June 2023 www.mepca-engineering.com

—

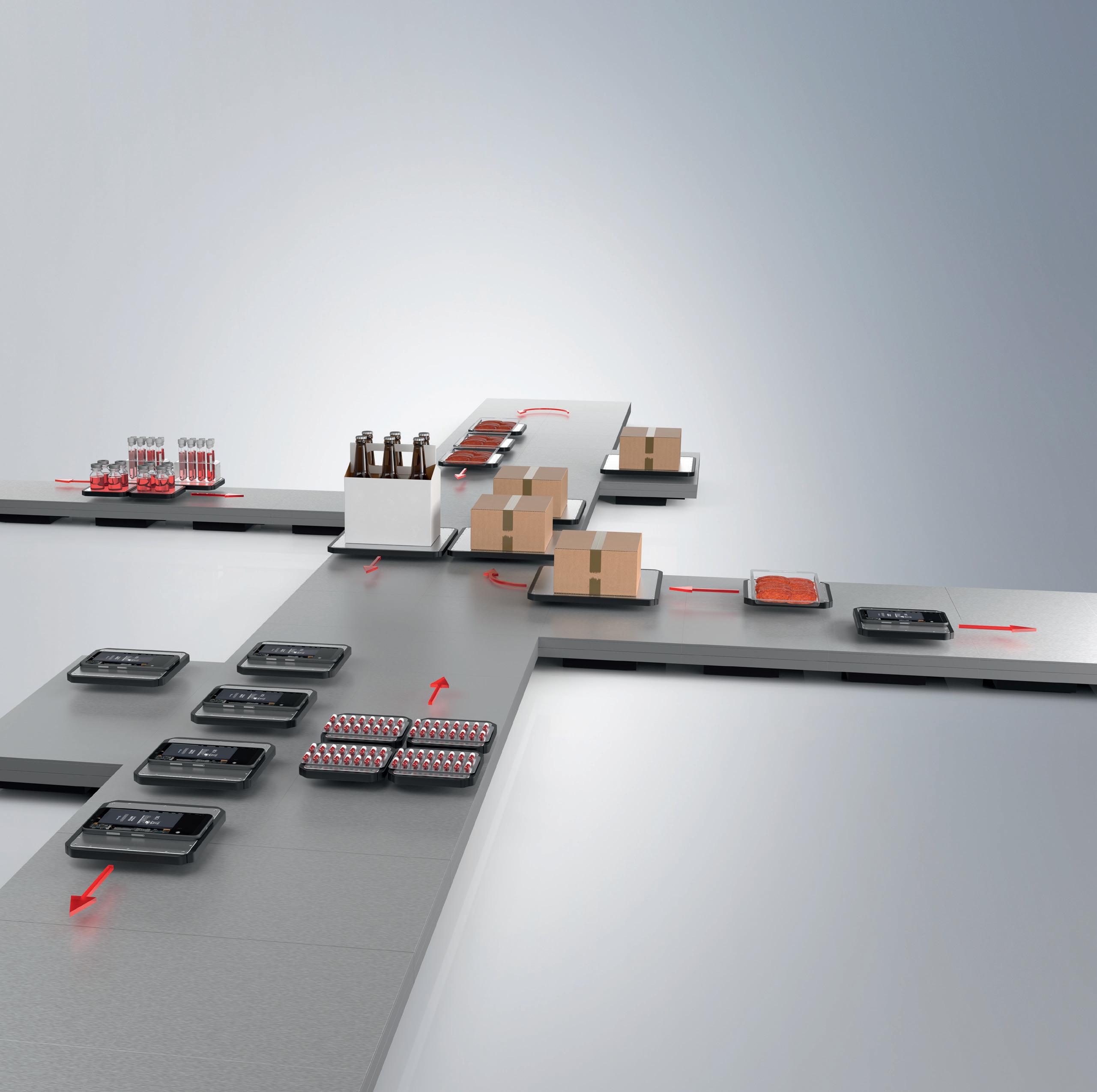

ABB and B&R to demonstrate integrated automation capabilities at Automation UK

Find out how we can be your one-stop shop for complete automated solutions at Automation UK (CBS Arena, Coventry, 20-21 June). Stand A01 will include a demo featuring our GoFa cobot and B&R’s ACOPOS 6D new handling system, plus an example from our range of autonomous mobile robots for logistics and intralogistics applications.

To discover ABB’s complete range of automated solutions visit: https://bit.ly/MEPCAAutomationUK — Visit us at stand A01 on 20-21 June for Automation UK

Editor

Chris Callander chrisc@cimltd.co.uk

Publication Manager

James Davies jamesd@cimltd.co.uk 01795 509105

Account Manager

Hannah Moody hannah@cimltd.co.uk 01795 509115

Design & Production

Grant Waters Grant@cimltd.co.uk

James Taylor james@cimltd.co.uk 01795 509108

Credit Facilities Manager

Lauren Sharpe creditcontrol@cimltd.co.uk 01795 509103

Administration Manager

Natalie Murray admin@cimltd.co.uk 01795 509103

Sales Director

Tom Woollin tom@cimltd.co.uk

Chief Executive

John Denning jdenning@cimltd.co.uk

www.mepca-engineering.com

© 2023 TGM Publishing Limited,1st Floor, Saphir House, 5 Jubilee Way, Faversham, Kent, ME13 8GD. No part of this magazine may be reproduced or stored in a retrieval system or transmitted in any form – electronic, mechanical or physical – without express prior permission and written consent of the publisher. Contributions are invited and when not accepted will be returned only if accompanied by a fully stamped and addressed envelope. Manuscripts should be typewritten. No responsibility can be taken for drawings, photographs or literary contributions during transmission or in the editor’s hands. In the absence of an agreement the copyright of all contributions, literary, photographic or artistic, belongs to TGM Publishing Limited. The publisher accepts no responsibility in respect of advertisements appearing in the magazine and the opinions expressed do not necessarily represent the views of the publisher. The publisher cannot accept liability for any loss arising from the late appearance or non-publication of any advertisement.

June 2023

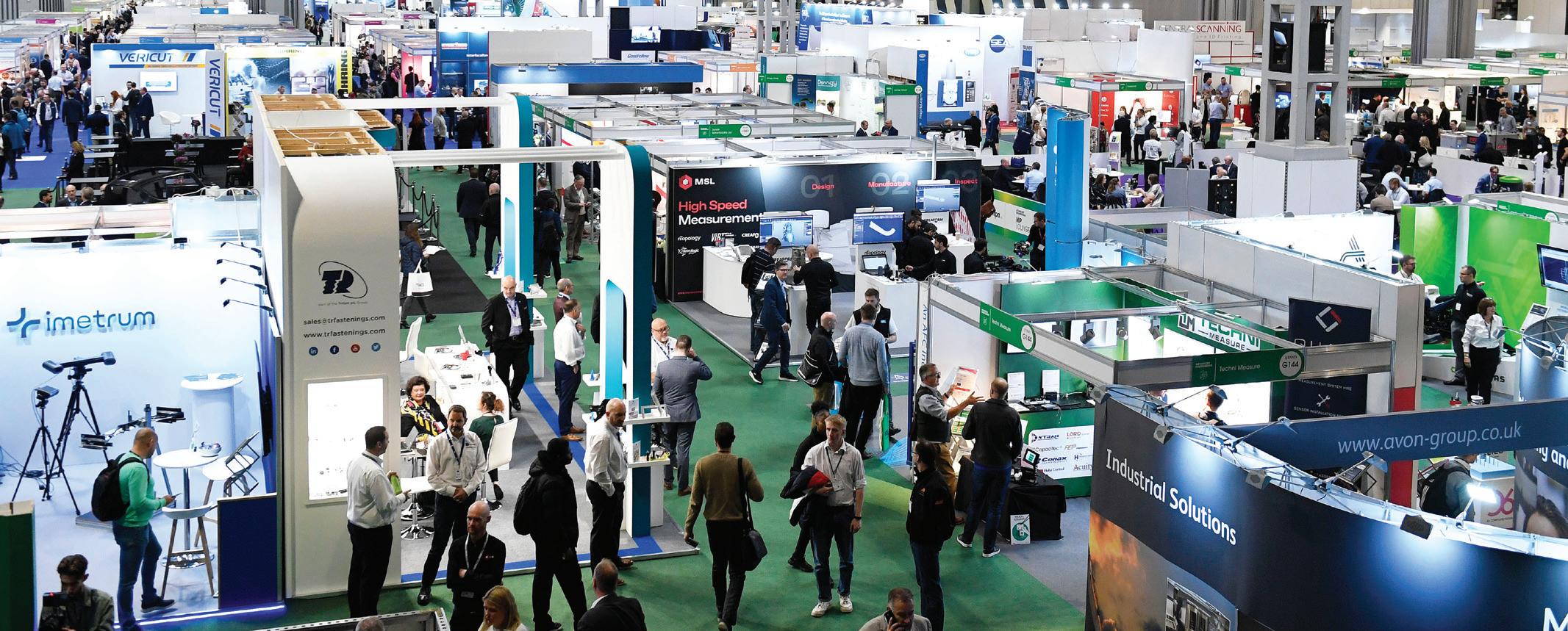

Idon’t seem to get out much these days. Partly this is because there are fewer press events than there were ‘back in the day’, partly it’s down to increased pressures on my time, and partly it’s because we can accomplish so much with virtual meeting tools like Zoom, Teams and Google Meet. But when I do leave the comfort of my office, it’s far less likely to be out of curiosity about what I’m attending and much more because I have a clear purpose.

I think my experience is pretty typical these days, and that was backed up by two exhibitions I attended last week – ChemUK and the Water Equipment Show. At both events, almost all the exhibitors I spoke to mentioned the quality of the visitors to their stands and that there were fewer ‘tyre-kickers’ than in the past. The visitors had a good reason to be there.

I also had a reason to be at the two exhibitions. There were specific people at both events that I had arranged to see, and meetings I had scheduled for which the events offered the ideal venue. At one, I had four scheduled meetings in one day, which would have been difficult if travelling between them. Yes, I could have had the meetings online, but I still believe you can’t beat face-toface interaction. For example, in an online meeting I wouldn’t have been able to see up close he new products from the companies I was meeting – not in the same way. I wouldn’t have stumbled across new technologies and ideas I wasn’t aware of in an online meeting either. And I wouldn’t have had the opportunity to discover some new companies I wasn’t familiar with and have a two-way conversation straight away.

The good news is we are in peak exhibition season, and over the coming months there are plenty of opportunities to get out, meet existing contacts and make new ones. In this issue of MEPCA we have previews of five upcoming events; Manufacturing & Engineering Week, Subcon, The Machine Vision Conference, Automation UK and Advanced Engineering, so you can plan which you will attend.

And if you are going to these events, maybe I’ll see you there, as it’s time to do what I’ve been told I need to do for a long time. I need to get out more.

Chris Callander, Editor @Mepca-magazine

4 www.mepca-engineering.com CONTENTS 18 To subscribe to MEPCA visit our website www.mepca-engineering.com or scan the QR code.

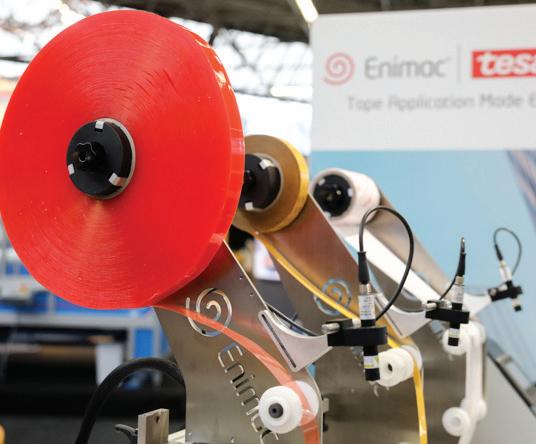

Industry Partners: www.mepca-engineering.com 5 CONTENTS 36 38 30 24 28 FEATURES 6 INDUSTRY NEWS All the latest news and updates 8 SOLUTIONS FOCUS ifm, SICK, HSM & KUKA 12 OPINION Gambica & BPMA 16 COVER STORY Bosch Rexroth 18 SENSORS & SENSING SYSTEMS ESI Technology & Pepperl+Fuchs 22 DRIVES, MOTORS & CONTROLS Beckhoff UK 24 PUMPS & PUMPING SYSTEMS Borger, Castle Pumps & Stuart Turner 28 PACKAGING & INSPECTION Cognex & Leuze 30 CONTROL SOLUTIONS HMS Networks 36 EVENT PREVIEWS M&E Week, Automation UK, Machine Vision Conference, Subcon and Advanced Engineering 42 EVENT REVIEW Tape & Functional Film Expo

Innovate UK helps chemtech firm scale-up game-changing solution

Achemtech company has scaled up the manufacturer of a game-changing smart material solution that eliminates cancer-causing ‘forever chemicals’ from water following funding from Innovate UK.

Puraffinity, based in London, has developed adsorbent granules that remove hazardous pollutants from water in various settings, including industrial manufacturing facilities.

This smart material targets PFAS (Per- and polyfluorinated alkyl substances), also known as ‘forever chemicals’, found in everyday products and responsible for contaminating the world’s food and drinking water supply and causing cancer.

Puraffinity has accelerated the design, testing and synthesising of its solution after working with the National Measurement Laboratory (NML), the UK’s designated institute for chemical and bio-measurement.

The project was supported by Analysis for Innovators (A4I), a grant funding programme which gives businesses access to cuttingedge R&D and expertise. A4I is run by Innovate UK, the UK’s national innovation agency.

Now

with a £1.54m Innovate UK Continuity

Loan, Puraffinity can boost its UK manufacturing capability 20fold to five tonnes per year.

Launched in 2015 as a spin-out from Imperial College London, Hammersmithbased Puraffinity is delivering a sustainable solution to treating PFAS, a group of 4,700 manmade industrial chemicals linked to cancer and COVID-19 and widely regarded as the most severe global water quality challenge in modern times.

But the critical bottleneck for the business was gaining detailed insight and assurance on the product’s stability and safety. It also saw a growth opportunity to take a more data-driven approach to its development work where it had already carried out proof-of-concept work to embed data-driven analytics into its design, build, test and learn cycles.

After securing funding from A4I, Puraffinity partnered with the NML where it used critical equipment and deep sector expertise to speed up its development cycle and improve the data integrity of its quality assurance/ quality control processes.

The methods developed significantly

de-risked the product development process, reduced discovery-design-synthesis cycles, facilitated more precise production scale-up, mitigated batch variations and increased yields.

Puraffinity can now provide prospective clients assurance of the safety and the longterm stability of the products, a crucial element in commercialising public health innovations through water treatment.

A4I has been running since 2016 and brings together nine national centres of excellence in measurement, tackling challenges affecting existing processes, products or services.

Celebrating 35 years delivering advanced automation projects

Mitsubishi Electric and its Automation Solution Partner, Ashdale Engineering, are celebrating 35 years of partnership, focused on bringing highly customised, effective automation solutions to various industries in Northern Ireland. Spanning over three decades that featured significant technical innovations, the anniversary marks an occasion to look back at key achievements reached by the two companies and how their relationship has grown.

During this 35-year period, Mitsubishi Electric has assisted the electrical

engineering and system integration specialist with state-of-the-art equipment technical support. This dedication to helping Ashdale Engineering deliver value-adding solutions to the market has been driving the company’s competitiveness as well as that of its customers.

Ashdale Engineering, in turn, has continued to grow and become an integral Automation Solution Partner. From investing in talent to training members of its team to become Mitsubishi Electric Certified Engineers, the company has ensured that it can help end users and OEMs benefit from the latest advances in automation. Over time, Ashdale Engineering has also

become one of the region’s largest stockists of Mitsubishi Electric equipment and has had its facility recognised as a Centre of Technical Excellence. Also, thanks to the close relationship with the automation vendor, it has been shedding a unique light on the needs of different industries to help the development of new products.

