For fire resistance and protection of people and property

Multifunctionality in fire protection

PYRAN® S is a pre-stressed, monolithic borosilicate single pane safety glass in accordance with EN 13024-1.

As a component in fire-resistant glazing that meets the requirements of resistance classes E 30, E 60, E 90 and E 120, it has proven its outstanding optical and mechanical characteristics over the years in a wide variety of buildings.

Areas of application

PYRAN® has been internationally approved and ideally suited for:

• Facades

• Partition walls

• Skylights and rooflights

• Doors

• Roofs

• Smoke screens

• lift door glazing

• lift shaft glazing

Facts

• Higher ability to withstand temperature differentials: In comparison to soda-lime glass, tempered borosilicate glass can better withstand temperature differentials and can therefore be glazed with normal edge covers (20±2 mm).

• Higher softening temperature: Because the glass is selfsupporting for more than 30 minutes, large panes and simple frame constructions are now possible.

• Higher viscosity: The glass flow rate is low due to the high viscosity and durability of borosilicate glass, so with more edge cover, greater fire resistance times in excess of 90 minutes can be achieved.

• NiS crystals do not form: Due to the chemical composition of borosilicate glass, nickel sulphide crystals cannot form. Spontaneous glass fracture due to embedded NiS crystals cannot happen with PYRAN®.

Further information is available from our sales and technical offices or visit www.firmanglass.com

Tel: 01708 374534 Email: Pyran@firmanglass.com

Firman Glass, 19 Bates Road, Harold Wood, Romford, Essex RM3 0JH

FUTURE CONSTRUCTOR & ARCHITECT MAGAZINE

EDITOR IAL

Rebecca Kemp rebecca@redhutmedia.com

PRINT & DIGITAL ADVERTISING

Sam Ball sam@redhutmedia.com

Jim Moore jim@redhutmedia.com

PRINT DESIGN MANAGER

Jack Witcomb jack@redhutmedia.com

DIGITAL DESIGN MANAGER

Matt Morse matt@redhutmedia.com

ACCOUNTS/ CREDIT CONTROL

Rachel Pike accounts@redhutmedia.com

PUBLISHER

Sam Ball sam@redhutmedia.com

2, The Old Stable Block, Crescent Road, Faversham, Kent, ME13 7GU Tel: 01795 515288 Rebecca

Now that we’re in October, many establishments are gearing up for the festive season, and transport facilities are no exception. From scheduling and capacity planning to staffing, maintenance and security, transport providers are working to ensure they’re well-prepared to handle the surge in passengers and provide a seamless travel experience. However, the initial design and accessibility of these facilities also play a crucial role in delivering that smooth experience.

In this issue, David Saunders, Head of Stannah’s Major Projects Division, explains the importance of choosing the right lift solution for transport facilities and public infrastructure. Understanding the distinctions between different types of lifts is essential, as each one serves a unique purpose and meets specific project requirements. Turn to page 22 for his full insights.

Meanwhile, on page 12 , we spotlight Belfast’s newest transport hub, Grand Central Station. Designed by John McAslan + Partners’ Belfast design studio in collaboration with Arup and Juno for Translink, this project is a key part of Belfast’s ongoing urban regeneration. The station has already welcomed its first passengers, with bus services now operating from the new multi-modal terminus. Once the rail platforms open later this month, it will become the largest integrated transport facility on the island of Ireland.

Elsewhere in this issue, Chris Anderson, Technical Manager at Ansell Lighting, delves into the benefits of smart lighting technology in commercial settings; Ben Hancock, Managing Director at Oscar Acoustics, addresses some of the most frequently asked questions about creating the ideal acoustic environment; and Ruth Evans, Associate at CPMG Architects, discusses the principles of dementia-friendly design.

I hope you enjoy this issue. Don’t forget, you can also access the magazine’s features, product news and supplier information on FC&A’s user-friendly and engaging website. Fully responsive, the website allows you to read all the latest stories on-the-go either on your phone or tablet. Simply search www.fca-magazine.com.

Attenborough Line project by Able Partners. Bill Webb, Architect and Co-Founder of Able Partners, talks to FC&A about his journey from art student to architectural innovator. SEE PAGE 08. REBECCA KEMP

sweeps, curves, level changes, windposts, closer-links, balcony protectors, threshold isolators, adjustable height integrators

COMPLY WITH NHBC 2024 DIRECTIVE: At complicated junctions preformed cavity trays must be used

COMPLY WITH LABC 2024 DIRECTIVE: Trays must rise 150mm and be self-supporting or fully supported

The Cavity Trays Helpdesk – your route to compliancy and consistency in construction

The widest range from the longest-established cavity tray company with over 100 years of proven specialism.

VOICE OF THE INDUSTRY:

Jake Stephens, Technical Manager at HiiLIFE, shares insights on how luxury technology can elevate the living experience in shared accommodations.

LEGAL & BUSINESS:

Elle Clarke, PPE and Workwear Manager at Milwaukee, sheds light on the hidden risks of customising PPE and emphasises the crucial need to use equipment as intended for optimal safety and compliance.

BUILD FOCUS: TRANSPORT FACILITIES:

LANDSCAPING, EXTERNAL WORKS & GROUNDWORKS:

ACOUSTICS & SOUNDPROOFING:

12 14

De Matos Ryan and Dorothée Meilichzon (CHZON) have unveiled a stunning new pavilion at Cowley Manor Experimental, blending history with modern elegance. 20 18 24 28 32 34 30

From platform and passenger lifts to escalators and walkways, David Saunders, Head of Stannah's Major Projects Division, breaks down the key factors when choosing the right lift solution for transport facilities.

David Hedley, Technical Sales Engineer at Mainmark UK, investigates how modern underpinning methods like grout and resin injection are transforming foundation repair.

Ben Hancock, Managing Director at Oscar Acoustics, answers your top FAQs on overcoming noise challenges in architectural design.

LIGHTING & ELECTRICALS:

Chris Anderson, Technical Manager at Ansell Lighting, explores how smart lighting creates dynamic, sustainable and adaptable environments for today's workspaces.

UNIVERSAL DESIGN & AGE-INCLUSIVE ARCHITECTURE:

Ruth Evans, Associate at CPMG, examines the crucial role of dementia-friendly design in healthcare architecture.

SITE PLANNING & URBAN DESIGN:

Should grey belt land with heritage assets be reconsidered for development? Dr Emma Wells of SLR Consulting argues for a thoughtful approach to preserving history while meeting housing targets.

TECH INSIGHT: WATERPROOFING:

David Naylor from Schlüter Systems explains how high-quality materials and holistic waterproofing solutions can protect your bathroom and home from moisture trouble. 26 22

BELFAST GRAND CENTRAL STATION, JOHN MCASLAN + PARTNERS:

Belfast’s Grand Central Station, designed by John McAslan + Partners, has opened its doors, marking a new era for public transport in Northern Ireland.

COWLEY MANOR EXPERIMENTAL, DE MATOS RYAN:

“Changes of direction of a cavity tray or interfaces with other elements in the cavity are more complicated than simple joints and the design should be provided, and preformed cavity trays used.”

Satisfy NHBC technical requirements first time, every time. 100 years of proven specialism from the longest-established company designing and manufacturing cavity trays and flashings. The Cavity Trays Helpdesk – your route to compliancy and consistency in construction

get a quick quote today ... the UK’s leading independent glass processor

Barratt David Wilson Homes has announced it will deliver on plans for the redevelopment of Fort Halstead – which received planning permission from Sevenoaks District Council on 1st December 2023. After years of public consultation prior to the application being consented, the plans for the historic site –previously occupied by The Defence, Science and Technology Laboratory – will see it transformed into a vibrant 635-home community, of which 20% will be affordable, and existing and new employment space delivering jobs. Other key benefits within the planning permission include a new ‘village centre’, which will host a range of different facilities, including shops and community buildings.

