For fire resistance and protection of people and property

Multifunctionality in fire protection

PYRAN® S is a pre-stressed, monolithic borosilicate single pane safety glass in accordance with EN 13024-1.

As a component in fire-resistant glazing that meets the requirements of resistance classes E 30, E 60, E 90 and E 120, it has proven its outstanding optical and mechanical characteristics over the years in a wide variety of buildings.

Areas of application

PYRAN® has been internationally approved and ideally suited for:

• Facades

• Partition walls

• Skylights and rooflights

• Doors

• Roofs

• Smoke screens

• lift door glazing

• lift shaft glazing

Facts

• Higher ability to withstand temperature differentials: In comparison to soda-lime glass, tempered borosilicate glass can better withstand temperature differentials and can therefore be glazed with normal edge covers (20±2 mm).

• Higher softening temperature: Because the glass is selfsupporting for more than 30 minutes, large panes and simple frame constructions are now possible.

• Higher viscosity: The glass flow rate is low due to the high viscosity and durability of borosilicate glass, so with more edge cover, greater fire resistance times in excess of 90 minutes can be achieved.

• NiS crystals do not form: Due to the chemical composition of borosilicate glass, nickel sulphide crystals cannot form. Spontaneous glass fracture due to embedded NiS crystals cannot happen with PYRAN®.

Further information is available from our sales and technical offices or visit www.firmanglass.com

Tel: 01708 374534 Email: Pyran@firmanglass.com

Firman Glass, 19 Bates Road, Harold Wood, Romford, Essex RM3 0JH

The Old Stable

Crescent Road, Faversham, Kent, ME13 7GU Tel: 01795 515288

FUTURE CONSTRUCTOR & ARCHITECT MAGAZINE

EDITOR IAL

Rebecca Kemp rebecca@redhutmedia.com

PRINT & DIGITAL ADVERTISING

Sam Ball sam@redhutmedia.com

Jim Moore jim@redhutmedia.com

PRINT DESIGN MANAGER

Jack Witcomb jack@redhutmedia.com

DIGITAL DESIGN MANAGER

Matt Morse matt@redhutmedia.com

ACCOUNTS/ CREDIT CONTROL

Rachel Pike accounts@redhutmedia.com

PUBLISHER

Sam Ball sam@redhutmedia.com

As industries across the globe adopt new technologies to enhance efficiency, transparency and safety, construction remains on a journey of integrating digital processes. Although traditionally slower to innovate, the sector is now seeing the substantial benefits that data and digitisation bring to sustainability, safety and accountability, paving the way for a smarter, more connected industry.

On page 20 , Jozefa Lewis, Sustainability and Wellbeing Manager at ODGroup, dives into the role of digital transformation in meeting ESG (Environmental, Social and Governance) goals within the built environment. Despite the challenges in digitising data across complex supply chains, the industry is starting to unify information, which aids in reducing carbon footprints and waste. Here, she reveals how digitalisation not only enhances ESG reporting but also supports collaboration and transparency, providing essential benchmarks for future projects.

Meanwhile on page 24 , Nicola John, Managing Director of Fire Door Maintenance, discusses the Golden Thread approach to building safety. This framework, recommended in the 2018 Hackitt Report, stresses the need for consistent, accessible digital records that link stakeholders and ensure safety standards throughout a building’s lifecycle. By bridging information gaps and reducing siloed practices, the Golden Thread is a vital step toward preventing future safety hazards, with lessons underscored by the tragic events of Grenfell. In this article, Nicola details how the industry is beginning to adopt these digital practices, creating safer and more resilient buildings.

Lastly, on page 30 , Graphisoft UK spotlights the growing influence of digital tools in modern methods of construction (MMC), which promise to reshape how buildings are designed, assembled and retrofitted.

I hope you enjoy this issue. Don’t forget, you can also access the magazine’s features, product news and supplier information on FC&A’s user-friendly and engaging website. Fully responsive, the website allows you to read all the latest stories on-the-go either on your phone or tablet. Simply search www.fca-magazine.com.

Zaha Hadid Architects (ZHA) has been announced as the designer of the Alisher Navoi International Scientific Research Centre in New Tashkent, Uzbekistan. SEE PAGE 14.

curves, level changes, windposts, closer-links, balcony protectors, threshold isolators, adjustable height integrators

COMPLY WITH NHBC 2024 DIRECTIVE: At complicated junctions preformed cavity trays must be used

COMPLY WITH LABC 2024 DIRECTIVE: Trays must rise 150mm and be self-supporting or fully supported

The Cavity Trays Helpdesk – your route to compliancy and consistency in construction

The widest range from the longest-established cavity tray company with over 100 years of proven specialism.

VOICE OF THE INDUSTRY:

With new fire safety regulations on the horizon, Alex Bardett of Ambar Kelly emphasises the urgent need to dispel misconceptions about riser shafts and prioritise non-combustible materials in higher-risk buildings.

LEGAL & BUSINESS:

BUILD FOCUS: Interactive & Kinetic Architecture :

Danny Pickard, CEO of Kinetic Solutions Group, explains how retractable roofs, pivoting seating and movable pitches are reshaping modern venues.

SAFETY, SECURITY & FIRE PROTECTION:

ENERGY EFFICIENCY:

Recently, Harwood Building Control, SEA Building Compliance and OSG Architecture teamed up to deliver a secure, innovative shutter design, tackling Part O requirements head on.

KBB:

OFFSITE & MMC:

Nicola John, MD of Fire Door Maintenance, clarifies how the Golden Thread approach, a cornerstone of the Hackitt Report, can help mitigate risks associated with siloed practices in construction.

Sophie Weston, Head of Marketing at Geberit, explores how innovations like shower toilets are helping to create a smoother transition from home to office in the return-to-work era.

GREEN ROOFS & LIVING WALLS:

Wallbarn explores the myriad benefits of green roofs, highlighting their role in enhancing biodiversity, reducing urban heat and improving air quality.

TECHNICAL FOCUS:

Dr Jeremy Richings of PermaRock shares how roofline closure systems are transforming EWI installations by providing compliant, efficient solutions that align with net-zero goals.

RCR ARQUITECTES, MURABA VEIL:

Muraba Veil, rising like a mirage above Dubai’s skyline, is the latest creation from Muraba and Pritzker Prizewinning RCR Arquitectes.

THE ALISHER NAVOI INTERNATIONAL SCIENTIFIC RESEARCH CENTRE, ZHA:

Zaha Hadid Architects (ZHA) has been announced as the designer of the Alisher Navoi International Scientific Research Centre in New Tashkent, Uzbekistan. 20 18 24 28 32 34 30

Modern methods of construction are transforming the building industry, with Graphisoft, McAvoy, Bond Bryan and Waugh Thistleton demonstrating the power of digital tools in creating sustainable, efficient projects.

Jozefa Lewis from ODGroup shares insights into how embracing digitisation can help tackle the industry’s carbon challenges while setting new standards for sustainability. 12 16

“Changes of direction of a cavity tray or interfaces with other elements in the cavity are more complicated than simple joints and the design should be provided, and preformed cavity trays used.”

Satisfy NHBC technical requirements first time, every time. 100 years of proven specialism from the longest-established company designing and manufacturing cavity trays and flashings.

The Cavity Trays Helpdesk – your route to compliancy and consistency in construction

get a quick quote today ... the UK’s leading independent glass processor

Heatherwick studio has launched a three-year creative education programme that will work with 600 young people aged 10 to 14. Named In The Making, the initiative will be one of the biggest programmes run by any design studio in Britain. It aims to inspire young people to see themselves as creative and support all 6000 architecture practices across the UK to engage with schools. Heatherwick studio has developed a unique programme of light-touch, high-volume creative learning. This has been co-designed with young people and tested through a yearlong pilot involving 230 teenagers, 21 architects and designers, and 14 workshops with two youth organisations.

Workplace design and build specialist ODCreate has delivered a category A+ project, reimagining 7000ft 2 of office space in central London. The offices – situated close to Leicester Square at 101 St Martin’s Lane – have been refurbished for landlord KGAL, an independent German investment and asset manager, with ODCreate repurposing the original fit-out to make the space even more attractive for prospective tenants. The reimagining of the existing space has been undertaken with sustainability and adaptive reuse in mind, with the additional benefit of minimising marketing times of the offices for the landlord. ODCreate’s fit-out of the space is tenant ready.

