CHANCE TO AN EDUCATION

20 YEARS CENTRO EDUCATIVO IN GUATEMALA

BEJO IN SOUTHEAST ASIA

“THE POTENTIAL IS HUGE”

PLANT BREEDING THE LATEST DEVELOPMENTS

BEJO MEXICO

THE SECRET BEHIND THE RAPID GROWTH

SPINACH

PROMISING PROGRAM IN THE US

2024

Editor-in-Chief Jelger van Weydom

Editors

Thea van der Eng, Daniëlle Bruin, Mirjam Both, Jorien Smak, Yvonne Bijvoet, Ilse Oorthuis, Nathalie España.

CEO

John-Pieter Schipper

Design and layout

Nathalie España

Mieke Schilder (Studio Mieke)

Photography and image editing

Petra Tesselaar

Kim van Straaten

Design In Beeld | visuele communicatie

Translations

Translation agency Wilkens c.s., DeepL

Printing

Koopmans’ Drukkerij, Zwaag

Questions or suggestions about the content of the magazine?

Please contact Jelger van Weydom: jelger.vanweydom@bejo.nl.

The Echo is published once a year for all Bejo employees. The magazine has been compiled with care and is subject to printing and spelling errors.

4. THE RAPID GROWTH OF BEJO MEXICO

Director Carlos Leal and area business manager Ralph Koopman about the origins and future plans.

8. MAKING AN IMPACT TOGETHER

An interview with Sustainability Program Manager Peter Buter.

12. SUSTAINABILITY CASE BROER BV

What actions has the onion set supplier taken?

14. PROMISING SPINACH PROGRAM

Bejo’s opportunities in the American market.

16. BEJO BUILDS ON THE MAP

Read more about some recent construction projects.

23. ANTICIPATING

John-Pieter Schipper about changes within Bejo.

24. INNOVATION

Bejo’s new varieties and seed treatment methods.

27. BEJO IN INDONESIA AND SOUTHEAST ASIA

The potential is enormous, see colleagues Agung Pratama and David Fisher.

32. PLANT BREEDING

R&D Director Bert Schrijver writes about the developments.

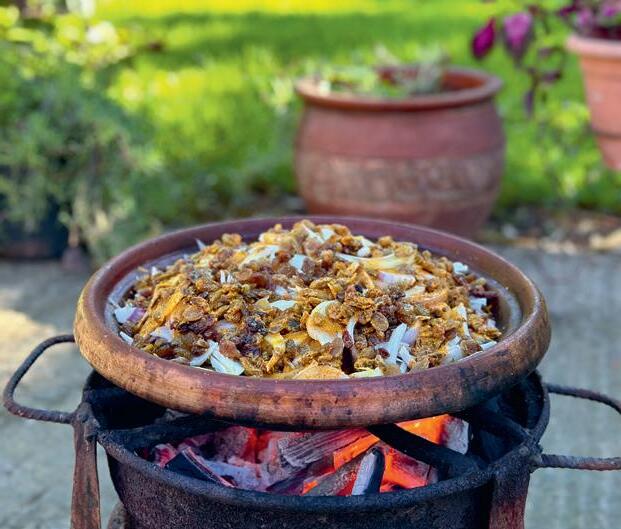

36. CULINARY: DISHES WITH ONION

Colleagues Juan Vinicio Sánchez Escobar and Sara Alaoui share a favorite recipe.

40. 20 YEARS CENTRO EDUCATIVO

An opportunity to receive agricultural training for children in Guatemala.

43. BEET IT!

Discover the beet revolution.

44. 7 QUESTIONS ABOUT BIO

The answer to frequently asked questions.

46. BEJO DICTIONARY

The source for uniform descriptions and consistent translations.

It is difficult not to have heard about some of the topics at Bejo. Even colleagues who do not work in Warmenhuizen will have read about the construction and opening of the new office on Yapp. And also about various projects, Simple for example, have been widely communicated. In the Echo we therefore try every year to give attention to subjects that come up less frequently.

In this edition you can read about the developments. At our Mexico office, which was established more than 20 years ago now. You’ll learn about the growth we’re experiencing in Indonesia and Southeast Asia, and the opportunities Director Agung Pratama and Area Business Manager David Fisher see in the region. Our spinach breeders talk about the promising program they have developed for the U.S. market. Speaking of America, last year you were able to read about the construction of the seed cleaning facility in Pasco. This is now in full operation and colleagues Rich Pollard and Brandon Kania share their experiences.

Fine contributions can also be read from the board of directors. In his column JohnPieter Schipper discusses the challenges of a growing organization and Bert Schrijver talks extensively about modern breeding techniques.

We have once again found two colleagues willing to don a kitchen apron and prepare some delicious recipes. Juan from Guatemala and Sara from Morocco make their favorite dish with onions.

But read it all for yourself. We think we have all managed to make a beautiful and varied Echo.

We wish you much reading pleasure, and until the next edition!

Jelger van Weydom Editor in Chief Bejo Echo

Jelger van Weydom Editor in Chief Bejo Echo

08 16 36 Echo 2024 P. 3

THE SECRET

BEHIND BEJO MEXICO’S RAPID GROWTH

A nice portfolio of varieties, a team of 25 colleagues, and regular new product introductions. The Mexican Bejo subsidiary has been around for more than 20 years and in that time a lot has been achieved. The future also looks promising in terms of growth and sales activities. We speak to Bejo Mexico director Carlos Leal and area business manager Ralph Koopman about the origins and future plans of Bejo Mexico.

THE START

“Bejo started in 2002 in the small city Celaya. This is well before I joined the company myself,” Carlos begins to recount. “There are four people working for Bejo Mexico at that time and the seeds are imported from Bejo USA. The focus at that time is on carrots and onions. Six years later, the company moves to Querétaro, where it is still based.”

The move immediately creates additional job openings, Carlos explains. Several more salespeople are hired and the first product developer in Mexico joins the company. The company also starts selling fruit crops. He himself starts in 2012, in a growing team with an assortment that is expanding rapidly.

“In that year, carrot and onion are still the main crops,” Carlos continues.

“To these are added radicchio, celery, cauliflower (industrial and fresh market), and spinach. This gives Bejo a strong position in the country, the company becoming number one in cauliflower seed sales, among other things.” The director proudly adds, “With Skywalker and Altamira, among others, Bejo Mexico gains 65 percent market share in the industrial segment. In the fresh market segment, we even manage to achieve 90 percent market share.”

Selling fruit crops also has an impact on the business, Carlos continues. “As soon as you start selling tomato seeds, you are watched by both growers and competitors. They start seeing you as a big player.”

With sales of the tomato variety Torreon and pepper Rioverde, Bejo is able to establish itself as a fruit crops company in Mexico. The market demand and climate in Mexico require extra attention from the breeders, and they are giving that attention. Cooperation with

the breeders of Bejo Zaden is strengthened and this leads to a wider range and stronger varieties especially for Mexico. Soon Bejo is selling varieties in many different areas within the country, they have a wider assortment and more collaborations with dealers are emerging. “The focus on Bejo Mexico is paying off,” Carlos concludes.

CURRENT SITUATION

A leap in time: in 2024, Bejo Mexico will now have more than 25 employees and an even wider range of products for the various areas in Mexico itself. That diversity is a big advantage, explains area business manager Ralph Koopman: “The broad assortment in the different segments allows Bejo to respond quickly to changes in the market. In addition, we are not dependent on a specific crop; multiple crops provide the company’s stable income. This gives us a strong position for both the short and long term.”

Ralph cites the recently launched broccoli crop Salinas as an example. “We have high expectations from this. Also, Bejo started developing the slicer cucumber market several years ago.

Echo 2024 P. 5 MEXICO

A lot of time and attention has been put into this crop, with a particular focus on developing the Mexican market. Consequently, in three years, the cucumber variety Marvila has conquered the market. In fact, Marvila is now the strongest variety for the domestic market.” Ralph continues, “Radish should certainly not be missing from this list, with our new hybrid varieties Recife, Rhino and Rafting we have incredibly nice genetics in our hands to further develop this market segment. In addition, a lot of attention is being paid to our peppers and chilies, so growth in these crops cannot be out of the question.”

IMPORTANCE OF EXPORTS

Another important development in the growth of Bejo Mexico is the export of vegetables from the country. Mexican growers buy seed from our facility in

Mexico, but they export the yield, i.e. the finished product, to surrounding countries. In particular, the United States and Canada are popular destinations. Mexico is becoming a bigger and bigger export country and Bejo Mexico is benefiting from this. Ralph explains: “We see a production shift from the southern US to Mexico. This is because Mexico is a very attractive export country; the weather is stable, many crops can be grown year-round, there is now sufficient availability of water, and labor costs are much lower compared to surrounding countries.”

Meanwhile, 70% of the yield of growers from Mexico is exported and the amounts involved are substantial. If we look at tomato, the most exported crop, we are talking about sales of $40 million. Some crops, Ralph explains, are even entirely for export. Yellow onion, for example, “A lot of yellow onions are grown in Mexico, but this

product is not consumed in Mexico itself, because Mexicans eat mostly white onions. So, 100 percent of yellow onion production is for export.”

THE FUTURE

In more than two decades, much has been achieved in Mexico. And if it is up to both men, the growth is far from over. “Twenty years ago, Bejo Mexico began as a small business in Celaya,” Carlos says. “We have since moved to a larger office with a large warehouse, but it looks like this location will be too small in the future. More space for a large warehouse will probably have to come soon.”

And there’s more to come, Ralph adds: “We are currently working on the realization of our own fruit crops facility in Culiacán. The land on which the site will stand

has already been purchased and construction will start soon. The location has been strategically chosen; it is a very important growing area for fruit crops especially tomatoes, sweet peppers, and hot peppers.”

