Equip your firefighting arsenal with the ultimate aerial advantage. Our state-of-the-art firefighting aircraft are designed to tackle the most challenging wildfires with precision and efficiency. Our extensive selection of parts ensures you have optimal performance and longevity for your aircraft.

With more than 60 years of experience working alongside the firefighting community, Perimeter Solutions offers the most comprehensive set of fire retardant solutions on the market today – featuring field-proven products, infrastructure, equipment and logistics services. We invest in all of these to help you meet your goals of performance and safety in wildland firefighting operations.

When you choose PHOS-CHEK® you’re getting more than just retardant. You’re getting a company that understands your mission-critical needs and how to deliver them –every day. So you don’t have to worry about meeting the challenge of your next fire.

Trusted. Solutions That Save.

Experience

Performance

Fire Support Infrastructure

Resilient Response

Knowledge Base

Innovation

Reliable, 24/7 Response

DISPLAY

Casey Armstrong casey@marsaylmedia com

Melanie Woodley melanie@marsaylmedia com

CREATIVE DIRECTOR:

Felicia (Lisa) Pannell lisa@marsaylmedia com

CIRCULATION: Mary Jane Virden maryjane@marsaylmedia com

CONTRIBUTING WRITERS: Igor Bozinovski bozinovski igor@gmail com

Robert Craymer robertc@covingtonaircraft com

Dan Reese dan@intwcg com

Paul Seidenman avwriter@sbcglobal net

Dave Soderstrom davesoda727@hotmail com

Babak Taghavee babaktaghvaee@gmail com

CONTRIBUTING PHOTOGRAPHERS:

Kane Arlow

Igor Bozinovski

Marissa Fortney

Aaron Maurer

Jeff Serpa

Dave Soderstrom

Marty Wolin

PROUD MEMBER: FIND US ON:

© COPYRIGHT 2025 AerialFire retains all rights for reproduction of any material submitted, to include but not limited to articles, photographs, emails and bulletin board posts. All material remain the copyright of AerialFire. No part of this publication may be reproduced, in part or whole, without the written consent of the publisher. Editorial published do not necessary reflect the views of the publisher. Content within AerialFire is believed to be true and accurate and the publisher does not assume responsibility for any errors or omissions. Unsolicited editorial manuscripts and photos are welcomed and encouraged. We cannot be responsible for return unless submissions are accompanied by a stamped, self-addressed envelope. Advertising deadline is 12 noon, on the 1st of the month preceding the month of publication.

AerialFire is Published bi-monthly by Marsyal Media P.O. Box 850, Perry, GA 31069 USA 475 Myrtle Field Rd., Perry, GA 31069 USA

Phone / Fax: 478-987-2250

info@marsaylmedia.com

Graham Lavender | graham@marsaylmedia.com

In keeping with tradition, this issue looks back at the previous six issues and the phenomenal stories they told.

Each issue is highlighted, and a QR code follows the paragraph to read more about the particular cover story. The complete issues are also posted online. Some memorable stories, such as the Israeli Police Force’s SEAT program, Orange County’s Firehawks and Polish Domaders, were told.

But let’s go back to the central theme of this editorial. A new year is a time to renew, review and reevaluate. What worked

last year? What didn’t work last year? What are you planning on changing? What are you planning on improving?

What can you learn from any incidents that you experienced? Are their new systems to be implemented and new SOPs to utilize? The first of the year is an excellent time to answer those questions.

After many conversations with George Parker, an aerial application operator from Idaho, he finally submitted his first article to our sister publication AgAir Update. Now, I am running the same story in this issue of AerialFire. It applies to this industry as well. If you know George, which I assume most do, you know not only does he have a

wealth of knowledge on all things aviation-related, but he also has a unique gift to explain them. George has taken an unknown amount of man hours and developed a program he uses on his first-year pilots. The program is adopted from many sources, but the main focus is having a take-off “profile.” It’s exceptional information for both the new and experienced pilots.

March will bring the first International tradeshow, in Bordeaux, Franc e hosted by Tangent Link. You can find AerialFire there. Please stop by the booths and give me your next story idea!

Fly Safe!

Robert Craymer | robertc@covingtonaircraft.com

Many things in life come with a warranty, but you can be disappointed and infuriated if you don't read the terms and conditions or understand them. Hopefully, the Ag engine warranty that Pratt and Whitney Canada provide is clear to you. Let's ensure that you are getting the most out of the warranty provided to you.

Pratt & Whitney Canada has a two-part warranty coverage in their enhanced warranty for Ag engines. Just for your information, militaryuse engines have different warranties. For older Ag engines, the warranty period is the first 1000 engine operating hours from the date of engine shipment. For newer Ag engines, based on the serial number, the warranty period is 2500 operating hours or five years, whichever occurs first. After five years, if TTSN is below 1,000 hours, a basic warranty will still apply up to 1,000 hours. P&WC warrants that the new engine will be free from material and/or manufacturing workmanship defects. The warranty defines a defect as a part's breakage

or failure as determined by P&WC caused by a material defect or manufacturing workmanship. You need to check the warranty coverage information for your coverage and other exclusions.

Alongside this basic warranty exists some additional warranties provided to you—the Primary Parts Service Policy or PPSP and the Extended Engine Service Policy or EESP. The PPSP includes support for a specific group of parts. This coverage extends beyond the 2500 warranty, sometimes to TBO or even 5000 hours. The group of parts is listed in the warranty documentation. This is pro-rated coverage, and the list includes a formula for determining available coverage. If the primary part affected is repaired during the process, it will continue its class life. If the part is replaced with a new one, the primary part warranty starts at zero. This has the potential to be a huge benefit that not many people are aware of.

The EESP or Extended Engine Service Policy was brought about by an engine suffering extensive damage from a warrantable, chargeable event. The P&WC warranty administrator may determine that a premature overhaul is required. If this happens, you may receive a LCO or Limited Cost Overhaul. The other thing that could happen

(Continued on page 14)

is a like value engine exchange. This coverage is again based on hours and cycles consumed. Items like engine age, environmental, operational, and maintenance conditions may also be viewed to determine coverage. We have had several engines that have fallen into this coverage. You might be surprised at the level of support P&WC can provide.

P&WC also provides Commercial Support Programs Notices or CSPNs for some events. There are program notices for various parts, for example, an inspection of some fuel nozzle tips and replacing some gear sets in the reduction gearbox. A wide variety of items have been identified as requiring commercial support. P&WC has also provided coverage for the power turbine blade replacement at 5000 hours on the PT6A-67AG through a CSPN. If you are unaware of this coverage, the blades can be replaced at 50% off the list through commercial support coverage. Questions about commercial support? Time to ask them.

Now, let's review what is not covered. As with every warranty, some things fall into this category. Routine line maintenance and adjustment costs, including other standard maintenance items, are not covered. Engine overhaul or major refurbishment costs are not covered. Hot section inspections and refurbishment costs associated with hot section inspections are not covered. This doesn't mean that if a part in a hot section prematurely needs repair, it isn't covered. More times than I can count, P&WC has covered components in a hot section by covering repair costs or replacing them. Items like seal rings or segments are not typically covered; their replacement is normally as a refurbishment to reestablish proper sealing or clearances. This also falls into the category of normal wear, tear and deterioration. P&WC also reserves the right to exclude warranty coverage if other than original or authorized parts are used. Parts used in your engine must have traceability or certification, including filters. If parts have been involved in a previous accident or are not repaired in accordance with P&WC approved process, it can also lead to exclusion. Another group of factors beyond P&WC's control is listed in the literature, and I strongly recommend reviewing those. If you need a copy of the warranty program, contact your field service manager, or we can help.

Your responsibilities are simple. Operate and maintain your engine in accordance with written instructions, including the maintenance manuals and service bulletins. For instance, document the results of

your borescopes when you do your fuel nozzle maintenance. P&WC has asked me for this data before asking for warranty consideration on a hot-section project. This brings me to my next point. Keep adequate maintenance records. You may be requested to provide this data to the warranty administrator. Claims must be made within 30 days of discovery, and claims must be submitted within 180 days. Claims must include the defective part and must be made through a designated facility or distributor. This is where repair or replacement parts must be procured. If you have a warranty issue, please get in touch with your Pratt & Whitney Canada Field Service Manager. That is the place to begin. Send the engine for repair to an authorized facility, such as Covington Aircraft. For more help, feel free to reach out, and I can help you through the process.

Robert Craymer has worked on PT6A engines and PT6A-powered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and is an instructor of PT6A Maintenance and Familiarization courses for both pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member.

Robert can be reached at robertc@covingtonaircraft.com or 662-910-9899. Visit us at covingtonaircraft.com.