Stephen George + Partners (SGP), in conjunction with AHR, has submitted plans for the £20m redevelopment of Huddersfield’s bus station, fronted by a sweeping 120m-long glulam, green roof and solar PV canopy. The bus station transformation is a partnership between Kirklees Metropolitan Borough Council and West Yorkshire Combined Authority to create an innovative gateway to the revitalised town centre along with enhanced passenger facilities. SGP’s design for the canopy and the public realm beneath it was developed through extensive discussions with clients, the local authority and other stakeholders.

FC&A ROUNDS UP THE LATEST INDUSTRY NEWS AND UPDATES.

Holmes Miller has been working with the Dundee Football Club, LJRH and wider team of consultants to shape up the proposals for a new stadium at Camperdown, Dundee, in parallel with a planning permission in principle (PPiP) application.

As well as a new 12,500-capacity home for Dundee FC, the City of Discovery is set to gain a new sustainable, allelectric multifunctional venue that can also be used for civic, entertainment, business and community events.

In line with FIFA’s Green Goals initiative and the UN’s Sustainable Development Goals, the stadium is designed to minimise embodied and operational carbon. Sustainable features include low-energy LED floodlights and screens, photovoltaic panels, natural ventilation, 100% recyclable seating, a ‘green roof’ to promote biodiversity and rainwater reharvesting. Stadium design features, such as a safe standing tribune, beer hall and high-res video screens, will appeal to Dundee FC fans.

The stadium is part of a wider masterplan that is currently awaiting planning permission

in principle, with a decision set to be made by Dundee City Council this season.

This also includes a 140-room lifestyle hotel with health and wellbeing facilities, a carbon-neutral residential development and a city crematorium, as well as the potential refurbishment and expansion of the existing Dundee ICE Arena.

Net-zero design underpins the masterplan, which will promote the reduction of both embodied and operational carbon through building specification, construction and operation.

To encourage green travel, the new destination will be served by a dedicated e-bus terminal, cycle hub and EV charging facilities, all set within a high-quality public realm.

w ww.holmesmiller.com

The latest appointments from the construction and architectural industries.

CPMG has expanded its teams in London, Birmingham and Nottingham. Joining the experienced collective at CPMG’s London studio, Amit Patel arrives as a Part 1 Architectural Assistant, after completing his placement as an Architectural Assistant. Alongside Amit is Architectural Assistant Student Isaac Ma, who has joined the team while studying at the University of Bath. Strengthening CPMG’s Nottingham headquarters, Architectural Assistant Ieuan Thomas and Part 1 Architectural Student Elliot Tiney join the practice to continue their respective journeys in the sector. With more than eight years’ experience in the industry, Matthew Drewitt joins the Nottingham team as an Architect, with core knowledge in areas such as residential, civic, cultural, office and leisure sectors.

Howes Percival has recruited Partner Piet van Gelder as the firm’s first-ever Head of Construction to meet the growing demand for construction law services. Piet’s appointment follows a period of sustained growth for Howes Percival’s wider real estate and development team, which is nationally recognised and has advised on some of the largest development projects regionally and beyond. Piet is a specialist Construction and Engineering Lawyer who advises clients in the construction, engineering and renewable energy sectors, and in respect of compliance with the new regime under the Building Safety Act. Piet has experience over the whole lifecycle of projects from compliance with Building Regulations, procurement and resolving commercial issues.

Leading UK planning and development consultancy Lichfields has announced the appointment of an Associate Director as it continues to expand its operations in the capital. Andrea MacGregor-Barbour has joined Lichfields and is based in the company’s London office. She will work closely with Ian Anderson, Senior Director, and the rest of the team to support and develop the company’s portfolio of commercial projects. She joins from Marks & Spencer (M&S), where she spent 17 years as Town Planning Manager, playing a pivotal role in the strategic reshaping of the store estate and leading the planning and development programme across the UK. At Lichfields, she will be advising key clients, including David Lloyd Leisure and McDonald’s.

Proposals for the development of a landmark 251-bed aparthotel offering high-quality accommodation and public facilities in central Manchester have been approved by Manchester City Council. Bennetts Associates was appointed as architect and principal designer for the scheme, which encompasses the Grade II-Listed former Union Bank building and an adjacent ‘gap site’, a vacant and derelict plot of land that currently has an adverse visual impact on the streetscape. The site is minutes away from Piccadilly Train Station and is situated on a prominent corner at the heart of the city centre, bound by Piccadilly, Gore Street and Chatham Street.

McLaren Construction (Midlands and North) has announced the start of works on a significant new project, B4, at one of the UK’s largest and busiest airports. Valued at £12,844,105.00, the development of the World Freight Terminal at Manchester Airport marks a crucial addition to its infrastructure. Delivered on behalf of Columbia Threadneedle Investments, the project follows a previous phase of works for the client at the World Freight Terminal development to the west of Manchester Airport, which concentrated on the build of a 100,000ft 2 warehouse sub-divided into three commercial units, with internal office spaces.

In this Q&A, Bill Webb, Architect and Co-Founder of Able Partners, reflects on his journey from art student to architectural innovator. Bill discusses the pivotal moments that shaped his career, the inspirations behind his designs and his insights into the architectural world. Discover how his unique experiences have influenced his approach to creating impactful spaces.

Tell us about your career journey. How did you get started in the field of architecture? It always seems to start in a fantastic school art department, doesn’t it? Developing photographs, screen printing, casting plaster and Jesmonite models, and learning about the history of art.

I had a place to study fine art but spent the summer before university as an assistant to an Architect called Anthony Blee. As we travelled to planning enquiries and construction sites, Anthony would tell stories about the characters and gossip behind projects, and I saw architecture in a new way. Cities were about people, and it took collaboration, hard work and tenacity to create them. Architecture has an important social function, and I wanted to be part of that. I changed my degree last minute and am delighted that I did!

Were there any pivotal moments or experiences that solidified your decision to pursue a career in architecture and design?

My first job out of university was in Hong Kong. Fast, dense, intense, filled with modern architecture and incredibly fun. I was 22, working hard by day and exploring the city at night. This is probably where I became a skyscraper geek, eating my lunch in the shadow of Fosters’ HSBC and I.M. Pei’s Bank of China and getting the ferry home to Tsim Sha Tsui, where I could see the whole skyline.

If you hadn’t followed your passion for being an architect, what other career path would you have pursued?

I’m optimistic about cities and their role in addressing climate change, inequality, longevity and other big challenges we face. At Able Partners, we conceive and deliver ideas

that improve cities and the experience of being in them. If I wasn’t doing this as an architect, I would have liked to do it in Government.

Who has been your greatest influence and source of inspiration?

Richard Rogers and Norman Foster. In my artobsessed adolescence, ‘high tech’ was in full flow. Rogers was the unofficial city architect of London under Ken Livingston, and big ideas were being delivered in the can-do attitude of the 1990s. The Lloyds building, Millennium Dome, Terminal 5, Channel 4, The Gherkin, City Hall, Millennium Bridge – their designs are the backdrop to the London I grew up in.

What’s been the most memorable project you’ve worked on?

I spent 10 years at Make Architects, a great London practice designing large buildings. In my first four years, I worked on 5 Broadgate, a vast Swiss bank located next to Broadgate Circle. It was controversial, mainly because it was the first time a major office building was not clad in glass. It looked somewhat alien to its surroundings, but advanced in performance and sustainability. To work with a world-class team on something ahead of its time and weather the ensuing storm was good preparation for my career.

Can you share a personal anecdote or experience that taught you a valuable lesson about being an architect?

When I finished my Part 2, there weren’t many jobs available, and I managed to get a role at a small London practice. Most friends had gone to impressive firms, but I learned a lot about managing clients, basic accounting and project management.

When I co-founded Able Partners after working in a big practice, I quickly realised what valuable insight that job gave me, so my lesson was that all experience has meaning – no matter how irrelevant it may feel at the time.

