29 minute read

SERVICES

Philipp Lithographing

Advertisement

Philipp Litho Faces Current Industry Challenges Head On

Th e challenges facing the packaging and point-of-purchase industry today are unprecedented and real. Demand is up, supply is down, and many are left spinning their wheels on how to service their customers in the face of a paper market that is struggling to keep up. While these industry challenges may have come as a surprise, Philipp Litho, leader in large format off set printing, is prepared. Because of our longterm vision, strategic planning, and commitment to quality and innovation, we are perfectly situated to grow with you. When you and your customers ask about our business, this is how we answer:

Do You Have …

PAPER?

Yes! We have paper, tons of it! Although lead-times are longer for large orders and board stock, we have an abundance of litho label stock in dedicated warehouses to fulfi ll your orders.

CAPACITY?

Yes! We have added a third shift and installed a brand new KBA 64" press that prints 6 colors + coating at 15,000 sheets/hour!

INLINE UV?

Yes! Our 81" and 64" presses have inline UV capabilities! Ask us about printing on foil and special coating eff ects.

DIGITAL?

Yes! We have a high-tech digital facility with a high-speed, HP Scitex 11000 digital press—perfect for printing direct to corrugated—and a Zünd dual beam CAD table.

HIGH QUALITY?

Yes! Quality is key at Philipp. We have one of the most experienced teams of pressmen and state-of-the-art pressroom equipment with high-tech quality control features.

QUICK TURN OPTIONS?

Yes! Philipp Litho is the Insty-Prints of large format printing! On average, our four presses run 15,000 sheets/hour … that’s fast!

At Philipp every customer, every job, and every project is met with the utmost professionalism, integrity, speed, and focus on quality. We urge you to stop spinning your wheels and trust Philipp. You won’t be disappointed!

Stacy Buening President stacyb@philipplitho.com 262-377-1100

Roosevelt Paper Co.

The Roosevelt Difference

For over 90 years Roosevelt has been providing a quality generic product to those in the paper and paperboard market. Our 1,000,000 square feet of warehouse and converting based in New Jersey, Kentucky, and Illinois enable us to meet both volume and quick turn needs.

Our day-to-day business of acquiring, converting and distributing paper and paperboard has become increasingly sophisticated as technology has advanced. Orders are taken by highly-knowledgeable salespeople who can suggest answers to every customer need.

Shipments coming directly from North American mills are bar-coded, labeled and staged so they can be retrieved quickly when orders are received.

Rolls to be converted are processed quickly by Roosevelt’s high-speed precision sheeters and slitter-rewinders, constantly monitored by our Total Quality Assurance (TQA) program.

Still a family-owned business, Roosevelt maintains its long-held traditions of standing behind its paper and board, providing fast, reliable deliveries and off ering pricing that gives our customers a competitive edge.

For liner, chip, bag, SBS 1 & 2 side in both sheets and rolls—Give Roosevelt a call!

With 7 sheeters & 7 rewinders we are working around the clock to meet your needs! Mount Laurel, NJ | 800-523-3470 Alsip, IL | 800-323-1778 Richwood, KY | 800-354-9829

Corrugated Chemicals Inc.

Building Partnership Through Chemistry, Process, and People

Since opening our doors, we have spent over 40 years committed to improving the industry—growing from a regional manufacturer to a global supplier of specialty products.

Our growth has been fueled by the ever-evolving needs of our clients while focusing on the bottom line. No matter your situation, we have a solution for you.

Th e corrugated industry is going through a transformation, like so many other industries, the competition for qualifi ed personnel, retention of employees, and loss of industry knowledge has created a need for qualifi ed industry specialists and qualifi ed trainers. CCI’s team of experienced technical specialists has been recognized as the company to call. While other suppliers off er training, no other supplier can match the in-depth approach CCI off ers.

CCI has anticipated this industry need and has put together a technical team that can provide the knowledge, training, and products that will impact your bottom line. CCI’s comprehensive training is plant specifi c, classroom, hands on, communication, machine, troubleshooting, formulation, follow up, and much more.

