2,600 dedicated employees, and one of the most extensive product offerings of value-added treated lumber, we can deliver in ways few others can.

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves • sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Claudia St. John, Dave Kahle

CONTRIBUTORS

Simon Cameron, Nichole Gunn, Henry St. John, Katy Tomasulo

ADVERTISING SALES (714) 486-2735

Chuck Casey • ccasey@526mediagroup.com

John Haugh • jhaugh@526mediagroup.com

Nick Kosan • nkosan@526mediagroup.com

DIGITAL SUPPORT

Katherine Williams kwilliams@526mediagroup.com

CIRCULATION/SUPPORT info@526mediagroup.com

151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 Phone (714) 486-2735

CHANGE OF ADDRESS Send address label from recent issue, new address, and 9-digit zip to address below.

POSTMASTER Send address changes to The Merchant Magazine, 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626. The Merchant Magazine (ISSN 7399723) (USPS 796-560) is published monthly at 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 by 526 Media Group, Inc. Periodicals Postage paid at Newport Beach, CA, and additional post offices. It is an independently-owned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 western states. Copyright®2025 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. We reserve the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles are intended for informational purposes only and should not be construed as legal, financial or business management advice.

Volume 104 • Number 3

Update

Construction in California is facing significant challenges, including increasing threats from wildfires, a growing demand for sustainable building, and more rigorous building codes. Builders call for supply partners that take their success in overcoming these challenges seriously. That is why many industry leaders turn to Western Woods. We have over 53 years of proven success throughout the West Coast, offering premium-quality lumber and producing industry-leading guides that empower success with our products. Your success is our success and we’re here to help.

Excellent products. Unrivaled service. It ’s what we do.

Like the foods we buy, when it comes to decking, we want natural and real. Redwood is always available in abundance of options. So stock the shelves! Unlike mass-produced and inferior products, Redwood is strong, reliable and possesses many qualities not found in artificial products. They maintain temperatures that are comfortable in all climates.

Redwood Empire stocks several grades and sizing options of Redwood.

------------ BY PATRICK ADAMS

IS KNOWING a tomato is a fruit. Wisdom is knowing not to put a tomato in a fruit salad. I’m not sure anyone would attach either word in a description of me. And yet, here we are beginning another new chapter of our business.

Some of you may have heard that we recently made another acquisition. Instead of another publishing company in one of our four target industries, we made Lumber Blue Book part of the 526 Media Group family! While there was some intelligence, and perhaps a bit of wisdom behind this, the main driver was something more.

As you know, we have a strong “service culture” within our team. In everything we do, our first question is, “How does this serve our industry or our audience?” When we heard that Lumber Blue Book, the industry’s only credit and marketing data service, was being closed, it brought several things to mind. Why? What, if anything will fill that void? What else could be added to make it even more valuable to the industry? And also, it brought back memories of when the industry’s only real pricing report went up for sale. I regrettably passed on that opportunity and feel partially responsible that the industry doesn’t have a better resource than what’s currently available. This time, I decided not to let that happen again.

We had to rename this trusted industry service and decided to hearken back to the “beginning” and name it Red Book Lumber Data. No matter how old you are, you remember the Lumbermen’s Red Book being a trusted source of information that was used to make critical business decisions. And so it will again! While everything the industry has counted on for both credit rating decisions and sales lead and market data will remain, we are already underway with developing new data services that will help you drive your business.

In addition, the Lumber Newswire, the industry’s only daily e-newsletter, is also now part of our family. This will continue, while also growing to be the best and most

trusted source of breaking news in our industry.

All of this has made me think deeply about our organization and our future. In the early years, I pursued a deliberate strategy to grow in four different industries as a means of diversification and hedging economic volatility. Each industry holds a unique place in my heart as they are all what we call “American Bedrock Infrastructure Industries.” We knowingly joke that if any segment of our audience decided to not come to work for a week, our country would shut down. That is not far from reality.

However, as time has gone on, it is the LBM industry that I enjoy, admire and, honestly, learn the most from. The friends I have made here have made me a better leader, a better husband, father and man. Because of this, we have made a corporate decision to divest ourselves from the investments in industries that are outside of LBM and instead, focus exclusively on how best to serve the evolving needs within lumber and building materials. Our industry is changing, and so is the world around us and I believe it is important the industry has a trusted and reliable partner for news, information, data and countless other services. While we are proud of what we have done to serve other industries, each of us are excited about this new laser focus and commitment to those we hold as our closest friends. Whether it is news, or data, or even coffee, we want to be your go-to source to solve problems and uncover opportunities!

Without each of you and all that you have done to support us, none of this would be possible. Only time will tell whether this was wisdom, or intelligence, or perhaps something else. Regardless of the outcome, as I have closed this column each month for over a decade, I cannot express the honor and gratitude I have for the opportunity to serve this great industry and each of you.

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

------------

BY DAVID KOENIG

WESTERN TIMBER FRAME has been building and selling custom shade structures since 2008, from installing yard-wide projects in Utah and surrounding areas to shipping kits throughout the U.S. Douglas fir has been the species of choice for pergolas, pavilions and gazebos. But the company has also begun working with redwood timbers so it can offer a premium/upsell option.

“Redwood’s got it all—durability, natural beauty, and it holds up great against the elements,” says founder Hyrum Thompson. “It’s naturally bug- and rot-resistant, meaning less upkeep and a longer-lasting structure. Plus, it checks and cracks less than Douglas fir, so it stays looking better over time.”

Customers have been very receptive to the new redwood offerings. Thompson notes, “Customers love it!

They’re commenting on how redwood transforms their spaces. They like that it’s both beautiful and tough—and they don’t have to fuss with a lot of maintenance. We’re still building our first dozen or so projects with redwood and are very, very excited with the results. Plus, we’re looking forward to helping with more coastal projects since redwood weathers beautifully in salty air and naturally keeps bugs away from making the structure their home.”

Western Timber Frame works with Mendocino Forest Products/Humboldt Redwood Co. to procure the redwood timbers. They kicked the new partnership off with an eye-catching display at the most recent Salt Lake Fall Home Show. The display, featuring a stunning redwood deck, gazebo and pavilion, won Best of Show.

The display, Thompson says, “showed off just how good redwood can look and perform. Folks at the show couldn’t stop talking about the rich color and craftsmanship—it really turned heads!”

The company also shows off what redwood can do in displays at its showroom in Lehi, Ut. All signs are bright.

“We’re paving the way for redwood in a market that hasn’t fully realized its value in years,” Thompson says. “By focusing on key projects, we’re showing its strength, beauty and versatility firsthand. We’re also sharing the story of redwood’s unique qualities—how it holds up in tough climates and offers natural resistance to pests. Through new builds and customerfocused outreach, we’re introducing it as a fresh, premium option for outdoor structures, and the response has been energizing. This is just the start, and there’s a lot of excitement about what’s ahead.” MM

• The Auto-Stak System

• Cantilever Rack Systems

• Metal Buildings

• Drive-Thru Systems

• Millwork Storage Systems

• Pallet Rack Systems

• A-Frame Systems

THE LUMBER and wood industry is a highly important supporting structure of the nation’s economy, with average sales in the 12 figures (yes, that’s in the hundreds of billions), creating hundreds of thousands of jobs and contributing to a wealth of communities. Having customers and specifiers knowledgeable of the many attributes and advantages of using natural wood over other non-wood products is obviously crucial to the health of the softwood business, but educating those inside the industry is essential to the future of the whole industry.

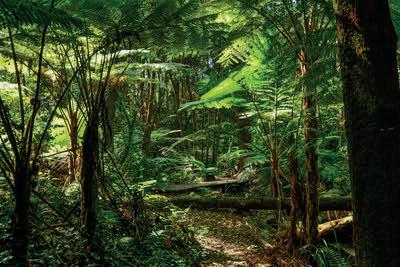

Since the founding of the Western Red Cedar Lumber Association (WRCLA) in 1954, the association has maintained a fundamental objective of training the next generation of members; not just on how to sell, install and maintain western red cedar, but also on the quality, sustainability, numerous attributes and wealth of finishing options the species provides. To achieve this goal, the association has created a robust and comprehensive marketing and educational program which is executed on an ongoing basis. One of the most central components of the program is the annual WRCLA Cedar School: a weeklong practical and instructional program aimed at the next generation of salespeople in the building products distribution network.

