17 minute read

As models become more popular, P

from Auto Service Professional - March/April 2013

by EndeavorBusinessMedia-VehicleRepairGroup

Hybrid vehicle air conditioning service

As models become more popular, demand for A/C service will increase

By Mike Mavrigian

There are over 1.5 million Toyota hybrid vehicles in North America (and well over 2 million hybrids total, including Toyota and other brands). Even though these numbers represent perhaps less than 1% of the total North America vehicle population, it’s evident that hybrids are here to stay, and their population will increase. Based on this, it’s time to become familiar with A/C systems in hybrids.

Before attempting any service to the A/C system, you need to be aware of important battery voltage concerns. Remember, hybrids don’t feature a traditional 12-volt battery alone; a high voltage (HV) battery pack is present that, in the case of the Prius, contains from 201 to 273 volts. It’s vital to be familiar with the power system before attempting any service work. We strongly suggest obtaining HV training, either from Toyota or from an independent hybrid specialist training center. Hybrid battery basics

While there are several variants of hybrid designs among the OEMs, here we’ll take a

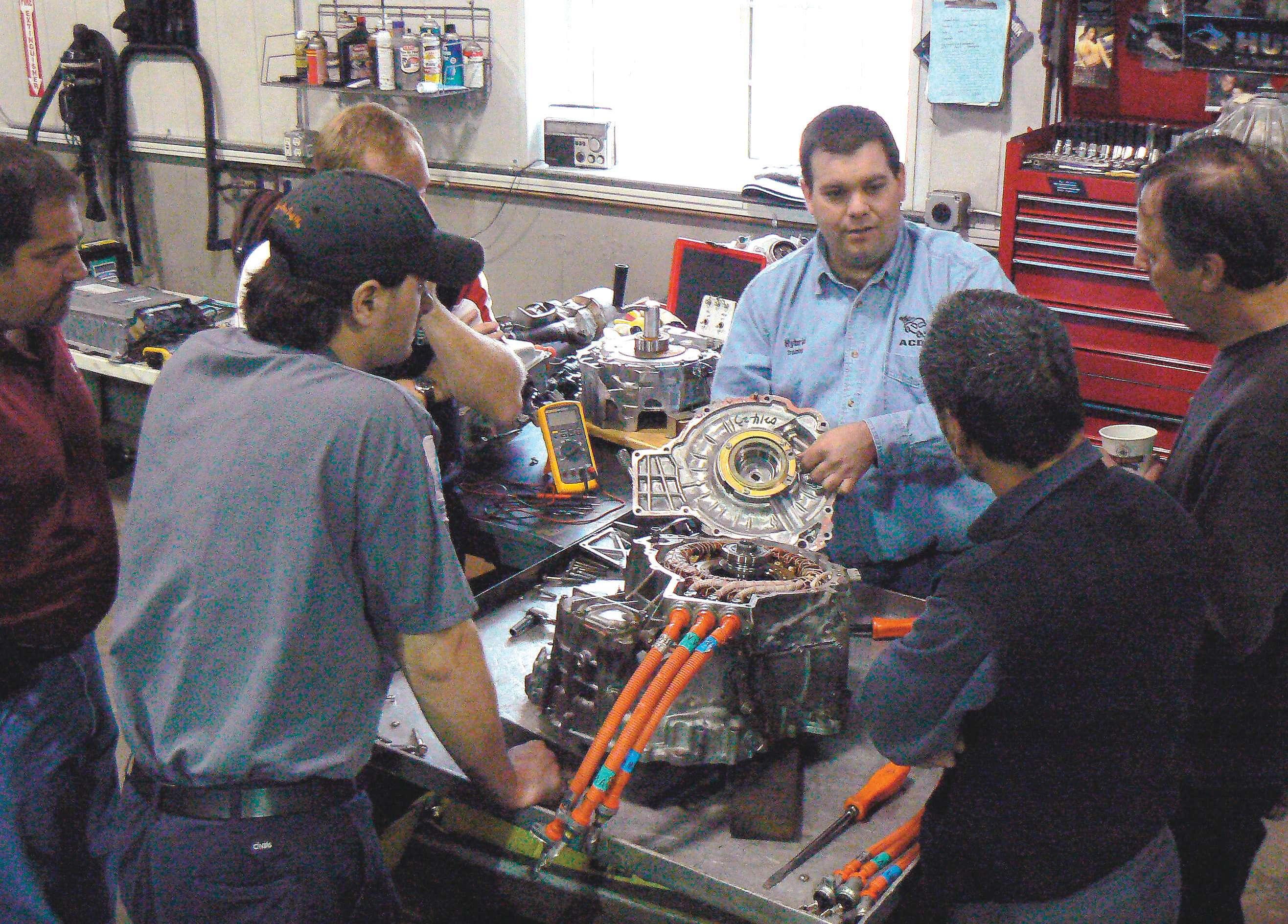

Craig Van Batenburg of ACDC explains the critical handling safety concerns when testing voltage once the HV battery has been removed from a Prius HV.

specif c look at the most popular, Toyota’s Prius hybrid.

One of the notable features relates to the battery approach. The hybrid features two battery “divisions”: an HV 201 or 273-volt trunk-mounted AGM (absorbent glass mat) battery group, and a 12-volt auxiliary battery. If charging is required, the primary battery group (AGM) must be either tricklecharged or charged with a charger that is rated for AGM. Otherwise, irreversible battery damage could result. The 12-volt auxiliary battery (this is assigned to provide power to various 12-volt accessories) maintains its charge via a DC-DC converter (instead of using an alternator).

The 2001-2003 Prius (referred to as Gen 1) features a 273-volt HV battery, while 2004-2009 Prius models (Gen II) feature a 201-volt battery. The later generation features a NiMH (Nickel Metal Hydride) battery pack. A “boost inverter” was added to raise the voltage used by MG2 to up to 650 volts in order to boost vehicle acceleration performance.

High voltage powers the A/C compressor, electric motor, generator and inverter/ converter. All other conventional automotive electrical devices such as headlights, radio, gauges, etc., are powered by a separate 12-volt auxiliary battery. Numerous safeguards have been designed into the Prius hybrid to ensure that the high voltage Lithium-ion Hybrid Vehicle (HV) battery pack is kept safe and secure in an accident. The Li-ion HV battery pack contains sealed batteries that are similar to rechargeable batteries used in some battery-operated power tools and other consumer products (but at a much higher voltage). The electrolyte is absorbed in the cell plates and will not normally leak out, even if the battery is cracked.

