Translucent Post Larvae Disease

Melanin Spots in Salmon

Views

Managing

Translucent Post Larvae Disease

Melanin Spots in Salmon

Views

Managing

SHENG LONG BIO-TECH INTERNATIONAL CO., LTD

Add: Block A5, Duc Hoa 1 Industrial Park, Duc Hoa District, Long An Province

Tel: (84-272) 3761358 - 3779741 Fax: (84-272) 3761359

Email: thanglong@shenglongbt.com Website: www.shenglongbt.com

SHENG LONG BIO-TECH (INDIA) PVT LTD

Add: Plot No. A-11/1, Part-A, SIPCOT Industrial Park, Thervoykandigai Village, Gummidipoondi Taluk, Thiruvallur District, Tamil Nadu 601202, India. Tel: 91-44-6790 1001 Fax: 91-44-6790 1017

Email: info@shenglongindia.com Website: www.shenglongindia.com , a complete range of quality fish feeds are formulated by our experienced aquatic animal nutritionists covers freshwater and marine species. The quality diets will maximize feed intake and improving feed conversion ratio, promotes performance by supplying a specific amino acid balance to deliver excellent growth and reducing environmental impacts.

Pangasius in India: Mismatch

Pangasius harvest in Andhra Pradesh, p40.

Editor/Publisher

Zuridah Merican, PhD

Tel: +6012 205 3130

Email: zuridah@aquaasiapac.com

Editorial Coordination

Corporate Media Services P L

Email: irene@corpmediapl.com

Web: www.corpmediapl.com

Design and Layout

Words Worth Media

Management Pte Ltd

Email: sales@wordsworth.com.sg Web: www.wordsworth.com.sg

AQUA Culture Asia Pacific is published bimonthly by

Aqua Research Pte Ltd

3 Pickering Street, #02-36 Nankin Row, Singapore 048660

Web: www.aquaasiapac.com

Tel: +65 9151 2420

Printed in Singapore by Times Printers Private Limited 18 Tuas Avenue 5 Singapore 639342

Subscriptions

Subscribe via the website at www.aquaasiapac.com

Subscriptions can begin at any time.

Subscriptions rate/year (6 issues): SGD 70,

Email: subscribe@aquaasiapac.com

Tel: +65 9151 2420

Fax: +65 6223 7314

Copyright © 2024 Aqua Research Pte Ltd.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying or otherwise, without the prior permission of the copyright owners.

Volume 20, Number 6

From the editor

2 An Ardous 2024

Industry News

4 larvi 2024: the fish and shellfish hatchery conference returns after 7 years

Shrimp Aquaculture

8 Replacing Artemia nauplii in shrimp hatcheries

A micro-encapsulated diet ensures biosecurity and economics in hatchery operations

By Mark Rowel Napulan, Peter Van Wyk and Ramir Lee

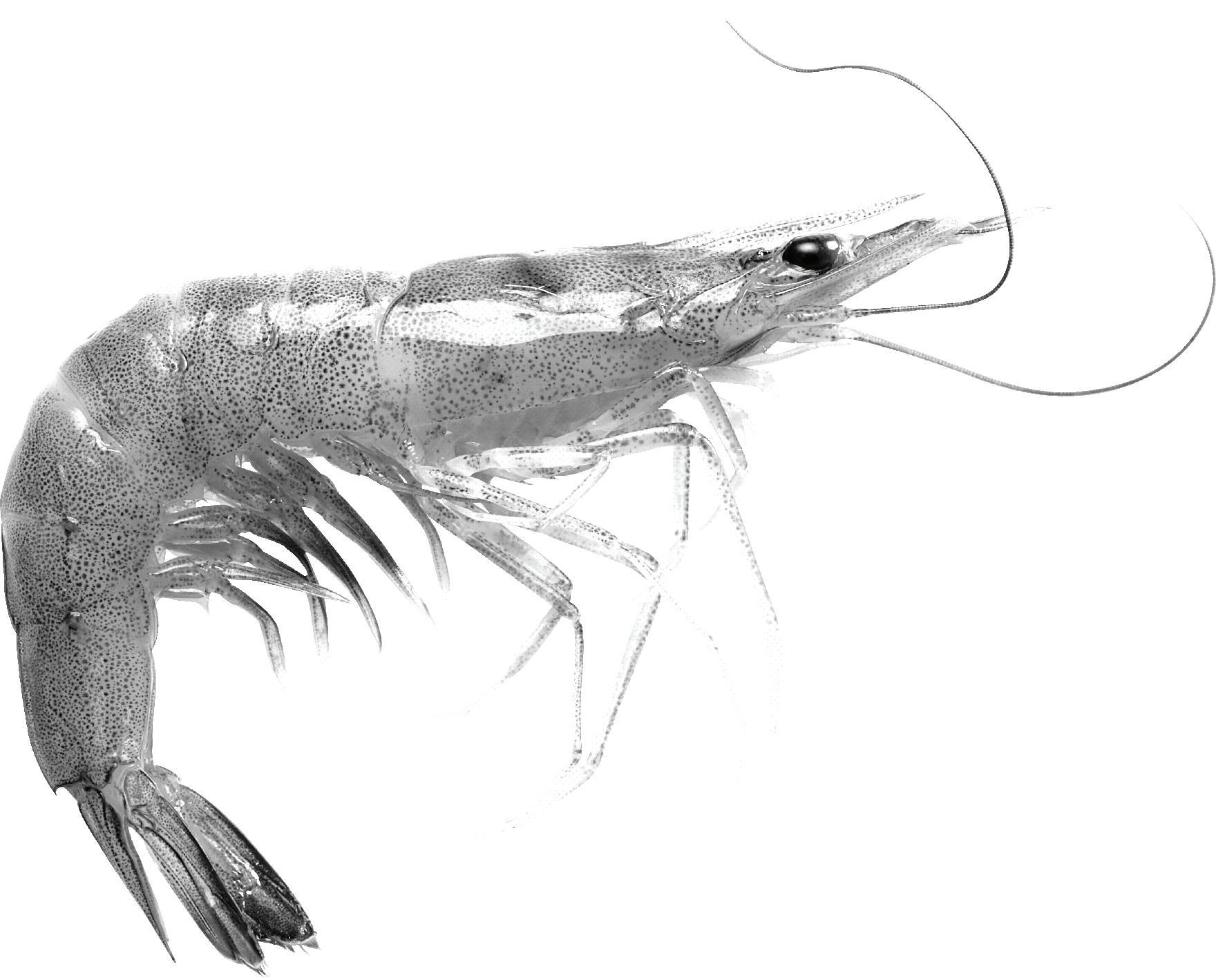

11 Translucent post larvae disease

Andrew Shinn and colleagues caution that molecular testing is essential for accurate identification of the specific cause

13 Future proofing shrimp farming at GSF 2024

16 Assessing the environment footprint of commercial shrimp operations

A conversation with Benedict Standen and Thiago Soligo on environmental footprinting made easy

Feed Technology

20 Feeding the future: The critical role of early stage nutrition in aquaculture

Marc Campet says the nursery stages require micro feeds with precise and functional nutrition to support a strong start for fish and shrimp growth

22 Optimising aquafeed formulations

The potential of using enzymes technology to improve sustainability in Asian aquaculture. By Vivi Koletsi

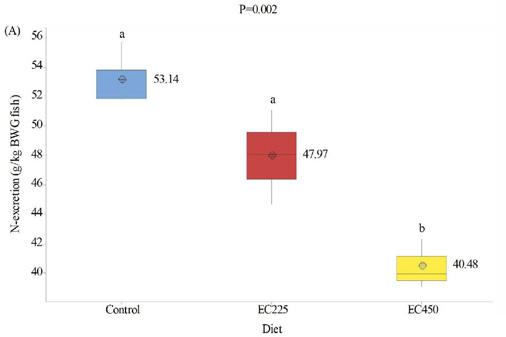

25 Research on enhancing quality and reducing melanin spots

There is whole fillet downgrading, says Marianne Nergard

Finfish Aquaculture

28 How can Asia’s core fish farming industry enter the mainstream investors portfolio

A discussion at TARS 2024

Disease Management

32 Phytobiotic -based functional additives to reduce the impact of EHP-WFS in shrimp

Shrimp farming in Asia is confronted with significant challenges due to disease outbreaks, particular white faeces syndrome. By I-Tung Chen, Khin Thiri Khit, Phuc Hoang, Maria Mercè Isern-Subich, Loc Tran and Waldo G. Nuez-Ortín

35 Disease mitigation in marine fish and tilapia

At TARS 2024,the boundaries of current knowledge were pushed in managing outbreaks in marine fish and tilapia. By Zuridah Merican

38 Too late to prevent a shrimp disease outbreak

A caution on Point of Care testing after clinical signs of disease in shrimp. By Jade Nauman

Industry Review: Freshwater Fish

40 Pangasius catfish farming in India: Development and challenges

Laxmappa Boini and Ravinder Rao Bakshi say frequent lows in farmgate prices are pushed by seasonality and demand mismatch

45 Carp culture in Nepal receives a post-COVID boost

Local feed company spearheads innovation across the supply chain. By Moushumi Shrestha, Pradip Paudel, Anton Immink, Bishal Gautam and Miroslav Kostecki

48 The case for marine tilapia aquaculture in Singapore Shubha Vij, Joe Ng and Rajesh Joshi present this option

Show Review

50 Aqua 2024 – A joint EAS and WAS conference and trade show

53 IAFET 2024- Empowering the regional aqua business

55 At larvi 2024, solutions for early stage farming

Aqua Culture Asia Pacific is a print and digital magazine. View E-magazine & Download

PDF of past issues for free www.aquaasiapac.com

59 Company and Event News

Zuridah Merican

Global prices for shrimp are currently at their lowest since the last decade and without doubt from an oversupply. Farmers are struggling and the most frequently asked question in 2024 was, “when will the low prices end!” During a panel at the Global Shrimp Forum (GSF) 2024, Balasubramaniam V said that in India, few are giving up, but more are working on efficiencies to be ready when prices are better. Unlike previous years, there is less room for error for Indonesian farmers practicing intensive culture. For them, meeting P&L targets is key as they struggle with poor support from banks. In June 2024, Kontali estimated the year’s growth at 5% for India and 6% for Vietnam; all of which are relative to the slowdown in 2023.