Now in its 26th year, the Cedar School is a comprehensive week-long course that includes guided forest and

mill tours, business sessions on subjects like marketing, lumber grading, best practices for finishing WRC, and installation seminars.

“The school is really about the life cycle of the western red cedar tree,” said Brad Kirkbride, managing director of the WRCLA. “Students taking the course learn about and see firsthand every touchpoint from sapling to log to lumber and then the various applications of the final products. Our goal is to have engaged, knowledgeable members that will continue to be ambassadors of this great product.”

For an industry beset with numerous market threats from non-wood substitutes, it’s a smart strategy that’s helped keep WRC competitive.

“The WRCLA is known as the ‘The Voice of the Cedar Industry,’” continued Kirkbride, “but the strength of our voice comes from our members. Where a lot of industry associations struggle with member retention and satisfaction, we’ve been incredibly fortunate in that programs like the Cedar School really help to inspire, teach and engage our members. We’ve all been to run-of-the-mill conferences that are pretty hard to stay interested in, let alone get excited about. But compare that to something like a week-long, hands-on program where members come knowing specifically what they’ll learn to not only propel their careers forward, but where they’ll also be

an active part of the future of the industry. That’s a massive difference, and the response to it over the last quarter century speaks for itself.”

The itinerary for the school changes slightly from year to year, but strives to provide a comprehensive look at both coastal and interior logging and lumber production, as well as the market and technical aspects of the species. This year, the program includes manufacturing theory, marketing, grading theory, as well as a forest and sawmill tour at Loon Lake’s Malcolm Knapp Research Forest, tours of Power Wood Corp., Woodtone remanufacuring, Interfor’s Adams Lake Division, and a Tolko reforestation tour. Additionally, seminars will be held on western red cedar finishing techniques, and a how-to-install WRC and exam.

“The more someone knows about western red cedar,” Kirkbride added, “the more they’re likely to choose it over a non-wood product. As an association, we strive to keep our members knowledgeable and engaged; as an advocate for the cedar industry we also focus on educating specifiers and consumers on the advantages of western red cedar. Its role in biophilia, for example—how it helps reduce stress and stress-related disease—and how it mitigates climate change are very topical today, particularly in light of the fact that environmental considerations continue to grow in importance when it comes to making home-improvement decisions.”

The WRCLA’s educational outreach seeks to engage architects, builders and other specifiers through field reps who conduct both virtual and on-site training for member distributors and their customers, as well as through Continuing Education Unit courses (CEU’s) developed in partnership with the American Institute of Architects and made available to architects, engineers and other industry professionals who take the courses to maintain their accreditation. The association also allows architects to specify cedar through their affiliation with ARCAT.

“We aim to educate consumers on why WRC is the right material for the job as well,” furthered Kirkbride. “DIY and informational videos have been great vehicles for that audience, and our website is an incredible educational tool for things like how to

specify, install and finish WRC.”

“To be successful in any business you have to provide customers with what they want,” added Kirkbride in closing, “but to be viable for the long term in an industry like ours, it’s essential that customers are informed on the benefits and the impacts of choosing natural products like western red cedar. As our awareness of why we should be choosing materials

and building practices that benefit both customers’ and the well-being of the planet’s needs continues to grow, educating the next generation becomes an increasingly essential job.” MM

– Established in 1954, the WRCLA is the voice of the cedar industry and has members in 142 locations throughout North America.

ACROSS RESIDENTIAL construction, continued attention toward high-performance homes is driving efforts to design building envelopes with increased energy efficiency and greater durability.

Here are a few of the trends Benjamin Obdyke is seeing for 2025.

1. Resilience: The growing threat of wildfires and hurricanes has homeowners and builders alike seeking techniques and materials that can withstand increasing weather extremes. This includes fire-resistant cladding, decking, and roofing materials, such as those with WUI (Wildland Urban Interface) compliance, and siding and roofing options with high wind resistance ratings. Robust envelope designs that help bulk water drain away also are key. On the roof, a self-adhered underlayment can provide some initial protection in case shingles are blown off during storms.

2. A systems approach to energy efficiency: The 2021 International Residential Code, which brings greater energy efficiency requirements, is starting to be adopted in more jurisdictions around the country. In the past, tighter homes meant less drying potential in the wall system, leading to moisture problems. Today, more builders are recognizing the possibility of failures from water intrusion and are putting a larger percentage of their construction budget toward weatherization, including for HERS raters, building science consultants, and computer modeling, to help design building envelopes with a systems approach that

increases efficiency while also managing moisture and preserving indoor air quality.

3. Rainscreen requirements for stone veneer and stucco: Another change in the 2021 code is a requirement for using rainscreens behind manufactured stone veneer cladding and stucco. A full ventilated drying space is essential behind absorptive claddings such as these. A ventilated rainscreen incorporates an opening at the top of the wall as well as the typical opening at the bottom, creating a convective air flow that helps further dry the cavity.

4. Continuous insulation: The 2021 building code also requires continuous exterior insulation in Climate Zones 4 and above. Installing continuous insulation to the exterior of the building envelope can add an extra R-5 insulation value while helping to eliminate thermal breaks. It’s important to factor in how the addition of exterior foam board can impact the installation of weather resistive barriers and flashing.

5. Conditioned attic spaces: With the ongoing move toward more energy-efficient homes, conditioned attics have become more common. These spaces are often not designed with proper vapor permeability nor adequate ventilation, which can lead to trapped moisture, condensation, and eventually mold and rot on wood sheathing, and premature roof failure. For homes with conditioned attics, a vapor-permeable underlayment like VaporDry SA can allow moisture escape to help keep the roofing system dry. MM

------------

BY NICHOLE GUNN

THE LBM INDUSTRY is facing headwinds. Between shrinking budgets and evolving consumer priorities, it’s no surprise that 34% of homeowners plan to scale back on home improvement spending in the coming months. This means fewer projects and fiercer competition. For LBM dealers, distributors, and contractors, staying competitive requires out-of-the-box thinking—and incentive programs could be the solution.

Incentive programs reward specific actions that help your business hit its goals—whether that’s increasing sales, promoting higher-margin products, or delivering exceptional service. As the CMO of Extu, a provider of incentive programs, I’ve seen firsthand how their flexibility makes them an excellent fit for businesses of any size.

For instance, imagine a distributor launching a campaign that rewards sales reps for surpassing monthly targets on premium siding. Or a contractor offering bonuses to crews for finishing jobs ahead of schedule with stellar reviews. By aligning rewards with the outcomes you want, you create a win-win scenario: your team feels valued, and your business reaps the benefits.

A heating and cooling company recently teamed up with Extu to increase sales of specific HVAC systems. The program was simple but effective: sales reps earned branded debit cards with instant payouts for every approved sale. It created a stunning 45% increase in claimed incentives. It worked so well they turned it into an annual initiative. This is one example of finding the right combination of targeted rewards and immediate gratification to motivate and engage your employees.

Here are four straightforward steps to get started:

1. Define Your Goals: Be clear about what you want to achieve. Are you aiming to boost sales for a particular product line? Improve job completion rates?

2. Choose Rewards That Matter: Think about what motivates your team. Cash is popular, but don’t underes-

timate the power of unique perks like tools, event tickets, or gift cards.

3. Make It Simple: Complicated programs turn away participants. Keep rules clear and concise so everyone understands how to earn rewards and when to expect them.

4. Measure and Adjust: Track your results—participation rates, sales boosts, customer feedback—and refine your program to keep it fresh and effective.

Beyond boosting sales, incentive programs bring added value to your business:

• Boost Efficiency: Motivate your team to focus on high-margin opportunities.

• Elevate Quality: Reward performance metrics like ontime deliveries or glowing customer reviews.

• Strengthen Loyalty: Recognize your team’s hard work, and they’ll stick around longer.

• Maximize ROI: Target your top performers to get the most bang for your buck.