6 www.mepca-engineering.com

INDUSTRY NEWS

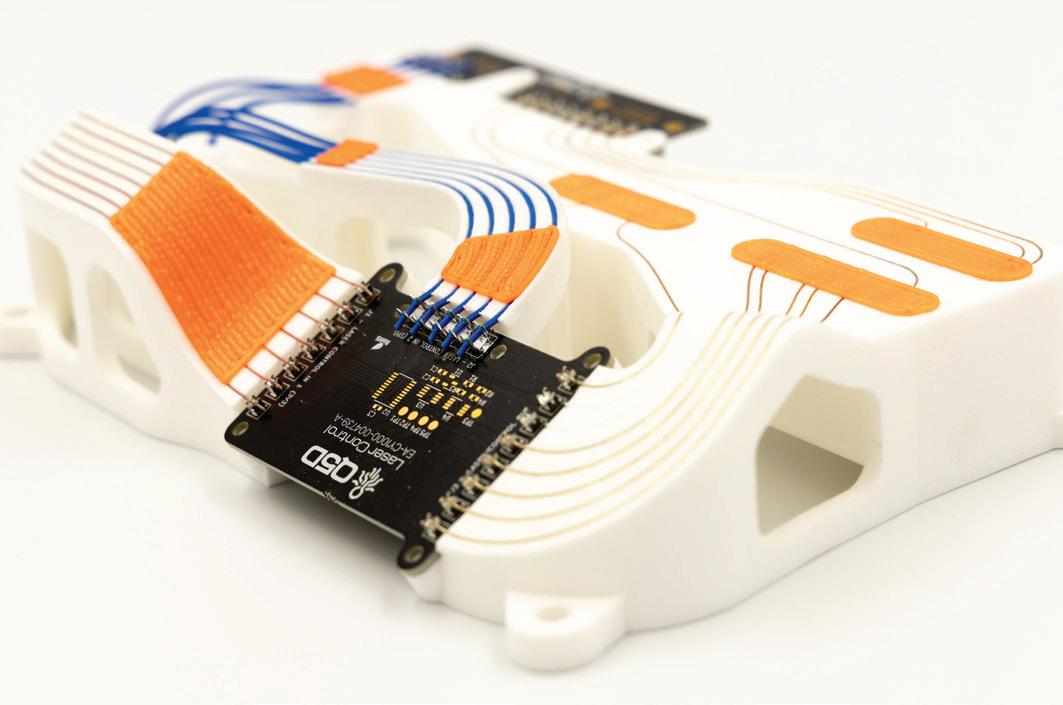

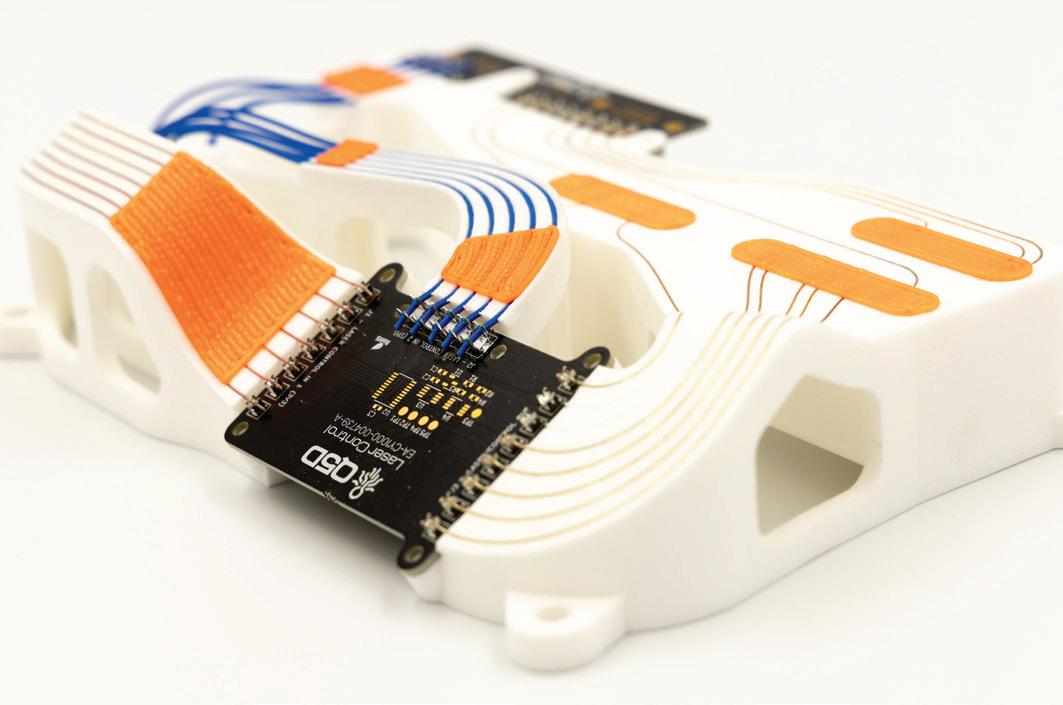

Robotic solution for complex aerospace parts

A£1.7m project is being delivered by Q5D Technologies in collaboration with the University of Sheffield Advanced Manufacturing Research Centre (AMRC) to accelerate automation within the aerospace industry by using a novel robotic solution to add embedded wiring into complex aircraft components.

Project LiveWire, led by Bristol-based Q5D, aims to automate the manufacture of airline seating components and control systems by embedding wiring into the structures which make up these parts, helping reduce costs and build lighter, higher-quality components.

Wiring in aircraft, cars and many consumer electrical goods is currently done by hand, making it an expensive and laborious process that is prone to errors and can cause failures and sometimes even fires. As part of this project, Q5D has created a 5-axis robotic tool that can add wiring to a complex shaped component in a new, improved way.

The AMRC, part of the High Value Manufacturing (HVM) Catapult, was tasked with devising a proof-of-concept solution to calculate the position and rotation of a workpiece to enable the robot to fully automate the process of embedding wiring into them for use in the aerospace sector, as well as creating integrated validation processes for quality inspection.

Edwin Anarcaya Roca, research engineer

at the AMRC, said: “Q5D tasked the AMRC with making sure the position and rotation angle of the workpiece produced the best possible accuracy, while maintaining high repeatability and a fast computational process.

“To obtain this, AMRC engineers performed a number of trials to identify the right hardware and software that would be best suited and supported the company in implementing a proof-of-concept solution using a stereo vision camera.”

The benefits of automating the robot path using a vision system will provide Q5D’s robotic technology with greater flexibility to adapt to dynamic environments. Making automatic adjustments to the robotic path on the fly will increase productivity as it will decrease the manual programming needed to re-adjust the robot tool path.

Roca added: “The AMRC also implemented proof-of-concept computer vision solutions to automate the wiring inspection. These solutions include algorithms that detect defects such as wire breakages, crushed wires, stripped wire insulation, wires escaping from the track and incomplete track walls.

“The techniques used in these defect detection algorithms could lead to the development of a real-time, embedded wiring defect detection system integrated with the machine itself. Even though this project was looking at a pathway for use in the aerospace sector, this concept can be transferable to any robotics automation system.”

Peter Todd, Operations Manager at Q5D, said: “Our goal is to automate the largely manual processes currently employed to make wiring harnesses with a CAD/CAM approach that will also create new product design opportunities, reduce weight, and use less space.”

The project, funded by Innovate UK as part of the ATI program, is a collaboration between Q5D, the University of Sheffield AMRC, as well as other companies, including OnePLM, M-Solv and Safran.

ABB completes divestment of UK technical engineering consultancy business

Following a strategic portfolio review, ABB has completed the divestment of its UK technical engineering consultancy business, part of its Energy Industries division, to TÜV Rheinland. The financial terms of the transaction have not been disclosed.

ABB’s consultancy business, which complements TÜV Rheinland’s existing risk, safety and integrity management services, has been integrated into the Industrial Services and Cybersecurity business of TÜV

Rheinland in the UK.

ABB’s UK technical engineering consultancy, including a network of subcontractors and associates, has around 160 people operating from two main sites in northeast and northwest England. A specialist team of technical experts helps global energy customers improve process safety, equipment and asset integrity, as well as technical design for new and existing industrial plants.

www.mepca-engineering.com 7 INDUSTRY NEWS

T-slot cylinder sensors

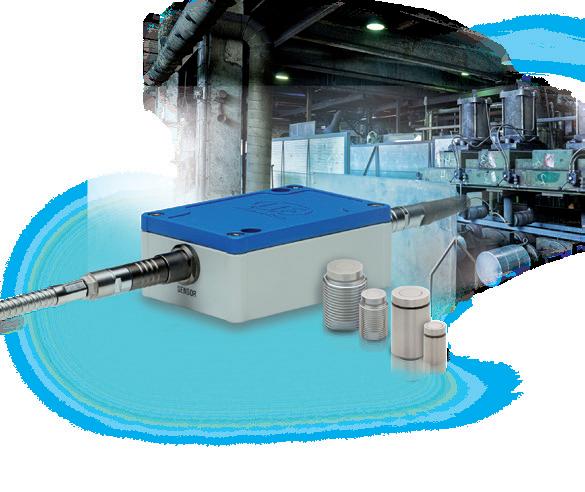

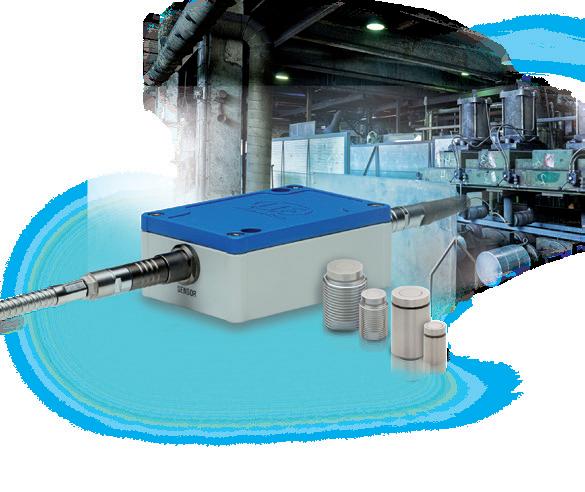

When used with shortstroke pneumatic cylinders, a single sensor from ifm electronic’s new MK59xx range can detect both cylinder end positions, whereas, in the past, two separate sensors would have been needed. This reduces both cost and installation time.

Designed for T-slot mounting, the new sensors have a detection range of 50mm and, as well as conventional switching outputs, they feature an IO-Link interface that allows continuous high-resolution monitoring of cylinder position.

If the IO-Link interface is used, MK59xx sensors also provide additional functionality, including a stroke counter which is invaluable for evaluating the service life of

critical cylinders, a stroke timer which can provide a useful warning of mechanical or air pressure problems and a temperature monitor. An additional benefit is that thanks to a teach function and a Bluetooth adaptor, the sensors can be adjusted from outside the machine after installation.

MK59xx sensors are currently available in versions with either one or two switching outputs and with a range of connection options, including 2 or 6m cables or pigtails with either M8 or M12 connectors. All types provide two digital outputs accessible via IO-Link, and all have a maximum switching frequency of 200Hz. The sensors have an IP67 ingress protection rating which allows them to be used in all normal industrial applications.

www.ifm.com

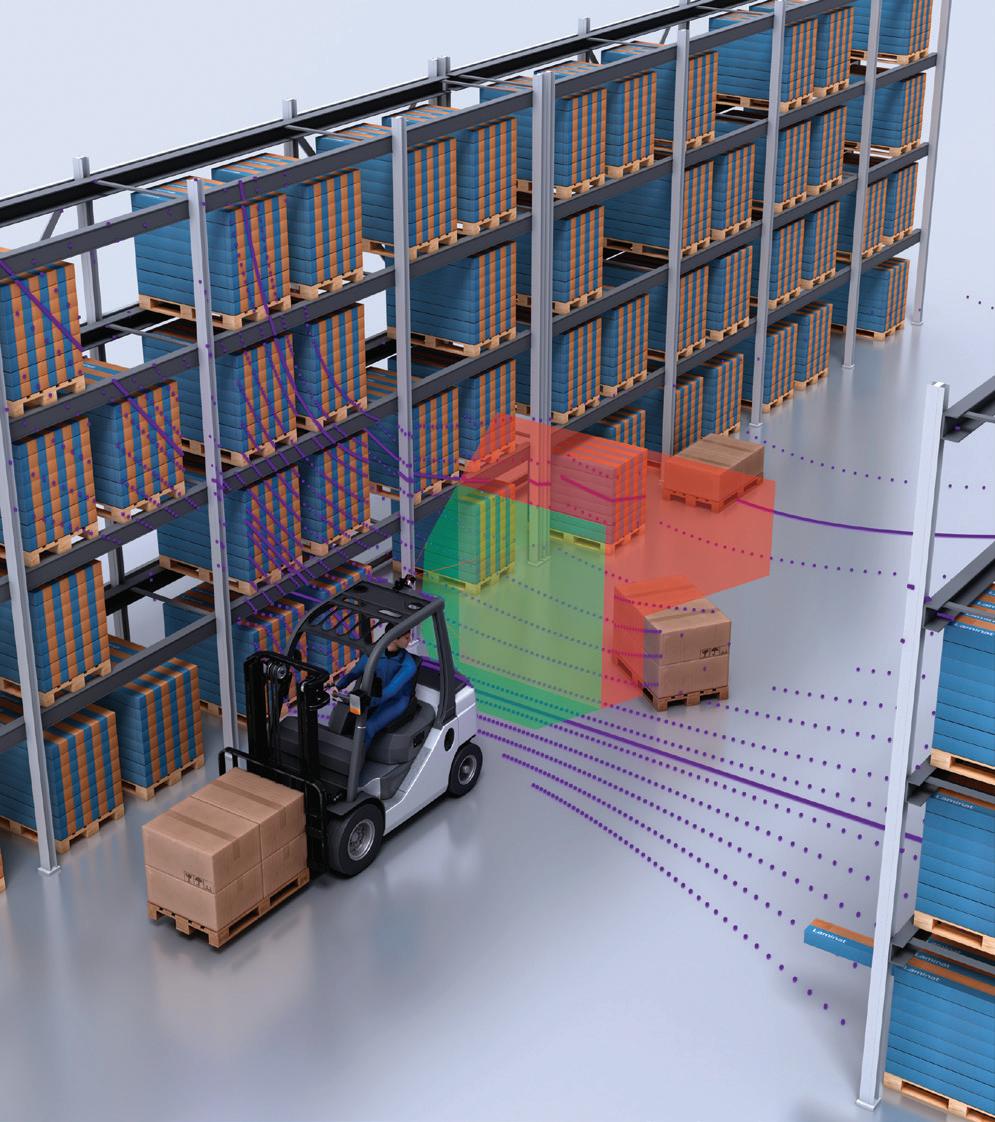

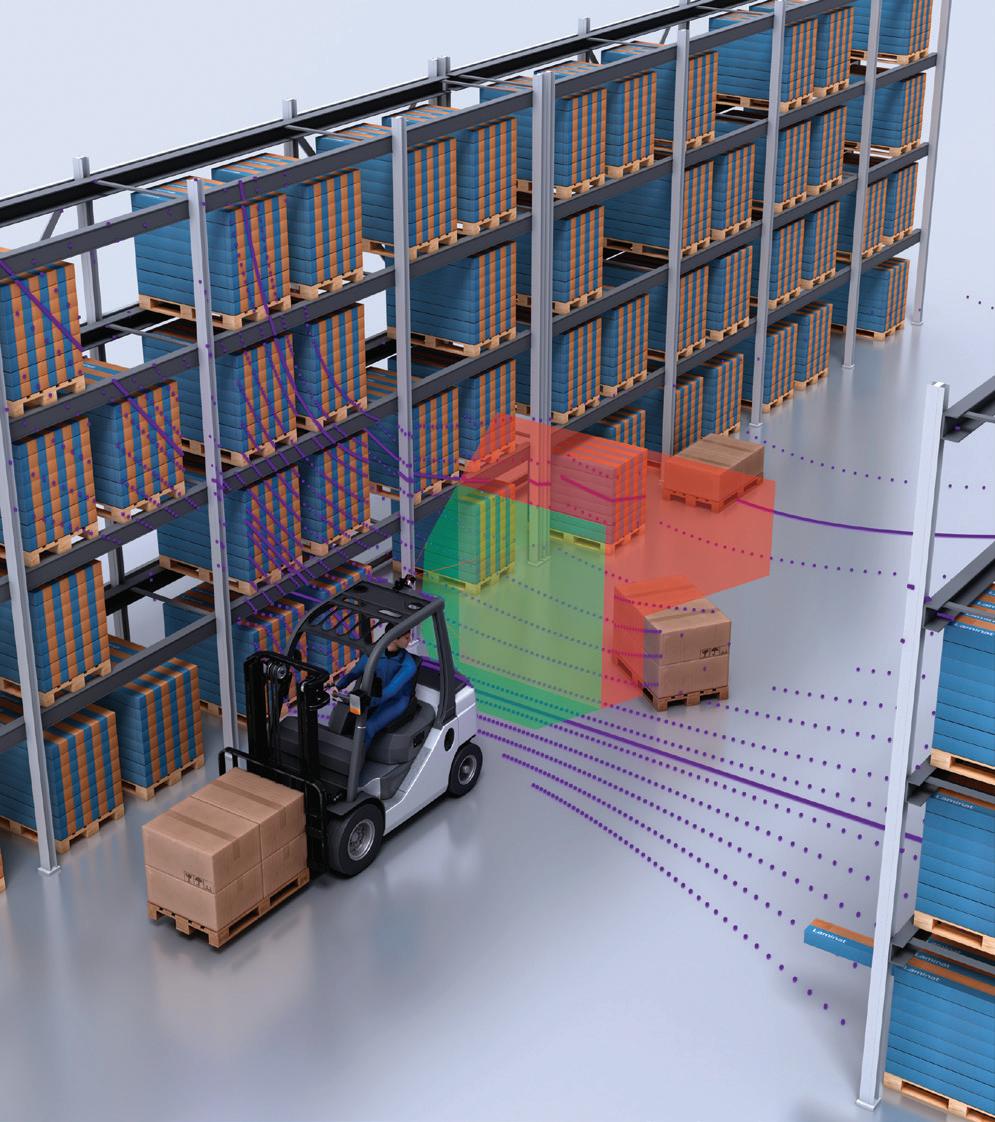

Precision 3D LiDAR navigation and collision avoidance

SICK has unveiled a milestone advance in its threedimensional LiDAR technology with the launch of the multiScan multi-layered LiDAR sensor. The SICK multiScan combines floor-to-ceiling 360° environment perception with high-resolution navigation for reliable real-time localisation, mapping and collision avoidance in automated mobile robots (AMRs) and industrial vehicles

Developed on the foundations of SICK’s industry-leading multi-echo LiDAR technology, the multiScan is a compact, lightweight and rugged 3D sensor designed to maximise vehicle availability in both indoor and harsh outdoor environments. With their broad 360° x 65° field of view and 16 scan layers, the LiDAR sensors in the multiScan100 family use on-device pre-processing to output a dense 3D point cloud with 690,000 measuring points, complemented by a high-resolution 0° 2D scan plane for precision navigation.