YOU CAN READ MORE ABOUT THE CONSTRUCTION OF THE NEW FRUIT CROPS FACILITY IN THE BEJO BUILDS ARTICLE ON PAGE 21.

When asked what Bejo Mexico will bring us in the future, Carlos replies, “We are going to further develop our position in all crops. Especially in the short-day segment of white onions, I foresee tremendous growth. Also, broccoli, tomatoes, peppers and paprika are important crops that will play a major role in the further development of our establishment. This should put Bejo in the top five best breeding companies in Mexico. We already have a strong team, and it continues to grow. Together we will do everything we can to achieve our goals”.

Both men are confident that these goals can be realized. Carlos: “The strength of Bejo Mexico and the successes we have achieved comes from our strong distribution programs. The good cooperation with the breeders has played an important role in this.”

But the “secret” of success, both emphasize, still lies primarily in all the employees who are committed to Bejo Mexico. Carlos, with pride: “The colleagues put in their efforts with great enthusiasm and dedication. Together we ensure that Bejo Mexico continues to grow. It is the combination that ensures success: an extensive assortment, good genetics, and a strong team!”

By Jorien Smak

Carlos Leal

I am an active person, with some extreme activities that give me fun, adrenaline and rock my life. I practice paragliding in several places in México and also in other countries like Colombia and Peru. For 16 years. Also I do diving, activity that allows me know beautiful places like Cozumel in the Caribbean ocean, and Los Cabos in Baja. I practice tennis 2-3 times a week, when I am not traveling, and I do some cycling but not too much.

I have 2 grandchildren, a boy and a girl and really enjoy visit them and have them in my arms. Is the shine of the life.

In my work in Bejo México I love to be part of the grow of the company, in sales but also in the team. We are more colleagues in the different departments and I like to help them in their personal development and as a team. That is the strongest part of Bejo México, the people.

Ralph Koopman

Together with my wife and 3 children we live in the small village of Valkkoog, on the outskirts of Schagen. It is a nice busy family with growing teenagers and much of my free time is spent with the family. With my friends I play billiards on the regular Thursday evenings and I enjoy biking and hiking. I am a real lover of music and try to go to some concerts every year.

Echo 2024 P. 7 MEXICO

THE SUSTAINABILITY DEPARTMENT, WE ALL ARE!

MAKING

AN IMPACT TOGETHER

SUSTAINABILITY

As Program Manager Sustainability, Peter Buter is responsible for implementing the sustainability strategy within Bejo. He ensures that projects are managed properly and responsibly. A complex task, because a lot is happening in this area. We speak to him about developments.

WHAT IS YOUR FIRST IMPRESSION OF SUSTAINABILITY AT BEJO?

Many colleagues feel committed to the subject. I notice that in the conversations I have, but also from the reactions to the “Waste Challenge”. I am impressed by the multitude of projects and initiatives that are running internationally with regard to sustainability. Something I did not know about before my current position. This makes me feel positive!

ARE WE GOING TO DO THINGS COMPLETELY DIFFERENTLY NOW?

No, you shouldn’t see it that way. Don’t forget that we have always been working on sustainability in our core business as well. Think of the breeding of more resistant vegetable varieties, our organic activities and our seed technology research, with the sustainable coating and B-Mox® as concrete results.

SO WHAT EXACTLY IS THE DIFFERENCE?

We scrutinise the impact of our processes on people and the environment. The use of energy and water, CO2 emissions and the use of chemicals and synthetic fertilisers. Can we do less or can we do it in another more sustainable way?

BEJO SUSTAINABILITY

1 AMBITION AND 3 THEMES

IN EVERY MARKET IN WHICH WE ARE ACTIVE WE STRIVE TO BE AHEAD WHEN IT COMES TO SUSTAINABILITY AND AT THE SAME TIME, TURNOVER GROWTH OF 65% TO BE REALIZED BY 2030.

THEMES

1. REDUCTION OF CO2 FOOTPRINT

2. WORKING TOWARDS SUSTAINABILITY SEED PRODUCTION

3. WORKING TOWARDS SUSTAINABILITY FINISHING PROCESSES

Echo 2024 P. 9

BESIDES THE FACT THAT WE WANT TO BECOME MORE SUSTAINABLE, ISN’T IT ALSO A MATTER OF OBLIGATION?

Besides Bejo’s desire to become more sustainable based on its own intrinsic motivation, there is also a ‘must’ as a result of European regulations: the Corporate Sustainability Reporting Directive (CSRD). From 2026, large companies like Bejo (with a turnover greater than 40 million euro) must report on their impact on people and the environment, and what they are doing about it. To this end, Bejo is following a CSRD implementation path via Plantum and external advisor PwC (PricewaterhouseCoopers). Together with 20 companies from our sector, we determine which relevant sustainability themes we want to report on. Therefore, we are jointly drawing up a sustainability reporting framework. Our previous footprint measurements come in handy here. We notice that as Bejo we are quite ahead with the CO2 footprint measurement compared to other companies in our sector. We are currently working on the third footprint measurement, while other companies have not even started, or are still working on their first measurement.

WHAT DO YOU RUN INTO?

It was mentioned earlier that sustainability is a broad concept. So where do you start? As a direct contact, I get the most diverse questions on the subject from within the organization. Questions to which I don’t

always have an answer either. I then try to find the connection within Bejo, and link the questioner to the right person. Another issue is time. For most of us, sustainability is still a task that comes ‘with it’. That has to change. Sustainability should be part of our daily work. Fortunately, I see some nice initiatives here and there in the organization, which is nice.

CAN YOU SAY SOMETHING ABOUT THE PROGRESS ON THE GOALS?

I am happy with the concrete targets that have been set at Bejo. To actually measure progress, we need a starting point against which we can measure future results. We do that with the footprint measurements. The third measurement is (almost) complete at the time this Echo comes out. We now hope to have reached the point where we can accurately compare two consecutive years.

OKAY, SO THEN

WE KNOW

HOW TO START MEASURING THE RESULTS, BUT HOW ARE WE GOING TO CONCRETELY REDUCE OUR FOOTPRINT?

A lot is really already happening. Certainly within the energy theme. I am thinking of the energy savings achieved at onion supplier Broer BV (editors: read more about this in the Broer article in this Echo). And for the intended transition from fossil to

renewable energy, we are currently mapping the energy consumption of all buildings and processes in the Netherlands. A roadmap of each building will be delivered by the end of 2024, containing the plan of action to achieve the set targets. An energy supply master plan is also being drawn up for the entire Trambaan area. This involves connecting all buildings (from 1A to 8) by means of an energy street and making use of each other’s heat and cold. This is already happening on a smaller scale at the new part of 2A, where the heat from the climate cells is transported to the greenhouses, and the new office building on 1A. Both buildings are individually fitted with a heat pump, but will eventually become part of the Trambaan energy street.

WHY START IN THE NETHERLANDS?

Simply because all buildings and processes in the Netherlands combined show the highest energy consumption. We will then turn our experiences in the Netherlands into a blueprint for Bejo sites worldwide.

IS SUSTAINABLE SEED PRODUCTION A COMPLEX PROCESS?

Bejo has over 6,000 ha of land area in use for seed production worldwide, both in-house and from partners (contractors). During the international seed production summit, we jointly defined four themes (water, chemical, fertiliser and waste) on

SUSTAINABILITY

which we will initially focus. The seed production department will first focus on making these themes more sustainable, but in the future, building soil health and biodiversity, issues that fall under regenerative agriculture, may also be picked up. But we are not that far yet, one step at a time.

DOESN’T OUR BREEDING PROCESS IN ITSELF CONTRIBUTE NICELY TO SUSTAINABILITY? AFTER ALL, WE BREED FOR MORE SUSTAINABLE VARIETIES THAT ARE RESISTANT AND ROBUST.

Certainly, but in this case we focus on our own activities and look at energy, water, chemical, pesticide and (synthetic) fertiliser use. A working group within breeding is currently defining the concrete goals, after which actions can be set out. (Editor: at the time this Echo went to print, the output of this was not yet known)

Bejo wants to be a sustainable and responsible company for people and the environment. Partly for this reason, we started organic seed production more than 25 years ago, initiated by Ger Beemsterboer and supported by former colleagues Fred van de Crommert and Dick van der Zeijden. Today, we have ambitious energy and CO2 emission targets and feel great responsibility and passion for sustainable agriculture and food supply. Our business is therefore dependent on nature; think soil, bees and climate. We cannot do without it.

There is a long way to go, but the initiatives are promising. Our slogan “Exploring nature never stops” sums it up nicely. That’s right, the solutions to the big challenges we face, including climate change, are hidden in nature. We just have to discover it.

By Thea van der Eng

By Thea van der Eng

I am Peter Buter, living in beautiful Tuitjenhorn in the Netherlands. I have now been with Bejo for over 13 years, previously as Business Area Manager in the Americas and Sales Manager for Bejo Benelux.

Since 1 July 2023, I have been Program Manager Sustainability at Bejo, responsible for implementing the sustainability strategy within Bejo worldwide. I ensure that all initiatives, projects and activities are managed properly and responsibly. Furthermore, my job is to increase sustainability awareness and involvement in the subject within the organization.

The subject of sustainability is close to my heart. Handling our business activities together in a responsible and sustainable manner for a positive contribution to people and the environment. This gives me a lot of energy, inspiration and job satisfaction. Ultimately, together we make for a better and more liveable world, now and in the future.

Echo 2024 P. 11

SUSTAINABILITY CASE STUDY BROER BV

Onion set supplier Broer BV made great strides in energy efficiency. What actions did they take and what impact did they have on the organization?

