SUPPLYCHAINTRIBE.COM May - June 2021 Volume 5 Issue 3 For private circulation only

Celerity Webinar on

VACCINE SUPPLY CHAIN & CHALLENGES – INDIA & GLOBALLY Leaving no room to absorb disruptions, COVID-19 became the last straw that broke the lean supply chain back. The world-wide vaccination drive itself has been one of the largest ever. Experts share their first-hand experience from the ground.

INSIDE Preparing for resilience and future shocks Muthu Maruthachalam.C, Vice President – Supplier Management & Logistics, Daimler India Commercial Vehicles Pvt. Ltd. (DICV) Aniruddha Banerjee, Sr. Vice President – Supply Chain, Spencer’s Retail Ltd. & Nature’s Basket Ltd.

A Second Wave of Resilience Dear Readers, The second wave has hit me too as it has so many others. My core vital readings are fine though and the doctor has assured that my first vaccine dose will help me fight it. The biggest vaccination campaign in history is underway in India. When the vaccination drive opened, people showed a lot of reluctance. Our Cover Story talks about the challenges that a vaccination drive of such humongous proportions brought in India and globally. Do read through to understand first-hand from experts in the field and what lessons can be learnt from earlier drives and the current one. Sustainability in transportation is gaining popularity. Companies like DICV are rolling out BSVIcompliant portfolio of commercial vehicles. They have also launched Reefer containers which can be assembled and dismantled easily, as an answer to vaccine delivery challenges. Nominations for the Celerity 40-under-40 and 30-under-30 Supply Chain awards are now open. We have introduced a new category – ‘The Exemplars’, where the jury will choose the best-ofthe-best. To give a voice to our earlier under-40 winners, we have started Celerity Supply Chain Super Achievers’ column. These voices are truly making a difference in their organizations and we would like to get their insights. It is very heartening that many companies have learnt well from last year and have prepared their supply chains well against future shocks. Read our sections to know everything. Happy reading.

Charulata Bansal Publisher Charulata.bansal@celerityin.com www.supplychaintribe.com

Published by Charulata Bansal on behalf of Celerity India Marketing Services Edited by: Prerna Lodaya • e-mail: prerna.lodaya@celerityin.com Designed by: Lakshminarayanan G • e-mail: lakshdesign@gmail.com Printed by: Xposures, A 210, Byculla Service Industrial Estate, D K Cross Road, Byculla, Mumbai- 400027. Logistics Partner: Blue Dart Express Limited

2 CELERITY May - June 2021

CONTENTS

May - June 2021 Volume 5 Issue 3

17 | COVER STORY

India’s Vaccination Drive: Beginning of the Endgame? Our recent webinar, ‘Vaccine Supply Chain & Leadership Challenges’ dwelled on the imperatives that are needed from all quarters to ensure effective & efficient vaccination drive. Our august panelists highlighted and elaborated on the global vaccination efforts, India’s vaccination strategy, our logistical prowess and people participation that will ultimately aid in the success of the Vaccination Drive. This Cover Story brings you the excerpts of the expert panel and the humungous task that is there upon us all individuals to make it succeed – TO GET VACCINATED! INTERVIEW 6 | Trucking

with an ‘X’ Factor

“We will continue to focus on providing safer and more modernized trucks, ensuring industry-leading fuel efficiency, safety, comfort and reliability,” highlights Muthu Maruthachalam. C, Vice President – Supplier Management & Logistics, Daimler India Commercial Vehicles Pvt. Ltd. (DICV). 10 |

Disrupting the Disruptors

“Understanding the supply chain vulnerabilities that emerged during lockdown plays an important role in helping us prepare for the future shocks,” shares Aniruddha Banerjee, Sr. Vice President – Supply Chain, Spencer’s Retail Ltd. & Nature’s Basket Ltd. 29 | Be

Sure

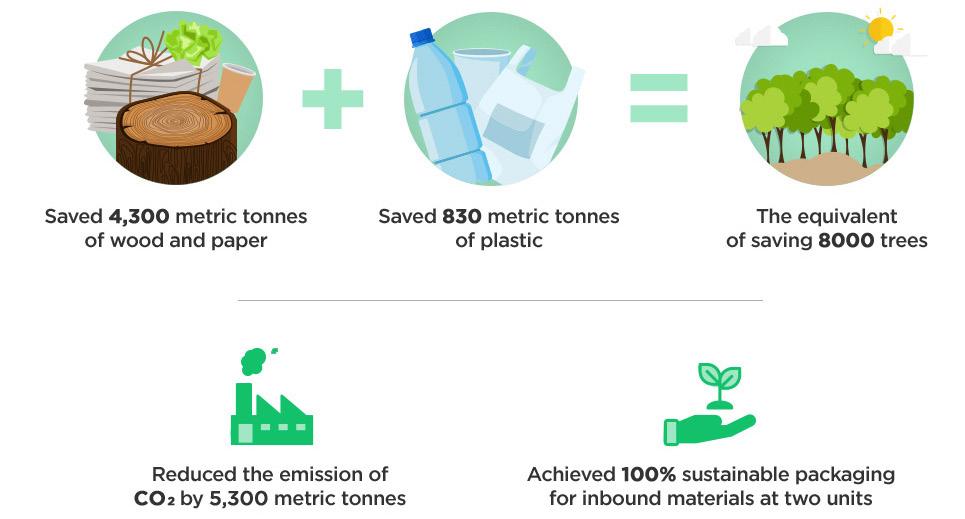

“We have adopted a clean, lean and green approach to creating a responsible supply chain,” shares Nikhil Puri, Global SCM Head – Communication Cabling Solution, Sterlite Technologies Ltd. (STL).

UNDER-40 SUPER ACHIEVERS 14 | Augmenting

to Boost Export

Infrastructure Facilities

Dr Abhijit Singh, Executive Director, Indian Ports Association, writes about the initiatives undertaken at Major Ports to transform them into world class facilities and to boost exports. 15 | Digital

Strategies in Procurement

Prachi Misra, Senior Director, Refinitiv Ltd., highlights how new technologies are shaping digital procurement strategies and transforming the function. 33 | SPECIAL REPORT

Press the Reset Lever Supply chain leaders need to STRESS TEST their existing supply networks and accordingly devise a comprehensive supply chain strategy to lead organizational growth. This special story offers you the strategies to prep up for the future. 37 | INFOGRAPHICS

Manufacturing Systems Hierarchy and Associated Analytics Opportunities

Editor: Prerna Lodaya

An effective Manufacturing Analytics program design needs to extend beyond the factory floor. Afterall, one of the key obstacles Supply Chains face is siloed planning and optimization, presents Kumar Singh, leading global supply chain consultant.

DISCLAIMER: This magazine is being published on the condition and understanding that the information, comments and views it contains are merely for guidance and reference and must not be taken as having the authority of, or being binding in any way on, the author, editors, publishers who do not take any responsibility whatsoever for any loss, damage or distress to any person on account of any action taken or not taken on the basis of this publication. Despite all the care taken, errors or omissions may have crept inadvertently into this publication. The publisher shall be obliged if any such error or omission is brought to her notice for possible correction in the next edition. The views expressed here are solely those of the author in his private/professional capacity and do not in any way represent the views of the publisher. All trademarks, products, pictures, copyrights, registered marks, patents, logos, holograms and names belong to the respective owners. The publication will entertain no claims on the above. No part of this publication can be reproduced or transmitted in any form or by any means, without prior permission of the publisher. All disputes are subject to the exclusive jurisdiction of competent courts and forums in Mumbai only.

supplychaintribe.com

3

INTERVIEW

TRUCKING

‘X’factor

with an

“The lockdown gave us the chance to take a step back from our daily operations and take a fresh look at our core functions. We have taken the opportunity to improve efficiencies in our business processes and have started our operations in a safe, sustainable manner. One of the most important lessons was that we need to build more self-reliant supply chains as we continue to work towards achieving higher localization levels. Moving on, we will continue to focus on providing safer and more modernized trucks, ensuring industry-leading fuel efficiency, safety, comfort and reliability,” highlights Muthu Maruthachalam.C, Vice President – Supplier Management & Logistics, Daimler India Commercial Vehicles Pvt. Ltd. (DICV).

