THE ONLY INDUSTRY SOLUTIONS GUIDE FOR THE INDEPENDENT

January/February 2023 Volume 27, No. 1 A PUBLICATION OF AICC, THE INDEPENDENT PACKAGING ASSOCIATION ALSO INSIDE Thriving in 2023 AICC Innovation: Seven Questions for Sales Managers

BOXSCORE www.AICCbox.org 1 TABLE OF CONTENTS January/February 2023 • Volume 27, No. 1 BoxScore is published bimonthly by AICC, e Independent Packaging Association, PO Box 25708, Alexandria, VA 22313, USA. Rates for reprints and permissions of articles printed are available upon request. e statements and opinions expressed herein are those of the individual authors and do not necessarily represent the views of AICC. e publisher reserves the right to accept or reject any editorial or advertising matter at its discretion. e publisher is not responsible for claims made by advertisers. POSTMASTER: Send change of address to BoxScore, AICC, PO Box 25708, Alexandria, VA 22313, USA. ©2023 AICC. All rights reserved. Visit www.AICCboxscore.org for Member News and even more great columns. Scan the QR code to check them out! 4 4 THE BIG ASSOCIATE ISSUE VI The only industry solutions guide for the independent 6 EQUIPMENT 58 DIES, ROLLS, PLATES, AND ACCESSORIES 64 INKS, COATINGS, AND ADHESIVES 69 SHEETS, PAPER, AND PRINTING 76 SERVICES 90 SOFTWARE AND ELECTRONICS 104 THRIVING IN 2023 Despite lingering challenges and an uncertain economy, boxmakers are preparing to make the most of their opportunities over the next 12 months 104 COLUMNS 3 CHAIRWOMAN’S MESSAGE 110 THE ASSOCIATE ADVANTAGE 116 THE FINAL SCORE DEPARTMENTS 100 WELCOME, NEW & RETURNING MEMBERS 101 AICC INNOVATION 112 FOUNDATION FOR PACKAGING EDUCATION 114 INTERNATIONAL CORRUGATED PACKAGING FOUNDATION Editor’s note: The November/December 2022 BoxScore issue cover incorrectly identified Central Package and Display as that issue’s Member Profile. The Member Profile was on Arvco Container Corp.

OFFICERS

Chairwoman: Jana Harris, Harris Packaging/American Carton, Haltom City, Texas

First Vice Chairman: Matt Davis, Packaging Express, Colorado Springs, Colorado

Vice Chairs: Gary Brewer, Package Crafters, High Point, North Carolina Finn MacDonald, Independent II, Louisville, Kentucky Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada

Immediate Past Chairman: Gene Marino, Akers Packaging Service Group, Chicago, Illinois

Chairman, Past Chairmen’s Council: Jay Carman, StandFast Packaging Group, Carol Stream, Illinois

President: Michael D’Angelo, AICC Headquarters, Alexandria, Virginia

Secretary/General Counsel: David Goch, Webster, Chamberlain & Bean, Washington, D.C.

AICC Canada: Lee Gould

DIRECTORS

West: Sahar Mehrabzadeh-Garcia, Bay Cities, Pico Rivera, Califormia

Southwest: Jenise Cox, Harris Packaging/American Carton, Haltom City, Texas

Southeast: Michael Drummond, Packrite, High Point, North Carolina

Midwest: Casey Shaw, Batavia Container Inc., Batavia, Illinois

Great Lakes: Josh Sobel, Jamestown Container Cos.

Macedonia, Ohio

Northeast: Stuart Fenkel, McLean Packaging Pennsauken, New Jersey

AICC Canada: Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada

AICC México: Sergio Menchaca, EKO Empaques de Cartón S.A. de C.V., Cortazar, Mexico

OVERSEAS DIRECTOR

Kim Nelson, Royal Containers Ltd., Brampton, Ontario, Canada

DIRECTORS AT LARGE

Kevin Ausburn, SMC Packaging Group, Springfield, Missouri

Eric Elgin, Oklahoma Interpack, Muscogee, Oklahoma

Guy Ockerlund, OxBox, Addison, Illinois

Mike Schaefer, Tavens Packaging & Display, Bedford Heights, Ohio

Ben DeSollar, Sumter Packaging, Sumter, South Carolina

Jack Fiterman, Liberty Diversifies, Minneapolis, Minnesota

EMERGING LEADER DELEGATES

Lauren Frisch, Wasatch Container, North Salt Lake, Utah

John McQueary, CST Systems, Atlanta, Georgia

Jordan Dawson, Harris Packaging, Haltom City, Texas

ASSOCIATE MEMBER DIRECTORS

Chairman: Greg Jones, SUN Automation Group

Glen Arm, Maryland

Vice Chairman: Tim Connell, A.G. Stacker Inc Weyers Cave, Virginia

Secretary: John Burgess, Pamarco/Absolute, Roselle Park, New Jersey

Director: Jeff Dietz, Kolbus America Inc., Cleveland, Ohio

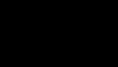

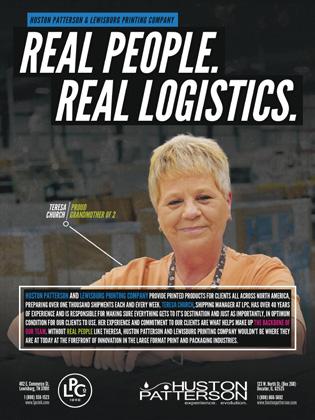

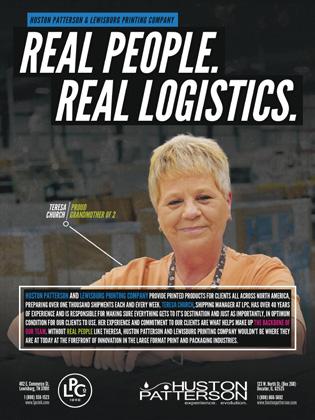

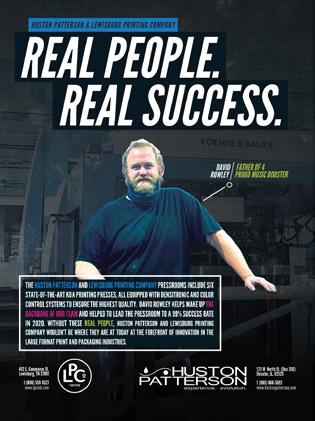

Immediate Past Chairman, Associate Members: Joseph Morelli, Huston Patterson Printers/Lewisburg

Printing Co., Decatur, Illinois

ADVISORS TO THE CHAIRMAN

Al Hoodwin, Michigan City Paper Box, Michigan City, Indiana

Gene Marino, Akers Packaging Service Group

Chicago, Illinois

Greg Jones, SUN Automation, Glen Arm, Maryland

PUBLICATION STAFF

Publisher: Michael D’Angelo, mdangelo@AICCbox.org

Editor: Virginia Humphrey, vhumphrey@AICCbox.org

ABOUT AICC

EDITORIAL/DESIGN SERVICES

The YGS Group • www.theYGSgroup.com

Vice President: Serena L. Spiezio

Content & Copy Director: Craig Lauer

Managing Editor: Therese Umerlik

Senior Editor: Sam Hoffmeister

Copy Editor: Steve Kennedy

Art Director: Alex Straughan

Account Manager: Frankie Singleton

SUBMIT EDITORIAL IDEAS, NEWS, & LETTERS TO: BoxScore@theYGSgroup.com

CONTRIBUTORS

Maria Frustaci, Director of Administration and Director of Latin America

Cindy Huber, Director of Conventions & Meetings

Chelsea May, Education and Training Manager

Laura Mihalick, Senior Meeting Manager

Patrick Moore, Membership Services Manager

Taryn Pyle, Director of Training, Education & Professional Development

Alyce Ryan, Marketing Manager

Steve Young, Ambassador-at-Large

ADVERTISING

Taryn Pyle 703-535-1391 • tpyle@AICCbox.org

Patrick Moore 703-535-1394 • pmoore@AICCbox.org

AICC PO Box 25708

Alexandria, VA 22313

Phone 703-836-2422

Toll-free 877-836-2422

Fax 703-836-2795

www.AICCbox.org

PROVIDING BOXMAKERS WITH THE KNOWLEDGE NEEDED TO THRIVE IN THE PAPER-BASED PACKAGING INDUSTRY SINCE 1974

We are a growing membership association that serves independent corrugated, folding carton, and rigid box manufacturers and suppliers with education and information in print, in person, and online. AICC membership is for the full company, and employees at all locations have access to member benefits. AICC o ers free online education to all members to help the individual maximize their potential and the member company maximize its profit.

WHEN YOU INVEST AND ENGAGE, AICC DELIVERS SUCCESS.

Thanking Our Associates

When my sister, Jenise Cox, and I got into the family business in 2006, we knew very little about the industry, including the products and services our company needed. Through attending AICC’s meetings and utilizing AICC’s educational offerings, we began to learn a thing or two. Whether we have learned from the speakers at a meeting or from other converters and suppliers whom we have had the pleasure to get to know, with every AICC interaction, there is always a takeaway.

I tell people this Association has been invaluable to us. I truly believe being an active member of AICC has played a part in our company’s growth during our time as second-generation owners. We believe everyone, general members and Associates alike, is there to support one another and make our industry stronger and better for independents.

I have always appreciated the Big Associate Issue because it highlights our Associate members and gives them an opportunity to tell us who they are and what they do. Our Associate members are so valuable to independents and to our Association. Not only do they have products and services that support our industry, but they also play a big role in supporting AICC. We rely on them to keep us up to date on the most recent technology; we lean on them to volunteer as speakers and contributors at our meetings and for educational courses and publications.

Many Associates also offer support by sponsoring AICC events and donating to the Foundation for Packaging Education. We owe them a big thank-you for that. This financial support is greatly appreciated, and it helps AICC invest into more offerings for all members.

Our company has benefited from the relationships we make with the Associate members. We try to always look first at an AICC Associate member when we are getting ready to make a purchase. Supporting companies that support our Association is important, and in addition to that, they have great products and services to offer us.

So, take the time to read about our great Associate members and their products, and next time you see one of these members, thank them for all they do for us and our Association.

Always remember to “buy local.”

Jana Harris CEO and Co-owner, Harris Packaging and American Carton Co. AICC Chairwoman

BOXSCORE www.AICCbox.org 3 Chairwoman’s Message

4

Associate members have always been welcomed in AICC. The Association often relies on them to keep us updated on the market and technology, as suppliers, as expert speakers and trainers, and as contributors to AICC publications, including BoxScore. Associate members also offer significant fi nancial support that allows AICC to invest in benefits for all its constituents, such as free education, advocacy, networking opportunities, and much more.