If you need help with production, quality, or training, call us today at 513-561-7773 or visit our website at https:// corrugatedchemicals.com.

Equipment Finance Corporation

Equipment Finance Corporation has provided long term, fi xed rate fi nancing for new and used Paper Converting machinery since 1993.

Our commitment to the industry continued throughout the Covid-19 shutdown/slowdown period by providing payment extension and rewrites to alleviate our clients’ cash fl ow concerns. Unlike commercial banks, we are not paralyzed by the fear of the virus slowdown and are lending as always with fi nancing of up to 100% of the total project cost of new machinery with amortization terms of up to 15 years. Loans for used equipment typically include 100% of the cost of equipment, including rigging, shipping, and installation costs with terms of from fi ve to eight years.

We believe that the corrugated packaging industry is stable and growing with the expansion of on-line purchases being the new norm. Equipment Finance is ready to provide the capital required by our clients to take advantage of their opportunities. We are not hampered by bank regulators and Fed regulations which can result in banks being overly conservative in both their lending availability and programs in the current environment.

Our loan options include early prepayment, annual additional paydown, and loan term adjustment options allowing our clients to take advantage of the low monthly payments of a long amortization repayment term, while having the options to shorten the loan term later, make additional principal paydown, or early prepayment. Th erefore, you can have low payments without locking yourself into a long term commitment.

Investment in upgraded equipment continues to be an ongoing requirement for corrugated operations in order to satisfy customer requirements, improve production speed, capacity & effi ciency, and reduce unit labor cost. Th e need to acquire more effi cient, productive, and less labor intensive equipment will only increase in the future, as will the cost of machinery. EFC’s 30+ years of industry knowledge and experience allows us to off er qualifi ed clients longer repayment terms plus fi nancial fl exibility not available through commercial banks or bank leasing/fi nance companies.

In addition to loans for newly acquired equipment, we provide debt refi nancing to reduce existing loan payments, fi x fl oating rate debt or reduce higher rate debt. Unlike bank lenders, our fi nancial terms and structures are set based on the parameters which best serve the needs of each individual borrower, not a regulatory agency. With our historical knowledge of the resale value of packaging equipment, our credit requirements are also much more fl exible than other institutions. We do not burden clients with blanket asset liens, restrictive loan covenants, and personal guarantees as are typically required by banks and other lenders. You have worked hard for many years to build a strong, successful business. We recognize that and provide lending terms which you deserve based on your fi nancial strength and time in business, not terms determined by federal bank auditors.

While repayment terms and structure fl exibility are extremely important, so is interest cost. Equipment Finance Corporation off ers fi xed rates which are equal to or less than those of commercial banks, bank leasing & fi nance companies, or other fi nancial institutions serving the Packaging Industry. Our large fi nancial services volume allows us access to funding at below market rates which we can then pass on to our clients in the form of lower rates, but with the attractive long term, fl exible repayment plans which are not available through regulated banks and bank owned capital and leasing companies.

Contact Ed Gargiulo at 800-469-1082 or 770-714-0662 or ed@efc-fi nance.com. We will be pleased to provide you with a list of your colleagues whom we have had the pleasure to assist in the past. Th ey can advise you how Equipment Finance has helped them, and can help you, grow your business and improve your bottom line.

Ed Gargiulo EVP ed@efc-fi nance.com 770-714-0662

Aduco Communications Inc.

Pixels and Stones Won’t Break Your Bones – Communication Essentials in the Digital Age

Nothing—and yet everything—has changed. Th e pandemic hit us all in more ways than one. From labor shortages and lockdowns to travel and other related restrictions brought about by the COVID crisis, corrugated OEMs and box plants alike fought hard to keep up with growing demand amid a challenging supply chain.

But the show must go on. Forever resilient, the industry maintained its essential status and converters churned out boxes faster than Santa during Christmas.

