22 minute read

DIES, ROLLS, PLATES, AND ACCESSORIES

TRESU

Advertisement

Cut down cleaning time and improve quality consistency

TRESU is a highly specialized company off ering fl exo printing machines, ancillary products and concepts for fl exo, digital and off set printing and genuine spare parts as well as customer service and technical support. TRESU has 40 years of experience and expertise in the development, production and maintenance of engineered solutions and supplies directly to end-customers, OEMs and partners worldwide.

TRESU has production facilities in Denmark and sales companies in USA, Germany, Italy, Japan and China as well as an international agency network providing local support and know-how.

TRESU presents solutions to optimize wide web corrugated applications through faster cleaning cycles and higher print quality consistency. From 40 years of accumulated experience with printing and coating solutions supplied to leading brands all over the world, we know that automation, simple logistics and easy handling are central qualities of the printing line.

TRESU’s ancillary equipment provides fully controlled ink logistics on each fl exo station, regulating ink fl ow throughout the production run in an enclosed environment from bucket to printing sleeve.

Benefi ts include optimized drying effi ciency, higher refl ective and gloss values, automatic cleaning and ink changes in minutes without manual intervention.

Key equipment includes: • Chamber doctor blade systems with ceramic surfaces for high corrosion resistance or carbon fi ber chambers with unique ink repellent surface for extra protection against inks and detergents • Complete range of genuine end seals in felt, foam or EPDM and proven doctor blades in polymer, carbon steel or stainless steel for any pre- or post-printing process • Clamping systems for fast, safe doctor blade exchange—we off er XL blade holders for coating and printing presses requiring thicker doctor blades—with the industry’s fastest pneumatic or eccentric clamping • MaxiPrint CFC chamber with automated cleaning reduces a complete ink change and cleaning cycle down to 3 minutes and improves quality consistency. MaxiPrint carbon fi ber chambers feature integrated cleaning nozzles with water-shot mechanisms. • MaxiPrint Concept off ers signifi cantly faster emptying performance because the ink or coating fl uid is evacuated through both the inlet and the unique quick-emptying outlet • TRESU F10 iCon ink supply system regulates fl ow and provides automatic, fast chamber cleaning and with an automated ink supply concept the

F10 iCon ink supply provides a lean solution for safe and automated ink circulation and full process control of fl ow, ink pressure and viscosity • Extending the performance of corrugated printing equipment, TRESU presents a special low foaming biodegradable cleaning detergent—TRESU

Wash & Print—based on a recipe only available from TRESU

Nick Gerovac Head of Sales TRESU Ancillary Americas nge@tresu.com +1-214-631-2844

Young Shin USA / STOCK

Young Shin Diecutters/PreFeeders – Meet Your New Employees

Looking ahead into 2022, several factors will continue to impact our industry and production capabilities. One of the most challenging factors of the past 18 months has been locating and maintaining a full and trained employee base thereby creating an even greater demand for high-performance, fully-automated diecutters and feeders.

Young Shin’s premier diecutter product line is focused on consistent reliability, operator ease-of-use, and time-saving innovations that reduce manpower requirements and produce the highest quality output—attributes that are essential for today’s essential profi tability goals. Certain production fl oor equipment upgrades and additions that Young Shin provides can step in and fi ll the place of those hard-to-secure employees. We welcome you to meet your new employees.

YOUNG SHIN DIECUTTERS Th e entire series of Young Shin Diecutters including the Zenith, Giant, Revotec and Meridian models provide an unprecedented two (2) year parts and equipment warranty, comprehensive installation and thorough operator training. Young Shin USA’s service technicians are employed directly by the company and are supported by two U.S.-based parts depots in Atlanta and Wichita. Th is team manages all service and support calls while competently and rapidly handling any parts orders requested by our clients.

YOUNG SHIN FULLYAUTOMATIC SUPERFEED Young Shin recently rolled out its new fully-automatic SuperFeed series of pre-feeders. Seamlessly integrating into Young Shin diecutter models, the SuperFeed is also compatible with most standard fl atbed diecutters, digital printers and litho-laminating equipment. Th e unit can process up to 7,000 SPH with minimum production fl oor space yet expedites the automatic one-by-one staging and feeding of sheets. Th e SuperFeed features an automatic sheet turning system for laminated boards that are inverted or that require that all sheets be inverted and incorporates an automatic pallet or base sheet discharging system. Th e SuperFeed immediately increases productivity and profi tability, reduces labor costs and is available within sixty (60) days from date of order within the North American market.