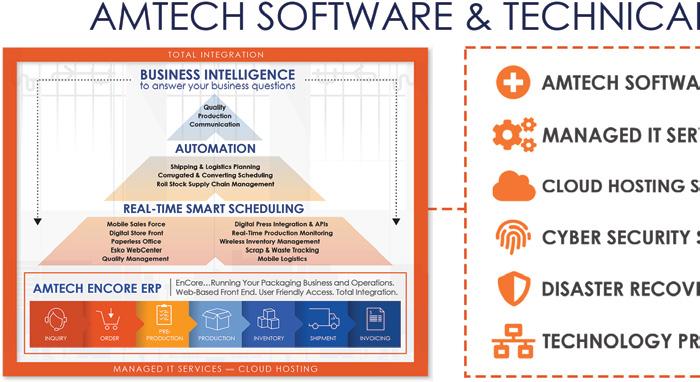

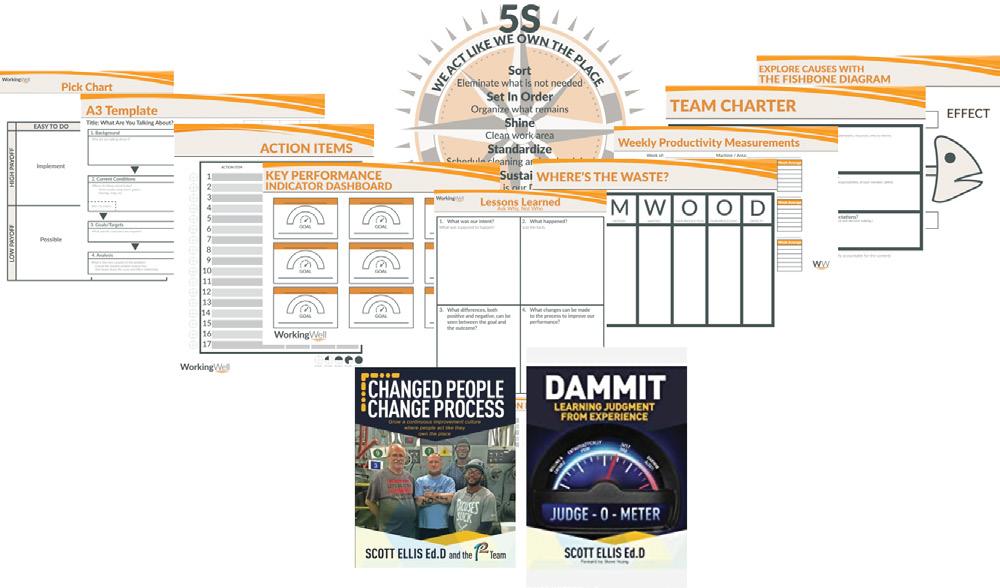

AICC’s goals with this annual edition of BoxScore —the only such guide in our industry— are to help members see opportunities and gather information and materials that will guide the future of their businesses. We hope the Big Associate Issue will serve as an effective tool for informing you of all the useful, innovative products and services at your fi ngertips. It is a reference book of what is available to independent converters today, segmented into:

• EQUIPMENT

• DIES, ROLLS, PLATES, AND ACCESSORIES

• INKS, COATINGS, AND ADHESIVES

• SHEETS, PAPER, AND PRINTING

• SERVICES

• SOFTWARE AND ELECTRONICS

To the converters reading this magazine and using it throughout the year, give your fellow members a fi rst look. Support the companies that support you and your Association. When you speak with an Associate member, please let them know you saw their article in BoxScore to allow us to continue to offer this member benefit.

When you invest in and engage with AICC and its Associates, you bolster the foundation for continued growth—for all independents.

BOXSCORE www.AICCbox.org 5

THE BIG ASSOCIATE ISSUE, now in its sixth year of publication, is a venue for AICC Associate members to communicate who they are, what they do, and how their products and services support independent paper-based packaging businesses. The opportunity to submit a company article was opened to all AICC Associate members in good standing, and nearly 100 companies provided material.

A.G. Stacker

2022: A Year of Investments, Innovation & Recognition at A.G. Stacker

Founded in 1996 by Clarence and Helen Allen, A.G. Stacker is a leader and custom manufacturer of corrugated material handling equipment and technology. A proud American manufacturer, A.G. engineers, fabricates, and assembles all equipment and parts in their Weyers Cave, VA, facility. Equipment offerings are focused on complementing the G3™ RDC stacker, including systems such as the X12™ pitless lift conveyor, the ePX™ pallet inserter, the ball-belt bundle conveyor systems (BCS), and more. When combined with the fully electric eBREAK™ Bundle Breaker and the eZF™ Load former, 2022 became the year A.G. installed multiple full line systems.

2022 EQUIPMENT INNOVATIONS

Automation and digital connectivity were the focus in 2022. The patented and patent-pending Divert & Separate System (DSS), eXT™ stacker front end system, and eTAMP™ servo-driven tampers are newly engineered stacker innovations that allow full automation, order recipe recalls, and eXTreme board and scrap control, up to 20,000 kph!

Unveiled in 2021, A.G.’s fully electric, fully integrated eSERIES equipment line is proving successful in the market, with the fi rst systems installed in early 2022. The new line of equipment boasts digital connectivity, energy savings, and multi-faceted support options, without pits, pneumatics, or hydraulics. Part of the eSERIES line, the newly patented eBREAK™ Bundle Breaker is a game changer with the ability to break bundles in ways that were previously impossible.

“Our new systems are built to master the challenges of today’s corrugated market, with the ability to meet the speed and

automation demands of the future,” states Tim Connell, A.G. Director of Sales.

2022 DIGITAL INNOVATIONS

With the launch of DUO™ digital twin technologies, A.G. became one of the first OEMs to successfully implement digital twins in corrugated manufacturing. The new technology allows A.G. to innovate equipment, collaborate with customers, and train employees/operators, using a risk-free digital environment. In 2022, A.G. engineered its newest DUO™ asset for the eXT™ Stacker Front End system, providing eXTreme board and scrap control at speeds up to 20,000 kph. The customized digital twin systems were featured in the January 2022 issue of Control Design magazine and were also a large factor in A.G. winning the 2022 Innovation in Utilization award from the Shenandoah Valley Technology Council (SVTC).

Launched at CorrWeek 2022, SIMCORRA™ is the newest technology solution at A.G. The innovative software is a full factory simulation, customized to each client’s facility dimensions, equipment layout, and process flow. In SIMCORRA™, converters can create and test custom factory environments through a visual planning and evaluation tool, digitally manufacturing their most productive factory environment for real world application.

“In SIMCORRA™, the possibilities are endless. You can explore simulations custom to your unique operations to discover opportunities and downfalls in your facility, without the guess work. The technology is tailored specifically to the environments found in corrugated and will offer a virtual look into real world problems and/or solutions that would likely occur in a true production environment,” states Joe Wunder, President at A.G.

In early 2022, A.G. opened the doors to its new Digital Innovations Lab in Weyers Cave, VA. The dedicated space allows A.G. to train employees/operators, provide tours and demonstrations, and house their digital technologies.

2022 OPERATIONAL INVESTMENTS

A.G. has recently invested in new equipment and processes to increase manufacturing capacity and operational excellence at its Weyers Cave facility. Th is year the company purchased:

• Multiple CNC machines to assist with parts production, precision machining capabilities, and manufacturing capacity.

• COBOT welder to work alongside production staff for faster, safer welding processes.

• Laser tube cutting machine to increase production throughput and efficiencies.

• A dedicated electrical panel manufacturing space with advanced dust ventilation and tailored lighting, seating, and organization for efficient electrical manufacturing.

“We are incredibly proud of our team and all they accomplished this year. From new patents to new digital twins, new technology to new machining capabilities, we look ahead confident in our ability to deliver on our promise of innovation and service,” concludes Clarence Allen, Owner and Co-founder of A.G.

Please contact the A.G. Sales Team at 540-234-6012 or visit www.agstacker. com for more information.

BOXSCORE January/February 2023 6 EQUIPMENT THE BIG ASSOCIATE ISSUE

Air Conveying Corporation

From Concept to Completion

Founded in 1968 in South Holland, Ill., and now located in Memphis, Tenn., the company provides trim removal systems, including all of the components, stateof-the-art electrical control systems and accessories needed in today’s corrugated box plants, folding carton plants and printing plants.

ACC is recognized as a dedicated partner, providing information and insight into the pros and cons of each type of system to make sure board converters get the best possible system for their budget.

ACC’s motto is to not intentionally stop the paper from moving until it is in the baling chamber. Systems that have multiple moving parts will require maintenance. A trench conveyor or rotary airlocks are examples where if they fail, all of the machines on the line will have to be evacuated by hand. A Draw Th ru or Neutralizing System does

not only work much better to precisely regulate the down pressure in the baler chute, they require no maintenance and if they do fail, all of the trim removal systems can still operate until the problem has been resolved at the convenience of the plant.

Unnecessary maintenance and cleanup jobs are labor costs that can be avoided if the trim system is confi gured properly ahead of time. Labor is also a cost that needs to be factored in when justifying the equipment for the trim removal system. ACC can supply and install all of the equipment needed. We make everything we sell from our own shredder line, belt conveyors and Airveyors, bale transfer and weighing systems, TangentAir® Separators, Low Profi le TangentAir® Separators, the unique Classifier® Filter, Vacuum Transfer Systems, support steel, material handling fans and all of the fittings, elbows and hardware. We can also provide the best briquetters in the world

that are not sensitive to either positive or negative pressure from the fi lter.

ACC is a quality provider to all of the major integrated companies as well as a huge base of independent converters. With about 150 years of combined experience, the company has the resources to handle every phase of a project, from concept through completion, whether it’s a new plant or an existing operation. This includes professional engineering analysis for support steel and foundation design with stamped and certified drawings for permit acceptance. Other support functions include rental equipment, crane and electricians, plumbers and concrete contractors. ACC is also well versed in EPA, OSHA and NFPA related requirements, inspections, certifications and permits.

Mark Bruno Project Sales mbruno@accfi lter.com 901-454-5016

BOXSCORE www.AICCbox.org 7 THE BIG ASSOCIATE ISSUE EQUIPMENT

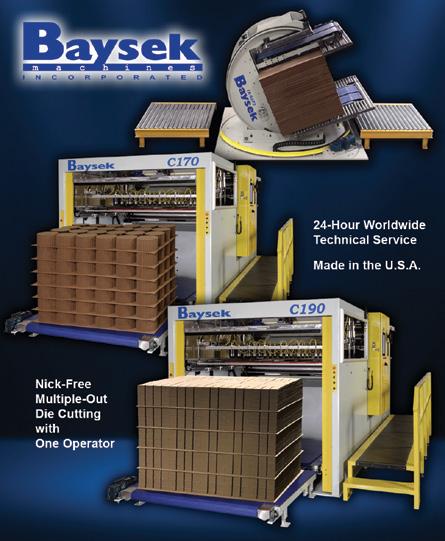

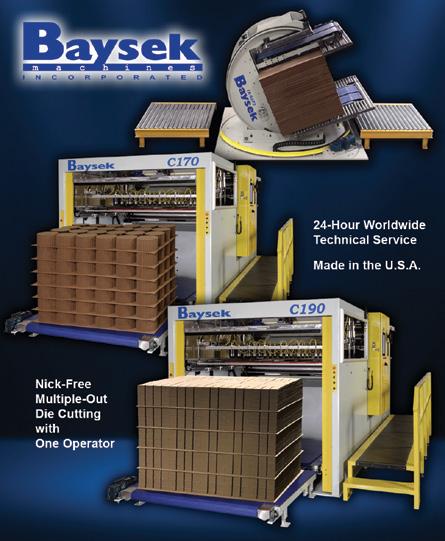

Baysek Machines, Inc.

One Operator Nick-Free Multiple-Out Die Cutting

A prolonged state of world change and a diminished dependable workforce continues to keep decision makers on a quest for the ability to increase converting quality and production while reducing labor. Fortunately, proven technology of the “one operator” Baysek flat die-rotary anvil die cutting method strongly and consistently delivers on both fronts.