For marketers, this meant the typical communication rush around buying season and trade shows was replaced by an 18-month daily communication chess game. Unable to meet in-person, many suppliers turned to digital communications in hopes of staying top-of-mind. In fact, ResearchAndMarkets.com recently reported that “digital marketing spending is poised to grow by $128.83 bn during 2021–2025, progressing at a CAGR of 6.53%.” Th e study further pointed out that “the market is driven by global digital transformation and increased credibility.” On a micro level, the increased demand even forced us at Adduco to triple our digital department and bring in additional partners where necessary.

For many B2B leaders, the digital proliferation over the last year came as an unexpected surprise. Th is was especially true for the corrugated market, where most have grown accustomed to more traditional forms of marketing. Antiquated websites and graveyard social media accounts were quickly losing favor with customers, and many companies were forced to switch tactics quickly. Several took advantage of the new era in communication and started up relevant podcasts and blogs. Others focused on what they needed to fi x ... and a few are still waiting for the tide to turn back. [Spoiler Alert: It’s not.]

Th e good news is that the landscape is forever evolving, and as long as you have something to sell, you have something to tell and someplace to share it. According to Siteefy, there are “133,361,676 websites in the US as of August 2021” with 500,000+ more added each day globally. Furthermore, of those sites more than 23% are not mobile friendly.

Begging the fi rst question, is your site mobile friendly? If not, that’s a fi rst step in optimizing brand awareness and visibility as some statistics show more than 60% of site traffi c comes from mobile devices. Th is also means there are ample opportunities to be seen and heard. Many of these blogs, newsletters, and related industry websites are always looking for new content. As an added bonus, the more sites that you share your brand story with, the greater your own web results will be.

Speaking of content, digital marketing allows for content to be spread further but also demands more of it. According to Forbes, “global online content consumption doubled in 2020,” and social media alone grew by 48%, followed by news websites and apps increasing by 47%. Th is doesn’t necessarily mean you must double your eff orts, but it does pose our second question—how much original content does your company currently produce? If the answer is “not much” or “we don’t have enough to say,” it might be time to give us a call or seek out some help.

As previously mentioned, if you have something to sell, there is a story to tell. I should note this is overly simplifi ed as we recognize not all content is good.

Th is brings up our third and probably most important question—do you know your audience? Simple as it sounds, for marketers this means a lot more than just recognizing who your ideal buyer is by the traditional categories of company and title. We need to know their personalities, likes/dislikes, preferred modes of communication, and channels they visit. It’s a science. Social media is great for providing that data and we often leverage it for both prospecting and communicating.

In the end, the world has changed but business has not. How we communicate and conduct business has gone largely digital—and many will need to adapt before they fall too far behind. For those of us entrenched in the digital age, we will continue to work hard to ensure the voice of our customer is etched in both pixels and stone.

Simona Georgescu Founder & President Simona@adducomm.com 702-434-0341

Athena SWC

AICC Packaging Members Are Seeing Revenue Growth – Don’t Be Left Behind

Athena SWC partners with packaging manufacturers (corrugated, POP display, retail-ready packaging, medical packaging, rigid box, and custom folding cartons) to assist with strategic sales growth initiatives by providing a proven process model and methodology for new account development eff orts (focused on larger repetitive programs with six to seven-fi gure revenue potential). Packagers that choose to partner with Athena often experience the following sales situations: • Lack of sales growth (fl at or declining YTY sales) • Need to replace bad margin, diffi cult customer programs • Need to replace customer projects that are nearing the end of their life cycle • Needed to diversify customer revenue base (80/20 rule) • Targeted the wrong type of accounts

HERE IS HOW IT WORKS: Our best-practice model combines inbound and outbound marketing tactics and allows you to measure eff ectiveness and quantify ROI. Programs are designed based on your specifi c sales goals and desired return. As part of our process, you will see a fl ow of qualifi ed leads from both inbound and outbound sources (SEO, website visitor tracking, outbound emails, etc.). Th ose leads and any of your internal lead sources (prospecting, referrals, tradeshows) that you’d like to include are qualifi ed to ensure they meet your company’s specifi c growth requirements, whether based on industry, geography, potential revenue, or other criteria.

We manage those leads as they move through your sales cycle, set up meetings with the prospects, nurture future interest prospects, and follow up on RFQs and quotes, allowing your salespeople to do what they do best: Close the sale!

