7 minute read

STRENGTH IN NUMBERS

What You Need to Know About Remote-Assistance AR Programs

BY STEPHEN LASLO

Advertisement

Lack of knowledge transfer from retiring workers, inexperienced operators, and continued production pressures remain signifi cant challenges for independent box plants. One solution to keep equipment up, running, and productive is the new world of remote assistance augmented reality (AR) programs. Such programs enable plant managers, technicians, operators, and engineers to share issues and collaborate with an OEM’s technical support staff in real time, direct from their facility via a provided smart tablet and dedicated app.

When properly designed and executed, these platforms allow technical support staff to resolve machine issues and assist in troubleshooting—complete with annotating and drawing right on the device. Th is allows them to share text on the screen and take pictures or videos for optimal documentation.

Another hallmark of these solutions is the inclusion of a comprehensive library of intuitive reference manuals and training materials using 3D models of the equipment. Ideally, this will include all basic machine calibrations, wear parts replacement, operations, lubrication, and other advanced machine protocols.

A key benefi t is the ability to troubleshoot machine issues without involving expensive emergency service visits. Plant managers, engineers, and technicians are able to rapidly share issues in real time from their facilities directly with OEM staff ers, enabling them to minimize downtime and provide fast solutions.

From my position at the Corrugating Machinery division of Mitsubishi Heavy Industries America, I can share a telling anecdote from late last year that shows a remote-assistance AR program in action.

A customer in Brazil was encountering what seemed to be a major equipment malfunction, in this case one of our EVOLs. Communicating over the phone and via email was challenging, between the language barrier and inexperienced maintenance techs. After days of struggling, this customer was convinced that an emergency rebuild was required. We were told to immediately ship parts and send a technician, as they couldn’t aff ord even more downtime. Sending a technician quickly would be diffi cult. Th e COVID-19 Delta variant was raging, our technicians had not done any international travel for 18 months, and all of the technicians’ work visas for Brazil had expired. Travel to Brazil at that time was extremely diffi cult in any event, as the U.S. government was requiring all internationally traveling citizens to show proof of a negative test taken within one day of their return fl ight and then another test after landing. My team knew that shipping emergency parts to Brazil was diffi cult during normal times, and these times were far from normal.

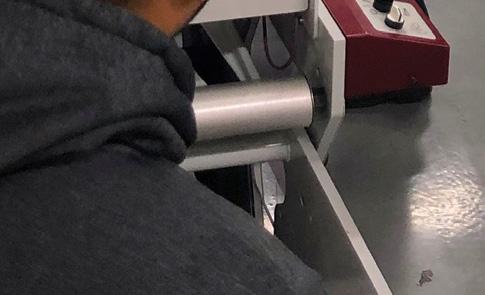

Th is is where a remote-assistance AR program came to the rescue. It allowed our engineers to see what users were looking at in the fi eld, using AR annotations to put virtual instructions on top of physical objects. Th e team was able to walk the customer through every relevant checkpoint on that section of the machine.

Th e visual representation of instructions really helped to overcome the language and experience barriers. Th rough several key measurements, our technicians learned that there was no major mechanical problem at all. It turned out that an uncommon machine calibration issue was the real cause of the problem. Under the team’s guidance, our customer recalibrated the machine and got it back up and running—no need for an expensive on-site emergency job.

Our investment in this sophisticated technology platform has been well worth it, benefi ting customers far beyond our friends in Brazil. OEMs can play an even more vital role in partnering with their customers to ensure productive operations.

Stephen Laslo is digital technology and training supervisor, Corrugating Machinery division, at Mitsubishi Heavy Industries America.

Do You Support Industy Education & Growth?

Support the Foundation for Packaging Education.

www.PackagingEd.org/Donate

Alternative Business Modeling

BY MITCH KLINGHER

For many years, I have been urging converters to break with the conventional wisdom of full absorption costing, but without it many of you seem lost. Pricing based upon some concept of return on sale (ROS) seems deeply ingrained in your business DNA, and even though you know in your heart of hearts that it doesn’t really work, you desperately cling to it. Your current system may be a “black box” created by someone else based upon a mysterious but supposedly rational system, but you are hesitant to give it up until you fi nd something that makes sense to you.

Th e answer to this problem is really quite simple and straightforward. Conventional absorption accounting is geared to calculating contribution margin and ROS. Using the concepts of throughput and velocity, as I’ve discussed in many previous articles, requires adding the dimension of time to this equation. Th e key issues here are the methodology used to calculate throughput or contribution, and how can you best measure time/velocity, without completely scrapping your existing system? All of you have a system that creates specs, orders, invoices, etc. Your people know how to use these systems, and it would be costly and disruptive to try to replace them. My recommendation is to use the existing systems but with an alternative simplifi ed business model that is based upon hours.

Conventional cost models start with the following: 1. Expense budget for the following year stratifi ed by fi xed, semifi xed, and variable costs. 2. Expected footage to be converted at each machine center. 3. Other information used for allocations, such as: a. Square footage occupied by the machine center b. Horsepower of the machine c. Expected crew sizes d. Projected delivery miles and cube utilization e. Expected setup times and run speeds for each piece of equipment

Based upon the above, a machine center rate is calculated, and every order will contain a calculation of materials, charges for other variable costs such as labor, repairs, utilities, supplies, a machine center charge, a delivery charge, an allocation of overhead, and a provision for profi t. Th e system will then calculate the expected contribution from the sale and the expected ROS. Th e worksheets and various other calculations that underly all of this are complicated and cumbersome and often very hard to discern. Th e theory is that each order must absorb a portion of the company’s overhead. As long as the expected expenses are the same as or lower than the budgeted expenses and the projected volume is higher than the expected volume, this type of system should always produce a profi t. Th is of course assumes that you can make every sale at the desired ROS, which, in point of fact, is rarely the case. If you are going to use this type of system, you must look at the material and labor variances in each job and the total budget variance and the total volume variance that will invariably occur at the company level each month. By looking at these variances and adjusting the model and the effi ciency of each order, you can ultimately achieve a well-functioning system. In practice, almost no one looks at these variances on a regular basis and adjusts the machine effi ciencies on each order or the expense and volume budgets that are fundamental to the system. So, what you end up with is fi nding ways to “trick” your system to come up with what you think are competitive prices that will generate profi ts for you. A better approach would be to model your company based upon projected machine hours that are available for sale and setting a goal for the contribution dollars per hour. You can defi ne contribution (sales less variable costs) any way that you think makes sense within your operating

ABC SHEET PLANT ALTERNATIVE BUSINESS MODELING F/YE 12/31/20X2

20X1 20X2 $/HR CONTRIB NOTES MACHINE ROUTING RUN SETUP TOTAL RUN SETUP TOTAL Small Flexo 1020 476 1496 1500 650 2150 $875 $1,881,250 Adding a Shift Midsized Flexo 877 523 1400 1100 600 1700 $1,100 1,870,000 Jumbo Rotary/Gluer 452 522 974 700 600 1300 $900 1,170,000 New Accounts Jumbo Rotary/Stitcher 543 623 1166 500 575 1075 $1,050 1,128,750 3-C Rotary D/C 1234 422 1656 1250 400 1650 $1,250 2,062,500 4-C Inside Out Rotary D/C 0 750 250 1000 $1,000 1,000,000 New Machine Label/Rdc/Sfg 874 345 1219 1000 400 1400 $1,100 1,540,000 10,652,500 Fixed Costs 8,175,000 Operating Income $2,477,500