To p p e r f o r m a n c e .

Fo r t h e e n v i ro n m e n t a n d

y o u r b o tt o m l i n e .

M O B I R E X M R 1 3 0 i P R O

To p p e r f o r m a n c e .

Fo r t h e e n v i ro n m e n t a n d

y o u r b o tt o m l i n e .

M O B I R E X M R 1 3 0 i P R O

When the job demands a serious excavator, rely on the quality of Liebherr. The R 945 is perfect for heavy-duty jobs like mass excavating and truck loading, trenching, demolition, land clearing, and moving large amounts of material in a quarry.

With its new improvements including more engine power, greater productivity, increased safety, and better fuel efficiency, this excavator offers superior performance. www.liebherr.ca

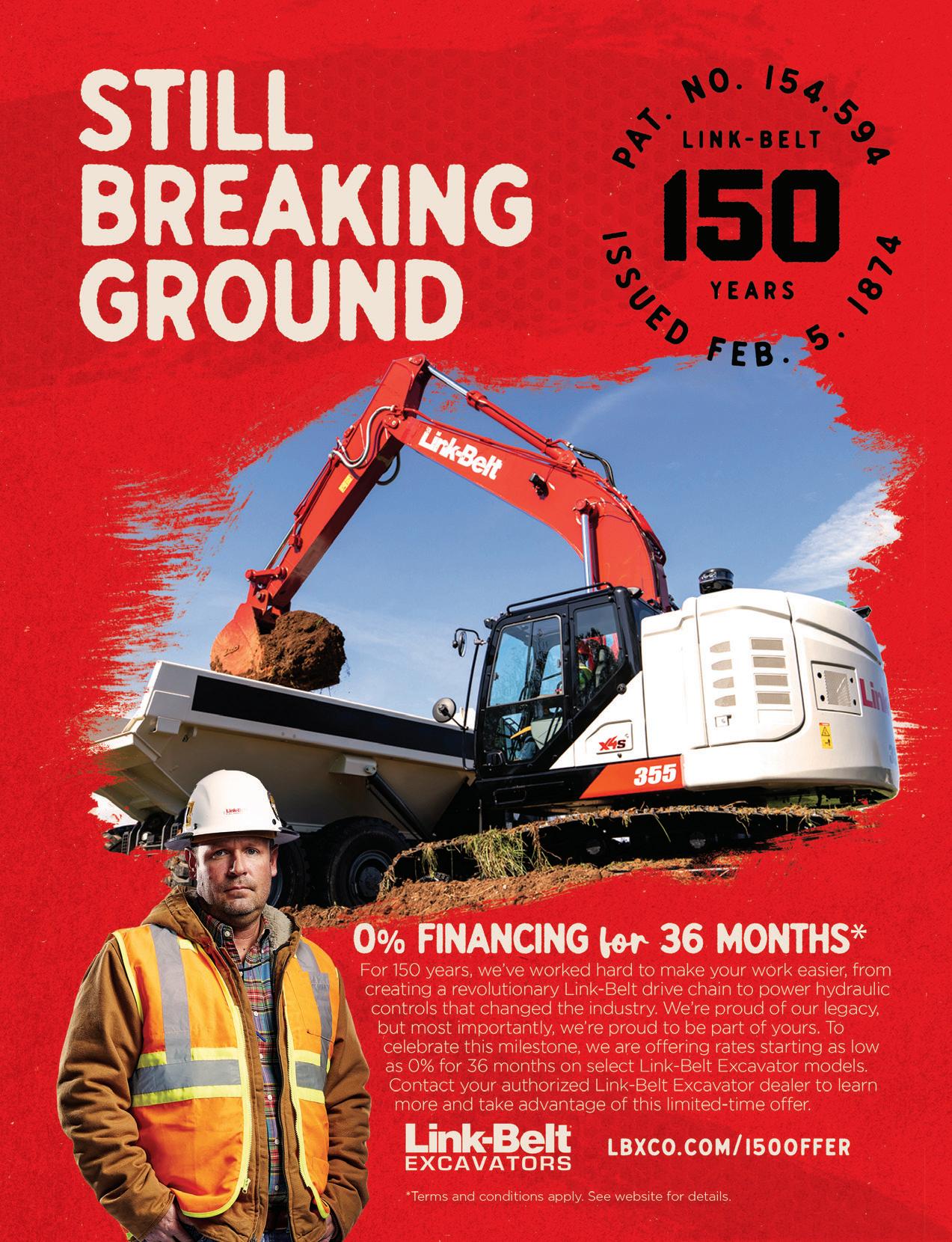

FEATURE STORY CLEARVIEW DEMOLITION GROWS WITH LINK-BELT EXCAVATORS

FOCUS ON EXCAVATORS

COMPACT TRACK LOADERS FOR SNOW REMOVAL

SMARTDETECT FOR WHEEL LOADERS

Tel: 604-291-9900

Toll-free: 1-888-286-3630

Fax: 604-291-1906

www.baumpub.com www.heavyequipmentguide.ca @HeavyEquipGuide

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com

604-291-9900 ext. 325

PRESIDENT/PUBLISHER

ksinger@baumpub.com

604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER

Melvin Date Chong mdatechong@baumpub.com

Engelbert J. Baum

Clearview Demolition grows with Link-Belt excavators

Turn to page 46 .

Do you have a job site story, innovation, or industry concern that our readers should know about? We’d like to hear from you.

Contact: Editor in Chief Kaitlyn Till at ktill@baumpub.com or 604-291-9900 ext. 330

FOR ALL CIRCULATION INQUIRIES

Toll-free: 1-866-764-0227

email: heg@mysubscription.ca

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: http://mysubscription.ca/heg/

Heavy Equipment Guide serves the Canadian engineered construction industry including: roadbuilding and maintenance; highways, bridges, tunnels; grading and excavating; earthmoving; crushing; trucking and hauling; underground utilities; trenching; concrete paving; asphalt paving; demolition; aggregates production; fleet maintenance; and asset security and management. The magazine is distributed to key industry personnel involved in these sectors.

Subscription Price: In Canada, CDN $91.00; Outside Canada, US$149. Heavy Equipment Guide is published eight times a year in January/ February, March, April, May/June, July/August, September, October, and November/December.

Heavy Equipment Guide accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

Copyright 2024, Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

We acknowledge the financial support of the Government of Canada.

Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013.

PUBLICATIONS MAIL AGREEMENT NO. 40069270

Return undeliverable Canadian addresses to:

Circulation Dept., 124-2323 Boundary Road, Vancouver, BC V5M 4V8 email: heg@mysubscription.ca Toll-free: 1-866-764-0227

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s NEW HX355ALCR compact radius excavator.

• Engineered to redefine efficiency, comfort, and safety

• RH and rear camera (standard)

• AAVM 360° camera with ultrasonic system (option)

• LED lights

• Dozer blade (option)

• 8” touchscreen color LCD monitor (standard) and 2nd monitor (optional)

• Free Hi-MATE mobile telematics for 5 years

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com NEW MODEL

As winter approaches its time to start winterizing your fleet and, if you conduct snow removal operations, preparing your machines for those tasks. But in addition to following the recommended maintenance procedures, it’s important to take snow removal safety concerns into account. Your operators working in snow removal may not be the most experienced part of your crew, and, regardless of experience, reviewing safety procedures and common winter hazards will keep your people, your equipment, property, and bystanders safe.

Winter can be wonderful, but no one should be enjoying the snow or working in cold temperatures without the right gear to keep them warm and visible. Operators should be outfitted appropriately with waterproof, hi-vis gear, and if your equipment is going to be used in winter conditions regularly, it could be worth selecting a heated seat when buying a new machine. Operators should practice safe entry and exit of the cab, always using three points of contact to avoid slips and falls, a serious safety issue in any season. They should also be aware of patches of ice in their work area. Up-to-date weather report monitoring will keep them alert to potential storms and whiteouts. When operating the equipment, common hazards include obstacles hidden by snow and other equipment or vehicles that may be travelling too fast for the conditions. Pedestrians may be in unexpected places if snow buildup has made normal pedestrian rights-of-way impassable. Operators should watch for overhead hazards where built up snow may fall.

Excellent machine features and aftermarket solutions are available to promote a safe working environment in winter conditions. Newer equipment is designed for better visibility through the windows and to the attachment, and camera systems and object detection technology will keep your operators attuned to hazards in their surroundings.

Winter can be wonderful, but no one should be enjoying the snow or working in cold temperatures without the right gear to keep them warm and visible.

Finally, maintain your equipment and attachments so that your operators are not left out in the cold in the event of a mechanical failure. Your operators should conduct daily pre-operation checks, which includes ensuring horns, cameras, and lights are all in working order before starting snow removal.

To learn how to select and maintain a compact track loader for snow removal, turn to page 42. Winter is a beautiful time of year, and a great opportunity to generate more revenue for your business and retain your operators, but stay safe.