How was the year 2020 in a nutshell? What are the biggest learnings that Covid-19 taught us? The worst is behind us. We continue to make DICV even more resilient and have used the crisis as an opportunity to emerge even stronger. For us, it was important that during the crisis, we had full transparency with our suppliers during the pandemic. We also focused on strategic inventory placing; this allowed us to have a more flexible supply chain despite the uncertainties. It was also crucial to understand the end-to-end supply chain up to Tier ‘n’ and identify potential risk (if any) & hence work on the mitigation plan.

What were the innovations that took

6 CELERITY May - June 2021

the shape at DICV during the last year? We transitioned to BSVI and were able to ramp-up our operations smoothly. Our prime focus during this time was to continue our journey towards process improvements, Digitalization, Transparency etc. As part of this, we implemented SAP - Warehouse Management, which helps us to improve our warehousing operations and also improves the accuracy of inventory apart from creating transparency. We also created lot of engagement platforms with our supplier partners like “Partner connect” and “Supplier spotlight”. Partner connect is a platform where we share our performance in the market, our expectations, understand

Muthu took over Supplier Management Logistics in February 2020. He is an integral member of the Senior Management team currently responsible for leading & transforming the E2E Supplier Management & Logistics. He has actively guided the supplier management task force to ensure smooth ramp up of the entire supplier base during the global pandemic of Covid 19. In addition to the responsibility of domestic exports of our trucks, he heads the CKD, CC business in DICV & the Commercial vehicles business of Indonesia Daimler Commercial Vehicles Manufacturing Indonesia (DCMVI). With 23 years of work experience in the automotive sector covering Tier 1 and OEMs, Muthu believes in leading a team to success with high focus of people development. Muthu is a Mechanical Engineer with post graduate diploma & Masters in Quality Management.

the perspective of our supplier partners & hence improve our collaboration further. DICV Supplier Spotlight is a strategic engagement platform with selected partners to discuss long-term business strategies.

Kindly enlighten us on BharatBenz ‘BSafe Express’ and how is it going to address India’s cold chain infrastructure challenge going ahead? The biggest challenge faced by the government is seamless and safe transportation of vaccines via an adequate number of advanced reefer trucks. One of the most critical challenges is to ensure that the vaccines are maintained at the exact correct temperature for the entire journey. Daimler India Commercial

INTERVIEW

Vehicles (DICV) is committed to supporting our government’s plan to ensure timely and secure transportation of the COVID-19 vaccine to India’s population. DICV has been a steady partner of India’s self-reliant journey and further in line with our endeavors to support the government, we have launched BSafe Express’, a specialized reefer truck for safe transportation of vaccines. The combination of a strong, reliable chassis with a lightweight, insulated reefer and state-of-the-art connectivity device makes BharatBenz’s ‘BSafe Express’ the perfect solution to India’s cold-chain infrastructure challenge. Unique feature of our Reefer containers is that it can assemble locally in maximum 96 hours. One can easily unpack and assemble it conveniently. With this truck, we can deliver vaccines in perfect condition to even the most remote destinations, bringing hope of a return to normalcy to over 1.3 billion people.

During the last year, companies survived majorly on trusted partnerships between dealers and

supplychaintribe.com

distributors and vice versa. What’s your take on this? What were the measures that DICV take to ascertain that your partners also progress in tough times or otherwise? We work with over 400 suppliers and are in a position to optimize their capacity and our capacity. It’s a win-win situation. And by doing what we do — which is believe in our suppliers — we have access to the entire knowledge of India. Our collaborative approach, transparency has helped us tide this pandemic together. We learnt to look at supply chain as E2E Value chain starting from raw material. We realized that our focus has to be also on the tier ‘n’ suppliers for a smooth business operation.

What are the German best practices that DICV has brought into the Indian market? As part of the global powerhouse of Daimler Truck, DICV has full access to Daimler’s vast array of state-of-the-art technologies. This means that we are able to cater to emerging new business opportunities in a very fast and focused manner, as evidenced by our quick

localization and roll-out of an all-new, BSVI-compliant portfolio earlier this year.

How can companies move towards sustainable pastures? What’s DICV’s strategy towards the same? The transport transformation requires sophisticated vehicle technology with the quality, reliability and durability that commercial vehicle customers expect. In addition, it requires economic efficiency and the necessary infrastructure: Customers must be able to earn money with CO2-neutral vehicles and, of course, be able to charge them and use them in everyday transport without complications. Vehicle technology, economy, and infrastructure - all three factors must be present in order for a market for CO2-neutral vehicles to emerge.

Please share with us your strategy, ‘Make in India, Make for the World’. DICV serves not only the growing domestic demand but also more than 60 export destinations across the globe including markets in Africa, Asia, Latin

7

INTERVIEW

America and the Middle East. Since the start of its export operation in 2013, DICV has exported more than 32,000 trucks and 3,500 buses. In October 2020, DICV reached important milestone with over 35,000 commercial vehicles and 150 million parts exported. We also added Malaysia as a new CKD market. DICV is the only Daimler location worldwide that produces engines, transmissions, trucks and buses at the same site under four brands – BharatBenz, FUSO, Mercedes-Benz and Freightliner. By shipping more and more Indian-made products to an increasing number of overseas markets, DICV is helping India become an international manufacturing hub.

One of the most important lessons was that we need to build more self-reliant supply chains as we continue to work towards achieving higher localization levels. Going forward, supply chains will need to turn digital with more usage of Robotics, Internet of Things, Artificial Intelligence and other technologies that will help make them more resilient. Moving on, we will continue to focus on providing safer and more modernized trucks, ensuring industry-leading fuel efficiency, safety, comfort and reliability. We will also further increase our focus on digitalization for our customers.

Were there any challenges faced in terms of inbound supply chain during COVID? How did you manage them?

Our warehouse plays an important role in supply management and logistics. It already handles more than one million transactions a year – that is about 2 transactions every single minute and aims to improve its efficiency further by adapting modern measures. The kitting concept and internal sequencing operation has brought positive results in the way we feed parts from warehouse to the line. It actually helped a lot in handling BSVI ramp-up and complexity seamlessly. The upgraded WMS will also enable tracking of parts in the warehouse until the bin level including

The lockdown gave us the chance to take a step back from our daily operations and take a fresh look at our core functions. We have taken the opportunity to improve efficiencies in our business processes and have started our operations in a safe, sustainable manner. At DICV, localization has been a high priority since the introduction of our vehicles in 2012. We currently source around 80-90% of our parts locally and hence were resilient in the current situation.

8 CELERITY May - June 2021

We would like to know more about DICV’s warehouse modernization journey.

pre-defined storage locations, storage levels and optimize the material flow using advanced put-away and picking techniques.

How do you foresee the economy to move from here on? We strongly believe the challenges we are seeing lately are short to mediumterm challenges and India offers a huge potential for growth as economic revival happens and CV market matures in its dynamics, efficiency, and business models. One reason we are so confident about this is India’s size. There is a strong correlation between a country’s population and the number of trucks sold. Compared to other economies like the US and Germany, India has far fewer trucks per person. So, there is clear room for the market to grow.