Each multiScan arrives factory-calibrated and ready for use, whether it is specified as a standard pre-configured product or using the specially-developed Online Configurator. Machine builders and integrators can select

the features they need for their application using the time-saving online platform with access to software apps and add-ons for easy customisation.

To enhance the 16-layer 360° horizontal coverage, the multiScan’s vertical aperture angle is configured to optimise the layers between -22.5° to +42.5°. This ensures reliable collision avoidance for objects at ground level, as well detecting cliff edges and ramp inclinations. Objects protruding into the field of view at height, e.g. on warehouse shelving, can also be reliably avoided. The multiScan136, the first sensor to be launched in the product family, has a 360° x 65° field of view and a 60m working range with further variants available from later in 2023.

Equipped with 100Mbps Ethernet, eight multifunctional I/Os and matching system plugs, the SICK multiScan is easy to integrate and saves engineers valuable time during commissioning.

www.sick.co.uk

8 www.mepca-engineering.com

SOLUTIONS FOCUS

www.io - link.ifm www.io - link.ifm More data = more control Smart sensors from ifm electronic use IO-Link • Easy parameter setting, monitoring and diagnostics from sensor level to the cloud • Process data without conversion losses • Easy troubleshooting and prevention of tampering • IO-Link still allows connection of standard binary sensors and actuators • All with standard wiring, just more data, more control Your route to Industry 4.0 ifm Telephone (020) 8213 1111 ifm Telephone (020) 8213 1111 years WARRANTY on ifm products

Sustainable and economic waste reduction

Mountains of waste create a disposal problem in every business, which HSM can solve.

HSM baling presses can reduce the volume of waste by up to 95%. That means users can save valuable space, which would otherwise be taken up at a site; plus, users benefit from the generation of a secondary and valuable raw material – baled recyclable waste.

No matter how many and what materials are involved and what the local conditions are, the HSM baler range has a machine of the right size. The German company is the only manufacturer to offer the entire range of ‘Made in Germany’ powerful and economical baling presses – vertical, horizontal and fully automatic.

Engineering, consulting, planning and service are all in the baling presses from HSM. The HSM experts not only

understand the interplay of a wide variety of technologies, but they also think ahead with one goal in mind – process optimisation.

Typical of HSM is the high level of production technology available in its own three factories. Made in Germany is an uncompromising quality principle for HSM, as well as a promise to the customer. Even the loading, delivery and installation are entirely in the hands of HSM. Due to its own

tight-knit customer service network, HSM also takes care of its customers when the baling presses are in operation. Customers can rely on fast on-site personal service.

Using a baler can save cost, time, energy and CO2. In the best-case scenario, there are additional revenue opportunities in addition to the savings. The use of a baler pays off in any case.

bit.ly/HSMbaling

New delta robot promises productivity, precision, and speed

The KUKA Hygienic Oil (HO) portfolio is expanding with the addition of the new KR 3 D1200 delta robot, which can perform various pickand-place tasks at previously unattainable speeds. With maximum precision, it now moves up to 6kg of food, medicines or electronic parts.

Although the KR 3 D1200 has a rated payload of 3kg, it is designed for loads of up to 6kg, which makes it one of the strongest delta robots on the market. The small footprint with a diameter of 350mm makes corner mounting space-saving and efficient. The robot has a reach of 1,200mm and a vertical working range of 350mm. With a position repeatability of +/ 0.1mm and an angular repeatability of +/- 0.2°, the KR 3 D1200 works very precisely.

The new KR DELTA impresses with unprecedented speed. In the small adept cycle and with a load of one kilogram, the

cycle time is less than 0.32s. To avoid downtimes, the KR DELTA has been designed to be particularly low maintenance. Encapsulated gears with lifetime lubrication and self-lubricating ball joints help to ensure that the KUKA robot can always perform. The fact that it is made mainly of carbon fibre makes it particularly light and robust. As a result, it impresses with low costs for care and maintenance and maximum productivity.

When handling foodstuffs or pharmaceuticals, the new KR 3 D1200 displays further strengths. It contains food-safe H1 lubricants as standard, which qualifies it for handling foodstuffs in secondary applications. In particular, dry, packaged products such as chocolate, bread or sweets are in good hands with it. For direct contact with raw foods, i.e. the primary sector of this industry, the KR

3 D1200 HM (Hygienic Machine), launched in 2021, is suitable. Even under the most sensitive conditions, such as those encountered in the raw processing of meat or cheese, the KR DELTA in the HM version promises excellent hygiene. A combination of the two KR DELTA variants can bring many companies in the food industry a significant step forward.

www.kuka-robotics.com

10 www.mepca-engineering.com

SOLUTIONS FOCUS

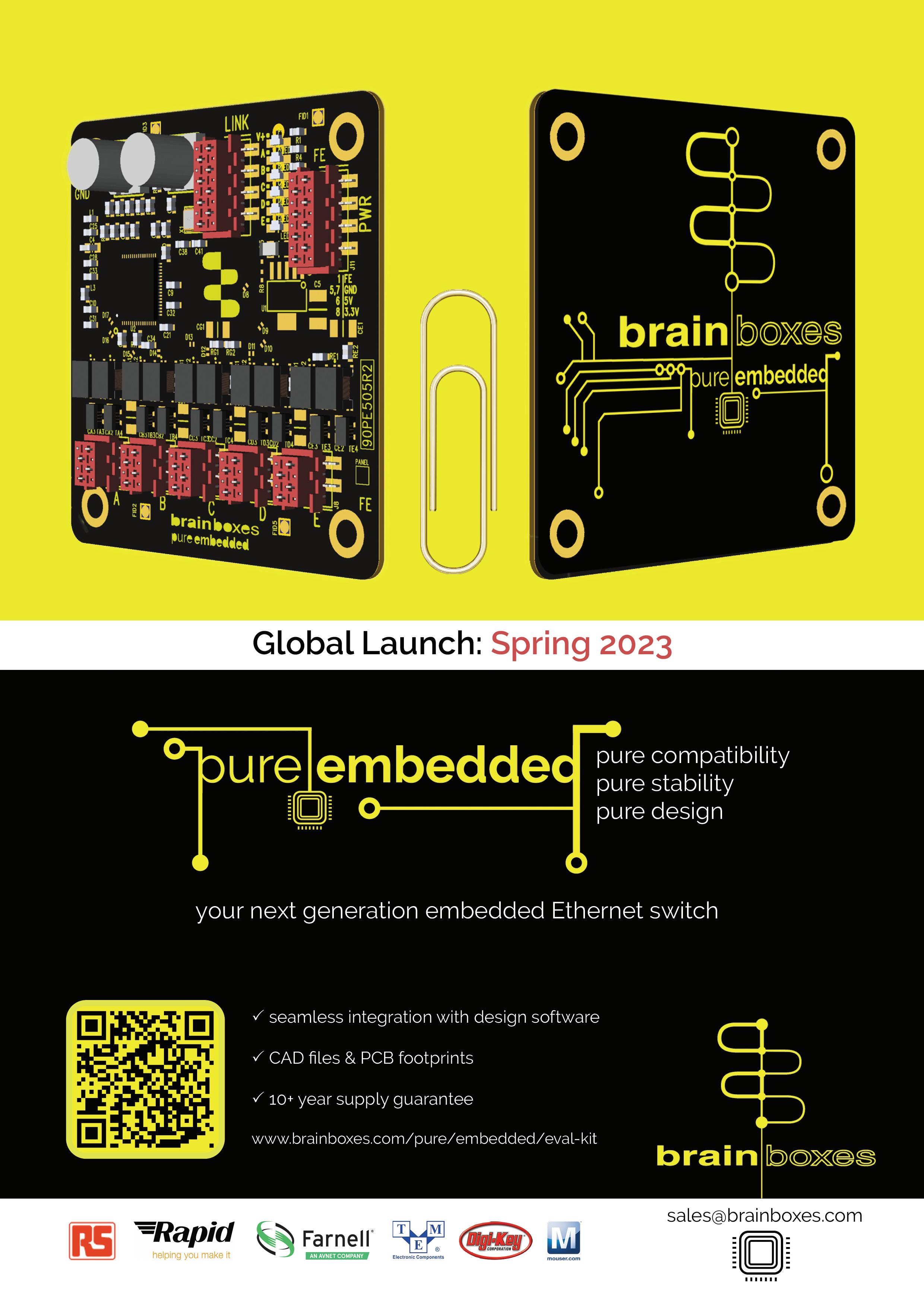

EXCELLENCE – MADE TO LAST FLOW OPTIMIZATION SECOND TO NONE www.newblueline.com NOVA BLUEline THE NEW BLUELINE NOVA ROTARY LOBE PUMP The BLUEline Nova sets new standards in pump technology. With or without protection plates and liners – the BLUEline Nova achieves unrivaled volumetric efficiencies. Made for one another – the newly developed DIUS rotors in combination with the flow-optimized pump chamber ensure perfectly smooth running at pressures of up to 12 bar. Börger UK Limited • East Wing • Watling St. Gailey • Staffordshire • + 44 1902 798977 • uk@boerger.com • www.boerger.com

A STEM-based career offers long-term success

GAMBICA’s Nikesh Mistry explains why it is crucial for our future workforce that young generations in the UK manufacturing industry continually pursue STEM qualifications to maintain the UK’s competitive advantage. Not least because the transferable skills and knowledge gained will allow them to adapt to technological advancements, secure better job prospects and higher salaries, and make a real impact on the industry and the world.

The manufacturing industry in the UK has always been an essential sector that contributes significantly to the country’s economy. However, it has faced a significant challenge in recent years – a shortage of skilled workers. This is where STEM (science, technology, engineering, and mathematics) subjects come into play. Pursuing a career in STEM subjects is important for individuals and the manufacturing industry as a whole. A career in STEM subjects is crucial for young generations in the UK manufacturing industry.

Through rapid technological advancements, STEM subjects are crucial for driving changes within our industry. The modern manufacturing industry is becoming increasingly automated, with advanced robotics and artificial intelligence being more frequently implemented to control basic repetitive tasks. This has led to a shift in the skills required of workers, with a greater emphasis on technical and digital skills. For example, additive manufacturing, which is now widely used in manufacturing, requires a deep understanding of computer-aided design (CAD) software and mathematical modelling. Similarly, implementing the Internet of Things (IoT) and smart factories require workers who can program and maintain complex networks of sensors and other technologies. Therefore, a strong foundation in STEM subjects is essential for young people to adapt to these changes and thrive in the manufacturing industry.

Furthermore, contrary to popular belief, pursuing a career in STEM subjects can lead to better job prospects and higher salaries. The manufacturing industry is renowned for

needing highly skilled workers, and those with STEM qualifications are always in high demand. In fact, according to a report by Engineering UK, STEM graduates in the UK earn, on average, 20% more than nonSTEM graduates.

A career in STEM subjects can also offer a wide range of opportunities for progression and career development. For example, a qualified engineer could progress to become a team leader, project manager, or even a CEO of a manufacturing company. By pursuing a career in STEM subjects, young people can position themselves for longterm success in the manufacturing industry. This is becoming more evident through our newly formed GAMBICA Young Council (GYC).

Founded a year ago now, the GYC is a group of 16 individuals spanning all five GAMBICA sectors, Industrial Automation, Process Instrumentation and Control, Laboratory Technology, Test & Measurement and University Engagement.

The main criteria to be eligible for the council is to be within the first ten years of a career within industry. At present, the council has a multitude of different backgrounds, some being university graduates, others apprentices, and some having moved straight to industry after leaving school. So their range of knowledge, experience and expertise really does vary amongst the group.

The exciting element of this council, despite the unrivalled enthusiasm, is a fresh take on trade association activities. This group aims to be a voice of early career professionals within GAMBICA’s member sectors and complement the experience in the current GAMBICA strategic governance

structure. But alongside this, each member of the council, including myself, has now registered to become active STEM ambassadors. The application process to do this is simple and straightforward, and once acceptance is confirmed, you are provided with an online dashboard whereby you can easily access information on all upcoming STEM events within your local area. It’s a brilliant initiative and has encouraged our young council to engage more with schools.

Being a STEM ambassador combined with sitting on the GAMBICA young council really provides a route to form a powerful community. This can lead to exciting opportunities to learn about existing projects, learn from different cultures, and develop a global perspective.

Having younger individuals in our councils act upon this has proven to work wonders, as it is much easier for those younger generations to relate to them and picture themselves within their positions.

If you want to find out more about this, please reach out to a GAMBICA member of staff today.

12 www.mepca-engineering.com OPINION

Can we practically restrict the use of PFAS?

and

For many years, Europump, the Association of European Pump Manufacturers, has been at the forefront of the health & safety, environmental and sustainability agenda, advising and lobbying Governments as they look to update and improve the legislative landscape for industry.

It is commonly recognised that pumps and their related equipment are essential for many applications affecting daily life. From central heating and water supply in our homes, sewage and wastewater treatment in our cities, through to the extraction and processing of raw materials to manufacture finished products, pumps and pumping systems play a fundamental role. Industrial applications can range from water treatment, food processing, chemicals, oil & gas, mining, paper mills, firefighting, dredging, waste removal and many more. Future applications linked to the all-important green transition would include the transportation and storage of hydrogen, geothermal, and other green gases.

Due to their unmatched thermal and chemical resistance, unique tribological properties, and any combination of these characteristics, Perand polyfluoroalkyl substances (PFAS) containing materials are used in virtually all of the applications outlined above, as sealings, bearings, cable sheaths, coatings, pump inserts and membranes. However, given that PFAS

materials, are up to one hundred times more expensive than any of the natural or synthetic elastomers, they are only used in those cases where absolutely no alternative is available, and currently, no alternative

and leakages, which could result in the release of aggressive media, harmful gases, or steam, which could, in turn, cause serious injury to both humans and the environment. Furthermore, the challenge faced by the lack of PFAS-free alternatives for essential use is not limited to pump applications and applies equally to other key pieces of equipment, such as valves and compressors in downstream industries like pharma, chemicals, petrochemicals, and aerospace. Additionally, some electronic components which are critical for the safe and efficient operation of these applications also require the use of PFAS.

So, although Europump fully supports any regulations aimed at preventing PFAS substances from entering the environment, it must be stated that in certain pump (and other related product) applications, the use of PFAS remains essential due to safety, efficiency, and functionality concerns. And given that no suitable substitutes for these specific applications are currently available, the use of PFAS materials should remain possible so that the pollution of the environment by other acutely hazardous substances can be prevented, and any harm to humans is avoided.

material guarantees the same levels of performance, safety, and lifetime.

Therefore, any substitution with other less suitable materials would lead to rapid failures

Europump’s full position statement on the restriction of PFAS materials can be found on both the Europump and BPMA websites, or you can request a copy by contacting s.smith@bpma.org.uk

Wayne Rose, Secretary of the Europump Marketing Commission

14 www.mepca-engineering.com OPINION

newly appointed CEO of the BPMA, offers insight into the pump sector’s position in relation to the restrictions of using Per- and polyfluoroalkyl substances.