Broer BV is part of Bejo and De Groot en Slot. Together with Broer and De Groot en Slot, Bejo breeds new onion sets, which are marketed under the brand name ‘Quality inside’. Broer has been producing, processing and selling onion sets to more than 50 countries in Europe and Asia for over 70 years. It also exports to the United States and Canada. It employs 20 (permanent) employees at two sites in the Netherlands, and an additional four colleagues at Broer Iberica, in Spain.

WHAT PROMPTED IT?

Broer has a total of almost four hectares of farm buildings. A heat pump system was installed for part of this (2.5 hectares) back in 2012; the largest within the onion world, according to reports. With this, Broer became a major consumer of electricity, which was relatively cheap at the time. However, with the gas price rising in 2022, the electricity price also went up drastically. And so much so, that serious problems could arise for the continuity of the business. That was the moment to start thinking further about reducing and making the company’s energy consumption more sustainable.

WHAT ACTIONS HAVE BEEN IMPLEMENTED?

• A second heat pump system was installed in 2023, which means that all business premises now run on electricity. Due to the local congestion problem (the cable network can no longer handle power transmission at busy times), gas is still used for heating on rare occasions.

• Broer has switched to propane gas, stored in propane tanks. Progas gas tends to be cheaper than natural gas and also has a higher efficiency, so less gas is consumed overall.

• There is no longer continuous ventilation in storage, but in hourly blocks when power prices are low. Every day at 3pm, staff set the ventilation schedule for the next day, based on current power prices.

• For insulation, tarpaulin has been placed around the drying walls, blocking cold air from the shed. This allows the onion sets to reach sorting temperature faster.

• During coffee and lunch breaks, processes such as lights, forklift trucks and machines are switched off.

• The doors of heat and cold cells are kept closed as much as possible.

• Incoming and outgoing trucks are loaded and unloaded inside the cold store.

WHAT ARE THE RESULTS AND LEARNING POINTS?

Electricity and gas consumption decreased by 25% and 50% respectively in 2022 compared to 2021. A great result.

In the process, Broer experienced that it works to make employees share in the process. The extremely high energy bills have been shared with all employees, making everyone aware of the urgency. Current consumption figures are also transparent, making energy consumption tangible for everyone. Employees are more aware of their own impact on energy consumption and come up with new ideas themselves.

WHAT’S NEXT?

By 2030, Broer wants to be energy-neutral. To this end, the use of solar panels will also be investigated in the future. A point of attention here is that Broer uses a lot of power in winter (when there is little sun) and little in summer (when there is a lot of sun). Excess power cannot (yet) be fed back to the grid. One option is then to store power yourself in a large battery. These are all issues that need further investigation.

Besides energy consumption, there are other environmental issues that have Broer’s attention. Consider, for instance, maintaining sufficient fresh water in the area. With the large roof area of the industrial halls, a lot of rainwater is lost. Broer feels it is a duty to society to collect this for further use, in the form of water storage. And the waste released during sorting is taken to a biogas plant where natural gas is extracted. These are great examples of sustainability.

To conclude with a quote from Siem Beers, Director of Broer BV: “Climate change is also a change for us. And in this, we will all have to do our bit.”

By Thea van der Eng

Echo 2024 P. 13 SUSTAINABILITY

PROMISING SPINACH PROGRAM FOR THE US MARKET

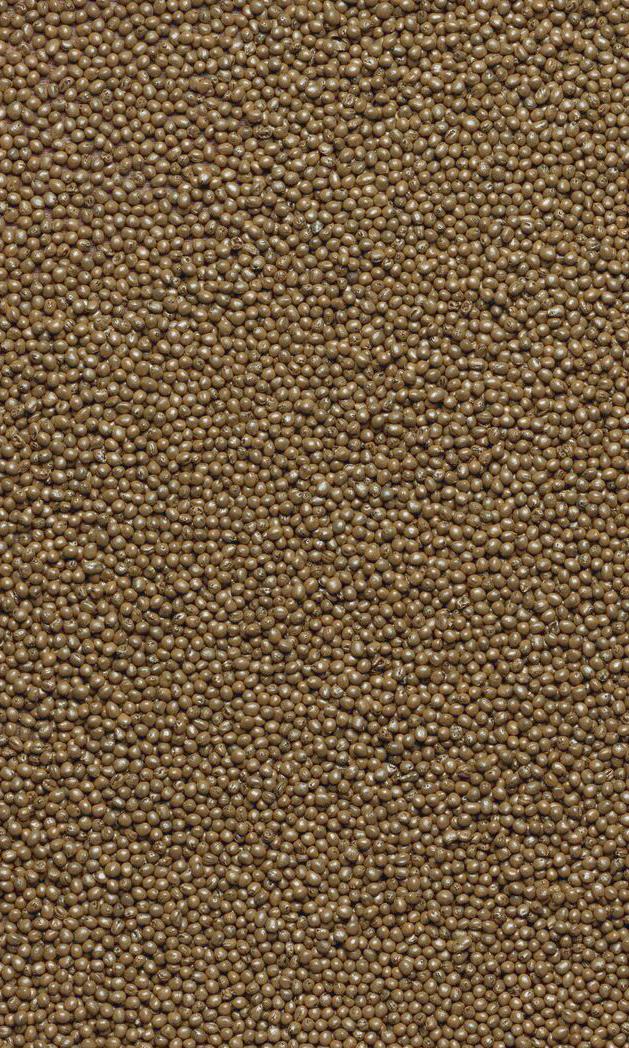

Bejo has been breeding spinach for 30 years, but never before have our new varieties had as much potential as they do now. Pershing, MacArthur and Marshall show good growing results and are resistant to downy mildew physios strains 1 to 19. Pershing was marketed in the US in autumn 2021 and sales of Marshall and MacArthur started in 2022. Reason enough to ask Crop Research manager Roel Veenstra and spinach breeder Raimon Laan all about these new opportunities in the market and their role.

“Spinach fell under the ‘Diverse Crops’ crop group for many years, but these diverse crops, which also included beets, celery and celeriac, were becoming larger and more important to Bejo and therefore needed more and more attention,” Roel says. “In the 1990s, Bejo was reasonably successful in spinach, but the resistances to downy mildew strains were breaking through faster than we could breed. Bejo gave relatively too little attention to spinach and competitors developed faster. We were lagging behind.”

In late 2013, there was a ‘Crop Strategy Meeting’ at which the future of the spinach program was discussed. It was decided to focus on the ‘baby leaf market’ in the United States. On the initiative of Bert Schrijver (Director of Research), spinach was taken away from the Diverse Crops’ crop group and placed under its own column, for which Roel became responsible. A new team had to be created with its own breeder.

Finding the suitable breeder was a challenge, but in 2016 Raimon Laan joined the team to fill this position. From Phytopathology, Jordi Boshoven joined the project and Steven Kaandorp (from the Marker Technology department) completed the team. Both researchers have since been succeeded by Joëlle Schachtschabel and Iris Haverkorn, and Nicole Kollerie has joined the team as a junior breeder.

RESISTANCE BREEDING

“As diseases continue to adapt, the resistance of varieties is broken, so this means a variety becomes susceptible at some point. It is a constant race against the downy mildew fungus strains. When resistance is broken, we start looking for a new resistance again,” Raimon explains. “When the spinach team started in 2016, there were already 16 physios strains and we could not make a fully resistant hybrid. So a resistance breeding plan had to be drawn up. Elly Stam and Jack van Dorp had already developed good quality parental lines. So we could build on this.”

The spinach team managed quite quickly to make backcrosses with wild related spinach varieties that had unique resistances. Resistance was first tracked with disease tests, then markers, genetic structures in the DNA that indicate that the trait is or is not present, were developed. In this way, resistances could be properly tracked. Through much effort by the spinach team, and a bit of luck, within four years we managed to create a unique Bejo number. This number, now the variety Pershing, is in fact resistant to the 19 named physios of downy mildew strains.

MARKET OPPORTUNITIES

For now, Bejo only breeds spinach varieties for the US market. Seed prices are relatively high and there are 8 to 10 million seeds per hectare. Bejo has not been a big player in spinach in recent years, but it has a good name in the market and is seen as a reliable and professional partner. As a result, there is trust among growers. “Currently, we have around 6 per cent market share and seed quantity is the limiting factor,” indicates Roel. “We aim to increase the market share stably to 20 per cent.”

The really big player in spinach was Pop Vriend, with a 60 per cent market share. Seminis and Rijk Zwaan accounted for the remainder of the market. However, these companies have lost a lot of market share recently and Nunhems in particular has grown. Bejo, too, is now gaining more ground.

WHAT’S NEXT?

Roel is pleased that there is a lot of interest in the new varieties from the field and about the good contact with the US dealers. Here, Crop Manager Gordon Spurgin has an important role to play, as he is the liaison between sales and breeding. “Spinach seed is very coarse, so it takes up a lot of storage space. As a result, we cannot have too large stocks,” Roel explains. “So the idea is to produce only what we expect to sell the following year. So a good match between supply and demand is very important.”

In addition, he continues, the variety must also be brought to the attention of spinach growers: “The variety Patton has already played an important role in this. Although this variety is not fully resistant, it is still highly appreciated in the United States because of its outstanding quality. Patton is therefore selling well. Due to this good performance, the variety has given us a lot of positive brand awareness among spinach growers. As a result, we now have the opportunity to conduct trials.

“Bejo’s three new varieties are the first fully resistant varieties to be sold. Meanwhile, there are more potential numbers on the shelf and many more in the pipeline. Raimon therefore expects that these varieties will soon be succeeded by even stronger varieties. Roel adds: “Thanks to this development, Bejo can play a bigger role in the spinach market.”

