MAY 2023 ISSUE INSIDE Advertising cover wrap: your regular issue of Autotechnician is inside

MAY 2023 P14 VW Golf case study tech vs owner mindset P31 reman on the rise ingenius, not inferior P36 on the move mobile servicing & repairs it's Time to come together! Automechanika Birmingham is Back 6-8 June & we prepare for our workshop takeover in cheltenham Joinusatthisyear's AutomechanikaEventattheNEC Bookyourdemotoday:info@gds.co.uk/01482330735/gds.co.uk GarageManagementSoftwareforCommercialVehicleWorkshops

MAY 2023

P4 Industry news

P8 autotechnician’s Workshop Takeover

P10 ALLDATA garage review

P12 KTS Diagnostics made ESI

P14 VW Golf case study

P20 Closed loop air suspension explained

P22 Bearings update

P24 Gasoline Direct Injection issues

P26 Human Resources 101

P31 Remanufacturing

P36 Mobile servicing & repair

P42 Automechanika Birmingham preview

P64 Parts, Tools & Tips

P70 New Car: Volvo EX90

P74 Support from Ben

NICOLA ST CLAIR, EDITORIAL DIRECTOR Nicola@autotechnician.co.uk

07904 521 923

PAUL DEARING, COMMERCIAL DIRECTOR Paul@autotechnician.co.uk

07808 077 611

ROB MARSHALL, TECHNICAL EDITOR

NATHAN WISE, DIGITAL BRAND MANAGER Nathan@autotechnician.co.uk

MIKE SMITH, EDITORIAL ASSISTANT admin@autotechnician.co.uk

CONTRIBUTORS:

Julia Crawford, Gareth Davies

To ensure you continue to receive the magazine, register here: https://autotechnician.co.uk/subscribe

DEAR READER,

Over the past few years, we have had to adjust to communicating, learning, and conducting business online but the bene ts of meeting face-to-face with peers, suppliers and colleagues cannot be underestimated, especially in a trade that never stands still. If you are looking to strike a deal on your next investment in tools or garage equipment, want to prepare your career or workshop for the future, or learn about the latest technology and products to help give you the edge on your competitors, you cannot beat getting together in person to discuss what best suits your needs.

Automechanika Birmingham, the UK’s biggest trade event, is back after a four-year break and will run from 6-8 June at the NEC, providing an expected 12,000 visitors with access to 500 exhibitors, £50k of show discounts, product launches, giveaways, and 192 hours of free skills training. Organisers promise that ‘You’ll test, see and learn more in a few hours than you can in months from your garage.’ We have no doubt that a visit to Automechanika Birmingham will reap rewards for garages. We provide an event preview from p42 which highlights some of the show features that will justify some time out of your workshop.

We are also counting down to our Workshop Takeover in Cheltenham on Saturday 24th June, where three groups of technicians will tackle live faults on petrol, diesel, and electric vehicles to enhance their diagnostic skills –see page 8 for details and grab a subsidised ticket while you still can. Enjoy the issue – myself and the team hope to see you, in-person, very soon.

NICOLA ST CLAIR

EDITOR

Nicola@autotechnician.co.uk

facebook.com/Autotechmagazine

twitter.com/autotech_mag

* View and download previous digital issues at: www.autotechnician.co.uk

Subscription to the magazine is free to those who ful l the publisher’s criteria. UK independent workshops can subscribe at www.autotechnician.co.uk/subscribe Nine issues will be published throughout 2023 and will be mailed out free of charge to qualifying readers - you must work in a UK independent workshop, have buying responsibility and reside in the UK. Those who do not meet the qualifying criteria can request to receive a link to the digital issue free of charge or can opt to pay £25 for an annual subscription to receive an issue in the post. All material, unless otherwise stated, is the copyright of Aftermarket Media Solutions Ltd and reproduction in whole or in part of any text, photograph or illustration, without prior written permission of the publishers, is prohibited. While all due care is taken to ensure the content of Autotechnician is accurate, the publishers cannot accept liability for omissions or errors. Any written material or pictures supplied by contributors are published in good faith and on the understanding they are free from any copyright or other restrictions.

Published by: Aftermarket Media Solutions Ltd, The Joiners Shop, Historic Dockyard Chatham, Kent ME4 4TZ

3

PAGE 14 PAGE 42

AUTOMECHANIKA

BIRMINGHAM

HIGHLIGHTS NEW TRAINING HUBS FOR THE EVENT IN JUNE

With just over one month to go until Automechanika Birmingham 2023, the UK’s largest automotive trade exhibition event has highlighted its brand-new training hubs and popular show features for visitors.

The aim of the hubs is to support business owners, technicians, and specialists by providing insights into trends, technical information, practical sessions and the latest advice and tips to futureproof businesses.

Show features include Workshop, EV and Bodyshop Training Hubs providing technical training and demonstrations, plus conferences for Aftermarket, Supply Chain and Talent and Skills,

GARAGE AWARDS FINALISTS UNVEILED

The nalists have been announced in the Automechanika Birmingham 2023 Garage Awards, hosted by the IAAF. The awards acknowledge the dedication independent garages and technicians have made to ensuring a ordable mobility in the UK over the past few years.

The winners will be announced at an awards evening on Wednesday 7 June at Hilton Metropole NEC.

Finalists of the Garage of the Year, sponsored by LKQ

o ering the latest news and advice from the sector. New for 2023 is a Detailing Hub, Collision Repair Live and Paint & Spray Live, providing practical demonstrations, and Modern Garage and EV Parc, looking at all things electric vehicles and garages of the future.

Take a look at our show preview starting on page 42 to see why the event running at the NEC from June 6-8 is a fantastic opportunity for technicians and workshop owners to get practical advice from the best suppliers, trainers, and experts in the trade.

Euro Car Parts, are: Coles Automotive, West Sussex; Hillclimb Garage, High Wycombe; Jackson & Phillips

Automotive Services, Leighton Buzzard; Lindleys

Autocentres, Nottingham; Old elds Garage Services, Leominster; Plantexpand, Wickford and Uck eld Motor Services, Uck eld.

The full list of nalists can be found at https://iaaf. co.uk/news/

4 industry INDUSTRY

EV QUALIFIED TECHNICIANS REACH 39,000 IN 2022

Year-end gures from the Institute of the Motor Industry (IMI) show that over 14,800 dedicated technicians undertook the training and quali cations required to obtain IMI TechSafe professional recognition in 2022. This boosted the total number of quali ed technicians able to safely work on electric vehicles in the UK to 39,000 by the end of last year.

The IMI welcomes the e ort by employers and individuals to upskill for decarbonisation but is calling for an acceleration of training to avoid the potential shortfall of 16,000 quali ed technicians currently predicted by 2032. The IMI is highlighting that previous market expectations of electric vehicles requiring less time for servicing may be misplaced, increasing pressure on a workforce already dealing with an ageing UK car parc.

“Despite a long-held belief that EVs – with less moving parts –will be quicker to service than their ICE counterparts, in-depth analysis conducted by the IMI for our response to the MOT

Consultation suggests otherwise”, explained Steve Nash, CEO of the Institute of the Motor Industry. “In particular, tyre wear on electric vehicles is heavier than on ICE models; according to Garage Industry Trends analysis of 2021 MOT test data, EVs had a failure rate of 11.43% for 2018 registered vehicles compared to 10.45% for petrol vehicles and the weak point was identi ed as tyres.

“The assumption that more EVs can be serviced by a single technician compared to non-EVs therefore no longer rings true. Garages and workshops can’t simply assume they will need fewer technicians to service EVs. Add to this the fact that the UK car parc is ageing rapidly, increasing the need for maintenance, and adding to the already sizeable workload of technicians, and it is easy to see how the training and deployment of technicians quali ed to work on EVs needs to shift up a gear.”

IS YOUR EQUIPMENT ENGINEER GEA ACCREDITED?

For peace of mind always use a Garage Equipment Association member.

GEA accredited engineers work to an industry code of conduct. Your assurance their skills and knowledge have been independently assessed.