SUBARU BELL 412EPX

The most reliable work trucks are transformed and reborn year after year for decades. When you’re fighting wildland fires from the sky, critical moments require experienced and renewed solutions. The upgraded transmission of the new 412 EPX provides 11% more shaft horsepower at takeoff, resulting in a 15% boost in the hot and high hover. Add in an unprecedented increase for internal, external and cargo hook with 1100 payload pounds added. Proven operational readiness now with more payload, more firemen and women, more water…and more power to fight fire.

bell.co/publicsafety

Tiffany Taylor | ttaylor@uafa.org

The United Aerial Firefighting Association (UAFA) hosted its Annual Conference from November 1214, in downtown Boise, Idaho, bringing together key stakeholders in the wildland fire industry for comprehensive discussions on industry developments and challenges.

With 170 attendees, the conference saw a impressive 70% jump in participation compared to last year, highlighting the growing importance of this industry gathering.

The two-day conference featured an extensive agenda focused on strengthening collaboration among federal, state, and private sector partners in wildland firefighting operations. The first day centered on a crucial After Action Review (AAR) with federal and state agencies, including leadership from the U.S. Forest Service, Bureau of Land Management, and Department of Interior’s Office of Aircraft Services. State forestry representatives from Nevada and Idaho also participated in these discussions.

New UAFA Board Members, Bridger Blaine (Billings Flying Service) and Nic Lynn (Neptune Aviation Services), were elected to twoyear terms, replacing Jennifer Draughon (term expired) and Tim Sheehy (resigned).

A key event at the conference was the member meeting on day two with keynote speaker, Montana Senator-elect Tim Sheehy. He emphasized the significance of the aerial and ground industry and the need for contracts which help to sustain the industry, promising to work on the issue when he joined the Senate. Idaho State Director of Lands, Dustin Miller, spoke on the need for states to be collabrative yet self-sustaining in their

wildfire response. A recap of the UAFA committee activities was presented, highlighting the work towards development of a wildland fire standards of cover, a key recommendation of the Wildland Fire Mitigation and Management Commission.

Particularly significant were two workshops focusing on critical operational aspects: a response to accidents and incidents workshop, and a contracting workshop addressing recent changes and future expectations. These sessions aimed to enhance safety protocols and provide insight of federal government priorities the industry should plan for.

New this year was the presence of the ground industry, with the National Wildfire Suppression Association (NWSA) and Grayback Forestry providing sponsorship. The meeting concluded with a mutual commitment by the UAFA and the NWSA Boards to collaborate on improvement of the entire industry.

The event also benefited from the support of sponsors 10 Tanker, AeroLeds, Billings Flying Service, Bridger Aerospace, Cirro by Airsuite, Dauntless Aviation, FireHawk Helicopters, Neptune Aviation Services, Overwatch Aero, Perimeter Solutions, PJ Helicopters, Titan Aviation Fuels, Tracplus, Trident Sensing, Trotter Controls, and United Rotorcraft.

For more information about future UAFA events or membership, contact membership@uafa.org or visit uafa.org/contact.

This year, AerialFire reflects on the standout stories that shaped the past 12 months, offering readers quick summaries and a chance to revisit these highlights. Scan the accompanying QR codes with your smartphone to dive back into the articles that defined the year.

Billings Flying Service (BFS), a family-owned aviation enterprise based in Montana, has evolved over its 40-year history from modest beginnings in agricultural aviation to a prominent position in aerial firefighting.

Founded by Gerhart Blain in the 1950s as Blain’s Spray Service, the company initially focused on crop spraying. Gerhart’s sons, Al and Gary, inherited his passion for aviation, becoming skilled mechanics and pilots. In the late 1970s, the acquisition of a Hughes 300 helicopter marked the family’s entry into rotary-

These aircraft are renowned for their capacity and versatility in combating wildfires. Al emphasizes that the company’s success is attributed to its dedicated team, stating, “Our team—they are our most important resource. They will truly move heaven and earth when asked.”

Today, BFS stands as a testament to the Blain family’s dedication and innovation in the aviation industry, maintaining a strong commitment to excellence in aerial firefighting and other aviation services.

(Continued on page 20)

San Diego Gas & Electric (SDG&E) has developed a comprehensive aerial firefighting program to enhance wildfire response in the San Diego area. This initiative began in 2010 during the Sunrise Powerlink project, which utilized helicopters extensively for construction in remote areas.

Recognizing the need for organized aerial support, SDG&E established an Aviation Services department to manage and audit contracted helicopter services, ensuring safety and efficiency. Over time, the company expanded its

capabilities to include a dedicated fleet of two aircraft, supplemented by two additional call-when-needed aircraft, providing 24/7 aerial firefighting support year-round.

This proactive approach positions SDG&E as a unique utility provider with robust aerial firefighting resources, demonstrating a commitment to community safety and wildfire mitigation.

Read More in our March/April 2024 Issue:

(Continued on page 22)

In early January 2024, Hillsborough County, Florida, hosted a comprehensive multi-agency aerial firefighting training exercise. Participants included the Florida Forest Service, Tampa Police, Hillsborough County Sheriff’s Office, Hillsborough County Fire, Martin County Sheriff, Charlotte County Sheriff, and Seminole County Sheriff. The event featured over ten aircraft, including Bell UH-1H helicopters, Bell 407s, Airbus H125s, and the Florida Forest Service’s recently acquired Leonardo AW119Kx. Ground crews contributed with bulldozers, trucks, and fire apparatus. The exercise involved controlled burns to simulate real-world wildfire scenarios, enhancing

coordination between air and ground units. The Hillsborough County Sheriff’s Training Academy served as the operational base, with a nearby lake utilized for water sourcing during aerial drops. Sergeant Jason Doyle, Unit Supervisor of the Hillsborough County Sheriff’s Aviation Section, led the meticulous planning and execution of the event.

Read More in our May/June 2024 Issue:

Since May 2011, the Israeli National Fire and Rescue Authority has utilized AT-802A/F Air Tractors as primary aerial assets for firefighting operations. Initially operated by the Israeli Air Force’s 249 ‘Elad’ Squadron at Sde Dov airport near Tel Aviv, these aircraft have been under the Israeli Police Aviation Unit’s jurisdiction since November 2016. The fleet, comprising fourteen AT-802s, is based at the historic airfields of Kedma and Megiddo and has been extensively deployed to combat wildfires in Israel and abroad, notably in Cyprus. In response to numerous arson-induced wildfires during the past summer,

the Air Tractor fleet is being readied for intensive aerial firefighting in the forthcoming fire season.

The 249th ‘Elad’ Aerial Firefighting Squadron was established following the devastating Mount Carmel forest fire in December 2010, which resulted in 44 fatalities and significant displacement.

Read More in our July/August 2024 Issue:

In response to the devastating Silverado, Blue Ridge, and Bond Fires of 2020, which collectively scorched over 27,000 acres in Orange County, the Orange County Fire Authority (OCFA) initiated a comprehensive modernization of its aerial firefighting capabilities.

Under the leadership of Fire Chief Brian Fennessy, appointed in 2018, OCFA retired its aging Super Huey helicopters in 2021, leaving the fleet with two Bell 412EPs acquired in 2009. Recognizing the need for enhanced aerial support, OCFA selected the Sikorsky S-70 FireHawk as its next-generation firefighting aircraft. A purchase agreement for two identical S-70M FireHawks was finalized in November 2022, with

the aircraft delivered to Orange County on June 22, 2024. Following rigorous crew training, these advanced helicopters entered service on August 19, 2024.

OCFA’s pilot cadre comprises six highly experienced aviators, many with military backgrounds, each meeting stringent flight hour and specialized experience requirements. The agency mandates a minimum of 4,000 total flight hours, including 1,500 hours in mountainous terrain and at least 100 hours of night flying, ensuring operational proficiency in diverse and challenging conditions.

The integration of the S-70 Firehawks significantly enhances OCFA’s aerial firefighting capabilities, positioning the agency to more effectively combat increasingly severe wildfires in California.

Read More in our September/October 2024 Issue:

Mieleckie Zakłady Lotnicze Sp. z o.o. (MZL), formerly known as ZUA, is a Polish company specializing in aerial firefighting and agricultural aviation services. Established in 1972 as part of WSK PZL Warszawa Okęcie, the company has undergone several ownership changes, including acquisition by EADS CASA (later Airbus Poland S.A.) in 2001. In October 2022, it became an independent entity under the Łukasiewicz Research Network – Institute of Aviation.

MZL operates a fleet primarily composed of 25 PZL M-18 Dromader aircraft and 9 AN-2s. The M-18 Dromader, a singleengine, low-wing monoplane designed for short and unpaved airstrips, is particularly suited for firefighting operations.