Kaitlyn Till Editor In Chief

ktill@baumpub.com heavyequipmentguide.ca

Frontline Machinery has expanded its distribution network into Eastern Canada. The industrial material processing solutions provider is now the authorized distributor of CBI grinders and chippers in Quebec, Newfoundland and Labrador, Prince Edward Island, Nova Scotia, and New Brunswick.

“Frontline Machinery has built a solid reputation for delivering and supporting our products and customers. In 2019, they were recognized as CBI’s North American Dealer of the Year,” said George Wilcox, sales and marketing director of CBI and Ecotec. “We are confident they will continue to provide excellent service in these regions.”

CBI grinders and chippers are designed to be durable and feature up-to-date technology, ensuring reliable and efficient processing of wood, green waste, organic, and C&D materials for biomass production — a key industry in Eastern Canada. Quebec is a leading province in forest biomass energy, with over 40 biomass heating systems. The province aims to increase bioenergy production by 50 percent and reduce greenhouse gas emissions by 37.5 percent by 2030.

“We are very excited to bring CBI and Frontline Machinery to Eastern Canada. This expansion means businesses from all corners of our country will have access to our CBI fleet and, just as importantly, our experienced and professional team,” said Daryl Todd, president of Frontline Machinery. “Our roots began in Western Canada, a region with a rich and deep history in forestry. Wood recycling has always been a key part of what we do, and we are proud to do it well, contributing to the region’s bioenergy goals.”

Topcon Positioning Systems’ Ray O’Connor, president and chief executive officer, will retire in September 2025.

O’Connor will transition to the role of chairman of the Topcon Positioning Systems Board of Directors. Succeeding O’Connor as president and CEO is Ivan Di Federico, who currently serves as executive vice president and chief strategy officer.

Hyundai CE, DEVELON, and Wallenius Wilhelmsen executives joined to cut the ribbon on their new North American customization plant in Brunswick, Georgia, on September 4. DEVELON, Hyundai CE, and Wallenius Wilhelmsen, a global logistics and shipping company, have had a long-standing relationship and will continue by collaborating in the relocation and operation of this new facility.

HD Hyundai Construction Equipment will be able to manage assembly work and modifications required by North American dealers and their customers through this consolidated customization plant. The centre’s primary purpose is to streamline the machine delivery process while maintaining adequate inventory.

DEVELON’s first North American customization centre opened in July 2019, also in collaboration with Wallenius Wilhelmsen.

“Our new customization plant in Brunswick will allow us to expedite our services for our dealers and our customers,” said Chris Jeong, president and CEO of DEVELON. “It’s a much larger facility than the previous customization plant, with dedicated space for our machines, and will better meet the custom needs of our dealers and our customers with an array of final assembly options.”

Hyundai CE and DEVELON employees, in coordination with Wallenius Wilhelmsen, will manage the final assembly and configuration of construction equipment. The new facility is 50 percent larger than the current customization plant in Savannah, Georgia, offering enhanced production capabilities, a dedicated machine storage yard, and an expanded indoor warehouse.

The customization facility in Brunswick is located close to Interstate 95, allowing for convenient transportation once machines are ready for shipment, optimizing delivery lead times. DEVELON maintains its North American headquarters in Suwanee, Georgia, including a parts distribution centre for readily available machine parts.

“This state-of-the-art facility will help us reduce the lead time needed to get fully assembled machines to our customers,” said Stan Park, president and CEO, HD Hyundai Construction Equipment North America.

Volvo Construction Equipment has recognized Canadian dealer Great West Equipment as Dealer of the Year for 2023. According to Volvo, the award “celebrates the dealership that exemplifies the Volvo brand and values and demonstrates consistently high performance in all areas, including customer uptime, service offerings, and share performance over time.”

“Great West does business with purpose, and their strong customer base is evidence of that,” said Scott Young, head North America region for Volvo CE. “They are dedicated to building relationships and understanding their customers’ needs so they can deliver the best solutions possible.”

Great West Equipment is a full-service dealership with 11 locations across British Columbia and the Yukon.

A roundup of 2024 excavator introductions, including mini and compact, wheeled, and fullsize machines.

Turn to page 22.

Rotochopper has completed its newly expanded Research and Development Innovation Center which was celebrated with a ribbon cutting ceremony in late August. The company says the new facility marks a significant milestone in its ongoing commitment to innovation, customer-focused solutions, and growth. This 12,000-square-foot expansion includes a state-of-the-art production space, significantly increasing the company’s manufacturing capabilities, along with an office area to enhance collaboration and efficiency. Additionally, the new facility features a dedicated space for research and development.

All Access Equipment, Inc. has rebranded as CMC North America. This brand transformation follows the February 2024 acquisition of All Access Equipment by CMC. All Access Equipment is a longtime dealer of CMC tracked aerial lifts, and this rebranding aims to align all operations more outwardly with CMC. The company will continue to offer the full range of CMC’s tracked aerial lifts for the arbour care, building maintenance, construction, and heavy equipment rental industries.

Metso has acquired Diamond Z and Screen Machine Industries from Crane Group. Diamond Z manufactures durable mobile and portable grinders for the infrastructure recycling sector. Screen Machine Industries broadens Metso’s portfolio in the North American mobile crushing and screening markets.

“We are very happy to welcome Diamond Z and Screen Machine Industries to the Metso group of companies. Diamond Z allows us to extend our offering in the growing infrastructure recycling equipment market and Diamond Z mobile grinders portfolio provides a great addition to our Materials Processing Products offering,” says Markku Simula, president of Metso’s aggregates business area.

West Coast Machinery, a provider of equipment solutions with its two divisions ShearForce Equipment and Work Truck West, has acquired Shear Power Corp. in Strathroy, Ontario.

By combining the strengths of Shear Power with the expertise of ShearForce Equipment and Work Truck West, West Coast Machinery will be able to offer a range of equipment solutions from coast to coast.

Shear Power specializes in providing hydraulic attachments to the metal recycling, demolition, construction, forestry, and mining industries. Since establishment in 2014, the company has increased its workforce and expanded its plant capacity threefold through the leadership of Greg Morley.

Manitou Group has inaugurated a 75,000-square-foot expansion to its 220,000-square-foot plant in Yankton, South Dakota. This event coincided with the 50th anniversary of this site, which produces telehandlers and articulated loaders.

This new expansion will support production of the new range of telehandlers dedicated to the North American market. This $20 million investment will provide the Yankton site with innovative industrial resources, such as laser-cutting machines, and an automated moving assembly line.

Spectra Precision has agreed to acquire Unicontrol. Unicontrol joins Spectra Precision in Precisional’s portfolio of construction-related measurement businesses along with Seco and Loadrite.

“We are excited to join forces with Spectra Precision, whose technological expertise and global infrastructure will enable us to expand our reach and accelerate our innovations,” said Niels Bjerregaard, CEO of Unicontrol. “This partnership not only supports our growth ambitions, but also strengthens our ability to serve and expand our customer base.”

Sandvik Mining and Rock Solutions and Boliden’s Kevitsa mine have partnered to test and develop Sandvik’s battery-electric concept surface drill rig in order to gain real-world data on its operation and performance.

Boliden Kevitsa, a multi-metal open-pit mine in Sodankylä, Northern Finland, is known for its efforts to minimize environmental impact while maximizing the energy efficiency of the operation.

The modern infrastructure at Kevitsa makes it an ideal

field-testing lab for the new concept of drill rig, which Sandvik introduced in November 2023. The lessons learned during the testing phase will be used to further develop the machine.

The battery-electric concept surface drill rig combines the flexibility of battery operation with the endurance of a power cable. The battery pack, which lasts for up to one hour of drilling or up to seven hours of tramming, is primarily intended for tramming and drilling individual holes, while the bulk of production relies on more than 590 feet (180 metres) of tethered cable.

Toromont Industries Ltd. has acquired Tri-City Equipment Rentals, a prominent heavy equipment rentals company in Southwestern Ontario.

“The heavy equipment rentals market is a long-term strategic focus area for us,” said Mike McMillan, president and CEO of Toromont. “This acquisition expands our Toromont Cat heavy rents business to better serve and expand our customer base and provides a rental hub in the Southwestern Ontario region. We are pleased to welcome the Tri-City Equipment Rentals team to the Toromont family.

“Tri-City Equipment Rentals will continue to operate as it does today, with Jeff Armishaw, president, joining the Toromont team as a strategic advisor,” said Mike McMillan. “This will enable a smooth transition and support business continuity going forward for our customers and new team members.”

Get the best of both worlds with the TCi 920 dozer.

Power and durability for tough applications. Finesse and response for fine grading.