FC&A ROUNDS UP THE LATEST INDUSTRY

Danish architecture firm Cobe has shared its vision for the transformation of the historic ‘Krulli’ steelworks into a mixed-use city district in the Estonian capital, Tallinn.

Dating back to 1899, the ‘Krulli’ steelworks have been an important workplace in the Estonian capital. The former industrial area has remained vacant for years, and today features a blend of pioneering nature and temporary activities within and surrounding its abandoned structures. The project’s goal has been to integrate urbanism, landscape and architecture, transforming the area into a mixed-use city district with a focus on entrepreneurial community and start-ups, while providing 600 new homes and 3000 new workplaces. By repurposing existing materials, components and entire buildings found on site, and building on the local identity through colours and materials, the project is grounded in a comprehensive transformation strategy that will shape the future identity of Krulli. Transforming three neighbouring industrial heritage halls, an innovation hub will serve as a kick-starting project and the central public destination in the Krulli neighbourhood. These buildings will be transformed

into the heart of the new neighbourhood with co-working spaces, cafes, shops, artist studios and exhibitions. T he design explores the neighborhood vision in detail, focusing on reusing as much of the existing as possible. This includes mapping out the existing building structures and

components in the three halls as the basis for the new design. The halls will be transformed, complemented by new office spaces constructed from timber arranged in a chequerboard pattern within the existing structures.

www.cobe.dk

The latest appointments from the construction and architectural industries.

Architecture and Interiors firm, TINTO, has announced the launch of its Glasgow office and the appointment of its Glasgow-based team. Following the successful completion of several projects in the region, delivering fees of over £250k, the team have witnessed the potential of the city as it undergoes a period of transformation. Over the past 18 months, TINTO has worked with a number of blue-chip companies, including the Avis Group, to deliver a range of services, including architecture, interior design, construction, design and management (CDM) and project management. In a strategic move, TINTO has appointed Ciara McInnes as Associate Architect to lead the Glasgow office based in The Briggait. Lizzi Nutt, Associate Interior Designer, will also now be based in the Glasgow office.

The Hill Group has appointed Tom Starkey as its new Build to Rent and Commercial Asset Manager, the company’s first role dedicated to Build to Rent (BTR). In this newlycreated position, Tom will help shape Hill’s BTR strategy and oversee the company’s expansion into the sector. Drawing upon its reputation as a partner of choice, Hill is perfectly placed to ensure the delivery of high-quality rental homes within thriving communities. Forming part of Hill’s five-year business plan and growth strategy, it’s exploring new opportunities to work with potential investors and partners on forward funding, forward commit and joint venture bases. Having started his career as a land buyer at Taylor Wimpey and then at Berkeley Group, Tom has most recently worked as a Senior Acquisitions Manager at HUB.

CIBSE is proud to announce that its President, Fiona Cousins, has been appointed as an Honorary Fellow of Trinity Hall, Cambridge. This prestigious recognition reflects Fiona’s exceptional contributions to the engineering sector and her commitment to the advancement of the built environment. Fiona’s remarkable journey began at Trinity Hall, where she graduated in 1989 with a degree in engineering science. Since then, she has forged a distinguished career in engineering, currently serving as the Arup Americas Region Chair and as a member of the Arup Group Board. Her impressive portfolio includes high-profile projects such as the US Embassy in London, Fulton Street Station in New York and the Frick Chemistry Building at Princeton University.

Following the news that it is to relocate its global HQ next year, international property and construction consultancy Gleeds has announced that it will convert from a general partnership to a Limited Liability Partnership (LLP) structure in January 2025. The switch is part of an ongoing action to simplify the group as it gears up for future growth. As part of this simplification, Gleeds will be reducing the large number of legal entities that it currently has registered in the UK to streamline its accounting and operational processes. In preparation, around 70 people in offices nationwide are being asked to resign their statutory directorships on a voluntary basis. This is an administrative realignment, and the changes will have no discernible impact on individuals involved, who remain in their current roles.

Multi-discipline principal contractor, Miller Knight, is set to host its first annual Building Safety Forum on 6th November at the iconic Villa Park, home to Aston Villa football club. The event will centre on some of the major challenges the construction and property management sector are facing, predominantly in light of the country’s legislative changes surrounding building safety and fire regulations. Bringing together industry leaders, the Building Safety Forum will serve as a platform to explore key regulatory updates, initiate conversations and encourage collaboration while aiming to create the future of a safer and more accountable built environment.

Pamela Wackett has had a remarkable journey in architecture, shaped by a unique background and an unwavering passion for design. From reimagining her desert hometown in Chile as a child to directing major projects at Kohn Pedersen Fox, she has always seen the potential to create more beautiful and functional spaces.

Tell us about your career journey. How did you get started in the field of architecture?

I’ve always had a strong curiosity about how to make places nicer. As a child, I was constantly reimagining my surroundings. I grew up in a city in the desert of Chile, with sand dunes along a long beach but very few green areas, so I would dream up improvements like lush gardens. I knew architecture was for me, and I studied at the Universidad Nacional Andres Bello in Santiago, Chile.

Were there any pivotal moments or experiences that solidified your decision to pursue a career in architecture and design?

My degree showed me that I was on the right track, and then I was lucky enough to work on some fantastic projects and with great mentors when I started my career, so I’ve never looked back.

If you hadn’t followed your passion for being an architect, what other career path would you have pursued?

As a child, I loved dance, music, sports, acting and photography, all activities that allow people to express creativity and connect with the world around them. I like to think that if I wasn’t an architect, I would be spending my time on these hobbies.

Who has been your greatest influence and source of inspiration?

I don’t think I can name one person here. I’ve been lucky to work on some incredible buildings with dedicated and talented

colleagues and consultants. On every project, I find something to inspire me – such as responding to a historic neighbourhood or finding the most efficient way to detail a complex facade. There’s always someone to learn from, too. We work with such a broad range of people, all of whom are experts in their field, whether in computational design, structural engineering, or art.

What’s been the most memorable project you’ve worked on, and for what reason?

I’ve worked on a wide range of projects, including the Zayed International Airport in Abu Dhabi and a supertall tower in Shenzhen, China. But I’m always most focused on the project I’m working on now, and that absorbs me completely. The Lucan is a really lovely residential project in Chelsea, which has 31 apartments and state-of-the-art amenities that are currently under construction. Inspired by Chelsea’s classic Victorian-era mansions, there are some beautiful details, such as integrated artwork and bay windows. The apartments are going to be wonderful!

Can you share a personal anecdote or experience that taught you a valuable lesson about being an architect?

Watching the way that Gene Kohn, one of the Founders of KPF, was able to connect with people was a valuable lesson for me. Architecture is all about communication. As architects, we need to understand our clients’ briefs and aspirations, and we need to be able to express those to the various consultants

that make up the project team. We need to be good storytellers. Often, people are worried when they hear that a new development will be built nearby; we need to be able to be storytellers who can bring people along on the journey, making sure that they understand what’s being proposed and how it will benefit them.

Could you walk us through a typical workday in your current role?

My days can vary depending on the stages of projects I am working on. It could start with a site visit, then the daily

team catch up to review the progress of a project design. Meeting with a client or a consultant. Respond to emails, hand sketch ideas, prepare a presentation and make phone calls. The Lucan is currently under construction and is in its final stages of completion, so I might go on a site visit there to assess the progress and check material samples. Days finish very quickly!

What is your favourite building and why? Palacio la Alhambra, in Granada, is the closest to perfection I have ever experienced. Beautiful architecture

merges so well with the landscape that it makes you flow between gardens and interior spaces, bringing dramatic emotions of joy, isolation and peacefulness. Views, light, nature and the sound of water are all integrated so magically that I could just stay there and never leave.

In your opinion, who is the greatest architectural mastermind of our time?

It’s so hard to choose just one. Zaha Hadid transformed architecture with limitless innovation and creativity and showed how a woman could succeed in a profession that had been traditionally male. Tadao Ando, for his unique vision of spiritual spaces. And Antoni Gaudi, for creating the most beautiful places using nature, light and challenging engineering.

Looking ahead, what exciting projects or initiatives can we anticipate from you in the coming year?

The Lucan, which marks the very first standalone Autograph Collection Residences in Marriott’s Global residential portfolio, is near completion. I’m looking forward to seeing the project completed and people moving in. I’m working on a couple more residential projects in London, and I’ve also been looking at some adaptive reuse as well, investigating ways that an outdated building can be reimagined to provide new uses.

