AN INDUSTRY UNITED

OFFICERS

Chairman: Matt Davis, Packaging Express, Colorado Springs, Colorado

First Vice Chairman: Gary Brewer, Package Crafters High Point, North Carolina

Vice Chairs: Finn MacDonald, Independent II, Louisville, Kentucky

Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada

Joseph Morelli, Huston Patterson Printers/Lewisburg Printing Co., Decatur, Illinois

Immediate Past Chairwoman: Jana Harris, Harris Packaging/American Carton, Haltom City, Texas

Chairman, Past Chairmen’s Council: Gene Marino, Akers Packaging Service Group, Chicago, Illinois

President: Michael D’Angelo, AICC Headquarters, Alexandria, Virginia

Secretary/General Counsel: David Goch, Webster, Chamberlain & Bean, Washington, D.C.

Administrator, AICC México: Veronica Reyes

DIRECTORS

West: Sahar Mehrabzadeh-Garcia, Bay Cities, Pico Rivera, Califormia

Southwest: Jenise Cox, Harris Packaging/American Carton, Haltom City, Texas

Southeast: Michael Drummond, Packrite, High Point, North Carolina

Midwest: Casey Shaw, Batavia Container Inc. Batavia, Illinois

Great Lakes: Josh Sobel, Jamestown Container Cos. Macedonia, Ohio

Northeast: Stuart Fenkel, McLean Packaging, Pennsauken, New Jersey

AICC México: Sergio Menchaca, EKO Empaques de Cartón S.A. de C.V., Cortazar, Mexico

OVERSEAS DIRECTOR

Kim Nelson, Royal Containers Ltd., Brampton, Ontario, Canada

DIRECTORS AT LARGE

Kevin Ausburn, SMC Packaging Group, Springfield, Missouri

Eric Elgin, Oklahoma Interpack, Muscogee, Oklahoma

Guy Ockerlund, Ox Box, Addison, Illinois

Mike Schaefer, Tavens Packaging & Display Solutions

Bedford Heights, Ohio

Jack Fiterman, Liberty Diversified International, Minneapolis, Minnesota

EMERGING LEADER DELEGATES

John McQueary, CST Systems, Atlanta, Georgia

Jordan Dawson, Harris Packaging, Haltom City, Texas

Evan Clary, National Corrugated Machinery Hunt Valley, Maryland

ASSOCIATE MEMBER DIRECTORS

Chairman: Tim Connell, A.G. Stacker Inc., Weyers Cave, Virginia

Vice Chairman: John Burgess, Pamarco/Absolute Roselle Park, New Jersey

Secretary: Jeff Dietz, Kolbus America Inc., Cleveland, Ohio

Director: Mike Butler, Domtar Packaging, Fort Mill, South Carolina

Immediate Past Chairman, Associate Members: Greg Jones, SUN Automation Group, Glen Arm, Maryland

ADVISORS TO THE CHAIRMAN

Al Hoodwin, Michigan City Paper Box, Michigan City, Indiana

Gene Marino, Akers Packaging Service Group, Chicago, Illinois

Tim Connell, A.G. Stacker Inc., Weyers Cave, Virginia

PUBLICATION STAFF

Publisher: Michael D’Angelo • mdangelo@AICCbox.org

Editor: Virginia Humphrey • vhumphrey@AICCbox.org

EDITORIAL/DESIGN SERVICES

The YGS Group • www.theYGSgroup.com

Vice President, Association Solutions: Craig Lauer

Creative Director: Mike Vucic

Managing Editor: Therese Umerlik

Senior Editor: Sam Hoffmeister

Copy Editor: Steve Kennedy

Art Director: Alex Straughan

Account Manager: Jillian Mengel

SUBMIT EDITORIAL IDEAS, NEWS, AND LETTERS TO: BoxScore@theYGSgroup.com

CONTRIBUTORS

Cindy Huber Director of Conventions and Meetings

Chelsea May, Education and Training Manager

Laura Mihalick, Senior Meeting Manager

Patrick Moore Membership Manager

Taryn Pyle, Director of Training, Education, and Professional Development

Alyce Ryan Membership Marketing Senior Manager

Steve Young, Ambassador-at-Large

ADVERTISING

Taryn Pyle

703-535-1391 • tpyle@AICCbox.org

Patrick Moore

703-535-1394 • pmoore@AICCbox.org

AICC

PO Box 25708

Alexandria, VA 22313

Phone 703-836-2422

Toll-free 877-836-2422 Fax 703-836-2795 www.AICCbox.org

ABOUT AICC

PROVIDING BOXMAKERS WITH THE KNOWLEDGE NEEDED TO THRIVE IN THE PAPER-BASED PACKAGING INDUSTRY SINCE 1974

We are a growing membership association that serves independent corrugated, folding carton, and rigid box manufacturers and suppliers with education and information in print, in person, and online. AICC membership is for the full company, and employees at all locations have access to member benefits. AICC offers free online education to all members to help the individual maximize their potential and the member company maximize its profit.

WHEN YOU INVEST AND ENGAGE, AICC DELIVERS SUCCESS.

Slow Down to Go Fast!

If you are reading this, you must have corrugated dust in your veins. I know I do, and I love this industry. AICC’s 50th Anniversary was a tremendous milestone. It was a real pleasure to connect with so many people I admire in the industry at the celebration in Palm Desert, California, and celebrate the success of our members. As this is my last column, I want to leave you with just a few ideas of what I think it takes to be successful in the box business.

First, in our quest to become safer, faster, and more profitable, I think it is important to adopt this mantra: “Slow down to go fast.” Make sure you take the time to plan and be open to ideas and discussion that will encourage innovative thinking. During these past few years through the COVID-19 pandemic and beyond, the industry has felt the go-go-go. Now that we have all caught our breath a little bit, take the time to strategically plan for the next big push.

The next thought is: Talent is the whole ballgame. Kip Tidwell, retired chairman and CEO of the Container Store for nearly 40 years, came up with the idea that when you hire, follow the 1=3 rule—one great person equals three mediocre people. Surround yourself with people you trust and who have different strengths than you. It helps to be the best, when you hire the best.

The third thought is the quote, “Don’t be upset with the results you didn’t get from the work you didn’t do.” This is a quote our customer experience manager, Robert Roane, has plastered on his wall at our box plant. My golf game and my abs (or lack thereof) would attest that this is a true statement. It takes a lot of work to really make it in the box business, so make sure you are putting in the work.

My fourth thought is inspired by conversations with my friend and colleague Andy Reissmann. I believe what we can do as independents, far better than our competitors, is service the daylights out of your customers. Stay in front of your customer. They need to know that when they deal with an independent, they get the royal treatment. It is personal. We listen. We take feedback. We pay attention to detail. We are empowered to make decisions on the spot to benefit them. It is premium, seamless, reliable, fast, and secure. Our customers need to know that when they do business with an independent boxmaker, their experience is going to be different than what they will receive from the integrated companies. We stay up all night so our customer does not have to.

My final thought is that the Association is in wonderful hands with Mike D’Angelo as president. He is supported by a dedicated staff who works tirelessly on behalf of all members, and we are blessed with an incredible incoming chairman, Gary Brewer. He is a true independent entrepreneur and will do a great job leading us forward.

It has been an honor serving you. Thank you, and here’s to the next 50 years!

Market Insights

EPR and Performance-Based Pricing

BY RYAN FOX

In our previous column titled “Alternative Price Mechanism,” we discussed how “Big Paper”—the group led by International Paper, Packaging Corp. of America, and Smurfit WestRock—is looking for new ways to think about pricing. The current method, tying box prices to the open market price of containerboard, hasn’t helped those producers stay as profitable as they’d like.

A more data-driven approach offers advantages. New extended producer responsibility (EPR) legislation also could play a part in accelerating a change in pricing paradigms.

EPR Overview

EPR laws may shape markets for recovered commodities by setting prices and controlling which companies can process and use the materials. California, Oregon, Colorado, and Maine were the first states to pass EPR laws, and Minnesota, New York, and Tennessee are close behind. Another 12 to 14 states have initiated legislation.

