HydraulicFracturePotentialduringDrillinginDams

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16 7

Figure6.(a)Cut-offwallconstructedinMudMountainDam,WA(USACESeattleDistrict).Noteverysteepandnarrowrockvalley,which resultsinlowconfiningstressintheembankment.(b)Longitudinalcrackthatdevelopedintheworkplatformduringconstructionofthe cut-offwall.(c)Verticalcrackinthesideofacut-offwallpanelexcavation.

Figure6.(continued)

drilling(HDD)tocausehydraulicfracture.The groutleaksandfractureswereeasilyidentifiedwith thered-dye-coloreddrillfluid(Figure9).

Duetothesignificantnumberofknownincidents, wecanconcludethatitisnotrareforhydraulic fracturestooccurfromintroductionoffluidsinto embankmentsandtheirfoundationsduringdrilling, grouting,orunbalancedslurryconstruction.Intheauthor’sopinion,itisalsolikelythattherearemanymore casesthathavenotbeenreportedduetoamisinterpretationofdrillfluidlossorexcessivegrouttakes.

ESTIMATINGHYDRAULICFRACTURE PRESSURES

Severalmechanismsforhydraulicfractureinsoils havebeenproposedbydifferentresearchers.Aliteraturereviewrevealedthattherearemanydifferentconceptsandmodelswithwhichtoestimatedamaging fracturepressuresinsoils,including tensilestress, undrainedshearstrength, unconfinedcompressionstrength,

Figure7.(a)Sketchshowingthelocationofahydraulicfracture thatoccurredontheGreenPocketLevee.(b)Photographshowing aslurry-filledhydraulicfracturefoundinanexcavationoftheembankment.

elastictheory, linearelasticfracturemechanics, empiricalformulas,and cavityexpansion.

Thesemodelsrangefrompracticaltoverytheoretical.Inthisstudy,itwasdesiredtodetermineifthere wasapracticalmodelthatwouldgivereasonableresults.Sherard(1973,p.273),statedthat,“Fromapracticalstandpoint,acrackmaybecausedtoopenona givenplaneiftheeffectivestressactingontheplane goestozero;thatis,ifthetotalstressontheplaneis equaltoorlessthanthewaterpressure(providedthe soilcannotwithstandtensilestress).”

Documentationintheliteraturerelatedtofieldhydraulicfracturetesting(Bozozuk,1974;Calcagno, 1983;ChenandZhang,1989;Hamoucheetal., 1995;andSherard,1973)revealedthatthepressurerequiredtoinitiatehydraulicfracturewasalwayssomewhatgreaterthantheminorprincipal stress.Thefieldtestresultsshowedthatthefracturepressurewasapproximately300to3,000psf

Schaefer

8 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16

(14to144kPa)greaterthantheestimatedminorprincipalstress,whichsupportstheideathat thesoilstrengthcontributestothefracturepressure resistance.

TheapproachtakenbyAndersenetal.(1994)was basedonthegeneralprinciplethathydraulicfracturingcanoccurifthegroutpressureexceedstheminorprincipalstressplusthetensilestrengthofthe soil.ThiswassupportedbyastudybyAlfaroand Wong(2001),whereinthevariousconceptswereinvestigatedandcomparedtolaboratorytesting,and thetensilestrengthapproachbestapproximatedlaboratorytestsforhydraulicfracture.AdditionalbackgroundonhydraulicfracturingcanbefoundinSherard(1970),Sherardetal.(1972),Sherard(1986),and Bjerrumetal.(1972).

Becausetensilestrengthisnotcommonlydeterminedforsoils,itisproposedthattheundrained strengthofthesoilcanbeusedtoreasonablyapproximatethetensilecapacityofthesoil.Hydraulicfracture ofclaysoccursinanundrainedloadingconditionbecausethereisaquickloadactingonanimpervious soil.Severalresearchershavepublisheddatafromlaboratoryhydraulicfractureteststhatalsoincludedinformationontheundrainedstrengthofthesoil.The author’sevaluationofthemeasureddatafoundinthe literaturereviewrevealedthattheboreholefracture pressurecancloselyapproximatethemeasuredfracturepressureinthelaboratoryusingtheminimum principalstressplustheundrainedstrengthofthesoil intermsoftotalstress. P

which,fornormallyconsolidatedsoils,wouldreduce to:

Ifenoughdatawereprovidedinthepapers,theresultswerereplottedandoverlainwiththeproposed predictionfromEq.1.Figures10and11showthatthe predictionfromEq.1agreeswellwiththelaboratory

HydraulicFracturePotentialduringDrillinginDams

Figure7.(continued)

f = σ3 + σ3 tanφu + cu , (1)

Pf = σ3 + cu . (2)

Figure8.(a)Asurfacecrackand(b)anexcavatedslurry-filledhydraulicfracturecrackfoundontheAmericanRiverLeveeduring constructionofaslurrywall.

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16 9

hydraulicfracturetestsandhighlightstheimportance oftheundrainedshearstrengthofthesoil.

DELFTCAVITYEXPANSIONEQUATION

TheHDDindustrycommonlyusestheDelftCavity ExpansionEquation.Thecavityexpansiontheorywas firstdevelopedbyVesic(1972)andthenfurtherdevelopedforuseinHDDprojectsbyresearchersatDelft Geotechnics,LugerandHergarden(1988).Thetheory isthatastheannularfluidpressureincreases,theboreholeradiuswillexpand.Initially,thedeformationwill beelastic,butasthepressureincreases,thedeformationwillbecomeplastic.Asthezoneofplasticdeformationincreasestothegroundsurface,blowoutwill occur,anddrillingfluidwillflowtothesurface,creatinga“fracout”or“inadvertentreturn.”USACEguidancedocumentEM1110-2-2902—Conduits,Pipes, andCulvertsAssociatedwithDamsandLeveeSystems(USACE,2020),describesseveralissueswiththis equationandapproach.Theprimaryissuesare(1)the equationisusedtolimitpressuretopreventdrilling fluiddischargeonthesurfaceratherthanpreventing theinitiationofhydraulicfractureand(2)thethe-

oryisbasedonisotropicstressconditions,whichalmostneverexistinrealsoils.Fordamandleveesafety, weareconcernedwithpreventingdamage,notjust fluidreleaseonthesurface.However,forclays,ifwe simplifytheequationbyassumingundrainednormally consolidatedsoilconditionsandtheminorprincipal stressisusedinsteadoftheisotropicstress,theDelft equationreducesdowntobeequivalenttoEq.2given above.

USACEREGULATIONER1110-1-1807

TheapproachusedbyUSACEinER1110-1-1807— DrillinginEarthEmbankmentDamsandLevees(USACE,2014)shouldbeimplementedwithintheprofessionalpracticeandfollowedwheneverdrillingorother invasivetechniquesareusedondamorlevees.Ifpossible,theuseofdrillingfluidsshouldbeavoidedin orneardamorleveeembankments.Ifdrillingfluids mustbeusedduetothedrillingobjectiveorthesubsurfaceconditions,theDrillingProgramPlan(DPP) mustcontainananalysiswithcalculationsforthepotentialtocausedamageandthemeasuresthatwillbe usedtominimizerisk.ForUSACEdams/levees,all DPPsthatproposetheuseoffluidsmustbereviewed bytheStandingCommitteeonDrillingandInstrumentation,ledbytheUSACEGeotechnical,Geology, andMaterialsCommunityofPracticeLeadandapprovedbytheDamSafetyOfficerortheLeveeSafety Officerattherelevantdistrict.Thetotalminorprincipalstressplustheundrainedstrengthofthesoilshould beusedtoestimatethehydraulicfracturepressure. TheUSACEregulationdoesnotrecommendafactorofsafety.Designersshouldselectanappropriate factorofsafetybasedontheimportanceofthestructureandlevelofuncertaintyintheanalysis.Itwould bereasonabletouseafactorofsafetyinthe1.3to 1.5range.

CONFININGSTRESS

ThefirstparameterinEq.1andEq.2isthetotalminorprincipalstress.Todeterminethisforflatground conditionswithnormallyconsolidatedsoils,thesteps are:

1.Determinethesoilunitweights.

2.Estimatetheporepressureusingseepagemodeling ormeasureddatafrompiezometers.

3.Calculatetheverticaleffectivestress.

4.Estimate k0 byusingtheequationinJaky(1944), whichgivestherelationshipbetweenthemajorand minoreffectiveprincipalstressesas

Schaefer

Figure9.Red-dyedslurry-filledhydraulicfracturecrackoverahorizontaldirectionaldrillingboring.

k0 = σ 3 /σ 1 = 1 sinφ . (3) 10 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16

However,therealconditionsfordamsandmanyleveesaremuchmorecomplicated.Theconfiningstresses cannotbeaccuratelyestimatedbysimplecalculations duetothefollowingissues:

Embankmentsalwayshaveslopedgroundconditions.

Majorandminorstressesarenotalwaysverticaland horizontal.

Theupperzonesoftheembankmentmaybeoverconsolidatedduetolocked-incompactionstresses, whilethelowerzoneswillbenormallyconsolidated becausethesoilweightisgreaterthanthecompactionstresses.

Thephreaticsurfacecanvarysignificantlyacrossthe coreofadam.

Irregularrocksurfaces,pinnaclesandslots,steep abutments,overhangs,conduits,concretedamcontacts,anddifferentialsettlementwillallcauselocalizedlowconfiningstressconditions.

SeeSherard(1986)foragooddiscussiononthespecialconsiderationsforlow-stresszonesthatcontribute tohydraulicfracturing.

Withmodernnumericalanalysistoolssuchas SIGMA/W,FLAC,andPLAXIS,atwo-dimensional modelcanbedevelopedtoestimatethestaticstresses inanembankmentdamatthelocationoftheproposed drilling.Inspecialcaseswithcomplexgeometry,threedimensionalmodelsmaybeappropriate.Thiswilltypicallyrequireevaluatingdifferentsections,including bothlongitudinalandtransversesections.Thegeometryofthemodelshouldbebasedonconstruction recordsandanyavailableboringdata,sothefoundationgeometryandembeddedstructuralfeatures,such asconduits,areproperlyincluded.Multiplepoolelevationsandpiezometricconditionsmayneedtobe consideredbasedonthepotentialforpoolfluctuations.Alinearelasticsoilstrengthmodelcanbeused. Theunitweightofthematerials,anestimateofPoisson’sratio,andcharacterizationofgroundwaterconditionsaretheprimaryvariablesrequired.Poisson’sratio isusedinthemodeltodeterminetheratioofhorizontaltoverticalstress(k0 ).

Oncethemodelisconstructed,itisloadedwithselfweight(gravity),andstressesarecalculated.Contour plotsofdepthversusstressprofilesofthetotalminimumstressescanbedeveloped.Thisanalysiswillprovideanapproximateestimateofthestressesinthedam

HydraulicFracturePotentialduringDrillinginDams

Figure10.LaboratoryhydraulicfracturetestresultsonfivesamplesfromMoriandTamura(1987)comparedtoproposedpredictionequation.

σ 3 =

σ 1 (4)

5.Calculatethehorizontaleffectivestress,

k0

6.Addtheporepressuretodeterminethetotalhorizontaleffectivestress.

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16 11

andfoundation.Moredetailedevaluationcanbedone usingmultistagesequencemodelingandmorerigorous materialmodels.SeeMcCookandGrotrian(2010)for proceduresformorerigorousmodelingforhydraulic fracture.Multiplesimplifiedrunscanbeperformed parametricallybyvaryingtheinputparameterstoestimatetherangeofstresses.