Its durability and reliability make it adaptable for both firefighting and agricultural missions.

Since 1960, Polish aviators have been integral to forest protection, responsible for fire spotting and reporting to authorities. MZL continues this tradition, contributing significantly to aerial firefighting efforts in Poland and internationally.

Read More in our November/December 2024 Issue:

Conair Group Inc. (Conair) has expanded the in-house ability to perform Non-Destructive Testing (NDT) on their aerial firefighting aircraft maintained in Canada, a fleet of over 55 planes.

ABBOTSFORD, CANADA (November 15, 2024) – This expansion mitigates the need to rely on third party providers, further enabling the company the ability to schedule and complete inspections between fire season contract periods, ensuring bird dog lead planes, airtankers and water scoopers are available to government agencies when needed.

Non-Destructive Testing is an essential component to safety and sustainability

within aerial firefighting as aircraft fly in dynamic environments that challenge airframes, facing heat, repeated changes in altitude, and turbulent conditions, as well as dramatic changes in weight during flight due to water and retardant drops.

A thorough NDT inspection of a large airtanker, such as a Dash 8-400AT, requires one to two weeks of dedicated time to complete, including Eddy Current analysis, both conventional and Eddy Current array, on wings, fuselage skin and the

interior. The NDT team and Engineering teams at Conair work collaboratively to enhance inspection requirements.

“NDT is split into surface and sub surface techniques. Conair is now fully equipped to support the fleet using both technique types, performing inspections utilizing Eddy Current, Ultrasonic, Liquid Penetrant, and Magnetic Particle testing” shares Alfred Modino, Conair’s Component Shop Level 3 NDT Technician. “We have six accredited NDT technicians within our shop, and a two-person team dedicated to executing inspections, performed to OEM (Original Equipment Manufacturer) standards.” All Conair-converted airtankers are fully supported by OEMs following OEM guidelines to maintain airworthiness specific to aerial firefighting missions.

“In the future, we plan to develop the NDT program further, performing inspections on our US subsidiary’s fleet, located at Aero-Flite in Washington state. And we are investigating adding Digital X-Ray capability” continues Modino.

This essential service is necessary to secure continued airworthiness of the aerial firefighting fleet, ensuring safe missions and ongoing response. Each Conair aircraft undergoes a thorough period of heavy maintenance once a fire season

contract with a government agency has closed, typically taking four to six weeks to complete, performed to the highest standards in the industry.

Headquartered in Canada, Conair is a world leader in emergency response aircraft production and operations, delivering a range of aerial firefighting and multi-role aircraft and services globally. Founded in Canada over 55 years ago, Conair manufactures special mission aircraft converted from commercial planes, with more than 200 aircraft modified to date. Conair also maintains, crews and operates a fleet of 70 aerial firefighting aircraft, the largest, privately owned, fixed-wing fleet in the world. Conair’s operations are global, supporting missions in North America, Europe, Australia and beyond. Conair provides aircraft for purchase, lease or under contract and offers specialized services including aeronautical engineering design, flight operations and aircraft maintenance. Learn out more at www.conair.ca.

Helitak Firefighting Equipment has achieved a significant milestone with the FAA’s approval of its innovative FT-1300 retractable aerial firefighting tank for the Airbus AS350/H125 helicopter.

Announced on December 16, 2024, the FAA Supplemental Type Certificate (STC) marks the culmination of years of development and rigorous testing.

The FT-1300 tank is groundbreaking as the first retractable firefighting tank tailored specifically for the AS350/H125 airframe. Its unique retractable design enables seamless integration without necessitating structural modifications to the helicopter or sacrificing internal space for carrying water or retardant.

• Capacity: Holds up to 343 gallons (1300 liters) of water or fire retardant.

• Efficiency: Can be installed or removed in under 20 minutes

• Adaptability: Compatible with all AS350/H125 airframes without altering the aircraft’s structure.

CEO’s Statement

Jason Schellaars, CEO of Helitak, expressed his enthusiasm:

“We see the AS350/H125 as a great initial attack helicopter and are very happy to see the FT-1300 tank certified by the FAA. The FT-1300 is our latest tank to receive FAA STC certification and will give aerial firefighting companies another airframe to add to their toolkit that can be used to fight fires around the world. We look forward to seeing it at work on fires in the near future.”

The certification solidifies Helitak’s role as a leader in advancing aerial firefighting technology. The FT-1300’s quick-deployment capability and robust design promise to enhance the efficiency and effectiveness of firefighting operations globally.

Coulson Aviation, a global leader in aerial firefighting, has announced a successful contract award with Chile’s National Forest Corporation (CONAF) through its strategic partnership with BRYSA.

PORT ALBERNI, BRITISH COLUMBIA – This contract expands Coulson’s ongoing commitment to supporting firefighting efforts in Chile with a diverse fleet of aircraft, including a Boeing 737 FireLiner™, C-130 Hercules, and Citation Air Attack aircraft.

“We are pleased to continue strengthening our partnership with CONAF, bringing our proven aerial firefighting solutions to Chile once again,” says Coulson Aviation President and COO Britton Coulson. “By leveraging the unique capabilities of our aircraft, Coulson is proud to be the trusted supplier for Chile’s aerial firefighting needs. We look forward to supporting CONAF in their mission to safeguard Chile’s forests and communities.”

The addition of Coulson’s 737 FireLiner, a converted passenger aircraft specifically designed for aerial firefighting, will bolster CONAF’s aerial firefighting fleet, offering enhanced coverage and rapid response times to suppress fires across challenging terrains. This deployment represents Coulson Aviation’s dedication to innovation and operational excellence, utilizing state-of-the-art firefighting technology to meet the evolving needs of global fire management agencies.

As part of its expanding global presence, Coulson Aviation continues to strengthen its position as Chile’s leading provider of integrated aerial firefighting services. Building on its successful operations since 2021, Coulson’s integrated fleet of aircraft continues to set the industry standard in the region, reinforcing the company’s international leadership in aerial wildfire suppression operations.

Coulson’s strategic collaboration with BRYSA was instrumental in securing this contract, reinforcing their shared commitment to providing unparalleled firefighting capabilities in the region. As a trusted partner, Coulson Aviation remains dedicated to

delivering reliable and effective aerial firefighting services worldwide, ensuring communities are better protected against the increasing threat of wildfires.

Throughout the company’s 60+ years, the mission has remained the same: to protect the world from forest fires. Our organizational capabilities allow our team to provide simultaneous aerial support across numerous continents. As a leading supplier to county, state, and federal governments worldwide, Coulson has focused its next-generation multi-mission fleet on sustainable, in-production aircraft. Working in partnership with OEMs and leveraging the latest technology allows Coulson to provide superior all-hazard response aircraft. Learn more about us by visiting: coulsonaviation.com..

by George Parker, III

In the aftermath of a recent ag aviation fatality in Northern California during rice application, it's essential to take pause, reflect on what is happening and then apply that knowledge to what we do everyday.

While the NTSB report has yet to be released, specific facts are clear. The accident involved a pilot with less than 500 hours of ag experience flying a turbine Ag-Cat loaded with heavy foliar fertilizer. The aircraft rolled downwind, failed to achieve flight, and struck a set of trailers at the runway's end. Critically, no attempt was made to dump the load—an action that could have saved both the aircraft and the pilot’s life.

Those who know me know I’ve spent the last five years developing dump training scenarios for ag aviation. My inspiration came partly from transport-category recurrent training models, particularly concepts like the Advanced Qualification Program (AQP) used in commercial airline training. Conversations with my oldest son, a Delta Air Lines 737 First Officer, and insights from Dan Gryder’s push to bring AQP principles to general aviation have been invaluable. Our unique challenge in ag aviation is leveraging our ability to dump a load on command and integrate it into practical training scenarios.

Initially, my goal with these training exercises was simple: reduce runway overruns, minimize aircraft damage, and prevent unnecessary bumps, bruises, and insurance claims. We’ve seen at least four or five avoidable overruns in the 2024 season alone, typically non-fatal. But with Hugh’s passing, the stakes are now tragically clear—we aren’t just saving airplanes; we’re saving lives.

Had the tools outlined in my AQP for Ag Aviation syllabus been part of Hugh’s mental toolbox, he would have had three clear chances to avoid this accident:

1. Chance One: Pre-Takeoff Mental Briefing

Knowing density altitude (DA), gross weight percentages, and adhering to the 70/50 rule. This is the critical first step to ensuring the aircraft is ready to fly.

2. Chance Two: Recognizing the Tail-Up Point

A key checkpoint in any takeoff run is when the tail comes up. If the tail fails to rise before a predetermined point, the pilot should begin dumping immediately—potentially saving much of the load while ensuring the aircraft will fly. This is covered in my Scenario #3.

