5 minute read

FABRICATION.

from Portfolio 2025

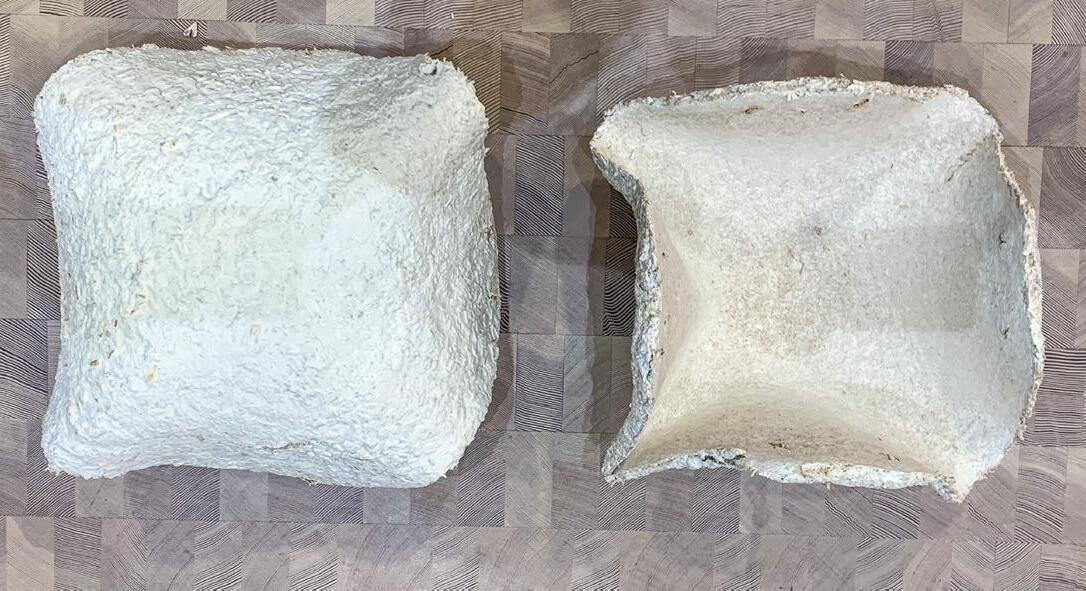

Use of Gravitational Form Finding techniques to uniformly shape Modular Mycelium Sheets without Formwork.

Advertisement

This experiment focuses on finding ways to grow mycelium as flat surfaces and determining their final shape without need for formwork. Ideally, these building materials would be modified to a degree in which they could be stacked as modular units. The research team uses the term mycelium to define the end product that occurs when fungal spores are allowed to grow in a sterile environment surrounded by substrates made of natural materials such as hemp. The spores branch out and form hyphae, or terminations, that present the unique capability of binding to the hyphae of other strands to form a unitized structural web. In mycelium growth, the hyphae is allowed to grow until it has completely engulfed the substrate that was previously sanitized and determined by Ecovative, the company that provides the material at a commercial level. Once the growth of hyphae is satisfactory, the mycelium can either be dehydrated or baked in order to stop further growth of branches and potential flowering into fungi. The researcher’s chosen course of action for preventing growth was air drying through hanging in order to take advantage of gravitational form finding.

For the purpose of this research paper, the term, “building materials,” isn’t exclusively applied to the material once it is used in construction, rather, it discusses the processes of manufacturing materials and their byproducts as an important factor. Due to the nature of the class, the task presented to the group was to design a manufacturing process for mycelium that addressed this particular aspect of construction.

read the full paper here

Jericho: Concrete Panels Using Recycled Fabric

The ambition behind Jericho was to rethink how building materials are utilized from the standpoint of ecology and sustainability that challenges the preconceived connotations of construction. In consideration of the project objective, our team chose to employ the strategy of sewing together clothing refuse into a quilt to be used as a mold for concrete panels. Textile waste is a significant contributor to landfills; Jericho acts to combat this by repurposing part of these heaps into usable formworks that have individuality based on the context in which they come from. Various pipe structures suspended this cloth work in the mold to forge unique variance in the panels that provide both structural rigidity and creative intricacies.

The variability in the clothing patterns and materials creates a unique texture and form in the wall construction. Shirts designed using vinyl heat transfer prints cast a mirror image of the pattern into the concrete. In addition to this, thick and overlapping sews on garments such as jeans leave behind an imprint that unmistakably reads as pockets and belt loops. The deviation between the materials’ elasticity forms an irregularity in the thickness of the wall, adding a third-dimensional quality that cannot be achieved with standard precast concrete practices.

Apertures are effortlessly added to the panels by incorporating sleeve and pant leg segments perpendicular to the quilt that protrude out of the formwork. This method allows for a smooth transition between wall and aperture that continues to afford the appearance of being formed by fabric. The interaction between formwork and pattern creates endless possibilities for unique panels giving the structure both personability and liveliness. Jericho breaks the barriers of materiality set by the construction industry and carries around the value of a cleaner future.

Steel Sheet Connection for Panelling

Hypar Exploration

Exploring Conics, Ruled, and Developable Surfaces I created a flexible tectonic machine for a developable surface of a hypar. The form of hypars are used in the iconic work of the Philips Pavillion by Le Corbusier. The flexible play of the piece allows manipulation and configuration to find hypar forms. This was prepared as a precursor to generate ideas for my final graduate architecture studio course.

Net Positive Home: From Fabrication to Site