MEASUREMENTOF INSITU STRESS

Itispossibletomeasure insitu stressusingtools suchastheself-boringpressuremeter(Benoit,1995).

Theself-boringpressuremeterisconsideredtobethe mostreliablemethodformeasurementoflateralstress insoils.Thepressuremeterisplacedinthebottomof aboringandadvancedusingarecessedcuttingbit.

Afteradvancementtothedesireddepth,testingisdelayedtoallowforthedissipationofporepressure.

Themembraneisthenpressurized,andtotalpressure

versuscavitystrainismeasured.Thetotalhorizontal stressisdeterminedateachstrainarmbyinspectionof thetotalpressureversuscavitystrainplots.Thepressureatwhichthemembraneliftsoff(beginsdeforming thesoil)isequaltothe insitu totalhorizontalstress. Schmertmann(1985)providedadditionalinformation on insitu lateralstressandmethodsformeasurement. Measurementof insitu stresscanreallyonlybeused asaconfirmationoftheestimatedstresses,sincea boringusingdrillfluidmustbeperformedtodothe measurement.

DRILLINGNEXTTOCONDUITSANDSTEEP ROCKABUTMENTS

Cautionshouldbeusedbeforedrillinganyboringsnexttoconduitsorsteeprockabutments.Numerousincidentsofdrillfluidlossadjacenttoconduits

Schaefer

Figure11.Laboratoryhydraulicfracturetestresultsfromfourotherstudies(SeedandDuncan1981;LoandKaniaru,1990;Yanagisawaand Panah,1994;andAlfaroandWong2001)comparedtoproposedpredictionequation.

12 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16

orabutmentshaveoccurred.Stressesaroundconduits canbeverylow.Itispossibletohavetensilestresses adjacenttoconduitsduetoarchingeffects,asdemonstratedinaresearchreportbyCasagrandeandCovarrubias(1970)fortheUSACEWaterwaysExperiment Station.Iftensilezonesarepresent,thentheuseofany drillingfluidwilllikelycausehydraulicfracture.Figure 12showsacommonconditionwhereoutletworksconduitswereconstructednearasteeprockabutment.In theareamarkedbytheredarrowinFigure12,arching ofthesoilswilloccur,andtheconfiningstressesinthe areabetweentherockabutmentandtheconduitwill beverylow.

UNDRAINEDSTRENGTH

ForthesecondpartofEq.1andEq.2,the undrainedstrengthofthesoilisrequired.Thiscanbe determinedfrompreviouslaboratoryorfieldtestingor correlationstoindexproperties,oritcanbeestimated usingcriticalsoilmechanics.Aconservativeestimate canbeobtainedbyassumingtheembankmentdamor leveeisnormallyconsolidated,andEq.2canbeused.

Thisassumptionisvalidinmostcases,exceptin theuppersoilzones,wherethelocked-incompaction stressesaregreaterthantheoverburdenstress,andthe undrainedstrengthwillbemorethanestimated.Ifno previoustestingforundrainedstrengthisavailable,for normallyconsolidatedclays,theundrainedstrength ratiototheverticaleffectivestresscantypicallybeestimatedas ½ sin φ orintherangeof0.22to0.25. Equation5canthenbeusedtoestimatetheundrained strength.

Figure13showsdamagetoabottomoutlettunnel linercausedbyexcessivegroutpressureswhenrefusal pressureadjacenttothetunneldidnotconsiderthetotalpressure.

PRESSUREMEASUREMENT

Whencomparingestimatedfracturepressuresto pressuresinthefield,therelevantvaluetouseisthe totalpressure.Thetotalfluidpressureistheinitial porepressureplustheadditionalpressureappliedby thecolumnoffluidorgrout.Pressuremeasureddown theholeinthefieldwillbethetotalpressure.Groutingprojectstypicallyuseeffectivepressurestomonitor groutingprograms.Thisisappropriatefordeterminingtheeffectivenessofthegrouting.Inorderforthe grouttobepushedintosubmergedrockjoints,theinjectionpressuremustfirstovercomethe insitu groundwaterpressure.Theadditionalpressureistheeffectivepressure.However,totalpressureshouldbeused toevaluatehydraulicfracture,andeffectivepressure shouldbeusedtoevaluategroutingeffectiveness.Also, whendeterminingtheloadappliedtounderground structures,thetotalpressureshouldbeevaluated.

Onewaytoimproveourabilitytomonitorpressuresiswiththeuseofinstrumentedpackers,which candirectlymeasurethetotalgroutorwaterpressure directlyatthetopofthegroutorwaterpressuretest stage.Detailsofaninstrumentedpackerdevelopedby ACTforuseontheRoughRiverDamprojectcanbe foundinIvanovetal.(2017).Itisalsocommonfor HDDdrillingequipmenttohavepressuresensorsat thecuttingheadtodirectlymeasurethedrillfluidpressure.Forstandardgeotechnicaldrilling,directmeasurementoffluidpressuresinnotcommonlydone.If pressurizedfluidsareused,amethodtomeasurethe appliedpressureatthedrillrigshouldbeused,which willneedtobeaddedtothecalculationofthestatic headofthedrillfluid.Oncethethresholdpressures

HydraulicFracturePotentialduringDrillinginDams

cu = σ 1 × 0 5sinφ (5)

PRESSURECOMPARISON

Figure12.Exampleofpotentiallow-stresszonebetweenrockabutmentandoutletworksconduit.

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16 13

Figure13.Steel-linedbottomoutlettunnelwasdamagedbygroutingusingeffectivepressurecriteriainsteadoftotalpressure.

Figure14.Simplifiedexampleofhydraulicfracturepressurecalculation.

Column1:DepthofCalculation.

Column2:MajorTotalStress = Column1 × γsoil .

Column3:PorePressure = (Column1 DepthtoWater) × γwater ifpositive,else0.

Column4:MajorEffectiveStress = Column2 Column3.

Column5:MinorEffectiveStress = Column4 × k0 .

Column6:MinorTotalStress = Column5 + Column3.

Column7:UndrainedStrength = Column4 × 0.5 × sin φ

Column8:FracturePressure = Column6 + Column7.

Column9:GroutFluidPressure = Column1 × γgrout .

Column10:FactorofSafety = Column8/Column9.

arecalculated,apressurereliefvalvecouldbeusedto protectagainstpressurespikes,whichcouldhappenif cloggingoccursinthedrillfluidreturnpath.

SIMPLIFIEDEXAMPLE

Figure14showsasimplifiedexampleoffracture pressurecalculationsforgravitygroutingonaflat groundsite.Thisisforillustrativepurposesonlyand doesnotapplytoconditionsthatarefoundinand underdamsandlevees.Theboringisplannedtobe drilledinasingleclaysoillayertoadepthof100ft (30m).Calculationswillbedonefor5ft(1.5m)in-

crementsofdepth.Thesoilunitweightis120pcf(18.9 kN/m3 ).Thegroutunitweightis80pcf(12.5kN/m3 ). Theinitialwatertableisatadepthof50ft(15m).The drainedstrengthisassumedtobe φ = 30degrees.The k0 valueiscalculatedusingEq.3.

Notethatthelowestfactorofsafetyisnotatthebottomoftheboring.Groundwaterhasasignificantinfluenceonthefracturepressures.Practitionersshould considersettingupthecalculationsforsmallincrementsofdepthandincludeallsoillayerspresenton thesite.Fordamsandleveeswherenumericalmodelingisusedtoestimatethestresses,valuesoftotalminorprincipalstressversusdepthcanbeoutputfrom

Schaefer

14 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16

HydraulicFracturePotentialduringDrillinginDams

themodelingsoftwareandusedinasimilarspreadsheettocalculateprofilesforfracturepressure,drill fluidorslurrypressure,andfactorofsafetyversus depthforeachproposedboringorslurry-supported excavation.

SUMMARY

1.Numeroushydraulicfractureincidentshaveoccurredondamsandlevees.

2.Holesshouldnotbedrilledindamsorleveesunless thereisawell-reasonedcasethatjustifiestherisk.

3.Aplanshouldbedraftedtomanagetheriskinthe bestwaypossibleto“donoharm.”

4.Riskcanbeminimizedthroughcarefulplanningof boringlocation/samplesites.

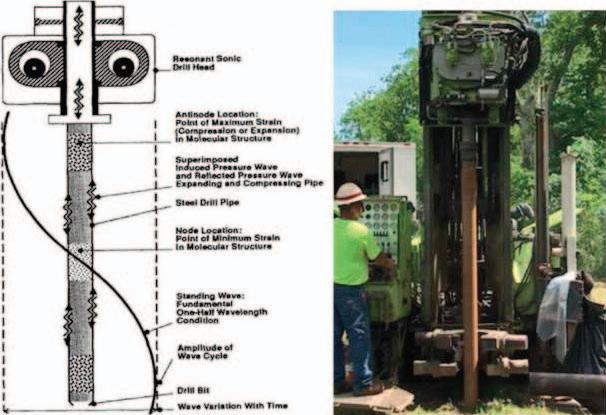

5.Theuseofsonicdrillingorhollowstemaugers shouldbeconsideredtoavoidtheriskofdrilling withfluids.

6.Iffluidsareused,onlygravitypressureshouldbe used,ifpossible.

7.Ifpressurizedfluidsmustbeused,thenahydraulic fractureanalysismustbeperformedtodetermine theestimatedfracturepressure,estimatedfluid pressurefromdrillingactivity,andestimatedfactor ofsafety.

8.Pressuresshouldbemonitoredandkeptbelowthresholdsusinganappropriatefactorof safety.

9.Ifpossible,apressurereliefvalveshouldbeused toprotectagainstspikesinpressurecausedbydrill fluidreturnclogging.

REFERENCES

Alfaro,M.C.andWong,C.K.,2001,Laboratorystudiesoffracturingoflow-permeabilitysoils: CanadianGeotechnicalJournal,Vol.38,pp.303–315.

Andersen,K.H.;Rawlings,C.G.;Lunne,T.A.;andBy,T.H., 1994,Estimationofhydraulicfracturepressureinclay: CanadianGeotechnicalJournal,Vol.31,pp.817–828.

Benoit,J.,1995,Advancesinpressuremetertechnologywithspecificreferencetoclays.InBallivy,G.(Editor), ThePressuremeterandItsNewAvenues,Proceedingsofthe4thInternational Symposium, 17–19May1995,Sherbrooke,Québec,Canada: CRCPress,BocaRaton,FL,pp.125–139.

Bjerrum,L.;Nash,J.K.;Kennard,R.M.;andGibson, R.E.,1972,Hydraulicfracturinginfieldpermeabilitytesting: Geotechnique,Vol.22,pp.319–332.

Bozozuk,M.,1974,Minorprincipalstressmeasurementsinmarineclaywithhydraulicfracturetests.In Proceedings:EngineeringFoundationConferenceonSubsurfaceExploration forUndergroundExcavationandHeavyConstruction,Henniker,NH:AmericanSocietyofCivilEngineers,NewYork, pp.333–349.

Calcagno,F.,Jr.,1983,HydraulicfracturestudyoftheTiber spillwaycofferdam: AEGNewsletter,Vol.26,pp.25–26.

