OFFICERS

Chairman: Matt Davis, Packaging Express, Colorado Springs, Colorado

First Vice Chairman: Gary Brewer, Package Crafters High Point, North Carolina

Vice Chairs: Finn MacDonald, Independent II, Louisville, Kentucky

Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada

Joseph Morelli, Huston Patterson Printers/Lewisburg Printing Co., Decatur, Illinois

Immediate Past Chairwoman: Jana Harris, Harris Packaging/American Carton, Haltom City, Texas

Chairman, Past Chairmen’s Council: Gene Marino, Akers Packaging Service Group, Chicago, Illinois

President: Michael D’Angelo, AICC Headquarters, Alexandria, Virginia

Secretary/General Counsel: David Goch, Webster, Chamberlain & Bean, Washington, D.C.

Administrator, AICC México: Veronica Reyes

DIRECTORS

West: Sahar Mehrabzadeh-Garcia, Bay Cities, Pico Rivera, Califormia

Southwest: Jenise Cox, Harris Packaging/American Carton, Haltom City, Texas

Southeast: Michael Drummond, Packrite, High Point, North Carolina

Midwest: Casey Shaw, Batavia Container Inc. Batavia, Illinois

Great Lakes: Josh Sobel, Jamestown Container Cos. Macedonia, Ohio

Northeast: Stuart Fenkel, McLean Packaging, Pennsauken, New Jersey

AICC México: Sergio Menchaca, EKO Empaques de Cartón S.A. de C.V., Cortazar, Mexico

OVERSEAS DIRECTOR

Kim Nelson, Royal Containers Ltd., Brampton, Ontario, Canada

DIRECTORS AT LARGE

Kevin Ausburn, SMC Packaging Group, Springfield, Missouri

Eric Elgin, Oklahoma Interpack, Muscogee, Oklahoma

Guy Ockerlund, Ox Box, Addison, Illinois

Mike Schaefer, Tavens Packaging & Display Solutions

Bedford Heights, Ohio

Ben DeSollar, Sumter Packaging, Sumter, South Carolina

Jack Fiterman, Liberty Diversified International Minneapolis, Minnesota

EMERGING LEADER DELEGATES

John McQueary, CST Systems, Atlanta, Georgia

Jordan Dawson, Harris Packaging, Haltom City, Texas

Evan Clary, National Corrugated Machinery, Hunt Valley, Maryland

ASSOCIATE MEMBER DIRECTORS

Chairman: Tim Connell, A.G. Stacker Inc., Weyers Cave, Virginia

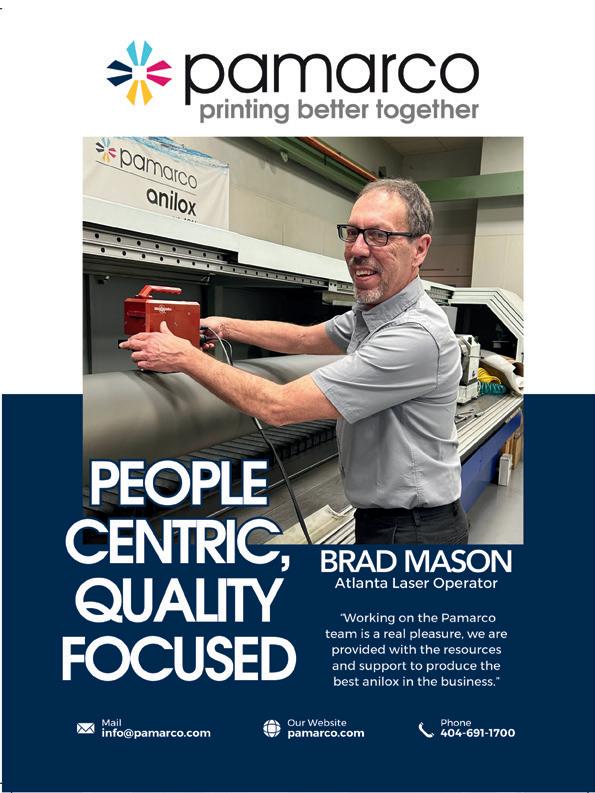

Vice Chairman: John Burgess, Pamarco/Absolute, Roselle Park, New Jersey

Secretary: Jeff Dietz, Kolbus America Inc.

Cleveland, Ohio

Director: Mike Butler, Domtar Packaging, Fort Mill, South Carolina

Immediate Past Chairman, Associate Members: Greg Jones, SUN Automation Group, Glen Arm, Maryland

ADVISORS TO THE CHAIRMAN

Al Hoodwin, Michigan City Paper Box

Michigan City, Indiana

Gene Marino, Akers Packaging Service Group, Chicago, Illinois

Tim Connell, A.G. Stacker Inc., Weyers Cave, Virginia

PUBLICATION STAFF

Publisher: Michael D’Angelo • mdangelo@AICCbox.org

Editor: Virginia Humphrey • vhumphrey@AICCbox.org

EDITORIAL/DESIGN SERVICES

The YGS Group • www.theYGSgroup.com

Vice President, Association Solutions: Craig Lauer

Creative Director: Mike Vucic

Managing Editor: Therese Umerlik

Senior Editor: Sam Hoffmeister

Copy Editor: Steve Kennedy

Art Director: Alex Straughan

Account Manager: Frankie Singleton

SUBMIT EDITORIAL IDEAS, NEWS, AND LETTERS TO: BoxScore@theYGSgroup.com

CONTRIBUTORS

Cindy Huber Director of Conventions and Meetings

Chelsea May, Education and Training Manager

Laura Mihalick, Senior Meeting Manager

Patrick Moore Membership Services Manager

Taryn Pyle, Director of Training, Education and Professional Development

Alyce Ryan Marketing Manager

Steve Young, Ambassador-at-Large

ADVERTISING

Taryn Pyle

703-535-1391 • tpyle@AICCbox.org

Patrick Moore

703-535-1394 • pmoore@AICCbox.org

AICC

PO Box 25708

Alexandria, VA 22313

Phone 703-836-2422

Toll-free 877-836-2422 Fax 703-836-2795 www.AICCbox.org

PROVIDING BOXMAKERS WITH THE KNOWLEDGE NEEDED TO THRIVE IN THE PAPER-BASED PACKAGING INDUSTRY SINCE 1974

We are a growing membership association that serves independent corrugated, folding carton, and rigid box manufacturers and suppliers with education and information in print, in person, and online. AICC membership is for the full company, and employees at all locations have access to member benefits. AICC offers free online education to all members to help the individual maximize their potential and the member company maximize its profit.

WHEN YOU INVEST AND ENGAGE, AICC DELIVERS SUCCESS.

Ionce heard that when you are the leader of a company, you are like a thermostat. You control the temperature in the room. People are watching and feeding off your behavior.

I truly believe the key to effective leadership and success isn’t just crunching numbers or making strategic decisions; it’s also understanding people and their emotions. It is often overlooked, but it’s a critical skill for any leader. Mastering emotional intelligence is a game changer for our independent box plants, enabling us to set the tone with our employees and customers! It’s the cornerstone of effective leadership and teamwork. The independent advantage is how we treat people.

Like any good sports coach, you need to be relatable and make everyone on your team feel important. It all starts with trust. It is much easier to be agile as a company when your whole team has buy-in. You have to find out what motivates your team. At our plants, you are not just a number. I would encourage you all to spend a little extra time and think about what more we can do to create an environment in which employees feel valued, supported, and motivated. I think, as independents, we can do that better than anybody.

Furthermore, I believe emotional intelligence is a competitive advantage for us in the marketplace. It is an invaluable asset for independents as it enables us to understand and respond effectively to the emotions and needs of our customers. It includes empathy, effective communication, and adaptability that can create positive experiences and lasting impressions on our customers. I believe the companies that are able to embrace this will be better prepared to adapt to change and thrive in today’s business environment.

Emotional intelligence is key to my leadership style. I am a big believer in taking care of the internal and external customers in order to be successful. At Packaging Express, we fight hard to take care of both! No matter the technological innovations or new artificial intelligence tools, at the end of the day, our success is driven by people and our relationships. That is our competi tive advantage!

I will leave you with this quote from Theodore Roosevelt: “No one cares how much you know, until they know how much you care.”

