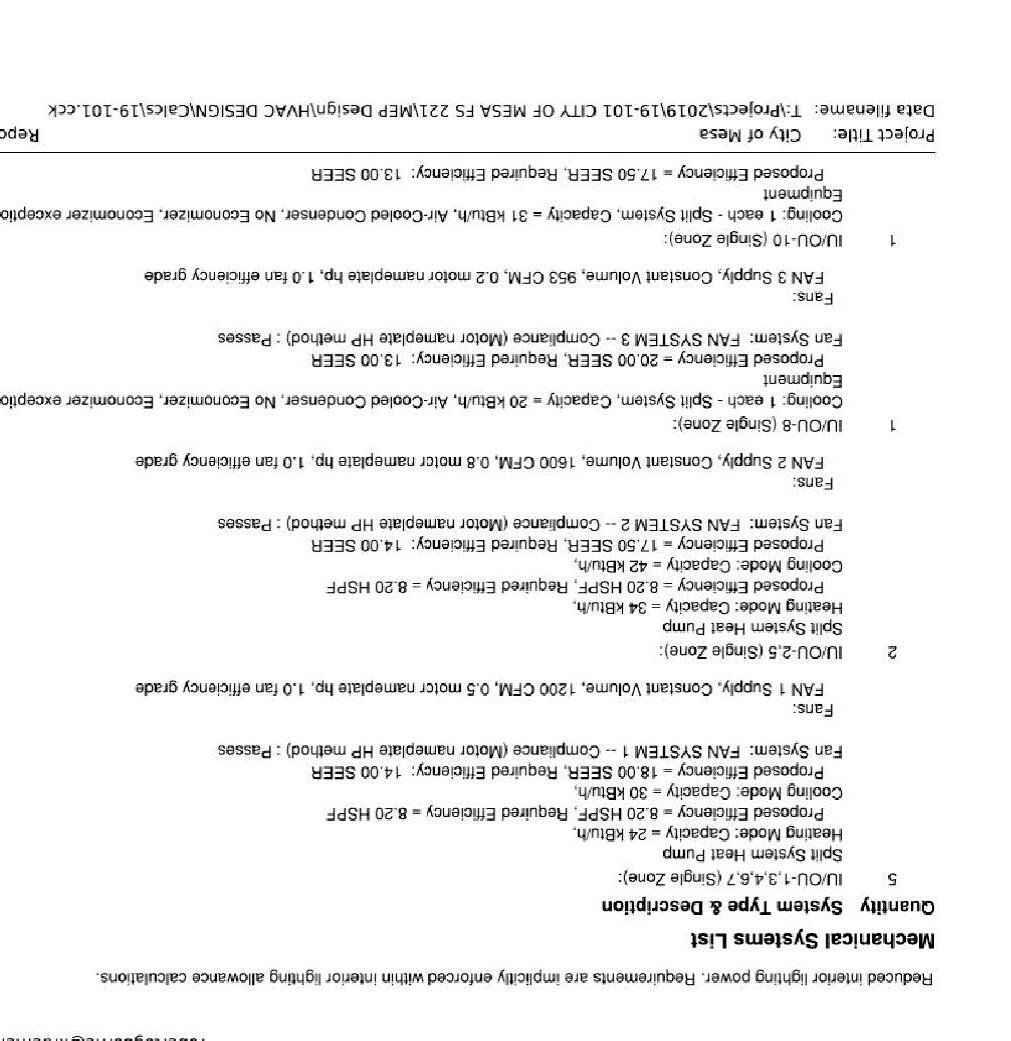

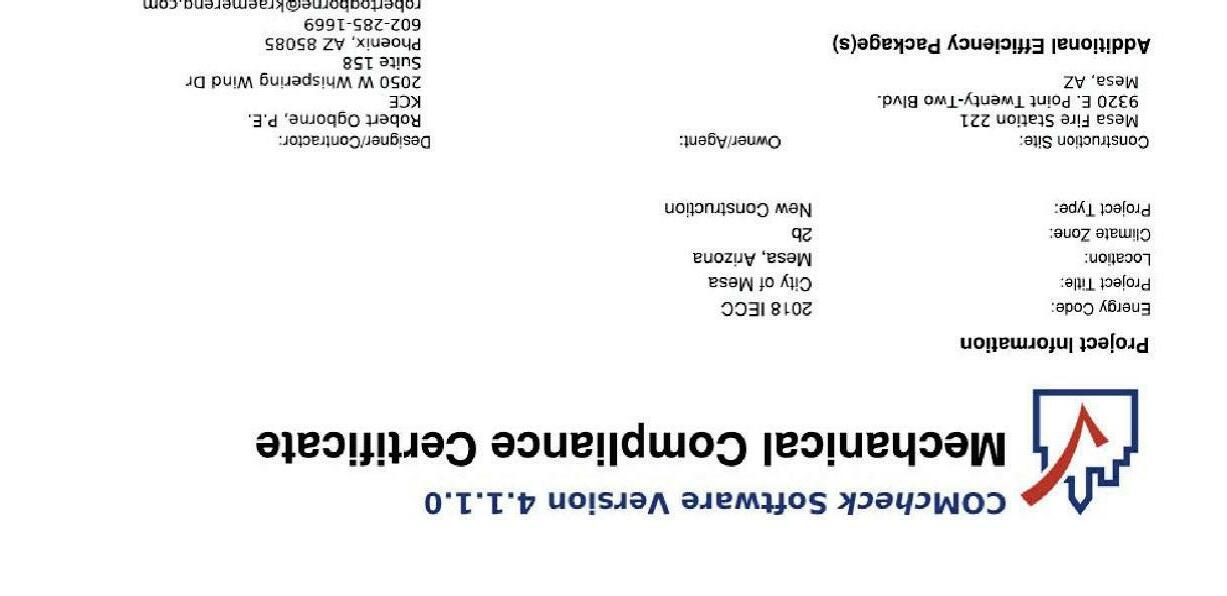

TRAFFIC SIGNAL PLANS FOR MESA FIRE STATION NO. 221

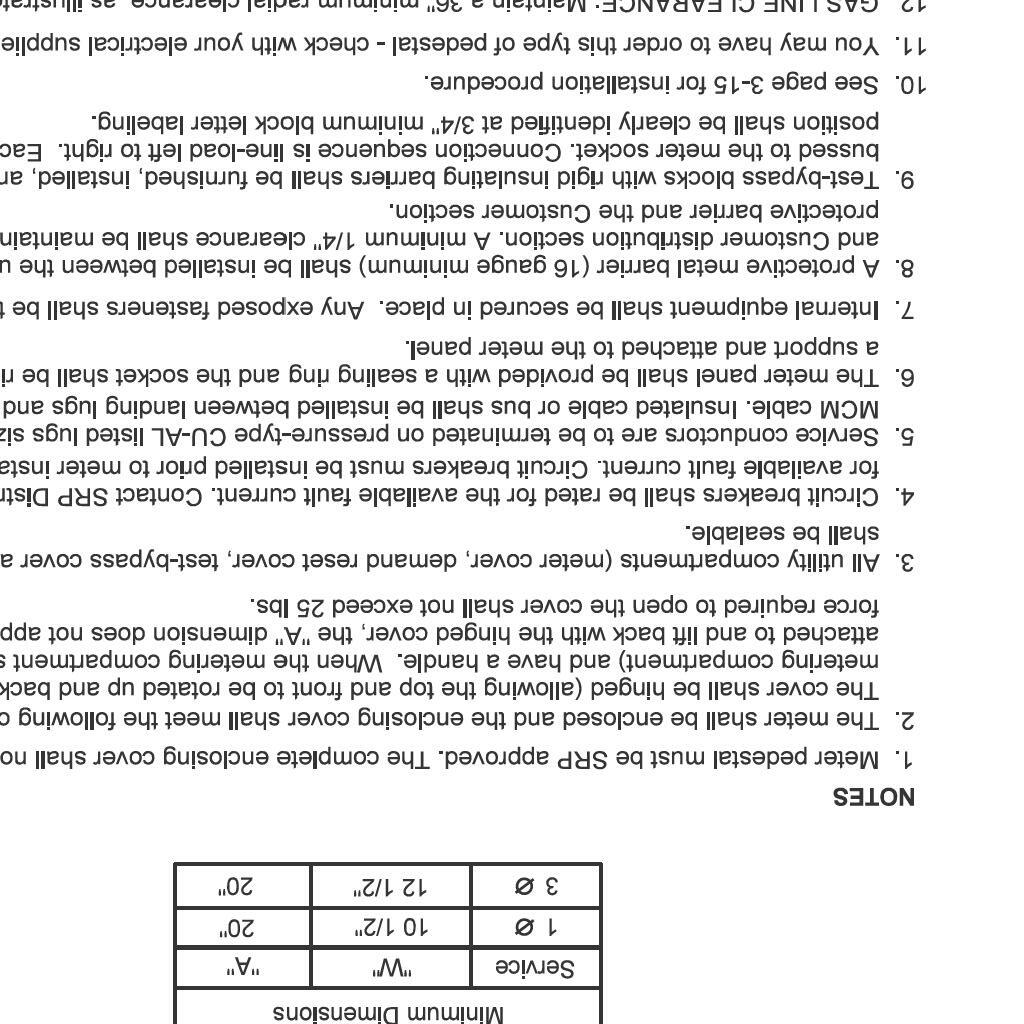

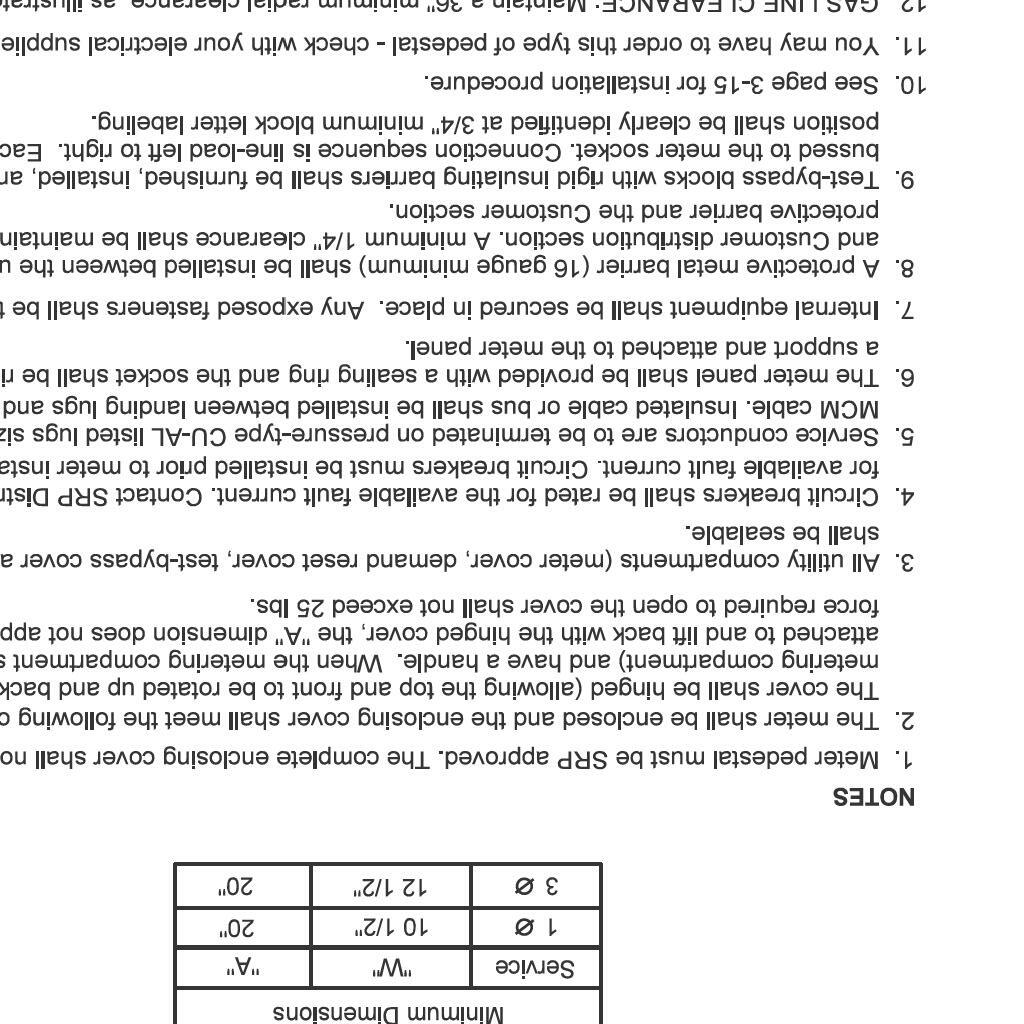

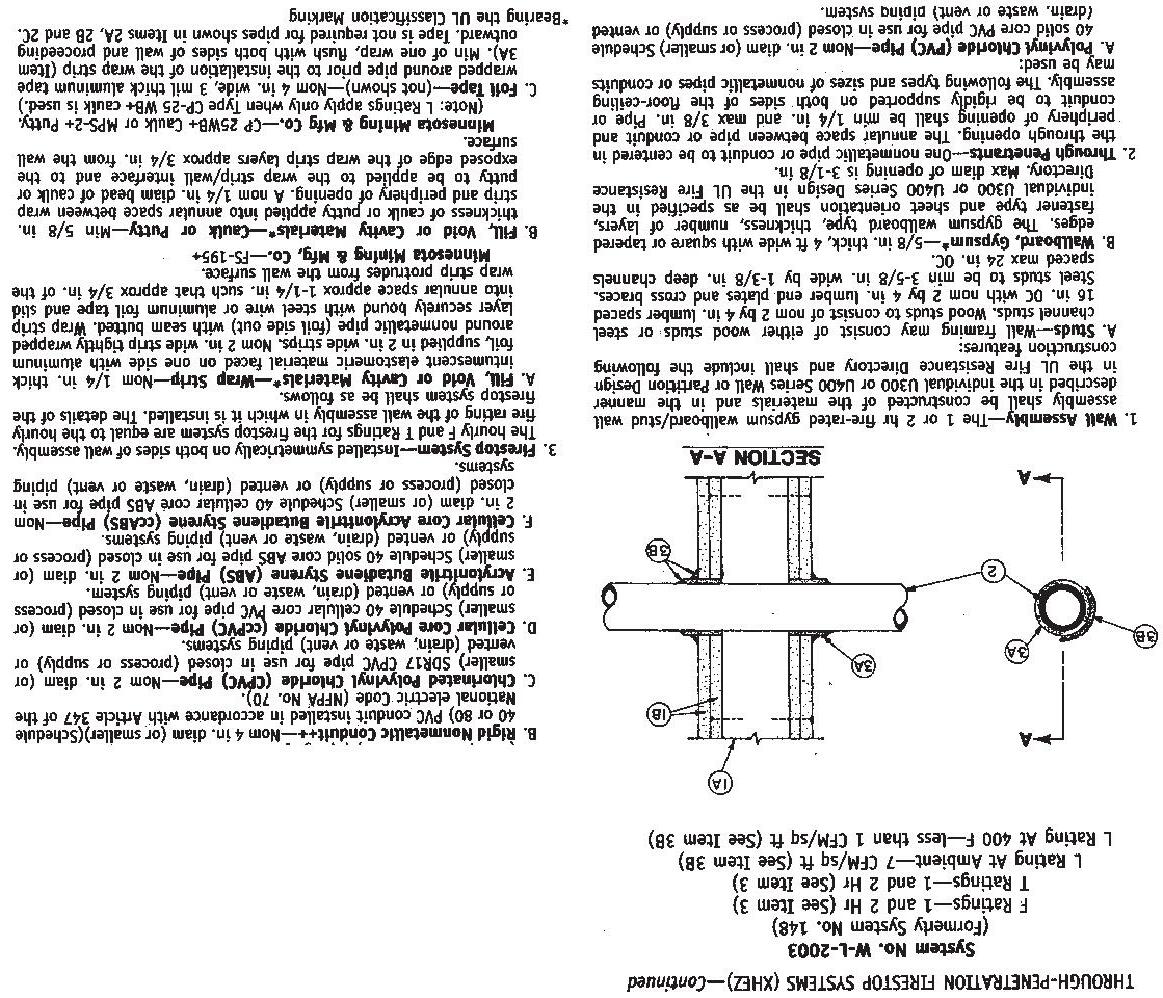

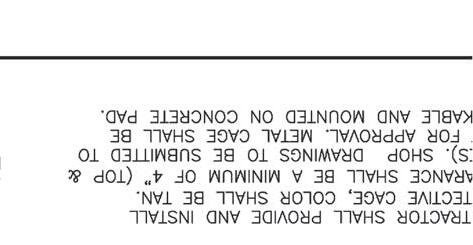

9320 E. POINT TWENTY-TWO BOULEVARD

SHEET INDEX

CV01COVER SHEET & SHEET INDEX

GN01TRAFFIC SIGNAL GENERAL NOTES

TS01TRAFFIC SIGNAL PLAN SHEET

TS02CONDUCTOR SCHEDULE & DETAILS

SM01SIGNING AND MARKING - POINT TWENTY-TWO BLVD SM02SIGNING AND MARKING PLAN - S. PASTEUR

BENCHMARK

CITY OF MESA 2006 BENCHMARK, BRASS TAG IN TOP OF CURB LOCATED AT THE NORTHWEST CORNER OF MERIDIAN AND WARNER ROAD.