What are the latest and upcoming products that we can look forward to? How are they slated to enhance the transportation infrastructure of the country? BharatBenz is known for offering solutions to the dynamic needs of customers and society. BharatBenz just recently introduced eight new models including the BSafe Express (Intelligent Reefer for vaccine transport), 1917R, 4228R Tanker, 1015R+, 42T M-Cab,

INTERVIEW The combination of a strong, reliable chassis with a lightweight, insulated reefer and state-of-the-art connectivity device makes BharatBenz’s ‘BSafe Express’ the perfect solution to India’s cold-chain infrastructure challenge. Unique feature of our Reefer containers is that it can assemble locally in maximum 96 hours. One can easily unpack and assemble it conveniently. With this truck, we can deliver vaccines in perfect condition to even the most remote destinations, bringing hope of a return to normalcy to over 1.3 billion people.

and 2828 Construction vehicle. The two new BharatBenz buses to hit the road soon are the wide-body 1017 variant with a seating capacity of up to 50, and the 1624 chassis available with a parabolic suspension. Additionally, we also introduced the BSafe Pack, a range of features available across the entire portfolio that will enhance safety for drivers and passengers. BharatBenz vehicles are characterized by top-most safety, high performance, fuel efficiency, excellent reliability, and low maintenance cost. The new portfolio is DICV’s solutions that help our customers to excel in their businesses

supplychaintribe.com

and benefit the society.

What are DICV’s future plans for the Indian market?

classification. Instead, we will focus on creating ‘the best truck for every need’, customizing vehicles for use applications that target specific sectors.

DICV is a long-term partner in driving India’s economic growth and automotive expertise. DICV is the only facility across Daimler producing four brands – BharatBenz, FUSO, Mercedes-Benz, and Freightliner. We have seen overwhelming demand for BharatBenz, and we are absolutely prepared to benefit from this recovery and continue to grow profitably in this market. With the new generation of BharatBenz portfolio, we are looking to move away from the traditional tonnage

9

INTERVIEW

DISRUPTING THE DISRUPTORS “Learning never stops. Flexibility, agility, resilience, adaptability, and effective collaboration are essential to meet the challenges of doing business during a period of significant disruption. Digitalization of supply chain supports these requirements. Understanding the supply chain vulnerabilities that emerged during lockdown plays an important role in helping us prepare for the future shocks, including a potential second wave of Covid-19,” shares Aniruddha Banerjee, Sr. Vice President – Supply Chain, Spencer’s Retail Ltd. & Nature’s Basket Ltd., during an exclusive interview…

How was the year 2020 for Spencer’s Retail? What innovative idea made its way to reach consumers? Evolution and change are the only constant – a philosophy that was exemplified during the pandemic, made companies to think differently. Retail sectors (both food and non-food) having Omni-channel presence had to evolve and so did Spencer’s as an organization. Curbing the primitive thought processes and harping on the old normal of scheduling, planning, and forecasting, Spencer’s took initiatives that were not only nimble and flexible but also involved a lot of dynamism. Every function in the organization played their own part in developing newer and leaner ways of achieving objectives. Right from customer feedback-based forecasting algorithm to capacity planning based on sale outlier normalization to developing robust mechanisms for inventory load balancing, and planned increase of

10 CELERITY May - June 2021

DC throughput, Spencer’s has done it all. The approach was simple yet efficient. Everything evolved from the vision – Makes fine living affordable and convenient. Keeping customer at the helm, Spencer’s as an organization has treated each business case with equal importance, and the results are encouraging. Spencer’s hopes to be always with their customer.

How has FMCG sector been performing over the years? The main trends for this sector have been growing awareness, easier access and changing lifestyles of millennials. The sector's primary growth drivers have been rising wages and increasing youth populations. Also, brand recognition has helped demand. Demand for quality products and services in rural areas is on an upward trajectory on the back of increased manufacturing and FMCG distribution networks. The increasing

Aniruddha Banerjee is leading the supply chain effort for Spencer’s Retail & Nature’s Basket with key focus on enhancing operational efficiencies and scale to accelerate profitable growth. Aniruddha’s expertise lies in driving large scale analytics & technology-driven disruptive initiatives aimed at sustainable, tangible improvements across the supply chain. After finishing his Graduation from University of Calcutta and M.Com. from Annamalai University, he has pursued Post Graduation in Sales & Marketing. He has completed an MDP in Strategic Management while working with Tata in a joint programme with IIM-Ahmedabad. Recently he has done his Post Graduation in Digital Marketing from DMI Ireland – NIIT, to keep pace with the fast changing digital & analytics field.

youth population, especially in urban regions, is another major factor driving the need and demand for food services in India. India has a large base of young consumers who make up majority of the workforce, and hardly get time for cooking because of time constraints. Growing internet penetration and increasing digital maturity in India, along with infrastructure growth, have helped improve online transactions. Around 72% of Indian customers are most likely to shop online for premium items locally. FMCG companies are launching products online before making them available in traditional retail stores with e-commerce sales recording 56% growth in the first quarter of 2020 and 38% increase in June 2020. Because of the direct cash transfer system, disposable income has increased in rural India. Another rising category is exports. By 2030, the e-commerce segment is projected to contribute 11% to total FMCG revenue. Stock availability

INTERVIEW has become much simpler because the internet and multiple distribution outlets have made it easier for consumers to access the desired product at the right time and location. Post pandemic, the consumer behaviour had been brand agnostic for a few days. But the ones adhering to the MT section has come back to look for product width rather than depth.

to panic and buying patterns are based on market feedback. The evolution of the second strain may entice in hoarding even if not like the last one. Learning from the past, panic buying might be a little more structured if planned on the criticality scale.

What are the crucial learnings gained from the pandemic?

We started off with Residential Welfare Association list preparation for essential SKUs of FMCG, Staples & General Merchandise by identifying high throughput essential SKUs so that it can be shared with manufacturers and distributors to plan their production and distribution. This helped us in ensuring the supply connect for the essentials demand. To ensure the business continuity in hotspot, virus-stricken areas and to avoid disruption owing to this, the large format store was chosen as the as a hub for cluster with the smaller ones as spokes, enabling a pseudo-DC and catering to the demands. Strategic tieup with Omni-channel delivery partners was an important lever, especially down South. We have implemented staggered shift working at warehouses for DC manpower to mitigate the risk of virus spread, promote social distancing and to cope up with manpower crunch. We focused on phone delivery model, Spencer’s App and WhatsApp enabling

COVID-19 has taught us many lessons. COVID-19 has dramatically and suddenly shifted more customer traffic to digital channels. The growth in e-commerce is irreversible and will continue to witness traction. Owing to the rising trend of internet consumption and the sheer ease of disposal at the end of the customer, the purchase paradigm has moved towards Omni-channel delivery services. COVID-19 has taught businesses to embrace an agile operating model. The ability to move fast and adapt is a clear characteristic of winning businesses & retailers throughout this ongoing crisis. Health and safety of employees & customers remains the first and foremost priority and customer and community engagement remains vital. Digital, convenience, speed, cleanliness, health, trust and community are all keywords that will become the future foundations upon which retailing rebuilds. Consumers tend

What were the strategies adopted to mitigate risks and ensure Business Continuity?

the consumers to get the products delivered to their homes.

How did the inventory planning happen during the same time? When supply is restricted or lead times are unreliable, it’s important to identify stock items that are critical to your business and build an inventory plan to alleviate the risks. We identified focus articles across each category along the ones which are fast movers and have set stocking policies to help secure their supply and the optimum inventories. To ensure that stocks don’t pile up at warehouses during this period, a case lotbased allocation model was developed which helped in efficient picking in case lot, thereby reducing the warehouses turnaround time. A unique hub & spoke model for stock replenishment was made where a unique store had been chosen as the back-up or alternate hub location, which acted as a DC and catered to the essentials SKUs supplies with strategic tie-up with Omni-channel delivery partners for the delivery.