STOCK MASCHINENBAU GMBH Young Shin USA is also the exclusive North American representative of the STOCK Maschinenbau GmbH brand of comprehensive in-line systems, pattern gluers, litho-laminating and labeling equipment. Th e STOCK SLLM 2025 Combinator Labeler is a high-production unit that off ers speeds up to 10,000 SPH with an integrated automated full- and spot-labeling capacity designed for labeling and full lamination of boxes and displays including single-face corrugated and RSC’s.

To learn more about Young Shin’s and STOCK’s comprehensive product lines, contact Phil Mack, Vice President, at 847-331-0573 or via email at philmack@ youngshinusa.com.

Phil Mack established Young Shin USA, the North American headquarters of South Korean-based Young Shin Industries in 2008, and has successfully expanded Young Shin’s market presence within the fl atbed diecutter market. Young Shin USA also serves as the North American representative of the globally-acclaimed products of German-based STOCK Maschinenbau, a premier manufacturer of labelers, laminators, in-line systems and single-face sheeters and the UK-based Cartostrip, a hand-held stripping device.

Phil Mack Vice President philmack@ youngshinusa.com 847-331-0573 (mobile) www.youngshinusa.com

Apex International

Superior Glue Sets & Anilox Rolls: Get on board with Quality and Reliability

Th e uptick in demand for corrugated box products spells opportunity for box manufacturers and printers. But with increased demand come competitive challenges to increase quality without raising costs. Reliability in box-making and printing are now equally as important as quality, given tight deadlines and profi t margins. Quality and reliability are just what Apex delivers in its innovative, problem-solving glue sets and anilox rolls.

GLUE SETS: BUILDING BETTER BOARD Th e two most common problems with glue sets on the market today are 1) Total Indicated Runout (TIR) & Outside Diameter (OD) imprecision; and, 2) Surface Fragility. Defects in TIR cause improper starch application, fl ashing, slinging, and even crashing. Fragility results in fl aking of chrome-plating, scoring, and roll corrosion. Th ese problems impact board quality, corrugator speed, and time/cost effi ciency. With the Accora glue set product line, Apex has all but eliminated these two problems from modern board-making.

MIND THE GAP: PRECISE MANUFACTURING Box manufacturers know that the secret to fl at board is the optimal application of starch (glue). Th e accuracy of the gap where this glue is applied to the applicator roll by the doctor/metering roll is of paramount importance. Too much starch can warp or washboard the fi nal board; not enough starch can cause board delamination.

Th e Accora glue set is crafted from high-longevity materials appropriate to the harsh corrugator environment. Accora’s glue/applicator roll is made of double-clad welded stainless steel, and then hardened during engraving, thus providing a surface twice as hard as chrome glue rolls. Th e doctor roll is mirror-fi nished plasma-coated ceramic over a corrosion barrier, resistant to scoring and with superior hydrophobic surfacing. Glue set fl aking and corrosion are eliminated.

Equally important is Accora’s precision: TIR and OD across the entire roll face is 0.0003" which will enable a consistent gap down to 0.007".

Accora’s one/two punch of precision and durability have enabled box-makers of all sizes to print fl atter board at higher speeds, save money on starch and energy consumption, and enjoy longer glue set lifespans.

ANILOX ROLLS: PRINTING WITH PRIDE GTT is the Apex’s patented fl agship open-channel anilox engraving that enables box printers to print single-plate solids and screens, resolve fi ner screens, stronger solids, and sharper lines & reverses. What’s more, GTT cleans up faster & requires less-frequent deep cleaning.

Th e UltraCell anilox product line has perfected closed-cell engravings for corrugated and is off ered in a variety of standard and custom engravings. Whether standard 60° hex, tri-helical, Channelox, or elongated, UltraCell’s high-density/low-porosity ceramic enables thorough ink release and ease of cleaning.

Apex International gets you on board with quality and reliability.

