INTERVIEW

BE SURE “We have adopted a clean, lean and green approach to creating a responsible supply chain. Our Sustainability, User-Friendly, Reliable and Efficient (S.U.R.E) packaging is just one initiative to achieving our vision. Driven by a firm belief in the 5Rs (Remove, Refuse, Reduce, Reuse and Recycle), we designed a process to sustain this environmentally responsible supply chain. The welldefined process included forming a focused team with internal and external members; applying scientific techniques; implementing ideas and actions across locations and finally verifying results and continuously improving outcomes,” shares Nikhil Puri, Global SCM Head – Communication Cabling Solution, Sterlite Technologies Ltd. (STL).

Why was circular economy an important pillar for your organization? In the linear economy, raw natural resources are taken, transformed into products and get disposed of. On the contrary, a circular economy model aims to close the gap between the production and the natural ecosystems’ cycles – on which humans ultimately depend upon. This means, on one hand, eliminating waste – composting biodegradable waste or, if it’s a transformed and non-biodegradable waste, reusing, remanufacturing and finally recycling it. On the other hand, it also means cutting off the use of chemical substances (a way to help regenerate natural systems). Additionally, people are getting more vocal, criticizing companies involved in (or staying quiet on) deforestation, pollution, or using unsustainable materials. Brands selling poor-quality products use non-recyclable packaging or allowing ecosystem destruction is being ‘called-out’ on social media. There are certain reasons why circular economy is important pillar for our organization. We need to secure the

supplychaintribe.com

resources. Working out which materials are critical for our business, and which are most at risk, was a great starting point for this approach. Is future demand likely to exceed supply? Are there geopolitical factors at play, likely to affect price or access? Swapping from finite, potentially risky or under-pressure resources to safe, sustainable materials provides resource security and price stability. We focused on regeneration; applying the circular economy mantra that ‘all waste = food’ for resources used for the product and the production process might involve regenerating our own resources or partnering with a specialist recycler. Resource security and regeneration have the additional benefit of reducing business risks, and diversifying both the locations and materials in our supply chain also helped. Circular economy approaches build stronger brand reputations, by doing things better and doing better things.

What were the challenges that came your way in implementing S.U.R.E? The major challenge was the type of materials that we use. Traditionally these

An alumnus of IIM Ahmedabad, Nikhil Puri has over 16 years of experience with large multinationals & Indian businesses in developing and managing Responsible, Safe & Sustainable Supply Chain and Procurement. His areas of expertise in end-to-end supply chain & procurement includes automation, manufacturing ecosystems, global & local strategic sourcing & procurement, direct & indirect services, contract management, supplier relationship management, environmental, health and safety, risk, legal and regulatory material/inventory management, and customer fulfilment. He has a leadership track record on business turnaround assignments, handling bigger portfolios, executing challenging projects, bringing innovation to disrupt market within Sterlite, General Motors & Honda.

materials are not easily recyclable and we had to apply a different approach to counter this challenge. These are special materials. In line with the same, we came up with recycling of at least 100% of packaging materials. We wanted to create value for our Company, Customers and the Society through environmentally conscious initiatives. We called this initiative as S.U.R.E (Sustainable, UserFriendly, Reliable, Efficient) Packaging. The approach that we followed up for this was of 5R i.e Remove, Refuse, Reduce, Reuse, and Recycle.

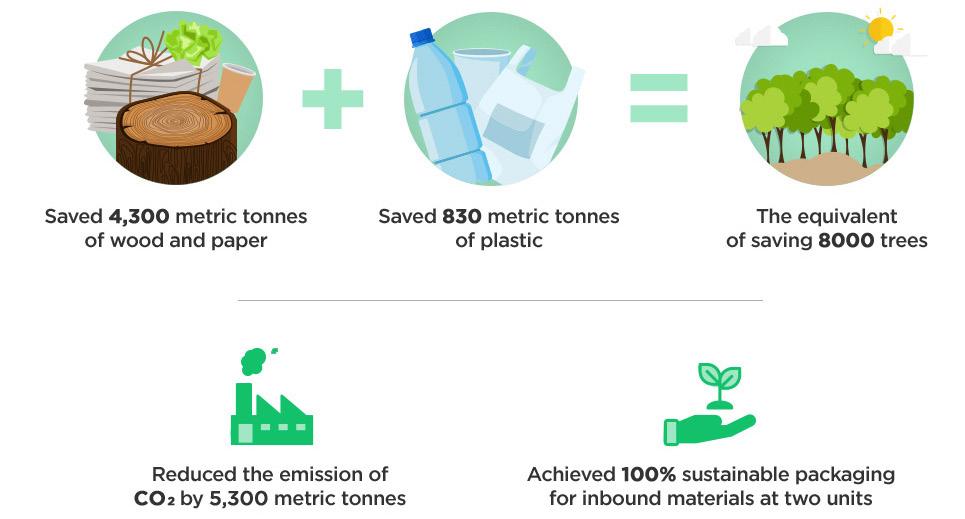

Please highlight the technical aspects of S.U.R.E. What does it take to save 8000 trees every year? It turns out, just a small shift in perspective. It’s no surprise that our resources are under threat from overuse, though you might not know that a major player contributing to this phenomenon is industrial packaging, that uses onetime use cardboard packaging. Alarmed by the increasingly dire reports of the far-reaching environmental impact of packaging across the globe, STL has

29