After 135 years trading, F.H.Brundle knows a bit about its customers – and it knows there’s little they hate more than wasting time.

F.H.BRUNDLE

In stalling can be tough – you’re working long days in all weathers, fitting products that are often heavy and cumbersome.

Worse, when it comes to the actual installation, some products are incredibly complex and time consuming to fit, especially if they need adjusting.

T he more time an installation takes, the less work you get done in a day, the longer the overall project takes and the less time you have to do other jobs and win new business.

T hat’s why, when we’re choosing products to offer, ease of installation is always one of F.H.Brundle’s highest priorities.

There are few systems that demonstrate this better than the company’s Fortitude metal railings –the most versatile, off-the-shelf steel balustrade and handrailing solution on the market today.

For instance, the unique, adjustable raking panels can be fitted on site without any pre-fabrication, galvanising or powder coating. That means less hassle for you and a happy customer who gets their project finished faster.

W hat’s more, there’s no welding required. Fortitude’s clever brackets and components are designed for simple assembly.

Fortitude is also aesthetically versatile. As well as F.H.Brundle’s classic Traditional metal railings, it also offers a choice of two other timeless styles –Contemplation, a modern, minimalist balustrade system pairing stylish toughened glass with steel posts and glass clamps, and Contemporary, incorporating narrow upright posts with toughened glass and aluminium channels.

I t requires minimal maintenance, reducing the likelihood of costly and time-consuming callbacks.

A nd, best of all, it offers everything you need for a complete railing system, from posts and panels to brackets, glass clamps and even gate kits.

I t’s also extremely easy to incorporate gates.

F.H.Brundle’s off-the-shelf adjustable gate kits let you quickly turn any Fortitude Traditional panel into a gate – simply cut a panel to the required size and attach the hardware to the panel and the end post. It’s as simple as that.

B ut those aren’t the only reasons Fortitude has proved so popular with thousands of installers around the country – including the Decking Network, and its Founder, Karl Harrison.

A part from its stunning aesthetics, ease of installation and vast versatility, it’s worth noting that the system has undergone rigorous testing in accordance with BS 6180 standards.

I t also offers a range of fixing methods –concrete-in, bolt-down and side-fix – which, again, helps it cater to an array of different projects.

T he option to add handrail capping is another string to its bow. F.H.Brundle’s quality-engineered component sections allow the installer to quickly and easily add Fortitude handrails to any 50mm post system – and, just like the system as a whole, there’s no need for laborious welding.

F.H.Brundle’s fleet of over 70 delivery vehicles is constantly on the road, delivering quality products to customers right around the UK, with free delivery on any order over £150.

A new development by Muraba and Pritzker Prize laureate (2017), RCR Arquitectes has introduced a contemporary style of architecture that draws upon vernacular heritage and tradition to its latest collaborative project, Muraba Veil.

RCR ARQUITECTES

Th e culmination of a 10-year partnership, this is the fifth collaboration between Dubai-based Muraba and Spanish RCR Arquitectes, bringing a shared aspiration to work in harmony with the natural environment and allowing each location’s unique characteristics to guide the concept. With Dubai’s culture and climate, Muraba and RCR present a new form of skyscraper for the region – an exercise in acclimatising architecture to place, working with nature rather than against it.

M uraba Veil towers to 380m. Uniquely, the entire building is the width of a single apartment at 22.5m. Approved and registered with RERA, the 73-storey tower will comprise 131 units, ranging between two- to five-bedroom exclusive residences, together with a range of curated leisure amenities, including a wellness spa, restaurant, gallery, padel court, private meeting rooms and a private cinema. The appointed engineer for Muraba Veil is the worldleading engineering consulting firm WSP, with client advisory by Arup.

Awe-inspiring yet understated, Muraba Veil rises from the dunes above the UAE’s most cosmopolitan and futurefacing city, presenting a daring, stopyou-in-your-tracks spectacle, even in Dubai’s supercharged architectural vista. The building is revealed behind a series of layers, the first being the ‘veil’ itself –a bespoke stainless-steel mesh, porous and responsive, reflecting the different shades of the sky and dematerialising the architecture’s presence. The structure, whose unusually narrow profile and appearance could only be achieved by the latest design and engineering, is inspired by a domestic architecture that is centuries old, traditionally seeking to meet basic human needs for refuge, security, privacy and a close connection to nature.

I nside, the Veil takes its cue from the model of the Arabian house, which reveals itself through subsequent layers softened by shade and greenery before finally coming to the inner courtyard, the cool, communal and convivial centre of the dwelling; the representation of a paradise on earth. Each of the 131 exclusive residences occupies the entire width of the building. Screened by the

Mashrabiya-inspired veil and bordered by generous outdoor spaces on both sides, the residences enjoy dual aspects and a gentle through breeze, reducing temperature by natural means – the Arab courtyard reimagined.

T he Veil is ultimately designed as a sanctuary for this place and, this time, offers the opportunity to live a serene, private, perhaps meditative existence floating high above the city – a retreat from the instant, the material and virtual, conceived as an oasis for the mind as well as the body. Wherever a visitor goes in the Veil, the impression is of being simultaneously swathed and shielded from external heat and liberated by space. It’s as true of the deep, high, wide rooms and terraces of individual residences as it is of the Veil’s other world, the cavernous subterranean spa –a wellness club consisting of a series of experiential pools, treatment rooms and gym, as well as restaurants, lounges, an ‘oasis’ and amphitheatre, hidden beneath a vast dune-like carapace at the foot of the tower.

S ituated in a prime canal-side location next to Dubai’s main transport artery, Sheikh Zayed Road, the slender profile

of the residential tower belies its use of time-honoured techniques for ventilation and use of natural light, harnessing an architecture that is both inventive and reflective. Crafted for precision, performance and beauty, the architectural gem is a well-guarded work of art, with a by-appointment-only gallery tour dedicated to its unique features.

I brahim Al Ghurair, Managing Director of Muraba, says: “This is more than a beautiful residence. What we set out to achieve is a life-enhancing work of architecture, which speaks to the heritage of the built environment of the UAE. We want Muraba Veil to be synonymous with exquisite serenity, with the same calm that you feel when you enter the courtyard of an Arabic house.”

Rafael Aranda, Founder of RCR Arquitectes, adds, “We are passionate about ensuring our buildings are responsive to the place; that they belong to the site and the native landscape where they are situated. They must communicate with nature and be infused with the atmosphere of the local culture.”

www.muraba.ae

www.rcrarquitectes.es/en

CA Twin-Therm® is the market leading complete metal roofing and cladding built-up system, available with the CA Group Complete Assurance Guarantee with periods of 25, 30 or 40 years.

Find out more

Visit our website to learn more about us and what we do at: www.cagroup.co.uk

CA Group 01388 834242 enquiries@cagroup.co.uk

This year CA Building Products is proud to announce the expansion of our range of profiles available for CA Twin-Therm®, creating greater choice for architects, increased flexibility in design and improved ease-of-use for installers.

CA Twin-Therm® offers:

• Independent Agrément certification, LPCB, LPS1181, LPS1175 and Secured By Design accreditation

• Fire Resistance as standard offering, with up to 240 minutes Integrity and 120 minutes Insulation, valid for either external or internal fire resistance

• Backed by Confidex® and Confidex Sustain® by Tata Steel for up to 40 years

• No reduction in Guarantee period for inclusion of solar PV or EV charging installations

• Stringent quality, environmental and Health & Safety control measures, ISO 9001, 14001 and 45001

• Twin-Therm® Chronus and Chronus Ready [pat pend] unique solution for future proofed controlled environments

• Environmental Product Declarations gathering full life cycle data Modules A1-5, B1-5, C1-4 and D, with independent third party endorsement and building design life of 60 years

The Alisher Navoi International Scientific Research Centre in New Tashkent will incorporate the Navoi State Museum of Literature together with a 400-seat auditorium for performances, events and conferences. The design also comprises the International Research Centre and a residential school for 200 students specialising in Uzbek language, literature and music.