Casagrande,A.andCovarrubias,S.W.,1970, CrackingofEarth andRockfillDams,TensionZonesinEmbankmentsCausedby ConduitsandCutoffWalls:U.S.ArmyEngineerWaterways ExperimentStationContractReportS-70-7.

Chen,Yu-JiongandZhang,Shu-Lu,1989,Testembankmentof fracturegrouting: JournalofGeotechnicalEngineering,Vol. 115,No.11,pp.1668–1672.

Davidson,R.R.;Levallois,J.;andGraybeal,K.,1992,SeepagecutoffwallforMudMountainDam.In ASTMSTP 1129—SlurryWalls:Design,Construction,andQualityControl: AmericanSocietyforTestingandMaterials,Philadelphia,PA,pp.309–333.

Erwin,E.D.andGlenn,J.M.,1992, ASTMSTP1129—Plastic ConcreteSlurryWallforWisterDam,SlurryWalls:Design ConstructionandQualityControl:AmericanSocietyforTestingandMaterials,Philadelphia,PA.

Hamouche,K.K.;Leroueil,S.;Roy,M.;andLutenegger,A.J., 1995, Insitu evaluationof k0 ineasternCanadaclays: CanadianGeotechnicalJournal,Vol.32,pp.677–688.

IndependentPaneltoReviewCauseofTetonDamFailure, 1976,FailureofTetonDam:ReporttotheU.S.Departmentof InteriorandStateofIdaho,U.S.GovernmentPrintingOffice, Washington,D.C.

Ivanov,D.;Horvath,D.;andHeenan,D.,2017,Advancesin measuringgroutingpressuresusinganinstrumentedpacker. InByle,J.,Johnson,L.,Bruce,D.,ElMohtar,C.,Gazzarrini, P.,andRichards,T.(Editors), Grouting2017:AmericanSocietyofCivilEngineers,Honolulu,HI,pp.313–322.

Jaky,J.,1944,ThecoefficientofEarthpressureatrest: Journalof theSocietyofHungarianArchitectsandEngineers,Vol.25,pp. 355–358.

Lo,K.Y.andKaniaru,K.,1990,Hydraulicfractureinearth androck-filldams: CanadianGeotechnicalJournal,Vol.27, pp.496–506.

Luger,H.J.andHergarden,A.M.,1988,Directionaldrilling insoftsoil:Influenceofmudpressures.In Proceedings:NoDigConference: InternationalSocietyofTrenchlessTechnology,WashingtonD.C.

McCook,D.K.andGrotrian,K.O.,2010,UsingSIGMA/W topredicthydraulicfractureinanearthenembankment.In Proceedings:DamSafety: AssociationofDamSafetyOfficials, SeattleWashington,pp.247–271.

Mori,A.andTamura,M.,1987,Hydrofracturingpressure ofcohesivesoils: SoilsandFoundations,Vol.27,No.1, pp.14–22.

Schmertmann,J.H.,1985,Measureanduseofthe insitu lateral stress.In ThePracticeofFoundationEngineer,OsterbergVol. DepartmentofCivilEngineering,NorthwesternUniversity, Evanston,IL,pp.189-213.

Seed,H.B.andDuncan,J.M.,1981,TheTetonDam—Aretrospectivereview.In ProceedingsoftheTenthInternationalConferenceonSoilMechanicsandFoundationEngineering,Vol.3: Stockholm,Sweden,pp.219–238.

Sherard,J.L.,1970,Lossofwaterinboreholesinimperviousembankmentsections.In Proceedingsofthe10th ICOLDCongress,Vol.VI:Montreal,Quebec,Canada, pp.377–381.

Sherard,J.L.,1973,Embankmentdamcracking.InPoulos,S. andHirschfeld,R.(Editors), EmbankmentDamEngineering: JohnWileyandSons,NewYork,pp.272–353.

Sherard,J.L.,1986,Hydraulicfracturinginembankmentdams: ASCEJournalofGeotechnicalEngineering,Vol.112,No.10, pp.905–927.

Sherard,J.L.;Decker,R.S.;andRyker,N.L.,1972,Hydraulic fracturinginlowdamsofdispersiveclay.In Proceedingsof

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16 15

Schaefer

theSpecialtyConferenceonPerformanceofEarthandEarthSupportedStructures,Vol.1,PartI:AmericanSocietyofCivil Engineers,NewYork,pp.563–590.

USACE(U.S.ArmyCorpsofEngineers),1998, Installationof PipelinesBeneathLeveesUsingHorizontalDirectionalDrilling: U.S.ArmyCorpsofEngineersTechnicalReportCPAR-GL98-1.

USACE(U.S.ArmyCorpsofEngineers),2014, ER1110-11807—DrillinginEarthEmbankmentDamsandLevees:U.S. ArmyCorpsofEngineers,Washington,D.C.

USACE(U.S.ArmyCorpsofEngineers),2020, EM1110-22902—Conduits,Pipes,andCulvertsAssociatedwithDamsand LeveeSystems:U.S.ArmyCorpsofEngineers,Washington, D.C.

Vesic,A.S.,1972,Expansionofcavitiesininfinitesoilmass: ASCE JournaloftheSoilMechanicsandFoundationsDivision,Vol. 98,pp.265–290.

Yanagisawa,E.andPanah,A.K.,1994,Twodimensionalstudy ofhydraulicfracturingcriteriaincohesivesoils: Soilsand Foundations,Vol.34,No.1,pp.1–9.

16 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.3–16

BestPracticesforPlanningandImplementingSite InvestigationsatFederallyOwnedorRegulatedDams andLevees

KATHLEENBENSKO

FederalEnergyRegulatoryCommission,OfficeofEnergyProjects,DivisionofDam SafetyandInspections,888FirstStreet,N.E.,Washington,DC20426

BRYANK.SIMPSON

U.S.BureauofReclamation,GeotechnicalServicesDivision,EngineeringGeologyand Geophysics,DenverFederalCenter,POBox25007(86-68320),Denver,CO 80225-0007

THOMASA.TERRY

U.S.ArmyCorpsofEngineers,RiskManagementCenter,12596W.BayaudAvenue, Suite400,Lakewood,CO80228

SCOTTR.WALKER*

TennesseeValleyAuthority,DamSafetyGovernance&Oversight,1101MarketStreet, LP1F-C,Chattanooga,TN37402

KeyTerms: DamSafety,LeveeSafety,Geotechnical SiteInvestigations,DrillingProgramPlans,Drilling Guidance,FederalAgency

ABSTRACT

Management,regulation,andreviewoftheplanning andexecutionofintrusivesiteinvestigationsvarywithin eachoffourfederalorganizationsinvolvedwithdam andleveesafetybaseduponvariousrolesandresponsibilities.TheU.S.BureauofReclamation(USBR),the TennesseeValleyAuthority,andtheU.S.ArmyCorps ofEngineers(USACE)areowner-operatorsofdams thatservemultiplepurposes,includingfloodcontrol,hydropower,watersupply,andnavigation.TheFederalEnergyRegulatoryCommission(FERC)regulatesandinspectsnon-federalhydropowerdams,anddevelopsand implementspolicies,programs,andstandardstoensure thesafetyoftheselicensedprojects.Eachorganization (exceptFERC)isalsoresponsibleforoversight,rehabilitation,andrepairofstructuresincludingdamaged levees,canals,anddams,includingsome(inthecaseof USBRandUSACE)thatareoperatedandmaintained byothers.Thispaperprovidesabriefoverviewofthe variousregulationsandguidancerelatedtotheplanning andexecutionofintrusivesiteinvestigationsconducted atstructureswithineachorganization’sportfolio.Italso

*Correspondingauthoremail:srwalker3@tva.gov

providesaprogrammaticoverviewoftheprocessesutilizedbythedifferentfederalorganizationsforplanning, reviewing,andimplementingintrusiveinvestigations.It coversspecificrequirements(guidanceandregulations), timeframesthatareinvolvedwiththereviewprocess, anddiscussesupdatesandchangesthatareplannedor beingconsidered.

OVERVIEW

Thepurposeofthepaperistoexplainhowthefour majorfederalorganizationswithdamandleveesafety programs—theU.S.BureauofReclamation(USBR), U.S.ArmyCorpsofEngineers(USACE),Tennessee ValleyAuthority(TVA),andFederalEnergyRegulatoryCommission(FERC)—planandimplement intrusivesiteinvestigationsforhydraulicstructures. Eachorganizationhasdifferentprimarypurposesand rolesrelatedtodamsandleveeswhichaffectwhyand howsiteinvestigationsforeachareperformedand implemented.

Topicsdiscussedincludethefollowing:

Asummaryofeachorganization’srolesandresponsibilitiesrelatedtodamandleveesafety,including thepurposesoftheirdamsandlevees,regulatory position,emergencyandpost-emergencyworkfor others,andworkforotheroutsideentitiesrelatedto damandleveesafety

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 17

Adescriptionofthebasicsiteinvestigationprocessestheorganizationsallfollowandhowriskassessmentsareutilizedininvestigationplanning Abriefdescriptionofhoweachorganizationplans andexecutesintrusivesiteinvestigations,including adiscussionofthevariousregulationsandguidance documentseachorganizationfollows Contracting,communications,levelofinvolvement, andoversightoftheintrusivesiteinvestigation process

DiscussiongenerallyfollowstheorderofUSBR, USACE,TVA,andFERC.Thisreflectsaprogression fromfewertomoreentitiesinvolved,andfromanalmostfullyinternalprogram(USBR)toamixedinternal/externalprogram(USACE)toowneroversightof theprocess(TVA)toregulatoroftheprocess(FERC).

Notalldamandleveesafety-relatedaspectsthatare importanttositeinvestigationprogramsarediscussed. Additionalrequirementscouldincludepreparedsubmittalssuchashealthandsafetyplans(HASPs), qualityassuranceandqualitycontrol(QA/QC)processes,TemporaryConstructionEmergencyAction Plans(TCEAPs),siteaccess,realestateissues,utility clearances,tribalconsultations,NationalEnvironmentalPolicyAct(NEPA)and/orStateHistoricPreservationOffice(SHPO)reviewsorrestrictions,andother archeological,biological,orhistoricalevaluations.

BACKGROUNDONORGANIZATIONS

USBR

Establishedin1902,theUSBR(alsoreferredtoas Reclamation)isbestknownforthedams,powerplants, andcanalsitconstructedinthe17westernstates(see Figure1).Thesewaterprojectsledtohomesteading andpromotedtheeconomicdevelopmentoftheWest. Reclamationhasconstructedmorethan600damsand reservoirsincludingHooverDamontheColorado RiverandGrandCouleeDamontheColumbiaRiver.

Reclamationisalsothesecondlargestproducerof hydroelectricpowerintheUnitedStates.USBR’s53 powerplantsannuallyprovidemorethan40billion kilowatthours,generatenearly$1billioninpowerrevenue,andproduceenoughelectricitytoserve3.5millionhomes.Today,theUSBRisacontemporarywatermanagementagencywithastrategicplanoutlining numerousprograms,initiatives,andactivitiestohelp thewesternstates,NativeAmericantribes,andothers balanceamultitudeofcompetingusesforwater.The missionistoassistinmeetingtheincreasingwaterdemandsofthesestatesandentitieswhileprotectingthe environmentandthepublic’sinvestmentinReclamation’sinfrastructure.

Reclamationplacesgreatemphasisonfulfillingwaterdeliveryobligations,waterconservation,waterrecyclingandreuse,anddevelopingpartnershipswith customers,states,andNativeAmericantribes,and findingwaystobringtogetherthevarietyofintereststoaddresscompetingneedsforlimitedwater resources.