WHAT’S IN IT FOR YOU? You will see compressed sales cycles, increased sales rep productivity, and of course, an increased fl ow of new business opportunities. Plus, you can clearly quantify and link your marketing investments to improvements in both sales productivity and increased sales revenue. To learn more about our packaging experience and see success stories from other packaging manufacturers (including AICC members), visit https://bit.ly/corrugated-packaging!

Todd Zielinski Managing Director & CEO tzielinski@athenaswc.com 716-799-9324

Corrugated Gear and Services, Inc.

We’re more than just a parts supplier...

For over 40 years, Corrugated Gear and Services has served the corrugated industry with not only quality replacement parts, but unmatched excellence in the rebuilding and upgrading of machinery from roll stands all the way up to complete Flexo Folder Gluers from most manufacturers. With specifi cations for well over a half million parts, an in-house manufacturing/fabrication facility, and a fully capable ReBuild center, Corrugated Gear and Services is the name you can count on.

Providing the best service available is what keeps the GEAR turning, and we take pride in doing so every day. 100 Anderson Rd. Alpharetta, GA 30004 770-475-8929 www.corrugatedgear.com

GAPCO

Good to the Core Strapping Solutions

“With 6 National locations in the USA, GAPCO provides its customers with the fastest lead times. Contact us TODAY for fastest lead times. Contact us TODAY for your FREE sample coils.” your FREE sample coils.” Patented Dust Free Strapping Patented Dust Free Strapping www.GAP-CO.com www.GAP-CO.com Bobby Atkinson III Packaging Specialist b3@gap-co.com 404-388-6690 404-388-6690 GAP-CO GAP-CO http://www.gap-co.com http://www.gap-co.com

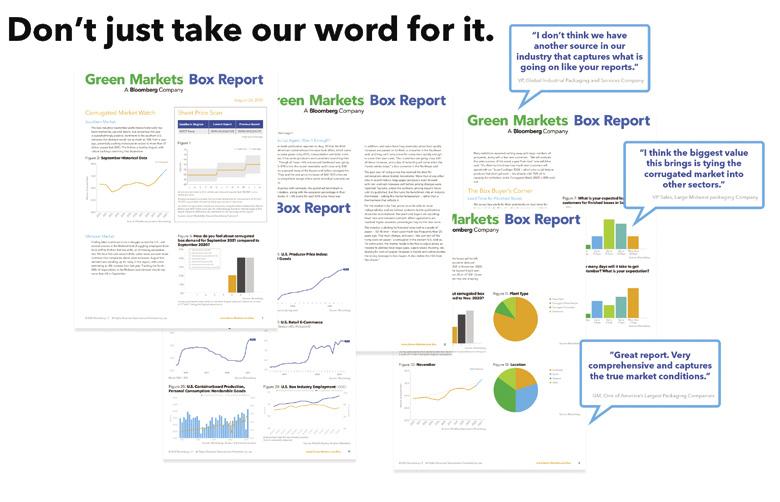

Green Markets, A Bloomberg Company

Corrugated Market News For Box Plants, By Box Plants

Sheet plants across the US have desired an alternative to FastMarkets RISI for many years. Th at Alternative is here in “Th e Box Report”. Each month we publish market insights that are confi dentially gathered from box plants of all sizes. We ask participants for their sentiments about upcoming demand, track lead times for sheets and fi nished boxes, and provide a price index based on 32ECT. We report what we hear from the street.

CORRUGATED SHEET PRICING, MARKET SENTIMENTS, NEWS, AND MORE FOR BOX PROS. Th e Green Markets Box Report uncovers the latest sheet price movements, market demand direction, and insight from inside the box industry. Th e Box Report gives you access to time-sensitive market intelligence including: • Corrugated Prices &

Market Assessments • “Th e Box Buyers Corner” • Market Trends • Macro Indicators

Each subscription includes access to the month-end Box Report and mid-month Box Market Trends report. Th e Trends report covers market moving ideas like: • E-Commerce • Sustainability • Digital Printing • New Innovations • Logistics • Software

“Your report has more live info and what is actually occurring vs. tracking to a sort of indices. What are people saying for sheets ... what a liner is per ton ... is all important information for me to know. Th e Box report commentary is great.” —VP of Packaging “[Th e Box Report] is tangible, easy to read, and what the industry needs to know.” —GM at Sheet Feeder

Ryan has over 10 years of corrugated packaging industry experience with sheet plants.