Corrugated box shipments, often cited as a leading indicator of economic activity, could be offering some good news for box producers. The Association of American Railroads (AAR) tracks pulp and paper products (P&PP) as a category of rail originations. This may be the most current indicator of box demand, since roughly 60% of containerboard is shipped by rail. AAR aggregates and reports weekly data from North American rail operators. Each month, Green Markets gathers the figures to assess changes in P&PP originations. CSX, the largest volume shipper of P&PP, saw a 6.9% decrease in shipments in the segment in 2023 (Figure 1). For the corrugated packaging industry, shipments fell 5.1%.

Source: CSX

Source: Fibre Box Association

Source: Association of

Shipment originations, along with our assessments of sentiment among box producers, help us better understand trends in industry demand. For example, it would be odd for box demand to spike 5% without a corresponding increase in rail shipments.

In 2023, cumulative box shipments bottomed out with April’s 14% plunge (Figure 2). After Week 18, they only got better. Yet there was an 18-week lag before originations reflected the trend. P&PP rail improvements became visible starting in Week 36, when originations were down 5.8% and started climbing to finish the year at minus 3.3%.

The lag is likely due to how quickly box shipments slumped relative to a year earlier. Shipments slid nearly 10% through April, a sign that some box plants probably held more paper than desired and needed to draw down inventory. Starting in Week 13, average monthly rail shipments began to drop about 7%. In weeks 27–30, they fell 8.5% from the first four weeks of the year.

In the first quarter of 2024, P&PP rail shipments continued to trail the 2023 period’s before picking up heading into the second quarter (Figure 3). Combined with other economic reports, there’s reason to think box shipments may be rebounding, as well. The March Manufacturing Purchasing Managers’ Index came in at 50.3, and the New Order Index was at 51.4, while corrugated boxes showed up among commodities that were increasing in price. Together, the data point to a potential resumption of industry growth after 16 months of contraction.

Ryan Fox is a corrugated market analyst at Green Markets, a Bloomberg company.

AICC, through its membership in the Small Business Legislative Council, monitors legislative developments in Washington, D.C., and from time to time, there’s something to report to you, our members. First on the list is a move in the U.S. House of Representatives and U.S. Senate to delay the implementation of the Corporate Transparency Act (CTA). I wrote about the CTA in September (Legislative Report, BoxScore, September/ October 2023). In that article, I wrote, quoting the American Bar Association, that “at its core, the CTA is a mechanism to deal with issues related to ‘dirty money’—i.e., guarding against money laundering, terrorism financing, and other forms of illegal financing—as well as the general lack of beneficial owner (i.e., ‘true owner’) information with respect to many domestic entity structures ... The CTA was born of the view that the availability of beneficial ownership information is a crucial tool in the fight against tax evasion, money laundering, corruption, terrorist financing, and other financial crimes.”

I dare say that if anyone in our industry were to be found guilty of violating the law, it’s highly unlikely the crimes listed here would be among them. The law was slated to go into effect on January 1, 2024, but the U.S. Court of Appeals for the Northern District of Alabama on March 5, 2024, ruled in a lawsuit brought by the National Small Business Association (NSBA; National Small Business Association v. Yellen) that the CTA exceeded the U.S. Constitution’s enumerated powers and was, therefore, unconstitutional. Yet the ruling’s application was strangely limited, giving relief only to the members of the

principal plaintiff, the NSBA. All other businesses would still be subject to the law’s deadlines.

On March 19, 2024, AICC joined 125 other business and industry associations in appealing to the House and Senate to delay the effective date of the law to allow the NSBA suit to make its way through the judicial process and to be consistent with the original congressional intent on giving businesses a full two years to learn about and comply with its reporting requirements. And what are those requirements? Businesses will have to report their beneficial ownership annually to the Financial Crimes Enforcement Network. “Beneficial ownership” means anyone who has a financial interest in the business, which in the eyes of many critics is an invasion of privacy and a precursor to greater

reporting demands on the business community going forward. We hope sound reason will prevail in this discussion and the voices of 125 business and industry associations are heeded. The two pieces of legislation that would extend this bill’s deadlines are S. 3625 and H.R. 5119. Urge your representatives and senators now to support them. Go to www.house.gov or www. senate.gov to find your congressional representatives. Or call the U.S. Capitol switchboard at 202-224-3121.

Eric Elgin is owner of Oklahoma Interpak and chairman of AICC’s Government Affairs subcommittee. He can be reached at 918-687-1681 or eric@okinterpak.com

FILTRONA TAPES INC.

SARAH RUTLAND

Market Development Manager

1625 Ashton Park Dr. Colonial Heights, VA 23834

804-518-1067

www.filtrona.com

ALLIANTGROUP

LENA DZIECHOWSKI

Associate

3009 Post Oak Blvd., Suite 2000 Houston, TX 77056

713-877-9600 www.alliantgroup.com

OPUS PACKAGING GROUP, INC.

LOUIS SICILIA

Chief Financial Officer 6995 Southbelt Dr. Caledonia, MI 49316 833-526-4445 www.opuspkg.com

ERHARDT+LEIMER INC.

DENI MOHAMMAD

350 Tucapau Rd. Duncan, SC 29334

864-486-3000 www.erhardt-leimer.com

HARPERLOVE ADHESIVES

JEFFREY BUCHANAN

Director of Sales and Market Development 11101 Westlake Dr. Charlotte, NC 28273

704-588-1350 www.harperlove.com

LARSON PACKAGING COMPANY

SCOTT GRILLS

Chief Operating Officer 280 Cypress Lane El Cojon, CA 92020

619-579-7166

www.larsonpkg.com

SUPPLYONE, INC.

GEORGE VAN KULA

Chief Administrative Officer and General Counsel 11 Campus Blvd., Suite 150 Newtown Square, PA 19073 484-582-5005

www.supplyone.com

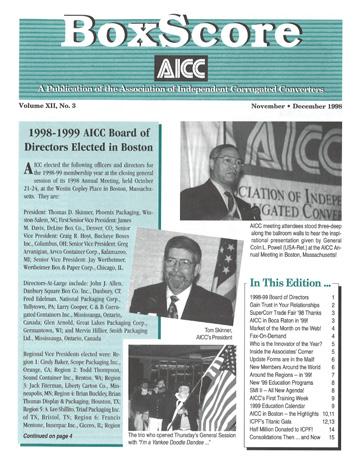

The AICC 2024 Spring Meeting and 50th Anniversary Celebration concluded with resounding success, marking a historic milestone for AICC. Held in the scenic backdrop of Palm Desert, California, the event brought together 850 industry leaders, emerging talent, and esteemed guests for a memorable occasion of learning, networking, and celebration.

The extravaganza featured myriad sessions, speakers, and activities, offering attendees invaluable insights into industry trends, essential information, and networking opportunities. Event highlights included the commemoration of AICC’s 50th Anniversary, the 10th Annual Independents’ Cup Charity Golf Tournament, and 10th Anniversary of the Emerging Leader program, marking a decade of growth and innovation.

The enthusiasm of attendees was palpable throughout the event. “We are thrilled the AICC 2024 Spring Meeting and 50th Anniversary Celebration was such a high note this year,” says Matt Davis, president of Packaging Express and AICC chairman. “This event provided a platform for connecting with new friends and old, having meaningful discussions, and it also allowed us to honor the legacy of AICC while looking forward to a future of continued growth and success.”

From the moment attendees entered the event space, they were steeped in AICC history. They enjoyed a Walk of Fame, with past U.S. board chairs remembered on stars on the floor, an

AICC Board Chair Matt Davis of Packaging Express and AICC President Mike D’Angelo recreate the moment from the first AICC meeting of breaking one stick but unable to break a bundle of them. This highlights that independents are still stronger together.

8-foot timeline of AICC’s history, and signs honoring the accomplishments of Hall of Fame recipients, AICC Canada and México past board chairs, safe shop winners, and many others who have been part of AICC’s history.

The meeting kicked off with the Sales Managers Forum, a dynamic training session designed exclusively for sales managers in the corrugated manufacturing industry. Led by industry experts John Ballentine of the University of Arkansas and Trent Halasek of Akers Packaging Service Group, the forum delved deeply into the financial implications of sales decisions, equipping attendees with valuable skills to drive value-based choices.

The event featured insightful sessions on hot industry topics, including Sarah Meiburg of the Paper & Packaging Board sharing tools and insights on selling sustainability and Derek Mahlburg of RISI offering an economic outlook and emerging trends. Both sessions provided attendees with a comprehensive understanding of the challenges and opportunities facing the industry today.