ZAHA HADID ARCHITECTS (ZHA)

An choring the new cultural quarter within New Tashkent (a 25,000-hectare masterplan designed by Cross Works to accommodate the city’s growing population), the Alisher Navoi International Scientific Research Centre celebrates the traditions of Uzbek literature and Shashmaqom music. A fusion of vocal and instrumental music, melodic and rhythmic idioms and poetry, the classical music tradition of

Shashmaqom is an integral part of Uzbek culture, with Tashkent renowned as a centre of excellence.

Named after Alisher Navoi, the 15thcentury Poet, Author, Linguist and Stateman – whose works had a profound influence in the cultural heritage of Uzbekistan – the 23,000m2 International Research Centre has been designed with a variety of interconnected spaces to encourage dialogue between literary education, research and the performing arts.

T he centre’s arched facades and interiors will be crafted from bricks produced in Tashkent’s local kilns, echoing the curvilinear geometries of Uzbekistan’s acclaimed traditional architecture. Courtyards, another defining feature of the region’s vernacular tradition, are incorporated within the new centre to provide natural light and ventilation while creating a variety of outdoor gathering spaces and areas for private contemplation.

S ituated in Tashkent’s Mediterranean climate with the continental influence of its Central Asian location, the centre’s design is defined by passive architectural principles to provide optimal conditions for visitors, staff and students while minimising energy consumption.

Informed by the wind towers of Central Asian and Middle Eastern vernacular architecture that maintain cooler interior temperatures, the geometries and composition of the centre’s supporting arches have been designed as hollow structures with openings that capture the wind and channel cooling ventilation into the building. In the hottest months, this system will be supported by fans and misting to cool the air before it circulates within the structure.

I n weather conditions without wind, these hollow arched structures create a pressure gradient that extracts hot air upwards, producing a thermal chimney,

allowing warmer air to escape through the openings at the top of each arch.

T hese cooling principles are enhanced by the day-night cycle, extracting warmer air while trapping cooler air below.

Coupled with high thermal mass of the centre’s structure, optimum conditions of comfort can be maintained with minimal energy consumption. Courtyards and skylights bring natural light into the heart of the centre, while deep roof overhangs provide its facades with effective solar shading in summer yet permit winter sun into the building to warm the interiors.

The Navoi State Museum of Literature, at the heart of the institute, will provide comprehensive programmes of research, archives and exhibitions, which include a restoration workshop and a repository housing a collection of 3500 historical books and manuscripts. Incorporating 13 permanent exhibition halls around a

central courtyard, the museum will present centuries of Uzbek literary history and contemporary works by the nation’s most renowned authors.

Taking inspiration from the dynamic performances of Shashmaqom music to create a setting where the city’s artists and the wider community come together, the centre’s outdoor spaces define a sequence of landscaped terraces with open-air amphitheatres and gardens with shaded pavilions for impromptu performances.

C elebrating Uzbekistan’s rich cultural heritage while also showcasing its diversity and depth, the Alisher Navoi International Scientific Research Centre aims to become a hub of creativity with an ensemble of traditional and contemporary venues for the arts as well as hosting educational and research programmes. www.zaha-hadid.com

With the Grenfell Tower tragedy bringing fire safety in higher-risk buildings (HRB) sharply into focus, the role of riser shafts in reducing fires and improving safety has never been more important. However, they still face many misconceptions. Alex Bardett, Managing Director of Ambar Kelly, underlines the importance of educating the industry on the truth behind these misconceptions and the vital role that modular riser flooring can play in improving HRB fire safety, says Alex Bardett, Managing Director at Ambar Kelly.

AMBAR KELLY

Wh en it comes to fire safety, the construction industry faces many challenges, not least a lack of understanding of the perils of installing combustible materials in any UK buildings. This is exacerbated by the perceived notion that non-combustible materials are more expensive.

A s the Grenfell Tower inquiry highlights, the chosen material can have a significant impact on the spread of fire and smoke throughout any building – especially HRBs.

I n fact, the tragic Grenfell Tower fire in 2017 involved a combustible material being lit and then, amongst other things, a fire rising in a void and forming a vertical shaft due to the lack of a horizontal fire break.

Furthermore, the King’s Cross station fire of 1987 involved a shaft ‘trench effect’, when a discarded match lit a combustible material and then developed into a ‘flash over’ due to the fire rising in the ‘trench’ of the wooden escalators.

While upcoming Building Regulation changes are set to sharply focus attention on fire testing and certification, more education is needed on the vital roles that non-combustible products play in improving fire safety in HRBs.

T he Ministry of Housing, Communities, and Local Government (MHCLG) recently issued a new parliamentary statement that will see changes to fire safety and evacuation provisions, including Approved Document B. Fire safety information must be given to the relevant duty holder when the project is complete or the building is first occupied.

To further support enhanced fire safety from 2nd March 2025 onwards, the new updates will remove references to the national classification system for fire resistance, known as BS 476. Parts 6 and 7 will require construction products to be classified in accordance with EN 13501-1, with performance classes A1 and A2 for noncombustible products and B, C, D and E for combustible products.

Non-combustible products are believed to be more expensive

N on-combustible steel plate materials, featuring pre-cut holes for M&E services that are covered by a lid, are often seen as being too expensive. While the initial cost will typically be more, that cost won’t increase as the project progresses.

H owever, the outlay for combustible GRP grating riser flooring options will increase over time due to postinstallation works. For example, GRP grating has to have holes cut into it to account for any services being fed through. Temporary fire doors will need to be fitted on every floor to meet codes of practice and prevent the spread of fire during construction, as, by its very nature, grating allows smoke and flame to pass through. This increases the overall project cost.

Products are often labelled as having a fire rating – that doesn’t mean they’re not combustible

S pecifiers will often see suppliers promoting products that have a BS 476 Part 6 and 7 fire rating, which is actually a measure of the spread of flame.

T his is typical for GRP grating used by UK contractors as a riser flooring solution. However, all GRP grating is combustible and will add fuel to any fire that occurs in a riser shaft. The Grenfell Tower inquiry found this surface spread of flame test (BS 476 Part 6 and 7) does not measure combustibility, hence why it’s being withdrawn in March 2025.

I f the designed product for riser flooring in an HRB is specified as non-combustible at Gateway 2, contractors may believe the GRP grating has the required ‘fire rating’ and attempt to hand the project over to ‘Gateway 3’. However, despite it having a BS 476 Part 6 or 7 declaration, it is combustible, meaning it will likely be rejected. Which leads us to…Mistaken assumptions of responsibility (or lack of).

O ften, a contractor will be under the impression that the product’s supposed fire rating is correct, handing over the project to the next person in the chain.

I ndeed, there are many occasions when a main contractor will say “The sub-contractor has bought it and said it’s fire rated, so it’s not my problem”. However, the situation isn’t always that straightforward.

U nfortunately, the main contractor will often hold all the risk and they won’t even realise they’re in this position. Additionally, if a non-combustible Class A1 steel riser flooring product is specified in Gateway 2 and replaced by a combustible Class-C GRP product, this needs to be recorded in the change control plan so the impact of these combustibility changes can be considered by the relevant teams.

Furthermore, it must be documented before the building safety regulator (BSR) signs off the building for handover at Gateway 3.

Education is essential

H elping suppliers and main contractors understand the benefits of non-combustible materials will go a long way towards improving fire safety in the built environment.

T he Golden Thread will ensure that anyone involved has up-to-date information readily available, ensuring a better understanding of the fire risks of using certain materials and the earlier identification of issues.

I ndustry leaders and the Government also need to ensure quality standards are adhered to and regulations met. This will improve the quality of materials being used in construction for the benefit of the end user.

While it’s essential that contractors know their responsibilities if they change a specified non-combustible product for a cheaper combustible alternative, suppliers also play a huge role. Their products must be tested and certified to EN 13501-1 to allow design teams and contractors to make an informed comparison between products.

W ith fire safety a vital aspect of any building’s construction, it’s imperative contractors are aware of the noncombustible opportunities, and associated benefits, available to them. They, along with the end user, will truly benefit as a result.

As we all know, the construction industry has a carbon problem. In the UK, the built environment produces more than 10 million metric tons of carbon per year, making it one of the most significant polluters of the major industries, says Jozefa Lewis, Sustainability and Wellbeing Manager at ODGroup.

ODGROUP

At the same time, we are universally regarded as being one of the slowest sectors to adapt to new technologies and approaches, seemingly decades behind the likes of manufacturing and automotive industries.

A gainst this backdrop, it’s easy to see why ESG credentials and net-zero targets are challenging to meet, but the industry is taking positive steps every day, and digital transformation is playing a key role on the frontline in making these changes.

