EQUIPMENT ENGAGEMENT

We speak with JCB’s Business Head –Excavators, Paul Swallow

DATA DUMP

Packed feature devoted to Dumpers and Loaders inside

BUSINESS INSIDER

We salute owner of Machines on the Market and former Grenadier Guardsman, Richard Cross

EQUIPMENT ENGAGEMENT

We speak with JCB’s Business Head –Excavators, Paul Swallow

Packed feature devoted to Dumpers and Loaders inside

We salute owner of Machines on the Market and former Grenadier Guardsman, Richard Cross

FROM 1.8 TO 95 TONNES THE ALL NEW F-SERIES BREAKS THE MOULD.

On the rare occasion that my social life is spent with non-industry friends, when the subject of work comes up it is invariably prefixed with the words “Oh, it’s JCB you promote, isn’t it?” Yep, still and almost every time when talking about any type of construction equipment.

This is definitely testament to the proud name JCB has built globally but also to its marketing over the years – I grew up seeing these yellow diggers along the motorways as I sat in the back of my parents’ car listening to Queen, Erasure and more shaping my musical tastes. JCB is without doubt a byword for a digger and although it took a while, this year in particular we have got closer to them with our Editor Toby being invited to a number of launches as well as having more and more news sent directly to us.

Now we can boast of a strong 2025 advertising campaign beginning in this very issue, check out the centrefold.

This closer relationship continues with JCB debuting in our regular supplier interview EQUIPMENT ENGAGEMENT, in which we spoke to Paul Swallow, Business Head – Excavators. It is quite the read.

Machines dominate our interviews as in BUSINESS INSIDER we talk to the owner of Machines on the Market, Richard Cross, regarding its three years in operation, its growth in that time, and with stats like 400 machines being on their books right now, some extremely impressive numbers. This alongside the revelation that he shares Las Vegas with me as a desirable destination.

It is also good to be able to support friends with such coverage as close friend Louise Bradshaw-Black happens to be doing an awesome job as the Creative Director there. Keep doing what you are doing MOTM – we and the industry are right behind you!

We bow out of 2024 with awesome memories of Hillhead, World of Concrete, RWM, The Executive Hire Show and the British Demolition Awards all indelibly implanted in our heads, as we put together this, the last edition of the year.

I want to thank everyone for being involved in this challenging but extremely rewarding year. It’s been a hell of year in every possible way and we cannot wait to be reunited in January in what will be our sixth calendar year as Diggers LIVE! Wow.

Have a brilliant end to 2024 – you know where we are.

v Ben Chambers, Publisher

EDITORIAL TEAM

PUBLISHER

Ben Chambers ben@chambers.media

EDITOR

Toby Wilsdon toby@chambers.media DESIGN Joe Chambers joe@chambers.media

Nicki Chambers GENERAL ENQUIRIES info@chambers.media 01903 952 640

Ben Chambers ben@chambers.media 01903 952 648

PRODUCED & PUBLISHED BY Demolition Hub Ltd

Suite 5 & 6 Chapel House 1-6 Chapel Road, Worthing West Sussex BN11 1EX ben@chambers.media 01903 952 640

Diggers LIVE! is published six times a year by Demolition Hub Ltd

Articles and information contained in this publication are the copyright of Demolition Hub Ltd and may not be reproduced in any form without the written permission of the publishers.

The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

6

Industry leaders give their take on Rachel Reeves’ first budget

8

EQUIPMENT ENGAGEMENT

With Paul Swallow, JCB Business Head – Excavators

12

With Richard Cross, Owner of Machines on the Market

16

JCB unveils a series of new additions to its extensive range of construction equipment

28

• Dates announced for Hillhead 2026

• PlantWorx 2025: One year to go

• Rethinking Futures at PlantWorx 2025

34

• AUSA

• Bobcat

• DEVELON

• JCB

• Kramer

• Liebherr & Strabag

• Rokbak

• Komatsu Europe

With Abigail Scott, Operations Manager at Digger Delivery

CEA response to UK government’s industrial strategy –Invest 2035

SANY UK sells first 23-t electric excavator in UK to Explore Plant and Transport Solutions

Smarter fleet management from Bell Equipment

Peter Fitzpatrick Ltd futureproofs and expands with CDE investment

Distinctive Hyundai HX140A L blends into wildlife landscape

Doosan Bobcat to create synergy through vertical integration with Doosan Mottrol

Boliden and Komatsu accelerate on fast lane to a zeroemission mining site

Komatsu PC700 with special boom conversion for raw gravel extraction

The construction site of the future according to MB Crusher

Red Rhino crowned Family Business of the Year at the coveted Midlands Family Business Awards

Terapro Construction and Rokbak announce distribution agreement

Looking back on three years since the delivery of Rokbak #1

Bearing the emotional weight – focusing on World Mental Health Day, by Sarah Bolton CEO, Lighthouse Charity

Wacker Neuson introduces HVO as an alternative fuel

Hitachi transforms fleet management with CONNECT

Job stress affects 70% of construction workers, University of Cambridge study finds

CPA Appoints Decarbonisation and Sustainability Manager in Newly Created Role

SANY reinvents the eight-tonne excavator

Key figures in the construction plant and property law and finance sectors give their first reactions to the Chancellor, Rachel Reeves’s first budget, delivered on 30 October.

Following the Chancellor Rachel Reeves’ autumn budget, Steve Mulholland, Chief Executive Officer of the Construction Plant-hire Association (CPA) said:

“Today’s budget was an opportunity for the new government to show it is serious about providing the business community with stability and certainty. Despite not being part of the Industrial Strategy there appears to be an acknowledgement that infrastructure shall play its part in this new era of intended stability and growth with a commitment to spending on roads, rail, hospitals, schools, and homes.

“We welcome the news that fuel duty remains frozen, however it is disappointing that employers will have to pay more in National Insurance and that the plant-hire sector remains excluded from being able to take complete advantage of the Full Expensing

Allowance in its current form. We need further clarity on what fiscal conditions must be met before this can happen. We look forward to seeing more detail.”

Commenting on the budget, Viki Bell, Director of Operations at the Construction Equipment Association (CEA), said:

“This budget brings some positive developments for the UK’s engineering and construction sectors, especially with the £6 billion allocated to R&D in engineering. This investment, alongside the £520 million for a life sciences manufacturing fund and £20 billion committed to R&D, has the potential to support new technology, improve equipment safety, and encourage more sustainable practices – essential elements to keep UK construction competitive on a global scale. Such funding could open doors for both SMEs and OEMs as we work to meet the demands of modern infrastructure projects. The government’s renewed commitment to rail, road, and infrastructure development is a promising step for the construction equipment sector.

“The commitment to resume HS2 construction to London Euston, the pledge to invest and maintain hospitals and the investment in 300 new planning graduates all signal a strong focus on essential infrastructure and housing reform. This investment in the planning workforce is encouraging, but projects of this scale will still require sustained funding, coordinated planning and broader industry support to be delivered effectively and on time.

“The investment in 11 green hydrogen projects is another positive step, supporting the transition to cleaner energy and encouraging sectors like ours to consider alternative fuels. Despite these positive moves, it’s disappointing to see limited direct financial relief for construction firms.

“Doubling the employment allowance to £10,500 helps smaller construction equipment firms by reducing National Insurance liabilities, however, the planned increase in employer National Insurance from 13.8% to 15% in April 2025, coupled with the reduced secondary threshold from £9,100 to £5,000, is a double blow for firms. These added costs are likely to

strain budgets and limit opportunities for new hires or expansion, putting significant pressure on SMEs and OEMs at a time when stability and investment are critical. While we welcome the forward-looking approach, more targeted support is essential to help our sector fully contribute to these ambitious goals.

Sarah Fitzpatrick, Head of Planning and Jennifer Glasgow, associate at international law firm, Norton Rose Fulbright, said: “The key focus of the autumn budget is reform of planning policy and procedure with the intention of providing sustained long-term growth. We have already seen the draft amendments to the National Planning Policy Framework (NPPF), but the budget confirmed the government’s intentions for planning reform enabling the removal of barriers for growth. This will be aided through simplifying the planning system, developing a 10-year infrastructure strategy, which is currently expected to be published alongside the Phase 2 Spending Review, as well as increasing funding.

“The government has already started to progress projects through the planning system having approved six National Significant Infrastructure Projects (NSIP) since taking office – four of which related to green energy. The Deputy Prime Minister has also taken decisions on appeals below the NSIP threshold, within the 13-week decision period. This goes some way to support the government’s intentions they want to speed up the planning decision making process.

“The government is also focused on housing delivery and affordable housing. As the Deputy Prime Minster has previously set out, the government is committed to delivering 1.5 million homes and this was reiterated in today’s budget. The government’s remedy is its commitment to NPPF consultation, the New Homes Accelerator and New Towns Taskforce as well as over £6 billion of investment to promote affordable housing and support small housebuilders.”