Contrary to 2023, shrimp demand has stagnated. Today, there is a costof-living crisis in the EU and the US affecting the shrimp market. Shrimp remains a luxury item in the eyes of middle to low-income consumers. China was the great hope for many shrimp producing countries until We strive to be the beacon for the regional aquaculture industry. We will be the window to the world for Asia-Pacific aquaculture producers and a door to the market for international suppliers. We strive to be the forum for the development of self-regulation in the Industry.

recently, as consumers feel the pain of the decline in real estate valuations and face depressed consumer confidence. Ecuadorian shrimp exporters have been shifting their focus from China to the EU and elsewhere. Farmers in the Asian region also feel the pain of global trade, when Ecuadorian shrimp, destined for the Chinese markets, are diverted and flood markets in Southeast Asia.

In fish aquaculture, the task set at TARS 2024 included targeting potential marine fish species for mass market adoption, to be the ‘tropical salmon’. The choice of fish does not depend on the fastest growth or sustainable farming technology but the fish popular with consumers at any point in time. Industry leaders discussed marketing, branding and sustainability (MBS) as ways to gain market access.

The continuous decline in US consumption of frozen tilapia fillets, down to 48,000 tonnes until June 2024, was reported. The US tariffs of 25% on Chinese tilapia imports have significantly impacted the margins of exporters. The year saw China losing the frozen tilapia market whilst emerging producers in Latin America gain with fresh chilled tilapia, now a growing segment in the US.

In the US white fish market, Vietnamese pangasius fillet has gained significant market share in lieu of tilapia. This shift can be attributed to several factors, including competitive pricing, improved quality, and increased demand for sustainable seafood. There is also a high demand for pangasius in China, albeit at lower prices than locally produced freshwater carp.

In terms of aquafeed, all commodity prices have dropped. Being optimistic, can we expect a reduction in feed costs giving farmers some room to breathe. As of October 2024, the price of fish meal was USD1,638/

tonne. The average price of fishmeal in 2023 was around USD1,738/tonne (Source: ycharts.com). With this decline in prices and with fishmeal as the gold standard, will aquafeed millers increase fishmeal in their formulations? This year saw some traction on the push for sustainable feeds, led by certification bodies and EU’s deforestation law. Fortunately, ASC has moved the compliance date to October 2026 from the original in January 2025. The EU’s deforestation regulation, applicable for imports into EU was also pushed back to January 2026 for large operators and June 2026 for micro- and small enterprises.

Disease is the major cause of poor productivity (yield/ha) and mitigating outbreaks amidst low prices has not been easy for farmers. Poor prices lead to cost cutting and less investment in functional health additives to pre-empt outbreaks. Facing poor survival rates, a Malaysian farmer reflected that profitable shrimp farming is now just an illusion. In general, to overcome the double jeopardy (low prices and low survival), steps include reduction in stocking densities to as low as 60PL/m2 in Malaysia and in India to 20-25PL/m2

Sustainability is not just for differentiation but a necessity for the continuation of aquaculture in Asia. The push to nurture the next generation of farmers was successful in 2024, all because we have visionaries willing to step-up to the plate, such as Rizky Darmawan (Indonesia), Chodpipat Limlertvatee (Thailand) and Bettina Valerie Lim (Philippines). Fortunately, they still find aquaculture sexy despite an arduous 2024.

If you have any comments, please email: zuridah@aquaasiapac.com

A revolutionary liquid diet harnessing the advantages of algae and probiotics to enhance the health and performance of shrimp in the early life stages.

This specialised conference and trade show for early stages in fish and shellfish aquaculture - Fish and Shellfish Larviculture Symposium returned to Belgium after a long 7-year break. The first symposium was held in 1991 and continued every 4 years until 2017. COVID disrupted this 4-year trend. It was with much relief to academics, industry and students involved in the fish and shellfish hatchery and nursery segments to finally have a platform to share knowledge, innovations and network at the 8th meeting in Ostend, Belgium.

Throughout the 3-day conference and trade show, over September 9-12, several of the 350 participants from 50 countries, remarked on how they have missed this conference focusing uniquely on larviculture. The organising group from the Laboratory of Aquaculture and Artemia Reference Center, Norwegian University of Science and Technology (NTNU) and SINTEF, Norway promised to resume with the next symposium to follow the 4-year Olympic style interval in 2028.

Conference Chair Professor Dr Annelies Declercq from the Laboratory of Aquaculture and Artemia Reference Centre, Ghent University said that feedback from attendees was overwhelmingly positive, with many expressing their excitement about being back at larvi. “Seven years was truly too long but the wait was worth it” was a common sentiment. Attendees emphasised that this is a conference like no other—very thematic, no parallel sessions, allowing everyone to attend all the presentations and ensuring that no valuable insight was missed. We are very grateful to our scientific committee for helping to draft the scientific program.”

This conference had 47 selected speakers. The diversity of topics ranged from larval nutrition, innovative approaches to disease management, broodstock maturation, deformities, and larval development, to commercial upscaling. “These highlighted the remarkable expertise within our community. Those not presenting orally had the chance of poster presentations and selection for a panel discussion on their work. We bridged theory and practice,

The opening of larvi 2024 had musical intermezzos by the Koninklijk Jeugdmuziekkorps Onze-LieveVrouwecollege Oostende (OLVOBand).

offering valuable insights for both academia and industry,” said Declercq. She complimented the presenters on the level of detail, the strong methodology, and the clear focus on addressing real-world challenges which truly set the tone on the quality of the presentations.

The conference started with two keynote presentations. Kari Attramadal, Norwegian University of Science and Technology (NTNU) presented on “More arguments for microbial management in aquaculture hatcheries” and Patrick Waty, CEO INVE Aquaculture, Gold Sponsor, discussed the status of marine fish and shellfish hatcheries around the world (https://bit.ly/3C2rT6a).

Microbial control in aquaculture systems requires understanding the processes governing the composition of the microbiota associated with different compartments - fish larvae, rearing water, and live food. Attramadal said that water and fish microbiota are not the same and water microbiota is not the same as biofilm microbiota. Her

runner up for his poster on “Mature Biofilters Safeguards Recirculating Aquaculture Systems (RAS) from Opportunistic Bacterial Invasions”.

recommendations to increase microbial control in culture of marine larvae included biosecurity of intake water, its microbial maturation and closure of the gap between the load of organic matter and the number of competing bacteria. The rearing water affects larval microbiota more heavily than diet. The idea is not to kill all bacteria but to ensure that fish is exposed to good bacteria.

Declercq said, “Today’s industry challenges present a wealth of opportunities—disease prevention and management, food security, and improving livelihoods of local communities. After speaking with a range of fish and shrimp producers, consultants, and suppliers, the feedback was clear: larvi inspired new ideas. The solutions presented were both practical and scientifically grounded, offering direct applications for the industry. In conclusion, it’s all about applied, upscaled solutions, and incorporating AI into the next wave of industry advancements.”

Patrick Sorgeloos recalls the critical role of larval nutrition for global aquaculture

It was also an opportunity for the global larviculture community to recognise Professor Patrick Sorgeloos, the man behind the global hatchery industry and who continues to have a genuine interest in nurturing academia and industry alike. At the closing of the conference, he was named as larvi ambassador and founder.

Patrick Sorgeloos: I started this conference series back in 1991, during my tenure at the Artemia Reference Centre, Ghent University , Belgium. Back then, aquaculture was just growing, but its future growth required predictability and cost-effective availability of larvae, fry and fingerlings production. Year by year, there are major breakthroughs in the hatchery and nursery segments but improvements must be continuous.

Back then, why the need for such a specialised conference series?

PS: The unique nature of the larvi conferences is that we focus on one specific theme, larviculture of fish and shellfish species, not only a multibillion aquaculture industry but still the key to successful aquaculture outputs. We need to admit that there is still much room

for improvement, particularly when it comes to making the industry more predictable (i.e. how many successful hatchery runs in a year), low standard deviations and high hatchery survivals!

When I compare the hatchery practices of today with 20 and 30 years ago I can say that there is much room for improvements. Of course, the hatcheries are much bigger than ever before, but they are no longer operated by the highly skilled technicians that operate the hatcheries, especially for shrimp. Obviously, for cost savings less skilled technicians have taken over and much of the knowledge and practices of the past are not considered anymore. Many Vibrio infections in the shrimp hatcheries can be traced back to poor Artemia management (and algae as well), as basic principles of how to produce Vibrio free Artemia instar I are not known/considered anymore.