Joe Settanni VP Sales jsettanni@apexinternational.com 708-214-7740

ARC International

Your Full-Service Supplier

Whether you’re a box plant with a corrugator, laminator and multiple fl exo folder-gluers and die-cutters, or merely a sheet plant with a few converting machines, your equipment utilizes many types of rollers that need to be reconditioned or replaced from time to time. With all the supply chain nightmares that our industry is facing recently, having to deal with multiple vendors even adds to those headaches!

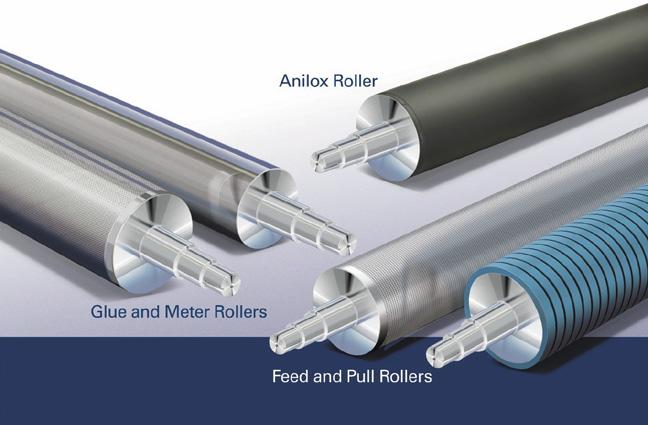

ARC International, with manufacturing plants in Charlotte, NC and Las Vegas, NV, is your full-service supplier of the following rollers for the corrugator: single facer applicator/meter, pressure, infeed, splicer, glue machine applicator/meter and pull/exit knife rollers. Applicator rollers are clad with stainless steel and come with a 5-year guarantee against rust or delamination. Th ese have become an industry standard due to their durability and longevity! Meter rollers are off ered with tungsten carbide and many other standard surfaces such as stainless steel and chrome, while knife rollers are covered with an array of surfaces— tungsten, molybdenum, stainless or carboxylated nitrile.

For fl exo folder-gluers and die-cutters, ARC off ers the following: upper/lower feed rollers in single or dual durometer, laser anilox, wiper, impression and creaser rollers. ARC utilizes the latest fi ber optic laser engraving technology to produce the following engravings: Opticell™ 60-degree, HV™ (High Volume) 70-degree, HG™ (High Graphic) multi-hit 60-degree, and HD™ (High Defi nition) multi-hit 75-degree, as well as the latest HVV™ (High Volume Vortex) extended cell pattern designed for use with the latest plate technology.

ARC’s feed rollers are designed to provide the most consistent delivery of the board to the print section with the least crush. Visual wear grids can be added to the feed roller surface to let the operator know when the roller needs replacement in order to avoid additional crush. Lower knurled feed rollers are off ered in 45-degree or straight knurl, dependent upon OEM specifi cations.

On reconditioned rollers, ARC pays strict attention to journals, bearing surfaces, bores, threads, keyways, gear steps and seal areas. All these are repaired in-house by seasoned machinists, which minimizes lead times for the customer. ARC’s customer service personnel have over 85 years of combined experience with handling rollers and understanding OEM specifi cations. And in addition to performing anilox roller audits in the fi eld to analyze roller conditions, ARC’s technical fi eld personnel can provide graphic support and anilox roller care and handling seminars.

Make life easier in your maintenance department and call ARC International today at 800-526-4569 for ALL your roller needs!

Steve Woodard has been with ARC for 35 years.

Steve Woodard Vice-President of Corporate Services swoodard@ arcinternational.com 704-469-4791

Quest7, Inc.

Quest7, Inc. was established on March 3rd, 2003. Our commitment to the corrugated box industry has established us as a proven leader in the manufacturing and distribution of essential components.

Our current stocked product lines include: corrugator cut off knives, slitters, stones, wicks, splicing tapes, fl atback tape, re-enforcement tapes, strings and tear tape. We also manufacture custom-made converting knives including male & female slotters and strippers.

During 2020 we moved into our new state-of-the-art manufacturing facility in Machesney Park, IL. Th is will allow us to provide faster service, inventory control, and additional opportunities in the future.

Over the past 18+ years we have always strived to have the best customer service in the industry. We excel above customer expectations. We are extremely responsive to customer requirements. Many times, we have received phone calls that our customers are down and need products immediately. We will either put the parts in the car and drive them there ourselves, or work with a delivery service to get them on a plane and delivered hours later. Countless times we have worked with our customers to solve an issue one of their machines is having or create a custom-made knife to meet their unique needs.

