Whitepaper

MYTHIC- MYterials for THermal Insulation in Construction

May 2024

Authors

MNEXT/Avans: Ilse Rovers, Fran Ortega Exposito, Shannon Peuling, Stefano Roccio, Neha John.

Caradt/Avans: Simone van den Broek.

Utrecht University: Jordi Pelkmans

Whitepaper

MYTHIC- MYterials for THermal Insulation in Construction

May 2024

Authors

MNEXT/Avans: Ilse Rovers, Fran Ortega Exposito, Shannon Peuling, Stefano Roccio, Neha John.

Caradt/Avans: Simone van den Broek.

Utrecht University: Jordi Pelkmans

MYTHIC - MYterials for THermal Insulation in Construction

In a rapidly changing world with environmental problems like climate change, pollution and waste, biobased materials are becoming increasingly important. This is partly because traditional raw materials are depleting rapidly, making building materials more expensive. As a response, the construction industry is turning its attention to circular material alternatives, with mycelium bio-composites (MBCs) emerging as

one of the most promising fully biodegradable options. In previous projects, MNEXT developed MBCs using various agricultural byproducts and different types of mushroom mycelium. The most successful combination proved to be rapeseed straw with Ganoderma resinaceum mycelium, resulting in a foam-like material ideal for insulation.

If you're curious to see how MBCs are grown, check out our movie.

The Mythic project aimed to create the best insulation material from MBC for the market. This involved four key research themes: Growth Optimization, Material Properties Optimization, Prototyping & Design, and Feasibility & Upscaling.

In Growth Optimization, the focus was on streamlining MBC production to yield insulation material quickly and consistently, while minimizing energy consumption. Methods such as sterilization and pasteurization were compared, with pasteurization showing promise for scalability and energy efficiency. Additionally, various inoculation methods were tested to improve growth speed and homogeneity in order to meet the requirements for industrial upscaling.

Material Properties Optimization concentrated on enhancing key characteristics essential for a biobased construction material, including thermal conductivity, fire resistance, water repellence, and dimensional stability. The emphasis in this project was on improving fire resistance, thermal conductivity, and hydrophobicity.

Prototyping & Design phase involved creating prototypes to showcase the material, its adaptation to different designs and explore its potential applications. Additionally, research was conducted on the mycelium material's acceptance, resulting in a scientific article.

Feasibility & Upscaling assessed the efficiency of large-scale MBC production for industrial applications. By optimizing the production process, both time and budget can be reduced, enabling MBCs to compete with traditional non-biobased insulation materials. Energy calculations and feasibility studies were conducted to ensure scalability.

This whitepaper provides a summary of the key findings from the Mythic project, focusing on the most important insights. For more detailed methods and results, including figures and explanations, please refer to the accompanying factsheets, accessible via links provided after each research topic in this whitepaper.

"CREATE

This section provides an overview of the research conducted to enhance the mycelium production process, focusing on comparing pasteurization versus sterilization methods for decontamination and assessing liquid versus solid inoculum for the inoculation step. The first part examines the differences between sterilization and pasteurization, while the second part investigates various inoculation techniques. Both aspects are evaluated in terms of growth speed to determine the most suitable method for reducing incubation time.

Sterilization vs pasteurization

Sterilization is the current method applied for decontamination of substrates in the mycelium bio-composite production which is done by exposing the substrate to high temperature and pressure in an autoclave. Pasteurization was researched as an alternative due to the possibilities it offers for scalability of production. It was experimented with different types of pasteurization including hot air-, hot water- and steam pasteurization. For each of the pasteurization methods there was research performed with different temperatures and durations which were based on available scientific literature and ranged from 60° C to 100° C and from 1 hour to 6 hours respectively.

Following the application of different disinfection methods, the substrate was inoculated with Ganoderma resinaceum and grew for 14 days. Throughout this period, samples were scanned daily using a flatbed scanner to monitor the mycelium growth. The growth quantification was carried out using Image J and Studio R, analysing the grey value to determine the time required to reach maximum growth, denoted as point A in the following chart.

