Special Features

[rnsr, n Heppv New Yeen to all our readers. I hope you had a wonderful holiday I' with your families and are charged up for the year to come. May 2014 be profitable personally and in business.

This year certainly holds a lot of promise, as forecasts suggest the gains of the last two years will continue in2014.Indeed, at the top end of the housing starts forecasts, numbers will approach historical averages. Most businesses that have survived are already facing the challenge of how to grow again. In speaking to many owners, I know some are neryous about the thought-and for good reason. When and where to invest is a tough question.

I think that many would admit that in the years 2004-2007 we were all drinking the Kool-Aid and, as the market grew, we may have taken actions that our instincts told us not to. Companies entered the market and, just as quickly, exited it with no solid foundation of business. Others invested heavily, taking on debt to manage what turned out to be phantom business. Many paid a heavy price, and the industry today is a fraction of what it was only six years ago, with an awful lot of pain during the process. But the good news is that if you are reading this issue, you were one of the great survivors of our "Great Depression."

We as an industry (and this is your comment to me over the years) never learn. So the question perhaps to ask as the industry grows again is, how are we going to grow the right way? Whether large or small, we will face the challenge of growth this year.

The challenge is, if you are seeking out new business, it has to be worth the time and risk. Too often we chase new opportunities without considering whether these activities can be short- and long-term profitable, a good use of resources, worth the risk of adding new resources, or fit into the culture of our company. Perhaps the latter is what we do not take heed of often enough.

For any growth decision you take (developing or stocking a new product, adding staff, expanding, remodeling, rebuilding, etc.), make sure you have the funds. Monitor your cash flow intently. Nothing chases off your friendly banker like money wildly flowing in and out, as many discovered last time round. Indeed, get the bank to buy into your growth and any short-term negatives that you anticipate. Line up financing before you expand. No surprises!

Keep staffing increases to the minimum to protect cash. Staffing is normally one of our top expenses-consider outsourcing in the beginning.

Work with your suppliers, where appropriate, on scheduling, co-op marketing, training, etc.-all to get your new program off the ground as quickly as possible.

The key to any business success for the long term is to have a strategy that is focused, concentrates on profit opportunities with healthy margins, and allows you to work with customers that are profitable to the company. (Yes, you know the ones you don't want: the ones who are low-margin to start and get even lower with their constant demands). Don't waste time or resources on unprofitable business. Let those customers go elsewhere. Don't let them bleed you.

Identify the driver of your business and concentrate your energies on building that. Understand where you can gain the most. In previous columns I have suggested ranking your customers by their value to your business (by the way, that value changes every year). Pay attention to the quality of their business. Their value is not only the hard profit on products sold, but also includes the costs of servicing them. When that is done, you probably will get a better understanding of their true value.

It's the same with new customers. New business is great-in fact, the lifeblood of every company-but if you lack the skill set in your company to manage this new business, and if it does not fit in with your culture (sales or otherwise), stay clear. All business is not created equal.

Again, have a great year. I look forward to meeting you on my travels.

Alan Oakes. Publisher aioakes@aol.comwww. bu ld ng-prod ucts. co m

A publication of Cutler Publishing 4500 Campus Dr., Ste.480, Newport Beach, CA 92660

Publisher Alan Oakes ajoakes@aol.com

Publisher Emeritus David Cutler Director of Editorial& Production

David Koenig dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Carla Waldemar, James Olsen

Advertising Sales Manager Chuck Casey ccasey@building-products.com

Administration Director/Secretary Marie Oakes mfpoakes@aol.com

Circulation Manager Heather Kelly hkelly@building-products.com

HowtoAdvertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www.building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com.

CLASSIFIED MARKETPLACE

David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-products.com

SUBSCRIPTIONS Heather Kelly Phone (949) 852-1990 Fax 949-852-0231 hkelly@building-products.com

or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A.: One year (12 issues), $24 Two years, $39 Three years, $54

FOREIGN (Per year, paid in advance in US funds): Surface-Canada or Mexico. $49 Other countries, $65 Air rates also available.

SINGLE CoPIES $4 + shipping

BACK TSSUES $5 + shipping

BUILDING PRODUCTS DIGEST is oublished monthly at 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-1872, (949) 852-1990, Fax 949-852-0231, ww.buildingproducts.com, by Cutler Publishing, Inc. (a California Corporation). lt is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright@2014 by Cutler Publishing, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it.

+ hte|Jd&, !t! ^bclm@b.me&€i)

r= hlqw&. !F ^'tr|fucembbnb.lM!ffAd5

f\eserra wArLlNG FRoM experts on the necessity of coml-f panies being active on Twitter to instantly communicate with customers and prospects, few LBM dealers tweet.

Of the nation's estimated 10000 LBM retailers, the vast majority appear to have never set up a Twitter account and, among those who have, only about 30 independents send out more than two tweets a week. Next to feeling the service is not worth their time, the next primary reason for not using Twitter more is that dealers feel they don't have anything worthwhile to say. So just what are those 30 active users finding to talk about?

BPD surveyed the communications of 30 indpendent lumber dealers most active on Twitter. What we discovered is that few are dreaming up long, complex posts to amaze the masses (after all, the service limits messages to 140 characters or fewer). Most are building an identity, such as:

'Ihe Linker. Linking to home improvement articles (like "How to Install Crown Moulding") may kickstart a project-and a purchase. Linking to industry news (the latest NAHB housing statistics) can also get pros thinking

about you as an expert.

-

^ hl4|ffr.

l- e m hilo Fr@ - o@ hm il drMld$

x'!ll. dhdfidY.rPTu

| < blryl.ff.&

b. aheU.dm@n{ybnddtbbenp'

^ biqwo. tr erF-.Fdrydtutuffih

hlE|.trQ. II Abffiryturrsr 9ntu..ghd4t..tu trcHGndd@

Links can also be time-savers. It can be doubly timeconsuming to maintain presences on multiple social media platforms, so some dealers use their Twitter account primarily to link to updates on their blogs or Facebook page (which allows posts in excess of Twitter's 14O-character limir).

In addition to links to its Facebook page, Parr Lumber, Hillsboro, Or., sends out several links a day to photos it's collected on its Pinterest site, highlighting glamorous projects and interesting new products.

The Conversation Starter. Ideally, tweeters want their name spread not only to their followers, but in turn to their followers' followers, so it's key to engage them and turn the monologue into a dialogue. Dealers ask what their followers' latest project is, what their dream purchase is, or what their plans are for the holidays. Peter Lumber Co., Pleasantville, N.J., and City Lumber Co., Dyer, Tn., solicit participation with a weekly trivia contest.

The Commenter. No one joining your conversation? Chime in on theirs! Dunn Lumber, Seattle, Wa., has collected more than 8,500 followers by themselves following an equal number of users and regularly commenting on their tweets and photos-and thanking anyone who mentions Dunn Lumber. The idea is to get the Dunn Lumber name out wide and often, and to be seen as a friend to the community.

The Promoter. Got something on sale? Tweet it. Ashby Lumber, Berkeley and Concord, Ca., publicizes specials on a near-daily basis. Meek's Lumber, Springfield, Mo., even tweets out downloadable coupons.

How about an upcoming contractor night or other event? Ro-Mac Lumber, Leesburg, Fl., uses Twitter to direct followers to its weekly "Around the House" radio show.

The Recruiter. About half of the 5O-plus Tweets a month by Lyman Lumber advertise the various job openings at its Wisconsin and Minnesota facilities. (With more than 250 locations, 84 Lumber has so many positions available that it maintains a separate Twitter feed, 84LumberCareers.)

ll rfosr BUSTNESS LEADERS are comIYlfortable discussing things like risk, ROI, and market share. They are less comfortable discussing sales tax, but it's a conversation that needs to happen.

States are getting increasingly creative about finding new revenue sources through sales tax. Businesses can easily incur "surprise" tax liabilities without realizing it. Assuming sales tax rules are the same across all your territories can be a costly mistake.

Sales tax starts with something called "nexus." Nexus is the relationship a business must have with an authority (like a state or local government) in order for that authority to collect taxes. Let's simplify that. Imagine you have a store in Nebraska: you own your building, pay employees, and complete business transactions in the state. All these things give you nexus in Nebraska, and the state will collect sales tax from your business.

Say you have a customer, Jim, who works in Iowa, but comes to Nebraska

to purchase his materials. You probably don't have nexus in Iowa just because your customer works there. But let's change the situation. Jim calls in his orders from Iowa and your employees deliver materials to his jobsites in that state. Now Iowa might argue you have nexus in their state and you owe them sales tax.

The problem businesses face lies in the words "probably" and "might." Each state has different nexus triggers. If your Nebraska store sells an item to people in two different states, you may have nexus in one but not the other. Things like buildings and equipment are almost universal triggers, but many states are starting to define nexus based on activity rather than physical presence. Sending an employee to a trade show, industry conference, or training seminar can all give you nexus in a state. You can establish nexus in Arizona if an employee spends two days of the year there. If your Nebraska store has a lot of Iowa customers like Jim, Iowa might argue you have an "economic nexus" in their state, even if all your

sales take place in Nebraska.