In the unlikely event the electrolyte does leak, it can be easily neutralized with a diluted boric acid solution or vinegar.

The HV battery pack is enclosed in a metal case and is mounted to the cargo f oor pan cross member behind the rear seat. The metal case is isolated from high voltage and

concealed by carpet in the cabin area. The auxiliary 12-volt battery (in the 2010 model, for example) is mounted in the right rear quarter panel area.

Battery safety

Toyota hybrids feature bright orange cables that indicate that those cables carry dangerous high voltage. When you see an orange cable, STOP and take a moment to realize that extra caution is needed. Seriously, the high voltage present in this system can An ACDC trainer explains how a CVT, equipped with be extremely dangerous if miselectric motors inside, powers a Prius hybrid. handled, and can, in a phrase, kill HV capacitors to discharge (just to be safe). you. Extra precautions and care must be After this wait period, with the gloves still taken whenever dealing with the HV (high on, use a category III/1,000-volt meter to voltage) battery, motor-generators (MG), conf rm that the component that you’re DC-AC inverters, DC-DC converters, any about to handle is no longer powered. The orange power cables (AC or DC) and electric reason for this caution: The capacitors A/C compressors. Once the HV system has (located inside the DC-AC power inverter) been powered-down, you can still utican hold around 450 volts, which is enough lize the 12-volt battery source to operate to potentially be lethal. accessories. NOTE: According to Toyota training mate

Before you begin to perform any work on rials, Gen III Prius HV hybrids (starting with or around these areas, you must powerthe 2010 model) feature a 346V Lithium-Ion down the HV system to reduce risk. battery pack consisting of 3.6V cells con

The HV power requires the power button nected in a series-parallel circuit. to be pressed while applying the brake pedal. Also, the 12-volt auxiliary battery Gen 1 Prius S HVAC (2001-2003) must be connected in order for the HV Gen 1 models feature a Denso scroll-style power to come on-line. To avoid the HV belt-driven compressor (Toyota calls this an power from coming on-line, remove the ES18 inverter compressor) with an electric key (bear in mind that just because the clutch. The condenser features a two-stage key is removed, the HV system can still setup: A lower section serves to cool the come on-line if the power button is pressed refrigerant via a gas liquid separator, which while applying the brake). If the vehicle is Toyota calls a “modulator.” The condenser equipped with a “smart key,” follow the ser(coated with a special resin to reduce vice manual to deactivate that system. evaporator odor) is built into the radiator