Please share with us Spencer’s technology transformation story with respect to supply chain. There was a misrepresentation of the Average Daily Sales due to sales spikes due to bulk/liquation sales at the stores. This in turn provided a wrong average daily sale number, which is a driver in

Companies are aggressively digitizing their supply chains to boost annual growth of earnings before interest and taxes. New Omni-channel supply chain engagement models such as Buy online Pick up at store (BOPIS) are becoming increasingly popular. Technological development is transforming the last mile delivery. Congestion, emission, and delivery cost are three key challenges in the last mile delivery operation and digital infrastructure will help in addressing these challenges. The uberization of last mile will become a significant factor in meeting the e-commerce and digital surge. Last mile delivery is the most deconsolidated form of shipping strategy, implying it is multiple deliveries at numerous locations. Digital transformation would ensure that last-mile distribution operations are flexible and scalable, allowing for the rapid accommodation of shifts in demand for e-commerce shipping. supplychaintribe.com

11

INTERVIEW inventory planning, computation of Manual, Gap Fill PO calculation or affixing DOH norms. This computation considers the ADS comprising bulk sales and hence, excess stocks gets triggered, thereby resulting in higher inventory as required. So, it is required to reduce the effect of outlier sale spikes (bulk/liquidation sale) from stores, misrepresenting the ADS (average daily sale numbers). We developed sale outlier normalization model on SAP ABAP. The model encompassed identifying the effect of outlier sale on the time frame of D-91 days. Comparing the daily sale number with the moving segment of 91 days prior to the sale day, if an outlier was recognized by the model, based on the z-score on the curve, the rationalization takes place in the form of a replacement value. On implementation of the project, skewed and outlier sale numbers were eliminated. The data became useful and gave exact scenario to merge forecasted inventory phasing with capacity planning. Average daily sale reduced by 8-12%, days of inventory holding reduced by 13-18%.

What peculiar consumer behavioural shifts have you observed during the last year till now? The trust towards the efficacy and authenticity of digital platform has increase many folds. More and more consumers now prefer to opt for internet shopping. About 40% customers now intend to increment spends on diversion and tech empowering agents - Apps, OTT, DTH, and WIFI. Customers now prefer to have less discretionary spend on leisurely activities and lifestyle while

the focus towards health, hygiene and financial security has increased. The focus on quality and efficacy – hygiene and immunity has increased many folds since the onset of the pandemic. New products introduction with focus on quality and efficacy are on surge as Indian consumers are highly adaptable to new and innovative products. Purchasing power for consumers are same, but brand preference for FMCG is steadily making its way into the basket, e.g.: demand for Maggi across retail chains. For staples, the region-wise preference still plays a dominant role. But the new normal has shifted towards a bullish few than towards a bearish many. Online retail has become the mainstay today with the onset of pandemic and prolong lockdowns. How aligned was your business before the lockdown was imposed? If not, how did you reach your consumers to get the business rolling? We initially focused to plug the gap for essential SKUs supplies by focusing on Essentials Needs. To ensure the hassle and risk-free deliveries for these essential SKUs, we also moved ahead in diversifying the delivery services with strategic tie-up with Omni-channel delivery partners with Uber and Swiggy. WhatsApp Bot Deliveries and Phone Delivery for bulk essential deliveries for societies have been a rescue lifeboat for us and that is how we kept on reaching our consumers to get the business rolling.

As a supply chain professional, what do you think were the most important classroom lessons that helped you take the right decision during tough times and especially the

covid-19 pandemic? Learning never stops. Flexibility, agility, resilience, adaptability and effective collaboration are essential to meet the challenges of doing business during a period of significant disruption. Digitalization of supply chain supports these requirements. Understanding the supply chain vulnerabilities that emerged during lockdown plays an important role in helping us prepare for the future shocks, including a potential second wave of Covid-19.

What are the upcoming trends in FMCG supply chain that we would witness in the years to come? Increase in disposable income in rural India and low penetration level in rural market offers room for growth for FMCG supply chain logistics portfolio. Many multinational FMCG players are seeing India as a strategic sourcing hub for cost-competitive product development, high performance supply chain and manufacturing to cater to international markets. Also, the number of online users in India is likely to cross 850 million by 2025. 1 in 3 FMCG shoppers goes online first and then to stores. Trends such as research online purchase offline are becoming quite common and it is expected that 40% of all FMCG purchases in India will be online by 2020, thereby making it a US$ 5-6 billion business opportunity. Companies are aggressively digitizing their supply chains to boost annual growth of earnings before interest and taxes. New Omni-channel supply chain engagement models such as Buy online Pick up at store (BOPIS) are becoming increasingly popular.

Most traditional and modern supply chains do not have the capability to be very resilient or flex with a major disruption due to their linear nature. If there is one thing that the companies need to learn from the ongoing pandemic, it is the agility in the supply chain. Companies can make their supply chain future proof and pandemic proof by designing their supply chain in such a way that it is flexible enough to absorb shocks, major or minor, which come along its ways. Today’s supply chains need to be highly resilient, scalable, and flexible to meet the challenges of doing business during a period of significant disruption. 12 CELERITY May - June 2021

INTERVIEW When supply is restricted or lead times are unreliable, it’s important to identify stock items that are critical to your business and build an inventory plan to alleviate the risks. We identified focus articles across each category along the ones which are fast movers and have set stocking policies to help secure their supply and the optimum inventories. To ensure that stocks don’t pile up at warehouses during this period, a case lot-based allocation model was developed which helped in efficient picking in case lot, thereby reducing the warehouses turnaround time.

Technological development is transforming the last mile delivery. Congestion, emission, and delivery cost are three key challenges in the last mile delivery operation and digital infrastructure will help in addressing these challenges. The uberization of last mile will become a significant factor in meeting the e-commerce and digital surge. Last mile delivery is the most deconsolidated form of shipping strategy, implying it is multiple deliveries at numerous locations. Digital transformation would ensure that lastmile distribution operations are flexible and scalable, allowing for the rapid accommodation of shifts in demand for e-commerce shipping.

How can companies make their supply chains future proof and pandemic proof? Most traditional and modern supply chains do not have the capability to be very resilient or flex with a major disruption due to their linear nature. If there is one thing that the companies need to learn from the ongoing pandemic, it is the agility in the supply chain. Companies can make their supply chain future proof and pandemic proof by designing their supply chain in such a way that it is flexible enough to absorb shocks, major or minor, which come along its ways. Today’s supply chains need to be highly resilient, scalable, and flexible to meet the challenges of doing business during a period of significant disruption.

How should the new age supply chain network design happen? The unorganized retail sector in India has a huge untapped potential for adopting digital mode of payments as 63% of

supplychaintribe.com

the retailers are interested in using digital payments like mobile and card payments. Companies should delve into ways to interact and deliver directly to consumers. We need to focus on Omnichannel and flexible online delivery models. Also the focus should be on investing more towards infrastructure development for strong last mile delivery setup and on personalization of shipments. FMCG Players need to build infrastructure that allows customization of orders within the supply chain, without adding any cost. Smart supply chain control tower are the need of hour, which can anticipate potential problems in an automated and optimized fashion at a regional and global level. More and more companies are trying to transform their traditional supply chain models to digital supply networks (DSN). It is seen as a long-term solution to build a more resilient supply chain that can withstand disruptions like COVID-19.

What are the five aspects that are needed to make Indian supply chain network efficient? Agility in the network: Quickly responding to disruption necessitates a flexible network of vendors and stakeholders capable of handling unexpected shortfalls or even developing new goods. Setting up alternate manufacturing sites and assembly points, as well as using resources to reduce costs, would increase network efficiency.

capacity data with real-time market signals, businesses can better balance supply with projected demand. Digital Collaboration: The Supply Chain Network would be more effective as a result of digital collaboration between internal and external supply chain associates, retailers, and distributors. Knowledge collaboration can be supported by cloud-based supply chain systems and shared networks and software. It will also boost the quality and speed of decision-making within a company, as well as with suppliers and other stakeholders. Automation: Manufacturers have requested better insight into their vendors' supply chains in the wake of the Covid-19 pandemic, a trend that should be continued. To maintain business sustainability, companies are using automation and robotics to make their supply chains more autonomous. Decentralized Workflow: Decentralized teams will adapt rapidly to applied analytics insights and develop the rapid-recovery tools that can help businesses move during periods of disruption.