Delivering purchased items is a common nexus trigger, but there are a variety of ways states approach the issue. In Georgia, the "taxable event" takes place at the ship-to location, but in Kansas, it occurs at the ship-from location. In some cases, just delivering an item may not trigger nexus, but offering a service can. (lt's the difference between delivering a door, and delivering and installing a door.) The method of transportation may be a trigger as well. Are you using your own fleet, a common carrier like FedEx, or a third-party vendor? The bedding store Mattress World is an excellent cautionary tale about ignoring delivery-related sales taxes. Mattress World is located on the Oregon-Washington border. Many Washington residents would cross the border to purchase and pick up mattresses. Mattress World started offering delivery and set-up service to their Washington customers through a third-party vendor. But hiring and sending that vendor across state lines created nexus under Washington's tax code. The company didn't plan for this and ended up with a $ I .7 million (plus tax) debt to the state.

We've been discussing nexus triggers as a state-by-state issue. The truth is you can create additional nexus within the same state by crossing into new tax jurisdictions. States might define their tax jurisdictions by cities or countries, but the boundaries aren't always so clear. To further complicate the matter, some states allow jurisdictions to set their own sales tax rules. Getting business from a new area in town means you could owe a com-

plctely new sales tax to a complctcly ncw authoritl'. Colorado is notorious ftrr this: thcy hal'e sir diffbrent ratcs in a singlc zip codel

Definitions lrre onc of the stickicst points in sales tar. ir"r part bccausc they can seem so albitrary and absent of ct-rr.r'rn'ron sensc. KitKats, Twizzlers and Whoppcrs arc not "candy" under thc Strcamlined Salcs Tax dcfinition bccausc they all contain flour. Indiana catcgorizcs marshnrallows as "candy" (taxable) and r.narshmallow crdme as "foocl" (exempt). Pennsylvania docs not tax clothing. but does tax "ful articles," which include "articlcs made olwoven animal hnir or wool that rescmblcs fur in appcarancc." (Prcsumably a wool swcatcr u'ould bc cxcr.npt. but a coat with shccpskin trirn would not.)

Culifrrrnil's 20 l.l trrx ()n "ccltirin lumber ancl cnginccrccl wood proclucts" is a gfcat examplc of definitiorrrclated chaos. Under this lule. "tcncing, railing and decking" are sub.ject tcr the tirx. htrt humboo lr'rrcing. plc-c()nstructecl railin-e sectit'r.rs. and "deck packagcs" are exempt. Retailcrs spcnt countlcss I.rouls clctcrrlining w'hich items in their catakrgs were taxablc. It r"'as a huge invcstnrent of tirlc and

monc)' lbr the businesses. but it needed to bc done. Shortly befbrc cna.^ting this ncw rule, Califbrnia announced a plan to hire 3(X) auditors. Businesses arc held responsible for complying with tax rulcs. clen if thosc rules are alnrost impossi ble tcl undclstand.

The Take-Away

Chet'k tltc tte.rus trigg,crs .fbr evtrt' tcrritory \'out' ( onlputl ittlct'ttcts vitlt. Don't assun'rc you ncccl a buildin-u or permanent cmployee in a state to owe sales tax thcrc.

. Clteck tlte tu.r rula.s regorditt.e, rleliveric.r fitr etart urcu tort dclircr 1o. You rnay need kl collect additional sllcs tirr lfonr eusl()mers in strtttc areas but not others.

. Cltcck the .iurisdictiottul boLtttdaries,for aver)' .\tolc t'ou tlo lttt.sittess lri. Make surc you'rc collectin,g the corrcct amount ol' salcs tax for each juriscliction and rcmittin-c payrrent tc) the corlcct authofity.

. Pu)' attctttiott ttt da.fittitittrt.s dttu(ltc(l lo sulcs 1a.res. TI'rc distinctiortr hetrr ee rr tlrr;lhle lrrrtl excmpl itcrns rnay seenr arbitraly' and silly. bul thc state is going to bc vcry serious about collecting fincs and pcnalties. Sales tax is incredibly cornplicatecl. You neecl a good tax consultant to

rnake surc you fbllow the rules in all jurisdictions where you have r"rcxr"rs. But once you know what you're supposed to do. the ncxt step is doing it consistently.

Automating tax calculation is a creat strategy because it virtually eliminates the risk of human crror. Serviccs like Avalara work with your ERP system and calculate the appropriatc rate for each transaction. Your software platfbrms should be robust, yet flcxible enough to handle the inevitable changes in sales tax rules.

California's lumber tax impacted products so inconsistently that most POS programs couldn't apply it correctly. Miinl businesscs resorted to calculating sales tax by spreadsheet. Agility softwarc was one exception. It adaptcd to thc change easily. and Llsers likc Petcrman Lumber. Fontana, Ca.. and S&J Lr-rnrber. Madera. Ca.. w'cre able to incolporate thc tax 'u"ithout a problern.

You nrav not want to think about this topic. but it's far better to discuss sales taxcs now witl'r your collcagucs. rather than later with an auditor'.

Jt rr1q 11 .\t'ttttt i.t ( (tlllltllttlit (tlit'll t rtt'l' clitttttrtr lltt DMSi Softttare, Ontultu, Ne. Rcu c lr ltc r ot jurutt t Cl' tt rrt.si.t ottt.

From the industry's deepesl Star Drives to oun patented Decklok advanced lateral anchor, nobody delivers quality pnoducts as quickly or rcliably. Now whh a new East Coast warehouse, oven a quarter of a million dollars in inventory is waiting to ship to you even faster". Depending on youn location, it could arrive as soon as tomorrow.

To become an authorized dealer on distributon call us direct at 1-888-888-9661 Shop our online catalog. Prepaid freight available, onders ship same day.

ll rTaNupacruRED sroNE veneer IYlpromises to be more popular than ever in the residential building materials market this year, as its ease of installation and extreme versatility make it a perfect solution for customers looking to keep pace with today's design trends.

Whether it's a production builder seeking innovative ways to add curb appeal to a community or homeowners wishing to update their residence through a creative remodel, consumers continue to favor manufactured stone veneer because of its varied uses. And the number of applications are still growing: the product's high adaptability means it is often a natural fit for even the most innovative developments in design.

Pioneered more than 50 years ago, manufactured stone veneer is cast

from natural stone molds and then meticulously hand colored with mineral oxide pigments to give it the depth, pattern, complexity of color, and unique pattern of stone. Due to its lighter weight, it actually has many more design uses than natural stone.

Manufactured stone veneer can be adhered to most wall surfaces, since it is one-third the weight of full-thickness stone. To comply with building codes, stone veneers cannot exceed l5 pounds per square foot, which allows for greater design flexibility.

Durability is another prime characteristic of stone veneer, which is of crucial importance to developers, builders and architects who need predictable strength, consistency and quality in their stone veneer products, ensuring materials are safe to handle and remain secure over the lons term.

Concrete mix used to make stone veneer must withstand at least 1,800 psi without damage, which ensures its durability for years of service. In fact, stone veneer products usually come with a 50-year limited warranty.

Made with Portland cement and lightweight aggregates, manufactured stone veneer is low maintenance and can tolerate a wide range of climates. Boral's Versetta Stone, for example, is rated for wind resistance of over 100 mph. This panelized stone veneer is easily installed in any climate, because its mechanical fastening system does not require heating the wall to a certain temperature during cold weather.

Residential projects of all types can benefit from the installation advantages of panelized stone veneer, as evidenced by the recent completion of a $27.9-million affordable assisted living community in Lansing, Il. The community, known as St. Anthony of Lansing. houses 125 apartment units in a three-story building on a four-acre parcel. General contractor LedCor selected panelized stone veneer for its ease of installation in cold weather. The portion of the building that involved 27 900 ft. of product applied via traditional stone masonrv methods

took three months to complete and required a full wall tent and heat. In comparison, installer Residential Exteriors applied 21 ,OO0 ft. of panelized stone veneer (along with an additional 54900 ft. of fiber cement shake siding and trim) to the building in just three weeks. without the need for a wall tent and heat. Even with the cold weather, there were no delays.

Morc cost effective than natural stone and available in more than 100 colors and textures. stone veneer is increasingly popular for both exterior and interior applications. Stone veneer can be utilized in almost any manner, --1 even as cornices, copings, wall brackets, and door surrounds. No matter where it's used. stone veneer makes good construction and design senseand even a small amount makes a large statement. Following are some of the varied applications that dealers can now target to sell stone veneer:

Fireplaces: With the wide variety of stone veneer styles available, it is easy to achieve virtually any look for fireplaces. Stone veneer fireplaces can feature anything from a traditional, rubble texture to a modern, sleek feel. They can be ornate, reminiscent of Victorian styles, given a Tuscan or

Mediterranean appearance, or simply a stone wall and floor on which a wood burner sits.