USACE

In1853,USACEbeganworkontheWashington Aqueduct,whichsupplieswatertotheDistrictof Columbia(WarDept,1939)andisstilloperatedby USACE.Subsequently,USACEbecameinvolvedin floodcontrolandnavigationalongtheMississippi Riverin1879withthecreationoftheMississippi RiverCommission(StatutesatLarge,1881).In1885 USACEcompletedthreereservoirsinMinnesotanear theheadwatersoftheMississippiRiverforflood controlandnavigationpurposes(USACE,1885and 2020a).TheRansdell–HumphreysFloodControlAct of1917(StatutesatLarge,1917)wasthefirstfederal FloodControlActpassedbyCongress,andthenthe FloodControlActof1936(StatutesatLarge,1936a) madefloodcontrolafederalpolicyandofficiallyrecognizedUSACEasthemajorfederalfloodcontrol agencywithofficesandprojectsacrossthecountryand overseasterritories(Figure2).

USACEself-regulatesitsdamsandleveesandinspectsandpartiallyregulatesothersunderaprogram authorizedbyPublicLaw(PL)84-99(Statutesat Large,1955andU.S.C.,2020c).USACEisthelargest producerofhydropowerintheU.S.asmeasuredby hydroelectricgenerationcapacityinmegawatts.Additionally,USACEprovidesfloodfightingassistance andaidstheFederalEmergencyManagementAgency (FEMA)indisasterrecoveryefforts.USACEmanagestheNationalInventoryofDamsandtheNational LeveeDatabaseandisworkingwithFEMAonthe NationalLeveeSafetyProgram.

TVA

TVAisacorporateagencyandinstrumentalityof theUnitedStates,createdonMay18,1933,when CongresspassedtheTennesseeValleyAuthorityAct of1933(TVAAct;StatutesatLarge,1934andU.S.C., 2020b)inresponsetoPresidentFranklinDelanoRoosevelt’svisionfor,“acorporationclothedwiththe powerofgovernmentbutpossessedoftheflexibilityandinitiativeofaprivateenterprise”(Roosevelt, 1938).Incontrasttoauthorizationsforotherfederal agencies,theTVAActreferstoTVAas“theCorporation”anddescribesitspurposesasimprovingnavigabilityandprovidingfloodcontrolontheTennessee

Bensko,Simpson,Terry,andWalker

18 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39

River,initiatingenvironmentalimprovements(reforestationandimprovingfarmingpractices),stimulatingeconomicdevelopmentwithintheTennesseeValley,andprovidingfornationaldefense.

Asthenation’slargestpublicpowerproducer,TVA utilizesmultiplegenerationsources,includingnuclear, naturalgas,coal,andrenewables.Hydroelectricrepresentsabout10percentofTVA’soverallgenerationmix, andtwenty-nineofTVA’sriverdamprojects(along withtheRaccoonMountainPumped-Storagefacility) generateelectricity.TVAceasedreceivingfederalappropriationsin1999andmadeitsfinalscheduledrepaymentonCongress’original$1billioninvestmentin theTVApowersystemin2014.TodayTVAisfullyselffunded,withnearlyallrevenuederivedfrompower sales.WhilethisfiscalmodeldifferentiatesTVAfrom USBRandUSACE,akeysimilarityisthatTVA’sDam SafetyProgram(DSP),likethoseofotherfederaldam owners,isself-regulated.

TVAoperateswithinapowerserviceareathat coverspartsofsevenstates,asshowninFigure3. AllbutoneofTVA’sriverdamsarelocatedwithin thedrainagebasinoftheTennesseeRiver,whichis alsodepictedinFigure3.TVA’scurrentriverdam

inventoryincludes49projectscomprisedof88individualstructures(includingsaddledams,dikes,etc.). TVAconstructed42riverdamprojects(80totalstructures),purchasedsixotherprojects(sevenstructures), andacquiredoneprojectfromUSACEaspartofthe TVAAct.

Inadditiontotheriverdams,TVA’sDSPoversees ninewaterretentionstructuresconstructedtosupport ongoingfossilandnucleargeneration,sixleveesoriginallyconstructedforvectorcontrolandwhichnow providerecreationandwildlifehabitatbenefits,and onehistoricgristmilldamsituatedonlandTVAacquiredaspartofaflowageeasement.Allnon-river damsareclassifiedaslow-hazardpotentialstructures. AseparateregulatoryprogramatTVAprovidesgovernanceandoversightofcoalashandcoalwashfinesimpoundmentsatactiveanddecommissionedfossilgenerationsites.

FERC’soriginbeganwiththepassageoftheFederalWaterPowerActof1920(FWPA;Statutesat Large,1921)whichprovidedthefederalgovernment

BestPracticesforPlanningSiteInvestigationsatDamsandLevees

Figure1.U.S.BureauofReclamationregions.

FERC

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 19

withmorecomprehensivecontrolofthenation’snavigablewaterresources.In1935theFWPAbecame PartIoftheFederalPowerAct(U.S.C.,2020a),underwhichtheFederalPowerCommissionevolvedinto anindependentregulatoryagency(McKernan,1950). In1977,asaresultoftheDepartmentofEnergyOrganizationAct(StatutesatLarge,1980),theFederal PowerCommissionwasre-designatedastheFederal EnergyRegulatoryCommission.Sincetheenactment oftheFederalPowerAct,CongresshasassignedexpandedresponsibilitiestoFERCthroughvariouslaws toincludeproposalreviewofinterstatenaturalgas pipelines,storageprojects,liquifiednaturalgasterminals,responsibilitiesrelatingtobulk-powersystemreliabilityandcybersecurity,andlicensesfornon-federal hydropowerprojects.

FERC’soversightofnon-federalhydropowerdevelopmentishandledbythreeofsixdivisionswithin theOfficeofEnergyProjects.TheDivisionofDam

SafetyandInspections(D2SI)executestheCommission’sDamSafetyandPublicSafetyProgramsbyimplementingpolicies,programs,andstandardsfordam safetytoensurethatjurisdictionalprojectsareinspectedandevaluatedintheirdesign,construction, operation,maintenance,andsecurityphasestoprotectlife,health,property,andtheenvironment.Project compliancetothetermsandconditionsofthelicensesandexemptionsregardingdamsafetyarealso assessed.D2SI’soversightroleisexplainedintheCode ofFederalRegulations(CFR;CFR,2020).D2SIis comprisedoffiveregionalofficesasshowninFigure4, andaHeadquartersofficeinWashington,D.C.,totalingabout130personnel.

FERCregulatesover2,500hydropower-producing projectswithintheUnitedStates.Federallyowned hydropower-producingprojectsdonotfallwithin FERC’sjurisdiction;however,FERCdoesregulate privatelydevelopedhydropowerfacilitieslocatedat

Bensko,Simpson,Terry,andWalker

Figure2.UnitedStatesArmyCorpsofEngineersdistrictsandheadquarterslocations.

20 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39

USACE-andUSBR-ownedprojects.(Therearecurrentlynoprivatelydevelopedhydropowerprojectsat TVAfacilities.)TheprojectswithinFERC’spurview varygreatlyintype,size,design,age,purpose,andoperation.Thenumberoflicensedprojectsandlicensees resultsinaratherdynamicportfoliobecauseitfrequentlychangesasnewprojectsarelicensedandother licensesaresurrendered.Figure5showsthedistributionofbothFERC-regulatedandfederalhydropower projects.

Figures6through8summarize(asapplicable),the inventory,structurepurposes,roles,anddegreeto whichdamorleveesafetyriskisappliedtoeach organization’soveralldamsafetyprogramandintrusivesiteinvestigations.Thenumberofregulated structuresforUSBRandUSACEreferstoadditionalfacilitiestheyregulate.Emptycellsindicate not applicable.Collectively,thesefiguresprovideasummaryofthesimilaritiesanddifferencesbetweeneach organization.

Asummaryoftheorganizationalrolesshownin Figure8isasfollows:

Self-governing–organizationregulatesitsownactionsrelatedtodamorleveesafety.

Regulator–regulatesallaspectsofdamorlevee safety.TheFERCregulatoryroleislimitedtothose structuresthatarepartofnon-federalhydropowerproducingfacilities(however,thefacilitiesmaybe locatedatfederalprojects).Pertinentstructuresrelatingtothesefacilitiesareincluded,suchassaddledams,etc.USACE’sregulatoryroleislimitedto leveesthatwerebuiltbyUSACEandturnedover toalocalsponsortooperateandmaintain,structuresforwhichanentityhaselectedtoparticipate inthePL84-99program(whichprovidesreimbursementforspecificdamagestoleveesthatresultfrom high-waterevents),andreviewofrequestsbynonUSACEentitiesforpermitstomodify,alter,oroccupyanyexistingUSACE-constructedpublicworks projectorassociatedlandsthatwouldotherwise beprohibitedby33U.S.C.§408(U.S.C.,2020d). (ThisstatuteiscommonlyreferredtoasSection 408,andtheassociatedauthorizationsareknownas 408permits.)

BestPracticesforPlanningSiteInvestigationsatDamsandLevees

Figure3.LocationsofTennesseeValleyAuthority(TVA)riverdamswithintheTennesseeRiverwatershed(lightershading)andTVApower servicearea(darkershading).

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 21

Emergencyassistance–aidsduringfloodemergenciestolocalsponsorsuponrequest.

Repairandrehabilitation–forstructuresthatare partofthePL84-99programsrelatedtoleveesand limiteddamsthatwerebuiltbyUSACEandarenow operatedandmaintainedbyalocalsponsor.USACEalsoactsasFEMA’sengineeringandcontractingbranchwhenrespondingtonationallydeclared disasterssuchashurricanesandfloods.

USBR,USACE,TVA,andFERCaretransitioningtowardfullyrisk-informedmanagementoftheir respectivedamandleveesafetyprograms.However, internaldesignandguidancestandards,externalregulations,treatyobligations,andcontractsdocontinue tocontrolsomeaspectsoftheprograms(tovarying degrees)andsiteinvestigationsisoneareawhereriskinformedprocesseshavebeenslowertoimplement.

USBRisthefurthestalongintheprocess,withthe majorityofitsdecision-making,design,andsiteinvestigationsinformedbyrisk.TVAandFERCaretransitioningtorisk-informedprocessesformanagementof theirfacilities,includingsiteinvestigations,butboth alsohavestandards-basedcriteriaandrequirements thatmustbefollowed.

USACEisusingrisktomanagedamandleveeportfoliosandtoinformdesigns;however,forsiteinvestigations,integrationofriskvariesbetweenthedam andleveeprograms.USACEtypicallyavoidsdrilling inorneardams(particularlyearthembankments)exceptinsupportofdesigns,aspartofissueevaluation studies(IESs)followingriskassessments,ortorepair orreplaceinstrumentationorreliefwells.Leveesfully ownedandoperatedbyUSACEaregenerallytreated similarlytothedamswhenitcomestointernalinitiationofsubsurfaceinvestigationprograms.However, unlikedamsthatoccupycomparativelysmallfootprints,leveesarelongstructuresthatoftenparallelmajorriversformanymiles.Thisgeometryandgeography commonlyplacetheminconflictwithtransportation andutilitycorridorsandmakethemattractiveaslocationsforparksorsimilaropenspace.Entitiesexternal toUSACEthatwishtoplacestructuresin,on,orunderUSACE-ownedleveesutilizetheSection408permitprocess(whichdoesnothaveariskcomponent)to requestpermissiontoconductsubsurfaceinvestigation insupportoftheirneeds(e.g.,designofbridges,directionalboresforpipelines,utilitytowers,picnicsheltersandoutbuildings).TheSection408processalso appliestodrillinginleveesthatareownedandoper-

Bensko,Simpson,Terry,andWalker

Figure4.FederalEnergyRegulatoryCommissionregionalofficesandcoverageareas.