By Jorien Smak

Echo 2024 P. 15 SPINACH

BEJO BUILDS ON THE MAP

With FOCUS 2030, we focus on maintaining our leading market positions and strengthening and expanding them where possible. To achieve this and to be ready for the future, it is important that we continue to invest in new locations or renewing existing locations. A number of these locations have been completed and new projects are in the starting blocks to be implemented. An update of these projects can be read on the following pages.

BEJO BUILDS

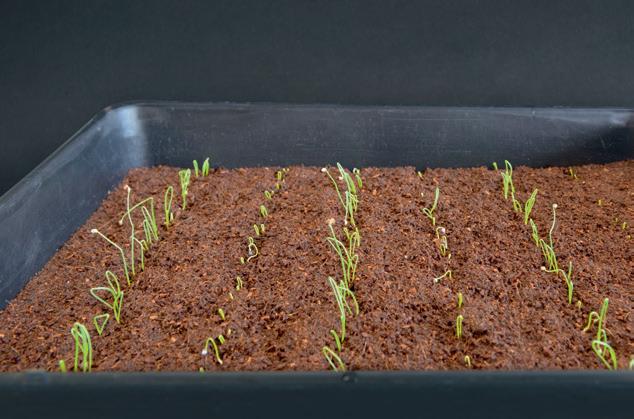

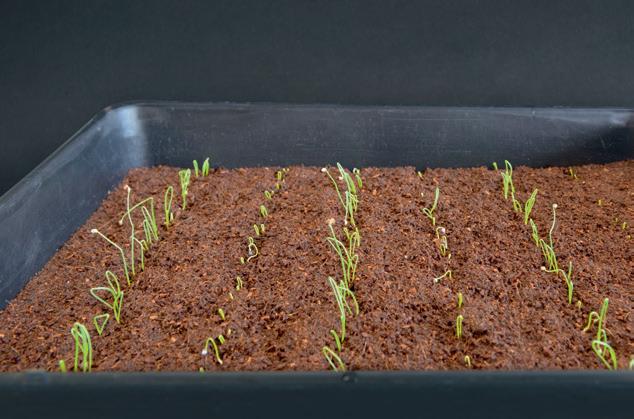

NEW PLANT GROWING LOCATION, WARMENHUIZEN

Bejo’s new location for plant raising in Warmenhuizen was inaugurated last September. For colleagues not so familiar with the purposes of the building: Trambaan 8 houses the activities that used to take place on the Oudevaart (plant raising and manual pollination). It also contains some offices and storage space. The overall complex is impressive; a 100 x 25 meter building with adjacent 2.8 acres of greenhouses.

Building consultant John Klaver enjoys giving a look behind the scenes: “There are two teams of 6 or 7 people working per team, so the permanent staffing is not very high. During one period of the year, manual bud pollination takes place here, which involves about 30 to a maximum of 45 to 50 ladies. It’s a lot fuller here then.” John emphasizes that Bejo’s growth has been taken into account during construction and thought of the future: “Flexibility in terms of layout has been very important to us.”

GREEN OPERATIONS

The Plant Breeding Department team will sow and raise an estimated 15 million plants per year. A large part of this consists of plants from trial crosses that are later evaluated for desirable traits by our breeders outside in the trial fields. In addition, plant rearing is necessary for seed production and for planting the demo fields for the Bejo Open Days. During the pollination period in spring, a team of specialized seasonal workers works on crop pollination for the development of new trial crosses and parental lines.

PROGRESS WITH TECHNOLOGY

The complex is built for the future and equipped with new technologies that ensure an optimal working environment for the employee and the best conditions for the plants.

John looks back: “It was a project of considerable size: in area and in terms of technology, but also financially. After good preparation, we found ourselves in a turbulent time of price increases and uncertain deliveries. An extra challenge on top of an already quite complex project. In the end, I can say that we achieved a wonderful result with the project team. I think also a very nice workplace for our colleagues.”

Project manager Koen Beemsterboer concludes, “We have been working at this beautiful location for a few months now and we still have plenty of room to grow and increase and ensure quality in the coming years.”

• Spray trees for watering equipped with CleanLight UV light that biologically protects plants from fungi, viruses and bacteria.

• Special LED light matched to different crops, this promotes crop growth in dark days and extends the season.

• High-pressure misting helps control optimal indoor climate.

• 39 compartmentalized rooms, each with its own climate control that can be set to the needs of the crop in that room.

• Physically separated departments (propagation and hand pollination) with a special wall, preventing pollinators (such as bees) from flying over and keeping pathogens (such as fungi) inside.

• Efficient use and reuse of water. An ingenious example is that condensation in the greenhouse is collected to wash the plant crates.

Echo 2024 P. 17

USA, PASCO

BEJO BUILDS ON THE MAP

USA - ARVIN

The construction of the seed cleaning facility completed. With this facility we are less dependent on third parties and we have complete control about planning and quality of the process.

In Arvin, there will be a conditioned storage for short-day onions where we can determine the temperature and humidity. The storage will be used for the breeding program and the mother bulbs that are used for the seed cultivation.

MEXICO, CULIACÁN

Location for a new pilot and demonstration station and covers ten acres: three acres for open field, three acres of net greenhouses and 3.8 acres for various functions. Construction activities will begin the fall of 2024.

BEJO BUILDS

WARMENHUIZEN - PLANTRAISING

A new location for plant raising for all outdoor vegetables and manual pollination. Per year 15,000,000 plants are processed for Breeding and Production. At the hand pollination department there is room for 24,000 plants.

WARMENHUIZEN - OFFICE

The office has 326 workstations and 52 meeting rooms. The 3,000 square feet of glazing reflects our open and transparent culture. The building is completely gasless and meets current energy standards.

Check out Yapp for more fun facts about the new office!

Echo 2024 P. 19

THE RESULT OF AN AMERICAN DREAM

In the previous Echo you could read that the seed cleaning facility in Pasco is built and ready for the next steps: installing machinery and training staff. The most hurdles are cleared and the first lots are cleaned and ready for shipment to Warmenhuizen. A perfect moment for a retrospective with Regional Production Manager Brandon Kania and Director of Seed Production Rich Pollard who were intensively involved in the project. Both are enormously proud of the facility and their team.

Rich starts: “We started cleaning seed in October 2023 and internal experts from The Netherlands and Tasmania came in and went through the process step by step to train the staff how to clean the seed practically.” He continues: “This was such a positive experience for us: working with Mattijs de Vries, Arjen Slagter and Grant Pearce” continues Rich “An international

team working closely at the project with one focus: to get the best results and quality. It really was a day to day basis collaboration.”

Brandon adds: “After the training we split up a batch of seed between a third party cleaner and ourself to do a check. The results told us that the amount of usable seed was higher and the quality was higher as well. When you’ve been working on this project for so long and you get to see these first results: what a moment! And that’s what we were hoping to achieve with our facility. But…” Brandon continues: “That is what the results are showing us this time. In the little bit that we have done.”

“Our next dream or goal?” Brandon shows his original pencil drawing he made in France in 2017 and says “For me personally the realization of this drawing was my biggest dream for a long long time. My goal for the future is to be the best in what we do. And one day Warmenhuizen will ship seed to us to clean to take the load off

there. We not only want to clean seeds for the US but give global support for Holland in what we do.” Brandon ends: “With this project we realized the ‘American dream’. And I encourage everyone to dream, make mistakes and set high goals! It was an amazing experience and the result is that we want to develop ourselves more and more.”

What Rich found great to see in this project is that it really was an opportunity to allow people to grow. “There was room for making mistakes, for learning and improving. We developed ourself professionally, personally and as a team. The next project that we do will be that much better of this experience.” His ending words “This projects was really a vision of Ger Beemsterboer: It goes back to 2012 to have a seed cleaning facility in North West America. He was the driver of all these developments in the US. He gave us the feeling: try, fail, learn from it. Really ensuring encouragement from him. We truly feel he is part of our team.”

NEW FRUIT CROPS LOCATION IN CULIACÁN, MEXICO

Mexico is one of the largest and most important countries for the production of fruit crops aimed at the Americas. This production takes place mainly in Culiacán, in the state of Sinaloa, on Mexico’s west coast. This area has a perfect location and fruit crops such as tomatoes (indeterminate and semi-determinate), slice cucumbers, jalapeño peppers and sweet peppers grow excellently here.

The region has many other advantages. Area Business Manager Americas Ralph Koopman explains: “The soil there is excellent and the area is near the export market in the United States. In winter, despite the low temperatures, mainly thanks to the amount of sunlight it is possible to produce high-quality vegetables. The growers in this area have tremendous technical expertise and the right strategy for production. They have an important influence on the rest of the agricultural areas. To convince them of new fruit crops, the range offered must really be of high quality.”

He continues: “Right now in Mexico we are working with external parties, but actually you also want to have a piece of land under your own control for your fruit crops activities. We therefore started looking in Sinaloa looking for a piece of land to build a trial and demonstration field station. And with success: the land has been purchased and construction activities will start in the fall of 2024.”

ADVANTAGES OF ITS OWN LOCATION

The pilot and demonstration station in Culiacán covers ten hectares: three acres for open field, three acres of net greenhouses and 3.8 acres for various functions. Ralph explains the advantages of investing in our own site: “Currently we depend on outside growers and the acres they can make available for our trials. With our own location, we can conduct them year-round and carry out our own breeding activities (such as screenings and VOs) to evaluate.”

This, according to Ralph, provides an acceleration in breeding and selection activities. And, he concludes, “Because of all these developments we are able to always accommodate customers and display the new commercial varieties under the right conditions, without any restrictions.”