Economic challenges demand innovative solutions, and incentive programs are a powerful tool to keep your business competitive. They build morale, drive results, and set you apart from the crowd. Whether you’re running a small contracting business or managing a large distribution network, the right incentives can help you turn challenges into opportunities.

With a little creativity and a well-thought-out plan, incentive programs can help your business not just survive but thrive—even in a tough market. MM

NAWLA established the John J. Mulrooney award to commemorate his life and career, emphasizing his important contributions to the forest products industry. Since his passing, NAWLA has recognized an elite group of individuals who exemplify the qualities Mulrooney embodied: steadfast leadership, strategic thinking, personal integrity, and service to others.

Nominate an Industry Leader for the John J. Mulrooney Award This Spring Scan the QR code to learn more

I BEGIN ALL my individual sales training sessions with the question, “How’s it going?” What I’ve found over the years is that students who begin with a negative answer, often repeatedly in session after session, struggle to achieve success more than the students who give a positive answer.

One of the most common answers I get is, “It’s a grind.” Think about this mindset. Forty hours a week for an entire career—“grinding away.” No wonder these salespeople are miserable and under-performing; it feels like forced labor in a prison camp.

For the first seven years of my career, “grinding away” was my mentality. I once told my mother, “I spend my day begging for orders.” At some point I looked around me and saw salespeople who, although not making as many calls as I made, made more money and were enjoying the process much more than me. I took a hard look in the mirror and said, “I have to figure this out.” I then began my search for what they had that I was missing.

Flow

Mihaly Csikszentmihalyi (pronounced Me-high Chick-sent-me-high) wrote the book Flow: The Psychology of Optimal Experience. I was lucky enough to find this book in my search for better results in my sales life.

Csikszentmihalyi’s research led him to the following conclusion: “The best moments in our life are not the passive, receptive, relaxing times. The best moments usually occur if a person’s body or mind is stretched to its limit in a voluntary effort to accomplish something difficult and worthwhile.”

That pretty much sums up sales, don’t you think?

------------

BY JAMES OLSEN

I wasn’t just trying to find a way to be better at sales but how to enjoy it more, because what I saw about the great salespeople around me is that while I was “grinding away,” they really enjoyed selling.

(1) Complete concentration on a task

(2) Clarity of goals and reward in mind and immediate feedback

(3) Transformation of time (speeding up or slowing down)

(4) The experience is intrinsically rewarding

(5) Effortless and ease

(6) There is a balance between effort and skill

(7) Action and awareness merge losing conscious rumination

(8) There is a feeling of control over the task

My suggestions for getting into flow in our day-to-day sales lives:

Planning – We have three people running our business—us the manager, us the salesperson, and us the admin person. Us the manager needs to plan out us the salesperson’s year, month, week and day. This leaves us the salesperson free to be an unconscious, nonjudgmental doer—in a flow state. The salesperson no longer needs to ask the question, “What do I do next?” but moves from one task to another seamlessly.

Concentrate on Process not Outcome – When a shooter in basketball is worrying about making or missing a shot, they usually “choke.” Michael Jordan is considered one of the most “clutch” players that ever played, but

he missed 26 game-winning shots in his career. He also made 28. Most players won’t even take game-winning shots for fear of missing. As salespeople, we have to take game-winning shots all day long. I’ll take a 51.8% closing rate any day.

“We are in charge of the process; the sales gods are in charge of the outcome” is what I tell my students. If we give a great sales call, we will close more business. One of the things we see with great salespeople is we can’t tell if they are having a great day or not because their demeanor is the same. They concentrate on the process.

Positive Self Talk – We need to sell ourselves before we can sell anyone else. We need to go into each call knowing that we are going to get the order. This mindset is done pre-call. We must know why what we are promoting is a good deal and be ready to overcome any objections to the contrary.

This article is a Reader’s Digest look into the science of flow. I encourage you to look more deeply into it. Another book that touches on this science is The Inner Game of Tennis by Timothy Galway—a game changer for me as a basketball player. MM

JAMES OLSEN

James Olsen is principal of Reality Sales Training, Portland, Or., and creator of SellingLumber.com. Call him at (503) 5443572 or email james@realitysalestraining.com.

Our lattice, privacy screens and natural wood building products are made from the most stunning material there is: Western Red Cedar. Completely sustainable, absolutely beautiful and naturally long-lasting and durable, they’re almost too nice to keep private. For more information on our full product line, contact us today.

------------ BY HENRY ST. JOHN

AS IT HAS BEEN for centuries, the arrival of a new generation into the workforce brings in new uncertainties and challenges for employers. Up until a couple of decades ago, employers generally understood and could expect that a new, inexperienced workforce must adapt to the industry it enters to perform well. Today, however, many executives are concerned that the relationship has been reversed and that, given the labor shortage and the challenges of attracting entry-level workers, the tables have turned, and now industries must adapt to the expectations of the entering workforce to thrive.

This change has had a negative stigma attached to it. Gen Z workers are seen as too demanding, even as they enter entry-level jobs with little to no experience. However, with new challenges come new opportunities. Rather than being wary or frustrated with the Gen Z workforce, understanding them could offer a much more positive workplace relationship and could benefit the company. Here are the biggest factors an employer needs to understand to build a positive relationship with Gen Z workers.

• COVID Changed Everything: In order to adapt to the coronavirus, Americans had to shift their work habits to an online environment. Save for essential workers, Americans had to do their jobs from home on a computer, separated from their employers and usual worksites. The bulk of Gen Z transitioned into adulthood during this period. For over a year, their school, college and work experience happened through a computer screen, and this had a lasting effect on how they understand work ethics.

Gen Z workers have become much less partial to a fully in-person or remote work schedule, favoring a hybrid work schedule. This has been a tough ask for some companies,

as the end goal of most companies post-COVID has been to fully return to the workplace. However, the data is clear: those who keep the hybrid model have actually seen more positive results. “For the foreseeable future, the dominant working arrangement will likely be hybrid, offering a compromise that provides career-minded individuals with remote flexibility while addressing employer concerns about productivity,” according to Tracy Power at HR Executive.

• Gen Z isn’t technology-obsessed; they’re technology-familiar: As AI becomes more integrated into the workplace, it has become increasingly practical to be familiar with the various ways AI is used, and since Gen Z has proven to be the most familiar with AI technology, this makes them increasingly valuable to employers. And it isn’t just AI. Gen Z has proven to be quick learners with the use of new technologies as they roll out.

According to Lin Grensing-Pohpal at SHRM, “Generation Z, the youngest cohort now in the workforce, is known to be an extremely tech-savvy generation.”

However, this familiarity with new technology brings a heightened concern about its ethical applications among younger generations. In a report done by Rhea Kelly at Technical Horizons in Education Journal, 64% of Gen Z participants claim they use AI in work, but 59% also believe AI will negatively impact society, with the main area of concern being how AI will be used to invade privacy and replace workers.

• Gen Z are more demanding of an ethical work environment: When you mention the words Gen Z and work ethics alongside each other, employers shudder. Most articles on the subject paint Gen Z as difficult and demanding.

However, while some reports may paint Gen Z in that light, employers can also view these aspects more positively.

In a survey done by ResumeBuilder, 74% of employers claim Gen Z workers are the most challenging generation to work with, but at the same time, they claim that they are incredibly innovative and adaptable. To quote Haribo marketing director Adam Garfield, “[Gen Z] are not afraid to challenge the status quo and bring new ideas to the table. They also value authenticity and transparency and expect companies to be socially responsible and ethical.”

• Communication is key to engagement: Just as much as any other generational workforce, Gen Z requires clear and consistent communication with the company in order to work effectively. What differs between Gen Z and previous generations is not communication in general or lack thereof, but the specific methods of communication. As Gen Z has grown up with social media and texting as a main form of communication, their communication skills have developed to be much shorter and to the point. This less formal style of communication has often bled into the workplace.

A study on Gen Z workers by Corporate English Solutions found that Gen Z workers often prefer instant messaging over emails, with short texts that contain fragmented sentences and abbreviated words. In many situations, this leads to much less formal communication between

Q. We issue employees valuable equipment including cell phones and laptops to perform their job duties. Employees also have access to valuable information such as client files. What actions can we take to ensure we get it all back?