Disconnect the 12-volt battery. Without to further reduce size and weight. Since 12-volt power, the relays inside the HV batthe compressor is belt-driven, idle stop will tery can’t go on-line. be interrupted when the driver selects A/C

Wearing a pair of Class 0/1,000 volt safety demand. Even if the gas/electric powerplant gloves, with leather gloves placed over is idle-stopped, when you turn on the A/C the safety gloves, remove the HV battery to max cold, the gas engine can start. disconnect plug. While HV power-down When the A/C is operated in the MAX should occur in a matter of seconds, play it position, the engine will always run to safe and wait at least f ve minutes for the maintain compressor operation. If the power-down, allowing ample time for the HV battery becomes too warm while the

recirculation mode is on, the HV battery ECU will switch to FRESH in order to increase the f ow of air across the battery.

The refrigerant gas that is discharged from the discharge port f ows by rotation around the cylindrical pipe in the oil separator. The centrifugal force separates the refrigerant gas and the compressor oil due to the difference in their specif c gravity. The lighter refrigerant gas passes through the inside of the pipe and travels from the discharge service port to the outside of the compressor. The heavier compressor oil is discharged through the oil discharge hole in the shutter and is stored in the oil storage chamber. The compressor oil travels back to the compressor and circulates inside the compressor.

The A/C compressor contains a built-in oil separator that helps to separate oil intermixed with refrigerant that circulates in the system, reducing drag on the compressor.

Toyota specif es the use of ND-11 lubricant, a special ester with high dielectric properties designed to lubricate the compressor while protecting the compressor’s electric motor windings’ insulation.

While Toyota specif es its own oil, aftermarket sources now offer the equivalent of this ND-11 oil (NOTE: ND-8 oil is not compatible). If you opt to use a different type of compressor oil (PAG), it is possible to not only damage the compressor, but there is a chance of shorting the high voltage compressor, which would completely shut down the vehicle. In the worst case, this could also result in a harmful and potentially lethal shock.

Editor’s note: It’s critical to avoid crosscontamination of PAG oils when servicing a hybrid A/C system equipped with electric compressors. Ideally, it’s best to dedicate a recovery machine for servicing these applications, while some recovery machine makers have addressed this concern for cross contamination in their features. Gen II Prius HVAC

In 2004-later models, a three-phase, AC voltage dropped to 201 volts, with a brushless, variable-speed A/C compressor. An orange sheath containing three orange cables runs from the compressor to the transaxle-mounted inverter/converter assembly. A smaller inverter is located inside the main inverter assembly. This inverts a portion of the HV battery DC power into AC, which operates the A/C compressor. Since the engine is not always running, the A/C compressor must still be able to operate. Through the use of an electric inverter compressor (as opposed to a belt-driven unit), the compressor is driven by an electric motor that’s built into the compressor housing and powered by AC voltage from the vehicle’s power supply system. Except for the portion that is actuated by the electric motor, the basic construction and operation of this type of compressor is the same as the scroll compressors used in other Toyota vehicles.

The Gen II Prius features an evaporator temperature sensor as well as a humidity sensor. The heater core is located in front of the evaporator. Small ceramic (PTC) heaters also are featured in the heater core and ducting (similar to those in Gen 1) which are located directly behind the heater core. These heaters run off of 12 volts and aid in generating a bit of cabin heat when the gas engine isn’t running (and therefore not producing coolant heat). The expansion valve is located to the right of the evaporator (accessed under dash).

Prius Gen II compressor with internal permanent magnet three-phase motor.

The Gen II Prius evaporator is notably smaller and lighter than that found in Gen 1 models.