Under EPR, brands such as Pepsi, Conagra, General Mills, and Clorox pay into a producer responsibility organization (PRO). It distributes those funds to help cover the costs of recycling, equipment upgrades, training, education, marketing, and labor. The PRO also becomes the main driver of recycling policy in the state. The current PRO in the U.S., the Circular Action Alliance (CAA), and its members represent over 900 brands.

EPR laws place the cost of recycling onto the brands that generate the products. Brands are essentially “taxed” based on the material in their packaging and how much is used. Commodities are listed by type and accompanied by a fee schedule. Brands must report how much

of a product was sold into a state and pay accordingly.

Self-reporting will be key to the program’s effectiveness. Brands will need to collect data from packaging suppliers that identify the packaging’s material, percentage of recycled content, and weight. Smaller companies with up to $10 million of revenue, which use little packaging, may pay flat fees ($600 on the low end in Oregon, for example) to help cover recycling costs in their states.

Packaging commodities that aren’t easily recycled or lack vibrant aftermarkets have higher fees per unit of weight than those with high recycling rates and aftermarket demand. In some cases, a commodity may be exempt from fees after a threshold recycling rate is reached. This is called eco-modulation, and details are still being discussed by CAA and states.

Performance-Based Pricing

If major brands are incentivized to adopt lighter-weight packaging, demand may rise for producers able to make lightweight containerboard. As more brands adapt to the new fee structure, choosing paper combinations that perform to specifications at the lowest possible weight may become the preferred option.

Amazon has succeeded in lowering many boxes to 26 edge crush test (ECT), but many (if not most) mills lack the capability to run light-basis-weight paper. New-Indy’s Catawba mill and ND Paper’s Biron boast new machines that can produce paper down to 18# or less.

This shift and the potential for higher old corrugated container prices might pivot the industry toward pricing based on performance rather than material

type and weight. For over 40 years, 42# kraft linerboard has been the benchmark for box sales. By contrast, Green Markets has chosen to track prices for the lighter kraft weights used by boxmakers to form 32ECT boxes.

Performance-based pricing could be based on dollar per short span compression test or dollar per box compression test. Either way, the classic approach to pricing— virgin versus recycled board—may change. That could free mills and box producers from their heavy reliance on the industry’s benchmark index. Tying box pricing to linerboard has frustrated mills that want to increase prices to cover rising costs.

Lightweighting and performance-based pricing would put more power in a producer’s hands to make the best box possible at a competitive price. Now that EPR fees are poised to become a consideration, the “value over volume” pricing strategy may find a footing.

Ryan Fox is a corrugated market analyst at Green Markets, a Bloomberg company.

Legislative Report

AICC Signs Letter to President Biden Regarding Federal Regulation

BY ERIC ELGIN

In early July 2024, AICC signed on to a letter to President Joe Biden along with nearly 50 other organizations representing millions of businesses operating in every state and community across the United States, on behalf of the millions they employ in all sectors.

The purpose of the letter was to ask the Biden administration to pause all current rulemaking and not to allow any new rules to take effect until there is a thorough legal review of any agency’s constitutional and statutory authority to regulate in the way it proposes. This is a direct result of the U.S. Supreme Court’s recent decision in Loper Bright Enterprises et al. v. Raimondo, Secretary of Commerce, et al.

The court’s decision alters the legal landscape within which federal agencies operate. Prior to Loper Bright, agencies enjoyed broad judicial deference in what, how, and whom they regulated when the legality and scope of their authority was challenged. The court’s opinion in Loper Bright overruled what had come to be known as the Chevron deference, essentially finding current practice at odds with the instructions for courts’ review of agency actions under the Administrative Procedure Act. We will spare the reader the mundane language of the court’s opinion.

Essentially, the decision, as spelled out by Supreme Court Chief Justice John Roberts, “makes clear that agency interpretation of statutes—like agency interpretations of the Constitution—are not entitled to deference.” In other words, only the courts can decide legal questions. Previously, the deference went to the involved federal agency.

This is a big deal for independents, even if you feel far removed from the goings-on in Washington, D.C. This decision impacts all current and future regulations being pursued by the administration. As of July 1, 2024, over 1,000 major rules are in various stages of review by federal agencies. Just 145 of those rules would have an impact on the U.S. economy of more than $200 million.

Your Association understands the need for federal regulation. Along with the other signing organizations, our hope is that the regulatory process, with this court decision, will become less arbitrary, capricious, and costly. Manufacturing is

interconnected to so many other business functions that regulation in a seemingly remote corner of the economy can have far-reaching consequences—and costs. We believe the Supreme Court’s ruling will bring greater order to the regulatory functions of the government going forward.

Eric Elgin is owner of Oklahoma Interpak and chairman of AICC’s Government Affairs subcommittee. He can be reached at 918-687-1681 or eric@okinterpak.com

The newly designed Lian Tiee Mini is stronger and faster! The Lian Tiee is now capable of running 350 sheets per minute while holding tight registration. The redesigned folding section gives precise joint control at every speed.

BCM has the most unique solutions to your storage problems. They can take advantage of space in your plant you previously thought unusable.

The KT series of large format display size die cutters is one of the most flexible die cutters available today. With fast set-ups, the ability to run a variety of material and its one man operation, the KT is truly unique.

Contact Hitek today to learn more!

www.askhitek.com

info@askhitek.com

262.842.1700

The Maxi Box is the only high speed box making machine that fits into a true production environment. If you would like to produce both large and small boxes with runs from 1 box to 10,000 boxes, take a look at the Maxi Box!

The Marumatsu was designed from the ground up to set up fast, run fast and last a lifetime, making it the leader for short or long run production.

Welcome, AICC’s New Members!

VALMET AUTOMATION

DAVID MADDUX

Corrugated Board, Automation Sales

Manager, NA

3720 Davinci Ct., Suite 300 Norcross, GA 30092 423-309-8277 www.valmet.com

CRESPEL & DEITERS

NORTH AMERICA INC.

ADRIAN BECKETT

President 118 W. Main St. West Dundee, IL 60118 224-762-8644 www.crespeldeitersgroup.com

COMPANY BOX

KYLE DeJESUS

President 13347 S. Point Blvd. Charlotte, NC 28273 980-215-0960

www.companybox.com

PIEDMONT PACKAGING

H.B. WALLACE

President 1141 Foust Ave. High Point, NC 27260 336-822-6422

PRIME PACKAGING SOLUTIONS

TODD LOTZER

President 13101 Eckles Rd., Building 2 Plymouth, MI 48170 734-762-3372 www.primepacksolutions.com

MM BOARD & PAPER NORTH AMERICA

INGER HEINKE

Business Development Director 285 Ridge Rd., Suite 1 Dayton, NJ 08810 475-259-6373 www.mm-boardpaper.com

Members Meeting

Members Engage in the Lone Star State

The AICC Southwest Summit, held June 19–20, 2024, in Arlington, Texas, proved to be an event filled with engagement, education, and networking. The summit kicked off with a reception at Globe Life Field, where attendees enjoyed a baseball game between the Texas Rangers and New York Mets from the comfort of a suite sponsored by BPS AI Software and Haire Group.

The following morning began with plant tours. Nearly 70 attendees visited Harris Packaging in Halstom City, Texas, where they toured the busy and clean sheet plant and were treated to a

Southwest breakfast. After Harris, the group visited the new Greif CorrChoice facility in Dallas. Still in startup mode, the facility will add to Greif’s ability to supply large-format boxes up to triple wall. Then, the group toured Dieco/ Graphics 2 Press before heading to the University of Texas at Arlington (UTA) for lunch and a roster of speakers.

AICC’s Southwest Regional Director Jenise Cox of Harris Packaging and American Carton Co. opened a strong afternoon program featuring esteemed presenters who delivered informative and thought-provoking presentations:

• Steve Jarmon, Stambaugh Ness, delivered a crucial presentation on cybersecurity, highlighting the importance of protecting digital infrastructure. His presentation outlined key strategies for mitigating cyber threats and emphasized the need for comprehensive security protocols.