22 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39

JOINTOPERATIONSBETWEENTHE ORGANIZATIONS USBRandUSACE

USBRandUSACEjointlyoperateseveralfacilities, withtheUSBRtypicallymakingday-to-dayoperationaldecisionsrelatedtowaterandhydropower,while USACEtypicallymakesdecisionsrelatedtofloodcontrol.Theentitythatcontrolsthemainoperationisconsideredtheleadorganizationanddetermineswhich ofthetwowillleadindamsafetypractices.ExamplesoftheseincludetheFolsomDamjointuseproject andtheGarrisonDamproject’sSnakeCreekEmbankment,whichseparatesLakeAudubon(whichis controlledbyUSBRforirrigationwatersupply)from LakeSakakawea(whichiscontrolledbyUSACEprimarilyforfloodcontrol).

TVAandUSACE

TVA’sportfolioincludes10damswithnavigation facilities—nineontheTennesseeRiverandoneon theClinchRiver.Ateachfacility,TVAownstheinfrastructureandisresponsibleformaintenanceofthe dam,whileUSACEisresponsibleforoperationand maintenanceofthenavigationlocks.TVAmanages reservoirlevelsanddischargesacrossthesystemto supportnavigation.USACEdesignedandisnowcontractingforandmanagingconstructionofnewnavigationlocksattheKentuckyandChickamaugaprojects becauseUSACEcanreceivethefederalappropriations necessarytofundtheprojects.Additionally,thenorthernendoftheTennessee–TombigbeeWaterway(which isoperatedandmaintainedbyUSACE)is8.5miles upstreamfromTVA’sPickwickLandingDam.WaterfromPickwickLakeisreleasedwhenvesselslock throughJamieWhittenLockandDaminMississippi.

TVAalsocoordinatescloselywiththeUSACEdistrictofficesinNashvilleandCincinnatiforroutineand floodoperationsontheTennesseeandCumberland

BestPracticesforPlanningSiteInvestigationsatDamsandLevees

Figure5.FederalEnergyRegulatoryCommission(FERC)-regulatedandfederallyownedhydropowerprojects(FERC,2017).

atedbyasponsor(forwhichUSACEonlyservesa regulator).

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 23

Bensko,Simpson,Terry,andWalker

Rivers.Thelowermostreservoirsoneachriver(KentuckyLakeandLakeBarkley,respectively)arehydraulicallyconnectedbyanavigationcanal.TVA runsthehydraulicmodelforthecombinedsystem andschedulesnormaloperationdischargesfromboth dams.TVAalsoscheduleshydroelectricgeneration fromtheotherUSACEdamsupstreamontheCumberlandandprovidesUSACEwithdischargesfrom

GreatFallsDam(whichistheonlyTVAriverdam intheCumberlandwatershed).Duringfloodevents ontheOhioRiver,USACEschedulesdischargefrom KentuckyandBarkleyDamstoreduceimpactstothe lowerOhioandMississippiRivers.Inaddition,TVA utilizesUSACEcadrestoassistwithroutinesemiquantitativeriskassessments(SQRAs)forselected dams.

Figure6.Summaryofstructureinventories.

Figure6.Summaryofstructureinventories.

24 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39

Figure7.Primaryandsecondarypurposesofdamsandlevees.

TVAandUSBR

Althoughtherearenocurrentjointoperations,TVA andUSBRcollaboratedcloselyintheyearsimmediatelyfollowingpassageoftheTVAAct.Becauseit tooktimetocreateadesignbranch,TVAhiredUSBR todevelopthedesignsforNorrisandWheelerDams (whichiswhyNorrisistheonlyTVAdamwithdrum gates).TVAiscurrentlyworkingwithUSBRonrehabilitationofringsealgatesatHiwasseeDam,thedesignforwhichisvirtuallyidenticaltothoseatGrand CouleeDam.

FERCandUSBR,USACE,orTVA

TherearenumerousprojectswhereUSACEor USBRisthedamownerandoperatorwitha third-partyhydropowerproviderthatisregulated byFERC.ForUSACEstructures,thehydropower providergenerallycontrolstheday-to-dayoutflow operationsincoordinationwithUSACE,whileUSACEcontrolsthefloodpoolandfloodcontrol operations.Iftheprojectsalsohavenavigation, thenUSACEcontrolsthenavigationthroughthe locksandthenavigation-relatedpools;examples

BestPracticesforPlanningSiteInvestigationsatDamsandLevees

Figure8.Summaryoforganizationrole(s).

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 25

Figure9.SimplifiedTennesseeValleyAuthorityDamSafetyProgramorganizationalchart.

oftheseincludemanydamsalongtheColumbia River.

ForReclamationassets,thirdpartiesarepermittedunderaleaseofpowerprivilege(LOPP)contract.LOPPprojectsmustnotimpairtheefficiency ofReclamation-generatedpowerorwaterdeliveries, jeopardizepublicsafety,ornegativelyaffectanyother Reclamationprojectpurpose.

TVAcoordinateswithFERClicenseesthatoperate damswithintheTennesseeRiverwatershed(mostnotablyontheLittleTennesseeRiverdownstreamfrom FontanaDam),buttherearenoformaljointoperationsbetweenFERC,theirlicensees,andTVA.

GENERALCONSIDERATIONS, REGULATIONS,ANDGUIDELINES

ThepartiesinvolvedandthereasonsforconductingintrusiveinvestigationsatstructuresownedorregulatedbyUSBR,USACE,TVA,orFERCvary.For structuresownedbyoneoftheorganizations,theprocessmaybeself-initiated(suchastocollectinformationtobetterquantifyanidentifiedpotentialfailure mode(PFM),ortosupportdesignofamodification), orinitiatedbyanoutsideorganization(e.g.,transportationdepartments,pipelineowners,orthird-party hydropowerdevelopers).Forstructuresregulatedby USBRorUSACE,theprocessistypicallyinitiatedby anoutsideorganization;inadditiontotheexamples above,thesemayalsoincludealocalfloodcontrolor irrigationdistrict.ForFERC-regulatedstructures,the processisalwaysinitiatedbythelicensee.

Eachfederalorganizationutilizesregulationsand guidelinesthatdescribepermissibleorpreferredinvestigationtechniques,minimumqualifications,andsubmittalrequirements.Whilethespecificsofthevarious documentsdiffer,theunderlyingfundamentalprincipleis DONOHARM tothestructure.Theprimary governingdocumentsforeachorganizationareas follows:

USBR: GuidelinesforDrillingandSamplinginEmbankmentDams (USBRDrillingGuidelines;USBR, 2014)

USACE: DrillinginEarthEmbankmentsandLevees (ER1110-1-1807;USACE,2014a)

FERC: GuidelinesforDrillinginandNearEmbankmentDamsandtheirFoundations,Version3.1 (FERCDrillingGuidelines;FERC,2016)

TVA: EvaluationsandDesignofDams (TVAStandardProgramsandProcesses(SPP)-27.001; TVA,2022a),whichreferencestheFERCDrilling Guidelines

Supportingdocumentsthatmaybeusedtoassist withtheplanningofintrusiveinvestigations,including

internalandexternalguidancefordrillingandabandonmentofborings,andmethodologies,arelisted inthe References section.TheseincludeAustralian DrillingIndustryAssociation[ADIA],2020;ASTM, 2014,2016,2017,2018a–e;Dustmanetal.,1992;Farrar,1999;FEMA,2005;Luteneggeretal.,1995;Ruda andBosschler,2005;TVA,2013;USBR,1990,1998a, 1998b,2001;USBRandUSACE,2019;andUSACE, 2020b.

Whiletheintentofthisarticleisnottoreiterateinformationpublishedinthesedocuments,thefollowing areconsiderationsthatconstitutegoodpracticeand aregenerallyapplicabletointrusiveinvestigationplanningforprojectsatanydamorlevee(whetherforor regulatedbyafederalorganizationornot).

ResearchingAvailableBackgroundInformation

Researchistheleastinvasiveandsafestwayto gatherinformation.Thistaskincludesgathering,organizing,andreviewingallavailableinformationabout thestructureandsubsurfaceconditions.Potential sourceswillvaryfromprojecttoprojectbutshould includeallrecordsheldbytheownerandpriorownersattheiroffices(local,regional,andnational),at thesite,historicarchives(newspaper,county,state, andfederal–includingtheNationalArchivesand RecordsAdministration),stateandfederalagencies (e.g.,UnitedStatesGeologicalSurvey;stategeologicalsurveys;UnitedStatesDepartmentofAgriculture, NaturalResourcesConservationServicesoilsurveys), andotherresourcesasneeded.

Itisessentialtounderstandthefollowinginformationataminimumaspartofthepreparationforarisk assessmentandanysiteinvestigation:

Originaldesignplansandspecificationsforthe structure

As-builtdocumentation,andhistoryofmodifications

Recordphotosfrompreconstruction,duringconstruction,andpost-construction

Relevantanalyses(particularlystabilityandseepage)

Bedrockgeology,includinginformationaboutgeologicstructure,seismotectonicfeatures,joints,or discontinuities

Surficialgeologyincludingthegeomorphologyof thesiteandsurroundingarea

Hydrogeologicconditions

Inspectionrecords,includinginstrumentationreadings,recordsandperformanceevaluations

Muchofthisinformationistypicallycontained inthesupportingsummarydocumentationforeach structure;however,forvariousreasonsthisisnot

Bensko,Simpson,Terry,andWalker

26 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39

Table1. Supportingsummarydocumentnomenclatureby organization.

Organization

SupportingSummaryDocumentName andAcronym

USBRComprehensiveReview(CR)

USACEPeriodicAssessment(PA)orRiskAssessment (RA)

TVASupportingTechnicalInformation(STI)

FERCSupportingTechnicalInformationDocument (STID)

USBR = U.S.BureauofReclamation;USACE = U.S.ArmyCorps ofEngineers;TVA = TennesseeValleyAuthority;FERC = Federal EnergyRegulatoryCommission.

alwaysthecaseinpractice.Eachorganizationusesdifferenttermsforthesupportingsummarydocuments; seeTable1fortheorganization-specificnomenclature.

PlanningSiteInvestigations

Intrusiveinvestigationprogramsshouldbedesigned bygeotechnicalandgeologicalprofessionalswithexperienceindamandleveesafety.Thefirststepisto definethequestionstobeansweredaswellasthegoals andtargetsoftheprogram,whichwillinformthelocationsanddepthsfortheexplorations,thesamples andotherinformationtocollect,andtheinstrumentationtoinstall.Inmanycases,intrusiveinvestigationprogramsareinitiatedfollowingriskassessments. ForPFMswithadispositionof“InsufficientInformation,”drillingorexcavationmaybenecessaryto collecttheinformationrequiredtoproperlyevaluate thePFM.ForSQRAsorquantitativeriskassessments (QRAs),informationfromtheinvestigationsmaybe neededtoreduceuncertaintyrelatedtorisk-driving failuremodesidentifiedbytheSQRAortoinformor refinenodalestimatesinaQRA.

