Welcome to the Januar y 2023 issue of Marine & Maritime G a z e t t e t h e m o n t h l y m a g a z i n e a i m e d a t Wo r l d w i d e coverage of the commercial marine, shipping and waterbased renewables markets

As we look for ward to a purposeful 2023, with the promise of the maritime world pushing through some of the recent challenges, we hope for continued improvement across the sector and a positive environment for all

Inside this issue, we are, as usual, covering a vast amount of topics, from ‘Anchors, Mooring, Rope & Chain’ on page 28, to the ‘ins and outs’ of ‘Vessel Build, Repair & Maintenance’ from page 20 There is also a quick look at ‘Training, Cer tification & Courses’ on page 42 and from page 36 we also have a ‘peek ‘Marine Sur vey & Inspection’ Anyway, we would like to wish you all best for the coming year and, of cou happy reading

If you have any New Year news, review product launches or absolutely anythi else of interest across the whole mari market, please email it through to me info@- plus com for future consideratio in our for thcoming issues

Peaches - Editor

Peaches - Editor

Just what do we all have to look for ward to in 2023?

MacGregor introduces new electric transloading crane to complete the electric crane series

A s p a r t o f i t s m i s s i o n t o suppor t cust omers with more s u s t a i n a b l e p r o d u c t s a n d s o l u t i o n s , M a c G r e g o r i s proud t o introduce the fully electrically driven heavy -duty transloading crane, with the type name “ TCE”.

The new heavy-duty transloading crane is a r e s u l t o f c o m b i n i n g d e c a d e s o f e x t e n s i v e c u s t o m e r e x p e r i e n c e i n transloading operations The crane is based on the latest generation of the electric drive system with experience of more than 580 electric cranes delivered since 2007

Launching the new TCE crane finally closes the gap in MacGregor´ s electric crane por tfolio, and enables offering the most efficient cranes up to SWL 50t in this demanding segment

Transloading cranes are usually used for heavy-duty work in areas with draft r e s t r i c t i o n s o r l i m i t e d i n f r a s t r u c t u r e Consequently, the cranes typically run 2 4 / 7 t o e n s u r e t h e m o s t e f f i c i e n t handling of bulk material worldwide B y e l e c t r i f y i n g t h e d r i v e s y s t e m , M a c G r e g o r ’ s n e w T C E c r a n e b r i n g s efficiency to the next level In combination with an energy storage system, to get the maximum benefit from the regenerated p o w e r, t h e c r a n e c o n s u m e s a p p r o x i m a t e l y 6 0 % l e s s e n e r g y, compared to a hydraulic drive system. As a result, the CO2 emissions will be reduced by more than 5,500t within a typical lifecycle of a hydraulic crane The a m o u n t o f r e d u c e d e m i s s i o n s i s c o m p a r a b l e t o 1 , 2 0 0 g a s o l i n e c a r s driving 20,000 km per year www macgregor com

Hundes t ed Propeller have been contract ed t o supply t h e i r c o m p l e t e p r o p u l s i o n s y s t e m , r e g e n e r a t i o n solution and thrus t ers t o two additional sail cargo boats in build.

Currently in production at Hundested Propeller are the hybrid marine gearboxes, CP Propellers and propeller shafts, stern tubes and thrusters for TOWT TOWT, a sail transpor tation company, has contracted Piriou to build two 81m, sailing cargo boats that will continue their mission to decarbonise the shipping industr y These new builds will ship goods around the world using wind power “This is a growing market for us Our CP Propellers that enable power regeneration are proving popular for the sail-cargo industr y, ” commented Rune Græsdal Zilcken Sales Manager at Hundested Propeller “Our complete system is designed for this p u r p o s e , c o m b i n i n g o u r l o n g experience in propulsion for sailing vessels, regeneration, and reliable p r o p u l s i o n e q u i p m e n t f o r commercial vessels ” E a c h v e s s e l w i l l h a v e t w o

Hundested CPGD50 Hybrid Marine Gearboxes, Hundested VP10 CP Propellers, and propeller shaft They are also equipped with Hundested O i l g u a r d i n g S t e r n Tu b e s a n d Hundested SFT5 Tunnel Thrusters both of which use biodegradable oil The propellers each with a 2m diameter will provide 2 x 426kw of power The gearboxes are free s t a n d i n g , l o w n o i s e , a n d l o w vibration Regeneration of at least 20% of the power of the propeller is possible when under sail Wo r k i n g w i t h Ly n g a a M a r i n e , Hundested Propeller is supplying a complete control system T h e o f f e r i n g f r o m H u n d e s t e d Propeller fulfills the BV Cleanship criteria

Vincent Faujour, CEO PIRIOU said t h a t t h e c o m p a n y i s “ F i r m l y c o m m i t t e d t o d e c a r b o n i s i n g m a r i t i m e t r a n s p o r t , P I R I O U i s d e l i g h t e d t o i n v i t e H u n d e s t e d Propeller to this great adventure with TOWT, and proud to be able to count on its exper tise and knowhow ”

T h e e q u i p m e n t i s c u r r e n t l y i n production and on target to meet deliver y ahead of the first boat launch in 2023 with the second scheduled for 2024

Kalmar, par t of Cargot ec, has secured an o r d e r f r o m M a p u t o Po r t D ev e l o p m e n t Company in Mozambique for 14 Kalmar T2i t

The order will be in Cargotec’s for th quar ter of last year and the machines are scheduled to be delivered towards the end of the second quar ter of 2023

MPDC, a joint venture between the Mozambican Railway Company and Por tus Indico, was first awarded the concession to run Por to de Maputo in 2003

The company also acts as the por t authority with responsibility for maritime operations, piloting, stevedoring, and terminal and warehouse operations as well as por t planning and development

MPDC currently operates a fleet of over 35 Kalmar forklift trucks and terminal tractors, used for bulk operations

The por t currently handles around 26 million tons a year and is looking to expanding this to 43 million tons within the next decade

“We have been operating Kalmar machines since 2008 and have always found them to be reliable, economical and easy to maintain,” commented Elísio Langa, Maintenance Manager, MPD

“If we are to achieve our ambitious capacity expansion target, we need the best equipment available on the market - this is why we believe that Kalmar is the best choice for us ” he added

Kalmar just concluded an agreement with Uwe Kleinwor t GmbH to supply six Kalmar Gloria reachstackers. The reachstackers come with a lifting capacity of 45 tons

The British Por ts Association has w r i t t e n t o t h e U K Pa r l i a m e n t Environment, Food & Rural Af fairs s e l e c t c o m m i t t e e t o ex p re s s concerns over the Committ ee ’ s recommendations on dredging. Last month the Committee wrote to Ministers with a series of recommendations including reviews of dredging activity, reviews of l i c e n c e c o n d i t i o n s , t h e ‘ m i n i m i s i n g ’ o f dredging until investigations are complete, and new dredging assessments. In their response, the Minister defended the current process for issuing dredge disposal licenses

T h e B PA s t r o n g l y w e l c o m e s t h e Government’s response and is calling on Defra to continue to defend the robust procedures already in place to assess and a p p r o v e h u n d r e d s o f d r e d g e d i s p o s a l licences The Committee’s recommendations has been based upon the idea that there are two competing theories to explain the cause of the mor tality event, one put for ward by regulators and another by a marine scientist

commissioned by the local fishing industr y The latter concludes that dredging activity may have had an impact

Having reviewed a copy of the paper, which has not been formally published, the BPA is concerned that recommendations that could have far-reaching consequences for the por ts industr y are being made based on its conclusions The BPA does not believe the c o n c l u s i o n s r e a c h e d i n t h e p a p e r a r e credible or even reflective of the results found by the researcher The results in the paper suggest that over 5,000 dredge disposal events would have had to occur in a single day to have the impact stated in the repor t The paper also contains a number of factual errors

The BPA’s letter to the Committee offers to p r o v i d e a d d i t i o n a l e v i d e n c e o n t h e impor tance of dredging to the UK economy and on its environmental impact

www britishpor ts org uk

erminal tract ors and three Kalmar forklif t truc ks.

A study from The Royal Institute of Technology in Stockholm says emissions from ships could be reduced by 97.5% by switching from diesel vessels to a new type of electric hydrofoil ship that will be introduced in Stockholm next year.