Hyundai Construction Equipment North America Crawler dozer

Hyundai Construction Equipment North America’s first crawler dozer is the 115 hp (86 kW) Hyundai HD100. The new dozer is in the 10-ton size class and has a standard blade capacity of 2.9 cubic yards (2.2 cubic metres) and a digging depth of 1 foot 6 inches (457 millimetres). The standard operating weight is 23,589 pounds (10,700 kilograms), and the track length on the ground is 108 inches (2,737 centimetres). A hydrostatic transmission provides smooth control of speed and torque. The HD100 has a maximum travel speed of 5.6 mph (9 km/ hr), seven track rollers, a shoe width of 1 foot 8 inches (508 millimetres), and ground contact pressure of 5.6 psi (38.6 kPa) with a standard blade.

Blue Diamond Attachments has launched a new line of rubber tracks. Available for compact track loaders, mini-excavators, mini-loaders, and multi-terrain loaders. The rubber tracks are also available in the four most common track patterns: block, c-lug, multi-bar, and zig-zag. Ideal for use in the construction, agriculture, landscaping, and rental industries, Blue Diamond’s rubber tracks are custom-manufactured with a blend of rubber compounds. The abrasion-and-wear-resistant materials provide operators with a comfortable and safe ride, reducing fatigue and vibration-related equipment issues. A continuous steel cord structure with solid steel forged links and a reinforced roller path minimizes the risk of track breakage by distributing the tension forces along the entire track instead of just small areas. This reduces downtime and maintenance costs. Application-specific lug patterns offer enhanced traction, as well as chunk and tear resistance.

Terramac is complementing its carrier line of rubber tracked crawlers with a new series of wheeled dumpers. The new machines offer customers a versatile, higher-speed alternative to the rubber tracked series. The introduction of the wheeled dumper series offers customers increased choice when ground conditions are more forgiving, enabling faster cycle times and increased productivity. The wheeled dumper series is available in a variety of models and sizes, and the rear dump, swivel dumper, and multi-view swivel dumper each offer unique advantages designed to excel in diverse construction applications.

Caterpillar has updated its 6020B hydraulic mining shovel with a new Cat C32B engine and hydraulics. Now known as the Cat 6020, this mining excavator’s hydraulic optimization assigns individual pumps or groups of pumps to deliver the exact flow pressure that each hydraulic function requires. This reduces waste and heat, prolongs component lives, and improves fuel consumption. Higher-flow oil and baffles in the oil cooler keep the engine core cooled and lubricated, while the engine’s new cylinder head with optimized water jacket maximizes heat transfer. Caterpillar also offers a range of on-board and optional technology offerings to boost the productivity, efficiency, and health of the hydraulic mining shovel.

The ASV VT-75 Posi-Track is a new mid-frame compact track loader designed for construction and landscaping applications. This versatile vertical-lift, 74.3-hp machine is powered by a Tier 4 Final Yanmar engine. The 8,310-pound compact track loader has a 10-foot 5-inch lift height and a 2,300-pound rated operating capacity with a 6,571-pound tipping load. Two independent torsion axles per undercarriage provide a smooth ride over all types of terrain and contribute to a high speed of 9.1 mph. The flexible track and suspension create traction and pushing power even in steep, wet, muddy, and slippery conditions. A ground pressure of 4.5 psi minimizes turf damage and contributes to more flotation, and the machine’s 12-inch ground clearance gives the CTL the ability to work in a variety of conditions.

The most iconic machine for the construction industry is the excavator. Able to dig, lift, demolish, and more, excavators are the linchpin machines for most construction job sites. New excavators introduced in 2024 include a wide variety of mini and compact machines, a handful of wheeled models, and mid-size and large machines — including long reach models. These are the newest excavators available for the North American market.

Mini and compact excavators have evolved into multi-use tool carriers that can dig, load, do demolition, and clear land. It has been a notable year for mini and compact excavator introductions, and with the wide variety of new machines available, there is a solution for every constricted job site — whether you need diverse attachment capability, or just robust digging power.

DEVELON’s smallest excavator is the new 16-hp DX17Z-7. It weighs approximately 4,200 pounds (2 tons) and has a retractable rubber track undercarriage with a collapsible dozer blade. Unique within the DEVELON lineup, this enables the mini excavator to squeeze into small spaces. When fully expanded, the undercarriage optimizes stability, particularly when working over the side.

Offering a 48-inch track width, the zero-tail-swing DX17Z-7 can travel between homes or work against structures. It has a hydraulic quick-coupler-ready design with piping installed to the end of the arm and is thumb-ready. Blade float allows the blade to follow the contours of the ground without operator input.

A mini excavator designed for outsize performance, the CASE Construction Equipment CX50D slots into the 5-metric-ton size class. Multi-functional hydraulics are standard, as is a second auxiliary circuit for handling a range of specialized attachments. A third auxiliary circuit is optional, enabling advanced attachments like tiltrotators and grapples. Another

dedicated auxiliary circuit is available for power mulchers. An optional Object Handling Kit includes check valves on the boom and arm to improve safety and efficiency in material handling operations.

Hitachi Construction Machinery Americas has focused on upgrading its compact excavators to maximize their utilization as tool carriers. ZAXIS-5N compact excavators range from 1.10 to 6.61 U.S. tons (1.7 to 6 metric tons) and include the ZX17U-5N, ZX26U-5N, ZX30U-5N, ZX35U-5N, ZX50U-5N, and ZX60USB-5N. Models are either short-tail-swing radius (U) or ultra-short-tail-swing radius with swing boom (USB).

To maximize attachment utilization, Hitachi upgraded the ZX50U-5N and ZX60USB-5N with a five-stage auxiliary flow rate changer. The company added a blade float option for the ZX30U-5N to ZX60USB-5N and now offers complete hydraulic quick coupler piping on the ZX30U-5N to ZX60USB-5N models. Second auxiliary hydraulic piping is available on the ZX30U-5N to ZX60USB-5N.

Kubota Canada’s new 8-ton KX080-5 power utility excavator offers a substantial digging depth of over 15 feet, a dumping height of 17 feet, and a digging radius of 24 feet.

The two-pump load-sensing system improves the overall smoothness of operations when using front attachments, letting operators perform simultaneous operations. Automatic travel shift from high to low, depending on traction effort and terrain, gives the operator smoother simultaneous operations when dozing and turning.

The engine RPM automatically idles when the control levers are in neutral for more than four seconds, and the engine turns off automatically when it has been idling for too long. Operators can also set the idling time to suit their application.

Volvo Construction Equipment’s two new compact excavators, the 3.5-ton EC37 with conventional swing and the 4-ton ECR40 with short swing radius, have been designed to replace the EC35D, ECR35D, and ECR40D. A new elongated undercarriage provides better weight balance and improves

stability of both machines, and Volvo has redesigned the cab and boosted fuel efficiency by 10 percent.

Slim pillars and wide, flat glass give operators impressive visibility. The armrest and controls float with the seat, and the door opening and travel pedals are larger than in previous models.

These excavators now have an ECO mode and auto engine shutdown in addition to auto engine idle. With auto engine shutdown, hours not worked are not recorded, keeping the machine operating efficiently for longer while reducing maintenance costs. This also contributes to a 10 percent boost in fuel efficiency. Customizable hydraulics flow setting and work modes for a wide range of attachments and applications make it easier to match the excavator to the job. Load-sensing hydraulics, the control setup, and smooth movements of the machine all combine to improve fuel efficiency, according to Volvo.

Weighing in at 16,072 pounds (8 tons), the E70D compact excavator slots into a new size class for New Holland Construction. It delivers a dig depth of up to 168.1 inches and a dump height of 180 inches; a monoboom design ensures ideal manoeuvrability, and buyers can choose between rubber and steel tracks. Heavy counterweights of 1,102 pounds can be added to the machine to enhance lift performance and stability. Operators can also adjust joystick sensitivity and hydraulic response to match their personal preferences.

Hyundai Construction Equipment North America has introduced four new models: the HX17AZ, HX27AZ, HX55ACR, and HX60A. The HX17AZ and HX27AZ models are true zero-tail-swing machines and the HX55ACR is a compact-radius model. They range from 4,370 to 13,580 pounds (2 to 7 tons).

The HX55ACR is equipped with a standard load-sensing hydraulic system that reduces wear and tear on hydraulic

Remotely monitor your machine Know exactly where your machine is located and how often it is being used. This can also be helpful if you’re concerned about unauthorized use of the excavator when you and your operators aren’t on the job site.

Make informed decisions Review your telematics system for data on machine hours and fuel usage to determine operating costs and labour costs for more accurate bids and billing.

Minimize machine downtime Collaborate with your dealer to get ahead of preventive maintenance. When an issue does arise, your dealer will be more informed about what’s wrong with the machine and can send the right parts with a technician to fix the problem.

Train operators If your company has lessexperienced operators, your telematics data can serve as a training tool. Identify habits like prolonged idle time and coach operators on how to help reduce operating costs.