Kitchens/Bathrooms: Stone veneer islands and backsplashes can add texture and variation to kitchens, while decorative stone veneer accents can lend a rustic or natural vibe to bathrooms. A little wall cladding in stone veneer goes a long way.

Arches/Doors/Windows: An ordinary arch, door or window can be transformed into a stunning architectural feature just by adding some stone veneer accents. Using stone veneer to offset brick window accents is a growing trend, as is combining different stone veneers to glve a very customized look. Kcystone windows and arches are also trendy as are window and door surrounds made from carved or inset stone.

Exterior Facades: Whether used as an accent or a full wrap, stone veneer can add curb appeal to any home. Using different materials and colors can provide a three-dimensional quality, creating more interest and depth to a building. Layering also helps articulate human scale while complementing the architecture and surroundings. More earth-toned colors are being favored by architects, who are incorporaling stone veneer into exterior facades as a way to complement the natural scenery around many homes. In some cases, styles that emulate the natural stone found in nearby surroundings are used, giving the illu-

sion that a piece of the landscape has been incorporated right into the home.

Outdoors: A major trend today is the use of stone veneer for outdoor fireplaces, kitchens, barbecue islands, and cabanas. Stone veneer walls can be used to add character and form to gardens and outdoor yards. Their beautiful aesthetics and extreme durability also make them a perfect option for lining driveways and property borders. A Tuscan vernacular is also popular, in which elements are completely claddedas if the materials were "pulled off the land" and the outbuildings (such as a pool house or shed) have the same look.

Columns: With columns a preferred solution for housing heat structures in backyards, stone veneer makes for an ideal wrap because of its light weight. Stone veneer columns in a square shape are a favorite at the moment for backyards, while traditional , Tuscan-style columns are a classic choice for adding old-world charm to entranceways.

No matter what your customers' design needs and interests, stone veneer is likely to be an ideal fit, given its beautiful aesthetics, adaptability, durability and relatively low cost.

- Ed Perez is the area sales manager for Boral Stone Northern CaLfornia and Northern Nevada. Based in Roswell, Ga., Boral USA subsidiaries include Boral Bricks, Boral Roo.fing, Boral Stone, and BoraL Material Technologies. Reach him at ed.perez@ boral.com.

j-lven rHE vEARS, I have shared \-f your pain. struggles and sleepless nights with-dare I say it?-IS (Information System) or, as it is sometimes called, IT (Information Technology). I've never liked either of those descriptions. Let's move to a much broader description: ERP, or Enterprise Resource PIanni ng.

Why is it that we spend countless labor hours on budget meetings, integration methodologies. maintenance. inappropriate functionality, and the inflexibility to adapt to changing business needs? What frustrates me even more is that we allow this IT to rule our business lives with substandard performance, only to be assured, "Don't worry, your software provider will have it fixed in the next enhancement release."

I contend that LBM industry-specific solutions don't have to be your only options. A SKU is a SKU is a SKU. You're telling me that the barcode on that Victoria's Secret shelf is different from the barcode on a gallon of paint at your store? I guarantee you that walking down Fifth Avenue and visiting the Ralph Lauren store or Gucci store, that they don't have the ERP struggles that our industry does.

You don't need to have exponential budgets, either. There are solutions outside our industry that offer these ancillary benefits for us to run our day-to-day operations. They are just as efficient and also effective for our internal and external customer.

Let's look at the facts. Compare the growth of our industry in terms of dealers, market share, revenue and profitability to that of Home Depot,

Lowe's and Menards. They, like most Fortune 500 up to 5000 companies, use outside ERP systems.

The experts at your local "geek shop" have probably never even heard of your system. If you search Monster or any of the other employment networks for IT or ERP jobs that relate to our industry's specific software package, you won't find a huge pool of qualified prospects.

Why is it that some co-ops use systems like SAP, but offer their dealers different ERP solutions? I guess they never read Harvard professor Michael Porter's work on value chain and the importance of transparency to the customer in order to bring value to all stakeholders. The basis of his thesis is that Enterprise Resource Planning facilitates improvement to a company's value chain, thus generating significant competitive advantage.

ERP is the intesration of a busi-

ness software solution into a company's activities and strategy. The theoretical motivation behind implementing an ERP project is to increase efficiency, thereby reducing costs and increasing profitability and customer satisfaction. In addition, there should be increased efficiencies around the supply chain, consolidation of information, and an overall business improvement, which gives those who use ERP an advantage over their competitors.

According to Porter, a company's ERP project can be assessed by the level of improvement in terms of productivity and customer satisfaction. The analysis of the data presented by ROI figures will clearly show that ERP systems provide a significant benefit to the value chain, increasing competitive advantage within an industry.

Companies like SAP and Oracle have been leaders in creating value efficiently and effectively by adapting quickly to business changes for their clients.

To better compete in the 2lst Century, dealers may want to consider more than just industry-specific ERP packages. Like most owners who grew up in this business, I have sawdust in my veins. I love the independent lumber industry and want to see all of us succeed.

- The former president of LumberJack Building Centers, Algonac, Mi., where he spent 22 years, Gordon Birgbauer is now a lumber distribution consultant, as president of AIIS/MFP, Algonac. He can be reac hed at gbirgbauer3 @ gmail.com.

With more thon 80 yeors of mochine opplied cootings experience ond reseorch ond development, PPG introduces your replocement to oil-bqsed primers, PPG Seo/ Gnp MC exterior ocrylic primer. ldeol for use over tonnin rich woods, PPG Seol Grip MC offers the following cootings benefits:

/ Woter bqsed, low VOC (<100 g/L)

/ Seols ond blocks tonnin stoining

,z Excellent odhesion

,/ Fost drying

,/ Ease of opplicotion using o voriety of opplicotion equipment

,/ Con be force cured

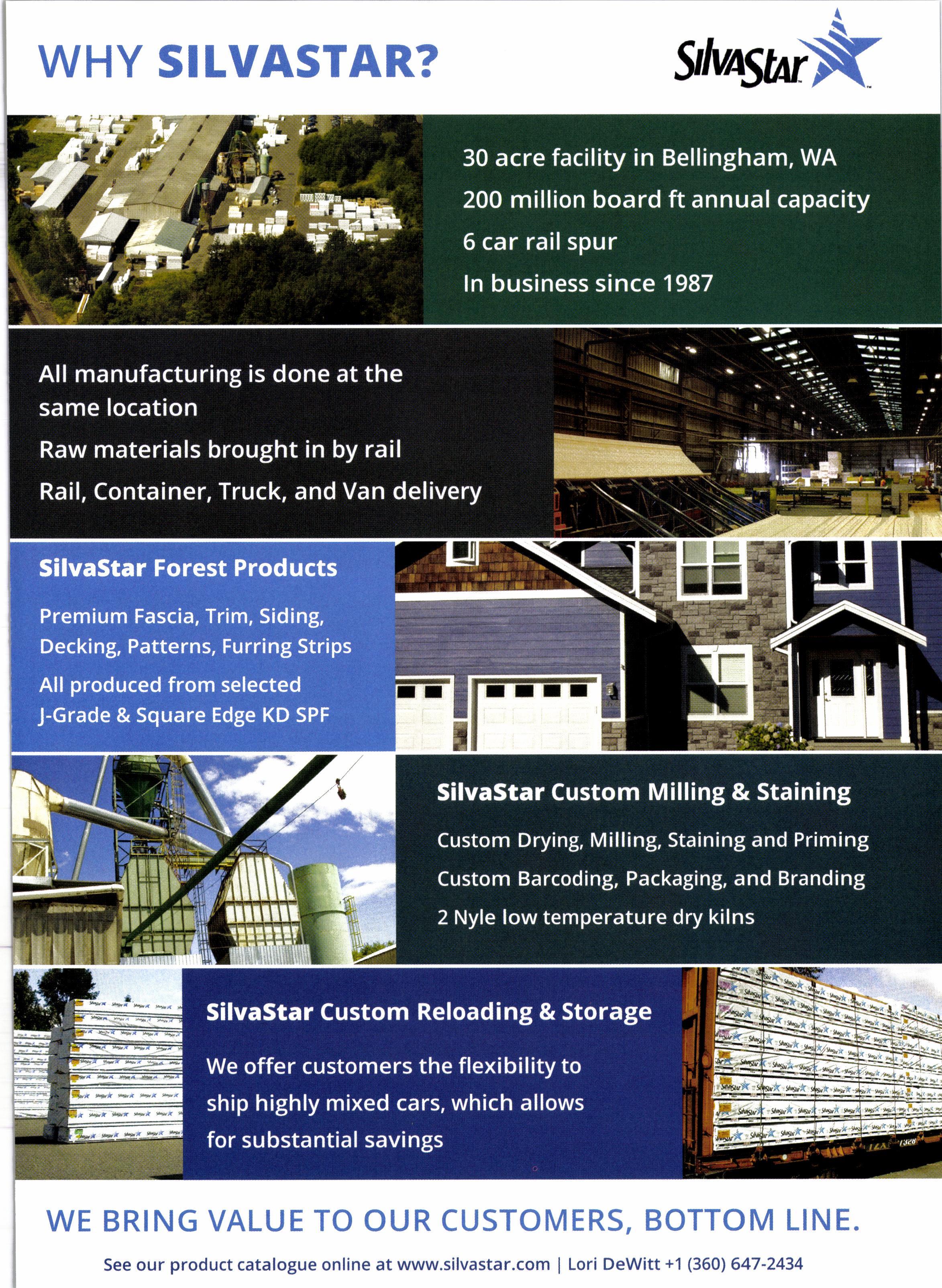

TROMA"t vEAR AFrER being acquired by the owners of \-fWelco Lumber, Vancouver, B.C., SilvaStar Forest Products, Bellingham, Wa., is expanding its business by introducing new products and services.

