Volume 22 Issue 4 June 2024 Logistics & Transport Response to the Abley Cable Car studies’ appraisal Maersk’s new integrated cold chain facility Retirement villages and the need to rethink transport and land use $15.00 THE OFFICIAL PUBLICATION OF CILT NEW ZEALAND

LOGISTICS & TRANSPORT NZ IS THE OFFICIAL JOURNAL OF THE CHARTERED INSTITUTE OF LOGISTICS & TRANSPORT NZ

ON THE COVER

Two 11-metre satellite dishes have been hoisted into place at the uplink and ground control centre being constructed at Awarua, Southland as part of the Southern Positioning Augmentation Network for the New Zealand and Australian Governments. You can read more about this project on page 16.

In the next edition

The editorial team welcomes expressions of interest for submitting an article for the September 2024 edition of this journal, especially from young professionals (those under the age of 35). Contributors should in the first instance contact the editorial convenor, Murray King (email murray.king@xtra.co.nz) to discuss their article. Deadline for the September 2024 edition: August 4 2024.

Photo: Lockheed Martin

Photo: Lockheed Martin

12 Contents 16

9 6 Published under contract (print) by: Excel Digital 21 Jamaica Drive, Wellington 5028 Tel: 04 499 0912 Email: studio@exceldp.co.nz Advertising Contact: CILT national office Tel: 09 368 4970, Email: info@cilt.co.nz Editorial Contact: James Paul, The PR Company Tel: 022 514 0716 Email: james@theprcompany.co.nz CILT NZ National Office: PO Box 1281, Shortland Street, Auckland Tel: 09 368 4970 Fax: 09 368 4971 Disclaimer: This publication is the official magazine of the Chartered Institute of Logistics and Transport New Zealand Inc (CILT NZ). It is published quarterly. All material appearing in this publication is copyright and may not be reproduced without the permission of CILT NZ. The views expressed in this publication are not those of the editorial committee, CILT NZ, its council, officers or The PR Company, unless expressly stated as such. SPREAD THE WORD ABOUT CILT … If you enjoy reading this magazine and think others would too, please share it with others – leave it on the coffee table at work, or out at reception. Also published under contract (web) by: Webstruxure 29 Tory St, Wellington Tel: 04 801 7053 Email: hello@webstruxure.co.nz Web: webstruxure.co.nz Response to the Abley Cable Car studies’ appraisal ..........................................3 Railway signalling globalisation: a view from the shaky isles...........................5 Fairfield Freight Hub proving popular .................................................................. 8 Maersk’s new integrated cold chain facility .......................................................10 Help Protect New Zealand ..................................................................................... 12 Border Protect Update – Be aware of break-ins!.............................................. 13 Retirement villages and the need to rethink transport and land use .......... 14 New network will improve GPS accuracy to as little as 10 centimetres ..... 16 Making the most of Tāmaki Makaurau’s port and prime waterfront ........... 17 Hiringa Energy launches refuelling network ......................................................18 The Great Synchronisation and The Great Asynchronisation ....................... 20

LETTER TO THE EDITOR

Response to the Abley Cable Car studies’ appraisal

I am writing to you in response to the recent article by Ian Wallis (Logistics & Transport NZ, Volume 22 Issue 3) on the work done by Abley on cable cars as a public transport option. Mr Wallis makes some points that I would like to respond to, clarifying aspects of our work on cable cars.

The article asserts that our high-level economic analysis (benefit-to-cost ratios or BCR) of the proposed cable car routes is incorrect: I would argue that it is a preliminary assessment, but it does give a reasonable guide. Also, the article discusses cable cars as a replacement to the 28-stop No. 2 bus service in Wellington whereas the Abley cable car work is mainly aimed at measuring cable cars as a potential mass rapid transport (MRT) solution – not competing with local bus services.

I would like to draw Logistics & Transport NZ readers’ attention to the concern Mr Wallis raises about transfer penalties in his article. These relate to the potential travel time disbenefits that can result from the need to change the transport mode to complete a journey, and Mr Wallis’ subsequent conclusion that our BCR estimates are off-track.

Firstly, all MRT solutions (with typically wider station spacings than local bus routes) can possibly suffer from this transfer penalty.

Therefore, it is my view that our BCR estimates are useful as indicators of the efficiency relative to other MRT solutions such as heavy rail, light rail or bus rapid transit.

Secondly, Mr Wallis says our BCRs may possibly be an order of magnitude overestimated for our cable car routes. This implies that our BCR analysis does not have merit. I do not agree. We need to inform the transport community that the journey experience (that Mr Wallis refers to as a positive in his article) is not taken into account in our benefits estimates.

Also, cable cars offer unparalleled public transport reliability amongst MRT solutions (cable car gondolas arrive at around 30-second intervals and have a defined, constant ropeway velocity) and this may have been underestimated in our work.

In addition, the transfer penalties that Mr Wallis is concerned about (which I reiterate are common to all MRT solutions) can be mitigated through first leg final leg strategies.

I have worked on several transport business cases involving such strategies and am convinced that they can often be successfully deployed if optimised alongside the main MRT business case.

I understand that other business cases (such as the 2021 Airport to Botany Bus Rapid Transit business case – which can be found at https://at.govt.nz/projects-roadworks/ airport-to-botany-rapid-transit) eliminate cable cars during the initial sieve of potential options and before the long list citing the transfer penalty cost as a reason. Other more expensive options such as heavy rail make the long list but not the more cost-effective cable car options. Given all public transport modes face the same challenges concerning patrons transferring between services, in my view, cable cars are not being assessed on a consistent basis with other MRT options in New Zealand transport business cases.

Cont. on page 4

Abley Techinical Director Andrew Couch responds to concerns made by Ian Wallis in the previous issue, citing all public transport modes face the same challenges concerning patrons transferring between services. Dr Couch believes cable cars are not being assessed on a consistent basis with other transport options in New Zealand.

Photos: Doppelmayr New Zealand Ltd

Abley Techinical Director Andrew Couch responds to concerns made by Ian Wallis in the previous issue, citing all public transport modes face the same challenges concerning patrons transferring between services. Dr Couch believes cable cars are not being assessed on a consistent basis with other transport options in New Zealand.

Photos: Doppelmayr New Zealand Ltd

June 2024 3

Scenarios for cable cars could be run through the Wellington Transport Strategic Model (the Wellington transport community’s 4-stage demand model used for full assessment of proposed transport interventions) to test all these factors and compare them on an equitable basis with other MRT options. Our cable car work was carried out at a strategic level – not attempting to carry out a full benefits analysis – to determine whether a cable solution should be taken to the next level of consideration.

One of the conclusions that the Abley cable work reached was that cable cars work best as a potential replacement for MRT solutions, especially in a constrained environment. This could be a topographical constraint or because a city faces the challenge of installing transport infrastructure late in the game to facilitate housing growth. Wellington is one of our favourite cities for cable cars as it experiences both these challenges.

In this regard, any comparison with a local bus route (such as the successful No.2 bus service to Karori, referred to in Mr Wallis’ article) should be made with this in mind. I envisage a cable car solution would be MRT-orientated:

designed to deal with the situation where demand became excessive, to facilitate housing growth in Karori or to provide a fast, one or two-stop cable car service for Karori residents into the Wellington CBD. Thus, it supports public transport options into the centre rather than competing with existing local bus services.

We thank Mr Wallis for the interest he has taken in our work; these are the discussions

we need to have for cable cars and other transport technologies that may serve to improve the New Zealand transport sector.

Disclosure: Doppelmayr is a client of Abley but the comments made by Andrew Couch are as an independent transport analyst.

Andrew Couch

Technical Director – Abley

Cable cars can support public transport options into the centre rather than competing with existing local bus services. Alternatively, they also work best as a potential transport replacement , especially in a constrained environment.

Cable cars can support public transport options into the centre rather than competing with existing local bus services. Alternatively, they also work best as a potential transport replacement , especially in a constrained environment.