This year, the Region of Stockholm will sea trial the fastest and longest-range electric ferr y to date; Candela P-12 Shuttle, the world’s first hydrofoil passenger ship

In addition to being fast and comfortable, a new study from Stockholm’s KTH Royal Institute of Technology suggests that ships with electric hydrofoil technology could reduce emissions from marine transport by 97 5% compared to current diesel vessels

In Sweden, domestic shipping emitted roughly 680,000 tonnes of CO2 in 2020, more than trains, buses and domestic flights combined The countr y's leading technical university, KTH, has compared the Candela P-12 Shuttle with the city's diesel-powered vessels in a life cycle analysis The analysis examines the different stages of the product's life; extraction of raw materials, manufacturing and use phase until the product is no longer used, and must be disposed of or recycled The study shows that over a lifetime of 30 years, the carbon footprint of a Candela P-12 Shuttle is 97 5% lower than that of the compared diesel ships According to the authors, the study is the first to demonstrate the difference in environmental impact between electric hydrofoil ferries and traditional ferries It shows that electric flying ferries can play a significant role in the transition to more sustainable maritime transport The combination of using hydrofoils and being powered by electricity is the main factor in lowering emissions And since the Swedish electricity grid is almost free of carbon dioxide emissions, this type of ship has a clear advantage, says Felix Glaunsinger, one of the authors of the study

The hydrofoil technology means that the boat is lifted on wings that ’fly’ under water, eliminating water resistance from pushing the hull through water The hydrofoils reduce energy consumption by 80% compared to conventional ships When the 30-knot Candela P-12 enters sea trials in 2023, it will be the fastest electric ship in the world and also the fastest passenger vessel in the Stockholm public transport fleet With a range of 60 nautical miles, it can cover the archipelago's longest routes Since the flying ferr y doesn't create any wake, the city has granted it an exemption from the speed limits, cutting travel times from 55 minutes to 25 minutes on the maiden route from the suburb of Ekerö to central Stockholm

The KTH study also shows that the Candela P-12 Shuttle has a low carbon footprint from production compared to the diesel ferries examined – an interesting finding, since other electric vehicles, such as cars, often have a heavier carbon footprint from production than fossil fuel-driven equivalents due to the negative impact of manufacturing the batteries

Just like aircraft, our vessels are made to be as light as possible to maximize the number of passengers and performance A welcome side effect is that we ’ re able to use smaller batteries and less raw material, which in turn means a lower negative climate impact, says Erik Eklund, head of Candela's commercial vessels Worldwide, ships account for around 3% of global greenhouse gasses, comparable to the global aviation industr y ’ s emissions Emissions are expected to rise considerably in the coming years despite the International Maritime Organisation’s ambition to cut ships’ carbon intensity by 40% by 2030 www candela com

Fugro has been awarded two geot echnical investigation contracts for the development of the Dutch IJmuiden Ver Sit e V-VI, Neder wiek (zuid) Sit e I and Hollandse Kust (west) Sit e VIII of fshore wind zones. This is the largest campaign under t aken by the Netherlands Ent erprise Agency (RVO) t o dat e and par t of the accelerat ed development by the Dutch Government in line with the Of fshore Wind Energy Roadmap 2030. Once complet ed, the wind farms will deliver a t ot al inst alled capacity of circa 4.7 GW.

The comprehensive Geo-data will be used by wind farm developers as input for preliminar y engineering design studies and future tenders, and will also be available for power cable design, archaeology and marine biology investigations.

Specialist geotechnical vessels from the Fugro fleet will commence the sur veys in March 2023 and continue into the four th quar ter of 2023; fur ther processing, laborator y testing and repor ting of results will take well into 2024.

The fieldwork will comprise investigations of the seabed and subsur face under taken using state-ofthe-ar t techniques and innovations, including Fugro’s SEACALF® Mk V DeepDrive ® system for seabed cone penetration tests and WISON® Mk V Ecodrive Fugro’s data deliver y platform will provide secure and easy client access Increased laborator y capacity onboard the vessels will ensure faster processing of results Subsequent extensive laborator y testing will take place in Fugro’s recently extended laboratories in the UK and Belgium

P e t e r- P a u l L e b b i n k , RV O ’ s C o o r d i n a t o r S o i l C h a r a c t e r i s a t i o n , commented: “By awarding this extensive geotechnical sur vey, RVO is taking another impor tant step in the realisation of the Offshore Wind Energy Roadmap 2030 We are looking for ward to receiving high quality geotechnical results in 3 different Dutch offshore wind farm zones from Fugro”

Erik Jan Bijvank, Fugro’s Group Director Europe & Africa stated: “We are delighted to have been awarded this impor tant project and suppor t the Dutch Government in achieving its new fast track sustainability goals Our unique combination of technical capabilities, resources, innovations and talented people underlines our commitment to secure a safe and liveable world by delivering the best possible data to assist with the energy transition”

Swedish Defense mat eriel organization FMV Direct or Naval Division Patric Hjor th per formed the keel laying ceremony for the series of St an Tug 1706 ICE vessels at Albwardy Damen. Four cust omised ice class harbour tugs are under c o n s t r u c t i o n f o r t h e S we d i s h N a v y t o b e delivered t o Sweden st ar ting in 2023. The ceremony star ted with three coins placed in a stainless steel plate: a Swedish Crown, a Dutch Rijksdaalder and an Emirates Dirham This symbolises the co-operation of the three countries in manufacturing the special tugs The plate with the coins was then welded by General Hjor th to the hull construction The four tugs as ordered by FMV are based on the Damen Stan Tug 1606 The Defense organization ordered an extensive range of equipment to be installed on these vessels and had special requirements for operational capabilities The design of the tugs was there for lengthened to 17 meter The hull is capable of navigating through ice, as the vessels will also be active in nor thern harbours along the Swedish coast They are capable of operating in temperatures as low as twenty degrees below zero Celsius The wheelhouse is equipped with double glazing and high capacity heating is installed Navigation lights will be heated to prevent ice and snow blocking the light Winter days have daylight only for a few hours at nor thern latitudes The hulls will be protected by an extra robust coating system to withstand the chafing of ice along the water line

General Hjor th memorised the naval tradition of putting coins in a vessel for good luck “In the days of wooden sailing vessels, ship builders placed a coin on the keel under the mast before it was raised Today, we like to keep up this tradition to honour and maintain the skills of the seafarers that developed the ar t of navigation and safely sailing a vessel under all circumstances ”

“We are happy with the approach of Damen to answer all of our wishes and demands for the arrangement of these vessels,” the director continued. “They have taken the per formance fundamentals of a workboat to adapt these into a tailormade vessel that is equipped to militar y standards.”

FMV ordered the four Stan Tug 1706 with an option for two extra.

Engaging her impressive 70 t on bollard pull, Azimuthing St ern Drive tug Fairplay -93 will be per forming t owage ser vices in Por t of Rott erdam from the firs t months of 2023 onwards. Fairplay Towage has closed a lease contract with Damen Marine Ser vices, who is able t o deliver the vessel at ver y shor t notice following the contract signing on 27 Oct ober.

The contract marks the third contract that Fairplay Towage concludes with Damen within the last 18 months, encompassing a total of four vessels. The newly built Shoalbuster 2711 with Ice class 1D notation, called Fairplay-37, was delivered to the Group on 13 October Two RSD 2513 tugs, Fairplay-90 and Fairplay-91, are in the final stages of outfitting at Damen Song Cam Shipyard These vessels will be delivered from the yard in this month

The 23 metre long vessel, with a 12 metre beam and 5 40 metre draught, is built to the Damen standardized ASD 2312 design It was constructed at the Damen Song Cam Shipyard in Vietnam to be available for European deliver y in the four th quar ter of this year Just before her depar ture from Vietnam, Fairplay decided to add the vessel to their fleet The possibility of ver y quick deliver y of this ready-built tug enables rapid deployment in the Towage Group’s operations

Two azimuthing stern drive propellers in nozzles each span a diameter of 2 8 meter Power comes from two Caterpillar 3512TA engines, providing total of 5102 horsepower propulsion Twin fins under the hull allow for side stepping as a special manoeuvre in narrow harbours An exhaust gas after treatment system is installed to ensure the vessel’s compliance with IMO tier III emission standards The vessel has a FiFi-1 fire extinguishing system that can spray up to 1400 cubic meters of water per hour www damen com

IHC Dredging and Coc hin Shipyard ha ve signed an agreement for a design and engineering, hardware and suppor t pac kage for the licensed cons truction of a Beagle® 12 trailing suction hopper dredger (TSHD).

