Firefighting Solutions are More than Just Products.

With more than 60 years of experience working alongside the firefighting community, Perimeter Solutions offers the most comprehensive set of fire retardant solutions on the market today – featuring field-proven products, infrastructure, equipment and logistics services. You need all of these to meet your goals of performance and safety in wildland firefighting operations.

When you choose PHOS-CHEK® you’re getting more than just retardant. You’re getting a company that understands your mission-critical needs and how to deliver them – every day. We think that’s a value that you’ll recognize and want.

Trusted. Solutions That Save.

WHAT YOU GET WITH PERIMETER SOLUTIONS

• Experience

• Performance

• Fire Support Infrastructure

• Resilient Response

• Knowledge Base

• Innovation

• Reliable, 24/7 Response

DISPLAY ADVERTISING: Melanie Woodley melanie@marsaylmedia com

PRODUCTION:

Felicia (Lisa) Pannell lisa@marsaylmedia com

CIRCULATION: Mary Jane Virden maryjane@marsaylmedia com

Bozinovski bozinovski igor@gmail com

Robert Craymer robertc@covingtonaircraft com

Dan Reese dan@intwcg com

Paul Seidenman avwriter@sbcglobal net

Dave Soderstrom davesoda727@hotmail com

Babak Taghavee babaktaghvaee@gmail com

CONTRIBUTING PHOTOGRAPHERS:

Kane Arlow

Igor Bozinovski

Marissa Fortney

Aaron Maurer

Jeff Serpa

Dave Soderstrom

Marty Wolin © COPYRIGHT 2024 AerialFire retains all rights for reproduction of any material submitted, to include but not limited to articles, photographs, emails and bulletin board posts. All material remain the copyright of AerialFire. No part of this publication may be reproduced, in part or whole, without the written consent of the publisher. Editorial published do not necessary reflect the views of the publisher. Content within AerialFire is believed to be true and accurate and the publisher does not assume responsibility for any errors or omissions. Unsolicited editorial manuscripts and photos are welcomed and encouraged. We cannot be responsible for return unless submissions are accompanied by a stamped, self-addressed envelope. Advertising deadline is 12 noon, on the 1st of the month preceding the month of publication.

PROUD MEMBER: FIND US ON:

AerialFire is Published bi-monthly by Marsyal Media P.O. Box 850, Perry, GA 31069 USA 475 Myrtle Field Rd., Perry, GA 31069 USA Phone / Fax: 478-987-2250

info@marsaylmedia.com

What a season it has been, from recordbreaking early devastating fires to the first PL5 declaration this late in the season since the 1990s. Yet, despite how close the transition to a “fire year” versus a “fire season” has become, the same recurring issues continue to endanger people living in fire-prone areas.

The aerial firefighting apparatus, from the rule makers to the decision makers, the contracting officers, and those responsible for ordering contract fleets that help combat these ever-

done,” while others claim no one wants to be held responsible for making crucial decisions. These explanations are frustrating and point to a larger issue.

The challenges the industry has faced this year are extensive. Ensuring that sufficient firefighting assets are available at a moment’s notice and that they are stationed in appropriate locations is crucial, yet these processes remain disorganized.

Reports from the field indicate that aircraft carding was again problematic this year. Excuses ranged from a lack of carding staff to insufficient funds for inspectors to travel and perform necessary evaluations. Additionally, there were instances where aircraft were released from contracts, yet the federal system still showed them as assigned, preventing their

This is why many choose to engage with organizations like UAFA, hoping to be part of the solution. By surrounding themselves with industry experts, they aim to contribute to real change within the industry, a process that has already begun. Though outward signs of progress may not be immediately visible, UAFA continues to collaborate with federal and state agencies to improve the aerial firefighting sector.

One hopes that the United States does not have to experience a tragedy like Australia’s “Black Summer” of 2019/2020, where massive loss of life and property spurred reform. As fire seasons worsen, it becomes increasingly important for meaningful changes to be made proactively rather than waiting for disaster to force the issue.

–

Tiffany Taylor | ttaylor@uafa.org

The United Aerial Firefighting Association (UAFA) invites you to its 2nd Annual Member Meeting in Boise, Idaho on November 13-14, 2024.

This event offers a unique opportunity for the global aerial firefighting community to:

• Gain Insights: Hear from representatives of key agencies like the National Association of State Foresters and the U.S. Forest Service on their latest plans.

• Expand Your Network: Forge valuable connections with colleagues and industry leaders.

• Champion the Industry: Advocate together for the best interests of aerial firefighting.

• Informative Sessions: Featuring agency briefings, collaborative after action reviews, legislative updates, and a workshop on accident response.

• Enhanced Networking: Dedicated time for socializing and building relationships with fellow professionals.

• New This Year: A vendor exhibition showcasing leading companies like TracPlus and Trotter Controls.

Anyone can attend the meeting! UAFA members benefit from significantly reduced registration fees. Secure your spot and access exclusive hotel room block rates by registering now at UAFA Meeting.

Maximize your experience by becoming a UAFA member. Membership is open to all companies involved in aerial firefighting or its support. Joining now offers:

• Discounted Meeting Rates: Save on registration costs for this and future events.

• Free Membership Extension: Pay 2025 dues now and gain access for the rest of 2024.

Robert Craymer | robertc@covingtonaircraft.com

Does your engine have a time when it sits unused? Are you properly preparing to let it sit on or off the airframe?

Like any machine, the times the PT6 engine is not used can be just as hard or harder on it than the times when it is being used routinely.

Pratt and Whitney Canada has given us some very easy-to-follow guidelines that will make sure that when you are ready to work, your engine is as well. Everything regarding preservation is scheduled around a time frame and has significant consequences. If an engine is not preserved per the published schedule, the engine could suffer corrosion damage, and the warranty could be voided. The only way to check for corrosion damage is to disassemble the engine to visually inspect ALL components. Therefore, we always provide time to discuss the importance of engine preservation.

Here is what you need to know:

If the engine will be inactive for 0 to 7 days, all that is required is to make sure that the engine is sheltered. Humidity and temperature changes that can cause condensation are grounds to move your preservation plan to the next level. Also, if there is a lot of salt in the atmosphere you live in, you want to do a clean water rinse (desalinization wash) prior to storing the airplane. Exhaust covers, inlet covers and securing the prop are really the only other requirements.

The second calendar interval classification is 8 to 28 days. This area of the calendar is the most common in ag aviation. The first step is to run the engine and follow the 0 to 7-day instructions. Next, you will need to add desiccant bags and

(Continued on page 16)

a humidity indicator in the exhaust duct. The objective is to maintain and confirm the humidity level at 40% or less. Check the humidity indicator every couple of weeks; replace the desiccant and indicator if it turns pink. Make sure there is no source of humidity near the engine, and if there is, make sure to remove it.

If your time dictates that your engine must sit for 29 to 90 days, there are a couple of additional steps to take. Washing the engine inside and out, touching up any of the missing protective coatings and lubricating the linkage. Next, disconnect the fuel supply line and cap at the oil-to-fuel heater. Disconnect the fuel line at the flow divider inlet and then add the proper preservation oil. Instructions in the maintenance manual show you how to do a motoring run to replace the fuel in the system with the preservation oil. Then, of course, you cap and cover everything. Make sure that you also follow the 0 to 28 days steps, and don’t forget your humidity indicator.

For some, the engine may sit over 90 days. For those, you must do all the above plus drain the oil, remove the oil filter and coat the flanges and other exposed surfaces with either oil or a preservation compound as described in the engine maintenance manual. Add a tag to your oil filler cap advising that the oil has been drained and include the preservation date. If you expect the engine to sit for longer than a year, the best practice is removing it, doing all the above, and storing it in a proper shipping container.

If your engine is not preserved 8-28 days before starting, you must do a Total Acid Number test on the engine oil. Up to 90 days, there are numerous other things you must check and do, as well as specific start-and-run procedures. If your engine goes up to a year unpreserved, fuel nozzles, accessory bench checks and additional inspections are required. In addition, the engine must be disassembled and inspected for corrosion.

The easy alternative is to run the engine weekly. That may seem like a nuisance, but maybe not when you compare it to the cost of parts replacement or downtime for inspections. When you perform these runs, you want to run at 80% power for 10 minutes, reducing the oil system’s condensation and preventing fuel stagnation.