After multiple rounds of experimentation, hot air and water pasteurization were deemed ineffective, resulting in minimal or absent mycelial growth. Further research focused on comparing sterilization (AU-autoclave) with different temperatures and durations of steam pasteurization (ST+ temperature). The graph indicates no significant difference between sterilization and pasteurization at 100°C for one hour and 80°C for 4 hours. In terms of growth speed, pasteurization averaged 5.6 days to reach maximum growth, while sterilization took an average of 6.7 days.

When looking at the speed of growth, pasteurization took on average 5.6 days to reach it’s maximum growth whereas sterilization took 6.7 days on average.

Conventional inoculation of substrate for mycelium bio-composites is performed using a grain-based spawn, often sorghum or millet. Every grain forms a spawning point through the substrate and the quantity and spatial distribution dictate the speed and homogeneity of the colonization. Furthermore, both sorghum and millet are used as feed for birds and livestock and therefore have economical value.

This investigation focuses on whether it is possible to use different inoculation methods that upcycle a waste product and offer more homogenous distribution throughout the substrate. As one option a blended liquid inoculum was investigated to improve homogenous distribution.

Figure 2. Graphic depicting variations in mycelium growth rate and volume between samples cultivated on sterilized substrate versus those cultivated on pasteurized substrate.

A liquid extract was made of either rapeseed straw or reclaimed cellulose by Recell B.V, both considered waste stream products. Potato dextrose broth (PDB; Becton Dickinson, Vianen, the Netherlands) was included as a commercially available medium. G. resinaceum was grown for 3 days as a shaken culture in abovementioned options and used as inoculum either blended or unblended. Growth on rapeseed straw in microboxes (SacO2, Deinze, Belgium) was tracked using the flatbed scanner method and showed more growth for reclaimed cellulose extract compared to the rapeseed straw extract and PDB.

As an alternative solid inoculum, again reclaimed cellulose was chosen for its more granular composition and negative carbon footprint compared to millet. G. resinaceum was grown on the reclaimed cellulose for 5 days in a Microsac (SacO2, Deinze, Belgium) before inoculation of the rapeseed straw, either blended or unblended.

Next, both solid and liquid extract inoculums based on reclaimed cellulose were compared to the conventional millet-based inoculum regarding growth on rapeseed straw. Both blended and unblended inoculums were included for all variants. Samples were grown for 15 days in microboxes and growth was tracked using the flatbed scanner method. From these results it is suggested that both unblended cellulose and millet showed relative improved colonization rate with respectively 5.3 and 5.5 days to reach full colonization. Blended millet and blended cellulose reached full colonization in respectively 5.9 and 5.6 days, while both blended and unblended liquid extract performed worst at respectively 6.5 and 6.1 days. Blended cellulose showed a significant increased final grey value which suggests more final mycelial growth compared to the other methods.

Biological triplicates were grown on rapeseed in micro boxes using different inoculation methods (unblended) millet, (unblended) cellulose and (unblended) liquid extract. Growth curves are modelled using a modified Gompertz function.

Summarized:

• Water and hot air pasteurization were found unsuitable for substrate decontamination.

• Steam pasteurization emerges as a promising alternative to sterilization.

• Additional investigation is required to assess the effects of different decontamination methods on material properties.

• It is expected that high-temperature decontamination methods may compromise substrate integrity, potentially resulting in weaker bio-composites.

• Moreover, more in-depth research should be performed on the energy consumption of both decontamination methods.

• Blended cellulose showed a significant increased final grey value which suggests more final mycelial growth compared to the other methods.

• Since density of mycelial mass in a substrate might influence certain properties in the final bio-composite product, these are factors to keep in mind alongside growth speed when choosing the method of inoculation.

For more detailed information on this topic, please refer to the accompanying factsheet and article.