ELEVATION: 1481.15 CITY OF MESA DATUM BENCHMARK OBSERVED ON APRIL 30, 2012

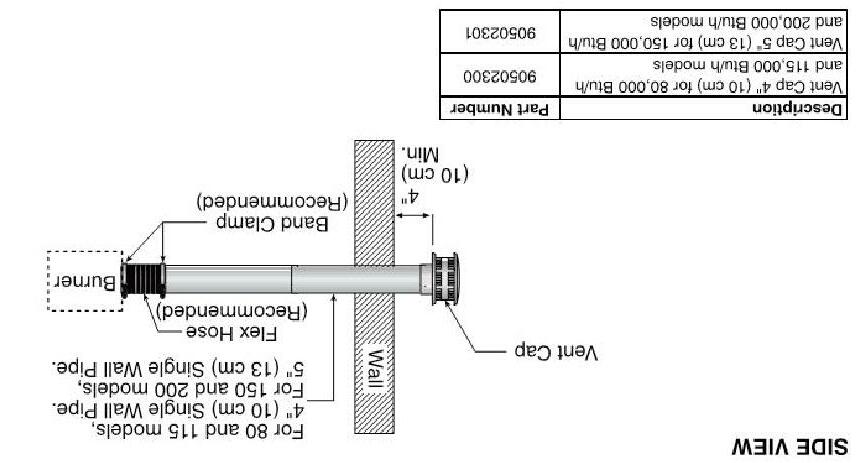

6 CATALOG NUMBER: SHEET OF Dial 8-1-1 or 1-800-STAKE-IT (782-5348) in Maricopa County: (602) 263-1100 Call at least two full working days before you begin excavation. Arizona Blue Stake, Inc. DRAWING NORTH DRAWN BY: R. STEPHANI ENGINEER: C. WILLIAMS APPROVED BY: C. WILLIAMS ACTIVITY: ____ PROJ. NO.: ______ Y2K ENGINEERING, LLC. 480.696.1701 www.y2keng.com CITY OF MESA 2006 BENCHMARK, BRASS TAG IN TOP OF CURB LOCATED AT THE NORTHWEST CORNER OF MERIDIAN AND WARNER ROAD. ELEVATION: 1481.15 CITY OF MESA DATUM BENCHMARK OBSERVED ON APRIL 30, 2012

CV01 COVER SHEET & SHEET INDEX

PROJECT LOCATION MAP

GENERAL NOTES (REVISED 03-15-18) (2018 VERSION)

1.ALL WORK AND MATERIALS SHALL CONFORM TO CURRENT UNIFORM STANDARD SPECIFICATIONS AND DETAILS FOR PUBLIC WORKS CONSTRUCTION AS PUBLISHED BY THE MARICOPA ASSOCIATION OF GOVERNMENTS AND AS AMENDED BY THE CITY OF MESA. ALL WORK AND MATERIALS NOT IN CONFORMANCE WITH THESE AMENDED SPECIFICATIONS AND DETAILS ARE SUBJECT TO REMOVAL AND REPLACEMENT AT THE CONTRACTOR'S EXPENSE.

2.THE INFORMATION SHOWN ON DRAWINGS CONCERNING THE TYPE AND LOCATION OF EXISTING UNDERGROUND UTILITIES IS APPROXIMATE AND HAS NOT BEEN INDEPENDENTLY VERIFIED BY THE ENGINEER OR THE ENGINEER'S AGENT. THE CONTRACTOR SHALL DETERMINE THE EXACT LOCATION OF ALL EXISTING UTILITIES BEFORE COMMENCING WORK, AND AGREES TO BE FULLY RESPONSIBLE FOR ANY AND ALL DAMAGES WHICH MAY OCCUR BY THE CONTRACTOR'S FAILURE TO EXACTLY LOCATE AND PRESERVE ANY AND ALL UNDERGROUND AND OVERHEAD UTILITIES.

A.CALL 602-263-1100 OR 811 FOR BLUE STAKE SERVICES.

B.CALL SALT RIVER POWER FOR POLE BRACING, ELECTRIC SERVICE OR CONSTRUCTION SCHEDULING AT 602-236-8888.

C.CALL CITY OF MESA ELECTRICAL FOR POLE BRACING, ELECTRICAL SERVICE OR CONSTRUCTION SCHEDULING AT 480-644-2251 WITHIN CITY OF MESA ELECTRICAL SERVICE TERRITORY (DOWNTOWN MESA).

D.WHEN EXCAVATING IN OR ADJACENT TO A CITY PARK OR AQUATIC FACILITY THE CONTRACTOR SHALL CONTACT AQUATICS AND PARKS MAINTENANCE AT 480-644-3097 TO REQUEST ASSISTANCE IN LOCATING UNDERGROUND UTILITY FACILITIES.

E.WHEN EXCAVATING IN OR ADJACENT TO LANDSCAPING WITHIN THE RIGHT-OF-WAY, THE CONTRACTOR SHALL CONTACT TRANSPORTATION FIELD OPERATIONS AT 480-644-3380 TO REQUEST ASSISTANCE IN LOCATING UNDERGROUND IRRIGATION FACILITIES.

3.TRAFFIC CONTROL SHALL CONFORM TO THE CITY OF MESA TEMPORARY TRAFFIC CONTROL MANUAL. ELECTRONIC COPIES ARE AVAILABLE AT http://www.mesaaz.gov/business/barricading-temporary-traffic-control-permits. HARD COPIES CAN BE MADE AVAILABLE AT DEVELOPMENT SERVICES, 55 N. CENTER ST., MESA, ARIZONA

4.CONTRACTOR TO NOTIFY TRAFFIC OPERATIONS AT 480-644-3126 PRIOR TO SIGN REMOVAL AND WHEN READY TO PERMANENTLY RELOCATE SIGN.

5.CONTRACTOR TO OBTAIN ANY PERMITS REQUIRED UNLESS OTHERWISE INDICATED, AND COORDINATE ALL IRRIGATION DRY-UPS, RELOCATIONS, AND REMOVALS BY OTHERS.

6.CONTRACTOR SHALL POTHOLE EXISTING UTILITIES AHEAD OF CONSTRUCTION TO ALLOW FOR ANY NECESSARY ADJUSTMENTS IN GRADE LINE AND TO VERIFY PIPE MATERIALS FOR ORDERING THE APPROPRIATE TRANSITION AND TIE-IN FITTINGS THAT MAY BE REQUIRED.

7.THE CONTRACTOR IS RESPONSIBLE TO REMOVE ALL ABANDONED UTILITIES THAT INTERFERE WITH PROPOSED IMPROVEMENTS. THE CITY OF MESA UTILITIES DEPARTMENT LOCATING SECTION WILL ASSIST THE CONTRACTOR AS NEEDED, IN DETERMINING IF THE UTILITY (GAS, WATER, AND WASTEWATER ONLY) IS ABANDONED BY CALLING 480-644-4500.

8.PRIOR TO START OF CONSTRUCTION ON PRIVATE PROPERTY (EASEMENTS), THE CONTRACTOR SHALL GIVE THE OWNER SUFFICIENT TIME (MINIMUM 48 HOURS) TO REMOVE ANY ITEMS IN CONFLICT WITH CONSTRUCTION. THE CONTRACTOR SHALL ARRANGE TO REMOVE AND REPLACE ALL OTHER CONFLICTS AS REQUIRED.

9.THE CONTRACTOR SHALL COORDINATE WORK SCHEDULES TO PREVENT ANY CONFLICTING WORK CONDITIONS WITH THE CITY OF MESA UTILITY AND TRANSPORTATION CREWS.

10.THE CONTRACTOR IS ADVISED THAT A DUST CONTROL PERMIT AND A DUST CONTROL PLAN MAY BE REQUIRED BY THE MARICOPA COUNTY AIR QUALITY DEPARTMENT. IT SHALL BE THE CONTRACTOR'S RESPONSIBILITY TO OBTAIN THIS PERMIT, IF NECESSARY, AND COMPLY WITH ITS REQUIREMENTS. PRIOR TO CONSTRUCTION, THE CONTRACTOR SHALL PROVIDE A COPY OF THE DUST CONTROL PERMIT AND DUST CONTROL PLAN TO THE CITY FOR REVIEW.

11.INSPECTIONS SHALL BE PROVIDED BY THE CITY OF MESA. THE CONTRACTOR SHALL NOTIFY THE CITY INSPECTION DEPARTMENT AT LEAST 48 HOURS IN ADVANCE OF ANY CONSTRUCTION.

12.THE JOB SITE SHALL BE CLEANED OF ANY DEBRIS OR SPOIL RESULTING FROM THIS PROJECT AT THE COMPLETION OF CONSTRUCTION.

13.ALL EQUIPMENT AND MATERIALS NOT SHOWN OR SPECIFIED ON THE PLANS OR SPECIFICATIONS, BUT REQUIRED TO COMPLETE THIS PROJECT, SHALL BE SUPPLIED BY THE CONTRACTOR AS PART OF THIS CONTRACT WORK (NO ADDITIONAL COST TO THE CITY).

14.WHEREVER PAVEMENT REPLACEMENT PER MESA STD DETAIL M-19.04.1 OR MAG STD DETAIL 200 IS REFERRED TO WITHIN THESE PLANS, BACKFILLING SHALL BE PER THE CITY OF MESA STREET TRENCH BACKFILLING AND PAVEMENT REPLACEMENT POLICY STATEMENT, REVISED SEPTEMBER 29, 1999.

15.FOR PURPOSES OF PAVEMENT PER MAG STD DETAIL 200 OR MESA STD DETAIL M-19.04.1, INTERSECTIONS ARE DEFINED BY THE CURB RETURNS IN ALL DIRECTIONS.

16.ANY SURVEY MARKERS DISTURBED OR DAMAGED BY THE CONTRACTOR SHALL BE REPLACED IN KIND BY A REGISTERED LAND SURVEYOR AT NO ADDITIONAL COST TO THE CITY.

17.ALL EXISTING PAVEMENT MARKINGS, SIGNS, AND SIGNAL EQUIPMENT THAT ARE NOT PART OF THIS PROJECT BUT NEED TO BE REMOVED, REPLACED, RELOCATED, OR REPAIRED BECAUSE OF CONTRACTOR'S WORK WILL BE DONE AT THE CONTRACTOR'S EXPENSE.

18.THE CONTRACTOR IS ADVISED THAT DAMAGE TO ANY PUBLIC SERVICES OR SYSTEMS AS A RESULT OF THIS PROJECT SHALL BE REPAIRED BY THE CONTRACTOR AND INSPECTED BY THE CITY INSPECTOR. DEPENDING ON DAMAGES, ALL REPAIRS SHALL BE DONE WITHIN 24 HOURS.

THE CONTRACTOR IS ADVISED THAT ANY COSTS RELATED TO REPAIR OR REPLACEMENT OF DAMAGED PUBLIC SERVICES OR SYSTEMS AS A RESULT OF CONTRACTOR'S NEGLIGENCE SHALL BE BORNE BY THE CONTRACTOR.

ITS/TRAFFIC SIGNAL GENERAL NOTES

(REVISED 06-26-18) (2018 VERSION)

1.THE CITY OF MESA REQUIRES AT LEAST TWO INTERNATIONAL MUNICIPAL SIGNAL ASSOCIATION (IMSA) CERTIFIED TRAFFIC SIGNAL TECHNICIANS ON SITE DURING ALL PHASES OF ANY TRAFFIC SIGNAL WORK. AT LEAST ONE TECHNICIAN MUST BE LEVEL II CERTIFICATION OR HIGHER WITH IMSA FIBER OPTICS FOR ITS LEVEL II CERTIFICATION IT WILL BE THE RESPONSIBILITY OF THE CONTRACTOR TO PROVIDE VERIFICATION OF CERTIFICATION. IF A JOB SITE IS INSPECTED AND CERTIFIED TECHNICIAN IS NOT ON SITE, A STOP WORK ORDER WILL BE ISSUED. TEMPORARY AND CONTRACT EMPLOYEES DO NOT SATISFY THIS REQUIREMENT.

2.THE CONTRACTOR SHALL IMMEDIATELY REPORT ANY TRAFFIC SIGNAL DAMAGE TO THE ENGINEERING INSPECTOR OR ITS OPERATIONS SUPERVISOR AT 480-644-3129. IT IS THE RESPONSIBILITY OF THE CONTRACTOR TO REPAIR DAMAGE TO ANY TRAFFIC SIGNAL EQUIPMENT SUCH AS CONTROLLER CABINET AND EQUIPMENT, DETECTOR LOOPS, PULL BOXES, CONDUIT, POLES, MAST ARMS, HEADS OR RELATED EQUIPMENT AS A RESULT OF THIS PROJECT. A CITY OF MESA TECHNICIAN SHALL INSPECT THESE REPAIRS.

A.A TRAFFIC SIGNAL CANNOT BE DARK OR IN FLASH FOR MORE THAN TWO HOURS.

B.A LOSS OF COMMUNICATION SHALL BE REPAIRED WITHIN 24 HOURS.

C.DETECTOR LOOPS SHALL BE REPLACED IN TWO WEEKS UNLESS THE TRAFFIC SIGNAL FOREMAN AGREES IN WRITING TO A DIFFERENT SCHEDULE.

3.IF THE CONTRACTOR CANNOT RESPOND OR MAKE THE REPAIRS WITHIN ABOVE NOTED TIME FRAMES, THE CITY TRAFFIC SIGNAL GROUP WILL MAKE THE NECESSARY REPAIRS AND CHARGE THE CONTRACTOR USING A "REPAIR ORDER FORM”.

4.THE CONTRACTOR IS ADVISED THAT ANY COSTS RELATED TO REPAIR OR REPLACEMENT OF DAMAGED TRAFFIC SIGNAL EQUIPMENT AS A RESULT OF THE CONTRACTOR'S NEGLIGENCE SHALL BE BORNE BY THE CONTRACTOR.

5.IF THERE IS A TRAFFIC SIGNAL PROBLEM (INDICATION OUTAGES, KNOCKDOWNS, UTILITY POWER OUTAGES, ETC.) THAT IS NOT A DIRECT RESULT OF THE CONTRACTOR'S OR SUBCONTRACTOR'S WORK, AN ITS TECHNICIAN SHALL BE CALLED TO RESPOND. IF IT IS DETERMINED THE CONTRACTOR'S OR SUBCONTRACTOR'S WORK CAUSED THE TRAFFIC SIGNAL MALFUNCTION, THE CONTRACTOR THROUGH A “REPAIR ORDER FORM” SHALL PAY ALL COSTS OF REPAIRS.

6.TRAFFIC SIGNAL DETECTOR LOOPS SHALL BE INSTALLED IN ASPHALT CONCRETE PAVEMENT BEFORE THE FINAL LIFT. THE LOOP CONDUCTORS SHALL BE INSTALLED PER MESA STD DETAIL M-96.1.

7.THE CONTRACTOR IS ADVISED TO CONTACT THE CITY'S TRANSPORTATION MANAGEMENT CENTER AT 480-644-5888 AT LEAST 48 HOURS PRIOR TO ANY WORK WITHIN THE VICINITY OF OR THROUGH A SIGNALIZED INTERSECTION WHICH WILL CHANGE TRAFFIC LANE PATTERNS.

8.THE CONTRACTOR SHALL BE RESPONSIBLE FOR TESTING THE FIBER OPTIC CABLES AT THE PICK-UP POINT PRIOR TO CONNECTION AND TEST AGAIN AFTER CONNECTION IS COMPLETED.

6 CATALOG NUMBER: SHEET OF Dial 8-1-1 or 1-800-STAKE-IT (782-5348) in Maricopa County: (602) 263-1100 Call at least two full working days before you begin excavation. Arizona Blue Stake, Inc. DRAWING NORTH DRAWN BY: R. STEPHANI ENGINEER: C. WILLIAMS APPROVED BY: C. WILLIAMS ACTIVITY: ____ PROJ. NO.: ______ Y2K ENGINEERING, LLC. 480.696.1701 www.y2keng.com CITY OF MESA 2006 BENCHMARK, BRASS TAG IN TOP OF CURB LOCATED AT THE NORTHWEST CORNER OF MERIDIAN AND WARNER ROAD. ELEVATION: 1481.15 CITY OF MESA DATUM BENCHMARK OBSERVED ON APRIL 30, 2012

GN01

SIGNAL GENERAL NOTES

TRAFFIC

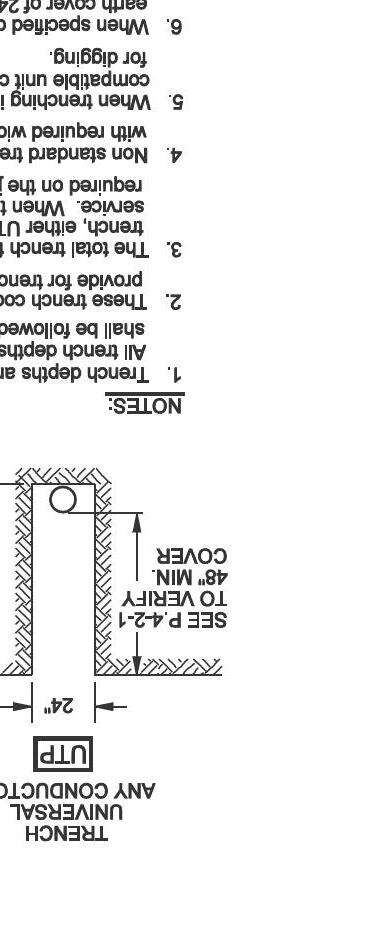

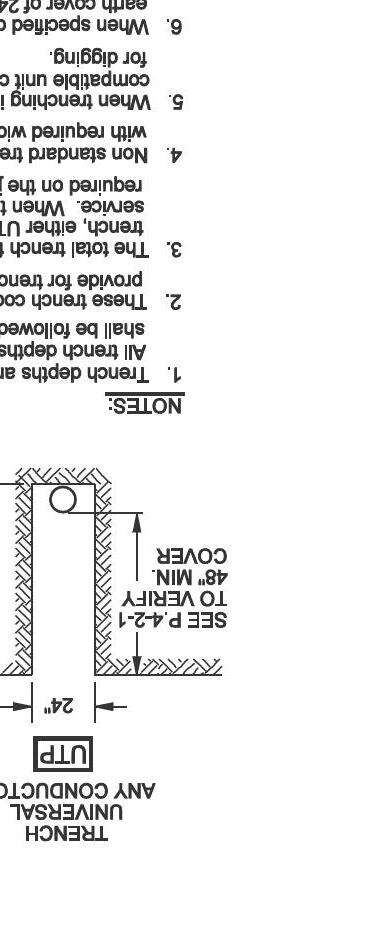

GENERAL NOTES:

1.THE CITY OF MESA REQUIRES AT LEAST ONE INTERNATIONAL MUNICIPAL SIGNAL ASSOCIATION (IMSA) LEVEL AND ONE LEVEL II CERTIFIED TRAFFIC SIGNAL TECHNICIAN ON SITE DURING ALL PHASES OF ANY TRAFFIC SIGNAL WORK. IT WILL BE THE RESPONSIBILITY OF THE CONTRACTOR TO PROVIDE VERIFICATION OF CERTIFICATION. IF A JOB SITE IS INSPECTED AND CERTIFIED TECHNICIAN IS NOT ON SITE, A STOP WORK ORDER WILL BE ISSUED. TEMPORARY AND CONTRACT EMPLOYEES DO NOT SATISFY THIS REQUIREMENT; THEY MUST BE FULL-TIME PERMANENT EMPLOYEES.

2.ALL TRAFFIC SIGNAL EQUIPMENT AND CONSTRUCTION SHALL CONFORM TO THE CITY OF MESA STANDARD SPECIFICATIONS, DRAWINGS AND PROCEDURES (CURRENT VERSION) SUPPLEMENTED BY ADOT SPECIFICATIONS AND STANDARD DRAWINGS.

