With more than 60 years of experience working alongside the firefighting community, Perimeter Solutions offers the most comprehensive set of fire retardant solutions on the market today – featuring field-proven products, infrastructure, equipment and logistics services. You need all of these to meet your goals of performance and safety in wildland firefighting operations.

When you choose PHOS-CHEK® you’re getting more than just retardant. You’re getting a company that understands your mission-critical needs and how to deliver on them –every day. It’s a value and a commitment we take seriously.

P.O. Box 850, Perry, GA 31069 USA 475 Myrtle Field Rd., Perry, GA 31069 USA

Phone / Fax: 478-987-2250

info@marsaylmedia.com • aerialfiremag.com

PUBLISHER: Graham Lavender graham@marsaylmedia.com

EDITOR IN CHIEF: Ryan Mason ryan@marsaylmedia.com

ACCOUNTING/ADMINISTRATION: Casey Armstrong casey@marsaylmedia.com

CONTRIBUTING WRITERS: Igor Bozinovski bozinovski.igor@gmail.com

Robert Craymer robertc@covingtonaircraft.com

Dan Reese dan@intwcg.com

Paul Seidenman avwriter@sbcglobal.net

Dave Soderstrom davesoda727@hotmail.com

PROUD MEMBER:

DISPLAY ADVERTISING: Melanie Woodley melanie@marsaylmedia.com

PRODUCTION: Felicia (Lisa) Pannell lisa@marsaylmedia.com

CIRCULATION: Mary Jane Virden maryjane@marsaylmedia.com

CONTRIBUTING PHOTOGRAPHERS: Kane Arlow

Igor Bozinovski

Marissa Fortney

Aaron Maurer

Jeff Serpa

Dave Soderstrom

Marty Wolin

FIND US ON:

© COPYRIGHT 2024 AerialFire retains all rights for reproduction of any material submitted, to include but not limited to articles, photographs, emails and bulletin board posts. All material remain the copyright of AerialFire. No part of this publication may be reproduced, in part or whole, without the written consent of the publisher. Editorial published do not necessary reflect the views of the publisher. Content within AerialFire is believed to be true and accurate and the publisher does not assume responsibility for any errors or omissions. Unsolicited editorial manuscripts and photos are welcomed and encouraged. We cannot be responsible for return unless submissions are accompanied by a stamped, self-addressed envelope. Advertising deadline is 12 noon, on the 1st of the month preceding the month of publication. AerialFire is Published bi-monthly by Blue Sky Investments, Inc., 475 Myrtle Field Road, Perry, GA 31069

Ryan Mason | ryan@aerialfiremag.com

As the fire season in the United States begins, operators have started contracts or are finishing up maintenance on their fleet to be ready for the call to deploy to firegrounds and bases around the country. In the case of our international brothers, sometimes around the world, there is still much work to be done.

As I stated in my last column, there are massive issues with accountability across the board. Accountability within federal, state, and sometimes local governments creates unnecessary red tape. That red tape, at times, has no end, leading me to my next point, which has become a pain point for the industry through no fault of its own.

When we look at the fleet of aircraft from VLAT to LAT’s, Scoopers, SEATS, and the three different helicopter types, one of the hardest things to accomplish to make sure the fleet is ready isn’t something obvious like maintenance issues, but the arduous task of carding.

I have talked to operators all over the country from every corner and aircraft type used in the industry, and one of the main pain points is the carding process and the availability of staff to perform the task. Not only is its lack of staffing, but at times across the industry, due to varying levels of the aforementioned red tape or government bureaucracy, carding times are increasing to the point where if this trend continues, there may be a significant delay in the readiness of substantial portions of the fleet should a massive fire erupt.

As I have discussed many times previously and as you may have seen referenced in many articles in AerialFire, readiness is critical. Operators must have all the necessary paperwork and sign-offs to be ready to fight a fire at a moment’s notice, the key to an early initial attack on the fire, and to be able to dispatch as many assets as necessary to bring a large fire under control.

Suppose there is one thing that the Texas Panhandle fires have already taught us this year. In that case, inadequate aircraft positioned to take immediate action can have vast and devastating consequences. Those fires, while devastating to property and farmland, were fortunate not to have taken more lives due to the ferocity and rapid spread of the fire into something massive in a very short period.

A fire like the one seen in Texas took hold on the outskirts of Los Angeles County and burned toward the City of Los Angeles with the ferocity and speed of the Texas fires. Aircraft were grounded for innocuous issues like paperwork or carding still waiting to be completed, and the potential for loss of life and property would be nothing short of devastating.

While I do not have a perfect solution to this problem, I, like many others in the industry, have already realized that it is a problem and one that could have potentially deadly consequences if there is no effort to find a solution that speeds up the carding process and the removal of often cumbersome certification processes each year that seem to get more complex for the operators and spaced out longer and longer until it appears that there may be aircraft that are not ready to go when the time comes that they are desperately needed.

I know that UAFA is aware of the situation facing many operators. While it is not currently a desperate situation, I hope that action is taken at the government level to take a long, hard look at the issue and what can be done to remedy it before it costs lives.

Like any problem, there can be many solutions. Still, we need to address it as an industry and identify it as an issue so that the appropriate people can take the required action, be that on Capitol Hill to hold industry heads feet to the fire or said industry heads get out ahead of the problem

“ ...due to varying levels of... red tape or government bureaucracy, carding times are increasing to the point where if this trend continues, there may be a significant delay in the readiness of substantial portions of the fleet should a massive fire erupt... ”

and come up with some real solutions while consulting the industry to get their input so as not to work in a silo and come up with a poorly thought out solution that then becomes a more giant headache than operators already face.

Addressing an issue before it becomes a bonafide problem is the right move. Otherwise, instead of addressing a problem in a room full of peers, those same agency heads may be the same people called to testify to Congress after the problem that wasn’t addressed causes a large gap in aerial firefighting capabilities that could cost lives.

Robert Craymer

Ihear this repeated many times to pilots. As a mechanic, it applies to me, too. One thing I want to bring everyone’s attention to, so everyone is aware, is that there have been some changes to the Pratt & Whitney Canada manuals that could directly affect you.

First, when changes are made to the manuals, you can grab a quick overview of what was updated. When you open your manual, and look at the chapter list, there is a section called highlights. This section gives quick details of what has changed. If you are using the customer portal, it also includes hyperlinks to each change for your review.

Many maintenance manuals have recently been updated. For the purpose of this discussion, I am looking at the manual for the PT6A-34AG Manual 3021242 Issue 72.0. This particular manual and several others were updated in January 2024. The revision includes incorporating several service bulletins, additions to lubricate specific areas after washing, and some inspection procedures for fretting on fuel nozzles.

The biggest change, in my opinion, has to do with changes in prop strike and sudden stoppage inspection. Pratt & Whitney Canada has now provided a very detailed description and a decision tree for determining the level of maintenance required. This includes props striking the ground or striking a wire at speeds above and below flight idle. These factors go into the level of maintenance required.

If you had a strike, here are some additional changes. As part of the inspection, if any damage is found to the

accessory gearbox housings, if any components sheared or separated from the engine, or if foreign object or metallic debris is found in the engine, a specific disposition or additional parts replacement must be determined and provided by Pratt & Whitney Canada. The initial first step of the inspection should be the completion of the Service Information Letter (SIL) Gen-135. This report describes the incident and helps the repair shop determine how to get the engine back in the air as quickly and safely as possible. Please let me know if you need help locating this SIL or

Highlights from Manual

completing it. I am glad to help. Pictures of the airframe and any engine damage are also very helpful.

Once you go through the on-wing inspection and determine that you must send the power section or engine in for repair the manual changes have not stopped. When we receive a power section or engine for prop strike/sudden stoppage repair, the overhaul manual also has some revisions. Using the PT6A-34AG Overhaul Manual, 3021243 Revision 51, dated November 27, 2023, the entire prop strike and sudden stoppage section has been revised. Again, it starts by saying that the shop may need a SIL Gen-135 to determine the proper work scope. If you already completed this step, it will help save time, which can be critical.