Reduce fuel consumption There may be times when your excavator is burning more fuel than it needs to get the job done. Monitor power mode operation and adjust the power mode to do the same work while using less fuel.

components. The HX17AZ and HX27AZ feature conventional open centre hydraulic systems. Standard adjustable hydraulic flow control through the cluster on all four models lets the operator set optimum flow range for multiple attachments and switch between them using a two-way diverter valve that directs hydraulic flow to either of two attachments simultaneously.

The HX55ACR and HX60A have standard blade float and auto engine idle. Auto-shift travel speed is also standard.

Wheeled excavators are growing in popularity in North America, and this year several smaller wheeled excavators were introduced.

Takeuchi-US has entered the wheeled excavator market in North America. The TB395W weighs 23,424 pounds (12 tons) when equipped with outriggers and a blade. A closedloop, load-sensing hydraulic system delivers smooth control of the work equipment and powers a range of hydraulic attachments.

Steering modes are two-wheel and four-wheel with crab. A two-piece boom with a long arm allows the operator to pull the bucket back to the dozer blade. An auto cruise feature enables operators to set and adjust the machine’s travel speeds with a toggle switch.

The excavator’s 13-foot 5.2-inch digging depth and 27-foot cutting height make it particularly useful on construction sites. Maximum bucket breakout force is 13,241 pounds, maximum arm digging force is 8,925 pounds, and traction force in 12,994 pounds. Three auxiliary circuits cater to different hydraulic requirements. The primary circuit delivers 32 gpm, ensuring ample power for use with hydraulic attachments. The secondary circuit provides 14.5 gpm. The third auxiliary circuit is specifically designed for use with a hydraulic quick coupler. The TB395W is ideal for pairing with a tiltrotator.

DEVELON says its new 12-ton DX100W-7 mini wheeled excavator is one of the fastest mini excavators on the market (up to 24 mph). Multiple steering, power, and work modes help operators customize the excavator’s performance.

The large articulated boom and boom swing further help this excavator perform in tight spaces and access hard-to-reach areas. The reinforced articulated boom features an additional pivot point which enhances the working range, lifting capacity, and digging force. It has a 1.35-ton counterweight, and a large hydraulic capacity to hoist and manoeuvre heavy loads while minimizing fuel consumption. The standard one-way/two-way switch lever provides hydraulic flow that is activated through the joystick, not the pedal.

A standard hydrostatic system uses hydraulic fluid to ensure seamless, responsive operation for better control. By transferring power directly from the engine to the excavator wheels, the system provides high torque even at low speeds, enhancing manoeuvrability and efficiency.

Operators can work efficiently and safely with the parallel dozer blade and independent rear outriggers. Double tires come standard to minimize ground disturbance.

The 10-ton 12MTX wheeled excavator loader from Mecalac combines the capabilities of a compact excavator, wheel loader, and telehandler into a single machine. It is also a powerful tool carrier that can handle attachments, such as asphalt planers and flail mowers, that require high-flow hydraulics.

A three-piece, variable angle, side-mounted boom provides the compact 12MTX with an excellent range of motion. The 12MTX’s top speed is 20-mph. It can lift up to four tons, and an articulated undercarriage, four-wheel drive, and five different tire options give operators precision and control.

Strength, visibility, and hydraulic precision have been the focus of excavator OEMs this year. With the latest camera technology, job site awareness has never been better for operators of big machines, and optimizing machine performance contributes to significant fuel savings.

This next generation is Volvo CE’s biggest update to its excavator line in 20 years; upgrades include up to 15 percent

greater fuel efficiency, increased productivity, new safety technology, and more operator-friendly features. The initial launch includes multiple medium and large excavator models: the ECR145 short swing, EC210, EC230, EC370, EC400, and EC500. They range from 16 to 58 tons.

Volvo says that a newly optimized electro-hydraulic system and other features, like smart cooling and engine speed regulation, add up to a 15 percent improvement in fuel efficiency compared with the previous generation while outperforming the prior models.

Work modes expand to 10 settings, including two specific to power and four specific to automatic ECO modes. A new creep travel mode coupled with boom and arm shock reduction settings reduces spillage.

Volvo Smart View with Obstacle Detection gives operators 360-degree visibility of the machine’s surroundings. It combines camera technology and a new radar detection system to distinguish between objects and humans.

The HX355A LCR is Hyundai CE’s new 35.5-ton compact-radius excavator. The company says it is typically equipped with a one-and-three-quarter-cubic-yard (1.34-cubic-metre) bucket and has 18 inches (475 mm) of ground clearance. Hyundai also offers an 11-foot 10-inch (3.6-metre) dozer blade as an option.

Four selectable power modes and one-touch power boost give operators control over machine power and efficiency. An SPC system (smart power control) is integrated. SPC uses sensors

STEELWRIST’S NEW ROTOR COUPLER DELIVERS TWO THIRDS OF THE FUNCTIONALITY OF A TILTROTATOR BUT AT A FRACTION OF THE COST

Tiltrotators are incredible technology, but they require a hefty up-front investment. This has been a barrier to adoption in North America, but interest has been growing steadily in recent years. Steelwrist has introduced two new rotor couplers which provide two thirds of the functionality of a tiltrotator for half of the outlay, giving contractors some of the advantages of tiltrotators without the full financial commitment.

Ideal for road construction, shaping embankments, or digging trenches, rotor couplers add new flexibility to excavators. This precision attachment coupling solution rotates 360 degrees so the excavator doesn’t have to be repositioned to access more parts of the job site. Rotor couplers are both powerful and safe for operators. Cast steel construction optimizes the weight, making these rotor couplers as compact and light as possible. Operators can safely swap the attachment mounted on the rotor coupler without leaving the cab, and each rotor coupler is equipped with either a front pin hook or Steelwrist’s LockSense safety solution. Installation is simpler than for a tiltrotator. The rotor

coupler does not require a separate control system, and the carrier machine just needs one dual-connection auxiliary line. An additional auxiliary line can be used to operate an optional gripper or a hydraulic work tool.

Two Steelwrist rotor couplers are currently available: the XR7 for excavators from 4 to 7 metric tons and the XR20 for excavators from 12 to 20 metric tons. Steelwrist plans to introduce two more rotor coupler models.

Sized right for tight spaces. Steel-built for heavy-duty work. With groundbreaking power in a nimble package, Takeuchi Compact Excavators are proof positive that it’s not the size of the machine in the work, it’s the size of the work in the machine.

EXTENSIVE EXCAVATOR LINEUP: INCLUDES CONVENTIONAL TAIL SWING, SHORT TAIL SWING, SIDE-TO-SIDE (STS) OFFSET BOOM, HYBRID AND FULLY ELECTRIC MODELS.

and software to monitor the excavator’s workload in real time. Based on this data, it automatically adjusts engine power and hydraulic flow to match the required digging force.

The KOBELCO SK520LC-11 is a 55-ton-class excavator with an operating weight of approximately 121,000 pounds. It delivers dynamic bucket digging force of 72,200 pounds and achieves a lifting capacity of 46,540 pounds, even while minimizing fuel consumption. Energy-saving modes and automatic idle shutdown contribute to lower fuel consumption and reduced emissions.

The auxiliary flow rates are all adjustable through the in-cab

monitor, providing quick tool changes. Mode settings for other attachments, like a tiltrotator, can be added or changed easily.

Independent Travel enables the SK520 to move, lift, and swing simultaneously without experiencing loss of power. An optional counterweight removal system is available for easier transportation between job sites.

Hitachi introduced three Super Long Front (SLF) excavators this year starting with the 21-ton ZX210LC-7 SLF, which provides 50 feet 4 inches (15.35 metres) of reach at ground level and a 39-foot 2-inch (11.94-metre) dig depth with fewer trade-offs due to its dedicated design. A proprietary hydraulic circuit has been engineered for smooth and safe operation. The excavator also has an upgraded swing motor. The heavier counterweight, proprietary hydraulic circuit, and enhanced swing motor provide confidence while operating the super long arm. An updated hydraulic control valve provides an immediate response, even when operating at or near maximum extension. Two work modes (Economy and Power) allow operators to tailor operations for job site conditions.

Additional Hitachi SLF excavator introductions include the 25-ton ZX250LC-7 SLF and the 35-ton ZX350LC-7 SLF. The ZX250LC-7 SLF has ground level reach of 59 feet 8 inches (18.19 metres) and digging depth of 47 feet 4 inches (14.43 metres), while the ZX350LC-7 SLF has ground level reach of 71 feet 11 inches (21.92 metres) and digging depth of 57 feet (17.38 metres).

An Aerial Angle camera gives users a 270-degree bird’s-eye view. ConSite Oil, unique to Hitachi, consists of two sensors that detect if oil quality has deteriorated and transmit data to Global e-Service. This helps drive uptime by catching oil degradation before damage to critical systems can occur.