3.LOCATION OF UTILITIES SHOWN ON THIS PLAN ARE FOR REFERENCE ONLY, THE ENGINEER DOES NOT GUARANTEE THESE LOCATIONS NOR THE FACT THAT SOME MAY BE LEFT OUT. IT IS THE RESPONSIBILITY OF THE CONTRACTOR TO CONTACT ARIZONA BLUE STAKE AND ALL INVOLVED AGENCIES PRIOR TO CONSTRUCTION.

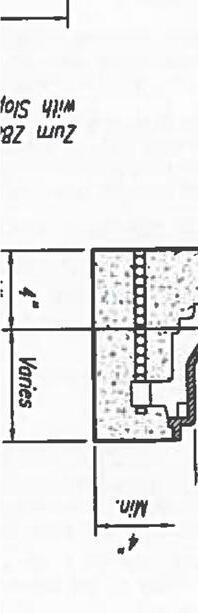

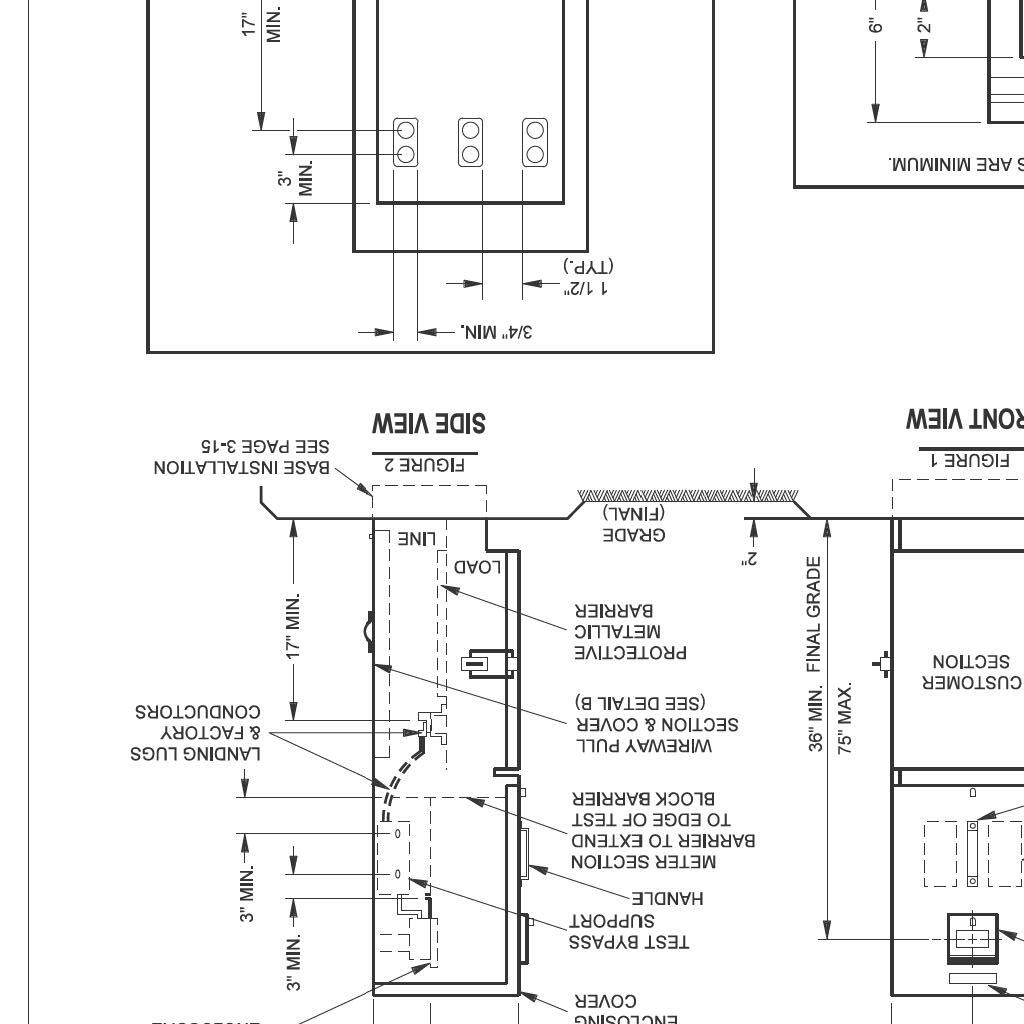

4.TOP OF SIGNAL POLE FOUNDATIONS AND PULL BOXES SHALL BE AT THE SAME ELEVATION AS THE BACK OF SIDEWALK PER M-92.03 & M-93.01.

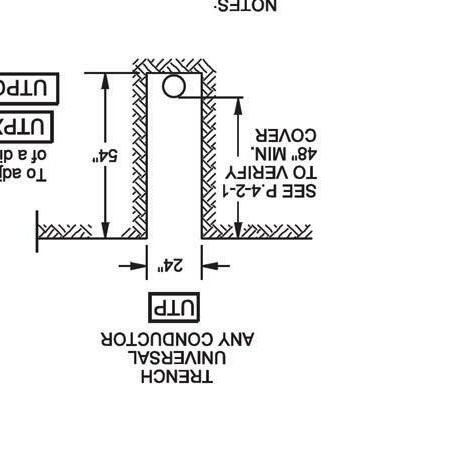

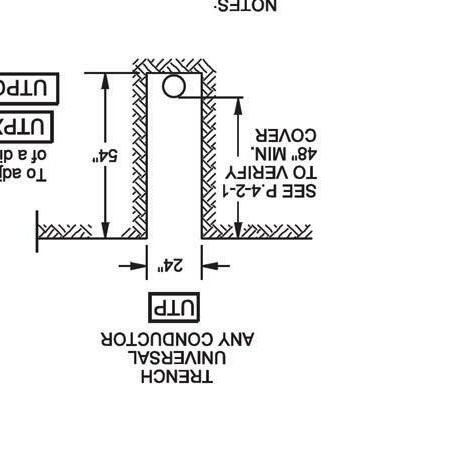

5.NEW CONDUIT UNDER ROADWAY SHALL BE PLACED BY JACKING OR BORING METHOD (M-18). CONTRACTOR SHALL NOT TRENCH EXISTING PAVEMENT WITHOUT PRIOR APPROVAL OF ENGINEER.

6.CONTACT APPROPRIATE UTILITIES FOR UTILITY LOCATION PRIOR TO START OF CONSTRUCTION: SOUTHWEST GAS GAS CITY OF MESA WATER CITY OF MESA SEWER CITY OF MESA STREET LIGHTS CITY OF MESA STORM DRAIN CITY OF MESA ELECTRICITY COX CABLE TV SRVWUA IRRIGATION SALT RIVER PROJECT ELECTRICITY CENTURY LINK TELEPHONE ARIZONA BLUE STAKE (602) 263-1100

7.ALL NEW VEHICLE AND PEDESTRIAN INDICATIONS SHALL HAVE LED INDICATIONS. ALL NEW PEDESTRIAN INDICATIONS SHALL BE COUNTDOWN TYPE SPECIFICATIONS FOR LED MODULES ARE AVAILABLE AT: HTTPS://WWW.MESAAZ.GOV/RESIDENTS/TRANSPORTATION/SIGNAL-MAINTENANCE-OPERATION/ TRAFFIC-SIGNAL-SPECIFICATIONS.

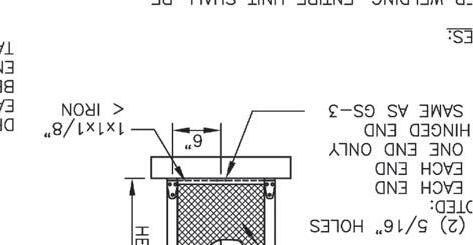

8.CONTRACTOR SHALL PROVIDE CONCRETE

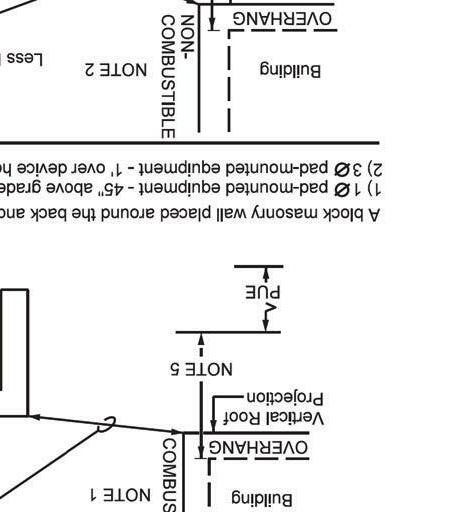

BE LOCATED WITHIN 6 FOOT (PREFERRED) OR 10 FOOT (MINIMUM) FROM THE CURB. TWO PUSH BUTTONS ON THE SAME CORNER SHOULD BE SEPARATED BY AT LEAST 10 FEET.

9.MOUNTING LOCATION AND ORIENTATION OF ALL PEDESTRIAN INDICATIONS AND SIDE MOUNT SIGNAL INDICATIONS SHALL BE CONFIRMED WITH THE TRAFFIC SIGNAL INSPECTOR IN THE FIELD PRIOR TO DRILLING POLES.

10.CONTRACTOR IS RESPONSIBLE FOR OBTAINING CONSTRUCTION AND TEMPORARY TRAFFIC CONTROL PERMITS FROM THE CITY OF MESA, FROM THE ARIZONA DEPARTMENT OF TRANSPORTATION (IF APPLICABLE) AND FROM THE MARICOPA COUNTY DEPARTMENT OF TRANSPORTATION (IF APPLICABLE).

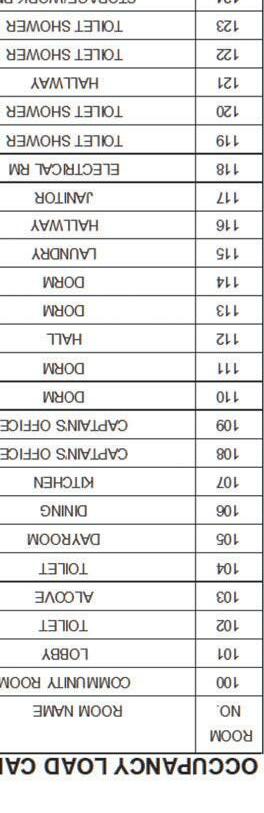

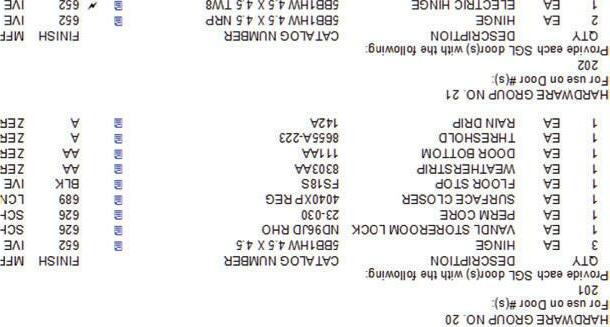

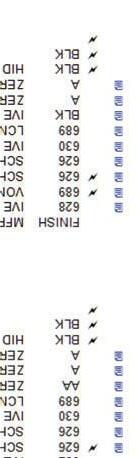

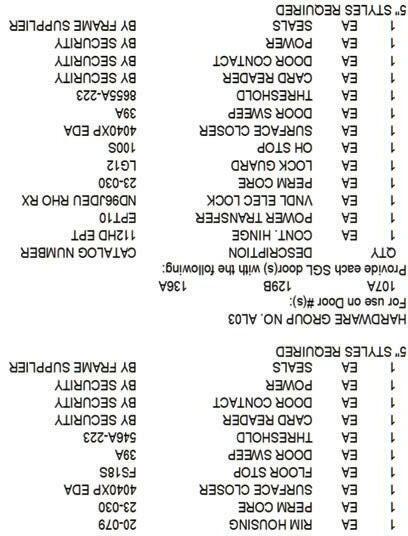

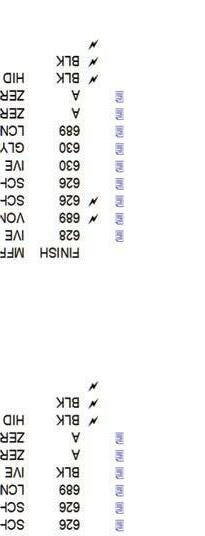

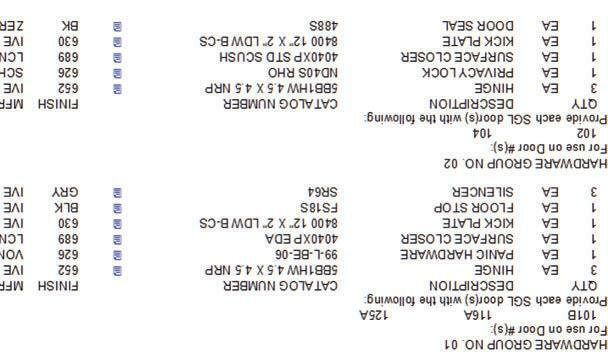

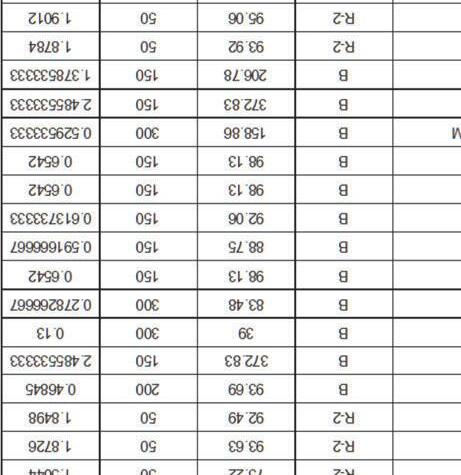

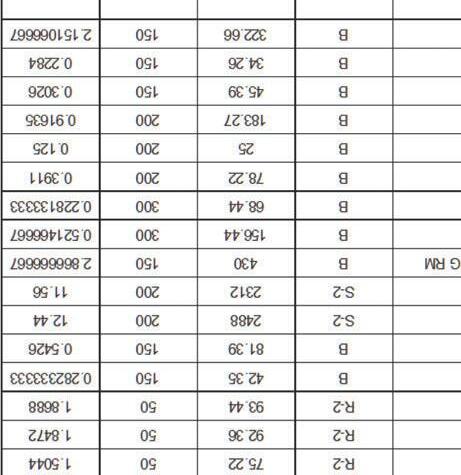

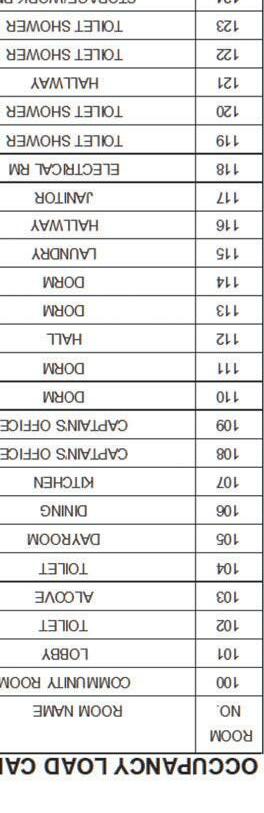

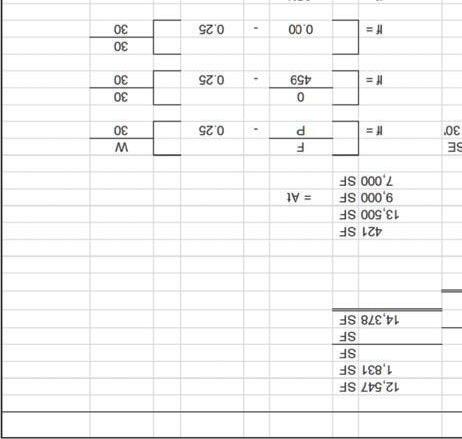

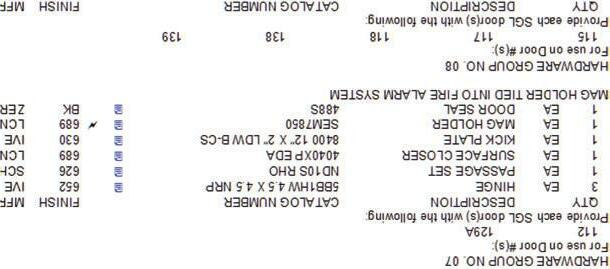

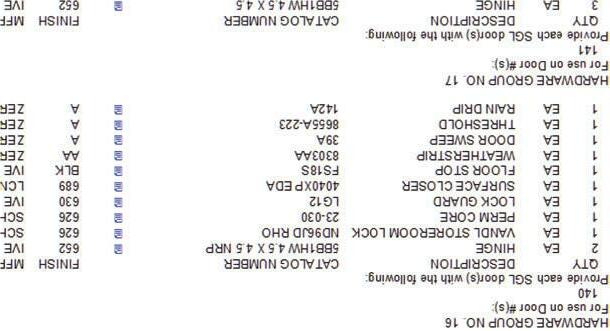

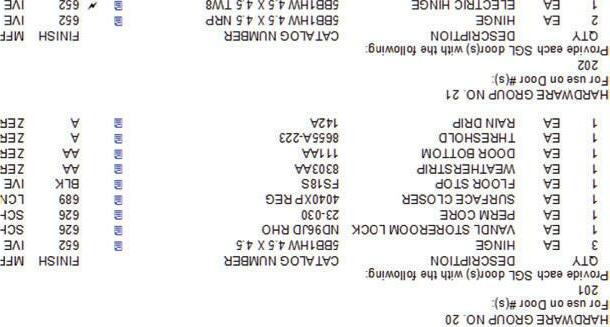

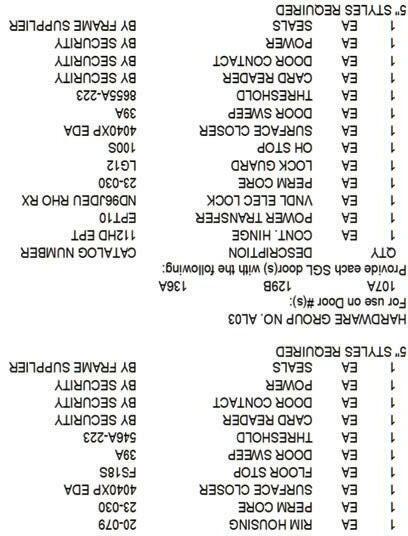

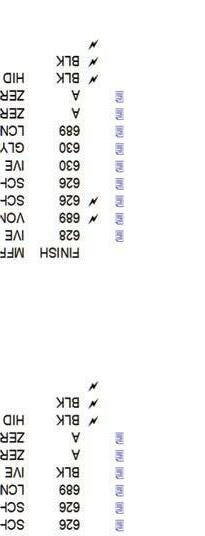

PULL BOX SCHEDULE NO.TYPELOCATION*REMARKS

1 2 3 4 5

#7-REMOVE EXISTING

#8 STA 19+51.2, 33.7' RT PROVIDE AND INSTALL NEW PER COM STD DET NO. M-93.01 #7 STA 18+74.7, 34.0' RT PROVIDE AND INSTALL NEW PER COM STD DET NO. M-93.01 #7 STA 18+45.4, 36.2' LT PROVIDE AND INSTALL NEW PER COM STD DET NO. M-93.01

#7-EXISTING TO REMAIN

#9 STA 19+15.1, 37.4' RT PROVIDE AND INSTALL NEW PER COM STD DET NO. M-66.07 *ALL STATIONING FROM POINT TWENTY-TWO BLVD. STATIONS AND OFFSETS SHOWN ARE APPROXIMATE, ACTUAL LOCATIONS TO BE FIELD VERIFIED BY THE TRAFFIC SIGNAL INSPECTOR PRIOR TO PULL BOX INSTALLATION.