Do you see any changes in larviculture over the years?

PS: Furthermore, it appears from the Artemia session organised just prior to the larvi conference that in shrimp hatcheries and perhaps in marine fish hatcheries as well, we might have reduced the Artemia feeding levels below a critical quantity and especially quality-wise. We know that older Artemia nauplii with lower nutritional value and likely contaminated with Vibrio , while not affecting larval survival and growth, are compromising the immune competence of the post larvae prior to their transfer to the stressful grow out conditions. This might explain the many Vibrio -related disease outbreaks in recent shrimp farming.

We finally see also an increased interest in marine fish larviculture with several new species considered for farming in different parts of the world. We all admit that this is a sector with considerable potential in the future.

Reflections on larvi 2024 with previous editions?

PS: These larvi conferences go back to September 1991 when we had few participants from the private sector and mainly from the Mediterranean marine fish hatcheries. The academic representatives were mostly from Europe. Many were also from our cooperation projects (often with INVE) in Latin America, Southeast Asia with shrimp and marine fish, in particular Asian seabass.

Over the 8 past conferences, we have seen an increase in participants from the private sector reaching about 50% at the 2017 conference. This is the first time we reached over 350 participants with large groups from outside Europe, showing the worldwide interest in such a specialised conference.

Moving forward with extractive aquaculture

There were a few presentations on molluscs and seaweed larviculture, although this sector of extractive aquaculture deserves more international attention if we want to make aquaculture more sustainable through more integration with ‘fed’ aquaculture.

PS: Furthermore, it appears from the Artemia session organised just prior to the larvi conference that in shrimp hatcheries and perhaps in marine fish hatcheries as well, we might have reduced the Artemia feeding levels below a critical quantity and especially quality-wise. We know that older Artemia nauplii with lower nutritional value and likely contaminated with Vibrio, while not affecting larval survival and growth, are compromising the immune competence of the post larvae prior to their transfer to the stressful grow out conditions. This might explain the many Vibrio-related disease outbreaks in recent shrimp farming.

We finally see also an increased interest in marine fish larviculture with several new species considered for farming in different parts of the world. We all admit that this is a sector with considerable potential in the future

Reflections on larvi 2024 with previous editions?

A summary of some takeaways came from the closing words by representatives from the private and academic sectors. Eamonn O’Brien, Skretting, commented, “Life start sets life performance” is a phrase that resonates strongly, as the focus on early life stages across various aquaculture species is critical for the industry’s success. Innovation, collaboration, and clever minds will continue to drive us forward.”

PS: These larvi conferences go back to September 1991 when we had few participants from the private sector and mainly from the Mediterranean marine fish hatcheries. The academic representatives were mostly from Europe but were not limited to Europe. Many were also from our cooperation projects (often with INVE) in Latin America, Southeast Asia with shrimp and marine fish, in particular Asian seabass.

Over the 8 past conferences, we have seen an increase in participants from the private sector reaching about 50% at the 2017 conference. This is the first time we reached over 350 participants with large groups from outside Europe, showing the worldwide interest in such a specialised conference.

For Professor Atsushi Hagiwara, Nagasaki University, it was clear - “No Larvae, No Aquaculture”. Larviculture forms the foundation of successful aquaculture. However, a key question remains: What is egg quality? Since egg quality directly influences larval survival, improving it is essential for the sustainability of the industry. Therefore, finding the right parameters to determine egg quality remains a key challenge, as was often identified at previous larvi conferences. Despite advances in molecular biology and genome breeding, we have yet to focus fully on enhancing larval survival rates. This is an area ripe for future exploration.”

Moving forward with extractive aquaculture

At the pre-conference Artemia session, members of the newly FAO-recognised International Artemia Aquaculture Consortium presented overviews on the worldwide situation regarding Artemia production and use in aquaculture. A highlight was the finding that feeding more Artemia in shrimp hatcheries might not affect survival and growth but have a significant impact on improved immune competence of the postlarvae, thus improving their survival once transferred to stressful grow-out conditions.

There were a few presentations on molluscs and seaweed larviculture, although this sector of extractive aquaculture deserves more international attention if we want to make aquaculture more sustainable through more integration with ‘fed’ aquaculture.

Box at bottom

UGent Mama Magda Aquaculture Fund

“The quality of presentations has been outstanding at previous meetings. This year, seeing it from a different perspective, this time as conference chairperson, in fact, they exceeded my expectations. We consistently bring in top experts in the field alongside passionate students, and the depth of knowledge and innovation presented was truly impressive. From cutting-edge research to practical, industry-relevant applications, larvi 2024 bridged theory and practice, offering valuable insights for both academia and industry,” said Declercq.

Many followers of larvi conferences will remember Magda Vanhooren, who was very much involved in the practical organisation of the larvi conferences and supported international students at the Laboratory of Aquaculture & Artemia Reference Centre Ghent University established this fund in her memory. The fund finances a 6-month research stay for PhD double degree candidates between UGent and their university in the South

For the next edition, organisers aim to build on the success and feedback from this year’s event. One of the key goals will be to provide even more opportunities for in-depth discussions and exchanges between attendees, to allow for longer conversations, which were something attendees particularly appreciated. “The current setup, kept our sponsors at the front and centre, ensuring that practical, immediately applicable solutions for aquaculture were always within reach. The interaction between industry and academia was a highlight, with both sides benefiting from each other’s expertise,” said Declercq.

Many followers of larvi conferences will remember Magda Vanhooren, who was very much involved in the practical organisation of the larvi conferences and supported international students at the Laboratory of Aquaculture & Artemia Reference Centre. Ghent University established this fund in her memory. The fund finances a 6-month research stay for PhD double degree candidates between UGent and their university in the South.

BRINE: The writer, the professor, and the shrimp that changed the world by Dieter Honoré, is the story of the extraordinary life of Patrick Sorgeloos, as he journeys around the world connecting with young scientists, nurturing them on artemia biology and hatchery technology. Sorgeloos had developed a fascination for Artemia and committed full time to this tiny crustacean which would play an important role in solving global food shortages through aquaculture. Honoré weaved an excellent biography of Sorgeloos’ life - crafting a tale based on intuition and imagination and not so much on hard facts and science. This book offers excellent information on Patrick – from the time he was born, his childhood interest on nature, his family life, his beloved wife - Magda, and on his life-long passion on Artemia research.

BRINE: The writer, the professor, and the shrimp that changed the world by Dieter Honoré, is the story of the extraordinary life of Patrick Sorgeloos, as he journeys around the world connecting with young scientists, nurturing them on artemia biology and hatchery

ROBUSTNESS AND DIGESTIVE SYSTEM INTEGRITY +

PERFORMANCE

Partnering in microbial solutions for a changing world. Using sound science, proven results and knowledge from experience, Lallemand Animal Nutrition helps our customers and industry partners be more successful – and animals lead healthier lives.

Lallemand Animal Nutrition provides a full range of speci c, natural microbial products, services and solutions that improve animal well-being and performance while respecting animals, people and the environment.

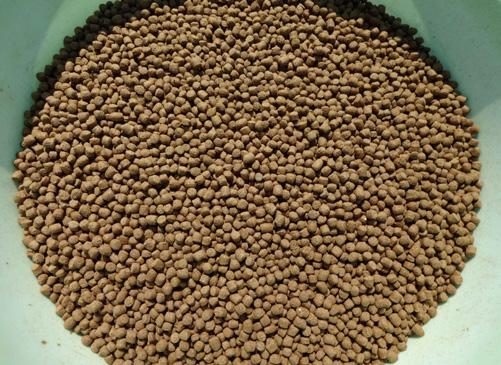

The focus is on the advantages of a micro-encapsulated diet - from ensuring biosecurity during hatchery operations to its economics

By Mark Rowel Napulan, Peter Van Wyk and Ramir Lee

Artemia nauplii have been a critical live diet for penaeid shrimp larvae in commercial marine shrimp hatcheries since the 1960s (Cook and Murphy, 1966). They are rich in essential fatty acids, proteins, and other nutrients required by shrimp larvae for optimal growth and development. Artemia nauplii have several attributes that have contributed to their widespread use in commercial shrimp hatcheries. The size of Artemia nauplii is highly suitable for shrimp larvae. The cysts can be easily stored with a long shelf-life and can be hatched on demand. Despite all these advantages, Artemia nauplii do not epitomise as a perfect feed.

Issues with Artemia nauplii

The nutritional value of Artemia nauplii can be highly variable. It is at its maximum immediately after hatching. The nutritional value of the Instar 1 nauplii declines continuously with time after hatch as the nauplii deplete the nutrients stored in the yolk sac. The nutritional value of Artemia nauplii varies considerably between different geographic strains and from one year to the next.

A common practice in commercial shrimp hatcheries is to parboil and then freeze Artemia nauplii prior to feeding. Feeding frozen nauplii makes it easier for shrimp larvae to capture them, reducing the risk of overfeeding and preventing tanks from becoming over-populated with adult Artemia. However, the process of parboiling and freezing nauplii leads to the degradation of some proteins and further loss of nutritional value.