Commenting on the budget and its impact across the housing market, Daniel Austin, CEO and co-founder at specialist independent property lender, ASK Partners, said: “Following today’s budget, there is good news for property developers. The promise of £5 billion of investment for new homes contained within today’s announcement will be warmly welcomed. Increased supply should buoy the market and level out values; a plus for first time buyers, who conversely will be hit by the new lower stamp duty thresholds.

“Further, it was encouraging to hear specific reference of help being offered to SME housebuilders, who can unlock smaller projects to revitalise towns and cities, and the help for cities such as Cambridge to meet its potential as an area rife for property development amidst key life sciences campus developments, and the homes needed for the workers this attracts.

“The decision to not include buy-tolet properties in the Capital Gains Tax increase will also be well received. The exodus of buy-to-let mortgage holders has been heaping pressure on the UK rental market causing prices to rise due to a lack of supply. However, the wave of private landlords selling off properties ahead of the budget may offer a short-lived upside

in supply of properties for sale. We have already seen a rise in mortgage approval rates back to levels previously seen before Truss’ mini-budget. The impact on the rental market should entice developers of schemes such as co-living and build-torent to fulfil the lack of supply, provided planning reforms allow.

Paresh Raja, CEO of independent bridging finance and residential and commercial buy-to-let mortgage provider Market Financial Solutions, said: “The government had warned of tax rises to fill the black hole in public finances, so there was apprehension across the property and finance sectors heading into today’s budget. Unlike previous budgets – think Kwarteng’s mini-budget – Reeves refrained from pulling any proverbial rabbits out of the hat, although the increase to Stamp Duty surcharge on second homes was unexpected. This approach should calm the lending and property markets, easing some of the uncertainty that has lingered in the leadup to this announcement.

“The government’s commitment to house building should stimulate activity across all segments of the housing market, creating a wide range of opportunities for buyers and investors. But people can be forgiven for listening to today’s budget pledges with a degree of scepticism –almost every budget includes promises to build more homes, but the devil is always in the detail.

“Reforming the planning system is clearly key, so the government’s focus on this area is welcome, with the rumoured additional planning officers being confirmed by the Chancellor today. It not only needs to be easier for new developments to get the green light, but also for investors and property owners to do more with existing real estate –conversions, renovations and extensions can do a lot to boost the national housing stock.

“It’s equally important that the government ensures new homes are delivered where demand is highest. If the location, type and quality of property is not high enough, there will be a struggle to attract buyers and renters, so there has to be a sharp focus on building the right properties in the right places.”

Interviewee: Paul Swallow

Role: Business Head –Excavators

Company: JCB

Paul Swallow is Business Head – Excavators at JCB. He joined the company in 2013 and has worked extensively on the development and promotion of the JCB X Series range of tracked excavators, now heading up the JCB excavators division

QTell us about the new JCB 145XR crawler excavator

One of the key products in JCB’s expanding X Series range is the brand new JCB 145XR crawler excavator, just launched. The JCB 145XR is a reduced tailswing model with compact dimensions yet maintains full-size performance and operator comfort.

QWhich sectors does it serve and what needs does it meet? What technologies are key?

The 145XR is designed for exceptional performance and productivity despite its reduced tailswing operation, making it ideal for confined applications such as housebuilding sites, highway carriageways or urban areas.

Key specifications and functions include:

• 27% shorter tailswing than a conventional 140X, making it perfect for working in tighter spaces,

• Optional TAB boom layout for improved reach and versatility,

• Full-size X Series cab with enhanced comfort features such as heated air suspension seats and climate control,

• The new JCB UX operator interface, which includes a 10" touchscreen display, customisable hot keys, up to 25 user profiles and mobile phone connectivity,

• Up to 10% improvement in fuel economy thanks to Auto-Stop

and Auto-Idle functions and an optimised engine speed of 1,700 RPM,

• Extended maintenance intervals, including a 250-hour greasing interval and fewer filter changes, reducing operating costs,

• JCB’s LiveLink fleet management system provides real-time data on performance, fuel consumption, and maintenance schedules, allowing fleet managers to keep operational costs low and productivity high and also enhance the security of the machine.

“The 145XR is designed for exceptional performance and productivity”

The 145XR is suited for sectors such as construction, urban development and highway maintenance, where space constraints require compact yet highperformance equipment.

QHow is the 145XR critical for potential users?

The 145XR is critical for users who require high performance in restricted spaces. It offers a reduced counterweight overhang and compact design, making it ideal for projects where space is limited but fullsized machine power is needed. Potential buyers will benefit from:

• Increased fuel efficiency: Up to 10% fuel savings,

• Reduced downtime: Faster cycle times and lower downtime thanks to intelligent hydraulic systems and robust engine designs,

• Lower maintenance costs: 24% fewer filter changes over 10,000 hours of service and extended greasing intervals up to

250 hours reduce operating and maintenance costs,

• Enhanced comfort: The full size JCB CommandPlus cab, which includes a heated air suspension seat and intuitive touch screen monitor, offers bestin-class ergonomics, reducing operator fatigue and improving productivity,

• Greater safety: Features like 360° cameras, impact detection and proximity alerts ensure peace of mind on site,

• Improved site accessibility: 27% shorter tailswing than a conventional 140X allows the 145XR to access tighter sites.

QTell us about the development of the 145XR

The development of the 145XR is part of JCB’s broader strategy to offer products that address the specific challenges of confined job sites. It builds on the success of the larger 245XR, delivering the

same level of performance in a smaller, more compact package. This approach represents an evolution of JCB’s X Series excavators, blending proven durability with new, advanced technologies and a more compact design to meet the growing demand for machines that can operate more efficiently in smaller spaces.

QHave you had any feedback?

The JCB 145XR itself is a brand new machine that is not yet with customers in the field. However, it benefits from all the hallmarks of the wider JCB X Series range which has proved hugely popular since its introduction.

With the X Series, JCB redesigned key elements, including the undercarriage, cab and hydraulics, based on feedback from operators across various industries bringing superb build quality and durability.

Testimony from users including contractors, hire firms and operators from across the industry confirm the X Series is a high quality excavator and a major step forward for JCB.