Hitachi has also added six new models to its ZAXIS-7 medium and large excavator line. The new machines range in operating weight from 58,433 to 192,938 pounds (29 to 96 tons) and include the ZX250LC-7H, ZX300LC-7H, ZX350LC-7H, ZX490LC-7H, ZX690LC-7H, and ZX890LC-7H. A two-way pattern change valve is standard on many models and available on others. Auxiliary piping and relief valves are standard on models from Hitachi’s ZX130-7 to ZX490-7. This is a dealer-installed option on the ZX690LC-7 and ZX890LC-7.

Protect

Protect

Keep

Avoid

Avoid

Hitachi has strengthened these machines, including the X-beam undercarriage. An anti-mud-compaction lower roller design helps prevent mud from damaging oil seals, and upper and lower rollers also have improved idler sealing. A track undercover protects the joint from potential damage. Strengthened boom ends and feet add to long-term reliability. For durability, the bushings are installed in the brackets at the boom ends and boom feet.

Critical components are protected, including engine air filters, which have an inner element that protects the engine from dust while cleaning the outer element. The air conditioner has a sealed internal filter.

Like the SLF machines, these excavators are outfitted with Hitachi’s Aerial Angle camera system and feature ConSite Oil to monitor engine and hydraulic oil conditions. HEG

BY JOSÉ ROSALES

If you’ve owned or operated an excavator for any length of time, you know that proper maintenance will not only help keep you up and running but also preserve the machine’s resale or trade-in value in the long run. Without the luxury of unlimited timelines or budgets, we have to take every step pos sible to protect that bottom line — and an excavator that isn’t working can be the bottom line’s worst nightmare.

The good news is that it doesn’t have to take a lot of time and energy to maintain your excavator if you give it a quick in spection at the beginning and end of each day. The even better news is that this will actually save you a lot of time and energy because you’ll catch potential problems sooner and keep your operators and mechanics safer.

Here’s how you or your operators can spend five minutes each morning to keep your excavator happy:

1. Start in the same place every time. The front of the cab is a logical starting point because you can just hop in and head out if everything looks good when you get back to that point.

2. Develop a routine and/or checklist that becomes second nature. Be sure to look in less obvious (but still critical) areas. Look up and down, left and right. Be as thorough as possible.

3. Talk through any findings with a supervisor or mechanic and provide a written version so nothing is forgotten.

The goal of a daily inspection is to visually examine every possible compartment and component for leaks, damage, etc. Make sure to look closely at the boom and arm for cracks, especially if you’re working in harsh conditions or cold temperatures.

Other parts you cannot skip:

• Boom and cylinder mounting, arm and cylinder mounting, and bucket and cylinder mounting

• Main pump compartment and battery compartment

• Swing drive and main control valve

• Track drive, track chain, and shoes

• Lower frame and superstructure

• Side doors and cowl frames

• Electrical box

• Engine air filter and cabin air filter

• Radiators and coolers

• Hydraulic lines and all hydraulic connections, pipes, and hoses

• Mirrors, cameras, seat belts, and safety levers

• Transmission, hydraulic, and coolant fluid levels

A

Bonus tip: When an excavator is new and the engine has only run for a few hours, it’s smart to check the engine oil level. This can be done from the cab by looking at the display. If you prefer to use a dipstick, that’s fine too.

There are a few things you should do at the end of a shift as well. Refill your fuel to reduce the risk of condensation developing in the tank overnight. And while you’re doing that, you might as well top off the DEF. Always disconnect the main battery switch and park the excavator with the digging equipment fully extended to protect the piston rods.

Clean the undercarriage to reduce strain on the components, especially when temperatures are below freezing. If you don’t, any mud or debris in the chain could freeze and you may not be able to move the machine the next day. Cleanliness also makes it easier to spot potential issues earlier.

Speaking of undercarriages, they’re one of the most expensive components to repair or replace, so be sure you pay them enough attention. The undercarriage supports the full weight of the machine and is continuously subjected to rocks and other debris. Dealer technicians are great resources for undercarriage inspections, but I also recommend conducting your own detailed visual inspection once a week or every 40 operating hours.

Remember: Visual inspections should not replace regularly scheduled undercarriage management. Proper management entails measuring and tracking wear, replacing worn components, and swapping component positions as appropriate. Be sure to inspect the track shoes, links, pins, bushings, top and bottom rollers, idlers, and sprockets. Carefully check the links for cracks, spalling, side wear, and wear on the pin boss. You can also count the links to see if any were removed in an effort to tighten the undercarriage. If someone has made it too tight, that could spell trouble down the road. And finally, compare the two sides of the undercarriage assembly to see if one side shows more wear than the other.

Want a few more suggestions for easing maintenance-related headaches? First, get your excavator from a brand that offers service contracts — this will keep you on schedule and provide a go-to team you can trust when questions or problems pop up. Some OEMs will offer different packages or levels of these contracts to better fit your needs and budget.

A great telematics program can support your maintenance regimen because it will send you simplified alerts on only the most critical issues with clear information on how to resolve them and the consequences of ignoring them. A strong warran-

It

doesn’t have to take a lot of time and energy to maintain your excavator if you give it a quick inspection at the beginning and end of each day.

ty is a sign that the OEM is confident in the quality of its excavator and will be helpful should an issue arise. And, of course, if you are ever unsure about what might need to be done to your excavator, connect with your local dealer.

We hear “time is money” so often in this industry that it could drive a person mad — but it’s the truth. A few minutes at the beginning and end of your shift can save you many more minutes (and hours and days and weeks) in the long run, so don’t skip inspections.

JOSÉ ROSALES is head of product management — maintenance, Volvo Construction Equipment.

THE SAKAI R2H-4 IS A PURPOSE-BUILT HIGH-PRESSURE MACHINE

BY LEE TOOP

Asphalt pavement is always expected to be smooth, but in some cases — highways or specialty jobs like race tracks, for example — where International Roughness Index (IRI) tolerances are very tight, there’s a need for big, heavy rollers that can get the finish just right.

Large static rollers are good finishing machines that provide a smooth surface. SAKAI’s R2H-4 three-wheel roller fills that role with a design that features two large-diameter drums on the front and a third drum behind the operator station.

The three-drum design, says Brad Belvin, SAKAI manager of sales and marketing, is one way the machine is set apart from other rollers.

“When you put the two drums up front, and then have the rear one, you have better visibility, and there is zero curb clear-

ance since it’s just the drum by itself,” Belvin describes. “You can get right up next to a structure and get compaction right to the absolute edge of it without damaging the side of the machine.”

The R2H is a static machine — it has no vibration or oscillation capabilities and does all its compaction work with one tool: 30,955 pounds of weight (with all drums filled with water). Two 22-inch-wide drums are side-by-side on the front of the roller, with a 43-inch-wide drum at the rear, for an 83-inch total rolling width. All of the drums are 64 inches in diameter. Larger diameter drums deliver higher pounds per linear inch, Belvin says.

“A lot of times when a contractor needs a finish roller they’ll take one of their old ones that still goes forward and back but the vibration isn’t working. The thing to know about those machines is you’re probably looking at anywhere from 160 to 180 pounds per linear inch of static weight,” he says. “The R2H-4 is right around 355 pounds per linear inch. You get much better downward pressure, but you can also build density while getting the smoothness.”

In cases where thick lifts are being compacted, smaller drums can cause a bow wave in front of the machine. Larger diameter drums reduce the likelihood of a bow wave for a cleaner finish.

Static rollers, especially larger ones, also cut down on segregation in asphalt mats, which can result in non-uniformity of the surface, Belvin describes. Smoothness is the signature of large static machines like the R2H-4.

“If you have a tight IRI requirement, which you see on race courses, test tracks, and some highway jobs, this is your smoothness machine,” he says.

There’s also the case of jobs where vibration is simply not allowed at all. Many urban paving jobs are picky about vibration, which can negatively affect the surrounding area with noise and movement. Belvin points to bridge work as another spot where vibratory compaction, and in many cases oscillation, is out — leaving static machines as the only option.

“I was up in Canada not long ago talking to some contractors who do a lot of bridge deck work, and if I was doing that this is one of the machines I’d have in my fleet,” he says.

Beyond its size and compaction ability, the R2H-4 has a simple design that makes it easy to run and maintain, Belvin says. A standard sprinkler system includes an anti-clog package with direct access to the nozzles from the operator’s station. Other maintenance work can be done easily from ground level.

Options like a temperature sensor can be included to ensure that the mat is at the right temperature before compaction starts. Like other SAKAI machines, the R2H-4 is designed for visibil-

If you have a tight IRI requirement, which you see on race courses, test tracks, and some highway jobs, this is your smoothness machine.