• Mariam Yousuf, Federal Reserve Bank of Dallas, provided an insightful analysis of the regional economy, offering valuable perspectives on economic trends and their implications. Her discussion focused on

Attendees watch the Texas Rangers take on the New York Mets in September at Globe Life Field in Arlington, Texas, during the AICC Southwest Summit.

Photos courtesy of AICC.

A History of Corrugated Excellence

With almost 40 years of experience, SUN Automation Group® continues to form strategic partnerships and expand its range of trusted solutions, building on its storied past towards an even brighter future.

Members Meeting

current economic indicators, regional economic performance, and future economic projections.

• Caitlin Salaverria, International Corrugated Packaging Foundation, discussed strategies for finding your

future workforce, emphasizing the importance of attracting and retaining talent in the industry. Her presentation highlighted successful approaches to engaging with educational institutions and

promoting careers in packaging to younger generations.

• Ben Dolezal, UTA, highlighted the benefits of student internships at UTA, showcasing how internships can bridge the gap between academic knowledge and practical industry experience. He presented case studies of successful internship programs and their positive impact on students and companies. He then led a tour of the UTA facilities that include packaging education resources within the Department of Art and Art History.

A closing reception was held at the Choctaw Lounge at Texas Live! The reception was sponsored by AG Stacker.

This year’s summit was also supported by Harris Packaging, Koenig & Bauer, Alliance Machine Systems, Fosber, Pacificolor, Baysek, Pamarco, and SUN Automation Group.

AICC extends its gratitude to all participants, presenters, and sponsors for their contributions to making the 2024 Southwest Summit a success.

Learn more about upcoming summits at www.AICCbox.org/calendar

Attendees tour the new packaging education facilities in September at the University of Texas at Arlington during the AICC Southwest Summit.

Attendees tour the new Greif CorrChoice facility in September in Dallas during the AICC Southwest Summit.

Ask Ralph

Caliper: The Least Effective Quality Control Measurement

BY RALPH YOUNG

The original version of this article first appeared in this publication in November 2012. While we have questions on this property frequently, there has been an uptick in activity this year from members.

Often, I am asked to provide the calculation for determining the potential caliper for a given flute profile. Of course, we have to factor into the calculation the caliper variations of the liner and mediums used by the combiner and the degree of variation within any specific liner or medium. And this calculation is not what one may think should be the case, as medium is compressed in the corrugating roll labyrinth and rolls have varying amounts of wear. If you would like to know more about this formula, contact me directly. On the Ask Ralph blog (www.NOW.AICCbox.org/corrugated-2), you will find categories of dialogue that pertain to caliper. There are at least six additional resources on this matter.

Different mediums’ compression strength or resistance between the steel plates in a caliper gauge is dependent on the type of fiber and the papermaking process. We can often look to the differences between hard caliper and soft caliper to begin to evaluate the compressibility factor. These two procedures are highlighted in the Technical Association of the Pulp and Paper Industry (TAPPI) T-551 om-06 and TAPPI T-411 om-05, which describe the difference between the use of hard steel platens and soft synthetic rubber platens.

I am also often asked to comment on the loss of the edge crush test (ECT) because of the reduction of combined board caliper

through converting equipment. There is not a solid answer for this question because the board can be “sev” crushed, yet the memory/rebound/recover rates of different mediums provide some spring-back of the crushed board—but ECT is lost forever. Also heavily impacted is the reduction of flexural rigidity or bending stiffness, the other key component of box compression.

The research study and report that AICC conducted in 2008 and independent studies that I have participated in through my private consulting company show that 25% of ECT can be lost through the crushing of the combined board. You can study this further in the Fibre Box Association and AICC jointly published fourth edition brochure, Understanding Box Performance. Order this from AICC at www.AICCbox.org/store

Once again, we are talking about measurable caliper after the corrugator and the presses. While caliper is a very simple and convenient tool for smaller sheet plants to at least have as a gauge to measure crush, the measurement can be deceiving. While I would not be advocating for a $75,000–$100,000 TAPPI fully conditioned test lab with all of the test equipment to quantify various containerboard and combined board characteristics, it is important to have finished board tested by a facility whenever process changes occur in the manufacturing operation.

Relatively new to the United States— but not other countries and regions—is a rather inexpensive piece of test equipment that can measure the impact of board crush and its impact of medium degradation and loss of ECT. Please contact

me to receive more information on this dynamic stiffness tester technology. While this way of testing combined board was brought forth by the U.S. Department of Agriculture’s Forest Products Lab in the 1950s, it was not until the mid-2000s that a commercial machine was developed elsewhere. In the U.S., we did the research and invented the idea, but it took another to design the commercial apparatus. Above, we mentioned there are differences in mediums’ elasticity, resistance to crushing, and their resurgence in converted combined board. Semichemical neutral sulfite, medium from recovered fibers, and compression-engineered mediums all perform differently to converting nip pressures. Generally, mediums with high amounts of neutral sulfite semichemical pulp and lignin will exhibit lower caliper losses when confronted with the same operating conditions as combined board containing mediums with high amounts of recovered fiber. There I go again being technical. If you want to see some of the accumulated data that supports this article, contact me. Many other pertinent resources are available through AICC and many outside sources. Be careful about caliper: Sustainability issues and newer ultralightweight containerboards will challenge us in this area.

Ralph Young is the principal of Alternative Paper Solutions and is AICC’s technical advisor. Contact Ralph directly about technical issues that impact our industry at askralph@AICCbox.org

Ask Tom

The Right Approach to Supplier Audits

BY TOM WEBER

Icontinue to receive personal inquiries from members surrounding best practices regarding the formal qualification of an on-site audit of both new and existing suppliers—obviously critical to many.

I suspect the questions continue to stem from our members’ continued COVID-19 supply chain interruptions and key material sourcing adjustments that may or may not have been called out during that troubling period. Many changes were made on the fly and not spelled out.

The AICC Supplier Qualification Document I is available via this article (scan the QR code at right to download), and it is one of the most comprehensive I have personally seen over my four decades in packaging leadership. As I operated many facilities that were qualified suppliers of folding cartons to both pharmaceutical and health care clients, I became acutely aware of just how critical it was to be in an unannounced, keyclient-visit-ready mode every day. This was a culture that I spoke to daily to ensure each and every employee understood the critical nature of what we provided to our clients and how important it was to walk the qualified talk every day with suppliers and clients.

The top five foundational elements of my supplier qualification system readiness were usually as follows:

1. A basic ISO 9000/9001 quality system in place, functioning at a high continuous-improvement level.

2. An SQF, cGMP, HACCP, and/or other suitable plan(s) in place to meet clients’ particular needs.

3. A functional accountability plan to make certain all plant and office personnel were trained

and documented in their specific standard operating procedures and responsibilities.

4. An accounting plan that measured the subsequent cost of quality, with assigned leadership.

5. A follow-up mechanism to facilitate engagement and conversations regularly with all employees.

I hope you enjoy reviewing the supplier audit plan provided for your personal use via AICC NOW, and I

look forward to any comments or suggestions you may have to improve this critical and ever-evolving qualification document to help you and your teams develop the most robust supply chain possible.

Tom Weber is president of WeberSource LLC and is AICC’s folding carton and rigid box technical advisor. Contact Tom directly at asktom@AICCbox.org

KOLBUS RD 115S Flexo Rotary Die Cutter

Excellence in Motion

"We have been thoroughly impressed with the machine quality. Simply put – the machine is an engineering marvel. From the 4” thick cast iron side frames, print quality, on-time installation with exceptional training, and after installation support, we couldn’t be more pleased with our investment in the Kolbus RD115S. It’s allowed us to print jobs immediately, that took us years to perfect.”

- S teve MacDonald

Production Manager, New England Wooden Ware

888.705.0051 | sales@kolbus.com parts@kolbus.com | service@kolbus.com

Selling Today

The ‘Mafia’ Offer: One They Can’t Refuse

BY TODD M. ZIELINSKI AND LISA BENSON

The paper packaging industry has witnessed significant growth over the past decade, driven by a shift toward sustainable packaging solutions, the expansion of e-commerce, and consumer demands for convenience. Because the market is so competitive, companies must distinguish themselves from competitors by providing real value to their customers. It becomes challenging because when one company does something different, whether at a lower price or adding a new service, others seem to follow, and you end up in a never-ending chase to stand out. One way to rise above your competitors is by creating a “mafia” offer.