We will follow one of two charts in the shop based on the incident. The first is another decision tree which steers us to the proper level of inspection required. The second is a table to advise us on how to treat each component of the power section/engine being repaired. The manual requires mostly visual inspection for the gas generator unless specific damage is noted or witnessed. Most of it has to do with rubbing, scraping, or binding. The power section inspection is where the biggest changes have been made.

this discussion with your Designated Overhaul Facility or Field Service Manager if you have a prop strike.

Almost all the components of a power section now require a full overhaul level of inspection. This includes nondestructive testing and measuring. This is a change from the visual inspection requirements on some components. The propeller governor and overspeed governor also must be submitted for an overhaul. The biggest change and potentially costliest is the automatically rejected parts. We all know from years of experience that the #6 bearing on a small PT6 is an automatic replacement item. This hasn’t changed. However, the propeller shaft and the #5 bearing are now on the list of items automatically discarded. These three components can add up to a significant amount. There also could be delays in procuring these parts, as more shops will need them. The large PT6 instruction may allow inspection of some of these components but could also include discarding the #7 bearing.

Potentially, there is help. If you choose to use a shop that is part of the Pratt & Whitney Canada network, some additional cost-saving measures may be available. It has been discussed at several events that the parts identified above may have support available. Potentially, new parts could be priced below overhaul-condition parts. I always encourage everyone to take full advantage of anything Pratt & Whitney Canada offers at a great discount. Please have

Not everyone is aware but there is also a requirement to perform a test cell run after repair of the power section. Historically, we have received a waiver from engineering that allows us to perform this run on wing. That isn’t a guarantee as now engineering is reviewing the parts replaced within the power section before determining test cell or not. Sometimes, we have a gas generator that we can use for the testing purposes of the power section, but in some cases, we ask that the complete engine be sent in. Even if no work is required on the gas generator, we will need it to perform the testing.

Robert Craymer has worked on PT6A engines and PT6Apowered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and is an instructor of PT6A Maintenance and Familiarization courses for both pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member.

Robert can be reached at robertc@covingtonaircraft.com or 662-910-9899. Visit us at covingtonaircraft.com

Tiffany Taylor | ttaylor@uafa.org

There’s a saying: “the more things change, the more they stay the same.” Usually, we are forward looking but we decided to look back to check on progress and let you know how UAFA is working to make sure these are not still issues in another ten years.

Yes, firefighter pay is still a major concern. The recent Bipartisan Infrastructure Law provided temporary raises, but these revert to inadequate levels in October 2024. Strong ground crews are essential for aerial firefighting success. Without them, many believe drops are ineffective, jeopardizing aerial firefighting support altogether. UAFA firmly supports increased pay for federal firefighters. It’s the right thing to do, and it ensures a critical line of defense for aerial operations.

Ever come across an article that feels eerily familiar? That’s how I felt reading Bill Arsenault’s piece, “Big plane, little plane, or no plane at all?” A firefighter’s quote at the time resonates even today: “What aviation tools will US firefighters need in the coming decade? After spending time on the Texas firelines in 2011 — the state’s worst season on record, with 4 million acres burned, 4000 houses destroyed, and 10 people dead — What type of aviation support do we need on the line? Or does the type of air support matter at all, if you can’t get the drop when and where you need it?”.

So, the question remains: what aviation tools do we truly need? The failed Aerial Firefighting Use and Effectiveness (AFUE) study left us with more questions than answers so there is still no national analysis used to determine the number of firefighting aircraft needed. A recommendation from the Wildland Fire Management and Mitigation Commission (WFMMC) is to review the feasibility of “Standards of Cover”

for aircraft. UAFA is poised to lead the effort to provide the agencies data to determine the optimal number and types of aircraft. This data will also be crucial for shaping future strategies on Workforce and Unmanned Aircraft Systems, also recommended in the WFMMC’s report.

Imagine running a business with no guarantee of income from one year to the next and customers who take you for granted. That’s the reality for many aerial firefighting companies. An article from 2013 by Walt Darran, relevant even today, highlights the issue in “Stalled Air Tankers.” As of April 2024, there are still no new exclusive-use contracts for large airtankers or Type 1 helicopters. The current system, mainly reliant on “Call When Needed” orders, fails to provide the stability needed for essential maintenance, pilot retention, and attracting top mechanics. Multi-million-dollar aircraft can’t be sustained on a hope and a prayer.

The lack of long-term contracts creates a vicious cycle. Strapped for cash, companies struggle to secure lines of credit needed to invest in upgrades and new technology. Thus, pilot retention also becomes an issue. The result: an aerial firefighting industry increasingly ill-equipped and understaffed to face the ever-growing wildfire threat. There is competition worldwide for firefighting aircraft, the U.S. no longer has the luxury of taking the current domestic fleet for granted.

UAFA is advocating for an end to the artificial separation of “preparedness” and “suppression” funds Congress provides for aircraft contracts. Allowing agencies to use any type of Wildland Fire Management funds to award contracts when it is needed would provide the stability companies need. Furthermore, UAFA is pushing for simpler processes for the agencies to issue multi-year contracts. This wouldn’t just save the government money in the long run, it would ensure a ready fleet of aircraft when wildfires inevitably strike.

by Babak Taghvaee

Since May 2011, AT-802A/F Air Tractors have been used as the primary aerial assets in support of the firefighting operations of the Israeli National Fire and Rescue Authority. Once operated by the Israeli Air Force’s 249 ‘Elad’ Squadron at Sde Dov airport near Tel Aviv, they have been used by the Israeli Police Aviation Unit since November 2016. Based in the historic airfields of Kedma and Megiddo, the fleet of fourteen AT-802s has seen extensive use for tackling wildfires in Israel and overseas, particularly in Cyprus. As many wildfires in Israel were created by arsonists this past summer, the fleet of Air Tractor AT-802s is now being prepared for extensive aerial firefighting use in the upcoming fire season.

In December 2010, the Mount Carmel forest fire killed 44 people, causing injuries to many others, and displaced 17,000 people in Israel. Due to the absence of any firefighting aircraft and also the existence of an old tradition banning the use of military resources (including the aircraft of the Israeli Air Force) for aerial firefighting, it took two days until finally, on request of the Israeli government, several countries sent firefighting aircraft and helicopters to the country to tackle the massive fire. Based on the lessons learned from that wildfire, the Israeli government, headed by Prime Minister

(Continued on page 18)

Benjamin Netanyahu, ordered the Israeli Ministry of Defence to create an aerial firefighting unit serving Israel.

In January 2011, the Israeli Air Force was tasked to reform its 249 Squadron as an aerial firefighting unit to operate a fleet of two AT-802F two-seaters and five AT-802A singleseaters (all second-hand) that the Israeli MOD procured from Spain under a USD 20 million contract with Elbit Systems. The squadron was formed under the command of Lieutenant Colonel Rami on March 31, 2011.

On May 23, 2011, the first three Air Tractors, two AT-802Fs, and one AT-802A, which had arrived on March 31, became fully operational with the 249 Squadron at Sde Dov airport near Tel Aviv. Maintained and operated by Chim-Nir Aviation and Elbit systems. The small fleet of seven Air Tractors (two AT-802Fs and five AT-802As) was later expanded into fourteen when one more AT-802A and six more AT-802Fs were purchased in 2014. Most of 2011 was spent to train and prepare a group of retired and reservist pilots of the Israeli Air Force to fly them in the 249th Squadron.

In 2011, the 249th Aerial Firefighting Squadron was named ‘Elad’ after a 17-year-old volunteer firefighter, Elad Riben, who lost his life during the 2010 Mount Hermel fire. Before the procurement of the AT-802s and formation of the squadron dedicated to aerial firefighting, the Israeli National Fire and Rescue Authority employed a single Ayers S2R-T34 Turbo Thrush commander of Chim-Nir Aviation at Herzliya airport, whose primary use was fertilizing and air spraying farms in Israel. Their small number and unavailability due to maintenance works and issues would cause problems for the National Fire and Rescue Authority.

When S2R-T34/45s from Chim-Nir Aviation were used for aerial firefighting, their operator could guarantee to have them airborne in a maximum of 90 minutes. Each carries a maximum of 1,500 liters (400 Gallons) of water. Thanks to the acquisition of AT-802s in 2011, the Fire and Rescue Authority of Israel was capable of being assigned and on the way to a firefight in the country in less than 30 minutes.