3 Mycelial growth of G. resinaceum measured as grey value using flatbed scanning over 15 days.

In this section, we explore whether the MBCs meet the rigorous standards set by the building sector for insulation materials. Following the growth analysis, the material properties of the MBC were examined to determine the optimal conditions for producing MBC-foam for insulation purposes. These MBCs are intended for insulation; therefore, moisture behavior, compressive strength, thermal conductivity, and fire retardance were investigated to elucidate the current characteristics of the MBC and to compare to building sector industry standards. The research indicates the technical feasibility and highlights areas that perform well and those that need improvement.

The research implemented two approaches for material testing: assessing the properties under three conditions: dry, wet, and postdrying, which constitutes a single drying-wetting cycle (DWC). The second strategy entailed to subjection to up to 10 DWCs. Throughout this section, the two approaches will be called ’DWC-1x’ and ’DWC-10x’, respectively.

Humidity is an external factor faced by insulation materials. Understanding the reaction of MBCs under humid environments will indicate its viability for this application. The capacity of the material to resist high moisture is essential to preserve the material’s mechanical properties. After the two set-ups, the dimensional stability was measured. Additionally, hydrophobicity of the MBCs was investigated.

With dimensional stability, the ability of a material to retain its original shape post-processing is measured: potential of expansion, shrinkage, warpage, or deformation. ISO 2796 was used.

For DWC-1x, the percentage change for both volume (blue) and weight (green) is plotted in Fig. 4. Weight differed more compared to volume. Both the volume and weight post-drying were lower than the original volume and weight, with the post-drying volume and weight being 0.41% and 2.58% lower compared to the initial state, respectively. More research into potential coatings to preserve the initial state and dimensions of the material is encouraged.

4. DWC-1x dimensional stability results

For DWC-10x, an extra variable was added: non-coated (green) and coated (blue) samples. The coating was supplied by Impershield.

Fig. 5(a-b) graphs the change in volume and density, respectively, across the DWCs for both non-coated and coated samples. Throughout the 10 DWCs in Fig. 5a, there was a nearly linear decrease in volume noticed for both non-coated and coated

samples; however, the coated samples retained a higher average volume. Between 5 and 10 DWCs for the coated sample, there was little to no change in average volume, indicating dimensional stability of the component. For the average change in density across the 10 DWCs in Fig. 5b, there was a less noticeable trend as compared to Fig. 5a. Furthermore, the non-coated samples had little variability with an average density of 0.117 - 0.123 g/cm3. For the coated samples, a slight increase in average density was observed from 0.106 - 0.116 g/cm3.

Figure

Figure

Hydrophobicity is the physical property of a molecule or component that is repelled from water. Insulation materials should resist water uptake. To measure the hydrophobicity, an ‘ink’ test was employed, which measured the incidence and contact angle. Fig. 6 displays the different samples and incidence angle with red lines indicating what is superhydrophobic, hydrophobic, hydrophilic, or superhydrophilic. The samples tested were non-coated (NC), coated with 1 to 4 layers of coating (C1 – C4), and EPS. EPS is a common insulation material for comparison. Most of the samples fell within the hydrophilic range, meaning that water absorption took place. MBCs are not highly hydrophobic, mainly in parts that are not covered by mycelium. However, it is noticed that with several layers of coating, the samples have hydrophobic properties.

Compression mechanical tests were conducted to evaluate the ability of the MBC to resist deformation under compressive forces. Only DWC-1x samples were used as the DWC-10x samples were already mechanically and structurally influenced. NEN-EN 826 was used.

The compressive stress at 100% strain measures the maximum compressive force at the yield stress or rupture point of the sample. From Fig. 7, there is a higher compressive strength after the samples had a full DWC: the wet samples have the lowest compressive strength, meaning they could not take a high force, which correlates to the increase of volume and weight from Fig. 4.