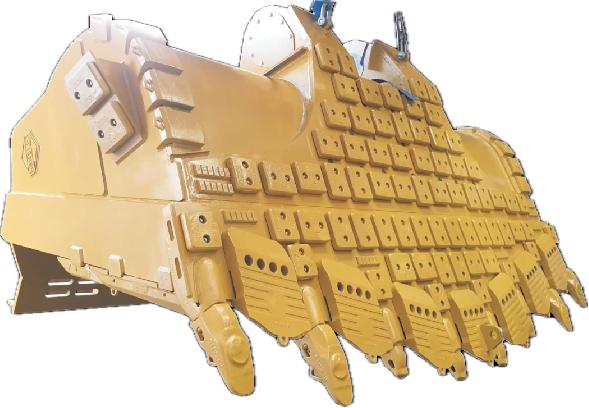

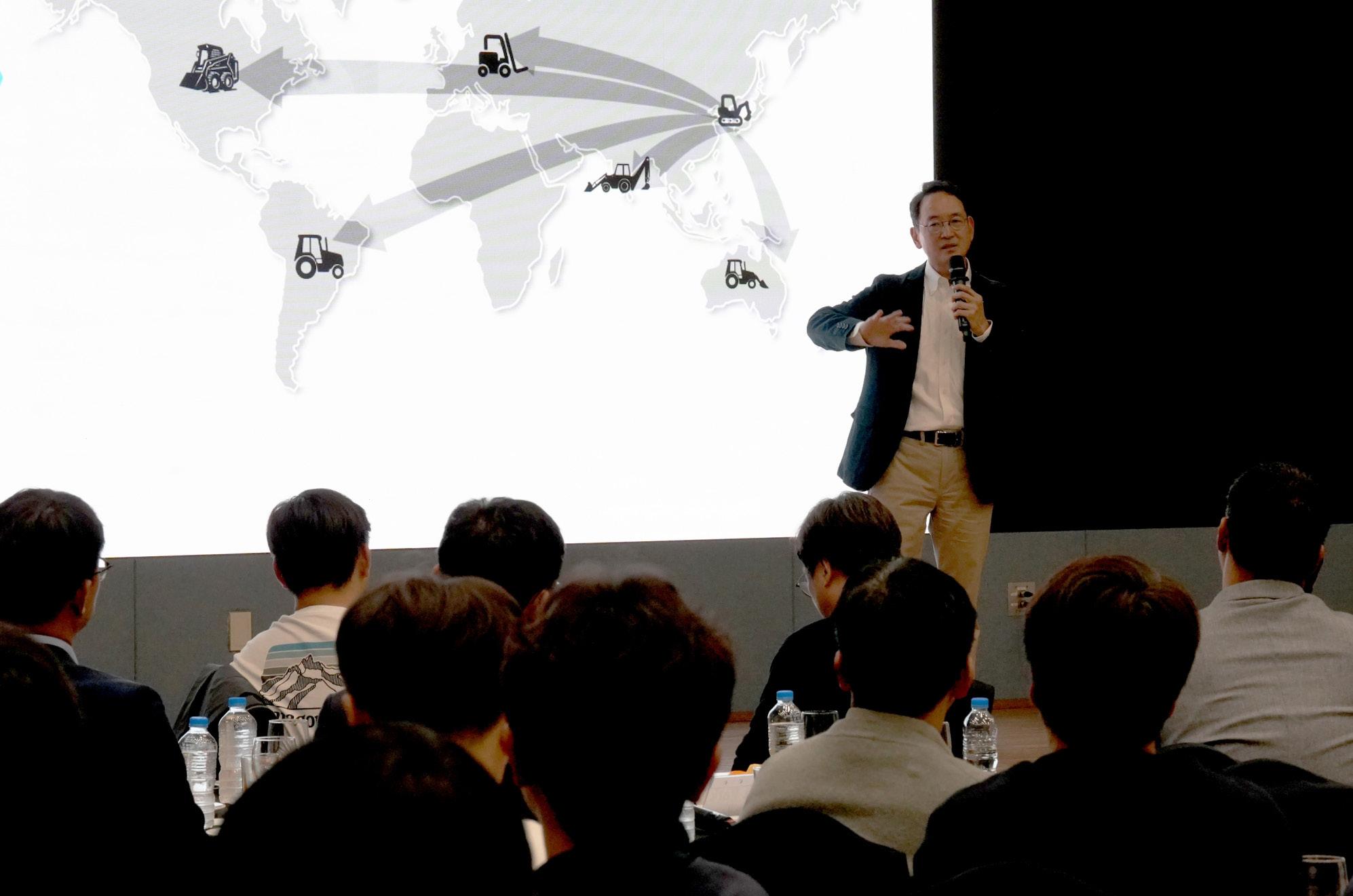

QBriefly introduce us to Machines on the Market and your role in it I’m the owner of Machines on the Market. com. We are a transparent worldwide sales platform where buyers and sellers are connected. Our website caters for waste and recycling, crushing and screening, construction and handling equipment, forestry and auxiliary parts.

Interviewee: Richard Cross

Role and company: Owner, Machines on the Market

Sector: Online plant marketplace

Geographical reach: Worldwide

When established: 2021

The website offers one of the most diverse selections of waste, recycling and handling equipment available and caters for all customer requirements. We are creating realistic residual values, whilst helping customers move machinery in a fast timeframe to reduce depreciation.

QTell us about your career progression

After an eight-year career in the Grenadier Guards, I moved into the waste industry in 1998 and through a variety of positions became Contracts Director for Cheshire West council, running the refuse and waste department. This further sparked my interest in recycling and two years later I took the step of creating and developing my first company, Future Recycling. The company was one of the first in the UK to start exporting waste materials around the world and was the beginning of my journey to Machines on The Market. I briefly

moved into the forestry side of recycling after this, before moving to a multi-brand UK dealership to handle the sales of large machinery. I appreciated the opportunity to expand my knowledge base into more areas and niches of the industry, something that has proved priceless experience for Machines on The Market.

QHow is what you do personally at Machines on the Market developing and how does that relate to the development and growth of the company?

I handle a general wide reach in the company, everything from customer visits and acquiring machinery to sales, handling export and closing sales. Both my personal and business values have always been that transparency is key and that way of working is something that I have been able to develop into a recognised corner of the industry.

Machines on The Market has developed its own organic following by offering a more transparent way so that both the customer and purchaser retain the true value of the machine. Unless specifically requested, all prices are visible for everyone to see. We don’t believe in hiding pricing, I believe the industry should be an open book where machines can be easily valued

and moved on as required.

Trading by this straightforward, uncomplicated business model takes all the cloak and dagger out of sales and gives us an uncapped potential for growth. We are taking on new customers daily and this growth is without a doubt down to the core values we trade and grow by.

QTell us about Machines on the Market’s growth path until now and into the future. Tell us about the rebrand

We’ve grown massively since the launch in 2021. The company has always been self-sufficient from day one and as it stands today, we currently have over 400 machines live on our books, with a value of over £36 million.

The aim has always been to be the largest resale site in Europe and that goal hasn’t changed. In order to achieve that end goal, I knew a plan for expansion was needed and in 2023. The first step of that expansion was Louise Bradshaw-Black coming onboard in the role of Creative Director.

Louise and I have now worked together for the best part of a decade and I knew she was coming onboard with a clear vision for developing the company image.

We rebranded in September 2023, giving the company a next level online presence. We are also working on the end stages of a very exciting project which will propel us further towards our goal. This will be announced in the coming months.

QGive us the sales pitch. What’s Machines on the Market for?

The company offers free evaluation, diverse and wide markets for all types of waste, recycling and handling equipment, regardless of condition or age. Construction, demolition, material

handling, we have a platform that needs your machinery.

QTell us about its range of services, how these relate to each other and how they relate to customers

We offer one of the most comprehensive sales packages in the industry with unrivalled marketing for maximum exposure. No matter the size or price of the machine, all customers receive the same level service. We don’t have any hidden fees and we don’t charge anything unless we sell the machine. We offer as standard:

• Listing of all stock on our website. We provide comprehensive descriptions of each machine, including its make, model, year of manufacture, operational condition and any maintenance records. Highresolution photos and, in some cases, video demonstrations and viewings are also available,

• Listing of all stock on multiple other platforms that we hold premium advertising accounts with. These platforms reach over 20,000 visitors per day,

• Expert, custom written SEO to place your items highest on search engines,

• Dedicated email marketing mail shots to our extensive CRM,

• Advertising on Facebook to over 250 groups,

• Premium advertising on our social media platforms,

• Word of mouth sales where we can offer items directly to customers as appropriate,

• Handling of all export as required (we charge this to the customer separately, making the sale hassle free for the seller),

• Arranging visitor visas as required if items are to be viewed and attending site with the visitors, including collecting them from the nearest airport.

QWhat are your criteria to sell on your marketplace?

Having a machine! If you have it, we will sell it. It doesn’t matter what age, condition, brand or location, we can match you with a buyer.

Q

What are Machines on the Market ’s USPs?

We often get machines with no plates or information and that feet on the ground experience definitely gives the company the edge over others where machines are being advertised by telesales staff for example, who often don’t have experience in custom or older machines.

We appeal to the broader market because we don’t cap ourselves by only selling certain categories. There is literally no machinery limit to what we will sell. If someone contacted us tomorrow with, say, tanks, we’d make new categories and put our full resources into expanding our product range. We are not scared of taking on anything out of the ordinary.

Q

Tell us about the working culture. Is there a fundamental company philosophy?

Transparency is our philosophy. Clear pricing, clear fees, clear T&Cs. We are also very open with our customers on pricing expectations against current market values.

QWhere does the knowledge base within Machines on the Market come from and how do you keep this up to date – in terms of machines, the market, marketing and any other business skills?

Experience and priceless contacts you build up through the years are the biggest assets any company in our industry can have. We have a lot of industry friends and as most people reading this will know, the industry is small enough for us all to keep up to date on what is going on. It also goes without saying that we are always learning as new machinery comes in and the general sales

process around it. Every machine teaches you a lesson that can enhance the next sale. Louise has a strong interest in analytics and SEO, as well as a distinctive marketing style and extensive brand experience. We run reports on all our machines so that we can give our customers accurate feedback on popularity, view counts etc so that if a machine isn’t moving as fast as anticipated, price point can be looked at, along with tweaking information and photo updates. We cover all aspects of marketing on an individual basis to keep us at the forefront of the resale market. At any point if a customer contacts us, we can tell them within minutes what number their machine is ranking on our website.

When and where are you happiest? Spending time with my two children, my daughter Alex who is 12 and my son James who is nine.

What would you do for a team building, money no object? Las Vegas!

What ’s your favourite cuisine? Any Asian cuisine, I love eating out and exploring different menus.

At a two-day launch event at its World Headquarters in Staffordshire, JCB unveiled a series of new additions to its extensive range of construction equipment. Infrastructure was on the agenda on day one as JCB launched the latest addition to its X Series range of tracked excavators.

With inclement weather forecast, day two opened in the comfort of the JCB Theatre where JCB’s pioneering

AI pedestrian safety system was demonstrated brilliantly on stage. The event then moved to JCB’s Kevin Quarry where the manufacturer showcased groundbreaking developments in technology, sustainability and safety alongside a new rotating Telehandler range that takes JCB’s world number one telescoping handler range to new heights.

Key features include:

• A 27% shorter tailswing than a conventional 140X,

• Reduced front swing and optional TAB boom layout,

• Full-size X-Series cab,

• Innovative JCB UX operator interface with 10” touchscreen display,

• Up to 10% fuel economy improvement,

• Extended maintenance intervals reduce operating costs.