ONE OPERATOR C-170 DIE CUTTER

Baysek’s fl agship die cutter model C-170 has a large 1400mm x 1700mm die format that handles micro-flute through double wall corrugated with solid/thin board and single/open face capability and more. Setups and changeovers can be accomplished in as little as 10–15 minutes. Food and pharmaceutical grade Nick-Free multiple-out fi nished products

(up to 60,000 pieces per hour) are produced with little to no human handling. There are no stripping jigs or ancillary stripping devices with the Baysek method as all waste is automatically removed via the pneumatic waste hood. Whether hand stacking the standard load trolley or utilizing the optional conveyor in-feed system and extended out-feed conveyor, Baysek C-170 operation is reduced to a single person and the touch of a computerized screen.

ONE OPERATOR C-190 DIE CUTTER

Maintaining the same small floor footprint but expanding the sheet size to a larger 1400mm x 1900mm format, the NEW Baysek model C-190 die cutter has been field tested for over 3 years with multiple placements and new machine orders. Speed is not compromised on this larger format as the C-190 operates at the same maximum speed of the C-170 at 1800 sheets/ hour. Beautifully straight stacked, step/ stagger stacked, or stacks with tie sheet inserts are nearly effortlessly formed at the command of one person via a new and improved remote access HMI touch screen with job recall capability.

IR-6072 LOAD TURNER/PRE-FEEDER

The I-6072 and IR-6072 load turners require no pit and contain no messy hydraulics. Variable speed vibration allows easy squaring and removal of damaged sheets and dunnage. One operator can flip and/or rotate sheet stacks without the risk of physical injury. Optional multiple conveyor lines from the IR-6072 allow service to multiple Baysek die cutters or other equipment. It is not uncommon for Baysek customers to own and operate multiple Baysek die cutters in one facility.

TRADES & RECONDITIONED EQUIPMENT

Baysek accepts rare trade-ins of older machine models when upgrading to a new Baysek C-170 or C-190 die cutter. Servo and conveyor infeed conversions are also offered in the field upon request.

COMMITMENT TO EXCELLENT CUSTOMER SERVICE

Baysek was built on customer service, caring for machines around the world with 24-hour technical service to keep customers running at maximum potential, and all Baysek equipment is engineered and manufactured in the U.S.A. Additionally, Baysek Machines & Engineering is located in Gloucestershire, United Kingdom, which services all of Europe. Parts are stocked for customer convenience at both Baysek locations.

Baysek’s knowledgeable and friendly team stands ready to assist. Contact Baysek at 715-824-5300 or sales@baysek. com. Livestream machine demonstrations and headquarters tours remain available by appointment.

BOXSCORE January/February 2023 8 EQUIPMENT THE BIG ASSOCIATE ISSUE

EMBA Machinery

Upsize your output with the new 295 QS Ultima™

The latest model in the Ultima™ machine family has been unboxed—our 295 QS Ultima™. It brings flexibility and top-class performance to the larger box segment, and by adding this machine size to the corrugated packaging industry, EMBA Machinery Inc. now offers a machine range that will cover many of its customers’ needs.

Besides the outstanding output, the 295 QS Ultima™ has all the features and benefits recognized in the other Ultima™ machines like quick-set, true non-crush converting technology, four shaft slotter featuring the two sheets converting in one revolution doubling output, up to six printing units with either rubber doctor rolls or closed chamber doctor blade system and naturally, for this size of machine, the well proven heavy duty bottom die-cutter.

The 295 QS Ultima™ features the special DualBox™ innovation in its standard confi guration. Equipped with the extended four shaft Magna XL VSC Slotting enables making all slots of both sheets in the slotting unit at speeds up to 27,000 boxes per hour without any tolerance variations between the boxes. DualBox™ is already available as an option for the 245 QS Ultima™ and without a doubt much appreciated by users around the world. An encouraging

testimony of this is the fact that the majority of the 245 QS Ultima™ machines specified by our customers are with the DualBox™ feature.

The 295 QS Ultima™ includes the latest addition to our Ultima controls platform: CareControl™, a full condition monitoring system containing production data and statistics, full historic machine data for enhanced support, automatic countdown to next maintenance, dynamic on-screen maintenance manuals, plus machine “fi ngerprint”—a regular health check tool for machine function analysis, and building data for real predictive maintenance.

“With our true non-crush converting to increase box strength and allow paper grammage reduction, the 295 QS Ultima™ offers great potential for better sustainability also to the larger box operations in the 114" machine segment,” says George Linn, Director North American Sales, EMBA Machinery Inc. “and with its energy efficiency optimization through fully regenerative servo motion control with power factor correction, it provides much better energy efficiency compared to conventional machines.”

Linn concludes, “It creates great customer value by the fact all sizes are based on the Ultima™ technical platform with the same technologies and benefits and with a high degree of recognition for operation and maintenance.”

EMBA Sales

For sales inquiries contact:

George W. Linn, Sales Manager George.Linn@ embausa.com

+1-770-329-8586

Scott Davidson, Western Region Sales Manager Scott.Davidson@ embausa.com

+1-713-542-7202

General Sales inquiries

usa-sales@embausa.com

For complete information on our range of EMBA and McKinley products and services, visit us at www.embausa.com.

BOXSCORE www.AICCbox.org 9 THE BIG ASSOCIATE ISSUE EQUIPMENT

DualBox

Two-in-one productivity

Revolutionising box production with the EMBA unique solution enabling double production capacity of RSC boxes:

TwinFeed™ + XL Slotter = DualBox™ = 2x Output

TwinFeed™ is an option for the EMBA 245 QS Ultima™, which feeds two identical sheets from 280 mm up to 520 mm in running direction in a single machine cycle.

The extended 4 shaft EMBA Magna XL VSC enables making all slots of both sheets in the slotting unit at speeds up to 30 000 boxes per hour – with no tolerance variations between the boxes. Like having two machines in one.

The DualBox™ innovation combined with the intelligent Ultima™ platform, unique Non-Crush Converting™ and Quick-Set™, makes EMBA 245 QS Ultima™ unbeatable. Converting knowledge into productivity.

To double your output: EMBA 245 QS Ultima™ with DualBox™

TM

www.emba.com Liljedal Communication 2021

Equipment Finance Corporation

ˆLarge Enough to Serve You, Small Enough to Know You Equipment Finance Corporation (EFC) has been providing long-term fi xed rate fi nancing for new and used Packaging machinery since 1993. Unlike commercial banks and bank-owned fi nance companies, our fi nancial terms and structures are set based on the parameters which best serve the needs of each individual borrower, not a regulatory agency allowing us to be a true “Relationship Lender.” We typically provide up to 100% of the total project cost of new and used machinery projects with amortization terms of up to 15 years for new equipment and 5 to 8 years for used equipment.

The corrugated packaging industry is stable and growing. EFC is ready to provide the capital required by our clients to take advantage of their opportunities. Our loan options include early prepayment, annual additional paydown, and loan term adjustment options, allowing our clients to take advantage of the low monthly payments of a long amortization repayment term, while having the options to shorten the loan term later, make additional principal paydown or early prepayment. Therefore, you can have low payments without locking yourself into a long-term commitment.

Investment in upgraded equipment is an ongoing requirement for packaging

operations in order to satisfy customer demands, improve production speed, capacity, & efficiency, and to reduce reliance on unreliable labor resources. The need to acquire more efficient, productive, and less labor-intensive equipment will only increase in the future, as will the cost of machinery. EFC’s 35+ years of industry knowledge and experience allow us to offer qualified clients structured and extended repayment terms plus fi nancial flexibility not available through commercial banks or bank leasing/ fi nance companies.

In addition to loans for newly acquired equipment, we provide debt refi nancing to reduce existing loan payments, fi x floating rate debt, or reduce higher rate debt. With our historical knowledge of the resale value of packaging equipment, our credit requirements are also much more flexible than other institutions. We do not burden clients with blanket asset liens, restrictive loan covenants, and personal guarantees as are typically required by banks and other lenders. You have worked hard for many years to build a strong, successful business. We recognize that and provide lending terms which you deserve based on your fi nancial strength and time in business, not terms determined by federal bank auditors.

While repayment terms and structure flexibility are extremely important, so

is interest cost. Equipment Finance Corporation offers fi xed rates, which are equal to or less than those of commercial banks, bank leasing & fi nance companies, or other fi nancial institutions. Our large fi nancial services volume allows us access to funding at below market rates which we then pass on to our clients in the form of lower rates, but with the attractive long-term, flexible repayment plans which are not available through regulated banks and bank-owned lenders. Most importantly in the current rising rate environment, all of our term fi nancing are fi xed rate loans which ensure that your monthly equipment loan payments will be fi xed for the entire agreed upon loan term.

Contact Ed Gargiulo at 800-469-1082 or 770-714-0662 or ed@efc-fi nance.com. We will be pleased to provide you with a list of your colleagues whom we have had the pleasure to assist in the past. They can advise you about how Equipment Finance has helped them, and can help you, grow your business and improve your bottom line.