(Continued on page 20)

Also, thanks to the larger and more powerful engines, they can carry a maximum of 3,100 liters/800 Gallons of water, and 20% can be replaced with fire retardant chemicals. They can create a 100-meter-long protective line against fires and can land and be refilled within 10 minutes.

Two airfields, Megiddo in the North of Israel and Kedma in the South, were prepared with special equipment to fill the tanks of the aircraft during firefighting operations. Once a fire was detected, the aircraft could be airborne within 15 minutes and reach the affected zone seven to 15 minutes after take-off. Starting in 2011, during fire seasons, the Israeli Air Force could deploy one or two of them to each of the frontline airfields to support the National Fire and Rescue Authority in tackling the wildfires. This was later expanded to six to seven in each airfield when the number of Air Tractors reached 14 in 2016.

On March 28, 2012, one of the AT-802As of the squadron

airfield in the south of Israel. According to its pilot, Aryeh Horev, a former C-130E/H pilot with over 15,000 flight hours experience, the throttle lever of the aircraft suddenly went into reverse position. At the same time, it was airborne at an altitude of 30 feet. The wounded Pilot of the aircraft returned to service after the incident, and the aircraft was repaired in a year.

In its four years of operations, the squadron participated in extinguishing more than 500 fires, for which its aircraft logged 4,600 sorties and 2,500 flight hours. Some of these operations took place in Jordan and Cyprus. A temporary unavailability of one of the AT-802s caused by an incident on March 28, 2012, led to the procurement of an eighth AT-802 by Elbit Systems for the 249th Elad Squadron. After completion of the repair work of the damaged AT-802, the

(Continued on page 22)

F or two-seater models) through Elbit Systems Ltd for the IAF’s 249th Squadron.

For the first time in summer 2012, the 249th ‘Elad’ Squadron was tasked to deploy two aircraft to a country overseas to fight wildfires. They were deployed to Bulgaria to help fight a wildfire in the Vitosha Mountains near Sofia. It was just the beginning of their participation in international operations. Later, in June 2016, one of their largest international operations took place in Cyprus. That year, the Republic of Cyprus faced one of the largest wildfires in its history between June 19 and 23. The wildfire burned several thousands of hectares of pine forest in Troodos

After a request of the Cypriot government from its allies to support its ongoing battle against the wildfire on June 18, Israeli Prime Minister Benjamin Netanyahu ordered the Israeli Air Force to deploy three of its thirteen AT-802s (at that time). They were accompanied by a C-130H Hercules tactical transport aircraft of the IAF’s 131 Squadron, carrying special firefighting equipment, including fire retardant for the aircraft. All arrived early on June 19 at Andreas Papandreou Air Base, Paphos. A fourth Air Tractor arrived at Paphos in the afternoon of the same day. The Elad Squadron’s AT-802F Air Tankers flew in two-ship formation flights and dropped fire retardant every 20-30 minutes over the Forest.

SUBARU BELL 412EPX

The most reliable work trucks are transformed and reborn year after year for decades. When you’re fighting wildland fires from the sky, critical moments require experienced and renewed solutions. The upgraded transmission of the new Subaru Bell 412EPX provides 11% more shaft horsepower at takeoff, resulting in a 15% boost in the hot and high hover. Add in an unprecedented increase for internal, external and cargo hook with 1,100 pounds/499 kg payload added. Proven operational readiness now with more payload, more firemen and women, more water…and more power to fight fire.

bell.co/fire

On June 20, C-130Hs ‘428’ and ‘661’ of the Israeli Air Force arrived to deliver additional fire retardant for the four Israeli Air Tractors there. By the end of June 20, estimations showed that 15 square kilometers of land and forest had been charred in Troodos, which made it the biggest fire in Cyprus after the Saittas fire in June 2007. Finally, a day after the fire was put out in Troodos, the AT-802s returned to Israel on June 24.

As the Cypriot Police Aviation Unit and the Cypriot Forestry Department deployed their helicopters and aircraft to Israel to help the country battle wildfires between 2016 and 2023, the Israeli Police Aviation Unit, which became the operator of the 14 AT-802A/Fs in November 2016, did the same for Cyprus. In 2022 and 2023, the Israeli AT-802s were deployed to Paphos to help the country fight wildfires several times.

On August 7, 2023, two AT-802Fs under the control of four Israeli Police pilots were flown to Paphos. A C-130J-30 of the Israeli Air Force airlifted a technician and several firefighters alongside six tons of fire retardant for use on the AT-802Fs in Cyprus. After flying several aerial firefighting missions, the two AT-802Fs were finally flown back to Israel on August 9, 2023, while a KC-130HI (427) airlifted their ground crew and ground equipment back home.

In November 2016, the Elad squadron was transferred to the Israeli Police Aviation. This resulted in its relocation from Sde Dov Airport of Tel Aviv to Herzliya Airfield, where

Chim-Nir Aviation and Elbit Systems previously performed heavy maintenance. Every year, the fleet of six AT-802As and eight AT-802Fs were kept in the highest state of readiness. During the fire season, six to seven of them are kept on alert in each of the Kedma and Megiddo airfields, tasked to battle wildfires in the south and north, respectively.

The majority of wildfires of late in Israel have been attributed to arsonists, including those with ties to Hamas and Palestinian Islamic Jihad (PIJ) terrorist organizations. Before the start of the recent war, Palestinian arsonists used condoms filled with Helium gas as small balloons carrying explosives to create wildfires. A group of these balloons were being flown on windy days towards the North of the Gaza Strip to burn vegetation and cause wildfire around Israeli villages and towns. The AT-802s on deployment at Kedma assisted the Israeli Fire and Rescue Department in putting out any fire created using this method in southern Israel.

In November 2016, wildfires and urban fires occurred in Israel from Beersheba in the south to Nahariya in the north. On January 13, 2017, the Israeli fire investigation’s “Gal Report” found that of 80 fires in November 2016, 71 resulted from arson. Two Arab citizens of Israel confessed to deliberately setting those fires. At least 35 people were arrested on suspicion of setting fires or inciting to do so. 15 were citizens of the Palestinian Authority, while 10 were Arab citizens of Israel. These massive fires kept the fleet of 14 AT-802s of the Israeli Police overwhelmed, resulting in the Israeli government asking for the help of its allies to fight the wildfires. Cyprus, Greece, Russia, Croatia, Italy,

Turkey, Jordan, Egypt, Azerbaijan Republic, France, and Ukraine sent firefighting helicopters, aircraft, and other equipment to help fight the fires.

In 2021, massive wildfires near Jerusalem burned almost 11000 hectares/28,000 acres of land on fires starting August 15, 2021. AT-802s flown from Herzliya, Kedma, and Megiddo fought the fire until the blaze was brought under control on August 19. A year later, in July 2022, four of the AT-802s were flown from Megiddo Airfield assisted by 20 firefighting teams of the Fire and Rescue Services as well as additional teams from Jewish National Fund (KKL-JNF) to put out a wildfire around Route 886 (highway) which connects Manara and Yiftah near Lebanon border.

In May and June 2023, almost 180 fires erupted across Israel during a heatwave. The fires kept the Police’s AT802s extremely busy for three weeks. One fire erupted in a playground after 100 people had gathered for a party, leading to a massive wildfire after party goers failed to extinguish a barbeque fire.

Since October 7, 2023, the Israeli Defence Force (IDF) has been busy with Operation Swords of Iron against the Hamas terrorist organization in the Gaza Strip as a response to their deadly terrorist attack, which took the lives of over 1,200 Israelis and other nationals in the villages around Gaza. As a result of the operation, a vast majority of Gaza territory has so far been under the control of IDF, thus making it difficult for Hamas and PIJ to launch airborne arson attacks in the south of the country. However, the risk of facing similar arson attacks in the North of Israel is very high during summer.

Both Palestinian terrorists in the South of Lebanon and the Hezbollah terrorist organization are expected to conduct arson attacks in the North of Israel in the summer of 2024. In addition to that, the launch of unguided rockets as well as one-way attack drones at IDF’s outposts and Israeli villages in the North are still dangers for wildfire in Israel. The AT-802A/Fs of the Israeli Police Aviation on deployment at Megiddo Airfield, supported by the surveillance drones of the Israeli Air Force, will play an important role this year in fighting any wildfire created as a result of the current ongoing war in North Israel.