The biggest weakness associated with the use of Artemia nauplii in hatcheries is that they present a major biosecurity risk. Hatched nauplii are an important vector for the introduction of Vibrio into larval rearing tanks (Lavilla-Pitogo et al., 1990; Lopez-Torres et al., 2001). Glycerol released by the cysts during the hatching process provides an ideal culture medium for Vibrio (Van Stappen et al., 2024). As a result, Vibrio loads in both the hatching water and in the nauplii themselves can be extraordinarily high (Table 1). Decapsulation of the cysts prior to hatching reduces Vibrio loads, but only slightly. Disinfection of hatched nauplii prior to feeding reduces Vibrio counts but is not 100% effective.

counts

Capsulated cysts De-capsulated cysts Water (x 106 CFU/mL) Artemia (x 109 CFU/mL) Water (x 106 CFU/mL) Artemia (x 109 CFU/mL) 6.20 ± 0.45 1.20 ± 0.90 2.00 ± 1.50 0.45 ± 0.24

Table 1. Vibrio counts isolated from Artemia hatching water and Artemia nauplii from hatching tanks stocked with nondecapsulated and de-capsulated cysts (Interaminense et al., 2014).

In studies conducted at the University of the Philippines Visayas, it was demonstrated that Rescue administered in the feed eIectively colonised the gut and provided significant improvement in challenge trials with Vibrio parahaemolyticus and Vibrio harveyii (Figure 1).

In studies conducted at the University of the Philippines Visayas, it was demonstrated that Rescue administered in the feed eIectively colonised the gut and provided significant improvement in challenge trials with Vibrio parahaemolyticus and Vibrio harveyii (Figure 1).

Figure 1. Results of challenge trials where the survival of juvenile shrimp fed with feed top coated with Rescue is compared with survival of shrimp fed with feed without Rescue. The graph on the left shows results when challenged with Vibrio harveyii, while the graph on the right shows results when challenged with Vibrio parahaemolyticus

Figure 1. Results of challenge trials where the survival of juvenile shrimp fed with feed top coated with Rescue is compared with survival of shrimp fed with feed without Rescue. The graph on the left shows results when challenged with Vibrio harveyii, while the graph on the right shows results when challenged with Vibrio parahaemolyticus.

Figure 1. Results of challenge trials where the survival of juvenile shrimp fed with feed top coated with Rescue is compared with survival of shrimp fed with feed without Rescue. The graph on the left shows results when challenged with Vibrio harveyii, while the graph on the right shows results when challenged with Vibrio parahaemolyticus.

PL8 improved survival by 33% compared to a control group. In both trials, the final weights of the post larvae harvested were the same for both treatment groups.

Trials conducted at Zeigler’s Aquaculture Research Center (Z-ARC) showed that EZ Artemia Ultra can replace 100% of the nauplii in the larval rearing protocol. Nevertheless, most hatcheries prefer to use the liquid microencapsulated diet to replace 30-50% of the nauplii in the diet. When the diet is used to partially replace Artemia nauplii, many hatcheries reported higher survival rates as compared to when no nauplii were replaced.

In 1997, Zeigler developed a biosecure liquid microencapsulated diet called EZ Artemia to replace live Artemia nauplii. This diet was formulated with marine protein and lipid sources to exceed the nutritional value of enriched Artemia nauplii. The marine protein sources are PCR-tested to guarantee the final product is free from Vibrio and all World Organisation for Animal Health (WOAH)-listed shrimp pathogens. In addition, this diet contains Vpak , a blend of ingredients promoting improved larval immune function.

Trials conducted at Zeigler’s Aquaculture Research Center (Z-ARC) showed that EZ Artemia Ultra can replace 100% of the nauplii in the larval rearing protocol. Nevertheless, most hatcheries prefer to use the liquid microencapsulated diet to replace 30-50% of the nauplii in the diet. When the diet is used to partially replace Artemia nauplii, many hatcheries reported higher survival rates as compared to when no nauplii were replaced.

Replacing Artemia nauplii in the feeding protocol can potentially reduce production costs. When costs are compared based on equivalent usage rates, the liquid microencapsulated diet is likely to be cheaper than using Artemia nauplii, whether hatched from cysts or purchased pre-hatched as an Artemia nauplii paste (Table 2). Additional costs associated with hatching Artemia cysts should be considered.

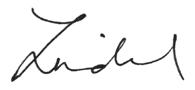

In recent trials at an Indonesian hatchery (Figure 2), replacement of 100% of the Artemia nauplii in the diet between zoea 3 (Z3) and post larva 1 (PL1) resulted in survival increasing by 32% . In the second trial at the same hatchery, replacement of 33% of the nauplii fed from PL1 to PL8 improved survival by 33% compared to a control group. In both trials, the final weights of the post larvae harvested were the same for both treatment groups.

In recent trials at an Indonesian hatchery (Figure 2), replacement of 100% of the Artemia nauplii in the diet between zoea 3 (Z3) and post larva 1 (PL1) resulted in survival increasing by 32% . In the second trial at the same hatchery, replacement of 33% of the nauplii fed from PL1 to PL8 improved survival by 33% compared to a control group. In both trials, the final weights of the post larvae harvested were the same for both treatment groups.

In 2021, EZ Artemia Ultra was launched after nearly 25 years of continuous R&D. Compared to the original EZ Artemia, this product has a higher nutrient density and improved ingredient digestibility. The microcapsules are almost neutrally buoyant and will remain suspended in the water column nearly indefinitely with minimal aeration. The microcapsules contain 1.0 x 107 CFU/g of Rescue, a proprietary blend of four species of Bacillus bacteria selected for their ability to control the most pathogenic species of Vibrio. The liquid fraction of EZ Artemia Ultra contains 1.0 x 107 CFU/g of Remediate, a blend of Bacillus species selected for their ability to digest organic matter and control ammonia.

In studies conducted at the University of the Philippines Visayas, it was demonstrated that Rescue administered in the feed effectively colonised the gut and provided significant improvement in challenge trials with Vibrio parahaemolyticus and Vibrio harveyii (Figure 1).

Commercial trials

Trials conducted at Zeigler’s Aquaculture Research Center (Z-ARC) showed that EZ Artemia Ultra can replace 100% of the nauplii in the larval rearing protocol. Nevertheless, most hatcheries prefer to use the liquid microencapsulated diet to replace 30-50% of the nauplii in the diet. When the diet is used to partially replace Artemia nauplii, many hatcheries reported higher survival rates as compared to when no nauplii were replaced.

In recent trials at an Indonesian hatchery (Figure 2), replacement of 100% of the Artemia nauplii in the diet between zoea 3 (Z3) and post larva 1 (PL1) resulted in survival increasing by 32% . In the second trial at the same hatchery, replacement of 33% of the nauplii fed from PL1 to

The Hydrotech Drum Filter Value series focuses on reduced maintenance, increased component quality and simplified operation – all to give your plant maximum filtration performance at a minimum operational cost.

Let us help you! Call +46 (0)40 42 95 30, or visit www.hydrotech.se

100% Replacement of Artemia Nauplii z3 - PL1

33% Replacement of Artemia Nauplii PL1 - Pl8

Figure 2. Comparison of survival rates in tanks fed with EZ Artemia Ultra replacing a percentage of the Artemia nauplii in the feed protocol. The graph on the left shows the results of a trial in which 100% of the Artemia nauplii were replaced with EZ Artemia Ultra from Z3 – PL1, while the graph on the right shows the results of a trial in which 33% of the Artemia nauplii were replaced with EZ Artemia Ultra from PL1 – PL8.

However, when comparing the economics associated with the use of Artemia nauplii with the use of EZ Artemia Ultra, one must also consider how differences in survival affect hatchery profitability. If improvements in biosecurity and reduced viral loading result in higher survival rates, revenues from the sale of post larvae will increase. The impact of higher survival on revenues will often have a much larger impact on hatchery profitability than the impact of the price differences for different feeding protocols.

References

Cook, H. L. and Murphy, M. A. 1966. Rearing penaeid shrimp from eggs to postlarvae. Proceedings 19th Annual Conference Southeastern Association Game and Fish Commissioners 19: 283–288.

Interaminense, J.A., Ferreira Calazans, N., do Valle, B.C., Lyra Vogeley, J., Peixoto, S., Soares, R. and Lima Filho, J.V. 2014, Vibrio spp. Control at Brine Shrimp, Artemia, Hatching and Enrichment. J World Aquacult Soc, 45: 65-74. https://doi.org/10.1111/ jwas.12096

*Note: The price of Artemia cysts can vary widely based on quality, origin, and annual supply.

Table 2. Cost per kg of EZ Artemia Ultra, Artemia cysts, and Artemia nauplii paste expressed as cost per 100 million Artemia nauplii equivalent amount.

Artemia nauplii have been demonstrated to be a major vector for the introduction of pathogenic Vibrio into larval rearing tanks which causes severe diseases such as acute hepatopancreatic necrosis disease (AHPND) and transparent post larva disease (TPD). These diseases can lead to high mortality rates in hatcheries, significantly impacting hatchery productivity and profitability. When Vibrio infected shrimp are introduced to farms the bacteria can result in outbreaks and major losses for the farms. EZ Artemia Ultra is a biosecure larval diet that can help reduce bacterial loads in larval shrimp tanks and support higher survival rates. This diet is an economical and convenient biosecure alternative to Artemia nauplii.