6

CONSTRUCTION NOTES

DIG DOWN AND INTERCEPT EXISTING ITS CONDUIT. SWEEP NEW CONDUIT BETWEEN NEW FIBER SPLICE BOX AND EXISTING ITS CONDUIT RUN.

INSTALL NEW R10-13 "EMERGENCY SIGNAL" 42"X30" SIGN ON MAST ARM.

DIG DOWN AND INTERCEPT EXISTING TRAFFIC SIGNAL CONDUIT. SWEEP INTO NEW PULLBOX. ABANDON CONDUIT RUNS TO THE WEST.

CONTRACTOR TO CLEAN/MANDREL EXISTING CONDUIT BEFORE CONDUCTOR INSTALLATION. IF EXISTING CONDUIT IS NOT USEABLE, THE CONTRACTOR SHALL IMMEDIATELY NOTIFY THE ENGINEER.

CONTRACTOR TO INSTALL CITY PROVIDED 144 STRAND SMFO CABLE FROM EXISTING VAULT ON THE SEC OF ELLSWORTH ROAD AND POINT TWENTY-TWO. UTILIZE EXISTING GRAY CONDUIT.

6

TERMINATE 12 STRAND SMFO ON CITY PROVIDED FO TERMINATION MODULE. SPLICE 12 STRAND SMFO IN NEW SPLICE ENCLOSURE IN NEW #9 PULL BOX.

6 CATALOG NUMBER: SHEET OF Dial 8-1-1 or 1-800-STAKE-IT (782-5348) in Maricopa County: (602) 263-1100 Call at least two full working days before you begin excavation. Arizona Blue Stake, Inc. DRAWING NORTH DRAWN BY: R. STEPHANI ENGINEER: C. WILLIAMS APPROVED BY: C. WILLIAMS ACTIVITY: ____ PROJ. NO.: ______ Y2K ENGINEERING, LLC. 480.696.1701 www.y2keng.com CITY OF MESA 2006 BENCHMARK, BRASS TAG IN TOP OF CURB LOCATED AT THE NORTHWEST CORNER OF MERIDIAN AND WARNER ROAD. ELEVATION: 1481.15 CITY OF MESA DATUM BENCHMARK OBSERVED ON APRIL 30, 2012

4 E

S. PASTEUR

POINT TWENTY-TWO BLVD

1 2 3 4 5

LOCATED NEXT TO A LEVEL LANDING PAD (36" 48" MINIMUM). LEVEL IS DEFINED AS HAVING A SLOPE LESS THAN 2%. THE PUSH BUTTON MUST BE WITHIN 10 INCHES REACH OF THE LEVEL LANDING PAD AND MUST BE WITHIN 5' OF EXTENSION OF CROSSWALK LINE. PUSH BUTTON MUST