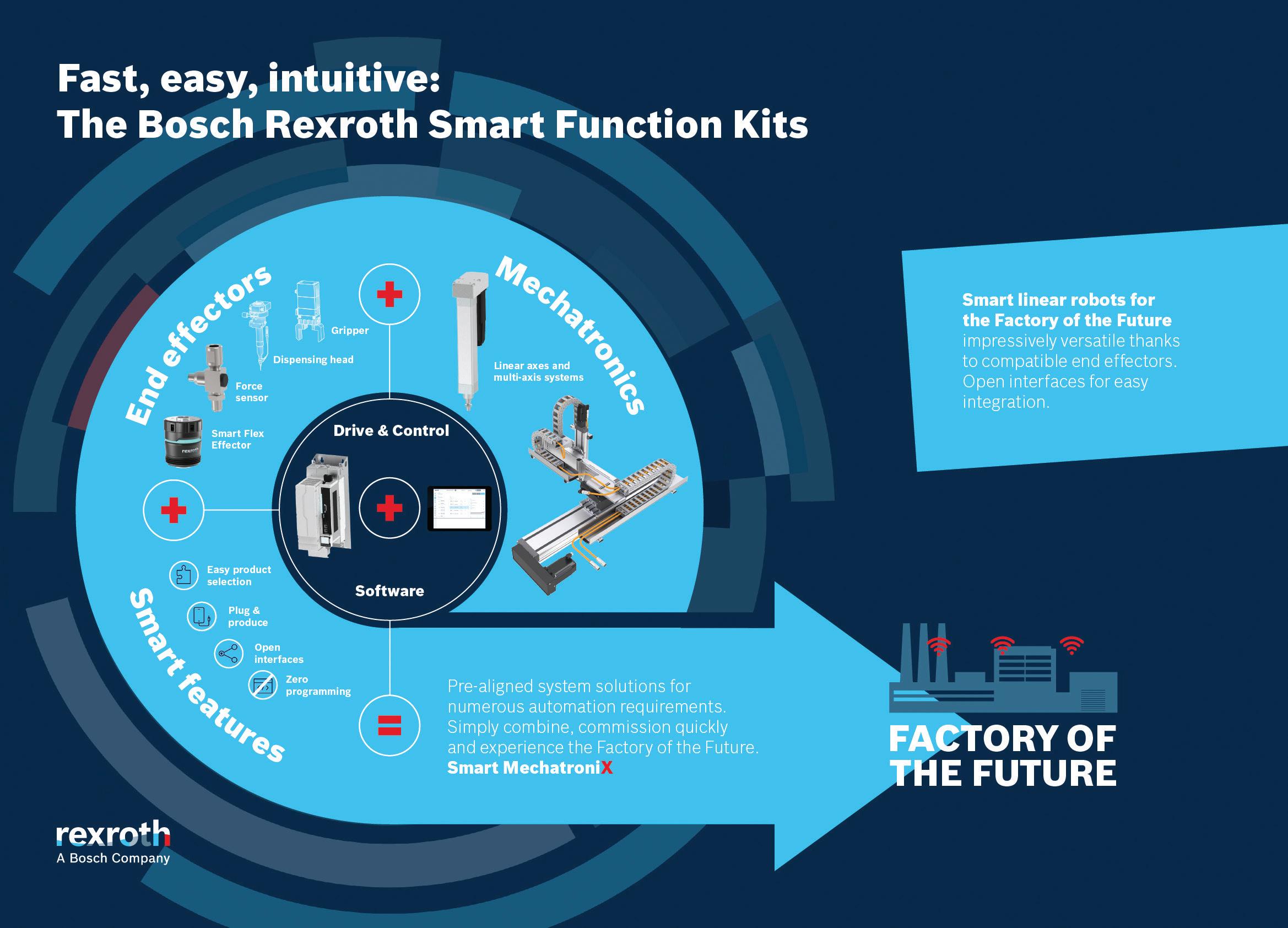

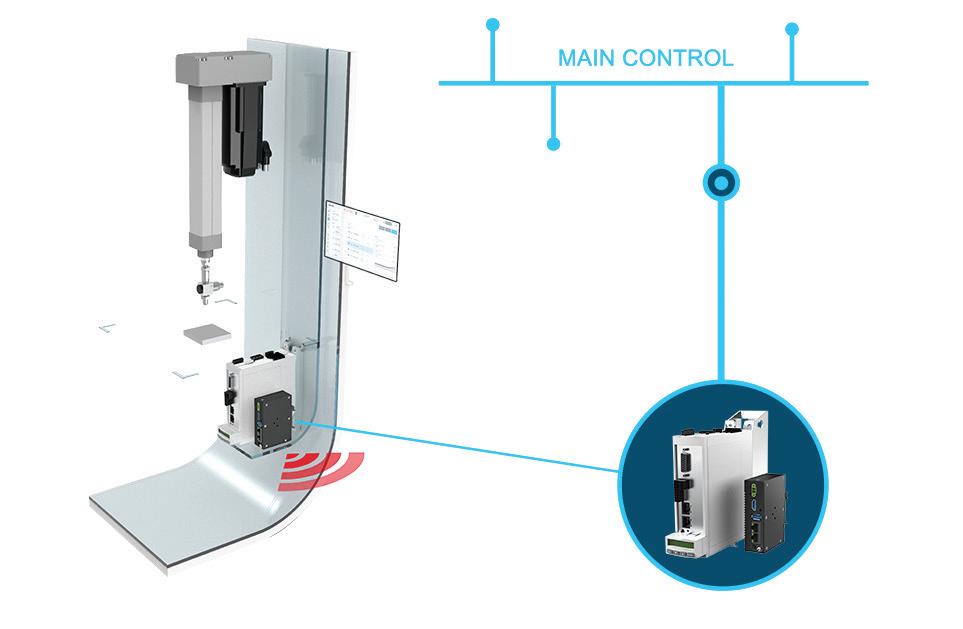

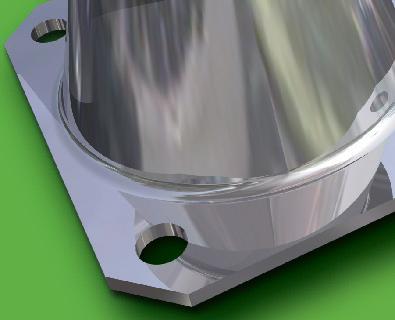

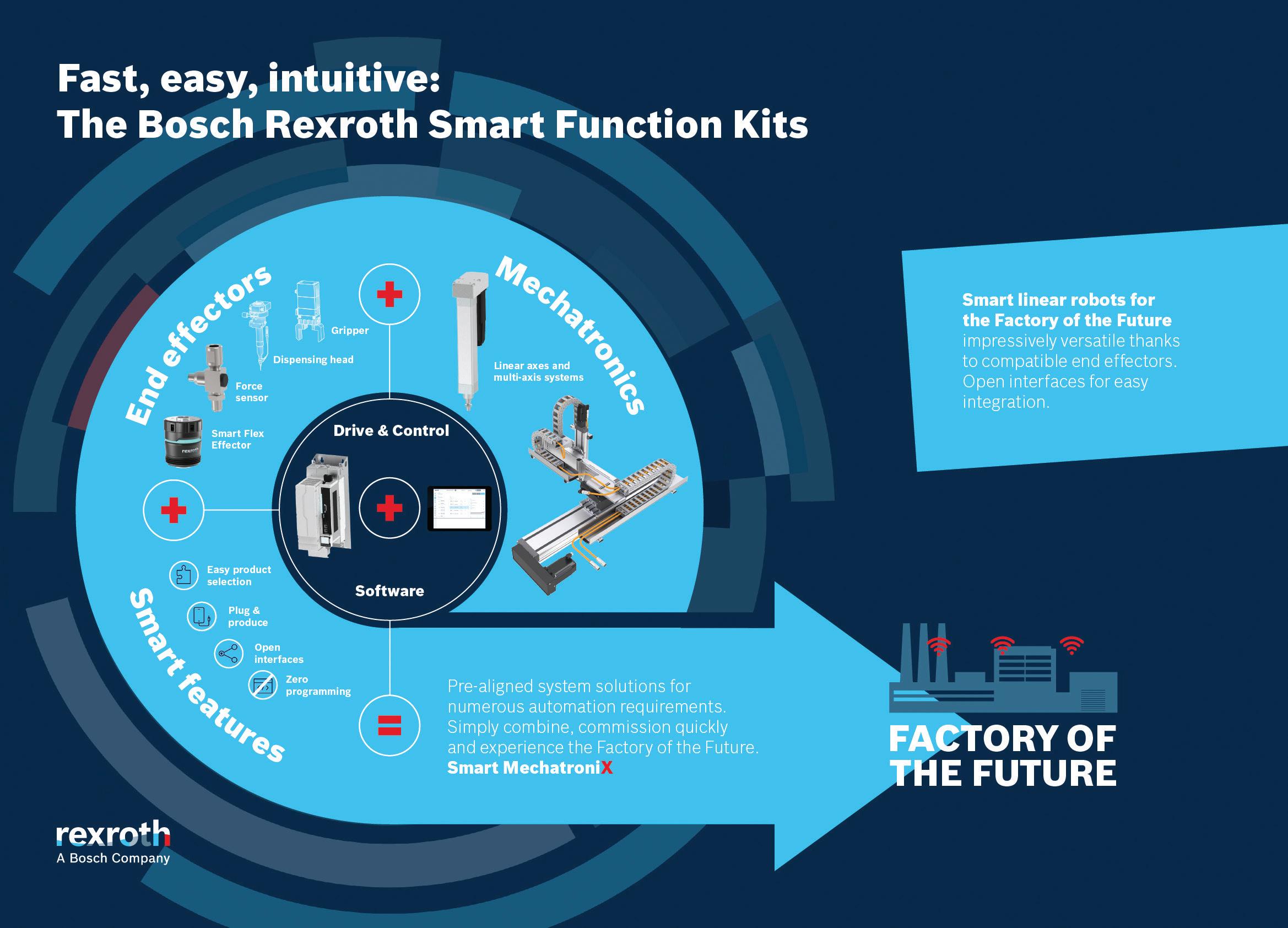

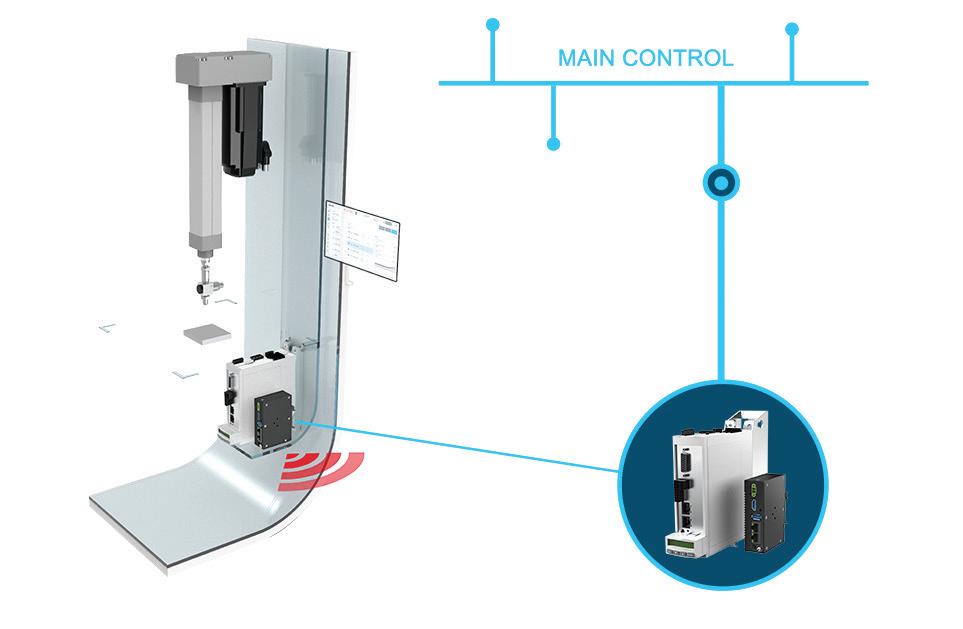

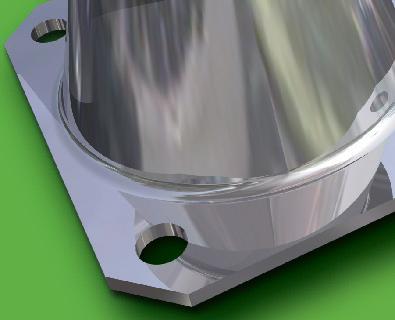

An ecosystem for smart mechatronics

It is widely recognised that constructing linear motion systems can be a drawn-out, expensive process. Thanks to Bosch Rexroth, this can now be changed with Smart MechatroniX, as MEPCA found out.

Do you sometimes feel like Sisyphus, who has to carry out the same laborious task over and over again? If you dimension, configure, programme or commission subsystems for assembly or handling processes, you’ll know exactly what we mean. But this is now a thing of the past.

Bosch Rexroth has now broken the cycle of process adjustments, time shortages, high programming costs and interface losses. How? With an ecosystem for mechatronic solutions and subsystems, in short: Smart MechatroniX. The first two systems, the Smart Function Kit Pressing and the Smart Function Kit Handling, are revolutionising engineering and the commissioning of typical applications for pressing, joining and handling. These

factory automation tasks can now be carried out quickly and easily with no need for complex mechanical engineering, timeconsuming catalogue research, error-prone media disruptions and costly programming.

Select, configure, go online

Another reason why the new ecosystem is so innovative is the fact that it’s made up of tailored, standardised modules and components, which can be put together quickly to form smart subsystems. Simply select and adapt the basic type online, configure and order it and commission it with software guidance. This way, best-inclass components can be used to create smart mechatronics solutions for the Factory of the Future with minimal use of resources.

Everything fits together seamlessly

Whether it be a handling robot from linear axes or an electromechanical press solution – the online configurator offers users exactly the right motors, servo drives, mechanic and control systems. The heart of the subsystem, a piece of preinstalled operating software, guides users intuitively through the commissioning process. Thanks to visual programming, there is no longer any need to type in lines of code. The drive controllers automatically parameterise themselves as soon as they are connected. In the case of the Smart Function Kit for Handling, the software can even reference the linear axes.

Programming was yesterday

Users define what the subsystem is to do

16 www.mepca-engineering.com COVER STORY

within the machine or line with the help of ready-made functional modules. These are simply selected from a library, arranged in the correct order via drag and drop and given the correct parameters. With plug and produce, Bosch Rexroth meets a key requirement when it comes to modern-day factory automation. Integration into higherlevel systems and larger IoT environments is also straightforward, thanks to open interfaces and ready-made functional modules. The most important properties and benefits include:

• Easy product selection, dimensioning, configuration and ordering via e-tools. This saves time, money and hassle, and everything fits together perfectly.

• Plug and produce. The commissioning wizard, automatic drive parametrisation and axis referencing speed up the time to market and the ROI.

• Zero programming. An intuitive graphical user guidance makes process configuration easier and requires no costly expertise.

• Open interfaces make the subsystems IoT-capable and allow them to be

integrated quickly into higher-level control and IT systems.

With the Smart Function Kits for pressing, joining and handling tasks, production companies can save huge amounts of time, avoid island solutions and pave the way to the Factory of the Future. But the development work goes even further. After all, Bosch Rexroth is gradually extending the Smart MechatroniX ecosystem to cover other

areas of application. Already lined up are The Smart Function Kit Dispensing for dispensing tasks and the Smart Flex Effector, which gives linear and folding-arm robots almost human sensitivity opening up completely new automation scenarios. The toolbox for smart mechatronics is growing, but the aim remains the same: fewer resources, greater flexibility and a minimal time to market.

www.boschrexroth.co.uk

COVER STORY

Fast flexible plug-andplay pressure data

ESI Technology takes a closer look at why it believes its award-winning GD4200-USB is quickly becoming industry’s leading choice for digital pressure measurement solutions.

The plug-and-play nature of the GD4200-USB digital pressure transducer allows users to be up and running viewing live pressure data within ten minutes. The ESI-USB software is available for direct download from ESI’s website and is programmed to recognise the transducer by its serial number.

Whether users are looking to perform test and calibration, spot checks or local, direct monitoring, the GD4200-USB is the convenient solution. With no need for any additional hardware or software, users can test and record data on site and easily disconnect and move where and when needed.

SOS sensor technology

As with a large part of ESI’s portfolio, Siliconon-Sapphire (SOS) sensor technology is incorporated into the manufacture of the GD4200-USB. SOS is incredibly stable and exhibits virtually no hysteresis. With outstanding insulation properties, the sensor is protected from electromagnetic pulse radiation, which allows it to operate over a very wide temperature range without loss of performance.

The advantages of the sensor and its SOS technology include a welded Titanium pressure diaphragm requiring no O-ring seals, high accuracy, a high resistance to over-pressure and pressure transients, and excellent chemical resistance. The technology is stable at elevated temperatures, has a high sensitivity of 10 to 20mV/V and can measure pressures from -1 to 5000 bar. The sensor is constructed using machined titanium parts, while the high pressure HP range is machined from a single piece of Titanium.

The GD4200-USB is available in nine pressure ranges, carefully selected to enable the user to cover any pressure that the application requires, from vacuum up to 5,000 bar.

High speed and accuracy

The GD4200-USB boasts a standard accuracy of 0.15%, making it the ideal solution for high-accuracy applications. The temperature co-efficiency is excellent, so no matter the temperature (Ambient: -20 to

create and save templates of personally branded test certificates and reports. These can be set up with user-defined parameters, ensuring only the data that’s most important is presented, using the user’s company branding where required.

+85°C, Media: -50 to +125°C), users can rely on the data that the sensor provides. The sample rate enables dynamic pressures to be measured with up to 21-bit resolution at user-selectable speeds up to 1,000 Hz.

Data logging can be expensive; however, the GD4200-USB transducer is an extremely cost-effective solution for monitoring and recording pressure data with no need for costly I/O interface boards.

But what really makes this product stand out is the ESI-USB software. Freely downloadable from ESI’s website, the software includes features such as easy leak-testing, temperature analysis, and autoupdating.

Customised reports

Using the ESI-USB software, users can

Measure 16 Inputs

Through the use of a USB hub, users can detect up to 16 independent pressure sources at any one time, each identifiable by the unique transducer serial number. Of course, these can be easily renamed within the software to allow the user to recognise pressure data sources.