A. Your options will vary depending on where you are located and what policies and practices you have in place.

You should have policies outlining that these items and information remain company property and must be returned at termination or upon request. If required, they may be subject to legal recourse to recoup the equipment or replacement costs and that this may include wage deductions if allowed by federal, state, and local laws, of which there are many restricting such deductions.

When you issue valuable property, you should have the employee complete an acknowledgment form outlining policies, usage and return expectations, and legal action options. The form should also include a detailed chart outlining the cost of each item as well as the employee's initials and date upon receipt. This form will be required to defend a claim of improper wage deductions or if you need to take legal action such as filing a police report or a claim in civil court.

You should also have strong policies covering confidential information and the prohibited and permitted uses of that information during and after employment. These policies should state that all information and files must be returned and/or deleted from any electronic device if kept electronically.

Establishing a solid structure of policies, practices and forms will help you protect your company's valuable assets.

Gen Z workers and their employers. However, coaching and setting workplace communication expectations can easily overcome this obstacle.

• High standards due to high education: An employer will often hear that one of the worst aspects of Gen Z workers is that they have higher standards when it comes to job searching. They’ll often search for higher pay and better benefits than their experience or education may warrant. And while some hiring managers would view this as “spoiled” behavior, it is, in fact, the exact opposite. According to Dr. Alan Dennington at TimelyCare, Gen Z is on track to become the highest educated generation, with a higher graduation rate and lower dropout rate than all previous generations. In turn, Gen Z workers will value their education experience in order to apply it to a career they worked hard to pursue in academia.

The idea of newer generations being difficult to work with is a tale as old as time. Even Socrates complained that, “Our youth love luxury. They have bad manners and despise authority. They show disrespect for their elders and love to chatter instead of exercise. Young people are now tyrants, not the servants of their household.”

New generations will always bring new challenges to the table as much as they will bring new benefits. What separates successful employers from their peers is how they choose to tackle those challenges and benefit from their youngest workers. MM

– Henry St. John is Gen-Z content provider for The Workplace Advisors, Inc. (theworkplaceadvisors.com).

------------ BY DAVE KAHLE

“I DON’T WANT to ask my team to make too many changes at once. We need to manage change slowly and methodically.”

I’ve heard words to that effect from a VP of sales or CEO dozens of times. Typically, the specifics have to do with changes in the sales force, because that’s the world in which I practice, but the sentiment applies to every job title. That idea ranks up there with the most destructive myths in business.

In truth, managing change doesn’t have to be slow. It can be rapid and transformational and still be effective.

When we hire a new employee, we expect that person to adjust to radical, pervasive changes—a new compensation plan, a new boss, a new work environment, a new set of co-workers. In the case of a B2B salesperson, a new set of products or services to sell, a new set of software to master, a new set of customers. We are asking them to adjust to changes in everything. And, we expect them to acclimatize to all these changes within a few weeks.

Why is it then, after they’ve been employed for a while, we don’t feel like we can ask them to change? Why can’t we ask them to change their compensation plan, adjust to a new automation tool, and support a new product line all at one time? They have done it before. They can do it again. To create an expectation of slow change is to hinder the organization from fully realizing its potential. Slow change in a rapidly changing world is actually

falling behind.

We all understand that the world is changing more rapidly than at any other time in our lifetimes. This pace of change is unprecedented in the history of mankind. And, in this rapidly changing world, those who learn to change and adapt as rapidly as the world around them is changing will survive and thrive in the new marketplace reality. Those who don’t will gradually be jettisoned to the margins and left behind by the pace of change around them.

“I am convinced that if the rate of change inside an organization is less than the rate of change outside, the end is in sight.” – Jack Welch

I was taught this lesson by one of my clients. The company had four geographically arranged divisions, which were run as separate profit centers, and had no incentive to work together. The CEO wanted to change the structure of the company.

Since I was laboring under the common misconception that you had to change things slowly, I expected that he would gradually phase in a new organizational scheme over the next six or eight months. He chose to take a different route. He gathered all his employees from the supervisor level on up for a weekend retreat. On Friday afternoon, he announced that their jobs no longer existed because the company’s organization was obsolete. They had until Monday morning to redesign the company, create the

jobs the new system required, and, on Monday, they could apply for one of the new jobs. What followed was a set of feverish small group meetings that resulted in new corporate organization. They completely changed the company in a weekend. Most people applied for new jobs, and some left the organization. With the exception of the CEO and CFO, everyone changed jobs. My primary contact was the VP of sales, who wound up as a sales manager. Of course, it took a couple of weeks to implement the changes, but within a few weeks the new organization was in place, people were in their new jobs, and business went on. Radical, transformational change for this company of a couple of hundred employees in the blink of an eye.

In our rapidly changing environment, to accept the ideas that change should be managed slowly is to hinder the organization from the opportunity to not fall behind, but to change with the pace of change around them. To do anything but expect rapid, transformational change is to do a disservice to the organization and its people. MM

DAVE KAHLE

OFFERING:

• Superior skid resistance

• Surface durability

• Weatherability

• Moisture resistance

• 4x8 panels, ¾" thick

• ADA Approved

Swanson Tuf-Tred is ideal for interior or exterior stair applications where skid-resistant surfaces are desirable.

Digger Specialties Inc. (DSI), a leading manufacturer of aluminum railing, is expanding its distribution network into the Colorado market through a strategic partnership with Monsma Marketing Corp.

Headquartered in Grand Rapids, Mi., Monsma has been a trusted provider of building products across the Midwest since 1930. Following its 2024 acquisition of Majestic Hearth Distributors in Denver, Co., Monsma has extended its reach to serve the growing Colorado marketplace.

A distributor of Westbury aluminum railing and columns since 2014, Monsma will initially focus on distributing Westbury products along Colorado’s Front Range, from Cheyenne, Wy., to Colorado Springs, Co., before expanding statewide. Inventory was established on Jan. 20, 2025, and DSI’s Westbury demonstration and training trailer will be deployed throughout Colorado for a full month to support contractors, builders and distributors.

Brian Stephens, Monsma executive vice president of sales & mar-

keting, said, “We are expanding our decade-long relationship with Digger Specialties, which will include the states of Michigan, Indiana, Ohio and now Colorado. Our new Denver facility will allow us to service Colorado for building materials and several western states for our Hearth Products division.”

BlueLinx plans to continue its greenfield expansion strategy, with new distribution center locations in the works.

The distributor opened its first greenfield location late last year in Portland, Or. The branch is expected to generate $40 million to $100 million in net sales at maturity. New locations will prioritize a 70-30 specialty-structural product mix, eventually shifting to 80-20.

BlueLinx is also actively pursuing digital transformation, implementing a new master data management platform, piloting an e-commerce platform, and planning a transporta-

tion management system to be completed by third quarter 2025. The initiatives aim to improve efficiency and the customer experience.

Taiga Building Products has added a slew of new product lines at its distribution centers in Rocklin and Sanger, Ca., including Eva-Last composite decking.

Both locations will be distributing the full range of Eva-Last decking products, including Pioneer, Apex Plus, and Infinity, across California and northern Nevada.

Other new lines at both locations include LP SmartSide ExpertFinish siding and trim, Sahara weather resistant barriers from Sentry, Brandguard fire-rated vents, and Fortress railing, deck framing, and fencing.

Weyerhaeuser’s MDF plant in Columbia Falls, Mt., was rocked by an explosion and fire on Feb. 19, possibly caused by an electrical arc in its power distribution center. No one was hurt in the blast, which blew out walls of the building and garage doors off their hinges.

The AZEK Co. has acquired Northwest Polymers, a postindustrial and post-commercial plastic recycling company based in Molalla and Aurora, Or.

Truitt & White Lumber Co., Berkeley, Ca., is now offering INICIO Windows & Doors from BMD Manufacturing, Galt, Ca.

PWT, Burlington, Wa., reported that its PWT Treated LVL was recognized for design excellence in the Chicago Athenaeum Good Design Awards.