Tim Connell of A.G. Stacker moderated a panel with AICC experts Ralph Young, AICC corrugated technical advisor; Doug Friel, risk management advisor at JKJ; and Jeff Putt of Deline Box and the AICC AI & Technology Committee chair. They answered members’ technical questions and offered resources to help boxmakers be more efficient and productive.

Members dance long into the night and truly have a celebration to remember.

AICC is grateful to the sponsors who helped make the Spring Meeting a success:

PREMIER 50 th

• Bradford Co.

• Flint Group

• Haire

PREMIER PLATINUM

• Domtar Packaging

PREMIER GOLD

• eProductivity Software

• A.G. Stacker

• SUN Automation

• A.G. Stacker

• Bobst

• JB Machinery

• Pamarco

• Quest7

• A.G. Stacker

• Pacificolor

• Göpfert

ADDITIONAL SPRING MEETING SPONSORS INCLUDE:

• Oklahoma Interpak

• HP

• Kao Collins

• Geo. M. Martin Co.

• Alliance Machine Systems

• Bay Cities

• Stafford Corrugated Products

• Kolbus America

• Mitsubishi Heavy Industries

• Global Boxmachine

• EFI

• Arco Murray

• Bradford Company

• Huston Patterson

• Lewisburg Printing Co.

• Dusobox

• Amtech

hairegroup.com

Jerry Frisch of Wasatch Container gave a heartwarming and entertaining presentation about how his company began and grew and offered advice to the next generation of leaders.

Moderators Joe Morelli of Huston Patterson and Lewisburg Printing Co. and Jeff Pallini of Fosber America Inc. led an industry panel with Chad Wagner of Peachtree Packaging; Larry and Richard Grossbard of President Container; and Bill, Jim, and Andrew Akers of Akers Packaging. The panelists discussed family dynamics, industry challenges, and their vision of the future.

Ron Sasine of Hudson Windsor took a deep dive into consumer purchasing behavior, changes in distribution, and the differences between what retailers say they need and what the industry thinks they need.

Keynote speaker Pippa Malmgren, former special assistant to former President George W. Bush and authority on geopolitical, economic, and technological trends, took attendees into the future with her presentation. She described the turbulence she sees coming and the opportunities on the horizon and discussed a different form of globalization, the new space race, and the speed of new technology.

Henry Winkler, aka “The Fonz,” Emmy award-winning actor, author, director, and producer, closed the meeting with the enthralling story of his youth, how he got into acting, and how discovering his dyslexia later in life put many of his experiences into a new context. He was called dumb by his parents, who did not support his dream of acting, but he never let their words stop him; they only motivated him to be and do more. He shared emotional stories with a humorous twist to captivate the audience before taking questions and signing his latest book for attendees. New members and first-time attendees were treated to a special networking reception with their AICC ambassadors,

who helped them navigate their first meeting and make new connections.

The celebration’s highlight was the 50th Anniversary Dinner, where attendees dressed in their finest. The room was beautifully decorated with centerpieces created by Bay Cities, glowing trees, and stars covering the room. Many attendees took advantage of a 360-degree photo booth to memorialize the evening. They also watched a video tribute to AICC’s history and future. Bringing in the golden age of Palm Springs for AICC’s golden anniversary, attendees watched a Rat Pack tribute show. They then danced the night away to lively big-band music, providing the perfect finale to a memorable evening.

• 50 years: Automated Conveyor Systems

• 40 years: Packaging-Atlanta Corp. and Alliance Machine Systems

AICC thanks BHS, WestRock, and Domino for their support in creating the 50th anniversary video shared during the celebration. “Words cannot express how grateful I am to past AICC members for 50 years of memories and to current members who made the celebration in Palm Desert a new and fitting memory. AICC is clearly ready to support its members for the next 50 years,” says AICC President Mike D’Angelo.

During the meeting, AICC also celebrated the milestones of its members, recognizing the following companies for their years of continuous operation:

• 110 years: Utah PaperBox

• 100 years: Bradford Co. and Standard Printing Co.

• 70 years: Global Boxmachine

• 65 years: Lonestar Container

• 60 years: Corrugated Supplies Co.

“As we reflect on the success of the AICC 2024 Spring Meeting and 50th Anniversary Celebration, we are grateful for the continued support and participation of our members, sponsors, and industry partners,” says Terri-Lynn Levesque of Royal Containers, chair of the AICC Convention Content Committee. “This event served as a powerful reminder of the significant influence AICC has had on our industry. We will be talking about our time together in Palm Desert for the next 50 years. We look forward to building on this momentum and shaping the future of the independent packaging industry together.”

Videos of many sessions are available to attendees upon request. Contact Laura Mihalick at lmihalick@AICCbox.org for more information.

AICC members will come together again for SuperCorrExpo, September 9–12, 2024, in Orlando.

For more information about upcoming events, visit www.AICCbox.org/calendar.

Throughout the Spring Meeting, attendees participated in various activities, including the Independents’ Cup Charity Golf Tournament, where they tested their skills on championship courses against the backdrop of the Santa Rosa Mountains in California. The tournament not only provided a platform for friendly competition but also supported a charitable cause. The tournament raised $15,000 for the Foundation for Packaging Education.

“We are thrilled that the Foundation for Packaging Education was the beneficiary of the Independents’ Cup Charity Golf Tournament,” says Gene Marino, president of Akers Packaging Service Group and board chair of the Foundation for Packaging Education. “The tournament not only raises funds to benefit our educational programming but also showcases the camaraderie within our industry.”

Major Sponsor

• Hood Container Caddies

• Schwarz Partners

ADDITIONAL GOLF SPONSORS INCLUDED:

• BHS

• Equipment Finance Corp.

• EMBA

• Bradford Co.

• Fosber

• BCM Inks

• Bobst

• Cuir

• Litho Press

• Flint Group

• Crossroads Paper

• Isowa America

• EAM MOSCA

First Place—Palm Course

• Bobby Atkinson, GAPCO | Gulf Atlantic Packaging

• Cody Bryant, A.G. Stacker

• Colin Moynihan, Columbia Container

• Tom Murphy, Reliable Container

First Place—Valley Course

• William Berg, Menasha Packaging

• Brant Dixon, A.G. Stacker

• Brian Kentopp, Topp Corrugated Products

• Bryan Rabb, Rabb Corrugated

• Engineered Recycling Systems

• Huston Patterson

• Lewisburg Printing Co.

• A.G. Stacker

• Akers Packaging Service Group

• Alliance Machine Systems

• American Corrugated Machine

• Atlantic Packaging Products

• BW Papersystems

• Clean Print USA

• Dicar

• EAM Mosca

• Isowa America

Gift Cards

• Bobst

• Jamestown Container Cos.

• M&T Capital Leasing

• McLean Packaging

• Pacificolor

• Pamarco

• Philipp Lithographing

• Quantum Ink

• Royal Containers Ltd.

• Standard Printing Co.

• Standfast Group

• Two10 Technologies

• Valco Melton

• Wasatch Container

Kiwiplan has provided robust, mission-critical software solutions for the corrugated and packaging industry for more than 30 years. Kiwiplan provides powerful tools and functionality to drive improvements, enhance productivity, and improve quality for packaging manufacturers of all sizes.

Abaca Systems business management suite puts optimum performance at the tips of your fingers. Our flexibility enables our work with corrugated, paper related, and distribution & maintenance companies of all sizes. Whatever your operation, Abaca system is designed to meet your complex requirements.

Drive revenue growth with Advantzware, a scalable and customizable ERP solution tailored to fit midmarket packaging manufacturers. With a centralized database and seamless integration with optional modules, Advantzware ERP improves operational efficiency and maximizes employee productivity.

Over the past 15 years, we have published several AskRalph blog posts and BoxScore articles on this often forgotten significant variable to box compression/box performance, which is four-point bending stiffness . To review those pieces, you can go to the search bar on AICC NOW, NOW.AICCbox.org, and enter this subject or contact me directly.

The definition in the Technical Association of the Pulp and Paper Industry T 836 states that “bending stiffness measurements of the combined board when used with the edge crush test and box dimensions can accurately predict the top-to-bottom compression strength of a box.” McKee’s short formula makes an estimation of this property by using the caliper of the combined board. As we will see in the example below, the equal compression strength is improved by moving from a 69/23C/69 combination to 35/23E/35/23N/35.