5 INDUSTRY

Ask your engineer for his accreditation card ! The Upholders of Industry standards since 1945 The Garage Equipment Association www.gea.co.uk GEA ACCREDITED ENGINEER Name Company Discipline Exp Date ID Number XX123456 XX123456 XX123456 XX123456 XX123456

2023 STAR AWARDS SHINES SPOTLIGHT ON EXCELLENCE

The 2023 Star Awards, encompassing both the Garage Star and Customer Service Star accolades, are now open for customer nominations on The Motor Ombudsman’s Awards portal (www. TheMotorOmbudsman.org/Awards).

The annual competition recognises individual team members and businesses accredited to one or more of its four Motor Industry Codes of Practice, that have gone the extra mile in the eyes of consumers. Since the Star Awards were launched, around 3,500 nominations have been submitted, highlighting examples of excellence and remarkable acts of kindness and generosity to help motorists in their time of need.

More than 7,000 Motor Ombudsman-accredited franchise dealerships, independent garages and body repair centres across the UK are eligible to be put forward by motorists for one of the eight Garage Star trophies representing di erent regions of the UK, spanning Jersey in the south, to the Shetland Islands in the north.

Entries can be submitted by consumers up until the 15th October 2023, during which time, businesses can promote the contest, and be recognised in return by their customers. From the nominations received over the coming months, a shortlist of three names will then be compiled by The Motor Ombudsman for each of the 11 awards available in the competition.

The nalists will then be passed to a panel of judges to collectively decide the respective trophy winners for this year’s Garage Star and Customer Service Star Awards and the

LEAGUE OF TRUE MECHANICS RECEIVE THEIR REWARDS

Denso’s annual League of True Mechanic (LOTM) competition puts technicians through their paces with IMI accredited, online technical training and assessment. Prizes up for grabs included a DENSO WEC sports prototype model, laptop bag, Toyota Gazoo Racing polo shirt, a team racing jacket, Sonos One speaker, wireless Bose headphones and a Sonos Playbase. The seven high achieving technicians receiving these rewards were Jason Sprake, Brian Hurst, Darren Douglas, Sam Buettner, Andrew Tweedle, Roan Troy, and James Cauvain. In third place and winning a £500 Red Letter Day was Mark Lamont of Grasmere Garage, pictured, second with a £1,000 holiday voucher was Philip Scott of Robsons Motor Services and taking the top spot and winning the £2,000 luxury holiday rst prize, as well as taking the accolade of 2022 LOTM champion, was Edd Hunt of The Car Consultants.

“Our congratulations go out, not just to Edd, Philip and Mark, but to all the prize winners and everyone that entered the LOTM competition in 2022,” said DENSO Europe, Pan European Strategic Marketing Manager, Fatiha Laauich. “We launched the 2023 competition in

National Garage Star Award, chosen by the panel from eight regional winners.

This year, the Motor Ombudsman has partnered with the Chartered Trading Standards Institute’s Hero Awards. The National Garage Star Award will be presented in-person to this year’s winner at a ceremony within the Houses of Parliament in London’s Westminster. The business or team member will receive £2,000 worth of vouchers and marketing exposure; including a video lmed at their premises to highlight their achievement.

April, so we urge both previous entrants and technicians who’ve so far yet to enter, to register this year and aim to knock Edd o the top spot and take the prestigious title.” Registering for the e-Learning platform is free via the following link www.denso-technic.com/uk/ and you can also sign up to the LOTM competition.

6 INDUSTRY

WHO DO YOU THRUST TO HAVE YOUR BRAKE PARTS REPAIRED? Your expert in the remanufacturing of electronic car components Let’s keep it cost effec�ve & reliable together WWW.ACTRONICS.CO.UK 01206 849920

Bring it on!

Are you ready for autotechnician’s workshop takeover? We are counting down the days until we get together with readers and trainers once more at Autotech Live – our rst o cial Workshop Takeover!

Trust us, you cannot a ord to miss this – here’s the deal…

What is it? A full day of diagnostic troubleshooting side-byside with a great bunch of technician trainers within Matt Cleevely’s impressive workshop

When? From 9.30 to 4.30 on Saturday 24th June

Where? Cleevely EV, Cheltenham GL51 8PS

What’s the format? Small groups of technician/workshop owners will rotate around three workshop bays, focussing on diesel, petrol and EV/hybrid faults. There are no presentations,

just hands-on faultnding with justin-time learning thrown in by each guide trainer as and when required

How much will it cost me? Tickets are just £99+VAT

What! Why is it so cheap? Thanks to ACtronics, Alldata, Bosch Aftermarket and JLM Lubricants who support the campaign, we are able to o er cost-price tickets to ensure that everyone who is committed to upping their game can a ord to do so.

Sign me up! A limited number of subsidised tickets to the one-day event are available at www. autotechnician.co.uk/ training

Andy Crook of GotBoost will guide a team through diesel faults

Andy will be challenging technicians to stick to the process while ensuring the business has the systems in place to bene t from diagnostics. If the business wants to be e ective and the technician wants to be e cient, you need systems and processes. Andy will challenge you to diagnose the fault(s) e ciently and deal with the customer e ectively. Are your systems and processes robust enough? Come and nd out….

Gareth Davies of Euro Performance will help you tackle petrol vehicle issues

"I’m delighted to be involved in another autotechnician event where we get to meet like-minded industry professionals. This year the format is heading back to its roots and I’m looking forward to setting a broken car task for technicians and business owners to get their teeth into. As a small group, we’ll look at the real-world faults that have been presented, with some added customer twists and turns for good measure, and use a variety of dealer and aftermarket tools in combination

with shared knowledge and decision-making on how to attack the faults, from fault to x. We’ll cover all the meat and potatoes of the technical task, with opportunities for questions and pitstops for learning and development throughout the task. Above all we’ll have some fun while learning about the serious business of troubleshooting faults within the workshop. I look forward to seeing you all there!"

Host Matt Cleevely and Eliot Smith of Pro-moto will lead a team of techs through EV faults Matt says delegates will learn how to gain con dence repairing and diagnosing High Voltage circuits. Get a good understanding of what is required from a HV ready workshop and be inspired by working on EV’s within the busiest EV specialist workshop in the country.

Eliot will be tackling charging faults, so you can con dently attain whether you’re facing a faulty charger, charge lead or vehicle system. Learn how to diagnose common, and not so common, EV faults and get ahead of your competition.

In association with: Media Partner:

8 AUTOTECH 2023

Don't miss out

Tickets to this event are limited to ensure a hands-on, valuable learning experience. A number of subsidised tickets to the one-day event are currently available at www. autotechnician.co.uk/training. Email Nicola@ autotechnician.co.uk if you have any booking queries.

ACtronics are pleased to be continuing its sponsorship with Autotech for 2023

“As the market leaders in remanufacturing electronic automotive components, not only do we o er a rst-class solution for garages, but we also support rst-class training and technical support for the automotive trade. It’s more important than ever for technicians to have access to world-class training and ACtronics are very happy to work alongside autotech to provide this. It’s important that we all work together to futureproof garages ready for the changes ahead.”

Technicians to be supported by ALLDATA’s OEM repair data during autotech

“ALLDATA Europe is delighted to announce its partnership with autotech, a workshop training initiative that complements the OEM repair data provider’s strategy of supplying managers and technicians with accurate and up-to-date repair information.

With 89,000 make, model, engine and year vehicle combinations available on ALLDATA Repair, converting to 95% of vehicles on the road today, autotech participants can capitalise on this abundance of data while xing faults in the Autotech Live workshop arena. Consequently, they can boost their rst-time x rate when returning to the real-world garage environment.”

Bosch Aftermarket UK & Ireland are delighted to sponsor Autotech Live 2023 – an event where technicians work together and solve live vehicle faults

“Autotech Live gives workshops the opportunity to highlight any skill or knowledge gaps and provides the right tools and training to support them. The event on June 24th gives technicians the chance to work on both ICE vehicles and EVs.

To support workshops, Bosch’s training centre delivers a full range of technical training courses for all levels and roles in modern workshops, accredited by the IMI.

Bosch is a well-known supplier of workshop solutions, o ering a range of diagnostic testers such as the KTS series, and ESI[tronic] 2.0 Online software with ADAS Calibration, Air Conditioning, Emissions Testers, and Vehicle Systems Analysers, all EV compatible.”