While suggesting you create a mafia offer may sound as if we are asking you to channel your inner gangster and strong-arm prospects into buying from you, that is not the case. A mafia offer, popularized by the “theory of constraints,” is so compelling that it is impossible for customers to refuse and challenging for competitors to duplicate. It’s about creating an irresistible proposition that addresses your customers’ core needs in a way that is significantly better than that of the competition.

Understanding Value

Before creating your mafia offer, you must define the value you bring to customers. This allows you to find gaps within the industry that you can fill with products or services that bring value. Value is the perceived worth of a product or service in the eyes of the customer. It is the balance between the benefits received and the costs incurred by the customer.

Benefits are the positive attributes a customer gains from a product or service such as quality, features, convenience, reliability, and emotional

satisfaction. These benefits can be tangible such as the functional advantages of a product or intangible such as prestige or stress relief.

Costs in this equation are not the same as a unit cost. Total costs must be considered, and understanding your prospective customers’ pains is crucial in identifying these total costs. Prospect pains are the specific problems, frustrations, or unmet needs potential customers experience. These pains contribute to the total cost from the customer’s perspective and can include direct financial losses, operational inefficiencies, or intangible costs such as stress and reputational damage.

To determine the relative value, customers will compare the perceived benefits with the costs of a product or service and then compare that with alternatives available in the market. They will often use the relative value to make purchasing decisions. This is an essential component of the mafia offer.

Crafting a Mafia Offer

Creating a mafia offer involves a strategic approach that ensures your proposition is not just appealing but irresistible to your target customers. A mafia offer is not easily re-created or emulated by your competitors. While price, quality, and custom service are elements of an offer that need to exist, they don’t create vast differentiation between your offer and that of your competition. They are required just to play the game. You will need to think bigger and broader in terms of the offer. This process requires a thorough understanding and, in some cases, creativity.

Before creating a mafia offer, it’s crucial to thoroughly understand your customers’ needs and pain points. Conduct comprehensive market research using surveys, interviews, and customer feedback to gather detailed information about what drives customer decisions in the paper packaging industry. This helps identify

Selling Today

the common pain points customers face such as high costs, lack of customization, slow delivery times, or environmental concerns. Quantify the total cost of these pain points in terms of money, time, and stress to understand their impact. The cost of the pain must be significant enough to urge change.

Next, analyze your competitors’ strengths and weaknesses. This helps you identify areas where competitors fall short and uncover unmet needs in the market. Create a comparison chart to benchmark your offerings against those of your competitors, highlighting the unique features and benefits your products or services offer that competitors do not. This analysis will help you find opportunities to differentiate your offer and provide superior value to your customers.

Once you have a clear understanding of customer needs and competitor offerings, focus on highlighting the unique benefits of your product or service by emphasizing aspects that deliver exceptional value and address customer pain points more effectively than competitors do. These benefits could include innovative features, exceptional customer service, or sustainability initiatives. Develop a clear and concise value proposition statement that communicates these unique benefits, ensuring it is easy to understand and resonates with the customer’s needs and desires. Whenever possible, quantify the value you offer. Use metrics and data to demonstrate cost savings, efficiency gains, or quality improvements.

To make your offer irresistible, include compelling incentives such as discounts, bundled packages, or flexible terms. These incentives enhance the attractiveness of your offer and reduce perceived risk. Additionally, offer guarantees such as satisfaction or lead time to further mitigate customer concerns. Simplify the decision-making process by providing clear, straightforward terms and conditions. Use testimonials and case studies to

build credibility and trust, demonstrating the value and reliability of your offer.

Communicating Your Mafia Offer

Develop targeted marketing messages that speak directly to the specific needs and pain points of different customer segments. Use multiple channels to reach your audience, including social media, email marketing, and direct sales. Creating a sense of urgency is also essential. Offer limited-time promotions or highlight the potential losses of not accepting your offer to encourage prompt decision-making.

Here is an example of how a mafia offer might be structured. Use your own value proposition to create a unique mafia offer.

• Pain Points Identified: Inflexible order quantities, late deliveries, and long lead times.

• Associated Costs: Ordering more than needed increases waste, late deliveries require stock to be held and managed or halt packaging operations, and long lead times get us to market later and potentially impact market share and revenue.

• Unique Value Proposition: The packaging company provides customizable order quantities with no minimum order requirement, shorter lead times, and 98% on-time delivery.

• Mafia Offer Statement Example:

“Switch to custom packaging and receive all your orders in as little as two weeks, even sooner for repeat orders. No minimum order quantities are required, so you can order only what you need when you need it. For qualified customers, if your packaging doesn’t ship and arrive when we say it will, we will credit you back up to X% of your order each day it is late, no questions asked.”

The mafia offer will not be for everybody. Making it exclusive to qualified customers will make people want it

more. You can determine what “qualified” means and how they will learn about it. For example, the mafia offer does not apply to one-time orders or simple jobs. A qualifying program may include specific volumes, minimum annual spend, or a larger percentage of their annual packaging spend. To qualify for this offer, you should require the prospect to meet with a packaging consultant and have them do a short packaging assessment to customize the mafia offer specific to their packaging needs. The mafia offer is not to create more orders but to establish long-term customer relationships and programs.

Your sales and market teams must reposition the messaging differently than selling boxes and packaging supplies. Selling on price is not a mafia offer. A mafia offer is a more consultative approach to selling and focuses on the value and return it delivers to the customer. Sales reps will need to be willing to walk away from a deal or not provide the mafia offer if a prospect or current customer is not qualified. The exclusivity aspect is important as, typically, when you tell someone they can’t have something, they want it even more.

By following these steps, you can craft a mafia offer that not only meets but exceeds the expectations of your customers, making it an offer they simply cannot refuse.

Todd M. Zielinski is managing director and CEO at Athena SWC LLC. He can be reached at 716-250-5547 or tzielinski@athenaswc.com

Lisa Benson is senior marketing content consultant at Athena SWC LLC. She can be reached at lbenson@athenaswc.com

Andragogy

Importance of Prototyping: A Student’s Perspective

BY MAXWELL WILLIAMS

Imagine yourself relaxing on a beach. The warm ocean breeze leaves you feeling a little parched, so you reach into the cooler at your side for a refreshing beverage. As your hand slides into the cooler, you realize your entire day’s worth of ice has become nothing but a lukewarm puddle, leaving your drinks quite the opposite of refreshing. Since you plan to be in the sun all day, you decide to reapply sunscreen to protect your skin. After a couple of sprays, you notice not as much sunscreen is being dispensed as it should. The strange thing is, the relatively new bottle was at least half full the last time you checked. Upon further inspection, you notice the tube that runs into the lotion is not long enough to get to the bottom quarter of the bottle. Great. No beverage and no sunscreen. As a last resort, you pull out a brand-new beach umbrella to protect yourself from the intense sunrays. Now that it’s up, you can finally return to what you started trying to do—relax, breathe in the fresh air, and close your eyes. All of a sudden, the soothing darkness that was the inside of your eyelids turns to a reddish-yellow, semiblinding wall of light trying to invade your tranquility. You reluctantly open your eyes, only to find that your so-called “quality beach umbrella” couldn’t handle a gust of wind and had completely folded inside out, ripping the nylon cloth blocking the beams, and is now rendered useless. How did this carefree day in the sun turn so quickly into a less-than-ideal situation, and could something have been done to prevent these mishaps altogether? This is where prototyping and design come into play, and why it is critical to ensure

the package successfully complements the product, to design with the customer in mind, and to ensure structural integrity is at the forefront of testing and decision-making.

Before I continue, I’d like to introduce myself. My name is Maxwell Williams, and I’m a senior at Clemson University studying packaging science and brand communication. This summer, I have the pleasure of interning for the Packaging School. The reason I opened with a rather irritating situation is to put a spotlight on the way packaging impacts our lives without us noticing—until it’s inconvenient. One of the main principles for packaging is to provide convenience to the user; this is what makes a standard package that much more successful.