"Many companies offer one or more of the same services we do, but none offer the same unique, complete solution," says Mike Thelen, SilvaStar's chief operating officer. "Our motto is: 'Together, your product line combined with ours builds a world of possibilities."'

Here's how it works: The company produces its own fascia, trim, siding, decking, patterns and furring strips in its 100,000-sq. ft. manufacturing plant. However, with annual production capacity of 200 million bd. ft., there's also room to dry, mill and stain to customers' specifications. An additional 40,000-sq. ft. of additional covered storage keeps everything in great shape.

"Customers bring their raw material to our plant," he explains. "If it's wet, we re-dry it in our kilns. We then process their lumber to match their individual specifications."

A six-railcar spur on the 30-acre property-which is paved and fenced-simplifies delivery."We offer a unique advantage for our rail customers, allowing them to order highly mixed cars combining material from our inventory with their custom milling and staining orders," he says.

Adding product from nearby producers isn't a problem either. "Framing lumber from nearby sawmills can be used to complete their orders," he adds. "This allows purchasing flexibility and substantial savings."

More than two-third's of SilvaStar's business is with two-step distributors, such as Boise Cascade, Boise, Id. "We currently supply 14 Boise locations from Woodinville, Wa., to Pompano Beach, F1.," says Thelen. "We also supply custom-branded products to the big boxes."

Mike Bland, general manager of Boise Cascade Building Materials Distribution in Riverside, Ca., says that Boise decided to partner with Silvastar because "they understand that customer loyalty is all about building longterm relationships. I would rate them right at the top."

By Carla Waldemar

By Carla Waldemar

/-\ nec CI-rNe 's Gor Hrs dream

\Ijob-just ask him. He signed on a year ago as retail merchandising manager for Bloedorn Lumber, headquartered in Tonington, Wy., with 2l stores and a truss plant in four western states.

Joe Maya's crazy about his job, too. He's worked 17 years in the Worland, Wy., lumberyard he manages, which Bloedorn bought in 2000.

"I love merchandising," swears Greg, who recently masterminded the complete rehab of the Worland store Joe runs. And you couldn't pry Joe himself out of it with a forklift. "This is my hometown, where I grew up. I love working here," Joe jubilates. And after the remodel, he loves it even more: Sales are skyrocketing, and new-customer count is on the

uptick, too.

Bloedorn, launched back in 1919 selling lumber and coal, is on track to remodel the majority of its locations, two stores at a time-some, like Worland, drastically; others with a more subtle touch. The Torrinston and Buffalo locations, already Jompleted, each shifted focus in slightly different directions-one toward the retail market, the other to the pro. No cookie cutter in the grand design: "Each store is a little different." savs Greg. So we'll look ar Worland, which celebrated its grand reopening in late September.

What's the town like? Let's ask Joe, who's one of the 5,000 folks who live here. First of all, "it's not a bedroom community," he laughs. "In Wyoming, every little town is out on

its own. We're the only lumberyard in town."

But they don't write off thc challenges. "Very strong competition" thrives here, according to Greg, who's spotted an Ace, True Value, Big Horn, and big boxes looming down the highway. "So, we saw a need to diversify, to update things."

If you, too, are feeling that urge but hesitate to undertake a huge expansion, take note: "remodel" doesn't have to mean "expand." Worland's 10,000-sq. ft. footprint stayed the very same. And, challenging as it was, the store never closed during the top-to-bottom rehab. Customers not only took the upheaval in stride, they acted as cheerleaders, creating a buzz around town (a.k.a. free advertising) about the progress.

"I started on the outside-I always do, where it's most visible," Greg explains. "We put in new lawn and planting, new paint (from an orangey-red color scheme to one of muted green-more stylish), added new signage. It was right on a busy highway, so people took notice.

"Before, business was 80/20, focused on pros. Contractors had their own counter, back near the office, which (unfortunately) they couldn't see from the front door. Now they can spot it, plus there's more to appeal to the walk-ins. With the recession, we knew we couldn't rely only on the building trade, so we decided this was the time for an update and a repositioning of the departments to attract the retail trade-especially those with a female appeal. Today, ladies tell us, 'I like the way the store is organized. Now I can come in with my husband."' The paint department, Greg gives an example, used to be right up front. Now, it's halfway back, on the power aisle, so folks can see it easily.

Same for contractors goods. "'I never knew you had faucets,' they tell me," says Greg, "yet there'd been a 28ft. aisle of them, where the pros first came in the store. They were right in front of them." Wrong! Explains Greg, the master merchandiser, "You need a transition zone. When customers first come in, they need to get their bearings, decide where to head. They need space. So we created a foyer with tiled floor and an automatic door (used to be swinging). And"-big deal-"we've added shopping carts. They're used to grabbing carts in other stores, and it's working here. They're buying more, filling them up."

Everyone-especially the ladies-likes the new look, too. Formerly the interior was lit by fluorescent tubes hanging on chains from a vaulted ceiling. ("We were heating a lot of empty space.") Now, there's a new drop ceiling with new insulation, drywall, paint and lights. Restrooms, offices and break rooms got upgrades, too.

During the months-long transition, gondolas had to be shifted from one side of the store to the other, and products dropped in the power aisle to be sorted through-which to save and which to sell off in the $l bin. Several brand-new departments were added.

Planning was done with input of store management. "We spent a lot of time working together," Joe reports, "back and forth, exchanging ideas. Sometimes I couldn't believe the new items Greg would suggest-'Not a chance!'-but we went ahead with many of them, and they're doing very, very well."

Not by accident. Greg had done his homework, patrolling the aisles of the competition, counting the linear footage in their stores. "I did a market and site analysis, which spurred us to add whole new categories, like RV accessories (lots of tourists along the highway), Dickies work wear, and outdoor camping and cooking gear. We positioned these new features all together in an area of their own, and they've been very well-received. We plan to advertise them with circulars and with Ladies Night events."

Those ladies are thrilled with the store's brand-new cabinet displays, Greg reports. "Talk about a wow factor! Plus chandeliers and ceiling fans and new positioning of windows and doors." Speaking of wow, the floor now showcases working fireplaces and pellet stove and a brandnew outdoor kitchen in the home d6cor area, complete with grill and fridge. The lawn and garden department has tripled, including a garden tower and 17-ft.-by-35-ft. greenhouse nurturing live plants. Joe's staff of I I will expand in spring to include a nursery-products expert. A new cabinet specialist is already on board.

Bottom line: Bloedorn has become a destination store. "You don't have to run to the boxes. Now it's more in line with what the d-i-yer expects from a retailer," Greg allows. "We've incorporated items customers have been asking for, and it's greatly expanded our customer base-especially females. We'll be holding events like Powder Puff Mechanics-mowers, weed cutters-and classes in canning and food preservation."

Fine, but how about those pros? "Well, you know," Greg laughs, "when change happens, it's, 'I can't find itl' But then I hear, 'I didn't know you carried X.' They were so locked into their patterns that they never walked the other aisles."

The night before the grand reopening, the store hosted a contractors' night (wives-thrilled-were invited, too) with a catered barbecue dinner, demos and prizes. Then followed the public reopening. "That day-wouldn't you know it?-was the first big snowfall of the year. We were worried, but the store was full. Lots of new faces, and faces we hadn't seen for a long time, coming back to us. Sales are definitely up, and (unlike the pro accounts) they're paying in cashl"

Carla Waldemar cwaldemar@ comcast.net KICKED OFF with a recent grand reopening celebration, the makeover has turned Bloedorn Lumber into a destination store.

f,

oNCE ToLD me, "If

crazy and, poor, you're called crazy. If you're crazy and rich, you're called eccentric." Let's just say, if they had been born rich, my parents would have been eccentric.

My mother read John Steinbeck's Grapes of Wrath about the Dust Bowl migration of millions during the Depression from Oklahoma to California looking for work. A powerful novel, the book won the National Book Award, a Pulitzer, the Nobel Prize, and drove my mother to think that it would be a good for our family to pick fruit in the summer, like mierant workers!