ONION STORAGE FOR NONSTORABLE ONIONS, ARVIN

A new construction project is just around the corner in Arvin, California. This location houses a breeding station focused on shortday onions. The focus is on the breeding program and propagation of our commercial parental lines.

Short-day onions by nature have poor storability because they are softer and contain less dry matter. A benefit is that the flavour is milder as a result. These are onions suitable for the fresh market and not for storage. Storing these bulbs is therefore a big challenge for our colleagues there.

Crop Research Manager Timo Petter says: “In Arvin, autumn is the time to plant the bulbs for seed multiplication. These bulbs come from the trial fields that we already harvest in spring. So we have to store bulbs that don’t store well and can’t take heat well from May to October in a period where the temperature rises to 40 degrees. It is quite a job for our team to store the onions in such a way that they can still be used in autumn. At the moment, we lose quite a lot of material in that intervening period.”

The storage method used now is used more often at our Allium breeding sites: a covered shed where onions are stored in bags and crates and, with the help of a fan, air is blown through the material. A workable solution for many of our locations, but for the short-day onion, colleagues had to come up with another solution. It was decided to invest in conditioned storage where we can control the temperature and humidity ourselves.

Echo 2024 P. 21 BEJO BUILDS

Breeder Ryon Ottoman, who works in Arvin, adds: “We have been testing which storage and conditions are best for these onions since 2012. You want to test the results of year 1 in year 2, 3, and so on. The set-up can be the same, but the weather changes all the time. In addition, after the tested storage, you also want to see how the material subsequently grows again in the field and whether good seed is produced from it.”

This conditioned storage will be used for the breeding program and for the mother bulbs used for stock seed multiplication. This seed from the commercial parent lines will then be used for hybrid seed production.

What are the expectations from this new storage? Timo: “The breeding team and Stock Seed Planning make advanced plans and calculations for how many bulbs

we need to grow on our trial fields and the yields that can be expected, so that we know the estimated bulb quantity in autumn. If you then lose a lot of bulbs during storage, you will never meet the planning that you started with and sowed for in the trial field. With this conditioned storage, we hope to lose less unique breeding material and mother bulbs. And thus meet the need for breeding and stock seed.”

WHY NOW?

After 30 years of breeding short day onions, we have managed to develop a variety range that Bejo can introduce to the market. To achieve a good market share in this relatively new market, it is essential that we have sufficient seed from our parental lines. Therefore, we can no longer afford to lose important bulb material.

WITH THANKS TO COLLEAGUES

Ryon concludes, “That where we are today is thanks to a great chain of hard-working and patient people working with shortday onions. Think of the highly skilled colleagues at the research centre, the people in the field who work with great care in a very challenging environment, the perseverance of the breeders and the investment from the management. All these efforts help enormously to create a good assortment.”

NEW BUILDING STARTS

When this Echo comes out, construction has already started. It is expected to be completed by the end of 2024.

By Yvonne Bijvoet

BEJO BUILDS

TO ANTICIPATE

Anticipating things that you expect to happen or know for sure will happen, is something positive and smart to do isn’t it? In principle you can’t have anything against it one could say.

But the anticipatory action itself may not always be fun, causing stress or make you nervous. This winter in the Netherlands, people had to leave their homes because of rising water due to heavy rainfall and a southwest storm. That was sensible, but very stressful and certainly not fun.

At Bejo, we hope not to have to anticipate such fierce events. Nevertheless, we are also constantly preparing for events that we know or expect will happen and that require a different approach than our current way of working. Simple examples of anticipation are the construction or extension of buildings to facilitate further growth and development of our primary processes or investments in new technologies of which we are convinced that they will make a difference towards the future.

Another example of anticipating is the redesign of the central organization, which we aim for in the project Bejo 3.0. We know for sure that our worldwide activities will develop further and grow in number. That means activities in more locations and more countries. This growth comes with further professionalization, more complex strategic puzzles, and a bigger organization with more people. Given we already run against

our limits at some points of what we can manage with the standing organization, we know we have to anticipate the mentioned developments.

With Bejo 3.0 we aim to create a more independent senior management layer reporting to the board of directors, a stronger connection between the country organizations and the central organization, and to free-up time of the board members to be able to pay more attention to strategic topics and relationships.

With Bejo 3.0 we also anticipate the retirement of two board members, Bert Schrijver and Martin van der Voort. Instead of simply one on one replacing them, in the project Bejo 3.0 we think ahead about what composition we think we need in the board of directors for the future.

All wise things to do and logic given the developments Bejo is going through and are foreseen for the years to come. But doesn’t it make some of us nervous? Of course it does at some places in the organization!

For those positions that change the most, it causes uncertainty but also opportunities, both come with a certain amount of stress. Also the changing reporting lines of the country organizations might not always be in line with personal preferences.

When I speak for myself, I liked the complexity of the puzzle of Bejo 3.0, but also look ahead to the new structure with

some excitement. I am convinced the plan is good, but the execution of a plan is something different than the exercise of making the plan. Things will come together in the months ahead of us and then we will experience how it all works out. A new structure, with new positions, new people and new ways of working.

I am looking forward to work with a partly new team in the board of directors and the new dynamics that will give to the team. But I am also curious about who we will find to fill in the vacant positions and whether the team will work as close and easily together as the existing one.

Being less involved in the more operational issues is one of my challenges, allowing me to focus more on strategic topics and relationships. Making that change will take some effort. Because I may have to be less involved in operational topics, but I don’t want to be less informed about the primary processes. It is a nice challenge for me to find my way in this new way of working.

Anticipating things that you expect to happen or know for sure will happen is important for all of us, even when the anticipating action is not always what you personally prefer. If it is good for the bigger picture, as an organization it makes us stronger!

By John-Pieter Schipper

Echo 2024 P. 23 COLUMN

BEJO’S HARVEST OF INNOVATION

Bejo has new introductions every year, both in terms of varieties and seed treatment methods. Our breeders and researchers do not stand still! They are constantly working on improving our varieties, for instance in the field of disease resistance, yield, taste and ease of harvest. This results in a nice end product for the grower. But we are also looking at new product forms, for example for a good seed start. We would like to explain a number of important introductions.

B-MOX® IMPROVED PRIMING FOR ONION SEED

For a healthy, uniform crop, it is important that young plants get a strong start. This is why our researchers and specialists have developed the innovative seed enrichment technology B-Mox®. B-Mox® strengthens the seedling, stimulating growth at the earliest stage and making the plant more robust. Throughout the growing period, plants show increased stress tolerance and better overall health as a result of a stronger developed root system. For the grower, this means less risk in the vulnerable early growth phase of the plant, more stress-resistant plants and higher yields. In 2017, we successfully introduced B-Mox® technology for carrots and now it is also available for onions.

B-MOX® TECHNOLOGY HAS BEEN SPECIALLY DEVELOPED FOR MODERN CULTIVATION METHODS THAT EMPHASIZE STRONG PLANTS THAT ARE LESS SUSCEPTIBLE TO STRESS. WE ARE PROUD TO NOW ADD ONIONS TO OUR B-MOX® RANGE, ALONGSIDE CARROTS AND -ROOT PARSLEY. OUR RESEARCH CONTINUES. IN THE LONGER TERM, WE ALSO SEE POTENTIAL IN OTHER CROPS.

DR LIESBETH VAN DER HEIJDEN, SENIOR RESEARCHER AT BEJO’S SEED TECHNOLOGY DEPARTMENT

NEW VARIETIES

There are also great developments in terms of varieties. In leafy crops, such as endive and lettuce, there are several new introductions. In the ‘Italian’ crop fennel and cucumber, for example. Some brief highlights:

ALL YOU NEED FOR SALAD – WE HAVE IT!

We already had a strong range in radicchio, treviso, green hearted chicory and lettuce. Now we have also made great strides in endive. We are introducing three new endive varieties: the curled varieties Kimolos (Bejo 3581) for autumn, Krokos (Bejo 3582) for early winter cultivation and the smooth-leafed variety Savalia (Bejo 3222). These new varieties are mainly intended for the French, Italian and Spanish markets and are very suitable for the fresh market and processing industry. This launch completes Bejo’s range of leafy vegetables and further establishes Bejo as a knowledge partner and producer of salad crops.

‘HAVING SEEN SEVERAL TRIALS AND SPOKEN TO GROWERS AND PROCESSORS, I BELIEVE BEJO CAN AGAIN BECOME A REAL ENDIVE PLAYER AND ADD VALUE TO OUR ‘SALAD CUSTOMERS’ FOR THE LONG FUTURE.’

JOLANDA DUINEVELD, AREA CROP MANAGER WESTERN EUROPE

Echo 2024 P. 25 INNOVATIONS

INNOVATIONS

RESISTANCES

In addition, we remain strong on bremia in our lettuce varieties. In 2023, three new bremia physios strains were identified in lettuce. Several tests showed that almost all our commercial varieties with resistance to Bl:16-37EU are also resistant to Bl:1640EU. Or as of now Bl:29-40EU, the new resistance description for highly resistant varieties. Iceberg lettuce variety Cherice, a new variety for northern Europe suitable for spring cultivation, is a promising launch and is being promoted in several countries. Even under poorer growing conditions, Cherice is very productive. It can be perfectly used for both slicing and fresh market, allowing consumers to enjoy a delicious crisp iceberg lettuce early on!

Finally, we highlight our first mini romaine lettuce to launch commercially: Bejo 51-227. This variety was developed mainly for the German mini romaine market, but can also be grown perfectly well in, for example, Spain and the UK. We know mini romaine lettuce mainly for its use in the famous Caesar salad.