Remember that if you don’t record the work you do to preserve your engine in the engine logbook, it doesn’t happen. Engine preservation must be documented. All of this is especially important if you have a Pratt & Whitney Canada warranty on your engine. You don’t want to jeopardize your warranty claim because the engine wasn’t preserved or stored correctly.

As always, I just want to provide you with the best practices to allow the engine to run trouble-free for the longest possible time. Take as much time to protect your engine as you do protecting yourself, and your engine will be there for you when you need it.

Robert Craymer has worked on PT6A engines and PT6Apowered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and is an instructor of PT6A Maintenance and Familiarization courses for both pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member.

Robert can be reached at robertc@covingtonaircraft.com or 662-910-9899. Visit us at covingtonaircraft.com.

SUBARU BELL 412EPX

The most reliable work trucks are transformed and reborn year after year for decades. When you’re fighting wildland fires from the sky, critical moments require experienced and renewed solutions. The upgraded transmission of the new Subaru Bell 412EPX provides 11% more shaft horsepower at takeoff, resulting in a 15% boost in the hot and high hover. Add in an unprecedented increase for internal, external and cargo hook with 1,100 pounds/499 kg payload added. Proven operational readiness now with more payload, more firemen and women, more water…and more power to fight fire.

bell.co/fire

In 1972, the WSK PZL Warszawa Okęcie company started a ZUA (Agro Aviation Services Unit) operational division to provide aerial firefighting operations and agro-aviation services. This division began in Poland and has grown to be a global provider of firefighting services , now operating under Mieleckie Zakłady Lotnicze Sp. z o.o. or MZL for short.

During its more than 50 years, ZUA has undergone various ownership changes. In 2001, the European consortium EADS CASA (later Airbus Poland S.A.) purchased 51% of PZL “Warszawa-Okecie” shares. Thus, ZUA was incorporated into the structure of the largest European aviation company.

On October 31, 2022, a company of the Łukasiewicz Research Network - Institute of Aviation from Warsaw, established in May

2022 under the name Mieleckie Zakłady Lotnicze Sp. z o.o., became the buyer of the Aviation Services Business Unit (former ZUA) from Airbus Poland S.A., taking over all the assets and employees and continuing its current operations as an independent entity.

In 1980, ZUA began purchasing a new specialist aircraft, the PZL M-18 Dromader. It was manufactured in Mielec as a development of the famous Thrush Commander aircraft in the West. Since 1980, 84 units have been purchased. Currently, MZL owns 25 units of PZL M-18 Dromader, which, in addition to the 9 AN-2s, constitute the primary fleet of MZL. Due to its development plans, the company has supplemented its fleet with additional units. It has long-term plans to develop its own aerial firefighting and agricultural aircraft native to the Polish manufacturer.

MZL chose the PZL M18 Dromader as a specialist aircraft designed with firefighting in mind. The M-18 is a single-engine, low-wing, allmetal monoplane with a tricycle fixed-type main gear, a tail wheel, and a hopper located forward of the cockpit. The aircraft is

(Continued on page 20)

designated for operation from short and unpaved airstrips, which are invaluable in firefighting, where access to airport infrastructure can be limited in specific service areas the company works in. Its durability and reliability make it “an aircraft we can rely on in all conditions, which offers exceptional performance, providing unmatched efficiency and versatility in implementing our operations.,” said the company. The 25-strong M18 Dromader fleet owned by MZL can be easily modified to an agricultural version, making it a truly multi-mission aircraft.

Since 1960, every aviator has been responsible for forest protection duties and fire spotting. They report what they see from the air, be it fire or smoke, to the Polish authorities for action. However, in

1967, the government introduced its first constant patrol of forested areas with a greater fire risk.

Initially, Poland employed the AN-2 aircraft for aerial firefighting; however, the AN-2’s small tank and canvas wings were significant limitations. The later introduction of the M-18 Dromader brought considerable progress and was the best suited for aerial firefighting operations. Tests of its use for aerial firefighting began in 1983 at Poland’s Forest Research Institute.

Field testing of the Dromader also occurred in 1983 at the OBR Mielec experimental base in Krystkowice, Poland, and then in Gozdnica, Poland. Here, ZUA pilots were also trained in all aspects of

(Continued on page 22)

aerial firefighting operations, which was an entirely new concept for the country.

Also, in 1983, the country’s fire protection system began to be organized using technology developed at the Forest Research Institute. 1984 saw the establishment of the first Aviation Forest Bases (LBL) in Warsaw and Szczecin. In the following years, the number of bases expanded dramatically to 14 nationwide. Bases were established in Poland’s most fire-threatened forested areas to provide maximum efficiency.

Fire bases in Poland are open from March to October, and the planes are intended to be a rapid response factor in detecting and extinguishing fires in their initial phase and to stop them from spreading. Each base is stationed with one or two M-18 Dromader aircraft. The base contains water tanks, refueling devices, fuel supplies, and foaming agents. The crews are on constant duty in constant readiness for flights, especially on weekends and public holidays when the forests are more frequently visited by tourists and locals alike.

Each base cooperates closely with State Forest employees, who supervise and coordinate the work of the bases, and with local Fire Department units as needed for fire operations. Cooperation and communication with the air traffic controllers are also necessary for planning and obtaining flight permission. As part of the contracted

firefighting services, the aircraft in Forest Bases are also used for agricultural purposes to perform spraying missions to combat forest pests. They are equipped with firegates and spray booms and are equipped for whatever mission is necessary.

From 1999-2009 ZUA was contracted to fight forest fires in Portugal with 8 M-18 Dromader aircraft, while the company also provided key support in Chile, providing 11 PZL M-18 Dromaders from 1998-2008. Since 2023, MZL has also been providing fire protection services in Germany, based within the Harz district, and in 2024, the company also expanded operations into Turkey, operating out of a base in Adana. MZL focuses the core of its activity still protecting Polish forests against fire and pests, with work covering almost 80% of Poland operating out of 17 aviation forest bases. However, their global footprint continues to expand.

Regarding international contracts, MZL always operates in close coordination with local fire services, including crisis intervention agencies and fire departments dependent on the country. Collaboration for MZL is the key to aligning each country’s needs with the scope of operations, which also involves utilizing available resources, such as aerial coordination, allowing the company

(Continued on page 24)

to effectively manage operations while ensuring support and compliance with local procedures.

Working in other countries offers many challenges for MZL, with one of the main challenges being communication, thanks to the different languages spoken and the diversity of geographical conditions that impact firefighting strategies and

cooperation with local services. Each country has its unique procedures, requiring flexibility and adaptation. Understanding local regulations and building relationships with local agencies is crucial for effective response to crisis situations and enhancing the efficiency of our operations for MZL during overseas operations.

(Continued on page 26)

MZL pilots use several techniques depending on the type of fire they are fighting. These include Isolation drops, line drops (indirect), and direct fire attacks. The purpose of isolation drops is to decrease the area of fire by building wet curtains and barriers. This technique is recommended for grass and young tree fires.

Direct drops, or “water bombing,” involve dropping directly on the fire or part of it to extinguish flames. This type of dumping is recommended when the fire begins, aiming for early suppression before flames reach the tops of tree canopies. After-burning drops are used to saturate the ground of an already burned-over area to prevent flare-ups and reignition of almost-contained fires. Foam is also used by MZL pilots for border isolation of a fire, much like retardant to wet down trees and dry grass.

AWhen fighting fires in often inhospitable terrain in foreign countries, MZL relies on the strength of the M-18 Dromader, with its strong landing gear facilitating many landings at off-base

strips. This is in addition to the ASz-62 IR model 1000hp Piston engine, which suits the company for work in all conditions (including smoke, sand, and dust). The engine can also restart in the field hot and does not require prior cooling after operation, which is a massive plus on quick turns during fire operations.

The M-18 fleet is also equipped with a multi-function firefighting system able to drop a ground pattern size – 25x90m with a hopper discharge time of 2.2 seconds for a full salvo release. The smaller framed M-18 is also capable of isolation drops with a width of 20 meters (65 Feet) and a total pattern length of 470 meters (1500ft).

The Dromader fleet uses a ‘fire gate’ system, which allows for precise application of firefighting agents. The Dromader has a water discharge system in two variants: ‘water bomb’ and ‘drop line.’