JCB has expanded its popular X Series range of crawler excavators with the launch of the brand new 145XR – a second reduced tailswing model that delivers exceptional performance and productivity with compact dimensions and a full-size operator cab.

The 145XR reduced tailswing model builds upon the success of JCB’s larger 245XR, delivering impressive performance in a compact design with a minimal counterweight swing. The 145XR has a 27% shorter counterweight overhang than a conventional 140X, making it an ideal machine for working within a highway carriageway or on confined urban job sites.

The machine weighs in at 15-18 tonnes, depending on specification, and can be supplied with a monoboom or a two-piece triple articulating (TAB) configuration. The monoboom layout provides a maximum digging depth of 6,027 mm with a three-metre dipper, while the TAB boom has a maximum of 6,167 mm. Forward reach is up to 8,801 mm for the monoboom and 9,230 mm for the TAB specification.

Powered by JCB’s proven Stage V Dieselmax engine, the 145XR boasts an output of 81 kW. This features AutoStop and Auto-Idle engine functions, to reduce fuel consumption and emissions when idling. Engine working speed has been reduced to 1,700 RPM, increasing

fuel economy by 10% and cutting overall noise levels.

As with all JCB X-Series machines, the 145XR has undergone rigorous testing, to guarantee maximum durability and robust strength. The machine is built with heavy-duty track components, plates, bearings and features graphite bushings on key pivot points, allowing up to a 250hour greasing interval. Hydraulic filter changes are extended to 2,000 hours, meaning this new machine requires 24% fewer filter changes over 10,000 hours of service, reducing operating and maintenance costs.

As with all X-Series models, the 145XR benefits from the full-sized JCB Command Plus ROPS cab. As well as being one of the largest on the market, with 2.86 m³ of volume, the Command Plus cab benefits from a heated air suspension seat and a reduced in-cab noise level.

The cab is further improved with a new 10" touchscreen monitor, with the JCB UX interface. The switch panel incorporates customisable hot keys, allowing personalisation for the operator. Climate control, keyless start, and twin cameras for added visibility are all standard.

The JCB UX interface has up to 25 user profiles, which can be customised for the operator to set preferred joystick

configuration to meet their individual requirements. Mobile phone connectivity has been improved, with phone book integration via the monitor. The machine is easy to use and help guides are available within the monitor, along with ‘how to’ videos covering all of the features of the JCB UX system.

The 145XR is available with a range of options, to tailor the machine to an individual customer’s requirements. These include auxiliary hydraulic circuits with up to 15 attachment settings and a premium heated and cooled operator’s seat. LED lights are now standard, with options available to increase to up to 14 LED work lights. A bird’s eye 360 ° camera system, integrated within the 10" display, can also be offered, along with high visibility, all-round handrails.

JCB’s Business Head for Excavators Paul Swallow said: “The JCB 145XR delivers all of the performance that customers need in a compact design with an ultra-tight slewing radius. It is perfect for working in tighter areas, delivering best-in-class performance and ultimate operator control.”

Key features include:

• A 300 kg boost to 5,800 kg maximum lift capacity,

• Standard safety pack with side and rear cameras, white noise reversing alarm,

• New radio control system with real-time load parameter display,

• Standard heated air suspension seat and air conditioning,

• Available on 21-m and 26-m PRO models.

JCB is expanding its rotating telescopic handler range with the launch of the JCB 558-210R PRO and the 558-260R PRO. The range-topping machines feature increased lift capacity, a higher standard specification, a range of new options and attachments, plus a three-year warranty.

The 21-m lift 558-210R PRO and the 588-260R PRO, which offers a 26-m lift height, have a maximum lift capacity of 5,800 kg – an increase of 300 kg. The machines benefit from a range of upgraded components, including a hardened slew ring, to cope with the increased weight capacity.

With a revised colour scheme mirroring other PRO models in the JCB lineup, the two rotary telehandlers feature a range of option packs as standard. This includes a safety pack, consisting of side and rear cameras, plus a white noise reversing alarm. There is also a vision pack, of LED amber beacon and LED working lights on the cab and boom,

along with a storage pack that includes a front chain box and a side tool box.

Operators will welcome the standard comfort pack, incorporating air conditioning and a heated air suspension seat, along with the security pack’s keypad immobiliser. A maintenance pack comprises grouped greasing points on the front and rear of the chassis for reduced regular service work, while a handling pack includes JCB’s free-standing fork frame and 1,200 mm clear view forks, with a travel retention system built into the frame.

The 558-210R PRO and the 588260R PRO are powered by Stage V compliant JCB Dieselmax engines delivering 112 kW. This drives through a proven Bosch Rexroth two-speed hydrostatic transmission, delivering a top

speed of 40 km/h. The machines feature individually configurable X-style outriggers with one-touch deployment and retraction and the rotary telehandlers have +/- 8° degrees of chassis levelling capability.

A variable displacement hydraulic pump with proportional servo electric joysticks provides fingertip control to the operator and the two machines now come with an Autec remote control system, offering full remote control of all hydraulic functions. The control system has a display screen, showing real-time operating information. It comes with an easy stop/start system and a one-touch joystick unlock button.

A Clearview carriage with Radio Frequency Identification (RFID) attachment recognition makes it easier

for the operator to change between attachments. The machines are available with 5.8-tonne capacity forks, with a 5.5-tonne winch and a 2-tonne capacity 2-m jib winch. Attachments include a 5.5-tonne carriage-mounted hook and a 5.5-tonne capacity reduced height jib. The two telescopics can also be used with a 1-tonne capacity, 2.4 x 4.4-m access platform, or with a 400-kg capacity 4-m extension jib. If required, operators can work the machines with a 0.9-m 3 bucket or with 1.7-tonne capacity rotating forks.

The 558-210R PRO and the 588260R PRO will be supplied as standard with a new cost of ownership pack, which includes a three-year/2,000-hour warranty, providing peace of mind for customers and ensuring maximum uptime for end users.

Many wheel loader operations can, by their very nature, be repetitive. Driving into a stockpile, reversing back, tipping into a truck and repeat. For the operator that means plenty of repeated inputs, mainly twirling the steering wheel from left to right and back again.

Lever steer, or stick steer as some call it, is the most comfortable, productive alternative. Rather than using the steering wheel, many manufacturers offer a small servo lever to the left of the operator’s seat. This acts as a tiller, steering the machine left and right with fingertip control. The pod that contains the lever will usually also house a forward and reverse switch and a transmission kickdown button.

While it has been possible to have a JCB wheel loader converted to Lever Steer as an after-market option, the company has never offered the system as a factory option, until now. The company has developed a Lever Steer system that can be included on all 457 and 457 Agri models, along with any of the smaller 427 or 437 loaders.

The option includes a sidepod to the left of the operator’s seat with a short lever to steer the machine. There is a fingertip transmission selector, offering F/N/R positions and a kick-down button that drops the transmission to the lowest gear ratio for hard stock piling. The pod also includes the activation button, that switches from steering wheel to lever steering, along with buttons for the horn and the front windscreen wipers.

seatbelt as part of the installation. Operators may not realise how much they brace themselves with a hand on the steering wheel when turning and on rougher terrain. With no steering wheel to hold on to, the three-point belt provides far better location in the seat, boosting comfort and safety for the operator.

This allows the operator to drive the machine without needing to take their hands off the levers, with the right hand working the bucket and boom control. It also greatly reduces the effort required by the operator, as there is no need to constantly spin the steering wheel from side to side, it’s just a slight movement of the wrist to work the lever.

The steering lever is proportional, so the further you push to one side or the

other, the faster the machine will turn.

With JCB’s lever steer it is possible to make very gentle inputs and there is none of the jerkiness that could be found on some earlier after-market systems. The transmission control is also well placed for repetitive stock piling and loading operations.

While using the lever, the steering wheel can be pushed forward, increasing the feeling of space around the operator’s seat. Likewise, if you move to the steering wheel, the Lever Steer pod can be folded back out of the way, making it easier to access the seat or to leave the machine.

If Lever Steer is specified, JCB automatically includes a three-point

JCB is also boosting productivity for its wheel loader models, with the launch of Intelliweigh. Available across the 427, 437 and 457 models, the Intelliweigh Loadmaster 100 weighing system, can now be specified as a factory option. Offering both dynamic and target weighing, the system allows for multiple operator profiles and a range of attachment settings.

Intelliweigh can be used to load and weigh multiple vehicles on a site, using a split system. Individual target weights can be set for each truck, while maintaining the overall target weight for a contract. This allows for combined weight tickets, to provide customers with total material moved figures.

An on-board printer provides weight tickets for individual trucks from within the loader cab. The data can also be uploaded to a customer’s own in-house

system if required, to provide live updates on production and machine use.

Intelliweigh comes with a 7" touchscreen display with separate keys for regular functions. It is compatible with up to 10 attachments, including a range of buckets and pallet forks and offers a +/- 2% accuracy rating. The touchscreen can also be used as a reversing camera monitor if preferred.