We have known of the edge crush test (ECT) inclusion for almost 35 years now, but we often ignore or never understood the other major characteristic of corrugated in building box performance. This seldom considered property, while not as significant as ECT, still has a contribution to top-to-bottom compression—also,

but not discussed here, the measurement of torsional stiffness as determined by dynamic stiffness tester (DST) instrumentation. This is not an issue of virgin/ semichemical fiber versus recycled fiber as one would obtain the same results.

My associate, Tom Weber, and I led a webinar in June 2022 titled “Testing Requirements to Guarantee Board Strength” that covered many physical properties of corrugated, folding carton, and rigid box. One of these properties was four-point bending stiffness for corrugated and taper stiffness for paperboards. It needs to be emphasized that the bulging resistance of the corrugated vertical side panels has an impact on box compression.

A third consideration of the impact of transport on the corrugated box is flexing or twisting. The way to measure this and the contribution of proper combining and converting is the use of a DST. More than 70 are in use in North America but very few among the independent portion of the corrugated industry. What do the big companies know?

The program above was a follow-up to a major 2018 national meeting presentation titled “Fluted vs. Paperboard,” with a panel discussion with converting experts. After this faceto-face presentation, we published an extensive white paper that includes a chart

of some bending stiffness values for a few combined board combinations.

This particular member combiner and converter does not have access to lower substance linerboards like 29# or 21#, so we were not able to run other permutations. Additional resources are available at AICC, including expected values of containerboards such as SCT and CFC, to assist you in coming up with multiple options in reengineering the corrugated structure and box.

Although the environmental sustainability savings is less than 10% fiber reduction, the financial sustainability savings is 25%. What would your customer benefit from most? Consider the marketing advantage! Not many have all these flutes and options, but some do, and you can do something with small-flute double-wall and low-substance linerboard and medium.

Ralph Young is the principal of Alternative Paper Solutions and is AICC’s technical advisor. Contact Ralph directly about technical issues that impact our industry at askralph@AICCbox.org

An award-winning printing line for corrugated

An award-winning modular printing solution Up to 3 flexo units + single pass inkjet + rotary die cutter

The low-capex option to stepinto single-pass hybrid

With Kento Hybrid’s modular approach, you get the power to decide how and when to scale up your corrugated printing operation, starting with a price tag similar to a multi-pass digital printer.

Flexo printing for solid backgrounds, white ink, special colors

Digital printing for high-quality images and personalization

Rotary die cutting for increased overall equipment efficiency

Join us at Super CorrExpobooth #2770, September 2024

We are corrugated

download a brochure ask for a live demo

After receiving several member inquiries about plant safety inspections, the use of a third party to do so objectively, and preparation for an Occupational Safety and Health Administration (OSHA) inspection, I thought I would share below what I orchestrated while leading a privately held folding carton and blister card company in Northeast Ohio.

We expected an unannounced OSHA inspection due to a workplace injury that resulted in a partial finger amputation from a drug-impaired employee, who was treated and then summarily terminated under our company drug testing for cause policy.

The inspection was performed based on the Safety Plus program, a free Council of Smaller Enterprises service to small Ohio-based businesses. This report details inspection findings and a list of recommendations. It also provides examples of safety and health hazards for future employee trainings and demonstrates what you could possibly expect, in the form of violations, after an on-site OSHA inspection.

The identified conditions in this report are those that might be addressed during an OSHA inspection and may be considered safety hazards. This safety inspection was performed as a service and is intended to be used as a tool to improve your company’s health and safety.

OSHA inspections are initiated by one of the following and are prioritized in the order presented:

• Imminent danger

• Catastrophes and fatal accidents

• Employee complaints

• Programmed high-hazard inspections

• Follow-up inspections

Of these inspection priorities, our industry would be most susceptible to employee complaints. Sometimes, disgruntled employees contact OSHA after a discordant separation.

1. Emergency Action Plan

• There is an emergency action plan in place.

2. Material Handling and Storage

• Production paper rolls were mostly stored properly in a horizontal position.

• Some production paper rolls were stored in a vertical position with no roll chocks to prevent the rolls from moving and potentially causing a crushing injury.

• The facility flammables storage room was appropriately maintained and included sill construction, an Ansul system, bonded containers, and a fire door.

• The ink room and flammables storage room were equipped with a combustible gas (LEL monitor) and a Magnehelic pressure gauge.

• The maintenance room was cluttered and difficult to get around. In addition, a large number of flammables were stored on shelves, not in a flammables cabinet.

3. Fire Prevention and Protection

• Fire extinguishers are inspected and tagged annually.

• Fire extinguishers are also inspected monthly.

4. Hazard Communication

• A hazard communication program is implemented and includes Globally Harmonized System of

Classification and Labeling of Chemicals (GHS) requirements and the proper labeling of secondary containers.

• Material data safety sheets (also referred to as safety data sheets) were available for review.

5. Machine Guarding

• Multiple machine-guarding deficiencies were observed.

• Potential pinch points were observed.

• The guards are insufficient; worker can reach under and/or around the device.

• Foot pedal must be independent of the two-handed operation.

• Multiple pinch points on the folder were observed.

• The guards are compromised.

• Gates provide some protection, but much of the folder has open pinch points.

6. Forklifts

• Operators have been trained, certified, and evaluated per OSHA standards.

• Manuals are not present on all of the forklifts.

• Pre-use inspections are not being performed.

• Paper roll clamp attachment is not reflected on the forklift data plate.

• Propane fuel tanks are not properly secured to the vehicles.

• This inspector observed a truck pull into the loading dock. The leveler was placed, and the employee began loading with a motorized pallet jack without the trailer wheels being chocked. The employee stated they had training within the past three months.

• Open hatches present thermal hazard. If the hatch must remain open, install a screen or cage.

7. Electrical

• Electrical panel not labeled with appropriate arc-flash personal protection equipment (PPE) per National Fire Protection Association (NFPA) 70E requirements.

• Damaged extension cord should be taken out of service.

• Uncovered electric junction box has energized conductors outside the box.

8. Confined Space

• A confined space assessment has not been done and any confined spaces labeled as such.

9. First Aid

• Eyewash stations must be properly maintained and inspected on a weekly basis.

• Temporary eyewash solution was expired and must be replaced to prevent added injury.

10. Miscellaneous

• Abrasive wheel grinder is not properly guarded or maintained.

• It appears voluntary use of ear protection is allowed. However, this inspector concluded noise monitoring should be performed based on a noncalibrated sample.

MATERIAL HANDLING AND STORAGE

• Provide shocks for vertically stored or moved paper rolls.

• Continue the policies relative to the flammables storage room.

• Develop a housekeeping plan for the maintenance area and provide a flammables cabinet for storage.

HAZARD COMMUNICATION

• Develop and implement a written hazard communication program, which includes GHS updates.

• Enforce the proper labeling of secondary containers.

• Perform a complete machineguarding assessment and properly guard all machines.

• Acquire forklift manuals and keep them on the forklifts.

• Ensure daily inspections are being performed, and the inspections are documented and retained for record-keeping purposes.

• Contact the forklift manufacturer and get approval and updated data plate for the paper roll clamp attachment.

• Retrain or refresh forklift operators on the OSHA requirements for powered industrial truck operators, especially related to the refueling of propane-powered vehicles and the loading of semitrailers and rail cars.

• Mark electrical panels with appropriate arc-flash PPE per NFPA 70E.

• Remove the damaged extension cord from service.

• Cover or eliminate the open electric junction box.

• Perform a confined space assessment and label any spaces identified as such.

• Develop and implement a weekly eyewash station inspection and maintenance program.

• Replace the expired eyewash solution.

• Adjust the guards for the abrasive wheel grinder to the correct distances—one-eighth of an inch from the wheel for the tool rest and one-quarter inch for the tongue guard.

• Perform noise monitoring to ensure the facility falls under the OSHA

85dB trigger point for hearing protection program.

This inspection focused primarily on hazards identified on the day of the inspection and is not intended to be a comprehensive review of your overall annual health and safety program.

A total of eight (plus the number of machines on-site with improper guarding) potentially serious violations had been found. A serious violation is one in which there is substantial probability that death or serious physical harm could result and the employer knew, or should have known, of the hazard. A penalty of up to $7,000 for each violation is proposed.