ADA ACCESS PAD TO PEDESTRIAN PUSH BUTTON TO MEET ALL ADA ACCESSIBILITY REQUIREMENTS (M-44.01). PUSH BUTTON MUST BE

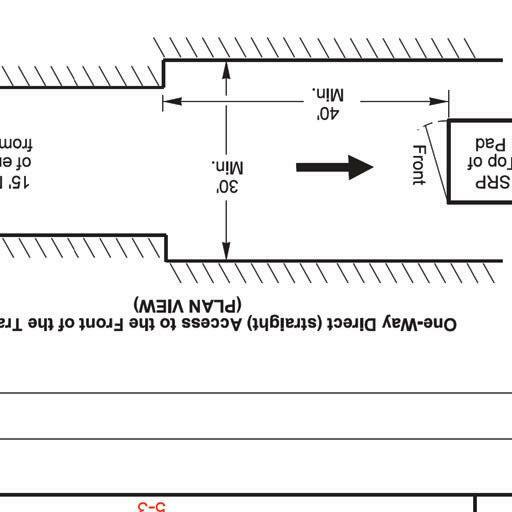

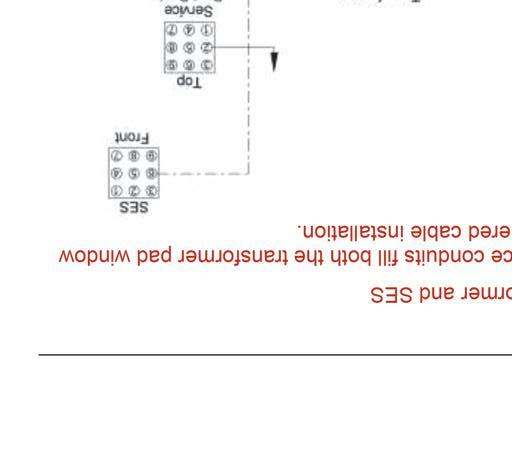

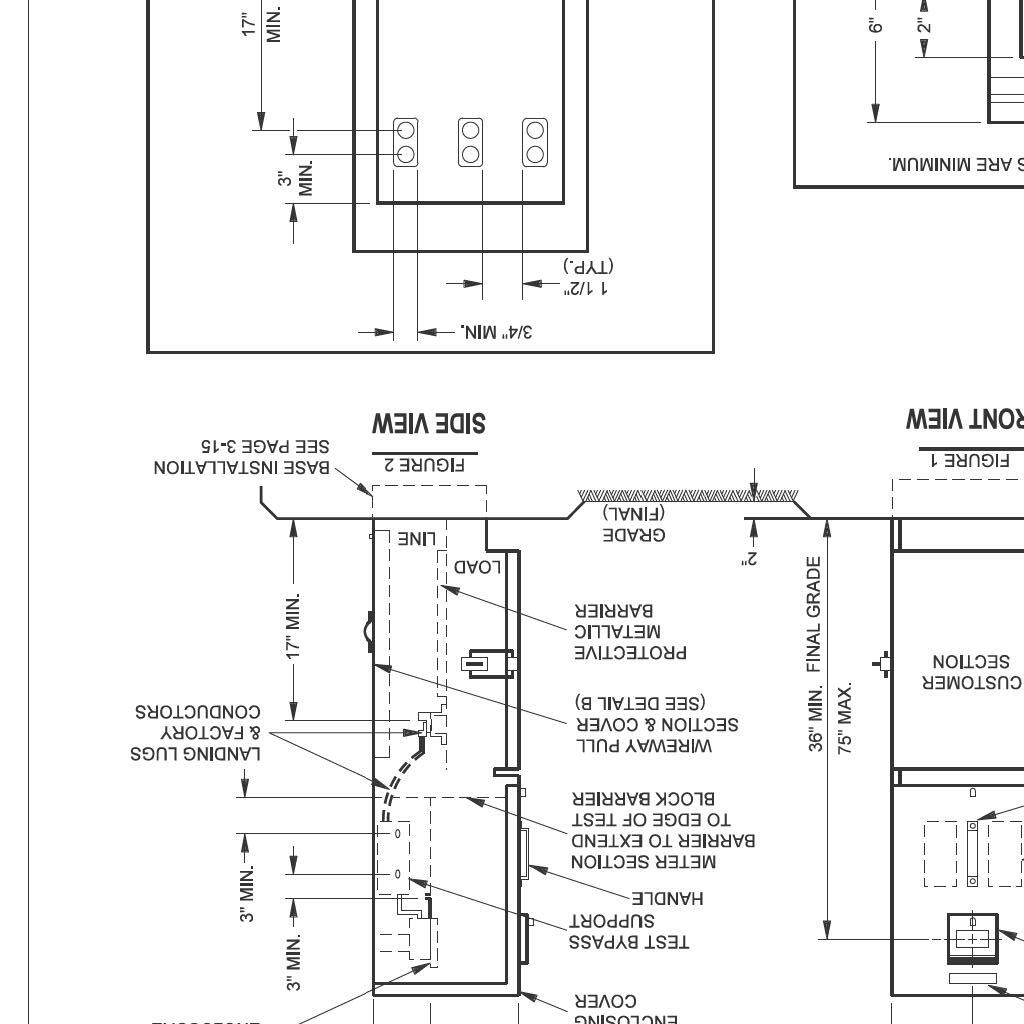

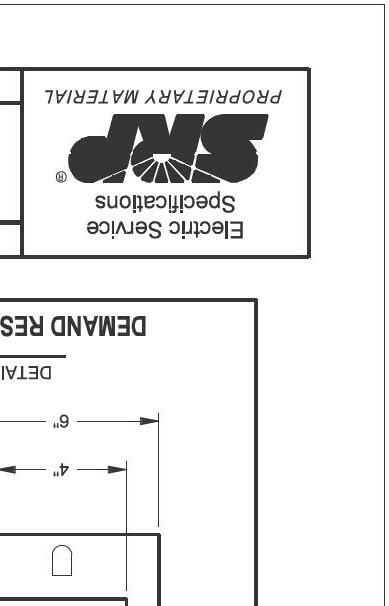

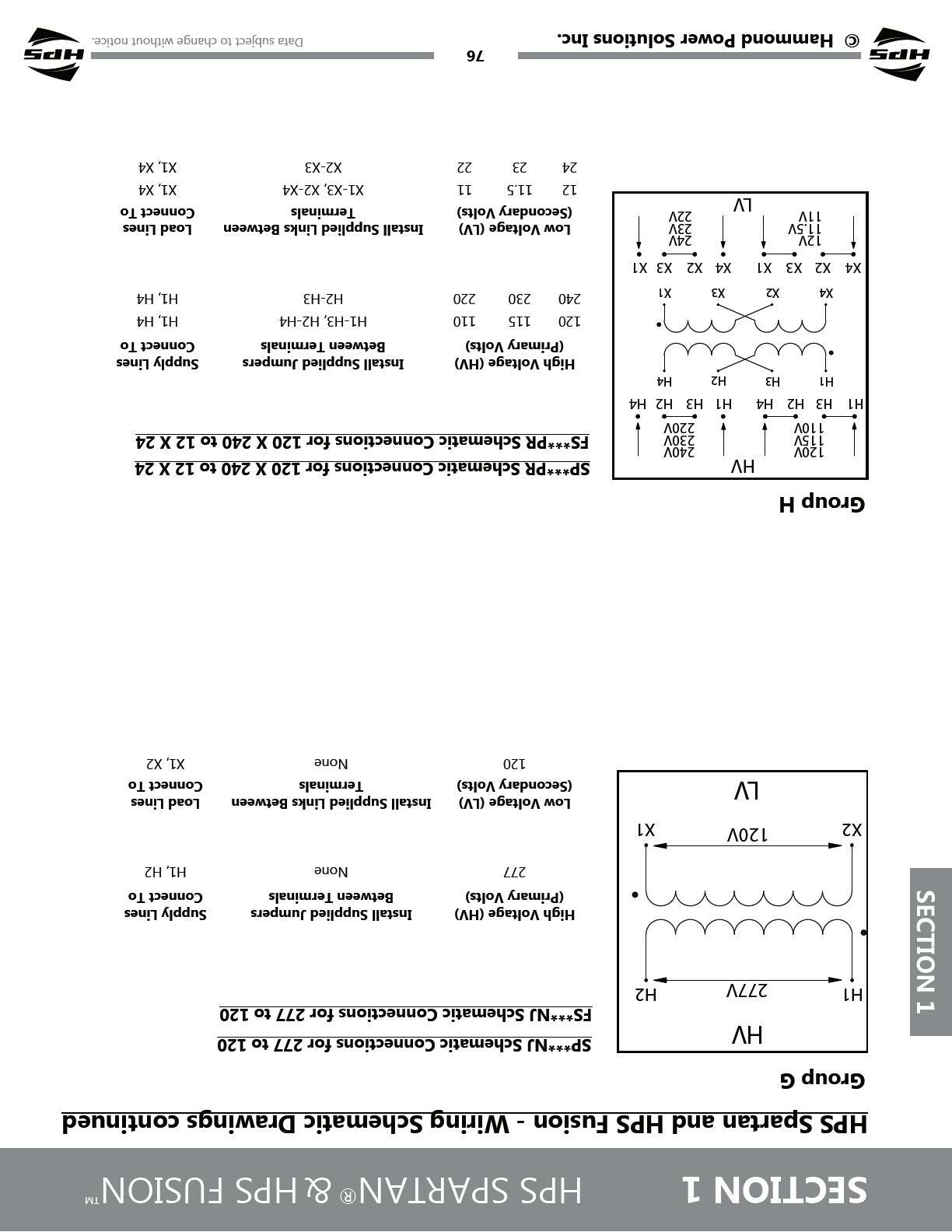

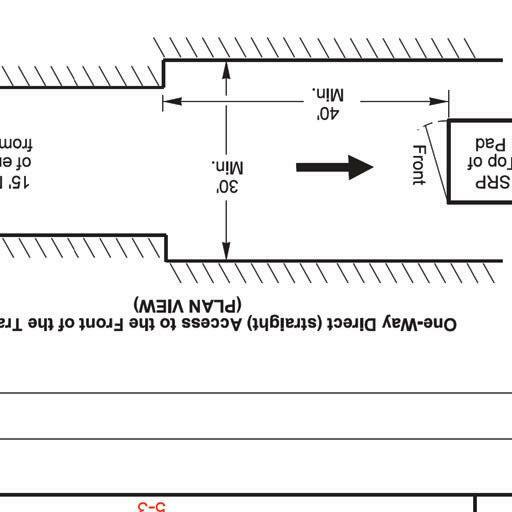

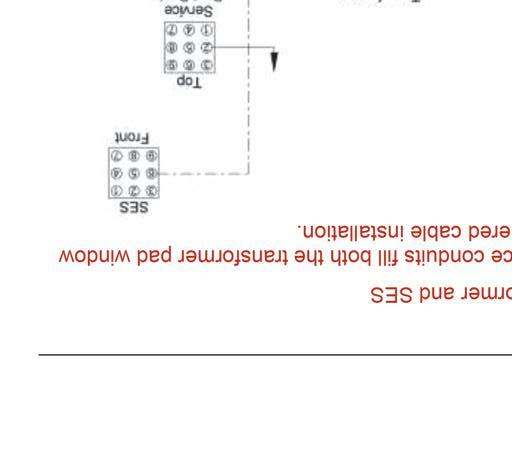

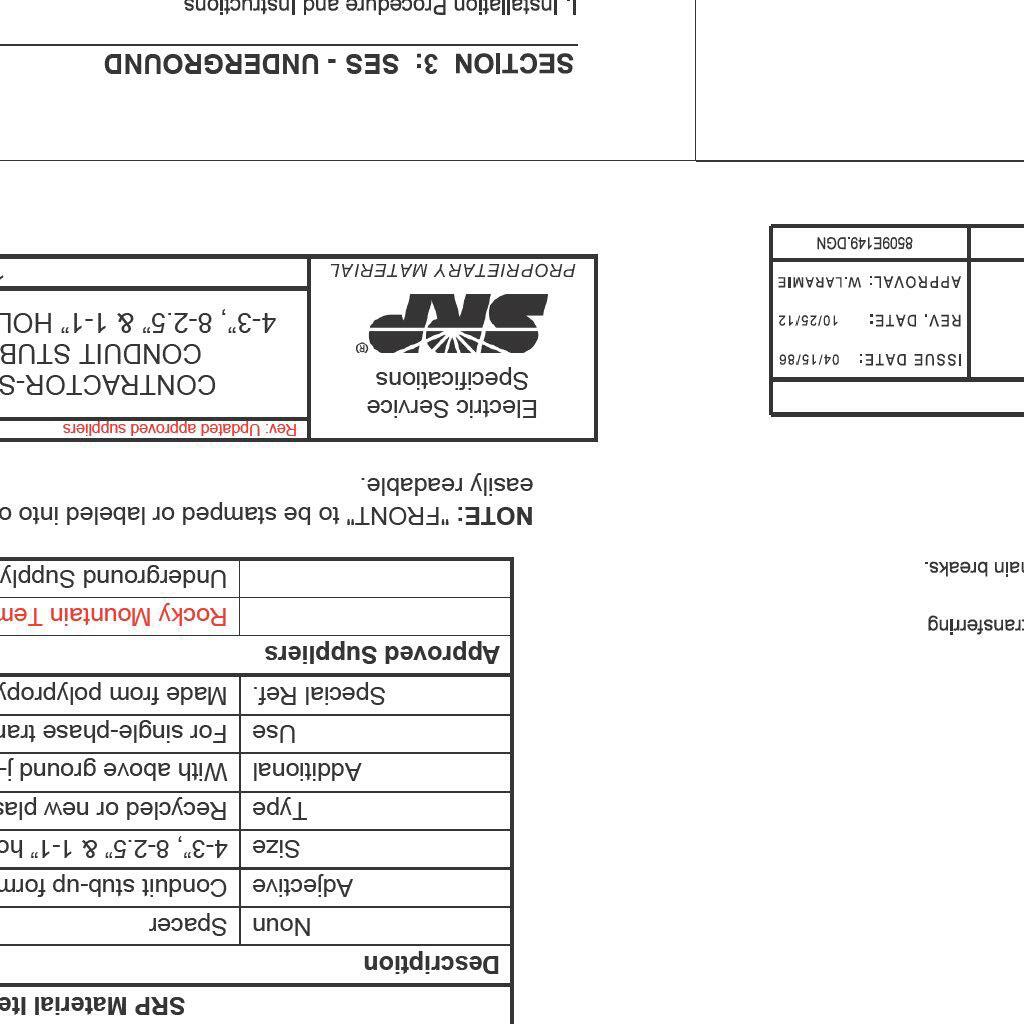

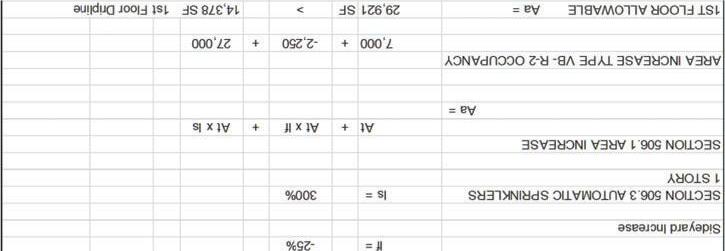

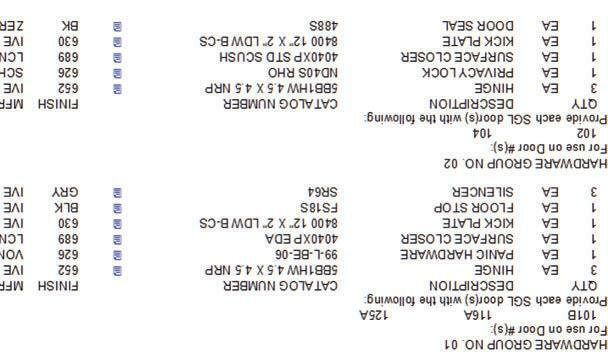

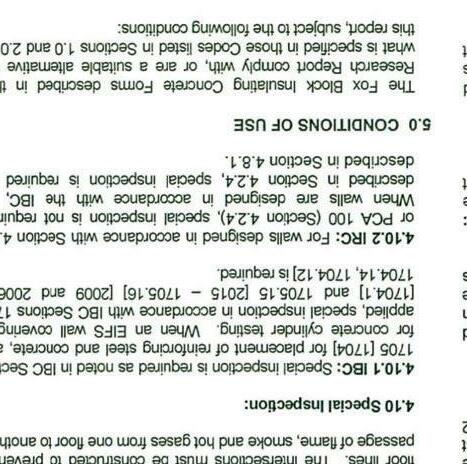

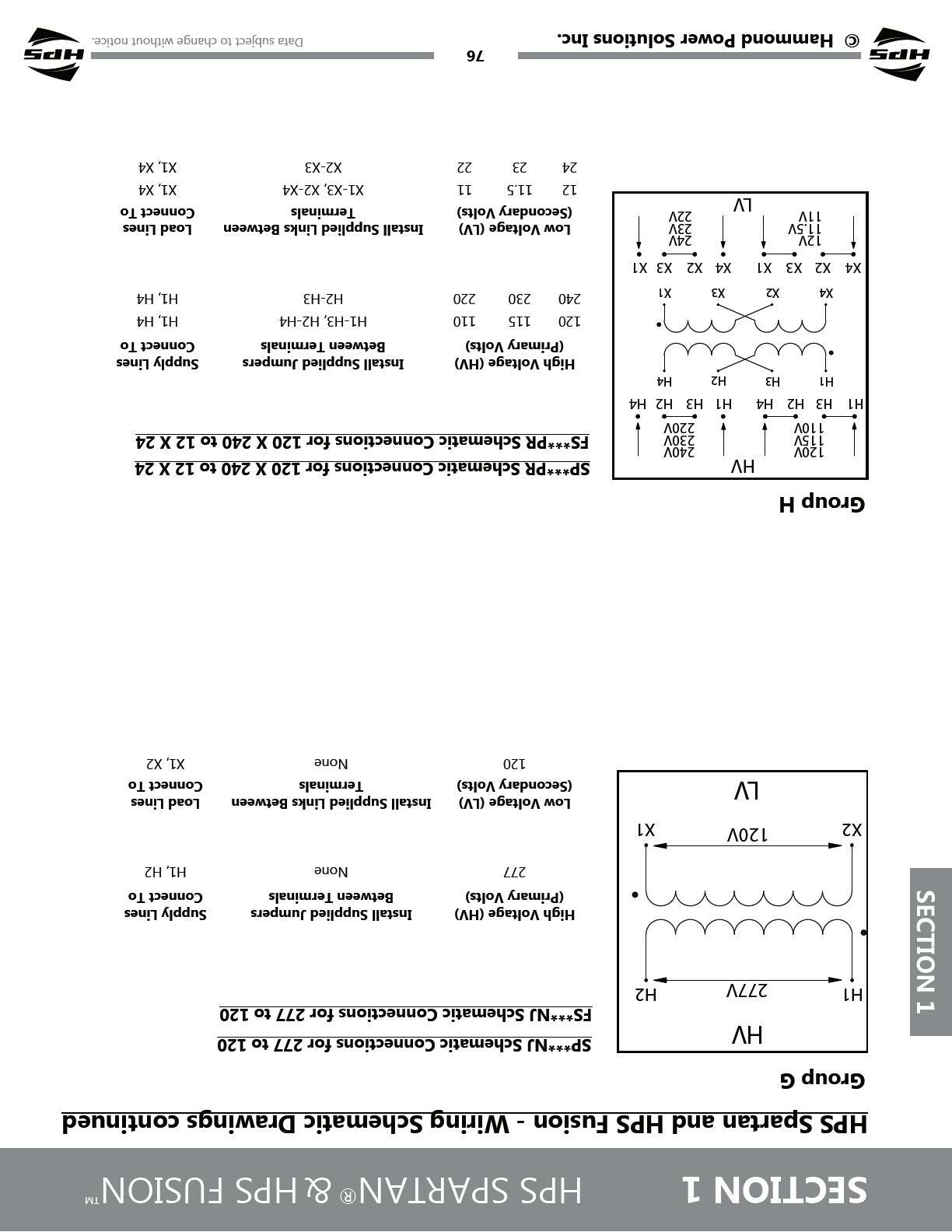

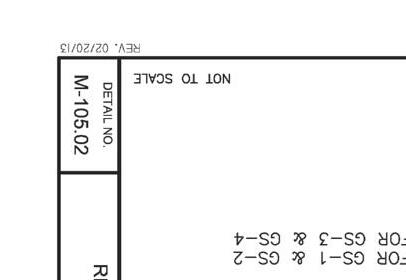

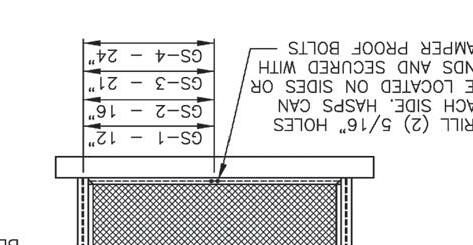

3 A B C D SCALE: 1" = 10' 05'10'20' TS01 TRAFFIC SIGNAL PLAN SHEET 1 FOUNDATION SCHEDULE NO.TYPELOCATION* METER PEDESTAL (M-91.02) STA 19+43.0, 52.1' RT CONTROLLER CABINET(M-92.01) STA 19+31.5, 52.1' RT J POLE (M-94.04, M-94.05, M-94.06) STA 19+40.8, 40.6' RT A POLE (M-94.04, M-94.06) STA 18+46.1, 39.0' RT J POLE (M-94.04, M-94.05, M-94.06) STA 18+32.7, 39.5' LT *ALL STATIONING FROM POINT TWENTY-TWO BLVD. STATIONS AND OFFSETS SHOWN ARE APPROXIMATE, ACTUAL LOCATIONS TO BE FIELD VERIFIED BY THE TRAFFIC SIGNAL INSPECTOR PRIOR TO FOUNDATION INSTALLATION. A B C D E ROW 1 2 3 4 7 8 13 14 15 A NO. NEW 100 AMP SPLIT METERED SERVICE PEDESTAL (M-91.02) SERVICE ADDRESS: 9329 E POINT TWENTY-TWO BLVD TS POLE LAYOUT NEW TYPE V CONTROL CABINET TRAFFIC CONTROLLER ECONOLITE COBALT C P/N: COBS12120120000 POLE SCHEDULE B N N N F,II F,II F,VII TYPE J POLE WITH 30' MAST ARM (M-94.04, M-94.05, M-94.06). INSTALL CONVENTIONAL METRO SIGN (M-21.07). POLE AND MAST ARM TO BE PAINTED BROWN TO MATCH EASTMARK THEME. F,II F,II F,II TYPE A POLE (10') (M-94.03, M-94.06). POLE TO BE PAINTED BROWN TO MATCH EASTMARK THEME. TYPE J POLE WITH 30' MAST ARM (M-94.04, M-94.05, M-94.06). INSTALL CONVENTIONAL METRO SIGN (M-21.07). POLE AND MAST ARM TO BE PAINTED BROWN TO MATCH EASTMARK THEME. ROW

DRIVEWAY 16 6 2 2 INSTALL R10-13 (42"x30") ON OVERHEAD MAST ARMS 2 1 5 6 17 12 11 5 9 10 C D E D,VII D,IV 3 3 4 4 4 2 5 6 RFI 165