The ‘water bomb’ variant enables quick and effective dumping of large amounts of water on the fire-affected area, particularly in intense flames and large fires. In contrast, the ‘drop line’

(Continued on page 28)

system allows for creating isolation barriers, making it ideal for preventing the spread of fires.

MZL’s success in Poland and other countries is a mix of many successful traits as a company, but the speed of deployment has always been a prided tactic of the company, evidenced in 2020 in Poland when MZL crews were dispatched to a large fire in Biebrza National Park. The Minister of the Environment presented medals to pilots on that fire, “For Merit for Environmental Protection and Water Management,” for taking part in the firefighting operation over Biebrzawhich was the highest level of government appreciation for their professionalism and commitment.

Several other instances where MZL has dispatched aircraft quickly have saved many acres of forested land, including sending additional aircraft and crews, who responded quickly to a firefighting operation in the Harz National Park in Germany in September this year.

Part of the challenges of operating in multiple countries mean that logistics are a huge concern. In addition to aircraft, staff have to be ferried to the location; the need for maintenance crews on the ground at each base is just as essential to MZL as pilots, in addition to the need to ferry the aircraft to each location and make sure each location has enough spares, staff in rotation when the company is operating in three countries at a time can prove a challenge for MZL, but nothing the company hasn’t overcome in the many years of operating in multiple countries.

Mieleckie Zakłady Lotnicze (MZL) values safety as the most significant priority in the company. Operations are based on strict adherence to procedures and the implementation of modern systems that ensure high safety standards and operational efficiency. Key elements of safety procedures used at MZL include the use of a Safety Management System (SMS) - a

(Continued on page 30)

a comprehensive approach to safety management in an aviation organization, which includes risk identification, threat assessment, monitoring and analysis of events, and implementation of corrective actions.

MZL also employs a Personnel Support Program (PEERS) - The PEERS Aviation Program, implemented at Mieleckie Zakłady Lotnicze, is an integral element of their approach to managing safety and operational efficiency. The company ensures the highest safety and efficiency standards in firefighting and agricultural aviation missions through systematic training, support, monitoring, and implementation of modern technologies.

Crews working for the company are also subject to a duty time register, a system for monitoring and documenting crew members’ working hours and rest times. The register ensures that working hours do not exceed permitted limits and that crews have adequate time to regenerate.

One of the biggest challenges in developing a firefighting business is equipment. Using the M18 Dromader aircraft, which formed the backbone of the firefighting services at MZL since the company’s inception, will not last as the aircraft ages. The company sees the growing need to introduce a new aircraft to the market that could further enhance its efficiency.

MZL also holds a manufacturing organization certificate, which opens up new development opportunities. The company plans to introduce a new firefighting aircraft based on the M18 model but with significant improvements. MZL intends to increase the tank’s capacity and implement a turbine engine, allowing even more effective and efficient firefighting operations. This will enable the company to meet the market’s growing demands and respond better to crises.

(Continued on page 32)

Coastal Air Strike’s agile, forward-attack SEAT (single engine air tanker) and Single Engine Scooper aircraft are your best chance to contain small wildfires, to prevent them from becoming big wildfires. Their ability to operate from virtually all airports, ranging from large tanker bases to remote airstrips – even reloading at portable retardant bases – along with the Single Engine Scooper’s ability to scoop nearby water sources, proves them invaluable.

PAYLOAD:

The Dromader carries up to 2,200 liters of payload, allowing for more operations in fewer flights, increasing the efficiency of our operations in both firefighting operations and agricultural spraying.

WATER TANK:

The large tank allows for longer flights without the need for frequent replenishment of water.

MULTI-FUNCTION FIREFIGHTING SYSTEM:

Water-Bomb: Ground pattern size – 25x90 m; Hopper discharge time – 2.2 sec.

Line-Drop: Isolating drops – small flap, from width of 20 m at the line-drop start to 10 m at the end; Total pattern length - 470 m; Extinguishing load can be divided into a few portions; Hopper load discharge time (2200 l.) - 11 sec.

ABILITY TO OPERATE IN DIFFICULT CONDITIONS:

Short Take-off and Landing: The Dromader can operate on runways as short as 400-500 meters, even if they are unpaved, which is ideal for forest fires with limited access.

Strong Landing Gear: Designed to operate on uneven surfaces, minimizing the risk of damage.

HIGH RELIABILITY AND LOW MAINTENANCE COSTS:

Robust Construction: Known for its strength and reliability, reducing downtime and maintenance costs.

Simple Servicing: Allows for quick and easy service work, crucial for high operational readiness.

VERSATILE APPLICATIONS:

Firefighting: Quickly adapted to extinguish fires, invaluable in the protection of forests and agricultural areas.

Agro-Aviation: Ideal for precision spraying and fertilization, increasing the efficiency of agricultural operations.

SPEED AND RANGE:

Cruising Speed: Around 200 km/h, allowing for quick access to operation sites.

Range: Up to 1,000 km with a full tank of fuel, enabling long-term operations.

(Continued on page 34)

MZL employs 109 people throughout the operation, including 38 people responsible for contract management, documentation, operation planning, and organizational support. The company has 35 pilots specializing in agroaviation and firefighting operations backed up by a maintenance crew of 36 mechanics responsible for aircraft maintenance, repair, preparation, and ongoing maintenance. Their work ensures the reliability and safety of the fleet, which is necessary for effective operations performance.

What sets MZL apart from other global fire service providers is its versatile fleet, which can be quickly reconfigured for agricultural aviation use or firefighting with minimal notice. This flexibility allows MZL to respond swiftly to various needs of their customer base, whether in firefighting or agricultural support.

With over 50 years of global experience, MZL has honed its ability to adapt to customer requirements efficiently and effectively. With extensive industry knowledge and a proven track record, the company has continued implementing innovative solutions tailored to specific situations.

Mieleckie Zakłady Lotnicze stands out from other companies thanks to its comprehensive approach to developing the agricultural aviation and aerial firefighting industry in Poland and beyond. Despite national restrictions, it actively builds social awareness, participates in international fairs and tenders, and cooperates with global clients.

Mieleckie Zakłady Lotnicze’s philosophy of safe operation is based on systematic safety management, continuous training, maintaining high technical standards, precise operating procedures, a strong safety culture, and monitoring and analyzing operations. Thanks to this, MZL ensures the highest safety and efficiency standards in their aerial firefighting work.

The founder and CEO of Scott Aviation and later CO Fire Aviation, Kyle Scott, lost his life during an aerial application flight on September 5th, 2024, while flying his AT-602 in Colorado.

A former Minnesota native, Scott founded Scott Aviation in Fort Morgan, Colorado, providing aerial application service in and around the Fort Morgan area, approximately 90 minutes Northeast of Denver, before the founding of CO Fire Aviation in 2019 and Gold Aero in 2020. Both companies operate primarily out of their Fort Morgan base, including the Fort Morgan Airport FBO run by Scott Aviation. CO Fire Aviation has been a successful aerial firefighting company for several years, providing SEAT aircraft on contracts in Oregon, Washington, California, Nevada, and Colorado.

Not only was Kyle a contributor to the aviation industry, but he utilized his skill by supporting his local communities when called upon, providing fire relief in local grass fires, duck drops, and Easter egg drops, and donating helicopter and plane rides for local fundraisers. He felt humbled, honored, and fulfilled when he provided Angel Flights to those in need. Kyle was an Honorary Member of the Fort Morgan Fire Department since 2013 and Rural Board President for the Rural Fire Protection District.

His influence extended beyond his companies. Kyle was a dedicated member of the National Agricultural Aviation Association (NAAA), serving on the Executive Board and the Colorado Agricultural Aviation Association (CAAA), passing through the chairs and serving as President. He was a strong advocate for safety, innovation, and best practices within the industry. Kyle also served as the President of the SEAT Operators Association, where he was recognized for his leadership and commitment to the industry’s future.

Beyond his professional achievements, Kyle had a deep passion for the outdoors. He loved snowmobiling, hunting, and spending time with family and friends at their cabin in Wyoming. His enthusiasm for life and love for his family and friends were always at the forefront, and he was often found cheering on Piper and Skylar at their volleyball and basketball games (usually earning a warning from the local Athletic Director), additionally supporting their barrel racing events. Their daughters said he was their biggest fan and critic, constantly pushing them to learn and improve. Kyle and Jennifer celebrated 27 years of marriage and experienced countless moments of pure love full of respect and loyalty. They showed each other unwavering support for one another over time. They loved doing life together, celebrating all they had accomplished and the wonderful, independent, caring daughters they raised.