O ne thing the built environment isn’t short of is data, but the biggest issue facing most businesses on this front is how that data is captured and what it is used for. However, as a business that has gone through its own digital transformation process, we’ve found that having unified data brings more than just the obvious benefits of helping with ESG reporting.

W hile having this data to hand naturally helps with benchmarking against metrics such as carbon, waste, resource efficiency, procurement and social impact, it also creates a significant element of shared learnings that help the client, consultant and supply chain alike.

Embracing change

T hat isn’t to say that digital transformation is an easy journey for all businesses. The slow pace of

innovation across the built environment can make it a clunky process, especially when the rollout includes everyone from the C-suite down to teams on site and subcontractors.

I n terms of our supply chain, we were met with some resistance to the change, so we had to illustrate the benefits of this process and maintain an open dialogue, building on the understanding that this will eventually be industry wide and that, at this stage, logging data would inevitably help rather than hinder.

T he key learning from this was a sense of 'build it, and they will come'. It can be a difficult decision to grasp the nettle and take the lead with something like digitalisation, but it is an excellent opportunity to set the standard and lay out the roadmap for your supply chain ecosystem to follow.

O n the client side, it’s less about getting buy-in and more about illustrating how that data helps hold everyone to account and increases transparency throughout the process.

I n reality, the data that is created belongs as much to the client as it does to us, and with manageable access to it, clients can continue to set their ambitious targets safe in the knowledge that they have access to robust reporting against them.

IS THE SUSTAINABILITY AND WELLBEING MANAGER AT ODGROUP

Leading the way

W hen these systems are rolled out, the benefits of aspiring towards certain accreditations, for example, are clear to see. When we first introduced our new digital systems on a Category B commercial fit-out in Knightsbridge for The Dorchester Collection, they helped track the fulfilment of a number of credits for an SKA Gold rating, such as waste, logging energy, water use and tracking delivery mileage.

T hose digital processes documented essential supporting evidence from the supply chain for the materials installed, ensuring the project received that SKA Gold accreditation.

O verall, this collaboration with our supply chain – enabled by digital processes – led to the successful delivery of the ESG targets and has created a benchmark for future projects.

A s our industry seeks to find ways in which it can be more accountable and transparent as we work towards net-zero targets, digital transformation needs to play a key role in ensuring not only that the data is available to track our progress but also in helping drag processes across the industry into the 21st century.

ARX – part of the Kinetic Solutions Group – has created some of the world’s most iconic kinetic architecture. From stadia to bridges to skyscrapers, ARX’s expertise makes the architect’s vision of moving structures a reality.

At first, kinetic architecture can seem challenging, expensive and even too showy to be practical. The truth, however, is that moving structures – planned and deployed correctly – can significantly enhance a building’s purpose and how the space within it can be used, says Danny Pickard, CEO at Kinetic Solutions Group.

KINETIC SOLUTIONS GROUP

AR X works closely with a broad group of stakeholders to deliver kinetic architecture projects. The architect is a key interface, of course. And there are consulting engineers, structural engineers, cost consultants, project managers, construction contractors and, of course, the end customer.

E ach has a need for interaction with, input into and feedback from ARX through all stages of the design and build of a kinetic architecture solution.

A RX engineered a world-first solution that splits the real grass Premier League pitch into three sections before rolling it away into a storage area beneath the South Stand. The 10,000-tonne pitch takes just 25 minutes to retract, revealing a dedicated synthetic NFL pitch beneath it.

In addition, the entire touchline, pitch surround and player tunnel ramps rise and fall hydraulically through a height of 1.65m to meet the different levels of the grass and synthetic playing surfaces.

T his multi-use stadium creates new revenue opportunities, hosting a diverse calendar of events, including national and

JOINED THE BUSINESS IN 2007, STRAIGHT FROM THE UNIVERSITY OF SHEFFIELD, AS A GRADUATE DESIGN ENGINEER. MOST NOTABLY, DANNY LED ARX’S BEST-KNOWN KINETIC ARCHITECTURE PROJECT: THE WORLD-FIRST DIVIDING RETRACTABLE FOOTBALL PITCH AT TOTTENHAM HOTSPUR’S STADIUM IN LONDON.

international football, NFL, rugby, boxing and concerts. These revenue streams help to maximise return on investment in the stadium’s construction and underpin a solid business case for kinetic architecture.

T he All England Lawn Tennis Club (AELTC) required a solution to avoid rain stopping play at its prestigious world-class tennis tournament. ARX engineered, built, tested and installed the retractable concertina roofs over both stadiums.

T he roofs provide rain cover when needed, keeping the courts and spectators dry whilst retaining Wimbledon’s traditional open-air feel. They also ensure that players enjoy uninterrupted tournament schedules, even during bad weather. The same applies to sports broadcasters and advertisers, who have greater assurance of an audience by avoiding match delays and cancellations.

E ach roof comprises 100-tonne trusses that span the 77m width of the court. Each truss can be moved independently, not only supporting the tensile fabric membrane but also carrying lighting and ventilation equipment.

K ai Tak Sport Park – a versatile, responsive venue

T he brand-new Kai Tak Sports Park in Hong Kong was built with multi-use in mind. ARX has installed two important kinetic solutions at the stadium – pivoting seating and a retractable roof sealing system.

Four sets of pivoting seating – known as ‘stage pockets’ – have been installed at the ground during its recent development. They create additional space, mainly for stage sets, but also to expand available floor space for events, opening up the opportunity for more ticket sales.

T he roof sealing system might, at first glance, be to protect the audience from wet and windy weather, and the system certainly does that. However, it has another primary use, which is to acoustically seal sound inside the stadium during concerts so as not to disturb the residential districts close by.

B oth the pivoting seating and roof sealing system are powered by hydraulics from ARX’s sister company, DHX.

For regular, flat-roofed buildings, accessing exterior elevations are well-served by standard roof-mounted rail traversing systems. For more unusual architectural designs without flat roofs and operating at substantial heights, a different approach is needed.

A RX has helped to create some very unique building access systems. At ‘The Gherkin’ on St Mary Axe in London, we designed five building access machines to access both the exterior and interior of this instantly recognisable building. They circle the building on a halo rail near the very top of the Gherkin.

A t ‘The Scalpel’ on Lime Street, and ‘The Vase’ at One Blackfriars, ARX designed and built the retractable doors from which building maintenance units are deployed. The

hydraulically-powered doors carry cladding to perfectly match the building’s exterior, allowing the access systems to disappear completely from sight.

S olutions great and small

K inetic architecture does not need to be on a grand scale. Small, discreet and well-chosen applications of kinetic architecture can add highly practical details.

A t 25 Wilton Road, a mixed-use development near Victoria, London, ARX developed a manually-operated portcullis door system. By hand power alone, the intricately laser-cut stainlesssteel portcullis gates gently rise and fall against a visible counterweight. The gates secure the building when closed and become striking backlit murals when raised.

A RX has worked on residential properties, too. For a private mews home in London, we created a retractable glass canopy using a single piece of gently-curved glazing. A rack and pinion drive system provides the power, precision and safety to deploy the roof over a rear garden terrace.

B link, and you might miss the sight screen that we designed and built for Lord’s Cricket Ground. Its purpose is to increase safety, ensuring that the batter has visibility of the ball while playing different codes of cricket. The sight screen rotates its triangular section panels to present a light or dark background. These can also be decorated with promotional designs, creating new revenue opportunities.

We believe that buildings will become increasingly kinetic, with moving structures being included more often in architectural designs.

M oving structures enable efficient packaging, they facilitate multiple uses of the same space, they create more interesting spaces for people and they offer new revenue potential. And moving structures deliver new forms of architectural expression, too.

W hen integrating static buildings with dynamic elements –especially in public spaces – it will always require the focused expertise of kinetic architecture engineers. Substantiated safety assurance and a solution engineered for reliability, repeatability and maintainability are key deliverables, whether moving a 10,000-tonne football pitch or a 700kg portcullis gate.

Nicola John, Managing Director of Fire Door Maintenance, part of UAP, discusses the importance of the 2018 Hackitt Report Golden Thread recommendation, exploring why businesses must address the risks of siloed construction practices as well as strategies for implementing the Golden Thread principle.