JLM Lubricants UK are proud sponsors of Autotech

“The range of high quality JLM diesel and petrol additives is perfectly suited to the professional technician, including those who will be attending the Workshop Takeover. Attendees will receive an exclusive JLM goody pack including comprehensive information on the JLM product range. More and more professional technicians are choosing JLM products for their workshop because they realise that JLM produces top quality additives for both diesel and petrol engines that deliver excellent results, every time.”

Find out more at www.jlmlubricants.com

Take a free online assessment now!

The latest autotech test joins the evolving bank of free knowledge assessments on www.autotechnician. co.uk/registration/ and looks at troubleshooting fundamentals and best methods to tackle the real-world fault assessments within your workshop.

This test has been created by VAG specialist, Gareth Davies, and presents the real data and investigation of faults on an Audi A3 within a multiple-choice format.

All you need to do is enter a few details at https:// autotechnician.co.uk/registration/ click an automated email reply and you get instant, free access to the multiple choice tests focussing on various topics and scenarios, including: Energy requirements of similar vehicles; Case Study – P0303; The SCR system; Hybrid & EV; Common sensors used in spark ignition engine management systems; Oscilloscope Quiz; Testing electrical components; Electrical Test; LIN Bus; CAN-Bus; Diesel case study & Ignition case study!

9 AUTOTECH 2023

HOW ALLDATA REPAIR WORKS IN THE REAL WORLD

ALLDATA UK pays Herefordshire-based Old elds Garage a visit after Tim Benson subscribed the workshop to ALLDATA Repair

Last November, ALLDATA Europe Marketing Manager, Julia Marra, struck a rapport with Old elds Garage Owner, Tim Benson, following a presentation of ALLDATA Repair at Mechanex Tim was persuaded to sign-up. Months later, Tim invited ALLDATA to his workshop to see how he and his colleagues have been getting on with ALLDATA Repair in the real world.

Old elds background

In 1991, Tim’s parents assumed control of a petrol station, with a built-in workshop at the rear. Tim’s dad was a mechanic, so his parents’ ambition was to forge a path to growing a successful workshop business – and so began the Old elds journey. Tim, though, took a di erent career path before returning to the family business a few years later.

He recalled: “Initially, I worked for a Volkswagen dealer, but I moved on to complete my national higher diploma and then a business management degree. I worked in IT, cosmetic surgery and two universities, then ended up back in the area. I was at a crossroads as to what I wanted to do, so I was slowly leveraged into the business.

“Unfortunately, we sustained a lot of damage from a re; however, that was the catalyst for some life-changing decisions. I decided to go all-in, and we moved to our current premises in 2011. My parents retired three years ago, so I now run the business exclusively.”

Tim is acutely aware of how vehicle technology and repair is becoming increasingly sophisticated. He is a business owner that wants to futureproof his business and be the best that Old elds can be – after-all, with a tight-knit community

of 12,000 people, word can spread fast and can make a huge di erence to businesses if it o ers a professional or unprofessional service.

Tim has invested signi cantly in Old elds’ facilities, infrastructure, training, tooling and equipment. He is an advocate of OE components too. That desire to improve the breadth of knowledge of Old elds sta and try to tackle every job that arrives in the workshop, not to mention the strive for OE quality, are just some of the reasons why Tim turned to ALLDATA Repair.

An annual subscription to ALLDATA Repair gives instant access to all repair data, as well as Technical Service Bulletins (TSBs), diagnostic trouble codes (DTCs) and electrical systems/wiring diagrams. The data is o ered with an intelligent search engine (o ering text string matching technology) to enable the technician to nd the data they need in seconds.

The portal o ers 91,950 make, model, engine, year (MMEY) vehicle combinations, which equates to 95% of vehicles on the road today. In the last 12 months alone, 301 models have been published. ALLDATA Repair possesses a library of six million technical drawings and wiring diagrams, including electrical connector views.

The connection between Tim, Old elds and ALLDATA Repair arose following an encounter at MECHANEX in 2022. Tim and ALLDATA Europe Marketing Manager, Julia Marra, met during the aftermath of a talk Tim was giving – about data!

Tim continued: “Julia approached me and asked if I’d heard of ALLDATA before, which I had, but the perception was that it was complicated to use; however, after explaining the product in more detail, Julia persuaded me to try it and see if my perception was wrong!

10 AUTOTECH 2023

ALLDATA’s Eric Ware and Annette Chamberlain with Old elds Garage Owner Tim Benson

“Obviously, using the original and unedited data from OEMs makes life a little challenging in that the manufacturers present and supply data di erently; however, that’s perfectly understandable. Vitally, it guarantees that the data supplied by ALLDATA, such as wiring diagrams or TSBs, hasn’t been reformatted or changed. We can have total con dence in what we’re being told.”

ALLDATA UK does o er training to subscribers, to help with setup, familiarisation of the software and suggest ‘tricks and tips’. And, indeed, Old elds has signed-up to receive training from ALLDATA Regional Sales Manager, Eric Ware. Tim described the added option of training as “bene cial and adds value” to ALLDATA Repair.

Tim added that ALLDATA Repair has also been useful on more complex jobs, which has allowed Old elds to go “further along with the process of the job”, thanks to “a test procedure, which is accurate, or a known problem on a particular vehicle that we wouldn’t have spotted previously”.

Perfect for diagnostic work

Tim has the philosophy of “there’s no such thing as too much data” and explained why ALLDATA Repair is a must for certain workshops. He said: “If a workshop is participating in any diagnostic work, I think it’d be foolish to not incorporate ALLDATA Repair into its overall package. Technical information, like testing procedures, TSBs and wiring diagrams, is easy to obtain.”

Focusing speci cally on TSBs, Tim pointed out that because ALLDATA Repair’s TSBs have come direct from OEMs, it means they can be relied upon – don’t need to be checked in fear of steps missing or incorrect.

Practical example

Tim illustrated how ALLDATA Repair works in the real-world. What should’ve been a straightforward task turned into a job for ALLDATA Repair’s data.

Tim picked up the story: “We had a fuel lter on a Volvo, a type that we’d never seen before. The tting was di erent to ones seen previously. It’s a job that we should be able to complete easily, but there was a particular clip that was unusual – it worked in a strange way: one pushes a bit up, then a bit down to unlock it. Logically, when one of our guys looked it, he pulled it but couldn’t undo the clip. Obviously, with the lter clip being made of plastic, there was the risk of it breaking when trying to force the issue.

“We logged onto ALLDATA Repair and found the exact procedure for replacing the fuel lter. It showed the type of clip and how it opened. Using ALLDATA Repair meant we were able to complete a 30-second job; whereas, before we invested in ALLDATA Repair, we probably would’ve broken the clip and ended up having to buy a fuel line. It’d be our fault and we’d have to explain that to the customer, which would likely be a tough conversation.”

He concluded: “The TSB element cuts down diagnostic time and testing time, and it sends users down a path which is the right one. It’s a useful partner. What’s more, certain repair procedures have also saved us and our customers time.”

Thank you to Tim Benson and the sta at Old elds for their hospitality and support.

Find out more

To learn more and discover how ALLDATA Repair works in practice, check out www.alldata.com/eu/en/video-EN. The website also o ers valuable information and the chance to request a free trial.

ALLDATA will be available for a chat during breaks at autotech’s workshop takeover in Cheltenham on 24 June. Tickets are available at www.autotechnician.co.uk/training

They will also be presenting at the Workshop Hub at Automechanika Birmingham, nd out more on page 47

11 AUTOTECH 2023

“For diagnostic work, I think workshops would be foolish to not incorporate Alldata Repair into their overall package”

KTS Diagnostics made ESI

LESSON 2: UNDERSTANDING SYSTEM OVERVIEW AND PROTOCOL REPORTS

Welcome to the second in a series of guides from Bosch to help your workshop make the most of its ESI[tronic] 2.0 software, designed to boost your know-how of the key features to maximise pro ts and enhance e ciency. This series of technical articles will break individual topics down and build all the way up from the basics to advanced expert tips.