Ryan Fox Corrugated Market Analyst rfox93@bloomberg.net 609-279-3849

For over 12 years, Lisa has provided sales leadership to multiple commodities in our portfolio.

Lisa Robel Director of Sales lrobel2@bloomberg.net 603-357-8181

JHF Capital, LLC

Alternative Funding/Financing Specialist

JHF Capital was founded by John Forrey, formerly the President of Specialty Industries and a member of the AICC Executive Board as recently as 2018. Subsequent to the sale of Specialty, John was not ready to retire and decided to utilize his strong fi nancial background to start his own company.

Recently, John was recognized as the Rookie of the Year award recipient at the National Alliance of Commercial Loan Brokers (NACLB) award ceremony in Las Vegas.

Having worked in the packaging manufacturing world for the better part of his career, John realized how much access to capital can be a struggle for many businesses. As such, JHF Capital brands itself as an alternative funding/ fi nancing specialist for small and mid-size businesses to traditional bank lending institutions.

Types of funding options provided by JHF Capital include: Accounts Receivable and Asset Based Lines of Credit, Equipment Leasing, Inventory Financing, Unsecured Business Lines of Credit, SBA Loans, Commercial Real Estate Financing, Purchase Order Financing and Large Project Financing.

Additionally, JHF Capital has relationships to help businesses reduce expenses in both the Merchant Services and Telecommunications cost centers.

Google “Entrepreneurs in Finance with Kris Roglieri” to see a recent Podcast with John discussing the JHF Capital business.

I look forward to reconnecting with old friends and colleagues of the AICC. Please feel free to contact me for help or advice when having any challenges with your primary bank lending institution.

John Forrey Owner jforrey@jhfcapital.net 302-386-9994

KPI Incorporated

World Class Customer Service

KPI Incorporated (Indianapolis, IN) – A United States market representative of high-quality engineered products and services. KPI diff erentiates itself with extraordinary customer service, engineering support and planning, factory relocation project management, and forward communication. KPI off ers warehouse storage and factory trained technicians to “service what it sells” to the corrugated box industry. Below is a list of its partners.

BRICQ Corrugator Belts (Montbron, France) – Established in 70 countries Worldwide, BRICQ specializes in corrugator belts for all OEM corrugators. Depending on customer equipment type and board mix, BRICQ off ers three diff erent belt options to fi t your needs: Power™ – Heavy Duty Woven (9mm) as well as its Needled Felt – Four™ (8.6mm) and its Lightweight Solution (5.5mm) Speed™. Its Siliconized Track™ off ers superior tack for board control. Stock parent rolls are stored in Indianapolis and cut to length for emergency service. Seams can be integral fl ap or traditional fl ocked. KPI off ers drum lagging and belt repair through its fi eld service team.

JKSP AirBond (Warrington, Cheshire, UK) – AirBond is a modern solution to improve board quality and deliver long term value on the corrugator. AirBond is an upgrade to a conventional double backer heat transfer system and has been engineered to increase the production speed of fl at, well-bonded, dry sheets on the corrugator. Its advantages over traditional heat transfer systems is lowered energy/maintenance cost and reducing waste off the corrugator and through converting equipment. Th e modular and lightweight formed aluminum frames can be fi tted to any OEM corrugator and installed over a weekend shutdown.

PIC Precision Industrial (Washington, USA) – is a Nationwide leader in corrugated equipment construction projects. With over 30 years’ experience, PIC has built its reputation as a full-service industrial contractor for larger projects and when time matters most. PIC off ers a single source provider for concrete foundations, full line corrugator installations, factory relocations, and green fi eld construction projects. Th e PIC fi eld team manages a variety of projects ranging from caustic to concrete services and from corrugator to converting equipment rigging. Equipment is mobilized out of its Pacifi c Northwest location or its Midwest hub.