Lavilla-Pitogo, C. R., Baticados, M. C. L., Cruz-Lacierda, E. R. and De la Peña, L.D. 1990. “Occurrence of Vibrio species, including Vibrio harveyi, in Penaeus monodon hatcheries in the Philippines.” Aquaculture, 91(1), 1-13.

Interaminense, J.A., Ferreira Calazans, N., do Valle, B.C., Lyra Vogeley, J., Peixoto, S., Soares, R. and Lima Filho, J.V. 2014, Vibrio spp. Control at Brine Shrimp, Artemia, Hatching and Enrichment. J World Aquacult Soc, 45: 65-74. https://doi.org/10.1111/jwas.12096

Lopez-Torres, M. A. and. Lizarraga-Partida, M. L. (2001). Bacteria isolated on TCBS media associated with hatched Artemia cysts of commercial brands. Aquaculture 194:11–20.

Lavilla-Pitogo, C. R., Baticados, M. C. L., Cruz-Lacierda, E. R. and De la Peña, L.D 1990. "Occurrence of Vibrio species, including Vibrio harveyi, in Penaeus monodon hatcheries in the Philippines." Aquaculture, 91(1), 1-13.

Lopez-Torres, M. A. and. Lizarraga-Partida M. L (2001). Bacteria isolated on TCBS media associated with hatched Artemia cysts of commercial brands. Aquaculture 194:11–20.

Van Stappen, G., Sorgeloos, P. and Rombaut G. (eds.) (2024) Manual on Artemia production and use FAO Fisheries and Aquaculture Technical Papers, No. 702. Rome, FAO. https://doi.org/10.4060/cd0313en

Van Stappen, G., Sorgeloos, P. and Rombaut, G. (eds.) (2024). Manual on Artemia production and use. FAO Fisheries and Aquaculture Technical Papers, No. 702. Rome, FAO. https://doi. org/10.4060/cd0313en

Authors details:

is Asia Sales Manager based in the

Email: mark.napulan@zeiglerfeed.com

Mark Rowel Napulan is Asia Sales Manager based in the Philippines. Email:mark.napulan@zeiglerfeed.com

Peter Van Wyk is Global Technical Sales Manager based in Florida.

Ramir Lee is Regional Technical Manager based in Vietnam. All authors are with Zeigler Bros. Inc.

Note: This article was adapted from Recent advances on Artemia replacement in shrimp hatcheries. Hatchery Feed & Management, Volume 12 Issue 1 2024

Molecular testing is essential for accurate identification of the specific cause combined with stringent biosecurity measures

By Andrew Shinn, Ratchakorn Wongwaradechkul, Jorge Piazza, Bruno Decock, Thomas Raynaud, Alfredo Medina and Emmy Léger

Understanding Vibrio infections in shrimp production

Infections associated with Vibrio species pose significant challenges in commercial shrimp operations. If unmanaged, these bacteria can establish populations in water, sediment, or biofilms within farm systems, leading to infections and high mortality rates.

In shrimp hatcheries, Vibrio species can infiltrate or proliferate through multiple routes. These include introduction via broodstock, infected shrimp nauplii, contamination through water sources, and transmission from microalgae, live feeds, or water and air pipelines. Moreover, they can be transported on personnel equipment, on skin, or dispersed through aerosols (Shinn et al., subm.).

Translucent Post Larvae Disease (TPD), also known as Highly Lethal Vibrio Disease (HLVD), is a severe condition that has impacted shrimp post larvae production in China and Vietnam since 2020.

The disease is primarily caused by a strain of Vibrio parahaemolyticus, though a Baishivirus has also been implicated in some cases. The V. parahaemolyticus strain associated with TPD produces a toxin that disrupts the hepatopancreas, affecting nutrition and leading to rapid mortality, especially in smaller shrimp.

Visually, affected post larvae (PL), particularly at stages 2-4, exhibit distinct symptoms such as an empty gut and a colourless, translucent hepatopancreas, leading to diminished activity and sluggish movements. Mortality occurs rapidly, typically within a few hours of infection, with rates reaching as high as 80-100% within 24-48 hours, often occurring 3-5 days post-stocking.

Since other pathogens can cause similar visual symptoms in shrimp, accurate diagnosis requires proper testing rather than relying solely on the visible symptoms.

The role of Vibrio parahaemolyticus in TPD

Most cases of TPD are caused by V. parahaemolyticus strains that carry an aerolysin gene, which produces a toxin leading to cellular damage in the hepatopancreas and resulting in death. Another shrimp disease, acute hepatopancreatic necrosis disease (AHPND), is also caused by V. parahaemolyticus, but these strains carry a different toxin gene. Although both toxin genes cause similar damage to the hepatopancreas and lead to comparable outcomes, molecular testing is essential for accurate identification of the specific cause.

Visual inspections alone are insufficient for diagnosing TPD or AHPND. Accurate diagnosis requires laboratory testing. To do this, collect a targeted sample of PL (i.e., those exhibiting pale and moribund characteristics, approximately 30-50 individuals). Rinse the PL with sterile distilled water and then fix them in 95-99% molecular-grade ethanol.

Laboratory tests can then identify the different toxin producing genes produced by Vibrio species. Simultaneously, request that the samples are tested for the presence of plasmid genes pir AB producing the toxins responsible for AHPND, utilising the AP4 nested PCR method developed by Dangtip et al. (2015) and for TPD using primers for the ldh gene, which produces the thermolabile hemolysin toxin (Vicente et al., 2020; Zou et al., 2020). If both tests are negative, request that samples are tested for the Baishivirus , using primers as specified by Xu et al. (2023).

Parallel assessment of microbiology results is essential. If all three PCR test results are negative, then look to other potential bacterial pathogens that might result in PL that are translucent in appearance.

Regular testing is crucial for identifying early-stage infections and preventing their establishment and spread. It raises awareness of the local risks of infection. Testing can offer valuable insights into disease dynamics and potential introduction routes. It facilitates timely interventions and enables the revision of biosecurity protocols to reduce the likelihood of future introductions and outbreaks, thereby minimising economic losses.

“Vibrios pose a serious threat to shrimp production, but strict biosecurity measures and regular surveillance can effectively manage these risks.”

If TPD is detected, take immediate action:

• Isolate infected shrimp and quarantine the affected areas.

• Conduct tests to confirm the disease.

• Assess the risk to other shrimp batches and the overall farm operations.

• Cull infected stock to prevent further spread.

• Strengthen biosecurity measures, including monitoring visitors and disinfecting equipment and water systems.

• Increase surveillance to monitor the situation and prevent future outbreaks.

Besides TPD, other Vibrio infections can also cause shrimp to appear translucent. For example, some strains of V. parahaemolyticus carrying a different toxin gene are responsible for AHPND, also known as early mortality syndrome, which can result in sudden and severe mortality. Additionally, other Vibrio species, such as V. alginolyticus and V. harveyi, can cause systemic infections leading to septic hepatopancreatic necrosis (SHPN).

The rapid and severe onset of Vibrio-induced mortalities in penaeid shrimp hatcheries, transitioning from a state of apparent health to moribundity and death within mere hours, underscores the critical need for stringent biosecurity measures and vigilant surveillance protocols.

Recognising the risks associated with Vibrio infections is paramount from a biosecurity standpoint, necessitating proactive measures to prevent and mitigate potential outbreaks. Establishing robust control and management procedures are essential to effectively manage these risks. Surveillance emerges as a crucial practice for early detection and containment of infections, ensuring swift intervention when necessary.

Best practices for biosecurity in shrimp hatcheries:

• Pond preparation: Disinfect ponds, use clean water, and avoid transferring contaminated water.

• Grow-out ponds: Monitor stocking densities and manage wastes effectively to minimise the risk of Vibrio outbreaks.

Vibrio bacteria pose a serious threat to shrimp production, but strict biosecurity measures and regular surveillance can effectively manage these risks. Early detection is crucial for minimising the impact of Vibrio-related diseases, improving shrimp survival, and ensuring the sustainability of shrimp farming operations.

References are available on request

Andrew Shinn is Global Technical Expert (Health).

Email: a.shinn@inveaquaculture.com

Ratchakorn Wongwaradechkul is an aquatic veterinarian, Regional Technical Support Asia

1. Disinfect water and equipment using ozone, UV light, or hypochlorite.

2. Conduct comprehensive and regular cleaning of the entire production system, including pipework, air lines, and air delivery systems, to remove biofilms and surfaces where Vibrio can establish.

3. Use separate, biosecure water systems to minimise contamination risks.

4. Add probiotics to the water to enhance shrimp health and reduce harmful bacteria.

5. Isolate broodstock in clean conditions and provide biosecure diets to maintain their health.

Vibrio infections can occur at any stage of shrimp farming, from broodstock to grow-out ponds. Implementing proper disinfection, maintaining strict hygiene, and adding probiotics to feed and water are essential for reducing infection risks.

• Hatcheries: Ensure biosecure water systems and conduct regular facility cleanings.