ESI’s technical sales team is trained to know just about all there is to know about our ESI-USB. The team is actively involved in the development schedule of the software and is happy to help guide users through any questions they might have. On-site or team training on the products can also be offered to give first-hand knowledge and experience with the technology.

esi-tec.com

18 www.mepca-engineering.com SENSORS & SENSING SOLUTIONS

A Kawasaki Robot for every application Kawasaki Robotics Tel:+44-1925-713-000 www.kawasakirobotics.com/uk/

RFID made simple

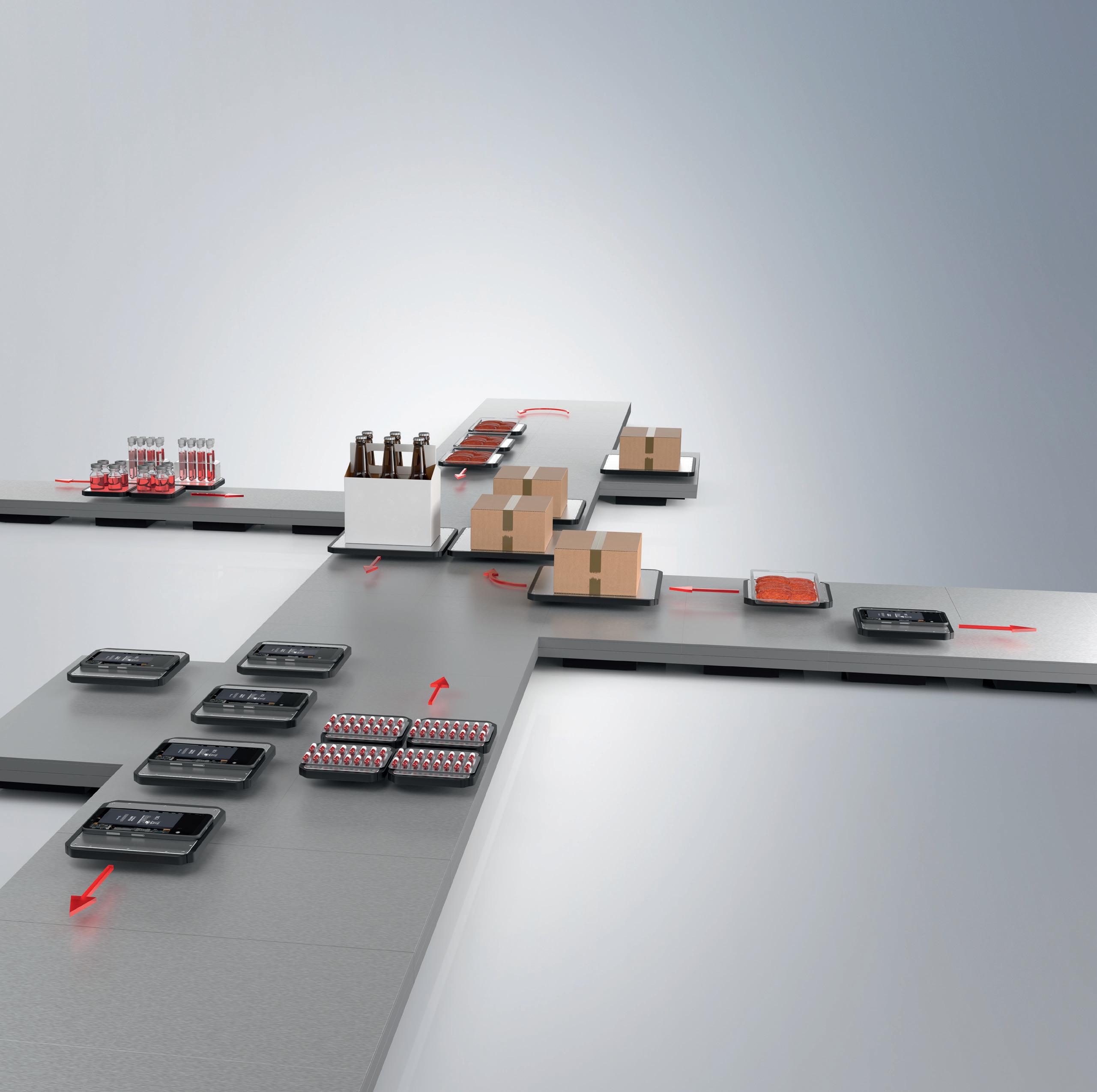

The F191 UHF RFID read/write device from Pepperl+Fuchs covers a wide range of applications cost-effectively. Users can seamlessly identify and track parts and goods according to the track and trace principle and establish transparency throughout the entire manufacturing process, creating the information basis for implementing Industry 4.0 concepts.

Pepperl+Fuchs now offers a practical solution for users looking for easy entry into the world of RFID with all its possibilities. The new F191 RFID read/write device combines the advantages of sophisticated industrial UHF technology with a standardised interface for IO-Link communication and is, therefore, a cost-effective enabler component for a wide range of standard applications in areas such as intralogistics, automotive, and material handling.

A strong combination

The IO-Link masters from Pepperl+Fuchs support the simple connection of the new UHF RFID read/write devices.

The F191 RFID read/write devices are commissioned without time-consuming programming via the future-proof, integrated IO-Link interface. In easy mode, the devices transfer their data to the higher-level system in accordance with the plug-andplay principle without integrating complex function blocks. It doesn’t matter whether this is an IoT-centric or PLC-centric architecture; Pepperl+Fuchs offers the appropriate IO-Link masters for connecting the RFID read/write devices from a single source for both applications. This means that up to eight RFID read/write devices can be operated cost-effectively on just one IO-Link master. The multi-protocol capability of the IO-Link master module ensures compatibility with almost any bus or control system.

Rugged UHF technology

When the F191 RFID read/write devices are in operation, they enable reliable detection of various UHF tag types in a sensing range of up to 1m by means of transmit power of up to 100mW ERP (adjustable). A wide range of application-specific tags from the Pepperl+Fuchs product selection is available. UHF technology makes it possible to simultaneously detect bulk data from multiple

tags in one read operation. With a rugged IP67 housing, integrated antenna, and a wide temperature range of -25 to +70 °C (or -25 to +60 °C in continuous operation), the F191 RFID read/write devices are also designed for use under adverse ambient conditions.

Decades of RFID expertise

In the Pepperl+Fuchs UHF RFID portfolio, the F191 read/write device joins the F190 and F192 versions already established on the market. Compared to the new F191, these devices support advanced setting options for the continuous solution of more complex special applications or a significantly increased sensing range (F192 up to 6m). Combined with the broad experience gained over 30 years of RFID development and other LF and HF frequency range solutions, a wide variety of applications can be covered by the identification experts at Pepperl+Fuchs.

Highlights of the F191 UHF Read/Write Device with IO-Link include it being an economical, high-performance identification solution with an IO-Link interface and an especially simple RFID solution with no programming required.

The device offers low channel costs for maximum efficiency by connecting

multiple read/write devices to an IO-Link master and flexible system integration with connection via an IO-Link master to almost all bus systems and controllers. It has an optimal read range of up to 1m for a wide range of applications, multi-tag reading of numerous tags for maximum efficiency and offers maximum process reliability due to a high degree of protection, an extended temperature range, and adjustable transmitter-radiated power.

www.pepperl-fuchs.com

20 www.mepca-engineering.com SENSORS & SENSING SYSTEMS

u Expansion module MCM for even more functions

u Category 4 / PL e according to EN ISO 13849-1

www.mepca-engineering.com 21

u Safety system with guard locking device

u Modular layout for maximum flexibility during operation

u Bus module with PROFINET/ PROFISAFE/ EtherCAT with FSoE

Multifunctional Gate Box MGB2 Modular SAFETY FOR PERSONNEL AND MACHINE More than simply safeguarding www.euchner.co.uk AZ 178x124 CTM, MGB2 Modular, EKS_UK.indd 3 13.07.20 11:32 C M Y CM MY CY CMY K

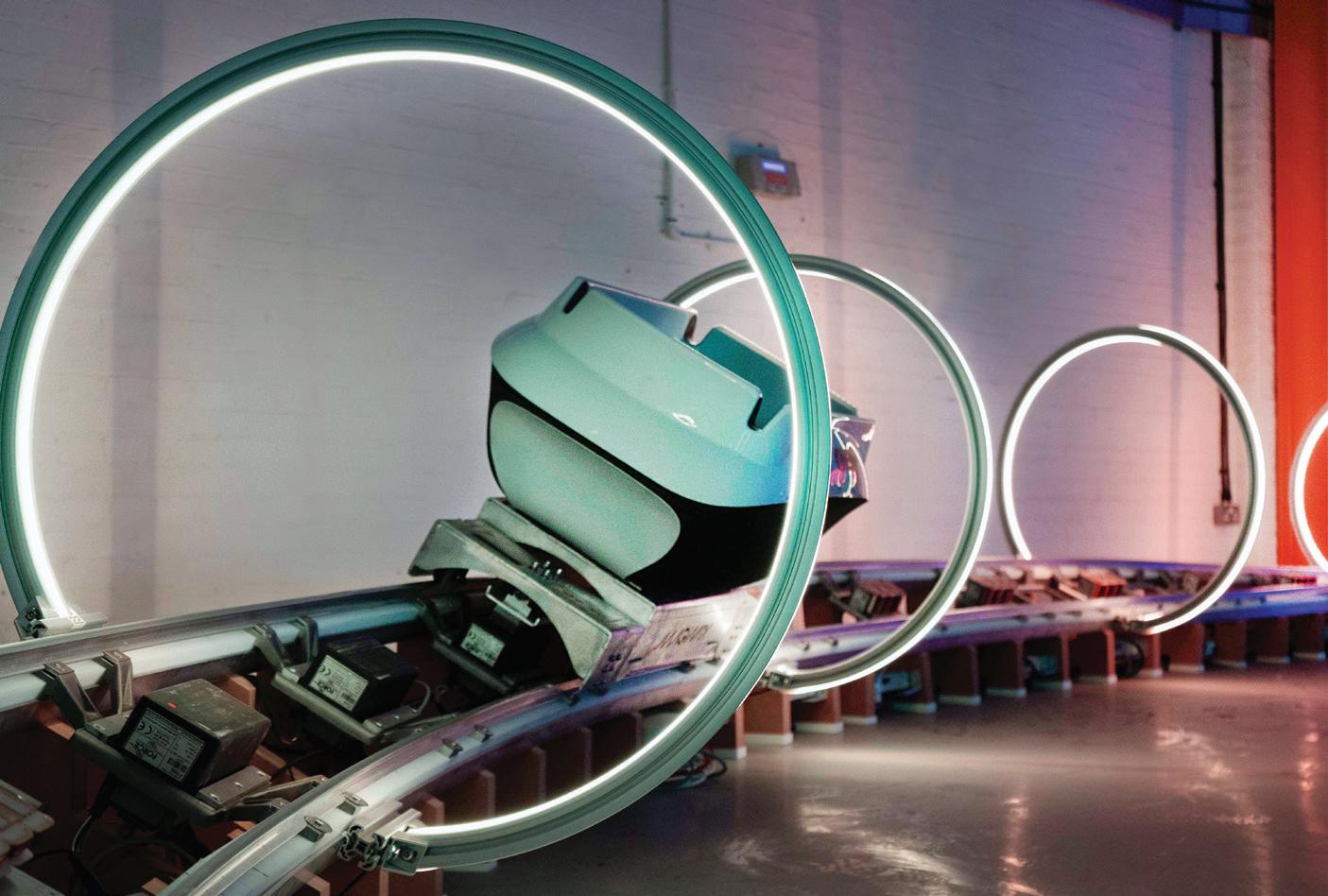

Delivering a greener future

We live in a world of convenience, where same-day shipping is the norm, and anything can be bought at the click of a button. But there is an environmental cost to this as one truck is estimated to have the same carbon footprint as 14 people. At a time when the environment is a top consideration, Magway, with the help of Beckhoff technology, is looking to do things differently.

Arecent study from the Centre for London think tank found that diesel and petrol vans ferrying goods and services around the city make up for a quarter or more of London’s greenhouse gas and polluting emissions from transport. With the number of parcels delivered in London expected to double by 2030 and the 2050 target of zero carbon emissions drawing closer, finding a new, sustainable delivery method has become essential.

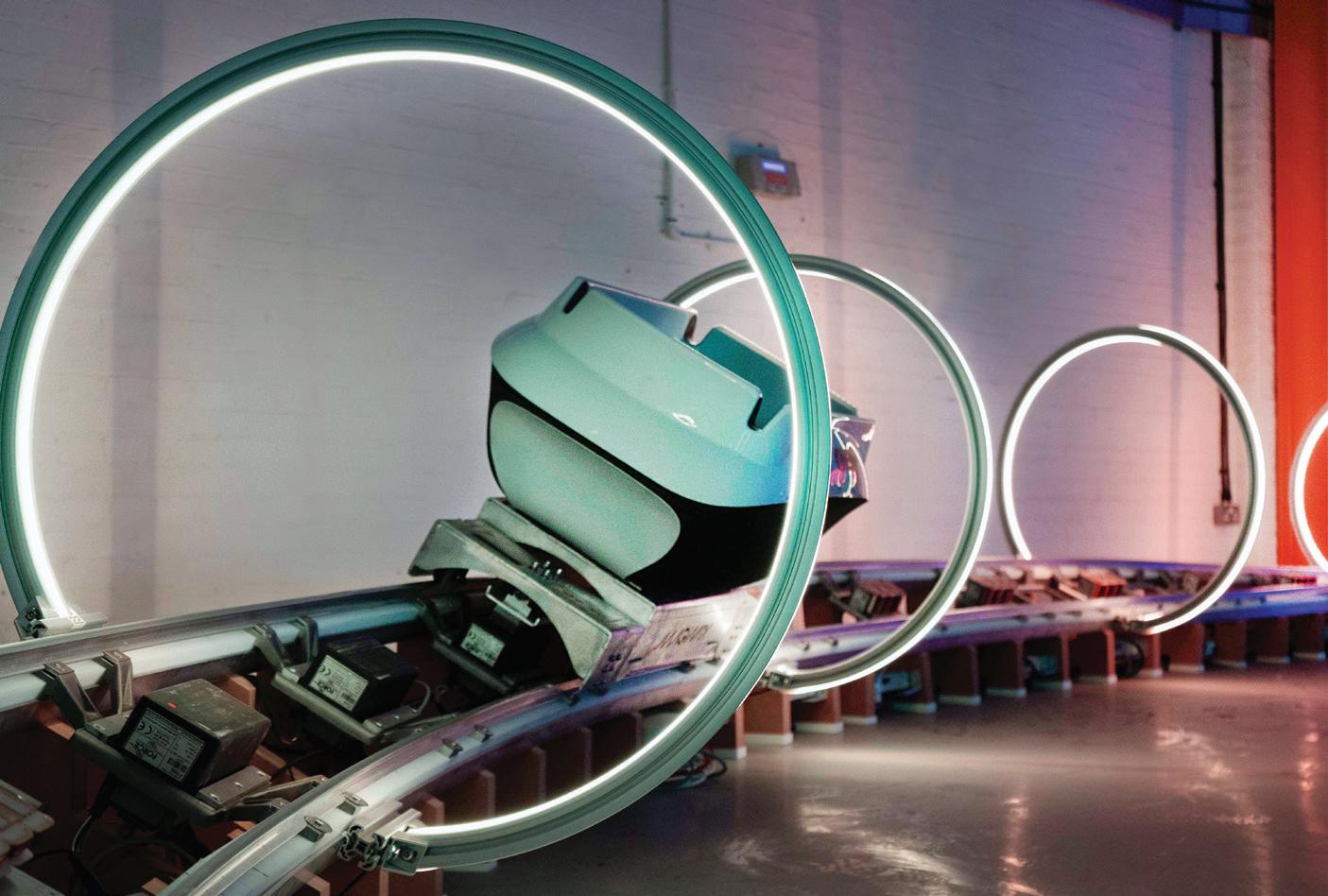

Wembley-based Magway Ltd. has developed an all-electric delivery solution that produces zero emissions whilst still managing a high capacity. The delivery system can deliver the equivalent of 3,000 articulated lorry loads daily through a single one-metre diameter pipe. Magway is using Beckhoff technology to automate its system.

Distributed servo drives

The underground system comprises a one-metre tube run on a track. On the track itself are track-mounted distributed servo drives. Beckhoff provided the technology in this area, as it was based on AMP8000 distributed servo drive systems which are known to offer compact and flexible solutions for modular machines. Due to Beckhoff’s in-house design and manufacturing capabilities, it was possible to customise a unique variant of the distributed drive system to fit Magway’s requirements.

“Magway is also using the EtherCAT Industrial Ethernet system with its technology,” explained Bradley McEwan, Business Development Manager at Beckhoff UK. “Due to a large number of trucks – and the speeds required from them – EtherCAT is the only bus system that can manage the data load with fast cycle times and minimal infrastructure. This is due to EtherCAT’s

virtually limitless network topology options, as the machine’s structure determines the network topology, rather than the other way around.”

Modular automation software

Magway is also relying on Beckhoff’s allpurpose automation software, TwinCAT 3, which runs on Beckhoff Industrial PCs (IPCs) using the Windows alternative TwinCAT/BSD operating system. By standardising on TwinCAT 3, Magway needs only one software platform for programming and configuration, which is easier and more efficient than having to juggle multiple platforms. TwinCAT 3 also provides open interfaces for expandability and adaptation to the tools landscape found in both automation and IT, which means that Magway can adapt the software as the company and its products grow.

TwinCAT/BSD gives Magway flexibility to use widely available Linux-based tools, for example, remote updates to multiple

devices. Beckhoff IPCs are designed and built for industrial environments and longterm availability. “The life-cycle advantages of Beckhoff IPCs come from the in-house design and production of our motherboards and owning the BIOS. The system architecture adds further advantages by supporting the execution of any TwinCAT project across the large offering of IPCs in the Beckhoff portfolio. This system architecture fully protects customers from system obsolescence, improving the overall system life cycle,” said Doug Schuchart, Global Material Handling & Intralogistics Manager at Beckhoff.

According to McEwan, these advantages ensure continued support for large infrastructure projects such as Magway’s: “Real-time data monitoring, diagnostics and fault tolerant infrastructure, including redundancy and high availability coupled with marshalling areas, ensures maximum uptime of the system.”

“It has been a close process throughout,” said Rupert Cruise, Technical Director

22 www.mepca-engineering.com DRIVES, MOTORS & CONTROLS

DRIVES, MOTORS & CONTROLS

at Magway. “We came to Beckhoff with ideas for the motor and track system, and they helped us make the ideas a reality. This allows us to continue our aims of revolutionising the parcel delivery industry and creating a greener future for everyone.”

Having worked closely on this project, Beckhoff and Magway are now looking at further developments. As an engineering partner, Beckhoff consistently optimises its existing technology to achieve maximum efficiency and performance for Magway.