Other than serious violations are those that have a direct relationship to job safety and health but probably would not cause death or serious physical harm. A proposed penalty of up to $7,000 for each violation is discretionary. A typical other than serious violation penalty would be $1,000 or less.

This report was completed to assist my company in understanding the types of citations we could have received from an OSHA inspection, which indeed did take place two months later as luck would have it. (Note: This report in no way reflects the opinions or positions of OSHA.)

I hope sharing this inspection report stimulates some of our readership to evaluate your plant safety programs and processes to make certain significant and long-lasting improvements are continually being made, just as you all do to your quality processes for all employees and clients involved.

Hats off to a safe and productive second half of 2024!

Tom Weber is president of WeberSource LLC and is AICC’s folding carton and rigid box technical advisor. Contact Tom directly at asktom@AICCbox.org

Lead generation is the cornerstone of sales growth. While there are often additional growth opportunities with current customers, the potential is finite, while the pool of new prospects is immense. Implementing lead generation strategies for new business development allows for scalability and exponential growth that can’t be accomplished through the current customer base alone. However, not all leads are created equal, nor should they be given equal attention. So, what is a lead?

The term “lead” by itself is extremely broad. When referring to sales and marketing, a dictionary definition of lead is “a person or thing that may be useful, especially a potential customer or business opportunity.” The word “may” is the key here. It is the role of the sales and marketing teams to vet them and move them through the sales pipeline.

First, let’s be clear about what a lead is not. Many unscrupulous companies are willing to sell you hundreds or thousands of leads, and most will be garbage. Lists of companies or people with contact information are not leads—even if the North American Industry Classification System codes classify them in an industry that uses your packaging or products. If you compile a list of contacts from companies that fit your target market profile—they match company size, spending potential, product mix, etc.—these are still considered prospects, not leads. They don’t become leads until they have demonstrated a desire to learn more or explicitly stated they need your product or service.

Leads can be broken down into two categories: marketing leads and sales-qualified leads.

A marketing lead is a prospect that has shown interest in your product. These are generally generated when they engage with your content through inbound marketing, social media, trade shows, or other events. This is someone who has demonstrated interest by performing actions such as submitting contact information, signing up for a webinar or newsletter, downloading materials, or repeatedly visiting your website.

A lot of junk can come through your website and online forms, so some level of investigation may be needed to weed out spammers, competitors, students looking

for information, and others with no potential to become a sale.

The primary goal with marketing leads is to engage and educate them, gradually moving them down the sales funnel until they are ready for a direct sales approach. Your marketing team may nurture marketing leads through the sales cycle by providing information relevant to where they are in the buying journey. This is often done through email campaigns, which may include lead scoring. These leads are not ready to buy and must be further vetted to ensure they align with your target market profile.

Sales-qualified leads are further down the sales funnel. Once a marketing lead has been further vetted to fit your target

ost compl print portf rrugate

The most The most complete digital print portfolio for the corrugate for the corrugated industry

market profile and has demonstrated an interest in speaking with your sales team, they become a sales-qualified lead. Often, prospects or market-qualified leads become sales-qualified leads through outbound calling. An inside sales rep calls the prospect and, during the course of conversations, uncovers answers to predefined qualifying questions that ensure they are a fit. If the person is interested and has been vetted as a fit through the qualifying questions, the inside sales rep sets up a meeting with an outside sales team member. Outside sales discusses the lead’s needs in detail, offers solutions, and moves them toward the quoting phase. In some cases, the journey from marketing lead to sales-qualified lead can happen quickly; in other cases, it might take much longer. The primary goal of sales-qualified leads is to convert them into customers. Since they are ready and willing to discuss their challenges and your solutions, the sales team focuses on direct engagement and closing the sales.

Understanding the difference between the two types of leads is crucial for several reasons directly impacting the efficiency and success of sales and marketing strategies within your organization. Those reasons are as follows:

• Resource optimization: Understanding the difference allows for better resource allocation between the sales and marketing teams and ensures sales teams focus on tasks that lead to closing sales.

• Improved sales cycle efficiency: When the sales team focuses on qualified sales leads, the sales process becomes more streamlined, potentially shortening the sales cycle and increasing the chances of closing more sales.

• Enhanced customer experience: Understanding the difference allows you to provide a personalized

experience. Marketing leads may require more educational information to move them through the funnel, while sales-qualified leads may benefit from targeted solutionoriented communication.

• Increase in conversion rates: Sales-qualified leads are further along in the buying process, so allowing your sales team to focus solely on these leads will increase conversions. When the sales team’s time is split or they are chasing unqualified leads, opportunities to close may be lost.

• Better collaboration between sales and marketing: It’s well known that sales and marketing often clash. By differentiating between marketing leads and sales leads, both teams will be on the same page regarding their roles in the lead generation and nurturing processes.

Without a strategic approach to converting marketing leads to sales-qualified leads, you may face low conversion rates, inefficient use of resources, poor lead quality, misalignment between sales and marketing, and lost revenue opportunities.

A repeatable process incorporating a customer relationship management (CRM) tool and a marketing automation system combines foundational elements for consistently converting marketing leads to sales-qualified leads. A repeatable process ensures that every lead is nurtured and assessed through a consistent framework. This consistency is critical to reliably moving leads through the sales funnel, as it eliminates guesswork and variability that can lead to leads slipping through the cracks.

A process streamlines operations, creating greater efficiency while allowing you to scale your efforts up or down as needed. A consistent process makes measuring performance easier and enables you to

identify bottlenecks or trouble spots and implement continual optimization of the lead-conversion process.

A CRM system centralizes all lead and customer data, which is crucial for maintaining an up-to-date understanding of each lead’s status and interactions. CRM and marketing automation tools enable sophisticated segmentation of leads based on various criteria that support highly personalized marketing and sales outreach, increasing the relevance and effectiveness of communications and allowing sales marketing to provide information relevant to where they are in the buying cycle. With a marketing automation tool, the outreach can be automated, creating greater efficiency in the process. Plus, both tools provide valuable analytics and reporting features to allow teams to track conversion rates, understand lead behavior, and adjust the process when required. Understanding the difference between marketing leads and sales-qualified leads is essential for optimizing your sales and marketing efforts. A defined process and proper tools provide the structure, efficiency, personalization, and insights necessary to nurture leads effectively, prioritize sales efforts, and ultimately close more deals. By leveraging technology and a systematic approach, you can enhance your lead-conversion capabilities, driving growth and maximizing the return on investment.

Todd M. Zielinski is managing director and CEO at Athena SWC LLC. He can be reached at 716-250-5547 or tzielinski@athenaswc.com

Lisa Benson is senior marketing content consultant at Athena SWC LLC. She can be reached at lbenson@athenaswc.com

After a long, cold winter—though we did get an early spring this year since the groundhog didn’t see his shadow—summer days can’t get here fast enough. Breaking out the Hawaiian shirts, sipping refreshing cocktails on the porch, and indulging in our favorite pint of ice cream as a reward for mowing the grass are checklist items we can’t wait to begin checking off. Fortunately for us, Memorial Day—the unofficial kickoff to those glorious sunny days—is right around the corner. With that in mind, you’d best believe we got ourselves ready for another trip to the store to see what brands would wow us this year with their summer-inspired designs.

Since we both love to travel and explore the world around us, the women’s travel kit below by Navajo Inc. caught our eyes first. For both of us, this is convenience at its finest—combining all the items we need to stay fresh and clean for a journey to, let’s say, Cabo. There’s even a bath puff with body wash to get the lather you deserve rather than scrubbing with the

hotel’s complimentary soap bars (though we are divided on this point—Alli loves her some soap bars). As an added bonus, everything in this resealable bag is Transportation Security Administrationcompliant, alleviating our anxiety of being pulled out of line due to a large mouthwash bottle that somehow made its way into our luggage. And they even have a version for men (also below) that includes a toothbrush, toothpaste, and mouthwash—a full set of toiletries to keep you from feeling too travel-worn on your summer adventures.

As we turned the corner, we ran smack into an endcap display that was unabashed in its summer days agenda. You can’t get by without sun protection,

and this display of sunscreen helps shoppers prepare for the upcoming season of vacations, barbecues in the sweet heat,

and the many get-outside-while-you-can activities. This endcap not only has a wide array of sunscreen options but also comes with fantastic sun care advice and a chart describing which SPF is right for you. This simple yet effective display was able to incorporate information consumers need to know directly into its in-store marketing materials—pretty cool, huh?