The combination of Lever Steer and Intelliweigh enhances the productivity and performance of any 427, 437 or 457 JCB wheel loader, while reducing stress and fatigue for the operator. By having both systems available from the factory, there is no lost time during machine supply waiting for third-party installation.

• 270° Artificial Intelligence (AI) camera coverage around the machine,

• Visual and audible alerts for the operator and pedestrians in close proximity to the machine,

• Full integration with JCB’s LiveLink telematics system to allow data to be accessed from a single source,

• Machine and cloud data storage as standard,

• Customer data encryption and full compliance with data protection regulations,

• Industry-first OEM factory-fit solution,

• Covered under the machine standard warranty.

JCB’s product launch event saw a number of high-tech innovations that will boost the safety and security of machines on and off site.

Its new integrated pedestrian recognition system – JCB INTELLISENSE – is a factory-fit solution for JCB Loadall telescopic handlers.

It includes an onboard data storage facility with a telematics box to provide a back-up of events for site reporting that can be downloaded for playback. Unlike aftermarket systems, the JCB INTELLISENSE is fully integrated into the machine’s LiveLink telematics system, allowing users to remotely access the data,

making it the ideal risk management tool for fleet and construction managers alike. It is designed to drastically reduce the risk of harm and injury to workers on UK construction sites. It is made to be used on Loadall telescopic handlers to reduce the risk to workers of being struck by moving materials handling machines on construction sites. The system identifies, assesses, and mitigates risks on construction sites and enables contractors and operators to manage potential hazards around the machine and its operating environment.

The JCB INTELLISENSE system is initially being launched on two key

construction models, the JCB 540-140 and the 535-125 Loadalls, following calls from UK construction firms for pedestrian recognition systems on site. JCB is the first major OEM manufacturer to provide a factory-fit solution.

The system utilises four cameras, three of which are AI cameras (two side mounted and one rear-facing) as well as a forward-facing standard camera to improve visibility to the operator in line with the object detection and visibility aids standard ISO16001:2017. The system is designed to detect pedestrians within a pre-set proximity of the machine. When the system senses a pedestrian in that area, there are audible and visual warnings inside the cabin for the operator and externally to warn the pedestrian and other site workers. The system also provides an operator alert button as standard, where the operator has the capability to record a 10 second data segment that is automatically sent to and stored in, the cloud.

JCB has launched a new product to help customers monitor the location of all powered or non-powered equipment, regardless of its size, function, or brand.

The LiveLink Asset Tag is a small battery-powered, Bluetooth-transmitting device that can be fixed to any asset –from hand tools, machine attachments such as breakers, buckets, and sweeper

collectors, through to skips, powerpacks and site accommodation units.

The tag integrates with JCB LiveLink, a fleet management system, providing complete visibility and improving productivity by eradicating the time wasted locating misplaced equipment.

At 68 mm x 32 mm x 16 mm and weighing just 50 g, the tags are compact, discrete and lightweight. Attached by bolts or adhesive, they are strong and durable, achieving the highest IP69K rating for protection against dust and water ingress. This makes them capable of withstanding the rugged outdoor conditions typically found in the construction and agricultural sectors.

They function by transmitting a Bluetooth connection from any enabled LiveLink unit or partner units, to track the location of any piece of equipment registered within the customer’s LiveLink account.

LiveLink Asset Tag uses the latest Bluetooth Low Energy 5.0 technology and can be located within an 800-m line of sight range of the nearest enabled LiveLink unit or partner unit. The tags feature an impressive four-year battery life.

JCB Aftermarket Managing Director Mario Moser said: “By integrating with the JCB LiveLink system, customers can now benefit from a single, central source for all asset management. The JCB Asset Tag is another great addition to the LiveLink portfolio to help businesses maximise efficiency and drive productivity.

“Losing or misplacing any piece of equipment can be costly and result in unnecessary downtime. Designed to bridge the gap between larger machine telematics and the types of site equipment not typically monitored, the Asset Tag provides increased visibility and control over all assets.”

Launched in 2011 and now with over 500,000 machines monitored by the system, JCB LiveLink gives machine operators and fleet managers easy access to all data through an online portal and mobile app. Every aspect of fleet management is covered with features including service tracking, security geofencing, what3words global location, machine utilisation data and mixed fleet functionality.

JCB launched the new TLT 30-22E HL Teletruk, bringing a 4.4-m lift height option to its innovative telescopic-boom battery electric lift truck range. This compact, high lift industrial telehandler offers a maximum lift capacity of 3,000 kg up to the full lift height of 4,400 mm, opening up a range of market sectors to the opportunity of a battery-powered, telescopic boom machine.

Building on the success of the existing TLT 30-19E and the TLT 35-22E E-TECH models, the TLT 30-22E HL uses the same 80V battery driveline, allowing up to eight hours of operation on a single charge. The machine’s telescopic boom greatly increases productivity for customers, permitting single-sided loading and

unloading of a road-going trailer thanks to its extended forward reach.

With zero emissions and low noise output, the electric TLT trucks are ideal for 24/7 operation in urban environments, inside buildings and in noise sensitive areas. Their forward reach, low overall height and compact running circle, with a 90 ° spin turn possible on the TLT 30-22E HL, deliver maximum versatility.

Now, with the increased working height of the High Lift machine, that versatility and productivity is available to a new range of customers. The additional lift height will allow the machine to compete with larger diesel models, making it possible for a wider group of customers to transition from diesel to

electric power as part of their net zero targets.

In addition, the increased working height will be popular with agricultural applications, such as potato growers, where boxes are generally stacked four or five high. The waste and recycling sector should also find a variety of applications for the machine, as it can now load into hoppers and into high cube containers.

The TLT 30-22E HL retains all of the JCB CommandPlus cab comfort and security that customers have come to expect, with single lever electro-hydraulic control for all boom functions. LED working lights and an LED beacon are standard, along with a white noise reversing alarm and JCB’s proven Load Motion Control safe lifting system.

The countdown to the sixth edition of PlantWorx, hosted by the CEA (Construction Equipment Association), has officially begun. From 23 to 25 September 2025, the Newark Showground, a new venue for PlantWorx, will be the hub for the latest developments in construction equipment and technology. With an anticipated 400 exhibitors and over 15,000 visitors, this is the must-attend event for professionals looking to stay ahead in the construction industry.

For anyone serious about advancing their business, PlantWorx offers an unparalleled opportunity. Industry veterans and newcomers alike will find the latest machinery, groundbreaking technologies and live demonstrations designed to transform daily operations. The event goes beyond the traditional trade show, providing a hands-on experience that aims to inspire and equip professionals with the tools and solutions needed to stay competitive.

Major names like Takeuchi, RSP UK Suction Excavators Ltd, SANY Heavy Machinery UK Ltd, Sunward, Avant Techno, XCMG, Hydrema, Liugong, Mecalac, Kubota, Steelwrist, Hidromek, Rototilt, Worsley Plant, Merlo, Manitou, National Highways and many more are already confirmed. These companies will showcase their machinery through live demonstrations, providing an up-close look at how they tackle the industry’s everyday challenges.

Simon Frere-Cook, PlantWorx Event Director, said: “Technology is advancing faster than ever and PlantWorx 2025 is where these innovations come to life. We’ve designed this event to ensure that whether you’re a contractor, operator or business owner, you’ll leave with insights and practical knowledge that can transform your operations. It’s about preparing for the future as much as seeing what’s available today.”

Back by popular demand, the Operator Challenge will once again give attendees a chance to test their skills and compete with the industry’s best. This challenge remains a highlight of the event, offering substantial prizes, including a significant cash award for the overall winner.

For exhibitors, PlantWorx 2025 offers a platform to demonstrate innovations to an engaged audience. New features like the Shared Dig Zone will allow more companies to showcase their equipment without the need for a large demo plot. Whether a market leader or an emerging brand, exhibitors will have the chance to demonstrate their capabilities to thousands of industry professionals.

Simon added: “PlantWorx continues to be the go-to event for the construction industry because it offers a unique space where companies, large and small, can showcase their technologies in action, and visitors can engage with them directly.”

With one year to go, now is the time to ensure your participation in the event. Whether you’re looking to discover the latest innovations, network with industry leaders, or experience the future of construction equipment first-hand, PlantWorx 2025 promises to deliver.

For exhibitors, spaces are filling fast. For visitors, mark your calendars –PlantWorx 2025 is set to be one of the most anticipated construction events of the year.

For more information or to register your interest in attending or exhibiting, visit Plantworx.co.uk.

Rethinking Futures will make a significant impact at PlantWorx 2025, offering secondary school and college students aged 12 to 18 a unique opportunity to explore careers in construction engineering. This initiative provides a platform for young people to connect with industry professionals, experience new technologies and learn about the construction sector.

Addressing the skills gap in construction, engineering and mechanics, Rethinking Futures connects educational institutions with industry leaders to engage and inspire young minds. With a focus on apprenticeships, training and recruitment, the initiative aligns with government objectives and supports schools in meeting Gatsby benchmarks.