As a family business, we acknowledge the relationship we have with employees and customers who are “like family” to us. Th is partnership and common bond strengthens Quest7’s focus and commitment to the corrugated box industry. To many, it is “just a box.” To us, it is the way we “do life” together. We appreciate the friendships we have made and look forward to the people we will meet in the future.

Please visit our website www.Quest7.us and contact us to learn more about the products we off er.

Tim J. Burns President 9853 N. Alpine Rd. Machesney Park, IL 61115 Phone: 815-654-7737 Cell: 815-979-7020

Anilox Roll Cleaning Systems

ARCS: Providing On or Off-Press Anilox Laser Cleaning Services & Equipment

Anilox Roll Cleaning Systems (ARCS) helps printers, packaging manufacturers, and converters improve their print quality and reduce their operating costs by cleaning out dried ink, coatings, and adhesives from their printing and coating rollers. ARCS is known for its industrial expertise in laser roll cleaning services.

ARCS is a turn-key Roll Cleaning Service and System provider. We can clean your rolls for you at your place or ours. For companies who wish to perform roll cleaning themselves, we off er for sale several equipment options from which to choose.

Our SERVICES DIVISION off ers nationwide coverage. Our on-site roll cleaning service can perform both on-press and off -press cleaning using either our unique Eclipse® Laser Cleaning System or specially formulated “Anilox” baking soda. We off er roll cleaning out of our three warehouse locations: Hatfi eld, PA, Greensboro, NC, and Grand Rapids, MI. Our deep cleaning process is eff ective on all types of rollers and residues. We can even clean out completely plugged rollers! Only need a few rolls cleaned? No problem—send them to one of our shops for fast, effi cient service—we will restore your volumes to their original specs and have them on their way back to you within 24–48 hours!

Our SYSTEMS DIVISION off ers

Laser Roll Cleaning Equipment

providing a cleaning technology using a unique, proprietary, circular, non-hot spot laser pattern. Th ese easy-to-use systems only require electricity to work—no compressed air, water, or media are ever required. Laser cleaning also helps companies achieve their sustainability initiatives and move away from the use of chemicals and other processes that produce waste during roll cleaning operations. Proudly MADE in the USA!

Also available: New Dust-Free ARCS Pro-Series Baking Soda Cleaning Systems and high quality refurbished Soda Systems.

Amanda DiGiovanni Customer Service Manager amanda@aniloxrollclean.com 800-699-3722

CleanPrint USA

The Covid pandemic has given our industry increased challenges to overcome. Increased demand for online packaging means increased productivity is vital. CleanPrint USA off ers increased productivity with our state-of-the-art retrofi t systems.

CleanPrint USA is a company totally focused on the corrugated packaging industry, we are industry specialists delivering world’s-best-practice, patented ‘End to end, cleaning in place’ bio-technology based systems and do that with a 100% emphasis on developing and supplying environmentally responsible products.

Our patented ‘Cleaning in Place’ technology sets new standards in anilox and machine cleaning. It means rolls, ink pumps, lines and all areas where ink fl ows in the machine are automatically cleaned with every wash—quickly and eff ectively without anilox roll removal.

EVOLUTION BIOCLEAN for converters, reduces a typical 12 plus minute cleanup down to a 2-4 minute ‘hands-off ’ cycle that improves quality—reduces set-up time, reduces downtime and maintenance while increasing overall production.

Depending on your shift structure, you may increase your production output and revenue by an extra hour per day.

‘AN EXTRA HOUR PRODUCTION PER DAY’ with EVOLUTION BIOCLEAN—even on older machines!

For converters we achieve and maintain clean ink lines and pumps, anilox rolls and chambers with a 2-4 minute full wash and rinse cycle after each print job. Plus, you’ll enjoy reduced ink pump failures, reduced PM clean up to 15 minutes and other long-term time and cost savings, with reduced anilox roll and chamber replacements. Th is has been proven in multiple plants over many years. • EVOLUTION BIOCLEAN is the latest patented development in a line of very successful bio-technology to automatically clean everywhere the ink goes giving a potential 1-hour extra production per day—perhaps 50,000 extra boxes a day.