Network visibility and monitoring in real time: Real-time insight is provided by control tower solutions that incorporate data across the whole supply chain, 5G technologies, and blockchain. By comparing internal production

13

UNDER-40 SUPER ACHIEVERS

Augmenting Infrastructure Facilities to Boost Export Dr Abhijit Singh, Executive Director, Indian Ports Association, writes about the initiatives undertaken at Major Ports to transform them into world class facilities and to boost exports.

A

S part of Maritime India Vision (MIV) 2030, recently published by Ministry of Ports, Shipping and Waterways, globally benchmarked targets have been defined to help India develop best-in-class port infrastructure. The development of Indian Ports is estimated to drive cost savings to the tune of Rs6,000-7,000 crore per annum for EXIM clients and help unlock Rs70,000 75,000 crore worth of potential revenue. MIV 2030 targets 423 MTPA of capacity addition at Major Ports for the next 10 years. A total investment cost of over Rs33,400 crore has been envisaged for this capacity expansion. Out of this, approximately 95% capacity expansion is likely to be planned under Public Private Partnership (PPP)/ Captive mode by Major Ports. Currently, India has 5 Major Ports and 2 Non-Major Ports with greater than 100 MTPA capacity. There is a significant opportunity for India to setup Mega Ports and compete with global ports. In MIV 2030, based on detailed evaluation across key criteria for Mega Ports and emerging growth potential of clusters, 3 Mega Ports - Vadhavan-JNPT Cluster, Paradip Port, and Deendayal Port have been identified to be developed into Mega Ports with >300 MTPA capacity and Kamarajar is to be further evaluated in next 1-2 years for additional Mega Port on the East Coast. These Mega Ports on both East and West Coasts will be able to cater to high traffic potential in the next decade and develop Indian Port’s strategic importance in the South Asian region. Further, in order to modernize the infrastructure at ports, landlord model adoption for berth operations is being

14 CELERITY May - June 2021

promoted at Major Ports. As part of the long-term strategic interventions, Major ports need to move to a landlord model and bring in more private sector participation to drive operational efficiency. Apart from physical infrastructure, there is a strong focus on strengthening the digital infrastructure of ports. Several initiatives have been undertaken in recent times to improve Ease of Doing Business in Indian Maritime sector. For instance, The Port Community System (PCS) 1X has been operationalized in 19 port communities across 27 stakeholder types, thus enabling vessel related message exchange between ports and customs. Enterprise Business System (EBS) is under implementation at 6 Major Ports (Mumbai, Chennai, Deendayal, Paradip, V.O. Chidambaranar, and SMP Kolkata) and will be extended to other ports in the future. Moreover, Indian ports have adopted some digital initiatives such as on-road examination of containers, automated gate processing enablement, online berthing systems, etc. Further, Ministry of Ports, Shipping and Waterways (MoPSW) is leading charge to create a unified logistics system – National Logistics Portal (NLP) – integrating all supply chain elements in India across various modes of transport like roads, railways, etc. As a part of the same, a National Logistics Portal (NLP) Marine has been envisaged to solve many current EXIM challenges. This step is aligned with the global trend of building end-to-end supply chain solutions in shipping. NLP Marine will be developed in conjunction with the existing PCS1x platform and will provide API integration facility with various Port Operating Systems, Terminal Operating Systems,

Dr Abhijit Singh is an accomplished maritime professional and passionate educationist with multifaceted work experience in shipping, on-shore and as well “at sea”. He attained the distinction of becoming the youngest senior officer, equivalent to Deputy Chairman of Major Port at the age of 34 years. In the past, he sailed onboard ship and worked onshore in senior capacity with UK based oil major shipping company. He is closely involved in the policy decision-making process to bring sectoral reforms by making ports as drivers of economic change, saving logistic cost & time, easing port congestion, enhancing employability, capacity building and digitalizing & modernizing of ports.

and other stakeholder(s) systems. This entire ecosystem will be built on open standards with plug-and-play capabilities to allow changes at sub-system levels without affecting other parts and enable a heterogeneous multi-stakeholder environment to collaborate seamlessly.

Ed’s Note: What started as an initiative in the year 2019 to honor excellence of the young under-40 talents in supply chain, has today become a movement. We are now providing them a voice by way of this newly launched Celerity Supply Chain Super Achievers’ column. These voices are truly making a difference in the way supply chains function today and we would like to get their insights. Dr Abhijit Singh is a Celerity Supply Chain Super Achiever 2020

UNDER-40 SUPER ACHIEVERS

Digital Strategies in Procurement Procurement is adopting new digital strategies to infuse and analyze data models to enrich day-to-day operations and decision making. This, in turn, transforms how buyers interact with suppliers as these digital platforms have introduced new levels and types of collaboration, writes Prachi Misra, Senior Director, Refinitiv Ltd. (A Blackstone Operating Company)

P

ROCUREMENT is actively endorsing new innovative technologies and is enabling a progressive digitization of labor through automation of existing routine processes, thereby enhancing levels of performance at every stage of the procurement process. Robotics Process Automation (RPA), Machine Learning, Natural-language-processing (NLP) and Cognitive Technologies are automating the process and improving efficiency by more than 50%.

BENEFITS OF DIGITAL PROCUREMENT Digital procurement is actively reducing the time to launch bidding events and hence more events can be conducted. Earlier only high spend threshold events were being auctioned but now even project spend can be bid and auctioned for best results. Additional benefits that digital procurement strategies are driving are mentioned below: • Increased spend under management to drive both cost savings and cost avoidance, leading to improved bottom line • Improved risk mitigation over factors such as cost volatility, supply disruptions and regulatory compliances issues • Better resource management, including the ability to manage a contingent workforce and address skill shortages • Greater spend visibility and spend management across categories with better ways to look at spend through technological enhancements

supplychaintribe.com

• Better management of spend as all events are stored in an electronic format in the systems • Improved performance by suppliers as in a global ecosystem, even their other clients can see rankings provided by a given company for their services. Also based on cumulative ranking, suppliers will automatically be recommended to new organizations in the market who are scanning the market for similar services. • More active tail spend management by companies as now more supplier spend can be managed by tools, thus freeing up resources. • Enhanced supplier innovation and collaboration to both retain and increase the value driven by strategic supplier relationships • Faster growth as now procurement has access to many more global suppliers. Here are many digital strategies that are aiding procurement professionals in bringing the fine balance: Contract Management: Automated programs assess contracts and compare them against best in-class templates, flags terms and conditions that are nonstandard. They also map the buy side contracts to sell side contracts for greater visibility. Transactional Procurement: Robotics Process Automation has been deployed to emulate repetitive tasks, which do not require much human interpretation such

Prachi Misra is an Oxford university graduate and is part of Procurement Leadership Team of Refinitiv (a Blackstone Operating Company). She has worked in IT Strategy, Procurement Strategy, Business Change Management in leadership positions. She is an ardent supporter of innovative technologies in the marketplace, which are instrumental in reducing bottom line in today’s business world.

as invoice upload and approval. Strategic Sourcing: Natural-languageprocessing (NLP) technologies process textual data and provide a convenient way for purchasers to document requirements without resorting to dropdown menus or structured lists. Realtime question and answer process are introduced so that specifications are precisely refined, and organizations can engage with qualified suppliers promptly for better results and faster time to market. Machine Learning Algorithms can handle tasks that involve complex rules and require some form of pattern recognition to be executed correctly. Based on multiple sourcing events executed, machine learning algorithms learn from them and provide recommendations for

15

UNDER-40 SUPER ACHIEVERS negotiation strategies to deliver the best outcome for a bidding event. Support Processes: Smart workflow technologies link tasks conducted by different people and machines into a coherent process with well-defined handoffs — for example different routes can be followed for payment for transactional suppliers and strategic suppliers. For strategic suppliers due to higher spend limit more approvals may be required including finance approvals whereas for transactional suppliers, we have shorter approval processes owing to lower spend thresholds. Category Management: Machine Digital Procurement learning can be used to identify category assignments based on requisition text, hence streamlining the categorization of purchases. This, in turn, helps assigning accurate categories to various requisitions and helps determining accurate spend across categories.