CUCUMBER MARVILA

A newcomer to the segment and well suited to Mexico, Central America and Chile. A very vigorous, healthy and productive ‘slicer cucumber’ for spring and autumn cultivation. Also suitable for winter cultivation in subtropical regions. Marvila retains excellent fruit sizes during the harvest period, which is a great advantage.

FENNEL

A versatile crop known and widely eaten especially in Italy. We introduced a number of new varieties for this market, such as Indus and Positano. Both are a nice addition to the current fennel range. Indus is suitable for autumn cultivation, grows easily and has a high yield. Positano has an outstanding tuber with a beautiful white colour and good skin quality. Fennel is increasingly appearing in other European cuisines and is therefore widely exported throughout Italy.

Besides the above-mentioned new introductions, there have been several new developments that we will also hear more about in the coming year. Broccoli Salinas (suitable for Mexico, the United States and Spain) for example, but also carrot Natuna. This has made a huge advance and comes close to our largest variety Nerac in terms of sales. In addition, Rhizomania-resistant beetroot varieties (such as Bazzu, Manzu, Rhizu) will also attract a lot of attention!

With all these introductions, our breeders and researchers have again achieved great results. They have once again proven to be true top athletes who look at the long term to achieve successes for Bejo!

By Daniëlle Bruin

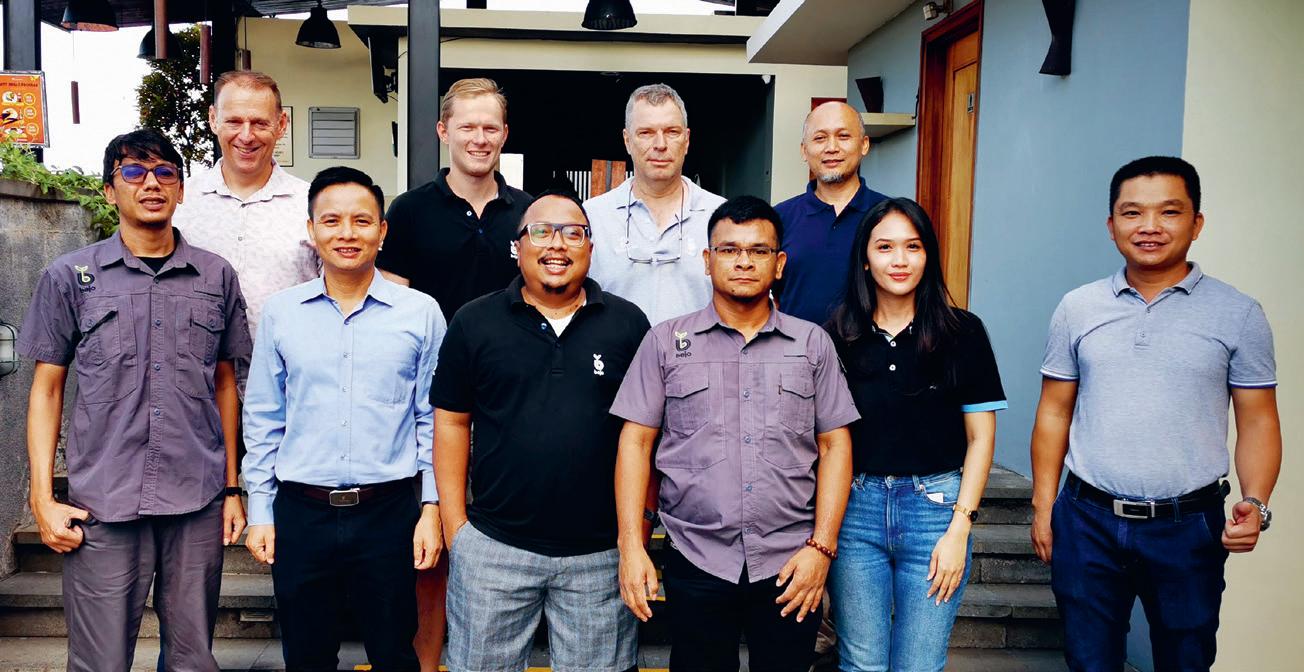

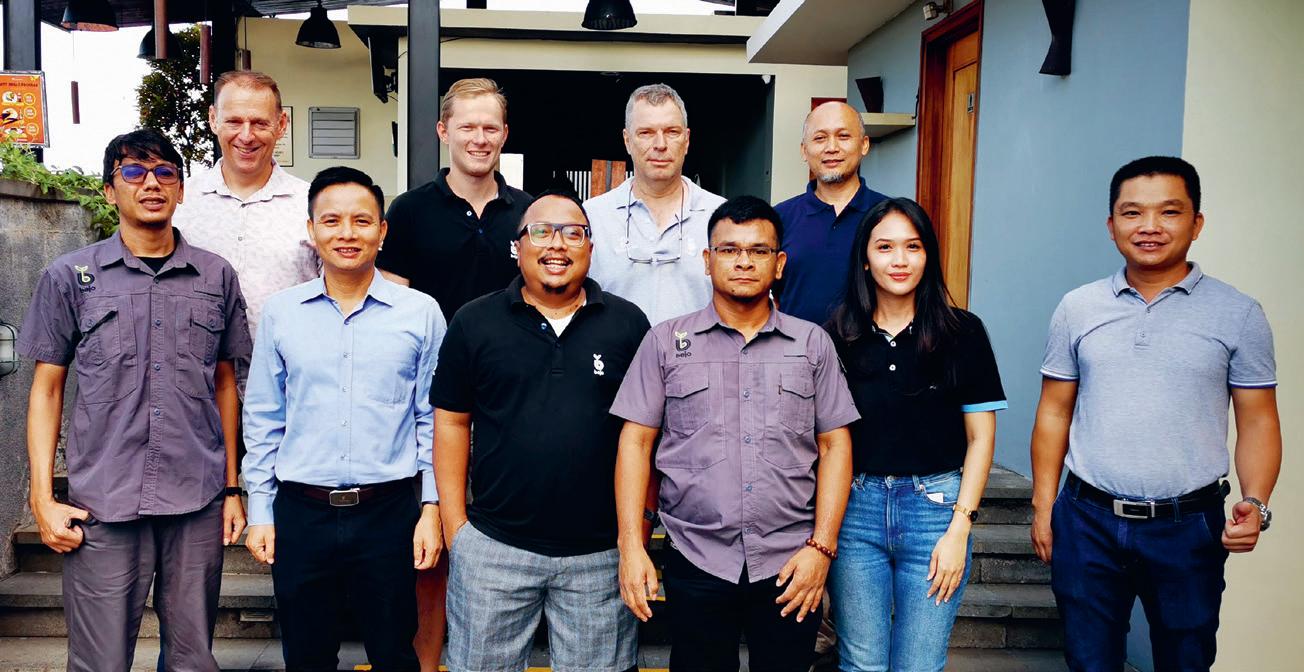

‘THE POTENTIAL IS HUGE: IT’S UP TO US TO EXPLOIT IT’

AGUNG PRATAMA AND DAVID FISHER ON BEJO IN INDONESIA AND SOUTHEAST ASIA

P. 27 Echo 2024 SOUTHEAST ASIA

Since 2017, Indonesia has been on the growing list of countries in which Bejo operates. Managing director Agung Pratama was involved in setting up the subsidiary at the time. Just under seven years later, he looks back on what has been achieved since then, and the opportunities he sees. David Fisher is Area Business Manager for the Northeastern Asian countries and works closely with Agung. They both still see plenty of challenges, but above all they state: “With 280 million people, Indonesia has huge potential.”

Although most activities in Indonesia have remained somewhat under the radar, regular readers of Yapp will have caught the main developments. Such as the establishment of the Bejo Allium Training Centre, where Bejo taught growers how to achieve good yields with shallots from seed. In April 2022, news followed that a new milestone had been reached: under the name PT. Bejo Benih Indonesia, a legal establishment license was obtained.

During those years, things also happened on the personnel front. After a period when he could speak of being “quite busy on your own”, Agung is now supported by a complete team: General Admin and Marketing Support Rania Reforasera, Tri Wiratama (Product Specialist Eastern Indonesia), Kosmas Sitorus (Product Specialist Western Indonesia), Darmawan Susilo (Trial and Regulatory Manager) and Niko Pradekso (Export and Import Specialist).

This allowed Agung himself to advance to a role where he has responsibility for the Southeast Asia area, which includes Thailand and the Philippines, among others. “I am happy with the growth of the team and the confidence I am getting from Bejo,” he says about it. “Having a team supporting is important to develop Bejo’s business in this area. They are contributing very well with good dedication to patch what we are lacking, which is not always easy in a startup environment. “

For practical reasons, mainly to do with the time difference, David represents Agung’s interests in crop meetings and other strategic consultations. It is therefore important for him to be well informed about what is going on in Agung’s market. When asked, obviously joking, whether Agung repays the trust he talks about, David

responds, “Absolutely. The numbers I see from the region are very positive, we managed to double the sales revenue from 4 years ago, and I think we are on a good path.”

Agung adds: “David and I work well together. Bejo’s goal is to develop Asia as a complete market and we are jointly striving to do that. There is also no difference between the two regions in the way we work with our customers, so we can work together on that.”

PORTFOLIO

The approach required for the Southeast Asia area does differ considerably from what Bejo is used to, Agung explains. “A major difference is in the size of the packages. Farmers in Indonesia and other Southeast Asian countries work on a very small scale and cannot afford the larger quantities of seeds Bejo works with. Dealers distribute the seeds in smaller packages and resell them to the farmers.”

That, he knows, is not a way of doing things that is common within Bejo, but it’s supported within the company. “For the future, we have a commitment for management support to expand our activities in Southeast Asia. We already see, for example, that attention is being paid from breeding to developing varieties for tropical climates.”