Could you walk us through a typical workday in your current role?

Our studio is in Fitzrovia, a wonderful corner of London, full of creative industries and interesting people. Once I’ve cycled in from Hackney, I might meet a client or partner for breakfast. We’re currently growing and interviewing new team members, so I like to do this first thing when I’m feeling bright.

We’re currently working on three large office refurbishment projects in central London, all within a 15-minute walk of the office, so may have workshops on site with various project teams.

My Co-Founder, Ben Stuart, and I try to have lunch to discuss our current ideas. We have similar design tastes and passions but different skills, so we like to stress test our solutions against each other.

In the afternoon, we work with colleagues on the project of the day; be that project bids, competitions, concept designs, reviewing Stage 4 delivery information or technical co-ordination.

We’re a RIBA chartered practice and are members of the British Council of Offices along with several other bodies, so we are often networking or at talks in the evenings.

What is your favourite building and why?

The Leadenhall Building by Roger Stirk Harbour Partners. Buildings in central London are subject to the London View Management Framework and are often left with awkward ‘jelly mould’ spaces within which they can build. The same constraints were true for this building, whose tapered shape avoids clashing with the critical views of St Paul’s, but Rogers then produced the perfect diagram of a tall building. The side core leaves a wide open floorplate with incredible views, reducing in size as it reaches into the sky. The structure nodes out flawlessly, and the ground plane sets a new standard for how skyscrapers should terminate on the ground and integrate into the city.

In your opinion, who is the greatest architectural mastermind of our time?

Sir Norman Foster. To be on the avantgarde of office design for so long is unparalleled. He has continued to outperform his industry for 30 years, which is incredible. There is no architectural field to which he hasn’t made a meaningful contribution.

If you were hosting a dinner party to discuss architecture and design, and you could invite three individuals, either from the past or the present, who would you choose to join your conversation?

Rem Koolhaas. He was the ultimate big thinker who felt architects should not be afraid to take on large, ambitious projects to meet the needs of modern society. I lived opposite his CCTV building in Beijing

for years and thought of him when looking out the window.

Ricardo Bofill. He is incredibly brave in the way he mixes classical and surreal elements to create work unlike anyone else.

Zaha Hadid. She changed the conversation about architecture for the whole world. The rise of parametricism and what could physically be done with buildings will inspire people for years to come.

Looking ahead, what exciting projects or initiatives can we anticipate from you in the coming year?

We spent the first half of our careers building new, sustainable megabuildings and it seems the second half will be spent reimagining existing buildings.

We’re working internationally on Hangar 21 in Trieste, having won an open ideas competition to transform a 100 x 30m three-storey grain store into a major innovation hub on the city’s port. We work with incredible stakeholders there and look forward to seeing the project come to fruition.

In the immediate future, we’ve been shortlisted by the LFA’s Reimagine London competition and hope to become finalists for our Attenborough Line entry this September. Our idea involves reimagining London’s transport priorities by lifting mass transit off the ground, with cable cars running above green space and a pedestrian superhighway to modernise infrastructure. If you’d like to vote for us, visit the link here: https://nla.london/ news/25-ideas-revealed-on-reimaginelondon-shortlist

SCONNEX® REDUCES THE ENERGY LOSS AT WALLS AND COLUMNS.

This innovative product range represents a breakthrough to a previously unsolved problem in energy-e cient construction. Schöck Sconnex® relies on tried and tested technology, reduces vertical thermal bridges and at the same time creates aesthetic and economic advantages. www.schoeck.com/en-gb/sconnex

STRIVING TO BE THE ‘BEST IN CLASS’ IN ALL WE DO

Sidey manufacture & install more windows in Scotland than anyone else in the marketplace.

Visit: sidey.co.uk

Tel: 01738 634 803

Email: info@sidey.co.uk

With recent reports of an upturn in retail construction showing a 21% increase in quarter two compared to the same period last year, this is not only good news for the sector but also for shoppers, as supermarkets and other retailers invest in attracting customers and responding to online competition with updated and more attractive shopping experiences.

ENCASEMENT

Th e purchasing environment is a key aspect of the retail experience and the importance of combining practicality with aesthetics is essential. Decorative column casings and building linings are key components in this process, as they provide practical solutions for concealing interior and exterior structural steelwork while adding to a building’s aesthetics.

U sed on both new-build and refurbishment schemes, Encasement’s Verta column casings and Vecta budling

linings ranges offer a wide choice of materials and finish options for exterior or interior applications and are installed in a diverse range of retail projects for wellknown brands, including Tesco, Porsche, ASDA, Kia Motors, Next and Greggs.

C irca and Quadra casings are manufactured from pre-formed MDF and plywood, respectively, while the Forma range is fabricated from metal. Alongside

these are Polyma GRP (glass-reinforced polymer) and Gypra glass-reinforced gypsum (GRG) options, as well as Metza casings, which are a specialised solution designed to provide fire protection for mezzanine floor supporting columns.

W here casings are needed for interior use only, Circa and Quadra allow circular, square and rectangular profiles to be specified. They also provide a wide range of finish options, with the most popular being decorative laminates, as they are resistant to scuffs and scratches and can be specified in plain colours, wood grain and metallics, as well as textured finishes.

W hile every Encasement column casing type is suitable for interior use, both the Forma and Polyma ranges are also widely used for exterior retail projects, such as storefronts, canopy supports or as a feature on retail park units, due to their durability and inherent weather resistance.

Available in aluminium or stainless steel, Forma casings can be specified in circular, square, rectangular or hexagonal forms, as well as bespoke shapes. A wide choice of finishes is available, including PPC options in any RAL colour, as well as brushed, anodised, embossed or textured finishes, such as Rimex.

Strength, durability and colour choice are also features of the Polyma GRP range, which can be key considerations in retail environments. As Polyma GRP casings are produced using moulds, this manufacturing process allows a high degree of design flexibility, with shape, size and colour options all open to specification to meet bespoke project requirements, as well as standard profile options.

A longside Encasement’s column casings, the Vecta building lining range provides high-quality solutions for interior wall linings, bulkheads, fascias, soffits and reveals, which are already installed on a range of projects, including major brands, such as Tesco, Prêt a Manger, Mini and Greggs.

D epending on the application, the Vecta range can be specified in a choice of materials and finishes. High-level bulkheads, such as the 100m-long solution at Tesco in Yardley, Birmingham, use PPC aluminium, although they can also be manufactured from stainless steel, as well as GRP or GRG, which can help save weight, although consideration should be given to the materials’ suitability for each application.

B y offering the Vecta column casing range and the Vecta building linings system, retail construction specifiers can source a range of specialised products from a single company.

Belfast Grand Central Station has welcomed its first passengers, with bus services now operating from the new multi-modal terminus, set to be the largest integrated transport facility on the island of Ireland when the rail platforms open later this month. The station sets a new standard for the forthcoming renewal of public transport infrastructure and connectivity across the island.

Th e integrated transport hub has been designed by John McAslan + Partners' Belfast design studio in collaboration with Arup and Juno for Translink as part of Belfast’s ongoing urban regeneration, providing not only state-of-the-art transit facilities but also a welcoming new front door to the city.

I nspired by the city’s rich industrial heritage, Belfast Grand Central Station has replaced the current facilities at Europa bus centre and Great Victoria Street railway stations and is expected to cater for around 20 million passenger journeys annually with flexibility for future growth. Configured around a 7500m 2 station concourse, over 10 times larger than the facilities it replaces, with a further 2000m 2 of retail. Beyond transport, Grand Central Station is intended to act as a prime location for people to meet, shop, dine and socialise.

L ocated on a nine-hectare site of former railway yards and bounded by Durham Street and Grosvenor Road, the expressed portalised design evokes engineering-led structures which typify railway architecture, such as repeating gantries and the scale of Victorian railway termini. It is arranged around an efficient step-free single level with bus operations to one side and rail platforms on the other.