Local schools will participate in a practical engineering challenge, where students design, build and test machinery inspired by equipment such as grab lorries, excavators and cranes. Equipped with the necessary tools and materials, teams will gain hands-on experience

emphasising creativity, teamwork, and problem-solving. Their projects will be evaluated by judges from the sector, giving students a unique opportunity to present their work to experts and explore potential career paths.

“Rethinking Futures is about igniting a passion for engineering and construction in young people when fresh talent is crucial,” says Stuart Favill, PlantWorx operations manager and co-founder of Rethinking Futures. “We’re creating a memorable, hands-on experience that connects young people with current technologies and potential employers. It’s an invaluable opportunity for students and the industry alike.”

Vic Boneham, a school teacher and cofounder of Rethinking Futures, brings an educational perspective to the initiative. “As a teacher, I know how powerful hands-on experiences can be for students,” she says. “This initiative gives young people a chance to tackle real engineering tasks and see what a future in this field could look like. It’s all about helping them

connect what they learn in school with real opportunities and showing them that these careers are within their reach.”

John Morrison, who has served as the Principal of Lincoln University Technical College and Director of the Lincolnshire Institute of Technology for the past seven years, will be instrumental in bringing Rethinking Futures to Nottinghamshire schools. “This is going to be one of the most exciting competitions we have ever run with students,” says Morrison. “I have organised countless regional and international engineering challenges over the years. This project is so clearly and closely linked to our construction industry partners that it will feel genuine and relevant to the young people involved.”

The engineering sector offers a wide array of career opportunities, many of which often fly under the radar. Rethinking Futures aims to raise awareness of these diverse paths and showcase the industry’s potential to students. While Nottinghamshire schools will be the first to benefit, the initiative

will expand beyond the region, with plans to bring it to other events and shows in the construction and agricultural sectors. By connecting students directly with industry, Rethinking Futures aspires to cultivate a new generation of talent equipped to tackle the challenges of tomorrow.

With over 400 exhibitors expected, PlantWorx 2025 is set to be the UK’s largest live-action construction equipment exhibition, featuring cutting-edge technologies and leading OEMs. The event will attract experienced professionals and, through the inaugural Rethinking Futures initiative, inspire the next generation of industry talent.

Sponsorship opportunities are available for those looking to support this exciting initiative and help cultivate the next generation of construction professionals.

For further information, please get in touch with Stuart Favill ‘Rethinking Futures’ stuart@rethinkingfutures.org or call 07970 534 644.

The QMJ Group has announced that the next edition of the iconic quarrying, construction and recycling exhibition will take place from 23 to 25 June 2026 at Hillhead Quarry, Buxton. With the dates now confirmed, demand for the 2026 show is expected to be very high and new enquiries to exhibit should be directed to Event Manager, Harvey Sugden on +44 (0)115 945 4377 or harvey.sugden@qmj.co.uk. All enquiries will be contacted next spring with an update of the latest availability.

Diggers LIVE! magazine and all at Demolition Hub Ltd look forward to seeing you at Hillhead in 2026!

ELECTRIC

KHD Brokk Hire is the ‘one stop shop’ for all things electric plant, with a sustainable twist too! From electric diggers & dumpers to Brokk machines – we do it all! WE OFFER:

AUSA, the manufacturer of compact all-terrain industrial vehicles, is launching two new six-tonne articulated dumpers. These new models are being introduced to build on the success of their predecessors and are equipped with new features to improve their functionality and increase their safety.

The new rear styling combines design with practicality. The size of the bonnet has been increased to provide unrivaled accessibility to the engine and maintenance parts. Air, oil and fuel filters, radiator, tanks… everything is optimally positioned to keep downtime to a minimum.

The new EN 474-1:2022 and EN 474-6:2022 standards that are coming into force in February 2025 require all dumpers with an operating weight between 3,500 and 4,500 kg to be fitted with additional safety measures to prevent the operator from being thrown out of the vehicle in the event of a rollover. At operating weights of 4,500 kg and above, all dumpers must be fitted with

enclosed cabs.

In order to comply with these new regulations, AUSA provides three different configurations for its new sixtonne models: Folding ROPS protective structure with safety rails 96% larger than current models; open cab; and heated enclosed cab.

This means that AUSA has ensured that all its dumpers that are shipped from the beginning of 2025 will comply with the new regulations. In addition to the different driver cabs that are available, as standard the D601AHG+ and D601APG+ models will continue to be

equipped with additional safety features such as a seat with a presence sensor, seat belt with buckle sensor, negative brake and front view camera.

Reducing operator fatigue on the machine is also essential for the safety of the operator and the surrounding area. As standard, the new D601AHG+ and D601APG+ dumpers are equipped with a high-comfort seat with built-in suspension, ensuring comfort in the vehicle and reducing tiredness during long working days.

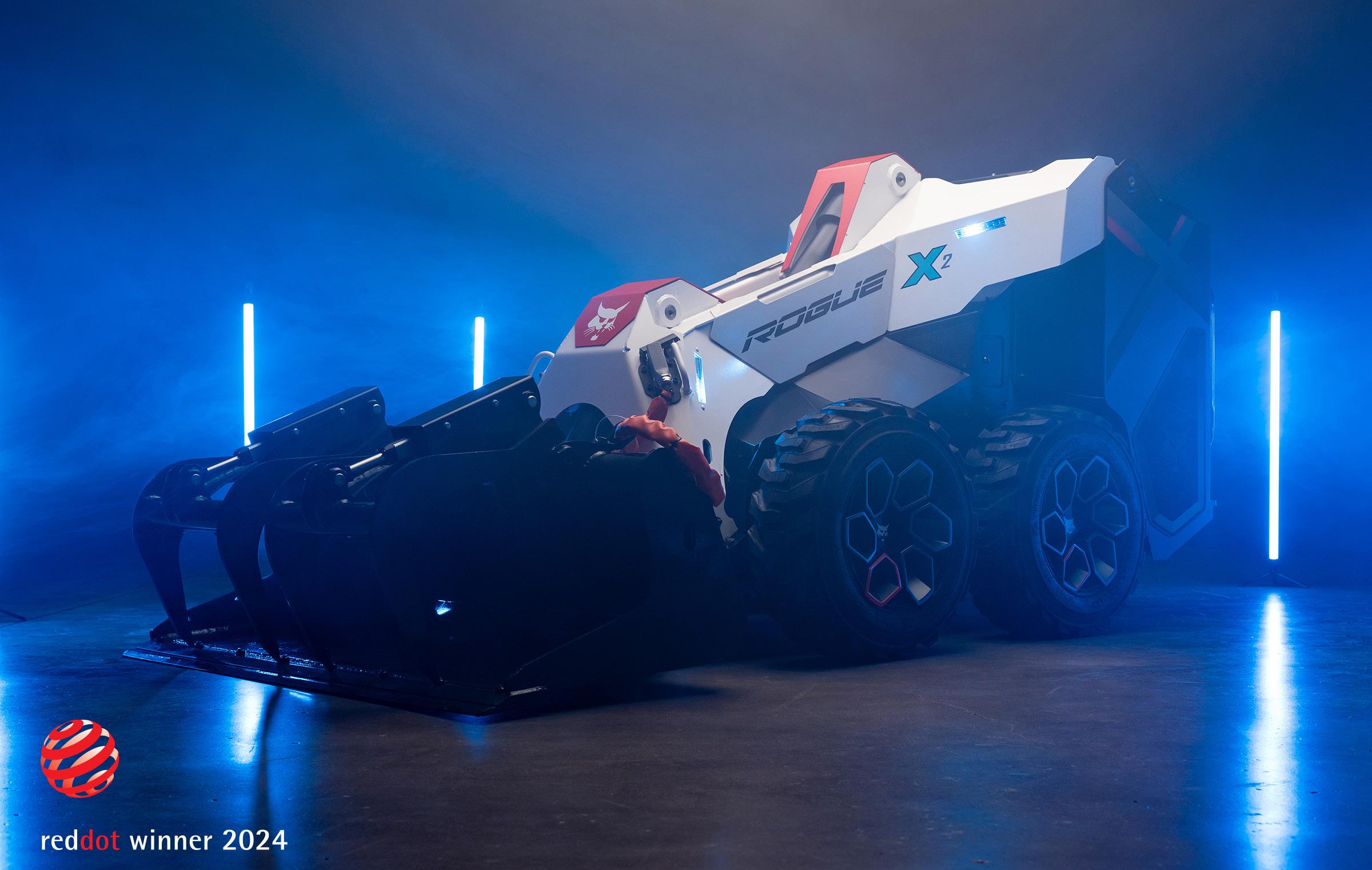

Bobcat has been selected as a Red Dot Award: Design Concept winner for RogueX2, an all-electric, fully autonomous concept loader.

The Red Dot Design Award is one of the most respected design awards in the world, with its Design Concept category identifying and celebrating new design concepts and innovations as the precursors of tomorrow’s great products.