Calendars & Promotional Products 0800 225 363 www.easy2c.co.nz - For The Cost Of A Coffee! YOU CAN’T GO PAST 365 DAYS OF BRAND VISIBILITY 4 Logistics & Transport NZ

Railway signalling globalisation: a view from the shaky isles

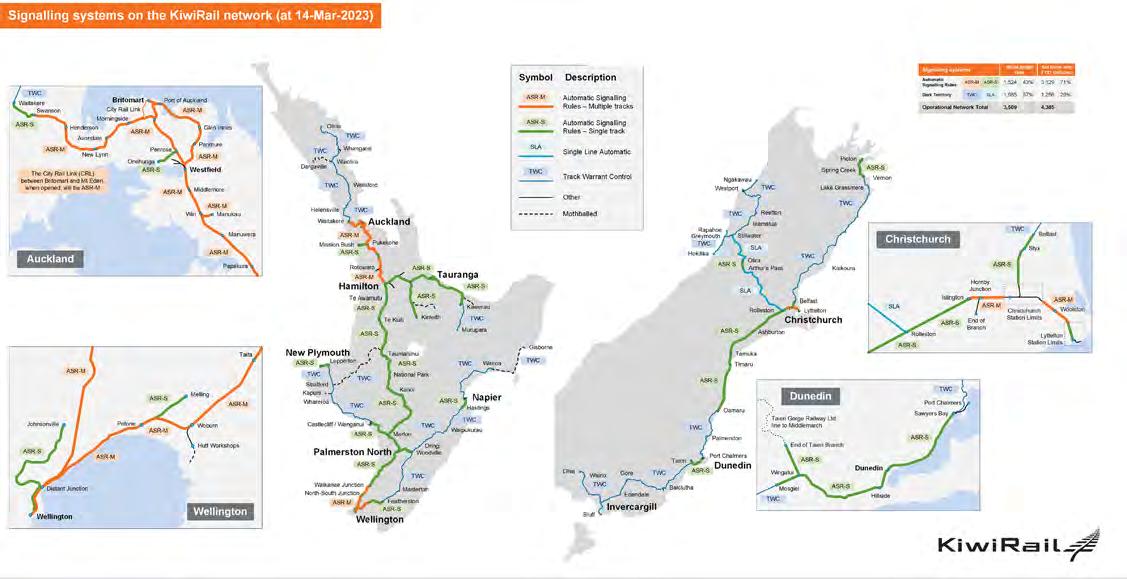

This article, a shortened version of a paper prepared as part of the Institution of Railway Signal Engineers Presidential series, explores the impact of globalisation from a railway signalling perspective through a New Zealand lens.

New Zealand railway network context

Railways in New Zealand date back to 1863 when the first public railway was opened as a 7-kilometre broad gauge section between Christchurch and Ferrymead. Although there were several other provincial railway developments around that time, the building of a national railway network didn’t begin in earnest until the 1870s when narrow gauge (1067 millimetres) was adopted due to the need to cross the mountainous terrain of the country’s interior and the lower cost of construction. By the early 1950s, the route length of the New Zealand rail network had expanded to more than 5,500km.

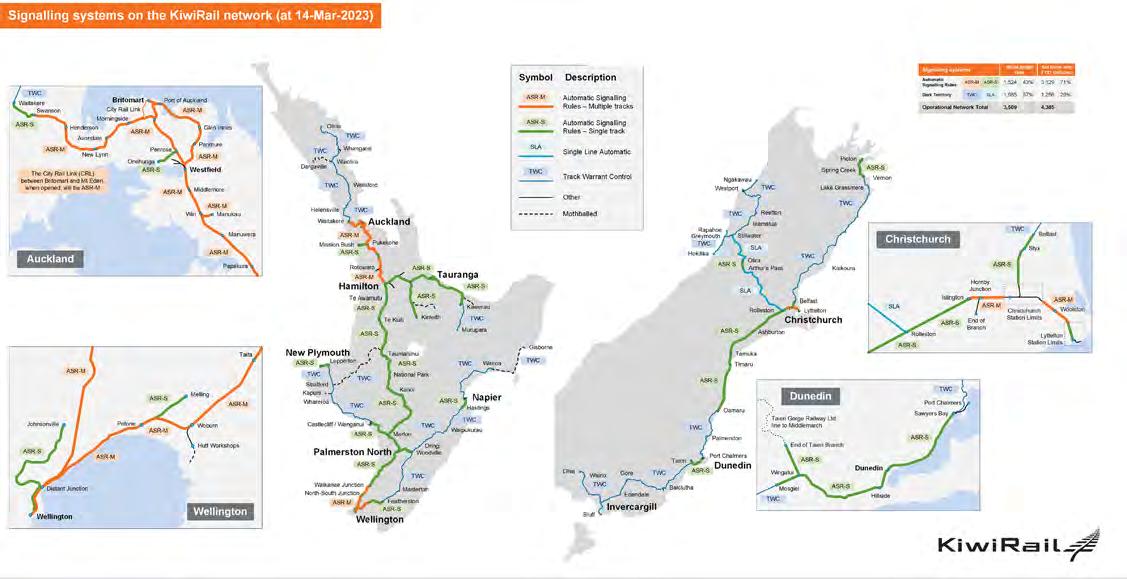

Since the 1950s, the size and extent of the New Zealand rail network has reduced and today comprises around 3,500km of operational route spanning the length of the country. The network can be broadly split

into two types of operation – freight and suburban passenger. Outside the suburban areas, the network is characterised by singletrack operation with crossing loops where trains can pass each other.

Brief history of signalling in New Zealand

Early signalling in New Zealand was based on British practice but from the early 1920s, there was a move towards North Americanbased Automatic Permissive Block. The association with North American practice continued through to the age of power signalling with current New Zealand principles delivering permitted speed information to train drivers (1). Favourable import tariffs for United Kingdom (UK) imports compared to those from the United States led to local subsidiaries for companies like Westinghouse being set up in New Zealand. Consequently,

the regulation of trains in New Zealand has often been characterised as North American speed signalling deployed with British equipment.

By the mid-1980s, the viability of the New Zealand railway network was threatened by a high-cost base and increasing competition from other transport modes. A review was undertaken by Booz Allen Hamilton which, among other things, resulted in the removal of signalling from a large portion of the New Zealand rail network. This signalling was replaced by Track Warrant Control (TWC) which is used extensively in North America for low-density rail operations. In TWC movement authorities are given verbally by radio. Currently, around 40% of the New Zealand rail routes are fully signalled with the remaining 60% operated under TWC (Figure 1).

Cont. on page 6

Figure 1 New Zealand Railway Network Operating Systems 2023. Picture: KiwiRail June 2024 5

New Zealand was an early adopter of centralised traffic control (CTC) which enabled, in conjunction with relay interlocking1, the control of increasingly large sections of the railway from a single control point. The first CTC installation was brought into use in 1938 and from then through to the 1990s, most signal boxes were removed from the network. During the 1990s and early 2000s, operations were further consolidated to the point where a single National Train Control Centre controlled train movements throughout the entire New Zealand rail network except for the Wellington A signal box, which controls the dense Wellington station area.

Standardisation

In the early years, signalling engineers were recruited from the UK. For this reason and despite several local innovations much of the signalling equipment traditionally used in New Zealand was based on UK standard equipment.

Over the last 10 years, the move towards standardised equipment and systems has continued and accelerated. A primary driver for this acceleration is the need to deliver reliable and safe signalling systems that are assured despite increasing levels of complexity. The mid-2010s electrification of the Auckland suburban network required a network re-signalling. This re-signalling saw the deployment of modular computerbased interlocking equipment, connectivity via ethernet IP-based communications, train detection via axle counters, and European Train Control System (ETCS) level 1 automatic train protection2. A typical trackside modular signalling installation is shown in Figure 2.

The Tyranny of Distance

New Zealand, as a low-population island nation located in the southwestern Pacific Ocean, has traditionally been challenged by geographical separation from major global centres of commerce. The modern digital world has largely eliminated this ‘tyranny of distance’ but there are still impacts in the railway signalling environment which are summarised below.

Human resources

The size of the New Zealand railway network does not allow for in-depth skills specialisation. New Zealand railway engineers tend to be excellent overall systems engineers with a good understanding of both railway system components and operation but there

is not the volume of work to allow for in-depth specialisation.