Brad Belvin

Sales and Marketing

Manager, SAKAI

ity using the one-by-one system — if a 1 metre by 1 metre cube is placed against the machine on the front, side, or rear, the operator should be able to see it from their station. The R2H-4 can also be equipped with SAKAI’s Guardman automated alert and braking system to enhance job site safety.

There are many different types of rollers, and many approaches to compaction that fit all kinds of contracts. SAKAI’s threewheel roller might not be needed every time, but on jobs that need a particularly smooth and well-compacted finish, it fits in just fine.

“We’ve had contractors say, ‘we had this in our fleet, we didn’t really know what to use it for, but we took it out on this job and it solved our problems,’” Belvin says. “If you’re doing a parking lot today, then a driveway, and then paving a road the next day and a highway after that, you may not need the R2H-4 for the parking lot or the driveway. If there’s an IRI spec on the road or especially the highway, you’ll want that machine out there.” HEG

When the engineers at Caterpillar were tasked with improving its line of compact track loaders and skid-steer loaders, they were invited to rethink the machines from scratch to deliver the performance that custom ers want.

“[Customers] said, ‘We want more’ and these machines provide that,” said Trevor Chase, senior product consultant and new product introduction lead for Caterpillar.

Increased lift height, enhanced power and torque, expanded capabilities, and more comfort were the practical challenges; the engineering team redesigned the engine compartment, the hydraulic systems, and the cabs from the ground up. The CTLs feature a robust, dozer-style E-bar undercarriage, and the line includes the largest CTLs ever produced by the company.

“We started with the targets and then engineered to get them,” Chase said at the launch of the new machines at the Cat erpillar Demonstration & Learning Centre in Edwards, Illinois.

Eight new next-generation Cat skid-steer and compact track loaders join the 255 and 265 CTLs announced in late 2023. Four new Cat SSLs — the Cat 250, 260, 270, and 270 XE — are the first SSLs to join the next-generation lineup, along with the new Cat 275, 275 XE, 285, and 285 XE CTLs. The 285 and 285 XE CTLs compete in a new class size with greater lift height and lift and tilt breakout forces.

“We are excited to launch the next generation design for our skid-steer loader line and expand the performance capabilities to more compact track loader models,” said Chase. “Their increased power, lift height, breakout forces, rated operating capacity (ROC), and multiple high-flow auxiliary hydraulic system options give customers a flexible, high-performance machine to get the job done.”

All models have a redesigned engine compartment that places the engine and cooling package lower into the frame. The four new CTL models and the 270 and 270 XE SSLs are powered by the Cat C3.6TA engine, while the 250 and 260 SSLs are powered by the Cat C2.8T engine. These new engines main tain horsepower across a wider RPM range, compared to the engines powering the previous D3 series, and boast significant torque increases: 13 percent for the 250 and 260, 35 percent for the 270, and 50 percent for the 275 and 285.

ALL NEXT-GENERATION CAT SSL AND CTL MODELS FEATURE A REDESIGNED ENGINE COMPARTMENT THAT PLACES THE ENGINE AND COOLING PACKAGE LOWER INTO THE FRAME FOR IMPROVED STABILITY.

these machines to operate all Cat Smart Attachments with the standard hydraulics provided. Standard hydraulic system pressure increases 5 percent to 3,500 psi (24,130 kPa) in the next generation models. Cat 250, 260, 270, and 275 machines equipped with standard hydraulic flow are shipped from the factory outfitted as “High Flow ready.” High Flow functionality is activated via a new software enabled attachment (SEA), permitting on-machine or remote activation of increased hydraulic flow to 30 gal/min (113 l/min) for the 250, 260, and 270 models and 34 gal/min (129 l/min) for the 275 at standard hydraulic system pressure.

The engineering team redesigned the engine compartment, the hydraulic systems, and the cabs from the ground up.

flow is increased to 30 gal/min (113 l/min) on the 250, while flow increases to 34 gal/min (129 l/min) for the 260, 270, 275, and 285 models. According to Cat, equipping the 250 with the High Flow XPS option gives customers auxiliary hydraulic performance not available before in a mid-size chassis SSL. Equipped for maximum hydraulic capability, the High Flow option for 270 XE, 275 XE, and 285 XE loaders increases auxiliary hydraulic system pressure to 4,496 psi (31,000 kPa) and hydraulic flow to 40 gal/min (150 l/min).

The four CTL models feature a new dozer-style E-bar (equalizer bar) undercarriage that provides increased stability for grading and handling heavier loads. The hybrid undercarriage solution delivers the benefits of a rigid-style undercarriage design when lifting heavy loads or using heavy attachments like mulchers and dozer and grader blades, while simultaneously providing the benefits of an oscillating undercarriage when encountering uneven terrain or obstacles.

All next-generation models have a larger cab design with significantly increased volume and foot space. With a 2.75-inch (70-mm) increase in interior width, the new cab expands footwell to ceiling height by 1.8 inches (46 mm) and allows for an additional 1.5 inches (40 mm) of hip room and 1.1 inches (28 mm) more width between the joysticks to improve operator comfort.

These new loaders are equipped with either a 5-inch (127mm) standard LCD monitor or an 8-inch (203-mm) advanced touchscreen monitor, depending on the selected technology package. The standard monitor features Bluetooth connectivity and supports functionality for rear-view camera feed, creep, job clock, maintenance reminders, and 32 languages. The advanced touchscreen monitor provides a higher level of control, including advanced radio control, and supports side cameras and 32 language choices. Control of the touchscreen monitor is integrated into the new advanced joysticks.

Low entry points make entering and exiting these loaders much easier. The operator can now open the cab door without the lift arms being fully lowered to the frame stops. A simplified two-step door removal process allows operators to quickly remove the door without tools. The machines’ lower engine mounting, larger rear window, and bigger top window provide

Both standard and advanced monitors provide the ability to run Cat Smart Attachments, such as the dozer and grader blades and backhoe. Attachment operation is integrated into the joysticks, and the machine automatically recognizes the type of attachment and the required joystick pattern for controlling it.

The optional Cat Product Link Elite tracks machine hours,

With a vertical lift design, these new machines give operators significant increases in lift height, breakout forces, and ROC:

The 250 features a lift height of 124 inches (3,150 mm), 3 inches (76.2 mm) more than the 242D3; a 36 percent increase in tilt; 26 percent increase in lift breakout forces; and 21 percent increase in ROC.

Offering a maximum lift height of 132 inches (3,353 mm), the 260 has 7 inches (193 mm) more lift height than the 262D3; 27 percent increase in tilt; 24 percent increase in lift breakout forces; and 17 percent increase in ROC.

With 6.4 inches (162 mm) more lift height than the 272D3, the 270 and 270 XE deliver a maximum lift height of 133.5 inches (3,391 mm) plus 11 percent and 5 percent increases in tilt and lift breakout forces, respectively.

The 275 and 275 XE CTLs have a lift height of 134.4 inches (3,415 mm), 8 inches (203.2 mm) higher than the 299D3, plus a 37 percent increase in tilt breakout force and 19 percent increase in ROC.

The 285 and 285 XE deliver a lift height of 146 inches (3,708 mm) and tilt breakout

Volvo Construction Equipment has updated its L30 and L35 compact wheel loaders to increase functionality and improve the operator experience.

“These improvements set a new standard for compact loaders in this size class,” says Darren Ashton, product manager — compact equipment, Volvo CE. “For customers who demand efficient handling in a small package, this is it.”

With the latest L30 and L35 compact wheel loaders, Volvo says that customers looking for 1.3 to 1.6 cubic yards (1.0 to 1.2 cubic metres) bucket capacity or 2.4- to 2.6-ton fork payload will experience faster work cycles in addition to improved manoeuvrability, tractive force, and performance. Volvo adds that these machines deliver the exceptional rim pull and breakout/lifting forces that customers might expect from larger machines. High traction comes from the combination of an articulating oscillating joint and 100 percent differential locks on both axles, while the high breakout force is a result of the powerful linkage.

Volvo has slimmed the dashboard to increase the range of sight to the front and sides of these wheel loaders. Operators

will appreciate more intuitive functions with a larger display that’s navigated via a jog wheel, and a more ergonomic multi-function joystick.

Volvo says that its new advanced boom kick-out and bucket leveller option is unique to this size class. With boundary limits that can automatically lift and tilt the bucket to pre-programmed positions, this function helps experienced operators ensure precise repetitive movement with less fatigue and helps less experienced operators carry out speedier loading cycles.

An electro-hydraulic main control valve enhances the flow sharing among the hydraulic functions. The adjustable boom and tilt function (optional), allows the operator to set the flow of these functions using the jog wheel and display. This enables customized flows for specialty buckets or attachments. Independent hydraulic pumps provide simultaneous lifting and steering at speed.

The L30 and L35 now have an eight-pin harness on the boom. It can be activated by a button on the joystick and allows a wider range of attachments to be used without installing additional wiring.