For corrugators, CleanPrint USA off ers an exclusive patented delivery system and product. EVOLUTION STARCH OFF is an amazing success, gelled and hardened external starch is softened, liquefi ed and rinsed away within 30 minutes. And this is all with eco-friendly non harmful technology. • EVOLUTION STARCH OFF off ers patent pending innovative technology for dissolving starch in your corrugators. Keeping your applicators clean allows for perfect spread of starch, reducing warp and delamination resulting in stronger board, lower

GSM and higher production values.

Clean Print products are used by major international companies such as Pratt/Visy, Orora, Packaging Corporation America, International Paper, Georgia Pacifi c, Atlantic Packaging, Green Bay Packaging and many independents, through distributors such as CST, Clean Print Chemicals, Harper Love and Sun Automation to name a few. Th e corrugated products produced in these plants are global ‘best quality’ and the machinery maintained by their ‘End-to-end, Cleaning in Place’ systems ensures these companies enjoy a continuing sustainable competitive advantage.

Our staff are specialists, ensuring our product and systems remain cutting edge and ahead of the competition, while delivering environmentally friendly and profi table outcomes for our clients. In some cases, we will install delivery technology with no up-front cost, to deliver a cleaning system that is vastly superior to anything else on the market, provided you engage our appropriate supply agreement.

We are the only company in the world with this technology.

For more information contact Geoff Literski on email: geoff @ecochem.com.au

Geoff has 30 years’ experience manufacturing cleaning chemicals, and is totally committed to the box industry, both in the US and internationally.

Geoff Literski CEO geoff @ecochem.com.au +61-416-275-634

Dicar

A Half Century of Industry Leading Innovation, Products and Service.

Dicar is a world-class supplier of top quality, durable urethane components for the paperboard packaging industry. Providing the global corrugated packaging industry with top-level products and outstanding service and innovation for over 50 years is why Dicar continues to be recognized as an industry leader.

Headquartered in Pine Brook, New Jersey, Dicar has manufacturing facilities in New Jersey and Texas, and maintains a global network of regionally located Technical Sales and Service Managers, and Diecutting Experts to provide Global coverage with Local support.

Dicar’s off erings include high quality, durable Anvilok® diecutting covers, lead edge feed wheels, Crushless® rollers and creasers, anvil system, die-making and diecutting supplies and much more.

A family-owned independent business, Dicar maintains a dedication to innovation, product development and customer service. From a humble start with a single product, Dicar now off ers an expansive range of products engineered to enhance the effi ciency, productivity, quality and safety of corrugated diecutting operations around the world.

Popular Dicar products include …

Anvilok® 2 die cutting covers, the latest version of the popular Dicar Urethane die cutting covers are available in sizes to fi t virtually every available rotary diecutter size. Our product lines include conventional bolted and Boltless® designs in both standard and Xtrawide widths. All Dicar blankets are cast and cut to precise specifi cation to provide outstanding quality and performance.

Anvilok® 3 glue Lap and Hand Hole system, converts steel to steel to the soft cutting of glue laps. Th is saves excessive wear on shaft bearings and extends the life of cross cut knives. Further, it prevents damage to the head through excessive knife pressure. Th is system can also be adapted to existing soft cut systems.

Equalizer™ G4, the latest version of the popular Equalizer anvil system uses Dicar’s patented Snap Sleeve “split bearing” design. Th is design allows removal of individual bearing sections for easier and more effi cient mounting and rotation especially in close quarters. Th e design accommodates thermal expansion maintaining consistent cover mounting and allowing the bearing to easily slide along the cylinder for simplifi ed installation and rotation.

AnviLatch™, Dicar’s ergonomically friendly modern anvil cover mounting technology eliminates the need to use a mallet when mounting or rotating. A simple indexing of the die cylinder secures the covers to the cylinder.

Dicar’s Emba Die Cut

Bearing Upgrade brings a new level of ease-of-use and effi ciency to Emba diecutting stations. Based on the Equalizer G4 design, this upgrade off ers the same benefi ts and advantages of the G4.