Theneedfortheinformation,however,mustbebalancedagainsttheriskassociatedwithcollectingit.To thatend,theplanningteamshouldidentifywhatinformationcanbeobtainedbynon-invasiveandminimally invasivemethods.Additionally,forsomeinvestigation programs,phasingmaybeappropriate,withtheprogramtoendwhensufficientinformationisavailable toanswerthequestionsposed,thegoalshavebeen achieved,ortheriskofcontinuingtheprogrambecomesunacceptable.

Documentation

USBR,USACE,TVA,andFERCallrequire detailedplansforfieldinvestigationswithsimilarcontent,althoughnomenclatureandspecificsof howinformationispresenteddifferbyorganization.

FollowingFERC’smethodfororganizinginformation, intrusiveinvestigationplansshouldgenerallyinclude:

(1)Purpose,objective,andjustificationforthework, includinganswerstothefollowing:

• Whydoyouwanttodrillordiginthedamor levee(i.e.,putadefectinthestructure)?

• Didyouconsiderotheralternatives?

• Howwilltheinformationhelpyoumakeadecision?

• Whatifyoudidnothavetheinformation? Wouldthedecisionchange?

(2)Existinginformationcollectedduringtheresearchphaseshouldbesummarizedandkeyinformationpresented,includingbutnotlimitedto thefollowing:

• Geologic,hydrogeologic,andgeotechnicalinformation

• Boringlogsandothersubsurfaceexplorations

• As-builtdrawingsandspecifications;record photographsoforiginalconstructionandmodifications

• Relevantdesignandconstructionreports

• Relevantanalyses

• Inspectionandassessmentreports

• Instrumentationplans,installationrecords, data,andperformancereports

(3)Essentialgeologicandengineeringdrawings shouldshowthefollowingitems:

• Embankmentzones

• Detailsofsubsurfacematerialclassification, geologiccontacts,andcontinuityinterpretationssupportedbyallnearbydrillingandsamplingdetails

• Depthtothetopofrockandallotherzonesof importance

• Piezometerlocationsshowingscreenedinfluencezonesandrecordedpiezometriclevelstied tothereservoirwaterlevel

• Otherinstrumentationsuchasinclinometers, movementmonuments,etc.,showninthecontextofthefoundationgeologycontactsandinterpretations

• StandardPenetrationTest(SPT)blowcounts orother insitu andlaboratorytestresultsdefiningengineeringproperties

• Geophysicaldata,whereuseful(e.g.,crosshole shearwavevelocityprofiles)

• Estimatedextentofanyzonesofinterest,both naturalandmade-made(e.g.,groutholes)

• Seepageareastiedtoembankmentzonesand geologicunits,wherepossible

• Locationsofallinternalandexternalstructures,includingseepagecontrolfeatures,conduits,etc.

BestPracticesforPlanningSiteInvestigationsatDamsandLevees

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 27

• Locationandtypesofanydistressfeatures (seepage,wetspots,sandboils,sinkholes,etc.)

(4)Drillingscopeandmethodology:

• Numberandlocationofproposedborings

• Utilities,surfaceandundergroundobstacles,and accessibility

• Materialsexpectedtobedrilled,sampled,and tested

• Depth,diameter,bearing,andinclinationofborings

• Drilling,sampling(e.g.,SPT,shelbytube,HQ3 wirelinerockcore),and insitu testingmethods (e.g.,vaneshear,pressuremeter,waterpressure [packer]tests,etc.)

• Detailsoftheproposeddrillingequipmentand tooling

• Instrumentationandboreholecompletionrequirements(influencezone,seals,etc.)

• Personnelresponsibleforloggingmaterialsand assuringgeologicdrawingsareupdatedregularly duringthedrillingprogram

• Fieldandlaboratorytestingprogram

• Verificationthat insitu testingpressureswillnot causehydraulicfracturing

(5)Boreholecompletionshouldanswerthefollowing questions:

• Howdoyouplantouseorrepairthedefect?

• Haveyoucheckedthetremiegroutingpressures (hydrostatichead)tomakesuretheywillnot hydraulicallyfracturethestructure?

• Doesgroutingneedtobestagedtocontrolthe pressures?

• Howwillyoubackfillacrossadrainagefeature?

• Istheinstrumentationplanned?

(6)Instrumentationinformation:

• Plannedconstructiondetailsandconstruction methods

• Verificationthatwelldevelopmentandrehabilitationwillnotcausehydraulicfracturingor damagethecasings

• Isinstrumentationtemporaryorpermanent? Willitbeautomated?

(7)Documentationandcoordinationshouldanswer thefollowingquestions:

• Whataretheloggingproceduresorspecifications(e.g.,UnifiedSoilClassificationSystem,InternationalSocietyforRockMechanics, organization-specific)?

• Whatformswillbeused?

• Whatinformationneedstobecollectedinthe fieldduringthedrilling?

• Whoisresponsibleforupdatingtheinformationonthedrawings?

• Howfrequentlywilltheboringlogsbesentin fromthefieldtoupdatethedrawings?

• Whodecidesonchangestotheplanduringthe investigation,andhowarechangesapproved?

(8)Personnelexperienceshouldincludethefollowing:

• Explorationteam:Listmembersoftheexplorationteamthatdevelopedthesiteinvestigationplan.Includename,organization,title, registration,andyearsofexperience

• Drillrigoperators:Includenameandyearsof experience.Noteexperiencedrillinginornear damsorlevees

• Fieldsupervisionpersonnel:Includename,organization,title,registrations,andyearsofexperiencewithdamandleveeinvestigations

(9)Evaluationofpotentialrisks:includeanevaluationoftheriskofhydraulicfracturing,erosion, contaminationofdrainagefeatures,heave,orany otherpotentialdamage.Thisshouldincludethe following:

• Adetaileddescriptionofanydrillingfluiduse includingdetailsonthecirculationsystem,locationswherefluidwillcontactsoil,andcirculationpressuresthatwillbeused

• Monitoringneedsduringdrillingandacontingencyplaniflossofdrillingfluidorothercomplicationsareobservedduringdrilling

• Measurestominimizetheriskofdamagetothe dam,levee,orfoundation

• Measurestopreventthepossibilityofcrosscontaminationandleakagefromconfinedand separategroundwateraquifers

• Measurestopreventdrillcontactwithstructuralfeatures,suchasconduits

• Nearbyinstrumentswhosebehaviorwillbe monitoredduringtheinvestigationandtheexpectedresponse,includingthresholdandlimit values,andcontingencyplansforanunexpectedresponse

• Anemergencyactionplanincludingalistof emergencyequipmentandsuppliestohaveonsite(phoneorradio,filtermaterials,groutmaterials,etc.)

• Potentialremediationproceduresforrisks identified

(10)Other:

• Siteaccessmethods

• Environmentalprotectionmeasures

• NEPA,SHPO,orotherrequirementsandrestrictions

SafetyBeforeScope

Afinalconsiderationisthatinallcases,damand leveesafetyshouldbeprioritizedabovescope.Owners, consultants,anddrillingcontractorshavebeenguilty

Bensko,Simpson,Terry,andWalker

28 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39

ofpushingtocompleteascopeofworkwhilelosingfocusontheoverallsafetyofthestructure.Ifthe subsurfaceconditionswereknown,therewouldbeno needfortheexplorationprogram.Thus,iftheconditionsencountereddifferunfavorablyfromwhatwasexpected,itbecomescriticaltostopandre-evaluatethe planandtheassociatedrisk.Thisis(inpart)whyminimumexperiencerequirementsexistforpersonnelexecutingtheprograminthefield.

ORGANIZATION-SPECIFICPLANNING AND/ORREVIEWPROCESSES

Thissectionprovidesadditionaldetailsregarding planningand/orreviewofintrusiveinvestigationprograms,specifictoeachorganization.

Oncetheneedforanintrusiveinvestigationprogram isjustified,amultidisciplinaryteamdeterminesexplorationcomponentsrequiredtoadequatelyaddressthe dataneeds.Ideally,theexplorationteamincludesthe principalengineer,principalgeologist,geophysicists, andexpertsinlaboratoryanalysis, insitu testing,and otherdisciplinesasneeded.Dataneedsandinvestigationplansarediscussedtoensurecompatibility.Items todetermineincludethefollowing:

Purposeoftheinvestigation

Costoftheexploration

Requiredsampletypeandsize(disturbedorundisturbed)

Acceptabledrillingandinvestigativemethods

Depth,diameter,andinclinationofdrillingrequired Materialstobedrilledandsampled

Utilities,surfaceandundergroundobstacles,andaccessibility

Developmentoffieldexplorationrequests(FERs) occursinternallywithintheUSBRforavarietyof clients,withthelargestpercentagefromtheUSBR DamSafetyoffice.OtherclientsforFERsincludethe BureauofIndianAffairs,BureauofLandManagement,NationalParkService,stateagencies,andother waterdistrictauthorities.Typically,FERsaredevelopedfortheDamSafetyOfficeattheTechnicalServiceCenter,alongwithotheragencies.FERsforother agenciesoccasionallymaybedevelopedwithinthevariousUSBRregions.

AmajorityofFERsarewrittentobettercharacterizesubsurfaceconditionsinsupportofexisting damsafetyissueevaluations,correctiveactionstudies,orfinaldesignsfordammodifications.Other casesforFERdevelopmentincludeassessmentor feasibility-levelsubsurfacecharacterizationsofnew damsites,retrofittingexistingdamsforhydropower, linearprojectssuchascanalsorpipelines,andmany otherprojectapplications.

FERsarewrittenfollowingtheUSBRDrilling Guidelines(USBR,2014),whichsupersedeUSBR’s 1989policydocument.TheUSBRDrillingGuidelinesprovideagencypolicyfortheinvestigationofembankmentdams,includinginvestigationplanning,site preparation,boreholeadvancement,subsurfacetesting,andboreholecompletion.

Specifically,theUSBRDrillingGuidelinesrequire considerationofwhethertheneedforcollecteddata justifiesthecostandpotentialrisktothestructurecreatedbythedatacollectionprocess.Thisincludesthe determinationofpotentialconsequencesifnoaction istakencomparedwithsubsequentinvestigationcost estimates.Consequencesincludeboththeriskandlikelihoodofworseningconditions,whichcoulddriveup futurecostsofremediationifrequired.

Damfoundationgeometryandhazardoffracturing Instrumentationandcompletionrequirements

Typicaldamsafetyinvestigationsincludesampling andtestingmethodstodeterminethepotentialforliquefaction(dynamicstability),seepageandpiping(includingfiltercompatibility),staticstability,collapse offoundationsoils,andcracking.Emergencyrepairs anddamremediationactivitiestypicallyrequiresome drillingcomponenttocollectneededdata.