Kyle’s sudden passing leaves an immense void for his family, friends, and aviation and firefighting communities. He will be remembered for his incredible contributions to the field, love for adventure, and devotion to his loved ones. His legacy will live on through the lives he touched and the countless contributions he made.

Kyle was remembered by many in Fort Morgan after his passing via social media for the impact he made in many areas of the community, including comment from former Morgan County Sheriff Jim Crone, who commented that Kyle was always willing to lend a hand to the community, be it for wildfire support or to provide an aircraft when needed for official duties or to support the local community or helping the Nebraska Panhandle Honor Flight with an escort as they arrived into Morgan county.

Kyle was a friend to many, a proud husband and father, and will be sorely missed by the industry. Our thoughts are with Kyle's family and the entire Scott Aviation, Gold Aero, and CO Fire Aviation families.

Georgia’s Ministry of Internal Affairs announced that its Border Police’s Special Purpose Aviation Division has received an Airbus H145 helicopter designed for firefighting and mountain rescue missions.

Pilots from the Division flew the helicopter from Germany to Georgia, marking the arrival of the first of three H145s purchased from Airbus Helicopters.

According to the Ministry, the helicopter is fully equipped with firefighting and mountain rescue tools and two engines to enhance flight safety. Pilots and maintenance technicians from the Division also completed both theoretical and hands-on training at the Airbus Helicopters facility in Germany.

In December 2022, the Ministry finalized an agreement with Airbus Helicopters to procure the aircraft.

The remaining two helicopters are expected to be delivered by June of 2025. The Ministry highlighted the aircraft’s agility and suitability for operations in the country’s mountainous terrain.

● APPROVED AROUND THE WORLD!

● PILOT IS ALWAYS IN CONTROL

● REDUCED PITCH - UP

● SIMPLE, USER FRIENDLY & RELIABLE

● SHAPE, SIZE AND DENSITY OF THE DROP PRODUCED TO MAXIMIZE FIRE CONTROL

● FULL SALVO DROP IN LESS THAN 2 SECONDS

● 4 LEVEL DUMP CONTROL

● APPROVED ALL MODEL OF AIR TRACTOR & THRUSH 660/710

● 20 YEARS PROVEN TRACK RECORD OF RELIABILITY & SAFETY

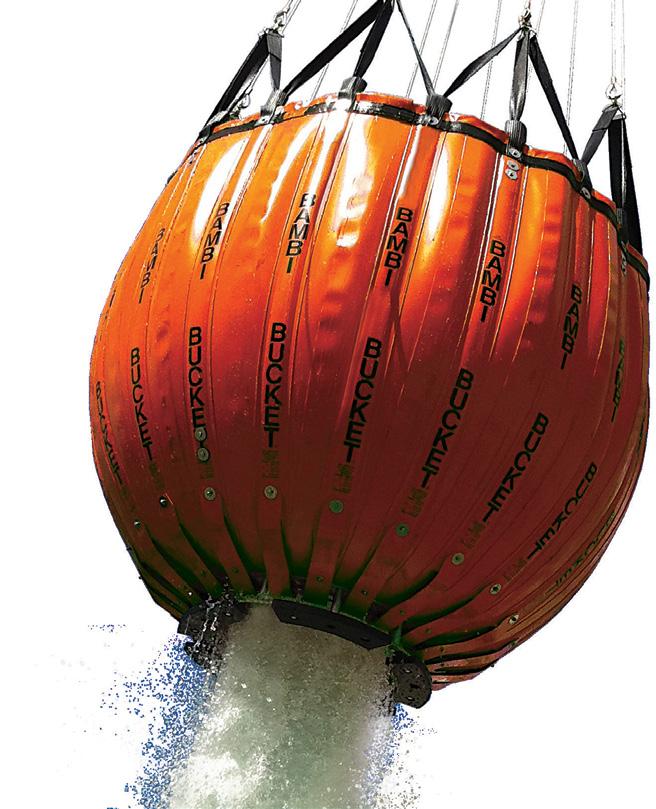

Aviators from the Louisiana National Guard’s 204th Theater Airfield Operations Group partnered with the Louisiana State Police on Sept. 25 to conduct aerial training on effectively using Bambi Buckets for firefighting.

The training at the Joint Emergency Services Training Center in Zachary, Louisiana, aimed to enhance LSP capabilities in responding to wildfires and other emergencies.

During the training, LANG personnel demonstrated techniques for operating the bucket, including precision water drops and strategic firefighting maneuvers.

(Continued on page 42)

The Center of Excellence for Advanced Technology Aerial Firefighting (CoE), a section of Colorado’s Division of Fire Prevention and Control (DFPC), announces the launch of its new real-time location-based service, the Colorado Team Awareness Kit (COTAK™).

Rifle, CO - COTAK™ offers Colorado public safety agencies a free of charge solution that provides up-to-the-second location information of team members and other important mission information, improving team coordination, situational awareness, and safety.

The U.S. Department of Defense originally created the Team Awareness Kit (TAK) software to assist military forces with situational awareness on the battlefield. “Colorado identified an opportunity to adapt the TAK software for use in public safety back in 2016. Since then, we have been developing the software as an innovative way to improve emergency responder collaboration,” shared Brad Schmidt, CoE Deputy Director of Spatial Technologies and COTAK Program Leader.

Colorado public safety agencies can access COTAK by downloading the TAK app on any smartphone or tablet and requesting access to the COTAK service. COTAK includes advanced features that are customizable to meet the specific needs of fire, law enforcement, search and rescue, and other public safety agencies. “Having access to this kind of intelligence on a device that emergency responders

already carry (a smartphone) is a game changer. We are providing public safety personnel with additional tools to enhance the efficiency, effectiveness, and safety of their jobs,” shared Schmidt.

Real-Time Location Information: Using dots on a map, emergency responders can locate themselves, their team members, and other COTAK agencies in real time.

Enhanced Team Coordination: COTAK enhances operational efficiency for emergency responders by sharing incident information with all relevant agencies, a crucial benefit during mutual aid incidents.

Improved Situational Awareness: Users can access real-time location intelligence and other critical incident information, such as maps of active wildfires, providing responders with the data they need to react with speed and efficiency in emergencies.

The CoE has provided early access to COTAK for over 140 agencies. Currently, there are more than 1,900 users, and the technology is now being offered to all Colorado public safety agencies. “We are proud to lead the charge in innovative public safety technology and know that COTAK will save lives. Knowing where your people are on any given shift or large-scale incident could make all the difference in the outcome,” stated CoE Director Ben Miller. COTAK is provided at no cost to all public safety agencies in Colorado. New agencies may sign up for COTAK access at cotak.gov.

The 10,000-litre LAT and crew have touched down at Bundaberg Airport, located approximately four hours north of Brisbane, the Queensland capital, for bushfire season.

Based in Bundaberg, the LAT can readily respond in coastal and inland areas across Queensland.

A Eurocopter and a waterbombing Blackhawk join the LAT in Bundaberg, supporting hardworking Rural Fire Service Queensland (RFSQ) staff and volunteer firefighters, and Queensland Fire & Rescue (QFR) personnel.

Two Bell 214B helicopters, two AirTractor AT-802 fixedwing bombers, two air attack supervision platforms, and a specialist intelligence-gathering light helicopter are on standby at Toowoomba Airport for the fire season.

This brings the Queensland Fire Department’s (QFD) contracted aerial fleet to 13 aircraft with a total waterbombing capacity of more than 32,000 liters.

QFD has access to approximately 150 additional aircraft, available on-call when needed.

QFD’s experienced State Air Desk coordinates the aircraft fleet, ensuring the best combination of aircraft, personnel and resources for major bushfires.

“The LAT is an important fire season asset for the Bundaberg community and Queensland. The LAT and fleet of firefighting helicopters and fixed wings are a Miles Government investment in doing what matters for bushfire safety,” said local government Member for Bundaberg Tom Smith.