3. Chance Three: The Hail Mary Dump

In the final 300-500 feet before overrun, when the impact is imminent, the pilot’s only option is to dump the entire load to get the aircraft airborne. This is my Scenario #6, and it’s designed to save lives even in the most dire circumstances.

I’ve posted the AQP syllabus, including Scenarios #3 and #6, for those who wish to run these exercises. I recommend pilots have at least 200 hours in their aircraft before practicing these scenarios. Training is often pushed aside in the rush of a busy season, but this is a small time investment with life-saving potential. For reference, it took me just one day to train three pilots—30 minutes of briefing, 1.5 hours of flight time per pilot, and a 1.5-hour group debrief.

The success of this training relies on understanding the following:

Human Factors:

• Complacency

• Habit patterns

• Muscle memory

Time Requirements:

• Decision time: Choosing to unload.

• Reaction time: Moving the handle or switch.

• Flow time: Allowing the product to exit and effect change.

Critical Figures:

• Manual gate liquid dump rate: ~50-60 gallons per second

• Hydraulic big door dump rate: ~100 gallons per second

• Speed at 80 mph: ~115 feet per second

• Average unload-to-ground-break distance: 325-450 feet (if executed perfectly, in 3-4 seconds)

The tragic accident in California highlights an unavoidable truth: pilots—particularly rookies—are vulnerable without the right tools. Dump training equips them with life-saving decision-making skills under pressure. This rookie pilot could have been at home with his family today if he had these tools.

I urge everyone to take the time to read the syllabus, watch the videos, and implement this training. A couple of hours of focused effort can make the difference between life and death. As an industry, we owe it to ourselves and Hugh’s memory to ensure that every pilot knows how to use the dump feature when it matters most.

Scan this QR Code to View Entire Syllabus and Watch Videos.

Segment 1 – From power up to 50 mph

Any emergency action is to abort takeoff and roll to a stop.

Any emergency action is to abort takeoff and roll to a stop. Dumping load to reduce stopping distance if runway length dictates.

Overrun planning in this segment is to assure the tail is up where it should be for a safe rotation position short of the end. If not, open the gate at that point, dumping enough product to get the tail up, and closing the gate again, resuming the takeoff roll with the remaining load.

Any emergency action is to dump load and continue straight ahead, pitching for DMMS, with flaps coming in, aiming for as clear an area as possible.

Overrun planning for this segment is to begin dumping the load at a reasonable distance short of the end with enough time to affect change. Roughly 500’ short of the end, considering a speed of about 125-150 feet per second and a discharge rate of 60-100 gallons per second depending on gate door.

Any emergency action is to dump load, turn no further than 45 degrees from the takeoff heading to find a suitable landing area, pitching for DMMS, with flaps coming in when appropriate for obstacle clearance, aiming for a clear of an area as possible.

The result of a collaboration between OCFA, Tivoli, Aliso Viejo Community Association (AVCA), the County of Orange, and Moulton Niguel Water District (MNWD), this new HeloPod will provide essential water replenishment services for firefighting helicopters combating wildfires across Orange County.

The addition to OCFA’s firefighting arsenal comes in response to increasing challenges posed by what is now a year-round wildfire season. It will bolster the agency’s ability to achieve its goal of keeping all wildfires 10 acres or less 95% of the time.”

TracPlus, a global leader in mission-critical operational intelligence software, announced its new enterprise solution, which transforms how large-scale aerial emergency response operations manage and utilize their operational data.

The announcement comes as industry leaders at European Rotors 2024 in Amsterdam highlighted the growing challenges of multiagency coordination and operational intelligence.

Supporting over 7,000 connected assets across 40 countries, TracPlus has developed this comprehensive offering based on its experience as the technology partner for major firefighting agencies, including CALFIRE and the national aerial firefighting operations of Australia and New Zealand. This solution represents the next evolution in operational intelligence, moving beyond basic tracking to deliver actionable insights that enhance mission effectiveness.

“Through our experience supporting state and national-level aerial firefighting operations and major emergency response agencies globally, we’ve seen firsthand how operational data requirements

have evolved,” said Todd O’Hara, Head of Product at TracPlus. “Our enterprise offering directly addresses these challenges, enabling operators to transform their operational data into measurable improvements in mission effectiveness - ultimately leading to better outcomes for the communities they serve.”

The offering includes enhanced operational reporting capabilities, sophisticated flight analytics, and advanced data integration features that enable operators to make more informed decisions about resource allocation and mission execution. These improvements help emergency response teams respond faster and more effectively, directly improving their ability to protect lives and property.

Beyond operational benefits, the platform addresses critical revenue challenges for large-scale operators and agencies, including the identification of unbilled operations, contract compliance monitoring, and contract penalty prevention.

Operators interested in exploring how TracPlus can identify underbilled operations and optimize their effectiveness can contact TracPlus at enterprise@tracplus.com for more information about the offering and trial program.

•

•

•

•

•

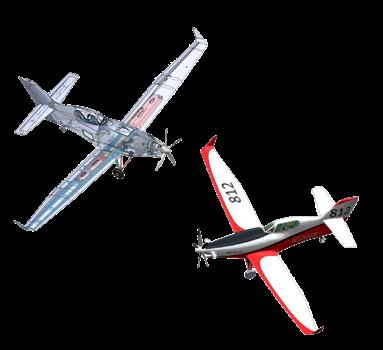

Game Aerospace, makers of the GB1 aerobatic aircraft, has indicated its intent to produce the GB2 Stormbird.

This all-composite, two-seat, low-wing aircraft is designed explicitly for aerial firefighting. Dubbed the Next Generation Single Engine Air Tanker, the GB2 will be capable of carrying up to 1,200 gallons of fire retardant at speeds exceeding 200 knots.

The GB2 will be constructed with lightweight carbon fiber with exceptional strength, speed, and payload capacity. With a projected empty weight of 6,000 pounds and a maximum takeoff weight of 19,000 pounds, the aircraft aims to achieve a useful load of more than double its empty weight—an impressive target. Composite materials resist corrosion and allow for aerodynamic

shaping, enhancing performance and durability. Its two-seat, tandem configuration accommodates an observer or second crew member, providing operational flexibility. The dual-cockpit setup also allows pilots to be trained on the new platform and offers additional training opportunities for pilots new to firefighting. Collaboration on this aircraft relied heavily on industry veterans, the late Kyle Scott of CoFire being among them.

Flight testing for the GB2 prototype is scheduled to start in late 2025. The first deliveries are planned for 2026; full FAA Type Certification is expected by 2027.

Game Aerospace already has four of the GB2s accounted for. Coastal Air Strike, located in Roe, Arkansas, has signed a letter of intent for the first two GB2s. “We look forward to adding this Next Generation SEAT to our existing Single Engine Air Tanker fleet. The carbon fiber construction, a technologically advanced glass cockpit and the increased payload capacity will be an asset to our organization,” comments Coastal Air Strike’s President, Michael Hutchins. GB2 #3 and GB2 #4 are slated for Boedeker Flying Service from Childress, Texas.

Game Aerospace, headquartered in Bentonville, Arkansas, has produced the GB1 Gamebird aerobatic aircraft since 2017. Philipp Steinbach, known for his expertise in high-performance composite aircraft, designed the GB1 and GB2. Steuart Walton, a skilled pilot, former Walmart executive, and dedicated Bentonville community advocate, owns Game Aerospace. For more information on the GB2, contact Zachery Sullivan, zsullivan@gamecomposites.com.

Aero-Flite Inc. is pleased to announce the completion of a second hangar in Spokane, Washington, enabling the company to meet the significantly increased demand for the Dash 8-400 airtanker.

SPOKANE, WASHINGTON, December 13, 2024 – The new hangar is adjacent to Aero-Flite’s current facility and adds 36,800 sq ft to the company’s existing footprint.

“Aero-Flite is growing and the customer response to the new Dash 8-400 airtanker has been so strong it is challenging to keep up with wildfire agency requests. In response, we are growing our fleet, expecting two new airtankers next year with production slots for new airtankers booked through 2026. This growth will allow us to continue creating new career pathway jobs, doing meaningful work,

at a living wage in the Spokane area and the State of Washington. It also means we need more space to complete our heavy winter maintenance. Our current facility is around 33,000 sq ft, so this addition more than doubles our operational maintenance space,” shares Chris Niemann, General Manager at Aero-Flite.

The new space ensures the Aero-Flite team can efficiently perform the required maintenance on its fleet of large airtankers and multi-engine water scoopers, working on multiple aircraft at once. Maintenance is performed faster, with less time wasted repositioning aircraft due to space limitations. The hangar also provides an expanded capability to shelter aircraft from inclement weather.