The companies are working together on integrating MATLAB and Simulink into the programmable logic controller (PLC) in hard real-time. This can be done using TwinCAT 3, as the software already comes linked with the programming language and programming environment of these popular platforms.

The environment and climate change have grown as pressing consumer concerns, with 81% preferring to shop sustainably. This means that companies need to consider ways to gain and maintain zero emissions to match what consumers are looking for. Magway’s delivery system allows companies to switch while keeping

the essential high delivery load that consumers demand. Such innovative ways of tackling climate problems are only possible with the right technology, which is

why companies like Magway and Beckhoff working together is the future.

www.beckhoff.com

WorkfloPlus provides easy to follow step-by-step instructions accessed via phones, tablets and wearable devices to make sure tasks are consistent, repeatable and compliant.

Stay ahead of the competition with digital workflows that streamline your processes to increase productivity, efficiency & auditability, while saving you time by instantly generating & distributing reports as soon as a job is complete.

Unlock a new era in manufacturing by putting people at the centre of industry 4.0.

www.mepca-engineering.com 23

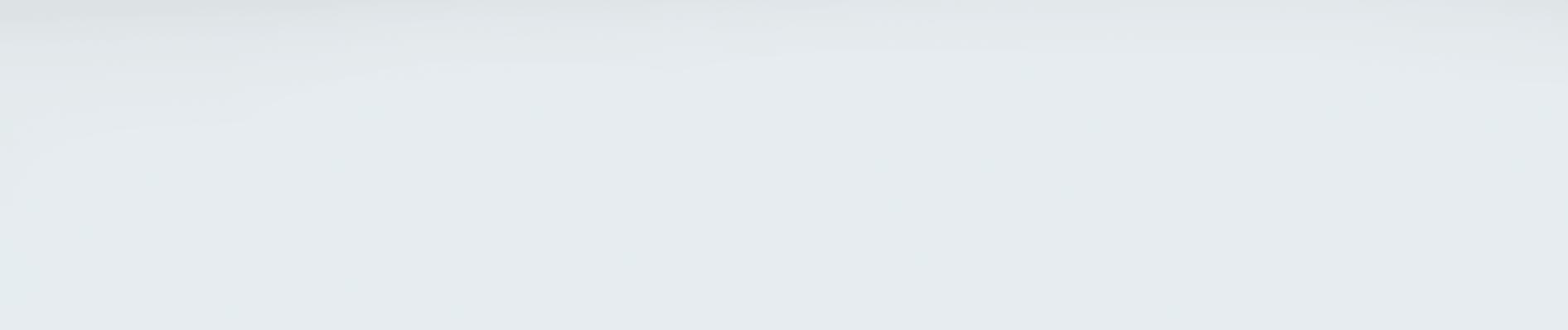

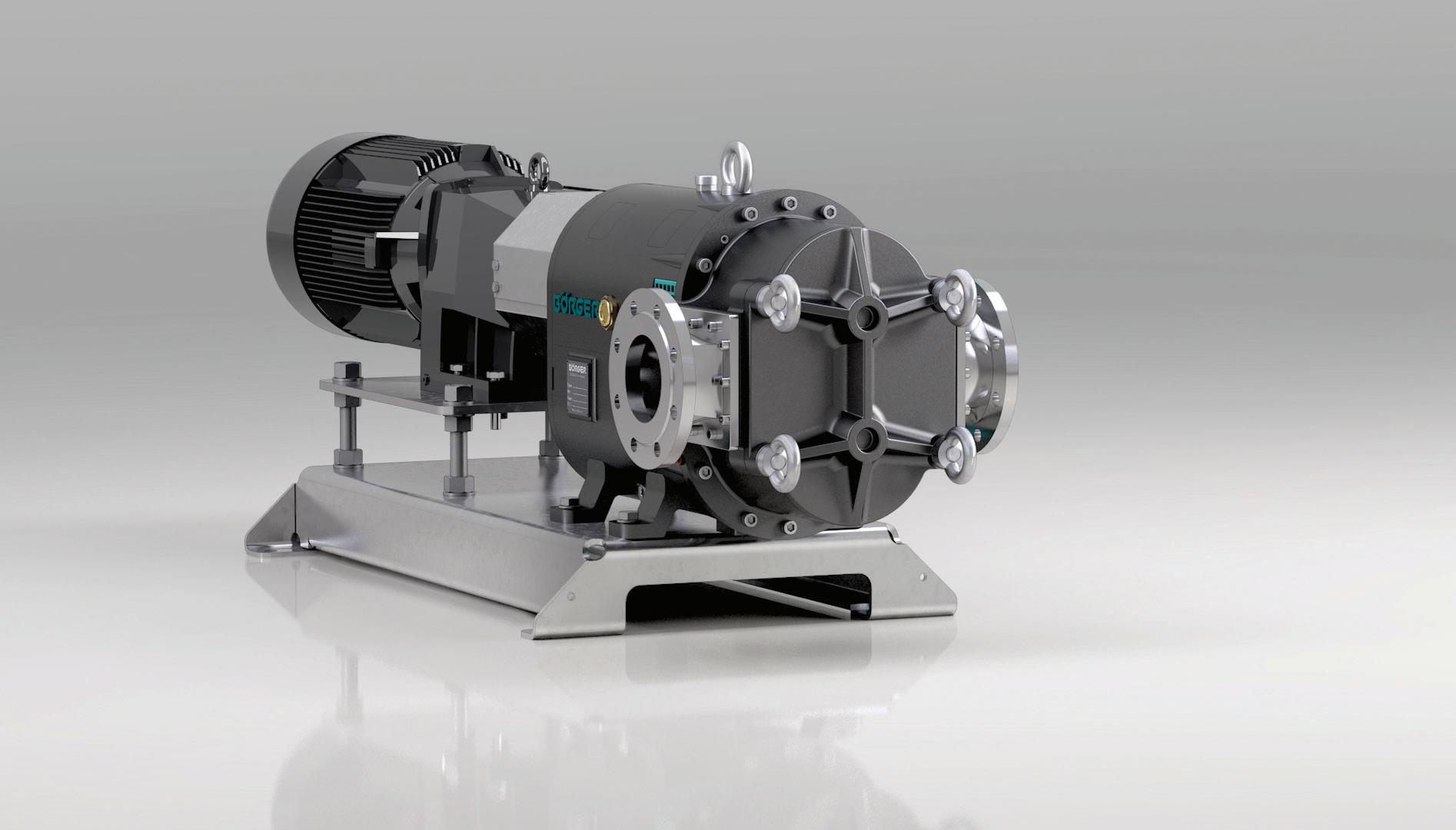

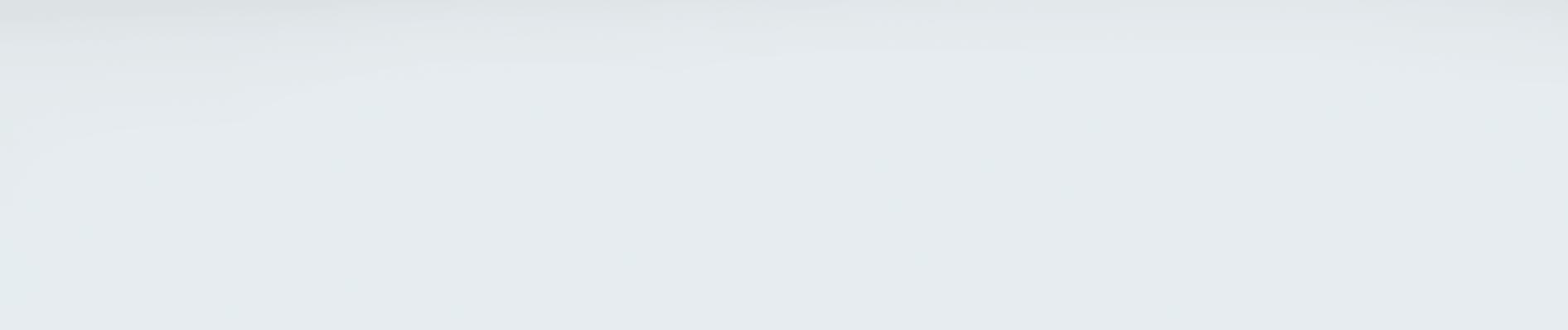

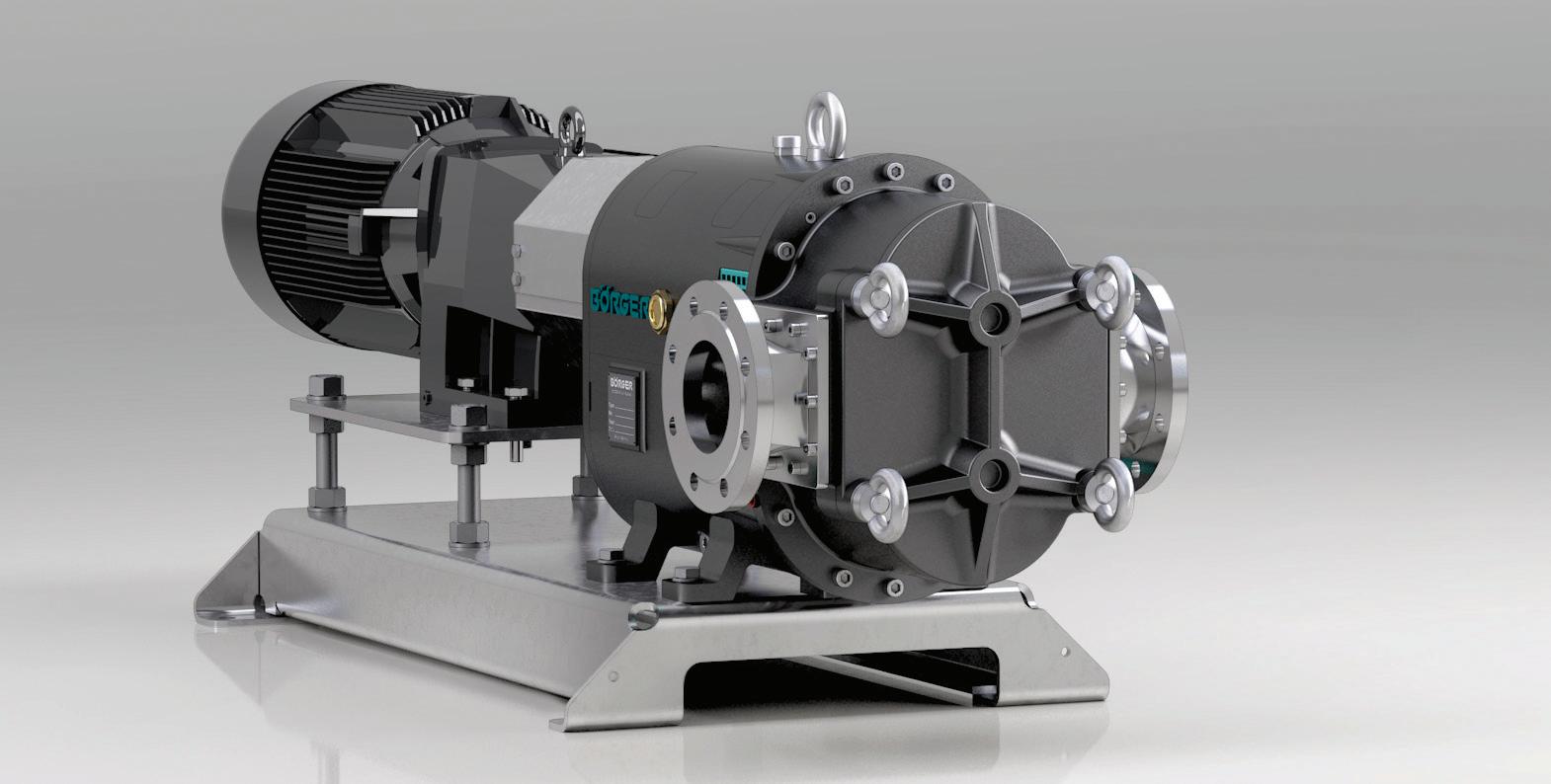

The right pump for waste cooking oil

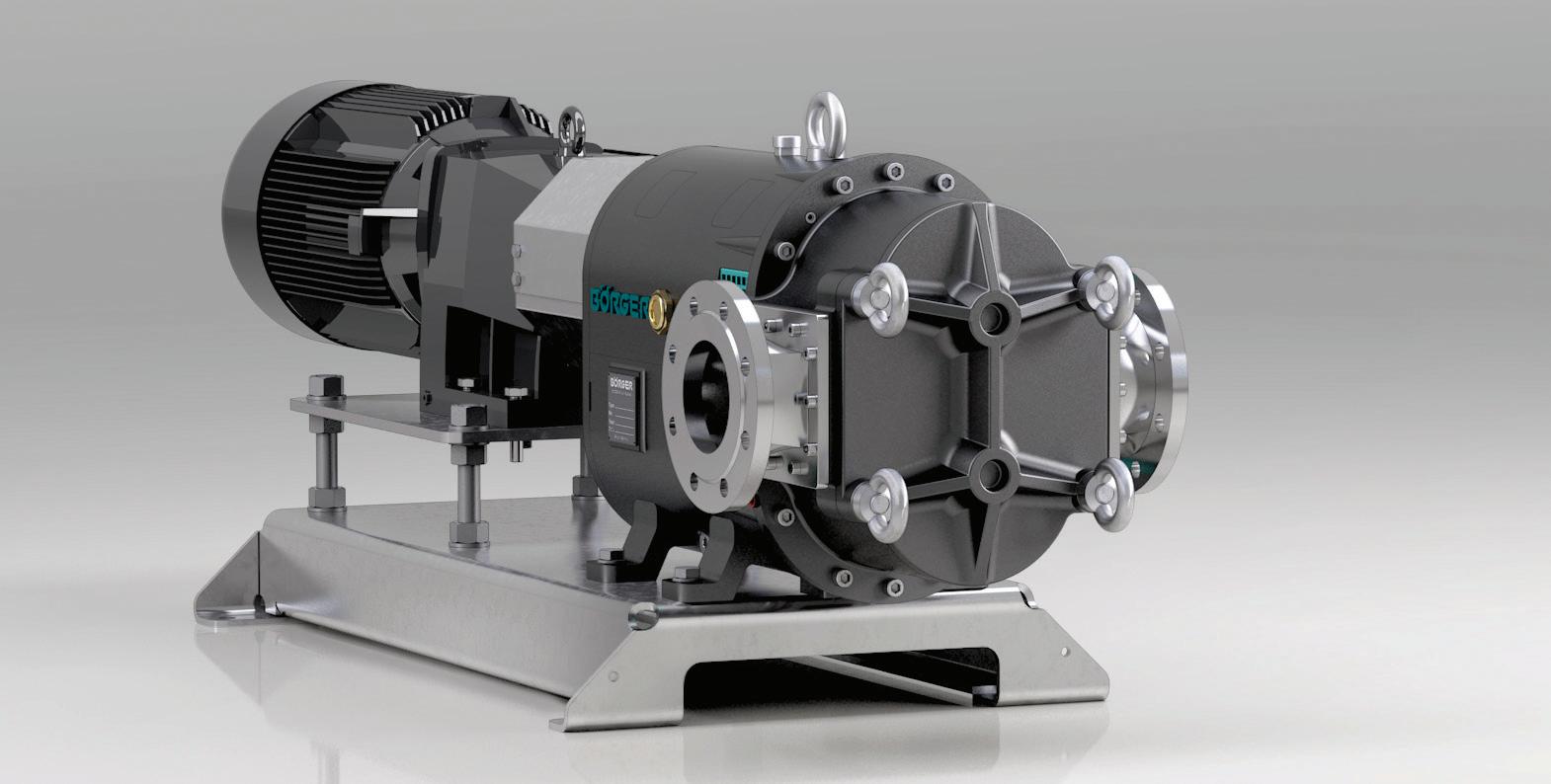

Supplying an ATEX-approved pump for a high-pressure, high-temperature application can be quite an ask. Yet, in many ways, for an oil refinery in the South West of England, their need was a typically specific one for the industry, especially as the challenge was to process waste cooking oil, as Borger UK’s Managing Director, David Brown, explains.

The global need to effectively utilise waste cooking oil (WCO) in petrochemical and highquality gasoline production has never been so great, but finding a long-lasting pump that could cope with high pressures and handle fluids with high viscosity was proving difficult for this particular refinery. That was until they consulted the local tank-cleaning company, who are regular visitors to the site. For their tankers, the industrial cleaning firm had been using pumps made by Borger for many years – and with no reported problems, had no hesitation in recommending them.

Robust solution

With its proven range of ONIXline pumps that benefit from a large-volume sealing area, Borger UK’s Managing Director, David Brown, was confident that his company could provide a robust solution for the demanding application.

“We enjoy a challenge,” said David, “but at 14.5 bar, a temperature of 70°C and more than 50% solid content with a Viscosity of 14 centipoise, we knew we had to create something special. There’s also getting the balance right between high internal fluid temperatures and ATEX surface temperature limits on the outside.”

Initially, the refinery wanted to take the customised pump on a rental basis, but Borger worked closely with its customer to provide a purchase option that (subject to a successful trial) would offer much better value for money.

David added: “Finding that sweet spot between a pump that can handle high temperatures but also handle highly viscous products has taken a distinct turn for the better in the world of pump evolution.