The often boom-bust nature of development and renewal of the New Zealand rail network also makes it difficult to retain specialist railway skills. New Zealand railway history is littered with examples whereby there is an influx of resources to deploy a project that soon dissipates once the project is completed and there is no forward work.

Small scale

The relatively small scale of the New Zealand railway means that there is limited capacity to develop safety-critical equipment and systems. The intense resources (knowledge, systems, time and financial) required to develop, test, and certify new safety critical equipment are normally beyond the capacity of the New Zealand railway. In many ways, the ability to innovate is diminished by both technical complexity and increasing safety assurance requirements.

Budget constraints

The small population of New Zealand (approximately 5.2 million as of June 2023) and the relatively long distances between population centres mean that the funding for public transport infrastructure, including railways, is significantly constrained.

Budget constraints amplify the tyranny of distance impacts and make it even more important to ensure that any infrastructure deployed is cost-effective across its full lifecycle.

Globalisation

Globalisation is defined by the National Geographic Society as a term used to describe how trade and technology have made the world into a more connected and interdependent place. The history of the development of signalling systems and equipment in New Zealand suggests globalisation of signalling is not a new concept. However, with the evolution of the Information Age, the opportunities offered by globalisation have increased. From a railway signalling and control perspective there are several potential benefits from globalisation. For a small, remote railway like New Zealand, these benefits include:

1. Common Safety Norms:

Compliance with Normative Standards means that signalling equipment can be procured and deployed in the knowledge that a level of safety integrity is assured. As interlocking equipment has moved towards electronic processors and requirements around proof of safety have increased, the ability of a small railway like New Zealand to undertake the required research, development and assurance of safety-critical signalling equipment has all but exhausted.

2. Standardisation:

Globalisation has driven the need for standardised signalling systems and protocols to ensure interoperability between different railways and rail equipment. Organisations like the International Union of Railways and the International Electrotechnical Commission have worked on developing global standards for railway signalling. Advanced signalling

1 Interlocking is the safety heart of the signalling system that ensures that once a train is authorised to occupy a section of track, it is safe for the train to proceed and that it will remain safe until the train has progressed through that section.

2 Automatic train protection prevents train derailments and collisions by automatically stopping a train if it exceeds a safe speed.

6 Logistics & Transport NZ

Figure 2 Trackside Modular Signalling Installation (front and back) showing power supplies, axle counter equipment, external interface to points machines and signals and communications equipment. Picture: Noel Burton

technologies developed in one country or region are often adopted by railways around the world.

3. Supplier globalisation:

Many railway signalling equipment manufacturers are global entities with a presence in multiple countries. This globalisation of suppliers has facilitated the exchange of signalling technology and expertise across the world. A current example of this is the project to replace New Zealand’s Train Control System (TCS)3 A global supplier has been selected and is bringing experience from other railways where the TCS is already deployed. A solution that both improves the efficiency of New Zealand rail operations and minimises system development will be achieved.

4. Best practices and knowledge sharing:

The globalisation of information and communication has made it easier for railways to share best practices, safety standards, and incident data. This exchange of information helps improve signalling systems and safety measures. From a New Zealand perspective, the ability to crossaccept equipment and systems is critical. If another railway has type-approved equipment in line with known standards, the local focus can be applied to understanding the impact of any differences that the New Zealand environment dictates. This negates the costly and time-consuming need to type approve from scratch.

5. Competition and innovation:

Globalisation has enabled signalling equipment suppliers to expand into new markets. This offers the potential for increased competition which can drive innovation in technology, safety, and efficiency. Interestingly, this global expansion into new markets has resulted in a reduction in the breadth of the supply market with large multinationals engulfing some of the traditional local suppliers. In some areas, this can and has reduced competitive tension.

6. Training and skills transfer: Railway signalling personnel often receive training and share expertise with counterparts in other countries, leading to the dissemination of knowledge and best practices. With similar systems and technology deployed across multiple railways, the available pool of expertise is expanded with a wider range of transportable skills.

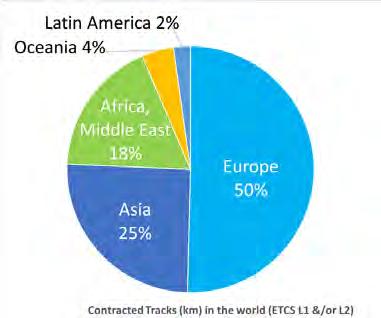

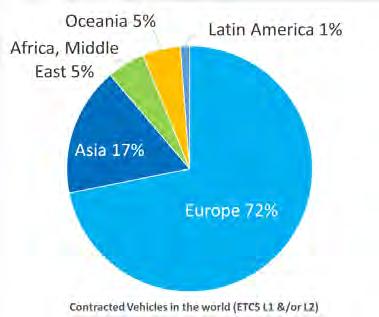

Case Study ERTMS/ETCS

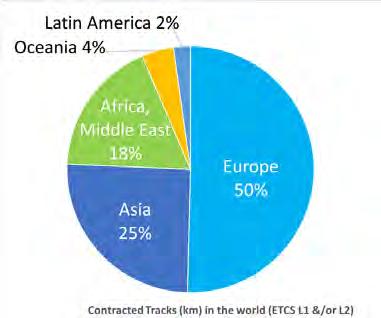

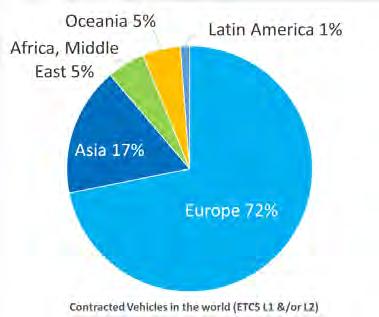

While initially devised as a system to enable interoperable rail operations throughout Europe, ETCS has expanded much wider with installations worldwide. Figure 3 shows that as of September 2022, half of the worldwide ETCS track kilometres installed are outside Europe.

From a New Zealand perspective, ETCS Level 1 was selected as the preferred method of automatic train protection when the Auckland suburban rail system was electrified and re-signalled between 2010 and 2014. The key reasons for the selection of ETCS were:

• No lock-in to a single supplier – Multiple suppliers manufacture and support ETCS which allows ongoing commercial operation.

• Large installation base protects against system obsolescence.

• Recognised international standards allow access to a wider pool of expertise.

These benefits have been mostly realised. Of particular note is that the Auckland network was initially deployed with both trackside and on-board subsystems provided by the same supplier. The on-board subsystem on new rolling stock is now being supplied by a different supplier. Although still requiring integration testing, the deployment of the new onboard system was relatively straightforward and was such a success that the original fleet has now also been retrofitted with the new onboard equipment.

Negative impacts of globalisation

As is well documented, the impacts of globalisation are not always positive. This is also the case for railway signalling from a New Zealand perspective.

Some of the negative impacts of globalisation are the flip sides of the benefits. From a knowledge and expertise perspective, a small railway like New Zealand cannot compete with international wage rates and our experience has been that locally trained engineering talent becomes marketable after three or four years. The more the local training encompasses internationally used systems and equipment, the more this risk increases.

A second negative impact is the loss of supply chain certainty. The COVID-19 pandemic created a dramatic and rapid change in supply chains in New Zealand. The ability to get goods into the country was hampered by both limited global supply and the additional cost and time required to get to New Zealand. This had the impact of significantly increasing the delivery time and cost for equipment procured from overseas.

A third and most often noted negative impact is cybersecurity. The use of standardised systems and equipment, no matter how good the protection systems are, increases the threat of cyber-attacks from international actors.

Mitigations to each of these risks exist. From a knowledge and expertise perspective, there is an opportunity to increase local resources above what is required for local systems. The additional resource can potentially be deployed remotely to other parts of the world providing a lower cost base and the advantage of ‘working overnight’ for other time zones.

A Train

enables the

of a

like air

for

3

Control System

control

railway and the running of trains from a centralised location. It is

traffic control

trains.

Cont. on page 8 June 2024 7

Figure 3 Global ETCS Deployment September 2022. Picture: ertms.net

Supply issues can be mitigated by increasing the quantities of local safety stock and planning around longer indent times. These mitigations all come with a cost.