“The additional space means we can operate more effectively, and results in our ability to respond to federal and state needs for longer periods during the year. We are finding that fire seasons

(Continued on page 46)

are becoming fire years, requiring the ability for Aero-Flite to respond year-round, not just during the expected summer months,” shares Niemann. “We experienced this in February when Texas and Oklahoma required one of our earliest-ever callouts to respond to the Smokehouse Creek Fire. We were able to send five large aircraft to them within days of the request. This season has also been slow to wind down. Most of our fleet operated until midOctober, with many aircraft called back into service to support firefighters in Utah and Wyoming. California had two aircraft on contract until November, and one of our RJ85s just finished in Texas. This week an RJ85 was called out to respond to the Franklin Fire in Malibu, California.”

Aero-Flite operates the largest privately owned fleet of large airtankers and scoopers in the country. “This isn’t the end of our growth,” Niemann concludes. “The nation needs modern, versatile airtankers to replace older airtankers as they retire due to high flight cycles, low parts supply, and increased maintenance costs.

The Dash 8-400AT is the newest airtanker in the world today. It is a cost-effective platform that will be in operation for decades. We plan to grow our fleet around these aircraft, and that growth will require additional space in the future.”

About Aero-Flite Inc.

Aero-Flite is one of the US’s oldest, largest, and most experienced aerial firefighting companies. Aero-Flite delivers a comprehensive range of purpose-engineered aircraft designed to fight wildfires. Founded in the United States over 60 years ago, Aero-Flite’s operations support missions in North America and beyond, providing an extensive range of Next Generation Aerial Firefighting aircraft. The team of 200+ professionals operate over a dozen aircraft, including Type 1 RJ85 airtankers, Type 2 Dash 8-400AT airtankers, and one of the largest fleets of newer-model CL415 amphibious aircraft available for contract. Aero-Flite can provide aircraft under contract, sale, or lease across the US and worldwide, providing specialized services, including flight operations and aircraft maintenance related to emergency response missions. Learn more at www.aerofliteinc.com.

Columbia Helicopters (CHI), the world’s premier tandem rotor helicopter OEM, MRO, and operator, announced the appointment of Chris Vandersteen as Chief Financial Officer (CFO).

PORTLAND, OREGON, USA — Chris joins Columbia to lead the company’s financial strategy, overseeing all financial planning, implementation, management, and controls. He will report directly to CEO David Balevic and join the Executive Leadership Team.

Chris brings over two decades of aerospace industry experience, having held leadership positions at Honeywell, Bombardier/Learjet, AAR Corp, TransDigm, and, most recently, MD Helicopters, where he served as CFO. He has a proven track record in driving operational improvements by integrating financial data with functional performance, including contract analysis, pricing strategies, cost efficiency, and cash management.

“Columbia Helicopters has an outstanding reputation as a combined OEM, operator, and maintainer. With clear opportunities for growth across all regions and sectors, I look forward to working with David and partnering with the executive leadership team during this exciting phase of expansion.”

- Chris Vandersteen

Chris succeeds Santiago Crespo, who has left the company to pursue other opportunities.

“Chris is a highly accomplished financial leader with a strong track record of delivering results,” said David Balevic, CEO of Columbia Helicopters. “His in-depth knowledge of the aviation industry will add significant value to Columbia. With Chris on

board, our leadership team is well-positioned to drive future growth and capitalize on new opportunities.”

Balevic continued, “I would like to thank Santiago for his contribution to Columbia over the past nine years, and wish him well in his future endeavors.”

Chris Vandersteen commented: “Columbia Helicopters has an outstanding reputation as a combined OEM, operator, and maintainer. With clear opportunities for growth across all regions and sectors, I look forward to working with David and partnering with the executive leadership team during this exciting phase of expansion.”

Coastal Air Strike’s agile, forward-attack SEAT (single engine air tanker) and Single Engine Scooper aircraft are your best chance to contain small wildfires, to prevent them from becoming big wildfires. Their ability to operate from virtually all airports, ranging from large tanker bases to remote airstrips – even reloading at portable retardant bases – along with the Single Engine Scooper’s ability to scoop nearby water sources, proves them invaluable.

Sikorsky, a Lockheed Martin company (NYSE: LMT) and Rain, a leader in autonomous aerial wildfire containment technology, successfully demonstrated how an autonomous Black Hawk® helicopter can be commanded to take off, identify the location and size of a small fire, and then accurately drop water to suppress the flames.

STRATFORD, CONN. ( November 11, 2024) — Sikorsky, a Lockheed Martin company (NYSE: LMT) and Rain, a leader in autonomous aerial wildfire containment technology, successfully demonstrated how an autonomous Black Hawk® helicopter can be commanded to take off, identify the location and size of a small fire, and then accurately drop water to suppress the flames.

Performed Oct. 29 at Sikorsky headquarters in Stratford, the Rapid Wildfire Response Demonstration showed the effective fusion of Sikorsky’s MATRIX™ flight autonomy with Rain’s wildfire mission autonomy system to suppress a fire in its incipient stage.

Representatives from NASA, Federal Emergency Management Agency (FEMA), Defense Advanced Research Projects Agency (DARPA), Los Angeles County Fire Department, Orange County Fire Authority, and the philanthropic and impact investment community witnessed the demonstration as part of a two-day wildlands firefighting meeting to discuss autonomy.

“Government agencies, aerial firefighting operators, and investors are coming together to learn and see how both flight and mission autonomy can help prevent high intensity millionacre wildfires,” said Maxwell Brodie, Rain CEO. “Wildfires cost the United States over $390 billion annually, and multiple risk

factors are set to grow up to 30% by 2030. We look forward to demonstrating to lawmakers how autonomous aircraft can stop fires from breaking out, or continue the fight into the night, and in turbulent and smoky conditions, where crewed aircraft wouldn’t venture.”

During the 30-minute flight demonstration, guests used a tablet to command the Black Hawk aircraft to take off, search and find the fire, then drop water from a Bambi Bucket slung 60 feet beneath the aircraft. Each of three successive water drops extinguished a 12-inch diameter propane-fueled fire ring emitting a 3-to-6-inch-tall flame, demonstrating the precision of the Rain fire perception and targeting capability. The Rain system also rapidly adjusted the flight path to account for an 8-to-10-knot crosswind during each water drop.

Sikorsky safety pilots in the Black Hawk cockpit monitored the flight controls, but were hands-off until the aircraft landed.

“With Rain’s wildfire mission software loaded onto the aircraft and a tablet, wildland firefighters in the field could deploy autonomous Black Hawk or FireHawk® helicopters to search and attack wildfires before they spread out of control,” said Igor Cherepinsky, director of Sikorsky Innovations’ rapid development/ prototyping group. “Having worked closely together for over a year, our two companies are ready to demonstrate the joint capability in more dynamic conditions chosen by firefighters.”

Representatives attending the demonstration provided real-time input and observations to the Rain and Sikorsky teams.

“This technology that we used to think of as being on the horizon is here now, no longer just a figment of our imagination,” said Genevieve Biggs, Director of the Gordon and Betty Moore Foundation’s Wildfire Resilience Initiative and Special Projects program. “It’s humbling to see this impressive machine, and think about the improvement in safety that becomes possible when you’re layering into wildland firefighting an autonomous operation, as Rain and Sikorsky have been able to do together.”

About Lockheed Martin

Lockheed Martin is a global defense technology company driving innovation and advancing scientific discovery. Our all-domain mission solutions and 21st Century Security vision accelerate the delivery of transformative technologies to ensure those we serve always stay ahead of ready. More information at Lockheedmartin.com.

About Rain

Rain, a leader in autonomous aerial wildfire containment technology, is helping fire agencies more rapidly suppress wildfires during the earliest stages of ignition. Rain software adapts existing military and civil autonomous aircraft with the intelligence to perceive, understand, and suppress wildfires, which enables numerous aircraft to be prepositioned in remote locations resulting in accelerated response time. Developed in tandem with fire professionals, Rain is a privately held company headquartered in Alameda, California. Visit www.rain.aero for more information.