“Seal-less magnetic (Mag) drive pumps are suitable for high temperatures and prevent

any leakage of fluid, which is clearly important when dealing with chemicals and corrosive liquids. They have a pretty simple design and are generally quite reliable. However, this isn’t the case at all when trying to deal with viscous fluids. Magnetic drive pumps are also far more expensive than mechanical seal pumps. Whilst Magnetic pumps can do a great job in certain applications, I don’t buy the argument that they’re somehow automatically better on maintenance because as soon as a slightly difficult, non-clean liquid comes along, the user is entering a whole world of pain, with an excessive need for maintenance and repairs”.

David continued: “You also won’t have to look too far to find a manufacturer of twin screw pumps, often described as ‘durable and low on maintenance’. This is true for durability and for handling highly viscous products, but it is a totally different story if it is a liquid that contains some solid particles. Less of a story and more of a nightmare, with arduous and very expensive maintenance bills on top of a hefty purchase price.”

With the Borger pump having more than proved itself during a lengthy trial at the refinery, the intake of waste cooking oil was increased almost six-fold, requiring a much

larger custom-built Borger ONIXline pump (30 kW) with specially machined stainless-steel rotors to operate 24/7 at 40m³/h (compared to 7m³/h for the first unit).

David added: “The new pump at the refinery has proved just as popular as the first because it gets on with the job and is easy to manage. As the need continues to address the pollution caused by waste cooking oil and, more importantly, treat it for reuse, refineries can see that there are now the right type of pumps available to process it efficiently and effectively, with just a small footprint. Refineries can choose leaner, more cost-effective pumps with superior rotors that promote maximum energy efficiency through gentle, almost pulsation-free pumping – with the added benefit of no wearing parts. There’s also maintenance-in-place (MIP) designed in, so routine servicing is much, much easier, with simple tools and very little downtime compared to other pumps. The installation at this refinery in the South West proves at last that the happy medium for high temperatures and highly viscous products is now possible – with much lower capital and ongoing maintenance costs.” www.boerger.com

24 www.mepca-engineering.com PUMPS & PUMPING SYSTEMS

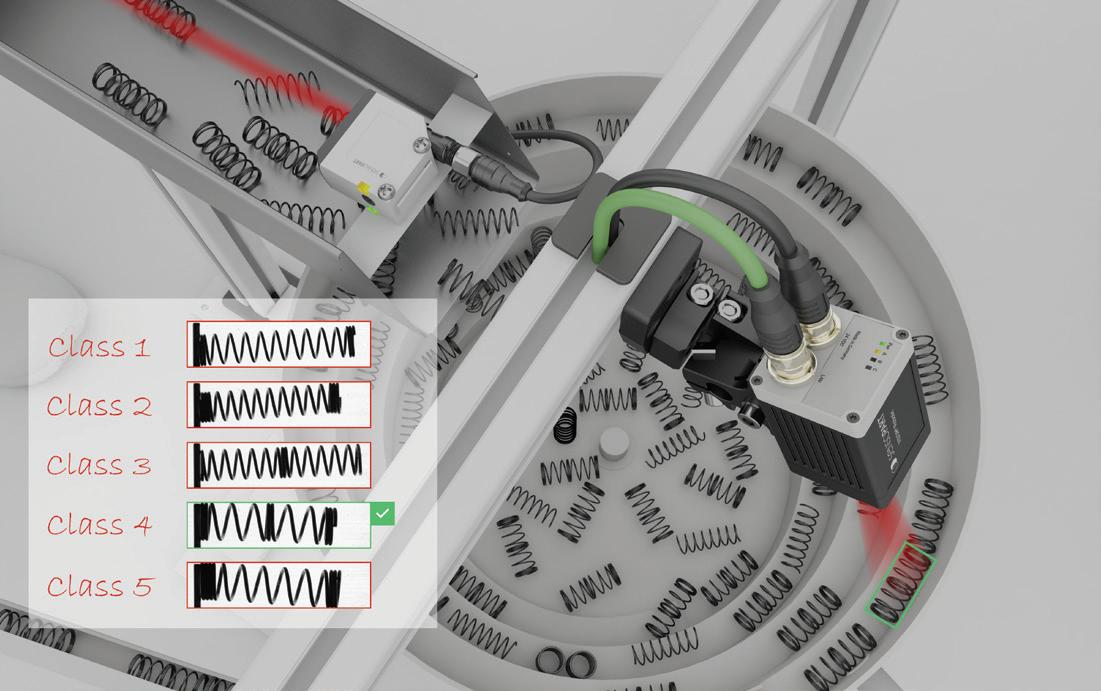

VISOR® OBJECT AI HIGHLIGHTS

• Easy setup without image processing knowledge

• AI technology in a robust vision sensor, made for industrial automation

• Train the detector with a few images on your PC

• Reliable results with strong varying processes and products

Sensopart UK Ltd info@sensopart.co.uk - +44 1664 561539 Find out more at: www.sensopart.com/ai

Pump automation techniques save valuable time

Castle Pumps explains nine ways to automate your pumps to free up your operators’ time for more value-adding tasks, while preventing pump damage, reducing waste and improving accuracy in the process.

Aquote says, “Wasted time is worse than wasted money”. In fact, it is highly likely that wasted time is wasted money for your business, as labour costs are one of the most expensive overheads. So it is worth considering if your processes or production lines involve the time and labour-intensive manual operation of your pumps. If they do, significant savings could be made by automating them to free up operative time. Here is a selection of ways to automate your pumping systems.

Pump timers

Sometimes your pumps need to run for specified periods before stopping. For example, a circulating application may require a product to be pumped for ten minutes every four hours to prevent the ingredients from separating or the oil in oilbased products from sinking to the bottom. Fitting a timer would not only reduce the amount of time someone has to spend walking to the pump and operating it, but it also eliminates the chance of someone forgetting and it not being done.

Batch meters

Pumps used for dosing a specific volume of fluid can be supplied with a batch meter that can turn the pump off once the amount has been dispensed. This reduces reliance on the operator and ensures the amount is accurate and easily repeated. Batch meters are ideal for container filling applications and adding a set amount of additive or ingredient into a mixture.

Stroke counters

A stroke counter is similar in principle to a batch meter but specifically designed for air-operated pumps. It counts the number of times the pump ejects air and can turn it off once a specified number has been performed. By knowing how much fluid is

transferred per stroke, you can use stroke counters for batching. However, it may be less accurate if the fluid’s viscosity can differ depending on the batch or temperature.

Level/float switches

Level switches can also control your pumps’ start/stop cycles. When the fluid in a container has reached a certain level, the pump can automatically turn on or off and continue until the sensor detects another specified level. This is popular for tank filling and emptying applications such as waste tanks.

Dry run protection

If your pumps are left to run with no fluid passing through them, they can overheat, and cause component seizure and damage to the seals and impellers. Pauses in your production line or operators forgetting to turn the pump off can result in dry running. A dry run sensor can automatically turn a pump off when a lack of fluid is detected.

Leak sensor

The fitting of a leak sensor can turn your pumps off upon detection of fluid leaking from them. These are particularly good practices for pumps handling high-cost products or hazardous fluids, and chemicals that can be dangerous or flammable.

Variable speed drive

Where there are differing duty demands on the pump at different times, VSDs can help automate the speed of the motor to actual requirements rather than maximum capacity. They can be used to slow down or speed up the pump’s motor depending upon the pressure detected in the system.

Condition monitoring

Increasingly sophisticated systems have integrated data loggers that, without the need for manual inspection, can monitor

factors such as vibration, pressure, temperature and motor current and track trends to ensure that issues can be spotted before they cause a pump or process to fail.

Remote control

Radio-operated control pads enable pump start/stop or reverse operation to be carried out without operators physically needing to go to the pump. If a pump is operated multiple times per day, productivity can be drastically improved with this approach. Whilst these are all excellent ways to automate a pump, it is rare that a particular installation will utilise them all. Castle Pumps advises users to think about what costs the most time or money in a process and decide which automation feature will be the best to employ. www.castlepumps.com

26 www.mepca-engineering.com PUMPS & PUMPING SYSTEMS

High performance from new compact Cat 5 booster set

Pump and water boosting solutions manufacturer Stuart Turner has launched the Aquaboost Aquabreak AB5 Cat 5 booster set with backflow protection which makes it ideal for wash-down applications.

Designed to meet the requirements of Fluid Category 5 as described in Schedule 1 of the water supply regulations, the Aquaboost Aquabreak AB5 includes specific features to prevent water supply contamination. The booster set offers backflow protection using a Type AB air gap. This gap is designed to prevent the inlet from ever being able to become submerged, which could lead to the contamination of the mains water supply in the event of a backflow pressure drop.

The Aquaboost Aquabreak AB5 is a complete, all-in-one single outlet booster set incorporating a single pump, pressure

sensor, controller, control vessel, non-return valve and a 5l (nominal) break tank fitted with a ½” solenoid valve and strainer. The device can provide a maximum pressure of 4.5 bar and a maximum flow rate of 26l/min.

The solenoid valve supports a faster inlet flow which can quickly fill the break tank and enable the Aquaboost Aquabreak AB5 to achieve its impressive specifications in a compact unit which is durable thanks to its 304 stainless-steel enclosure.

The Category 5 compatibility of the compact and wall-mountable Aquaboost Aquabreak AB5 makes the booster set ideal for applications involving fluids which present a serious health hazard. This includes use in processing plants, slaughterhouses,

mortuaries, laboratories, stables, kennels, waste bin stores and washdown sites.

The Aquaboost Aquabreak AB5 employs a Regulation 4 certified pump which offers dry-run protection. The entire device is currently going through the Regulation 4 approval process with both KIWA and WRAS, which, when confirmed, will enable it to meet the requirements of project specifications which call for these important product certification credentials. www.stuart-turner.co.uk

Precision detection from every angle

• Available in plastic or stainless steel AISI316L housings and featuring IP69K and ECOLAB approval

• Provides accurate detection of objects of different sizes, shapes, or surface structures

• Easy configurable functions via IO-Link ver. 1.1

• Machine downtime reduced thanks to the predictive maintenance functions: Quality of Run, Quality of Teach, Temperature and dust alarms, Excess Gain and Auto Adjustment

• Four new unique predefined and selectable application functions: Speed and length, Pattern recognition, Divider function and Object and gap

Carlo Gavazzi UK Ltd. - 4.4 Frimley Business Park, Frimley, Camberley, Surrey GU16 7SG Tel: 01276 854 110 - www.gavazziautomation.com

www.mepca-engineering.com 27

PD30 IO-Link Series: the smart photoelectric sensors for accurate detection of objects of different sizes, shapes or surface type

PUMPS & PUMPING SYSTEMS

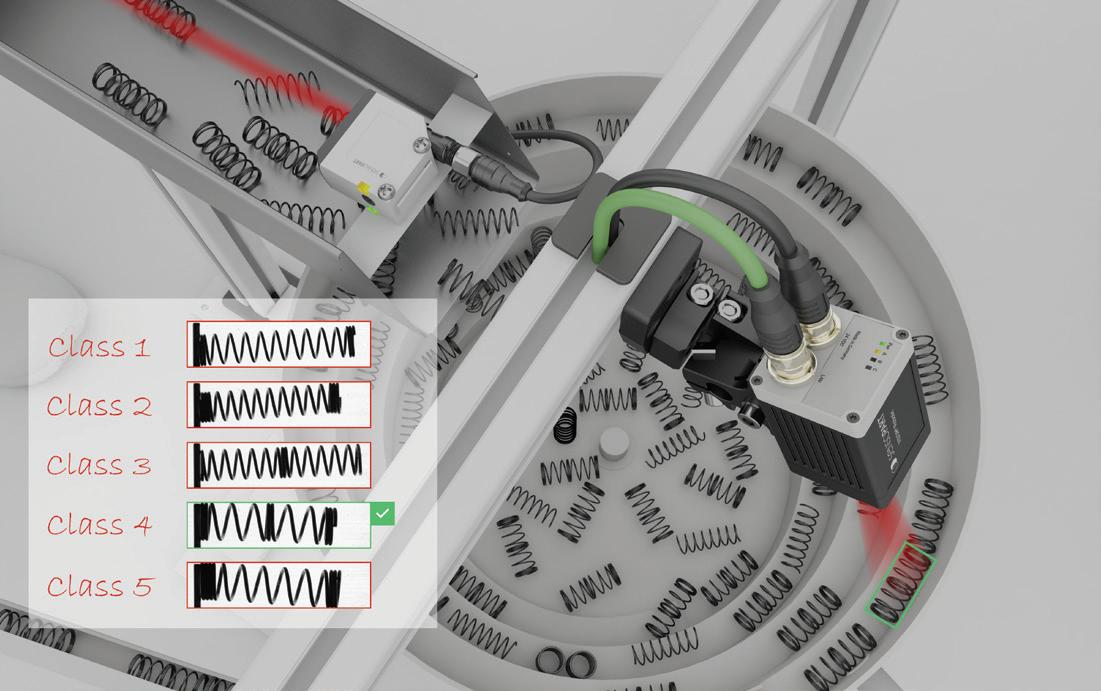

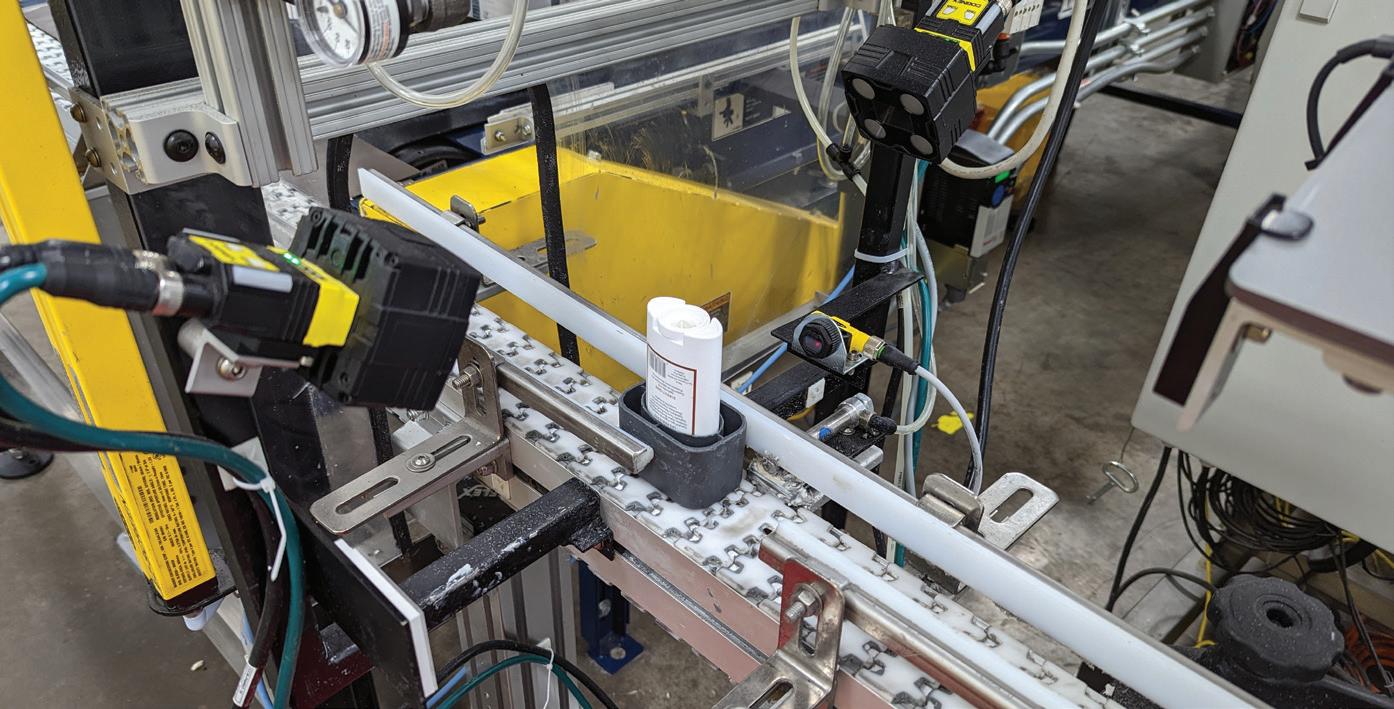

Edge learning technology improves product quality

Manufacturers of personal care products take great pains

to ensure their products are free from defects. Many leading brands outsource their manufacturing and packaging to third-party packaging partners that must adhere to the strict quality standards set by their customers. MEPCA found out how one such packaging partner is using an edge learning-based system from Cognex to maintain the highest quality for its customers.

Federal Package, based in Minnesota in the United States, specialises in the development and packaging of a wide range of well-known health, beauty, and personal care products. The company prides itself on delivering a quality product that supports its customer’s brand image.