Vokore Machine Knives (Remscheid, Germany) – Since 1961, Vokore machine knives have been seen on corrugating equipment all over the World. Until recently, these slotting heads and razor slitting knives have been unavailable in the United States. Vokore quality comes from the higher density steel it uses as its base metal. Th e knives are considered precision for their tolerances and off er longer life run time between changes. KPI stocks inventory in Indianapolis for select OEM equipment.

Visit www.kpiincorporated.com to view the KPI complete product and service off ering or call us directly at 317-288-0470.

Michael Harris President mharris@kpiincorporated. com 317-288-0470

Miller Valentine Construction

In today’s ever-changing environment, fl exibility is key. At Miller Valentine Construction, we partner with you to understand your current needs as well as develop a plan for tackling the challenges of tomorrow. From individual building layouts to campus planning, we have experience constructing highly productive environments for our clients’ needs.

As global industrial packaging companies expand their manufacturing, warehouse, and distribution footprints to meet demand and locate closer to their consumers, Miller Valentine has provided expertise in constructing and/or renovating over 6,500,000 square feet of space for many clients in the packaging industry.

Our preconstruction services allow us to anticipate and manage challenges from the very beginning and create a plan that’s designed to mitigate the inherent risk factors that can impact the project’s timing, budget, quality, and safety.

Superior project execution takes careful planning, focus on details, and diligent follow-up on the hundreds of moving parts that make a project successful. Our teams work together to ensure all aspects of a project are executed with certainty despite the risks and complexities involved.

At Miller Valentine Construction, we understand that no two projects and customers are the same. We work to create a unique customer care plan for each client, based upon their needs and preferences.

NOW LET’S GET TO WORK!

PROJECT SPOTLIGHT: PRATT INDUSTRIES • 704,000 SF Facility • 24,500 SF Offi ce • 56 Docks • Rail dock with canopy structure

People’s Capital and Leasing Corp

Are You Positioned to Fully Leverage Today’s Market Opportunities?

Where will your business be in fi ve years? Th e growth forecast for the corrugated packaging industry is strong due to a number of drivers that include: • Explosive growth in e-commerce, from direct ship-to-buyer to buy online/pickup in store • Rising need for sustainably produced, biodegradable shipping and storage materials • Increasing demand for packaging that helps businesses stand out in a crowded, highly competitive marketplace.

All of these represent tremendous opportunities. But realizing them will mean meeting the challenges that come along with them, such as: • Economical production at scale • Th inner yet stronger packaging • Customized, retail-ready printing with high impact and at a competitive cost

Succeeding in this environment will require an unprecedented level of innovation and agility, driven in large part by advanced production technologies and people who can get the most from them. But how will manufacturers get equipped and train their teams to stay on the cutting edge without driving their fi nancial position to the bleeding edge?

At People’s Capital and Leasing Corp, we believe a strong fi nancial partner with real expertise in the corrugated packaging industry will be key to positioning manufacturers for rapid growth without compromising budgets, cash fl ows, and operational fl exibility.

With a packaging team that has worked with the industry for more than 80 years, People’s Capital and Leasing Corp deeply understands not only the current challenges and opportunities in the corrugated packaging marketplace but also the context and history that inform a strategic path forward.

What will that path look like? Aff ordably acquiring the needed technology, keeping it up to date, and ensuring that teams can fully utilize it will require the kind of fi nancing strategy we’ve developed for the industry—one that includes elements like these: • Th e fl exibility to choose from loans, leases, and SBA agreements as the situation warrants, along with expert insight on the relative merits of each option in a given scenario • 100% fi nancing for equipment to relieve the upfront cash burden of equipment acquisitions and position businesses for maximum fl exibility as opportunities arise and evolve • Customizable terms that include options like progress payment fi nancing, competitive fi xed or fl oating rates, synthetic leases, operating leases, and other alternatives that give manufacturers a best-fi t solution to their needs now and the agility to modify their solution as business needs dictate • Local decision-making from a fi nancial partner that holds transactions in its own portfolio • Asset-secured lending that doesn’t require businesses to secure acquisitions with blanket liens or real estate

Is your business positioned to fully leverage the opportunities presented by an evolving marketplace? As a lender committed to facilitating growth in the corrugated packaging industry and a member of AICC for more than 20 years, People’s Capital and Leasing Corp is here with industry experience, fi nance resources, and strategic insight to help you drive exceptional results now and in the years to come. To start a discussion, contact us today.