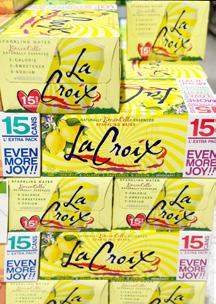

The next product (above left) that grabbed our attention, LimonCello LaCroix, seemed to transport us to another country—we must have been thinking about sipping a boozy, citrusy beverage on the Amalfi Coast of Italy—a girl can dream, right? But LaCroix, with its effervescence and refreshing aftertaste, gives us a version of that experience minus all the sugar, alcohol, and travel expense as we sip this beverage to our heart’s content in our version of Italy—under a striped

umbrella at the neighborhood pool. (Sidenote: We do hope Italy is on the itinerary one day.) The bold yellow color of the packaging— can and secondary container—and the use of lemon imagery radiate energy and optimism, much like the possibilities of a summer day. Finally, we strolled through the chilly frozen foods section, where we came upon a product we’ve never seen before— Nature’s Premium Strawberry & Cream Fruit Pearls. This healthier dessert alternative (above right) delivers innovation in a cryogenically frozen grab-and-go format. It’s not a completely new concept to us, but it pulls us in because it was previously found only at baseball games or concerts (Dippin’ Dots, anyone?). The package design offers a glimpse of one of the quintessential pleasures of summer— delicious, ripe strawberries swirled with cream. The vibrant red and green colors rounding out the background on the package are important because it’s been found that highly saturated colors boost perception of stimulus intensity. This means that a highly saturated packaging

color can lead consumers to have a stronger experience of the product and/ or taste it more intensely. We’ve yet to try this product, but trust that when we do, we will be doing so with the music turned way up and our toes in the sand. This trip was another fun break from our normal, run-of-the-mill shopping experience, and we had a blast searching for packaging that embodies summer with its vibrant colors, nostalgic images, and memorable design layouts. But what do you think? Did these brands successfully leverage a seasonal element into their packaged products? Let us know by emailing julie@packagingschool.com or alli@packagingschool.com.

Julie Rice Suggs, Ph.D., is academic director at the Packaging School. She can be reached at 330-774-8542 or julie@packagingschool.com.

Alli Keigley is production coordinator at the Packaging School. She can be reached at alli@packagingschool.com.

Imiss the idea of polite society. As a child of the 1960s, I have witnessed ever-decreasing expectations of decency, respect for differences, and responsibility for individual behavior. If this deterioration can be slowed, then it is incumbent upon people of influence to model respect and self-control. In leading and managing our companies, we have the opportunity, if not responsibility, to create a polite society at work. As the owner of one of the most successful businesses in our industry said, “We are smart, we are highly competitive, and we usually win. Now I want us to be kind.”

The current rules of engagement on the highways, on social media, and in our relationships have become increasingly volatile and reactive. We may not accept that there is a new standard of behavior, but neither are we shocked when we see people who “don’t know how to behave.” Counting Karens may soon replace the old Punch Buggy game.

Perhaps it is possible for leaders of any stripe to raise the expectation by sharing models for responsibility and respect within our scope of influence. I say perhaps because it comforts me to believe that ignorance drives this bad behavior. If they know better and they are still acting this way, then I must forfeit hope.

One such model that might easily be deployed in the workplace is taken out of the substance abuse recovery curriculum. It may be utilized to de-escalate a conflict between employees or as a description of your own process. The conversation might go like this: “You seem pretty upset. Let’s talk this through.” Having eddied out, the leader might explain that they are working on being more proactive than reactive in communication.

I choose this particular tool because, like most of us, I have overreacted with incomplete information and complete emotion, with the result of escalating conflict and being foolish. To avoid repeating this offense, I ask myself these questions: Who am I upset with? Who was/is the object of my resentment?

This could be a person, an institution, a political party, or a particular group. Prior to asking this question, I may believe I am upset about everything. I might default to generalizations (“Everything is ruined,” or “Nothing is going right”). The simple act of stating what I am specifically troubled by will focus the issue. Then it is a problem defined.

The cause. What specific action did that person take that hurt me? This further defines the event. It also might be an opportunity to explore alternative explanations for the event. Granted, if a person ran over my foot, then my pain is not diminished by their motivation. This may, however, create the opportunity to see the event from a different perspective. The ability to see things from another

perspective is a prerequisite to the respect and self-control in a relationship that is my ambition. Without perspective, the population degrades into good people like me and bad people like you. It is a simple way to live on the road to chaos.

The effect. What effect did the action have on my life? What did I feel? When I explore how I actually feel in reference to the other person’s actions, I must start by being brutally honest, even if it exposes an overreaction on my part. Only after being honest with myself about the feeling can I take the next step. Was my reaction in proportion to the offensive actions of the other person? If it was a level 10 response to a level five action, then why do I believe this occurred?

The damage. What harm came from the action of the other person? What damage was developed as a result of the effect I listed above? Has it changed my belief about myself or the workplace? Do I believe it is beyond repair?

My part. What part of the resentment am I responsible for? How did my behavior contribute, even in a small way,

to the problem? If I return to the example of someone having run over my foot, then I may need to take responsibility for my own lapse in attention or my decision not to wear steel toe boots on that day. Even if I am a victim, I can acknowledge my own choices. Even if it is determined that my foot-targeter did so with malice aforethought, I will be better equipped to avoid a recurrence.

Conclusion

These five questions might be answered alone or in dialogue. In either case, the result is often a reduction in the scope and effect of the event in question. Company culture models many tools for continuous improvement of quality regarding products and service. This

KraftCoat Opaque White Coating This innovative solution surpasses the conventional mottled white paper by leaps and bounds. Featuring unique attributes essential for printing vivid graphics, KraftCoat ensures unparalleled color fidelity and performance on recycled kraft materials. Its superior coverage lays the perfect foundation for vibrant colors, easily capturing attention, whether applied through digital, lithographic, or flexographic printing methods. Embrace the future of recycled kraft liner enhancements with KraftCoat Opaque White Coating, where brilliance meets clarity and innovation. Contact us to discover more!

AICC held its first Road Show in March at Bay Cities, an active member of the AICC community, in Pico Rivera, California. The event attracted approximately 30 attendees from five companies, all eager to learn about the myriad benefits available to AICC members.

The Road Show features the extensive resources, networking opportunities, and educational programs offered by AICC to its members, reinforcing the Association’s commitment to supporting the growth and success of the independent.

“We were honored to host the first Road Show in collaboration with AICC, which proved to be an invaluable opportunity for our key managers, employees, regional members, and prospective members,” says Bay Cities Executive Vice President of Sales Sahar Mehrabzadeh. “The AICC experts shed light on the many benefits the Association offers such as unparalleled education, robust networking opportunities, resources, and insights into seminars and events that include the latest industry trends and technological advancements.

“This event wasn’t just successful; it was transformative for our team as we have

integrated AICC’s offerings into our employee onboarding and training plans,” she continues. “Now, each manager has access to AICC’s comprehensive educational suite, equipping them with powerful tools to enhance their knowledge and performance. This exposure has significantly enriched our company’s understanding of the benefits AICC provides, enabling us to leverage these resources to elevate our business operations. The event was a pivotal moment, reinforcing the importance of continuous learning and networking to stay at the forefront of industry innovation. AICC remains an invaluable resource for our company.”

development opportunities, and a supportive community of industry peers.

Bay Cities’ participation as the host for this Road Show stop underscored the company’s leadership within the AICC community and its dedication to fostering a collaborative and innovative industry environment. The event served as a platform for learning and networking and demonstrated the tangible benefits of AICC membership, including access to cutting-edge resources, professional

The AICC Road Show’s stop at Bay Cities is part of a broader initiative to engage with members across the United States, ensuring companies of all sizes and scopes can leverage the full spectrum of AICC membership advantages. The positive feedback and enthusiastic participation at this event reflect the value that AICC provides to its members and the industry.

If your company is interested in being a stop on the AICC Road Show, a no-cost member benefit, contact AICC Director of Membership and Marketing Virginia Humphrey at vhumphrey@AICCbox.org or 703-535-1383.

In 2023, more than 88% of consumers recognized the word “sustainability,” but despite the high levels of awareness around the world, only 26% of those same consumers can name a sustainable product, according to The Hartman Group’s Sustainability Report of 2023. This massive awareness gap creates an opportunity for brands and boxmakers alike that are trying to position themselves as environmentally friendly.