The TSHD will be built by Cochin Shipyard for the Dredging Corporation of India (DCI) With the construction of this Beagle® 12, a high-capacity dredger (12,000 m3), DCI expands their fleet of trailing suction hopper dredgers

Ronald van Son, Director Dredging Custom Vessels at IHC Dredging: “We are proud to be par t of the 'Make in India' initiative by working together with DCI and Cochin Shipyard, India's finest shipyard, on the first Indian built dredger of this size and capacity With suppor t being organised from our local office and workshop in Mumbai ”

IHC Dredging has been active in India for almost 100 years, building the first dredger in 1926 Ronald van Son: “This new order underlines the good and longstanding relationship with DCI. We have built all ten trailing suction hopper dredgers in their fleet Our ambition is to build strong relationships with our customers Now and in the future Therefore, we are ver y keen to commence this new path of continued par tnership within the Atmanirbhar initiative ”

With the construction of this new TSHD for DCI, IHC Dredging is looking for ward to become the technical par tner of Cochin Shipyard Ronald van Son: “This par tnership speaks to the exper tise and experience we have in designing and engineering TSHD’s and state-of-the-ar t equipment, also par tly locally build at IHC Dredging in Mumbai In this way we are able to suppor t DCI in the growing demand for (por t) maintenance and dredging ser vices with sustainable solutions ” The new dredging vessel will be used by DCI for safeguarding and improving the accessibility of the por ts and water ways of India

The new vessel to be built is par t of the Beagle® series of medium sized TSHDs These TSHDs have a hopper volume ranging from 4,000 to 12,000m3 are designed for a wide range of dredging activities and are known for their high efficiency and maximum uptime

Colebrook Of fshore (CBO) a char t ering, sale and purchase, and market int elligence brokerage, and par t of the CSO Marine Group, has advised Global Marine Group (GMG) on their successful divestment in the of fshore power cable market.

The divestment strategy includes the sale of Global Symphony, a 130.2m purpose-built IMR and ROV suppor t vessel, which has been par t of GMG’s fleet since 2017

Sam Stout, Managing Director at CBO, said, “Colebrook Offshore worked closely with GMG, drawing on our in-house market intelligence to advise our client on their divestment strategy Utilising our comprehensive knowledge of the offshore vessels market, and our extensive network of industr y relationships, we successfully suppor ted a complex transaction involving a range of strategic assets ” www colebrooloffshore com

Damen Shipyards signed a contract t o deliver a CSD650 t o an Indonesian dredging operat or earlier this month. This giant dredger will be the largest st ationar y dredger owned by an Indonesian operat or. The vessel will operat e in a por t expansion project on the island of Kalimant an. A swif t deliver y was possible due t o Damen’s st ock program.

The stationar y dredger has been sold to Pelayaran For tuna Nusantara Megajaya (PFNM), a company that also operates the dredger Barito Equator. This 2,500 m3 Trailing Suction Hopper Dredger was built in Indonesia 10 years ago using a Damen design package To date, the Barito Equator remains the largest hopper dredger ever built in Indonesia. But now the same operator can add a new record: this CSD650 will be the largest Cutter Suction Dredger in Indonesia and will be able to reach unprecedented dredging depths. The stationar y dredger is an expansion of the operators current fleet Damen’s standard CSD650 will be fitted with a 700 kW cutter head which can work in water depths up to -25 m The suction ladder incorporates a submerged dredge pump, which works in series with the inboard dredge pump. 3,938 kW of installed power ensures an impressive discharge distance and dredge production of 7,000 m3/h on average The overall length of the dredger is 70 m, resulting in an impressive swing width of 71 m, and it has a weight of 660 tons.

Currently, the new CSD650 is being finalized and equipped to specification in the Netherlands The dredger will be transpor ted from the Damen Dredging Equipment shipyard early next year. Gysber t Boersma, Damen Shipyard Sales Manager, states: “It is a real pleasure to be able to deliver the dredger at such a shor t notice. Our fruitful discussions with the Indonesian owner have resulted in the deliver y of a complete dredging package including spares and training This will all ensure a fast deployment of the new dredger on site”.

www damen com

Windcat, Europe’s market-leading of fshore personnel transfer company recently announced an order for the c o n s t r u c t i o n o f a s e r i e s o f hy d r o g e n - p ow e r e d Commissioning Ser vice Operation Vessels (CSOVs), with Damen Shipyards.

The ‘Elevation Series’ CSOVs have been designed by Damen Shipyards in cooperation with Windcat and CMB TECH The result is a revolutionar y new design with increased capabilities and flexibility compared to existing vessels The vessels are 87 m long, 20 m wide, can accommodate 120 people on board and will be powered by hydrogen The series will be delivered from 2025 The CSOVs will be built at Ha Long Shipyard, Vietnam, and will be delivered to Windcat Offshore, a new business unit within Windcat, which will focus on offshore energy commissioning and ser vices Initially, two vessels have been ordered with options for fur ther vessels A CSOV is a vessel that remains in an offshore wind farm for an extended period of up to 30 days, providing maintenance materials and housing technicians in hotel-style accommodation This next step in Windcat’s journey builds on Windcat’s 20 years of experience in the offshore renewable energy sector and follows four years of market and vessel design evaluation To significantly reduce the vessels’ CO2 footprint, Windcat and CMB.TECH, will provide the same dual fuel hydrogen technology for the Elevation Series as on board of the Hydrocat, the world’s first hydrogen powered CTV (Crew Transfer Vessel) This approach will also make a critical contribution to the development of rules and regulations related to the use of hydrogen as a fuel in medium-sized vessels “Damen is committed to becoming the world’s most sustainable shipbuilder and is a recognized pioneer in the development of Ser vice Operation Vessels, having designed and built one of the world’s first dedicated walk-to-work vessels 5 years ago These vessels have set a benchmark in the Offshore renewables market and are still per forming ver y well in the Nor th Sea We are proud to work together with Windcat and CMB TECH to build these vessels and make the groundbreaking design of the Windcat Elevation Series come to life ” commented Joost van der Weiden of Damen Shipyards

“After 20 years of developing the CTV business in all aspects of vessel design, construction and operations, we star ted 4 years ago to lay the foundations for the creation of a ground-breaking CSOV design I am pleased that we have been able to expand our CSOV sector specific knowledge with the initial appointment of Stephen Bolton as Managing Director Windcat Offshore. With this order we are now positioned to offer best-in-class ser vices to both the CTV and CSOV sector on a side by side basis “ added Robber t van Rijk, Managing Director and Co Founder of Windcat “We are ver y proud and happy that less than two years after the integration of Windcat into the CMB family, we are able to take a significant strategic step by investing in these state-of-the-ar t CSOVs and leverage CMB TECH’s hydrogen know-how to bring hydrogen to the off-shore wind industr y I would like to thank Damen Shipyards for the excellent collaboration so far and am convinced that this is the beginning of a strong and longterm relationship between our groups ” said Alexander Saver ys, CEO of CMB “CMB and Damen are family companies that both value long lasting relationships where collaboration takes place in an open and constructive manner Both organizations also see a bright future for the offshore renewables sector and demand for vessels that fulfil the aspirations of their end clients for energy that is clean throughout the production and deliver y process We look for ward to a successful and long lasting relationship with CMB TECH ” added Arnout Damen, CEO Damen Shipyards The Elevation Series will be equipped with the latest gangway, crane, thrusters, hybrid batter y technology and offshore charging capability, among other industr y-leading features to be announced in the next weeks

“I truly believe the Elevation Series is an industr y-leading design, a real game changer A design that will lead the sector in exploring hydrogen as a fuel while delivering best-in-class per formance and flexibility Only with the combined team of Windcat, CMB TECH and Damen has this been possible Together we have addressed the current and future CSOV sector needs while star ting to answer the greater maritime industr y ’ s challenge: how to significantly reduce our industr y ’ s greenhouse gas emissions ” said Stephen Bolton, Managing Director Windcat Offshore www windcatworkboats com

L i n d l ey M a r i n a s r e c e n t l y l a u n c h e d t h e n ew cat alogue of floating solutions for the cons truction of marinas, leisure doc ks and fishing por ts.

Lindley, who specialize in the design and fabrication of floating equipment, is expanding its range of reinforced concrete pontoons with wave attenuators and continuous floatation pontoons in units up to 6 meters wide and 20 meters long The catalogue also incorporates the recent development of its new aluminium extrusion with a 26 kg/metre profile used for fixed pedestrian structures

From the integral construction of marinas to small piers, Lindley Marinas provides exper t advice and robust solutions tailored to customers requirements. Suppor ted by offices in Lisbon, Barcelona, Vigo and Rio de Janeiro, Lindley offers one of the most extensive ranges of pontoons in the market, including concrete, steel, aluminium, and timber pontoons

Recently, technical and sales capabilities of the companies have been reinforced with the acquisition of the marina production unit of AISTER

Orkney Harbours is an enviable, strat egic location with its full pot ential yet t o be unlocked. Situat ed in the nor th of Scotland the Orkney Islands and the surrounding seas have unique conditions which present an indigenous source of wind, wave and tidal power. Orkney’s of fshore wind of fering, for both fixed and floating, is incredibly strong d u e t o i t s n a t u r a l c a p a b i l i t i e s a l o n g s i d e t h e r e c e n t announcement of ScotWind by Crown Est at e Scotland, which provides the provides for and strengthens its future capabilities.