Supplier Management: Automated programs conduct supplier diligence across several risk categories to process, review and score supplier data related to key risk indicators. Another application is in bidding events. After each bidding event, suppliers are ranked based on price competitiveness and ability to deliver, which in turn, is available to all other companies who are registered on that platform. Self Service Procurement: By adopting artificial intelligence, organizations can immediately source price competitive services from any location. This platform also enables effective collaboration among business users, procurement, and suppliers, thus ensuring smooth coordinated hand-offs during bidding events and when evaluating proposals received from suppliers. Cognitive agents and chatbots are actively being deployed whenever a deep knowledge base must be quickly

Bringing It All Together

searched to recommend the correct course of action. The chatbots that several service organizations now use in assisting contact-centre staff can answer a wide range of customer queries by selecting appropriate responses from a previously documented set of answers. In the source-to-pay process, vendor and business-procurement help desks often require similar sets of interactions, suggesting that a similar solution can be implemented. As the capabilities of cognitive agents enhance, they can also handle more complex tasks, such as evaluating an item’s global-sourcing potential by assessing its cost, quality, and technology requirements with records of similar products and sourcing decisions. By scrutinizing supplier capabilities, cognitive agents may even be able to provide recommendations on the selection of specific suppliers.

Digital procurement solutions (figure 3) are allowing for many more physical and digital inputs to be connected, driving better decision making and improving efficiency, and ultimately producing results in the form of: • Improved insights and strategies, leading to accelerated cost leadership

Digital Procurement capabilities work together to drive results • Enhanced process excellence, leading to greater organizational efficiency and effectiveness • Better assurance of supply and improved risk mitigation

Figure 3: Digital procurement capabilities work together to drive results

IMPROVED INPUTS Physical Data Files

IMPROVED DECISION MAKING & EFFICIENCY EXTRACT DATA FROM PHYSICAL DOCUMENTS

• Contracts • Specs • Bills of Materials

Unstructured Databases

Movement of Goods Tracking

Intelligent Content

Cognitive Computing

Advanced Should Costing

Cognitive Computing DETECT MOVEMENT OF GOODS

• Deliveries • Demand • Material Consumption • Receipt of Goods

Third-Party Data

DECISION SUPPORT

CATEGORIZE UNSTRUCTURED DATA

• Supplier Spend • Accts Payable

Sensors

Digital Solutions …which grow in value when used together

Predictive S2C Insights and strategies Decision support Cost leadership

Cyber Tracking

Collaboration Networks

Automated P2P Process excellence Efficiency and effectiveness

Advanced Visualization

ENRICH WITH EXTERNAL DATA

• Supplier Data • Social Media • Commodity Trends • Duties & Tariffs • Country Risk • Third-party Payment Clearing

RESULTS

Blockchain Robotics

AUTOMATION

Proactive SRM Assurance of supplies Risk mitigation strategies Supplier and category strategies

Source: Deloitte Whitepaper ‘Digital Procurement: New Capabilities from Disruptive Technologies’

16 CELERITY May - June 2021

COVER STORY

INDIA’s VACCINE DRIVE:

BEGINNING of the

ENDGAME? Being seen as the endgame of the Covid-19 pandemic, India’s vaccination drive has been hailed as one of the largest vaccinations drives in the world with it being the second most populous country in the world. While there are mixed reactions from the industrial diaspora on the extent with which the vaccination is being conducted in the country, the ultimate truth remains that for a country with 1.39 billion population, there are bound to be teething challenges. Our recent webinar, ‘Vaccine Supply Chain & Challenges – India & Globally’ dwelled on the imperatives that are needed from all the quarters to ensure effective & efficient vaccination drive. Our august panelists highlighted and elaborated on the global vaccination efforts, India’s vaccination strategy, our logistical prowess and people participation that will ultimately aid in the success of the Vaccination Drive. This Cover Story brings you the excerpts of the expert panel and the humungous task that is there upon us all individuals to make it succeed – TO GET VACCINATED!

COVER STORY

For a supply chain professional, there was never a ‘Normal” and there never will be one. “In the 21st Century, companies do not compete, but their supply chains compete. If everything being equal (Product, Specs, Service, Price, Features), what separates organizations from each other is their Supply Chain prowess, capability, and efficiency. What we call “Globalization” had forced companies to move their supply chains across international borders making the chains more “Interconnected” but at the same time making them more “decentralized” and hence more “fragile,” emphasizes Sanjay Desai, Regional Director – Talent Development, Humana International Singapore.

Your view on status of global supply chains and the impacts that Covid-19 has had on them so far. Corona virus has had far reaching ramifications on the world economy, supply chains/ financial stability including people health. As of mid-April 2021, we have more than 136 million cases of infections & close to 3 million deaths across the globe. There was never a worst calamity in the world (other than Spanish flu) of this magnitude. Specifically for emerging markets, this could be the worst phase as well as a gamechanger over the next 5 years. The scars of year 2020 will be etched in our memory for lifetime. In the 21st Century, companies do not compete, but their supply chains compete. If everything being equal (Product, Specs, Service, Price, Features), what separates organizations from each other is their Supply Chain prowess, capability, and efficiency. What we call “Globalization” had forced companies to move their supply chains across international borders making the chains more “Interconnected” but at the same time making them more “decentralized” and hence more “fragile”. Over last three decades, organizations and their supply chain are trying to find new paths, new ways to gain advantage over their competitors in the pursuit of making their products cheaper and available at greater speed to Customers at the same time. And in this penchant, Cost superseded Quality in all aspects of the Value Chain…Supply Chains became leaner and leaner over the years, leaving no room to absorb any disruptions.

18 CELERITY May - June 2021

Eventually Corona Virus was the “Last Straw that broke the Camel’s back”.

A lot has been talked about “new normal” for supply chain in post covid period. As a Supply Chain professional of over 30 years and having run supply chains in 11 different organizations, what are your thoughts? Personally, I do not like the word “New Normal” if this is being used purely from a supply chain point of view, may be from a colloquial and business dynamics perspective the “new normal” may make some sense. I would rather address this as BC = Before Covid and AD = After Disease for supply chain organizations. For a supply chain professional, there was never a ‘Normal’ and there never will be one. Almost everything is dynamic in supply chain and that is the way it should be, else we will not be able to develop supply chain leaders. Businesses evolve every 3 to 4 years, so does supply chain professionals and with them the supply chain models too evolve. In supply chain, “change” is one “mantra” that drives efficiency, scale, creativity & eventually achieving better customer experience or satisfaction. As a leader, one needs to hedge working capital costs in multiple ways from time to time as the dynamics of the business demands. If you take a good look at organizations with world class supply chains, these supply chains are “tailormade” for their customers / markets/ geographies, often, you will find one common factor and that is supply chain thought leadership. These leaders have honed their ability to see into the

future, they are willing to invest in people, processes, and tools (In that exact order) as a driving force. In these organizations, the senior executives/ board members understand & acknowledge the value that supply chain brings to the table.

India is called “The Pharmacy of the World”. What efforts Indian government and companies are taking to ensure that India will be able to support the huge requirements of vaccines all over the world? India produces 20% of all pharmaceuticals consumed worldwide, making the country the largest manufacturer and supplier of drugs globally. At present, India is using two vaccines (AstraZeneca’s COVISHIELD and Bharat Biotech’s COVAXIN. Besides taking care of the domestic needs, India has already started to export vaccines to many countries like Bangladesh, Bhutan, Nepal, and Maldives as “neighbourhood first” policy. Serum Institute of India is geared up to produce 100 million doses of the AstraZeneca COVID vaccine each month. Plus, we have 5 to 6 more vaccines in the pipeline expected to be available by October / November 2021, for manufacture and domestic use. Some of these are (Zydus Cadila, Dr Reddy’s, HDT Biotech (US), and Biological E). However, considering the scale of these manufacturing requirements, India would require huge quantities of raw materials needed to make these vaccines possible. India is working with the US to address this key factor. We must recognize the effort of Bharat Biotech and Serum Institute for working 24/7

COVER STORY Almost everything is dynamic in supply chain and that is the way it should be, else we will not be able to develop supply chain leaders. Businesses evolve every 3 to 4 years, so does supply chain professionals and with them the supply chain models too evolve. In supply chain, “change” is one “mantra” that drives efficiency, scale, creativity & eventually achieving better customer experience or satisfaction.

even during shutdown periods with prior government approvals and assistance. As a supply chain professional, I strongly feel that India’s supply chain was “bent/ tested aggressively, but not broken” during the pandemic.