REMEDIATION AND REPORTING MADE SIMPLE

In our last article, we covered how users of the software can easily and e ciently select the correct vehicle, and the importance of retrieving reliable information on the vehicle being worked on.

In this short guide, we’ll dive into the detail of how the System Overview feature can help you identify potential issues to arrive at the right diagnosis, faster than ever before. As well as how our Protocol Reports option can help you document the remediation action taken by your technician team in a professional report.

ACCESSING YOUR SYSTEM OVERVIEW

The ‘System Overview’ feature on the ESI[tronic] 2.0 works as the users ‘complete vehicle diagnostic check’, allowing you to carry out the necessary tasks e ciently for every vehicle that comes through your workshop doors for a service or repair. It helps to quickly and easily identify intermittent issues, pending technical problems and mechanical di culties that the driver or customer may not be aware of.

This feature will also run a systematic check on the vehicle, ensuring it has a clean bill of health for when it is handed back to the owner after a repair or service. Allowing you to know that you are delivering the best service possible to your customers, see Figure 1

HOW TO PERFORM A SYSTEM OVERVIEW

STEP 1

Open the Diagnosis main tab.

STEP 2

Click on the ‘System search’ F12 soft key in the System Overview sub tab.

STEP 3

The KTS will then perform a full ‘Control unit search’ of all communicating systems.

STEP 4

Double click any of the system names in the categories for direct access to the ECU diagnostic functions for further information and testing. If a fault code is erased here, it will refresh when a user returns to it – enabling you to save and show the before and after status to show the vehicle owner.

STEP 5

Store the complete list in the job report with the F3 save button. You can also access a speci c list of Diagnostic Trouble Codes (DTC’s) and any available descriptions via the F5 fault details button. Again, this can be saved to the job protocol with a tap of the F3 save soft key.

12 DIAGNOSTICS

Figure 1

When the system overview is complete, you will see a list of all ECU systems that are communicating and an indication if any fault codes are present. This is particularly bene cial when users are analysing a vehicle prior to any in-depth diagnostic testing as some faults, for example ESP problems, can log a DTC in more than one ECU.

Once you have retrieved the overview list, if necessary, any of the system names in the categories can be double-clicked. This will take the user straight to the ECU diagnostic functions for additional investigation and testing. From here, if the fault code no longer shows up, the overview list will refresh itself once you return to it.

Alternatively, you can also select the ‘Delete All Faults’ button to delete all DTC’s across multiple systems or ECU’s – in a single click. It’s worth noting that many newer vehicles will now support a fast CAN Bus search of all of the ECU’s on the vehicle system communication network. In some instances, a vehicle brand can have up to 60 ECU’S that can all be checked in under a minute, speeding up the technician’s task of assessing the diagnostic state of the vehicle. Yet, for other vehicle brands, this process may take a little longer, due to the KTS checking each ECU individually for presence and fault status of each group. The new generation of KTS (560/590) can communicate simultaneously over two communication channels in parallel to signi cantly speed up the time required for a complete vehicle scan.

to save or erase whichever information you choose to, which can be bene cial when you are justifying a lengthy repair process or operation time, see Figure 3

PREPARING YOUR PROTOCOL REPORT

The System Overview function enables you to quickly and easily produce a professional and accurate vehicle report. The perfect tool to help you justify any repairs that you need to carry out on the vehicle to the owner, see Figure 2

SHOW THE FULL JOURNEY

Document the end-to-end process followed by your technicians during any diagnostic fault- nding work and share the before and after progress with your customers.

BUILD YOUR REPORT, YOUR WAY

Choose to include a variety of di erent information in your reports – from ECU system names and identi cation details to the number of trouble codes stores and their descriptions.

SAVE YOUR PREFERENCES

The amount of information included in your protocol can be stored under ‘User settings’ in the main menu. This allows you

You can also choose to include your garage details that will appear in the report, alongside the option to include the job number, customer’s details, and any advisory comments to be communicated to the customer.

Importantly, the protocol le can be saved in a PDF format, which is useful for technicians to print and attach to an invoice, highlighting to customers what problems were found and repaired.

Each time a technician selects a di erent vehicle with the software and some information is saved, a new protocol report will be created.

A key new feature of the ESI[tronic] 2.0 is that you can continually save data to a previous protocol within the ‘last 30 vehicles’ list if you return to an un nished job, see Figure 4

In the next issue, discover how the Bosch ESI[tronic] software streamlines your everyday service tasks in the workshop.

www.bosch-training-solutions.com/eventcalendar

13 DIAGNOSTICS

Figure 2

Figure 3

Figure 4

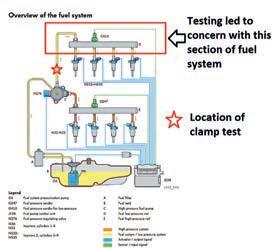

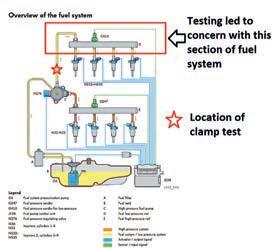

Overview of the fuel system

Technician

By Gareth Davies AAE FIMI, Euro Performance

Technician

By Gareth Davies AAE FIMI, Euro Performance

Case study:

016 VW Golf R TSI 45,000 miles

Long Crank no DTC’s

Last year, we were presented with a 2016 VW Golf R TSI, and its issues were well documented by the customer in a ‘love letter’ as we call them in the workshop. It explained the symptoms, a large list of work conducted to date in a previous workshop and what they believed was responsible for the issues starting on a fairly low mileage, well-loved car.

Initially this was not my task to examine; there’s six of us on the workshop oor. Initially it was perceived the issue resided with the High-pressure fuel pump (HPFP) and was duly repaired with a new genuine item, tested under failing condition, and collected by the customer. My assistance was required for a di cult phone call from a disappointed customer two days later who reported that almost the same symptoms were back,

14 CASE STUDY

vs business owner mindset

Testing led to concern with this section of fuel system

Legend G6 Fuel system pressurisation pump G247 Fuel pressure sender G410 Fuel pressure for low-pressure J538 Fuel pump control unit N276 Fuel pressure regulating valve N30-N33 Injectors, cylinders 1-4 N532-N535 Injectors 2, cylinders 1-4 AFuel lter BFuel tank CHigh-pressure fuel pump DFuel low-pressure rail EFuel high-pressure rail High-pressure system Fuel system / low pressure system Actuator / output signal Sensor / input signal

Location of clamp test

and that they weren’t best pleased given the amount of cash invested both with my garage and a previous garage, to be at the same point.

I listened to the customer issues and took the time to discuss how we could reach a mutually amicable position. We agreed to have the vehicle back in and carry out tests to try to understand how the symptoms were the same and provide an answer on what should be done to repair the issue. The customer was very sensible and relaxed about timescales, simply focused on the outcome of accurate diagnosis and recti cation of the issue. Furthermore, I had agreed I would spend as much time as needed, at my expense, to get to the route of the issue in testing charges. No pressure then!

I am sure we’ve all been in this position, xing a clear and present issue and being pleased the car is xed, only to nd, as Andy Crook describes, as peeling another layer from the onion. The heartache experienced by the customer of more problems and more expense magically then becomes your problem because the bit you xed was not it, or all of it. However it is dressed up, this phenomenon of the pressure being dialled up is a mental challenge that makes clear thinking and problem solving that much harder. Thankfully, unlike many customers who need their car back yesterday (I get it, it’s hard without wheels) this customer was magic and said they wouldn’t bother us, they’d hear from us when they hear from us – more of these please!

First port of call was to get the car into the workshop on the Friday afternoon in preparation for Monday morning. I wanted it to be in the workshop, in a position to connect any relevant tools and testing gear at the point at where the symptom occurs. What we were troubleshooting was a long crank, usually rst thing in the morning or when left for extended periods of rest. So, my point of testing to catch the fault is

extremely limited and I needed to make any of the tests I did count before having to do something else, for a few hours at least. The tech in question was also on annual leave for a week too, so the job narrative from its previous visit was all I had to go on.