To my father, an easy-going dreamer and English teacher, in that order, it must have seemed like a great idea, because we spent every surruner from age 5 to 14 picking fruit. School would get out on the 6th of June and on the 10th we were gone with the wind (really just an old Ford Fairlane wagon) like a band of fruit-picking gypsies for two-and-a-half months.

No baseball, golf or summer tomfoolery for the Olsen boys, no -ju st Grapes of Wrath

I have a twin brother, David. We picked fruit together for nine summers. Cherries, apples, peaches, strawberries, plums and pears. In nine summers, I never out-picked him.

David has the focus, drive and tenacity to finish big and small jobs. He is the senior v.p. of a Fortune 500 company. He is a machine with no off switch. His motor for work is bigger than mine. We have the same DNA, but the power is dispersed differently. (I sing and dance better, but no one is paying for that.)

You may have some David Olsens working for you. Congratulations, you've won the salesman's lottery. Treat them great; they are rare.

Realistically, you probably have more James Olsen types (not Superman, just his pal, cub reporter Jimmy Olsen) working for you.

Asking a player to make a play he cannot make and then getting angry with him for not making it is bad coaching, but it happens all the time.

It happens on sales teams, too. Any time you hear yourself saying, "If only he would _ more, he would sell more" or "All she has to do is _ and she would sell more," stop. You are not smarter than your sales team. They know what you are telling them. (How many times

have we gone over this?) They just may not have the motor to deliver on your expectations.

Many managers I work with have salespeople working for them who are'Just good enough not to fire." They have been haranguing (managing?) these same salespeople for years. Who's lazy? The sales team or the sales manager?

A dirty little secret of sales management is that it is a pain in the neck (read: difficult) to hire and train new salespeople. So it's easier to try to get growth from the team in front of you.

Most managers have some very good salespeople who will never be great. Are they profitable? Yes, more profitable than most, but all their manager can see is what they couldbe doing (if only), not the great work (especially visd-vis their motor) they are doing.

Expecting A+ results from a B+ salesperson is the same as a salesperson wanting A+ results from a B+ account base! SALES GROWTH IS YOUR JOB. Banging your fist on the table and saying, "Sell more!" will not get it done.

Set a profitability goal for all salespeople. Make it aggressive. Don't give in to mediocrity, but be realistic. Once your individual salespeople hit that number, work with them (give them RST Leadership sales training, for example) to get better, but when you get to maximization with your current team, hire more salespeople.

This strategy will work with the experienced yet underperforming salesperson who is holding your growth ,& x E. 1 hostage. Like the development in a city that must grow around a hard-nosed non-seller, build around him.

When your team knows that you are committed to growth, that you will hire new salespeople, they will work harder for you. New blood willdo what nagging never will-srow sales.

James Olsen Reality Sales Training (503\ 544-3572 james@ realitysalestraining.com25-y ear I im ited wa rranty

Reversi ble, sm oothltextured surface

Contains eco-friendly recycled materials

Complements any siding and architecture

Fiber cement for lasting performance

Smooth, square edges for finished appearance

Primed on six sides

Termite and weather resistant

Non-combustible

No specialized tools needed at jobsite

ISO 14001 and OHSAS 18001 certified

w€xrsffi** * **w

that complementi any siding and architecture

s*axrrxk**!i*y from long-lasting fiber cement

\&r{:}r"km *x* $ *fty that compares to wood Width.

Sasser Lumber Co., ta Grange, N.C., has placed its 80-year-old retail and wholesale businesses up for sale.

Salem True Value Hardware, Salem, In., switched co-ops after 45 years, is remodeling, and has become Ace Hardware of Salem. as of Jan. 2.

Avery True Value Hardware, Newland, N.C., has been sold after 51 years of Banner family ownership.

Ace Hardware franchisee Chad Homan will open a new store next month in Faulkton, S.D.

Swartz Hardware, Nonantum, Ma., has been acquired by Senneth Berrier after 123 years of Swartz family ownership.

Ace Hardw?IO, Monroe, Ct., is closing.

Pro Hardware, New Paris, In., has been purchased by Tim Spurlock from Fritz and Norman Weaver, who after 32 years of ownership are retiring to Arizona.

True Value, Columbus, Ks., has been acquired by Jason and Lisa Hulvey, who will reopen by spring, once a full remodel is complete.

Contractor Randy Coble is overseeing the renovation and will serve as manager once the doors open.

Ace Hardware opened a new store in Hampton, Va.

Bunnell Hardware, Clarks Summit, Pa., closed after 103 years and auctioned off remaining inventory Dec. 28.

Carl's True Value, Tonington, Ct., was seriously damaged in an early moming fire Dec. 11.

E&H Hardware Co., Wooster, 0h., this spring will open its Ace Hardware store, in Avon Lake, 0h.

Anniversaries: Economy Lumber Co,, Tulsa, ok., B0th ... Pearson's Lumlier, Lexington, ok., 75th Trendel Lumber Co.. ottawa. Ks.. 15th

Cedar Creek, Oklahoma City, Ok., anticipates an April I opening for a new distribution center in Atlanta, Ga., its sixteenth.

"This expansion into one of the nation's top housing markets underscores our ongoing commitment to growing Cedar Creek's geographic footprint," said c.e.o. Bill Adams. "Although we are currently servicing Atlanta from Birmingham, Al., our new location will assure that we provide the best possible service and localized product mix to our Atlanta-area customers."

D. Wayne Trousdale, c.o.o., added, "We found a great location, and we're in the process of assembling an excellent local team experienced in the Atlanta and greater Georgia markets."

U.S. LBM Holdings, Green Bay, Wi., has acquired twounit Musselman Lumber, New Holland, Pa., from Galen Eby, Joe Good, and Bob Quinlivan.

The l02-year-old dealer had yards in New Holland and Ephrata, Pa., which will continue to operate under the Musselman name.

Village Ace Home & Hardware is closing in Bloomfield Hills, Mi., this month and in Rochester, Mi., next month, reducing the chain to three locations.

The stores are currently liquidating. Owner Mark Elmer blamed the closures on an inability to renegotiate the leases with the landlords.

GAF, North America's largest roofing manufacturer, will relocate its corporate headquarters-and 600-person staff-to Parsippany, N.J., once renovations on its new offices are completed.

For more than 30 years, GAF has been based at a 99acre campus in Wayne, N.J., sharing space with its affiliated companies. In 201I, GAF sold International Specialty Products to Ashland Inc., which announced last year that it would relocate its employees from the GAF campus to other locations in New Jersey.

FSC (Forest Stewardship Council) Certified, manufactured in New Zealand to exacti eco-standards from the log to the

TruCore@ protected Centu resistant to rot.

used as Claymark's limited warranty.

giFffihrds are highly ffmite damage when are backed by

penetrates to the core of the board. result, cut surfaces, ends and drilled holes not require retreatment at the jobsite. This is ensured by a quality protection program that includes lndependent Auditor verification.

The TruCore@protection system is user friendly and does not include volatile organic solvents, heavy metals, arsenic, chromium or similar metals and has no offensive odor and thus can be used for interior applications.

The TruCoreo protection system components have been used for over 50 years with an excellent performance history.

The TruCore@ protection system components are recognized by the Window and Door Manufacturers Association (WDMA) and the American Wood Preservers Association (AWPA). Active ingredients are registered with the U.S. Environmental Protection Agency (EPA).

A new generation acrylic primer system: The prime coat has been formulated with excellent adhesion, minimum tannin bleed, and maximum filling properties. The undercoat has been formulated via use of modified acrylic technology delivering maximum toughness while not compromising the exterior durability of the product.

Distributed

Banowetz Lumber Co.. Anamosa. Ia., opened last month at the former site of Anamosa Building Supply, specializing in dimensional lumber, house packages, shingles, siding and hardware.

Owner Jeff Banowetz, a conftactor. is surprised the previous company closed last spring. "This community, with its growth, should be able to support a lumberyard," he said.

He's currently leasing the site, but hopes to purchase property to build a more modern facility.

MeadWestvaco Corp., Richmond, Va., has completed the sale of all of its U.S. forestlands to Plum Creek Timber Co.. Seattle. Wa.

The $ I .l -billion deal includes 501,000 acres of Southeastern timberland, associated mineral and wind assets, and interests in 109,000 acres of rural and development lands in the Charleston. S.C.. region.

MeadWestvaco continues to own and manage 135,000 acres of forestland in Brazil.

A&M Supply Corp., Pinellas Park, Fl., has acquired Atlantic Plywood's Richmond Va., distribution center, as its twelfth location.

Atlantic Plywood retains its l0 branches in the Northeast. "Atlantic

Plywood will continue to service its core customer base from New Jersey to Maine," said president Paul Vella.

The acquisition brings A&M added expertise in cabinet supply distribution, along with Richmond's HPL laminate manufacturing busiNESS.

"I am extremely excited about the opportunities to increase our service area in Virginia and to expand the manufacturing capabilities of the Richmond location into the Southeastern region of A&M Supply," said president and c.e.o. Raymond Prozzillo.