The Trump Administration proposed a 25% tariff on lumber and other wood products imported from Canada and Mexico, possibly to begin as early as this month.

Anniversaries: Collins Cos., Portland, Or., 170th ... Central Valley, Napa, Ca., 70th ... Weyrick Lumber, Templeton, Ca., 40th ... International Wood Products, Clackamas, Or., 30th.

Re Reddwwood i ood is

thrives in some of the most productive timberlands in the world. Redwood is known for its timeless durability without the use of chemicals. Due to its flawless formation, there has never been a Redwood recall. There is a grade of Redwood for every application, every budget, and every customer.

“Growing beyond measure.”

Call or visit us today. Our family of Redwood timberland owners will continue to be your reputable and reliable source of Redwood.

Terry Haddix, ex-Patrick Lumber, has joined Nova USA Wood Products Forest Grove, Or., as the new operations and strategic accounts mgr.

Clint Krueger is new to Thunderbolt Wood Treating, Riverbank, Ca., in regional sales & marketing.

Brady Foley, ex-Bozarth Cedar Sales, joined the inside sales team at International Wood Products, Tumwater, Wa.

J.T. Taylor, ex-Roseburg, has moved to stud sales at Douglas County Forest Products, Roseburg, Or.

John Rios has been named division general mgr. of Highland Lumber Sales, Anaheim, Ca.

Benjamin Sullenger is the new owner of Tri City Lumber, Kennewick, Wa.

Kiyle Playter has joined the outside sales force at Mendocino Forest Products, Fontana, Ca.

Joanna “Jo” Barney has been appointed executive VP of Boise Cascade’s Building Materials Distribution (BMD) division, Boise, Id., overseeing the company’s 40+ distribution facilities, including millwork and door shops, across the U.S. Nathan Sikes was promoted to senior VP of Western operations for the BMD division, heading the Western and Pacific regions. Jarren Brinton, ex-Stony Point Construction, is a new account mgr. with Boise Cascade in Salt Lake City, Ut.

David Hillenburg, ex-The Deck Superstore, has been appointed operations mgr. for Mile High Deck Supply, Commerce City, Co.

Rafael Vargas has been named wholesale mgr. for RojoWood Lumber & Building Supply, Otay, Ca.

Tyler Donaldson, ex-Continental Materials, is new to Tando Composites, as market development mgr. for the Mountain Region, which encompasses Colorado and surrounding markets.

Ramon Vargas, ex-Central Valley, has joined the sales team at Adobe Lumber, Napa, Ca.

Amber Clavelle is now Las Vegas, Nv.-based business development mgr. for AZEK Building Products.

Annie Lou von Mizener, ex-Simpson Strong-Tie, has moved to Roseburg, as territory sales mgr. for the Mountain region, based in Boulder, Co.

Heather Ehlis, ex-Cedar & Sage Homes, rejoined Builders FirstSource, Kennewick, Wa., in outside sales. Todd Sorensen is a new account executive with BFS in Layton, Ut. Derrik Raines, ex-West Coast Lumber, is now covering Ventura County, Ca., for BFS, and Steven Drake is new to outside sales in Denver, Co.

Daryl Getty, ex-Woodgrain Distribution, is now with OrePac Building Products, Tacoma, Wa., as production mgr.

Chris W. Wilson was named national sales mgr.-lumber products for Jewett Cameron Co., North Plains, Or.

Robert Smith has been promoted to inside sales at ABC Supply, Prescott Valley, Az.

Nick Imperial has joined the sales force at Montana Timber Products, Caldwell, Id.

Carson Purcell is a new account mgr. with Timber Products Co., Eugene, Or.

Sara Molenda is now with Westlake Royal Building Products as territory mgr. for the San Francisco Bay Area.

Michael Begley has joined Elk Creek Forest Products, McMinnville, Or., as assistant controller.

Christian Perry, ex-Quantum Windows & Doors, is now with BMD Manufacturing, as Southern California territory mgr., based in San Diego.

Jairo Segura, ex-Reno Truss, is a new truss designer with Truckee Tahoe Lumber Co., Reno, Nv.

Robert Emanuel, ex-Advanced Door, is new to sales at Argonaut Windows & Doors, Cupertino, Ca.

Christian MacDonald was promoted to chief marketing officer at Metrie, Vancouver, B.C. Nicole Rocheleau succeeds him as VP, marketing. Kevin Bartel is now VP & GM, U.S., leading the entire U.S. Pro business, including recently acquired California businesses Metrie EL & EL and Metrie Anderco.

Lance Grimm joined Kodiak Building Partners, Englewood, Co., as senior vice president of continuous improvement. Robert Doshi is new as VP of CI training & development.

Brian Kelly has been promoted to VP of sourcing for US LBM.

Timothy Kuebler, formerly CEO of parent company Elementia USA, has been named CEO of Plycem USA (dba Allura), Houston, Tx.

David Neal, Georgia-Pacific, has been promoted to executive VP of building products. He succeeds Andy Konieczka, who has retired after 30 years with G-P/Koch Materials.

Josh Entremont is new to LP Building Solutions as environmental leader-siding business.

Doug Asano, Roseburg’s senior VP of sales, marketing & communications, was inducted earlier this month into the McCoy’s Building Supply Partner Hall of Fame.

Tom Schultz has resigned as chief of staff and VP of resources & government affairs for Idaho Forest Group, Coeur d’Alene, Id., to serve as chief of staff for natural resources & environment with the U.S. Department of Agriculture.

Gladys C. Hugh is a new receptionist at Mungus-Fungus Forest Products, Climax, Nv., according to owners Hugh Mungus and Freddy Fungus

The National Lumber & Building Material Dealers Association released its 2025 National Policy Agenda, which outlines key priorities for the LBM industry this year.

With a new Congress and White House administration, the agenda serves as the framework for the association’s engagement with lawmakers on Capitol Hill, White House officials, and federal agencies. It outlines NLBMDA’s efforts to advance legislation that supports small business growth, including advocating

for the extension of tax provisions set to expire at the end of 2025.

This year, housing affordability continues to be a central focus, along with eliminating overly burdensome regulations. “With a new political environment, we are optimistic that we can find common ground with Congress and the White House administration to advance policies which address the housing affordability crisis and strengthen the residential construction industry,” said NLBMDA’s Jonathan Paine.

The Merchant Magazine parent 526 Media Group has acquired Lumber Blue Book, the leading provider of lumber-specific credit and business data.

“Acquiring Lumber Blue Book represents an exciting opportunity for 526 Media Group to expand our reach and elevate the value we provide to the lumber and building materials industry,” said Patrick Adams, president of 526 Media Group. “We recognize the long-standing reputation and importance of Lumber Blue Book, and we look forward to furthering its mission of providing critical business resources and connecting industry professionals.”

526 Media Group has been rooted in the lumber and building materials industry since its inception. The company publishes 103-year-old The Merchant Magazine in the West, sister publication Building Products Digest in the East, national contractor magazine Deck Specialist, composite-panel publication Surface & Panel, as well as related websites, digital newsletters, and other digital offerings.

Lumber Blue Book provides credit-reporting services, marketing data, and other valuable resources for lumber professionals, including The Lumber Newswire. Lumber Blue Book was launched in 2009 to fill the void left by the dissolution of the Lumbermen’s Redbook.

The sale includes all lumber industry-related assets, all of which will continue without change or interruption under the name Red Book Lumber Data.

“This acquisition opens up a world of prospects, allowing us to innovate and expand in ways we’ve only

imagined before,” said Trent Johnson, director of lumber services for Lumber Blue Book. “By combining our strengths, we’re poised to offer unprecedented value to our customers. We’re genuinely excited about this new chapter, as it’s a fantastic chance for our team to grow and achieve new levels of success.”

Johnson and Dalton van Esselstyn will continue to lead the Red Book Lumber Data team.

Through this acquisition, 526 Media Group aims to enhance its growing portfolio of industry-focused solutions and strengthen its role as a key player in connecting sellers to targeted buyers.

For a beautiful, reversible exterior trim that requires no special tools or handling, look no further than Forest Trim.