“We are honoured to win the world-renowned Red Dot Award for Design Concept in recognition of the groundbreaking design of the RogueX2,” said Joel Honeyman, Vice President of Global Innovation at Doosan Bobcat. “This award is a testament to the dedication of the Bobcat teams who are passionate about pushing design limits and advancing innovation to redefine the machines of tomorrow.”

Key to the machine’s development

was the Bobcat Global Design Studio, which supported the project in collaboration with the Bobcat Global Innovation team.

On display at CES 2024, the RogueX2 is a powerful, smart machine that produces zero emissions and features a lithium-ion battery, electric drive actuated lift and tilt kinematics with no hydraulics.

Specifically designed and built without a cab, RogueX2 explores the idea of how work machines of the future can be designed and optimised for new technologies and enable an entirely new work experience. Designed with wheels to optimise the electric battery run time, the RogueX2 features axial flux motors, which give the machine incredible tractive effort.

The RogueX2 was built as a proving ground to advance Bobcat’s innovation

leadership and has garnered many new patents pending.

“To build a smarter, more sustainable and connected future, we must ask the questions no one else has thought to ask before and invent new solutions that previously did not exist,” continued Honeyman.

In the research and development stage, the award-winning RogueX2 is not commercially available.

The Red Dot Design Award is an annual international competition that recognises excellence in design and business. With around 20,000 entries per year, it is one of the biggest design competitions in the world. The Design Concept category features projects in varying stages of development ranging from concepts to prototypes, to almost or fully developed products which are ready for market.

Rother Valley Tree Services Ltd, a family business that covers Doncaster, Rotherham, Barnsley, Sheffield, Leeds, Wakefield and surrounding areas, has purchased a top-of-the-range Bobcat T86 compact track loader.

Delivering a higher engine and hydraulic output, the Bobcat T86 is the most powerful compact track loader the company has ever built. The T86 uses a well-proven Stage V-compliant 3.4-l Bobcat engine – producing 78 kW at 2,600 RPM. Just like all of Bobcat’s R-Series loaders, the engine is mounted in-line with direct drive, which improves the cooling capacity of the engine and hydraulic components.

One of the most exciting aspects of the T86 is that for the first time there is a choice of three different auxiliary flow outputs. There is a standard flow configuration providing 87 l/min for applications such as load and carry, or where low hydraulic flow attachments are used. Bobcat also offers two additional hydraulic performance functions using the new Electronic Displacement Control (EDC) Pump on the T86: a High Flow function giving 138 l/min and a new optional, industry unique Super Flow function taking auxiliary flow to 159 l/min.

As well as the Super Flow, the T86 purchased by Rother Valley Tree Services features an enclosed cab with HVAC, an air-suspension seat, 7" touch panel display, two-speed Power Bob-Tach attachment system, a reversing fan, premium LED Lights, keyless ignition and joystick controls.

Steve Smith, Managing Director of Rother Valley Tree Services, said: “I was intending to purchase the T770 model from Bobcat, but AMS Bobcat introduced us to the idea of the new T86 and its Super Flow output and the more powerful attachments it can power. Now part of our fleet, the T86 has more than matched what we were promised.”

Carl Chadburn, Plant Manager of Rother Valley Tree Services, added: “The many jobs we are

able to do are specialist, with only a few companies being able to offer these services in the UK. The T86, the new forestry cutter and the other Bobcat attachments we’ve purchased from AMS complement the rest of the vehicles and machinery in our fleet, giving us access to an even larger array of solutions to help complete even the most difficult of jobs.”

In a host of applications in construction, landscaping, agriculture, disaster relief and many other areas, there are no other machines that offer the combination of versatility and productivity that can be provided by compact track loaders such as the T86. This is due to their unique characteristics as tool carriers and the wide array of attachments that they can work with, from trenchers, augers, graders, soil conditioners, scarifiers and dozer blades to more specialist attachments such as forestry cutters and stump grinders.

As tool carriers, compact track

loaders offer many advantages over the comparable wheeled machines. They can provide increased productivity in many conditions with a lifting capacity approximately 25% more than the equivalently sized wheeled loaders.

Carl Chadburn continued: “Combined with the low centre of gravity of the T86, the traction delivered by the tracked undercarriage gives us advantages for climbing and working on steep slopes in diverse applications such as scrub clearance on motorway verges, which would be difficult to carry out with the other machines in our fleet.

“Approximately three times less than a wheeled machine, the low ground disturbance of the T86 allows it to work on delicate surfaces, such as established lawns or asphalt, minimising damage and reducing the need for tidying up after the job is complete. As well as being perfectly suited for working anywhere on uneven terrain, the T86 can also work well on snow extending work into the winter, due to its superior traction and flotation.”

“The low ground disturbance of the T86 allows it to work on delicate surfaces, such as established lawns or asphalt, minimising damage and reducing the need for tidying up”

DEVELON now offers a range of three articulated dump trucks (ADTs), comprising the DA30-7 and DA45-7 6x6 models, complemented by a new 4x4 version of the DA45-7.

The DA30-7 and DA45-7 6x6 models have payloads of 28 tonne and 41 tonne, respectively. The DA30-7 is powered by the Scania Stage V compliant DC09 nine-litre diesel engine providing 276 kW of power. The DA45-7 is driven by the Scania Stage V DC13 13-litre diesel engine with an output of 368 kW.

Also powered by the Scania Stage V DC13 13-litre diesel engine with an output of 360 kW, the 4x4 version of the DA45-7 ADT is intended to compete

with rigid dump trucks (RDTs) in the 40-tonne class.

The DA30-7 and DA45-7 feature an articulation hinge positioned behind the turning ring to provide equal weight distribution to the front axle even during maximum steer articulation. This combined with a free-swinging rear tandem bogie ensures equal distribution of weight to each wheel and guarantees permanent six-wheel contact and drive for equal power distribution and excellent performance particularly on difficult terrains such as soft ground, uneven

surfaces, very steep slopes, tight turns or a combination of all of these difficult conditions.

Collectively, the forward turning point, the unique tandem bogie and the sloping rear frame results in best in class rough and soft terrain capabilities. The unique body shape and sloping frame ensure equal load distribution on all the wheels making these machines the best haulers for soft terrain work. The design of the articulation also provides equal load distribution on the wheels on both the left and right hand side when turning, which is very important for the traction and stability of the machines.

Superior performance in difficult conditions compared to RDTs

In the new 4x4 ADT, the front truck and cab unit is the same as in the 6x6 models, with modifications being made on the rear dumper unit only. Featuring a ZF EP8-420 transmission, the 4x4 DA45-7 is a two-axle ADT with twin wheels at the rear, and with a dumper section similar to that on RDTs in the 40-tonne class.

As well as performing better in conditions that are tough for RDTs, the new 4x4 DA45-7 ADT has a width of less than four metres to avoid the need for special transportation and offers a better turning radius than a comparable RDT. The shorter turning radius and

the design of the rear dumper unit, which is more suited to carrying flat and heavy rocks, provide particular advantages in the mining and tunnelling industries.

The latter are growing markets for ADTs, and include pioneering, short-term mining projects, quarrying and contract mining industries, especially those in southern Africa, the UK and Australia. Construction and bulk earthmoving contractors involved in roads, dams, airports, landfills and development projects are also large users of ADTs. Together these areas make the ADT market a wide and varied one, thereby ensuring a large customer base.

Summarising the advantages:

• The 4x4 ADT can climb steeper inclinations than equivalent RDTs.

• The 4x4 ADT performs better than RDTs in wet and slippery conditions,

• In heavy rain, RDTs may need to stop working – DEVELON’s 4x4 ADT does not.

• Thanks to the short turning radius, the 4x4 ADT operates effectively on compact sites.

• The two axle 4x4 ADT design causes less ground disturbance than 6x6 configurations.

DEVELON used the recent Resource & Waste Management (RWM) show at the NEC in Birmingham to present for the first time a new design of wheel loader aimed at the waste handling industry.

Based around the successful DEVELON DL280-7 wheel loader model, part of the award-winning DL-7 range of wheel loaders from DEVELON, the new waste wheel loader preproduction model increases safety and efficiency for the operator.

The new waste wheel loader has a novel design featuring a strong, light weight loader frame and a unique and innovative lifting arm that minimises

the front end weight of the machine, providing an impressive super high lift and reach capability to deliver a higher dump height, whilst maintaining excellent manoeuvrability. The light-weight loader frame is designed to offer optimum strength and heavy duty axles contribute to the exceptional stability of the new waste loader.

The super high reach on the new DEVELON waste wheel loader is designed for loading material into high sided containers such as walking or moving floor trailers specially developed for transporting waste. For assured loading, the new waste loader is equipped

with a high tip bucket supported by two robust cylinders. The lower bucket pivot pins have internal greasing lines to prevent them being damaged by material carried by the loader.