Orkney Harbours has developed a Masterplan which was launched in 2020, a large par t of which focuses on infrastructure to suppor t offshore wind It shows how Orkney can act as a hub for the whole life cycle of windfarm development from assembly, installation, marshalling, operations and maintenance through to decommissioning However, progress doesn’t happen overnight Those developing floating wind oppor tunities need to book por t infrastructure well in advance of the star t of windfarm installation Wind has shaped out islands over eons, sculpting and adapting the land Its incredible power has driven people to us and turned us into the adventurous, for ward looking community we are today Now it will drive on to power our future And we are ready to harness that power ful song and let it sing across all 4 winds! Our Masterplan sets out the blueprint for the future of Orkney and the winds of change that shape it State-of-the-ar t developments at Scapa and Hatston will make Orkney a world-leading innovation centre, suppor ting the needs of the renewables sector now and into the future But what does this really mean for Orkney? Our community? Plans like our landscape may take years to form but the benefits will be enjoyed and appreciated by generations to come The Masterplan has been created with the local community at its hear t, outlining a journey towards better oppor tunities, safeguarding existing jobs as well as creating new roles It is an ambitious blueprint that provides a framework for the long-term future of the island Greater investment, more skilled jobs, better oppor tunities, the list goes on - but they’re all designed to allow Orkney to evolve again into a more prosperous place to work and live In preparation for this Orkney has identified that constructing new por t infrastructure In July 2022, Orkney Harbours joined the Offshore Wind Por ts Platform, widening the global audience and increasing awareness surrounding the innovation across the Scottish island The construction of new deepwater quays will provide a foundation for current and future developers to pitch round Orkney’s waters and create a new generation of floating wind infrastructure Paul Olvhoj, business development manager at Orkney Harbours comments: “Orkney and its surrounding waters is naturally set up to suppor t the future of floating wind development Future development will not only improve renewable energy infrastructure for the UK and beyond, but will also place new systems in the local community in Orkney which will lead to a creation of long-term jobs and economic benefits at both a local and national level.

“Scotland has a great deal of potential floating wind resources, with its strong offshore winds providing the ideal conditions to harness this power ful natural resource. ” www.orkneyharbours.com

The large contract with Med Marine will deliver heavy duty, Escor t Series t owing winc hes for nine escor t tugs equipped with azimuth s t ern drives.

The large contract with Turkish tugboat builder Med Marine will deliver heavy duty, Escor t Series towing winches for nine escor t tugs equipped with azimuth stern drives.

“I want to thank Med Marine for their excellent cooperation over the past few months it has taken to negotiate these significant contracts,” said Ar to Salo, senior sales manager for towing winches, Kongsberg Maritime

“I’m ver y pleased that we were able to close such a large deal and I would like to extend my gratitude to the regional team in Turkey, who worked hard on this contract and were key to the final negotiations.” This order follows on from a contract signed earlier this year to supply winches for seven tugs to the same yard The new agreement brings the total number of Kongsberg’s winch supply contracts for Med Marine to 16 shipsets

Kongsberg Maritime’s Escor t Series of towing winches are a popular choice for tug operators in terminals and harbours around the world and there are hundreds of tugs in operation that are fitted with Kongsberg’s towing winches

The two companies have a longstanding relationship, with many Med Marine-built tugs featuring Kongsberg technology and equipment

“We are pleased to collaborate with Kongsberg Maritime on these projects We are confident that this par tnership will greatly enhance the mutual interests of both par ties in the development of a successful business relationship,” said Er tuğrul Çetin, procurement & technical group manager at Med Marine “Together with Kongsberg, we believe we are in an ideal position to meet the growing customer demand for Med Marine’s cutting-edge tugs ” www.kongsberg.com

Sanmar Shipyards delivered four tugs during the final week of 2022 rounding of f an extremely successful year, which saw the Turkish tugboat-builder deliver a t ot al of 30 tugs t o operat ors across Europe, the Middle East, Australia, South and Central America and Asia, along with others t o its domestic market in Turkey

The last tug to be delivered in 2022 was YENICAY XVI to Turkey based Marintug, where it was been renamed ADAKALE by its new owners The RAscal 1800 Class of compact tugs have been developed exclusively for Sanmar by world leading Canadian naval architects Rober t Allan Ltd, and are designed to address the challenges faced by modern, high-per formance Zdrive line-handling and smaller ship-handling tugs

They are intended for low manning and have a high standard of machiner y automation which enhances their green credentials Measuring 18 7m LOA, with a moulded beam of 9 2m and navigational drafts of 3 95m, ADAKALE is capable of ship assist work, line-handling, general harbour ser vice and coastal towing with highly manoeuvrable proper ties at slow speeds Ship assist work is generally done over the bow whereas general towing can be done over the bow with the winch or over the stern with either towing hook or towing winch

ADAKALE’s two Caterpiller C32 four stroke main engines each produce 970kW at 1 800 rev/min to drive standard production, 360-degree azimuthing Veth VZ 900 thrusters, enabling a bollard pull ahead of 32 tons and a speed ahead of 12 knots. The tug’s tank capacities include approximately 34 000 litres of fuel oil and 5 900 litres of fresh water It has been constructed in accordance with American Bureau of Shipping (ABS) requirements with the notation X A1, X AMS, UWILD, Towing Vessel, QR and FF Capable Sanmar has also sold and delivered Bozcay VI, another compact tug previously working in its own fleet, to Turkey-based operator Yalpaş where it has been renamed YALOVA 5 Based on the RAppor t 1900SX design from Rober t Allan Ltd, YALOVA 5 is a twin-screw, diesel-powered tug, designed for maximum efficiency in the per formance of ship-handling duties for seagoing vessels Measuring 19 3m LOA, with a moulded beam of 8 2m YALOVA 5 is powered by two Caterpillar C32 main engines, each achieving 970kW at 1 800 rev/min to enable a bollard pull ahead of 33 tons and a free running speed of 12 knots.

Ruchan Civgin, Commercial Director of Sanmar Shipyards, commented: “As 2022 comes to an end, we can reflect on a good year at Sanmar Shipyards with healthy production figures at both our Altinova and Tuzla shipyards, which actually drew 30 all in terms of number of boats delivered With our third purpose-built yard coming on line in the not-so-distant future specifically to produce and fur ther develop our low and no emission tugs of tomorrow, I am delighted to be able to repor t that prospects are looking good for 2023 and beyond ”

Damen Maaskant and New Zealand b a s e d s e a f o o d c o m p a ny S a n f o r d Limit ed have signed a contract for the design and build of a new scampi vessel. Both companies joined in a close co-operation for the development of a purpose equipped and laid out vessel for Sanford Limit ed’s operations in the Southern Ocean. The vessel, based on the Damen Sea Fisher 3210 will be built t o the lat es t s t andards in t er ms of sus t ainability, comf or t and safety.

Pim Schuurman, Regional Sales Director of Damen Shipyards: “We are ver y grateful that Sanford gives us the confidence by ordering a fishing vessel that will contribute to Sanford’s target of reducing the carbon footprint from its direct operations at sea ”

The fishing vessel, with a diesel-electric system and modern freezer, will be built in Stellendam at Damen Maaskant, the Damen yard specialised in fishing vessel newbuild and repair since 1948. Deliver y is expected in 2025.

For this assignment, Damen can show what they are good at: be a worldwide frontrunner in the development and production of innovative vessels that enable fishermen and fish farmers to m a x i m i z e t h e r e t u r n s f r o m t h e i r p r o f e s s i o n ; s u s t a i n a b l e cultivation, har vesting and catching of food from the sea

The unique vessel design for the scampi fisher vessel was created as a result of intensive and pleasant cooperation between Sanford and the management and technical teams of Damen Shipyards, Damen Maaskant and the Damen Representative for New Zealand. www.damen.com

At the annual Damen Maritime Fes tival held in Gorinc hem at Damen’s headquar t ers, of fshore ser vices provider High Speed Transfers (HS T) Marine and Damen Shipyards announced that a contract has been signed for the supply of three new Fas t Crew Suppliers 2710s.