T he station’s design also draws inspiration from the former linen mills that characterised the development of the local area, echoing the oversized, repeating forms of industrial architecture with a striking, exaggerated sawtooth roof and exposed truss structure reminiscent of the original Great Victoria Street station that was demolished in the 1970s. Large glazed northlights span the unified amenities and introduce natural light to the concourse below.

A n architecturally-impactful colonnade wraps around the front-facing elevations, with a dramatic swept soffit signifying the entrances to the station and welcoming passengers. At night, the soffit is washed with light, illuminating the station and further animating the surrounding public realm. The main entrance will be via Saltwater Square when it opens next year.

I nside, column numbers have been kept to a minimum, with large truss spans to create an experience of openness with clear sightlines, making wayfinding intuitive. The Translink bus and rail operations, both back-ofhouse and public-facing, are brought together around a central spine and lined with glazed panels and richlypolished plaster, activating its perimeter

with passenger facilities, including retail, restrooms and a customer support office.

S ustainability has been an integral part of the design throughout. Passive ventilation and considered orientation minimise transport fumes within the station, with actuated louvres incorporated strategically to exhaust while providing comfortable interior conditions. The southerly aspect of the sawtooth roof supports photovoltaic panels, and provision has been built in for any further electrification of the transport network. Wherever possible, local materials have been sourced to minimise carbon mileage, with the superstructure fabricated less than 20 miles from the site.

Ross Harrison, Associate Director at John McAslan + Partners' Belfast design studio, says: “Designed to cater for bus and rail travel under one roof, our collaboration on Belfast Grand Central Station with Arup for Translink has delivered a customercentred station on time, a real achievement for transport projects. More than that, it delivers a civic function – providing a forward-looking first impression of Belfast that is symbolic of the changing direction of the city. Globally, modern public transport hubs are increasingly used in this way, and it is timely that Belfast should unveil this gateway on the cusp of Ireland’s wider rail review.”

C olin Bennie, Director of Transport and Infrastructure at John McAslan + Partners, adds: “Over the years, our practice has worked on a number of major transport projects in London, Sydney and New York. We’re delighted to build on this experience in Belfast and are excited to see how transport architecture is increasingly considered the defining feature of a modern city that works for everyone. This is certainly what we have sought to achieve for Belfast Grand Central Station.”

C hris Caves, Director at Arup, comments: “The opening of the bus element at Belfast Grand Central Station is a key milestone for Northern Ireland. This state-of-the-art public transport hub will not only enhance connectivity across the region but also drive sustainable growth for the local economy. It’s a proud moment for all involved, and we’re thrilled to have played such a significant part in this flagship project, from the outset, in delivering such a transformative piece of infrastructure.”

C hris Conway, Translink's CEO, concludes: “We are excited to be opening this modern major transport interchange this week. With advanced customer features and integrated networks, it offers a huge opportunity to grow public transport, driving

economic development across the region and playing a major part in tackling the climate emergency. That means a betterconnected future for people and communities for generations to come. I would like to thank the minister and his department for the funding and the wider NI executive for their support in designating this as a flagship project. I would also like to thank the Translink team and the contractors for their commitment and dedication to get this project to this key stage.”

Client: Translink and the Department for Infrastructure

Architect and masterplanner: John McAslan + Partners

Engineer: Arup

Planning: Juno

Contractor: Farrans Sacyr

De Matos Ryan has collaborated with renowned Interior Designer Dorothée Meilichzon (CHZON) to create a new pavilion building for Cowley Manor

De Matos Ryan and Dorothée Meilichzon (CHZON) have unveiled a stunning new pavilion at Cowley Manor Experimental, blending history with modern elegance. Inspired by the site’s connection to Alice in Wonderland, this stone-clad, timberframed extension revives the spirit of a long-lost ballroom, offering luxurious guest accommodations amidst the enchanting Cotswolds landscape.

The new, stone-clad, internally timber-framed pavilion houses five generous guest rooms with a variety of interconnected family suite options. The extension reinstates a refined but striking masonry pavilion on the site of a long-lost former grand ballroom from 1900.

Sat within 55 acres of Cotswolds countryside, Cowley Manor Experimental is home to 36 bedrooms and suites, the awardwinning C-Side spa, restaurant (overseen by Chef Patron Jackson Boxer), Experimental Cocktail Club Cotswolds Bar, lounge, library and plentiful living rooms.

First constructed in 1695, the land was once owned by Edward the Confessor and the property designed by the renowned R.A. Briggs. It is also widely recognised as the inspiration for Lewis Caroll’s Alice in Wonderland. However, like many extraordinary country houses, Cowley Manor fell into institutional use during the war. It was revitalised as a leading country hotel in 1999 in what was De Matos Ryan’s first significant commission. The bedroom pavilion is a unique opportunity for the practice to continue its sensitive

design-led development of the estate, described by Historic England as “one of England’s best heritageled development schemes. It shows that with imagination and skill, old buildings can be given a new and positive future”.

Once the idyllic rural retreat of the Horlick family of malted drink fame and fortune, the Cowley Manor estate was purchased during the Art Deco era by the young HeberPercy and his American wife, who set about ‘modernising’ the house. While glass-walled bathrooms in the ‘modern’ style were added, most of the decorated ceilings, timber panelling, carvings and statuary were removed in an act that might now be considered unthinkable vandalism. The demolition of the ballroom gave way to a new outdoor swimming pool terrace, which the new pavilion now elegantly occupies.

Typical of De Matos Ryan’s work, the new pavilion playfully borrows from the past in order to create something meaningful for the future. Its arched openings and scalloped stone bays present a contemporary but respectful reinterpretation of the original Italianate arched and pilastered frontage designed by R.A. Briggs. The pavilion has a clear modern identity distinct from the body of the main house, yet suitably fitting, re-establishing a bookend to the main house and terrace.

M inimising environmental impact is central to all De Matos Ryan projects. This was a key driver in making material choices for the pavilion. Whilst dressed, carved stone was a relatively straightforward

contextual decision externally, the opportunity to reimagine historic timber linings internally presented the conceptual conditions to explore an exceptionally low-carbon typology of both materials brought together. The Cotswold stone was quarried locally from only three miles away. Aside from its cutting, it is, in effect, a ready-made, low-energy material that is self-finished and self-supporting when forming an external skin. Its ability to nowadays be primarily shaped by machine is almost certainly the envy of the original stonemasons.

T he internal timber frame structure is sustainablysourced, UK-grown Douglas fir. It offers the opportunity to engage an elemental constructional methodology that ‘looks like the way it is built’, using standard sizes and traditional carpentry techniques in a modern manner. Double-member columns clamp and bolt together about purlins, which then support joist decks. Ends are cut and notched simply to resolve junctions elegantly.

A cavity fire stopping solution suitable for vertical and horizontal installation.

Tested for use with steel frame substrate, composite panel and masonry applications

120 minutes integrity and insulation in cavities up to 600mm*

Tested to BS EN 1366-4:2021

Tested to curtain wall standard BS EN 1364-4:2014

Suitable for ‘installation from below’

W ithin the inner Douglas fir wall and roof build ups, Magply is employed to create a fire barrier, which is lined internally with an expressed sarking layer of Garnica reinforced maple ply. Subtle distinctions between these timber species are blurred by a tinted Envirograf intumescent treatment, which renders the whole in a calm, offwhite finish.

O ther sustainability measures include the use of air-source heat pumps providing heating and hot water, high levels of insulation and airtightness above Building Regulations, a natural ventilation strategy by means of clerestory windows. In addition, the building supports local biodiversity with a planted sedum flat roof.

D irect access and connection to the unique Grade II*-Listed gardens is provided via the arched doorways of the front elevation. A first-floor terrace provides an elevated platform from which to enjoy the landscape in the same way as the primary first-floor bedrooms of the original main house.