That said, we need to know how the initial design will perform and if it’s worth being put into production. The best way to come to these business-building decisions is to prototype. In our cooler example, the failure point of this package system was designing without any thought of the user or enough testing to see that the cooler would not last a full

day at the beach. If it can’t successfully keep drinks cold or ice frozen on a hot, sandy beach, the cooler is not worth your dollar. This is a prime example of a package not performing the task it was designed to accomplish.

An equal, if not greater, mistake was made with the sunscreen packaging—not recognizing that the length of the dispensing tube does not fit the bottle in a way that allows the consumer to use all of the sunscreen. This poses a multitude of problems. For one, some of the sunscreen is left in the container. Not only is this a waste of the time, energy, and money put into the production and transportation of the products, but they also leave a negative impression on the customer. Yes, the consumer could simply unscrew the lid and use the remaining sunscreen without the spray feature. But this plays against the role of convenience through packaging and adds a burden to the consumer that could have simply been caught during a testing and prototyping phase.

The last example from our mishap-filled beach day is more product-related; however, the same principle applies to

SHARE A COKE COZIE PROJECT

packaging. A new beach umbrella should withstand the natural elements in much the same way as a parcel being delivered to your doorstep should withstand the rigors of distribution. Should damage occur to such a degree that the consumer’s interaction with the product is impacted, especially in an environment where the elements encountered are expected, the result (not just an unhappy customer) includes negative environmental effects and a failure to reach sustainability goals. Much like what will happen with the now broken umbrella, a best-case scenario for a damaged-upon-delivery product is an immediate return and possible reorder. This translates into more fossil fuel emissions, more energy usage, more costs for either party, more time focusing on what should have been done the first time, and less satisfaction all around. This is why utilizing the correct packaging

components to ensure structural integrity is essential for a positive customer interaction and for business and environmental sustainability.

The ideas just discussed are, of course, not only related to coolers, sunscreen, and umbrellas, or even limited to the plastic, textile, or metal industries. These concepts are integral to every person or company with a product to sell or an experience to provide. In my personal endeavors, I look to exercise these principles whenever I get the chance, specifically in the annual 48HR REPACK competition. A few of my peers and I spend a weekend completely redesigning a package on the market. To be successful in the competition, we must think about how we can improve upon what already exists; consider the person using and interacting with the package; appeal to our target audience; and most

importantly, build a professional, working package that demonstrates our thought process. A recurring theme during our weekend redesign, no matter how much we love an idea, is a willingness to make a change if our package is not feasible in all aspects of the prototyping phase.

Maxwell Williams is a senior at Clemson University studying packaging science and brand communications. He is also an intern at the Packaging School.

Alli Keigley, who contributed to this article, is production coordinator at the Packaging School. She can be reached at alli@packagingschool.com.

Leadership Legacy

BY SCOTT ELLIS, ED.D.

With the passing of Willie Mays this summer, I am seeing the lasting impact of the man’s actions and attitude. Epithets like hero and legend are fragile these days, when we find joy in erecting and then toppling pedestals. The building of a legacy is not possible for mortals when perfection is the standard. Consistency is the thing; hard-won recovery and recommitment after error or distraction are the stuff of legacy. I am confident to say that this man consistently exemplified tenacity, excellence, joy in effort, and gratitude. Personally, I bore witness to his influence for over six decades.

I am told that I attended games at Seals Stadium in San Francisco circa 1958. I do recall watching practice games between the 1962 New York Yankees and San Francisco Giants when the series was delayed by rain. From my left-field knothole in the fence, I watched Mays work. It was poetry in

motion. Much later, I would learn some of the hardship he had endured leading up to that season, and it made his joy even more impressive. In countless games at Candlestick Park, he led his team by direction and example. He gave the impression that he was playing checkers so when opponents discovered he was playing chess, it was too late. In 1972, he went back to New York, where the Giants were originally based, to close out his career. I remember the first game in which Mays came to the plate in a Mets uniform; the standing ovation must have lasted five minutes.

After playing his final season in 1973, Mays returned to the Giants in various coaching roles. Countless players received guidance from him on baseball and less essential aspects of life. As an ambassador of sorts, he was a fixture at Giants games well into his 80s. He sat in the stands and readily engaged youth of all ages as we approached him to

talk about the game and the memories we shared.

With his passing, just days before the celebration of Negro League history at Rickwood Field in Birmingham, Alabama, where his career began, his impact continues. While he had more mainstream name recognition than the other players celebrated that day, there were many whose exemplary lives and contribution in baseball have left the world better for their efforts. Accordingly, I am contemplating leadership legacy and what can be gleaned from this example of a well-lived life. What I know so far is that perfection is not required. If that were the case, the obstacles and interruptions of life such as poverty, segregation, the draft, injury, or being traded to the Mets would have derailed him. For most of us, our own frailty and distraction knock us down. Legacy may require the tenacity to “fall down seven times, get up eight,” as the Japanese proverb says.

Leadership

The second aspect that seems to be true of legacy building is distilled purpose. I think this purpose is less about what you do and more about how you do it. Mays deployed extraordinary discipline to hone his natural skills and “do” baseball better than anyone else. However, I would argue that this only gave him fertile soil in which to grow a legacy. The way he lived his daily life is what grew his legacy, long after he could hit a curveball. I don’t know if he had a mission statement. I just know that he showed up. He was approachable, gracious, and helpful, even on days when arrogant players failed to listen—even when sticky children wanted to sit in his lap and awestruck fans wanted to share just one more moment. He consistently behaved as if he was glad you stopped by. He was not holding court; he listened and even asked permission before giving advice.

Leaving a legacy is about creating a positive, lasting influence that benefits others even when you are no longer present. Perhaps it would be a good start, then, to take some time to consider the lasting benefit we want to create through consistent behavior, in our professional and personal relationships, and in our communities. With that outcome in mind, we then plan accordingly. For example, if a part of your desired legacy were to create multigenerational success for your family-owned business, what would you need to do and who would you need to be on a regular basis to effect that outcome? Would you need to invest time or resources differently? I know that for myself, the accomplishment of any worthy goal has required that I temporarily override my own selfishness. To do that with any level of consistency, I need to believe the lasting impact is worth the effort.

My takeaway from these Mays musings? I’ll assess progress toward the lasting influence I’d like to have. Then, I will apologize and make course adjustments. I’ll try to take daily and weekly actions to turn my aspiration into something attainable. Oh, and note to self: Don’t get traded to the Mets.

Scott Ellis, Ed.D., delivers training, coaching, and resources that develop the ability to eliminate obstacles and sustain more effective and profitable results. He recently published Dammit: Learning Judgment Through Experience His books and process improvement resources are available at workingwell.bz AICC members enjoy a 20% discount with code AICC21.

Environ, form rly APPI En rgy, off rs manufactur rs nd-to- nd s rvic s to as th k y chall ng s of n rgy cost, carbon, and ffici ncy. Our xp rt advisors consid r all asp cts of your curr nt and futur n rgy usag and sustainability impacts to h lp your organization ff ctiv ly s t, m t, and v n xc d your ffici ncy and sustainability goals.

WHAT WE CAN DO FOR YOU...

Advanc your sustainability and ffici ncy targ ts.

Enhanc your facility's n rgy ffici ncy and r sili ncy.

Start your sustainability journ y with ESG Foundations.

Provid a smart r way to buy, manag , and sav on n rgy.

Form rly APPI En rgy

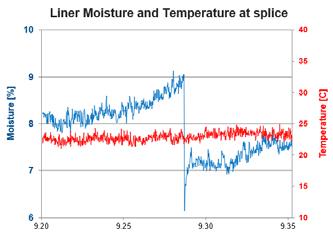

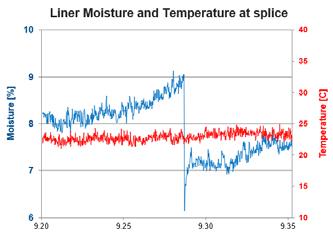

Process Automation for Optimized Performance & Profitability

◆ Quality Master™: Closed-loop Process Control

◆ Warp Wacker™: Laser Warp Correction

◆ Segmented Water Sprayer: Precision Moisture Management

◆ SyncMaster™: Synchronized Splice Control

TOTAL CORRUGATOR CONTROL

Many corrugators in operation today have provided decades of reliable service, but are they performing at their full potential in today’s competitive atmosphere? Copar Solutions’ Total Corrugator Control brings modern automated controls to aging, yet reliable equipment.