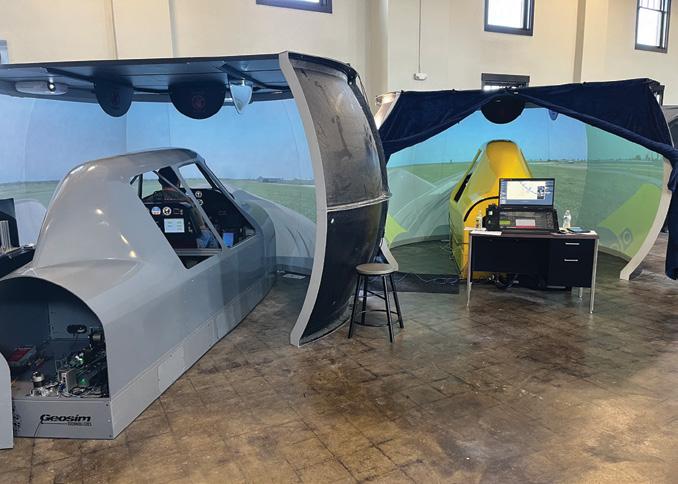

Delta State University is excited to announce the awarding of a $1,000,000 federal grant to its Commercial Aviation Department for the purchase of an Agricultural and Aerial Firefighting Flight Simulator.

CLEVELAND, MISS. – This innovative Air Tractor 802 flight simulator will be the first of its kind and will support DSU’s Agricultural Aircraft Operations Career Pathway (AAOCP) program, providing essential training for future aerial applicators and firefighters.

The simulator, designed to meet advanced specifications, will provide high-fidelity, scenario-based training. This cutting-edge equipment will significantly enhance the educational experience, allowing students to gain practical skills in aerial application techniques used in agriculture and firefighting. Students will engage in advanced training designed to replicate real-world conditions, honing their skills in precision aerial applications, which are vital for effective crop management and firefighting operations, and, above all, will save pilot lives by increasing their readiness for such dangerous flying.

The cost for the development and purchase for this state-of-theart simulator was funded by state and federal funds sponsored by Senator Cindy Hyde-Smith. The simulator will allow students to immerse themselves in high-quality training scenarios without the costs and risks associated with actual flight hours. Additionally, Delta State will allocate $60,000 annually toward a contractual agreement for simulator maintenance, repairs, and operational training.

No additional grant-funded personnel will be required to manage the simulator, as current Delta State faculty and staff will oversee its use and maintenance. The training capabilities of the

simulator will be available to both faculty and students within the AAOCP program, further elevating Delta State’s commitment to providing a cutting-edge aviation education.

Chair of the Commercial Aviation Department Major Allen Williams said, “This grant is precedent setting. For us to be able to continue to grow our ag training program, it’s going to give us an opportunity to increase the depth of knowledge for our students. It will give us the opportunity also to develop some streams where we can start off with some recurring training for the ag industry across the country because of the uniqueness and the capacity for this simulator.”

The university anticipates that the new simulator will be fully operational within the next two years. Upon its installation, Delta State will be able to increase its profile as a hub for highlevel aviation training, drawing students from across the nation.

Interim Dean of the College of Business and Aviation Dr. Tomeka Harbin said, “I am thrilled that we have been allocated congressional funds to purchase the Agricultural and Firefighting Airplane Simulator. These resources are vital in helping us achieve our mission of being the premiere academic aviation institution in the state. The congressional support empowers us to continue our work, and we thank Senator Hyde Smith for investing in our vision and our students’ futures.”

Aerial Applicator Program Coordinator Sheila Millican said, “It is reassuring to know that Senator Hyde-Smith is looking out for our program in Washington and helping us continue to grow. The opportunities in this industry are real, and our students can graduate with a skill set that is very much in demand around the country.”

For more information on the Agricultural Aircraft Operations Career Pathway program and other aviation offerings at Delta State University, please visit www.deltastate.edu/business-aviation/commercial-aviation/ or contact Sheila Millican at 662-846-4216.

All About Firefighting Operations of Sikorsky

S-64E/F and CH-54A/B Skycranes by

Babak Taghvaee

A close up view of the second Sikorsky S-64E Skycrane prototype ‘N6965R’ (c/n 64-002). The size of this powerful machine used for helicopter logging operations can be seen by comparing the size of the man standing on the fuselage making adjustments on the gas turbine engines in 1962. This helicopter crashed on June 27, 1991.

The largest helicopter ever operated by the United States Army Aviation and Army National Guard is CH-54 Tarhe, the military model of Sikorsky S-64 Skycrane helicopter. A total of 60 CH-54A Tarhe helicopters (including six pre-production helicopters) and 29 of its more powerful variant, CH-54B, were manufactured and operated by the US Army (USAR) and the Army National Guard (USARNG) until 1993 when their last examples were retired from service.

(Continued on page 56)

After retirement from service, 36 CH-54As and 22 CH-54Bs found use as firefighter and transport helicopters in 16 different helicopter services companies. As of today, 41 of these helicopters remain airworthy and are in use by four civilian and privately-owned helicopter services, as well as the Italian and Korean Forest Services for firefighting operations. Among these operators, Erickson Incorporated is a leading provider, with 16 CH-54 helicopters in its fleet.

As the USAR was looking for a replacement for its piston-engined CH-37 Mojave heavy transport helicopters after the Korean War, the need for a new heavy lift helicopter was determined. Sikorsky proceeded to meet the need and subsequently designed and developed the S-64. It was specially designed for carrying heavy loads externally. Thanks to its turboshaft engines, it was capable of carrying cargo twice as much as the maximum amount carried by the Mojave. This was achieved with the help of Pratt and Whitney, which modified its JT12 turbojet engines for installation on the S-64 as turboshaft engines.

The S-64 received the military name designation CH-54A Tarhe, and its first prototype, a S-64, ‘N325Y’ (c/n 64-001), logged its first flight on May 9, 1962. The CH-54A could carry a 10-ton payload and was designed to carry its cargoes externally. By means of a hoist, it could pick up or deposit loads without landing.

The S-64 was equipped with a revolutionary Automatic flight control system and altitude hold, which for its time was considered the most

advanced of its kind. It was equipped with kneeling landing gear to facilitate easier loading and help during steep slope operations. The Skycrane had a fly-by-wire system back in 1962, a system that by today’s standards is still advanced.

The S-64 was also equipped with a seat and an additional control system for an aft-facing crew who can control pitch, roll, and yaw with 10-percent control authority. The cyclic grip controlled pitch and roll by normal fore, aft, and lateral movement. Yaw inputs were made by twisting the weight and facilitated easier inspection and maintenance operations.

The 478th Flying Crane Company, 44th Air Transportation Battalion, later renamed the 478th Aviation Company (Heavy Helicopter) ‘Cyclones’, received the first six YCH-54As. After completing testing and training, the unit was deployed to Vietnam to support the 1st Cavalry Division, Airmobile. The ‘Cyclones’ transported bulldozers, road graders, armored vehicles, and downed aircraft, ultimately retrieving over 380 aircraft and saving several hundred million dollars worth of equipment.

The initial group of USAR aircrews were chosen from pilots with a minimum of 500 hours of rotary-wing flight time, a current instrument rating, qualifications for flying turbine-engined helicopters, and at least 250 hours as a pilot or instructor pilot (IP) in cargo or utility helicopters. Not all pilots going through initial entry rotary-wing training at that time received this specific training. The USAR was selective about who was trained to fly these new heavy helicopters.

As more CH-54As were constructed and delivered, more of them were involved in the Vietnam War. Some, like ‘67-18416’, were used

A grounded T-33A training jet, unable to fly under its own power, gets a lift from a CH-54A of the 295th Aviation Company, 58th Aviation Group in West Germany in 1970.

(U.S.

Army photo by SSG Moore)

to drop 10,000-pound bombs to clear landing zones (LZs) during the ‘Combat Trap’ program. The CH-54A would drop an M-121 bomb from 6,000 feet to clear helicopter LZs, detonating at about three feet to create a 100-foot diameter landing area.

The CH-54B was a significant upgrade from the previous CH-54A received by the USAR. The USAR received 54 more CH-54As before the production line transitioned to CH-54B. Following the delivery of the final CH-54A, ‘66-18413’, the USAR began to receive the more powerful CH-54Bs. These newer models featured an increased maximum gross weight and higher payload capability. While the CH-54A was powered by two 4,500 shp (3,400 kW) Pratt & Whitney JFTD12A-4A turboshafts, the CH-54B was equipped with two 4,800 shp (3,600 kW) JFDT12A-5A turboshafts. These enhanced engines allowed the helicopter to increase its maximum external cargo load capacity from 20,000lb (9,072kg) in older model to 25,000lb (11,340kg) in newer model.

In addition to the more powerful engines, another key improvement of the CH-54B was its smaller twin wheels designed for landing on soft ground. Along with these visible changes, significant upgrades were made to the avionic systems of the helicopter, including components of an improved AN/ASW-29 Automatic Flight Control System (AFCS).

The USAR lost six more CH-54As before transferring the remaining fleet (49) to the USARNG. Also two of the 29 CH54Bs of the USAR were lost before transfer the remaining 27 to the USARNG in 1979.