Covid-19 vaccines are relatively new to the world. What differences do you see in handling requirements in relation to the vaccines (non-Covid types) of the past? Both COVISHIELD and COVAXIN are easy to store as they require to be kept at 2-8 degree Celsius. Most vaccines commonly used in India are kept at this temperature range. This makes transport and local storage of both Covid-19 vaccines safe and easy for all parts of the country. There are two more vaccines, which are being administered globally are 1) Pfizer and 2) Moderna. Indian Government is still debating whether to allow these vaccines to be used in India. Both vaccines use mRNA technology, which involves using genetic material from the virus called mRNA, which directs the body’s cells to stimulate the immune system. This method has not been used to create a vaccine so far. While this method is simple, once you have the RNA Platform available, to manufacture on a large scale, both vaccines require stringent temperature requirements, and the range also varies considerably. Moderna’s vaccine needs long-term storage at minus 20-degrees Celsius (minus 4 Fahrenheit), while the Pfizer vaccine requires minus 70-degree Celsius (minus 94 degrees Fahrenheit) or even lower – one of the coldest temperatures ever seen in a vaccine. Given our infrastructure especially in

supplychaintribe.com

tier 3 and 4 cities and in rural areas, these two vaccines are not ideal to be used. However, we do have sufficient infrastructure available in our main metro and mini metro cities where we are able to store and transport (20-degrees Celsius and -70 degree Celsius).

As global economies are slowly finding their feet in a murky environment, which are the enablers of success to fight such a huge disaster? What have we (the industry) learnt from this experience to apply them? There are many lessons that we can articulate but I prefer to talk about these top 3-4 which can be industry agnostic: • First lesson was about conducting Risk Assessment. A significant learning from Corona virus that most global and world class organizations carried is to build “Risk Assessment” right upstream in your value chain. Incorporating risk management, upstream in value chain will drive a mindset of “engineering the supply chain” v/s engineering the quarterly Balance-Sheet”. • Second lesson learnt is to increase visibility in your entire value chain like your 3rd and 4th Tier suppliers, your employees, your inventories, major customers, and their demand / supply exigencies. If you have visibility of your entire supply and demand networks, your ability to be agile as well as resilient increases many times over. • Third lesson learnt, there is a certain benefit in “collaborating” across your value chain starting from left (your customers) all the way to right (your suppliers) creating value

driven collaborative strategies like demand sensing, integrated business planning, demand drive inventory planning, segregation of customers and finally a multi-source “Integrated Supply Network” of smaller supply networks across geographies. • Fourth lesson learnt is to “optimize your order management and fulfilment capabilities” to be able to fulfil your customers from anywhere to anywhere. Proactive customer engagement, adding huge value to customers P&L and speed of operations will be of prime importance as highlighted never before. • Finally, organizations realized that investment in technology, re-skilling your employees helping them to be comfortable with new tool sets and using advanced communication tools are critical success factors in future. The only way to improve in such situations, is to leverage your most valuable asset “Your People”.

19

COVER STORY

We are taking help from the representatives of the community to drive immunization in rural areas. “Believing in ‘One size doesn’t fit all’ strategy, we have observed that self-registration mechanism is pretty less in rural areas, therefore we have adopted facilitated cohort approach to increase the coverage. Strong leadership from the expert group, election model approach, learnings from Universal Immunization program, an efficient IT system and robust IEC strategy have been the strong pillars for the effective roll-out of the vaccination drive,” shares Dr. Mohan Lata, Surveillance Medical Officer at World Health Organization.

What are the key strategies in the effective roll-out of vaccines? The Government of India is using the experience of Universal Immunization Program dovetailed with the election model approach. MoHFW develops Operational guidelines whenever there is new vaccine introduction so that uniform practices are being followed across the country. Similarly, for COVID-19 vaccination as well operational guidelines have been developed and followed across the country. As enumerated in these guidelines, a covid-19 vaccination center needs to be prepared, which should have three dedicated areas: waiting area, vaccination area and the observation area. Each vaccination center is deployed with the dedicated trained vaccination team. This team comprises of one security personnel at the entrance, one verifier who checks for the identity and is also using Co-Win portal, this is the portal developed by MoHfW, which is being used for the registration, appointment and vaccination. then one vaccinator and the last 2 team members work in the observation room and also overall manages the session site. This dedication structure with the dedicated team is the adaptation of the election booth model. This adaptation has been

taken from the election booth model. We have also adopted some practices of universal immunization program and these practices are like development of micro-plans, information, education and communication materials and capacity building of healthcare workers on topics such as injection technique, cold chain maintenance, adverse event following immunization, four key messages and biomedical waste management. These are some of the protocols we are deploying for scaling up the vaccination drive. Along with this, the vaccination primarily is targeted for three major groups. These groups were identified by the National Expert Group on Vaccine Administration for Covid (NEGVAC). The first group was healthcare workers, then frontline workers and the priority age group which was earlier above 60 years and people above 45 years with selected comorbidities but now it is above 45 years. The list of healthcare workers was uploaded at the district level using the Co-Win portal and for every session, there was an automated generation of the due list. Beneficiaries receive messages regarding the time and place for the vaccination. The similar process was followed in the second phase as well. For the priority age group, Co-Win

2.0 which is the upgraded version of the earlier portal is being used where we no longer must upload a list of beneficiaries for registration and vaccination. The beneficiaries now can self-register themselves using Co-Win portal or Aarogya Setu app; or can also choose for on the spot registration. As you know health is a State subject, we have undertaken some targeted approach like campaign for women on women’s day, mobilization of pensioners, inclusion of Panchayati Raj representatives, retired government people etc. As one size does not fit all, we have also observed that the selfregistration mechanism is less in rural areas. Therefore, we have adopted facilitated cohort approach which included mass mobilization and on-thespot registration cum vaccination of the beneficiaries. Strong leadership from Expert groups, Election model approach, learnings from Universal Immunization Program, efficient IT system and robust IEC have been strong pillars for effective rollout and implementation for COVID-19 vaccination.

Is the current vaccination drive as successful as any other

This largest vaccination drive is effective through concerted and tireless efforts of the health workers, along with the gaiety inter-sector and inter-department coordination. For any mass drive to be effective, a definite structure with demarcation of roles and responsibilities is vital, which was done through the guidance of NEGVAC and development of operational guidelines. 20 CELERITY May - June 2021

COVER STORY immunization drives that India has been doing over the years? Usually in mass vaccination drives, we introduce vaccines at one go for the selected regions. But for Covid-19 vaccination, we have broken down the drive into phased manner. I believe we are keeping up pace with the planned roll-out and achieving the target. For elderly age group, different approaches have been deployed for the effective roll-out and implementation. Learnings from past vaccination drives and UIP is helping us.