Over the weekend, I read up on what the previous garage had done in terms of repairs and part changes and exactly what had been carried out in our workshop prior to my involvement. According to the customer, the vehicle had been lled up with ‘bad’ fuel that he had acquired ‘on the cheap’. It had caused a mis re and poor running with EPC and engine management light on which took him to his normal garage. They conducted tests and had replaced the spark plugs, ignition coils and four fuel injectors. The bad fuel was drained o , fresh fuel added, and an oil service conducted. The car appeared to work well for a week until the engine management light returned – it went back to said garage for further tests and was booked in with us around this point.

The vehicle was producing a DTC and engine management light but no mis ring at the point at which we rst saw the vehicle. The DTC being generated was P0087 – fuel pressure too low. It would take some time to return from clearing and pressure testing, including data logs, didn’t yield a huge number of clues to the problem area. The only anomaly found was with high fuel pressure being below the 50-bar required at idle, the scan tool reported a uctuating 43-46 bar. The technician removed the HPFP and found the spring and piston not to be quite square. This HPFP is driven o the camshaft on the engine, his theory being this could be a ecting that pressure reading. Before replacement, he straightened and lubricated the piston and re tted it. Coincidently, the pressure now resided at 50bar during idle testing and the actual and desired values when road testing under load showed almost identical in the logs. On this basis, and the bad fuel trauma, it was recommended to be replaced with a new genuine item. Not that it should matter as we try not to change parts because of whether they are common or not, but these pumps are fairly common on our brand base, noting that normal failure does display as a di erent failing symptom but similar DTC’s.

The repairs were actioned, and the same testing conducted after an overnight rest revealed no long crank and perfect performance, all appeared well.

18 CASE STUDY

Figure 2. Clamp attached to low pressure fuel feed to SRE plenum mounted injectors

Figure 1. Testing and evaluation of the low-pressure pre supply fuel pump with an inline gauge

Monday came, as it always does, and I had to begin my testing. Prior to leaving the car I had left the driver’s door open but with the catch rolled as a lot of modern cars give a pre-squirt from the low-pressure fuel pump when the car is unlocked or driver’s door is opened. I didn’t want this to skew any tests I was about to carry out or diminish the chance of catching and experiencing the symptom for myself. Symptom experienced with scan tool live data showed that there was virtually nothing to go on. A very small dip in pre supply pressure but the window of opportunity to catch the issue was so small before starting and running without issue was minimal, a few seconds or so.

Contemplating what test(s) could be carried out to try and expose or promote the failure was tricky. I found myself standing at the front of the car looking at the engine bay for inspiration. I decided to think about what could be causing the symptom, without a running or performance issue. The fuel delivery unit or low-pressure fuel pump has an integrated lter that is part of the pump assembly. I elected to remove the LPFP for inspection. At the bottom of the pump is a strainer and it was badly blocked. I couldn’t be sure this was from the bad fuel or just normal build up, either way I cleaned it, repressurised the system and opted to try it the next morning. Before trying it I also had my scope set up to evaluate the pump itself during pressure build up and normal operation. All of this checked out and the two tests carried out were checking the command from the controller (pulse width modulated) and the 3-phase pump. All was good, but sure enough, it faulted the next morning.

The next step was to evaluate the low-pressure fuel pump pressure build up and decay. I used an inline pressure gauge adapted to measure the pressure from the pump up to the engine bay, see Figure 1, previous page . What I noticed before attempting to crank it the next morning was that although ‘leak free’ I had no residual pressure on my gauge. I was not sure whether this was correct, but truthfully, I had expected to see some remaining pressure here. Sure enough, the gauge rose quickly to approx. 5 bar when the ignition was turned on and upon cranking, the car faulted again. Getting thin on ideas for this mysterious phenomenon I found myself staring at the engine compartment once again. I had failed to notice this later variant of the EA888 engine has two sets of injectors.

I pulled up one of the very useful VAG self-study programs (SSP’s) and read up on how this type of dual injector system works. I remember dual injection systems from back in the day when you were looking to extract big power from Ford Sierra Cosworth’s and the old Turbo Technics converted MK2 VW Golfs but hadn’t personally seen them to this point on this engine. If I had, I clearly wasn’t paying enough attention! With this in mind, I updated the customer with the relevant test ndings. I also queried which injectors were replaced. The group of injectors that had been replaced for mis res were the High-pressure injectors mounted in the cylinder head.

With pressure decay being at the forefront of my mind, given pressure generation had been proven on low- and highpressure fronts, I elected for a very crude test before going home for the day. I used a set of clamps on the low-pressure feed hose to rail supplying the plenum-based injectors, see Figure 2. All my other test equipment, including low pressure

gauge was still in situ and I was keen to see the pressure reading on the gauge on my return the next morning. To my surprise it was still registering around half of the pressure (around 3 bar) on the gauge. Hmm I have a change here. With eyes tightly closed and techs for an audience I cranked the engine. To my amazement it started straight away, no long crank and no running problems. With these so called SRE injectors the last stop on this line I opted to set up a Columbo Test, of sorts.

I removed the clamp and ran the engine for a time. I then removed all xings securing the rail and injectors so I could remove them quickly and easily on my return in the morning. What I was able to prove is that the SRE injectors were working but leaking/decaying due to being faulty. Figure 3 shows wet injectors before the vehicle was even cranked, just ignition on and pre supply pressure built. With them removed, I was also able to see dampness on the piston crowns, which shouldn’t be there after a full 14 or so hours’ rest from combustion. The failure in this instance was only responsible for one perceived complaint and not other running issues and proved very tricky to accurately pin down. Having read the full SSP for this fuel injection system it's explainable and understandable how this fault could be overlooked and not revealed with average symptom-based testing.

I submitted my ndings to the customer, and a repair was actioned. Follow up testing the next day revealed the symptom was cured and the test equipment still connected showed that full decay in the low-pressure system is not normal and some should be retained.

I was pleased to get to the bottom of the issue, but xing this particular fault raised questions as a technician and business owner. Did the original fault get xed with the HPFP and that’s why there was no return of P0087 DTC? Should I have discounted our diagnostic testing when the vehicle returned, was I obligated to or was I taking ownership for the customers car problems? It’s a di cult quandary and the mindsets of technician vs business owner play o against one another in situations like this.

19 CASE STUDY

Figure 3. Injector face found to be wet after ignition on and fuel pressure priming system

Closed loop systems – A deeper look

Fun fact – not all automotive air suspension systems use the same working principle! Therefore, it is important for a professional workshop to know what system they are working on: a conventional open system or a so-called ‘closed loop’ air suspension system. The technical know-how for properly diagnosing possible system errors or defects, ensuring the correct working procedure is followed, correctly installing new air suspension components, and checking the system and making it operational again after an air spring leak is di erent from the conventional open air suspension system. In this article, Arnott will provide more insight into the alternative closed loop system.

In ation and de ation processes

Now that we know that speci c technical knowledge and understanding is required, let’s take a look at the general di erences between the two systems’ working principles before diving deeper into the subject.

compressing atmospheric air. When the system has a leak, it will try to retain its required operating pressure by opening the (ambient) air intake. However, it can only compensate for a small loss of nitrogen and when the compressed nitrogen mass gets too low the system will stop functioning.

Looking at the graph above, it shows the workings of the compressor are quite di erent in a closed loop system. In an open system the compressor compresses ambient air to ll the reservoir and/or air bellows, a closed loop compressor uses the pressurized nitrogen that is already existing in the system. Additionally, in a traditional air suspension system excessive air is released into the open but for a closed loop system the nitrogen stays inside the system and excessive pressure is led back to the reservoir. This is an important aspect to keep in mind when working on this system.

For in ation/additional pressure, the closed loop system uses two reversing valves that will open towards the valve block. The solenoid valve for the appropriate air spring opens and the additional pressure is transferred. When de ating, the excessive pressure is not discarded but cleverly routed back to the reservoir by opening the two reversing valves in the other direction. The excessive pressure is now transferred back into the reservoir. The pressure ow diagram below gives an indication of how the pressurized nitrogen is routed when an air spring is in ated or de ated.