Specificconsiderationsrelatedtointrusiveinvestigationsincludethefollowing:

Hydraulicfracturingduringthedrillingprocess and/orboreholecompletioncanopenseepagepaths andcreateconditionsconducivetointernalerosion, piping,andultimatelydamfailure.Locationsorsituationsthatrequireparticularcare(orpreferably avoidance)areasfollows:

◦ Inornearcutofftrenchesorcutoffwallswhere stressconcentrationsand/orhighgradientsare morelikelytoexist

◦ Nearstructuresorconduitswithinembankments

◦ ImperviousZone1corewithaninternalslope ratiosteeperthan0.5horizontalto1vertical (0.5H:1V)

◦ ThinZone1core

◦ UpstreaminclinedZone1core

◦ Nearabutmentswhereabruptchangesinslopes (shoulders)occur

◦ Inareaswheretheembankmentissubjectto transversedifferentialsettlementduetolarge changesinthicknessofcompressiblefoundation soils

◦ Nearabutmentssteeperthan0.5H:1V

BestPracticesforPlanningSiteInvestigationsatDamsandLevees

USBR

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 29

◦ Imperviouszonesconsistingofsiltandmixtures offinesandandsilt(e.g.,lowplasticitysoilsthat aremoreeasilyfractured)

◦ Drillinginorthroughgroutcurtains

◦ Nearareassoftenedorweakenedbyseepage

◦ Inlocationsofknowndefectsincompactedfill Damagetointernaldrainagefeatures,eitherdueto drillingorcontaminationwithgroutduringboreholecompletionorabandonment

Drillingorexcavatingatthetoeofadamwherea criticalhydraulicgradientorartesianconditionsexist,includingtheneedtoconstructadrillingberm

Drillingandsamplinglooseorunconsolidatedmaterialsandbalancingdrillingtechniques(e.g.,mud rotary)againstthepotentialforhydrofractureifthe holeisadvancedthroughtheembankment

Presenceofloosecollapsiblesoilswherewetting couldleadtocollapse,cracking,andultimatelyfailureofthestructure.Collapsiblesoilsarepresentin variouslocationsinthearidwesternstatesandunderliesomeearthdamsandsaddledikes.

Qualificationsandexperienceoftheleaddriller whenuseofReclamationcrewsisnotanoption

Preferred,restricted,andprohibiteddrillingtechniques

Instrumentationinstallationsandboreholecompletionorabandonment.Whenusingneatcement grout,specifyingtypeKcement,oraddinguptoone percentgypsumoraluminumpowderwillgivethe cementexpansiveproperties,whichmaybeadvantageousinembankmentdamswhereinternalseepage isanissue.

InadditiontointrusiveinvestigationsconductedundertheFERprocess,drillingassociatedwithremediationcarriesrisksthatmustbeconsidered.Examples includetheuseofcompressedairasadrillingfluidfor advancinggroutholesandjetgroutingwhichinvolves drillingholeswithveryhighairandfluidpressuresat rapidrates.

USACE

USACEsiteinvestigationsfallundermultipleUSACEregulatoryandguidancedocuments(USACE 2001,2014a,2014b,2018,2019,2020,2021)foundin the References section.

TheDrillingProgramPlan(DPP)processdescribed inER1110-1-1807(USACE,2014a)appliestositeinvestigationsatUSACE-ownedandUSACE-regulated damsandlevees,includingsiteinvestigationsconductedunderSection408.Thisincludesanyintrusive workinto,through,orbelowUSACEdamsandlevees withafederalinterest.

ER1110-1-1807includesabackgroundsectionon thepotentialproblemsrelatedtodrillingindamsand leveesandspecificallyidentifiesbasicrisksandpotentialbenefitsofdrillingwithfluidsandtheneedtobalancetheneedforusingfluidswiththepotentialrisks tothestructures.Thedocumentlaysoutthepolicyrequirementsasfollows:

DPPsneedtodiscussoraddressthefollowing topics:

◦ Justificationfortheplannedexploration(s)

◦ Existingdatareview

◦ Restrictionontheuseoffluidsfordrillingindams andlevees

◦ Riskidentificationandmitigation

◦ Boreholecompletion

◦ Drillingpersonnelrequirementsforthedrillerand on-siteoversightbyageologistorengineer

◦ Approval

◦ Exemptionrequirements

AppendixBofER1110-1-1807containsfurther guidanceandageneraloutlineofwhatshouldbeincludedintheDPP.Thesecontentsaresimilartothose describedpreviouslyinthedocumentationsectionand alsoincludethefollowing:

Riskevaluation:thissectionshouldincludeallthe potentialproblemstheproposedinvestigationplan couldcausetothestructureandhowtheyhavebeen addressedbytheplan,includingemergencymeasuresandemergencycontacts

DistrictDamorLeveeSafetyOfficercertification thattheplanfollowsER1110-1-1807

Additionalrequirementsbeyondwhatislistedabove includeaminimumoffiveyearsofexperiencedrilling indamsandleveesforthedrillerandfieldpersonnel loggingtheboringsandtheneedforeitheralicensed engineerorgeologisttobeonsiteandinresponsiblechargeofthedrillingwork.Thispersonneedsto beknowledgeableenoughabouttheplanneddrilling tobeabletorespondtoanysituationsoremergenciesthatmayarise.Lessexperiencedpersonnelare notexcludedfromloggingborings,providedafully experiencedsupervisoryprofessionalispresentonsiteduringdrillingoperations.ER1110-1-1807coversalldrillingindamsorleveeswithUSACEinterestnomatterthepurpose,includingbutnotlimited toinvestigations,instrumentationreplacement,relief wells,andconstruction-relateddrillingincludingcutoffwalls,grouting,andinstallationofutilitiesthrough orbelowthestructures.

USACEreviewoftheDPPs,whethergeneratedinhouseorbyconsultants,forUSACEinvestigations orinvestigationsbyothersunder408permits,allfollowthesamebasicprocess.Requirementsarelisted

Bensko,Simpson,Terry,andWalker

30 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39

inER1110-1-1807,withadditionalguidanceprovided byEM1110-2-2902(USACE,2020).Theplansare firstreviewedbythelocaldistrictstoensuretechnicalcontentisappropriateandforquality-controlconsiderations.TheplansarethensubmittedforAgency TechnicalReview(ATR)bythedrillingandinstrumentationcommitteeoftheGeotechnical,Geology, andMaterialsCommunityofPractice(GG&MCoP). ThereviewprocessismanagedfortheGG&MCoP bytheRiskManagementCenter.TheATRbythe GG&MCoPisnormallydonebytwotothreemembersfromacrossUSACEwhoaregeologistsand/or geotechnicalengineers.Reviewcommentsareprovidedbacktothedistrictthatsubmitstheplanfor review.

Goalsandconsiderationsofthisprogramareas follows:(1)Donoharmtothestructures.(2)Fluids usedwhenneededduringthedrillingandabandonment(grouting)oftheboringshavealowriskofcausinghydraulicfracture.(3)Thedrillinghasalowriskof causingdamagetothestructure.(4)Theinvestigation plannershavethoughtthroughanddescribedpotentialproblemsalongwithappropriateresponseplans andmaterialstohaveavailabletoaddresspotentialissues.(5)Bereadytoreactappropriatelytoanyproblemsthatmayarise.

USACE’sreviewprocessforinternallydeveloped DPPsandassociatedworkdevelopedtosupportan IESisslightlydifferentfromthereviewprocessfor DPPspreparedbyentitiesexternaltoUSACE.The teamsthatdeveloptheplanspresentthemtoagroup ofseniorgeologistsandgeotechnicalengineerswith significantexperienceinplanningandexecutingfield workondamsandlevees.Thesepresentationsbythe riskassessmentteamaretypicallyvirtualmeetings. Duringtheseinteractivemeetings,thereviewersask questionsandprovidecomments,suggestions,andrecommendationsbacktotheteamwithfollow-upcommentswrittenbytwoorthreeofthereviewersprimarilyfocusedontheDPPportionsoftheplan.These plansaregenerallyphasedwithpredeterminedtriggers forthenextphaseofinvestigationandevaluationas needed.Whensiteinvestigationissuesarise,thereview teamsubjectmatterexperts(SMEs)arere-engagedto assisttheriskassessmentteaminfindingsolutions. ThisactiveinvolvementofSMEswiththeriskassessmentteaminupdatingandmodifyingtheplanshas reducedUSACE’stimeandcostrelatedtositeinvestigationsandriskassessments.

Inallcases,thereviewmanagerandreviewersare availabletodiscusstheircommentsandresolution ofthemwiththesiteinvestigationdesignteamto helpfinalizetheplansandwhenneededdiscussmodificationsduringthesiteinvestigationsorintrusive activities.

TVA

AsdepictedinFigure9,theheadofTVA’sDSPis theAgencyDamSafetyOfficial(ADSO),aposition currentlydelegatedbyTVA’schiefexecutiveofficerto thechiefoperatingofficer.FromtheADSO,thereare twobranches:governanceandexecution.Governance includestheDamSafetyOfficer(DSO),andtheDam SafetyGovernance&Oversight(DSG&O)organizationthatprovidesday-to-daygovernanceandoversightoftheDSPonbehalfoftheDSO.Ontheexecutionside,AssetOwners(AOs)aretheexecutivesfor thevariousbusinessunitsthatownresponsibilityfor assetsthatclassifyasdams.AOsdesignateaResponsibleEngineeringManager(REM)foreachstructure intheirrespectiveinventories,andtheREMisresponsibleforensuringthatDSPrequirementsaremetfor theirassignedstructures.

DamSafetyServices(DSS)providesin-housetechnicalsupport.Forintrusiveinvestigations,theAOwill generallyengageaconsultanttohelpdeveloptheexplorationprogram,andtheconsultantwillinturnhire theexplorationcontractor.

TherequirementsoftheTVADSParedescribedin aseriesofinternaldocumentsreferredtoas“Procedures.”Thetop-tierdocumentdefinestheframework oftheprogramitself;eighttier-downsectionsdescribewhatisrequiredconcerningevaluationand design,construction,operationandmaintenance,inspections,instrumentation,emergencypreparedness, governance,andriskassessment;andtheneachAO developsaparallelsetof“Procedures”thatdefine howtherequirementsoftheTVA-levelprocedureswill beimplementedwithintheirparticularbusinessunit. Overall,TVA’sDSPismodeledafterboththeFERC frameworkandFEMA’sFederalGuidelinesforDam Safety(FEMA,2004).Tothatend,theFERCDrilling Guidelines(FERC,2016)areincorporatedintoTVA’s DamSafetyProceduresbyreference.

SeparateorganizationswithinTVAactasowners andregulatorswhenitcomestointrusiveinvestigations.Foratypicalriverdaminvestigationproject, theREMservesastheprojectmanager;ageotechnicalengineer,geologist,orstructuralengineerfrom DSSservesasthetechnicalmanager;andresponsibilityfordevelopmentandexecutionoftheexploration scopeiscommonlyoutsourcedtoanexternalconsultant.AOsarerequiredbyprocedure(TVA,2022aand 2022b)tosubmitinformationaboutplannedintrusive inspectionsforreview,andDSG&OreviewstheAO’s submittalonbehalfoftheDSO.

ThetypicalprocessforplanninganintrusiveinvestigationataTVAdamstartswhenanAOidentifiesthe needforsubsurfaceinvestigation(tobetterquantify risk,supportthedesignofamodification,etc.).TVA

BestPracticesforPlanningSiteInvestigationsatDamsandLevees

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 31

developsthegeneralscopeandoverallprojectobjectivesandcontractswithaconsultanttoplantheprogram.Theconsultantthendevelopsaninvestigation planandothersupportingdocuments,asrequired. Next,theAOinformsTVA’sDSOoftheplannedwork andsubmitssupportingdocumentationtoDSG&O forreviewandcomment.