The three vessels will be fitted with 190kW batter y arrays that will enable them to operate emissions-free both when in harbour and when loitering offshore awaiting the retrieval of their technicians In zero-emission mode, the vessels will be propelled by an electrical motor that is connected via the gearbox (PTI) to the propeller shaft When sailing in diesel-mode, the electrical motors are able to work in reverse as PTO and can be used to charge the batteries and provide the hotel load for the vessel

With the FCS 2710 Hybrids already in build at Damen Shipyards Antalya, Turkey, in anticipation of future demand, the deliver y of all three will take place in early 2024 HST will be closely involved throughout as a key par t of the build team, with all involved working together to ensure their success Once operational, the FCS 2710s will receive ongoing suppor t and maintenance ser vices from Damen’s ser vice hub located at Por tsmouth on the UK’s south coast, as par t of Damen’s commitment to providing through-life suppor t for its vessels They will also be IMO Tier 3 compliant and feature all the latest upgrades made to the class based on customer feedback and technological advances

The development and build of these innovative crew transfer vessels is a milestone in Damen’s goal of providing a full range of sustainable vessels to suppor t the offshore clean energy sector In order to meet market demand, Damen is also investing fur ther in building additional stock vessels both at Damen Antalya in Turkey and in Damen Song Cam shipyards in Vietnam

The deliver y will also enhance the low emission credentials of HST Marine’s fleet of crew transfer vessels An existing and valued customer of Damen since its foundation, HST Marine is now par t of Purus Wind, the offshore wind business of Purus Marine, a company that provides lowcarbon maritime transpor tation and infrastructure systems HST’s current Damen fleet includes conventional FCS 2710s and a Multi Cat 2309

“The addition of the FCS 2710 Hybrids to our fleet suppor ts our strong commitment to providing low-carbon solutions to our customers in offshore wind,” said Tom Nevin, CEO of HST and Business Head of Purus Wind “We are delighted that HST Marine is the inaugural customer for this ground-breaking CTV class,” added Damen’s Frederik van der Linde “Tom and his team brought the first FCS 2710 into the market and now they are acquiring the first 2710 Hybrid Their foresight and confidence in Damen has played an impor tant role in the evolution of the modern CTV and we are ver y proud that they are taking deliver y of these highend vessels It is testimony to the strength of our relationship based on mutual trust and cooperation ”

With roots dating back to 1987, Dales Marine has been servicing the shipping, oil and gas, chemical, and power generation industries with bespoke engineering services, within the shortest lead time to the highest standard.

Providing specialist shipping solutions in dry dock and steelwork, maintenance and ship repair, Dales Marine is located within major Scottish ports and provides unrivalled access for clients 24/7, 365 days a year.

Harbour tugs Dóris and Tétis are successfully operating in the Por tuguese Por t of Leixões, near the city of Por t o, following ver y shor t t erm deliver y by Damen Shipyards. The vessels can per form a wide variety of t owing, pushing and indirect t owing operations that ideally suit the confined space inside the harbour.

Both Reversed Stern Drive tugs are built to the standard Damen design RSD 2513 After Damen won the tender process from APDL (Administração dos Por tos do Douro), the Por tuguese por t authority of Douro and Leixões late 2021, the shipyard group was able to deliver both swiftly. Both vessels arrived at the Por t of Leixões 13th of June 2022 and are operational under Por tuguese flag since July 21 this year The vessels are equipped with the Damen exhaust after treatment system to comply to IMO Tier III emission standards, achieving dramatic reduction of NOx emissions As the Por t of Leixões is situated nearby urban areas, this is an impor tant feature and a clear goal for APDL As a special feature agreed for this project, the emissions during the first years of operations will be monitored as well the operational profile Analysis of the tug’s operations will provide insight in the possibility of the employment of full electric tugs, that APDL may consider Clean but mighty, the RSD 2513 vessels have a 70 tonne bollard pull. The design features Damen’s revolutionar y Twin Fin skeg to enhance directional stability and to provide a higher indirect towing force This makes the vessel ideal for confined harbour spaces Renowned for its versatility and manoeuvrability, the RSD Tug 2513 can per form bow to bow towing, as a tractor or escor t tug. Vessels are also equipped with FIFI 1 notation, thus providing an additional safety feature for por t operations Notable safety characteristics include the special safety glass at the wheelhouse, whereas crew comfor t is enhanced thanks to reduced noise and vibration levels

The RSD Tug 2513 vessels are equipped with ‘Damen Triton’, a digitalised remote monitoring platform that collects data from sensors throughout the vessel, helping the operator to maximise operational insight and to improve ef fectivity, ef ficiency and utilization By using Triton monitoring and Triton Fuel repor ts, APDL is able to see where they can save fuel, reduce emissions and optimize operations Because Triton is able to run various data driven applications, independent of supplier, APDL is ready to use Triton as a state of the ar t digital platform to suppor t the operation of these vessels

Carlos Gonzalez Mar tin, Damen Sales Manager for Por tugal, comments: “We are really proud to see these great harbour tugs operating for APDL in Leixões We see it as a per fect match to the operational requirements but also with the vision of sustainable goals Definitely these are the most environment-friendly harbour tugs stationed in Por tugal so far.”

Mr Nuno Araújo, President of the Board of Directors of APDL, comments: “The acquisition of these state-of-the-ar t tugboats fulfils the purpose of APDL, to decarbonise the por t activity, reducing emissions of the por t of Leixões operations ”

The Damen RSD Tug 2513 is available with hybrid or full electric propulsion. The first fully electric RSD-E Tug 2513 has recently been awarded ‘Tug of the Year’ at the ITS conference www damen com

o floating of f shore wind energy

and anc

sys t ems.

Apar t from input on research priorities, DOE also highlighted information on state-of-the-ar t innovative technologies, state-of-thepractice common operations, and aspirational targets to help meet deployment goals.

The DOE also commented that mooring and anchoring topics of interest include technologies, methods, per for mance, costs, supply chain, U S manufacturing, workforce, and stakeholder impacts.

This RFI is intended to inform WETO’s strategic planning, including future research funded by the Bipar tisan Infrastructure Law aimed at advancing floating offshore wind energy systems toward cost-effective commercialization and industr y scale-up

The Biden-Harris administration announced its intent to use $30 million from President Biden’s Bipar tisan Infrastructure Law to fund research and development projects that will lower costs for wind energy projects on land and offshore to benefit communities across the countr y Wind energy accounted for more than 9% of total domestic electricity generation in 2021 and will play a significant role in achieving President Biden’s goals to reach 100% clean electricity by 2035 and a net-zero-emissions economy by 2050

"Floating offshore wind energy will be a key contributor to federal and state offshore wind deployment targets and to supplying clean energy to coastal cities. DOE’s Floating Offshore Wind Shot seeks to harness untapped renewable energy potential above the sea, promote an equitable clean energy transition, and create jobs and economic oppor tunities for U S communities," a DOE spokesperson commented

The Biden administration also said it would hold the first-ever offshore wind lease sale off the coast of California, which will be the first-ever offshore wind lease sale on the U S west coast and the first-ever U S sale to suppor t potential commercial-scale floating offshore wind energy development

The administration said the sale would be critical to achieving the Biden-Harris administration's deployment goals of 30 gigawatts (GW) of offshore wind energy by 2030 and 15 GW of floating offshore wind energy by 2035

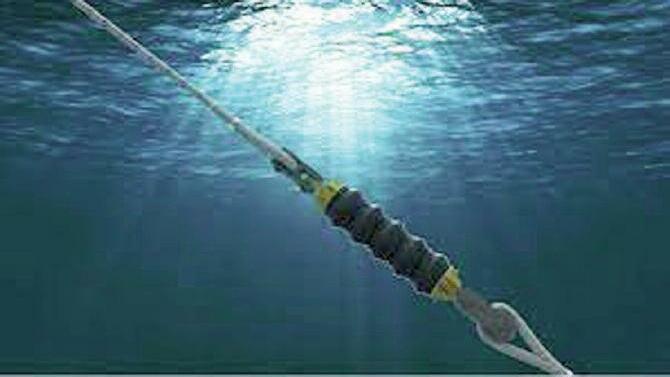

Bridon-Bekaer t

"As par t of this strategy, Bekaer t today announces an equity investment in TFI Marine (Technology from Ideas), a leading mooring innovator, which has responded to the market needs with essential, patent-protected load reduction devices for floating offshore wind and offshore fish farm mooring systems," the company said

According to the released statement, TFI Marine has developed and successfully demonstrated SeaSpring, ‘ a game-changing’ polymer-based mooring component that significantly reduces the mooring loads and fatigue experienced by floating platforms as a result of wind thrust and wave motion

The company said that the SeaSpring load reduction device brings down the footprint, costs, wear, and maintenance of mooring systems Moreover, the company said the SeaSpring is a self-powering device, enabling permanent digital monitoring of mooring systems

The investment is being used to construct TFI Marine's first manufacturing plant in Ireland to scale up the SeaSpring business to industrialization

The par tnership also launched a commercial collaboration between Bridon-Bekaer t Ropes Group (BBRG) and TFI Marine, whereby a smar t solution of BBRG synthetic ropes equipped with TFI load reduction devices will be introduced to the market