One of the clearest meanings consumers associate with sustainability is the recyclability of a product. With the potential for fiber reuse of up to seven times, the corrugated box is the golden child for recycling. And while many consumers claim to recycle regularly, the residential fiber recovery rate in the U.S. is estimated at only 40%, with two out of three boxes ending up in a landfill.

Improving this rate is the impetus behind a new residential recycling initiative rolling out nationwide by the Paper and Packaging Board (P+PB) The Box to Nature program’s goal is to tap into consumers’ desire to do their part for the environment, with a reminder of the simple steps they should take to properly recycle their boxes.

Reaching consumers at the point of package with an impactful message is the perfect opportunity to increase the residential recapture of fiber well above its current rate. But two key pieces need

to be in play: an emotional appeal coupled with instructive messaging. Recent message testing research by The Recycling Partnership shows that consumers’ actual recycling behavior improves when they receive more emotional and empathetic messages about recycling. When compared with other recycling marks, Box to Nature is significantly more motivating in part due to its emotional message: “This box has up to seven lives. Our planet has one.”

The other key component is the use of clear and simple instructions that help mitigate consumers’ confusion. The directive to “Empty, Flatten, Recycle” does just that. Qualitative research found that the Box to Nature graphic is dramatically more impactful at getting consumers to recycle than other recycling reminder marks—with 74% agreeing it would motivate them the most. This research shows that the Box to Nature mark presents the right message at the right time to engage consumers and to improve residential recycling rates.

The program has hit its stride throughout the packaging sphere with over 30 participating large and small box manufacturers. In terms of brand adoption, we have several well-known brands interested and moving toward adding the mark to their boxes.

Join the movement to get more boxes back. Contact P+PB at box2nature@ paperandpackaging.org, or learn more at www.paperandpackaging.org

Sarah Meiburg is director of the Box to Nature program at P+PB.

Monitor It — Identify It — Eliminate It

X Immediately identify and correct warp without operator intervention

X Continually measure 1200 points across the full web width with laser precision

X Produce high quality sheets sooner by utilizing Machine Learning algorithms (AI)

X Fully integrates and communicates with CoparSolutions’ QualityMaster™ System

Laser Warp Correction brings the latest AI technology to corrugator process control. This next generation of automation combines the precision of laser measurement with closed-loop process control to enhance sheet quality, improve consistency, eliminate operator error, and maximize productivity and profitability!

There’s a thoughtful, determined ethic in Brad Van Allen’s way of doing business: “We’re a good, family company. We’ve been around 70 years. We treat our people right, and we want to make sure our customers win.”

Van Allen is CEO of Northwest Paper Box (NWPB) in Camas, Washington, a small community across the Columbia River from the Portland, Oregon, metro area. The company was founded in Portland in 1953 by Marvin “Van” Van Allen and his wife, Betty, and William “Bud” Van Allen and his wife, Elsie. As Brad tells the story, his father and uncle worked at the time for Grigsby Paper Box, a setup box company. “My dad and my uncle and aunt all worked for Grigsby,” he recalls, “and at some point, the owner promised my dad and my uncle a bonus at the end of the year. He didn’t have any profits to give them a bonus, but my dad and my uncle

and aunt were counting on it. So, they said, ‘Maybe we can do it ourselves.’”

The seed thus planted, Van married, moved to Baltimore, and, while he was there, began buying up used setup box equipment. Meanwhile, back in Portland, his brother, Bud, got wind of the bankruptcy of another setup box company, Simpson Paper Box. The company and its assets were up for auction, and after rushing back to Portland with his truck filled with equipment, Van and Bud submitted a successful bid. “They found out how much the competition was offering,” Brad says. “So, they bid $1 more, and the next day, they started.”

The Van Allens named their company “Northwest Paper Box,” a tribute to their geography and their way of differentiating themselves from their competitors, Pacific Paper Box and Grigsby. It was also a sign to the market of the new company’s reach.

Company: Northwest Paper Box

Established: 1953

Joined AICC: 1996

Phone: 503-240-2800

Website: www.nwpaperbox.com

Headquarters: Camas, Washington

CEO: Brad Van Allen

The rich and diverse industrial base of the Pacific Northwest drove the company’s early growth. From its early location in Portland, NWPB served several industries, from food to metal stampings to commercial printing.

NWPB’s early success was founded in setup box specialty boxes and corrugated “triple-slide” boxes. Designed for heavier industrial parts, the triple-slide box consisted of three overlapping boxboard sleeves that essentially locked in the product. “Portland was a hub for Warn Industrial winches, and triple-slides were designed to carry heavy things,” he explains, adding that this style of box was common before die cutters became standard equipment in paperboard converting operations. “Most people have gone to die cuts now; the triple-slide was a really good package, but it was far more labor-intensive than a die cut.”

From the get-go, the new company was a family affair: Van, Betty, Bud, and Elsie ran the business, and when Van and Betty’s sons and their daughter, Debbie, were old enough, they worked, too. “All of the family worked there at different times, beginning when we were pretty young,” says Brad of his brothers Rod and John and sister, Debbie Guzie. “Sometimes my dad would bring home piecework for the whole family to do while watching TV— you know, jewelry boxes that get a piece of cotton in them or special inserts. He’d have this whole little setup for us.”

Brad and his brothers all came into the business at different times. Brad, the eldest, joined in 1981. After getting his engineering degree from Oregon State University, he went on to Indiana University for his MBA in finance. From there, he joined White Motors in Cleveland, Ohio, and Farmington Hills, Michigan. “I learned a lot during that time,” he says, adding, “I moved back because my dad started having health problems. I was 27 at the time.”

Rod, now a vice president, was the next brother to join the business in 1983. He received his industrial engineering degree from Oregon State University and spent two years working for Kraft Foods in Buena Park, California. “I was doing efficiency studies, layouts, and modifying work stations,” he says. “I joined Northwest Paper Box in 1983 after my father passed away.”

John, also now a vice president, is the youngest of the three brothers. He attended Santa Clara University in California, where he earned a business degree. He joined the company in 1987, after a brief career in the commodities business in San Francisco; now, his focus at Northwest Paper Box is sales and marketing. “Being the best looking of the brothers, it became apparent that they had faces for accounting and production, but not to be out amongst customers,” John recalls. “I was not thrilled with

the high-pressure sales arena of the commodities trade, and I was looking for a slower-paced living environment.”

In the late 1980s, the three brothers decided to expand their footprint beyond setup boxes. “At the time, the rigid box business was not a growth business,” John says. “We brothers wanted to continue to work together, and we chose corrugated as a logical expansion.”

It was not an auspicious beginning, according to Brad. “So, we opened up a plant to do corrugated and promptly lost our shirts. We had no idea what we were doing.”

The Van Allens began their bumpy ride into corrugated in a separate 20,000-square-foot building with a few pieces of rudimentary equipment: a 50" two-color printer slotter, a laminator, and a die cutter. Once the kinks were worked out, says Brad, things began looking up. “We thought we knew what we were doing at the start, but you know, there’s a learning process,” he concedes. “After we got our stuff together about how to price things, how to run things, we started making a little bit of money.”

That early profitability prompted the Van Allens to look for additional converting capacity in better equipment and, if the opportunity arose, to look for companies that may be interested in selling. Brad found both. “We found another company called Taylor-Made Packaging that did corrugated boxes,” he says. “They had a jumbo. We didn’t. They’d been in business a long time and were profitable, but the majority owner wanted to get out of the business.”

After the acquisition of Taylor-Made in 1993, the Van Allens consolidated their corrugated and their setup box businesses

in one location in the Swan Island Basin industrial area northeast of downtown Portland—a location they occupied until April 2023. It was during the 30 years at what Brad calls simply “the Basin” plant that the company continued to acquire equipment for both sides of their operations. “We were limping along with our printer-slotters and hand gluers, and we went to an AICC meeting and met Gene Wicks [former owner of Boxes Inc. in St. Louis]. He had bought a Langston Saturn III flexo folder-gluer, and he said, ‘We can run the hell out of this thing and swiftly change from one order to the next.’”