Total Corrugator Control isn’t limited to older equipment; it can be installed on virtually any corrugator, new or old. Any machine’s potential is elevated with better precision, performance, reaction time, and communication between individual components, while maximizing efficiency, productivity, and the quality of the finished product.

◆ Thermal Imaging: provides real-time thermal measurement across full web width

◆ Production Displays Network: Large overhead displays with real-time production data

Member Communications

New Faces, Same Great Stories

The AICC podcast, Breaking Down Boxes, is a cornerstone of insightful and engaging content for the independent packaging community. For 27 episodes, hosts Gene Marino of Akers Packaging Service Group and Joe Morelli of Huston Patterson and Lewisburg Printing Co. have led listeners through the inspiring and often personal stories of AICC members. As they step back from their roles, the podcast is set to continue its mission of bringing these compelling narratives to the forefront, this time with a lineup of esteemed guest hosts.

Marino and Morelli have been instrumental in establishing Breaking Down Boxes as a platform for sharing the rich, diverse experiences of independent packaging professionals. Their dedication to highlighting the human side of the industry has resonated with listeners, providing inspiration and practical insights. As they pass the baton, the podcast is poised to enter a new phase.

The podcast will feature a rotating roster of guest hosts, each bringing their unique perspectives and experiences to the table. Among the new voices are Mike Schaefer of Tavens Packaging & Display, Jeff Pallini of Fosber America, Simona Georgescu of Adduco Communications, and George Perreira of Moyy. These guest

hosts are not only seasoned professionals but also passionate advocates for the independent packaging sector.

Schaefer brings a wealth of knowledge. Known for his dry wit, innovative approach, and deep understanding of the industry, he is expected to offer fresh insights and spark thought-provoking discussions.

Pallini will add another layer of depth to the podcast. His technical expertise and strategic vision paired with his sense of humor will bring a comprehensive look at the industry’s evolving landscape while speaking with guests.

Georgescu will contribute her exceptional communication skills and industry acumen. Her background in marketing and communications will be invaluable in exploring the narratives that define the independent packaging world.

Perreira will round out the team of guest hosts. His innovative mindset and commitment to the industry will help dig into the stories of the independent.

Each episode of Breaking Down Boxes will continue to delve into the personal and professional journeys of AICC members. These stories are not only fascinating but also relatable on many levels. They embody the agility, innovation, and resilience that characterizes the independent

packaging community. Breaking Down Boxes remains dedicated to uncovering the lessons and experiences that AICC members have to share.

The transition to guest hosts represents a new chapter for Breaking Down Boxes, one that promises to maintain the high standards set by Marino and Morelli, while introducing new perspectives and ideas. Listeners can look forward to a dynamic and engaging continuation of the podcast.

As AICC members tune in, they can expect to hear stories that resonate with their own experiences and challenges. The independent packaging industry is rich with narratives of perseverance, creativity, and success, and Breaking Down Boxes will continue to be the platform where these stories are told.

While Marino and Morelli’s presence will be missed, the future of Breaking Down Boxes is bright. With a stellar lineup of guest hosts and inspiring guests, the podcast will continue to be a source of inspiration and knowledge for the AICC community, celebrating the independent spirit that defines the industry.

Hear from the guest hosts in the latest episode of Breaking Down Boxes, “Another Door Opens,” on all major podcast platforms or www.AICCbox.org/boxes

AICC Innovation

Member Resources

Together We Go Further

AICC offers online courses, webinars, seminars, conferences, meetings, and other ways to learn from industry experts. You can see all of them at www.AICCbox.org/calendar. There is great value in learning from peers, as well. Peer learning allows you to have conversations with people in the same position about their experiences with the issues you are facing today.

CEO Advisory Groups

The CEO Advisory Groups were formed as a resource for box manufacturing plant CEOs. Members of each group focus on real-world experiences, best practices, and the pitfalls to avoid. You are held accountable and helped by your peers. Connecting with other executives gives you the opportunity to see your company from an outside perspective and discuss changes that can positively impact your bottom line.

AICC Women in Packaging Group

Calling trailblazing women in the packaging space! Join us to unlock your full potential with the AICC Women in Packaging Group. Our vibrant community is dedicated to championing women’s voices, fostering growth, and propelling you toward new heights.

Emerging Leader Program

The Emerging Leader (EL) program is a series of training, networking, and leadership opportunities for young professionals in the paper and packaging industry. With the opportunities and information available in the EL program, young professionals who are ready to commit to their professional development

will have the chance to grow into proven, reliable future leaders in their company and industry.

Leadership Advisory Group

As a leader in an AICC member company, you face challenges many others do not comprehend: the pressure to succeed, to make the right decisions, and to create a positive future for yourself and the company. When involved in AICC programs, many of you can confide in others, share ideas, and receive honest feedback. This group will be even more intentional in meeting its members’ specific needs for connection, education, and discreet communication.

Sales Management Cohort

Production Leadership Advisory Groups

Production Leadership Advisory Groups include operations and production managers from AICC member companies. The group is open to all member companies regardless of location or market niche.

Continuous Improvement Leadership Group

This group is designed to serve managers of all departments. The Continuous Improvement Leadership Group is open to all member companies regardless of location or market niche. You will be part of a group marked by mutual trust, sharing of best practices, and respectful disagreement, for the advancement of each member company’s success and productivity, and for group members’ career development.

Sales management was tough enough prepandemic, but add in the pandemic and supply chain challenges and it has never been harder to be a sales manager than in the market of today. So, AICC has teamed with renowned sales consultant and coach Mark Roberts and bestselling author and sales training facilitator Ed Wallace to deliver AICC’s first Sales Management Cohort professional development program.

Sales Advisory Group

AICC has teamed with Roberts and Wallace to deliver AICC’s first Sales Advisory Group. This program is datadriven, using sales skills and relationship diagnostics that help you assess your selling strengths and skill gaps that could be costing you commissions.

Questions?

Read more at www.AICCbox.org/advisory or contact AICC Director of Education and Talent Development Taryn Pyle at 703-535-1391 or tpyle@AICCbox.org

An award-winning printing line for corrugated

An award-winning modular printing solution Up to 3 flexo units + single pass inkjet + rotary die cutter

digital single-pass module, stacker

The low-capex option to step into single-pass hybrid

With Kento Hybrid’s modular approach, you get the power to decide how and when to scale up your corrugated printing operation, starting with a price tag similar to a multi-pass digital printer.

Flexo printing for solid backgrounds, white ink, special colors

Digital printing for high-quality images and personalization

Rotary die cutting for increased overall equipment efficiency

Visit booth #2770at Super Corr Expo Sep.8-12, Orlando FL

We are corrugated

download a brochure ask for a live demo

Kento Hybrid Explorer: Feeder, 1 flexo unit,

The special articles from Kolbus and SUN Automation Group on pages 32 and 34, respectively, were meant to be part of this year’s Big Associate Issue.

Kolbus

Unlocking Efficiency and Innovation With Kolbus America in 2023 and Beyond

As we start 2024, Kolbus America stands proud as an industry leader in packaging and printing solutions, celebrating a year filled with significant achievements, new product launches, and a strategic relocation.

EMPOWERING BUSINESSES WITH CUTTING-EDGE SOLUTIONS

In 2023, Kolbus America continued to make an impact in the corrugated industry with its innovative products and unwavering commitment to customer satisfaction.

Most recently, at CorrExpo 2023, Kolbus America launched the KOLBUS BX Motion, a heavy-duty, all-in-one short run boxmaker. This innovative solution offers unparalleled versatility and efficiency, allowing businesses to produce customized boxes that meet their specific requirements. With its fully automatic quick setup time, scrap removal, and digital printing capabilities, the BX Motion is set to redefine short-run box manufacturing. The first installation of the machine was at a Canadian packaging company at the end of 2023. The European launch earlier in the year was met with great success, and Kolbus America anticipates similar enthusiasm in the North American market.