The twist

Although it is called a ‘closed loop’ system and the diagram above shows how the compressed nitrogen is transferred from one area to another to in ate/de ate the system, don’t be fooled! A closed loop system does have the capability to make up for small amounts of nitrogen loss by drawing in and

Indicators

Just like a conventional air suspension system, the system pressure will gradually drop when there is a big air leak present. Therefore, a symptom of an under-charged system is lack of operation. However, in a closed loop system, the ECU (Electronic Control Unit) continuously calculates the ‘nitrogen mass’ as an indication of normal operation. If too low, error messages like ‘max payload exceeded’ might appear on the dashboard (depending on the car manufacturer).

An indicator of an overcharged system is audible discharging of excess pressure. This only occurs when a mechanic has not followed the correct procedure when recharging the system after a leak repair. It goes without saying that an overcharged system can lead to damaged and defective components, alongside serious safety consequences.

www.arnotteurope.com

This information is provided to you by Arnott – Suspension Products. With more than 30 years of experience in engineering, designing, and manufacturing high quality air suspension components for the aftermarket, Arnott is the technical expert when it comes to air suspension systems. Arnott’s products are produced with high-quality, OE components o ering exact form, t and function. Each product is extensively tested in our American and European facilities and custom-tuned to suit the speci c vehicle make and model before being produced.

20 ADVERTORIAL

ADVERTORIAL

Keeping it Rolling febi Wheel Bearing Kits

Right Range -with a coverage of up to 95% of the required vehicle applications in Europe, we offer an appropriate and competitive range of wheel bearing kits.

Associated Products - we also provide a substantial range of wheel hubs, wheel speed/ABS sensors and wheel fastenings to complement our wheel bearing offer.

More Profit - by offering a competitive price, febi assures a higher profit to its customers - whilst simultaneously - providing components with OE matching quality.

Highest Quality - all febi products are designed, specified and manufactured to be direct OE replacements and our wheel bearing kits are no exception to this.

Your No.1 for Wheel Bearing Kits & Wheel Hubs SOLUTIONS DRIVEN BY YOU

Part Search Made Easy parts nder.bilsteingroup.com www.febi.com

New bearing designs enhance e-mobility

Schae er strengthens chassis system business and details its latest bearings for electric mobility

Innovative bearing solutions can play a key role in sustainable electri ed mobility by making powertrains and chassis systems more energy e cient. Every watt of energy that can be saved in an electric vehicle translates into increased range. Vehicle producers are therefore looking closely at every single bearing application as they seek to optimise friction performance and enhance usability for the customer.

As a global automotive and industrial player, Schae er understands the major potential impact of innovative new technology and has recently announced a new wheel bearing designed speci cally for electric vehicles, featuring three rows of ball bearings.

“Schae er is looking to t its e cient and high-precision bearing solutions in chassis systems and electri ed powertrains to further enhance these systems and make them more sustainable” said Matthias Zink, CEO Automotive Technologies at Schae er AG.

“E-mobility represents a major opportunity for our bearings business,” said Dr Dieter Eireiner, the head of Schae er’s Bearing business division. “We are expecting strong growth over the next few years, with major sales potential particularly for ball, cylindrical roller and tapered roller bearings, and we are already involved in a number of promising development projects with big-name vehicle manufacturers. Innovative bearing technologies are also very important for LCVs and HGVs, because they can signi cantly increase vehicle range. Working with our customers, we intend to take bearings to a whole new level.”

TriFinity: Three rows of bearings for maximum adaptability

Schae er’s TriFinity product is a triple-row wheel bearing designed for use in electri ed powertrains that is no larger than standard two-row ball bearings but is able to transfer greater axle loads whilst also o ering signi cantly longer service life and improved rigidity.

The advanced ball bearing design provides an alternative to preloaded tapered roller bearing units. Switching from tapered rollers to balls leads to signi cant improvements in frictional torque and rigidity, which results in a 0.7 percent reduction in electricity consumption per vehicle in FTP75 test cycles.

Combining a TriFinity bearing with Schae er’s face spline technology allows downsizing solutions in the form of hub units with smaller diameters, which reduces bearing and seal

friction and optimises weight, resulting in a smaller carbon footprint. Clearance-free face spline technology can also transmit up to 50% more drive torque, reduces noise levels and is easier to install.

High-performance bearing applications for drivetrains

Schae er has also developed a new high-e ciency ball bearing with integrated centrifugal disc for electro-mobility applications. It is a high-performance, friction-optimised and sustainable product that combines the bene ts of both openbearing and sealed-bearing designs.

It is a smart yet simple solution that has a major impact on overall performance, producing 0.3 Nm less friction and reducing CO2 emissions by around 0.3 gms/km. Reducing losses of up to 30 watts per bearing can also improve the range of an electric vehicle by up to one percent. This advanced new product also increases on the service life of a traditional open bearing tenfold, o ering a signi cant cost reduction. Schae er received the Magna Supplier Award and the German Innovation Award in 2022 for this innovative new technology.

info@repxpert.co.uk

www.repxpert.co.uk

22 BEARINGS

Bearing ADVERTORIAL

Bearing with Centrifugal Disc

Tri nity

THE CHASSIS EXPERTS

Schae ler is a trusted technical partner of the automotive industry, delivering high-tech components and systems for OE tment by vehicle manufacturers around the world. We have used this OE know-how and engineering excellence to create our FAG steering and suspension range, which o ers a genuine quality alternative to independent workshops. It is also the perfect accompaniment to our leading range of FAG hub repair solutions, which o ers garages genuine OE quality at a competitive price. And, as always from Schae ler, everything a technician needs to carry out a professional wheel bearing repair or hub unit replacement is in just one box, so you can simply t and forget.

FAG. The chassis experts.

www.repxpert.co.uk |

a

3

ermarket.schae ler.co.uk

Gasoline Direct Injection issues –what,

or who, is to blame?

Vehicle owners, workshops and vehicle manufacturers are seeing issues with Gasoline Direct Injected engines that cannot be put down to one fault. What’s behind the problems and what are the consequences? More importantly, what’s the solution? GDI specialist Phil Ellisdon of ASNU delivers his ndings within a three-part series of articles

Phil Ellisdon, CEO of ASNU, has been in this eld for nearly 50 years. Back in 1989, he became the ASNU distributor for Europe, gained Lucas and Bosch homologation, and eventually bought the ASNU business in 2000, shipping the manufacturing from Australia to Bushey in the UK.

The family business services thousands of ASNUs in over 60 countries worldwide through their distributor network and the equipment can be found in most vehicle manufacturer technical centres. In this article, Phil shares details of the symptoms, causes, consequences, and solutions on GDI issues that you need to be aware of...

Let’s start at the beginning. The concept of Gasoline Direct Injection, or GDI, is not new – the rst direct injection engine to use gasoline (amongst other fuels) to reach production was the 1925-1947 Hesselman engine, built in Sweden for truck and bus applications. As a hybrid between an Otto cycle

and a Diesel cycle engine, it could be run on a variety of fuels including gasoline and fuel oils.

So, if the design is perfect, the performance is fantastic and the reliability is outstanding, why are we seeing issues with GDI vehicles that cannot be allocated to anyone or any one thing? For those of you reading this and saying, “We don’t see problems with GDI”, you will understand more later in this article.

The GDI vehicle in use

The perfect driving conditions for a GDI engine are as follows: Using top grade fuel (as advised in the vehicle manual from the manufacturer) you start the engine and head out to the

24 ADVERTORIAL

ADVERTORIAL

motorway without tra c and without stopping. Drive 20 miles or whatever number of miles at the national speed limit up the motorway to your destination. Come o and drive without stopping, park up for the duration, then complete the same journey home.

The same scenario can be applied to the Diesel engine as well. If there were such a perfect condition, this would be it.

The reality is you start the engine and head out in the work/ school tra c to the M25 motorway in a Stop/Start enabled vehicle, so the engine automatically shuts o when stuck in the tra c and then starts and stops again 10 yards down the road when the tra c grinds to a halt again. This stop/start behaviour continues for the duration of the journey in the tra c. Then you hit the motorway and as its morning/evening the tra c is heavy and the stop/start process begins again. So, what is the problem we are seeing with GDI?

The answer is carbon build-up in the combustion chamber.