While in service with the USARNG, the CH-54A/Bs not only carried out military missions but also served the public. They were used for airlifting historic aircraft and helicopters to museums, antenna towers and telephone poles to marshes and mountains. Additionally, they were used for humanitarian missions, such as participating in a joint Soviet-US Navy

(Continued on page 58)

When no special water tank had yet been designed to be installed in the CH-54s, water buckets were used for firefighting missions in the United States. This image taken on October 6, 1975, shows a US Army’s CH-54B carrying a water bucket at Fort Sill,

Oklahoma.

(U.S. Army photo)

Operation named Breakthrough near Point Barrow in 1988. During this operation, a CH-54B, ‘70-18488’ named Isabell from the 207th Aviation Company, Alaska ARNG, used a five-ton hammer to break through the ice in an attempt to rescue three grey whales near Point Barrow, Alaska.

During their service with the USARNG, only three CH-54As were lost. This left the USARNG with 46 CH-54As and 27 CH-54Bs when the type was retired from service in 1993. On January 11, 1993, the last three CH-54s in service with the USARNG, all ‘A’ models in use by the 113th Aviation Regiment, Nevada ARNG were retired from service. The day before, one of these helicopters completed the final flight of the Tarhe in the US military service.

The USAR and USARNG retained ten CH-54As and five CH-54Bs for preservation, display, or transfer to various museums, leaving 36 CH-54As and 22 CH-54Bs to be divested. All of these helicopters quickly entered service with various civilian helicopter service companies in the United States. The ‘D’ Model of the Boeing CH-47 Chinook, a tandem-rotor helicopter, replaced the CH-54A/Bs in the service of the USARNG. Despite being smaller in size compared to the CH-54A/Bs, the CH-47Ds

could carry slightly heavier cargo thanks to their two slingpoints under their fuselage (26,000 lb or 12,000kg).

All three prototypes of the S-64 were used for commercial purposes after the end of their tests. ‘N325Y’ (c/n 64-001) was withdrawn from service following an incident on August 19, 1968. The third prototype (c/n 64-003) was turned into the first S-64F, which, together with the second prototype (c/n 64-002), entered service with Erickson Sky-Crane company in 1970. The second one received the ‘N6959R’ registration code and was operated by the company until it crashed due to control loss in Index, Washington on June 27, 1991. As of October 2024, when this article was written, the third prototype was still in use by Erickson, registered as ‘N176AC’ and named ‘Lucille.’

In addition to the first three prototypes used for commercial purposes, three more S-64s, all ‘E’ models, were manufactured (c/n 64-099 to 64-101) in 1975. The first and last of them (c/n 64-099 and 64-101) were sold to Siller Brothers Incorporated in Klamath Falls,

(Continued on page 60)

Cascade Pressure Cowl Delivers!

u Increase in Clean Air Volume to PT6 engine

u Decrease up to 32⁰ ITT Temps

u Decrease up to 1.5% NG

u Easy Access to Service Air Filter System ( Filter swap - 20 min) Fuel Nozzles Chip Detectors

Pilot Report: “Before the Cascade Pressure Cowl, this FIREBOSS was always at the back of the pack. Cascade Pressure Cowl installed, it’s always at the front with our best performing FIREBOSS! Performance is everything! ”

A U.S. Army Sikorsky CH-54A Tarhe prepares to lift a damaged U.S. Air Force Douglas A-1E Skyraider (s/n 52-133876) of the 1st Air Commando Squadron at An Khê, Vietnam on December 10, 1965. The A-1E 133876 was later written off following battle damage on December 6, 1967.

(U.S. Army photo)

Oregon (N4035S and N4037S), while the second (c/n 64-100) was delivered to Evergreen Helicopters and operated as ‘N4036S’ until August 8, 1978, when it crashed due to pilot error, killing one worker on the ground near Buffalo, Minnesota. As of today, the examples delivered to Siller Brothers are still airworthy.

In 1970, the Erickson Sky-Crane company acquired a second S-64E, a former USAR CH-54A, ’68-18432,’ that was withdrawn from service following an incident on January 9, 1970. The Erickson Company continued operating the two S-64Es until 1992 when the USARNG began retiring its CH-54As and CH-54Bs. In that year, Erickson SkyCrane (also known as Air-Crane) acquired the necessary licenses to perform all sorts of maintenance on the S-64E/Fs, perform modifications, and even rebuild their badly damaged examples.

Between 1992 and 1996, Erickson acquired five CH-54As and 13 CH54Bs and had them all rebuilt as S-64Es and S-64Fs with numerous modifications and upgrades. The company also used components, systems, and fuselage from two crashed and badly damaged CH-54As

of the USAR to build a new S-64F, ‘N189AC,’ known as ‘Gypsy Lady,’ which received c/n 64-1001. Erickson later acquired ten more CH-54As and two more CH-54Bs from other helicopter services companies that had procured them after their retirement from the USARNG service in the early 1990s. They were also converted into S-64E/Fs by Erickson.

Out of the 36 CH-54As retired from the USARNG service in 1992 and 1993, five were in service with the 1160th Aviation Company, Georgia ARNG; eight were in use by Company E, 185th Aviation Brigade, Mississippi ARNG; five were used by the 137th Transportation Company (Heavy Helicopter), Kansas ARNG; three were used by the 1028th Transportation Company, Pennsylvania ARNG; three were used by the 113th Aviation Regiment, Nevada ARNG; two were used by Company H, 104th Aviation Brigade, Pennsylvania ARNG; and one was used by the 117th Air Control Squadron, Georgia ARNG. The units of the remaining five CH-54As are not known to the author.

(Continued on page 62)

The USARNG’s CH-54Bs retired from service in 1992 and 1993 were in use by the 207th Aviation Company, Alaska ARNG (three examples); 208th Aviation Company, Connecticut ARNG (11 examples, including examples previously served with the 207th Aviation Company); and 292nd Aviation Company, Alabama ARNG (seven examples).

After their withdrawal from service, some examples of the CH54As and CH-54Bs were sent to the Aircraft Maintenance And Regeneration Center of the USAF’s 309th Aerospace Maintenance and Regeneration Group at Davis–Monthan AFB to be stored, while others were spread among multiple museums and bases for preservation. Six CH-54As and two CH-54Bs were transferred to the National Museum of Naval Aviation in Pensacola, which were

later sold to Erickson (one CH-54A and two CH-54Bs), Heavy Lift Helicopters Incorporated (two CH-54As), and Helicopter Transport LLC (three CH-54As).

In total, 16 companies acquired 36 CH-54As and 22 CH-54Bs after their retirement from the USARNG’s service. Heavy Lift Helicopters Incorporated acquired two CH-54As; Siller Helicopters acquired four CH-54As, including ’67-18423,’ from the Kenosha Military Museum after its closure in 2002; Erickson Air-Crane (now Incorporated) acquired five CH-54As and 13 CH-54Bs; Lenair Corporation acquired four CH-54As; Silver Bay Logging Corporation bought eight CH-54As;

This F-4B Phantom II of the US Navy’s Strike Fighter Squadron (VFA) 154 “Black Knights”, ‘149411/NK-100’ crashed near Cam Ranh Bay, South Vietnam on December 20, 1968. Its pilots ejected at low altitude and both lost their lives. Its wreckage was airlifted by this CH-54A of the US Army’s 478th Heavy Helicopter Company. (U.S. Army photo)

Greece has faced devastating forest fires for decades, exacerbated by global warming in the past two decades. These fires often overwhelm Greece’s fleet of Canadair CL-215s, CL-415s, and PZL M-18B Dromader firefighting aircraft operated by the Hellenic Air Force and two SA332L1 Super Pumas of the Hellenic Fire Department during the summer months. As a result, Greece contracts three different aircraft and helicopter service companies each year to assist in firefighting efforts.

Since 2000, Erickson Incorporated has utilized its S-64E/Fs to combat wildfires across Greece. In recent years, including 2024, the company has deployed six helicopters to Greece for firefighting operations from May to October.

In 2024, Erickson stationed six S-64Es in Greece (N154AC/748, N173AC/747, N176AC/741, N194AC/735, N218AC/734, N243AC, and N247AC/737) at various

Hellenic Air Force bases. These helicopters were instrumental in combating the massive wildfires in the Attica region from August 11 to 14, 2024, dropping tens of tons of water over burning forests near Athens. They also participated in firefighting efforts in the Corinth region between Athens and Patras from September 29 to October 5, 2024, where five helicopters completed four sorties per day in Pyrgos and other mountainous areas.