Ed Gargiulo Executive Vice President ed@efc-fi nance.com

770-714-0662

BOXSCORE www.AICCbox.org 11 THE BIG ASSOCIATE ISSUE EQUIPMENT

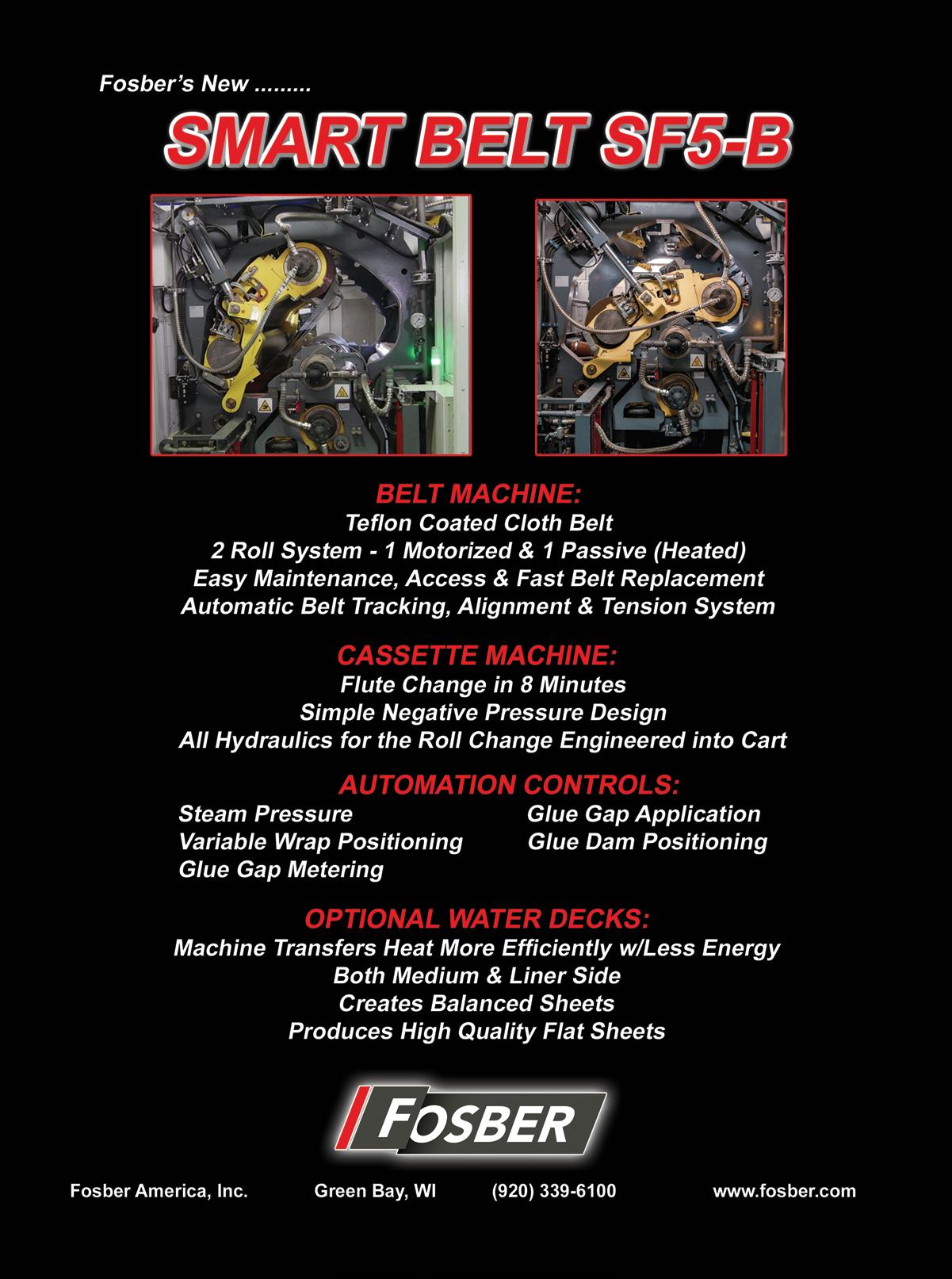

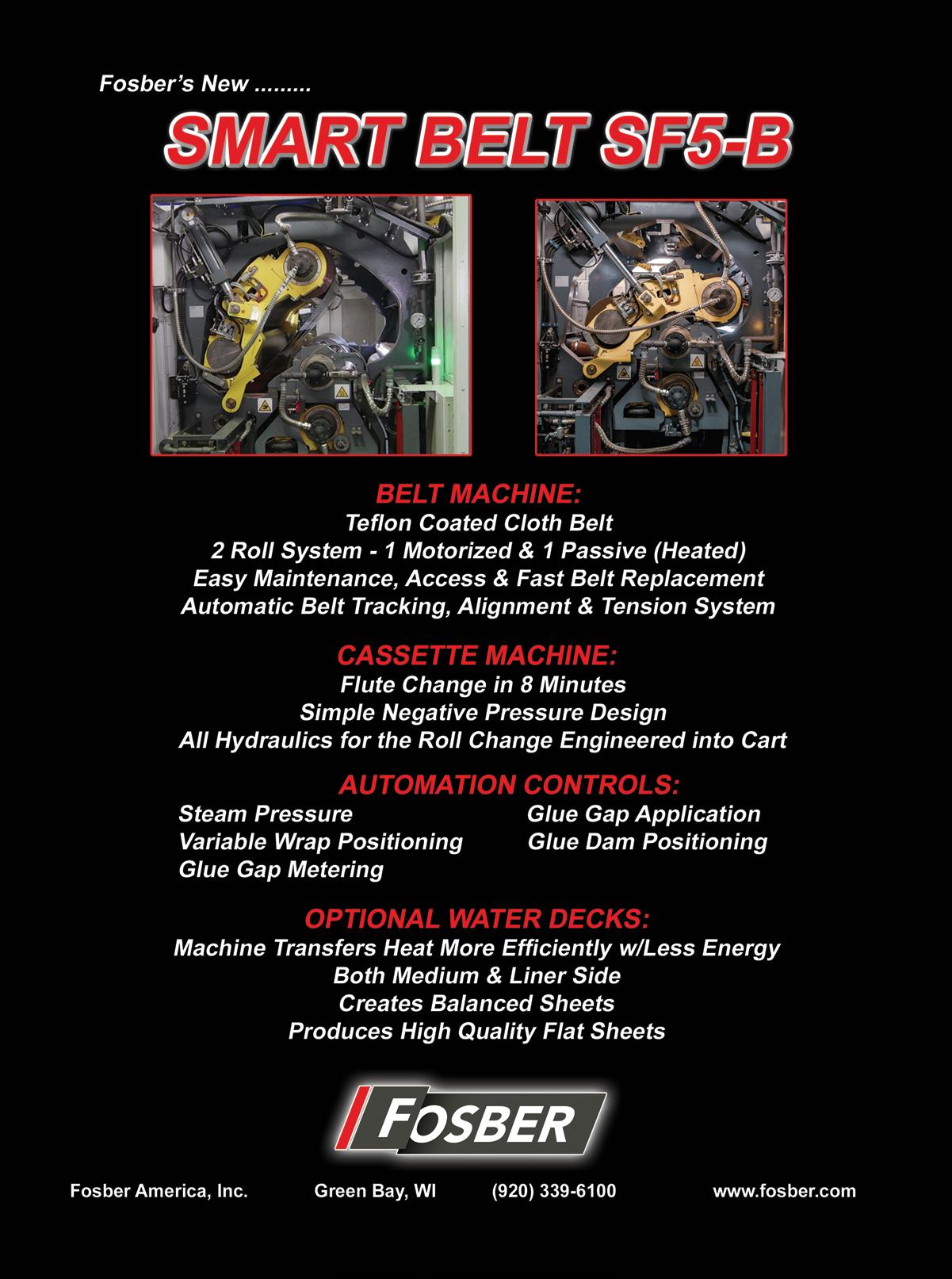

Fosber America, Inc.

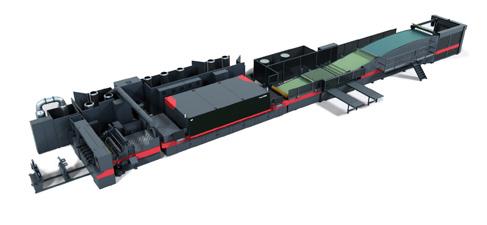

SMART BELT SF5-B

The Smart Belt SF5 SingleFacer is a quick flute change cassette machine, housed in a heavyduty cast-iron frame. The new design merges innovation, reliability, and technology to control belt pressure and tracking. Flute change can be accomplished from either side of the machine in as little as 8 minutes utilizing a motorized cart. All hydraulics for the roll change are engineered into the cart, resulting in a simple and reliable machine. Thanks to the machine design, maintenance operations are fast and very easy with 1 hour to change the pressure belt. The pressure belt is Teflon coated with a cloth base and merges innovation, reliability, and durability. Optional water decks for both the medium and the liner side create a balanced sheet that produces high-quality flat sheets. The water fi lm allows the machine to transfer heat more efficiently with less energy. A negative pressure designed machine allows for accessibility to glue roll and glue dams area.

The Smart Belt SF5 SingleFacer has automatic controls for wrap arm positioning, steam pressure, steam shower, and glue gaps. The machine can also utilize Fosber’s Syncro computer-based corrugator control system. Syncro utilizes intuitive touch screens to display information utilizing machine signals and production information of a complete corrugator. Syncro can provide control, monitoring, information display, data entry, diagnostics, and centralized operation for a complete corrugator or individual machines on the corrugator. The system is modular, flexible,

and can be confi gured to individual plant requirements.

The Smart Belt SF5 Belt machine can also utilize Fosber’s Syncro ProCare, a computer-based maintenance and diagnostic system. The program utilizes a fixed console and tablet to display information for machine procedures and advanced data monitoring. The maintenance intervals are automatically flagged to be completed based on time span (example: weekly), amount of product made (example: lineal feet), or number of sequence occurrences (example: cuts made). The system monitors upcoming and completed maintenance items and illustrates the relevant step-bystep procedures through easy-to-follow videos and instructional photographs. The ProCare system is modular, flexible, expandable, and can be configured to individual plant requirements.

Fosber’s Smart Belt SF5 Belt SingleFacer offers state-of-the-art technology, supported with the best service, parts, and training in the industry. Our

machines have been designed to guarantee maximum flexibility of the production process in terms of performance level and the quality of the fi nished product. Fosber America is committed as the leader in the manufacturing of corrugated machinery and services for North America.

Tony Battaglia Product Line Manager battagliat@fosber.com 920-339-6100

Tony Battaglia Product Line Manager battagliat@fosber.com 920-339-6100

Tony brings more than 20+ years’ experience in the paper industry, including positions as a Machine Operator, Corrugator Supervisor, Plant Superintendent, and Corrugator Superintendent. Tony joined Fosber America in 2015. Fosber customers are sure to benefit from Tony’s technical background and hard work and determination.

BOXSCORE January/February 2023 12 EQUIPMENT THE BIG ASSOCIATE ISSUE

Geo. M. Martin Company

For over 90 years, the Geo. M. Martin Company has provided innovative solutions that set industry standards for quality, high performance, reliability, and service.

PUSHING THE PRODUCTIVITY ENVELOPE

The LBX SCRUBBER™ Stacker is the industry leader in high-performance rotary die cutter stackers. The LBX SCRUBBER™ has created a new performance standard for the corrugated industry, raising the average production from 32 MSF/hour to 80 to 100 MSF/ hour, with top performers reaching 200 to 400 MSF/hour.

Geo. Martin’s patented Scrubber® Technology has transformed the latest generation of rotary die cutter stacker technology. Engineered to maximize the capacity and throughput of all rotary die cutters, the LBX Scrubber™ Stacker combines unmatched sheet control with superior scrap removal to produce perfectly square, virtually scrap-free stacks and bundles at maximum speed. Geo. Martin’s LBX and SBX Scrubber™ Stackers off er a wide range of standard and optional features that allow the stackers to be confi gured to meet the convertors’ specifi c needs. Feature compatibilities allow Geo. Martin stackers to be easily upgraded or reconfi gured for ever-changing market demands.

INNOVATORS OF PRODUCTIVITY, SAFETY, AND EFFICIENCY

Our latest innovations further enhance the capabilities, productivity, safety, and efficiency of the high-performance LBX and SBX stackers.

e SQC System automatically removes sheets from the stacker’s board line at all rated press speeds. SQC can be integrated with the LQC system for “on

the fly” operator side ejection of single or multiple short sheets or samples for safe and easy quality inspection pulls. SQC can also create a gap in the web for a stack or bundle change, thus eliminating “double inking” issues.

e SQX System combines the features of SQC with additional scrap removal capabilities. Placed behind an LBX Scrubber™, SQX further enhances the Scrubber’s already superior scrap removal capabilities to deliver virtually scrap-free boxes (well under 1%) making it ideal for scrap critical operations such as auto packing lines. Virtually all new or existing Geo. Martin stackers can take advantage of the enhanced capabilities of SQX.

e LQC System is excellent for quality conscious converters, especially those serving automatic packing lines. LQC scans the sheets and compares the length to a predetermined tolerance. When out of spec boxes are detected, the feed is interrupted allowing the operator to manually pull the bad sheets or automatically eject sheets when used with the SQC or SQX systems.

SINGLE SOURCE FOR COMPLETE BUNDLE LINES

Geo. M. Martin offers a full range of bundle line components. Quik-Break™

III, the heart of the Geo. Martin bundle line, easily handles typical and unusual die-cut bundles providing fast, efficient, clean breaking of unique shaped, deeply nested bundles, and even multiple bundles of varying heights.