Conclusion

Globalisation has had and will continue to have a significant impact on railway signalling systems and practices.

From a New Zealand perspective, the globalisation of railway signalling and control promises several benefits. The development and deployment of products and systems based on international standards along with the ability of suppliers to ‘crosspollinate’ between client organisations means that cost-effective, safe solutions are transportable.

Overall, globalisation has brought both opportunities and challenges to the railway signalling industry. The need for standardisation and interoperability, along with the ability to leverage global best practices and technology, has improved the safety and efficiency of railway systems around the world. However, it also means that the industry needs to adapt to global trends, cybersecurity threats, and the evolving needs of an interconnected world.

References

1. Heine, Richard W Semaphore to CTC: New Zealand Railway and Locomotive Society, 2000.

Author John Skilton BE

Author John Skilton BE

(Hons), CPEng, CMENZ, FIRSE

John joined New Zealand Railways in 1987 as an engineering cadet and has subsequently remained in the New Zealand rail industry in various roles with a focus on signalling, telecommunications, and control systems. John is currently the Programme Director of Future Rail Systems at KiwiRail and also the Chair of the Australasian section of the Institution of Railway Signalling Engineers.

Fairfield Freight Hub proving popular

The Fairfield Freight Hub has been described as a “game changer”, helping to smooth the supply chain in and out of the Canterbury region.

Just weeks after its grand opening, the Fairfield Freight Hub is already starting to show its benefits – aiming to smooth the supply chain in and out of the Canterbury region. Located at the Ashburton Business Estate, just north of Ashburton and adjacent to State Highway 1, the Fairfield Freight Hub has received glowing praise from importers and exporters throughout the motu – providing an alternative and reliable mode of transport via rail.

Officially opened by Minister of Transport Simeon Brown in April, the hub covering 4 hectares has been widely described as a “game changer” for Mid Canterbury. Owned and operated by the Wareing Group Limited, the facility offers a structured approach to freight movements –with KiwiRail suggesting the throughput could increase from 6,000 containers annually, to a commendable 20,000.

While this is the agreed target, Wareing Group Ltd Director Mark Wareing says it’s important to remain realistic about the overall possibilities.

“It’s early days so far, but going by the numbers we can achieve already, there is great potential to make these figures. We have a glut of produce that goes out of this area at certain times of the year, and now, some of it will go on rail.

“We’re already seeing evidence of the system working, and going forward, we only hope to create more room for other exporters.”

Starting as a vision five years ago, the concept has now well and truly come to fruition –standing as a testament to innovation, collaboration, and sustainable logistics. In fact, once the planning had been done and the details agreed to, the physical build itself began in May 2023 and took less than one year to complete – including the relocation of Ashburton’s shunting yard functionality that was previously situated in the township itself.

“There’s been many discussions to get to where we are, but it’s been a rewarding process to watch it come to pass.

Traditionally, the supply chain has been a lot more reliable pre-COVID than it has been since and this hub should benefit – and so far, it has – importers and exporters in this region (Canterbury),” Mr Wareing said.

“Essentially, there’s not many projects like this out there and in recent times, we’ve seen examples that show New Zealand’s supply chain has got very limited resilience through natural disasters, or any other disruptions. Typically, our country has never been good at investing in infrastructure and that lack of resilience has started to show.”

To be clear, Mr Wareing isn’t advocating for rail to replace all modes of transport – far from it. He’s simply referring to the multiple incidents that have hampered the supply chain – and virtually cut the South Island in two – most recently with the 610m-long rail bridge over the Rangitata River temporarily rendered out of commission due to floodrelated damage.

8 Logistics & Transport NZ

The hub development cost $18 million, with a $2.5m contribution from the government’s NZ Upgrade Programme and $2.3m from the Ashburton District Council. Photos: Wareing Group Ltd

“Listen, we’re not saying we need to get trucks off the road, we’re saying let’s smooth the supply chain out as much as we can and find the best result for exporter or importer to get the produce to and from market,” Mr Wareing said.

“Whether it’s coastal shipping, rail or truck, we use all forms of transport currently, and for us, it’s about collectively strengthening the resilience of the network. That means when those supply chain disruptions happen, whether natural disaster, shipping lines moving, or even a port strike occurs, we can negate some of the risks for people and keep the supply chain moving.”

Equally impressed with the new addition to Mid Canterbury, KiwiRail Executive General Manager Freight Markets Alan Piper says the hub has already helped to reduce road congestion on State Highway 1 (to and from Christchurch) and has improved truck-turn times at Lyttelton Port.

“Inland freight hubs such as Fairfield’s provide the ability to aggregate volume and access to unlock both domestic rail transport, and rail to and from ports for manufacturers, exporters and importers alike,” Mr Piper said.

“Access to rail reduces carbon emissions, reduces road congestion and associated wear and tear on roading infrastructure, improves road safety with fewer heavy vehicles on the road as well as providing supply chain efficiencies.”

Like Mr Wareing, Mr Piper says the opening of the hub couldn’t have come at a better time, referring to the damaged pier on the Rangitata rail bridge in April.

“Fairfield Freight Hub proved to be invaluable as a hub for road-bridge containers to and from Timaru during the period of the Rangitata Bridge repair. We are grateful to the Wareings Group and Fairfield Freight Hub for their assistance during this period.”

Asked how KiwiRail plans to increase the amount of local freight carried by rail from 6,000 containers to 20,000 containers per year, Mr Piper says “close collaboration” would be key.

“The hub has a storage capacity of approximately 800 containers and delivers greater rail capacity due to the bigger siding infrastructure. Increased freight can be achieved by closely collaborating with regional importers, exporters, manufacturers, growers, producers, Lyttelton Port Company and logistics providers like The Wareing Group to provide a sustainable, efficient, reliable and safe supply chain alternative.”

Sectors most likely to use the hub include various primary producers, reflecting the agricultural nature of Mid Canterbury and the need to export vegetables, grain, meat, and seed.

KiwiRail Executive General Manager Freight Markets Alan Piper says the hub has already helped to reduce road congestion on State Highway 1 (to and from Christchurch) and has improved truck-turn times at Lyttelton Port.

The Fairfield Freight Hub offers a structured approach to freight movements with KiwiRail suggesting the throughput could increase from 6,000 containers annually to a commendable 20,000.

KiwiRail Executive General Manager Freight Markets Alan Piper says the hub has already helped to reduce road congestion on State Highway 1 (to and from Christchurch) and has improved truck-turn times at Lyttelton Port.

The Fairfield Freight Hub offers a structured approach to freight movements with KiwiRail suggesting the throughput could increase from 6,000 containers annually to a commendable 20,000.

June 2024 9

The newly-opened hub is a great example of a public/private partnership and an exciting project, Ashburton Mayor Neil Brown says, and for the district. Photo: Ashburton District Council

Maersk’s new integrated cold chain facility

In an eye-catching investment into New Zealand’s infrastructure, global logistics giant A.P. Moller-Maersk (Maersk) celebrated the opening of its state-of-the-art integrated cold chain facility at the Ruakura Superhub in Hamilton last month.

The new facility effectively moves the ocean inland by offering customers end-to-end supply chain management, including import, export, and cross-docking services.

With approximately $150 million invested, the facility represents Maersk’s largest infrastructure commitment in New Zealand to date. Strategically located at the Ruakura Superhub in Hamilton, the facility helps to solidify the city as a key touch point within the Golden Triangle for freighting and logistics throughout the country.

The cold chain facility enables the exchanging of goods between rail and truck, creating a highly flexible and sufficient supply chain and helping to further enhance the region’s thriving freight hub.

The multi-modal 18,000 square metre facility harnesses the four-lane State Highway 1 and

direct rail connectivity to both the Port of Tauranga and the Port of Auckland – boasting the capability to load 40ft containers holding an impressive 29 tonnes of product on to wagons.

Key features of the facility will see cold chain facility customers retain the quality of their products during transit by housing nearly 30,000 pallets of products in both cold rooms and blast freezers.

Commenting on the investment, Maersk CEO Vincent Clerc says New Zealand has long played a pivotal role in the global supply chain and will continue to do so.

