DIGIT FAB

Building off my work last semester I wanted to explore more capabilities of non conventional of connection and how wall systems can be stacked up from non-uniform builds. I am also and movement within the pieces themselves. I wanted a light structure that would not be that grace through the arch and weightlessness.

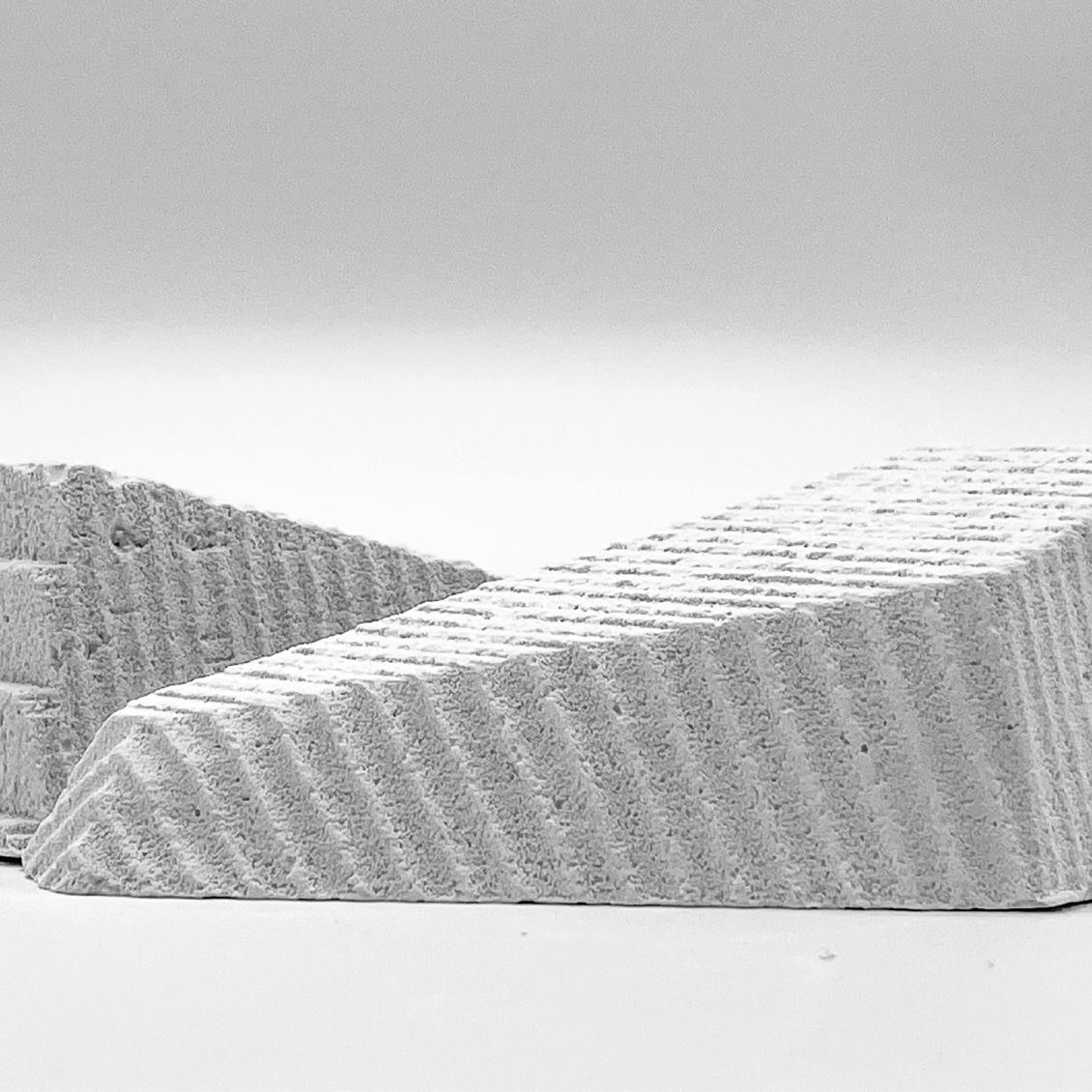

Iteration 2 beefs up the form as well as starts to employ light and shadow through an inner arch bevel. Larger gear triangled increase surface area when gripping to other pieces providing a stronge base.

Iteration 3 back slides in design as the inner arch

together of multiple pieces. The parallel arches

inner radius, again, an increase in gear triangles and thicker piece made the construction more sturdy in the end.

Concept Precedent: Architectural Amoeba, Cameron Wahlberg

Arch 433 Spring 2021

Isometric Removal Diagram

Measurement (units: mm)

PRINT TIME: 2 HR. 30 MIN

Measurement (units: mm)

PRINT TIME: 3 HR. 20 MIN

Isometric Removal Diagram

Measurement (units: mm)

PRINT TIME: 2 HR. 10 MIN

The question of how to create a piece that can engage with itself interconnected, as well as, a tesselation of the piece, decide volumentric qualities, and produce it through CNC, Mold, and Casting.

In iteration 2 The form is softened on top with a sight curve across its surface. It also added the second piece needed to complete the edge to edge tesselation missing from iteration 1.

hills across the pattern that results in a more coheisve look. Issues such as bit paths across the surface were also accounted for in iteration 2 completeing in a fully designed repeatble piece.

Straying away from vases seen in my Spring 2021 fabrication portfolio, Fall 2021 worked with created 3D printed, stackable blocks with a Potterbot. Working with scripts given by ISU

Iteration 1 is a two module system with A and B parts inverse of each other. Created with a positive and negative sine curve, inconsistences in printing created minute difference that made stacking cleanly unattainable. As well as the script creating a large print seam at one edge making the pieces not symmetrical.

simplifying its form in to one module. Again inverse of itself. The scale of the piece grew as well for a larger connection and foundation during stacking. the seam of iteration 1 is gone due to a spiral path for the potter bot. Iteration 2 also succumbs to the inconsitences of printing stacking methods.