Gossen Expands in the East Gossen Corp., Milwaukee, Wi., has signed on several new distributors and sales agents to expand the reach of its cellular PVC products.

Princeton Forest Products, Orange, Ma., is now distributing the full line of Gossen decking, porchboard, exterior mouldings, trimboards and sheets in New England and the mid-Atlantic.

Genesee Reserve Supply's distribution centers in Buffalo and Rochester, N.Y.. are now carrying Gossen's Passport and Trailways decking and porch products in western New York. Reserve Supply, Syracuse, N.Y., is stocking the same lines for central New York.

Windward Sales, St. Augustine, Fl., is now repping Gossen products throughout the East Coast and Midwest.

Canfor Southern Pine witt invest $8 million to expand its SYP sawmill in Darlington, S.C., and will add a second shift by the fall.

Spearfish Forest Products, Spearfish, S.D., suffered damage to a planer building and adjacent shavings bin in a Dec. 2 fire.

ECMD, North Wilkesboro, N.C., purchased the 132,000-sq. ft. former Lifetime Doors facitity in Hearne, Tx., to renovate into its new Texas DC, replacing a leased Houston facility.

Public Supply, oktahoma City, 0k., is liquidating the last of its door and window inventory by appointment, months after the 67-year-old manufacturer/distributor closed and was olaced in receivership.

Prime-Line Inc., Malvern, Ar., will build a larger, $6.7-million fiberboard plant to meet increased demand.

Green Meadow Lumber, Westfield, Ma., escaped a Dec. 17 sawmill fire with minor damage.

Richard White Wood Pro. ducts relocated its log yard and offices to a new site in Morehead, Ky., to be closer to its hardwood timber suppliers. The former location is for sale or lease.

Headwaters Inc., s. Jordan, Ut., agreed to acquire an 80% share in Enteora roofinq manufacturer Roof Tile Inc.. okeeihobee. Ft.

Russin Lumber, Montgomery, N.Y., is now distributing Cali"fornia Redwood Co. redwood products in 13 Northeastern and mid-Atlantic states, starting with Clear All Heart, All Heart B, and Classic Heart lumber.

Mid-State Lumber Corp.'s DCs in Branchburg, N.J.; Kingston, Pa., and Warwick, N.Y., now distribute Fairway Building Products railings in New England and the mid-Atlantic.

Falls City Lumber, Louisville, Ky., is now distributing Integrity Cbmposites' DuraLid deckin! ani railing in Ky., Oh., In., and W.V., from its DCs in Louisville and Cincinnati, 0h.

Huttig Building Products, St. Louis, Mo., has begun trading its shares on the NASDAQ exchange under the ticker symbol "HBP."

Denny Meillier has retired after 25 years as president of Alexander Lumber, Owatonna, Mn. He is succeeded by his son, Josh Meillier.

Patrick Curtis, ex-Seaboard International, was named v.p. of sales for Concannon Lumber's Swindeman Trading division, Manchester, N.H.

John Edwards, ex-International Beam, has been named EWP mgr. for Cedar Creek, Statesville, N.C.

Craig Mitchell has rejoined the sales team at Linworth Lumber, Worthington, Oh.

John Fijalkowski was named purchasing agent at Mid-State Lumber, Branchburg, N.J., responsible for western red cedar, Blue Star meranti, fir and Tamko products. Travis Risser, ex-Babcock Lumber, is new as territory mgr. for Lancaster County and surrounding areas. Chris Saidla is now territory mgr. for New England. Lyle Tompkins, ex-Russin Lumber, is territory mgr. for the Albany, N.Y., area.

Chad Naish, ex-Birmingham International Forest Products, is a new southern pine trader at Stringfellow Lumber, Irondale, Al.

Frank Parrott, Matheus Lumber, San Marcos. Tx.. has retired after 30+ years in the industry.

Brian Callahan, ex-ProBuild, is new to outside sales with ReVosWel Truss & Lumber, Marion,Ia.

David Quintana has been promoted to store mgr. at McCoy's Building Supply, El Paso, Tx.

Jeff Brazezicke, ex-Blue Ridge Lumber, is new to outside sales and Kevan Phares, ex-Associated Materials, is a new engineered lumber specialist at Somerville Lumber Co., Bridgewater, N.J.

Dan Smith, ex-Lakeside Quality Building Products, has joined the trimboard sales team at Versatex, Pittsburgh, Pa.

Scott Berchiatti is new to Holland Southwest International. Houston. Tx., as business development mgr.

Steve Couch, ex-Carter Lumber, is now district mgr. for 84 Lumber, Muncie, In. Ben Ignatowicz is a new mgr. trainee in York, S.C.

Susan Susnowy is the new mgr. of customer service for Houston Fence Co.. Stafford. Tx.

Gina Cali, ex-Allied Building Products, is now key account mgr. in metro N.Y. for Kemper System America, West Seneca, N.Y.

Frank Carroll, ex-Knaack, is now general merchandise mgr. for Ace Hardware Corp., Oak Brook, Il.

David D. Bogue, ex-Home Depot, is new to truss design and sales at Timber Roots Truss Co., Sioux Falls, S.D.

Gary Hartman has been promoted to director of marketing & new business development at Chelsea Building Products, Oakmont, Pa. Brad Fello is now quality assurance mgr.

Mike Jost has been named v.p.-operations for ABC Supply, Beloit, Wi. Kathy Hendricks is now executive director oI customer connectivity.

Tony Vaden succeeds her as chief information officer. Chris Slusar is now corporate controller.

Barbara Anthony and Joseph Lalli were appointed co-presidents of Creative Millwork, Ashtabula, Oh.

Bruce Bunn has joined BW Creative Railings, Maple Ridge, B.C., as director of sales. Frank Girard is now senior financial mgr., and Phil Jones, controller. Kalvin Eden has been promoted to sales mgr. for BW Vista Railing Systems.

Rob Schmiedel was appointed nation-

al sales mgr. for Do it Best Corp., Fort Wayne, In. Scott Orman is now national logistics mgr.

Jim Whitton, Hunter Panels, Portland, Me., was elected chairman of the Polyisocyanurate Insulation Manufacturers Association, succeeding Dr. Chris Griffin, Johns Manville. Denver. Co.

John Weinstein is now v.p. of sales & marketing for Xylem Group, Roswell, Ga.

Danny White, T.R. Miller Mill Co., Brewton, Al., was newly appointed to the Softwood Lumber Board by U.S. Agriculture Secretary Tom Vilsack, along with Charles W. Roady, F.H. Stoltze Land & Lumber, Columbia Falls, Mt., and Don Kayne, Canfor, Vancouver, B.C. Reappointed to three more years were Aubra Anthony Jr., Anthony Forest Products, El Dorado, Ar.; Alden J. Robbins, Robbins Lumber, Searsmont, Me., and Francisco Figueroa, Arauco USA, Atlanta, Ga.

Art Burne is manning the employee cafeteria at Mungus-Fungus Forest Products, Climax, Nv., report owners Hugh Mungus and Freddy Fungus.

D scnnolEss oF ouR eLACE in the lumber supply

I\chain-logger, mill, remanufacturer, wholesaler, retailer-the immediate future of our businesses will be determined by many forces beyond our control and several very much in our grasp.

The questions of growth and profitability will be impacted by the very small (the mountain pine beetle) and the very large (the urbanization policies of the Chinese government), and much in between (the ability of a young family to buy a new home, or the changing

t4E@

credit policies of business lenders). With so many factors in play, what lies ahead for the lumber companies that have persevered and survived the devastating impacts of the great recession and the housing collapse?

Real recovery has been evident in recent months and there are many positive trends, and we are guardedly optimistic as we look at 2014 and beyond. What is clear is that despite generally rosy outlooks for lumber, not everyone in the industry will emerge from the recession and recovery as a winner.

There are many challenges ahead: dealing with credit issues, identifying trustworthy partners, introducing innovative products and practices, and understanding international impacts. Chief among the realities we face is the likelihood that the lumber supply cannot keep pace with growing demand.

While there are varied predictions on how much the lumber supply will tighten, there is a strong consensus among industry experts that supply will not be able to keep pace with demand increases in the U.S. and Chinabeginning this year and continuing over perhaps the next five years.

To dig deeper into this issue, I talked recently with Henry Spelter, a partner and forecaster with Forest Economic Advisors. He predicts that by 2Ol5 or 2016 demand will double to 1.5 billion board feet-twice the current demand-a level that will come up against major supply constraints.

The biggest constraint is the pine beetle epidemic. It is reaching its climax in British Columbia (B.C.), but the

wood that has been infested is less useful and a good chunk of supply will be taken out in coming harvests. In 2013, demand was up 57o to l}Vo, but B.C.'s harvest was the same as the previous year and its ability to respond to increasing demand is very low. This is likely to reduce B.C.'s role in the supply mix.