“From dairy and meat to seafood and fruits, the primary industry sector drives the development of the country’s economy. We have operated in New Zealand for 27 years, and we are enthusiastic about fostering sustained growth and forging this long-term partnership with our customers.

“Over the years, we have made very significant investments in our ocean network and, now with the new

facility, offer a best-in-class experience from capacity, coverage and reliability perspective.”

The facility will leverage landside logistic capabilities allowing for larger quantities of imported and exported goods to flow through New Zealand and the wider AsiaPacific region, with high-profile customers such as Fonterra, BluePrint Global, Mega Food, and Service Foods set to utilise the new addition.

In addition, Maersk has also partnered with local iwi Waikato-Tainui as owners of the land on which the Ruakura Superhub sits. Through this partnership, Maersk will offer a clear training pathway for those wishing to take up a career in logistics - aptly reflecting the historic roots of the iwi with Waikato-Tainui ancestors reportedly trading up and down the nearby Waikato River in generations gone by.

Tukoroirangi Morgan, Chairman of Te Arataura, the executive committee of Waikato-Tainui, says: “Partnering with a global logistics giant like Maersk, who could

10 Logistics & Transport NZ

Maersk CEO Vincent Clerc says New Zealand has long played a pivotal role in the global supply chain and will continue to do so, especially with its newly opened cold chain facility. Photos: A.P. Moller-Maersk

see the massive benefits and efficiencies Ruakura Superhub offered, epitomises the vision we have for the Superhub as a critical supply chain enabler and driver of regional economic development.

“We’re proud to partner with Maersk to support their growth and ongoing contribution to Aotearoa New Zealand which will, in turn, support us to drive the economic resilience of our 86,000-strong iwi.”

Continually committed to reducing its environmental footprint, Maersk has ensured the facility meets the highest sustainability rating possible for a cold store – aiming to achieve at minimum, a Greenstar-5 rating to improve this to 6 stars, which will be the highest of any cold store in New Zealand.

With the installation of solar panels on all rooftops, using CO2 instead of ammonia in all freezers, collecting and re-using rainwater and providing electrical charging stations for cars and trucks - Maersk has put its money where

its mouth is and continues to be a key player in strengthening New Zealand’s logistics backbone.

Further to this, Maersk has committed to providing New Zealand international trade with “a stable, resilient and sustainable global supply chain, for primary industry exporters” with a newly signed long-term agreement until December 2034.

Signed in May with one of New Zealand’s largest containerised freight managers, Kotahi (founded in 2011 by Fonterra and Silver Fern Farms), the agreement is estimated to be worth $160 billione. Kotahi

Chief Executive David Ross said “the magnitude of this agreement is big, even by global standards”.

“The long-term agreement provides our shareholders, and exporters on our platform, with a backbone shipping network for reliable services to key export locations,” Mr Ross said.

“During the peak of the COVID-19 disruption, Maersk was the standout carrier in choosing to bring additional vessel

capacity and containers to New Zealand, which grew the capacity pie for the whole export market. This is an exciting partnership with Maersk. It enabled New Zealand exporters to stay competitive on the world stage and we look forward to the next 10 years.”

Since the parties’ first partnership commenced a decade ago, the relationship has shipped 1.8 million TEU or 23 million tonnes of New Zealand cargo to market, the majority being primary industry exports including dairy, meat, seafood, horticulture and forestry, through some challenging conditions.

Fonterra’s Chief Operating Officer Anna Palairet welcomed the deal. “Despite significant pressure on global supply chains over the past few years, Fonterra and many other New Zealand companies, have been able to keep products moving. We’re looking forward to seeing what this next decade of partnership between Kotahi and Maersk brings.”

June 2024 11

Heeni Katipa (right), sister of the Māori King of New Zealand, and Vincent Clerc, CEO of A.P. Moller-Maersk reveal a plaque at the opening of the new facility that will leverage landside logistic capabilities allowing for larger quantities of imported and exported goods to flow through New Zealand and the wider Asia-Pacific region.

HELP PROTECT NEW ZEALAND

Illicit drugs are causing harm to whānau and communities across New Zealand, and is a significant contributor to the rise in crime we are seeing.

People within the transport industry are ideally placed to help identify suspect shipments and activities that may help disrupt drug importations and other criminal activity.

Border Protect is a New Zealand Customs Service programme aimed at educating people on how to recognise signs of criminal activity within the supply chain. You can help protect New Zealand by being aware of the signs of suspicious shipments and criminal infiltration in the supply chain.

Dean O’Callaghan, Chief Customs Officer of the Border Protect Team, says “people within the transport industry are a key partner, and they have previously contributed to some fantastic referrals.”

“Past referrals have led to remarkable seizures of drugs, tobacco and other prohibited goods and have made our communities safer, while also saving millions of dollars in social harm.”

Organised criminal groups are actively targeting the supply chain and those who work in it to import drugs and also actively infiltrate supply chain businesses, including transport companies.

Customs can’t stop everything, and we need the help of industry to look out for and report suspicious shipments or activities. You know what normal looks like, and if you come across a situation that is not normal, we encourage you to report it.

Signs of suspicious shipments may be the type of goods, the nature of communications about storage and delivery, the behaviours of the importer or persons receiving the goods, how payment is made, or the nature of the delivery.

If in doubt, please report it.

The Customs Border Protect programme provides an ability to confidentially report information, either by calling 0800 WE PROTECT (0800 937 768) or using an online form www.customs.govt.nz/report

Customs also has a wide range of helpful resources to share. If you would like these resources or would like to engage with Customs about these topics, please contact the Customs Border Protect team on 021 957 928.

12 Logistics & Transport NZ

BORDER PROTECT UPDATE –

Be aware of break-ins!

Customs is seeing a significant increase in legitimate imports being targeted by overseas criminal groups who conceal illicit drugs within the container or container contents, which are later recovered by New Zealand-based criminals. Often this involves break-ins at supply chain businesses to collect the drugs.

Chief Customs Officer Dean O’Callaghan says, “break-ins have been occurring at various points within the supply chain including ports, freight forwarders, container companies and even importers’ premises”

“There is a noticeable pattern where break-ins are often occurring soon after other suspicious activity such as people or vehicles being observed at or near a premises without good reason.”

Specific indicators to be aware of include:

• Security cameras damaged or disabled by spray paint, wires cut, or turned away from areas of interest.

• Damage to buildings and premises allowing quick access in or out, including padlocks cut, alarms disabled, windows panes broken or removed, or holes cut in fences.

• Containers that have been damaged or accessed unexpectedly e.g. reefer motors damaged or removed.

• Drones being flown over or near commercial premises.

• Drivers of vehicles behaving suspiciously e.g. driving slowly back and forth, on to and around premises, or being parked nearby for long periods.

• People acting suspiciously, e.g. loitering, taking photos, walking on to properties and asking unusual questions. There is no profile for imports that will be targeted, because most imports are legitimate, and the drugs have been concealed without the supplier or importer’s knowledge.

Often the consignments or containers are unlawfully accessed at an offshore port while awaiting export or while the goods are in transit.

“No business is immune because the criminals will try and recover the drugs at whatever point they are able to gain access”, Mr O’Callaghan says.

Be aware of your security processes and ensure all staff are alert to any suspicious activity, including actual or attempted break-ins. If you identify any suspicious behaviour, then please follow your processes and contact Customs relevant Border Protect area.

Suspicious activity may be a precursor to imminent illegal activity occurring at your business. If you become aware of a break-in having occurred, please undertake your normal Police reporting along with advising the Customs Border Protect Team as soon as possible.

Maritime – Ports, Marinas, Coastline etc.

Contact your local port Customs Liaison or email maritime.pc@customs.govt.nz

Supply Chain – Freight Forwarders, Customs Brokers,

Couriers etc.