Photos by Steve Nelson, AerialFire photographer

On Wednesday, April 17, 2024, the Colorado Division of Fire Prevention and Control (DFPC) presented Colorado’s 2024 Wildfire Preparedness Plan to Governor Jared Polis during an event at Rocky Mountain Metro Airport in Broomfield, Colorado.

The event showcased several aircraft the DFPC plans to deploy this year, including SEATs, the department’s PC-12, and their newest asset, a Sikorsky S-70M Firehawk, one of two aircraft ordered by the state. The first was delivered to the agency by United Rotorcraft this week.

During the presentation, DFPC Director Mike Morgan discussed the 2024 wildfire outlook and an overview of State resources that are prepared to combat wildfires.

“The 2024 Wildfire Preparedness Plan outlines a holistic,

management, and mitigation activities of all types,” explained DFPC Director Morgan. “Together with our local and federal partners, the State of Colorado stands ready to respond to wildfires.”

“Colorado is no stranger to the impact of devastating wildfires, and we refuse to rest when it comes to preparing for the future. Colorado is a national leader in fire mitigation efforts, and we continue building on proven methods to protect Coloradans and our communities from wildfires,” said Governor Polis.

Colorado has been no stranger to wildfire, with USFS tanker bases now located at Broomfield and Colorado Springs. The state’s additional asset will now be aerial firefighting from a state level with the tank equipped S-70M, in addition to being capable of troop transport and able to insert firefighters into the mountainous terrain in Colorado.

Coastal Air Strike’s agile, forward-attack SEAT (single engine air tanker) and Single Engine Scooper aircraft are your best chance to contain small wildfires, to prevent them from becoming big wildfires. Their ability to operate from virtually all airports, ranging from large tanker bases to remote airstrips – even reloading at portable retardant bases – along with the Single Engine Scooper’s ability to scoop nearby water sources, proves them invaluable.

On April 24th, 2024, Premier Scott Moe and Corrections, Policing and Public Safety Minister Paul Merriman unveiled further details on the four re-purposed landbased airtanker aircraft, consisting of two Dash 8-Q400AT models and two Dash 8-Q400MRE models, being purchased for the Saskatchewan Public Safety Agency (SPSA) at an approximate cost of $187.06 million.

The planes will replace the current land-based airtanker aircraft fleet, consisting of four Convair 580 airplanes. Those planes will approach the end of their useful lifespan in 2027.

“Saskatchewan relies on land-based airtanker aircraft as part of its approach to managing wildfires,” Corrections, Policing and Public Safety Minister Paul Merriman said. “These aircraft are used when waterbombers cannot access lakes to fill up their tanks.”

The Dash 8-Q400AT planes are dedicated air tankers. At the same time, the Dash 8-Q400MRE models can be fitted as an airtanker and reconfigured to provide multiple roles for air operations (e.g., air evacuations, patient transport, cargo hauling, etc.). Both models have increased capacity and efficiency and produce 30 percent fewer emissions than a similar airtanker.

“Saskatchewan leads the country in preparing for future disasters with their order for four modern emergency

response aircraft,” Conair Aerial Firefighting President and CEO Matt Bradley said. “They are the first province to invest in the safety and security of their citizens with a purchase of the multi-role airtankers, built by Canadians for Canadians. Saskatchewan supports Canadian workers who build these aircraft, enhancing their fleet with aircraft designed to offer first in, last out capability, providing essential services from response through recovery, connecting all regions of the province in times of crisis.”

The financial impact for the SPSA’s 2024-25 capital budget is a $5.52 million deposit with an additional three-year payment plan commitment. Federal funding of $16.29 million is committed to offset the cost of the aircraft through Natural Resources Canada’s Fighting and Managing Wildfires in a Changing Climate Program (FMWCC).

“These planes will replace the SPSA’s aging land-based airtanker fleet with a modern, supportable aircraft with an anticipated useful life of 25 years,” Merriman said. “They will also support the SPSA’s ability to provide an operational response to more emergencies and public safety events beyond wildfires.”

The first of the four airplanes is expected to arrive in late summer 2025, and the remaining three are expected to arrive by the end of 2027.

by Master Sgt. Nieko Carzis

The U.S. Forest Service held its annual certification and training event for the aerial firefighting MAFFS (Modular Airborne Fire Fighting System) program with two of the four assigned Department of Defense aircrews from the Air Force Reserve’s 302nd Airlift Wing, Colorado Springs, Colorado, and the California Air National Guard’s 146th Airlift Wing nicknamed the “Hollywood Guard.” With wildland fire fighting agencies such as CAL FIRE and the Bureau of Land Management, the multi-agency MAFFS program kicked off its first training iteration this week at the Channel Islands Air National Guard Station.

The 146th Airlift Wing is hosting MAFFS training for the second year in a row during the same year as its 100year centennial celebration and one year after the 50-year anniversary of the MAFFS program.

MAFFS, a unique partnership between the U.S. Forest Service and the Department of Defense, shares a combination of resources supporting aerial firefighting operations. These include equipment, personnel, and aircraft that provide a critical “surge” capability to the U.S. Forest Service to slow or stop the spread of wildland fires when all commercial airtankers within the national airtanker fleet are fully committed or not readily available.

The U.S. Forest Service provides this training event annually, which requires any aircrew supporting this mission to gain their certification before they can support any wildland fire operations as a part of their annual training requirements. Afterward, MAFFS aircrew will continue to supplement their experience throughout the year once they start supporting MAFFS missions after

certification training. Depending on the cadence of a busy fire season, MAFFS personnel must ensure they are making the most out of every opportunity for training.

While the number of wildfires in the U.S. is measured as an average for last year, it did hold the record for the fewest acreage burned in the past 25 years. During this time, MAFFS air tankers were first used on August 3, 2023, and released on September 6, 2023. During that 35-day activation, MAFFS aircrew flew 69 missions, providing 73 retardant drops totaling 185,263 gallons.

While nobody can predict when the next major fire incident will occur, the one constant force ready to meet the challenges of a busy fire season is the people supporting MAFFS.

Col. DeAnna Franks, the operations group commander for the 302nd Airlift Wing and this year’s Air Expeditionary Group Commander for all Department of Defense assets for the MAFFS mission, says that the annual training events are a pivotal moment within the pre-fire season to ensure readiness across the MAFFS enterprise.

“MAFFS is a robust partnership with many agencies and support functions that work intricately to accomplish large-scale aerial firefighting missions. This is why MAFFS training is so important: it allows the Air Force to capitalize on collaboration efforts with all the agencies participating. Completing our annual training each year is paramount as it allows our aircrews to get those critical training hours we need before we respond to a real fire,” said Franks.

Franks says the intricate partnership’s success is built on a valued cooperation over the past 50 years.

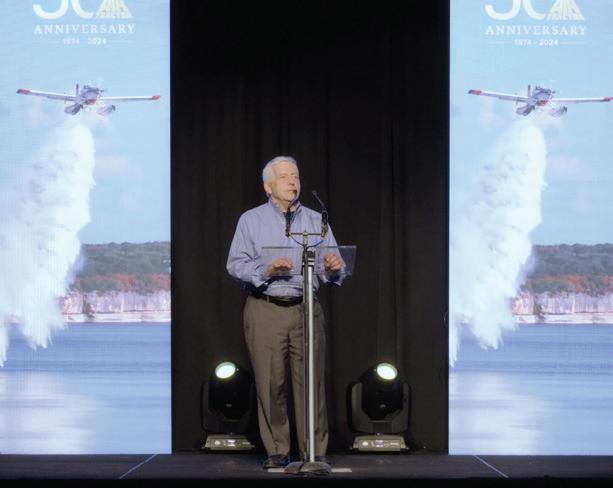

“Modular, the first word of the MAFFS acronym, might perhaps be the best word to corroborate how flexible and efficient our working partnerships have developed over the last 50 years. Last year in December, the MAFFS community collectively celebrated its 50th semi-centennial

anniversary with all our partners working within the U.S. Forest Service, CAL FIRE, the Bureau of Land Management, as well as many other valued firefighting assets across the county who support the MAFFS mission. It was a great opportunity to reflect on just how impactful this mission is and how special all the people involved with the MAFFS program are,” said Franks.