Mill closures due to recession are a factor. but not an enormous one, because much of their output has been replaced by more production at other mills. Still, there has been a loss of about 7 billion board feet in production capacity-about ll%o.

A third supply constraint is government policies, which are especially limiting in the U.S. Pacific Northwest. These include limitation of timber harvests from public lands, lumber trade restrictions, and log

to grow as China moves to urbanize its population. One result is likely to be higher prices for wood. If demand bumps against constraints, log prices will go up. Now about $400 per I,000 bd. ft., the price could get to $500 or even $600 or $700. If so, alternative building products such as steel, plastic and composites will become more attractive building products.

Keep your suppliers close. Regardless of the exact levels or causes of the supply shortage, it is increasingly important for lumber wholesalers to solidify relationships with your suppliers and reach out to new possible sources before we are desperate. The competition will intensify in coming months, and those who are well positioned with suppliers will have an advantage.

Listen to the sound of the future. I invite you to join me for what will be a very important 2014 NAWLA Leadership Summit, March 30-April I, at Callaway Gardens, near Atlanta. It will be a timely gathering for all of us, as we face these challenges. Seven industry leaders have agreed to speak to us about the futureabout outlooks in various regions, U.S. and international developments, and navigating changes in the supply chain.

The speakers are Don Kayne, president/c.e.o. of Canfor; Marc Brinkmeyer, chairman of Idaho Forest Group; Jack Koraleski, president/c.e.o. of Union Pacific; Kimmo Jarvinen, secretary general of the European Organization of the Sawmill Industry; Jon Biotti, managing director of Charlesbank Partners; Peter Alexander, c.e.o. of BMC, and Curt Stevens, c.e.o. of Louisiana Pacific. I urge you to consider attending this Summit as we begin a new phase of lumber industry recovery. For more information, go to www.nawla.org.

export duties and restrictions.

Spelter says the high point of production, in 20042005, was 65 to 70 billion board feet a year. Today, there is 50-55 billion board feet of capacity being used of the nominal capacity of 63 billion board feet (effective or real usable capacity is less because some mills are mothballed).

Supply limitations come at a time when U.S. housing starts are trending upward and Chinese demand continues

Position yourself to compete. In this new environment, securing good deals with suppliers will become very competitive. Also, anticipate competition from engineered woods, plastics, vinyl decking and composites, which are likely to become a large part of the market. As one insider said, "We're going to have to stay alert and act decisively to get our share."

Caution: sharp elbows may prevail.

T"u U.S uns more softwood trees

I- than you can shake a stick at. Analysis of U.S. Forest Service data indicates the South has nearly 3.5 billion tons of standing pine grade and pulpwood inventory on private, operable timberlands. That's about 140 million truckloads. Coastal Oregon and Washington, a region with 103 open softwood mills, has over 68 billion bd. ft. (over 400 million tons) of standing softwood grade inventory on privately-owned timberlands. And these numbers represent but a fraction of total U.S. forest stocks.

Forisk conducts research on the impact of local supply events (such as natural disasters) and trends (such as increased forest growth rates or plantation acreages) on timber markets to forecast timber and delivered log shipments. For the near-term, states with the most severe pine grade oversupplies show how stumpage prices become less sensitive to increases in demand in those states for which a quantitative basis exists for significant excess inventories.

Alternately, analysis of coastal markets in the Pacific Northwest indicates less quantitative evidence for dampened log prices in a region buffeted by robust export demand.

What do we think about the poten-

tial impact of forest supplies on timber prices across the United States in the short and long-term as housing markets recover and forest harvesting increases?

In evaluating the potential for softwood grade oversupplies or constraints, Forisk uses the "removal year" metric-accessible inventory divided by removals-to identify a local market with a potential supply imbalance. The removal year estimates how many years it would take to deplete standing inventories, given a set level of removals per year. For example, if we assume one extra year's worth of standing inventory, it would take four years of removals at 25Vo above the long-term average to deplete the backlog.

In the Pacific Northwest, estimated changes in operable inventories on private lands have been modest, with Coastal Oregon and Washington averaging 16 years of softwood grade removals on the stump on private lands alone.

The results in the Northwest change slowly for two reasons. First, the U.S. Forest Service analyzes onetenth of Oregon and Washington's forests each year. Therefore, we are continually looking at an average l0year forest. Second, Northwest markets have supplemented domestic downtime with increased export vol-

umes, reducing the impact on net harvests. We note that the total removal years in the Northwest are higher when operating public forests are included, but we focus on private lands to better reflect harvest responses to changes in market prices.

Log exports are important to forecasting models for the Pacific Northwest because exports, while volatile and inconsistent, influence domestic sawlog prices. Export pricing ripples inward from the Coast to the Eastern Washington and Inland markets. In addition, log exports are subject to substitution across products, species and size classes. This is especially critical in Washington, where the ratio of domestic-to-export demand is 5:1. For Coastal Oregon, this ratio is closer to 50: l.

On the other hand, analysis of timber markets across the South indicates that. in the short term. excess sawtimber volumes can delay the strengthening of pine grade prices. For the U.S. South, not including outliers associated with lower-volume Tennessee and Virginia, states historically average 18 years of pine grade removals on the stump on private lands. Recent data indicates inventories for these same states approaching 3 I years of pine grade removals on the stump. The largest gains have occurred in Georgia, Mississippi and Arkansas.

U,S.

Softwood Lumber Produetion by Region, 1990-2013

While the Northwest benefits from log exports, forecasts for the South enjoy an increasing share of U.S. softwood lumber production. Current and forward-looking views on U.S. lumber production by region must account for two shifts. One is the increased U.S. market share of domestic lumber at the expense of Canadian imports. The U.S. share has risen from 6lvo in 2OO4 to 72Vo for 2Ol3 based on year-to-date WWPA data.

Two is the U.S. South's increased market share of domestic softwood lumber production relative to the Pacific Northwest. The South grew its share of domestic production from 347o in 1983 through 1993 to 467o in 1993 through 2003. The 2008 to 2Ol2 five-year average was 50Vo.

Long term, we assume that the South will grow its share of U.S. lumber production as the demand for housing returns to trend. This assumption is supported by the location of capital investments made and announced by forest industry firms in the United States.

Forward-looking projections highlight differing potential impacts of the recent economic recession on future forest supplies in the South and Pacific Northwest. Reduced harvesting activities over the past five years resulted in fewer acres of replanted trees.

For the near-term, states with the most severe pine grade oversupplies continue to show material decreases in their price-to-demand relationships over the past five years. In other words, stumpage prices became less sensitive to increases in demand in those states for which a quantitative basis exists for significant excess inventories. This includes states, for example, such as Georgia, Mississippi and Arkansas. Alternately, coastal Oregon and Washington have less evidence of supply-driven price effects.

While these estimates do not specify the situation in any given wood basket or for any given timberland property, they do support the evidence that supplies have affected stumpage markets selectively.

- Brooks Mendell, Ph.D., is president and v.p.-research of Forisk Consulting, Athens, Ga., providing research and educational services to executives and analysts making decisions related to timber REITs, timberlands, and wood-using energy and manufacturing facilities. He can be reached at (770) 725-8447 or bmendell@forisk.com. Building-Products.com

Columbia Vista specidizes in kiln-dried Douglas fir 4 x 4s... high qualiry yet affordable alternatives to pine and cedar posts. Available in 8-, 10- and 12-foot lengths, our 4 x 4s are produced by skilled, dedicated people during a single shift for maximum consistency.

Wc rc pmud to bc certificd to ISO 14001 stmdards and by thc EPA for environment-friendly practices,

3-D ranning systcms, mechanized lumbcr-handling swtcms. and more.

including the usc ofnon-polluting rcurccs ofclcctricity. ' Employcc-fricndlyworkplacc mcans our pcoplc takc Columbia Vista ensures quality in mmy ways... pride in their work and products.

Our commitment to the finest extends beyond the mill. Mills are consistently upgraded with state-of-the-art Posts re carefully kiln-dricd for immediate us. ^7\.

Hil"1"f:,111,ill;'Jl''*"" 2ru 2010 2012

f T.S LUMBER DEMAND strengthened significantly in late L) 2ol2learly 2013 as home construction showed doubledigit growth.

While home building slowed late in the year, residential repair and remodeling-the largest lumber market by volume-picked up the slack. R&R construction spending finished the year up an estimated 9vo compafed to 2012. Higher interest rates coupled with continued slow economic growth is expected to result in modest but sustainable gains in 2014.

Responding to increased demand, 2013 U.S. lumber production increased an estimated 6Vo to 39.32 billion bd. ft., compared to 36.54 billion bd. ft. in 2012, according to WWPA. Lumber production in the West is expected to climb to 13.34 billion bd. ft. for 2Ol3 and is projected to be

13.97 billion bd. ft. in 2014.

Lumber and log exports both saw gains. Lumber exports to the Pacific Rim should top 2.2 million cubic meters in2Ol3, with overall lumber exports finishing about 97o higher.