Thermal conductivity measures the ability of a material to conduct heat. For insulation materials, low heat conduction is needed. Typical values for MBCs range from 0.04 - 0.08 W/mK. EN 12667:2001 and ASTM C351-92b (1999) were used. The associated results from DWC-1x for thermal conductivity are shown in Fig. 8. The wet biocomposites had the highest values for thermal conductivity: they are poor insulators. Meanwhile, the post-dry samples had a slightly lower value as compared to the initial samples, with values of 0.0378 - 0.0388 W/m K, respectively. There is still a large difference compared to EPS and/or PUR.

The thermal conductivity of the samples from DWC-10x are shown in Fig. 9. It is noticed that the coated samples have a lower thermal conductivity compared to the non-coated samples: they are better insulators. For the non-coated samples, there is an increase in thermal conductivity as the number of DWCs increases. For this reason, it would be optimal to coat MBC insulation.

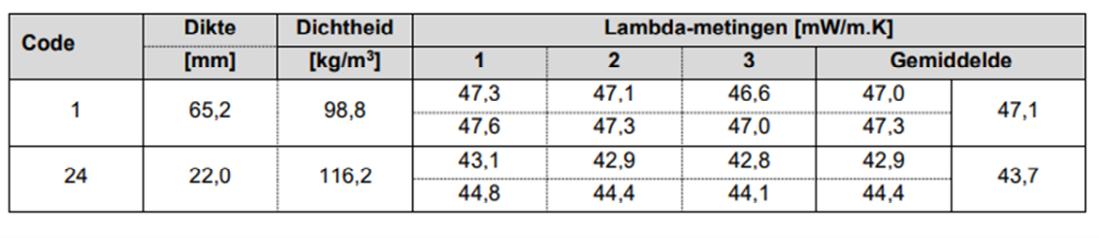

As a comparison, an external test was

Figure 8. DWC-1x results from thermal conductivity testing

performed according to the heat flow method - EN 12667. The results are presented in Table 1. A sample from a partner (Code 1) and from MNEXT (Code 24) were tested. Code 1 achieved 0.0471 W/mK, with a density of 98.8 kg/m³. In contrast, the sample from MNEXT had a thermal conductivity of 0.0437 W/mK, with interestingly a higher density of 116.2 kg/m³. These findings position MNEXT's MBCs as an effective insulating material, aligning within the established thermal conductivity

ranges characteristic of EPS, mineral wool, and cork.

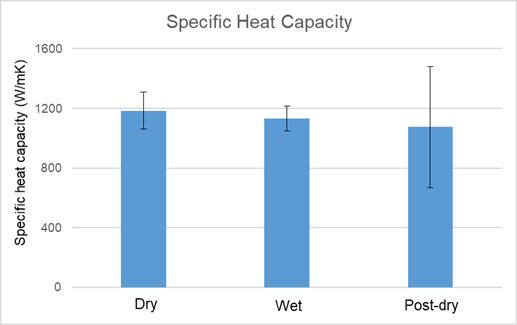

Specific heat capacity is the amount of heat absorbed by unit mass when the temperature is elevated by 1°C for a material. A high specific heat capacity means more energy is needed to change temperature, and thus is a good insulator. EN 1609 was used.

The graph in Fig. 8 displays the values obtained from DWC-1x. The specific heat capacity decreases during the DWC.

The fire resistance evaluation was conducted according to EN-13501-1, focusing on the single-flame fire source test (ignitibility test) EN 11925-2. Fig. 9a shows the experimental set-up. All 12 MBCs demonstrated resilience, withstanding a flame exposure of 30 seconds without the flame height exceeding 150mm: MBCs fall within the B-D classification for fire safety. See Fig. 9b. Further examination is needed for precise classification.

Summarized

• Moisture behavior: Good when coated

• Compressive strength: 0.20 - 0.22 MPa

• Thermal conductivity: 0.0437 - 0.0471 W/mK

• Fire safety classification: B – D

During this stage of the investigation, we focused on creating prototypes, designing products, and gauging societal acceptance of MBC insulation. Drawing from previous research on how people interact with living organisms and living bio-based objects and materials, we developed designs that incorporate MBC as primary material for their realization. Using a field research approach, we studied how users perceive and interact with these new materials in real-life situations.