Salt Lake City-based Wasatch Container became the only box plant in the region with the extensive capabilities, with the by installing a five-color 115” Kolbus RD 115S flexo rotary die cutter. This installation significantly increases their productivity and adds value to their Intermountain West customers. Wasatch Container, along with other RD 115S customers, incluing CompanyBox, New England Wooden Ware, and Green Bay

El Paso, continue seeing great success from their machines.

STRATEGIC RELOCATION AND TEAM EXPANSION

In May 2023, Kolbus America relocated its headquarters to Huntersville, North Carolina, from its previous location in Cleveland, Ohio. This strategic move aimed at positioning the company for continued growth, increased efficiency, and better customer support. The new facility offers a larger and more modern space to accommodate the growing workforce and ensure outstanding customer service. Its proximity to the airport and prominent customers in the packaging industry, like CompanyBox, streamlines operations and enhances customer accessibility.

This relocation brought with it the hiring of key team members to bolster the company’s financial, technical, and customer service capabilities. A full finance team, experienced service technicians, an office manager, and additional customer service representatives have all joined Kolbus America to provide comprehensive support and excellence in customer service.

A BRIGHT FUTURE AWAITS

As we look ahead to 2024, Kolbus America is poised for an exciting year with additional machine installations of the RD 115S and the BX Motion. The company’s commitment to delivering state-of-the-art solutions, innovation, quality, and customer satisfaction remains unwavering.

In the ever-evolving packaging industry, Kolbus America’s dedication to efficiency and innovation sets the stage for businesses to thrive and succeed. With a talented team, groundbreaking products, and a commitment to excellence, Kolbus America is ready to usher in a new era of possibilities in the world of packaging and printing.

Stay tuned for more exciting developments from Kolbus America as they continue to raise the bar for the corrugated packaging industry. For inquiries, contact our sales team at kolbusamerica. com or call 888-705-0051.

Contact our sales team to learn more sales@kolbus.com 888-705-0051 www.kolbusamerica.com

KraftCoat Opaque White Coating This innovative solution surpasses the conventional mottled white paper by leaps and bounds. Featuring unique attributes essential for printing vivid graphics, KraftCoat ensures unparalleled color fidelity and performance on recycled kraft materials. Its superior coverage lays the perfect foundation for vibrant colors, easily capturing attention, whether applied through digital, lithographic, or flexographic printing methods. Embrace the future of recycled kraft liner enhancements with KraftCoat Opaque White Coating, where brilliance meets clarity and innovation. Contact us to discover more!

SUN Automation Group

CONNECTING THE DOTS IN CORRUGATED

FROM

FEEDING TO CONVERTING, INDUSTRY LEADER OFFERS

COMPREHENSIVE SOLUTIONS

Corrugated production is no simple task; it’s a symphony of moving parts, each requiring unique equipment and expertise. To effectively serve this multifaceted industry, SUN Automation Group provides a comprehensive suite of solutions. By leveraging in-house expertise and a series of strategic partnerships, SUN is able to address the unique challenges of corrugated production and ensure the entire production line functions seamlessly.

“We take great pride in our breadth of capabilities,” says Greg Jones, Executive Vice President of SUN. “By combining our unique capabilities with expanded resources from our partners, we are able to offer individualized solutions that are tailored to our customer’s exact needs.”

Solutions Across the Production Line

SUN Automation Group stands at the forefront of innovation in the corrugated industry, delivering solutions that span feeding, printing, and converting to ensure comprehensive support and efficiency across the entire production line. A prime example of SUN’s versatility and engineering prowess is the SUN625 Rotary Die Cutter (RDC), an American-made, vertically opening machine designed to be a flexible, high-producing powerhouse. Capable of handling feeding, printing, and converting with seamless inside/outside print integration, the SUN625 RDC epitomizes the strength and dynamism of SUN’s offerings, running at an

impressive 200 kicks per minute—up to 12,000 sheets per hour.

Expanded Capabilities

With Strategic Partnerships

To offer truly comprehensive converting solutions to its customers, SUN has facilitated a series of strategic international partnerships with other leaders in the industry. In 2019, SUN partnered with Latitude Machinery Corp (LMC) and has since been the exclusive representative for LMC in North and Central America. LMC is a world-class manufacturer of Rotary Die Cutters, Flexo Folder Gluers, from Minis to Jumbos, and other solutions for the corrugated industry. The company’s equipment maintains an excellent reputation in the marketplace for its reliability and throughput, which is reflected in the placement of over 100 installations of LMC converting equipment in North America.

While RDCs and FFGs keep up with production, material handling plays an important role in minimizing labor demands and maximizing equipment productivity. Filling the gap for endto-end material handling needs, SUN serves as the exclusive representative for PARA Machinery material handling systems sold and serviced in North America, the United Kingdom, and Ireland. PARA’s extensive product range, with over 15,000 products installed worldwide, includes prefeeders, palletizers, RDC stackers, bundle breakers, pallet inserters, vertical storage solutions, paper mill roll transports, and unit conveyor systems.

To enhance digital finishing for packaging, SUN partnered with Highcon in 2021, bringing innovative cutting and creasing solutions to the North American market.

Optimizing With Next-Gen Technology

Learning from a rich history specific to the corrugated industry, SUN developed Helios, the first machine learning and IIoT platform built by corrugated professionals. This OEMagnostic software quantifies and analyzes key elements of the corrugated manufacturing process. Utilizing this data, box plant leaders are able to make more informed decisions around scheduling downtime and ordering parts, thereby mitigating machine failure and improving overall efficiency. Through machine learning, Helios’ predictive algorithms continuously improve, leading to larger and larger cost savings over time.

Complementing this innovative platform, SUN has partnered with ePS, introducing a suite of ERP and MES technology solutions that work to drive operational excellence and efficiency in corrugated plants across the globe.

Connecting the Dots With Continuous Support

A successful operation in the corrugated industry is contingent on the seamless integration and continued maintenance of complex machinery and systems. Understanding that the purchase of machinery is just the beginning, SUN places a strong emphasis on customer service and technical support. The company’s team of highly trained professionals is available around the

clock to assist with any challenges that may arise, ensuring minimal downtime and maintaining the efficiency of the production line.

As SUN Automation Group reflects on the strides made this year, the company is poised to carry this momentum forward into 2024 and beyond. With a firm commitment to innovation and customer satisfaction, SUN plans to continue its expansion of services and technologies, ensuring that customers are equipped with the latest and most efficient tools necessary to thrive in an ever-evolving market.

Greg has spent over 20 years in the manufacturing and packaging sector. In 2002, he began his tenure with ITW as the National Sales Manager for

ITW Shipper Products. He later joined ITW Muller and spent over ten years delivering equipment and material load containment solutions to clients across various sectors. Rigorously trained in the principles of 80/20, Product Line Simplification, Market Rate Demand, and the importance of cross functional team approach, he applied these skills further for a quick rise in the corrugated industry.

In 2012, Greg joined SUN as the North America Sales Manager. Within three years, he was promoted to Director of Sales and Marketing, then Vice President of Global Sales & Aftermarket overseeing the company’s international sales as well as SUN’s Europe and China operations. Backed by extensive experience and leadership, Greg assumed the

role of Executive Vice President at SUN in 2020.

Greg has been an active member of TAPPI since 2012 and currently serves on their Board of Directors. In addition, he is an active member of AICC and serves on their Board of Directors. He also serves on the Board of Directors of SUN Automation Group.

Away from work Greg serves in his church and is involved in the community. Greg is married to Karen and proud father of two children, Sarah and Paul.

Greg Jones Executive Vice President Greg.Jones@

SuperCorr Expo 2024

Central Package & Display: 65 Years and Growing Strong

BY STEVE YOUNG

Three generations of Haglunds (from left): Austin, sales; Jim, chairman; Kristin, communications, sales, and marketing coordinator; and Mike, CEO.