North Island

M: 021 957 928 E: ccateamakl@customs.govt.nz

South Island

M: 021 952 605 E: ccateamchc@customs.govt.nz

(0800 937 768)

Confidential 0800 WE PROTECT

June 2024 13

Retirement villages and the need to rethink transport and land use

Retirement villages around Aotearoa, New Zealand, vary significantly in size, facilities they offer, and locations. They can have very different configurations, feelings, and senses of community. Many have a range of housing styles and types available, offering levels of care from independent to respite care. The location of a retirement village will influence how easy it is for residents to access what they need or want. Villages are often located within suburban areas in the cities around Aotearoa, New Zealand. Some are closer to the inner city, while newer villages are more often found on the urban boundary. Within Aotearoa, New Zealand, six companies run 42 per cent of villages, making up 403 facilities across the country, mostly in larger metropolitan centres.

About 14% of New Zealanders aged 75+ live in retirement villages. There are multiple reasons why people choose to move into these villages, including a better quality of life, stronger community involvement, and the ability to live independently but with support when needed. As the average age of people living in retirement villages is mid-to-late 70s, one of the main reasons is declining health.

One such retirement village is located on the northern edge of Ōtautahi, Christchurch. Established in 2020, it provides living options from two- and three-bedroom houses with garages, which are architecturally designed around quality green spaces, to a care facility and serviced apartments. Its facilities include a heated pool, movie theatre, hair salon, gym,

café, and restaurant. It is on a busy road with poor walking access and limited and/or poor bicycle infrastructure.

In early 2022, some residents approached the University of Canterbury concerned about their future transport options. As part of a community-engaged course, a group of students surveyed residents about their transportation requirements. They concluded that as people’s health declined, residents would increasingly use some form of shared or public transport. However, further work was needed to understand more about these options.

Research was then carried out by researchers at the University of Canterbury, funded through a Transport Research & Educational

14 Logistics & Transport NZ

The Hokianga Road Masonic Village is close to hospitals and schools and is only a short distance from the rural hub of Dargaville. It offers a range of garaging at the village – with a communal garage, carports and some internal access garages in the mix. Photos: Masonic Villages Trust

Trust grant. They interviewed thirty residents about their transport use and needs. All but two of the residents interviewed had motor vehicle licences and owned vehicles. Several other transport options existed for residents. These included relying on friends and family for transport, public transport, a private shuttle service, an informal carpool arrangement within the village, car share services, taxis and subsidised taxis for people with mobility issues.

Access to public transport was difficult. The nearest bus stop was over 600 metres away over a steep motorway overpass, which many residents couldn’t manage. In addition, the bus route did not take people directly to their preferred destinations such as the central city or the hospital. The village did, however, provide a private shuttle service that ran scheduled supermarket visits and planned shared outings and activities.

Transport was not a primary consideration for most residents when moving to the village; instead, other factors, such as the living environment, were the main draw. Some residents had considered the limited transport options but did not see this as a barrier. Residents said that before moving to the village, they hadn’t considered their transport needs. They had hoped more options would become available but discovered this was not the case.

Some residents assumed that better public transport would arrive as the village continued to expand and surrounding residential subdivisions grew. Many said ideally, they wanted access to be flexible and affordable transport, options that would also provide similar convenience to a car.

All interviewees lived independently in twoor three-bedroom homes with single or double garages. Because the village was new, residents were, on average, younger than most people in retirement villages. With a few older exceptions, most were born between 1946 and 1964; baby boomers. This generation was the first to have access to motor vehicles for most of their lives, which created a sense of independence. Like many New Zealanders, they are also used to living in low-density suburban environments.

New Zealand has one of the highest rates of car ownership in the world, coupled with low rates of public transport use. For older people, losing a driving license due to health issues can be devastating. It has been associated with increased depression, feelings of dependence, and social isolation. This underscores the potential negative impacts of limited transport options on retirement village residents, highlighting the urgent need for improved transportation options.

Consideration needs to be given to the transport requirements of residents of retirement villages as they age, as well as the location of new retirement villages. Retirement villages are often large and require significant tracts of land, usually more readily available on the city edges. In cities around Aotearoa, New Zealand, this land is often zoned for such purposes through changes to District Plans.

In Christchurch, rezoning also occurred partly in response to the earthquakes of 2010/2011. However, residents in retirement villages occupying such land are generally dependent on private vehicle ownership as few other transport options exist. While not achieving other environmental goals, this situation is tolerable if people have access to motor vehicles but deteriorating health limits an older person's ability to use alternative forms of transport, such as walking, cycling or public transport.

There are several potential solutions to the transportation challenges faced by retirement village residents. First, building retirement villages closer to existing amenities and facilities would improve accessibility. However, this is contingent on the will of developers and the planning and policies in place. Second, encouraging residents to move to locations where they can easily access the facilities they need or want could also be beneficial, despite potential personal and financial implications.

Third, implementing delivery services for goods and services could alleviate some of the transportation burden. Finally, providing affordable shared transport options that are flexible and attractive to users, such as on-demand travel services, could significantly improve residents’ mobility. Each of these solutions has its pros and cons, but it’s clear that leaving retirement village residents with the only option of moving or paying for expensive transportation of goods and services is not a fair solution.

Transport Research and Educational Trust

The CILT’s Transport Research and Educational Trust (the Trust) was set up with aims to promote, encourage, and coordinate the study and advancement of the science of transport within New Zealand.

The Trust generally awards two different types of grants in alternate years, of up to $15,000 in value depending on the Trust’s income. The first is a small grant for personal development in transport and logistics, such as course fees. The other is a research grant of up to $15,000 or two smaller grants.

We make grants for projects that further the Trust’s aims – provided these aims are met, and the grants are within the educational and charitable purpose of the Trust, there is no limit on the nature of the project, nor the industry branch or discipline the applicant is involved in.

As transport touches on many aspects of New Zealand society and economy, the Trustees encourage applications from all disciplines and individuals with an interest in transport.

The last grant awarded was for personal development with the successful candidate undertaking a course to further develop their career.

Applications for the next grant round are likely to open in October/November 2024, and the successful applicant(s) will be advised by the end of the year or early in 2025.

Further information on the Trust is available at https://cilt.co.nz/transportresearch-and-educational-trust/

The website also has information on how to donate to the Trust. As TRET is a New Zealand registered charity, donations qualify for tax credit.

Simon Kingham, Jillian Frater and Karen Banwell

Te Kura Aronukurangi | School of Earth & Environment

Te Whare Wānanga o Waitaha | University of Canterbury

Ōtautahi | Christchurch

June 2024 15

New network will improve GPS accuracy to as little as 10 centimetres

A key piece of the network that will deliver more accurate and reliable GNSS positioning across New Zealand and Australia is fast taking shape near Invercargill.

Two 11-metre satellite dishes have just been hoisted into place at the uplink and ground control centre being constructed at Awarua, Southland.

The centre is one of two across the SouthPAN (Southern Positioning Augmentation Network) network being built for the New Zealand and Australian Governments. The first opened at Uralla, New South Wales, in December 2023.

At least six high-tech jobs will be created in Southland to operate the Awarua centre, due for completion by mid-2024.

SouthPAN is a satellite-based augmentation system (SBAS). It uses a network of space-based and ground infrastructure to compare satellite data against precisely measured positions and identify and correct positioning errors in global navigation satellite systems (GNSS) like GPS.

These corrections are sent to geostationary satellites and broadcast throughout New Zealand, Australia and our maritime zones.

SouthPAN will improve the accuracy of GPS from the current 5-10 metres down to as little as 10 centimetres, supporting businesses and industries that rely on precise location data.

The new infrastructure will improve the availability of the SouthPAN early open services offered since September 2022. The New Zealand and Australian sites will work in tandem to provide network resilience.

SouthPAN will support precision farming and improve safety in industries like construction where virtual barriers can help protect workers from heavy machinery.

Forestry operators are currently using SouthPAN for inventory mapping, harvesting and worker safety. It is helping crop sprayers with more accurate aerial application of fertiliser.

By 2028 when SouthPAN is expected to be fully operational, it will enable helicopters and planes to fly safely in poor weather they cannot fly in now.

SouthPAN is a partnership between Toitū Te Whenua Land Information New Zealand (LINZ) and Geoscience Australia. Economic benefits to New Zealand from SouthPAN are estimated at $864 million over 20 years.