• Live feeds: Source live feeds from biosecure providers to prevent introducing Vibrio

Jorge Piazza is Strategic Marketing Manager

Bruno Decock is Business Development Manager

Thomas Raynaud is Product Manager

Alfredo Medina is Global Technical Expert Shrimp Hatchery

Emmy Léger is Customer Success Director. All authors are with INVE Aquaculture

Since 2022, the Global Shrimp Forum (GSF) gathers industry leaders and experts, representing the entire shrimp value chain to join together in shaping the future of the global shrimp industry. “The feedback from GSF 2024 delegates was that it was the best one yet, and the board and I feel confident that with the additions we will be making to the event next year, it will continue to go from strength to strength,” said Willem van der Pijl, Board Member and Managing Director of the Global Shrimp Foundation. The third edition was held on September 3-7 in Utrecht, The Netherlands, and the attendance increased to 542, represented by over 320 organisations from 41 countries.

This year, the inspirational item at the opening session was how the shrimp industry can continue to grow. BioMar Group CEO, Carlos Díaz presented his views on how shrimp fits into the Blue Foods agenda. Chairman of Rynan Aquaculture in Vietnam, Dr My Thanh, followed with a video projecting his vision for high-tech shrimp farming and insights on future proofing the industry. The farm design integrates mangroves around shrimp ponds to naturally remove organic waste and excess nitrates, and absorb carbon dioxide from the atmosphere. My said that 1ha of mangrove can sequester 33 tonnes of carbon dioxide (CO2), making them one of the most efficient natural carbon sinks.

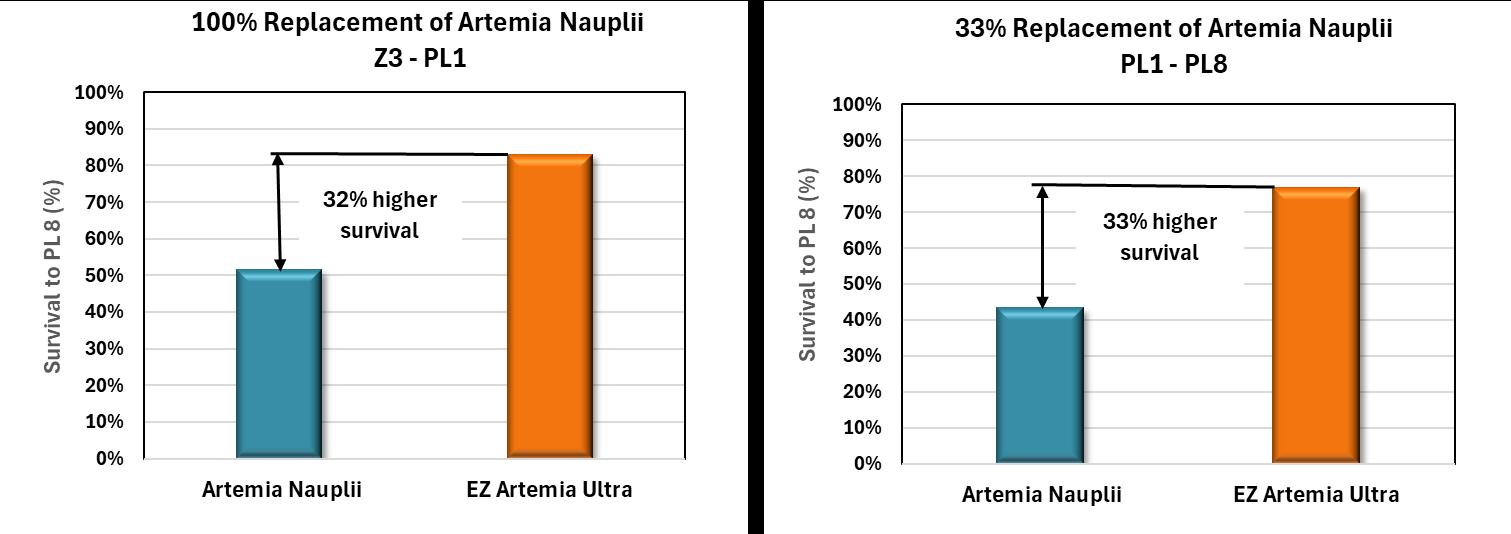

It all starts with feed, which relies on raw materials. Diaz showed how the company has decreased its original percentage of marine raw materials in salmon feeds. “For a while, we have been increasing the plant-based raw materials. The Forage Fish Dependency Ratio (FFDR) went down but the carbon footprint was up. But we have managed to bring this down by using circular and restorative raw materials (single cells, algae, etc).”

Biomar practiced this in Ecuador, which raised the question of the real life cycle assessment (LCA) of Ecuadorian shrimp. In the literature, on average, for fed aquaculture, the impact is 70:30 (feed:farm) and for shrimp, it is 60:40 (feed: farm). Working with 3 customers in 15 locations, carbon footprint (CO2e per kg) of Ecuadorian shrimp was 5.2 versus 4.8 for Norwegian salmon. In addition, pond management is much more important in shrimp farming than that for the salmon.

salmon cages, in shrimp, the future is hydrophones listening to shrimp feeding and developing behavioural feeding algorithms. However, one solution does not fit all, as conditions in each farm and country may vary. Diaz concluded, “Shrimp has the great potential as salmon or even better to be a sustainable choice for consumers. But the story needs to be told. Together, precision farming, traceability and technology as a tool will be more relevant in the future.”

feeling algorithms. However, one solution does country may vary. Diaz concluded, “Shrimp has be a sustainable choice for consumers. But the farming, traceability and technology as a tool

It all starts with feed, which relies on raw materials. Diaz showed how the company has decreased its original percentage of marine raw materials in salmon feeds. “For a while, we have been increasing the plant-based raw materials. The Forage Fish Dependency Ratio (FFDR) went down but the carbon footprint was up. But we have managed to bring this down by using circular and restorative raw materials (single cells, algae, etc).”

The Global Shrimp Council was formed in September 2023 to increase the per capita consumption of sustainable shrimp. This year, founders and co-chairs of the council, David Castro, Director General, Manta Bay, Mexico, and Gabriel Luna, owner of Gluna Shrimp, updated on the progress and introduced the marketing campaign to encourage consumption - Global Shrimp, The Happy Protein.

Biomar practiced this in Ecuador, which raised the question of the real life cycle assessment (LCA) of Ecuadorian shrimp. In fed aquaculture, generally, 70% of the impact comes from feed and 30% from farming. Working with 3 customers in 15 locations, it was shown that 40% came from farming and 60% from feed. However, it was clear that pond management is much more important in shrimp farming compared to salmon in cages.

Diaz described a scenario analysis with three factors; sustainable raw materials, FCR and green power. By optimising feed, the carbon footprint (g CO2 eq/kg LWE shrimp) was down to 4.5 from an average of 5.1. An FCR reduction brought this down to 3.5 and when combined with green power, it was lower at 2.1. A complete picture of the pond’s direct emissions and the influence practices requires information on stocking densities, feeding regimes and management approaches.

A cornerstone of the annual program is the latest export and import statistics. This was presented by van der Pijl.

1. Comparing the carbon footprint of Ecuadorian shrimp against Norwegian salmon.

Global Shrimp Council was formed in September consumption of sustainable shrimp. This year, Castro, Director General, Manta Bay, Mexico updated on the latest developments. A significant encourage shrimp consumption.

Diaz described a scenario analysis with three factors; sustainable raw materials, FCR and green power. By optimising raw materials, the carbon footprint (g CO2 eq./kg LWE shrimp) was down to 4.5 from an average of 5.1. An FCR reduction brought this down to 3.5 and when combined with green power, it was lower at 2.1. A complete picture of the pond’s direct emissions and the influence practices requires information on stocking densities, feeding regimes and management approaches.

Does sustainability pay o>?

In terms of exports, Ecuador showed a 2% increase in H1 2024, thus continuing with a slower growth trend but the 2024 Q2 exports of 344,000 tonnes was a new all-time record. This slow-down of growth rate is likely a long-term trend and is expected to continue into 2025. Prices did not recover but have slightly stabilised since September 2023. van der Pijl expects an 11% drop with exports to China in 2024 and the US and EU taking up the slack. If the decline continues, China’s market share could drop to 50%. Ecuador’s top 15 exporters had around 75% market share in 2023.

“The good news is that the focus on sustainability is not only the right thing to do but has paid off, at least with the salmon,” said Diaz citing the example of Tesco, which discloses the carbon footprint of different foods. Such retailers will help producers tell their stories. Fish and shrimp welfare, fresh quality, farming and processing excellence were mentioned as creating consumer value.

2023 actual 2024 forecast

A cornerstone of the annual program is the latest presented by van der Pijl.

Ecuador 1,214,104 1,285,164 (+10%)

India 712,913 734,333 (+5%)

Vietnam 293,593 307,593 (+5%)

Indonesia 209,066 187,716 (-10%)

“The good news is that the focus on sustainability is not only the right thing to do but has paid o^, at least with the salmon,” said Diaz citing the example of Tesco, which discloses the carbon footprint of di^erent foods. Such retailers will help producers tell their stories. Fish and shrimp welfare, fresh quality, farming and processing excellence were mentioned as creating consumer value.

Diaz said there are some very strong fundamentals for shrimp, which the industry should take advantage of, i.e., short cycle, good carbon footprint, flexible and easy-tocook. Building trust through traceability and transparency is essential. Consumers want to scan a code and know the origin of the shrimp, which fish meal was used, certifications and sustainability parameters such as footprint.

Farming conditions are changing and precision farming, from an art to a science, uses emerging technologies and automated systems. While cameras are used in

In terms of exports, Ecuador showed a 2% increase growth trend but the 2024 Q2 exports of 344,000 down of growth rate is likely a long-term trend not recover but have slightly stabilised since with exports to China in 2024 and the US and China's market share could drop to 50%. Ecuador’s share in 2023.