Dicar’s Geo. Martin Scrubber Replacement

Wheels feature a Wrap-on™ design for simple and quick removal and installation, meet or exceed the OEM specifi cations and deliver optimum wear and sheet control without marking the sheets.

mounting and allowing the bearing to

SpeedStrap™ reusable magnetic pull bands for printing or diecutting provide a quick and cost eff ective way to maximize sheet control through the printing and diecutting stations for enhanced registration, fewer jams and higher quality of the fi nished product.

Visit www.dicar.com for more information on Dicar products or to shop at our online store.

Shawn Spencer VP Sales & Marketing Shawns@dicarinc.net 800-323-4227 www.dicar.net

Proden

We Make Performance Happen.

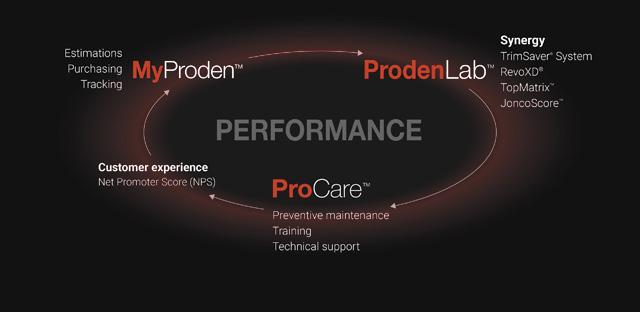

Proden delivers a distinctive customer-centric performance-oriented value proposition combining effi cient web services, high performance products, justin-time delivery and technical support, made to measure to each customers’ specifi c needs.

MyProden™ web portal provides customers with secured web access to all estimations, purchasing and tracking needs. Continuously improved and optimized, it is our commitment to effi cient transactions with our customers.

Our ProdenLab™ generates breakthrough innovations through patented technologies such as TrimSaver® and TopMatrix®, off ering world-class solutions through rotary and fl at cutting dies, Revo-XD® anvil covers and a wide variety of products designed with high performance in mind. Th e ProCare™ program off ers all the preventive maintenance, training and support necessary to enable uninterrupted production and maximum operational effi ciency of the die cutting process.

With all the above supported by an experienced team in 3 locations, proven best manufacturing practices and state-ofthe-art manufacturing equipment … We make performance happen!

Find out more at https://proden.com.

Guy Gagné Title: Director | Innovation – Marketing – Sales Email: ggagne@proden.com Phone: 514-248-0726

SGS & Co

Leadership that moves the industry forward

As the leading supplier for wide and narrow-web fl exo packaging, we are committed to delivering high-quality plates and unmatched customer service for the corrugated industry. In direct collaboration with our manufacturing partners, we are the fi rst to bring new innovations to our customers—advancing their business while simultaneously advancing our industry.

With an annual output of 580MM square inches of polymer, we produce more than 50% of the industry’s total footprint. It is this volume that ensures access to the widest array of fl exo plate technologies from MacDermid, Dupont, Flint and Kodak. Our Flexo Centers of Excellence off er full-service plates from simple to complex, including Basic Corrugated, Amazon FFP/SIOC and High End Displays. We understand that there is no one-size-fi tsall approach to production and provide customized solutions that marry the perfect combination of plate, screening, imaging and materials to deliver the desired result.

National coverage, local support

In a time when many businesses are consolidating, we are expanding to better service our customers. With the addition of a West Coast operation in the Greater Los Angeles Area, we will have the unique ability to respond to printer needs immediately, delivering plates within hours, not days, so they can get orders completed and delivered on time. Th is move will also help us reduce our impact on the environment, drastically reducing materials and emissions related to shipping across the country.

Th e Irwindale, CA plant will join our Atlanta, Florence, Minneapolis and Toronto locations, operating a total of 26 CDI imaging devices and four Kodaks. Across our network, we have the focused expertise to deliver what our customers need, when they need it.

Commitment to printer optimization

We are proud to off er a development program for our printer partners to help establish best practices and advise on equipment optimization. We train staff to be knowledgeable and invested in their careers and in their company’s success. By optimizing the corrugated printing process through quality hands-on training, printers are able to reduce employee turnover plus fi nd and keep experienced operators. Led by industry training experts with decades of experience in corrugated printing, our program is designed for brand new operators and seasoned print veterans alike. To learn more about our Printer Development Program, please reach out to scott.gilbert@sgsco.com.

Daniel Fournel Vice President of Sales daniel.fournel@sgsco.com 803-603-9516