Not an unnecessary luxury, as sales in Southeast Asia have long relied on varieties that are sometimes decades old, such as broccoli Lucky. “We are busy expanding the portfolio,” says Agung. “In general, we see more demand in Indonesia for new vegetables like kale and beets. In the past period, we have introduced the beet variety Boro, shallot Maserati and onion Trophy, among others.”

Bejo Benih Indonesia

Echo 2024 P. 29 SOUTHEAST ASIA

He also sees huge potential for products like cauliflower and Chinese cabbage: “In that case, it is not so much a question of shipping seeds here. Most of the Bejo range is suitable for continental climates, and few for tropical climates. The support from the breeders is therefore indispensable.”

He continues: “There is also a Southeast Asia development to grow vegetables in greenhouses. Following Vietnam, countries such as Thailand, the Philippines and Indonesia are also increasingly growing vegetables in greenhouses. For instance, the demand for tomatoes has increased exponentially and the Fruit Crops portfolio is expanding. Bejo can also respond well to that.”

GROWING MARKET

One challenge Bejo faces in the southern part of Asia in particular, says David, is the fact that prices are lower than in the rest of the world. That is talked about within Bejo, Agung agrees, while that observation has long since ceased to be the complete truth: “The market is changing, we are developing as a country and the agriculture sector is growing as well. And other companies also see the opportunities: Enza Zaden is based in Malaysia and has representation in all Southeast Asian countries. Rijk Zwaan has an extensive distributor network as well.”

In support of his comment, Agung cites a study by Statista Market Forecast a global statistics and reporting platform. It shows the Indonesian vegetable market is expected to grow by 7.29 per cent annually. Other studies show that the region’s middle class is growing and that consumers are willing to look beyond traditional Asian vegetables.

Therefore, to succeed in Southeast Asia, the focus will have to be on expanding the portfolio. A big cut in prices - which is not according to company policy anywaywould make little sense, according to David: “It doesn’t fit with Bejo’s philosophy, about the quality product we deliver.

And you are encouraging the reselling of seeds from Indonesia to countries in the region. And besides, of course we also have to make money on our seeds.”

FUTURE VISION

In a relatively short time, a lot has already been achieved in Indonesia and surrounding countries. What expectations does Agung have for the coming years, looking at products, for example? “Let me say first of all that I am happy with how things are going now, I can present growing

sales figures. But progress comes in small steps and it is not a matter of sitting down and see what will happen. Every day requires a new solution, it is very dynamic work.”

He continues: “When I look at the whole region, I think we can be a mature company there that is good at certain products. We can’t be a champion in all products, but we can be champion in, for example, key Bejo crops like brassicas and allium.”

David: “Where we took another good step as far as I’m concerned: some time ago we held a meeting in Indonesia with all our Asian colleagues, and Bart Kuin on behalf of the Netherlands. There we gained a lot of knowledge and understanding of the markets in Indonesia and Southeast Asia. Valuable information, with which we provide the crop teams with input they need to develop new products. Or to deploy existing ones. The broccoli Lucky is a good example of this: it was not developed specifically for Indonesia, but turned out to do extremely well there anyway.”

With the right approach, both agree, Bejo can achieve a lot in Asia. Agung, in conclusion: “Progress will certainly take time. But Indonesia alone has 280 million people who are open to trying our products. The potential is huge: it is up to us to exploit it.”

By Jelger van Weydom

Agung Pratama

Position:

Managing Director PT. Bejo Benih Indonesia and Area Business Manager for Southeast Asia

Education:

Queensland University of Technology, Brisbane Australia

Personal life and Hobbies:

Husband and a father of two children. We live in sunny Jakarta; my wife works in Fast-moving consumer goods industry, and our kids are still in school. Dio is in Junior High School while Lulu is still in elementary school.

We love to travel as a family, and I also enjoy traveling. What I like most is the interaction with smallholder farmers across Southeast Asia and to share knowledge with them. Hopping to small provinces in different countries in the region, mostly with propeller planes, is fun though sometimes challenging in bad weathers. I love to play golf during the weekends with friends and enjoying songs from the 80’s.

David Fisher

Position: Area Business Manager Northeast Asia

Education: M.Sc (Plant Sciences) Wageningen University and Research

Personal life and hobbies:

I am drawn to outdoor adventurous activities such as hiking, exploring, fishing, etc. Whilst travelling in Asia I take whatever opportunity I can get to sing some Karaoke with colleagues and customers, because I believe that it is the perfect ice breaker. Thankfully though, my singing skills are not related in any way to our seed sales, otherwise we would be out of business in Asia. I have a mild squash obsession (the sport, not the vegetable), so I play frequently with my friends and occasionally in competitions. In addition to this, I dabble in a bit of tennis, padel, and some other sports.

Echo 2024 P. 31 SOUTHEAST ASIA

“THERE IS STILL PLENTY TO DISCOVER IN TERMS OF

NEW TECHNIQUES”

BERT SCHRIJVER ON DEVELOPMENTS WITHIN PLANT BREEDING

In plant breeding and research, innovation in technology continues, but law and regulation on the authorization to be able to use them are not keeping pace, and worldwide there are major differences in regulation of these New Genomic Techniques (NGTs). Varieties using new breeding techniques are considered GMOs (Genetically Modified Organisms) in some parts of the world and not in others.

In the United States, for example, certain categories of products developed with new breeding techniques are already allowed. In these markets, the principle is that the product should not contain any foreign DNA.

Until 2023, a number of new breeding techniques in Europe fell under GMO legislation by default. Since early 2023, this is changing, driven by goals to achieve sufficient and more sustainable food production. England, for example, established the Precision Breeding Act, under which certain categories are no longer considered GMOs, depending on the process followed and the technique used.

In June 2023, the European Commission decided on a similar proposal. The proposal distinguishes several categories. Varieties that could have been developed with classical breeding, based on naturally occurring mutations, fall mainly into category I. These varieties may be developed and marketed in the European Union (EU) after a relatively simple assessment procedure. For Bejo, this category is relevant and the procedure feasible. The final decision is expected by April 2024.

Our R&D Director Bert Schrijver has been following plant breeding developments for over 40 years. We are curious about his vision and let him have his say in this interview.

WHAT DO YOU THINK ABOUT THE DEVELOPMENTS AROUND THE AUTHORIZATION OF NGTS IN THE EU?

‘Gene editing’ can greatly contribute to the development, acceleration and innovation of new varieties for the future, such as varieties with resistance to biotic stress (disease) and abiotic stress (heat and drought). I am therefore very much in favour of relaxing the regulations. However, I do think it is very important that access to the complete technology is made widely available to all seed companies through the provision of affordable licenses by parties that have the property rights to the technology. This is now the case with CRISPR-Cas, for example. In the past, this has not always been the case with development in breeding technologies, and that made me a lot more reluctant at the time. If the use of NGTs is allowed, it will be important for us to think about what choices we are going to make in breeding. In addition to the aforementioned benefits, it will also give us a chance to breed on, for example, more consumer-related traits such as taste and content matter. We may not have taken these into consideration in the past because the genetic variation was not available or the technical possibilities were too limited.

Echo 2024 P. 33 PLANT BREEDING

THE MOST WELL-KNOWN NEW GENETIC TECHNIQUE IS CRISPR-CAS. BUT IS THERE MORE?

Yes, several techniques are already available, such as MAD7 and TALEN. They all do what is called ‘gene editing’. In other words: very specifically changing, switching off or activating a gene at a certain place. This is faster and much more precise than existing classical mutation techniques. A few years ago Bejo decided to conclude a license agreement for the use of CRISPR-Cas and to make this technique applicable initially for our core crops, onion, carrot, Brassica and beet. Depending on the results, we may consider licensing one of the other techniques in the future as well. There is still much to discover which technique works well for which purpose.

DO YOU HAVE HIGH EXPECTATIONS OF THE NEW TECHNIQUES?

With the new techniques, you have an important additional tool available in your toolbox that you can use in your breeding programs. But in breeding more factors play a role in order to achieve success. After all, even if we know what we would like to develop, that doesn’t mean that we can realize it right away. For example, neck rot (Botrytis) and white rot (Sclerotium) have been global diseases in onion for many years and for which we are quite eager to find a genetic solution. A great goal would be to use gene editing to develop resistance to these diseases. However, we will then still have to find the susceptibility genes that cause the diseases before we can modify these genes.

HOW SOON WILL BEJO BE ABLE TO ADOPT THESE NEW TECHNIQUES?

Bejo arranged the licenses for CRISPR-Cas a few years ago. Because of EU regulations, we are currently only applying the technique for research purposes. This means that we are already gaining experience and can move quickly once we are allowed to apply the technique for the development of commercial varieties.

ARE NEW BREEDING TECHNIQUES SUITABLE FOR ALL CROPS?

In fact, yes. However, it requires that we comprehend the genome sequence of the crop and the particular genes involved. In addition, the technique is applied to individual plant cells that must regenerate into a complete plant via tissue culture after the mutation treatment. This is possible for many of our crops, but not for all of them.

NEW PROPOSED REGULATIONS EXCLUDE ORGANIC CROPS. WHAT IS YOUR OPINION ON THIS?

In terms of regulations, this is strange and, in my opinion, not possible. GMO regulations describe when a variety should genetically be considered a GMO and when not. This means that a variety can only have one status. At Bejo, we have varieties that are offered both conventionally and organically. The only difference is the method of seed production, which evidently does not determine whether or not a variety is GMO. I am curious to see how the legislator will deal with this. The organic sector is divided in opinion about the use of NGTs in breeding. Many growers want to work with varieties that give a better and more secure harvest thanks to technological development. The organic sector in particular benefits greatly from high class varieties. I would like there to remain freedom of choice for them. We can indicate if a variety is developed with NGTs and growers can then choose whether they want it or not.