Tom Davies, SVP Bridgeport, CT 203-232-6018 Tom.davies@peoples.com

Tony Castellanos, VP Overland Park, KS 913-484-4444 Tony.Castellanos@peoples.com

Tom Emery, VP Atlanta, GA 678-576-8166 Th omas.emery@peoples.com

Jeff Morrison, VP Bridgeport, CT 203-339-1006 Jeff rey.morrison@peoples.com

Precision Industrial Contractors

At PIC, our team of professionals has helped many clients design and install complex industrial corrugation processes.

PIC is recognized as a preferred turnkey corrugator and converting construction company. We work closely with our customers to expedite and complete projects according to their specifi cations.

Our construction services include layout, pre-planning, foundation design, civil/concrete, structure fabrication, steel erection, process piping and complete plant relocation and implementation. We

also provide corrugator and machinery profi les and precision optical alignment with capabilities up to ½ arc second.

We collaborate with our customers to expedite and complete projects safely, on time, on budget and with as little disruption to our customers’ production as possible.

For more information, contact us or visit our website. Eric Simensen President eric.simensen@ picateam.com 360-225-7955 Other information: www.picateam.com

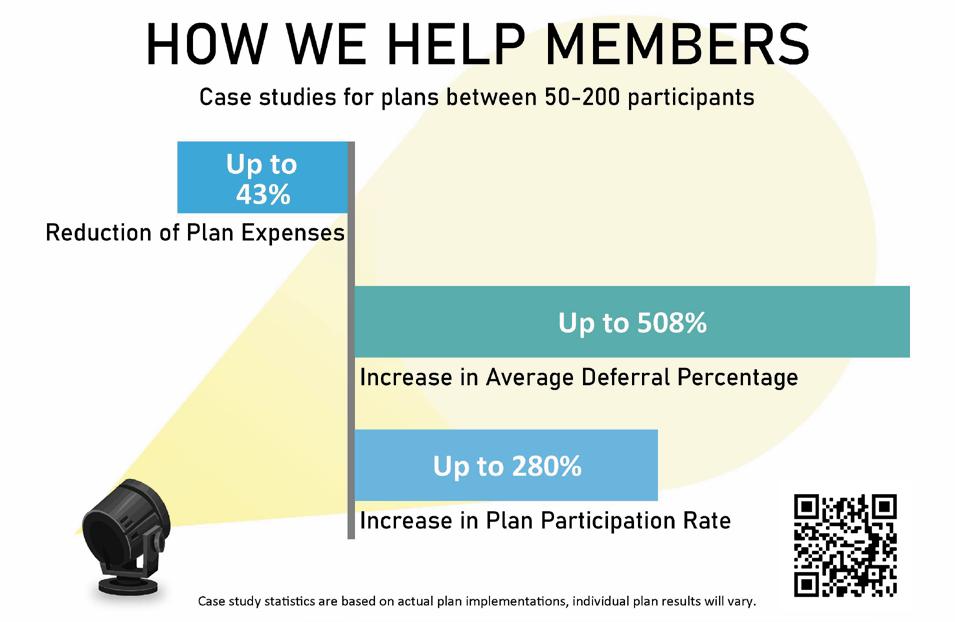

Printers 401k®

Spotlight on Retirement Plan Performance

Th ere is a lot to keep track of when sponsoring a retirement plan, especially when it comes to fi duciary responsibilities and regulations. It is vital to ensure you are fulfi lling your fi duciary obligations to maximize participant retirement readiness and to lower fi duciary risk and plan expense, but doing so can be confusing and time-consuming.