Our application specialists work closely with customers to design and integrate systems that meet their specific needs whether it’s dedicated bundle lines, wide-ranging product mixes, or “batch and stack” configurations that provide maximum versatility.

To learn more about maximizing the throughput of your converting line, visit geomartin.com or call 1-510-652-2200.

Dan D’Angelo

Geo. M. Martin Company

VP Sales

ddangelo@geomartin.com

1-510-652-2200

www.geomartin.com

BOXSCORE January/February 2023 14 EQUIPMENT THE BIG ASSOCIATE ISSUE

GEO. M. Martin Company • 1250 67th Street Emeryville, California 94608, United States 510.652.2200 • Fax 510.652.6447 • email info@geomartin.com The Martin logo and the word Scrubber are Registered Trademarks of the Geo. M. Martin Company. ROTARY DIE CUTTER STACKERS & PERIPHERALS SQC/SQX DIVERTER with optional SCRUBBER® TECHNOLOGY Q High-speed sampling Q Outstanding board control Q Automatic set-up Q Enhanced scrap removal Q LQC - Length Quality Control System LEARN MORE www.geomartin.com AUTOMATED SHEET SAMPLING

Global Boxmachine

More boxes, every minute … Period! Global Boxmachine’s versatile line of quality converting equipment is designed to produce more boxes, every minute!

Global is proud to be Keshenglong Machinery of Guangzhou, China’s exclusive North and South American Distributor of quality Die Cutters and Flexo Folder Gluers as well as the sole North American Distributor of the Zihong Specialty Folder Gluer.

We’re not just a distributor. We have a team behind every machine! Global’s internal service and install team has grown to more than 10 full-time technicians. Our highly qualified service staff offers professional installation of new equipment, 24/7 maintenance, and on-site training.

Looking forward to 2023, Global is very excited to be opening our new Tech Center, a state-of-the-art training demonstration center in Gurnee, IL. Th is facility will house a Shinko Super Alpha high-speed Flexo Folder Gluer, a fully stocked parts warehouse, and a dedicated training space for operators to train both before and after their machine is delivered!

The relationship we have built with both KL and ZH has allowed the Global Team to offer unique sizing and custom builds to suit your team’s needs. KL has dedicated a team who manufacture machines that have not yet been ordered; this means your new equipment will arrive in a matter of months, rather than years. Th is guarantees that the purchase and install happen within the same 12-month period. We also offer a limited number of quick ship machines.

OUR MACHINES K7 Inside Outside Capable Flexo Rotary Die Cutter

The K7 offers inside/outside printing, the ability to print on both sides of the box in

a single pass! Sizes are available from 66" x 110" and up to 66" x 190". With up to 5 colors on the inside and as many as you need on the outside. The K7 can come with an optional KL ST2800 Stacker; an economical full featured solution to your RDC stacker needs.

K1-X Jumbo Flexo

The Jumbo series of KL were designed to withstand the rigorous needs of Jumbo box making. With sizes available from 86" x 210" up to 98" x 230". Th is series is available as a printer/slotter/rotary die cutter or a full line FFG with die cutting and downstacker. The K1-X is capable of running speeds up to 4800 sheets per hour.

KLS Inside Outside Capable Flexo Folder Gluer

The KLS pairs new folding technology with proven flexo capability, catering to today’s boxmaker. Run speeds on the KLS of up to 322 sheets per minute can be expected. An optional tandem die cut cutting system makes the challenges of die cutting on a top print downfold machine a thing of the past!

Shinko Super Alpha High Speed Flexo Folder Gluer

The Super Alpha offers high speeds with labor and energy saving versatility by providing better feeding performance,

tighter print registration, unmatched folding accuracy, quick order change, and high-speed production. Set up in under 2 minutes and run speeds of up to 375 sheets per minute.

ZH Specialty Folder Gluer

The ZH specialty folder gluer comes equipped with vacuum stream feeder, motorized folding rails, HHS 4-gun glue system, servo driven backfold system, auto-lock, 4 & 6 corner gluing capabilities, squaring system, and compression section. Each ZH is equipped with a monitor camera and can come in sizes of up to 110".

Used Equipment

Global will never be far from our roots. Beginning in 1955, Global has grown to one of the largest distributors of both new and used equipment worldwide. While new equipment is a large part of who we are now, we remain true to our roots in used equipment. With our broad reach in the market, we can offer extraordinary value for trade in equipment.

Give us a call to fi nd out how Global can help you make more boxes … every minute! 847-949-5900.

Todd Olson National Sales Director Todd@Boxmachine.com

847-732-5548

BOXSCORE January/February 2023 16 EQUIPMENT THE BIG ASSOCIATE ISSUE

The newly designed Lian Tiee Mini is stronger and faster! The Lian Tiee is now capable of running at 350 sheets per minute while holding tight registration. The redesigned folding section gives precise joint control at every speed.

BCM has the most unique solutions to your storage problems. They can take advantage of space in your plant you previously thought unusable.

The KT series of large format display size die cutters is one of the most flexible die cutters available today. With fast set-ups, the ability to run a variety of material and its one man operation, the KT is truly unique.

Contact Hitek today to learn more!

www.askhitek.com

info@askhitek.com

262.842.1700

The Maxi Box is the only high speed box making machine that fits into a true production environment. If you would like to produce both large and small boxes with runs from 1 box to 10,000 boxes, take a look at the Maxi Box!

The Marumatsu was designed from the ground up to set up fast, run fast and last a lifetime, making it the leader for short or long run production.

Hitek Equipment, Inc.

Hitek meets demands from challenged boxmaking industry

With all the challenges our industry has faced in the past few years, Hitek has noticed a demand for quicker setups, easy maintenance, and shorter runs. Hitek has been leading the industry for over 30 years in just-in-time packaging. The demand for this has never been higher.

All these demands on our customers have resulted in a significant increase in tooling. With this has come an unexpected need for a larger footprint in many plants to store all this new tooling. Hitek introduced BCM Storage Systems to the market in 2008 and has put in systems all over the country. Hitek works with customers to examine their space constraints, tooling quantities, and budget to create a custom solution to our customer’s specific needs for cutting dies and print plates.

The Marumatsu Diamond has led the way for our customers to be incredibly profitable with the latest shifts in the market. Whether you have long or short runs, the Diamond is an excellent solution with the capability of setting up in 2 to 3 minutes and speeds of up to 4,000 sheets per hour. The Marumatsu Diamond can set up and run an order faster than most machines can even set up, all while removing the scrap with no tooling. These advantages and advanced technologies make the Marumatsu Diamond the perfect machine to put the maximum profit in any order.

Lian Tiee Rotary Die Cutters and Flexo Folder Gluers are reliable, accurate, low-maintenance machines that any company can use for years. Lian Tiee uses a top-loading counter ejector, so you no longer need to worry about your print getting smeared or scuffed. The folding accuracy is one of the best in the industry. The machines also come with a

state-of-the-art touch screen where you can save your orders.

The Cavec Maxi Box is the perfect boxmaker for orders of 1 to 10,000 boxes. Many boxmakers have been around for a long time and are not true production machines. The Cavec Maxi Box is different since it uses the latest technology with servo motors, a visual print quality control system, and an auto feeder. The Maxi Box allows you to stock only 1 sheet size and trims down as you produce your order.

The KT Semi-Automatic Platen Die Cutter is the perfect simple machine to run displays on. It is a true one-man operation. The KT uses a chaseless die system which lets it set up in as little as 5 minutes.

The KT can run a variety of different materials, from paper to double-wall corrugated. The KT can be hand-fed for thinner materials or use an automatic feeder when running thicker materials. The KT is the most versatile die cutter on the market.

The CleanFlex print plate washing system is the latest in labor-saving equipment. The CleanFlex can wash and dry a 100" print plate in as little as 2 minutes. The CleanFlex cleans your plates while freeing up operators to perform other tasks.

Contact Hitek at 262-842-1700 or info@ askhitek.com.

Ryan Ashley Sales Consultant

ryan@askhitek.com

262-842-1700

www.askhitek.com

With the shortage of operators, the Mobilator is a crucial advantage with its quick

The BCM Mobilator allows larger cutting dies to be mounted onto a machine by only 1 operator. With the shortage of operators, the Mobilator is a crucial advantage with its quick attachment and easy operation. The Mobilator allows customers to set up their machines faster and safer.

BOXSCORE January/February 2023 18 EQUIPMENT THE BIG ASSOCIATE ISSUE

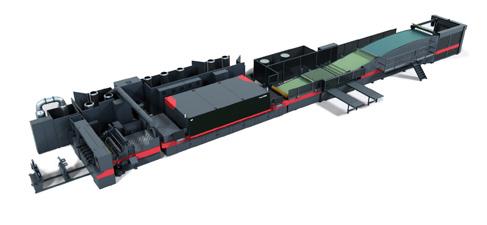

HPHP Corrugated Presses — Making a Sustainable Impact

Facing high demand, brands need to deliver products quickly, both to retail outlets and online customers. To stand out in the crowded online shopping arena, they need to provide exceptional unboxing experiences. And, to meet growing consumer expectations around sustainability, they also have to improve the environmental impact of their products and packaging.

Digital printing of corrugated packaging supports all three elements — fast delivery, unboxing, and sustainability. By allowing a flexible supply chain and enabling high-impact graphics, digital printing enables fast delivery and impactful unboxing. Digital printing can also have a significant impact on packaging sustainability.

SUSTAINABILITY THROUGHOUT THE PACKAGING LIFE CYCLE

HP’s commitment to making a sustainable impact and creating a positive, lasting change for the planet dovetails perfectly with the heightened focus on sustainability. HP PageWide printing technology addresses the full life cycle of a package to deliver sustainable solutions to customers and brands around the globe.

HP views the life cycle of a sustainable package in four main stages: from packaging raw materials, through printing and conversion, to consumption of the packaged products, and lastly to the packaging disposal processes.

HP’s true water-based inks contain no hazardous air pollutants, supporting a safe and comfortable work environment. They are designed to meet worldwide regulatory requirements and address a broad range of health and environmental considerations, such as UL ECOLOGO, EuPIA, USDA, and FDA.

Digitally printed packaging allows printon-demand, thus reducing obsolescence, waste, and the need for extensive warehousing. Digital printing also eliminates the need for harsh chemicals for plate creation.

HP’s printing process itself is designed with sustainability in mind. For example, an automatic cleanup procedure for the printheads uses less water for press cleanup compared to traditional print processes.

Supporting the circular economy and brand demand to meet standard end-of-life processes, boxes printed with HP PageWide inks can be recycled in standard processes and are certified to the PTS standard for recyclability.

HP OFFERS THE INDUSTRY’S BROADEST RANGE OF CORRUGATED PACKAGING PRESSES

HP serves the digitally printed corrugated packaging and display market with the industry’s broadest range of solutions to address any volume, from small box converters to industrial corrugators. With its HP Thermal Inkjet technology, true water-based inks, and support of the full packaging life cycle, HP’s portfolio of presses delivers the speed, quality, and flexibility to produce high volumes of boxes cost-effectively.

HP PAGEWIDE T-SERIES PACKAGING PRESSES

HP PageWide T-series digital packaging presses run papers up to 110-inch (2.8m) wide and are ideal for packaging converters seeking analog-to-digital transformation with high-volume productivity in offset quality for paper-based packaging

applications. The T1195i, T700i, and T470S Presses deliver high efficiency and can maximize business opportunities for single-face lamination, corrugation, and folding carton applications.