Log exports to China, predominantly Douglas fir and hemlock from the West Coast, are expected to top 6 million cubic meters in 2013-a 45Vo increase year-over-year. Exports to Japan are also up by double digits. Log exports to all countries are expected to top I 1.9 million cubic meters for the year, up 24Vo.ln 2Ol4,log and lumber exports should ease as domestic lumber prices rise and competition for logs increases.

Western Wood Products Association will celebrate 50 years of lumber industry service at the 2014 annual meeting March 2-4 in Portland, Or.

More than 200 industry professionals are expected to attend the three-day gathering, which will feature committee meetings, awards, receptions, lumber and housing forecasts, and events to commemorate WWPA's 50th anniversary.

And Blue Book Services helps you get there faster. Whether it's qualifying new sales leads, or locating a p0tential partner, we've got the critical information you need to make solid decisions.

Real-time information on more lumber companies than any other source Find new accounts with easy access, search, and sorting for over 19,fl)O companies

Proprietary "Pay Indicator'shows a company's recent payment histories with industry supplien

In-depth reports provide detailed pay histories, public filings, business & ownership background

Blue Book Services has been a trusted provider of credit risk data since 1901

The annual meeting will kick off with the industry welcome reception March 2. WWPA president Kevin Binam will provide the association's lumber outlook through 2O16 at a forecast breakfast. WWPA committee meetings will tackle such industry issues as lumber design values, grade requirements, and phytosanitary regulations for lumber exports. The aftemoon features an industry forum on a range of industry issues that impact western lumber producers and their customers.

Among this year's guest presenters will be Brooks C. Mendell, Ph.D., Forisk Consulting, providing an assessment of U.S. timber supply constraints on producers and their influence on western lumber markets. The nation's housing market and consumer demand for repair and remodeling will be covered by economist Jonathan Smoke. The day will close with the chairman's reception, offering opportunities to network with other industry professionals.

The annual meeting is open to all industry professionals, including retailers, wholesalers and manufacturers. Visit www.wwpa.org for more details.

Since 195I nc'r'c l',ccrr l.r, rlistriL'rrtors, rlclrlers,

nrlrking .1ualitv filrcsI pr..,..ltrcts rrse..l l.u ilrlc rs, rc utti.lclcrs, lrtrtl *.lt l - i t'r'orr rsel tc t-t.

For ovcr sirfl',,,g111-s ric hlrvc lirllilr.l,ctl rhc sirurc pritrcrplc.: tlrl<c clrlc ofrthc llrn,.l lrn.l it ri,ill trrkc crtre ()f \'()u; strivc firr crccllcncrc ltntl cfticicnci'in nltntriltctttrit'tg; iul(l trcilt irll supplicrs lllrtl cLlst()nlers thc u'iry 1'orr u,,rrrl..l likc t..' lrc trc:rtctl.

For sales call: 1.800,331-0831

www. swansongroupinc. com

'pneltulNnRY rESr onrn analysis of I Spruce-Pine-Fir (South) lumber samples from the western mills indicates no change to SPF's lumber design values is needed.

A report on SPF by the cooperating agencies is being finalized for submission to the American Lumber

Standard Committee board of review at this writing. It is anticipated the board of review will consider the submission at their meeting later this month.

SPF is a U.S. commercial species combination similar to the Canadian SPF combination. The growth range

of the species included in the group covers the western lumber producing region through the Great Lakes states and extends into New England. Lumber samples for the testing program in the West were taken from mills producing 2x4 lumber in Engelmann spruce, lodgepole pine,

and Sitka spruce.

The testing for the western lumber sample was conducted by Western Wood Products Association in cooperation with other western lumber agencies. Northeast Lumber Manufacturers Association had previously conducted testing for the Northeast SPF production region and the Northern Softwood Lumber Bureau completed testing for the Great Lakes area earlier this year.

The published lumber design values are based on the in-grade lumber testing program. The testing plan was approved by the ALSC board of review. The plan required destructive testing of lumber samples in bending of SPF No. 2 2x4.

The preliminary data comparison to the SPF properties established in Building-Products.com

the original in-grade testing program indicates no change is required to the currently published design values. The monitoring program affirms current uses and building code recognition. The recognized span data for the species group will also remain the same. Had the data indicated a shift in properties, the test findings would have reviewed by the cooperating agencies' memberships and appropriate actions taken.

The coordinating western lumber agencies, including Pacific Lumber Inspection Bureau, Redwood

Inspection Service, Timber Products Inspection, West Coast Lumber Inspection Bureau, and Western Wood Products Association, have been working together since early 201I on the testing program to monitor western lumber design values.

Hem-fir will be sampled and tested rn 2014. The testing of western species lumber is conducted periodically to monitor for changes and to allow for timely actions to be taken, if needed, to support western lumber products.

I. for U.S.-produced softwood lumber continues to be a small but steady destination for western softwoods, especially in Pacific Rim countries. The market fell back a bit in 2ol2,but recovered with the return of China as a major buyer of U.S. softwoods in 2013. Exports for 2013 should finish 20Vo ahead of 2012 at more than $1.15 billion and 1.4 billion bd. ft.-a possible new near-term record.

China reentered the market in a big way, pushing it to the number one spot with an estimated $223 million in value. Japan continued to improve with an estimated $166 million in value and 173 million bd. ft. received in 201 1. Two other $IO0-million markets were Mexico and Canada, which includes re-exports overseas.

The international markets cooled in 2Ol2 and were slow to start up again in 2013. Exports picked up during the second half of 2013 and are up from 2Ol2 and near the record levels of 201 1. Last vear. China reeained the

number one position for softwood exports after dropping back to fourth place in 2012, behind Canada, Mexico and Japan-markets that are steady or slowly growing.

Regional markets estimates in 2013 for U.S. softwoods include the Caribbean at $150 million, Southeast Asia at $50 million, and the European Union falling to $18 million. Upwardmoving markets-such as South Asia, including India and Pakistan, and the South Pacific, including Australia and the French Pacific Islands-combine for another $60 million in exports and Central and South America combine for over $12 million in shipments, up from 9 million in2Ol2.

Western species continue to have the major share of the international markets. Fir has climbed from $58 million in 2005 to $295 million (337o of all softwood export) in 2013. Hemlock has climbed from $11 million in 2005 to $161 million in2oll, but dropped in 2013 to $105 million, mostly from China. Ponderosa pine

has maintained a steady market at about $32 million in 2011, but up to $40 million in2013.

In the worldwide lumber market, U.S. softwood producers are still small suppliers in international softwood markets. Europe, Canada, Chile, New Zealand, and Russia are the major exporting regions or countries for softwood lumber products.

International markets requirements and product uses vary widely by species, sizes, grade requirements, and end use of the materials. Traditional structural species, such as fir and hemlock, are found in many non-structural products. Lower grades of all species, of limited value in structural uses, find a home in crating, pallets and packaging. They are used in many reman and gluing facilities, in parts of the world with much lower labor rates, for furniture and millwork components.

Wood frame residential construction is mostly limited to North America, Japan and Oceana. Even in those markets, the use of North American framing systems that incorporate 38mm x 89mm (2x4) structural members is limited to the U.S., Canada and a small segment in Japan.

Japan is the second largest wood frame building in the world, but of the nearly 540,000 wood frame units in Japan this year, only 108,000 were 2x4based. The vast majority were traditional Japanese metric post and beam timber construction using metric sizes. Structural framing sizes in Australia and New Zealand use 35mm and 45mm by 90mm and l00mm sizes. U.S. softwood producers successful in these markets are providing metric sized lumber to compete with other imported products, mainly from Europe and Canada.

Most U.S. softwood exports are for non-structural uses. Interior applications, such as doors, windows, frames, mouldings, flooring and paneling, are a prime destination for both pine and fir species. Furniture parts and glued panels are also major uses of softwood lumber. Western species, such as Douglas fir and hemlock, in clear and other upper grades are prized in Europe for window and door parts and frames. Ponderosa and other western pines are used in rustic furniture, and for upholstery frames in Mexico, China and Vietnam. U.S. producers sell both metric and imperial sizes into these markets, since much of the stock is ripped and resawn to provide "finished" metric sizes for local markets.

A large portion of exported lower grades are used in concrete forming for form walls, wailers and support posts. Much of the worldwide structural construction is based on the use of concrete, creating large demand for formwork materials at all levels. Some markets require structurally graded materials, but otheres see wood as a single-use material and aim for a costcompetitive, disposable supply, such as for fuel or local d-i-y projects.

The Pacific Rim is the leading market for western species, with China the top destination in 2013, after dropping back in 2012 behind Japan. China has grown by a factor of 10. In 2005, exports to China were $23 million (33,072,000 bd. ft.), rising to $245 million in 201 I In 2013. however. China jumped 537o, to an estimated $236 million. Hemlock was the top U.S. species imported in 2011 at $105 million; it took the big hit in 2012 and recovered in 20 l3 to $79 million. Douglas fir was $37 million in 2011, and increased to $53 million in 2013.