The steering column, seat, and right armrest are adjustable, and the repositioned wheel chocks are now farther away from the steps for ease of access.

The new-generation L30 and L35 come with additional sensors to monitor their engine and cooling performance. The standard reversible cooling fan is adjustable to handle dusty and high-debris conditions. The operator is informed of deviations in machine behaviour, further improving reliability and reducing unplanned downtime.

These wheel loaders retain their ground-level access to service points, including fuel, oil, air and hydraulic filters, battery, radiator, oil dipstick, and hydraulic oil level gauges.

New Holland Construction’s new 16,072-pound E70D, which the company calls a midi excavator, is the company’s first machine in this size class. The E70D slots into a versatile size category suited to a wide range of applications including urban construction sites, tight landscaping jobs, agricultural tasks, and municipal projects.

“This machine isn’t just about doing the job — it’s about transforming how it's done. With its powerful digging force, hydraulic performance and lift capacity, and automotive-style cab design, the E70D is set to redefine expectations and bring a new level of performance and efficiency for operators working in agriculture and construction segments,” says Dan Kakareka, product manager for New Holland Construction North America.

Powered by a 60.2-hp engine, the new excavator delivers a dig depth of up to 168.1 inches and a dump height of 180 inches. New Holland says its monoboom design ensures superior manoeuvrability. A 22.5-gallon fuel tank ensures extended operation, and buyers can choose between rubber and steel tracks.

Advanced safety technologies on the E70D protect oper-

ators and ensure smooth operation. The machine includes LED lights for enhanced visibility, a rear-view camera for an improved viewing vantage during operation, and excellent cab visibility to provide a clear view of the work area. Backup alarms are standard, alerting those in the vicinity to the machine’s movements.

The spacious operating environment features adjustable heated seats and an advanced climate control system designed to keep the operator comfortable during long work days.

Users can tailor the machine to their specific needs and preferences. Available attachments include buckets, augers, breakers, grapples, and mulchers. Heavy counterweights of 1,102 pounds can be added to the machine to enhance lift performance and stability. Operators can also adjust joystick sensitivity and hydraulic response to match their preferences.

Telematics and a five-year advanced subscription are standard, giving buyers access to real-time tracking, diagnostics, and performance monitoring. This connectivity enables owners and operators to stay informed about the machine’s status, schedule maintenance, and address any issues promptly. The machine also features adjustable controls and an auto-lubrication system, simplifying maintenance and reducing the need for manual intervention.

While skid steers are the most common equipment for snow removal, compact track loaders have become increasingly popular “winter warriors” in recent years. Since it’s expensive to operate two types of machines, many Canadian contractors are opting to purchase CTLs thanks to their year-round versatility. Not only are they more productive and operate with lower ground pressure than skid steers during summer landscaping jobs; but, when paired with the right track, they also have the pushing power to move a lot of snow in the winter.

Transitioning to snow and ice management once the ground freezes can help ensure a steady income over the winter. Furthermore, if you have employees on the payroll, you risk losing them if you don’t keep your equipment running year-round.

Like any purchase, you’ll want to do your research. Whether digging, loading, hauling, or pushing, you’ll need a CTL with the power, performance, and durability to manage your toughest worksite tasks. There are many additional things to consider for the cold winter months. Since a warm operator is a productive operator, you’ll want to verify the CTL has the correct vent placement for defrosting and keeping the operator cozy. Opting for heated seats is never a bad idea, as well. If you plan on removing wet, heavy snow from a parking lot, look for a larger CTL with a higher-rated lifting capacity. Since a lot of snow removal occurs overnight, LED lights are imperative for the best visibility. You may also want to invest in a block heater to ensure the CTL starts if you live in an especially cold climate.

TRANSITIONING TO SNOW AND ICE MANAGEMENT ONCE THE GROUND FREEZES CAN HELP ENSURE A STEADY INCOME OVER THE WINTER.

Light material buckets allow you to move large amounts of snow when loading a truck for removal in parking lots and commercial areas.

Snow pushers are also an excellent tool when clearing large areas. Be sure to look for one with a trip edge if you are working in a location where there are a lot of curbs and manholes as they’re often not visible in the winter and can cause damage to your CTL.

Snow blowers are ideal for driveways and paths in residential areas, and foldable chutes are an excellent feature, allowing operators to direct the snow to a precise location.

Wing blades provide incredible flexibility; the wings turn into a snow pusher when folded and can be adjusted when removing a larger width of snow.

If you plan on removing wet, heavy snow from a parking lot, look for a larger CTL with a higher-rated lifting capacity.

Having the right tracks in the winter is essential. A bar track will give you terrific traction over snow and slippery surfaces. To ensure your CTL is ready for snow removal season, be sure

as needed, and replace them if they’re showing wear. If you have no tread, you won’t have traction. Checking all fluids and changing the engine oil is also an important step when winterizing your equipment. Remember to swap out the summer diesel for winter fuel.

To limit downtime and lost profits, consider performing daily inspections to keep everything in working order. Winter is harsh on the equipment and salt is a killer. Ice tends to build up in the undercarriage on tracked machines, which can damage the tracks or the carrier.

Snow attachments are no different from others — they need to be greased often if they have hydraulic components. Keeping attachments clear of ice will also ensure optimal performance. You’re not going to get a clear path if there’s snow buildup or ice buildup on the cutting edge. Finally, check the blades to make sure they are not worn out. You want to clean the surface when removing snow and the blade is what achieves this.

Snow attachments are no different from others — they need to be greased often if they have hydraulic components.

If you’re looking to expand your business into the winter months, a compact track loader is the perfect machine. Operators with landscaping experience will find many of their skills transfer over seamlessly to snow removal.

With the right equipment and attachments, you’ll be ready to clear snow with the best of them.

Skid Steer Root Rakes Skid Steer Rototillers Skid Steer Screening Buckets Skid Steer Silt Fence Installers Skid Steer Snow & Dozer Blades Skid Steer Snow Blowers Skid Steer Snow Pushers Skid Steer Sod Rollers Skid Steer Spreaders Skid Steer Stump Grinders Skid Steer Trailer Spotters Skid Steer

Tree Booms Skid Steer Tree Grubbers Skid Steer Tree Pullers Skid Steer Tree Shears Skid Steer Trenchers Excavator Augers Excavator Breakers

Excavator Brush Cutters Excavator Buckets Excavator Cold Planers Excavator Drum Mulchers Excavator Log Splitters Excavator Plate Compactors

Excavator Post Drivers Excavator Rakes Excavator Rock Grinders Excavator Tree Grubbers Tractor

Rakes Tractor Moldboard

Silt Fence Installers Tractor Snow Pushers Trailer Spotters Tractor Tree Booms Mini Skid Steer Augers Mini Skid Steer Backhoes Mini Skid Steer Blades

Mini Skid Steer Breakers Mini Skid Steer Brooms Mini Skid Steer Brush Cutters Mini Skid Steer Buckets Mini Skid Steer Forks Mini Skid Steer Grapples

Mini Skid Steer Land Planes Mini Skid Steer Log Splitters Mini Skid Steer Mount Plates Mini Skid Steer Post Drivers Mini Skid Steer Power Rakes Mini

Skid Steer Rototillers Mini Skid Steer Snow Blowers Mini Skid Steer Snow Pushers

Skid Steer Trailer Spotters Mini Skid Steer Tree Booms Mini Skid Steer Trenchers Forklift

At Blue Diamond Attachments, all we do is manufacture attachments that make you better at all you do. From excavators, skid and track loaders to tractors and more, our commitment to quality shines through in every weld and every design. Crafted with precision and innovation, our complete attachment solutions redefine durability and performance.

Skid Steer Adapters Skid Steer Augers Skid Steer Backhoes Skid Steer Bale Squeezes Skid Steer Box Scraper Rippers Skid Steer Brooms Skid Steer Brush Cutters Skid Steer Buckets Skid Steer Cold Planers

So, whether you’re breaking ground or finishing a project, trust the experts who focus on one thing, and when it comes to your equipment, demand the attachments that excel. Choose Blue Diamond – where all we do is elevate everything you do.

Log Grapples Skid

Steer Log Splitters Skid Steer Material Rollers Skid Steer Mount Plates Skid Steer Nursery Forks Skid Steer Post Drivers Skid Steer Power

Rakes Skid Steer Rippers Skid Steer Road Saws Skid Steer Rock Buckets Skid Steer Rock Grinders Skid Steer Rollers Skid Steer Roof Truss Jib Skid Steer Root Grapples Skid Steer Root Rakes Skid Steer Rototillers Skid Steer Screening

Scan the QR code or go to www.AllWeDoBDA.com to find your nearest dealer. It’s time to take your projects to a whole new level.