HP PAGEWIDE C500 POST-PRINT PRESS

The HP PageWide C500 Press enables box converters to optimize the cost of manufacturing Flexo and Litho boxes and gain operational efficiency with digital post-print at scaled-volume production. With the HP PageWide C500, corrugated converters can deliver consistent off set print quality direct-to-board, coated or uncoated, for a wide range of corrugated packaging applications. Th is innovative single-pass, digital post-print solution helps create new business opportunities and competitive advantages.

To learn more, contact HP sales representative Stephen Shannon.

Stephen Shannon Business & Business Development Manager

Stephen Shannon Business & Business Development Manager

– Americas

HP Corrugated Industrial Packaging Solutions stephen.lee.shannon @hp.com

BOXSCORE www.AICCbox.org 19 THE BIG ASSOCIATE ISSUE EQUIPMENT

Contribute to the Circular Economy

Offer sustainable corrugated packaging solutions with HP PageWide digital technology

Right from creation to final disposal –corrugated boxes today can have a sustainable life cycle.

With HP PageWide corrugated technology, you can contribute to the circular economy while promoting your sustainable offering.

Scan to learn more HP PageWide C500 Press HP PageWide T1195i Press HP PageWide T700i Press HP PageWide T470S Press P e re P e 70S Pr

Inspire Automation

The corrugated packaging market is growing faster than ever, making it more important for corrugated manufacturers to focus on increasing efficiencies in order to stay competitive. Inspire Automation and its two brands, Systec and Automatan, are building a reputation on creating innovative solutions that help manufacturers leverage greater efficiencies.

SYSTEC — STRONG BUILD, AMERICAN PRIDE

The Systec brand has been at the forefront of corrugated manufacturing equipment and industrial conveyor automation systems. Its reputation is built on material handling devices that are produced with a laser-cut and formed steel construction that allows for tighter tolerances, which in turn provides a longer lasting piece of equipment for unbeatable return on investment. The Systec brand includes a broad range of material handling automation solutions for the corrugated and box manufacturing process, supporting everything from the corrugator to the fi nished goods.

AUTOMATAN — ROBOTIC AUTOMATION AND LITHO-LABEL LAMINATORS

The Automatan brand of robotic automation solutions, load-conditioning equipment, and litho-label laminators has been an industry staple for well over two decades. The Automatan brand is one of the fi rst robotic automation solutions for both feeding and bundle handling operations that provides efficiency, speed, and labor savings/ROI.

INSPIRE AUTOMATION —

THE VALUE OF PARTNERSHIP

Board converters have a lot of reasons to love Inspire Automation, the resulting partnership between two industry leaders that have become the Automatan

and Systec brands. By combining the functionality inherent in both companies, Inspire Automation has gained the power to craft custom material handling solutions that target efficiency and return on investment for specific applications. It doesn’t matter whether your operations require laminating, loadconditioning equipment, litho-labeling, or specialty applications, our team at Inspire Automation puts the combined catalogs of both companies at your fingertips, with one important addition—our dedication to service. Our expansive service team of field technicians, engineers, and in-house staff stand ready to support your operations. We offer material handling equipment training, servicing, repair, and replacement, and

long-term service contracts to ensure that your systems are working at maximum efficiency for the ultimate business continuity. With technical resources, after sales support services and the broad material handling automation and robotic automation product portfolio of both the Systec and Automatan brands, Inspire Automation is ready to be your material handling and robotic automation solution provider.

BOXSCORE www.AICCbox.org 21 THE BIG ASSOCIATE ISSUE EQUIPMENT

Tony

tcoats@inspireautomation. com 800-578-1755

Coats Vice President of Sales

JB Machinery

Total Saving, Energy Is Just the Beginning

It’s not breaking news that the price of energy seems to be setting new record highs every day. To maintain a competitive position in the market, boxmakers around the world are looking for ways to address and offset the substantial increase in overhead costs, without a negative impact on the quality of the finished product, or the service provided to their customers.

WHEN YOU TOTAL IT UP

Each JB product has its primary function, the one where it provides its biggest benefit. However, when considering the total combined benefits, such as the reduction or elimination of wasted product and manual labor, the total savings (energy, time, waste, labor, and customer satisfaction) are astounding.

ENERGY IS JUST THE BEGINNING

JB’s AutoDryer™ Control (ADC) focuses on dramatically reducing the unnecessary overconsumption of energy. Adopters of this innovative technology have reported dramatic reductions in energy usage. That savings alone substantially reduces

overhead costs, but the savings are not limited to the cost of energy. ADC also minimizes operator interaction during the initial job setup and virtually eliminates interaction once the job is running, or during repeat orders. Th is allows operators to focus their attention on other important tasks such as quality control or next order makeready.

A habit of operators is to “over-power” the dryers—setting all colors to 100% power or an equal power setting across all colors—to A) ensure drying of the most difficult to dry color and B) minimize their setup times. Certainly 100% will dry all the ink, but depending on the ink, coverage, substrate, machine speed, and other variables, one color may require a substantially lower power setting than another.

Using proven factors, a Global Temperature is assigned based on the JB algorithm and order recipe. Each dryer automatically follows the Global set point to maintain the desired temperature while optimizing power usage for each print station. Global or individual temperatures can be overridden though it’s seldom necessary.

SAVE MORE

ADC offers dramatic saving opportunities to ColorDry® XL3000 users, but JB offers opportunities for boxmakers to automate processes, optimize labor, enhance efficiency, and reduce operating costs.

JB’s AutoWash ™ automatic plate washing system performs pre, during, and post run plate washing of all plates, simultaneously in less than 4 minutes. Manual washing can take 5 to 10 minutes per plate. AutoWash™ reduces plate washing time by 80 to 90 percent, but more importantly eliminates manual washing. The system also includes a 1.5 second print defect (hickey) removal cycle that runs without interrupting production, while rendering no more than 7 to 9 waste sheets.

The InKomand ® precise ink management control continually monitors and automatically makes finite adjustment to ink characteristics (temperature, viscosity, and pH) to maintain perfect printing parameters. By automatically managing the ink, the use of ink and chemical adjusters is greatly reduced. If it becomes necessary, InKomand®, without operator intervention, adds the precise amount of adjuster needed. Automating ink management allows operators to address other production focused functions. It also eliminates dramatic viscosity and pH swings which lead to color variation, inconsistent drying, jams, and sheet wraps, which lead to significant waste of product, material, and time.

Visit

Dave Burgess Sales Director — The Americas

1-203-544-0101

www.jbmachinery.com

BOXSCORE January/February 2023 22 EQUIPMENT THE BIG ASSOCIATE ISSUE

jbmachinery.com to learn more about minimizing your overhead and maximizing your bottom line.

dburgess@jbmachinery.com

JB MACHINERY ® Productivity — Quality — Profitability X ‘Set-and-Forget’ (temperature/pH/viscosity) Eliminating Operator Intervention X Continuous Uninterrupted Printing X Color Variation Minimized/Eliminated X Faster Set-ups & Significant Reduction of Waste JB Machinery Inc., | +1-203-544-0101 | jbmachinery.com Get InKomand of the ink! Stay InKomand of the process!

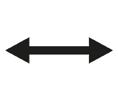

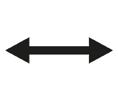

Koenig & Bauer

New Koenig & Bauer Celmacch Acquisition Expands Corrugated Printing and Converting Presence

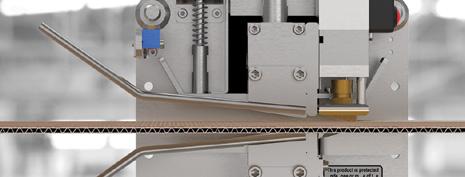

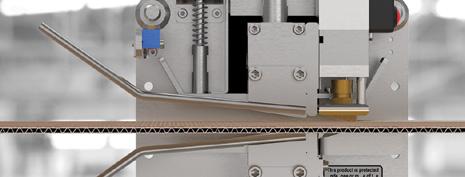

To continue to expand and strengthen its role in the corrugated printing market, Koenig & Bauer acquired Celmacch, a leading Italian manufacturer of highboard line flexo presses and rotary die cutters for the corrugated industry this fall. The new partnership, which is known as Koenig & Bauer Celmacch, expands the Koenig & Bauer Group’s extensive portfolio and will now include Celmacch’s line of well-known equipment including its three die cutters: the ChromaCUT X Pro, ChromaCUT High Tech, and ChromaCUT Smart.

The ChromaCUT X Pro rotary die cutter for corrugated board is Koenig & Bauer Celmacch’s top-of-the-range rotary die cutter. It has been designed for the high-performance rotary production of diecut corrugated products in ultimate flexo post-printing quality. It handles corrugated sheets with a width of up to 110.24-in and a thickness of 0.354-in, running at speeds up to 12,000 sheets per hour due to the machine’s ability to set up while production is running and fast job changes. It features DriveTronic shaftless drives. Operators

can keep track of jobs due to the machine’s press control via a flexible Profibus system and touch screen and focus on jobs due to its integrated error diagnostics and online remote maintenance.

The ChromaCUT High Tech features many advanced technologies, including stereo changeover while the machine is running, automatic anilox changeover, and the most recent zero-defect technology, which ensures the best printing quality and highest levels of productivity. The direct drive technology is the belt-driven vacuum transport system that guarantees extraordinary printing quality and precision. The rotary modules are appropriately distanced from the last printing module in order to ensure the best results. It also features HBL technology with fixed modules and printing from below and Siemens servo drive technology. Owners of the ChromaCUT High Tech enjoy its competitive operating costs and fast return on investment, while operators are pleased with its quick set up and on-the-run changeover, as well as its remote maintenance and faults diagnostic.

Print quality, die cutting precision, and productivity can all be found on the ChromaCUT Smart machine. Th is rotary die cutter with direct drive motors

represents a perfect combination of innovation and functionality that can meet the highest expectations and quality standards. It is equipped with Koenig & Bauer Celmacch’s quality control system. A high-spec bundle vacuum stripping stacker completes the machine, featuring a high dynamic nonstop system to guarantee perfect sheet cleaning and stacking. With Koenig & Bauer’s wide network around the world, this new partnership blends the strength of Koenig & Bauer’s global leadership with its own foothold in the corrugated printing and converting markets and its presses that are widely known for highly productive production of rotary die-cut boxes and printed corrugated sheets along with Celmacch’s fi ne reputation in the corrugated market. Th is collaboration will bring additional corrugated machinery solutions to customers, especially in the North American market.

Tom Fitzgerald Director, Post Press Products tom.fitzgerald@ koenig-bauer.com

502-310-1368

BOXSCORE January/February 2023 24 EQUIPMENT THE BIG ASSOCIATE ISSUE

ChromaCUT High Tech features many advanced technologies, including stereo changeover while the machine is running, automatic anilox changeover, and the most recent zero-defect technology, which ensures the best printing quality and highest levels of productivity.

It’s time to revolutionize The new ChromaCUT X Pro rotary die-cutter pushes what is possible

The ChromaCUT X Pro is designed for high-performance rotary production of die-cut corrugated products with ultimate flexo post-printing quality. You will achieve paramount performance from the latest embedded technology with a brand new operating concept. It is available with the industry's shortest lead time from our factory to your floor. The ChromaCUT X Pro has a maximum production output of 12,000 boards per hour, including setup while running, integrated remote maintenance for the ultimate uptime, and the easiest machine to operate – the ChromaCUT X Pro will increase your profitability.