• Easy-to-install

• 25-year warranty

• Long lengths mean fewer joints

Envision Outdoor Living Products is introducing new railing products while reorganizing its product lines to simplify selection for both pros and consumers.

With a robust lineup of aluminum, vinyl, composite and steel railings, Envision has taken the complexity out of choosing a system for any project and simplified it down to three easy steps:

(1) Railing style — choose a Modern, Designer or Traditional rail style, material and infill.

(2) Posts — residential or commercial heights with slim or large structural post and post sleeve options.

(3) Accessories — add style and function with lighting, drink rails, ADA handrails, and more.

New consumer-focused terminology that repeats across materials based on top rail design styles makes the decision process easy, while the launch of several new products, including a low-cost modern-style vinyl railing, several infill options across existing products, and E-Fit Railing Innovations, provide added versatility or save pros time on the jobsite.

Envision’s Fairway Railing Collection now includes:

• Aluminum (Designer Aluminum is available in Textured Black, Textured Bronze, and Matte White colors with six infill options and a new Drink Rail Adapter Kit.)

• Composite (Designer Composite is available in Black and White colors with five infill options. Traditional Composite, crafted with Envision’s patented Tri-Layer Technology, is available in White with five infill options.)

ENVISION’S diverse Fairway railing systems can now be ordered in an easy, step-by-step process.

• Steel (Modern Steel is available in Black Sand and Antique Bronze colors in Square Baluster panels.)

• Vinyl: (Modern Vinyl is a new 2.25” modern-style top and bottom rail, offered in White, Almond and Khaki with five infill options. Traditional Vinyl has a classic-style top rail and is available in White, Almond and Khaki with five infill options. Designer Vinyl is available in White, Almond and Khaki with six infill options. TimberLux Traditional Vinyl—the industry’s only wood-look

Sierra Pacific Industries has purchased a customized Bruks drum chipper for its Eugene, Or., sawmill.

The equipment has been ordered from Bruks Siwertell for a new cutting mill and state-of-the-art stud mill being built to replace SPI’s existing sawmilling operations in Eugene. It will efficiently handle sawmill byproducts for onward use in SPI’s biomass energy cogeneration plant and for pulp and paper customers.

SPI’s latest Bruks DH 400 (550) x 1,000 drum chipper features custom-designed infeed rollers and supplier-specific gearboxes. “The machine has been tailored to meet SPI’s operational preferences,” says Rafael Escamilla, project development engineer, Bruks Siwertell. “For example, the first two in-feed rollers are segmented, which reduces overall maintenance.”

The Eugene Bruks drum chipper installation is planned for delivery mid-2025. It will process sawmill byproducts, including softwood trim blocks and offcuts, at a rated capacity of around 20t/h, helping SPI

maximize efficiency and yields from its wood-processing operations.

“SPI has Bruks Siwertell equipment installed across many of its other facilities, and appreciates the quality, reliability and the ease of maintenance that Bruks drum chipping machines offer. Essentially, we deliver products that last and perform well under high-use, challenging conditions,” adds Escamilla.

Third-generation, family-owned SPI is one of the largest lumber producers in the U.S., operating 18 sawmills in California, Oregon and Washington, all of which use advanced technology to maximize raw material use. The company is also the largest private U.S. timberland owner and produces millwork, wood fiber products, windows, and renewable energy as well.

Pacific Lumber Inspection Bureau has published a new 2024 edition of its grading rules book, WCLB Standard Grading Rules for West Coast & Imported Softwood Lumber, No. 18,

2024. The new rule book replaces the 2022 version and includes many updates and improvements from the previous edition.

PLIB is recognized by the American Lumber Standards Committee (ALSC) as a lumber grading rules-writing authority. No. 18, 2024 edition is the second major revision to the rule book since the PLIB/ WCLIB merger.

“The new rule book includes all updates to the NGR grade rules as well as revisions to other grades specific to the WCLB rules,” said Jeff Fantozzi, PLIB’s president. “There are also several improvements to make the book easier to navigate and the coil bound covers more tear resistant. We put a lot of thought into making functional improvements.”

Among the most significant changes are the inclusion of the latest revisions to the National Grade Rule (NGR) interpretations and WCLB rule interpretations. No. 18, 2024 also features significant changes to the E-Rated Structural Laminations grade (para. 154), updates to MSR grade rules (para. 135), revisions to the Alternative Beams and Stringers rules and Alternative Posts and Timbers rules (para. ALT 130 and ALT 131) and their interpretations, updated design value tables, and the addition of several new imported species from Sweden, South America, and Japan.

Fantozzi said the 2024 edition

also added helpful graphics inside the cover pages illustrating knot, hole and slope of grain for common 2x4 grades, paragraph indexing on each page, and corrections from previous editions.

Coil-bound and perfect bound copies of No. 18 are available for purchase. Visit www.plib.org/resources or call (253) 835-3344 for ordering information. A downloadable PDF will also be available soon.

Anawalt Lumber reopened its Pacific Palisades, Ca., location in mid-February, about five weeks after the devastating Palisades wildfire forced its temporary closure.

The wildfire left much of the Pacific Palisades community in ruins, destroying homes and businesses across the region. Despite extensive damage to the area, Anawalt Lumber’s structure remained mostly intact, allowing the team to focus on cleanup, reconstruction, and restocking lost inventory.

Now, after weeks of hard work and dedication, Anawalt Lumber reopened its doors in hopes of playing a key role in rebuilding efforts, supporting the restoration of Pacific Palisades’ homes and businesses.

The store will operate under the following temporary hours: Mondays-Fridays 7 a.m.–3 p.m., Saturdays 8 a.m.–3 p.m., Sundays closed.

Anawalt Lumber is a family-owned business that has served Southern California since 1923, operating five locations throughout the Los Angeles area.

White Cap has acquired JLA Supply, a distributor of sealants, waterproofing and concrete accessories, serving non-residential and residential end markets throughout the Pacific Northwest and West Coast.

Founded in 1974 in Portland, Or., JLA Supply (formerly known as John Latta Associates, Inc.) has grown to six locations across Oregon, Washington and Idaho, and is known in different markets under three business brands: Sealant Specialists, SECO Construction Supply, or Cascade Construction Accessories. JLA Supply is now part of the White Cap suite of brands, branches and value-added services.

“The JLA team has immense product and service knowledge and an established footprint in this growing market. By joining forces, our customers will benefit from additional product offerings, locations and service excellence,” said Alan Sollenberger, CEO of White Cap. “I am excited about the opportunity to work with such a dedicated and talented team as part of the White Cap family.”

“JLA has been a committed and dependable partner to our customers for more than 50 years, assisting with their sealant, waterproofing and concrete supply service needs,” said Paul Von Goedert, president of JLA Supply. “I am proud of our team’s legacy and believe that aligning with White Cap will create new opportunities for success and pave the way for continued growth well into the future.”

White Cap operates approximately 500 branches across North America with more than 10,500 employees supporting approximately 200,000 customers.

Anawalt Lumber has signed on as host of this year’s TomatoMania!, Southern California’s premier tomato event, from March 29-30 at its Hollywood, Ca., location. The free public event will showcase over 60 tomato varieties, with plant experts on hand to guide visitors through the best options for their gardens. Everyone is welcome—whether an experienced gardener or a beginner—to explore rare and classic tomato varieties, discover unique flavors, and connect with fellow tomato lovers.

The event is more than a plant sale—it’s a gathering of people sharing their passion for the succulent red orb. Guests can meet fellow tomato enthusiasts, share tips on growing their own tomatoes at home, and purchase seedlings or adult plants they won’t find elsewhere.

As a lead-in to TomatoMania!, Anawalt will also stage

a “Tomato College” on March 15 at its flagship Pico Blvd./Los Angeles yard. Taught by garden expert and avowed Tomatomaniac Steve List, the class will offer growing advice, as well as showcase a small collection of tomatoes that scored high during Anawalt’s tomato tasting event last year.

The first TomatoMania! was held in the 1990s at Hortus Nursery in Pasadena, Ca. It has since blossomed into a series of events across California.