Franks added, “When I think about the success of this government program that has been around for as long as it has, it’s clear to me why the MAFFS mission has been so successful. The people of MAFFS are a testament to the program because of their great work, and it’s an absolute honor to work alongside everyone who supports the mission.”

Kim Christensen, deputy assistant director of operations for the U.S. Forest Service and one of the driving forces behind the MAFFS training at Channel Islands, has been a part of the MAFFS mission since 2012, says she still loves coming to work with the people involved with the MAFFS mission after all these years.

“Teamwork and partnerships are really what make the program such a success. In addition to the airlift wings, a number of other federal, state, and local departments are also involved. The members of the airlift wings that participate in the MAFFS program are consummate professionals. They take the annual training very seriously and are always prepared to assist us with wildfire suppression whenever asked,” said Christensen.

Utilizing the same training schedule as the year prior, both training events will take place on two separate weeks to help mitigate the busy schedules for the 3 Air National Guard and Air Force Reserve components involved. Two additional Air National Guard units assigned to the MAFFS mission from Nevada’s 152nd Airlift Wing and the Wyoming Air National Guard’s 153rd Airlift Wing will also travel to Channel Islands Air National Guard Station to complete their training and certification in early May.

Olney, Texas-based Air Tractor, producers of the AT-802, which later morphed into the AT-802 Fire Boss, an amphibious firebomber, celebrated its 50th anniversary with a celebration at the company’s factory in Olney. The company has produced over 4000 aircraft that serve the aerial firefighting and agricultural markets. The event, attended by customers and representatives from both market segments celebrated alongside long time Air Tractor CEO Jim Hirsch and the hundreds of dedicated staff that build the venerable aerial firefighting SEAT aircraft.

EXCLUSIVE, FAAApproved leading edge protection for your hardworking blades, performing in the harshest environments. Apply DSX to new or re-finished blades for up to 5X protection. Never have blade repair downtime again!

Dauntless Air announced on May 28th, 2024, the addition of five aircraft to its industry-leading Fire Boss fleet. The growth comes amid increasing global recognition of the effectiveness of scooper-centric aerial firefighting strategies and the superior performance of the Fire Boss in wildfire operations.

“By expanding our fleet, we are not only increasing our operational capacity but also reinforcing our commitment to leading the fight against wildfires wherever we’re needed.”

In the United States, demand for the Fire Boss has reached unprecedented levels, with a record number of new Fire Boss solicitations issued this past off-season. Now in the U.S. there are a total of 29 Fire Bosses, which meet the compliance requirements of the Office of Aviation Services (OAS), in operation across 24 exclusive-use (EU) and 10 call-when-needed (CWN) contracts. This is up from 15 EU and 7 CWN Fire Boss contracts from the year before. As the most experienced, longest running, and largest operator of Fire Bosses, Dauntless holds a large majority of these contracts. Many of the new contracts begin earlier in the season than previous years and were issued by states that have never before issued an EU Single Engine Scooper contract. Internationally, fire agencies have ordered dozens of Fire Bosses to secure the future of their country’s aerial firefighting fleet. In just the past 24 months, officials in Greece have ordered a record-setting 31 Fire Bosses, while Turkey and Slovenia have secured manufacturer contracts for 15 and four aircraft, respectively. This global activity has also created additional demand on U.S. aerial firefighting companies with Fire Bosses to operate in Europe.

“In the U.S. and globally, fire agencies are acting on what we have long known: the Fire Boss is a game-changer in wildfire suppression,” said Brett L’Esperance, CEO of Dauntless Air. “Growing demand for the Single Engine Scooper is no surprise, especially when it’s compared with

the only other fixed-wing scooper available – which is 10 times more expensive to acquire and operate than the Fire Boss. As Fire Boss demand continues to grow, Dauntless is committed to ensuring that our fleet matches the need, and that our ongoing investments in training and technology enable us to remain the safest, most experienced, most reliable Fire Boss operator globally.”

Supporting this new global demand is mounting evidence demonstrating the reliability and effectiveness of the Single Engine Scooper in aerial firefighting operations. The U.S. Forest Service’s 2020 Aerial Firefighting Use and Effectiveness (AFUE) study found that scoopers and helicopters achieved higher percentages of effective drops on wildfires compared to retardant-dropping air tankers. The study also found that during Initial Attack (when a fire is smaller than 100 acres in timber or 300 acres in grass or shrubland), Single Engine Scoopers and Type 2 helicopters are the most effective platform available for delaying fires and reducing their intensity. These findings prove the Single Engine Scooper’s ability to rapidly contain wildfires, helping create less taxing conditions for wildland firefighters on the ground while reducing devastation and mitigating the widespread health impacts of smoke from large wildfires.

As far back as 2012, the RAND Corporation recommended a scooper-centric aerial firefighting strategy for the U.S. Now, as climate change exacerbates the frequency and intensity of wildfires, more states and federal agencies are heeding the call for an increased focus on scoopers.

“It’s been a long time coming, but it’s clear that Single Engine Scooper-infused rapid initial attack is gaining ground around the world,” added L’Esperance. “By expanding our fleet, we are not only increasing our operational capacity but also reinforcing our commitment to leading the fight against wildfires wherever we’re needed.”

Trakka equips both aircrews and ground crews with the technology to see the fire, see the plan, and fight smarter. TrakkaCam high-definition thermal and color cameras pierce through the smoke to provide a clear picture of the entire fire scene, allowing teams to analyze wildfire activity more effectively. With TrakkaMaps real-time mapping overlays, firefighters can geographically target locations, mark points of interest, set perimeters, and identify active hotspots with pinpoint accuracy. Adapt faster and fight smarter with Trakka. See Us | 31 July – 2 Aug | APSCON | Booth #720, S2

See. Save. Protect.

TracPlus announced on May 16th, 2024, the launch of TracPlus Beacon, an innovative mobile application that transforms smartphones into advanced tracking devices. Integrated seamlessly with the TracPlus Cloud platform, this solution extends the trusted tracking, operational oversight and safety to more asset types across land, sea, and air. It is designed to meet the needs of diverse and complex environments, providing scalable, costeffective tracking capabilities without the need for additional hardware for assets within cellular reception.

As the only commercial provider delivering a complete country-wide tracking solution for the aerial firefighting market, TracPlus continues to redefine emergency management worldwide. By leveraging a team’s smartphone, leaders can now utilize these devices as sophisticated safety tools, providing real-time location updates directly within the trusted TracPlus Cloud platform. With just a tap, users can activate real-time tracking and use the phone’s GPS to send continuous location data, even caching data when out of cellular range to upload later and ensure uninterrupted tracking.

Todd O’Hara, TracPlus’ Head of Product says that this new capability is a game-changer because it extends the trusted TracPlus service to a connection that teams already carry with them—their smartphones.

“The future of our industry hinges on connectivity, and embracing ‘cellular over satellite’ technology is a key step. The acceleration towards ubiquitous data access, even over

fire fronts, is becoming more feasible and TracPlus Beacon represents our first step to capitalize on this shift.”

“Looking ahead, its not unrealistic to see an app like TracPlus Beacon to become AFF-compatible, providing critical firefighting data—including images and streaming video from fires, alongside other telemetry and analytics—at volumes that existing satellite infrastructures simply cannot support.”

With TracPlus Beacon, the company broadens accessibility to vital safety features by providing a straightforward way for customers to engage with the valuable insights and oversight capabilities of TracPlus Cloud. This integration with TracPlus Cloud delivers a unified operational view, offering real-time visibility that is crucial for managing remote field teams or coordinating complex logistics. As a result, customers gain a consistent and accurate overview of their operations, enabling effective safety management and operational efficiency across diverse environments.

TracPlus Beacon is now universally available to all organizations, regardless of their current aircraft tracking system provider. To showcase the groundbreaking advantages and ease of integration of TracPlus Beacon, TracPlus is offering one free license to any organization that operates aircraft anywhere in the world, including those that do not yet use the TracPlus system. This initiative invites entities to experience a major advancement in tracking technology that sets a new standard in the industry. With its commitment to innovation, TracPlus continues to redefine what’s possible in operational management and safety.

by Ryan Varjassy

The NDN-6 Fieldmaster was the brainchild of British aviation legend Nigel Desmond Norman starting back in the mid 1970’s. Desmond and his college friend and business partner, John Britten, formed a relationship starting in the 1950’s at the De Havilland Technical School where they were both studying aircraft design. In 1954 the two built their first aircraft called the BN1F which was a 36hp ultralight.