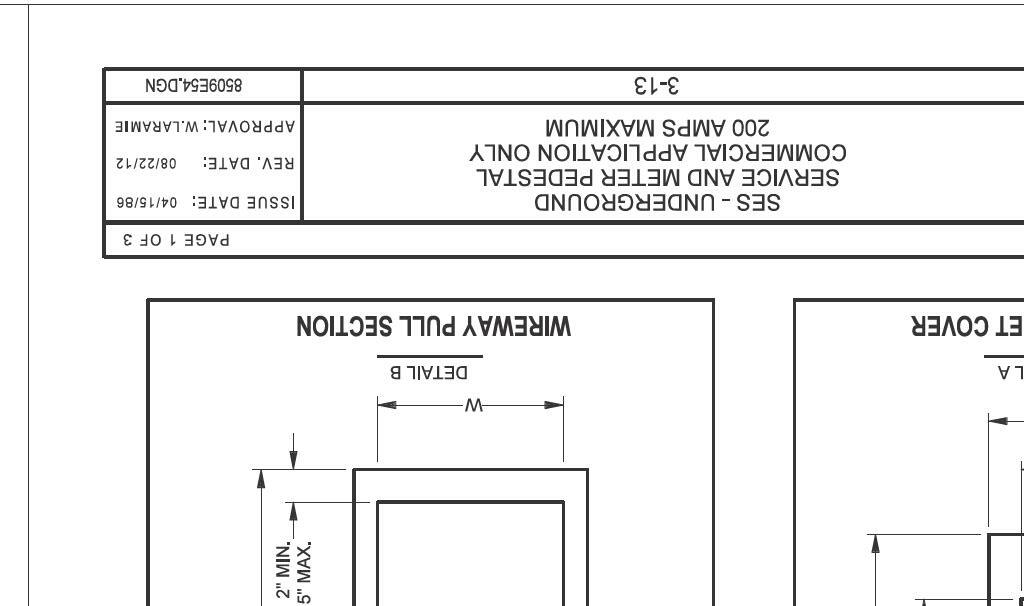

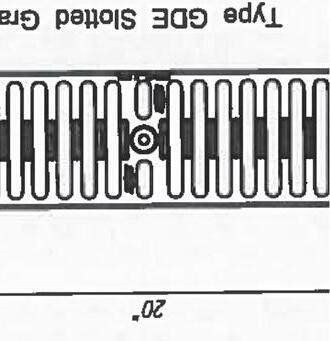

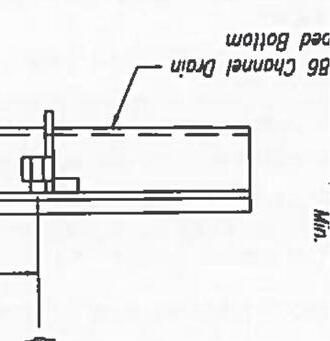

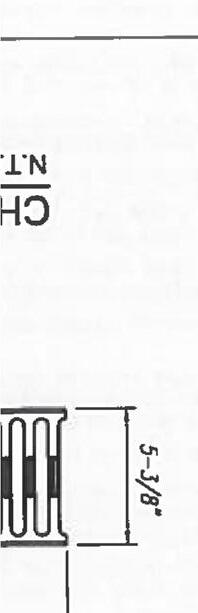

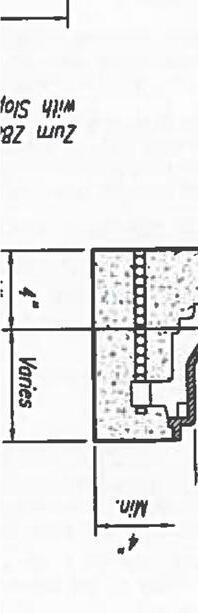

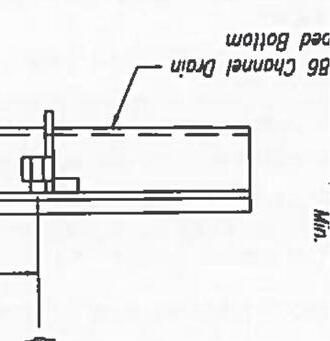

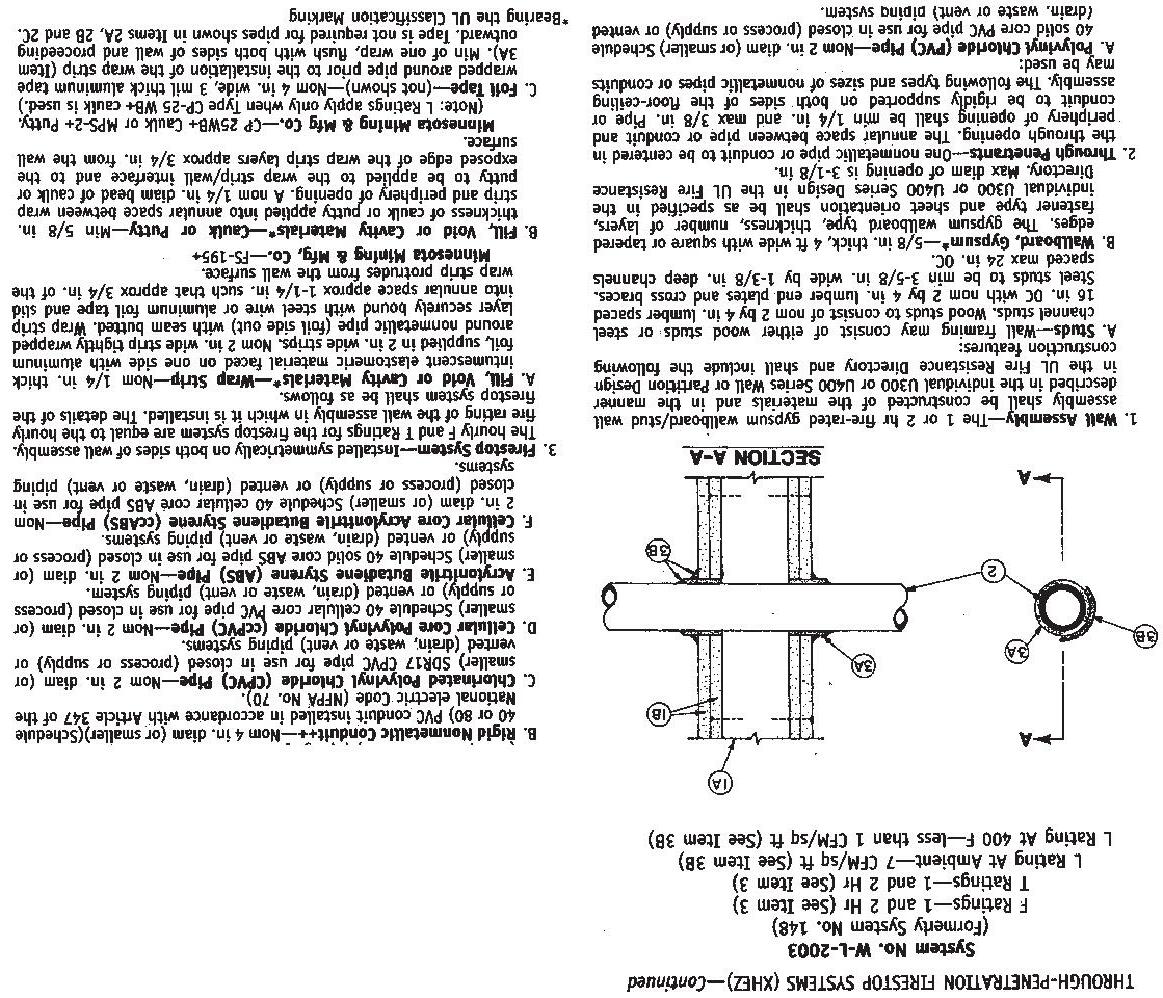

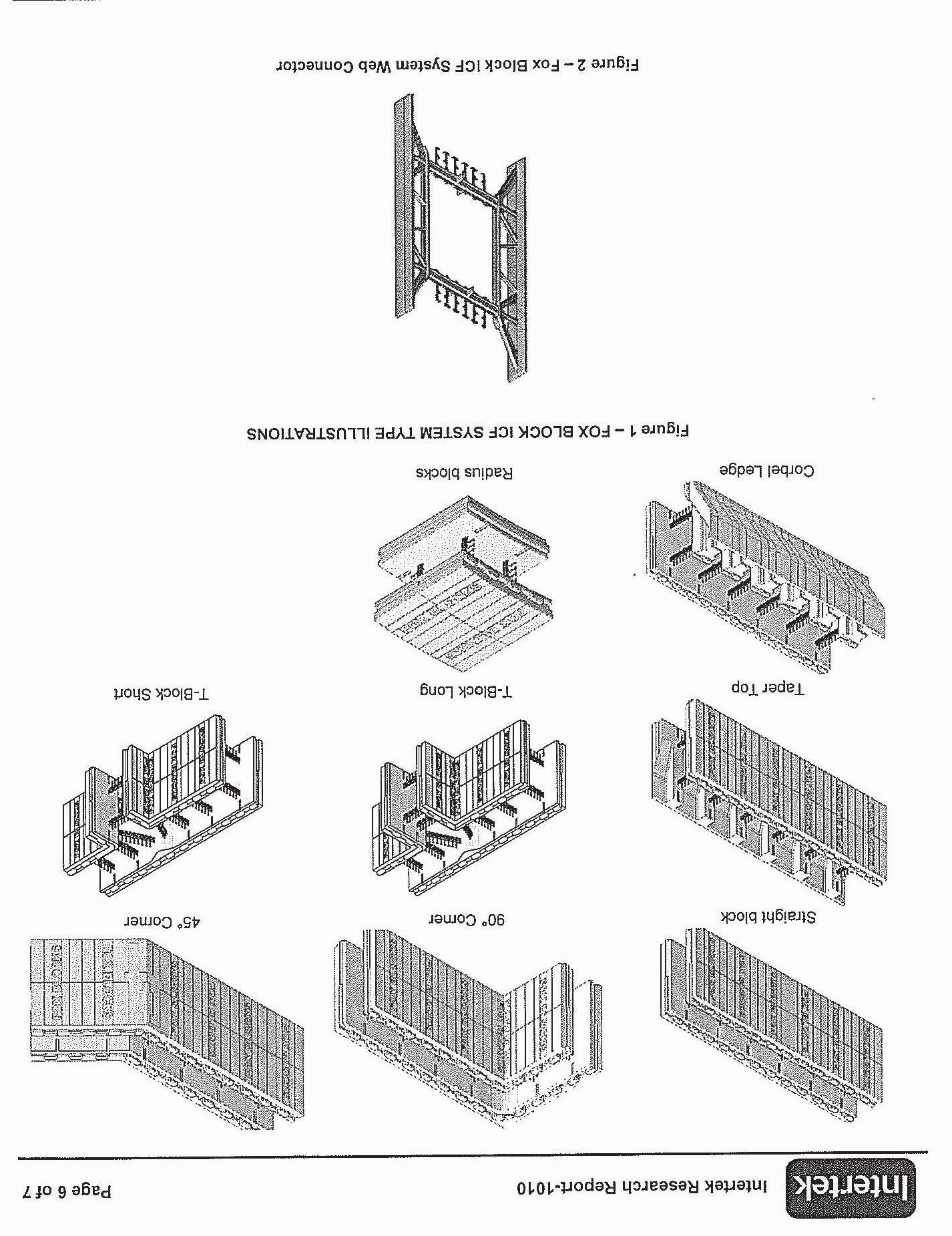

FIRE STATION 221

POINT

850 ft. 1,200 ft. SIGNAL SPACING DIAGRAM #16 IMSA 19-1 CABLE #1 - 25 CONDUCTOR 1 2.5 7-CONDUCTOR CABLE 5-CONDUCTOR CABLE GREEN, THHN/THWN STRANDED BOND WIRE #8 CIRCUIT PHASE AWG OPTICOM PRE-EMPT CABLE CABLE 12 STRAND SMFO BLACK (POWER RUN) WHITE (POWER RUN) CCTV #10 XHHW 2 2 3 3 4 3 5 3 6 3 ALL CONDUCTORS ARE NEW. VIDEO DETECTION CABLE PER MANUFACTURER SPECIFICATIONS I.M.S.A. CABLE 19-1, #16 AWG 2, 5, 7 & 25 CONDUCTOR, STRANDED COPPER, 90C HI-TEMP #20 AWG, 3 CONDUCTOR, STRANDED, 3M #138 12 STRAND SMFO CABLE SRP 2 2 CONDUIT, DEPTH AND WIRE SIZE/QUANTITIES PER SRP SPECIFICATIONS BORE INSTALLATION * 78910 3 111314 3 3 3 15 * 12 B CABLE #2 - 25 CONDUCTOR 33323 PHASING SCHEMATIC ɸ6 TS02 CONDUCTOR SCHEDULE & DETAILS ELLSWORTH ROAD 16 2 RAY ROAD CONDUCTOR SCHEDULE N ɸ2 N ɸ4 BARRIER BB MESA METRO SIGN DETAIL 1 N.T.S. #14 AWG 3-WIRE TRAY CABLE 120V 6 CATALOG NUMBER: SHEET OF Dial 8-1-1 or 1-800-STAKE-IT (782-5348) in Maricopa County: (602) 263-1100 Call at least two full working days before you begin excavation. Arizona Blue Stake, Inc. DRAWING NORTH DRAWN BY: R. STEPHANI ENGINEER: C. WILLIAMS APPROVED BY: C. WILLIAMS ACTIVITY: ____ PROJ. NO.: ______ Y2K ENGINEERING, LLC. 480.696.1701 www.y2keng.com CITY OF MESA 2006 BENCHMARK, BRASS TAG IN TOP OF CURB LOCATED AT THE NORTHWEST CORNER OF MERIDIAN AND WARNER ROAD. ELEVATION: 1481.15 CITY OF MESA DATUM BENCHMARK OBSERVED ON APRIL 30, 2012

LEGEND NEW TRAFFIC SIGNAL CONTROLLER CABINET METER PEDESTAL / UPS #9 COMMUNICATION VAULT #7 PULL BOX W/ EXTENSION EXISTING NEW XX XX XX XX XX XX XX #7 PULL BOX TRAFFIC SIGNAL POLE W/ LUMINAIRE MAST ARM SIGNAL HEAD TYPE F SIGNAL HEAD TYPE G PRE-EMPTION DETECTOR VIDEO DETECTION CAMERA (GRIDSMART) CCTV CAMERA PEDESTRIAN SIGNAL HEAD (COUNTDOWN MH) PEDESTRIAN PUSH BUTTON (PPB) TRAFFIC SIGNAL POLE / EQUIPMENT (SEE PULL BOX SCHEDULE) TRAFFIC SIGNAL PULL BOX (SEE PULL BOX SCHEDULE) CONDUIT RUN NUMBER CONSTRUCTION NOTE RAY ROAD

TWENTY-TWO BOULEVARD 535 ft. 1 1 1 1 1 1 1 1 1 1 1 2 1 1 1 1 1 3 1 1 1 11 1 11 1 11 1 11 1 [Fire Station] HIGHWAY GOTHIC D F ireStati o n 5" 24.1" 6" 47.9" 6" 14" 5" 18" 4" 4" 10" 108" 6.125" WHITE TEXT ON BROWN BACKGROUND TO MATCH EASTMARK THEMING 11 17 2

SIGNING GENERAL NOTES

1.ALL REFLECTIVE SHEETING MATERIAL(S) SHALL BE PRESSURE SENSITIVE ASTM TYPE IV WIDE ANGLE WHITE PRISMATIC SHEETING OR APPROVED EQUAL WITH THE FOLLOWING EXCEPTIONS:

-ALL WARNING SIGNS (YELLOW SERIES) SHALL BE ASTM XI (FLUORESCENT YELLOW SHEETING).

-ALL REGULATORY SIGNS SHALL BE ASTM TYPE XI SHEETING.

-STREET NAME SIGNS:

ANY ARTERIAL INTERSECTION (ALL BLADES) SHALL BE ASTM TYPE XI SHEETING. ALL OTHER INTERSECTIONS SHALL BE ASTM TYPE IV SHEETING

-ALL PEDESTRIAN AND SCHOOL AREA SIGNING SHALL BE ASTM TYPE XI SHEETING (FLUORESCENT YELLOW-GREEN)

2.SIGN IMAGING SHALL BE IN COMPLIANCE WITH THE REFLECTIVE SHEETING MANUFACTURERS MATCHED COMPONENT SYSTEM. SIGN IMAGING SHALL CONSIST OF A TRANSPARENT ACRYLIC BASED ELECTRONIC CUTTABLE FILM (3M 1170 SERIES OR EQUIVALENT) OR SILK SCREENED (DEPENDING ON THE QUANTITY OF SIGNAGE) WITH STANDARD HIGHWAY COLORS.

3.STREET NAME SIGNS:

-PUBLIC STREETS SHALL BE PRESSURE SENSITIVE 3M

PAVEMENT MARKING GENERAL NOTES

1.ALL SIGNING AND PAVEMENT MARKING MATERIALS AND EQUIPMENT SHALL CONFORM TO THE CITY OF MESA STANDARD DETAILS, MUTCD AND ADOT STANDARD SPECIFICATIONS AND STANDARD DRAWINGS, LATEST APPROVED EDITIONS.

2.WHEN STRIPING OBLITERATION IS NECESSARY, IT SHALL BE ACCOMPLISHED IN CONFORMANCE WITH ADOT STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE CONSTRUCTION, 2008, SECTION 701-3.06. IF PAID FOR PER FOOT, REFER TO SECTION 701-5.05. GRINDING IS NOT AN ACCEPTABLE FORM OF OBLITERATION. PAINTING OVER STRIPING DOES NOT CONSTITUTE STRIPE OBLITERATION.

3.ALL LANE LINES, EDGE LINES, BIKE LANE LINES, CENTERLINES, AND PAINTED MEDIANS SHALL BE CITY APPROVED PAINT AT A MINIMUM OF 15 MIL WET THICKNESS.

4.ALL STOP BARS AND CROSSWALKS SHALL BE 90 MIL THICK EXTRUDED ALKYD THERMOPLASTIC MARKING MATERIAL PER ADOT STANDARD SPECIFICATIONS SECTION 704.

5.ALL SYMBOLS AND WORD LEGENDS SHALL BE TYPE IV 90 MIL PREFORMED THERMOPLASTIC

OR RELOCATED DURING CONSTRUCTION SHALL BE THE RESPONSIBILITY OF THE CONTRACTOR. ANY SIGNING THAT IS TO BE RELOCATED OR REMOVED DUE TO CONSTRUCTION SHALL BE REINSTALLED IN ITS FINAL LOCATION PER CITY OF MESA STANDARDS.

8.THE CONTRACTOR SHALL ENSURE THAT AT NO TIME A TRAFFIC SIGN IS INSTALLED IN SUCH A MANNER AS TO BE BLOCKED BY A TREE OR ANY TYPE OF VEGETATION. IN THESE CASES, THE CONTRACTOR SHALL CONTACT THE TRANSPORTATION

MUST BE APPROVED BY THE CITY TRAFFIC ENGINEER 30 DAYS PRIOR TO INSTALLATION OF ANY SIGNING.

10.SIGNING QUANTITIES AND INSTALLATION LOCATIONS ARE SUBJECT TO CHANGE AT THE TIME OF INSTALLATION BASED UPON CURRENT ACCEPTED PRACTICE.

INSTALL W11-12P 36"x30" STA 16+39 INSTALL W16-15P (TEMPORARY) 24"x12" INSTALL W11-8 36"x36" INSTALL W3-3 36"x36" 6 CATALOG NUMBER: SHEET OF Dial 8-1-1 or 1-800-STAKE-IT (782-5348) in Maricopa County: (602) 263-1100 Call at least two full working days before you begin excavation. Arizona Blue Stake, Inc. DRAWING NORTH DRAWN BY: R. STEPHANI ENGINEER: C. WILLIAMS APPROVED BY: C. WILLIAMS ACTIVITY: ____ PROJ. NO.: ______ Y2K ENGINEERING, LLC. 480.696.1701 www.y2keng.com CITY OF MESA 2006 BENCHMARK, BRASS TAG IN TOP OF CURB LOCATED AT THE NORTHWEST CORNER OF MERIDIAN AND WARNER ROAD. ELEVATION: 1481.15 CITY OF MESA DATUM BENCHMARK OBSERVED ON APRIL 30, 2012

SM01 SIGNING & MARKING PLAN

DRIVEWAY 10' 10.5' 10' 10.5' 10' 6' 6' 64' ROW POINT TWENTY-TWO BLVD EXISTING STRIPING TO REMAIN (NEW) (NEW) STA 18+38 STA 19+36 20' 20' SCALE: 1" = 20' 010'20'40' 10' 10.5' 10' 10.5' 10' 6' 6' REMOVE EXISTING STRIPING STA 19+83 TO STA 20+53 (NEW) STA 20+53.43 TO 20+95.43 EXISTING R4-7 TO REMAIN

S. PASTEUR FIRE STATION 221

#1177 GREEN ELECTRO CUT FILM OR APPROVED EQUAL. -PRIVATE STREETS SHALL BE PRESSURE SENSITIVE 3M #1175 BLUE ELECTRO CUT FILM OR APPROVED EQUAL. 4.ANY REQUEST TO USE SHEETING OTHER THAN THAT SPECIFIED ABOVE SHALL BE MADE IN WRITING TO THE CITY TRAFFIC ENGINEER 30 DAYS IN ADVANCE OF INSTALLATION. 5.THE DEVELOPER IS RESPONSIBLE FOR THE INSTALLATION OF ALL SIGNS. SEE MESA STANDARD DETAILS M-20.01 THRU M-23.03. SIGN POST INSTALLATION SHALL BE PER M-39. -ALL STREET NAME SIGNS ARE SUBJECT TO APPROVAL BY THE CITY OF MESA PRIOR TO INSTALLATION. CONTACT THE SIGN SHOP AT 480-644-3175 FOR ASSISTANCE AND APPROVAL. -PRIVATE STREET NAME SIGNS AND TRAFFIC CONTROL SIGNS INSTALLED ON PRIVATE STREETS SHALL BE THE RESPONSIBILITY OF THE HOMEOWNER'S ASSOCIATION (PROPERTY OWNER(S)) IN PERPETUITY. 6.ALL SIGNING SHALL CONFORM TO THE REQUIREMENTS CONTAINED IN THE LATEST APPROVED EDITION OF THE MANUAL ON UNIFORM TRAFFIC CONTROL DEVICES (MUTCD), THE LATEST APPROVED EDITION OF THE STANDARD HIGHWAY SIGNS BOOK AND THE LATEST APPROVED EDITION OF THE ARIZONA SUPPLEMENT PUBLISHED BY THE ARIZONA DEPARTMENT OF TRANSPORTATION (ADOT). 7.SIGNS THAT ARE REQUIRED TO BE REMOVED

DEPARTMENT AT 480-644-2160 TO PROVIDE AN ALTERNATE LOCATION PRIOR TO INSTALLATION.

SIGNING INSTALLED WITHIN THE CITY OF MESA'S RIGHT-OF-WAY SHALL BE INSTALLED BY AN INDIVIDUAL THAT HAS CURRENT CERTIFICATION IN SIGNING INSTALLATION OR INSPECTION FROM AMERICAN TRAFFIC SAFETY SERVICES ASSOCIATION (ATSSA) OR THE INTERNATIONAL MUNICIPAL SIGNAL ASSOCIATION (IMSA). EQUIVALENTS WILL BE CONSIDERED BUT

9.ANY

PER ADOT STANDARD SPECIFICATIONS SECTION 705 UNLESS OTHERWISE NOTED. 6.THE CONTRACTOR SHALL PAINT ALL RAISED MEDIAN ISLAND NOSES REFLECTORIZED YELLOW, 10 L.F. BEYOND THE RADIUS POINTS. 7.THE LANE WIDTH DIMENSIONS FOR ALL PAVEMENT MARKINGS SHALL BE FROM THE FACE OF CURB TO CENTER OF STRIPE OR CENTER OF STRIPE TO CENTER OF STRIPE UNLESS NOTED OTHERWISE. 8.THE CONTRACTOR SHALL SET LAYOUT POINTS NO MORE THAN 50 FEET APART ALONG THE LINES TO BE STRIPED, INCLUDING AT ALL TRANSITION POINTS, BEGINNINGS, ENDS, BREAKS, AND CHANGES IN THE STRIPING. THE LAYOUT SHALL BE APPROVED BY THE TRANSPORTATION DEPARTMENT PRIOR TO PAVEMENT MARKING INSTALLATION. THE CONTRACTOR SHALL CONTACT THE TRANSPORTATION DEPARTMENT AT 480-644-2160 FOR SCHEDULING AT LEAST TWO WEEKS BEFORE THE LAYOUT.

W16-15P, W3-3 AND W11-12P SIGNS WITH (2) FLAGS AND TYPE "B" HIGH INTENSITY FLASHING WARNING LIGHT AS SHOWN IN PLANS FOR 30 DAYS AFTER SIGNAL ACTIVATION. AFTER 30 DAYS OF SIGNAL ACTIVATION, REMOVE SIGN POST, (2) FLAGS AND TYPE "B" HIGH INTENSITY FLASHING WARNING LIGHT, W16-15P, W3-3, W11-12P SIGNS. INSTALL W11-8 AND W11-12P SIGN ON CUSTOM EASTMARK / DMB SIGN POST AND ANCHOR. CONTRACTOR TO COORDINATE PERMANENT SIGN AND POST INSTALLATION WITH EASTMARK / DMB. 1 2 STOP R1-1 BY OTHERS 2 1 INSTALL W11-12P 36"x30" STA 21+35 INSTALL W16-15P (TEMPORARY) 24"x12" INSTALL W11-8 36"x36" INSTALL W3-3 36"x36" POSTED SPEED LIMIT IS 35 M.P.H. STRIPING LEGEND 18" SOLID WHITE LINE 18SW 8" DASH WHITE LINE WITH A 2' LINE SEGMENT AND A 6' GAP 2 1 18SW 18SW 18SW SEE TS01 FOR SIGNS SEE TS01 FOR SIGNS

CONSTRUCTION NOTES INSTALL

6 CATALOG NUMBER: SHEET OF Dial 8-1-1 or 1-800-STAKE-IT (782-5348) in Maricopa County: (602) 263-1100 Call at least two full working days before you begin excavation. Arizona Blue Stake, Inc. DRAWING NORTH DRAWN BY: R. STEPHANI ENGINEER: C. WILLIAMS APPROVED BY: C. WILLIAMS ACTIVITY: ____ PROJ. NO.: ______ Y2K ENGINEERING, LLC. 480.696.1701 www.y2keng.com CITY OF MESA 2006 BENCHMARK, BRASS TAG IN TOP OF CURB LOCATED AT THE NORTHWEST CORNER OF MERIDIAN AND WARNER ROAD. ELEVATION: 1481.15 CITY OF MESA DATUM BENCHMARK OBSERVED ON APRIL 30, 2012

SM02 SIGNING & MARKING PLAN SCALE: 1" = 20' 010'20'40' S. PASTEUR POINT TWENTY-TWO BLVD

EXISTING R4-7 TO REMAIN STOP R1-1 BY OTHERS INSTALLW11-836"x36"

FIRE STATION 221 DRIVEWAY

AND POST INSTALLATION WITH EASTMARK / DMB. 3 3

CONSTRUCTION NOTES INSTALL W11-8 SIGN ON CUSTOM EASTMARK DMB SIGN POST AND ANCHOR. CONTRACTOR TO COORDINATE PERMANENT SIGN

RFI 157

RFI 95 RFI 101 RFI 95 Step Downs Running Southto North Step Downs Running from West toEast RFI 101 Step Downs Running East to West RFI 101 RFI 99 RFI 92 RFI 91 RFI 48 Updated Mech. Yard Layout RFI 74 Sketch 01 RFI 89

RFI 127

RFI 94

RFI 117 RFI 117 RFI 117 CIRCULARSTYLE RFI 68

RFI 135 RFI 135 RFI 135 RFI 135

SD-26 REVISED APP BAY LIGHTING CIRCUIT. RFI 166 RFI 161 Metal Panels RFI 26 RFI 61 WindowF Wall Fabric RFI 60-R1 RFI 60 RFI 38 33 WindowF RFI 33 RFI 33 65 RFI 3

RFI 18 1'-5" 3'-0" RFI 104 RFI 29 RFI 20 REVISEDJTC ROOM LAYOUT RFI 33 5'-0" 10'-0" RFI 25

CR RFI 145 RFI 119 RFI 119 Conduit Chase from above located as shown which impedes into the door opening and roughly 16" off of the IT room wall RFI 112 Conflict with not havingsufficient spaceto serviceairhandlers with theskylightscoming downright in frontof the 4 airhandlers RFI 112 10'-0" 1 RFI 104 Frame false wall tomaintain the 4-6" off thewall for the conduit stubups RFI 112 We would have topossibly stack 1- 4"and 2- 2" conduits as shown W sta RFI 112

RFI 158 APPROVED APP BAY SAWCUT PLAN RFI 129 RFI 98 RFI 98 APPROVED HOUSING AREA SAWCUT PLAN RFI 79

SD-2

TYP. RFI 162 RFI 154 RFI 151 RFI 111 RFI 110

SD-22 DryerVent RFI 67 26'-0" RFI 55 26'-0" RFI 55

SD-27 RFI 172 Add masonry lintel. Add MCJs. SK03.pdf SK04.pdf RFI 82-R1 RFI 82 RFI 19-R1 RFI 19 26'-0" RFI 55 26'-0" RFI 55 Delete Window WindowF RFI 33 RFI 33 MCJ Locations RFI 21 MCJ Locations RFI 21

SD-28

RFI 155 RFI 125 26'-0" RFI 55 WindowF RFI 33

RFI 134 RFI 134 RFI 109 RFI 109

RFI 120

Revised Detail Affects: -Steel -Concrete -Masonry -Stud Framing RFI 56

RFI 152

CR RFI 47

SD-4 RFI 169 RFI 139 RFI 106 2'-0" 2'-0" 2'-6" RFI 25-R1 2'-6"

RFI 153

See RFI 93 for the descriptionofthe revised tile layout.