16 Logistics & Transport NZ

Reliable and accurate positioning information will enable better risk management and prevention across various sectors such as construction, transport, maritime and aviation, and in emergency situations such as search and rescue operations. Photo: Lockheed Martin

Making the most of Tāmaki Makaurau’s port and prime waterfront

In a deal that will see more space given back to public access, and more than $1 billion in profits handed to Auckland Council over the next 10 years – the Port of Auckland is staying put.

Under the new plan, Auckland Mayor Wayne Brown has announced his initial idea of leasing out port operations for 35 years is now off the table. Instead, the land, assets and operations will be retained by the Council, to the satisfaction of both the Port of Auckland and the unions.

The arrangement will see $1.1 billion in profits head to the Council over the next decade, far exceeding the projected net returns (from investing the proceeds of a port lease) by $172 million.

According to a council-produced plan issued at the same time as the Mayor’s announcement, the Port has agreed to deliver significantly improved profits to the city, improving its profit forecasts by $5 million in FY25, $15 million in FY26 and $20 million in FY27; at which point it will be contributing about $2 million a week to the city.

“These increased returns will require increased charges and improvements in productivity. The revised numbers are to be included in the Port’s Statement of Corporate Intent and the Council’s Long-Term Plan.

“They deliver more than $1.1 billion in profits over the LTP period: $200 million more than previously forecast under the “enhanced status quo” and $172 million more than the projected net returns from investing proceeds of the lease.”

Set to be formalised by way of Port of Auckland’s Annual Statement of Corporate Intent and the Council’s Long-term Plan (10-year budget) 2024-34 – the new plan is based on a tripartite relationship agreement between Auckland Council, Port of Auckland, and the unions, represented by the Maritime Union of New Zealand.

Commenting on the plan, Mayor Brown says it will provide a foundation for good faith,

cooperation, and long-term strategic alignment.

“By trade, I’m an engineer. I solve problems. We looked at a couple of options to improve returns and this is the best solution.

“This plan reflects my commitment to get better value and better returns from our strategic assets and strengthen the council’s long-term financial position. These higher returns will require increased port charges and improvements in productivity, and all parties are supportive of this.”

Auckland Council’s enhanced oversight of the Port’s strategic direction and long-term planning, together with Port of Auckland’s High-Performance High-Engagement model, have contributed in part to the Port Company’s financial turnaround.

“Upon entering into Office, I immediately put pressure on all council-controlled organisations and raised our expectations of Port of Auckland’s profits. To their credit, the board and CEO raised the Port’s performance and returns, and met our demands head-on,” says Mayor Brown.

“We will work together to make the most of the port and the space it occupies.

The Mayor’s proposal will also mean the return of Captain Cook Wharf and Marsden Wharf to Auckland Council, which will have have no impact on the Port Company’s profitability in the short term. Mayor Brown has also negotiated public access to parts of Bledisloe Wharf, as a shared space for public use and cruise ships – a major win for locals and tourists alike.

“Auckland’s harbour and waterfront are a big part of what makes our city special, and it’s important that we get this right. The success of the plan will be based on cooperation and joint planning, and the inclusion of mana whenua, stakeholders, and the public,” says Mayor Brown.

“We’ve taken time to explore all options for the Port and test the market. It’s helped us

understand what the opportunities are and what our expectations ought to be. Had the process been any less rigorous, and the debate any less robust, we may never have reached a consensus.”

Echoing Mayor Brown’s sentiments, Secretary of the Maritime Union Grant Williams says the agreement acknowledges the importance of the port to Aucklanders.

“The Mayor’s focus on the future of the port has highlighted its importance to the city and brought us together for a common cause. We’re pleased to see that the value and contribution of port workers has been recognised by the Mayor, councillors, and the community”.

Exceptional weight has been placed on the future of the waterfront, port and the upper North Island supply chain with the council plan outlining several areas for growth, including the Council’s support for Auckland Port to remain the key import port of Auckland for the foreseeable future.

While this could serve the supply chain well for “30 years or more”, the three parties agreed to work together to support a longterm strategy for port development outside Auckland’s city centre and the infrastructure required to support the Upper North Island Supply Chain.

The completion of Bledisloe North and Ferguson Wharf will continue unabated, creating “an intergenerational legacy for Aucklanders”, but there will be no further expansion into the harbour.

“The Port affirms its firm position that the planned infrastructure set out in this plan completes the Port’s footprint. It will not progress plans to extend the Port a further inch into the Harbour.”

The proposed agreement runs through to 2034.

To read the plan in full, see https:// ourauckland.aucklandcouncil.govt.nz/ media/ekqkx1t5/amwb_ports_v1-5.pdf

June 2024 17

Hiringa Energy launches refuelling network

Green hydrogen company Hiringa Energy (Hiringa) has launched Australasia’s first zero-emissions green hydrogen refuelling network, set to help move New Zealand towards its net-zero carbon emissions goal by 2050.

The refuelling network marks a groundbreaking milestone towards decarbonising the sector and will serve as a potential blueprint for similar infrastructure projects across the Tasman. Opened officially in May by Minister of Energy and Transport, Simeon Brown, the initiative is largely being touted as the impetus to attract and introduce large-scale decarbonisation efforts for the heavy transport sector across New Zealand.

Despite only making up 4 per cent of the vehicles on the roads, 25 per cent of New Zealand’s transport emissions come from the heavy road sector – something Hiringa is keen to address.

In partnership with the country’s leading independent fuel supplier Waitomo Group, and Australasia’s largest heavy vehicle fleet owner TR Group, the New Zealand Green Hydrogen Refuelling Network is visionary.

Initially launched with three locations, Wiri (South Auckland), Te Rapa (Hamilton) and Palmerston North – the network is positioned to service 95 per cent of the heavy freight routes across the North Island – including the “Golden Triangle” of freight movement (between Auckland, Hamilton, and Tauranga). A fourth station in Tauranga is also progressing as an integral part of the new Tauriko SH29 roading infrastructure developments. Green hydrogen production and refuelling infrastructure sites across the Australian east coast have also been identified as priority locations.

Commenting on the network, Hiringa Energy Chief Executive Andrew Clennett says the initiative provides operators with the infrastructure they need to switch to zero-emission transport in an efficient, scalable, and commercially viable manner.

“Heavy transport plays a vital role in our economy, but it’s also a significant contributor to our national emissions. As a first-of-its-kind across Australasia and one of the first networks set up globally to service heavy transport, the initiative addresses this major challenge,” Mr Clennett said.

Make no mistake, Mr Clennett says the time to address decarbonisation is now.

“Without an available commercial-scale refuelling network, the fleets would never be able to be introduced. We saw the need for a network, rather than a single station, that was able to support a range of commercial and heavy transport use cases (line haul, return to base), with reliable, safe, affordable, and available fuel.

“Our investment in the network will ensure that the barrier of hydrogen supply is removed, ensuring one of the vital tools in the decarbonisation toolkit is available to the market. We have had to build a network at scale to ensure there is a commercially sustainable and reliable solution that can enable greater fleet adoption beyond what has traditionally been piloting programs.”

With the opening of the network, hydrogen-powered trucks can go into commercial operation enabling heavy transport to begin its transition to zeroemission alternatives. The refuelling stations are powered by clean, renewable energy and equipped with state-of-the-art technology, enabling heavy vehicles such as trucks and buses to refuel with green hydrogen in 10 to 20 minutes.

18 Logistics & Transport NZ

The new network initiative provides operators with the infrastructure they need to switch to zero-emission transport in an efficient, scalable, and commercially viable manner. Photos: Hiringa Energy

Bringing the vision to reality, the network infrastructure has received support from the New Zealand Government via a $16 million loan, growth capital from key investors including Sir Stephen Tindall’s fund K1W1, international investments from Mitsui & Co Ltd and Green Impact Partners alongside Hiringa Energy.

The network has also received plaudits across the board, with many of Hiringa’s partners throwing their support firmly behind the initiative.

“We are pleased to see how Haskel’s worldleading hydrogen compression technology is being deployed across the world. The rollout of the reliable, and versatile technology in these hydrogen refuelling stations in New Zealand is a great example of how international collaboration, policy and a positive investment climate can accelerate demand for decarbonisation infrastructure,” said Haskel's APAC Region Hydrogen Business Development Manager Stewart Anderson.