Call us to set up a custom demonstration.

Koenig & Bauer

(+1) 502 310-1368

tom.fitzgerald@koenig-bauer.com koenig-bauer.com

Kolbus America

Kolbus America is the North American division of Kolbus GmbH, a German manufacturer producing precision engineered flexo rotary die cutters and AutoBox on-demand box making machines, in addition to their award-winning rigid box and luxury packaging machines.

SUCCESS FOR THE RD 115S

2022 proved to be a year of significant importance for Kolbus as they installed several of their newly released and highly anticipated Kolbus RD 115S flexo rotary die cutters.

Th is fully servo machine features advanced technology including image stretch/shrink functionality, plate skewing for fi ne adjustments without opening the machine, a feed unit with repeatable sheet separation with servo driven feed wheels and lift grid, and a rigid cast iron frame die-cutter module.

“The RD 115S is a premium, Germanengineered rotary die cutter with state-of-the-art automation, advanced servo-technology, and user-friendly controls. We are pleased to continue introducing more of these converting machines into the North America market throughout the next year,” said Jeff Dietz, President, Kolbus America.

New England Wooden Ware Packaging and Display, based in Gardner, Massachusetts, celebrated their 185th year of business with an investment in a five-color Kolbus RD 115S, installed in summer 2022. NEWW is the first company on the East Coast with this Kolbus die cutter, offering customers unmatched print quality with efficient, dependable production. The Kolbus RD 115S replaced a 2008 115" Six-Color Hycorr Hygraphics.

“We have been thoroughly impressed with the machine quality. Simply put, the machine is an engineering marvel,” said Steve MacDonald, Production Manager,

NEWW. “From the 4" thick cast-iron side frames, print quality, on-time installation with exceptional training, and after installation support, we couldn’t be more pleased with our investment in the Kolbus RD 115S. It’s allowed us to print jobs immediately, that took us years to perfect.

“Not only was our delivery and installation completed on time, their service team has responded quickly to address our initial questions and concerns with prompt support for this important machine installation,” added MacDonald.

Wasatch Container, based in Salt Lake City, Utah, has also installed a five-color Kolbus RD 115S Flexo Rotary Die Cutter with top print capabilities, as part of an 80,000-square-foot expansion project.

“We’re excited to upgrade our rotary die-cut print capabilities and offer our customers new options from the Kolbus RD 115S,” said Jerry Frisch, Founder. “The ability to print on two sides in a single pass will boost throughput in the plant and increases Wasatch Container’s value to our customers.”

“We look forward to partnering with Wasatch Container on increasing their print capabilities and continuing to grow their already successful corrugated business,” said Dietz.

In Q1 of 2023, CompanyBox of Charlotte, North Carolina, will also be installing a three-color Kolbus RD 115S with inside print capabilities to increase printing capacity and expand their current operations.

EXCELLENCE THROUGHOUT THE COMPANY

The Kolbus America sales team continues to grow. Phil Eads has joined Kolbus as Sr. Sales Manager – Corrugated, bringing more than 30 years

of corrugated industry experience. Eads manages sales for all corporate accounts and assists the Kolbus America sales team in all corrugated projects.

“Phil’s understanding of rotary die cutting and corrugated operations is a great asset to our organization and our customers,” said Dietz.

In addition to expanding their sales team, Kolbus has recently redesigned their website to provide customers with a premium user experience. Convenient features including online parts ordering, 24-hour service requests, enhanced product pages, and dynamic Sales contact forms allow customers to research products and make requests when it’s convenient for them.

“Not only is our team available for 24/7 FREE remote support, but parts orders can be received, processed, and shipped from our US parts warehouse in the same day through our online order system,” said Rebecca Rendon, Marketing Manager, Kolbus America.

Kolbus is focused on supporting the growing RD 115S customer base with a large, local spare parts inventory and through significant investments to grow the Kolbus technical service team in North America.

For more information, contact our sales team at sales@kolbus.com or call 888-705-0051. Visit us online at www.Kolbusamerica.com.

BOXSCORE January/February 2023 26 EQUIPMENT THE BIG ASSOCIATE ISSUE

“From

KOLBUS RD 115S Flexo Rotary Die Cutter

Excellence in Motion

"We have been thoroughly impressed with the machine quality. Simply put – the machine is an engineering marvel. From the 4” thick cast iron side frames, print quality, on-time installation with exceptional training, and after installation support, we couldn’t be more pleased with our investment in the Kolbus RD115S. It’s allowed us to print jobs immediately, that took us years to perfect.”

- Steve MacDonald Production Manager, New England Wooden Ware

- Steve MacDonald Production Manager, New England Wooden Ware

�KOLBUS ' AMERICA INC. KOLBUS America Inc. I T 216 931 5100 sales@kolbus.com I service@kolbus.com I parts@kolbus.com

Learn More I kolbusamerica.com

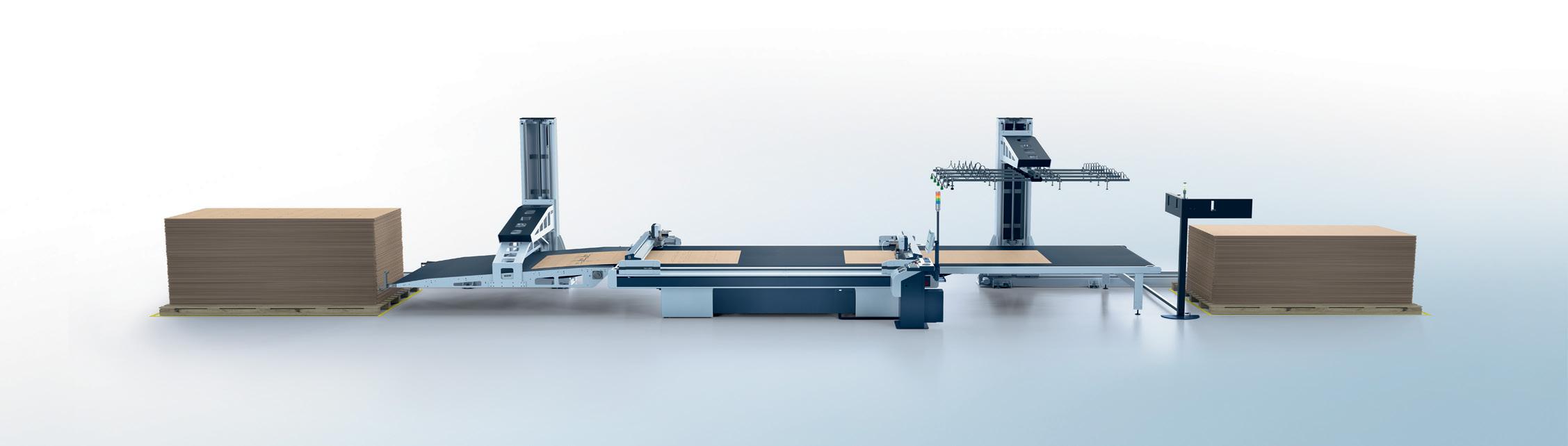

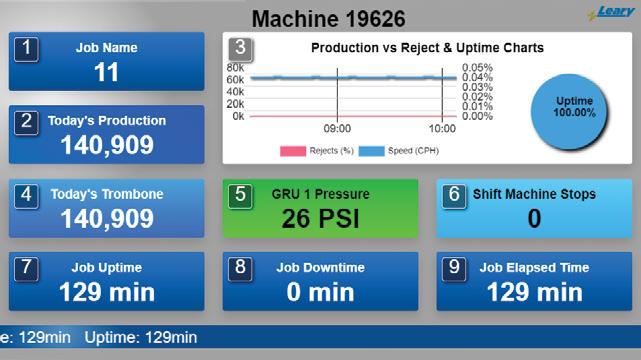

SUN Automation Group

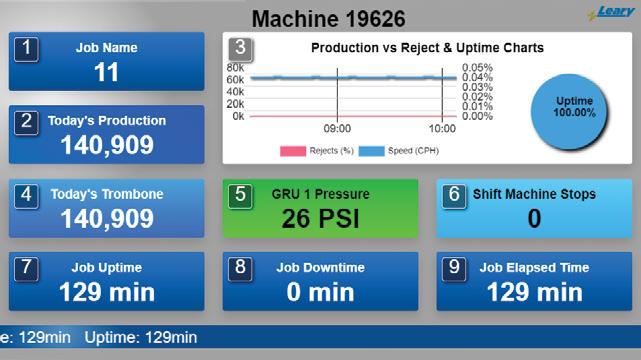

Laying The Foundation for Flexibility with Sun Automation Group®

INDUSTRY PIONEER PAVES

THE WAY FOR SUCCESSFULLY SEIZING OPPORTUNITIES IN 2023

With ever-present supply chain challenges carrying into the new year, converters need to be adaptable to capitalize on opportunities in 2023. Alongside a robust support team and strategic international partnerships, SUN Automation Group® can provide much-needed flexibility through more than just a portfolio of industry-leading equipment. SUN shines light on a diverse and well-rounded suite of converting, feeding and printing solutions, coupled with the parts, service, support and technology needed to ensure your operation is refined and ready for the new year.

“Demand remains high for corrugated packaging that is more dynamic, delivered faster, and at a competitive price,” says Greg Jones, Executive Vice President for SUN Automation Group. “Meeting these demands remains a goal for corrugated converters, and our goal is to provide such converters with the solutions they need.”

As a leading global provider of innovative solutions for the corrugated industry, SUN understands that the equipment you invest in directly impacts the versatility of your operation. That’s why the SUN 625 RDC was engineered to be a high-producing workhorse with low total cost of ownership. This American-made, vertically opening RDC features seamless inside/outside print integration and the ability to run 200 kicks per minute—up to 12,000 sheets per hour.

The next step in optimizing a system of high-performance equipment lies in leveraging smart technology to access detailed data and insights into the machinery.

Learning from a rich history specific to the corrugated industry, SUN developed Helios, the fi rst OEM-agnostic machine learning and IIoT platform by corrugated professionals. Helios has already showcased its effectivity through numerous installations, resulting in improved MSF/ hr to maximize TCO investment due to increased uptime of the machinery.

SUN’s devotion to excellence is showcased through key partnerships, providing converters with a wider range of solutions for increasing production, efficiency, and profitability.

“Part of catering to a variety of corrugated board operations is curating strategic international partnerships with other leaders in the industry,” says Jones. “Th is approach allows us to pinpoint and provide our customers with the solution that is right for them, and we look forward to demonstrating how our expanded knowledge, experience, and suite of solutions can serve the corrugated industry in the new year.”

Since August 2019, SUN Automation Group has been the exclusive representative for Latitude Machinery Corp. (LMC) in North and Central America. LMC is a world-class manufacturer of Rotary Die Cutters, Flexo Folder Gluers, from Mini’s to Jumbos, and other solutions to the corrugated industry. Their equipment maintains an excellent reputation in the marketplace for its reliability and throughput, which is a reflection of the placement of over 100 installations of converting equipment in North America.

While RDCs and FFGs keep up with production, material handling plays an important role in minimizing labor demands and maximizing equipment productivity. Filling the gap for

end-to-end material handling needs from roll stock to shipping dock, SUN serves as the exclusive representative for all PARA Machinery material handling systems sold and serviced in North America, United Kingdom and Ireland. PARA’s extensive product range, with over 15,000 products installed worldwide, includes pre-feeders, palletizers, vertical storage solutions, unit conveyor systems and more.