SD-5

RFI 93 RFI 93

RFI 174 RFI 114

5

5

RFI

RFI

RFI 28 RFI 23 7'-8" RFI 25 Revised Lite Dimensions RFI 36 2'-0" 4'-0" ALUM FIXED WINDOW TYPE:F GL-3 RFI 33 2" Head 2 RFI 22 3'-8" RFI 10 3'-8" RFI 10 3'-8" RFI 10

RFI 164 RFI 139 RFI 115

RFI 152

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 77 Wet setting bearing platesis acceptable RFI 62 or ladder style RFI 35 Wall Footing Epoxy Embedment Requirements RFI 16 Allow1 day minimum for concrete to cure before beginning any stem wall activities. Do not place grout at masonry stem walls or concrete at concrete stem walls until the footing has reached 75% of the specified 28-day strength or days have passed since footing conc rete placement. RFI 12

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 17 TFE VarianceFix RFI 30 RFI 34 Footing Tie-In RFI 37 StemGrouting Sequence RFI 73 RFI 75 APPROVED HOUSING AREA SAW CUT PLAN RFI 79 RFI 7 RFI 20 RFI 82-R1 SK03.pdf SK04.pdf RFI 82 CD-09

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 21 MCJ Location RFI 21 MCJ Locations RFI 33 L2 RFI 33 L2 RFI 49 8/S711 RFI 49 8/S711 Delete RFI 20 RFI 86 CD-10

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 108

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 Column Socket HSS5x5x3/8 RFI 39 #4AT18" OC RFI 27 Embed Requirements for Drilled & Epoxied Vertical Bars RFI 16 Alternate sides atlap splice locations in footing longitudinal reinforcing. RFI 15 RFI 14

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 41 RFI 87 RFI 80 Option to hook vertsatdooropenings RFI 42

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 78

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 70 Wet SettingPlatesisAcceptable RFI 62 Wet SettingPlates is Acceptable RFI 62

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 146 RFI 115 RFI 115 RFI 80

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 78 Sketch 01 RFI 8

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 GroutingSequence Approval RFI 63 REVISEDDECK SUPPORT/ATTACHMENT INFORMATION Affects: -Steel -Masonry -Concrete -Stud Framing RFI 56

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212 RFI 87

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SheetNo. Job No. Drawn Checked Date Revised TEL: (480) 539 8800 FAX: (480) 539 8608 459 N. Gilbert Road, Suite C-200, GILBERT, AZ 85234 HDA A RCHITECTS, LLC. CITY OF MESA MESA FIRE STATION 221 9320 E POINT TWENTY-TWO BLVD. MESA, AZ 85212

SYMBOL DESCRIPTION

PHOTOCELL, MOUNTED ON 1/2" RIGID CONDUIT. STUB UP 12"

SWITCHES

SITE LIGHTING

IN-GRADE PULLBOX. SIZE AND TYPE AS SCHEDULED. SCREW COVER JUNCTION BOX. SIZE AND TYPE AS SCHEDULED. JUNCTION BOX, WALL OR CEILING MOUNTED. JUNCTION BOX FLUSH IN WALL. HEIGHT AS INDICATED FOR CONNECTION TO J EQUIPMENT. SYMBOL DESCRIPTION BOXES DESIGNATION SYSTEM FA FIRE ALARM IA SECURITY PA PAGING/INTERCOM TEL TELEPHONE TVVIDEO DATA DATA CCTVCLOSED CIRCUIT TELEVISION PWR POWER A FIRE ALARM IA SECURITY PA PAGING/INTERCOM TVVIDEO COMMVOICE DATA COMMUNICATIONS CCTVCLOSED CIRCUIT TELEVISION PWR POWER IN-GRADE UNCTION BOX. SIZE AND TYPE AS SCHEDULED. J EXTERIOR MOUNTED EMERGENCY EGRESS. TYPE AS INDICATED IN FIXTURE SCHEDULE SELF-CONTAINED TWO-HEAD EMERGENCY BATTERY PACK FIXTURE. TYPE AS INDICATED WALL MOUNTED EXIT LIGHT FIXTURE AND OUTLET WITH DIRECTIONAL INDICATOR. TYPE AS CEILING MOUNTED EXIT FIXTURE AND OUTLET WITH DIRECTIONAL INDICATOR. TYPE RECESSED EMERGENCY FIXTURE. TYPE A INDICATED IN FIXTURE SCHEDULE. IN FIXTURE SCHEDULE. AS INDICATED IN FIXTURE SCHEDULE. SOLID PORTION REPRESENTS ILLUMINATED SIDE. AS INDICATED IN FIXTURE SCHEDULE. SOLID PORTION REPRESENTS ILLUMINATED SIDE. SYMBOL DESCRIPTION EMERGENCY/EXIT LIGHTING WALL MOUNTED COMBO EXIT EMERGENCY LIGHT FIXTURE AND OUTLET WITH DIRECTIONAL INDICATOR. TYPE AS AS INDICATED IN FIXTURE SCHEDULE. SOLID PORTION REPRESENTS ILLUMINATED SIDE. WALL MOUNTED DECORATIVE TWO-HEAD EMERGENCY BATTERY PACK FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. WALL MOUNTED LIGHT FIXTURE ON EMERGENCY. TYPE AS INDICATED IN FIXTURE SCHEDULE. RECESS MOUNTED TWO-HEAD EMERGENCY BATTERY PACK FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE.

ABOVE ROOF, WITH WINDOW TIMECLOCK IN NEMA 1 ENCLO URE UNLESS NOTED OTHERWISE. REFER TO DRAWINGS FOR TYPE. IGHTING CONTACTOR IN NEMA 1 ENCLOSURE. REFER TO DRAWINGS OR TYPE. FACING NORTH. LIGHTING CONTROL PC TC OCCUPANCY SENSOR WALL SWITCH. FLUSH MOUNTED UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED. OS OS OCCUPANCY SENSOR CEILING MOUNTED RP P OS S RELAY POWER PAK FOR 4VDC SENSOR DAYLIGHT/PHOTO SENSOR CEILING MOUNTED LS LIGHTING CONTROL OVERRIDE WALL SWITCH. FLUSH MOUNTED UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED. DS SYMBOL DESCRIPTION TRACK MOUNTED LIGHT FIXTURE AND OUTLET LENGTH AS INDICATED . TYPE AS INDICATED IN PENDANT HUNG FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. WALL MOUNTED FLUORESCENT FIXTURE AND OUTLET. TYPE AS INDICATED UNDERCOUNTER FIXTURE AND OUTLET. TYPE AS INDICATED IN FIXTURE SCHEDULE. LAY-IN 2x4 PARABOLIC FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. LAY-IN 2x PARABOLIC FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. FLUORESCENT UTILITY STRIP FIXTURE AND OUTLET. TYPE AS INDICATED IN FIXTURE SCHEDULE. FIXTURES. MAXIMUM 6'-0" LENGTH OF CONDUIT WITH REQUIRED CONDUCTORS ALONG WITH IGHTING FIXTURE INDICATED WITH CROSS SHADING IS CONNECTED TO EMERGENCY POWER SOURCE, OR HAS INTEGRAL BATTERY PACK 1 50 LUMEN MIN. FLANGED OR URFACE MOUNTED FLUORESCENT FIXTURE AND OUTLET. TYPE AS FLANGE OR SURFACE MOUNTED 2 2 FLUORESCENT OR HID FIXTURE AND OUTLET. TYPE AS FLANGE OR SURFACE MOUNTED 2x4 FLUORESCENT FIXTURE AND OUTLET. TYPE AS WALL MOUNTED LIGHT FIXTURE AND OUTLET. TYPE AS INDICATED IN FIXTURE SCHEDULE. SURFACE CEILING FIXTURE AND OUTLET. TYPE AS INDICATED IN FIXTURE SCHEDULE SQUARE DOWNLIGHT. TYPE AS INDICATED IN FIXTURE SCHEDULE. ROUND RECESSED DOWNLIGHT. TYPE AS INDICATED IN FIXTURE SCHEDULE. RECESSED WALL WASH DOWNLIGHT. TYPE AS INDICATED IN FIXTURE SCHEDULE. SUSPENDED INDIRECT FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. LAY-IN 2x FLUORESCENT OR HID FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. LAY-IN 2x4 FLUORESCENT FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. LAY-IN 1x4 FLUORESCENT FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. IXTURE SCHEDULE. IN FIXTURE SCHEDULE. GREEN WIRE GROUND. INDICATED IN FIXTURE SCHEDULE. INDICATED IN FIXTURE SCHEDULE. INDICATED IN FIXTURE SCHEDULE. LIGHTING LAY-IN 2x2 DIRECT/INDIRECT FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. LAY-IN 2x4 DIRECT/INDIRECT FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. EXTERIOR WALL SCONCE LIGHT FIXTURE AND OUTLET. TYPE AS INDICATED IN FIXTURE SCHEDULE. INTERIOR WALL SCONCE LIGHT FIXTURE AND OUTLET. TYPE AS INDICATED IN FIXTURE SCHEDULE. HI-BAY MOUNTED FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. LOW VOLTAGE LIGHTING STEP DOWN TRANSFORMER STEM MOUNTED DECORATIVE FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. STEP LIGHT. TYPE AS INDICATED IN FIXTURE SCHEDULE. RECESSED WALL WASH FLOURESCENT FIXTURE. TYPE AS INDICATED IN SCHEDULE SURFACE MOUNTED WASH FLOURESCENT FIXTURE. TYPE AS INDICATED IN SCHEDULE SWITCH CONTROLLED DUPLEX CONVENIENCE OUTLET, UP 18" OR AS INDICATED 250 VOLT RECEPTACLE UP 24" OR AS INDICATED. AMPERAGE AS NOTED ON DRAWINGS. SPECIAL RECEPTACLE UP 24" OR AS INDICATED. ROOF MOUNTED 20A WP GFCI SERVICE OUTLET PER NEC 10-63 OUTLET MOUNTED HORIZONTALLY, 6" ABOVE COUNTER OR TOP OF BACKSPLASH. DOUBLE DUPLEX OUTLET, UP 18" OR AS INDICATED. DUPLEX CONVENIENCE OUTLET. UP 18" OR AS INDICATED. TYPE AS DESIGNATED BELOW. DOUBLE DUPLEX OUTLET 6 ABOVE COUNTER OR TO OF BACKSPLASH. SYMBOL DESCRIPTION POWER DESIGNATION SYSTEM W WIREMO D TR TAMPER RES STANT C LUSH CEILING MOUNT CS G ISOLATED GROUND CEILING SURFACE MOUNT S SURFACE MOUNT WP WEATHERPROOF EXP EXPLOSION PROOF XX PEDESTAL MOUNT 20A 125V DUPLEX OUTLET MOUNTED 24" A.F.F. UNLESS NOTED OTHERWISE. PEDESTAL MOUNT 20A 250V OUTLET MOUNTED 24" A.F.F. UNLESS NOTED OTHERWISE. GFCI DUPLEX OUTLET, UP 18" OR AS INDICATED. 20A 125V SIMPLEX OUTLET MOUNTED 18" A.F.F. UNLESS NOTED OTHERWISE. SYMBOL DESCRIPTION FLOODLIGHT FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. LIGHT POLE AND NUMBER OF LUMINARES SHOWN. TYPE AS INDICATED IN FIXTURE SCHEDULE

ROADWAY FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE TWIN-HEAD ROADWAY FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE POST-TOP BOLLARD FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE HI-MAST ROADWAY FIXTURE. TYPE AS INDICATED IN FIXTURE SCHEDULE DUSK-TO-DAWN CONTROLLED LIGHT POLE AND NUMBER OF LUMINARES SHOWN. TYPE AS INDICATED IN THE FIXTURE SCHEDULE. WALL MOUNTED TRIANGULAR FXITURE. TYPE AS INDICATED IN FIXTURE SCHEDULE. SYMBOL DESCRIPTION DESIGNATION SYSTEM 4 FOUR WAY K KEYED P PILOT M MOTOR RATED F FAN SWITCH 3 THREE WAY 2 EC EVAPORATIVE COOLER THREE-STATION PUSH-BUTTON UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED. TWO-STATION PUSH-BUTTON UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED. INGLE STATION PUSH-BUTTON UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED. FLUORESCENT DIMMER SWITCH. FLUSH MOUNTED UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INCANDESCENT DIMMER SWITCH. FLUSH MOUNTED UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE SINGLE POLE WALL SWITCH. FLUSH MOUNTED UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED INDICATED. INDICATED.

D THREE-WAY INCANDESCENT DIMMER SWITCH. FLUSH MOUNTED UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED. 3D FD THREE-WAY FLUORESCENT DIMMER SWITCH. FLUSH MOUNTED UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED. F TYPE AS DESIGNATED BELOW DOUBLE POLE-SINGLE THROW EXP EXPLOSION PROOF WP WEATHERPROOF L LIMIT LV LOW VOLTAGE XX MERGENCY SHUT-OFF SWITCH UP 44" TO BOTTOM OF BOX UNLESS OTHERWISE INDICATED. HDA A RCHITECTS, LLC. Last S aved: 5-01-20 01:17pm Drawing file: C:\Users\shyrod\appdata\local\temp\AcPublish_44092\19101-E001 Plot Date: 5-21-20 01:15pm Drawing scale: 1:1 By: shyrod JJJ

REFERENCES AND ABBREVIATIONS

BOXES/POWERPOLES

ONE LINE SYMBOLS

MISCELLANEOUS SYMBOL

A-2,4

DESCRIPTION INDICATES CONDUIT RISER WITHIN BUILDING WALL.

INDICATES CONDUIT DROP WITHIN BUILDING WALL.

PE

EX

UG UG SE X

UG UG

T E X

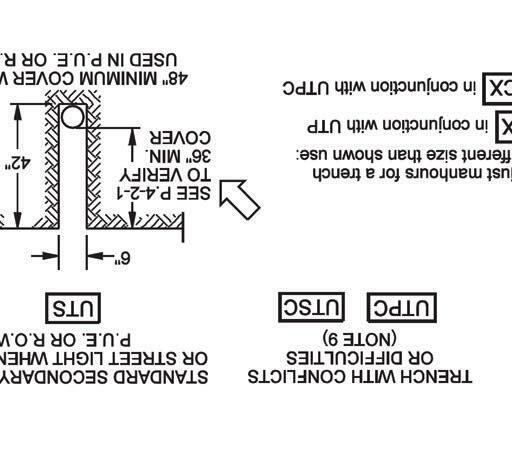

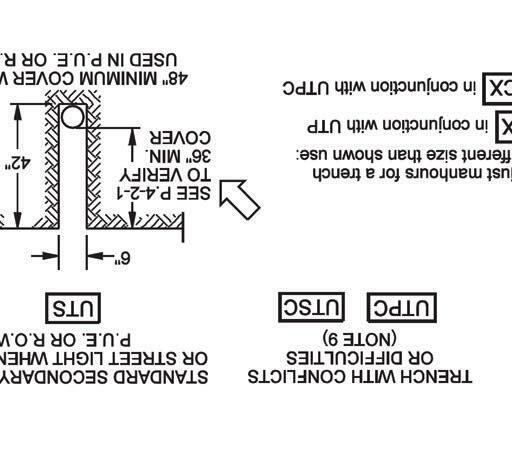

ELECTRICAL UNDERGROUND CIRCUIT, 4'-0" MINIMUM BELOW

SECONDARY SERVICE ELECTRICAL UNDERGROUND CIRCUIT, 3'-0" MINIMUM BELOW

GRADE. GRADE.

EYS" SEAL-OFF

EXISTING CONDUIT

EXISTING TO BE REMOVED

MOTOR CONTROLLER, PROVIDED AND INSTALLED UNDER DIV. 15. SIZE AND POLES OR MOTOR 208/120V SURFACE MOUNTED DISTRIBUTION PANELBOARD. SEE PANEL SCHEDULE FOR CHARACTERISTICS. 480/277V SURFACE MOUNTED DISTRIBUTION PANELBOARD. SEE PANEL SCHEDULE FOR CHARACTERISTICS. MOTOR CONTROLLER INTEGRAL WITH EQUIPMENT. MOTOR CONNECTION WITH HP INDICATED. COMBINATION MAGNETIC STARTER PROVIDED AND INSTALLED UNDER DIV. 16 SAFETY SWITCH, PROVIDED AND INSTALLED UNDER DIV. 16. TO HAVE POLES AND RATIN. NEMA 3R UNLESS 480 277V SURFACE MOUNTED PANELBOARD. SEE PANEL SCHEDULE FOR CHARACTERISTICS. 208/120V FLUSH MOUNTED PANELBOARD. SEE PANEL SCHEDULE FOR CHARACTERISTICS. 208 120V SURFACE MOUNTED PANELBOARD. SEE PANEL SCHEDULE FOR CHARACTERISTICS. 480 277V FLUSH MOUNTED PANELBOARD. SEE PANEL SCHEDULE FOR CHARACTERISTICS. SERVICE ENTRANCE RATED SWITCHBOARD.