What causes carbon build-up?

It’s not any one entity, so let’s take a look at the contributing factors.

1. Fuel quality

The vehicle manufacturers stipulate that to maintain maximum engine e ciency with the minimum exhaust pollution a GDI engine must use the top-grade fuel. Now where fuel has an Ethanol content, the quality of fuel will vary from country to country, some owners prefer to use cheaper fuels as they have a cheaper car.

2. Driving conditions

The roads today are seeing more congestion than ever before, even clear roads have lower speed limits, and with engines encased in a much smaller location with smaller air ow access, the modern engine runs extremely hot, this heat quickly dries any residual fuel on the injector tip, it also dries any residual fuel in the combustion chamber creating the start of a carbon build-up.

3. Emission control

Emission control is the single one factor that EVERY vehicle manufacturer must comply with and although the GDI engine is by far the most emission-e cient produced, does produce more particulates than a Port Injected Engine. To ensure their vehicles produce a minimum carbon footprint, the VM’s Engine Management System, EMS, uses an automatic engine Stop/ Start system that switches o the engine when in tra c.

4. Fuel trim adjustment

In addition, the EMS also has Short- and Long-Term Fuel Trims that can add or reduce the amount of fuel the engine requires, controlled by various combustion performance sensors located on the engine. Unfortunately, this system has a aw – it cannot see the injectors’ spray pattern and therefore cannot determine if the spray is good or bad, which could result in bad combustion, leaving residual fuel in the combustion chamber.

Are you now understanding where I am coming from?

5. Injector performance

The GDI Injector is the single most important component in the delivery and control of the fuel that is delivered directly into the combustion chamber; one of the harshest environments on the engine. It has the nest tolerance of any mechanical part on the vehicle, it has a 30-micron lter in the fuel inlet neck and it is required to deliver a very speci c amount of fuel in a very speci c spray format and droplet size in milli second durations. All this precision in one component and yet nowhere in the lifetime of the vehicle is the injector lter recommended to be replaced or the injector tested or serviced. We change the air lter, oil lters and fuel lters, but not injector lters, why not?

Individually, these contributing factors may cause issues in the long-term running of the vehicle, but only the petrol will cause the carbon build-up. An e cient engine driven in perfect conditions will prove to be trouble-free but collectively these contributing factors can cause short- and long-term problems that will require a diagnosis and x but, in some cases, damage the engine beyond economical repair.

Keep an eye out for Part Two in the June issue of Autotechnician where ASNU will be looking at the consequences.

For more information go to www.asnu.com or email enquiries@asnu.com

25 ADVERTORIAL

Human Resources 101 for workshops

Within a series of articles, Human Resources expert Julia Crawford from People Pillar provides practical advice on all things people related – here, she focusses her attention on recruitment

Do you know how to attract the right people to your vacancies? Deciding to hire someone for the rst time is a big decision and you’ve probably been thinking about the bene ts, disadvantages, and costs for a while.

Can the business a ord to pay someone else? Will their value pay for their costs? Can I do all the work myself? Will I be stuck if I don’t hire someone? With a little forward planning, you can handle the whole recruitment process relatively easily, keeping your recruitment costs down, whilst showing your business o to its full potential. Here are my seven steps to e ective lowcost recruitment.

Step one: Identify your needs

Is it a new position? Are you replacing someone who is leaving? Or perhaps your business is growing so you are looking for additional help. Creating a list of skills, knowledge,

and experience that you want or need for your recruit to have is essential. For example, are there any skill gaps within the business that your new hire might be able to ll? Have you considered whether the workload is su cient to justify a new full-time member of sta ? Is there anyone in the business who will be looking to retire or leave the business soon?

Step two: Create a job description

It’s essential to have a job description for every role in your business. This way, when it comes to replacing a member of the team, or even creating new positions, you already know the responsibilities, quali cations, and skills needed for all. Why not ask your current employees to write their own job descriptions? This doesn’t have to be anything fancy. It could be a bulletpointed list of their responsibilities. This helps to make sure that no vital tasks are missed.

Each advertised job description should include the job title, responsibilities of the role, needed quali cations, skills, compensation, bene ts, and the location of the role. You could also consider writing a candidate pro le for each role within the business. These are designed to help you discover what kind of person you’re looking for to ll each role. It could also help you to know where to look for your next employee, as it will give you an insight into where they may look for a job, and therefore where you should consider advertising your role.

26 BUSINESS

Step three: Plan your recruitment

How are you going to attract the best candidates? Is there someone within your business who could t the new role? Is there someone who is ready for the next step in their career? Do you have an apprentice who is nearing the end of their training, who would be looking for their rst quali ed role?

When it comes to advertising the job, how and where are you going to advertise it? Do your current employees know anyone who is looking for a similar role? Referrals are a great way of nding excellent candidates. You will need to decide who will be responsible for creating the job advert and eld responses, or any questions, you may receive. Will this be you? To keep everything consistent it would make sense to make this just one person.

Make sure the language you use isn’t discriminatory. For example, words like young, dynamic or mature could potentially be age discriminatory. Also, there is no reason to stipulate someone must hold a driving license if they are not going to be expected to drive for the job.

Step four: Screen and shortlist

You’ve received applications from people who want to work for you. Now it is time to lter out the good from the not-so-good.

1. Put aside any that don’t meet your essential criteria. That’s most likely to be skills and experience. Look at where they are geographically based too. If they need to be local, and aren’t, it may be that they are looking to relocate to your area.

2. Sort the remaining applications into two groups, those with the minimum quali cations, and those with preferred credentials. Those with ticks in both boxes become your short list.

Step ve: Interviews

Your candidates will want to impress you, but don’t forget that you also need impress them. Take the time to consider the candidate’s experience, if you want to attract and retain the best person for your business.

What will your process be? Will you chat on the phone rst, then in person? Will you be asking candidates to do a practical exercise? If you do, you need to also allow for nerves, as not everyone is at their best when under these conditions. How are you going to structure your interview process and document it?

Try to be as exible as you can with your candidates. They may be in roles that are tricky to take time away from, so insisting on a particular appointment, you may miss out on that outstanding candidate, because they cannot do the day or time you suggest.

Step six: Making an o er

Before you make an o er to your preferred applicant, there are a few things you need to consider:

a) Never turn down other candidates before you’ve o ered the job to your preferred candidate, and they’ve accepted (ideally in writing).

b) Choose a second favourite, in case your rst decides to take another job. If there are no other suitable candidates, you may have to go back to the start of the process.

c) Be clear what you are o ering the candidates because things said verbally can also form part of the contract.

d) Make any o ers conditional i.e., that the o er is made subject to…This could be quali cations, right to work documentation (this needs to be done BEFORE they start with you), DBS checks (if applicable) and references. That way, if something crops up in the coming weeks in relation to these, you can safely withdraw the o er of employment.

Once you have made the o er and they have accepted, you now need to prepare their contract of employment and send it to them before their rst day. When you have employees, you legally need to have 1) a disciplinary policy, 2) a grievance policy and 3) a data protection policy (including an Employee Privacy Notice). If you employ over ve people, you also need to have a Health and Safety Policy.

Also check references. Sometimes they aren’t much help. However, you’d be surprised at just how many businesses skip this step, only to be shocked when something goes awry. Do not contact their present employer unless they have given you permission to do so.

Step seven: Excellent on-boarding

This step is so often forgotten when it comes to the recruitment process, but it’s one of the most essential parts to get right when welcoming a new employee. You need a solid plan to help welcome a new employee into the business. What do they need to be able to start their new job easily? What will happen on their rst day? Who is going to do their induction, introductions to your employees, processes, training and development? Make sure you diarise to check regularly how they are doing. This may all seem like a lot of work to do for one recruit, but once you’ve created this plan, it can be used time and time again for each new hire you make.

BUT don’t forget about your current people, when employing new ones!

One thing to ensure you don’t do, when you are looking for a new employee, is alienate the ones that you already have. At the outset, share your plans and make them feel involved. If you shortlist candidates, why not show them around your business, so they can meet the rest of the team. Then, once you have started your new employee, make sure you take them around and introduce them, and arrange for them to spend time with all the team, as part of their on-boarding induction process. It really will make things easier for everyone to gel and become a great team!