“Our aircraft play a significant role in supporting crews on the ground during major bushfires but aren’t limited to waterbombing. They are also used for mapping, intelligence and planning throughout the season,” stated Queensland Fire Department Commissioner Steve Smith.

“As part of RFSQ’s preparations for each bushfire season, air operations personnel from RFSQ and QFR undertake training to sharpen their skills ahead of the season. Although we work closely with landholders and other agencies to conduct major mitigation work in the lead-up to bushfire season, it is so important that everyone’s properties are ready. It can make all the difference if the worst happens,” he continued.

“The biggest risk this bushfire season is expected to be grass fires, which have the potential to spread quickly in the significant fuel loads built up over the past two years due to rainfall. We are already starting to see fire activity and keeping a close eye on conditions. QFD’s aerial firefighting fleet will continue to support ground crews significantly as we see fire activity increase over the coming months,” stated Rural Fire Service Queensland Chief Officer Ben Millington.

The Future of Aerial Firefighting: The Dash 8-400AT

Fast, fuel efficient and tactically flexible. A modern airtanker with a 10,000 litre / 2,642 US gallon capacity to drop water, retardant, or gel over diverse geography.

Setting the standard for Next Generation aircraft with OEM support to keep the firefighter flying for decades.

South American Agricultural Aviation’s role in protecting people, land, and crops from fire is the focus of a new firefighting campaign launched this week by Sindag, the association representing the agricultural aviation sector in South America.

The campaign is being promoted on social media to raise public awareness of agricultural aviation’s vital role since the 1960s, both in crop protection and in safeguarding natural reserves.

Since at least 1990, agricultural aviation has been actively involved in firefighting efforts to protect Brazil’s major biomes. These efforts include annual operations in the Amazon, Cerrado, Pantanal, and even the Atlantic Forest, Pampa, and Caatinga. During the current fire season, which began in July and is expected to continue through early October, at least 36 agricultural aviation companies participate in aerial firefighting operations. Preliminary estimates suggest more than 15 million liters of water have already been dropped this year.

•

•

•

•

•

•

•

•

The Oklahoma National Guard partnered with Southwestern Oklahoma State University, the Oklahoma Highway Patrol and Weatherford Fire Department to host a multi-agency wildland firefighting unmanned aerial systems integration exercise at Crowder Lake near Weatherford, Oklahoma, Sept. 25-26.

The exercise brought the Oklahoma National Guard, state and local agencies and several private UAS companies together to develop a common operating picture, ensuring all public safety teams have a shared view of a multi-agency response to events like wildland firefighting.

Col. Shane Riley, director of military support for the Oklahoma National Guard, explained the importance of bringing these organizations together as the use of drones in domestic operations becomes more prominent.

“We’re looking at how we can be a better partner to the emergency management world and help provide an architectural structure for the employment of drones to help our agency and the agencies that we work with to safely respond to those things with all of the tools and assets that they’ve got at their availability,” Riley said.

The two-day exercise centered on scenarios designed to test the OKNG’s and public safety organizations’ ability to create and share a common operating picture among multiple UAS operated by multiple agencies close to one another.

Each agency operating a UAS platform fed their camera feeds, location data and other information to a single incident command post where the incident commander and their staff could view, coordinate and deconflict both unmanned and manned aircraft operations.

During one scenario, the incident command post was required to dispatch an emergency resupply to notional firefighters on the ground. As all agencies used the common operating picture, the ICP could quickly and safely clear the airspace for the resupply mission.

According to Chad Kinder, EdD, vice president of Strategic Partnership at SWOSU, as demand for unmanned aerial systems increases, the need for organized procedures and strategic planning is becoming more critical.

“As time goes on, we’re seeing more and more [unmanned aerial vehicles] in use,” Kinder said. “The Weatherford Fire Department just added drones in the last year, so it’s a great thing for these agencies to get together and learn how to use these UAVs in the same airspace simultaneously.”

Oklahoma Highway Patrol Lt. Scott Patton, the drone coordinator for the Oklahoma Department of Public Safety, said exercises like this are important to bringing together the many agencies operating UAS in an emergency before the emergency happens.

“When we’re operating our unmanned aircraft and getting the picture of the fire or the incident within the state, we can also

make it safe for manned aircraft to come into the picture and do their water drops and search and rescue,” Patton said. “We’re not inhibiting their [manned] operations by having a drone or a UAS up in the air, so we can mitigate those issues now and know what that’s going to look like so we can get our manned aircraft in without having an incident.”

Riley said most domestic operations missions, like fighting wildfires or responding to towns affected by tornadoes, will involve multiple agencies coming together to solve the problem. He is pleased with the outcome of this exercise, with all the different agencies doing their part to ensure successful training.

“I would say this has been a great exercise,” Riley said. “We’ve achieved everything we hope to come out and do, with partner support. I’m grateful for the industry, academic and state agency partners who came out to support us.”

As more people migrate from urban areas to the suburbs or countryside, the risk of wildfires threatening our homes and lives increases. We often see dramatic footage on the news and assume it won’t happen to us. Still, scientists and emergency responders warn that increased human activity near forests leads to more wildfire incidents.

(Continued on page 54)

We might feel secure knowing we have local fire stations or volunteer firefighters ready to respond. However, predicting wildfires is challenging, and there aren’t always sufficient taxpayer funds to be fully prepared.

Aerial firefighting involving unmanned aerial systems, planes, and helicopters is crucial in wildfire management. These aircraft can detect fires, provide critical information to ground firefighters, and drop water or retardant to slow the fire’s spread. Despite their importance, there are insufficient resources to address every fire, and the system is under strain.

One industry insider confides, “The public doesn’t know that there simply are not enough resources available to respond when their home is threatened. “

An estimated 45 million residential buildings across the US are at risk of destruction from wildfires, and the number continues to grow. California boasts over 60 state-owned aircraft that can respond swiftly, but the rest of the U.S. must share about 200 aircraft, mostly helicopters, for a vast area. This equates to one aircraft for every 3.3 million acres of public land, which doesn’t include your home!

Various entities are responsible for combating wildfires. The federal government protects public lands, while state and local taxes fund efforts to safeguard our homes. Yet, the division of responsibilities and funding is not always clear.

However, we are fortunate that, like our military, wildland firefighters are ready to put their lives on the line to safeguard their neighbors’ lives and property. So much so that they feel a heavy burden when they cannot do that. Zach Sullivan, a firefighter on the ground and in the air for over twenty years,

says that he once had to see over half of the homes he was sent to protect go up in flames, having little control over the result. He knew he wasn’t responsible but couldn’t help feeling a bit ashamed for the failure.

“I’m not sure the public understands how they are transferring the risk to firefighters who will do everything they can to extinguish the fire,” Sullivan says. His voice carries the weight of countless missions.

“Then we’ll go back to a camp or our car to eat a subpar meal, likely not take a shower after 12+ hours in the dirt and smoke, and sleep on the ground or in our vehicle.”

Along with the critical ground forces, there are pilots, mechanics, and other support personnel who ensure that the aircraft used to protect those ground firefighters is safe and ready to perform when needed. Unfortunately, this group of experts isn’t huge, and recruiting and keeping this critical workforce has become an increasingly daunting challenge.

“There’s a worldwide pilot shortage, and aerial firefighting pilots are an even more specialized group to try to hire,” explains Bart Brainerd, CEO of Firehawk Helicopters. The problem extends beyond the cockpit, as skilled aircraft mechanics are also hard to come by. Veteran aircraft mechanics from the military are sought after for their ability and employability. Still, they can often make more money and have more job stability working for an amusement park than for an aerial firefighting company, as Brainerd found out the hard way.

Wildland firefighting can be a tough sell, with all industries suffering from labor shortages. “Being gone five months during the year fighting fire and then more days in the winter training makes it tough to keep relationships. If you can find that special someone who understands that you are fortunate,” says Sullivan. Then there is the inconsistent work and low pay. Federal firefighters have been waiting for years to receive a permanent pay increase from Congress that they hope to see happen in 2025. Still, the often temporary nature of the work for them and the ground and aerial firefighters who work for private companies makes it hard for everyone to find and afford housing and maintain a work-life balance and relationships at home.

The business model of aerial firefighting companies is also fraught with challenges. Eric Komberec, a pilot and small business owner, says there is a saying in the industry,

(Continued on page 56)

...like our military, wildland firefighters are ready to put their lives on the line to safeguard their neighbors’ lives and property...