Complementing the different lines of equipment, SUN also came into agreement of representation in the United States and Canada with Highcon in March 2021. Highcon provides digital finishing machinery that can help improve efficiency and fuel innovation for brands. Corrugated box plants, especially those striving for maximum adaptability, are elevated by the teams behind the equipment. From the largest parts inventory in North America, to 24/7/365 service, SUN proudly provides industry-leading support worldwide.

The key to meeting demand for high-quality corrugated solutions in 2023 lies in operations that have planned, invested, and implemented systems that allow them to capitalize on every opportunity. SUN is here to guide the way with the equipment, technology, and support to set up converters for success.

To learn more about SUN, email info@sunautomation.com.

Editorial Contact:

Simona Georgescu

President

Adduco Communications

O: +1-702-434-0341

M: +1-916-213-5354

simona@adducomm.com

BOXSCORE January/February 2023 28 EQUIPMENT THE BIG ASSOCIATE ISSUE

Machinery and Handling for the Corrugated Board Industry EVERYTHING CORRUGATED UNDER SUN IS THE OFFICIAL REPRESENTATIVE FOR TAIWAN-BASED LATITUDE MACHINERY CORPORATION, ITALY-BASED PARA, AND ISRAEL-BASED HIGHCON 1-410-472-2900 sunautomation.com From Roll Stock to Shipping Dock End-to-End Automated Material Handling Solutions for the Corrugated Industry The PARA spectrum of equipment and automated production line solutions has everything you need to maximize the efficiency of your operation. 15,000+ INSTALLATIONS WORLDWIDE EVERYTHING CORRUGATED UNDER SUN Automation Group® is the exclusive representative of all PARA equipment, parts and service for the United States, Canada, Mexico, United Kingdom and Ireland. PARA’S PRODUCT RANGE INCLUDES: Pre-feeders, Loadformers, Stackers, Pallet Inserters, Roll Stock Storage and Handling, Vertical and Conventional WIP Storage, Full Plant Automated Material Handling. Machinery and Handling for the Corrugated Board Industry powered by

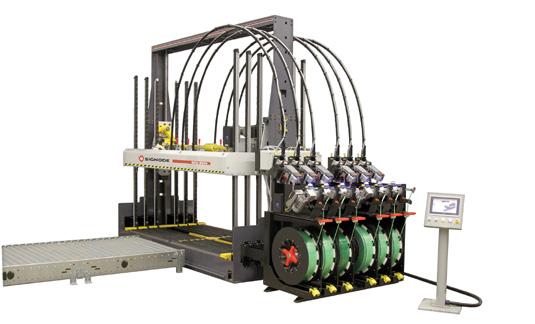

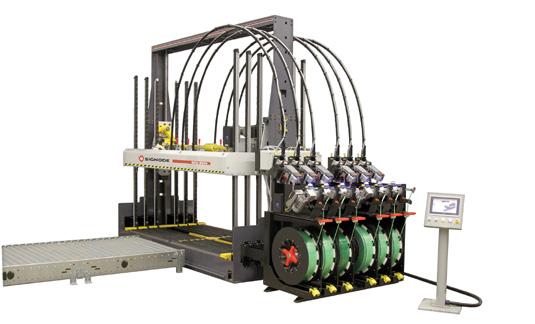

Valco Melton

PrintChek for Diecutters and Flexo/Folder/Gluers

As brand owners become more aware of the use of their logos on secondary packaging and that packaging is prominently used for displays in many retail outlets, the appearance of Flexo- or Digital-printed trays, wrap-around cases, and RSCs is increasingly important.

The ClearVision® division of Valco Melton is introducing PrintChek™—a camera-based inspection system for corrugated sheets. From spots and hickeys to color registration problems, stripes, scratches, and smeared, ghosted, or missing print, PrintChek™ is able to compare each sheet to a standard and highlight defect areas. Along with defect detection, PrintChek™ reads and evaluates barcodes for quality and assesses the geometry of the sheet for size, skew, and trim.

The principle involves line-scan cameras and light modules installed above or

below the sheet to take images of each sheet which are re-assembled for analysis. Minimum defects down to 2.0 mm are visible. Color measurements of a delta-E value of 3 can be resolved for accurate inspection of ink recipes and matching to desired corporate color standards. If there is no viable PDF standard available to compare to, a sample sheet can be run as a golden standard. The system can also “auto-arm” by skipping a select number of setup sheets and averaging a group of sheets for developing a reliable standard.

PrintChek™ uses the familiar ClearVision® BoxChek 7 interface to activate inspection tests, set tolerances, and view images. A defect viewer sorts images, allows them to be zoomed in for closer examination, and highlights the source of the defect. Defect data are stored in SQL format and images are stored for later inspection. A large variety of alarms, outputs, notifications, and even

emails can be generated depending on the defect type to aid in defect identification and removal. Trend alarms and SPC charts track the direction of a problem and allow others in the facility to be alerted via email.

MeasurementChek™ serves as both a local and remote access point for production data, per box details and all of the data are stored on the local device, not the cloud.

Valco Melton is a leading supplier of gluing and inspection systems in the corrugated industry. Since 1952, Valco Melton has been selling and servicing equipment and providing robust solutions for the industry. ClearVision® products are dedicated to using vision for inspecting corrugated production and making removal of defects from the production stream possible.

BOXSCORE January/February 2023 30 EQUIPMENT THE BIG ASSOCIATE ISSUE

Contact our sales team at 513-874-6555 or email info@valcomelton.com.

GLUECHEK PRINTCHEK GAPCHEK GLUE INSPECTION PRINTCHEK GAP INSPECTION

The Total Package/Gluing & Inspection for the Corrugated Industry

Register

A I C C 2 0 2 3 S P R I N G M E E T I N G

2 P L A N T T O U R S 2 P L A N T T O U R S 2 P L A N T T U R S

S u p p l y O n e & S c h w a r z P a r t n e r s P a c k a g i n g

M A N Y G R E A T T O P I C S M A N Y G R E A T T O P I C S M A N Y R E A T T O P I C S

S u s t a i n a b i l i t y M a r k e t i n g

E c o n o m i c & I n d u s t r y O u t l o o k

T e c h n o l o g y & W o r k f o r c e

A t t r a c t i o n

S u p p l i e r I n n o v a t i o n s

S o c i a l M e d i a I n f l u e n c e r s & T h e i r

I n d u s t r y I m p a c t

S u c c e s s i o n P l a n n i n g

Plus, the 9th annual Independents’ Cup Charity Golf Tournament!

2 P L A N T T O U

S 2 P L A N T T O U

S 2 P L N T O U R S

u

S

a

n e

s P a c k a g

n

M A N Y G R E A T T O P I C S M A N Y G R E A T T O P I C S M Y G R E A T O P I C S

u s t a i n a b i l i t y M a

k e t i n g

c

i c & I n d u

O u t l o o k

e A t t r a c t i o n S u p p l i e r I n n o v a t i o n s S o c i a l M e d i a I n f l u e n c e r s & T h e i r I n d u s t r y I m p a c t S u c c e s s i o n P l a n n i n g Plus, the 9th

S u z a n n e S h e l t o n S h e l t o n G r o u p S h e r y l C o n n e l l y F o r d M o t o r C o by March 31 & save! w w w . A I C C b o x . o r g / M e e t i n g A P R I L 2 4 - 2 6 | T R U M P N A T I O N A L D O R A L A P R I L 2 4 - 2 6 | T R U M P N A T I O N A L D O R A L P U M P N A N A L D O A L M I A M I , F L M I A M I , F L I M I F L 2 K E Y N O T E S P E A K E R S 2 K E Y N O T E S P E A K E R S 2 K E Y N T E S P E A K E R S S u z a n n e S h e l t o n S h e l t o n G r o u p S h e r y l C o n n e l l y F o r d M o t o r C o

R

R

S

p p l y O n e &

c h w a r z P

r t

r

i

g

S

r

E

o n o m

s t r y

T e c h n o l o g y & W o r k f o r c

annual Independents’ Cup Charity Golf Tournament!

.

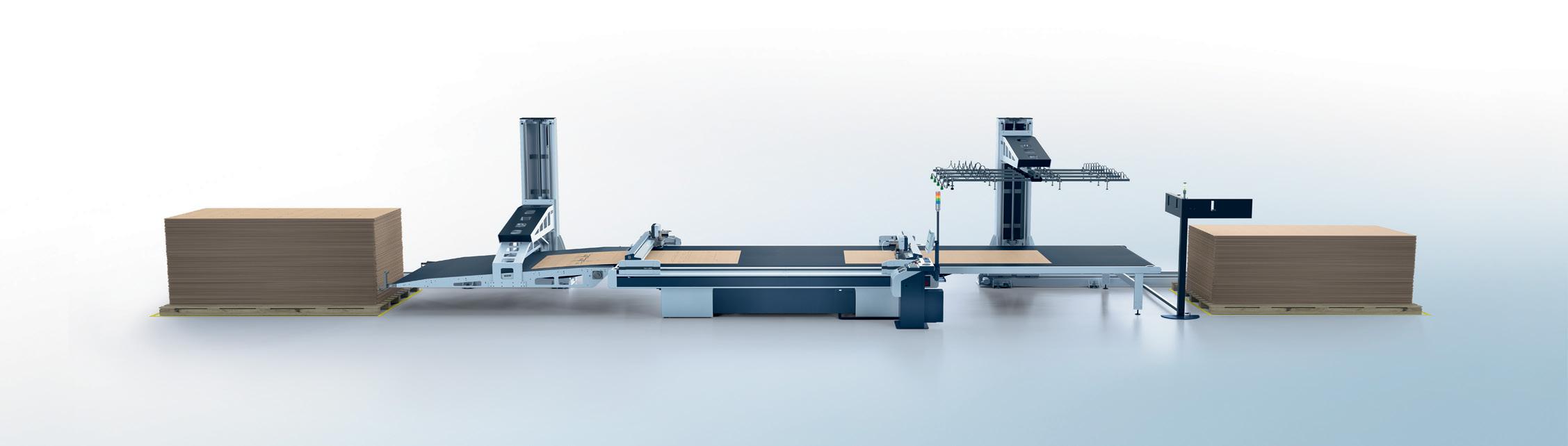

Zünd

Efficiency Beyond the Cut: #LetsTalkWorkflow!

WHO IS ZÜND AND ZUND AMERICA?

Zund America, with HQ in Oak Creek, WI, is the U.S. sister company of Zünd Systemtechnik, the family-owned manufacturer of multifunctional digital cutting systems based in Switzerland. For more than three decades, Zünd has been the world’s leading manufacturer of modular, single and dual-beam, multifunctional, and highly adaptable cutting solutions for applications ranging from custom manufacturing and prototyping to high-volume digital production.

WHAT DOES ZÜND OFFER PACKAGING MANUFACTURERS?

Zünd is known for its multi-capable, highly adaptable, and efficient cutting

solutions for packaging manufacturers looking to expand their digital cutting capabilities in anything from samplemaking to fully automated short-run

BOXSCORE January/February 2023 32 EQUIPMENT THE BIG ASSOCIATE ISSUE

Time to automate? #LetsTalkWorkflow! 1.5 m