, and the corresponding European and International standard BS EN ISO 7396-1: 2016. If requested, MediTrac can also be manufactured and supplied listed to UL1365 and in full compliance with NFPA 99: 2018. MediTrac represents innovation from end to end.

H O

S

P

I

T

A

L

MediTrac is an ideal solution to adding additional oxygen or other medical gas outlets (including vacuum lines) quickly and safely to address the new demands on healthcare facilities, including temporary hospitals due to the COVID-19 crisis.

meditrac.us info@meditrac.uk +44 (0) 7595 020301

story, 477,000-square-foot building can accommodate up to 1,000 hospital beds. Flexible medical gas piping was used for the rapid connection of new portable headwalls into the piping system. The installers used long continuous runs of the piping in the finished areas for a quicker, cleaner and a flame-free installation. The entire project was completed without using any hot work inside the existing facility.

One of the deciding factors to utilise flexible medical gas piping within these temporary hospitals was that it allowed a much faster installation (up to 5 times faster) on site than rigid copper pipe, since far fewer joints are required along the length of the pipeline using up to 70% fewer fittings. The joints which remain, such as to connect the pipe to valves and terminal units, required little to no hot work or inert gas shielding, and far less time to complete than traditional brazed joints in copper pipes.

FLEXIBLE MEDICAL GAS PIPING

Installers were able to unreel and pull the piping through the facility in long continuous lengths. When a change in direction was needed, the installer could simply bend the pipe by hand in a tight radius without any tooling. The pipe was cut by hand with a wheeled pipe cutter and the end fittings were assembled on site quickly and simply with a spanner.

The piping was delivered to site with internal cleanliness for oxygen service, supplied end capped and labelled as medical gas pipe, the end fittings were cleaned and degreased for oxygen service, and were packed and labelled as medical gas fittings. The piping offered a number of economic and technical advantages over traditional copper pipework, however in this instance the main criteria was speed and safety. There was little to no hot work or inert gas shielding required, eliminating purge gases and hot work permits. In addition to this the piping and fittings could withstand a minimum of 30 minutes at 840ºC without leakage in the event of a fire.

The product’s speed of installation and flexibility of use made it uniquely suitable to meet the current demands imposed on healthcare facilities reacting to the daunting challenges of the COVID-19 pandemic. MediTrac was developed and manufactured by Omega Flex, Inc. Backed by over 40 years of excellence, MediTrac relies on years of product design, engineering and testing to assure long-term durability and reliability for a variety of medical gas and healthcare uses. MediTrac flexible medical gas piping has been specially designed to conform to HTM 02 01, and the corresponding European and International standard BS EN ISO 7396-1:2016, and can be manufactured and supplied listed to UL1365 and in full compliance with NFPA 99 :2018. OmegaFlex CEO Kevin Hoben recently stated “OmegaFlex is committed to supporting its customers and communities through the unprecedented COVID-19 pandemic. We are redeploying our resources to meet the needs of customers by moving engineering and manufacturing personnel to the MediTrac business and prioritising the supply of MediTrac products. We are proud of the quick and nimble response of all of our employees as we work through the difficulties imposed by the COVID-19 crisis in supplying this much needed solution to our most urgent global problem.”

To learn more about the unique features and benefits of MediTrac ® please visit the OmegaFlex website, www.meditrac.us, or email info@meditrac.us

‘‘ Bringing many years of on the ground industry knowledge and skills ‘‘

WE SPECIALISE IN:

• Chemical Dosing • Water Consultancy • Auditing and Risk Management • Legionella and Bacteria Management

Based in Adelaide South Australia we support not only our clients here, but client’s interstate as required

SERVICING ACROSS THE COUNTRY:

• Hospitals • Residential Aged Care • Independent Living Homes • Defence • Schools • Universities • Commercial, Industrial and Domestic Properties We are a Quality ISO 9001, Safety ISO 45001 and Environmental ISO 14001 certified company through TQSCI.

WE OFFER OUR CLIENTS:

• Potable drinking water audits, water risk creation and consultancy • Warm water system council audits • Risk management plans & audits • New build water design reviews • Emergency & scheduled disinfections and decontaminations • Incident investigation and rectification • New internal water main commissioning disinfections • Reverse Osmosis system disinfections and decontaminations • Water sampling and findings reports • Specialist bespoke dosing and water treatment systems • Corrosion investigations • System permanent & temporary chemical dosing construction, installation, design, maintenance, training & recommendations as well as filtration systems • Hydraulic AutoCAD or Bluebeam drawings • Potable water contractor management • Client support services