The aircraft itself was a failure from a sales perspective but it did supply them with a third partner, Jim McMahon. Together they formed Crop Culture Aerial which became extremely successful and along with this new partnership came the early stages of the rotary atomizer spray nozzle.

Britten-Norman was formed as a company that specialized as ag operators and supplied ag conversions of Tiger Moths for export to New Zealand. They had taken over development and sales of spraying equipment, most notably the Micronair Rotary Atomizer, and at one point John and Desmond operated a fleet of approximately 80 aircraft. The need to consider a replacement ag plane resulted in a partnership with Leland Snow from Texas. Britten-Norman acquired a 1/3 share of Snow Aeronautical Corp. and when the company was sold to Rockwell it provided Britten-Norman with the funds to chase their dreams of designing and building their own aircraft. Their idea was to build a small island hopping passenger plane. So after selling off their shares of Crop Culture to the other Board members in 1963, their efforts were put forth into the development of the Britten-Norman Islander which made it’s maiden flight in June of 1965 after

only nine months of development. The factory was based at Bembridge on the Isle of Wight (IOW) off the south coast of the UK and the small island would remain the home of Desmond’s aviation career for years to come.

Over the years Desmond was involved with numerous other businesses and projects but in 1971 Britten-Norman went into liquidation and was purchased by Fairey Aviation in 1972. Desmond would stay on as the managing director until 1976 when he formed his own aviation company, NDN Aircraft Ltd.

The next few years would see the development 3 aircraft:

1. NDN Firecracker/Turbo Firecracker

A two-place military trainer

2. NDN-6 Fieldmaster Agricultural / Firefighting aircraft

3. NAC-1 Freelance

A folding wing four-place civil aircraft

The NDN-6 Fieldmaster took Desmond back to his ag aviation roots, and his aircraft design was indeed years ahead of its time. He wanted a modern ag aircraft that pushed the boundaries of what was already being manufactured...and pushed the limits he did.

The Fieldmaster appeared to be a state of the art ag aircraft or initial attack aerial firefighter with every option possibly available.

After a few years of initial concept work, senior/chief designer Bill Combs had the plans for the new aircraft and work began at the Sandown hangar. Foreman John Cox and his dog Trixi ran the small factory and the aircraft began to take shape. With a talented staff of machinists, sheet metal workers, fitters and engineers, the Fieldmaster was completely built by hand from raw materials assembled in the tiny hangar. An engineering sample was produced as well as all the assembly jigs, and the first flight worthy airframe was created after that.

In November 1981 the aircraft was rolled out of the hangar unofficially and it dwarfed the other aircraft at the small airfield. Desmond performed the first flight on December 17, 1981 at Sandown Airfield on the Isle of Wight and as the story goes, he was wearing his traditional pinstriped suit

Innovations of the NDN6 Fieldmaster:

• Designed from the beginning to have a Pratt & Whitney PT6A-34 750 HP turboprop and could be easily upgraded to the larger PT6A-65 1250 HP engine if desired.

• Integral titanium 625-gallon hopper as part of the structural airframe.

• Aerofoil ailerons and flaps with spray booms built into the internal structure.

• Tricycle landing gear to aid in ground visibility and the training of new pilots on the type, as most pilots are trained on a tricycle configuration.

• Standard dual cockpit with optional controls for training or a rear seat observer/spotter .

• Glass canopy for excellent visibility.

and set out to put the aircraft through its paces. A short flight was originally planned but the flight time gradually grew and grew without Desmond landing at the airfield. After approximately 30 minutes he finally landed unscathed and promptly stated that he could not make the aircraft turn with any real authority so he had to make a large loop in order to get back to the airfield. The landing was less than spectacular also as the nose wheel failed to straighten as it was anticipated to and the aircraft plowed a trench down the grass strip with the crooked nose wheel. The aircraft was subsequently dug out and towed by a tractor back to the hangar where they got to work fixing the turning problems. The aircraft had been designed with inboard ailerons and outboard flaps, unfortunately the German WW2 design

(Continued on page 44)

Options included:

• Firebombing drop gate

• 40 or 80 nozzle option

• Transland spreader

• Micronair Rotary Nozzles (8), Micronair Flow-meter and RPM indicator

• Automatic Flagman

• Lighting packages for navigation, instruments, strobe, beacon, and retractable working lights, both forward and tip mounted, for turning

• IFR instruments

• Heat and air conditioning

• 2-speed windshield wiper and washer system

Development Agency. On July 22, 1985 NDN officially moved to Cardiff and at the same time the name was changed from NDN to NAC (Norman Aeroplane Co.). The factory was staffed and preparations for production of the NAC-6 Fieldmaster were being finalized. Many notable hires were made at this time from production line workers to electrical, airframe and engine engineers.

NAC continued using the original aircraft, NRDC, for testing purposes by doing crop dusting tests in Lelystad, Holland

was operated by the rear seat spotter using a hand crank attached to a steel cable. Vic Osborne did much of the back seat work during this testing phase and says cranking that boom up and down was an awful experience and that his arm would go numb from raising the boom and recalls wondering why they didn’t set it up with an electric winch. Vic also did photo and video work for the boom testing and fire drops from the NAC Freelance aircraft (a small 4 place

(Continued on page 46)

general aviation plane with folding wings about the size of a Cessna 172) with Desmond at the controls. The back seater also was a lookout for watercraft and debris in the water while on the water scooping passes as the pilot was solely concentrating on keeping the boom scoop planted firmly in the water, adjusting trim and airspeed as the hopper filled. The filling sequence would take up to 1min 30 seconds as long as the boom wasn’t skipping off the water but the pilots would only keep the boom in the water for 15 to 20 seconds at a time due to the high level of concentration needed. The system did work but it was never implemented for commercial use and testing was ceased.

Years later, Neville Dunn of Dunn Aviation in Western Australia would travel to Sandown to look at the water scooping boom to see if he could somehow make a version of it work in their operations. It is unknown at this time if they ever tested the system but maybe Neville can shine some light on that some day.

The production line at Cardiff was moving along and in early 1987 the first production aircraft was nearing completion. G-NACL would be the first aircraft produced under the new NAC company name and on April 28, 1987 they received the type certificate from the UK CAA (Civil Aviation Authority). On the same day, NACL performed it’s first flight with the

prototype, NRDC, flying along in formation with Desmond Norman and test pilot Peter Phillips at the controls. NACL flew in primer as Desmond did not want to waste the cost of a new paint-job in case of an accident.

Through May and June of 1987, NACM & NACN were completed and flight certified. Desmond signed a lease firefighting contract to France Aviation Conseil General Des Alpes Maritimes in Cannes in the South of France for their summer firefighting season. All three completed production aircraft were dispatched along with maintenance staff from Cardiff, including Vic Osborne. Through July and August of ‘87, the aircraft performed well but were under-powered during high and hot conditions with a big load onboard. The planes were used for loaded patrols and initial attack on hot spots, as they shined in this role as they carried massive amounts of fuel over 4 internal wing tanks giving it a loiter time pushing 7 to 8 hours. The Fieldmasters were responsible for extinguishing approximately 120 fires during their first season in France. A mid morning takeoff for patrols would usually have them airborne for 4-5 hours doing what was described as a lose pattern grid search at an altitude of about 5000 feet and cruising at 130 to 140 kts.

(Continued on page 48)

JK it’s a military-grade camera system.

Learn more about the Sensor-Enhanced Air Attack

By the end of 1987, sales of the aircraft had been nonexistent so Desmond leased them to various companies to bring in revenue and to test them in real world situations. 2 aircraft, NACN and NACM were leased to Agricair in Zimbabwe, Africa to spray for Tse Tse flies and worked alongside two Turbo Thrush aircraft spraying during the night at treetop height. The Fieldmasters had been outfitted with special navigation equipment in the rear seat for the navigator and intense night lighting to light up the ground.