“The military is constantly training for the war they hope will never happen...No one would suggest we lay them off and call them back after an enemy attacks, especially if we expect them to win the battle. Then why are we expecting our wildland firefighters to be able to do it?”

“If you want to make a million dollars fighting fire, you must start with two.” People do this work for the mission, not the money.

Most services are bought by governments on a “call when needed” basis, which makes sense on paper for the taxpayer but creates significant financial instability for those businesses that provide these critical services. The financial realities of aerial firefighting companies are daunting. Unlike businesses that can balance their workload across multiple clients, these companies live and die by the severity of a single fire season and only a few government customers.

“If the season is longer than expected, we can sometimes make a profit,” says Brainerd. “But often, the income does not cover costs, and if there is any excess, it’s put towards prior expenses in years where firefighting was limited.” This feast-or-famine cycle forces tough decisions. “We have to lay off experienced personnel, sell aircraft, or may even need to shut our doors entirely,” Brainerd explains. “It’s a constant scramble to keep the lights on.” When companies don’t have enough income or bank credit to keep employees on staff, to support aircraft, to provide continuous training, it takes a toll.

Unfortunately for both the public and industry, there isn’t an expectation of readiness or levels of funding for wildland firefighting like there is for the military.

“The military is constantly training for the war they hope will never happen,” points out Paul Petersen, Executive Director of United Aerial Firefighters Association (UAFA). “No one would suggest we lay them off and call them back after an enemy attacks, especially if we expect them to win the battle. Then why are we expecting our wildland firefighters to be able to do it?”

The reality of aerial firefighting is sometimes they’re the last line of defense between a wildfire and people’s homes, or even firefighters. Andy Taylor, a veteran pilot and owner of NEW FRONTIER AVIATION INC, provides single engine airtanker (SEAT) services to the Bureau of Land Management. He speaks proudly yet humbly of a recent sortie where he was able to save an engine crew trapped by the fires. “If we hadn’t been close by, I’m not sure what would have happened to that crew, but it wouldn’t have been good. I worry about the number of crews who may not have that extra support from the air when we are at P.L. 5 or in the shoulder season when there are no aircraft on contract to call.”

Preparedness Level (P.L.) is a term used by the National Interagency Fire Center to describe the current level of resources available to respond to wildfire in the U.S. P.L. 5 means that national resources are heavily committed, and everyone must take their own emergency measures to sustain incident operations. It is the time, typically in August, when the country is having to pick and choose which fires get aircraft, how many ground crews can have their already completed 14-day rotation extended to 21 days, and where there just may not be as robust of a response as is desired or needed. Being at P.L. 5 today, in October, is not normal and its

(Continued on page 58)

Public and press attention to the matter helps for a short time, but it is quickly forgotten when the fires subside...

primarily due to lack of contracted resources being available to hire, not because they are committed to a incident.

This is what Taylor was talking about when he said there may not be an aircraft on contract. The government only pays for aircraft to be on standby when they are certain they will be used. That means in the shoulder months of October-April, aircraft may be undergoing maintenance or even in Australia or South America. This is one of the reasons aircraft were slow to arrive in Texas this past February. There were no aircraft on contract, and it took days to move the bureaucratic wheels to have them arrive. Something that a change in the way ground and air resources are hired could change.

If the situation in the U.S. isn’t daunting enough, the challenges facing U.S. aerial firefighting companies are compounded by soaring global demand. Rising fire threats in Europe, South America, Australia, and Asia have created fierce competition for these specialized resources.

“Aircraft manufacturers simply can’t keep pace with the growing need,” says Stephen Johnson, the Global Sales Director for Fire Boss, a company that makes floats for single engine air tankers.

This global squeeze puts U.S. companies in an impossible position: chase lucrative overseas contracts, rely on unpredictable domestic work, or risk financial ruin.

There isn’t a silver bullet solution for the issues these companies face, but there are recommendations. As part of the 2021 Infrastructure Investment and Jobs Act, Congress took bipartisan action to set up the Wildland Fire Mitigation and Management Commission (WFMMC). They charged the 50-member Commission with the ambitious task of creating policy recommendations to address nearly every part of the wildfire crisis, including mitigation, management, and post fire rehabilitation and recovery. Of the over 150 recommendations, many addressed changes to the way aerial firefighting and other private industries are hired to support suppression.

Longer term contracts, support for pilot recruitment and training, and a nation-wide aerial firefighting strategy that includes readiness in the shoulder seasons are just a few of the improvements which would help companies like Komberec, Brainerd, Johnson and Taylor’s to be able to “survive to fight another day” to protect your life and property.

Public and press attention to the matter helps for a short time, but it is quickly forgotten when the fires subside, much like what happens around hurricane preparedness. The United Aerial Firefighters Association (UAFA) and the National Wildfire Suppression Association have started working with Congress and the agencies to implement the WFMMC recommendations, but it can’t happen fast enough for the companies who are trying to keep the lights on.

Korean Aerospace Industries (KAI), a leading South Korean manufacturer of both fixed-wing aircraft and helicopters, has announced a significant partnership with Australian aerial firefighting specialists, Helitak.

This collaboration is set to deliver advanced aerial spray and firefighting systems for KAI’s KUH-01 helicopter, a heavy-lift platform designed for both civilian and military use.

KAI’s product portfolio spans a wide range, from two-seat training aircraft to cutting-edge 5th-generation fighter jets. In the rotorcraft segment, the company produces the Light Armed Helicopter (LAH), based on the Airbus 365, as well as the KUH-01, derived from the AS332 Puma. The KUH-01 has seen success across various sectors, and this latest development aims to enhance its versatility in emergency response roles.

Recognizing the growing demand for multipurpose helicopters, KAI secured contracts with several government agencies in South Korea. These contracts call for KUH

helicopters equipped with specialized aerial spray systems and advanced firefighting equipment. To meet the strict design and performance requirements for these systems, KAI launched an extensive consultation process with potential suppliers.

After months of careful consideration, KAI selected Helitak, a company renowned for its high-performance helicopter firefighting systems. The decision followed several in-depth meetings between KAI’s design teams and Helitak’s management at their headquarters in Queensland, Australia. These meetings focused on ensuring that the systems Helitak would develop could fully meet the operational needs of KAI’s clients.

(Continued on page 62)

The success of these discussions culminated in a final meeting in Australia from October 9th to 11th, 2023, during which KAI management and representatives from the end-users finalized the design. The two companies signed formal contracts, marking the beginning of a long-term collaboration.

Under this agreement, Helitak will design and manufacture two key systems for the KUH platform: a fixed belly tank aerial spray system and a 3,000-liter firefighting system. The first deliveries of these systems are scheduled for early 2025, with additional deliveries planned through 2027.

This partnership is expected to significantly expand the KUH-01’s capabilities, further establishing KAI as a major player in the global aerospace and defense markets. For Helitak, the contract represents an important milestone as the company continues to innovate and expand its presence in the international firefighting and aerial operations sector.

The collaboration between KAI and Helitak showcases the increasing importance of specialized systems in modern helicopter design, ensuring that platforms like the KUH-01 can meet the evolving demands of both civilian and military operations.

Our commitment to exceptional quality and personalized service aligns with our full range of services, all while keeping your budget in mind.

ADVERTISING AND PROMOTIONS:

Creation of niche publications, digital advertising, web development, and commercial printing

DESIGN & MARKETING SERVICES:

Graphic Design, Web Development, Ad Creation, Media Marketing, Digital Marketing

CUSTOM PRINTING:

Printing services for Brochures, Magazines, Business Cards, Postcards, and more!

Piasecki Aircraft Corporation and Columbia Helicopters (CHI), the world’s premier tandem rotor helicopter OEM, MRO, and operator, announced a strategic collaboration to deliver upgraded heavy-lift helicopters worldwide.

The collaboration will upgrade existing Model 107-II helicopters to a new, more fuel-efficient, powerful, and robust Columbia Model CHI-107-III configuration. This partnership supports customers in essential services such as emergency response, aerial firefighting, forestry, infrastructure, and defense. The military variant of the Model 107-II is the CH-46E Sea Knight (Phrog), which served with the U.S. Marine Corps and Navy, as well as allies in Sweden and Japan.