"BBRG's 'MoorLine' synthetic ropes have been specifically designed for floating offshore wind applications where customers demand reliable ropes that ensure floaters stay put in the most challenging conditions The combined exper tise of BBRG and TFI Marine will expand the value creation potential of the mooring solution as it will increase the overall lifespan of the mooring system and significantly reduce the maintenance costs and mooring footprints," a company spokesperson continued Christof Dewijngaer t, General Manager Synthetic Ropes of Bridon-Bekaer t Ropes Group commented: 'We are proud to work together with TFI Marine, who have innovated a game-changing solution that reduces peak loads and strongly compliments the synthetic ropes from BBRG for permanent mooring systems We see enormous potential in offering our shared customers a combined solution in what is to become an exciting new industr y Together, we will continue to develop the most advanced solutions in the floating offshore wind mooring market '

Noel Halloran, Executive Chairman of TFI Marine added: “This par tnership with BBRG will change the way people think of mooring solutions forever The smar ter mooring solutions for the future will combine TFI Marine's SeaSprings and BBRG synthetic rope along with several more initiatives currently being worked on With the BBRG team, we have a par tner who is totally committed to market change We look for ward to working with them Their suppor t is timely and essential to accelerate the deliver y of our solutions globally '

Bekaer t said that based on announced and committed investments globally, the current pipeline of floating offshore wind (FOW) projects represents a capacity build-up of 121GW, of which 15GW will materialize during this decade "This would represent an addressable mooring market investment of at least €1 4 billion before 2030 and exponential growth from then onwards Bekaer t's business segment Bridon-Bekaer t Ropes Group (BBRG) has established a strong position in the deep-water mooring market with synthetic rope solutions These BBRG solutions are a critical component in first demonstrator FOW projects in Japan, France, US, UK, China, Spain, and Nor way," a spokesperson added

Ropes Group recently announced it had concluded an inves tment and commercial p a r t n e r s h i p w i t h T F I M a r i n e , D u b l i n , t o accelerat e the digit al-enabled mooring solutions market for floating of fshore wind farms.

Marlow Ropes is turning the tide on how it manufactures rope – the energy it uses, the mat erials it sources and the wast e it generat es.

As a leading global producer of products for the leisure marine and other industries that depend on rope, the company ensures it operates an efficient and ethical plant where sustainability is an impor tant focus While high per formance has always been at the core of Marlow Ropes’ mission, the past few years have seen an ever-increasing focus on environmentally sound manufacturing Marlow has reduced reliance on fossil fuels by making all its standard synthetic rope products using sustainably sourced fibres manufactured from waste plastic or natural materials

To make sure it can produce products that are both high per forming and eco-friendly, the company has been collaborating with 11th Hour Racing Team – an organization that not only shares a passion for sustainability but where ocean stewardship is central to its ver y existence “11th Hour Racing Team has worked with us to test various high per forming Grand Prix products and this includes our sustainable material range, ” said Paul Honess, Marlow’s Leisure Marine sales director “The MGP series is sustainable by nature, and this is a priority that many of the top race teams now rank ver y highly in their campaigns Rope production is much lower as smaller customized lengths are manufactured,” Honess explains “Ever ything is cut to length, made to order, which ensures less waste and less energy is used ”

As a rope-maker, Marlow recognizes that its activities will have an effect on both the local and global environments, and the company is committed to responsible manufacturing practices With this in mind, Marlow’s innovation team has developed a line of eco-conscious products that embodies its ‘ green ’ initiative under the BLUE OCEAN® brand umbrella The company ’ s BLUE OCEAN® brand is not only its mark of sustainability but also an assurance to all stakeholders of its on-going mission to conduct operations with an eye toward preser ving the environment for future generations www marlowropes com

D i v e r s e M a r i n e a n d N R M a r i n e S e r v i c e s a r e p r o u d t o a n n o u n c e t h e c o n t r a c t s i g n i n g t o c o n s t r u c t t h e f i r s t o f c l a s s D i v e r s e M a r i n e 27 m C T V ( C r e w Tr a n s f e r Ve s s e l ) .

T h e i n t e r n a t i o n a l e x p a n s i o n o f t h e o f f s h o r e w i n d s e c t o r i s c r e a t i n g s i g n i f i c a n t o p p o r t u n i t i e s a n d c h a l l e n g e s f o r t h e m a r i t i m e s u p p l y c h a i n a n d r e w a r d i n g o p e r a t o r s , b u i l d e r s a n d d e s i g n e r s o f i n n o v a t i v e c r a f t t h a t m e e t l e g i s l a t i v e r e q u i r e m e n t s b u t r e d u c e v e s s e l e m i s s i o n s a n d f u e l c o n s u m p t i o n T h i s n e w v e s s e l , t o b e n a m e d ‘ N R P r e d a t o r ’ , i s a g r o u n d - u p d e s i g n u s i n g t h e e x p e r i e n c e a n d e x p e r t i s e g a i n e d f r o m a l l s t a k e h o l d e r s o v e r 2 0 y e a r s o f c h a r t e r i n g , o p e r a t i n g , a n d b u i l d i n g c r e w t r a n s f e r v e s s e l s T h e t r a d i t i o n a l c a t a m a r a n h u l l f o r m h a s b e e n e x t e n s i v e l y C F D t e s t e d a n d o p t i m i s e d t o p r o v i d e c l a s s - l e a d i n g s e a k e e p i n g c o u p l e d w i t h r e d u c e d f u e l c o n s u m p t i o n a n d e m i s s i o n s

T h i s f i r s t - o f - c l a s s v e s s e l i s b e i n g b u i l t a s ‘ h y b r i d r e a d y ’ w i t h a n i n s u l a t e d g e n e r a t o r s p a c e r e a d y t o r e c e i v e g e n e r a t o r s a n d b a t t e r i e s , b u t i n i t i a l l y, t h e v e s s e l w i l l b e c o n v e n t i o n a l l y p o w e r e d w i t h q u a d Vo l v o P e n t a I P S 9 0 0 e n g i n e a n d d r i v e s y s t e m , a l l f i t t e d w i t h I M O Ti e r I I I S C R a n d U r e a i n j e c t i o n e x h a u s t s y s t e m s t o r e d u c e t h e N i t r o g e n o x i d e & S u l p h u r o x i d e e m i s s i o n l e v e l s O t h e r f e a t u r e s o f t h e n e w c r a f t i n c l u d e e n h a n c e d f o r e d e c k c a p a c i t y a n d w h e e l h o u s e v i s i b i l i t y, w h i c h e n a b l e s s k i p p e r s , c r e w s , a n d t e c h n i c i a n s t o n a v i g a t e c h a l l e n g i n g l o g i s t i c a l a s s i g n m e n t s s a f e l y F o r N R M a r i n e S e r v i c e s , t h e v e s s e l w i l l s u p p o r t a n o n g o i n g c o m m i t m e n t t o t h e h i g h e s t s t a n d a r d s o f s e r v i c e f o r o f f s h o r e w i n d f a r m s , w h i l e a d d i n g n e w l e v e l s a n d s t a n d a r d s o f e f f i c i e n c y, v e r s a t i l i t y a n d f l e x i b i l i t y A n o p t i o n f o r a s e c o n d v e s s e l h a s a l s o b e e n s e c u r e d , a n d D i v e r s e M a r i n e i s p r o u d t o h a v e w o r k e d v e r y c l o s e l y o n t h e f i n a n c i n g o f t h e p r o j e c t w i t h P e t e r C u r t i s a n d L C M P a r t n e r s t o p r o v i d e t h e f u n d i n g a n d a l s o t h e s t a r t o f a s h i p y a r d s u p p o r t e d f i n a n c e o f f e r i n g w i t h m o r e i n f o r m a t i o n a v a i l a b l e i n d u e c o u r s e B e n C o l m a n , D i r e c t o r o f D i v e r s e M a r i n e , s a i d , “ T h e m a r i t i m e s u p p l y c h a i n i n t h e U K h a s h a d m a n y c h a l l e n g e s o v e r t h e l a s t f e w y e a r s , b u t i t c o n t i n u e s t o d e m o n s t r a t e t h a t t h e U K i s l e a d i n g t h e w a y w i t h i n n o v a t i o n s t h a t w i l l d e f i n e t h e w a y v e s s e l s a r e b u i l t a n d o p e r a t e d w o r l d w i d e We a r e v e r y p r o u d o f o u r U K a n d l o c a l I s l e o f Wi g h t s u p p l y c h a i n a n d h o w i t d e m o n s t r a t e s t h e v e r y b e s t o f U K S h i p b u i l d i n g c a p a b i l i t i e s T h e U K p r o v i d e s w o r l d - l e a d i n g q u a l i t y, i n n o v a t i o n , c o m p e t i t i v e p r o j e c t c o s t a n d c l o s e w o r k i n g r e l a t i o n s h i p s w i t h t h e c l i e n t , y a r d a n d s u p p l y c h a i n We h a v e w o r k e d c l o s e l y w i t h O w e n a t N R M a r i n e S e r v i c e s o v e r t h e l a s t f e w y e a r s o n r e f i t p r o j e c t s , a n d w e a r e p l e a s e d t o w o r k w i t h O w e n a n d h i s t e a m o n t h e d e v e l o p m e n t o f t h i s n e w c l a s s o f C T V ” O w e n N u t t , D i r e c t o r o f N R M a r i n e S e r v i c e s , a d d e d , “ O r d e r i n g o u r f i r s t n e w b u i l d w i t h a n o p t i o n f o r a n o t h e r i s a s i g n i f i c a n t m i l e s t o n e f o r N R M a r i n e S e r v i c e s A t p r e s e n t w e o p e r a t e a n u m b e r o f 2 0 m C T V ’ s a n d h a v e n u r t u r e d s t r o n g r e l a t i o n s h i p s w i t h o u r c l i e n t s a l l o w i n g u s t o t a k e t h e n e x t s t e p i n o u r b u s i n e s s d e v e l o p m e n t O v e r t h e l a s t f e w y e a r s , w e h a v e e s t a b l i s h e d a c l o s e w o r k i n g r e l a t i o n s h i p w i t h t h e D i v e r s e M a r i n e t e a m a n d a r e v e r y p r o u d t o b e w o r k i n g w i t h t h e m t o d e v e l o p a n d b u i l d N R P r e d a t o r i n t h e U K ” w w w d i v e r s e m a r i n e c o m