T he physical connection between old and new continues and builds from De Matos Ryan’s previous interventions at Cowley Manor Experimental, where juxtaposition is carefully handled. The pavilion is read as a secondary detached building volume that is respectful of its host and context.

T he reimagined Cowley Manor Experimental continues to embody a timeless contemporary style, as it embarks on an exciting new chapter in its history

FACT FILE:

Architect: De Matos Ryan

Interior design: Dorothée Meilichzon (CHZON)

Structure: Price & Myers

M&E services: P3r Engineers

QS: Monaghans

Contractor: CJN Concept

Timber structure: Timber Workshop

Stonemason: Farmington

GEA: 285m2

GIA: 236m2

Completed: July 2024

Photography: Hufton + Crow/ Patrick Locqueneux

As co-living models, student housing and other forms of communal living grow in popularity, property developers must respond to consumer demands. Many students and renters now seek a residence that can contribute to their social life, elevate living experiences and offer a sense of community, all while still meeting the functional needs of a home.

Th oughtfully integrated technology, especially luxury home tech, can enhance the appeal of communal spaces and bring residents together. Whether it’s a lounge, kitchen, gym or cinema room, these areas offer residents an extra place to call home and foster social interactions with one another. Technology provides entertainment and makes communal areas more comfortable and functional, therefore, encouraging frequent use. By allowing those who live in the building a high level of control over their living and technology preferences, it offers an enhanced sense of ownership and makes the accommodation feel like a true home.

Residents’ bedrooms can be on the smaller side compared to privatelyrented or owned homes, which makes the availability of extra rooms a key selling point of these properties. For instance, cinema rooms have grown in popularity for many co-living environments. A welldesigned cinema room can turn a standard space into a hub of social activity where people come together for movie nights, sports viewings or streamed concerts.

A n example of how cinema rooms elevate the communal living experience is Guilden Village, a student housing project HiiLIFE worked on in Guildford. It now features a 5.1 Sonance surround sound system and Epson projector with high brightness 4K video playback, which residents control via Control4 10 " touch panels. By implementing this technology, we transformed an otherwise basic communal area into a focal point for residents to enjoy evening entertainment outside of their bedrooms.

S imilarly at Guilden Village, a sky lounge, terrace and games room were installed that feature mini golf, outdoor TVs, video games and arcade machines. Providing extra spaces and entertainment value creates a point of difference against competitors, as Guilden Village offers more activities for residents to enjoy.

C omfort is another major factor in transforming the living experience. One way of achieving this is by introducing climate control technology. Advanced air conditioning systems allow residents complete control over their environment to

JAKE STEPHENS IS THE TECHNICAL MANAGER AT HIILIFE, A BESPOKE TECHNOLOGY PROVIDER FOR THE CONSTRUCTION, HOSPITALITY AND LEISURE SECTORS

HIILIFE

ensure it remains comfortable throughout the year. In the Guilden Village project, we installed Samsung air conditioning in every single room, providing residents with optimal comfort and flexibility.

E levating residents’ living experience in shared accommodation involves far more than simply providing additional communal areas; it’s about maximising and enhancing the space of each room, including smaller, more intimate spaces. One could equip a private dining room with high-end kitchen appliances, mood lighting and a seamless AV system that allows residents to host memorable dinner parties, celebrations or other social events. Adopting this level of design flexibility makes hosting gatherings a more attractive proposition, inviting collaboration and relaxation.

T he most effective use of tech in shared accommodation is when it works in the background, subtly shaping the atmosphere of a space. For example, one of our previous installations for Dandi Living involved integrating audio systems and hidden speakers in shared lounges and outdoor terraces. These audio

systems are designed to play birdsong and ambient sounds that are rarely found in cityscapes, creating welcoming environments that residents naturally want to use.

T he sound quality is crucial for outside spaces: Instead of one large, overpowering speaker, multiple smaller speakers can provide a balanced, highquality audio experience that fills the space without dominating it. Ambient lighting, whether inside a lounge or along an outdoor pathway, also plays a role in setting the tone of a space, improving the welcoming atmosphere and encouraging residents to spend more time there.

I nstalling hidden audio systems and atmospheric lighting is particularly effective in spaces designed for relaxation. Lounges or social spaces equipped with discreet, high-end audio systems and controllable lighting encourage spontaneous interactions and enhance the quality of life for those living in small spaces. For instance, while solo living allows residents that much-needed privacy, providing relaxing communal areas offers reassurance that they can step into an environment that invites socialising with neighbours without the need to leave home.

The key to using luxury technology to foster community in shared accommodation is intentionality. The goal isn’t just to install the latest tech, but to thoughtfully integrate it in ways that enhance both the functionality and appeal of communal spaces. Technology should

support the lifestyle and habits of residents while also elevating the user experience to new heights, encouraging them to come together and interact naturally.

A t its core, shared accommodation is about creating opportunities for connection. By investing in high-quality, well-designed technology, developers can not only elevate the standard of living but also provide the foundation for a strong sense of community.

Whether it’s through a state-of-the-art cinema room, a welcoming lounge with ambient music or a private dining space equipped with smart technology, the right tech can transform a shared living space into a home.

www.hii-life.com

In the UK, 138 work-related fatalities were recorded in 2023/241, with over half (51%) occurring in the construction industry. This alarming statistic highlights the critical importance of ensuring both the physical and mental wellbeing of employees, particularly in high-risk environments like construction sites, says Elle Clarke, PPE and Workwear Manager at Milwaukee.

MILWAUKEE

Pe rsonal protective equipment (PPE) is crucial for safeguarding construction workers. However, simply providing the right equipment isn’t enough; workers must also be trained to use it correctly. Any lapse in this area can lead to serious legal consequences for employers, making it imperative for site managers to enforce strict compliance with safety guidelines.

The challenge, however, lies in the face that the PPE industry has struggled to keep up with the evolving needs of modern job sites. Construction projects increasingly incorporate new materials, methods and technologies, making the one-size-fits-all approach to PPE less effective.

This gap has led many workers to modify their PPE to better suit specific tasks. For instance, some might cut the fingertips off gloves to use touchscreens or adjust hard hats to accommodate additional safety attachments. While these adjustments might seem harmless or practical, they can compromise the effectiveness of the protective gear, exposing workers – and their employers – to significant risks.

The hidden dangers of customisation

A key issue behind PPE modification is a lack of understanding about how this equipment is designed and tested. PPE

is engineered to meet stringent safety standards, which prevent accidents, injuries and fatalities. When workers alter their gear, even in seemingly minor ways, they compromise its integrity and effectiveness.

Take the simple act of leaving a highvisibility jacket open to avoid overheating. This may seem like a small change, but it can have severe consequences, especially when working at heights or in low-visibility conditions.

A s an industry, we must do a better job of communicating the risks associated with such modifications. Workers need to understand that what may seem like a simple, productivity-enhancing tweak could endanger their safety and that of their colleagues.

T he consequences of PPE modification extend into the legal and financial realms. If, in an accident, it’s found that PPE was modified, the company could be held liable.

T his liability doesn’t just result in financial losses; it could also lead to severe legal penalties. Should an investigation reveal a company allowed or overlooked the use of non-compliant safety gear, it could face significant fines, criminal charges and lasting damage to its reputation.

The moral responsibility of employers

O ther than the legal and financial implications, employers have a moral duty to ensure safety. Providing proper, certified equipment is a fundamental aspect of responsible business practice. If employees feel the need to customise their PPE, it could indicate that the provided gear is uncomfortable or unsuitable. Companies must address these concerns by investing in high-quality, well-designed PPE that meets safety and comfort requirements.