While NACM and NACN were working the Tse Tse fly contract in Somalia, Desmond decided to send NACL on a sales tour to Australia and then to Singapore for the airshow in January of 1988. Renowned female ferry pilot Janet Ferguson made the long trek to South Australia from Cardiff, Wales covering some 9000 miles one way. Once Janet arrived safely in Australia, NAC`s second test pilot, Doug Barden, flew out on a commercial flight and then took CL to various Australian states showing off it’s fire fighting capabilities. Australia was celebrating its bi-centennial so the aircraft was painted with a “Happy Birthday Australia” on the aft fuselage. After touring Australia, Janet flew the long trip back to the UK, stopping in Singapore along the way to participate in the Singapore International Airshow.

By the summer of 1988 the last two production Fieldmasters were completed. NACO & NACP were flight tested and ready to join the other three production aircraft. All five of the aircraft were essentially the same...Pratt & Whitney PT6A34 turboprops at 750 hp, 625 US gallon titanium hoppers, dual seating and the rest of the innovations that Desmond had designed. There were minor variations between each aircraft but nothing major or significant. The layout was working well and all 5 aircraft went to France for the 1988 firefighting season in Cannes. This would be the only time all the Fieldmasters would work together in one location, minus the original prototype NRDC.

The firefighting season in the south of France was providing good information on the performance of the aircraft in its role there but still there were no orders for the Fieldmaster.

Leading up to 1988, Desmond came up with an agreement to have some Fieldmaster fuselages and wings be produced by Utva Aviation in Yugoslavia. The airframes would then be shipped back to Cardiff for final assembly. Utva found some issues with the wing root and redesigned it providing more strength to the main spar as well. They also redesigned the nose section to accept a 724 shp M601D-1 Walter Turboprop as a less expensive alternative to the pricey Pratt & Whitney. This project lasted until 1992 when war broke out in Yugoslavia and Utva was notified that it was under Western sanctions and work on the British airframes was to cease immediately. The Utva factory suffered severe damage during the war but miraculously the airframes survived unscathed and were put into storage till 1999.

In early fall of 1988, NAC was under serious financial constraints due to the massive amount of money that was spent in order to get to this point of production. On July 26, 1988 NAC went into receivership with Price-Waterhouse directing the company. Desmond was out at the company that bared his name, but NAC would continue to operate until a buyer for the company could be found or the assets liquidated. As the story goes, Desmond had his Freelance aircraft and the original Fieldmaster prototype NRDC moved out of Cardiff the morning the receivers arrived to take over. For some reason these aircraft were not to be part of the sale of the company and Desmond made sure they were not confiscated. Some of the workers were laid off while others were paid to merely show up, sweep the floors continuously and drink coffee. But only two months later, a former financial backer of Desmond purchased NAC’s liquid assets and the rights to the Fieldmaster agricultural and firefighting aircraft, including the five production Fieldmasters.

Andrew MacKinnon and his company Croplease Ltd. began to plan on how to move forward with his new acquisition. However Andrew was not from the aviation world but rather the world of finance. He lived and worked in London while the aircraft were nowhere in his direct line of sight.

(Continued on page 50)

May 5, 1989: NACP Bournemouth.

All of the employees had been let go by this time but one engineer contacted Andrew and offered his services. It was at this point Vic Osborne became the sole engineer for the Fieldmaster aircraft.

After the 1988 summer firefighting ended in France, NACL, NACM and NACN were of f to Morocco in Northern Africa to spray for a massive locust infestation. They were based in Ouarzazate and once again Vic was there to keep the aircraft in tip top shape.

1989 started off slowly and NAC (now Croplease) had moved away from Cardiff to Bournemouth, UK and began to use Interair as a maintenance and parking facility as well as being their new home base of operations. The upcoming fire season was on the horizon and at the request of the French pilots, Croplease hired Brooklands Aerospace at Old Sarum to provide CAA M3 oversight for a planned engine upgrade from the -34 to the 1250 shp -65 Pratt & Whitney turboprop. The aircraft was designed to accept this upgrade from it’s inception with new parts consisting of the engine, engine mount, five bladed propeller and a new nose cowling. The rest of the aircraft would remain untouched except for a gauge or two in the cockpit.

Vic Osborne and an assistant from Brooklands did the conversion in an old WW2 hangar at the Old Sarum airfield beginning in late August with the first flight coming on Oct 28, 1989. The first flight of the newly named Firemaster 65 was performed by British aviation legend Neville Duke with Vic riding shotgun in the rear. Duke’s resume was legendary and his list of accomplishments and accolades is truly remarkable. He was a three tour veteran of WWII beginning his RAF career at 19 years of age in 1941 flying Spitfires from Biggin Hill over Europe. Duke was transferred to North Africa flying the Curtiss the P-40B Tomahawk and then the P-40D Kittyhawk. By September 1944, at the tender age of 22, he had amassed 27 victories in 486 sorties and 712 operational hours. He was flight commander by age 21 and squadron commander officer at 23.

After the war he became a RAF test pilot for Hawker in 1945 through 1948 and after retiring from the RAF joined Hawker again as their assistant chief test pilot until October 1956 when he was forced to retire due to injuries sustained in a few heavy and forced landings which fractured his spine

leaving him immobile for months. His later life revolved mostly around civil aviation and his company, Duke Aviation, where he was a personal pilot for Sir George Dowty and a test pilot for the Edgley Optica and the Firemaster 65. He wrote several books about his life and experiences and his legacy has left a lifelong impression on those who met the man.

At this same time the original Fieldmaster NRDC was also at Old Sarum, and in late 1989 Vic was instructed to dismantle the airframe for some unknown reason. He removed the wings, engine, propeller and she sat there in that state till she was moved back to her ancestral home at the Sandown Airfield on the IOW on Nov 11, 1991. She was laid to rest beside Desmond’s old hangar where she was born some ten years earlier. NRDC would remain there for the next 20 years along with the engineering sample and numerous parts. On Feb 14, 2011 NRDC and all the parts were loaded onto two trucks and shipped off to Jim Pearce who was a notable aircraft rescue and preservation specialist as well as being a former crop duster. Jim never got to restore the Fieldmaster and it was rumored to again be sold to some brothers near Wainfleet, UK who had planned to open a crop dusting museum. That plan never materialized and it seemed as though NRDC was then lost and it became a sad note in the history of the Fieldmaster story.

Neville and Vic did the flight testing and -65 certification program from Sandown in early 1990 and all went according to plan with no issues to report except for the nose landing gear which now would flap from left to right from the propwash produced by the 5 bladed prop. They devised a simple fix by extending the nose wheel mud guard which cured the issue. Vic recalls this 3 week time spent with Neville as the most rewarding and treasured time in his own long and distinguished aviation career.

Stay tuned for Part II of the Fieldmaster Aerial Firefighter story in the September/October issue of AerialFire Magazine

The Fieldmaster Resurrection Project can be contacted by the following outlets:

Email: fieldmasterresurrectionproject@gmail.com

Facebook: https://www.facebook.com/groups/1483419635727874 or search for NDN/NAC Fieldmaster Resurrection

Phone or Text: 306-737-4212

The Future of Aerial Firefighting: The Dash 8-400AT Fast, fuel efficient and tactically flexible. A modern airtanker with a 10,000 litre / 2,642 US gallon capacity to drop water, retardant, or gel over diverse geography. Setting the standard for Next Generation aircraft with OEM support to keep the firefighter flying for decades.

rookie smokejumper for BLM Alaska. I stayed with the Alaska Jumpers for almost 20 years, giving me a chance to really get to know the state and also to jump fires out of other bases in the lower 48. Smokejumping got me all around the country, giving me a chance to work with some great firefighters, experience different fuel models, and different fire behaviors, and see lots of great country.

AF: How did you transition from a smoke jumper into the next stage of your career?

JG: 1999 was the last year I worked as an Alaska smokejumper. The Alaska jumpers were one of the only jump bases at the time that encouraged their guys to work on advancing their fire qualifications, so mid-way through my smokejumper career, I was an experienced ICT3, DIVS, smokejumper spotter, and ATGS. In the course of that work, I gained a lot of experience working with air tankers from both the air and the ground, so that was my introduction to aerial supervision.

In Alaska, back in the day, the ATGS flew with the lead planes, so I was comfortable flying leads with the lead plane pilots.

AF: Was there a period in your career where you pivoted from adventure to a part of your career that was more stable with less of a dangerous element, like a smoke jumper?