Global supply (from export data and HS codes) from the top 4 countries in tonnes.

Santa Priscilla 216,423

Omarsa 136,771

Songa 119,963

Expalsa 73,892

Ecuador’s Top 4 exporters in 2023 in tonnes.

Diaz said there are some very strong fundamentals for shrimp, which the industry should take advantage of, i.e., short cycle, good carbon footprint, flexible and easy-to - cook. Building trust through traceability and transparency is essential. Consumers want to scan a code and know the origin of the shrimp, which fish meal was used, certifications and sustainability parameters such as footprint.

Willem van der Pijl, Board Member and Managing Director of the Global Shrimp Foundation (middle left) with from right, Balasubramaniam V, General Secretary of the Prawn Farmers Federation of India; Barbara Janker, Commercial Director Europe & Asia-Pacific, ASC and Lief Lief Hendrikz, EMEA Market Development Lead, The Global Dialogue on Seafood Traceability.

In 2023, India’s farmed shrimp exports increased by 3%. This year, in H1, exports are 5% ahead YoY. In 2023, India’s exports to the US slightly recovered and other major markets remained stable, while China continues to grow YoY. Vietnam’s nine biggest export markets in 2023 were 23% down YoY but 1H 2024 has shown some stabilisation.

US 779,772 722,743

China 945,791 1,049,631

EU27 328,674 320,650 (Penaeid shrimp only

Japan 213,140 190,189

Global demand from the top 4 countries in tonnes. (Note trade stats are not HOSO equivalent).

In 1H 2024, USA showed a slight 3% decrease in import volumes. Imports have continued to fall since 2022. After a jump during COVID-19, the average import value has fallen since 2022. While the imports of raw frozen shrimp stabilised in 2023, HLSO (Headless Shell On) and value-added shrimp have dropped. Since May 2024, imports of peeled frozen have stabilised further, but imports of shell on and value-added continued to fall. In 1H 2024, India and Ecuador maintained export volumes, but Indonesia saw a further drop.

After stunning growth in H2 2022 and H1 2023, van der Pijl showed four quarters of YoY drops in China’s import volumes. He added that 2024 will probably end with an 11% drop compared to 2023 imports of 1,049,631 tonnes. Despite temporary improvements in 2023 and early 2024, average import values are at an all-time low. Imports from Ecuador were almost 700,000 tonnes in 2023. However, this year, India was 9% ahead and Ecuador was 9% behind. Vietnam’s exports to China have decreased by 22% in 1H 2024.

For the EU market, although the growth rates of 2021 and 2022 for raw Penaeid shrimp not sustained, the volume has stabilised and van der Pijl expected 2024 to end with 330,337 tonnes. Contrary to Latin America, Asian suppliers failed to continue the upward trend in shipments to the EU with Vietnam experiencing a particularly significant drop. While 2022 set recordhigh price levels, the current prices are close to all-time lows.

The H1 2024 Trade Data Update is available at https://www.shrimpinsights. com/report-series/h1-2024-trade-data-update.

Andrew Campbell, CEO, AQ1, Australia (left) with Loc Tran, Founder/Director, ShrimpVet, Vietnam (middle) and Rizky Darmawan, CEO, Delta Marine Indonesia and co-Founder & President of Petambak Muda Indonesia (PMI). The latter two were in the panel on “Asian Farmers’ Perspectives.”

Proven to substitute up to 100% of Artemia cysts use

Promotes growth and survival

Unparalleled nutrition

Copepods

Ready for a positive change? Try now and unlock the incredible benefits of incomparable nutrition.

Only the best from the sea.

Let’s aquaculture together

www.megasupply.com orders@megasupply.net 100% natural Sterilized by Gamma Irradiation

www.thuysanOPS.com / 0913753035

A conversation with Benedict Standen and Thiago Soligo on the introduction of Sustell™ for shrimp aquaculture, environmental footprinting made easy

The global aquaculture industry has come under increasing pressure to embrace sustainability, as environmental impact and resource efficiency rise to the top of both regulatory agendas, including consumer preferences and impact criteria for investors. Within aquaculture, shrimp farming has often been scrutinised for its environmental impacts.

In 2021, dsm-firmenich (then DSM) introduced to its customers Sustell™, a SaaS (software as a service) full life cycle assessment (LCA) solution for animal protein. It provides the food value chain with a credible, sciencebased approach to collecting farm data, measuring the environmental footprint, and mapping a course for sustainability of the animal protein industry. There are already modules for feed, salmon and marine fish. In June it launched a shrimp module for Sustell, a first online life cycle assessment (LCA) platform tailored to commercial shrimp farming.

In September, during the Global Shrimp Forum (GSF) 2024, Utrecht, The Netherlands, Zuridah Merican sat down with dsm-firmenich’s Benedict Standen , Head, Aqua Marketing and Thiago Soligo , Sales Manager, LATAM, to learn more on this shrimp module and its benefits for the value chain.

Working along the value chain Benedict responded to why dsm-firmenich started Sustell. “Our customers are increasingly confronted with the need to report environmental footprints, which involve managing a large amount of data. As a company, we want to offer a full solution-based portfolio, combining services and products.

“Sustainability reporting across the supply chain is evolving quickly. Sustell makes it easy and rewarding for every company to be involved,” added Benedict.

The duo agreed that the task for companies can be enormous, especially as Europe introduces Corporate

Sustainability Reporting Directive (CSRD) regulations on reporting. This is a game changer for companies of all sizes because it makes environmental footprinting easy, with no need for in-house LCA expertise. Sustainability is becoming a market differentiator; the ability to offer a transparent, verified environmental footprint is more than just a regulatory necessity—it could be the key to long-term excellence in a rapidly shifting industry.

This new shrimp module offers on-demand environmental footprint metrics for all shrimp production stages, from hatchery, nursery and grow out, in addition to a feed module which is a critical contributor to LCA. It allows producers to input data and recognise the environmental footprint of their operations and look at ways to reduce it, through interventions. Coming soon there will also be a processing module.

“Sustell’s strength lies in its ability to move beyond industry averages and offer a personalised environmental assessment tailored to each farm’s unique operations. It factors in 19 different metrics across four critical areas: land use, human impact, water scarcity, and climate change,” said Benedict. “It prepares customers for potential or existing regulation, differentiating their product with eco-labels, and making the invisible, visible.”

This granular data allow shrimp farmers to understand where inefficiencies lie and to target specific areas for improvement. Performance, health and welfare are the base line to all sustainable operations. Feed inputs, which typically account for up to 80% of a farm’s environmental footprint, are a crucial focus, with the shrimp module tool offering actionable insights into how interventions can significantly reduce a farm’s overall impact by changing the feed formulation.

Grupo Almar, in the top five of Ecuador’s leading shrimp producers, was instrumental in working together with dsm-firmenich as they developed and validated the shrimp-specific module of the Sustell platform. Thiago said, “Grupo Almar has a genuine desire to know its own footprint and sees it as a requirement for best practice. We developed the module for shrimp together with them; it is now available to other customers anywhere in the world where shrimp farms operate.”

According to Wolfgang Harten, General Manager/COO of Grupo Almar, the company knew that it wanted to go beyond measurement by taking ownership of its full environmental footprint and with this new module for shrimp, it could take its sustainability efforts one step further.

According to Benedict, the customisation of Sustell is noteworthy; the platform is independently verified by a third party certified to ISO standards for LCA, ISO14040 and ISO 14044, and the data input from individual farms is customised to reflect the specifics of each farm’s production conditions. This allows for high precision in the footprint analysis, especially crucial given the vast differences in shrimp farming methods across geographies. “Another unique advantage of the platform is that it allows customers to create “what if” scenarios and then interventions to address the different scenarios.”

Thiago added, “An outcome with working with Grupo Almar is also to simplify the platform and customisation for each module. In Grupo Almar’s case, it is from hatchery, nursery, farm and processing. We are now at the stage where Grupo Almar has the numbers and can now work at interventions at selected phases to lower even more their environmental footprint and plan for the future.”

Benedict said, “In integrated operations, it is easy to work across the value chain, from nursery to farming to

“Every

shrimp farm is different - different pond sites, different parameters, so we have to make customisations.

It’s certainly very different from our salmon product.”

- Thiago Soligo

processing. But in the case of only farming enterprises, they need to work with suppliers across entire value chain, so it takes this platform Sustell to bring everybody together.”

The value of the module goes beyond environmental metrics. Benedict explained, “By helping producers quantify their sustainability efforts, it also paves the way for access to green investment. In markets like the US and Europe, where consumers and regulators are increasingly paying attention to the origins of their food, shrimp farms utilising Sustell can better position their products through eco-labelling and certifications.”

Thiago continued, “The ability to track and manage environmental performance opens the door to financial benefits. Financial institutions are increasingly factoring sustainability into their lending criteria, and having a verifiable environmental footprint helps companies navigate this evolving landscape.”

Benedict noted, “When you’re looking for an investment, sustainability is now a criterion - whether it is high risk, low risk or medium risk, according to the FAIRR Initiative or other industry benchmarks on animal protein.”