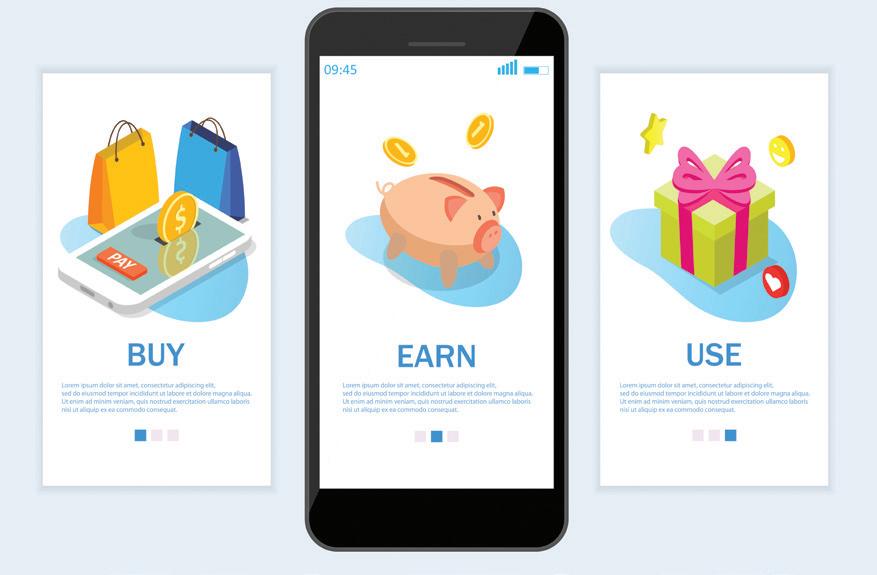

A year after launching the MyLowe’s Rewards program for homeowners, Lowe’s has updated its existing MVPs Pro Rewards & Partnership Program to become MyLowe’s Pro Rewards. The free program saves customers time and money, with earned points that can be redeemed for MyLowe’s Money, member deals, and more.

Redesigned specifically for the small-to-mid-sized pro, the program is easier than ever to use, with pros starting to earn points from the first dollar spent at sign-up. Offering an intuitive customer experience that mimics Lowe’s successful homeowner loyalty program MyLowe’s Rewards, MyLowe’s Pro Rewards “builds” on these benefits with added features and functions pros use most like access to merchandise, sports memorabilia, gift cards to support their business, volume discounts, business tools, and more. Plus, customers who shop with their MyLowe’s Pro Rewards Credit Card will save 5% every day on eligible purchases and get a free upgrade to Platinum Pro status.

“If you’re a pro, we want you enrolled in MyLowe’s Pro Rewards program because we’re focused on saving

pros more when they choose Lowe’s first. This is one of the few rewards programs in the industry designed to reward pros from their first dollar spent—no special volume thresholds to earn and save at Lowe’s,” said Quonta Vance, Lowe’s executive VP of Pro and Home Services.

New benefits include:

· Earn points on eligible purchases per $1 spent, easily redeemed for MyLowe’s Money or for exclusive rewards like gift cards, experiences, products and more

· Access to member-only deals

· Free standard shipping (not available in Alaska and Hawaii)

· Access to a member volume discount on eligible quotes of $1,500 or more

· Instant 20% member paint discount after paint annual qualifying spend reaches $3,000

· Pro business solutions like purchase authorization and online order quoting

· Plus, a customized in-app experience that allows members to track their points progress, easily re-order from previous purchases, and receive personalized recommendations

The program is three-tiered (Gold Pro, Platinum Pro, Titanium Pro) with new benefits unlocked at each status level. New members start at Gold Pro and increase in status as they shop.

“We’re building a loyalty ecosystem that’s designed with our customers at the center—we want all of our members, no matter DIY or pro, to know that when they choose Lowe’s first, they get more,” said Jen Wilson, Lowe’s senior VP, chief marketing officer.

The LMC Executive Education Program brought leaders from the LMC network across the country together for a week of reflection and innovation. Held from January 20–23, 2025, at the Aresty Institute of Executive Education at the Wharton School of the University of Pennsylvania, the program continues to solidify its reputation as a must-attend event for industry professionals.

“Our partnership with Wharton Executive Education and the opportunity to offer such a unique program, unmatched in the industry, is one of the reasons LMC dealers stand out,” said Paul Thorne, VP of business development. “Since its inception in 2015, this executive education experience has been in high demand, and for good reason.”

Unlike traditional business school offerings, the program centers around an industry-specific case study, enabling participants to directly apply their learning to challenges within their own companies. This practical, hands-on approach has become a hallmark of the event.

One of the program’s most celebrated aspects is the chance to learn from Wharton’s world-renowned professors. Kevin Smith, from North Atlantic Corp., stated, “All the instructors were engaging and shed a different light on each of

their areas of expertise that I found to be incredibly valuable.”

Participants described the exclusive event as a “first-class experience” and a rare opportunity to grow under the guidance of Wharton professors—renowned experts in their fields.

“The experience of coming here was unlike anything I’ve ever had,” said Matt Koch from Suburban Lumber. “The knowledge I gained about business, finance, and operations has already made a difference in my role and company. But beyond the learning, the relationships I’ve built with other leaders have been invaluable. The connections and camaraderie are something I’ll carry forward.”

This transformative program is a testament to LMC’s commitment to empowering its dealers with unparalleled opportunities for growth, leadership, and success.

LMC is a leading forest products and building materials buying group owned by independent LBM dealers. There are over 1,800 LMC dealer locations in the U.S. “Building Business Together” is LMC’s philosophy, rooted in a history of working together and standing the test of time since 1935. LMC dealers are united in their purchasing, creating a strong foundation that supports the growth of unique supplier relationships and purchasing opportunities.

ABMDA CELEBRATES HALF-CENTURY OF INDUSTRY LEADERSHIP

ABMDA, Inc., the largest buying group exclusively dedicated to independent two-step wholesale distributors in the building materials industry, is thrilled to announce its 50th anniversary.

Since its founding in 1975, Associated Building Material Distributors of America, Inc. has been a steadfast advocate for independent distributors, fostering growth, innovation, and collaboration across the industry.

From humble beginnings, ABMDA was established with a mission to strengthen the market positions of independent two-step distributors. The founding charter emphasized three key pillars: leveraging collective buying power, sharing best practices, and embracing cutting-edge technologies. Over the past five decades, these principles have guided the organization and its members to unprecedented success.

This year, ABMDA proudly surpasses $9 billion in collective annual purchases—a testament to the strength and unity of its members. The milestone not only underscores the enduring value of ABMDA’s mission but also highlights the vital role independent distributors play in the industry.

“Fifty years ago, our founding fathers set out to create an organization that would empower independent distributors to thrive in a highly competitive marketplace,” said Garry Tabor, executive VP. “Today, we celebrate the incredible progress we’ve made together and look forward to continuing our legacy of innovation and collaboration for decades to come.”

Plans for the 50th-anniversary celebrations include a series of events, initiatives and acknowledgments to honor the contributions of its members, partners and industry leaders who have been instrumental in ABMDA’s journey.

Its annual convention is set for April 10-13 at the Sawgrass Marriott Golf & Spa, Ponte Vedra, Fl.

cally reject such an offer. As a result, the buyers face ‘adverse selection’—the only sellers who will accept $750 are those unloading lemons.

Sierra Pacific Industries, Anderson, Ca., has agreed to acquire Seneca, Eugene, Or., and affiliates, combining two complementary, family-owned forest products businesses with strong historical roots on the West Coast.

UFP Industries is phasing out its UFP Retail Solutions customer-facing identity—making way for an expanded ProWood business unit to better serve our customers.

“Smart buyers foresee this problem. Knowing they could be buying a lemon, they offer only $500. Sellers of the lemons end up with the same price they would have received were there no ambiguity. But the peaches all stay in the garage. “Information asymmetry” kills the market for good cars.”

Current customers will now work with a ProWood account representative and enjoy a more holistic business approach, placing products and services under a single brand presence that is well-recognized within the market. It also signals a new, more cohesive vision for the brand, better amplifying its unwavering commitment to superior customer support and solutions and next-level, science-based product innovations.