The new loader incorporates a waste kit with heavy engineering and strength at its core, including an exoskeleton around the machine and further protection provided by mesh type windshield guards, articulation guards, belly protection and fuel tank guards. The unit also features an air intake mesh and the cab has specialised air filtration. Other features of the new waste loader include a reversible fan to clear the radiator, a heavy duty

radiator guard, rim covers for the wheels and solid tyres with suspension cut outs.

Safety features include high visibility chevrons on the rear of the machine and a fire suppression system, with internal and external actuation points on the front and rear of the loader.

Inside the spacious cab, the new waste wheel loader offers significantly enhanced operating comfort, with joystick controls and a leather type upgraded operator seat. The seat is equipped with fully adjustable horizontal and vertical suspension settings, a pneumatic lumbar function and seat heating as standard. There is a three-point safety belt with alarm icons on the 8" touchscreen monitor and on the gauge panel, which features a new layout and anti-reflective glass.

The operator can also benefit from an optional 360 ° camera system with AI person detection to ensure the safety of personnel in close vicinity to the machine.

The operator has an excellent field of vision from the cab, with the large glass window area minimising blind spots around the cab. The new waste wheel loader also offers the option of electrically adjustable rear view mirrors for added safety.

Full LED working lights are installed on the cab (four on both the front and rear as standard, with the option of six each at the front and rear). For higher pedestrian safety, the LED lights on the rear bonnet have an automatic strobe function to indicate when the wheel loader is reversing.

Included in the information at the operator’s fingertips on the touchscreen

is the feed from the optional weighing system, the HVAC controls (heating, ventilation and air conditioning), radio and bluetooth devices (music streaming, hands-free) and the operator help function.

Overall, the cab interior offers a large, quiet and more comfortable operator environment, which improves safety and productivity and helps the operator work with high concentration. The operator also has increased leg room, an enlarged storage area and cool-box position and an improved air conditioning system (with optimised air circulation).

JCB has expanded its electric site dumper offering with a three-tonne swivel tip model powered by lithium-ion battery technology. Designed to work indoors and in emissions and noise-sensitive areas, the 3TE electric dumper offers all the benefits of the one-tonne 1TE with a three times greater capacity.

Key features include:

• Zero emissions and low noise levels,

• Fast charge capability,

• Full shift operation in typical use,

• Swivel-tip skip design to enable loading and unloading in tight, confined spaces. The 3TE site dumper is a durable,

compact machine with a full steel skip and heavy-duty articulated chassis. The machine dispenses with the hydraulic pump and engine featured in the diesel powered 3T-2 model and comes with an electric motor that connects to a drop box, to provide full-time all-wheel drive.

A 22.3-kW electric motor delivers drive to the drop box, while a second 16.1kW electric motor powers the machine’s standard hydraulic circuit, for steering and skip lift, via a hydraulic pump.

The power is supplied by a 20-kWh lithium-ion battery pack, capable of providing full shift operation in normal use. The batteries can be recharged from conventional site electrical supplies, with 110-V and 230-V cables available.

In addition, the optional JCB Universal Charger can be used to rapid charge the batteries for extended operation.

Designed primarily for European and North American markets, the 3TE delivers zero emissions at the point of use and low noise levels, making it ideal for indoor, underground and emissionssensitive working sites. A ROPS frame is standard, along with LED amber and green lap-belt beacons. In low light conditions, powerful LED working lights provide maximum visibility when working, and additional lighting at the operator station allows for safe egress. The machine offers a maximum payload of 3,000 kg and a maximum load over height of 1,566 mm.

JCB has developed a fully glazed, heated ROPS/FOPS cab alternative for the 403E electric compact wheeled loader. The cab comes complete with heated front and rear screens, a heated seat, and an efficient three-speed heater with boost feature. It is also possible to pre-condition the cab while charging, to preserve traction battery power and potential operating time.

The 403E uses a 2.2-kW Positive Temperature Coefficient (PTC) heater system with three temperature settings. There is also a boost switch that can be used to rapidly increase the temperature within the cab for 10 minutes, before switching off to conserve energy. The heater is automatically disabled if the doors are open, to further preserve battery power.

In the warmer months, the operator can use the blower function, even if the doors are open, to circulate air within the cab.

Cab pre-conditioning allows the operator to warm the cab while the machine is being charged prior to the start of work. This time-based system uses a rotary dial and the main digital display in front of the operator to set the time that work will commence. With the start time set, the heater will activate 30 minutes before work commences and will de-activate 15 minutes after the start time if the machine has not been used. This feature will only function when there is more than 25% battery charge available.

The heated seat provides rapid warming for the operator, reducing the need to run the main cab heater, conserving electrical energy and prolonging run time. Heated front and rear windscreens also allow rapid defrosting in colder climates and demisting during wet weather. Again, this reduces the requirement for the heater to be run, preserving battery power for loader use.

The 403E is JCB’s first full electric compact wheeled loader. The machine boasts a 20-kWh battery pack, among the largest in the sector, allowing up to

four to five hours of continuous use in a mixed operating cycle. Even with the full cab, the machine weighs in at less than 2.6 tonnes, allowing transportation on a 3.5-tonne trailer, behind a 4x4 or a light commercial vehicle.

The machine has a 33.4-kW peak power drive motor for the wheels, with three driving modes. Drive is transmitted through a ZF drop box, to both axles, which can be supplied with open differentials or with differential locks. In addition, it uses a 20-kW peak power motor to drive the hydraulic pump for the lift arms and attachments.

The 403E is aimed at both agricultural and construction customers. It is proving particularly popular with those farming customers who have solar or

wind turbine power generation on their land and buildings. By harvesting this green renewable energy, it is possible to operate the electric loader while incurring virtually no fuel cost.

The machine is also proving popular in urban construction and paving work, where the ability to carry palletised loads with zero emissions and low noise levels is in demand. The addition of a fully glazed, heated cab will add to that appeal, particularly in countries with colder, wetter climates.

JCB X-Series excavators are leading the way in lowering fuel consumption. The 145XR now uses up to 10% less fuel than our previous model, the JZ140. We’ve made this possible by reducing the working speed of the engine from 2050rpm to 1700rpm, whilst maintaining performance by optimising the hydraulic system. We’ve also improved slew control and increased bucket tearout by 13% for smoother operating. Start saving today.

* £2000 saving is versus the JZ140 Stage V and is based on an

Kramer is expanding its portfolio with the new 5045 wheel loader, which impresses with its combination of low weight and high payload. With an operating weight of approx. 2,600 kg, the 5045, with a full cab including standard bucket and stacking device, can be easily transported on a 3.5-tonne trailer, which not only saves time but also significantly increases machine use.

The 5045 wheel loader is perfect for transporting standard paving stone pallets or stone packages and masters the loading and unloading of lorries effortlessly. Thanks to its high performance and compact dimensions, the 5045 is ideal for use in confined areas, such as underground car parks or multi-storey car parks.

Depending on customer requirements, the 5045 offers two engine variants: the wheel loader is equipped with a 19-kW engine as standard, while a 33-kW engine is available as an option, which enables a top speed of up to 30 km/h. There is also a choice of two full cab variants – a comfort cab with a height of 2.3 metres and a low cab with a height of 2.1 metres for maximum compactness. Both cabs offer excellent all round visibility and ergonomically arranged controls that ensure simple and intuitive operation.

Thanks to the undivided vehicle frame, high stability, manoeuvrability and constant payload, the machine is easy and safe to operate. In addition, the 5045 offers three different steering modes – all-wheel steering, crab steering and front axle steering –which make manoeuvring easier even in difficult situations.

Another highlight of the new wheel loader is the standard quick hitch, which is also used on the next larger models. For the customer, this means that existing attachments can be used even

more flexibly. The fully hydraulic Smart Attach quick hitch system is available as an option, which enables hydraulic attachments to be changed quickly and safely without the driver having to leave the cab. This innovative function saves time, increases productivity on the construction site and is unique in this machine class.

With the new 5045 wheel loader, Kramer is setting new standards in the 2.8-tonne class and offers a machine that impresses in terms of both performance and versatility. Whether in the construction industry, in landscape maintenance or in urban applications –the 5045 is the ideal partner for a wide range of requirements.

Together with STRABAG, Liebherr is taking important steps towards a decarbonised construction site. In a project that recently started at the Kanzelstein quarry in Gratkorn, Austria, STRABAG is testing Liebherr’s large hydrogen-powered wheel loader over a period of two years. Energie Steiermark will supply green hydrogen for its own hydrogen filling station at the quarry. The L 566 H wheel loader is the world’s first large wheel loader with a hydrogen engine.

Leonore Gewessler, Austrian Federal Minister for Climate Action; Clemens Haselsteiner, CEO of STRABAG; Martin Graf, Director of Energie Steiermark; and Jan Liebherr, Chairman of the Board of Directors of Liebherr-International, attended a special event at the Gratkorn quarry to mark the start of the project for the first test use of the large hydrogen powered wheel loader.

In addition to technical presentations