The British Royal Researc h Ship (RRS) Discover y recently under t ook a six-week voyage t o the remot e British Overseas Territ ories of Ascension Island and St Helena, t o sur vey previously unexplored depths and searc h for unknown species.

The ship under took the project as par t of the UK government’s Blue Belt Programme, an international maritime conser vation project Scientists on board the Discover y used under water cameras to explore hydrothermal vents on the 4,000-metre-deep seabed

The team encountered a range of marine wildlife including fish such as inflated rattails, viper fish and the common fangtooth, which were identified on previous trips St Helena and Ascension were chosen for the mission as they are home to two of the world’s largest Marine Protected Areas and host a variety of species, such as whale sharks, yellowfin tuna, humpback whales and green tur tles The sur vey gathered extensive data to enhance scientific understanding of the unique marine environment Water samples were also taken to monitor quality and proper ties while assessing the number of species key to local fisheries to inform sustainable management quotas The team also monitored human activities, such as illegal fishing in the protected waters.

“Globally only around 5 per cent of the oceans have been explored, at a time when it’s never been more impor tant that they are protected,” said Paul Whomersley, scientific lead for Discover y 159, at the Centre for Environment, Fisheries and Aquaculture Science

“This latest Discover y expedition provided a new oppor tunity to advance scientific understanding of some of the most remote and unexplored areas of ocean on our planet

“Using the data collected and by growing our understanding of these biodiverse marine ecosystems, we can directly suppor t Ascension and St Helena governments in their work to sustainably manage their vast Marine Protection Zones ”

The team of 50 scientists and crew members spent 60 days at sea on board RRS Discover y, a 100-metre-long research vessel weighing 600 tonnes with facilities including a gym, mini cinema and cafeteria

The ship contained dr y and wet labs for scientists to store and analyse the samples collected, as well as state-of-the-ar t sur vey equipment such as deepwater cameras

“This vital expedition is using cutting-edge technology to explore untouched areas of the ocean and will potentially uncover rare species and habitats, allowing us to protect and enhance our marine biodiversity for the future,” commented International Marine Minister Scott Mann

“It demonstrates how our scientists are amongst the top in their field, and marks a crucial step for ward in our mission to protect 30 per cent of our international ocean by 2030, contributing to the global fight against climate change ”

Lord Goldsmith, Minister for Climate and Environment, said: “This is the latest example of British science leading the way in understanding and protecting our oceans for future generations

“The knowledge the sur vey contributes will help us understand the abundance of rare species in need of our protection”

In a push t o make Wave Energy competitive with wind and solar energy sources by 2030, Global M a r i t i m e h a s c o m p l e t e d m a r i n e w a r r a n t y sur veying (MWS) on CorPower Ocean’s HiWave-5, one of the world’s firs t grid connect ed wave farm demo projects.

Located approximately 5 5 km off the nor th coast of Por tugal, the project utilises CorPower Ocean’s C4 wave energy conver ter (WEC), which will form a foursystem array a bid to make wave energy competitive with wind and solar “We chose Global Maritime as the MWS Par tner on this landmark project because of their competitiveness and reputation as world leaders in Maritime Warranty Ser vices We needed a provider that had demonstrated exper tise on large scale projects and someone at the forefront of their industr y ” , commented Natalia Ivanova, Marine Operations Coordinator at CorPower Ocean “With the pile anchor on this project likely to be one of the main anchoring systems used for marine energy devices, in par ticular mooring systems for commercial floating wind farms, we are now well placed to suppor t future renewable energy projects that utilise the technology deployed at HiWave-5,” said Scott Cruttenden, director of business development and renewables at Global Maritime.

www globalmaritime com

Fugro Quest, a st at e-of-the-ar t vessel equipped with advanced deep-wat er t echnology, is the newest addition t o Fugro’s geot echnical vessel fleet Fugro uses this type of vessel t o det ermine the exact composition of the soil; the resulting dat a are essential t o est ablish the optimal location and design of of fshore developments, such as wind farms The vessel provides increased personnel and operational safety, whilst its energy ef ficient design results, on average, in significantly lower fuel consumption than for other geot echnical vessels Moreover, its ability t o t ake hydrotreat ed veget able oil (HVO) biofuel and remot e operations and dat a processing capabilities suppor t sust ainable operations

Barbara Geelen, Fugro’s Chief Financial Officer, per formed the naming ceremony ahead of the vessel’s maiden voyage and the vessel commenced operations in December for Vattenfall's offshore wind farm near Nor folk in the United Kingdom

Fugro Quest’s capabilities include the acquisition of high-quality geotechnical data from 2,000 metres below sea level The vessel is equipped with cutting-edge systems and advanced deep-water technology such as WISON® Mk V Ecodrive, SEACALF® Mk V Deep Drive® as well as dedicated coring systems and onboard soil-testing laborator y facilities. Its remote positioning and fast data-processing capabilities enable clients to access acquired project data in near real time from the cloud

Dennis Koenen, Fugro’s Ser vice Line Director for Geotechnics in Europe and Africa said: “Today’s launch is fully aligned with our path to net zero operations by 2035 Fugro Quest consumes less fuel than other large geotechnical vessels It is hybrid ready, comes with automatic handling of tubulars and geotechnical tools and has the latest IT capabilities onboard to safely carr y out operations across the globe. Bookings until July 2023 are already in place, and we ’ re excited to show how our new vessel can enhance the execution of our projects ”

www fugro com

Fugro launches state-of-the art geotechnical vessel for safe and sustainable offshore operations

Damen Naval has select ed German t echnology group Rheinmet all t o supply eight st at e-of-the-ar t MLG27-4 0 defence syst ems for the F126 frigat es the shipyard is building for the German Navy. Each frigat e will be equipped with two MLG27-4.0 syst ems. The contract includes an option for fur ther MLG27-4 0 syst ems for two additional vessels

The 27mm cal MLG27 4 0 light naval gun is a member of the new SeaSnake RCWS family of products made by Rheinmetall Waffe Munition GmbH of Unterlüß, Germany, a Group subsidiar y with multiple locations The core element of the remotely controlled MLG27 4 0 is the BK-27M revolver gun In use throughout the German Navy, the predecessor of the new MLG27 4 0 ser ves as secondar y armament on Germany’s current F125 frigates

Compared to previous models, the next-generation MLG27-4 0 defence system features a series of technological innovations It is a highly advanced ship defence system equipped with daylight cameras, infrared sensors and laser rangefinders, and can be integrated into an existing shipboard command system, taking full account of all applicable IT and OT security requirements Moreover, its new, fully digital system architecture enables direct impact on external target coordinates in standard WGS-84 format

The 27mm cal revolver gun can operate in single-shot mode, in adjustable bursts, or at a sustained rate fire of up to 1,700 rounds per minute. Its low weight and adjustable grid-firing capability, coupled with an integrated simultaneous tracker, make the MLG27-4 0 weapon system a power ful armament for modern frigates such as the F126 class

In combination with other weapon systems envisaged by Damen Naval for the project, the F126 frigates will feature a comprehensive, highly effective array of armament that delivers a critical tactical edge against a multitude of threats “We are extremely pleased to join forces with Rheinmetall on the F126 project for the German Navy The broad range of capabilities make their MLG27-4 0 weapon system the right choice for the F126 frigates,” says Hein van Ameijden, the Managing Director of Damen Naval Rheinmetall greatly appreciates its close, trusting relationship with Damen Naval, which, besides successful cooperation in the F126 project, could lead to follow-up projects “Our MLG27-4 0 weapon system and basically the entire SeaSnake family, have proven highly effective against asymmetric threats We’re ver y pleased to be taking par t in the ambitious F126 programme and to be suppor ting Damen Naval in building the frigates” adds Roman Köhne, managing director of Rheinmetall Waffe Munition GmbH

The Dutch shipbuilder Damen Naval, prime contractor for construction of the German Navy’s new F126 frigate generation, will work closely with key subcontractors Blohm+Voss Shipyards GmbH and Thales Netherlands B V in planning and building the four frigates All four ships will be built entirely at German shipyards (in Wolgast, Kiel and Hamburg), with the first frigate slated for deliver y in 2028. The contract between Damen and Germany’s Federal Office for Bundeswehr Equipment, Information Technology and In-Ser vice Suppor t (BAAINBw) includes an option for two more frigates www damen com

Ra d i x S o f t w a r e a n d Engineering, based in Brazil, recentl y announced it had c r e a t e d a v i r t u a l F P S O training environment f or a major operat or with the goal of reducing risk in the asset c o m m i s s i o n i n g p h a s e by training operat ors in process optimization and validation of operational manuals.