Allowing or ignoring the customisation of PPE is a dangerous practice that can have far-reaching consequences for any business. Instead, companies should partner with premium PPE suppliers who understand the risks of ‘user upgrades’ and proactively enhance their products to meet the evolving needs of workers. By providing properly tested and comfortable gear, companies can eliminate the temptation for workers to modify their equipment and, in doing so, protect their most valuable asset – their employees.

uk.milwaukeetool.eu

FOOTNOTE: 1https://www.hse.gov.uk/statistics/fatals.htm

With over 150 years of experience, we are experts in the lift industry. We supply and install a wide range of lift products. From our nationwide network of 11 branches we provide local lift services for both our own products and other makes and models.

As an independent, family-owned lift company our highly-trained lift engineers pride themselves on delivering expert support. So if you need a new lift, or someone to look after one, we can help.

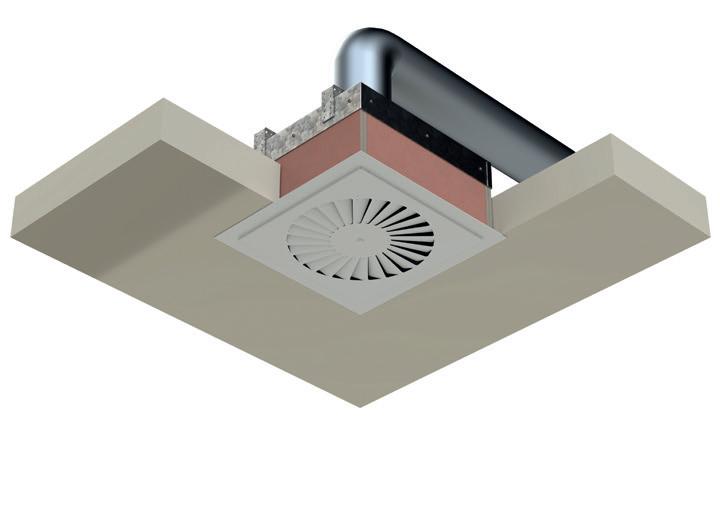

When it comes to finding a lift solution for transport facilities and public infrastructure, understanding the distinction between the different types of lifts is essential. Each type of lift serves a unique purpose and caters to specific project needs. David Saunders, Head of Stannah’s Major Projects Division, which specialises in infrastructure projects, explores this in more detail and looks at what to consider when choosing the right lift solution for transport facilities.

Platform and passenger lifts both serve the purpose of transporting people, but they are designed to meet different needs.

P latform lifts are ideal for tight spaces and enhancing accessibility for individuals with mobility challenges. Unlike passenger lifts, they are smaller, travel at slower speeds and are not designed for high capacity, making them suitable for access to areas such as firstclass lounges, secondary building routes or as an alternative to small stairs where ramps are impractical. They are also ideal for smaller stations or transport hubs with lower foot traffic.

P assenger lifts are designed to move people quickly and efficiently between floors in high-traffic buildings, such as stations and transport facilities. Often made to bespoke specifications, these lifts feature superior car and landing doors, advanced drive and control

systems and durable finishes for reliability and longevity. Unlike standard models, these bespoke lifts may need to work to specific transport specifications, so consulting with a lift specialist is recommended to determine the exact requirements.

P assenger lifts for the transport sector can be tailored to match a building’s aesthetics whilst offering energy-efficiency features. They can accommodate up to 33 passengers and serve up to 16 stops, and often larger and higher if needed. Unlike platform lifts, these high-performance passenger lifts can also function as goods/passenger lifts or evacuation lifts, featuring emergency mode capabilities, but require a dedicated power supply and integration with building systems.

H eavy-duty passenger lifts are built for demanding, high-traffic environments

like airports and train stations. Heavyduty lifts can be designed with robust features, such as reinforced doors, tamper-proof ceilings and vandal-resistant operating panels, offering clients enhanced durability such as water resistance and protection against vandalism.

Transporting heavy goods between floors in busy public infrastructure environments can put everyone at risk. Installing a goods lift is a great alternative to reduce the risk of incidents and efficiently transport deliveries and goods to their desired location. Goods lifts come in various types, including lifts designed solely for transporting goods, those that can accommodate up to two trained attendants and passenger lifts that are for back-of-house use.

A n escalator is ideal for efficiently transporting large numbers of people between floors within transport hubs and have been a well-established and widely used method in railway stations since 1920s. Like other lift systems, there are ruggedised versions designed to withstand the extra wear and tear of hightraffic areas. However, escalators do not offer a step-free solution for those with reduced mobility, prams or luggage, so lifts or ramps are also needed.

C ommonly used in larger airports or stations, moving walkways help transport passengers over short distances. They are ideal for efficiently moving people in areas where a step-free, continuous flow is necessary, accommodating a high volume of travellers.

A ll lifts serve a different purpose, but their common goal is to enhance accessibility within a building. Compliance with the Equality Act 2010, Building Regulations 2010, is essential for creating inclusive

environments. This includes providing access to all floors with DDA-compliant lifts featuring adequate wheelchair space for wheelchairs, tactile signage, accessible controls and audio communication systems.

P assenger lifts should also be equipped with essential safety features, including emergency communication systems, intercoms, alarms and automatic door sensors, to ensure both smooth and secure operation. Additionally, these lifts must comply with the Safety of Lifts Regulations Act 2016, which establishes strict requirements for maintaining safe operations.

Reliability is essential in lift systems, as out-of-service lifts can prevent passengers from completing their planned journeys, causing inconvenience and frustration. Wear and tear are the most frequent cause of lifts being out of service, but regular servicing and maintenance can reduce these issues.

A nother important factor to consider when selecting a lift for transport and public infrastructure environments is the potential for misuse and vandalism. Lifts are susceptible to deliberate and accidental damage from heavy luggage colliding with landing doors or car walls

or rubbish falling into lift mechanisms, which can lead to operational disruptions and increased maintenance needs.

S ustainability and energy efficiency are also an essential factor, as we have noticed a growing demand for these kinds of lift solutions. For example, the lifts in the Elizabeth Tower feature regenerative drives that return power to the mains, saving energy and costs.

G iven that every project features unique architectural styles and designs, passenger lifts can be customised to integrate seamlessly with a building’s aesthetics while fulfilling their functional requirements. This process often involves consultations with architects to align functionality with aesthetics.

In summary, selecting a lift for transport facilities involves numerous considerations, including placement, accessibility, capacity, speed, safety, reliability and aesthetic design. By choosing the right lift solution, you can significantly enhance user experience, ensure compliance with regulations and contribute to a more accessible environment by providing stepfree access.

www.stannahlifts.co.uk

Uneven buildings result from weak ground that causes subsidence – the gradual downward movement of a building or structure due to changes in soil conditions – making the original foundations unstable. This problem is often reflected through unexpected structural damage, such as sinking floors and cracks in the building walls, which not only compromise structural integrity but also affect the safety and functionality of a property. Traditionally, underpinning – reinforcing and stabilising existing foundations – has been the go-to solution for addressing subsidence. However, modern technologies offer an innovative alternative that saves time and money while being equally effective. Here, David Hedley, Technical Sales Engineer at Mainmark UK, discusses.

Throughout the construction sector, it is widely recognised that traditional methods have stood the test of time and have proven themselves in practice. Methods of underpinning have been used to settle and reestablish structures and buildings dating back to the 15th century. With a reputable solution and a clear way to execute this process, it can be suggested that alternative means and methods are not needed to refine this art. However, while traditional underpinning has a long and established history, it is not always the most practical or economical choice, especially in today’s fast-paced construction environment, where minimal disruption and cost-effective means are highly regarded. M ass concrete underpinning is perhaps the oldest and most frequently utilised foundation repair method. This involves digging holes/voids underneath a weakened surface and pouring new concrete or filler below the original foundation. This extends a structure’s depth and reinforces its foundation. As the definition of underpinning pertains specifically to the reinforcement and strengthening of the foundation itself, alternative solutions attempt to strengthen the soil.