The S-64E/Fs are preferred for firefighting in Greece due to their ability to snorkel both fresh and saltwater. With a 2,600-gallon water tank capacity, these helicopters stand out in their category. While only six were deployed in 2024, this number could increase to nine in years with more intense forest fires. At the end of each fire season, the helicopters have their rotor blades and water tanks disassembled, loaded onto ships, and sent to Australia and other parts of the world by the end of October.

S-64E of Erickson’s Incorporated, ‘N247AC/737’, a former CH-54A of 292nd Aviation Company, Alabama ARNG, ‘68-18450’ during firefighting operations in Corinth region of Greece on October 4, 2024.

(Photo by Babak Taghvaee)

S-64F of Erickson Incorporated, ‘N176AC/741’, during firefighting operations in Corinth region of Greece on October 4, 2024. This helicopter was built as the third S-64E prototype ‘N306Y’ (c/n 64-003) in 1962 and was later converted to the first S-64F.

(Photo by Babak Taghvaee)

Chet Rasberry Incorporated bought three CH-54As; Evergreen Helicopter Incorporated acquired one CH-54A; Aurora Motorsports Incorporated acquired one CH-54A; Scott-Matt Incorporated bought one CH-54A (later sold it to Heavy-Lift Helicopters Inc); Seco Aviation Company acquired a CH-54A (later sold it to Siller Helicopters); in 2005, Ventures Acquisition Co LLC acquired one CH54A and sold it to Evergreen Helicopters five years later; Blue Bird Helicopters acquired seven CH-54Bs; and Hawkins & Powers Aviation Incorporated acquired two CH-54Bs.

Many of the companies mentioned above sold these helicopters to other companies after several years of storing them or using them. US Leaseco acquired seven CH-54Bs from Blue Bird Helicopters

and had them all transferred to Helicopter Transport Service LLC; Columbia Helicopters acquired three CH-54As from Lenair Corporation, Chet Rasberry Inc, and Turbine Ltd; Erickson acquired two CH-54Bs from Hawkins & Powers Aviation Incorporated; and Siller Helicopters acquired two more CH-54As from Seco Aviation Company and Evergreen Helicopters Inc.

Erickson Incorporated, the holder of the licenses for modification and production of Sikorsky S-64E/F helicopters, has become the

(Continued on page 67)

A former CH-54A of the 113th Aviation Regiment, Nevada ARNG, ‘67-18415’ is now in use by Erickson Incorporated, ‘N194AC’, named ‘Delilah’. Seen here during firefighting operations in Corinth region of Greece on October 4, 2024.

(Photo by Babak Taghvaee)

A former CH-54A of the Company H, 104th Aviation Brigade, Pennsylvania ARNG, ‘67-18420’ is now in use by Erickson Incorporated, ‘N243AC’, named ‘Marty’. Seen during firefighting operations in Corinth region of Greece on October 4, 2024.

An Erickson’s S-64E, ‘N176AC’ dropping fire retardant on the Happy Camp Complex Fire in the Klamath National Forest in California in September 2014.

Helicopter Transport Service LLC known as HTS, Siller Helicopters and Evergreen Helicopters are other operators of Skycranes in the United States with nine, four and one of these helicopters currently in their operational use. HTS with two CH-54As and seven CH-54Bs currently in its use is the largest one. Similar to Erickson, the HTS is capable of performing all sorts of maintenance on them including overhaul or depot maintenance of the CH-54A/Bs, S-64Es and their JFTD12 engines. Similar to Erickson, its helicopters use 2,600 gallons (9,750 litres) water tanks, however they have different water Snorkel systems. These tanks are refillable in 45 seconds in as little as 18 inches of water. Their computer-controlled delivery system can systematically deploy water or other suppression agents at varying levels of coverage, as certified by the United States Forest Service Interagency Airtanker Board.

As of October 2024, Siller Helicopters, one of the four companies using S-64/CH-54 helicopters in the United States, has two airworthy CH-54As, two S-64Es and three stored CH-54As. Designed by Sikorsky Aircraft for civilian use in 1968, only twelve S-64Es were ever produced, making the aircraft one

of the most sought-after helicopters across the heavy-lift industry. Today, only a fraction of the original production run remains in service, with Siller Helicopters operating two S-64Es.

The Siller’s S-64Es were purchased from Sikorsky Helicopters brand new and they, similar to the company’s CH-54As are capable of carrying firefighting water buckets or fixed tanks.

Established in 1975, over the last 40 years the company has flown tens of thousands of hours, and today Siller Helicopters has grown to include firefighting, transmission line construction, ski lift construction, power grid expansion, HVAC (Heating, ventilation, and air conditioning) placement, logging, heavylift operations, and hydro-seeding across the U.S.. In addition to the CH-54As and S-64Es, Siller Helicopters has a single Sikorsky S-61A Seaking ‘N3173U’, a former US Navy’s SH-3A anti-submarine warfare helicopter (US Navy Bureau Number 149916) equipped with fixed landing gears and also provisions for installation of water tank and firefighting module under its fuselage, and a more modern variant of that, a S-61V-1, ‘N45917’, previously used by the Indonesian Air Force as VIP helicopter between 1965 and 1991.

A Siller Helicopters’ CH-54A,’N7095B’, dropping fire retardant on structures to protect them from the coming forest fire during the Mendocino Fire, Mendocino National Forest, California on August 15, 2018. This helicopter was operated by Company E, 185th Aviation Brigade, Mississippi ARNG as ‘67-18430’ until 1992.

(Forest Service photo by Cecilio Ricardo)

largest owner and operator of this helicopter in the world. The company sold six S-64Es and one S-64F to the Korean Forest Service (one of them, ‘HL9467’, crashed on May 9, 2013) for use as firefighter helicopters to combat forest fires in the country. These helicopters were maintained and operated by Erickson under leasing contracts and then after their procurement. Under a similar contract, the Italian State Forestry Corps (Corpo forestale dello Stato) acquired eight S-64Fs (all ex-CH-54Bs) from Erickson for firefighting operations, among which three, ‘I-CFAG’, ‘I-CFAH’, and ‘I-CEAD’, have crashed on July 22, 2024, July 6, 2005, and April 26, 2007, respectively, leaving five as of October 2024.

As of October 2024, a total of 41 Sky-Cranes were still airworthy around the world, consisting of 17 S-64Es, 12 S-64Fs, five CH-54As, and seven CH-54Bs. Ten S-64Es and six S-64Fs are in use by Erickson Incorporated; two CH-54As and two S-64Es are in use by Siller Helicopters Incorporated; two CH-54As and seven CH-54Bs are in service with Helicopter Transport Service LLC; a CH-54A is in use by

(Continued on page 68)

A former CH-54B of 208th Aviation Company, Connecticut ARNG, ‘69-18484’, currently in use of Helicopter Transport Services as ‘N716HT’, during firefighting operations in Crown King, AZ, Prescott National Forest, May 2012.

(U.S. Forest

photo by Kari Greer)

Evergreen Helicopters; the Italian Forest Service operates five S-64Fs, while the Korean Forest Service has five S-64Es and one S-64F. Siller Helicopters Incorporated also has four more CH-54As in storage, with one in external storage and the rest in good condition with the possibility of restoration in the near future.

Erickson Incorporated, with the largest fleet of Sky-Cranes in its service, currently leads operations worldwide. The company not only performs all maintenance on their fleet but also operates its own fleet, as well as the examples in use by the Korean and Italian Forest Services to combat forest fires globally. Since 1992, the company has completed over 4,000 modifications to the S-64 platform, extending their lives beyond what was expected over six decades ago when they entered service with the US Army.

The S-64E/Fs of Erickson have been equipped with one of the most advanced aerial firefighting systems in the world. In 1992, the company created a 2,600-gallon fire suppression system as a bolton accessory for the S-64 helicopters, and in 2000, the company designed and built the ‘Sea Snorkel’ system for dynamic filling (scooping) of the fire suppression tank using saltwater obtained from oceans or other water resources. Thanks to these innovations, the company was awarded its first USFS (U.S. Department of Agriculture Forest Service) exclusive-use contract, revolutionizing the aerial firefighting industry two years earlier (in 1998).

As the life of the main rotor blades of the S-64E/Fs neared its end, Erickson began designing and developing a new composite main rotor blade (CMRB) for them. The first prototypes were tested from 2015, and after five years of testing, the Federal Aviation Administration (FAA) approved it for installation on all of the S-64E/Fs of the company. Thanks to the new CMRBs, the S-64E/Fs will remain in service for several more decades, allowing them to outlive any other helicopter ever designed or built by Sikorsky.

With

Neptune and Aerotec & Concept collaborating to convert aircraft for wildland firefighting, expect first of new fleet to be operational for 2027 season.