The A/C amplif er (HVAC ECU) is located below the center of the dash, near the

f oor, and sends and receives messages on the inverter that you’ll f nd an additional the BEAN bus. The blower motor is located three-phase AC inverter for the electric A/C under the right side of the instrument compressor used on some hybrid models. panel. The blower is controlled by a pulse On these models, in most circumstances, width modulated controller (variable duty the HV battery pack has enough power cycle), which can be checked with a quality to supply energy to the A/C compressor DVM. A “room temperature sensor” (which to keep the cabin cool (even with the gas incorporates a humidity sensor) is located engine off) and still have enough power to the left of the selector lever. As humidto propel the vehicle down the road at low ity level changes (for example from dry to speeds for a limited distance. humid conditions), the voltage changes The Prius transaxle houses two AC motor from approximately 1 volt to approximately generators. Motor generator 1 (MG1) is 3 volts. When humidity is low, the compresprimarily used to start the gas engine sor spins slower. When humidity is high, and recharge the HV battery, while the the compressor spins faster. larger MG2 is connected to the transmis

The A/C amplif er (an ECU) utilizes a sion output, and primarily functions as logic program that takes into consideration a traction motor to power the vehicle at operation. These factors, or inputs, include low speeds (and assist the gasoline engine at higher speeds) and create electricity to recharge the HV battery under braking and deceleration. In addition to the gas engine’s cooling system, the Prius hybrid also features a separate liquid cooling system for the inverter/converter and for the two motor generators that are housed inside the transaxle (along with a dedicated 12-volt electric pump). Both the engine Cutaway view of a Toyota high voltage electric inverter A/C and additional inverter/ compressor. This is a scroll type, driven by an electric motor. Compressor speed is controlled by an ECU. converter/generator cooling multiple factors in order to control the A/C the same Toyota-approved antifreeze. systems are designed to use a sun load sensor, grille-mounted ambient Compressor oil temperature sensor, windshield wiper operaThe biggest difference (beside the obvious tion and actuator door position. According electric versus belt-driven design in Gen II/ to experts, the information from the ambiIII) is the type of lubricating oil used in the ent temperature sensor is multiplexed system. While PAG or Ester oil is primarily through a gateway module that translates used in traditional A/C systems, POE (polythe information into a BEAN bus message olester) type oil is used in hybrid vehicles. to the amplif er (since the A/C amp isn’t on The specif c type used and mandated by the CAN bus). Toyota is ND-11.

Since the AC produced by the motor ND-11 oil provides high dielectric propergenerators can’t be stored in a DC battery, ties, which helps to maintain the integrity the inverter’s second job is to rectify AC to of the compressor’s electrical windings. DC, to recharge the HV battery. It is inside According to Robinair, with just 1% of

PAG oil in the system, this can lower the insulation resistance of a compressor from over 10 mega ohms to under 1 mega ohm. If PAG oil is used to completely f ll an electric compressor system, the insulation resistance can essentially be reduced to zero. Based on recommendations from Honda, Toyota, Ford and GM (again, according to Robinair) it is unacceptable to allow even the slightest amount of PAG (or other oil) into the system. Honda even goes so far as to recommend replacing all A/C system components if the system is cross-contaminated with the wrong oil.

In June 2010, the SAE published a revised version of the SAE J2788 standard that covers the operation of an A/C recover, recycle and recharging (RRR) machine. A machine suitable for servicing both vehicles with a high voltage electric compressor that uses POE oil and traditional PAG oil systems must: • not have an on-board automatic/manual oil or dye injection, and • be capable of charging refrigerant into a system with less than 0.1% by weight of any residual oil.

A way to tell if a machine is certif ed as suitable for servicing vehicles that use high voltage electric compressors is to look for

Referring to the 2012 Prius V as an example:

B1411/11*1 Room temperature sensor circuit. The A/C amplif er assembly stores the DTC of the respective malfunction if it has occurred for 8.5 minutes or more.

B1412/12*2 Ambient temperature circuit. The A/C amplif er assembly stores the DTC if it has occurred for four seconds or more.

B1413/13 Evaporator temperature circuit. The A/C amplif er assembly stores the DTC if it has occurred for four seconds or more.

B1423/23 Pressure sensor circuit.

B1441/41 Air mix damper control servo motor circuit (passenger side). The A/C amplif er assembly stores the DTC if it has occurred for 30 seconds or more.

B1442/42 Air inlet damper control servo motor circuit. The A/C amplif er assembly stores the DTC if it has occurred for 30 seconds or more. DTC CHART

B1443/43 Air outlet damper control servo motor circuit. The A/C amplif er assembly stores the DTC if it has occurred for 30 seconds or more.