Structural wood panel buyers rely upon qualified inspection and testing agencies like the APA to routinely test and certify the quality of the products they buy. This creates an incentive for individual panel producers to “push” the standard. A passage from Ackerloff’s famous paper:

Founded in 1953, Seneca operates a 175,000-acre sustainably-managed tree farm, sawmills, and a biomass plant in Oregon. SPI, a leading lumber producer that manages over 2.1 million acres of timberland in California and Washington, as well as manufactures millwork, windows, and renewable energy. The combination of two highly complementary businesses with deep expertise in forest products will result in increased efficiency and significant benefits to employees and customers.

This evolution not only positions ProWood as an endto-end provider of treated lumber products able to deliver solutions in a whole new way, but also adds strong distribution capabilities alongside an ever-growing roster of products and services. Now, under one roof, consumers, builders, and contractors can find a trusted, highly efficient, performance-motivated partner.

“Aaron Jones and Red Emmerson are both icons of the wood products industry. They were also friends and had a deep mutual respect for each other as industry leaders,” said Seneca CEO Todd Payne. “This proposed transfer makes so much sense given the companies provide complementary products, and have shared family values and company culture.”

long, frigid winter climate, coupled with a short summer season, produces hardwoods with very tight growth rings. This creates lumber with outstanding color and fine texture, which is ideal for applications ranging from furniture, cabinetry and doors to flooring, paneling and more.

“There are many markets in which buyers use some market statistic to judge the quality of prospective purchases. In this case there is an incentive for sellers to market poor quality merchandise, since the returns for good quality accrue mainly to the entire group whose statistic is affected rather than to the individual seller. As a result there tends to be a reduction in the average quality of goods and also the size of the market.”

ProWood uses proven processes and practices driven by teams of wood technologists and sales/marketing experts as well as logistics and operational personalities.

This region supplies nine primary, widely used species, including: ash, basswood, cherry, hickory, hard maple, red oak, soft maple, white oak and walnut.

Both SPI and Seneca have a strong focus on sustainable tree management, also managing their timberland for thriving wildlife, healthy watersheds and soils, and world-class recreation. As Payne explained, “At Seneca, we grow more than we harvest annually. We have 92% more timber on our land today than we had 25 years ago. SPI also grows more than they harvest. Under their forest management plan they expect to have more large trees on their timberlands 100 years from now than they have today.”

Spanning several states, including Ohio, Pennsylvania, North Carolina, Virginia and West Virginia, the Appalachian region produces a wide range of hardwoods species—all with one thing in common: superior quality.

gives back by being dedicated to education and administering scholarship programs.

and fall seasons with cold winters, which allow that growth to be gradual—hardwoods from the Appalachian region feature tight growth rings, strong fibers, and consistent colors and grain textures. This leads to strength, durability and beauty in the lumber, in addition to excellent width and long length characteristics.

Primary species include ash, cherry, hard maple, red oak, soft maple, white oak, basswood, beech, birch, walnut, poplar and hickory, which are great for high-end furniture, millwork, cabinetry, doors, flooring and paneling, and more.

“Seneca is known for its commitment to its people and communities, sustainable forest management, innovation in manufacturing and quality wood products,” said SPI presi dent George Emmerson. “As a family-owned forest products company with similar values, SPI appreciates the opportuni ty to continue the legacy started by Aaron Jones and carried on by the Jones sisters. Seneca’s culture and operations are a natural complement to Sierra Pacific. We look forward to bringing together our shared expertise which will result in in creased efficiency and benefits to employees and customers.”

The transaction is expected to finalized by the end of the third quarter.

No matter the region they come from, there are many North American hardwoods species to choose from. The decision as to which one to use comes down to the application and overall quality and look of the project.

For some structural panel producers, product differentiation requires a major change in company culture. For instance, it is very difficult to produce innovative, differentiated products for the end use market if the company doesn’t also adapt a different supplier-buyer mindset. Supplierpartners are often critical to the structural wood panel producer’s differentiation.

Ganahl Lumber Co., Anaheim, Ca., expected to begin construction in August on a new hardware store and lumberyard in San Juan Capistrano, Ca. The facility will replace its nearby Capistrano Beach location.

Escrow on the 17-acre Lower Rosan Ranch property, which Ganahl Lumber purchased from the city for $5 million, closed in late spring, following more than four years of planning, negotiations and applications. Ganahl portion will use about nine acres of the site for its new store and yard.

we’ve become known for,” says Grace Bilbrough, director of marketing. “It promises strong partnerships and streamlined efficiencies, such as transportation and increased logistical bandwidth, helping customers drive quality solutions for their businesses.”

As industry competition comes to focus more and more upon only one of the “4P’s of marketing”—price— “lemons” tend to proliferate and industry sales volume tends to decline.

General manager Alex Uniack said the journey has been “a challenging and complex process to get to this point, and we are excited to move the project into the construction phase.”

The companies also share a company culture that recognizes employees as their most valuable asset, values the support of the communities they operate in and serve, and

Dealers, contractors and DIYers should expect to see changes in ProWood-branded materials, new logo, new website features, and added functionalities to better serve the growing community within the coming months.

Thanks to the region’s climate conditions—warm summers that assist with tree growth, and cooler spring

ProWood customers will now have the advantage of access to more innovative building solutions from Deckorators and UFP-Edge brands. Customers can look forward to building with and managing a more economical, competitive array of products based on order volume and projects to deliver lumber and innovative decking products together. “This new era for ProWood represents more than just the high-quality products

When the industry is young, industry production technologies vary little and raw materials are relatively homogeneous (e.g., OSB), this isn’t a major problem. But it is a serious problem when the inspection and testing agencies find it difficult or impossible to keep up with a very rapidly changing industry. An example would be today’s overlaid Douglas fir plywood industry. There are rapid changes underway on both the demand side (e.g., much higher alkalinity concrete mixes are now essentially “pulping” conform panels) and on the supply side (e.g., much reduced supplies of

Home Depot, among others, had spent nearly 15 years attempting to purchase the property before the city zeroed in on Ganahl in 2017.

–Roy Nott is president of Surfactor Americas LLC, Aberdeen, Wa., a German-owned producer of overlays, glue films, and press cleaning films for the global wood panel industry, with manufacturing operations in Finland, Germany and Malaysia. Reach him at roy.nott@surfactor.com.

Big Creek Lumber’s sawmill, in Davenport, CA, produces a wide variety of redwood lumber products to independent wholesalers, stocking distributors, and remanufacturing facilities. Big Creek is well known for producing high quality redwood products and providing an outstanding level of personalized service.

Designed for indoor and outdoor applications, Feeney’s new Kerrie Kelly Lasercut collection offers nine intricate panel designs inspired by architectural icons, global textures, and timeless patterns.

The laser-cut aluminum panels can be used as deck railing infill, decorative accents, privacy screens, or partitions.

FEENEYINC.COM (800) 888-2418

Majestick Goods Interlocking Wood Deck Tiles are so simple to install that even a child could assemble within minutes.

Made from sustainably sourced acacia wood, the herringbone deck tiles feature a snap-together system that's perfect for patio renovation. No special tools or adhesives are required.

MAJESTICKGOODS.COM

Milgard Windows & Doors’ new AX450 Aluminum Moving Glass Wall features an aluminum frame with wide openings that stack or slide into pockets, eliminating barriers between indoors and out.

Despite its large panel size, the AX450 glides seamlessly on a track for easy operation due to sealed stainless steel ball-bearing rollers.

A warm-edge spacer system and thermally improved aluminum frame provide top-notch energy efficiency, with optional upgrades like Low-E glass and gas between the panes to help reduce energy bills. The product is also AAMA and NFRC tested and certified.

MILGARD.COM (800) 645-4273

TYPAR Clear Acrylic Flashing is the first fully transparent window and door flashing on the market.

Developed in response to emerging code changes requiring better visibility of the nail and screw fin patterns during window installations and inspections, it helps builders and installers ensure proper window attachment and prevent costly callbacks. An advanced acrylic adhesive ensures excellent waterproofing and UV resistance while maintaining flexibility for long-term performance.

TYPAR.COM (800) 541-5519