Toyota New Zealand Chief Coordinating Officer Tatsuya Ishikawa added: “this is a big step forward as it means we can offer more decarbonisation products, like generators and fuel cells for trucks. We are committed to pioneering new technologies and actively driving decarbonisation efforts.”

According to Hiringa’s in-house data, there is a nascent fleet of two fuel cell trucks, five dual-fuel trucks, one fuel cell bus and approximately 15 light vehicles that currently use hydrogen.

Ministry of Transport statistics show there are around 47,300 registered electric vehicles in New Zealand and more than 160,000 heavy vehicles – the trucks are seen on the roads 24/7, carrying full payloads, to be commercially viable.

With the refuelling facilities, such as Hiringa’s network, now starting to come online – Hiringa is confident another 26 50MAX trucks are being converted to fuel cell and dual vehicles this year.

“An important feature of these heavy vehicles is that they are able to replace the largest, most emitting vehicles in New Zealand’s fleets – each truck being equivalent to replacing 100-150 cars, at a much lower cost – so rather than it being about vehicle count, it is about the type and emissions reduction impact of these vehicles,” Mr Clennett said.

“Decarbonising our supply chains is vital for New Zealand both to address our own Emission Reduction Plan goals

as well as satisfy our export market requirements. Our collective task is to displace emissions from fossil fuels such as diesel, and globally, governments and organisations are recognising hydrogen as one of the technologies that needs to be implemented at pace to support this. The technology is ready to deploy now and start scaling up.”

Looking ahead, the focus of hydrogen for transport is centred around the high utilisation of commercial and heavy vehicle space where the uptime from fast fuelling/ charging and range capability creates a natural advantage over other technologies.

In fact, it is estimated that over the next three years, the first fleets will be built into different sectors and the refuelling network itself will continue to expand. By the end of the decade, it is expected the industry will reach parity with the cost of running a diesel truck – something Clennett and Co. are actively pushing for.

“At this stage, we have reached a tipping point, and the adoption of hydrogen will accelerate as a proportion of the fleet replacement rates. Simply put, time is of the essence to address decarbonisation.”

June 2024 19

The refuelling stations are powered by renewable energy and equipped with state-of-the-art technology, enabling heavy vehicles such as trucks and buses to refuel with green hydrogen in 10 to 20 minutes.

The Great Synchronisation and The Great Asynchronisation

“The Great Synchronisation” is a shorthand for describing the long historical process of increasingly precise coordination of time and activities. This began with the development of standardised calendars for agriculture. Mechanical clocks, often accompanied by town bells and factory whistles enabled the precise measurement, coordination, and communication of time. Schedules became a fundamental part of daily life, dictating work shifts, school hours, and transport timetables.

The Industrial Revolution furthered the need for synchronisation, with factories requiring workers to adhere to strict schedules to maintain efficiency, comporting the human, transformed effectively into a robot for the duration of the workday, to the assembly line, replacing the craftsmanship of the artisan, allowing an upscaling of total economic output at the cost of individual autonomy.

Urbanisation demanded the coordination of public services and transport to accommodate city dwellers, particularly the precisely scheduled factory workers, and schools to watch their children while the workers laboured. The concept of Just-in-Time delivery and production in manufacturing exemplifies this synchronisation, requiring precise coordination of material orders with production schedules not only within organisations but also between them.

The advent of the internet and digital technologies over the past three or so decades have ushered in “The Great Asynchronisation”. The internet permits the transmission of information and communication across different time zones without the need for simultaneous presence. Asynchronous communication technologies such as email, forums, and social media enable people to interact without being online at the same time. The rise of remote work, especially with COVID, and globalisation further this trend, with employees working from different locations and at times that suit them best, and businesses operating across multiple time zones.

The transition from traditional to digital media is emblematic of this shift. Traditional

media, such as TV, radio, and newspapers, relied on scheduled programming and fixed publication times. In contrast, digital media like streaming services, podcasts, and blogs offer on-demand access, allowing users to consume content at their convenience. This transition reflects long-standing consumer preferences towards flexibility, personalisation, and interactivity that can now be served by newer modes of communication.

Asynchronisation of work (and shopping and other activities) may be better for mental health and allow more people to participate more fully in society. It may also be better for productivity (if bad for the ego of managers). It is just terrible for many traditional synchronised services: mass transit, mass media, mass market, mass production, mass education, really mass anything.

Mass transit, like mass everything, requires scale, with many people going from origin X to destination Y at time T. If we have a high enough frequency of service and high enough demand, then coordination of T matters less, (and in fact, less peaking is probably an easier service to provide in many ways) though coordination across space remains important. But once people no longer travel to the same places in the same numbers, fixed-route transit begins its slide down transit’s doom loop, the vicious cycle wherein service cutbacks reduce demand, lower demand reduces revenue, and lower revenue leads to further service cutbacks. If this trend continues, and there is no reason to believe it won’t, it will be a struggle for urban transit to recover ridership from its pre-pandemic peak, much less grow, as it competes with more convenient, time and space-untethered individual modes of transport (walk, bike/e-bike, car, taxi) that now have accelerated asynchronisation as winds in their metaphoric sails. To the extent that extant transit organisations do compete, it will be because they have become more like those modes (shared demand responsive transport), but that transformation is a costly endeavour, economically infeasible at scale in the absence of automation. And even if that

market is to succeed, there is no guarantee the incumbent players will be the providers.

So, the longstanding relative if not absolute “decline of transit”, a trend many countries have seen since the 1920s, with only occasional upswings, proceeds. Only in growing places with dense activity centres can transit thrive, and the minimum threshold of density for transit to be viable will continue to rise.

As we transit the great arc of history, exiting the “The Great Synchronisation” and entering “The Great Asynchronisation”, we witness a societal shift from a world governed by strict schedules and centralised control to one characterised by flexibility, decentralisation, and personalisation. This transformation is driven by technological advances that have reshaped the way we organise time and space, work, interact, and consume, reflecting a broader trend towards a more asynchronous society.

Author David Levinson david.levinson@sydney.edu.au

Author David Levinson david.levinson@sydney.edu.au

Prof. David M. Levinson joined the University of Sydney from the University of Minnesota in 2017 as a Foundation Professor in Transport Engineering. This article first appeared on his substack channel https://www. transportist.net/

20 Logistics & Transport NZ

Photo: Lockheed Martin

Photo: Lockheed Martin

Abley Techinical Director Andrew Couch responds to concerns made by Ian Wallis in the previous issue, citing all public transport modes face the same challenges concerning patrons transferring between services. Dr Couch believes cable cars are not being assessed on a consistent basis with other transport options in New Zealand.

Photos: Doppelmayr New Zealand Ltd

Abley Techinical Director Andrew Couch responds to concerns made by Ian Wallis in the previous issue, citing all public transport modes face the same challenges concerning patrons transferring between services. Dr Couch believes cable cars are not being assessed on a consistent basis with other transport options in New Zealand.

Photos: Doppelmayr New Zealand Ltd

Cable cars can support public transport options into the centre rather than competing with existing local bus services. Alternatively, they also work best as a potential transport replacement , especially in a constrained environment.

Cable cars can support public transport options into the centre rather than competing with existing local bus services. Alternatively, they also work best as a potential transport replacement , especially in a constrained environment.

Author John Skilton BE

Author John Skilton BE

KiwiRail Executive General Manager Freight Markets Alan Piper says the hub has already helped to reduce road congestion on State Highway 1 (to and from Christchurch) and has improved truck-turn times at Lyttelton Port.

The Fairfield Freight Hub offers a structured approach to freight movements with KiwiRail suggesting the throughput could increase from 6,000 containers annually to a commendable 20,000.

KiwiRail Executive General Manager Freight Markets Alan Piper says the hub has already helped to reduce road congestion on State Highway 1 (to and from Christchurch) and has improved truck-turn times at Lyttelton Port.

The Fairfield Freight Hub offers a structured approach to freight movements with KiwiRail suggesting the throughput could increase from 6,000 containers annually to a commendable 20,000.

Author David Levinson david.levinson@sydney.edu.au

Author David Levinson david.levinson@sydney.edu.au