T he 2018 ‘Building a Safer Future’ report, commissioned by Dame Judith Hackitt, noted that existing building and fire safety regulations and processes for constructing high-rise buildings were “not fit for purpose”.

T he report’s primary recommendation was a move towards digitisation of product information, dubbed the Golden Thread. It encourages effective and accurate storage and management of information concerning buildings’ designs, construction and uses.

T he Golden Thread is more than just a record-keeping tool. It is a framework for linking different parties within the construction industry. By connecting architects, engineers, contractors, manufacturers and building owners, the Golden Thread fosters transparency and collaboration. It ensures that all work not only meets regulatory standards but also enables the identification

and management of any safety risks throughout the building’s lifecycle.

This approach is a fundamental shift in how the construction industry approaches safety. It provides a safeguard against siloed practices, where vital information could be lost or overlooked, leading to potentially catastrophic consequences.

B y maintaining a comprehensive and integrated digital record, the Golden Thread helps ensure that safety remains at the forefront of every stage of a building’s life, protecting both the structure and its occupants.

The report highlighted the shortcomings of the industry, with Hackitt’s foreword calling out cultural issues across the sector, including ignorance, indifference to implementation, lack of clarity on roles and responsibilities and inadequate regulatory oversight and enforcement tools.

S ix years on, and the problem remains. Recent research by the Construction Leadership Council (CLC) has shown a widespread lack of understanding within the manufacturing industry over the nature of keeping a digital record and how it could be achieved.

In fact, 92% of product manufacturers do not see digitisation as a major concern and more than half “see no need to digitise”.

85% of companies still provided product information largely via PDF or hard copy only, and only 8% have ever made or commissioned a Building Information Modelling (BIM) object.

Just over half of respondents felt they were digitised to some extent, but even when provided with the definition of digitisation, few of the respondents fully grasped and understood what it meant in practice.

Even among those who consider themselves partially digitised, there is often a fundamental misunderstanding of what true digitisation is. Many equated digitisation with using computers or having online systems, rather than understanding it as a comprehensive approach to maintaining and integrating critical safety information throughout a building’s lifecycle.

It’s clear the industry is still not meeting post-Grenfell regulatory requirements to digitise product information, and widespread training to understand the Golden Thread is needed before we can put it into practice.

Digitisation is also set to form part of the requirements under the Building Safety Act 2023. Those working in the construction industry urgently need to implement the Golden Thread approach to ensure they are complying with the new laws.

M anufacturers, installers, inspectors and landlords often work in isolation, focusing solely on their tasks without considering the broader impact on other stages of the building lifecycle.

T his disconnection causes a lack of communication and oversight, with no Golden Thread to link all product information throughout construction. Without accessible product data, critical safety issues can remain hidden.

The consequences of siloed practices have been fatal. The Grenfell disaster was a stark reminder of this danger. Dr. Barbara Lane’s supplemental report on the Grenfell disaster revealed that none of the 106 fire doors replaced in 2011 complied with ADB 2013 Building Regulations. Alarmingly, fire door closers had been disconnected, potentially exacerbating the fire’s spread and obstructing residents’ escape routes – a tragic mistake that cost lives.

If a Golden Thread of information had been available, these flaws could have been identified and corrected, enabling the fire doors to perform their critical safety function.

The Golden Thread isn’t another legal hoop for the industry to jump through. It is a fundamental change to ensure sectors work together, and ensure buildings are safe.

Technological advances now make it easier to maintain the Golden Thread of information. For example, fire doors can be fitted with BIM data pins that, when scanned, provide instant access to an online database with critical details like installation, inspections and compliance. These fireproof pins ensure that essential data remains accessible, even if the door is destroyed.

D espite this innovation, industry adoption remains limited. Full digitisation needs wider adoption by industry and the supply chain to keep fire safety data consistently updated and accessible throughout a building’s lifecycle.

H owever, digitisation alone isn’t enough. There is also a shortage of

workers trained to understand the entire lifecycle of safety products like fire doors.

F ire Door Maintenance is training the industry to bridge this knowledge gap. It’s the UK’s first practical fire door training centre, covering everything from regulation compliance to how and why components were chosen in product engineering and how products are ultimately installed for the end user.

B y fostering a deeper understanding and ensuring seamless collaboration across the construction process, we can uphold the Golden Thread.

T his commitment is not just about legal compliance – it’s about safeguarding lives and ensuring that tragedies like Grenfell never happen again.

www.fdmltd.co.uk

Starting in 2025, all new homes must meet the Future Homes Standard (FHS). This includes low-carbon heating systems and enhanced insulation, with the goal of reducing carbon emissions from homes built after 2025 by 75 to 80% compared to those constructed under current Building Regulations.

Th e Building Regulation amendments that fall under the FHS will be some of the biggest changes in a generation and, with the exception of the deadline of 15th June 2023 now behind us and 2025 fast approaching, how is the industry preparing?

E arly collaboration and communication are critical for successful projects. Below, Harwood Building Control has explored one example where it teamed up with building compliance expert SEA and architectural firm OSG Architecture to look at a design solution that would meet the requirements of one of the new regulations, Part O.

A dam Dodd, Operations Director at Harwood, explains: “Approved Document Part O took effect on 15th June 2022 and sets out the requirements of mitigating overheating in new-build homes and buildings where people sleep overnight.

“ It’s about reducing the risk of overheating for health and wellbeing to stop building tenants and inhabitants getting too hot. Importantly, it’s about limiting solar gain – through shading devices, building or glazing design – and removing excess heat – through opening windows or ventilation louvres, for example, rather than cooling.”

A ll new-build properties will be assessed using the SAP assessment scheme, which determines whether a building complies with the Building Regulations. Tom Owen, Director at SEA, adds: “Until June 2022, all SAP

calculations had overheating within them, but now, the Part O calculations feed directly into the SAPs.

“ The SAP calculation works out the energy performance, but the measures that are used to reduce that heat are directly linked to SAPs – glazing, for example. The G-value of the glass is important – the rate of heat coming through the glazing into the dwelling. The higher the G-value, the more heat comes through into the building. With Part O, we are lowering the G-value to reduce the amount of heat that comes through the glass.

“ This ties into the SAP calculations because the more the heat gain is reduced, the more the heating demand increases and vice versa.”

What does Part O mean for building design?

U nder Part O, there is a stipulation that if a property has ground-floor bedrooms with windows that are being used as part of a ventilation strategy, they need to be secure. Inhabitants need to be able to sleep at night without being too hot, so shutters are needed as a security measure for ground-floor windows that can be opened.

“ The trouble with security grills,” Adam explains, “is that they’re not always in keeping with the overall aesthetic of the building, often being added as an afterthought as a security measure.

“ Tom and I noticed that there were very few attractive-looking shutters on the market, and through conversations with

Keith Owen, Director at OSG Architecture, we started to look at a way to address the challenge of meeting the new Part O requirements whilst maintaining an attractive design.”

A pplying the new regulations to a live project

Keith explains: “We had a client who was developing four larger detached dwellings, based around a farmhouse with a courtyard and a couple of converted barns, to a high-design quality.

“ Due to the sloping nature of the site, we realised we were going to have to come in on the first floor of at least one of the dwellings and then drop down to the ground floor, which led to bedrooms being at the ground-floor level. As such, under Part O, we needed the solar shading to deal with that. At the same time, Part O also stipulates that if you have a groundfloor bedroom, you also need to have a shutter for security reasons.

“ So, we designed a sliding timber shutter that would work not just to meet Part O but also the security aspect of the Building Regulations as well. This ensures that when inhabitants are asleep, windows can be left open, but the shutter can be locked.

“ We designed sliding doors on rails to tie in with the overall barn feel and used these on the ground-floor windows, particularly where they were south facing, to try and limit the amount of glass that was directly affected by the sun, which then helps with the overshadowing calculations.

“ This is one of the first schemes we’ve looked at since the change in regulations where we’ve started by designing elements to deal specifically with those two sections of the regulations at the planning stage.”

Adam comments: “It’s the first time I’ve seen a project approached like this. Every scheme will now need to take these changes into account, where there are ground-floor windows that have the ability to be kept open at night.

“ OSG have come up with a nice design solution specifically to deal with this, which also offers shading during the day.”

In conclusion: Start planning early

“ The point of this work,” Tom explains, “was to get us involved before the project goes into planning rather than after, which is typically when we get involved. It’s much better to get these design features incorporated at the beginning, rather than as an afterthought when it’s gone through planning.