B1471/71 A/C inverter high voltage power resource system malfunction.

B1472/72 A/C inverter high voltage output system malfunction.

B1473/73 A/C inverter startup signal system malfunction.

B1474/74 A/C inverter malfunction.

B1475/75 A/C inverter cooling/ heating system malfunction.

B1476/76 A/C inverter load system malfunction.

B1477/77 A/C inverter low voltage power resource system malfunction.

B1497/97 BUS IC communication malfunction. The A/C amplif er assembly stores the DTC if it has occurred for 10 seconds or more. B1498/98 Communication malfunction (A/C inverter local).

B14A2 Driver side solar sensor short circuit. The A/C amplif er assembly stores the DTC if it has occurred for 4 seconds or more.

U0100 Lost communication with ECM/PCM “A.”

U0131 Lost communication with power steering control module.

U0142 Lost communication with body control module “B.”

U0155 Lost communication with instrument panel cluster control module.

U0293 Lost communication with HV ECU.

1: If the cabin temperature is approximately – 1.48 degrees F or lower, DTC B1411/11 may be output even though the system is normal.

2: If the ambient temperature is approximately – 63.22 degrees F or lower, DTC B1412/12 may be output even though the system is normal.

a marking that features a yellow triangle with a lightening bolt, accompanied by the words “Certif ed for High Voltage Compressor Service.” This alert should appear somewhere on the machine either as a separate decal or on the decal that indicates SAE J2788 certif cation. An example of such a machine is Robinair’s 34788-H machine (which does not feature on-board oil injection). ●

All functions of the A/C system do not operate: – IG power source circuit – Back-up power source circuit – A/C control panel circuit – A/C amplif er assembly

Air f ow control (no blower operation): – Blower motor circuit – A/C control panel circuit – A/C amplif er assembly

Air f ow control (no blower control): – Blower motor circuit – A/C control panel circuit – A/C amplif er assembly

Air f ow control (insuff cient air f ow): – Blower motor circuit – A/C amplif er assembly

Temperature control (no cool air comes out): – Refrigerant volume – Refrigerant pressure – A/C pressure sensor circuit – Air mix damper control servo motor circuit – Evaporator temperature sensor circuit – Room temperature sensor circuit – Ambient temperature sensor circuit – A/C control panel circuit – Expansion valve – CAN communication system – A/C amplif er assembly – No. 2 engine wire – Compressor with motor assembly – Power management control ECU PROBLEM SYMPTOMS

Temperature control (no warm air comes out): – Air mix damper control servo motor circuit – Evaporator temperature sensor circuit – Room temperature sensor circuit – Ambient temperature sensor circuit – A/C control panel circuit – PTC heater circuit (with quick heater assembly) – Exhaust heat recirculation system – CAN communication system – A/C amplif er assembly – Power management control ECU

Temperature control (output air is warmer or cooler than the set temperature, or response is slow): – Refrigerant volume – Refrigerant pressure – Solar sensor circuit – Room temperature sensor circuit – Ambient temperature sensor circuit – Air mix damper control servo motor circuit – Air inlet damper control servo motor circuit – A/C control panel circuit – Radiator unit sub-assembly – Expansion valve – Exhaust heat recirculation system – CAN communication system – A/C amplif er assembly – No. 2 engine wire – Compressor with motor assembly – Power management control ECU

Temperature control (no temperature control... only maximum cool or max warm): – Air mix damper control servo motor circuit – Room temperature sensor circuit – Ambient temperature sensor circuit – Evaporator temperature sensor circuit – Solar sensor circuit – A/C control panel circuit – A/C amplif er assembly

Heater performance is low (engine is stopped... with quick heater assembly): – PTC heater circuit – A/C amplif er assembly

No air inlet control: – Air inlet damper control servo motor assembly – A/C control panel circuit – A/C amplif er assembly

No air f ow mode control: – Air outlet damper control servo motor circuit – A/C control panel circuit – A/C amplif er assembly

Micro dust and pollen f lter mode control function does not operate normally: – A/C control panel circuit – A/C amplif er assembly

ECO switch does not operate normally: – ECO switch circuit – A/C amplif er assembly

DTCs are not stored. Set mode is cleared when power switch is off: – Back-up power source circuit – A/C amplif er assembly