If you would like to talk further about the above, or nd out more about how People Pillar can help your business with HR, please do get in touch.

www.peoplepillar.co.uk

27 BUSINESS

hello@peoplepillar.co.uk 01303 769700

XTRA DEMAND

SUPERIOR STYLE, EXTRA PERFORMANCE

Expertly engineered by Brembo. Disc and pad have been developed to work perfectly together enhancing braking capability and delivering the pleasure of sports performance in every drive.

• Excellent friction coe cient for a greater grip and fast response

• Unparalleled brake pedal precision

• Enhanced heat and gas dissipation for improved braking system cooling

• Optimal braking stability

• Iconic design; for a stylish sports look

Demand Xtra. Get more.

bremboparts.com

BREMBO LOOKS FORWARD TO SEEING YOU IN AUTOMECHANIKA BIRMINGHAM 2023

HALL 19 • STAND R102

Automechanika Birmingham

Event preview Page 42-63

6-8 June | New product launches, demos, giveaways, show discounts and free training

REMANUFACTURING

Page 31-35

Parts, Tools & Tips

Page 64-69

New Car: Volvo EX90

Page 70-74

Mobile servicing & repair

Page 36-41

Running a mobile repair business presents di erent logistical challenges, compared to established garages with premises, leading Rob Marshall to ask leading tool suppliers how they can help.

INGENIOUS, NOT INFERIOR

Many green initiatives appear good for Mother Nature but come with the downside of performance and cost. With remanufactured car parts, the sceptical Rob Marshall is persuaded that garages and customers really can have it both ways.

Despite the motorcar having mud slung at it from every direction, it tends not to be realised that vehicles tend to be the most thoroughly recycled of all machines. While secondhand car parts have been available from various businesses for past decades, often on a cash-only basis and with a snarling Alsatian chained to the corner, salvaged parts' image is improving and are being viewed correctly as sustainable. With environmentally-friendly credentials to ful l on their company end-of-year reports, insurance companies and even the OEMs are taking an interest in salvaged components. Stellantis, the artist formally known as PSA and FCA, is one example of an OEM selling used parts as alternatives to new ones, through its B-Parts.com platform.

What are remanufactured parts?

Remanufacturing is a preferred de nition over 'reconditioning', or 'repaired' for instance. Associations that include the European Association of Automotive Suppliers and the Automotive Parts Remanufacturers Association Europe have agreed on a formal de nition, which is:

“Remanufacturing is a standardised industrial process, by which cores are returned to same-as-new, or better, condition and performance. The process is in line with speci c technical speci cations, including engineering, quality and testing standards. The process yields fully warranted products.”

31 REMANUFACTURING

While remanufacturing makes repairing an older, lower-value car more viable economically, it also lowers repair costs for newer models. Pictured is a 48-volt combined starter alternator from Autoelectro's range.

Global Remanufacturing Day fell on April 14th this year.

Remanufactured parts help garages provide more competitive repair quotes. Yet, this is not the only advantage.

The remanufacturing di erence

Despite being related, used parts are very di erent to those that have been remanufactured. Autoelectro explains that, for rotating electrics, the case, castings and everything that mounts to the vehicle are, indeed, reused. Yet, to remanufacture a part, the remanufacturer must have a comprehensive technical understanding of how a part, such as a starter motor or alternator, operates and why it fails. Autoelectro says that this is how it can support a workshop with technical information that would not be possible from a spurious source that imports new units.

Carwood asserts that, by retaining both the material and valueadded from the original product, remanufacturing is a lot more cost-e ective than new OE. Carwood, for instance, prices its parts to be at least 25% cheaper than a new OE part.

Shaftec reasons that remanufacturing is not just a coste ective nicety but a necessity. It says that remanufacturing is often the only aftermarket alternative to keep older vehicles on the road, especially as our car parc is ageing. Shaftec says that, should a customer supply a part for remanufacturing that the company does not hold in stock, it will remanufacture the same component, turning the job around within a few days.

Workshop tips

Returning your undamaged faulty parts is a vital technician contribution to ensure the circular economy's viability. Without the core parts to remanufacture, the process cannot work. Through lack of knowledge, or even carelessness, technicians can damage parts on removal, rendering them scrap. Therefore, Carwood and Shaftec recommend the following precautions:

• Always remove the part using the correct tools/ equipment and processes only. When removing a fuel injector, especially if it is seized, a removal tool designed speci cally for that application will damage neither the body, nor electrical connector.

• Separate ancillary components from the unit beforehand. With turbochargers, for example, remove unions, adapters, banjo bolts and sensors.

• The unit should be removed in one piece, as a complete unit – do not dismantle it.

• Once removed, the unit should be handled with the same care and attention as a new unit and should not be considered scrap.

• Ideally, any product drillings and threads should be capped, where appropriate, to prevent contamination during transit.

• Ensure any castings and mounts are neither cracked, nor broken

• Any threaded bolts (including brake bleed nipples) must not be snapped o .

32 REMANUFACTURING

It may look like a crate of scrap but usable core is valuable, because it is vital to the remanufacturing process.

"Remanufactured parts help garages provide more competitive repair quotes. Yet, this is not the only advantage"

Why choose remanufactured parts?

While many new copy parts are on the market, which undercut new OEM parts in price, Shaftec advises that they are not always the best option. While they can be more expensive than remanufactured parts, in quality terms, these parts do not have the integrity of using OE core to o er OE performance levels.

Furthermore, the remanufactured part may boast a superior warranty than not just the copy parts but also the new OEM replacement. Shaftec highlights that one of its remanufactured driveshafts, for instance, carries a ve-year, or 60,000 miles warranty.

The environmental argument is also a strong pull, because the remanufacturing is sustainable environmentally. Autoelectro says that it strives to save as much original material from the old core as possible and to reduce the use of raw materials, where feasible. Not only does this save wastage but it also means that the remanufacturing process consumes less energy.

Remanufacturing: Putting right past wrongs

Autoelectro reports that the remanufacturing process allows quality companies to address inherent defects within the original design. The rotating electrics exponent comments that identifying patterns with parts that fail for the same reason and having experienced and knowledgeable personnel allows it to do this.

Remanufacturing Mythbusting

"Remanufactured products are a poor substitute for new"

Products from an OE-approved remanufacturer are designed, engineered and remanufactured to meet, or even exceed the vehicle manufacturer’s original factory speci cation, so are as good as new, if not better.

"Remanufactured, reconditioned, rebuild and refurbished mean the same"

A remanufactured part has been returned to the original speci cation through a highly-engineered, regulated process, which includes core inspection, product disassembly, cleaning, re-inspection, replacement of all wearable parts with like-for-like OE, followed by assembly and test and calibration. In contrast, a reconditioned, or refurbished, part is dismantled and cleaned but worn/damaged parts only are replaced.

"Saying that a remanufactured product is better than the OE is marketing hype"

Quality remanufacturers bring the very latest technology changes to older remanufactured products. It can also engineer out any design defects. More often than not, the remanufactured part outperforms the original component on which it is based.

"All remanufactured parts are the same"

Not at all. Remanufacturing is a sophisticated process that requires signi cant investment in capital equipment, processes and skills. Not every remanufacturer has the same capability levels.

"Remanufacturing uses old parts"

While the base OE-quality castings are renewed (or improved in the event of a defect) all wearing ones are replaced. Yet, if any other part of the unit does not pass the many performance or functional inspections, it will not be reused.

"Remanufactured products do not come with a warranty"

After all the work is completed, every single part is reassembled and individually tested for compliance with the vehicle manufacturer’s original factory speci cation. All remanufactured parts come with a warranty, which is at least the same as the OE, sometimes better.

34 REMANUFACTURING

The majority of components have no prescribed remanufacturing procedures. You must have faith in your manufacturing supplier to conduct the task properly. For instance, would many other fuel injector remanufacturers pay the same attention to prevent contamination from entering the workshop as Carwood does with its clean rooms?

Thorough testing is also a priority for quality remanufacturers. Pictured is Shaftec's Electric Power Steering rack test rig.