“ Once it’s gone through planning, it can be very costly and time consuming for clients to go back into planning for brise soleil, for example, to mitigate overheating.

“ With this project,” Tom continues, “we’ve taken the bull by the horns. There’s no point in clients burying their heads in the sand – these changes are going to impact all developments that are not currently out of the ground.

“ It’s been great working with Adam and Keith as a team, and hopefully pushes the point across that this is what we’ve got to do as an industry. It’s part of the greater good to secure the safety of environment for future generations.”

To find out more about the specific project and the shutter design solution, contact Keith Owen at OSG Architecture. To discuss SAP calculations, contact Tom Owen at SEA Building Compliance, and for any building control queries, contact Adam Dodd at Harwood Building Control.

www.harwood.uk.com

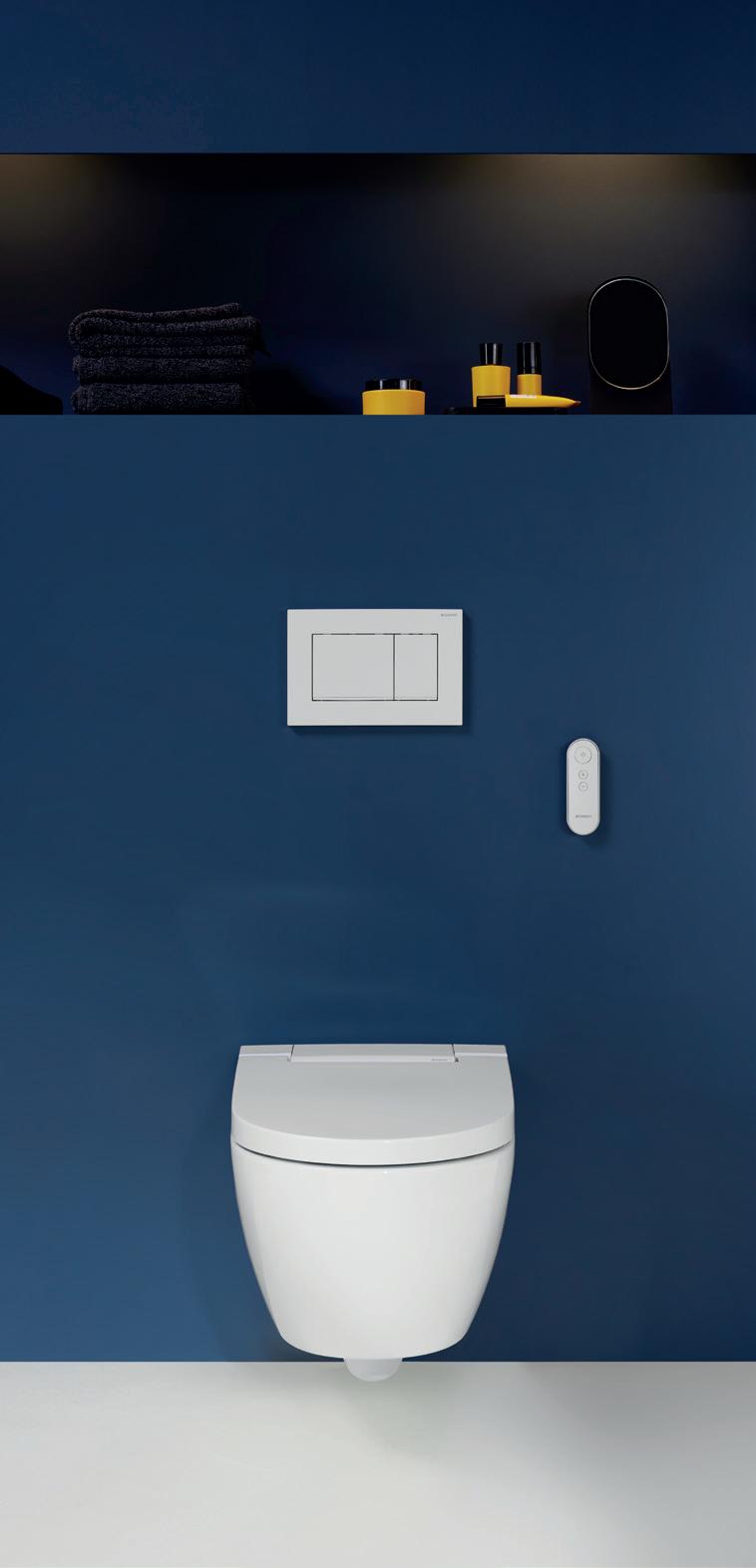

The return-to-work era has prompted many changes in architecture and design, and this includes the workplace bathroom. Workers across the country have become accustomed to the premium comforts in their own homes and if businesses want to ensure as seamless a transition from complete remote working to being in the office more often, office bathrooms must elevate to meet this new standard. Sophie Weston, Head of Marketing at Geberit UK, explains more.

GEBERIT

M ost workers across the country have returned to the office after a radical era of remote working. But, just as bathroom design in the home has adapted to meet new consumer demands in comfort and hygiene, workplace bathroom designs must transform, too.

Elegance has become an expectation for home bathroom design. A new wave of self-care and selfpampering has dictated a change in habits, with people spending more time in their bathrooms in pursuit of relaxation and serenity. As such, the bathroom has transformed into a tranquil place, with new aesthetics required to reflect this new, calm purpose. Sleek designs that are easy on the eye and flexible to individual tastes have dominated and become the goto choice when creating a sense of calm and comfort.

S imultaneously, there has been an upswell of conversation regarding hygiene and sustainability. People are actively looking to reduce their water and energy consumption through smart technologies, water-efficient water systems and the use of more sustainable materials. They are also looking at how innovations in toilets can enhance personal hygiene that doesn’t compromise aesthetics or eco-friendly choices.

W hen supporting a transition from remote working to flexible or office working, it’s important that the office implements some of these trends within its bathrooms to ensure a more seamless change. The perfect combination of these two trends is the introduction of the shower toilet. Despite what some might assume, the inclusion of shower toilets does not have to be an expensive or intimidating implementation, especially with manufacturers, like Geberit, making affordable and straightforward units within the sector.

S hower toilets are bridging the gap between at-home comfort and contentment at the office, making luxury experiences available to the workforce. Shower toilet innovations, like the Geberit AquaClean Alba, are doing it without the premium price.

E levating the bathroom experience is about more than the design, however. Ensuring high levels of personal hygiene is one of the biggest draws of the shower toilet, with new technologies, even in entrylevel models, proving a revitalising cleaning experience. Specifically, with the Geberit AquaClean Alba, original WhirlSpray technology utilises body-temperature water, allowing for the highest standards of personal hygiene after every use.

R egarding sustainability and cleaning, shower toilets are ahead of the curve, with most being designed with water efficiency and ease of washing in mind, ensuring practicality and environmentally-friendly washing. For example, the Geberit AquaClean Alba includes Geberit’s quiet TurboFlush 2.0 system, allowing for optimum cleaning of the pan and an automatic descaling programme for straightforward maintenance. The integrated washing function of shower toilets also decreases the use for toilet paper, reducing waste production. For any office looking to make sustainable changes, the shower toilet must be considered when taking into account the dual reduction in water and paper usage available.

As the bathrooms in our homes change, so do the bathrooms of our office spaces. In this new wave of wellness and enhanced hygiene practices, the shower toilet has become a key product that ensures gentle but thorough cleaning with style. Implementing a shower toilet in the workplace signals to workers that calm, luxurious experiences do not have to be relegated to the home and that experiences that enhance their wellbeing can be found within their 9-5.

M anufacturers, such as Geberit, are creating affordable shower toilets that are meeting the high demands of once-remote workers, and aiding in the transformation of the workplace bathroom. An office is never going to have the complete perks of a private home bathroom, but by prioritising comfort and cleanliness, shower toilets will aid in the smooth transition from home to office by providing a quality experience with every flush.

www.geberit.co.uk

A recent report from the Construction Leadership Council and the Supply Chain Sustainability School urges the Government to focus on modern methods of construction (MMC) to tackle the housing shortage, address the construction skills crisis and deliver environmentally-sustainable housing at scale.

UK

Although, to date, there has been mixed success in the housebuilding industry, MMC has been successfully deployed in the education, healthcare and commercial sectors for both new builds and retrofits, improving efficiency and productivity while reducing costs and carbon emissions.