The prototype showcases a distinctive modular room divider design, featuring a one-of-a-kind shape that seamlessly interlocks with others in any orientation. The sample has been coated with Impershield coating, giving it a glossier look. A 3-D printed mold, designed in SolidWorks was produced and used to make this prototype .

Figure 10. The MyMu prototype, along with its 3D-printed mold, showcased at MNEXT

bio-composite insulation

A 20cm thick prototype insulation panel has been developed to meet a desired R-value of approximately 6, aligning with regulatory requirements for new construction wall insulation. The panel measures 600mm x 300mm, half of the initially proposed dimensions.

Mycelium module design concept – Ruben Meaux

A wall-flooring unit produced out of MBC boards and insulation. This visionary concept envisions a full module including wall segments façade, outer wall, insulation and inner wall are merged to two layers of board flooring sandwiching a MBC insulation core, with the entire assembly scaled at a 1:10 ratio.

Conference booth unit concept – Biobased Technology & Business Development Minor

Designed to address the waste generated by conference booths, the prototype features five robust Robinia pseudoacacia wooden poles serving as support for the pressed MBC insulation. Unlike conventional methods involving heat-pressing to form boards, this material has been compressed into a dense MBC insulation, preserving its insulating properties.

DIY Pasteurization set-up – Armand Mirianon

Pasteurization is a sterilization technique revised in WP1. A DIY set-up was produced for this pasteurization, showcasing the design to ensure equal distribution of steam and heat. The set-up is upscalable and was used to test the sterilization at different temperatures and times. The MBC showed extensive white growth at 90 °C. For 2 hours.

80°C 4 hours

80°C 5 hours

80°C 6 hours

90°C 2 hours

90°C 3 hours

100°C 1 hour

100°C 2 hours

Results

Contamination, low growth

Slight contamination, regular growth

Slight contamination, regular growth

No contamination, excellent growth

No contamination, regular growth

No contamination, low growth

No contamination, low growth

Tiny library concept – Melike Karaslan & Niels van Rijsbergen

The Tiny library concept was carried out by students carrying out an internship at V2. They approached the research group with a design and requested expertise to produce the concept. The tiny library is a model to scale, with a design which allows books to be placed above and inside the opening.

For the successful implementation of MBC-insulation in the construction industry, insight into the user experience of the material is needed for designers to make informed design choices and promote user acceptance. To gain insights into MBC-insulation in the construction industry, a co-design workshop was developed for and conducted with an interdisciplinary group of potential stakeholders.

The workshop set-up enabled the collection of quantitative and qualitative data and enabled the comparison of 3 different ways of engagement with the material. Results of the workshop provided insight into the material experience, potential use, application and perceived bio-based and living qualities of MBC-insulation. The workshop consisted of 4 phases and a repetitive element (Figure 17). Phases 1-3 introduced a new way of engagement with

the MBC-insulation and guided participants through design thinking practices. The repetitive element documented data that was used to analyze if the phases impact the participants’ experiences. During phase 1 participants received a cup of tea in a glass with an MBC cup warmer (Figure 16). This design provided participants the chance to interact and experience the insulating qualities of MBC.

The results show that potential stakeholders have predominantly positive material experience and see multiple ways in which they would want to implement MBC-insulation. Interacting with the material fosters a favorable perception and supplementing these interactions with additional information enhances this positive stance.

The material qualities that potential stakeholders find most important and attractive are its sustainable, circular, bioeconomy, biobased, nature contentedness and lightweight properties. These insights could possibly inform marketing strategies and offer opportunities for integrating biophilic design principles.

Figure 16 Workshop set-up. Each participant received a booklet A3 forms, pen and tea served in a glass with a cup warmer made of MBC.