DO YOU UNDERSTAND THAT APPLYING NEW BREEDING TECHNIQUES CAN BE PERCEIVED BY PEOPLE AS EXCITING?

Yes, I do understand that. But I do continue to find it remarkable that new genetic techniques are already fully accepted in the medical world. Most techniques such as CRISPR-Cas were developed in medical science and are widely used worldwide. In plant development, discussion keeps on arising because people question the introduction of plants into the environment and they question food safety when consumed by humans.

This is not so much about science, or regulations, but it is about sentiment.

WE SHOULDN’T LET THAT STOP US: THE LATEST BREEDING TECHNIQUES CAN HELP US AND OUR SECTOR TREMENDOUSLY. THEY ARE GOING TO BECOME ESSENTIAL IN THE FOOD SUPPLY AND BEJO CAN PLAY AN IMPORTANT ROLE IN THIS.

By Mirjam Both

Echo 2024 P. 35 PLANT BREEDING

CULINARY: DISHES WITH ONION

For every Echo, we ask two colleagues to share their favorite recipe with a Bejo crop. In this edition, Juan from Guatemala and Sara from Morocco make delicious dishes with onion.

Onions are one of the most important vegetables in Guatemalan cuisine. They are often used as a base in stews and sauces, you encounter them in salads and meat is often accompanied by roasted onion. “You could definitely call it an indispensable vegetable” said Juan. “For me, the onion is one of the most versatile vegetables. It adapts well to different cooking methods, gives good flavor to dishes and has good nutritional values. At our house, the onion is never missing.”

There is no shortage of experience; Juan has been working for Bejo Guatemala for 23 years. “I deal with supporting breeding trials of various crops within ‘Farm Parramos,’ as well as other trials that fall under Bejo Guatemala and supporting the Open Days.”

What he enjoys most about his work? Especially the opportunity to learn something new every day. “Nature and crops teach us so much,” Juan says. “In addition, it’s great to see breeders, growers and vendors working together to develop better varieties for now and the future.”

When asked if he enjoys cooking as much as he enjoys his job, the answer is dubious. “I’m not in the kitchen very often. My wife is a great cook and really enjoys trying new recipes. I usually assist and occasionally make the side dishes.” The fajitas with beef and onions is really a traditional recipe. Every family, in every region has its own variation that gives the dish a unique touch and is passed down from generation to generation. The dish is usually made on the occasion of a birthday or anniversary or served on Sundays.”

That onions work medicinal wonders worldwide is evident when Juan also mentions the health benefits of onions. “Onions are used as a natural medicine to relieve stomach ailments and flu symptoms and to combat coughs. So a real allrounder!”

RECIPES

FAJITAS WITH BEEF AND ONIONS

JUAN VINICIO SÁNCHEZ ESCOBAR

Manager Farm Parramos, Guatemala

Ingredients

3 white onions ‘Santamaria’

1 red onion ‘Red Sensation’

1 kg of beef

1 red bell bell pepper

1 green bell pepper

1 yellow bell pepper

½ kg white rice

4 tablespoons olive oil

Half a tablespoon of paprika powder

Salt Pepper

Soy sauce

1 cucumber

2 tomatoes

1 lime (optional)

1 avocado (optional)

Preparation

Add olive oil to a pan and heat over medium-high heat. Meanwhile, season the meat with salt and pepper and let it rest for 15 minutes to allow the meat to properly absorb the flavors.

Cut the onion into julienne strips and the bell bell pepper into slightly wider strips. Then cut the meat into short thin strips and add them to the preheated pan. Also add the onion and bell pepper and cook collectively for ten minutes.

Then add three tablespoons of soy sauce, half a tablespoon of paprika and half a glass of water and cook on low heat for about fifteen minutes. Meanwhile, make a salad of cucumber, tomato and onion. Serve the dish hot with white rice and salad. Add slices of avocado, lime if desired and finish the dish with tortillas and hibiscus rose drink.

Enjoy!

Echo 2024 P. 37

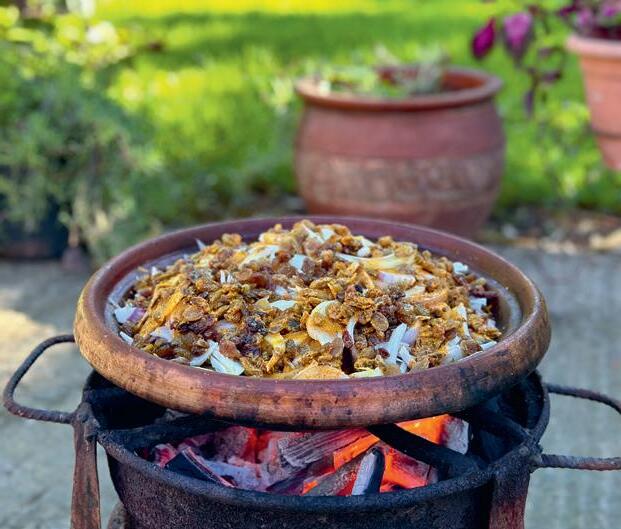

MOROCCAN MEAT TAGINE WITH ONIONS AND RAISINS

SARA ALAOUI

Responsible for logistics, marketing and sales support, Morocco

Ingredients

1 kg of Beef Meat

1 kg Onion (mix of yellow and red)

250 g of red Raisins

Spices; 1 tsp Salt

½ tsp black Pepper

1 tsp turmeric powder

Preparation

1 tsp cinnamon powder

1 tsp ginger powder

1 tsp of ground coriander and parsley

½ cup of olive oil

¾ L of hot water

1 tsp honey (optional)

Soak the raisins in water and mix all the spices and herbs with some hot water and put it aside. Peel and cut the onions into slices. Try to give a conical shape to the onions. Place the meat in the bottom of the tagine and cover with the sliced onions. Drain the raisins and scatter on top of the onions. Pour the spiced sauce on top of the ingredients. Drizzle the olive oil and add the rest of the hot water. Cover the Tagine and let it cook (if not on charcoal, on very low heat).

After an hour uncover the tagine by using a spoon under the lid of the tagine and let it cook. The water will evaporate, and you will obtain a thicker sauce. At this stage you should watch the tagine closely, the cooking water may evaporate quickly, and you risk losing all the sauce. At the end of cooking, you may drizzle some honey on top and let it bubble for a few minutes. Serve the meat tagine hot with bread.

THE REAL SECRET TO A DELICIOUS TAGINE

The rich flavors of Morocco often come from the tagine. The tagine is a fragrant stew and forms the basis of Moroccan cuisine, Sara says. It is perhaps the most widely eaten dish in Morocco. The name refers both to the dish and to the terra cotta pots in which the food is cooked. There are lots of variations with beef, lamb or chicken. But the real secret to a delicious tagine? That’s the cooking time, according to Sara. You have to take your time and cook it long and slow over charcoal or low heat.

Moroccan meat tagine with onions and raisins is a traditional family recipe. It has both sweet and salty flavors in it. Sara didn’t have to think very long about her favorite recipe. “I love visiting my grandparents’ farm in my free time. We often spend weekends there with the family. My aunt is a very good cook and then prepares the most delicious meals. The meat tagine is one of her specialties.”

Sara has been working for Bejo for five years now. “I started as an administration assistant, but have since become responsible for logistics, sales support and marketing activities. I am very happy with my current position.” The best thing about her job? “Happy customers, when an order is shipped and arrives at the customer without delay.” In her free time, you can also find Sara in the mountains. Hiking, trekking and discovering new places, Sara loves it. “Last summer we climbed the highest mountain in Turkey, a very cool experience. You can find pictures of that on Yapp.” Mountains also have a special link to onions. In the Middle Atlas mountains

in the Fes-Meknes region is a special location “El Hajeb”. Local farmers still use this location for the traditional storage of onions.

Onions are a very popular vegetable in Morocco. In fact, onions are indispensable in every household and kitchen. “I love onions myself and use it in almost all recipes, from stews to salads. In fact, onions are so unprecedentedly popular that Moroccans revolt when the kilogram price of onions goes up because it affects local onion consumption.” That onions are healthy is well known to most people. But that onions can also serve as medicine? For stubborn coughs, Sara recommends her grandmother’s recipe. “Mix a squeezed red onion with some honey and take a teaspoon every night. I’ve tried it many times and can assure you it works.”

By Ilse Oorthuis

Echo 2024 P. 39 RECIPES

20 YEARS OF

CENTRO EDUCATIVO GUATEMALA

‘MELANIE BEEMSTERBOER’

BEJO OFFERS AGRICULTURAL TRAINING TO CHILDREN OUTSIDE THE SCHOOL SYSTEM

It was 20 years ago this year that Bejo started a project in Guatemala to give children from agricultural families a chance at a better education. In 2004, Centro Educativo Agricola Guatemala “Melanie Beemsterboer” saw the light of day, a school at which some 24 children are educated each year. Two decades later, just under 400 children have graduated, a second school was opened (in 2023) and - in January of this year - even a third. Mainor España, director of Bejo Guatemala, talks about the developments.

For those unfamiliar with the foundation, a brief background: in many countries, children in rural areas fall outside the traditional school system; this is also regularly the case in Guatemala. At the school established in Parramos (50 kilometers west of capital Guatemala City) these children receive general primary education and practical agricultural education. Bejo also has a branch at this location and open days are organized here every year.

Dozens of students received their diplomas each year and many succeeded in making nice further steps in their careers afterwards. In 2019, for example, the foundation shared that of the 348 successful students, 90 had completed or were still studying further education, 92 were employed and 58 had become self-employed.