“The adoption by shrimp producers like Grupo Almar marks an important shift in the industry, signalling a broader movement towards precision-driven, datainformed sustainability at the company level. As more producers embrace such tools, the aquaculture sector is likely to see a transformation in how environmental impact is managed and reduced,” said Benedict. “This is a roadmap for shrimp farming to become more sustainable and ultimately, more profitable in a world that demands greater environmental responsibility.”

“It prepares customers for potential or existing regulations, differentiating their product with ecolabels, and making the invisible, visible.”

- Benedict Standen

dsm-firmenich is a pioneering sponsor of the Global Shrimp Forum. Together with Thiago Soligo and Benedict Standen, was the dsm-firmenich team from Asia, From left, Dr Rutchanee Chotikachinda, Manager, Aqua Technical Expert (Asia Pacific), Evelyn Feliciana, Key account Manager, Indonesia, Liew Chiow Yen, Regional Marketing Aqua and Abung Maruli Simanjuntak, Technical Expert Manager –Aquaculture (left).

Comparing to the work for the salmon module, Thiago commented that for shrimp, it is more complex. “Every shrimp farm is different; different pond sites - even ponds within farms and parameters are different. So, we must make customisations. You can also compare different footprints, using different feeds.” Working closely with the team at Grupo Almar, Thiago emphasised how he was impressed by some of the findings.

However, such thoroughness comes with significant challenges. Not every company is willing or able to invest the time and resources needed to compile the necessary data. This is where the true difficulty lies. But with Sustell customers are not alone and dsm-firmenich has a team of LCA experts to lend support in the journey.

Thiago said, “Once you log into your dashboard, you can complete the data line by line, and customers can try the demo before committing. We help them identify what inputs need to be uploaded. Customers can have access to see how easy it is to use, compared to excel files. With Grupo Almar, we worked with them to identify which data to upload.”

These are crucial elements. The platform allows companies to maintain proprietary data without disclosing sensitive information; it also preserves the trust between feed manufacturers and producers. However, achieving credible results requires full participation from across the value chain and a standardised methodology.

Customers’ data are closely guarded intellectual property, and by using this platform and its secure data handling criteria, companies can work together to submit data, without risk. Such systems are important to map together the information on environmental footprint. Benedict said, “Feed companies are increasingly willing to collaborate, knowing that being able to demonstrate the sustainability of their feed could offer a competitive edge in an increasingly environmentally conscious market. We are also working with formulation programs suppliers. The best formulations are not just from a nutritional profile standpoint, but also recipe based on footprint.”

Thiago added, “Feed producers use the feed module and develop their environmental footprint metrics and provide to the shrimp producer.”

In fragmented markets like Asia, where producers and suppliers are often disconnected, this adds an extra layer of complexity. Integrating feed supply data from different regions, whether it is soy from Brazil or the US, means understanding and combining different footprints, but Sustell makes the management of these changes easy and traceable.

“With the shrimp module, we believe that it can be the go-to standard for the industry, but the customers will be the testament! We are excited to get customer traction in Asia Pacific and open a conversation with these important players in the global shrimp market,” said Thiago. “We want the product to be accepted and understood by the customers, and that the customers can recognise its value. This will help the industry improve its sustainability credentials.”

The standout players- “the benchmark of the industry,” as Thiago described—are those with vision. “They have, ambitious forward-thinking teams that are quick to adapt to digital tools and are already fluent in the language of sustainability. They see sustainability not just as a buzzword but as a pathway to long-term viability.”

“The challenges are complex in accounting for all the inputs. But we must adjust for each case, each customer and each site. New customers have a lot of front-end loading of data, so taking the time to ensure the initial data are correct is an important step in the process.”

Benedict was clear that the uneven pace of adoption is particularly evident in Asia’s aquaculture sector, where many farms are run by individuals rather than companies. “A smallholder farmer may have neither the resources nor the know-how to implement cutting-edge sustainability technologies. Convincing these stakeholders requires working through networks, with a support system in place, possibly through industry initiatives and distributors, to collectively elevate standards.”

This challenge emphasises the need for tailored approaches. While multinational corporations with large teams may have sustainability divisions ready to implement best practices, small-scale operators in fragmented markets often need more support. Innovation, especially in sustainability, is rarely a onesize-fits-all solution.

Benedict acknowledged that despite these challenges, the vision remains, and with the help of Sustell, the obstacles to widespread sustainability are not insurmountable. “It is a question of finding the right partners, working in the right way, cultivating early adopters, and slowly building momentum across industries and geographies.”

The future, they seemed to suggest, will not come without challenges—but the seeds of change have already been planted and the future is bright.

In aquaculture, the right nutrition makes all the difference. Aquafeed can account for up to 70% of total production costs, and 80% of the environmental footprint. Our full range of aquaculture solutions and services improve water quality, maximize productivity, and optimize feed cost, reducing overall financial strain. Ready to feed your way to performance gains and healthy profits?

The nursery stages require micro feeds with precise and functional nutrition to support a strong start for fish and shrimp grow-out

By Marc Campet

Deeply intertwined with the region’s cultural traditions, farmed fish and shrimp play an important role in seafood supply to the Asia-Pacific region, serving as a major source of protein and nutrition. According to FAO (2024), total aquaculture production in the region, grew 193% from 2000 to 2022. In fact, the region accounted for more than 88% of global production in 2022 (FAO, 2024). From 2000 to 2018, the average annual growth rate was 5.1% (De Silva and Yuan, 2022).

Over the last 50 years, the average consumption of fish has nearly doubled across the world, spotlighting farmed fish and shrimp as one of the fastest growing sources of protein globally (New Scientist, 2021). FAO (2024) estimated an apparent seafood consumption at 20.7kg/capita/year for 2022. To meet the growing nutritional needs of the rapidly increasing population in the region and across the world, while also improving profitability, it is crucial to ensure that fish and shrimp receive adequate nutrition to reach their full genetic potential. Precision nutrition is essential in the early critical stages of development for all animals, including fish and shrimp, as the conditions experienced early in life can have impacts on their developmental trajectory, lifetime health and performance such as their physiology, behaviour, resilience and vulnerability to disease.

“..nutrition in their early life cycle is crucial for growth, organ development, resistance to pathogens, and ultimately, fillet yield at harvest.”

While there is need for precise and balanced nutrition at all stages for fish and shrimp, optimal nutrition in their early life cycle is crucial for growth, organ development, resistance to pathogens, and ultimately, fillet yield at harvest.

In the first days and weeks of life, fish and shrimp are particularly sensitive and vulnerable to fluctuations and stressors related to farm management, including environmental changes caused by transportation, transfer, vaccination, handling, population mixing, and variation in water conditions and temperatures. These commonly occur during the nursery stage where fish and shrimp are still developing their digestive and immune systems, hence resulting in mortality or reduced performance, with ultimate effect on the entire production cycle.

The nursery stage of fish and shrimp is therefore a key phase that aquafarmers need to look out for to achieve greater resistance to diseases among juveniles and increased productivity for farmers. For fish and shrimp in the nursery stage, a balanced and proper diet can help to reduce feed conversion ratios (FCRs), improve the survival of juveniles, support increased growth, as well as counteract stress factors that may come with counting, transportation and transfers into new environments.

Precise nutrition solutions to boost performance outcomes

Starting from early feeding, producers need to ensure that the nutritional needs of aquaculture species are met through specialised and high-quality feed dedicated to supporting healthy growth and performance. Precise feed formulations are particularly effective, by delivering adequate amounts of protein, amino acids, lipids, vitamins, minerals, digestive enzymes, and functional additives to maximise aquaculture success and profit.

A crop success begins at first feeding. With complete feed as their main source of nutrients, it is critical for feed millers to tailor the feed profile to meet the nutritional and physiological requirements of the specific species at every life stage. This involves not only adjusting the amount of feed, but also considering factors such as digestibility, particle size and its behaviour and stability in water. High-quality feed is typically adapted to hyper intensive culture conditions where good water stability for young fish and shrimp is critical. Precise nutritional solutions during the nursery stages can help increase fillet ratio, support size homogeneity and improve profitability for farmers in the region.

A study on the effects of initial feeding on rainbow trout (Alami-Durante et al. 2014) demonstrated that an early decrease in dietary protein to energy (P:E) ratio, achieved by adding lipids to feed, had a long-term effect on the muscle growth of juvenile rainbow trout. Trout that were fed a high-fat diet maintained higher body weights even after three additional months of feeding on a commercial diet during the first 75 days of life (Alami-Durante et al. 2014). The persistent effect of initial feeding with the high-fat diet on the muscle growth of rainbow trout juveniles might also result in improved fillet quality at harvest.

Early targeted measures, such as ensuring sufficient nutrition can also help decrease the risk of secondary disorders by improving the resilience and resistance to diseases, hence resulting in improved aquaculture performance.

To help farmers meet their production and profit objectives, ADM has developed a specialised and functional nutrition range to support fish and shrimp during their juvenile life stages. Manufactured using advanced micro-extrusion technology in specialised nursery feed production lines, the NANOLIS range is formulated to deliver a precise blend of functional additives, vitamins and minerals to enhance the feed palatability and digestibility for nursery fish and shrimp. The advanced micro-extrusion technology helps preserve essential nutrients and ensure particle size homogeneity to meet the physiological demands of young fish and shrimp.

In 2022, a dedicated tilapia trial was conducted at the ADM Aquaculture Research and Development Centre in