How has supply chain been maintained from the vaccination drive? Has the government of India formed any public private partnership or any secondary distribution mechanism? Supply in India includes delivery of the vaccines from Government Medical Store Depots (GMSDs). In total, we have 4 GMSDs in the country – Karnal, Mumbai, Chennai, and Kolkata. From GMSDs, the vaccines come to state vaccine stores followed by the Regional Vaccine Stores or Divisional Vaccine Stores. From there, the vaccines are delivered to District Vaccine Stores. From these district vaccines stores, the vaccines reach to Cold Chain Points and these are usually situated at Block level i.e., community health centers or primary health centers. During this entire cycle of supply, the cold chain of the vaccine is maintained through usage of the insulated vaccine vans and cold boxes. From these cold chain points to the session sites situated at the last mile, the vaccines are sent on the same day i.e., the vaccination day in the vaccine carriers. These vaccine carriers are usually accompanied by the conditioned ice packs in order to maintain the ambient temperature of +2 to +8 degrees. To track the entire system of supply chain, we have electronic vaccine intelligence Network (EVIN) system. This helps in temperature monitoring and tracking of stock of vaccines and expiry date. The concept of FIFO is used to avoid vaccine wastage. For any unopened vaccine vial at the sessions site, we maintain the reverse cold chain using the same prescribed conditions. Covid-19 vaccination is also done at the private hospitals, so GoI has

supplychaintribe.com

also acknowledged that if these private hospitals have sufficient capacity for storage or they can function as cold chain points, they can stock vaccines for their own consumption. This is the kind of PPP model the government is following as far as Covid-19 vaccination is concerned.

What is the role of NEGVAC? A National Expert Group on Vaccine Administration for COVID-19 (NEGVAC) has been established, which provides guidance on all aspects of COVID-19 vaccination including prioritization of population groups, procurement and inventory management, vaccine selection, vaccine delivery and tracking mechanism, etc. NEGVAC is chaired by Member (Health), NITI Aayog and cochaired by Secretary (H&FW). NEGVAC has representation of Secretaries from Ministry of External Affairs, Department of Expenditure, Dept. of Biotechnology, Dept. of Health Research, Dept. of Pharmaceuticals, Ministry of Electronics and Information Technology, representative from five State Governments and technical experts. The government is utilizing the experience of elections and universal immunization program and ensure that there will be no compromise on scientific and regulatory norms and other Standard Operating Procedures (SOPs). The group also ascertains equitable distribution of vaccines to other nations. The group also provides guidelines on the vaccine candidates’ selection, procurement mechanisms, prioritization of population group, financial resources requirement of vaccine procurement and logistics. The group guides the MoHFW on the vaccine safety, AEFI, and guides the department on creating awareness regarding the vaccination drive.

following in the rural areas. Likewise, teachers can be the role models for parents so that they can come forward for vaccination. We are using FAQs developed by MoHFW to give answers to the doubts and queries of people. As mentioned earlier, strong advocacy and interdepartmental coordination is our key of successful implementation.

What are the lessons learnt from the vaccination drive? What are the opportunities that it has presented? This largest vaccination drive is effective through concerted and tireless efforts of the health workers, along with the gaiety inter-sector and inter-department coordination. For any mass drive to be effective, a definite structure with demarcation of roles and responsibilities is vital, which was done through the guidance of NEGVAC and development of operational guidelines. IT and IEC are the two pivots for this vaccination drive which are also the opportunities to see forward. The strengthening of IT component of immunization system and robust IEC (like FAQs for citizens, regularly busting fake news) is yielding good results.

How are you motivating people to come out and get vaccinated? One size does not fit all. Strategies could be different for everyone be it state or a district. We are taking help from the people who are the representatives of the community. These practices have been replicated from the experience of previous vaccination drives. We are reaching out to panchayat level elderly people to motivate others by taking the vaccine jab. This is one strategy we are

21

COVER STORY

In our war against the Covid 19 pandemic, the battle is now. “We will win the battle against Covid eventually. Establishing a secure supply of vaccines, augmenting disease surveillance and scaling up social mobilization will be key to how soon we win the battle.” asserts Dr. Raj Shankar Ghosh, Senior Advisor – Vaccine Delivery, Bill & Melinda Gates Foundation.

Which are the factors that are critical for vaccination planning perspective? Which are the roles that you see technology can play in this? Before answering this question, let me take you three decades back. I was working for an NGO delivering Primary Health care in one of the desert districts of India in Rajasthan. One day when we were planning on improving coverage in far flung villages in the district, a health worker told us that planning for vaccination basically required a 3P fulcrum. Sufficient & stable supply of Vaccines. Product Enough vaccination centers. Improved access. Places Empowered People. People who are aware of the vaccine. People who are trained to vaccinate. And people who will mobilize the population for vaccination. The 3P fulcrum is relevant in routine immunization or large campaigns like Polio eradication or adult vaccinations like Covid vaccination. As we plan for scaling up vaccination coverage in routine program and campaigns, we must answer the following questions. • What is the production capacity of vaccines currently being used in the

program? What is the committed supply to India? We can only do as much as the product supply to our program is. • Are centers evenly distributed? Numbers & equity. Map the centers. Find out vacant spots. Are both public and private sectors being effectively utilized? • How many trained people do we have? Have we engaged the full potential of health care workers in both public and private sectors to vaccinate our people? India and many other countries in the region have prepared early for Covid vaccination program. Following 3 P principle. (i) Committed vaccine availability. Domestic and global supply. (ii) Covid-vaccination appropriate delivery infrastructure available in public and private sectors. (iii) Trained manpower available in public and private sectors. Completed their training through a mix of online and face to face trainings and demonstrations. Prioritized population based on local clinical and epidemiological data. Now let me address how India planned its Covid vaccination program. Before I come to planning, let me tell you an anecdote. About 20 years back in a district in Jharkhand State where I was in-charge of India’s National Polio Surveillance Program, there was one district which was a poor performer for many rounds.

A new district magistrate joined the district a few months prior to Pulse Polio program. In just about 2 months vaccination coverage improved. I went to meet him and asked him what has changed in the last 2 months. He told me that there were gaps in the program, and he had met the gaps with the GAP strategy. The GAP strategy is: Governance; Accountability and Planning. If we have a strong governance, if we have clear roles and responsibilities and make people accountable for their activities, and if we have a good microplan in place, then a program is destined to succeed. In India for Covid vaccination program, we have seen governance executed well by the NEGVAC committee which is a high level inter-departmental committee formed at the apex reporting to the highest authority in the Country. Principal accountability lies only with few people – at Central level, State land at district level. At district level District Magistrate is overall in-charge of the program coordinating all locally available resources for implementation. Micro-planning has been done by frontline workers at Primary health centers. As they have done for other programs like Mission Indradhanush and National Immunization Days. There is a 4th P – Partners. Partnership in vaccine delivery has always been strong

Surveillance both in terms of reporting, testing and action following availability of relevant data is critical to identify hot spots of transmission. Immediate action – both in terms of preventing transmission and protecting the population with vaccines must be deployed immediately. 22 CELERITY May - June 2021

COVER STORY in India. With Covid vaccination new partners like World Bank and ADB have come forward to support vaccine delivery in South Asia Region. Existing partners in India include WHO, UNICEF, UNDP, JSI, PATH, GAVI, CHAI, the Technical Support Units in the States and BMGF to name a few.

Is there any technology case study to manage the entire value chain in a cost effective and secure manner? For every successful technology, primarily in healthcare, there have been four attributes that we have to acknowledge: 1. Technology was developed because there was a demand. There was a problem or an aspiration that present solutions could not solve and therefore there was a need to design and introduce a new technology solution. 2. Technology must adapt to current health systems. This means it can be scaled up in the system with efficiency, speed, and minimal investment. 3. Technology needs to be affordable for the government to scale up in public health programs. 4. Technology must be user-friendly. One example that I would like to quote here is of Vaccine Vial Monitors (VVMs). A VVM is a label containing a heat sensitive material which is placed on a vaccine vial to register cumulative heat exposure over time. The combined effects of time and temperature cause the inner square of the VVM to darken, gradually and irreversibly. A direct relationship exists between the rate of color change and temperature: The lower the temperature, the slower the color change. The higher the temperature, the faster the color change. The VVM is a circle with a small square inside it. It can be printed on a product label, attached to the vaccine vial or tube, or attached to the neck of an ampoule. VVM is the only tool among all time temperature indicators that is available at any time in the process of distribution and at the time a vaccine is administered indicating whether the vaccine has been exposed to excessive heat over time and whether it is likely to have been damaged.

supplychaintribe.com