Potential users could be demotivated by significant amounts of loose fibers, a lack of certification, a considerably higher price or production not being able to meet demands. These insights motivate further research to explore if a thicker mycelium skin can improve the material experience concerning fibers, what price point would be considered appropriate by potential stakeholders and if production can meet potential demands.

• Stakeholders are open to accepting MBC insulation

• Having people interact with and be informed about MBCs enlarges potential users’ familiarity with the material, enhancing their awareness of their possibilities, opportunities and benefits.

• This prompts them to consider MBC-insulation for their future insulation needs, which provides opportunities for biophilic design and contributes to a more sustainable bio-based construction industry.

This section summarizes a market analysis was performed resulting in a Porter’s Five Forces analysis, together with opportunities and challenges of MBCs within the insulation industry. The economic valuation of the material, including the true pricing, was performed for: lab-, up-scale, and future situation.

To assess the competitive dynamics within the insulation market, a Porter's Five Forces analysis was conducted.

Opportunities

• Circular and Sustainable: renewable, biodegradable alternative to traditional insulation materials

• Rising Interest and Innovation: growing attention toward biobased and sustainable construction materials has spurred innovation and consumer interest

• Technical Viability: exhibit promising insulation-related properties

• Market acceptance: must overcome scepticism and unfamiliarity among consumers and industry stakeholders to gain widespread acceptance

• Scalability of production poses a significant challenge, requiring advancements in manufacturing processes and supply chain logistics

• Competition from established materials: highly competitive established materials.

An analysis on the current (lab-scale) production of 200x200x180mm MBC insulation panels was conducted. The results showed an estimated production of 70m2 per year, conducting to a price per panel of €55.17, and total production price per m2 of €1,702.72.

A small-scale, fully automated scaled-up production concept for 1m2 MBC insulation panels with 200mm thickness was analysed to determine the viability of MBCs in the short-term. The results showed an estimated production of 5840m2, conducting to a production price per m2 of €42.63. This scale-up requires an estimated investment of €250,000.00.

A cost breakdown prediction for future medium-scale production was carried out by Nýlausn, estimating the costs for a 100 ton per week production facility. The production cost of MBCs can be as low as €23.00 per m3, establishing itself in the range of the production costs of EPS and wood fibre.

The true price per insulation panel was calculated. According to the true price principle, MBCs have a true price of €5.34 per kg. This is due to it still being low scale and an energy intensive process. By utilising green energy, the true price of MBC insulation could be €3.59 per kg, where the impact of rapeseed straw, i.e., impact from the rapeseed oil industry, is fully accounted for. If the impact is alloca-

ted, the true price of MBCs could be as low as €1.54 per kg. The material is currently within the range of EPS and PIR and can improve once the energy requirements are lowered by further upscaling.

• At pilot-scale production, the material is not able to compete against conventional materials in terms of price.

• The true price of MBC insulation is not yet a factor to aid the introduction into the market.

• The material is promising and may be able to compete with conventional insulation materials at higher technical readiness levels upon upscaling.

The Mythic project could not have been conducted without the partners from (inter) national industry, research and education. Industrial partners were Fairm, FRAAi Architects, Impershield coatings, Troldtekt Benelux (previously Isolco), MOGU, Nýlausn, Recell and Verbruggen Mushrooms. Research and educational partners are Utrecht University, HZ University of Applied Sciences and Avans University of Applied Sciences (centres of expertise CARADT and MNEXT). The research was supported by branche-organisations Agrodome (for biobased building), Koninklijke CBM (interior construction and furniture industry) and NII (Dutch insulation industry). The research was coordinated by MNEXT. All partners originate from different sectors: agriculture to insulation manufacturers and architects. Link to movie with the urgence and application of MBC.

Thanks

Our profound gratitude goes out to SIA, the subsidy organisation from NOW, for financially supporting the research in the programme RAAK-MKB, which has the goal to stimulate innovations within SMEs.