Modifications and testing will take place at Piasecki’s 219,000-squarefoot Heliplex facility in Coatesville, Pennsylvania – acquired in 2023 from Lockheed Martin Sikorsky after the S-76 and S-92 helicopter production lines at the site were closed and hundreds of jobs were lost. Piasecki’s acquisition of the facility was championed by Pennsylvania Senator Bob Casey, Representative Chrissy Houlahan (PA-6), Governor Josh Shapiro, and the Chester County Economic Development Council to create new jobs that leverage the unique aerospace skills in the region.

The Heliplex will also serve as CHI’s new field site, expanding opportunities on the East Coast. The partnership covers the development of comprehensive product support plans for the Columbia Model CHI-107-III – including establishing an FAA Part 145 Repair Station at the facility.

“We are thrilled to partner with Columbia Helicopters, a company that shares our heritage with the tandem helicopter, and our commitment to innovation and excellence in the rotorcraft industry,” said John Piasecki, CEO of Piasecki Aircraft. “This collaboration represents a significant step forward in the evolution of tandem rotor helicopters and promises to deliver enhanced capabilities to a wide range of military and civil applications. We look forward to working together to advance the future of this vertical lift technology and generate hundreds of jobs for our communities.”

“The new Columbia Model 107-III will transform the heavy-lift helicopter market, providing unrivalled performance and versatility

for our customers” said David Balevic, CEO of Columbia Helicopters. “We are dedicated to pushing the boundaries of what is possible, and together with our partners at Piasecki, will deliver enhanced heavy-lift aircraft that save lives, protect nations, and build industries for decades to come.”

Piasecki, with a rich 80-year history in the design, development, fabrication, and testing of rotary wing aircraft, brings its extensive experience and cutting-edge research to this partnership.

The Model 107-II’s distinctive tandem rotor configuration was invented by the original Piasecki Helicopter Corporation, and then renamed Vertol and sold to Boeing in 1960. Columbia acquired the Model 107-II Type Certificate from Boeing in 2006.

The companies are engaged in developing rotary wing aircraft and enabling technologies on behalf of the US Department of Defense and commercial customers. The Model 107 military designation is the CH46 Sea Knight — nicknamed “Phrog” due to its distinctive amphibian-like appearance.

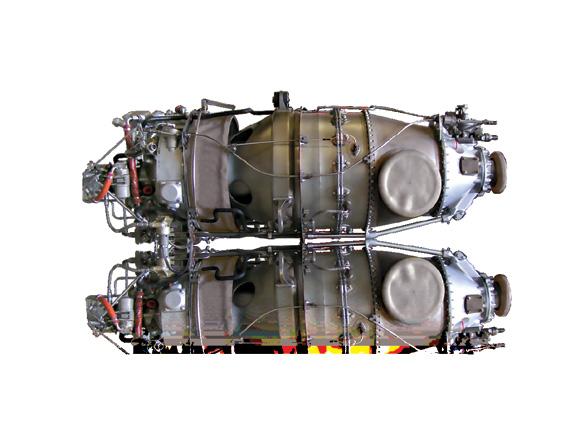

The CH-46E features a twin-engine, tandem three-bladed folding rotor design powered by General Electric T-58 turboshaft engines, which are mounted in the tail. First launched in 1958, the CH-46 Sea Knight has been a significant part of the U.S. military’s rotorcraft fleet for more than six decades due to its performance, safety, reliability, and maintainability. It is known for its impressive lifting capability with more than 8700lbs useful load at 24,300lbs Gross Weight, and a large cabin with rear ramp access, making it a versatile and powerful asset in various operations, including fire and disaster response.

Columbia Helicopters provides full Original Equipment Manufacturer (OEM) support for the Model 107-II and CH-46 helicopters, ensuring its reliable operation and maintenance. It holds the commercial FAA type and production certificates for the Columbia Model 234 Chinook and CHI-107-II helicopters and is a Total Logistics Support center for GE T58 and CT58 engines, which power all Model 107 helicopters. CHI has engaged the FAA to obtain certification for the next generation Model 107, the 107-III helicopter.

by Dr. Susan Northrup, FAA Federal Air Surgeon

Most of you know that there are specific limits regarding alcohol consumption when you plan to fly. You must abstain from alcohol for at least 8 hours prior (12 hours in the military), and your blood alcohol level must be less than 0.04% (grams/deciliter) per Title 14, Code of Federal Regulations (CFR), section 91.17.

The use of alcohol and other drugs (legal or illicit) proximate to flight is simply not safe. Studies have shown that there is an increased mishap rate among pilots who have had a DUI or DWI (driving under the influence or driving while intoxicated). In addition, a significant number of pilots involved in fatal accidents have had alcohol or other impairing drugs found in their system at autopsy.

The FAA is very concerned about this safety risk, so its regulations emphasize the importance of flying unimpaired. You should also know that pilots are required to report alcohol—or drug-related incidents to the FAA. Pilots who maintain an FAA medical certificate

and operate under part 121 or 135 face additional requirements, including random drug and alcohol testing.

Pilots are subject to the reporting requirements of 14 CFR section 61.15. You must provide a written report to the FAA Civil Aviation Security Division within 60 days of any action regarding your driver’s license, including suspensions, convictions, etc. Please note that this is required even if charges are subsequently dismissed. Also note that multiple reports might be required for the same offense, for instance, if a later conviction follows a suspension. This regulatory requirement reflects how the law was written.

Pilots maintaining FAA medical certification have additional reporting requirements under items 18 and 20 of the medical certificate application (FAA Form 8500–8). This is separate from the reporting due under section 61.15, and neither disclosure satisfies the reporting requirement for the other. Also, applicants for a medical certificate or those choosing the BasicMed pathway grant consent for a review of the National Driver’s Registry (NDR) as part of the application process.

Don’t drink and drive or fly. But if you do, prompt and full reporting is the best path forward.

There are also considerations for those who fly ultralights (part 103) and drones (part 107). The use of alcohol or other drugs is limited in section 103.9 and sections 107.23, 107.27, and 107.57, respectively, in addition to section 91.17. While there is no specific reporting requirement under part 103 or 107, a pilot who holds a certificate issued under part 61 must still meet the reporting requirements of section 61.15, even if they no longer exercise that certificate.

The take-home message is don’t drink, fly, or drive. Some that do are repeat offenders before they are caught by law enforcement. If you are going out and plan to drink, have a designated driver, take a cab, or spend the night at a hotel or with a friend. Some of you already follow this guidance. Hopefully, more of you will. However, some will test the system and get caught. You risk being involved in an accident or losing your pilot certificates, which will require a mandatory grounding period before retesting is permitted.

Let’s assume that the FAA’s legal team has determined enforcement action is unnecessary after reporting. There are still considerations for pilots who hold an FAA medical certificate. Both substance abuse and dependence are specifically disqualifying conditions listed in 14 CFR part 67. While a single event (DUI/DWI) can be relatively straightforward if an underlying dependence is absent, many times it will still require clearance from the FAA. For multiple events and/or cases where dependence is demonstrated, the pilot should anticipate that they will not be flying until the FAA is satisfied that the individual is in good recovery. Even then, years of monitoring is the rule.

Don’t drink and drive or fly. But if you do, prompt and full reporting is the best path forward.

Dr. Susan Northrup received a bachelor’s degree in chemistry, a medical degree from The Ohio State University, and a master’s degree in public health from the University of Texas. She is double board-certified by the American Board of Preventive Medicine in Aerospace Medicine and Occupational Medicine. She is a retired U.S. Air Force colonel and a former regional medical director for Delta Air Lines. She is also an active private pilot.

by Emily Hewitt

I have been working at the Coeur D’ Alene tanker base over the summer, where I ran into Angie Tanton, the pilot for the C-130, getting her steps in for the day on the ramp. I noticed her lovely smile and a tattoo on her right arm of a lady stabbing the Grim Reaper in the back.

I asked about it as that was an interesting “not today” image. She told me she flew a plane hit with shrapnel and survived. Angie, who turns 50 this summer, grew up in British Columbia and Alberta, where she also learned to fly. Her interest in flying was ignited on a career day when she was 16 in Canada, where a flight school handed out pamphlets saying, “You can be a pilot.”