Brad credits NWPB’s membership in AICC for helping the brothers make prudent capital equipment investments. He recalls meeting Jim DeLine and Jim Davis of DeLine Box and Kevin Hartney of Peoples Capital at a meeting in Chicago. “My brother, John, and I went to the meeting, and those guys kind of double-teamed us,” Brad says. “We weren’t married then; we were just a couple of single guys trying to figure out what the hell’s going on. They took us in and made sure we got to meet everyone. Kevin Hartney was a great advisor who helped us make the decision to purchase a new Saturn flexo folder-gluer from Langston’s Ken Normann.”

NWPB’s growth from that point required additional investment in converting capacity in its corrugated and setup box divisions. Initially, says Brad, the choice was used. “We bought other used equipment,” he says, “but we felt like it was all going to be a problem going forward, so [we] started buying new.”

Rod looks after the equipment side of the business. “Rod is an engineer,” says Brad. “Anytime we do any kind of machinery or moving things around, he gets involved.”

The company’s machinery acquisition philosophy is multifaceted, as Rod explains. “There are a number of things we look at when considering capital expenditures,” he says. “First, we want to know if there will be gains in production efficiency, quality, and safety. Then we ask, ‘What sort of ROI can we expect?’ Or perhaps we can fill a niche where there is market demand and we could better serve that demand. Finally, we look at the availability of replacement parts and ongoing technical support via in-person visit or remote troubleshooting.”

With these criteria employed, NWPB has built up a respectable arsenal of converting firepower: On the corrugated sheet plant side, an Apstar 6-color rotary die cutter; a Langston Saturn III 3-color and an EDF Europe Encore 4-color flexo folder-gluer; a Bobst specialty folder-gluer; an Eterna die cutter; and a Universal 74" printer-slotter. On the setup box side of the business, NWPB has five Emmeci setup box machines, multiple Crathern & Smith HNS setup box-wrapper lines, and ancillary equipment such as shrink wrappers.

Growing the setup box business in a static market challenged the company to look for viable acquisition targets in the Pacific Northwest. Brad credits his AICC connections with the guidance they needed at the time for valuations and structuring the deals. “We had a really good banker we were working with, and

then we also had Mitch Klingher of Klingher Nadler LLP to talk to. We were talking about how to structure a deal, and over time, I learned some of these things,” he says. “Now, having bought four companies in the last 40 years, they have been important for our growth.”

The chronology of the acquisitions goes like this: In 1995, NWPB bought the setup box assets of Grigsby Paper Box. In 1998, NWPB acquired the setup box assets of Pacific Paper Box. Then, in 2016, NWPB acquired the assets of Universal Paper Box in Seattle, a move that opened up the larger Seattle-Tacoma market, where Brad says there’s “way more business.”

“With these acquisitions, we have basically consolidated the setup box business in the Northwest,” he adds.

The growth in volume eventually caught up with NWPB at its longtime location in the Basin industrial area in Portland. “Eventually, we felt like we had to do something to get more room to manage this volume,” Brad says. “At one time, we had 20 truckloads of material outside for most of the summer because we could not process it fast enough through our plant. We moved our hand-fed die cutters around the building 14 different times to squeeze things in there and add new equipment, but in the end, it just was not an efficient plant. This, combined with our expiring lease and an increasingly unfavorable business climate, property tax structure, and crime near our facility, made us decide to look around for other options.”

The search took them to Camas, Washington, to a former pressure washer company’s facility, where NWPB invested heavily in the 2023 move and site improvements, including environmental

upgrades to be a “good neighbor.” Brad explains, “We have spent over $10 million moving our equipment and upgrading our capabilities with our move to Camas from Portland. All of our upgrades were accomplished in order to drive out costs, increase efficiencies, and create growth opportunities. Our plant now is a showpiece of our customer-focused direction and capabilities.

“About $1 million was spent on a waste building, which houses our wastewater treatment and scrap baler,” he continues. “We designed the building to have the cyclone under roof because we wanted to significantly reduce the noise associated with scrap conveyance and be a good neighbor. Having it all in one place also creates a cleaner environment for printing and processing.”

The Van Allens also improved the work environment through new lighting. “We also spent roughly $200,000 on all-new lighting in the plant to provide a great working environment for our employees, create more accurate color measurement, and reduce energy consumption,” Brad says, adding that the result is a plant with “improved workflow, quality, and safety. These initiatives help us create great products, service, and pricing.”

NWPB’s solicitude for its employees has been a core value since the beginning. Brad continues his family’s desire to provide good careers for those in their employ.

AUTOMATION

AUTOMATION

“Creating family living wage jobs” was one of four founding principles, he says.

The company lives this ethos today, even in a challenging labor pool such as Portland. NWPB currently has 97 employees and has found great success in finding people who, Brad says, “felt like there wasn’t a place for them in America anymore. The people that we have been able to hire and have success with might have had some past difficulties that made it hard for them to find employment. They are some of our better employees; they like it here. We’ve moved some of them up into greater roles of operators and supervisors.”

Recently joining the three Van Allen brothers is Steve McDonald, a 43-year veteran of the corrugated industry. His resumé includes longtime positions with Commencement Bay Corrugated, Western Kraft, and WestRock and its predecessors. McDonald’s role is that of a general manager, but his card has no title on it. “He gets into everything,” Brad says. “He helps John in sales; he helps the salespeople. He’s kind of my eyes and ears out there in the plant.”

He lauds McDonald’s talents in those areas important for a corrugated and setup box operation. “He’s really good with people and understanding what they want, and he does a really good job for us in purchasing, helping us get our material costs in line with where they need to be.”

The story of Northwest Paper Box is as much a family business success story as it is a story about success in the setup and corrugated box industry. Says Brad, “One of the craziest and most interesting stories about our business is the fact that we have three brothers working together—and have worked together— for 35 years. And there have been times we want to kill each other, sure, but each of us has our strengths.”

Not surprisingly, then, each of the Van Allen brothers has his unique view of the path forward for NWPB. “We anticipate

Civic and community pride is a recurring theme in conversations with independent boxmakers everywhere. Company lobbies are showcases for various Little League, United Way, and other community service commendations and certificates of appreciation. So, too, at NWPB.

The founding Van Allens’ location and investment in the City of Portland reflected their community-mindedness, which is evident in the company today. Even the company’s logo reflects its dedication to Portland—also known as the “City of Roses”—by the inclusion of a rose blossom in the letter “o” of Northwest. “My mother insisted on it,” Brad recalls.

In 1961, this civic loyalty was recognized when Marvin “Van” Van Allen was honored for his contributions to the city by being inducted into “The Royal Rosarians.” A few years later, William “Bud” Van Allen was also recognized. “At one of the various parades they attended, Betty, our mother, drove a float because the original driver came down with an illness,” Brad says.

The Royal Rosarians act by mayoral declaration as “the Official Greeters and Ambassadors of Goodwill for the City of Portland.” The Royal Rosarians were founded in 1912 as a public outreach philanthropy for the city, and membership is reserved for citizens of civic and philanthropic prominence.

The brothers have continued this family tradition of community service. They have been involved with church-related missions trips and church leadership; coaching sports teams; volunteering; and being on the board of a local charity, Sunshine Division.

creating cost-savings and competitiveness via robotics and systems improvements,” Brad says.

Rod agrees, emphasizing the workforce. “Finding skilled people or those with an aptitude for manufacturing is a challenge. We are always looking for the next ‘thing’ that will help relieve manual labor or methods to improve workflow.”

John’s perspective captures both, and he weaves into NWPB’s motto of “Integrity. Service. Quality.” Says John, “Overall, we believe there is an opportunity to stand

out with excellent quality and service. I honestly believe our reputation for being a stand-up company, with unquestioned integrity, has helped buyers and companies we deal with spread the word about NWPB in the marketplace.”

Steve Young is AICC’s ambassador-at-large. He can be reached at 202-297-0583 or syoung@AICCbox.org

superior graphics fast set-up

Max Speed: 12,000 s/h

Available Sizes: 2,800 (110”)

Max Sheet Width: 110.24 “

Max Sheet Length: 60.24”

Min/Max Caliper: .039/.354”

Features:

• 3 minute auto job change

• Setup while running

• Preset print and die cut

• Print and die cut inspection

• Anilox Roll Changing System (Full Automatic: 3+1)

inside-outside print fast set-up

Max Speed: 10,000 s/h

Available Sizes (max sheet):

2,100 / 82” (82 x 62.99”)

2,400 / 94” (94.5 x 62.99”)

2,800 / 110” (110.24 x 62.99”)

Features:

• 3 minute auto job change

• Setup while running

• Preset print