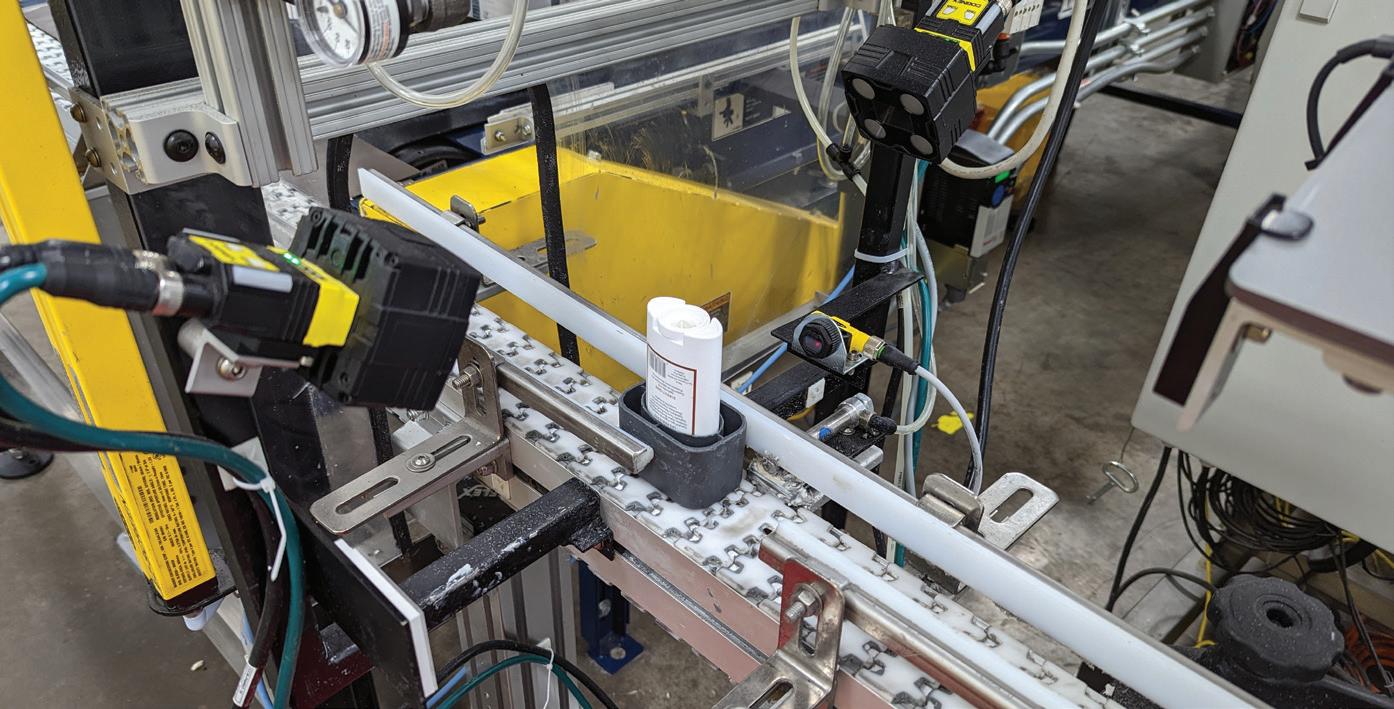

A recent project that involved producing deodorant for a personal care company helped spur an investment in automated inspection. One inspection point was checking the plastic packaging that housed deodorant for drips that not only indicated overfilling but also resulted in a poor product presentation. The second quality checkpoint was verifying the correct label was used and that it was applied in the correct position and orientation on the packaging. To improve productivity and increase quality, automated inspection of each package was an ideal solution.

Edge learning-based system

Federal Package has invested in machine vision in various areas of its business. The customer service provided by Cognex and a positive software experience led Federal Package to select Cognex with this deodorant inspection application.

Noah Leuer, a manufacturing engineer at Federal Package, got to know one of Cognex’s newest vision systems with embedded edge learning technology. Edge learning is a subset of artificial intelligence in which processing takes place on-device using a pre-trained set of algorithms. The technology is simple to set up, requiring less time and fewer images for training compared to other AI-based solutions, like deep learning.

Noah Leuer felt this new vision system could do the job, and the price point made it easy to justify as an automation technology investment. The drip inspection system evaluated each deodorant package body for excess deodorant that resulted from overfilling. According to Noah: “We have between 30 and 40 different deodorant designs with different fragrances, colours, and names. The system’s edge learning capability was intelligent enough to filter out the colours and names and focus on the actual defects of the product.”

The drip inspection line runs close to eighty units per minute, and the label inspection line runs around sixty units per minute. In both cases, the automation enables more throughput, as well as guaranteeing all units are inspected, which manual inspection could not achieve.

In addition to the attractive price point of the new Cognex edge learning-based vision system, Federal Package was impressed with how easy the system was to set up and train. Once initially installed on the line, the vision systems were deployed on the

production line within an hour and can be retrained for product changeovers in 5-10 minutes.

Delivering on brand image promise

Quality is the top priority for Federal

Package. According to Noah: “As a packaging partner to personal care manufacturers, it’s a requirement of the partnership to deliver high-quality consumer products that delight customers and preserve brand value.” The new edge learning-based automated inspection systems that have been put in place have enhanced the company’s quality assurance process, making its best even better.

Federal Package has also invested in a Cognex AI-based vision system which it plans to use to verify date and lot codes that must be printed on its products to enable tracking through the supply chain for inventory management and lot control as required by its customers and the FDA.

www.cognex.com

28 www.mepca-engineering.com IMAGING & VISION

Put packaging into the right light

With the KRT 3C contrast sensor, Leuze has introduced the smallest contrast sensor it has ever made for the packaging industry. As a result, plant operators can benefit from a compact device that can be used in many different ways.

The KRT 3C detects reliably and positions accurately even if there are only small contrast differences or with glossy surfaces or highly reflective materials. This is possible thanks to the multicolour functionality of its red, green, and blue light, as well as white and laser red light, which means that no object or printed label will be able to pass through unnoticed. This allows users to select the right light source for any material and contrast mark colour for their packaging and labelling processes.

The KRT 3C detects contrasts very

precisely and reliably and with a short response time of only 50μs (laser: 125μs) and minimal signal jitter. This helps to achieve optimal machine throughput.

With its small dimensions of 11x32x17mm, the sensor is designed for tight installation spaces. This means it can be fitted almost anywhere. Users can easily set up the KRT 3C via the integrated IO-Link interface. Changes are also made quickly when changing product formats.

The device’s housing is also robust,

meeting IP67 and IP69K degrees of protection. The KRT 3C is also ECOLAB certified, so it can even handle aggressive cleaning agents.

www.leuze.co.uk

RFID, Fast tag detection, reads all tags on the pallet in one pass

Advantages for industrial Automation with RFID from TURCK. More efficient production based on higher application speeds.

Simple integration into control environment and enterprise business applications, ERP, MES, SAP etc. Complete turnkey solutions Specialist data carriers. www.turckbanner.co.uk

www.turckvilant.com

Global Automation Partner

Your

Turck Banner Ltd. Blenheim House, Blenheim Court, Wickford, Essex, SS11 8YT Tel: 01268 578888

www.mepca-engineering.com 29 IMAGING & VISION

rfid@turckbanner.co.uk

The new KRT 3C contrast sensor from Leuze can be flexibly integrated into packaging processes thanks to its multicolour capability and small size.

Helping a container terminal work round the clock

MEPCA discovers how ComBricks, the first PROFIBUS-based automation system that unites repeaters and permanent monitoring in a web browser, enabled one of the leading and most advanced container terminal operators in Europe to prevent crane downtime in its busy Euromax container terminal.

Port cranes are the lifeline of any container terminal. Without them, cargo cannot be loaded or unloaded, and the entire operation comes to a standstill.

Hutchison Ports ECT Rotterdam (ECT) is one of the leading and most advanced container terminal operators in Europe, handling the majority of the containers at the port of Rotterdam. ECT’s Euromax container terminal relies heavily on its 16 port cranes, which are essential for transferring cargo to and from ships. However, the cranes were frequently breaking down due to problems in the PROFIBUS network, causing significant disruptions to the terminal’s operations.

To prevent such incidents from occurring, ECT turned to Procentec (now Anybus and part of HSM Industrial Networks) for a solution. ComBricks was chosen to segment and monitor the PROFIBUS network, providing ECT’s maintenance team with real-time alerts to any potential issues. As a result, ECT can now proactively address any problems before they escalate and cause crane downtime, ensuring that the terminal operates smoothly 24/7.

“We contacted Procentec because we had a lot of problems with breakdowns in the PROFIBUS network in the past,” explained Jos Poss, technical specialist at ECT’s Planning and Control Department and support officer for the Technical Maintenance Service. “This is because if any one part of a crane broke down, the rest did as well. A company like ECT can’t afford to let this happen as we work around the clock, and all the steps in the process are geared toward one another. So, we had to find a solution.”

To ensure that the cranes were operational 24/7, ECT required a reliable method of monitoring the PROFIBUS network, promptly detecting and resolving any issues

before they caused downtime.

ECT opted for the ComBricks modules to guarantee operational continuity now and in the future. “At that time, we were one of the first enterprises to work with ComBricks,” said Jos. “And we’re very happy with it. The new network with ComBricks has been running for a year now, and to date, we’ve hardly had any breakdowns at all. ComBricks is a very reliable system, and the most important aspect of the matter is that our previous problem has now been solved. This success is largely due to the support and advice we’ve had from Procentec. The company gave an on-site training course on working with ComBricks, and one of the incredible things about this was the practical part was carried out on one of our port cranes. It was really helpful.”

The new layout in the PROFIBUS network is a crucial success factor, and segmentation was one of the significant success factors

in this respect. “We opted for a new layout for the PROFIBUS network in consultation with Procentec engineers,” Jos continued. “A logical structure is key here. The driving mechanisms are in different segments right now. Each segment has its own string and is controlled by a ComBricks module without any of the strings affecting each other. This means that a breakdown in one string can be isolated from all the other strings, and we can safeguard the crane during a breakdown. And at the same time, the module tells us where exactly to find the error in the network. The analysis of the error made by the scope card in the module is really useful if the error is a frequently recurring one. The repairman can now go on the crane without any measuring equipment and repair the defect. And this means greater operational safety.”

www.anybus.com

30 www.mepca-engineering.com CONTROL SOLUTIONS

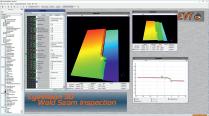

MACHINE VISION CAMERAS FOR AUTOMATION AND QUALITY INSPECTION APPLICATIONS

For measurement and inspection including print and barcode verification our cameras, lighting and powerful machine v ision software solutions prov ide the answers.

For materials inspection including surface analysis and sorting, we supply Multispectral & Hyperspectral v ision systems.

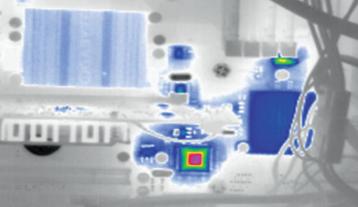

Do you need to monitor ‘Hot Spots’ for pre-emptive maintenance or design inspection?

Our Thermal Vision systems give you the hidden picture.

We offer a wide range of cameras, lenses, lighting, interface cards, cables, housings, software and much more...

Tel: +44 (0)1635 937000

Email: sales@alrad.co.uk

Web:www.alrad.com

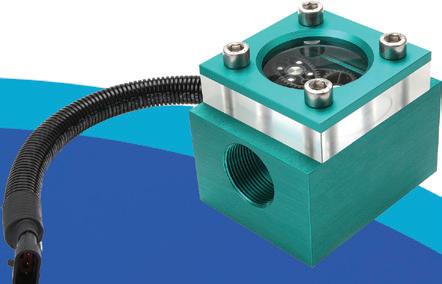

Titan Enterprises is a leading design and manufacturer of innovative end user and OEM high-performance flow measurement solutions.

Titan’s flow meters are:

• Designed and manufactured to ISO 9001 with traceable calibrations.

• Robust and reliable delivering high accuracy and repeatability.

• Capable of measuring a wide range of liquid flows.

• Ideal for use in a variety of environments, temperature & pressure ranges, and chemical compatibility.

Titan’s flow meter and instrument range includes:

• Ultrasonic Atrato® and Metraflow® flow meters

• Low cost turbine flow meters

• Oval gear flow meters

• NSF-approved mini turbine flow meters

• OEM bespoke design

To discuss your specific flow meter applications, contact us today: T: +44 (0)1935 812790 E: sales@flowmeters.co.uk W: www.flowmeters.co.uk

www.mepca-engineering.com 31

Breakthrough flowmeter technology NEWUKFLOWTECHNIK2023FLOWMEASUREMENT& INSTRUMENTATIONCATALOGUEAVAILABLENOW! CONTACTUSNOWREQUESTINGYOURCOPY Tel:+44(0)1159017111 | Email:sales@ukflowtechnik.com | ukflowtechnik.com

-

-

M & E week 2023 - conference programme announced

With just a month to go until Manufacturing & Engineering Week 2023 and its centrepiece exhibitions opening their doors on June 7 and 8 at Birmingham’s NEC, the full conference programme has been announced. Taking place across two Keynote Theatres and six Solutions

Theatres, the full programme can be viewed on the event website.

The free-to-attend conference programme at Manufacturing & Engineering Week 2023 is incredibly wide and diverse in the subject matter it covers while having sustainability, digital transformation, innovation, supply chain resilience and people and skills as key reoccurring themes.

Among the most notable sessions are those from some of the most prominent figures in the industrial landscape. On day one, Juergen Maier, CBE - former advisor to the government on industrial strategy and former Chief Executive of Siemens UK - will provide his perspective on UK manufacturing and the opportunities and challenges it is facing in a session titled What Next for UK Manufacturing?

Similarly, on day two, Make UK CEO Stephen Phipson, CBE, hits the stage for a keynote entitled State of the Nation. This session will provide an overview of how UK manufacturers can put themselves in the best position to succeed.

Other notable names presenting at the conference include Katherine Bennett CBE, CEO of the High-Value Manufacturing Catapult; Mike Wilson, CEO of Manufacturing Technology Centre (MTC); Libby Meyrick, CEO at the Institution of Engineering Designers (IED), Director of Siemens Digital and co-Chair of Made Smarter, Brian Holliday, National Manufacturing Institute of Scotland CEO, Chris Courtney and HVMC Policy Director, Rosa Wilkinson.

A second conference theatre, dedicated to Maintec and sponsored by RS, also has a full programme including a number of ‘firsts’ such as the first public output from the Maintenance Research Project. This session will provide the initial results from an independent report created by RS

Maintenance and the IMechE (Institution of Mechanical Engineers) that reveals the challenges facing maintenance professionals within UK manufacturing. This report contains key statistics and data taken from interviews with over 750 senior maintenance professionals.

The Maintec Theatre will also see the launch of a Global Responsibility Competency Compass by Engineers Without Borders UK. The Compass is for those who are struggling to respond effectively to the complexity, uncertainty and challenges of the age. The actionoriented tool, developed through extensive consultation and testing, articulates the essential skills, knowledge and mindsets that engineers increasingly need to deliver the most positive impact on the four principles of global responsibility: responsible, purposeful, inclusive and regenerative.

Additional free educational sessions are being hosted by the Institute for Manufacturing in the IfM Theatre. These masterclasses are designed to challenge

and extend the attendees’ thinking in relation to some of the most pressing challenges and opportunities they face. Previous strategic masterclass topics have included: Strategic roadmapping, technology and innovation management, sustainability – scope three emissions, sustainability - reducing energy waste and digital strategy. IfM masterclasses require advance booking, and this can be done when registering for your ticket to visit M&E Week’s Smart Factory Expo.

Finally, adding a little fun to M&E Week is the Guitar Legends competition. The competition will take place on both days of the centrepiece exhibitions at Birmingham’s NEC on June 7 and 8. Entrants will play the intro to a classic rock song or create their own solo to be in with a chance to win a Nexa3D printed guitar. A guitar will be awarded to each day’s competition winner, while the winner on June 7 will also get the chance to play with The Shadow Monkeys at the Day one drinks reception.

bit.ly/MEagenda

32 www.mepca-engineering.com EVENT PREVIEW

Showcasing leading automation and robotics suppliers

Taking place at the Coventry Building Society Arena, between June 20 and 21, 2023, Automation UK, the new exhibition highlighting the importance of robotics and systems integration to the future growth of the UK economy, is poised to be a sell-out event as the countdown to the show enters its final weeks.

Owned and organised in conjunction with BARA (British Automation & Robot Association), the event is designed to promote the use of, and assist in the development of, industrial robots and automation in British industry. Being owned by the industry, for the benefit of the industry, means there are many BARA members exhibiting – each showcasing their latest products and services, with experts on hand to offer advice and support.

Big names exhibiting include ABB, CKF, FANUC, Festo, KUKA Robotics, Mills CNC, Piab, Pilz Automation, RM Group, Schubert and Yaskawa. Joining them will be nearly 40 other companies, all active in the sector and looking to raise their profiles and generate new business.

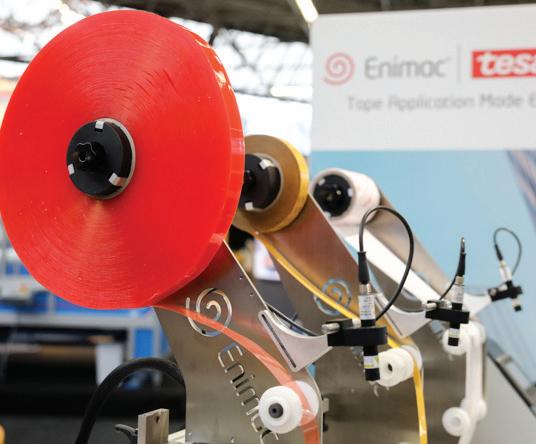

Oliver Selby, Head of Sales, FANUC UK, said: “The FANUC UK team is delighted to be a founding exhibitor at Automation UK. As evidenced by the increase in enquiries we are receiving, there is a real need for a dedicated automation and robotics show such as this. We’ve been a longstanding member of BARA and are proud to support them in helping to raise the profile of automation among UK manufacturers, showcasing the wide-ranging benefits it can deliver.”