She went for a familiarization flight, and she fell in love. She didn’t get the marks to enter the military, but undeterred, she enrolled in

flight school. In 1992, she started her flight training in a Cessna 172 and became a certified pilot in 1997 when her career took flight. She flew on the coast of British Columbia, Maldives, Burma, the Arctic, Saudi Arabia, and numerous other places on float planes. She had been flying in South Sudan in 2012/13, flying for the United Nations.

In 2015, She tried a different brand of humanitarian flying with the International Red Cross. This is where the story of the tattoo begins. On February 23, 2016, in the young country of South Sudan, Angie

was flying a Twin Otter, evacuating Red Cross employees who were in danger due to political tensions between different factions in South Sudan. She had two stops and would drop the workers off in a safer location. She picked up seven people at one stop, and then at the next stop, she would pick up two more in Pibor, South Sudan. When she landed at the second stop, It was a 3000’ runway with a parking lot in the middle of the runway. Off the plane’s left was the

(Continued on page 70)

runway and the town; off the right was the U.N. building and the Red Cross truck and people.

When she parked, everything appeared normal as she turned her radio off. She still had six passengers and her co-pilot in the plane. Her co-pilot said, “I haven’t done our H.F. call that we have landed yet.” Angie turned her radio back on. In hindsight, thank God her co-pilot was slow to call in; otherwise, she would have shut down her engines and not had time to get them running again. With engines running and her headset on, she noticed little grey specs in the parking lot and figured kids were throwing rocks again. Her brain was formulating what would make sense. She looked to her right, where her co-pilot was sitting, and saw a red cross worker on the plane bent over; she thought, oh, he must have diarrhea, “I bet he feels terrible and has cramps, and I hope he doesn’t

She looked to her left and saw people running across the runway and explosions on the far side of it. She realized what was happening and told her co-pilot, “They are shooting at us; we need to take off!”

crap in this plane,” She looked back at her first rows and passengers were huddled down on the floor.

Angie asked, “What are you guys doing?!” They pointed to the left and yelled, “They are shooting at us!” The passengers had more windows and could see better than Angie. She looked to her left and saw people running across the runway and explosions on the far side of it. She realized what was happening and told her co-pilot, “They are shooting at us; we need to take off!” All Angie wanted to do was get out of there and decided taking off was their best option. She looked to the right, and the Red Cross workers were gone. She worried they were trying to get on the plane but knew she couldn’t wait for them. She looked left, and hundreds more people were running across the runway. She couldn’t take off into the mass of people so she chose the other way but there

was a man with long dreadlocks and a “Bob Marly toque”. She slammed on the brakes and waved him out of the way. Once she had cleared, she took off. Angie doesn’t remember preparing the plane to take off. She had subconsciously known what she needed to do. Angie had her rudder locked out, flaps down, and propellers forward into take-off position, and at this point, all she had to do was add the power. As soon as she got in the air, she leveled off and did not turn away from the airport. The co-pilot screamed, “Why don’t you turn?!” That shook her out of her auto-pilot mode, and she told him, “I am good. I am going to fly the plane, get on the satellite phone and start making calls.”

Angie didn’t relax or take a breath till they got to their safe destination. She returned to the plane and got hugs from all her seven passengers. After the cigarette, hugs, and returning to reality, they examined the aircraft. There were holes in the aircraft. It was mortar shrapnel. It had lodged into the plane in some regions of the fuselage. It didn’t hit the fuel tanks or any crucial wires. She had asked a tall guy to ride in the back of the plane in the emergency exit where the leg room was as she wanted to balance her weight. He said he didn’t want to sit in the back, and she didn’t argue. His being adamant about where he sat saved his life when a piece of shrapnel went through the emergency exit door by that seat at head level. The staff she left behind that day did not leave Piborn and had to stay in the bunker for three days till they could come and get them. The reason for the attack was that someone did not agree with the new governor of the area, and they thought he was on the plane. They do not transport political figures, only Red Cross workers. They are a neutral organization, and the plane had a big red cross on the side of it.

Everyone on the plane that day had a different experience. This is Angie’s experience. Angie flew the aircraft back to Juba, where her coworkers were and where she felt safe and at home. She figured

it flew, and it would fly again. In hindsight, she maybe should have had maintenance look at it, but she was fixed on returning with her colleagues, which she considered her safe spot. She took one day off, and then she was back at work again. Some of the others were traumatized by that day, but Angie felt fine. She asked a Red Cross doctor about it, worried if she was cold or internalizing. He said everyone’s brains are wired differently. It would be interesting to hear the perspectives of the others that day.

Angie had close encounters with death before and after during her work in South Sudan. Previously, there was a suspected RPG (rocketpropelled grenade) shot at her plane. In July 2016, there was a lot of fighting in Juba; everything shut down, and she was stuck in the hotel for three days with her coworkers with tanks and bombs outside. The town was running out of food and diesel for the generators. In September, she returned to South Sudan, and her first flight was medevacs for wounded rebel soldiers. There was so much tension in the area. They were pulling people off airplanes that were trying to escape and beating them. She was standing there, almost shaking, thinking “Where I would go if they started shooting?” It took that moment for her to realize she didn’t want to do this job anymore.

Angie finished her rotation and never went back. At this time, her children were 10 and 12. I asked, “How could you do this dangerous work as a mother?” Angie had 50/50 custody, so when she was with her children, she was always with them. She worked five weeks on and five weeks off. She was fully present for her children when she had them. Angie grew attached to an orphanage in South Sudan, and her kids were proud of her work. Her kids would donate their toys to this orphanage and FaceTime with the kids there. She was drawn to the humanitarian aspect of the job. Angie has chosen the safer career path of flying low and dropping retardant in a C-130.

by Dr. Samantha Parker Lane

When talking about motorcycle accidents, a common saying is, “It’s not a matter of if, but when.” Unfortunately, this same phrase seems to apply to small aircraft pilots and in my near decade around the industry, I haven’t met a single pilot that hasn’t “put down” at least one plane.

Aerial applicators work in an environment with maximum obstructions, minimal altitude, and typically a split-second window to transition from normal to abnormal, or potentially emergency procedures. Training at the busiest trauma center in the country, I have treated more than my fair share of small aircraft pilots with devastating traumatic brain and spinal cord injuries. Here is what I’ve gleaned from that experience, as well as some of the current national data.

Let’s compare numbers shall we? According to the National Highway Traffic Safety Administration (NHTSA) and National Transportation Safety Board (NTSB) the annual rate of deaths per 100,000 registered vehicles is 127 in general aviation aircraft, compared to 58 in motorcycles, and 11.9 in cars. Looking at aviation specifically, the CDC reported the rate of agriculture pilot fatalities (one death per 100,000 hours flown) to be three times higher than that of pilots in other industries.

The best study to date was performed by Wiegmann et al. in 2003, in which 559 autopsies were performed to analyze the pattern

head injury from the pilot physically bouncing around inside the cockpit upon deceleration.

So what can you do?

• Wear a helmet with a visor or eye protection. Helmets absorb the impact of collision, reducing the risk of traumatic brain injuries, which have long-term consequences. Even if an injury occurs, wearing a helmet can significantly reduce the severity, potentially turning a life-threatening situation into a survivable one. Pilots wearing a helmet have higher chance of surviving accidents with lower need for neurosurgical interventions.

• Five-point harnesses reduce the risk of being thrown from the seat into the instrument panel, ceiling, or windows which are the primary causes of flail injury and the resulting blunt trauma to bones and solid organs.

• AmSafe offers seatbelt airbags that have become standard options in most new aircraft or can be easily retrofit into existing aircraft seats to further prevent against forward strike hazards, flail injuries, and cervical whiplash injuries.

So why are there still pilots that don’t wear helmets or fivepoint harnesses?

of injury sustained by pilots in GA accidents. The most commonly occurring injuries were fractures of the ribs (72.3%), skull (55.1%), facial bones (49.4%), and pelvis (36%). Blunt trauma resulted in organ hemorrhage, including the liver (48%), lungs (37.6), heart (35%), and brain (33%).

Seventy to eighty percent of deaths were attributed to crash deceleration to the face or head, aka a flail injury in which the body is thrown about inside the cockpit.

A second autopsy study performed by the FAA in 2009, looking at fatalities in Alaskan pilots spanning 2004 – 2009 suggested at least 33 lives could have been saved by helmet use.