I t is suggested that alternative solutions are, in fact, not great alternatives at all. With a limited time of effectiveness, some consider that these alternative means are only temporary solutions, whereas traditional underpinning removes the problem in its entirety.

W hen the ground beneath a property, whether that be residential or commercial, begins to show signs of instability, it is time to consider ground-strengthening solutions. These techniques combat issues such as subsidence, protecting the safety, stability and operational continuity for commercial buildings and the business that resides in them.

I n recent years, modern underpinning methods have gained popularity in the construction sector. One example is grout injection, which offers strengthening solutions that are quick to implement, reliable and cost effective. These methods are also less invasive and don’t require operations to cease for a sustained period of time while essential excavation works are carried out. Using a lightweight cementitious product, provides a non-invasive approach to what typically would have needed a traditional solution of underpinning. Removing the need for extensive digging and excavation, this alternative solution is minimal in its disruption proving favourable for commercial enterprises as works can be typically completed within a matter of days. Access is also less of a concern as heavy machinery isn’t required as it would be for more traditional treatments. When using a more traditional method, all operations would be required to stop, causing a knock-on effect to the operational needs and activities of an organisation, leading to costly downtime.

U nderpinning is not always necessary to rectify a subsidence issue and is increasingly only being used as a last resort. Solutions such as a resin injection are now more favourable in the construction sector. The modern resin injection method uses a precise process to deliver an expanding polyurethane resin into the ground through a set of small-bore injection tubes. The position of the injection tubes is tailored to the nature of the underpinning needed for each project. Once injected, the resin expands and solidifies to fill any voids and as a result strengthens the ground.

C ontrolled injection of further resin can then be used to return the building to the required level. There is consensus that this modern method can offer a

quick and timely solution proving most appealing in comparison to traditional underpinning. Though its permanency has been questioned, products, such as those used at Mainmark, come with a 20-year product warranty.

For many organisations, especially those who are sensitive to the environment in the commercial sector, it is essential to recognise the carbon implications of both methods. For some businesses where the environmental impacts of their actions are measured, the impact on the embodied carbon of any process should be considered. It is well documented that the traditional methods of using mass concrete pose a much higher carbon emission than that used in a geopolymer injection. The lower-

embodied carbon impact of this alternative method may, therefore, make it a more sustainable choice for businesses that are environmentally conscious.

I n essence, neither approach is particularly a silver bullet. Both are suitable solutions to problems that cannot be ignored and need to be addressed. To make the most informed decision, it is important to commission a ground investigation survey upon which to base the choice of treatment. The survey will cover a variety of factors to establish the soil composition, the load-bearing capacity of the ground, the impact of the volume of water in the soil and the depth and condition of the existing foundations. This i s vital to be able to assess and redress the problem with the most viable solution.

www.mainmark.com

Visual appeal is only part of the equation in today’s design landscape. Functionality is now just as important as the auditory experience of a space. Driven by a growing emphasis on employee wellness, neurodiversity and business productivity, architects now recognise that room acoustics are a key component, says Ben Hancock, Managing Director at Oscar Acoustics.

Ho wever, despite growing awareness, there’s often confusion about the correct products to specify – which can easily be misunderstood or overlooked. With that in mind, we’ve answered some of our most commonly asked questions, to help you, the reader, to create the perfect acoustic environment.

Why is acoustic design so important, and why should it be prioritised?

Acoustic design is the art of fine-tuning sound for specific interior spaces. Although attention is often given to aesthetics, usability and energy efficiency, acoustics are often neglected, having a large impact on the people using and occupying a space.

What many fail to realise is that constant noise exposure can be extremely harmful – negatively affecting both physical and mental health, causing stress and discomfort. This has also been evidenced in our multiple research papers on the impact of noise. From our 2024 study, two in three workers admitted that too much noise was affecting their work productivity. A quarter of staff also revealed that the issue had led to poor-quality work. What’s clear is that a huge percentage of the UK workforce is crying out for well-considered acoustics.

Why is it important to consult an acoustic expert?

How a space sounds, is just as important as how it looks. Many aesthetically pleasing buildings can lack the acoustic comfort needed for long-term use, making communication difficult due to overwhelming noise. But when sound design is done right, it transforms spaces into places people love to be.

Working alongside acoustic experts can make this possible –leaning on their extensive knowledge, they can suggest the right acoustic strategy for your space and highlight ways to combat noise so they remain inclusive for everyone.

What are the key architectural considerations for good acoustic design?

For architects, maintaining design integrity is paramount and it’s essential that acoustic solutions can work with any surface, allowing for flawless curves and shapes without compromising aesthetics. This means opting for solutions such as acoustic sprays, which are incredibly effective at controlling sound reverberation and echo – the main cause of deafening noise. There’s also a growing trend towards spaces that provide quiet contemplation and personal privacy. Acoustic sprays can come in a range of textures, offering different levels of sound absorption to suit individual needs, so it’s a good idea to enlist expert guidance to help you make the best choice.

How can we assess the appropriate acoustic requirements for a given space?

To ensure optimal acoustics, many commercial projects now consult with specialists who can specify the necessary treatments based on space calculations and intended use. For those without access to acoustic consultants, some offer free appraisals, giving recommendations on suitable specifications. Additionally, some offer acoustic modelling services to visualise the sound performance, helping architects to make more informed decisions.

How can acoustic design be integrated into the building process to achieve optimal results?

T he success of a project hinges on early consideration of acoustic solutions. Incorporating acoustics into the initial design phases will ensure a superior outcome. To streamline this process, specification platforms like NBS Source can be invaluable, allowing acoustic design to be integrated from the outset rather than as an afterthought.

What are the common mistakes in predicting the acoustic performance of a building?

The shape of the substrate can significantly impact acoustic performance, yet it’s often overlooked. We frequently receive enquiries from architects who have been advised to use a Class A absorber and have consequently over specified the required depth of our product. When applied to profiled or ribbed metal sheets, premium products significantly outperform the worst-case published acoustic data for concrete slabs. By leveraging technical expertise, architects can receive value-engineered solutions, saving on material depth, labour and project duration.

What are the issues involved in retrofitting existing buildings to improve environmental performance?

Spaces with heavy congestion of services often present the greatest acoustic challenges. To ensure swift installation, it’s best to apply acoustic treatments before these services are installed. When existing services are present, premium companies will prioritise careful wrapping and protection before installation. Retrofitting acoustic solutions can also impact building operations; however, experienced acoustic specialists will be able to complete work with a minimal amount of downtime.

www.oscar-acoustics.com

Smart lighting has emerged as a key technology in modern building design, driving energy efficiency, enhancing user experience and supporting sustainability goals. In this article, Chris Anderson, Technical Manager at Ansell Lighting, explains more about the technology and its many benefits in commercial settings.

ANSELL LIGHTING

Effective lighting is fundamental in commercial spaces, heightening safety, enhancing design and influencing productivity and wellbeing.

With many of today’s workplaces being multi-use in nature, lighting needs to cater to a diverse range of activities and technologies. Whether it’s collaborative team meetings, individual, focused work, presentations or virtual conferences, the lighting environment needs to be adaptable to support the varying needs of the modern workspace.

As organisations increasingly seek ways to optimise their operations and create more comfortable and productive environments for staff and visitors, smart lighting systems have soared in popularity. Offering an innovative solution to these many challenges, they offer more efficiency and better control and help to lower operational costs.

Applicable across both indoor and outdoor lighting circuits, smart lighting systems are highly functional, transforming how we can use and interact with lighting

to reap its benefits. Incorporating wireless technology in each fitting, smart lighting uses communication protocols such as Wi-Fi, Bluetooth and Zigbee to seamlessly connect luminaires together, creating a network of lamps that can be controlled and automated from one central point.