JG: I was still jumping at age 41, but my wife and I had also managed to produce two small children, and the seasonal firefighter gig wasn’t really working that well for family life. I took a detail as the Fire Management Officer for Alaska military lands for a short period before I applied for a job in 1999 as the Fire and Aviation Safety manager for the Bureau

of Indian Affairs at NIFC. For the next six years, I held that job, and it gave me an introduction to how the sausage was made at NIFC.

Over those years, I worked on many committees dealing with fire and aviation safety and also got a chance to work with a couple of great Type II teams flying air attack or working as an OSC. At the time, integrating a safety culture was becoming a bigger part of every agency program, so I had a chance to be part of creating some important national initiatives.

AF: What was your favorite agency role?

JG: I can’t deny that being a smokejumper for all those years has produced the best memories and longest friendships of my life, but working for the Bureau of Indian Affairs was also one of the best jobs I’ve had. The people were great and I got to experience landscapes and cultures that were totally new to me. Native Americans have been working with fire for eons, and I don’t think most people appreciate what great firefighters they are, much less the culture and history of Indian country. It was a real education and pleasure for me to experience a bit of that.

AF: After Indian Affairs, you moved back to Alaska. Can you tell us more about that?

In 2005, I was encouraged to apply for a job as the manager of the Alaska Fire Service, so I went back up to Alaska for the next five years and managed the only wildland “Fire Service” in the Federal Government. AFS is a large operation that hosts 80 smokejumpers, 25 fire specialists, two hotshot

(Continued on page 54)

crews, a type 2 training crew, a National Incident Support Cache, a mess hall, barracks, and the Alaska Interagency Coordination Center. Since it is Alaska, there is a strong aviation component to everything that happens there, but AFS is a great organization that deals with a complex interagency role in all aspects of Alaska fire. I spent the first 25 years of my fire career there, so I was no stranger to the politics or the logistical complexities of working in Alaska. Being the AFS Manager was a great job, and I’m proud to have been part of the organization’s history.

AF: At what point did you switch into the more aviationbased role?

JG: In 2011, I took the role of head of aviation for the Bureau of Land Management at NIFC. The National Office for BLM Aviation was a much bigger role for me in terms of contract oversight, policy and safety administration, and interagency engagement. That office also had a direct operational role through the five lead planes we contributed to the national lead plane pool.

AF: What were some of the achievements in your time there?

JG: I think when you run an organization, you find opportunities for improvement and make sure those opportunities don’t pass. When I was there, we tried to find improvement in our lead planes by bringing Cessna Citations into the fleet, but we had mixed results. We also began some upgrades in our Type 3 and Type 2 helicopter fleet that improved operational effectiveness and safety. Much of my time was spent working with the DOI payment system, trying to make the system more user-friendly, but especially trying to make it faster. I’m not sure I’d call any of those things great achievements, but I hope we bent the arc towards a more effective, sustainable system.

AF: How did you transition from the federal world into a role with 10 Tanker?

JG: I was doing a stint in DC in 2010 when the folks from 10 Tanker walked into my office. I thought they were nice folks, but in my operational experience, I didn’t really consider the DC-10 as a relevant asset…too big and not able to achieve the accuracy necessary. At the time, trying to sell a DC-10 to the fire world seemed a little unrealistic, and I didn’t give it much thought. With that said, we had a nice conversation and they stayed in touch.

I think in 2011, 10 Tanker had only CWN contracts, and they were working on getting some longer-term Exclusive Use work. I changed my mind about the DC-10 shortly after they paid me a visit for the second time at my office in NIFC. After they left, I was mildly badmouthing the DC-10, and one of my experienced lead plane pilots told me I should watch them in action before I passed judgment. I was still a qualified ATGS so, just to see the DC-10 work, I spent a few days with one of the BLM lead planes in Arizona

The first time I saw it work was on a fire Northeast of Phoenix. Heavy brush, dense pine, and downfall. It was 2:00 pm, and the fire was 25 acres and 100% active, and in my experience, setting up to be a project. If it’s not too late to make a long story short, the DC-10 put two loads on the fire, and shortly thereafter, it was a mop-up show. It blew me away. Watching it be such an effective use of retardant made me an instant DC-10 believer.

The next year 10 Tanker got their first EU contract, and I think they mistakenly believed I had something to do with that.

AF: In 2013, you left federal service and joined 10 Tanker. Did you immediately start as the head of the organization?

JG: When I left BLM to join 10 Tanker, based on my background, I joined as their business development manager,

(Continued on page 56)

essentially working to normalize the use of such a big airplane with the fire operations community. After several years of that, still working out of my home in Boise, the board asked me in 2017 to come to Albuquerque for six weeks and help the business transition as they searched for a new CEO.

That six weeks then became a few more months, before the board eventually asked me to become the permanent CEO in late 2017…..where I have been ever since.

AF: Regarding contracts for 10 Tanker, is it reasonably cyclical for the business?

JG: When I came on board as CEO, there were three DC-10s, with the fourth coming online. We had a couple 10-year EU contracts, which have now ended, but the company has always worked a mix of exclusive use contracts and CWN contracts both in the U.S. and abroad. The aircraft has been used overseas in Australia, Chile, and Mexico over the years, which we hope will continue with the global need for firefighting increasing. But to answer your question, yes, contracts are always cyclical when 50% of them are CWN. With that said, this year, for the first time, we have all four of our airplanes working on long-term EU contracts….which is a huge relief.

AF: Over all the years you have worked in the industry, what do you think is one of the larger achievements of your career?

JG: I’m not sure it’s an achievement, but I’m most proud that I spent the first 25+ years of my career as a firefighter, and everything I’ve done since then has been influenced by

that came about because of the work of the United Aerial Firefighters Association (UAFA). Wildland fire is having a huge impact on the lives of Americans, and I think our business has to adapt, grow, and change to keep up. I’ve said many times that the knowledge and experience we’re bringing together at UAFA can help drive that change. I hope that someday the work UAFA is doing is something that we can all be proud of.

AF: So the word is that you will be retiring at the end of the year?

JG: Yeah. So that’s the plan. When I hired my Director of

by Babak Taghvaee

ver 50 years have passed since the introduction of the Modular Airborne Fire Fighting System (MAFFS), a self-contained unit used for aerial firefighting for installation and use on Lockheed C-130 Hercules mediumlift tactical transport aircraft of the United States Air Force (USAF) and Air National Guard (USANG). MAFFS started a revolution in aerial firefighting which for over five decades has played an important role in fighting wildfires not just in the United States but in Latin America, Europe, Asia, and Africa. As of January 2024, over 20 out of 26 MAFFS I/IIs in 10 different countries were still operational and in use for firefighting missions.

As many European air powers have selected Airbus A400M Atlas as a replacement for their C-130 transport aircraft, subsequently some of them need a firefighting module with a similar capability of the MAFFS system to complete the aerial firefighting mission. To meet this need, Airbus Military has designed and developed its own Roll-on/Roll-off firefighting kit for installation on the aircraft. The system which is currently in testing in Spain will enable various operators of A400Ms, particularly the Spanish Air Force to use them for firefighting purposes, a similar role previously or still carried out using the C-130B/H/J aircraft around the world.

The MAFFS program was launched in the early 1970s following the lessons learned from a major wildfire that burned and destroyed hundreds of homes in Long Beach, California. Started on September 22, 1970, fires identified as the Laguna Fire, Kitchen Creek Fire, and Boulder Oaks Fire burned 175,425 acres (70,992 ha) of land through October 4, 1970. It was so massive, that the civil fleet of air tankers

(Continued on page 60)

in the US, one of the largest fleets in the world at the time, could not compete against it. The initiation of the MAFFS program would allow the US Forest Service to utilize C-130 Hercules tactical transport aircraft from the USAF and USANG to battle wildfires as an add-on to assist civilian air tankers that couldn’t do it alone.

Congress directed the USFS (Forest Service) to develop the MAFFS program in cooperation with the Air National Guard and Air Force Reserve to produce the equipment, training, and operational procedures to integrate military air tankers into the national response system. Subsequently, a Santa Clara, California-based company named FMC Corporation was contracted to design, build, and test the MAFFS system with the key objective of quick conversion of any standard C-130 into a tanker. As a result, a prototype of the system with two pressurized tanks was produced and was flighttested in July 1971. The MAFFS prototype was later improved and then was produced by the now-defunct Aero Union.