“In order to get somewhere, you have to be somewhere first.” Jim Haglund, chairman of Central Package & Display in Minneapolis, has harnessed this homespun philosophy throughout his 65-year career in the corrugated and paperboard packaging business.

“I always wanted to go where most other companies did not want to go,” he says. “I always wanted to put a toe in the water somewhere else. That’s what has served us to this day.”

Today, Central Package & Display is a global supplier of specialty packaging products, including corrugated, setup boxes, engineered foam, and industrial crating and casing for electronics and sensitive instrumentation. The company also provides fulfillment and

kitting services to its diverse customer base. Central Package employs 140 people working in two shifts out of its 175,000-square-foot facility in Brooklyn Park, a Minneapolis suburb, with another 35,000-square-foot off-site warehouse nearby. Bucking the conventional shipping models of most corrugated sheet plants, Central Package shipped 30% of its products outside of the state of Minnesota in 2023, with 9% going overseas to far-flung destinations such as Malaysia, Costa Rica, Puerto Rico, and Ireland. To support this worldwide reach, Central Package also has a third-party logistics warehouse in Canada, with plans to open a second in Ireland.

Company: Central Package & Display

Established: 1959

Joined AICC: 1996

Phone: 1-800-523-BOXS

Website: www.centralpackage.com

Headquarters: Minneapolis, Minnesota

Chairman: Jim Haglund

Early Years

Jim Haglund’s career started in the sample shop of a Minneapolis printing company. The young Haglund, fresh off the farm in northern Minnesota, assembled dummies of customers’ print jobs and delivered them throughout the city. Besides the benefit of a $250-a-month salary, Haglund says the job gave him the geographic bearings that would serve him well in his sales years ahead. “That’s how I learned Minneapolis,” he says, “because when you’re from out of the area, you have to learn it numerically and alphabetically and not just from local landmarks.”

Playing his strong suit, Haglund sold, first traveling for Federal Package, then going out on his own brokering boxes

Photos courtesy of Central Package & Display.

in the Twin Cities. It was during this time that he came to know Jerry Hinitz, Jack Persten, and Dick Page, who owned Central Container Corp., one of his regular suppliers. Haglund, knowing the company’s potential and learning of Persten’s impending retirement, offered to buy his half of the business. Persten demurred, however, saying he was committed to selling to his other partners. “Then around Christmastime, he called me back,” Haglund remembers. “He says his retirement is based on the company succeeding. ‘I know you can do it and they can’t, so I’m going to sell you my half.’”

The price, Haglund says, was quickly set: The book value of the business was $238,000; half was $119,000. So, Persten and he agreed to $25,000 down with the balance over 11 years at 7% interest. “I says, ‘OK.’ The only problem was, I didn’t have $25,000!”

Buying the Company

It is a familiar memory for any successful entrepreneur: the scramble to raise that initial capital to start the business. For their part, the Haglunds—Jim and Kathy, his wife of 62 years—sold their house and pulled out $15,000 in equity. Haglund borrowed the remaining $10,000 from his brother who did not give him a break. “I remember he charged me 7% interest over seven years,” Haglund says.

Within five years, Haglund owned 100% of the company, buying out Hinitz and Page. At that time, the Minneapolis packaging market was changing dramatically, from an industrial base of brown box users to highly specialized, technology-driven industries such as health care and medical equipment and instrumentation. In fact, that segment of the Minnesota economy grew so prolifically in the 1950s, ’60s, and ’70s that the Twin Cities area became to be known as “Medical Alley.” The growth of companies such as

3M, Medtronic, and Boston Scientific, aided by the University of Minnesota’s well-endowed medical research and development labs, created a demand for a highly specialized base of professional services and material suppliers. Against this backdrop, Haglund saw his early opportunities for investment and growth. “Selling is 50% personality,” he says. “If the customer likes you and you come in with a new product, you’ve got half the sale completed.”

Growing and Acquiring

Looking for those new product offerings for his customers, Haglund acquired two additional companies in the early ’80s: one, a local sheet plant, and the other, a manufacturer of setup boxes, Fisher Paper Box. It was this latter acquisition that Haglund points to as the driver of the company’s new direction. “Because we now had Fisher and they were in the folding carton business and the chipboard business, it led us to other industries,” he says. “It really was the foundation of our company today; it got us into the medical industry.”

Calling on the spectrum of companies making up the Minnesota “medi-sphere,” Haglund and his team then recognized that these customers frequently had other needs such as foam and partitions. “My theory is that once you’re in front of the customer, you say, ‘What do you need? What aren’t you getting?’ And then they would say something, and we’d look into it and find a way to do it. … This included foam, partitions, and inserts—the things that integrateds didn’t want to run.”

To Move or Not to Move?

The company’s growth through the 1980s and early ’90s strained the company’s capacity at its existing location in Minneapolis. Haglund considered the need to improve efficiencies, quality, and service levels, and move to multigraphics. Housed in a century-old building on

Hiawatha Avenue, an original industrial corridor in the city, Central’s operations were hampered by low ceilings, support posts, production on different levels, and small dock doors, to name a few of the obstacles. The choices for Haglund and his team were to add onto the main plant, add onto an existing addition on the plant, move to an existing building, build a new building, or do nothing. The company’s growing volume in the cramped space was a serious drag on its efficiencies. Hence, the last option of “do nothing” was easily ruled out. The limitations of its existing location also made expansion or improvements impractical.

“Never make future investment decisions based on the current economy,” Haglund tells his team. And in the case of Central’s future location, he took his own advice. The economic slump of the early ’90s gave Central a favorable build-to-suit environment of low interest rates, “hungry” contractors, and local communities competing for new businesses.

Brooklyn Park offered an ideal location and attractive incentives. In March 1992, the first spade of dirt for Central Container Corp.’s new location on 85th Avenue North was turned. Haglund marked the event by inviting thenMinnesota Gov. Jesse Ventura to attend the ceremony, and he did. The official ribbon cutting was held in November.

Equipped for Quality and Precision

Central Container Corp.’s new location, now 31 years young, is a showcase of efficiency. (Haglund is meticulous about maintaining the property.) The corrugated side of the business is equipped to support its diverse customer base of medical, high-tech manufacturing, food and beverage, retail distribution, and industrial companies. Three flexo foldergluers from Latitude, TCY, and Ward form the standard box production line, with Eterna, Brausse, Apstar, and TCY rotary die cutters augmenting the mix. In

Member Profile

addition, Central’s specialty folder-gluers from Bobst, J&L, and Brausse, plus a Herrmann Ultrasonic welder, provide the capacity needed for the intricate designs demanded in medical and electronic instrumentation packaging. On the setup box side of the business, Central maintains an Emmeci automatic rigid box line. Haglund follows a simple equipment acquisition guideline. “One thing I have always believed: reinvest, reinvest, reinvest,” he says. “We have always reinvested in equipment to improve quality. The medical industry has pushed us.”

Haglund was an early adopter of converting and finishing equipment from Asia, buying his first TCY flexo foldergluer from Taiwan 40 years ago. It was a decision, he says, made from necessity. “We were kind of pioneers,” he remembers. “Everyone was concerned about how do you get parts from Taiwan? But I could get a part from Taipei as fast as I could from New Jersey because Northwest Airlines had all these daily nonstop flights between Minneapolis and Taipei. When I say it was a gamble, it really wasn’t. I didn’t have a choice. We couldn’t afford anything else at that time.”

New Name and New Image

By the early 2000s, the North American supply chain had taken on a new form—containerization—and the term “container” took on a meaning beyond a simple corrugated, rigid box,

or folding carton. Ocean and rail freight had co-opted “container,” Haglund felt, so he sought a new identity for his company. After some careful consideration and taking what Haglund calls “a poll of one,” Central Container Corp. became Central Package & Display. “I felt ‘container’ had too broad an implication,” Haglund says. “Changing the name to Central Package & Display better described who we were and what we had become.”

Haglund remembers the excitement the change generated among the company’s employees and, significantly, among its customers. “When your customers see you moving forward like that, that’s a really good sign,” he says. “It gives a good feeling that the company will be around for a while.”