T he options this offers are endless. Every single detail of the lighting system can then be programmed to meet specific requirements, changing as required at different times of day, according to the use of the space or the mood required. The colour, brightness, intensity and combinations of lamps in use can all be automated and controlled to the most minute detail, meaning that energy use is controlled to this exact level, too.

I n fact, smart lighting provides incomparable energy optimisation and has the potential to cut the amount of energy used to light commercial buildings by up to two thirds – a huge saving when you consider that up to 40% of energy consumption in commercial

buildings can be attributed to lighting. It is particularly useful in spaces that may be used sporadically, such as in corridors or bathroom facilities, ensuring that lighting will not be left on unnecessarily and eliminating waste.

S mart lighting can also offer an array of health and functional benefits. Programmed to mimic natural light cycles, it can promote a healthier circadian rhythm among employees, supporting the wellbeing and productivity of building users. By adjusting the colour temperature and intensity of light throughout the day, it can also help reduce eye strain and fatigue, which are common issues in traditional office environments.

Furthermore, smart lighting can also improve the overall ambience of a space, making it more inviting and conducive to various activities. For instance, brighter, cooler lighting can be set for focused work spaces, whilst warmer, dimmer lighting can be implemented for meetings or relaxation areas.

Modern smart lighting systems are also a real contributor to interior design, helping to create spaces that are aesthetically pleasing. Whether it’s the sleek design of the fixtures themselves or the ability to highlight key elements, such as furniture, furnishings and artworks, smart lighting will ensure that the space has the real ‘wow’ factor.

S mart lighting is easy to install and integrate with existing lighting installations, which has further

boosted its popularity. Many systems now offer wireless connectivity and modular components, which are simply installed like traditional fixtures and seamlessly paired with user-friendly apps and control systems. This reduces the need for extensive rewiring or structural modifications, making smart lighting a viable option for both new constructions and retrofits.

Smart lighting is also highly measurable, with recent advances in equipment, meaning that many commercial solutions now come with dashboard controls. These allow energy usage to be monitored in real time, providing a clear view of lighting-based energy consumption data throughout a building or even across an entire portfolio of buildings. This provides further opportunity for wasted usage to be identified, helping organisations to further reduce unnecessary use, CO₂ emissions and costs.

T he adoption of smart lighting has had a huge impact on the way commercial spaces are illuminated and offers a range of benefits that traditional lighting installations can not come close to. By enhancing the wellbeing and productivity of building users, reducing energy use, offering flexibility and acute functionality, smart lighting systems are transforming buildings into dynamic, responsive and futureready environments.

www.ansell-lighting.com/en

Healthcare challenges are evolving, and architectural practices must meet new demands with innovative solutions, particularly when it comes to dementiafriendly design as dementia cases rise. The industry’s response cannot be just reactionary – it must work to proactively create spaces to support this growing demographic. Here, Ruth Evans, Associate at CPMG Architects, highlights embedding this responsibility to leading dementia-friendly design through healthcare design, emphasising its increasing importance.

CPMG ARCHITECTS

The NHS has recently disclosed that England is experiencing a record number of dementia diagnoses, with 487,432 diagnoses in the country as of June 2024. With one of the highest diagnosis rates globally, the urgency to address the needs of individuals living with dementia has never been more critical. High-income countries typically report diagnosis rates between 20 and 50%, positioning England at the forefront of this health concern.

T he implications of these statistics are profound. As architects, we must recognise that the built environment plays a crucial role in the quality of life for individuals diagnosed with dementia. Our designs must evolve to ensure safety, comfort and a sense of autonomy for those affected. At CPMG, our goal is to champion the creation of healthcare spaces that are conclusively dementia-friendly, with additional infrastructure to accommodate dementia patients who may be receiving treatment for unrelated conditions. This

holistic approach ensures that every environment within a healthcare facility is supportive and accessible, regardless of the primary reason for a patient’s visit.

D ementia-friendly design is guided by several core principles, each aiming to enhance the wellbeing of individuals living with dementia. These principles are pivotal to effective design and must be integrated at every stage of a healthcare project to ensure optimal considerations within the overall design are met.

1 . Safety and accessibility: Ensuring spaces are free from hazards and easily navigable. This includes clear wayfinding and signage, unobstructed pathways and the use of non-slip flooring materials that are also matte and unreflective to ensure the perception that a floor may be wet or unsafe is not possible.

2 . Familiarity and orientation: Creating environments that are easy to understand and navigate, with visual cues and landmarks to aid orientation, including elements such as single-colour signage. Consistent and intuitive design elements are incredibly effective here to reduce confusion and anxiety, with the simplest design often being the most effective option. An example of this is WC doors utilising one colour across both options, preventing confusion and allowing for cognitive recognition – which, in turn, can reduce anxiety and uncertainty.

T his is also prevalent in the implementation of design elements that match the modern perception of the condition, in which spaces must also work to support the reduction of stigmatism and increase privacy and dignity.

3 . Social spaces: Designing communal areas that encourage social interaction and reduce isolation. These spaces are integral to mental health and wellbeing, providing opportunities for engagement and community. Allowing for freedom of movement is vital here and can be done through appropriate accessibility measures included at the design stage.

4 . Calm and comfort: Utilising colours, lighting and acoustics to create soothing environments, prioritising natural light, reduction of noise pollution and the use of colour schemes that promote calmness, such as solid blues and greens. It is important to avoid bold patterns and stripes as the designs can be confusing and disorientating.

5 . Personalisa tion: Allowing for personal touches and customisation within living spaces to foster a sense of ownership and belonging. This can include areas for personal mementos and photographs. A space should act as a framework for shared decision making between the person with dementia and care or support workers to take place, allowing the person to maintain their health and wellbeing independently as much as possible.

Innovating with empathy

Facilities must be conceptualised with input from healthcare professionals, caregivers and, crucially, individuals living with dementia –before the architects can bring a space to life.

T he result of this is the creation of a space where every detail, from the layout of the rooms to the choice of furnishings, serves a purpose for the people who will be using it the most. This includes elements such as wide, well-lit corridors with handrails, colour-coded areas to signify different functions and safe outdoor garden spaces as just a few examples of how thoughtful design can make a difference.

P ivotally, this process showcases what is one of the most crucial stages in an architect’s work, and an increased focus on this stage when working towards the creation of these much-needed spaces is not only fruitful for the person with dementia and their support staff but also the architect involved. It provides the opportunity to work holistically, to improve skillset and client care that can only be learnt through being exposed to projects such as these, which are prominent within the healthcare industry especially.

D ementia-friendly design is not just a trend but a fundamental aspect of healthcare architecture. As diagnosis rates continue to climb, the need for environments that support and enhance the lives of those living with dementia will only grow, and the role of architecture becomes increasingly vital. Design elements must match the modern perception of the condition, with spaces also needing to work to support the reduction of stigmatism for those with dementia as awareness of the diagnosis continues to grow.

O ur commitment as architects extends beyond individual projects. We are advocates for industry-wide adoption of dementia-friendly standards.

B y championing dementia-friendly design, we are not only responding to a pressing need but also setting a new standard for healthcare environments. Our vision is a future where every healthcare facility is a sanctuary of safety, dignity and comfort for all individuals, regardless of their cognitive health.

W ithin our work at CPMG, we are proud to be continually growing our knowledge in designing spaces that respect and enhance the lives of those living with dementia, supporting a clear benchmark for the industry and paving the way for a more inclusive future.

www.cpmg-architects.com

The new Labour Government has set out plans to help meet its ambitious target of building 1.5 million homes over the next five years and ‘get Britain building again’. A large part of these plans involves green belt boundary reviews in attempts to release some of this land, known as ‘grey belt’, for housing. This will allow local authorities to identify areas of previously developed land, or those seen to make a limited contribution to the aims of the green belt, for development, and we can expect the new homes built on this land to bring huge benefits to local communities. But this is no band aid to building, and what may happen if a heritage asset is situated on land that could be designated as part of the grey belt?