THE LARGEST FLEET OF LINKBELT EXCAVATORS IN WESTERN CANADA IS RELIABLE FOR HARSH DEMOLITION WORK

BY MACK PLOVIE

Tearing down buildings made of concrete and steel is incredibly rough on heavy equipment, and Clearview Demolition, a B.C.-based demolition contractor with extensive experience in industrial, commercial, and residential demolition, has come to rely on Inland Truck and Equipment to supply a range of heavy-duty Link-Belt machines to satisfy its diverse demolition job sites.

Clearview Demolition Ltd has a long history of demolishing buildings in B.C.; however, the company didn’t start with demolition. The company was originally incorporated in 2006 as Clearview Grinding, a new venture for Mike Lalonde, who owned Blue Pine Enterprises, a company focused on land clearing, mulching, and grinding with a handful of excavators. In 2008, Brad Morrison (a friend of Lalonde’s since Jr. High) joined the Clearview Grinding team to shift the company’s focus in a new direction: demolition.

Clearview Grinding’s first large project was to demolish a large plot of houses for BC Housing. Once abatement had been completed, Clearview Grinding used a Morbark 4600 grinder to grind up all wood on site, recovering 96 percent of the material. Clearview Grinding was the first company to use a grinder for this type of project, reducing waste sent to landfills; ground materials were sold as fuel.

We focus on one thing, and we are very good at it.

Brad Morrison General Manager, Clearview Demolition

As the company continued to grow, taking on other demolition projects, the name was changed to Clearview Demolition. Clearview Demolition was soon working on bridge, high rise, and pulp mill demolition projects; the company purchased a mobile crusher for concrete recycling and later acquired excavator-mounted shears to recycle steel. Clearview Demolition’s first large project, a pulp and paper mill in Prince Rupert, required the complete demolition and recycling of the mill facility and surrounding infrastructure.

“Once you get a few of those projects under your belt, you get to be known as the guys,” says Morrison, now general manager of Clearview Demolition.

The company acquired its first high-reach excavator, originally spotted at a 2010 demolition conference in Las Vegas, in 2013 out of California. Adding the first high-reach machine to its fleet helped Clearview take on projects like a 10-storey high-rise project in Richmond and a building fire demolition project on Granville Street in Vancouver. The high-reach machine proved advantageous, as it could be positioned in the parking lot to preserve the building’s concrete slab.

Today Clearview Demolition has over 60 employees, 60+ pieces of heavy equipment, and is solely focused on industrial, commercial, and residential demolition across Canada. And, Morrison notes, “We focus on one thing, and we are very good at it.”

Clearview’s sister company, Blue Pine Enterprises, still operates and focuses on commercial landscaping, specializing in lock block walls and detail work.

Clearview’s fleet of equipment has expanded as the company has grown in the demolition space. Clearview has owned multiple brands of equipment, but now acquires primarily Link-Belt excavators and operates the largest Link-Belt excavator fleet in Western Canada, with 17 machines.

Clearview purchased its first two Link-Belt 350 excavators in 2019. “We were looking to try something different, we tested a few machines side by side, the Link-Belt price point was good, comfort was great, and fuel burn was less than other machines,” says Morrison.

The company operates Link-Belt’s 15-metric-ton 145 through to 245, 300, 350, 355, and up to the 490, which weighs in at 52 metric tons.

“Our overall operating costs have dropped. We are not easy on gear, we are hammering concrete, shearing steel, wrecking buildings,” notes Morrison.

Sold and serviced by Inland Truck and Equipment in British Columbia, the expansive Link-Belt product line covers nine conventional sizes from 13 to 75 tons in the construction, forestry, and material handler categories.

LBX Company recently celebrated the 150th anniversary of the Link-Belt brand, which started with the link-belt drive chain patented by William Dana Ewart 1874. The company started building crawler-mounted crane shovels, forerunners of modern excavators in the 1920s. In 1998, the excavator division of LinkBelt Construction Equipment Co., LBX Company, was formed and headquartered in Lexington, Kentucky. Today, Link-Belt excavators are manufactured in Chiba, Japan, and a new manufacturing plant recently opened in Indonesia.

Clearview has equipped each Link-Belt machine with demolition attachments, such as second member shears, pulverizers, hydraulic hammers, grapples, and magnetic buckets. All 17 excavators are set up with rotate hydraulic circuits and dedicated extra hydraulic flow circuits to run second member shears, grapples, and hydraulic hammers.

Clearview currently has second member LaBounty shears on four Link-Belt excavators and a Hitachi machine: a Link-Belt 145 with LaBounty 100, three Link-Belt 350 excavators with LaBounty 2500 shears, and a Hitachi EX800 excavator with a LaBounty 7500.

On Clearview’s newer 2023 Link-Belt 355 X4S excavator, prioritizing the hydraulic energy to swing motor, boom, or stick function is done through the new 10-inch in-cab screen.

“Changing hydraulic prioritization circuits is as simple as pushing a button on the console and selecting what circuit you want to prioritize on the screen,” says Mark Williams, equipment specialist with Inland Truck and Equipment.

Clearview is also looking ahead at configuring a Link-Belt excavator for high-reach applications using a 350 or larger machine as the carrier and customizing it with a third-party high-reach boom and work tool.

You can find Clearview’s fleet of Link-Belt excavators on demolition projects throughout B.C.’s lower mainland and beyond. While common for civil contractors, the zero-tail-

THE LINK-BELT 245 ZERO-TAIL-SWING MACHINE WAS IDEAL FOR THE SELECT DEMOLITION OF HOMES ON A LAND REDEVELOPMENT PROJECT WHERE PRESERVING ADJACENT STRUCTURES WAS ESSENTIAL.

swing machines aren’t what you would expect on a demolition project; however, they have proved very advantageous for Clearview.

The Link-Belt 145 and 245 zero-tail-swing machines have been versatile for select demolition of homes on a land redevelopment project. Due to permitting, only certain structures could be removed, with some relocated completely instead of being demolished. Clearview’s zero-swing fleet went to work removing garages, grubbing around homes needing relocation, and demolishing houses in close quarters while preserving adjacent structures. The zero-tail-swing machines were also ideal for demolition work on concrete slabs where machine weight is restricted but the performance of a full-size machine is expected.

“These machines have lots of power, Bluetooth is great, and they are comfortable for a full day’s work,” says Sasha Penner, heavy equipment operator for Clearview Demolition.

On a five-storey abatement and demolition project at UBC Vancouver, an old research facility, Clearview deployed a Link-Belt 210 excavator fitted with magnetic bucket for sorting steel from concrete, a 300 excavator with a concrete pulverizer attachment, and a 490 excavator with bucket and thumb for demolition of the structure.

Clearview’s Link-Belt 300 X4 HD excavator is a heavy-duty series machine to handle tough demolition applications. New as of 2023, the HD series machine builds upon the standard excavator, but is specialized for tough applications like demolition, land clearing, heavy excavation, and pipeline work. Available in the 210, 250, and 300 sizes, the HD series uses standard house with heavy-duty boom and stick set-up, boom cylinders mounted underneath giving 4 to 6 feet of extra reach. The undercarriage is upgraded with a high and wide road builder style that provides extra clearance and adds height to the machine. Rock guards and belly pan are included.

CLEARVIEW’S LINK-BELT MACHINES WORK IN THE HARSHEST DEMOLITION ENVIRONMENTS, BUT NONE HAVE REQUIRED A MAJOR REPAIR OR REBUILD.

“Our work is in the air all the time. With civil guys it’s how deep can you go, for us it’s how high can we reach,” says Morrison. Providing a good operator experience is also important, and operator feedback on the excavators has been great.

“[It’s a] very comfortable machine, easy to operate, easy to get into versus other machines,” mentions Ethan Nikula, heavy equipment operator of seven years with Clearview Demolition, operating the 490 X4.

“Super comfortable, great on fuel, lots of power compared to other brands of equipment in our fleet — reliable and smooth,” says John Bailey, heavy equipment operator with Clearview Demolition, running a 300 X4 used to topple the walls of a self-storage building.

The new X4 Link-Belt machines come with an updated cab complete with air ride seats, comfortable joysticks with endless adjustable positions, a large monitor, Bluetooth, and a quiet operating experience.

Equipment is only as good as the support and service you can get for it, and Inland Truck and Equipment has been available to support Clearview Demolition’s fleet from day one — but these robust machines haven’t needed it.

“I’d love to comment on the service, but we have never had to bring them in,” says Morrison. Clearview does regular maintenance in house and has never had to bring a machine in for major repairs or rebuilds. LBX offers a 5-year or 5,000-hour full-machine warranty, which includes complimentary oil sampling of major fluid circuits to catch any issues early.

Inland Truck and Equipment genuinely cares about its customers, taking Clearview to Chiba, Japan, where they got a

I’d love to comment on the service, but we have never had to bring them in.

Brad Morrison

first-hand look at the factory where 32 machines per day come off the assembly line.