"The per formance of professionals involved in the commissioning and operation of industrial units, specifically an FPSO, has been significantly impacted by the increased complexity of its units, equipment, and control systems. With this, the risk of deviations in the execution of operational activities such as star t-ups and s h u t d o w n s h a v e i n c r e a s e d , w i t h i m p a c t s m a i n l y o n s a f e t y, environment contamination, and operational efficiency," a Radix spokesperson commented

The company implemented a Proof of Concept (POC) to assess the latest technologies in integrated simulators for FPSO using AVEVA tools for it The focus was the development of training with the use of integrated simulators, for the operation and commissioning teams

"The premise was that the teams could per form the following initial checks vir tually, without assistance from the shipyard site: star t-up to steady-state operation, occurrence of disturbances, shutdown procedures, failures in equipment and instruments scenarios, specific commissioning procedures, abnormal process conditions: changes in load characteristics or product specification and operation interlocks and emergency stop checks," the spokesperson continued.

Radix technical leader for the project, José Ramos, said: "The integrated development and training of these teams in the abovementioned activities will have a significant impact on improving the safety, operational efficiency, and emission reduction aspects of our future FPSOs."

Ramos also said that with this, "we understand that the use of simulators integrated in the commissioning and operation of an FPSO is a solution capable of optimizing processes to maximize value creation, proactively adopt technological solutions as a per formance lever, and promoting value generation and resilience in the transition to low carbon ” www radixeng com

E u r o n a v S h i p M a n a g e m e n t (Hellas) Ltd. and the Panama M a r i t i m e A u t h o r i t y ( P M A ) s i g n e d a M e m o r a n d u m o f Unders t anding (MOU) with the aim t o open up oppor tunities for Panamanian seafarers on board Euronav vessels.

The MOU signed on December 5, 2022 has two main objectives Firstly, to promote an integral cooperation framework aimed at increasing job oppor tunities for Panamanian officers, cadets and junior personnel on board Euronav vessels Secondly, the establishment of specialized maritime training programs for Panamanian seafarers who require to work onboard the various vessel owned or operated by Euronav, for which the recruitment and allocation of officers, cadets and junior personnel is required

The MOU is effective as of December 5, 2022 and will remain in force for a period of five years.

The cooperation between Euronav and PMA became official back in June 2009 when the first memorandum of agreement was signed between Euronav and the International Maritime University of Panama (UMIP) Both par ties engaged themselves to provide seagoing practice to Panamanian cadets, assigned by UMIP, by ser ving on board Euronav’ s vessels. It provided the ideal oppor tunity for the students to turn their career dreams into reality and to acquire experience, knowledge and sea ser vice (cadetship), and to obtain an officer’s licence after completing 12 months on board, in two consecutive voyages Euronav and UMIP kept building a stronger relationship, entering a next phase in July 2013, when the Belgian Maritime Inspectorate officially recognized UMIP as the only training center in America to contribute to the development, operational knowledge and per formance of young seafarers This eventually led to the possibility of all Panamanian officers to join Euronav’s vessels without any limitation www euronav com

Fugro Middle Eas t ’ s remot e operations t eams have received the newly accredit ed uncrewed vessel operat or training course

Members of the Fugro uncrewed vessel operations team in the Middle East, being par t of the geo-sur veying giant’s global uncrewed operations workforce, have completed SeaBot Maritime’s newly MCA recognised Maritime Autonomous Sur face Ships (MASS) Cer tified Professional training

Designed for personnel conducting uncrewed sur face vessel (USV) operations, the training equips candidates with the necessar y skillset to enable safe and sustainable operations in the marine environment whilst promoting best practices within the maritime sector

This new MASS Remote Operator Training received MCA (Maritime and Coastguard Agency) voluntar y recognition in October 2022, which was developed by SeaBot Maritime in association with its long-term customer, Fugro

The MASS Operator Training is par t of SeaBot Maritime’s MASS Remote Operator Training Scheme, a new workforce career pathway, which has been devised by SeaBot Maritime as a framework for users of uncrewed vessels.

Hannes Swiegers, Director IRM Ser vices & Remote Operations Fugro Middle East, comments, “SeaBot Maritime’s curation and deliver y of this ground-breaking course plays a significant par t in Fugro’s Dynamic People Plan, being firmly focused on next-generation maritime ” Introducing new technologies into a well-established sector has inherent risks associated; having the right personnel who are sufficiently trained and competent, determines the ability to deliver quality remote solutions safely and consistently

Gordon Meadow, CEO of SeaBot Maritime comments, “The MASS Remote Operator Training Scheme was launched to help overcome the challenges associated with the adoption and operation of next gen maritime technology ”

“SeaBot Maritime’s framework of courses helps to manage the risks in the adoption and use of leading-edge systems A suite of fur ther MASS-related training courses is available, together with the new MASS Professional Operator career framework spanning enterprise and defence, which is being rolled out worldwide ”

SeaBot Maritime’s MASS Operations’ UK training facility is headquar tered at the National Oceanography Centre in Southampton, UK, providing solutions to a global customer base both directly and through its customers’ locations worldwide

SeaBot Maritime provides training, workforce learning and development solutions for customers evolving conventional workforces in the operation of sur face and subsur face autonomous marine vehicles; both from parent vessels and remote operations centres (ROCs) MASS training comprises a blend of instructor-led, synthetic environment and experiential onwater learning, complemented by SeaBot Maritime’s additional solutions including distancelearning solutions, VR, AR, and 3D visualisation tools

www seabotmaritime com

www fugro com

At the Of fshore Energy Exhibition & Conference 2022 Kommer Damen, Chairman of Damen Shipyards Group, and Arjan van St ee of Van St ee Of fshore signed a contract for the deliver y this year of an 80-metre Multibust er 8020 ultra-shallow draught, multi-purpose workboat

Van Stee’s Multibuster 8020 is the first of a new class that combines the key elements of Damen’s highly successful Multi-Cat and Shoalbuster workboat classes to create a large-scale platform capable of under taking a wide variety of projects in waters as shallow as three metres

The vessel is the brainchild of Damen CEO Arnout Damen who recognized that workboats of this size and capability were not only in shor t supply but would also be increasingly required in the years ahead The basis of the design was developed by naval architecture studio OSD-IMT, par t of the Damen Shipyards Group, and construction got under way at Albwardy Damen Sharjah in the UAE in 2020

Key features of the design in addition to the shallow draught include extensive deck space, ample accommodation and the high stability that enables the fitting of larger cranes than those on vessels of a similar size DP2 dynamic positioning is standard and the propulsion system includes a retractable tunnel bow thruster that ensures that two tunnel thrusters are available at all times for enhanced manoeuvrability All third-par t equipment is sourced from leading brands

As well as ser ving the offshore renewables and oil & gas sectors per forming duties ranging from anchorhandling and towing to ROV operations, cable laying and beach pulling The Multibuster is expected to be in demand for nearshore operations The vessel is built to ground out on the beach for tasks such as cable landings and shore approaches

Arjan van Stee, Director Van Stee Offshore, said: “As a specialist in shallow draft operations the Multibuster will give us new capabilities and oppor tunities to suppor t our clients in the offshore energy sector Its low emissions profile will additionally be valued by our par tners working on wind and other renewables We’re ver y pleased to be renewing our relationship with Damen and look for ward to a long and productive cooperation ” Joost van der Weiden, Damen Sales Manager Benelux: added, “It’s great to be working once again with Van Stee Offshore, a family-owned company known for its high-quality vessels and many prestigious customers We believe that the Multibuster 8020 is the right vessel at the right time, delivering a suite of capabilities that are sure to be in demand in the years ahead We all look for ward to seeing it in operation and to fur ther collaboration with Van Stee Offshore ”