As part of our spotlight services, we are typically able to provide companies with: 1. Better employee communication and education 2. Lower stated fees 3. Covered Fiduciary responsibilities – Printers 401k®

Retirement Plan Experts accept

Fiduciary responsibility 4. Better investment lineups

We off er a complimentary side-by-side comparison to assist you in identifying strengths and weaknesses with your retirement plan. Th is service helps cut

through the complexity of retirement plan operations, plainly shows you how your plan is performing, and reveals the total costs you and your participants are paying for your retirement plan.

Th e Printers401k® Program provides a complete solution to retirement plan management. Contact Joe Trybula CFP®, CPFA®, today at 800-307-0376 or joe@printers401k.com to receive your complimentary side-by-side comparison. Joe Trybula, CFP®, AIF®, is the Vice President of Diversifi ed Financial Advisors, LLC and a Registered Investment Adviser with more than 20 years of experience of providing professional management of corporate retirement programs.

Joe Trybula CFP®, AIF® joe@printers401k.com 800-307-0376

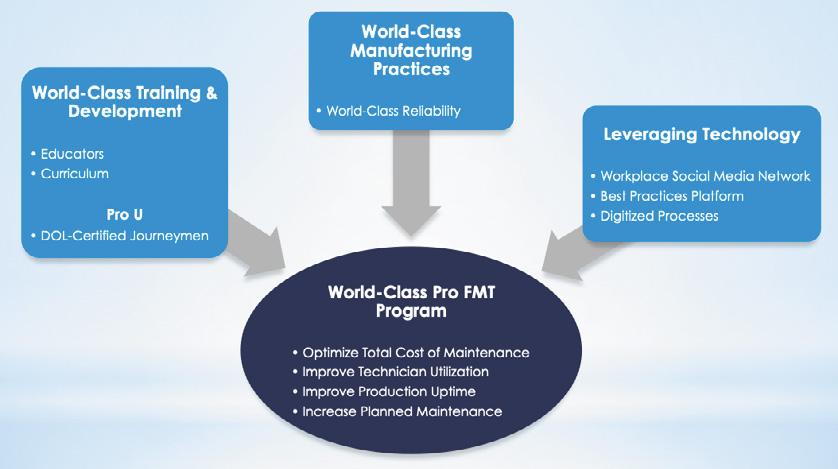

Pro Services, Inc.

Decrease Downtime and Improve Reliability with a Fully-Outsourced Maintenance Program from Pro Services

Since 1987, Pro Services has provided world-class Skilled Trades and Production Maintenance Services to manufacturing partners across the country.

Our Pro FMT (Full-Service Maintenance Teams) division provides full-service maintenance support programs to our industrial-manufacturing clients, allowing them to focus on their core competencies, leaving the maintenance details to the PROS.

Pro Services off ers fully outsourced maintenance programs to our manufacturing clients, allowing them to reduce their downtime and improve reliability and maintenance costs. Our full-program includes maintenance management, maintenance technicians, PM optimization, and complete asset ownership.

WHAT MAKES US DIFFERENT? • Our People º Our experienced and highly qualifi ed technicians are vetted through our specialized recruiting process, which allows us to provide you with top-tier talent. º We also have multiple CRLs (Certifi ed Reliability Leaders®) on staff helping maintenance teams change from a reactive to a predictive and preventative environment. Th ese leaders create a system of asset lifecycle management that reduces downtime and associated production costs. • Performance Guarantees º We provide industry-leading guarantees on performance, decreased downtime, and increased productivity. • Our Proven Process º Utilizing our FMT process has proven that with our maintenance support, customers can focus on their core competencies leaving the maintenance details to the PROS.

Are you facing obvious challenges like fi nding talent with the right skills, skilled technicians nearing retirement, and struggling to keep up with industrial and technological advancements? Pro Services has the solution for you! Contact our sales team at info@prosatwork.com to see how our fully outsourced maintenance program can help your company advance into the future.

info@prosatwork.com 269-327-2322 www.prosatwork.com