Here, Graphisoft UK showcases how MMC has helped to deliver a selection of successful projects, using digital technologies to create optimum designs, smooth collaboration and assist precision manufacturing.

Part of the New Model Institute for Technology and Engineering (NMITE), the Centre for Advanced Timber Technology (CATT) is a purpose-built facility designed to demonstrate advanced timber technologies and teach the next generation of engineers.

D esigned by Bond Bryan, the 2500m 2 building comprises five studios, event and breakout spaces, two large workshops and amenities, including a cafe and a dedicated quiet space.

Designed using DfMA (Design for Manufacture and Assembly) principles, the timber and steel panels, frames and beams were manufactured off site before being delivered to site for assembly. The timber frame was also designed so that it can be dismantled and reused in the future.

Aditi Saxena at Bond Bryan was the Project Architect and sustainability lead on the scheme. “The brief was a building of two halves,” she explained. “NMITE wanted to showcase as many ways of using timber as possible, so we combined a number of design approaches within the one building, including the use of offsite manufacturing techniques.”

Using multiple construction techniques meant that the team had to coordinate with two separate structural engineers, one for the steel elements and one for the timber.

Brad Stenson, Architectural Technologist at Bond Bryan, continues: “We incorporated their models directly into Archicad using IFC, which helped us to visualise what we needed to do in one place. This included working with

the supply chain early on to convert 2D drawings so that they could be used directly in the model, saving us lots of design time.

“ There’s so much flexibility within Archicad – it opens a different way of modelling and building. When you model in 3D, everyone in the room understands the design straight away, which helps collaboration and speeds up decision making.”

Designed and built by McAvoy, the Merstham Park School in Surrey provides 900 pupils aged 11 to 16 years with high-quality classrooms, play space, a dance studio and an all-weather sports pitch.

W ith a remit to significantly reduce the operational carbon of the 6850m 2 building, McAvoy followed the ‘Be Lean, Be Clean, Be Green’ energy hierarchy for the Department for Education (DfE) ‘Low Carbon Pathfinder’ project. This approach starts with passive design and a fabric-first approach, reducing energy demand at source through passive measures before implementing efficient systems and renewable technologies.

Designed using Archicad, McAvoy was able to easily compare different iterations for the modular building.

“The flexible and intuitive nature of Archicad meant that we were able to easily create and compare different design solutions,” explains Martin Harvey, Head of Design and Technical Services at McAvoy.

“This was particularly useful during early discussions with planning, where we easily prepared comparative options for cladding, signage and landscaping. This enabled us to submit the final planning proposals with a greater degree of confidence.”

Made from 178 modules, the school was transported to site and craned into place in just six weeks. This kept noise and disruption to the pupils attending the temporary school on the same site to a minimum – and ensured a fast delivery. Only the sports hall was built on site, due to its size.

M cAvoy’s design team worked closely with the DfE’s professional team to maximise energy efficiency and minimise energy loss throughout the build and beyond.

A combination of digital technology and modern methods of construction enabled the reduction of the school’s water demand by more than 30%, operational energy consumption by more than 73% and carbon emissions by almost 60% of the predicted regulated energy use. Low- or zerocarbon technologies also provide up to 44% of peak energy demand of the school.

Two distinctive buildings were renovated by Waugh Thistleton as part of the Sugar House Island development in East London. The first was the old Sugar House, a five-storey masonry warehouse building, that had previously been used for gin production. The second was an old Victorian print warehouse, which was retrofitted with a new internal structure, while retaining the existing Victorian facade.

Waugh Thistleton added three lightweight modern extensions to the Sugar House, which were manufactured off site from CLT. These provide double-height, self-contained workspaces suitable for lightweight industrial uses, such as joinery workshops. Meanwhile, the upper floors were converted into eight duplex apartments. All the internal joisted floors and partitions were also crafted from CLT.

“ We used the renovation filter within Archicad to build on the existing buildings,” explains Chris Kempster, Project Architect at Waugh Thistleton. “The prefabricated timber needed to be spot on, and the combination of Archicad’s renovation tool, the point cloud survey and clash detection meant that it was.”

T he practice retained the original brick shell of the Victorian print warehouse but removed the

roof and craned in a new panelised internal structure. The extensions were constructed from mass timber, with traditional lightweight partitions and space-saving joisted floors within the existing building supported on a steel frame. Fitted with state-of-the-art recording facilities and dance studios, the building is now the new home for music and dance collective East London Dance and UD.

M MC, in its many forms, offers a solution to design and construction for both new builds and retrofits, with digital technologies helping to ensure accuracy and efficiency.

www.graphisoft.com/uk

SOURCE:

https://www.supplychainschool.co.uk/clcmmc-report/

Wallbarn’s M-Tray modular green roof system has been installed on Turing House School in south-west London. As well as expanses of flat roof, M-Tray was also installed between solar panels, a straightforward process thanks to the entire green roof system being fully contained within one-man-lift 500 x 500mm trays, which can be easily be removed for roof deck access or repositioning.

Green roofs are one of the few – if perhaps only – building solutions that are effortlessly eco friendly, adding beautiful and individual finishes to projects and delivering a biodiversity shot in the arm to their immediate environment.

WALLBARN

No t only are they a magnet for insects –importantly, pollinators – green roofs of all sizes can positively impact their locale, turning a visuallyunappealing grey roof into a vibrant oasis that changes colour through the seasons.

A s well as environmental benefits, evidence suggests that looking out onto a green roof helps reduce stress and supports learning. There really is a lot to love about them. But looking beyond their aesthetic appeal, what are the main environmental benefits, and how far can their specification go to help address climate change and its impacts?

A major advantage of green roofs has always been their ability to absorb water and slow the flow of heavy rainfall into drainage systems. As more and more permeable surfaces are lost to building, the likelihood of flooding increases and green roofs can go some way to redressing the balance.

A ccording to the Green Roof Organisation (GRO), which includes them as a ‘source control’ for sustainable drainage systems (SuDS), a living roof with 100mm-deep substrate can reduce stormwater runoff by 45%, holding the moisture in its plants and growing medium before slowly releasing it over time.

A more in-depth insight into green roofs’ impact on water management comes from a study of a 90mm-deep sedum roof, which revealed that, for the first two hours of a day-long rainstorm, it retained 99% of rainfall (0.76mm of rainfall in the first hour, 2.28mm in the second hour). The third hour (3.55mm of rainfall) dropped to 98%, the fourth hour (5.33mm) to 97%, and the fifth hour (almost 12mm) to 95%. Over the next 19 hours, rainfall averaged almost 23mm/hour, classed as ‘heavy’ in UK terms.

U p to hour nine, the green roof retained more than 40% of the precipitation. From hours 10 to 11, this figure was more than 30%, dropping into the 20%+ band from hours 12 to 22. For hours 23 and 24, rainwater retention fell to 19%. Over

the course of the 24-hour storm, the green roof retained, on average, 44% of the precipitation (67% for the first 12 hours), a phenomenal impact.

The ambient air temperature of urban areas can be far warmer than less built-up, populated locations – up to 12°C according to GRO – with buildings and hard surfaces storing heat during the day and radiating it back into the atmosphere at night. Instead of this, the vegetation on a green roof absorbs the sun’s energy and heat and turns it into plant growth. Green roofs can deliver surface temperatures 30 to 40% cooler than standard roofs, helping lower the temperature around buildings through the evaporative cooling of vegetation (evapotranspiration). Installing green roofs also reduces the number of ‘grey’ roofs and their impact on the UHI.

Green roofs can lower heat flux from roof to building by up to 72%. The evaporative cooling effect of the vegetation, combined with the thermal mass of the green roof, can reduce demand for air conditioning, delivering both a cost saving and environmental benefit.

B ecause a green roof covers the waterproofing membrane, reducing UV degradation/pest interaction and protecting it from temperature fluctuations/atmospheric pressures, a whole system life of 40+ years can be expected from professionallyinstalled, high-quality systems.

S edum and other green roof plants absorb soot and other pollutant particles, helping improve ambient air quality in the immediate vicinity of the building.

A n extensive green roof can insulate up to 40 dB, and an intensive green roof up to 50 dB.

The modularity, ease of installation and futureproofing ability of Wallbarn’s M-Tray green roof system makes it perfect for a wide range of projects

S olar gain reduction