Intrusiveinvestigationandsubmittalsareintended tobescalablecommensuratewiththescope,complexity,andriskoftheproject.DSG&Oexpectsto receiveaworkplanthatgenerallyincludesthefollowinginformation(asapplicable):(1)reason(s)forthe investigation,includingjustificationthattheneedfor subsurfacedataorinstrumentationneedsoutweighs therisksassociatedwiththeintrusiveinvestigation(s);

(2)location(s),depth(s),inclination(fromvertical)and bearing(asapplicable)ofproposedinvestigationholes;

(3)dimensions(length,width,depth,andsideslope angles)oftrenchesortestpits;(4)anticipatedsubsurfaceconditions;proposedinvestigationanddrilling techniques,includingchangeoversbetweendrilling methodsandtype(s)ofplannedsamplingand insitu testing;(5)lengthoftimethatboringsand/orexcavationsareexpectedtoremainopen(notbackfilled);(6) plannedholecompletion(i.e.,instrumentationinstallationorabandonment),includingproposedproducts andmaterials,mixingproportions,andinstallation andplacementtechniques);(7)documentationthat boththeresponsibleon-siterepresentativeandlead drillrigoperatorandequipmentoperatormeetexperiencerequirements;(8)plannedsiterestoration andrepair,includingpatchingofreinforcedormass concrete,asphalt,orturf;and(9)anoverallproject schedule,includingthedurationofdrillingactivities. Fornon-drilledexcavations(testpits,testtrenches, etc.),adescriptionofthebackfillplan,including materialspecifications,placementtechniques,and compactionrequirements,shouldbeincluded,andif instrumentationisplanned,notewhichPFM(s)the instrumentsareintendedtomonitorordetect.When applicable,theriskofcausinghydraulicfractureof theembankmentand/orunderlyingformationdueto theintroductionoffluid(whetherduringdrilling, in situ testing,orbackfillingthehole)alsoneedstobe consideredandevaluated,andmethodsforcalculating andmonitoringallowablehydrostaticand/orapplied pressuresinthefieldneedtobedescribed.

Acontingencyplantoaddressand/ormitigatethe risksassociatedwithdrillingchallenges,geologichazards,and/ordamsafetyissuesthatcouldbeencounteredortriggeredbytheintrusiveinvestigationactivitiesneedstobeprovided.Thisrequirementoriginatedduetotheextensivepotentialforkarstacrossthe TennesseeValleyandhasexpandedbasedonindustrylessonslearned.Potentialdrillingchallengesand

hazardstoaddressinclude(butarenotlimited to)voidsandroddrops,lostcirculation,heaving sands,artesianconditions,pipingandinternalerosion, blowout,contaminationofdrainagematerials,inducementofslopeinstability,presenceofhazardousand explosivegasses,andthepresenceofburiedorembeddedconduitsandotherappurtenances.Anexampleof acontingencymeasureisstockpilingmaterialsnecessarytoconstructareverse-gradedfilterandcoordinatingwithamaintenancebasetostationabackhoeor excavatoratornearthedamwhendrillingnearthetoe ofanembankmentinknownkarstterrain.

TheotherrequireddocumentisaQualityManagementPlan(QMP).TheQMPisintendedtoensureintrusiveinvestigationactivitiesmeetTVA’sdamsafety andcontractrequirementsbyensuringQAandQC activitiesareperformedcompetentlyandconsistently andinamannerthatwillidentifyandaddressdam safetyissues.TheQMPcommonlyincludesanaccountabilitymatrixthatdescribeswhoholdstheultimatedecision-makingauthorityforvariousactivities throughoutexecutionoftheinvestigationprogram, andwhoisauthorizedtostopthework.

AttheAO’sdiscretion(orifrequiredbyTVA’s DSO),twoadditionaldocumentsthatmayberequired (typicallyformorecomplexand/orhigherriskinvestigationprograms)areatemporarysupplementtothe EmergencyActionPlan(TEAP)andTemporaryInstrumentationMonitoringPlan(TIMP).TheTEAP addressesdetectionofandresponsetoeventsduring intrusiveinvestigationsthatcouldthreatenthesafety ofthestructureanddescribestheresponsibilitiesand communicationproceduresshouldanemergencyoccur.ATIMPidentifiestheinstrumentstoberead, thefrequencyofreadings,andresponsibilitiesfordata evaluationduringtheinvestigationprogram,aswell asalertandactionthresholds,communicationprocedures,andresponseprotocolsifathresholdisexceeded.WhenaTIMPisnotrequired,theworkplan shoulddescribeanymonitoringofexistinginstrumentsand/orinspectionsplannedtobeconducted duringtheinvestigationprogram.

DSG&Oreviewsthesubmittalforcompliancewith TVAproceduresandgeneralindustrybestpractices (includingtherequirementsoftheFERCDrilling Guidelines)andprovidescommentstotheAO. DSG&OalsodeterminesiftheprojectrequiresformalDSOconcurrence.(Concurrenceisgenerallyreservedforprogramsthatareunusuallycomplexor whichcarryelevateddamsafetyrisk;forexample,the programscopeinvolvesdrillingthroughthecoreofan embankmentdamorinjectingfluidsunderpressure.) Oncecommentsareresolved,DSG&OeitherrecommendsthattheDSOconcurwiththeAO’splanned program,or(morecommonly)notifiestheAOthat

Bensko,Simpson,Terry,andWalker

32 Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39

concurrenceisnotrequired,andthatDSG&Otakes noexceptiontotheexecutionoftheproject.Inthe eventofsignificantmodificationstotheplannedactivities,AOsarerequiredtoinformtheDSOandallowtimeforsupplementalreviewandcommentby DSG&Oasnecessary.

Separatefromthesubmittalreviewdescribedabove, AOsalsoneedtoobtainadrillingandchippingpermitand/oranexcavationpermitinaccordancewith TVATechnicalInstructionTI-DS-0002(TVA,2022c). ThisisaninternalTVAprocessthatevaluatespotentialconflictswithundergroundorembeddedinfrastructure.Drillingandchippingpermitsapplytopenetrationsgreaterthan2in.(5cm)inconcreteandto geotechnicalboringslessthan12in.(30cm)indiameterinconcrete,rock,earthenembankments,orareas adjacenttothedam.Excavationpermitsapplytotest pitsorotherexcavationsopenedbynon-rotarymethodsandboringsgreaterthan12in.(30cm)indiameter. Forinvestigationsofnavigationstructures,theprocess alsoincludescoordinationwiththeUSACELockmaster.Additionally,TVArequiresaHASPbedeveloped (althoughthisrequirementoriginatesoutsideofDam SafetyandDSG&OdoesnotformallyreviewHASPs).

DSG&OalsoreviewsconstructionandmodificationprojectsonbehalfoftheDSOandmakesrecommendationstotheDSOaboutprovidingformal concurrence.DSG&Oconductsanoveralldesignreviewandforconstructionprojectsthatincludedrilling (e.g.,secantpilewalls,shaftfoundations,confirmation borings,etc.)aspartoftheproject.DSG&Oreviews thedrillingscopeforconsistencywithtypicalindustry standardsandTVAprocedures,andAOsareobligated toresolveDSG&O’scommentstothesatisfactionof theDSObeforeconcurrenceisprovided.

Oncetheintrusiveinvestigationprogram(orconstructionandmodificationproject)iscomplete,theresultsneedtobeincorporatedintothenextregularupdatetotheSTIdocumentforthedam.

FERC

D2SIisresponsiblefordevelopingandimplementingFERC’sDamSafetyProgramtoevaluatethe integrityofwaterretainingstructures,theadequacy oftheemergencyactionplansdevelopedtoachieve publicsafety,andthesecuritymeasuresdevelopedto includethethreatofcyberattacks.Thisincludesoversightofthedesign,construction,operation,andmaintenanceofthedamsandwaterconveyancestructures withinFERC’sjurisdiction.Theregulatoryauthority vestedtoFERCisdescribedin18CFRPart12(CFR, 2020)whichalsooutlinestheresponsibilitiesofthe projectlicensees.D2SIhasonecriticalmission:the safetyofdamsunderFERC’sHydropowerProgram.

TherolesandresponsibilitiesthatFERCplaysduringdesignandconstructiondiffergreatlyfrommost agencies.FERCisnottheowneroftheprojectsand doesnotdesignorprepareplans,specifications,or contractdocuments,nordoesitgetinvolvedwithany contractorprocurement.Astheregulatorybody,for theconstructionofanewprojectorremediationof anexistingprojectaddressingPFMs,FERCservesto reviewandapprovetheplanandscheduledeveloped bythelicenseetoperformtheworkanddefinethe pathmovingforwardtoensurethesafetyoftheproject (Figure10).

Damsclassifiedashavingahighhazardpotential, havingaheightgreaterthan32.8ft(10m)abovethe streambed,orthatimpoundmorethan2,000acre-feet (2.5millionm3 )ofwater,fallundertherequirements ofPart12DoftheCommission’sregulations.InApril 2022,arevisiontotheregulationsbecameeffective thatchangesthewayPart12Dinspectionswillbeexecuted.AsdescribedinChapter16oftheEngineering GuidelinesfortheEvaluationofHydropowerProjects (FERCEngineeringGuidelines;FERC,2021a),the inspectionswillalternateeveryfiveyearsbetweena PeriodicInspection(PI)conductedbyanIndependentConsultant(IC)andaComprehensiveAssessment(CA)performedbyanICandateamofSMEs. APIisprojectperformancefocused,whileaCAisa morein-depthandcomprehensiveassessmentofthe project.ThescopeoftheCAincludesaPotentialFailureModesAnalysis(PFMA)alongwithaLevel2 RiskAnalysis(L2RA)asdefinedinChapter18ofthe FERCEngineeringGuidelines(FERC,2021c).The PFMAprocessisdescribedinChapter17oftheFERC EngineeringGuidelines(FERC,2021b)andincludes identificationandscreeningofPFMs.TheL2RAthen estimatestheriskassociatedwithcrediblePFMstoinformprioritizationoffutureriskreductionactivities.

BoththePFMAandL2RAprocessesmayidentifytheneedforsite-specificinvestigations.Duringthe PFMA,theinformationavailablemaybeinsufficient tofullyevaluatesomepostulatedPFMsandaccurately determinetheircredibility.DuringtheL2RA,limited informationmayintroduceahighdegreeofuncertaintywhenestimatingtheriskassociatedwithacrediblePFM.Subsurfaceinvestigationtocollectadditionalgeologicandgeotechnicalinformationthenbecomesnecessarytoclosedatagaps,supportadditional evaluationsandanalyses,orrefineriskestimates.Informationobtainedfromsiteinvestigations,associated testing,andinstrumentationcanalsobeusedtoinformdesignofbothremediationandnewconstruction projects,andtoaidindetermininganyRiskReduction Measuresthatmaybenecessary.

Afteritisdeterminedthatasiteinvestigationisrequired,theDPPispreparedandsubmittedbyali-

BestPracticesforPlanningSiteInvestigationsatDamsandLevees

Environmental&EngineeringGeoscience,Vol.XXIX,No.1,February2023,pp.17–39 33

censeetoFERC.TheDPPisrequiredbyFERCfor anydrillingprojectandmustfollowtheFERCDrilling Guidelinesthatprovideinformationonthehazardsof drillingatanembankmentdamandguidanceforplanningandpreparingaDPP.Theguidanceprovidedin theFERCDrillingGuidelinesalignsverycloselywith thoseofUSACEandUSBR.Thedifferencebetween theseorganizationsisbasicallyhowtheDPPsrequired foranydrillingprojectarehandled,processed,and implemented.