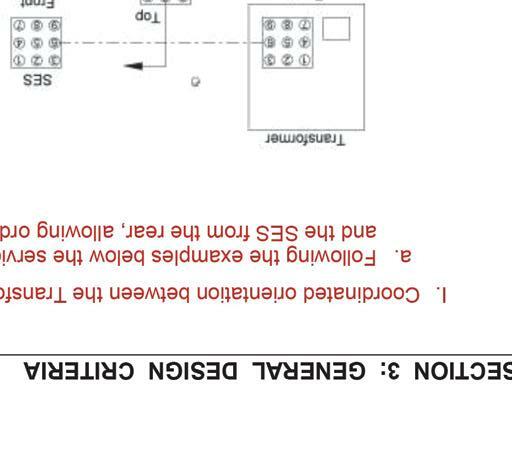

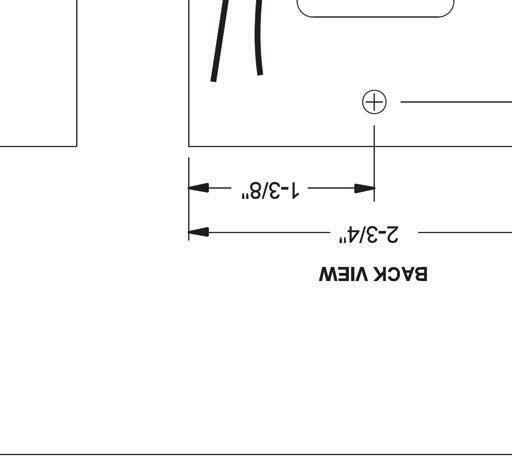

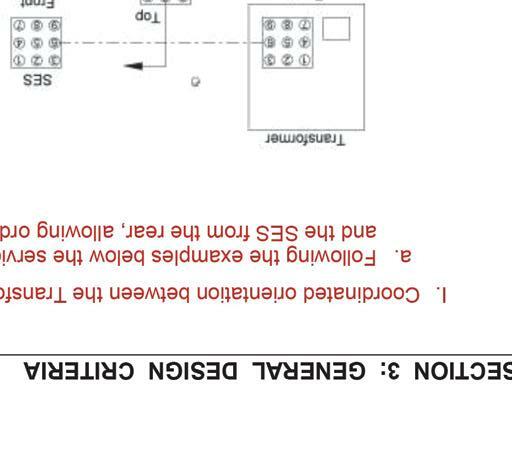

DRY-TYPE TRANSFORMER AS NOTED. M T SPECIAL CABINET AS NOTED. FURNISHED. SYMBOL DESCRIPTION NOTED FURNISHEDOTHERWISE. ENCLOSED CIRCUIT BREAKER, FRAME SIZE, TRIP SIZE, # POLES, AIC RATING UTILITY PAD-MOUINT TRANSFORMER AS NOTED. UTILITY PRIMARY SWITCH AS NOTED. MULTI-OUTLET SURFACE RACEWAY WITH RECEPTACLES AS CALLED FOR IN SPECS OR DRAWINGS. 4-COMPARTMENT RECESSED MOUNTED FLOOR OUTLET POWER/DATA) AS NOTED. VERIFY EXACT LOCATION DUPLEX FLUSH FLOOR POWER OUTLET OR AS NOTED. VERIFY EXACT OCATION IN FIELD FLUSH FLOOR 2-GANG RECTANGULAR OUTLET BOX WITH RECEPTACLE FOR POWER AND COVER DUAL-COMPARTMENT TELEPOWER POLE, STEEL TYPE, IVORY COLORED FOR TELEPHONE. WITH ARCHITECT. IN FIELD WITH ARCHITECT. SYMBOL DESCRIPTION FLOOR

SINGLE-COMPARTMENT POWER POLE, STEEL TYPE, IVORY COLORED TP PP FLUSH FLOOR 3-GANG RECTANGULAR OUTLET BOX WITH RECEPTACLE FOR POWER, COVER FOR TELEPHONE AND COVER OR DATA. FLUSH FLOOR 2-GANG RECTANGULAR OUTLET BOX WITH RECEPTACLE FOR POWER AND COVER FOR DATA/TELEPHONE. FLUSH FLOOR 2-GANG ROUND OUTLET BOX WITH RECEPTACLE FOR POWER AND COVER FOR DATA/TELEPHONE. DETAILIDENTIFIER FEEDER LABEL DESIGNATOR KEYED NOTE DESIGNATOR

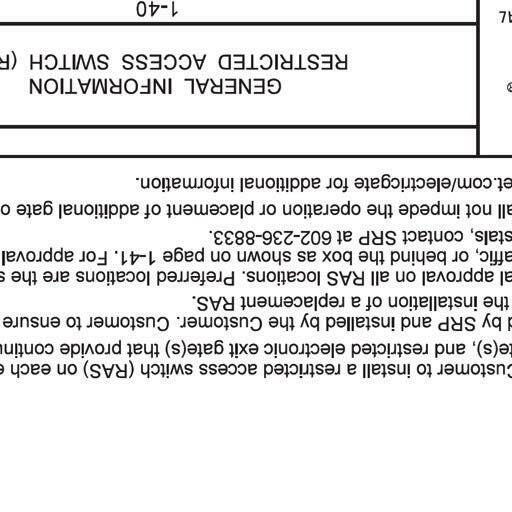

APPARATUS LEGEND

MECHANICAL EQUIPMENT IDENTIFIER SYMBOL DESCRIPTION 1 1 AC 200Y 2 E8.3 AMP A ABOVE FINISHED FLOOR AFF CONDUIT C CIRCUIT BREAKER CB COPPER CU ELECTRICAL CONTRACTOR C MERGENCY EM EXISTING TO BE RELOCATED EXR GROUND G GROUND FAULT CIRCUIT INTERRUPTER GFC ISOLATED GROUND IG MOTOR CONTROL CENTER MCC MAIN LUGS ONLY MLO SERVICE ENTRANCE SWITCHBOARD SES MAIN CIRCUIT BREAKER MCB MAIN DISTRIBUTION PANELBOARD MDP PANEL PNL VOLTS V WEATHERPROOF WP EQUIPMENT IDENTIFIER 205A EXI TING EX TELEPHONE UNDERGROUND CIRCUIT, 2'-0" MINIMUM BELOW GRADE. ELECTRICAL UNDERGROUND CIRCUIT, 2'-0" MINIMUM BELOW GRADE. HOME RUN TO PANEL WITH BRANCH CIRCUIT NUMBERS INDICATED. NEUTRAL", "A HOT AND SWITCH LEG", "A NEUTRAL AND SWITCH LEG", OR "HOT RESPECTIVELY. CONDUITS WITH NO TIC MARKS SHALL BE: "A HOT AND TIC MARKS REPRESENT NEUTRAL, HOT, SWITCH LEG, AND GROUND CONDUCTORS NEUTRAL, AND GROUND", AS APPLICABLE. BRANCH CIRCUIT IN WALLS OR CEILING. BRANCH CIRCUIT EXPOSED. BRANCH CIRCUIT UNDER FLOOR. PRIMARY SERVICE

UTILITY PAD-MOUINT TRANSFORMER AS NOTED. UTILITY PRIMARY SWITCH AS NOTED. MAIN BREAKER PANELBOARD MAIN LUGS ONLY PANELBOARD 25 HP 5 H VFD WITH INTEGRAL CIRCUIT BREAKER 25 HP 5 H VFD WITH INTEGRAL FUSIBLE SWITCH G E GENERATOR WITH MAIN BREAKER MOTOR CONTROLLER, PROVIDED AND INSTALLED UNDER DIV. 15. SIZE AND POLES FOR MOTOR MOTOR CONNECTION WITH HP INDICATED. COMBINATION MAGNETIC STARTER PROVIDED AND INSTALLED UNDER DIV. 16 USIBLE SAFETY SWITCH, PROVIDED AND INSTALLED UNDER DIV. 16. TO HAVE POLES AND RATIN. NEMA 3R UNLESS

DRY-TYPE TRANSFORMER AS NOTED. M AUTOMATIC TRANSFER SWITCH CIRCUIT BREAKER, FRAME SIZE, TRIP SIZE, # POLES, AIC RATING FUSIBLE SWITCH, SWITCH SIZE, FU E IZE, FUSE TYPE DRAWOUT BREAKER FURNISHED. SYMBOL DESCRIPTION NOTED OTHERWISE. UTILITY METERING MAIN UGS ONLY CONNECTION PS 300AF 600AS 35K AIC 3P 200AT 225AF ENCLOSED CIRCUIT BREAKER, FRAME SIZE, TRIP SIZE, # POLES, AIC RATING UTILITY OVERHEAD TRANSFORMER AS NOTED. NON-FUSIBLE SAFETY SWITCH, PROVIDED AND INSTALLED UNDER DIV. 16. TO HAVE POLES AND RATIN. NEMA 3R UNLESS NOTED OTHERWISE. LOADBANK INE GENERATOR LOAD ON ON OFF N DOUBLE POLE, DOUBLE THROW SAFETY SWITCH, PROVIDED AND INSTALLED UNDER DIV. 16. TO HAVE POLES AND RATIN. NEMA 3R UNLESS NOTED OTHERWISE. SWITCHPAD WITH ( ) FUSIBLE SWITCHES WITH LOAD-BREAK SWITCH HDA A RCHITECTS LLC Last S aved: 5-01-20 01:17pm Drawin g ile: C \ Users sh y rod appdata \ local temp \ AcPublish_44092 \ 19101-E00 2 Plot Date: 5-21-20 01:15pm Drawin g scale: 1:1 B y : sh y d JJJ

ADJACENT TO PANEL. CONTACTOR SHALL BE PHOTOCELL ON TIMECLOCK OFF. PROVIDE WITH MANUAL OVERRIDE H-O-A SWITCH.

7.UTILIZE #10CU. CONDUCTORS THROUGHOUT THE ENTIRE LENGTH OF THE CIRCUIT.

8.NOT USED.

9.(3)-3"C WITH PULLSTRING FOR PRIMARY CABLES (CABLES FURNISHED AND INSTALLED BY SALT RIVER PROJECT). MINIMUM BURIAL DEPTH SHALL BE 48" BELOW FINISHED GRADE.

10.NOT USED.

11.WP JUNCTION BOX FOR IRRIGATION CONTROLLER MOUNTED 24" ABOVE FINISH GRADE. COORDINATE WITH LANDSCAPE ARCHITECT FOR EXACT LOCATION AND REQUIREMENTS.

12.WEATHERPROOF JUNCTION BOX FOR COMPLETE CONNECTION OF ABOVE GROUND DIESEL FUEL TANK AND DISPENSER. VERIFY LOCATION AND REQUIREMENTS PRIOR TO ROUGH-IN.

13.CLASS 1, DIVISION 1 LOCATION, BELOW GRADE AND CLASS 1, DIVISIONS 2 LOCATION UP TO 18" A.F.G. WITHIN 20' HORIZONTALLY OF ANY EDGE OF ENCLOSURE.

14.1" PVC COATED RGS WITH THREADED COUPLINGS FROM LEAK DETECTOR TO CONTROL AND MONITOR LOCATIONS IN TELE/ELEC ROOM. VERIFY EXACT LOCATION.

15.(3)-1-1/2" EMPTY CONDUIT STUBS WITH PULL CORD FROM ELECTRICAL ROOM INTO EDGE OF FUEL DISPENSING AREA, PROVIDE SEAL AND CAPS FOR FUTURE.

16.PROVIDE EMERGENCY SHUT-OFF SWITCH AND RESET BUTTON, RED MUSHROOM TYPE, WITH SIGN "EMERGENCY FUEL SHUT-OFF". LOCATE SWITCH ON WALL AT 42" A.F.G. WITHIN 75' OF FUEL DISPENSER. VERIFY LOCATION WITH FIRE MARSHAL PRIOR TO ROUGH-IN. SWITCH TO SHUNT TRIP ALL FUEL SYSTEM POWER CIRCUITS.

17.ABOVE GROUND DIESEL FUEL TANK WITH DISPENSER. ELECTRICAL CONTRACTOR SHALL CONNECT ALL FUEL SYSTEM CONTROLS AND MONITOR AS DIRECTED BY FUEL SYSTEM SUPPLIER/INSTALLER. VERIFY PRIOR TO ROUGH-IN.

18.STUB UP AND CAP (2) 2" CONDUITS AND (1) 1" CONDUIT WITH PULL STRING TO DATA CLOSET ROOM FOR VOICED/DATA CABLES.

19.PROVIDE

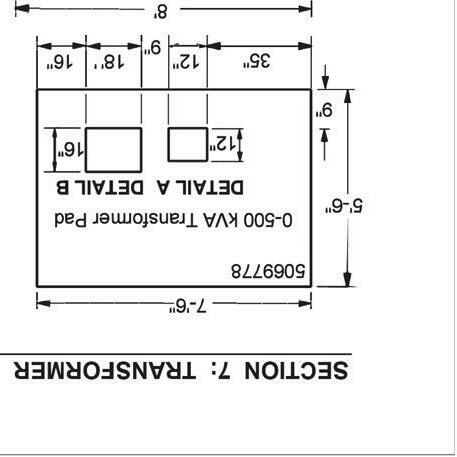

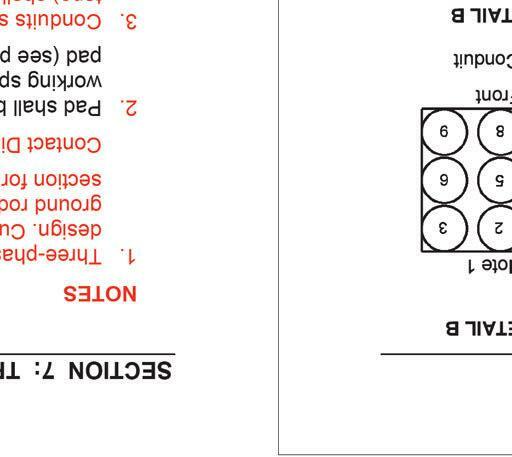

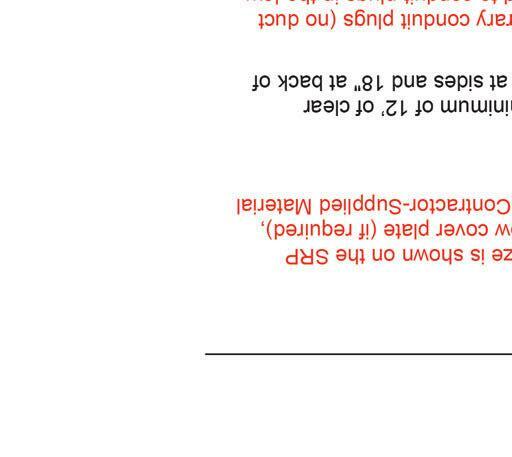

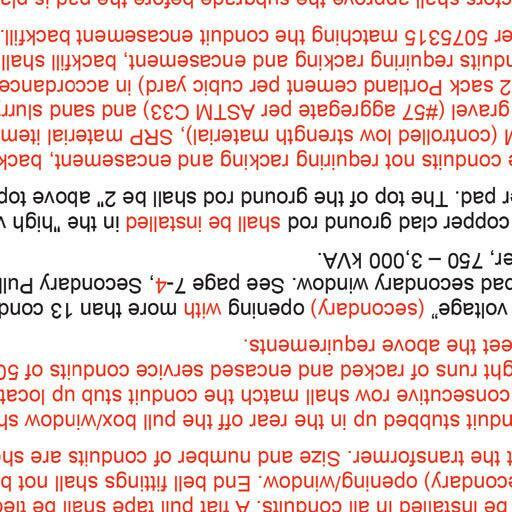

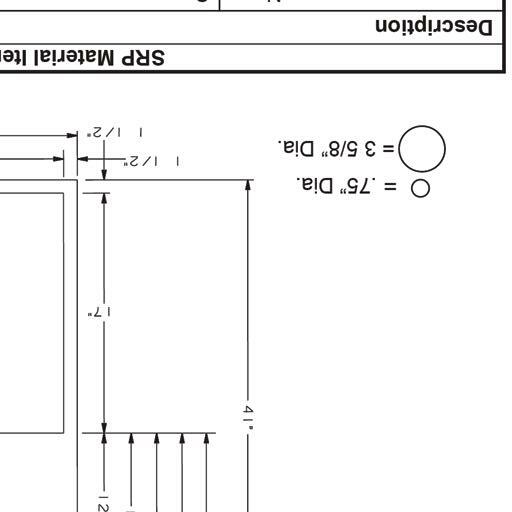

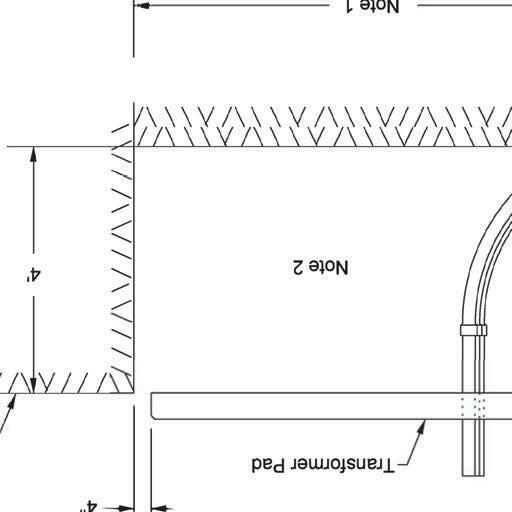

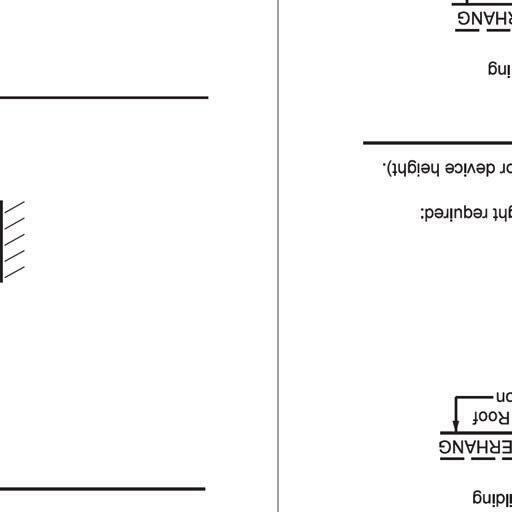

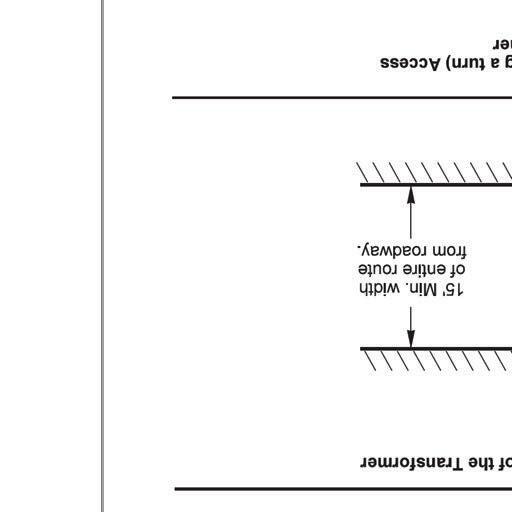

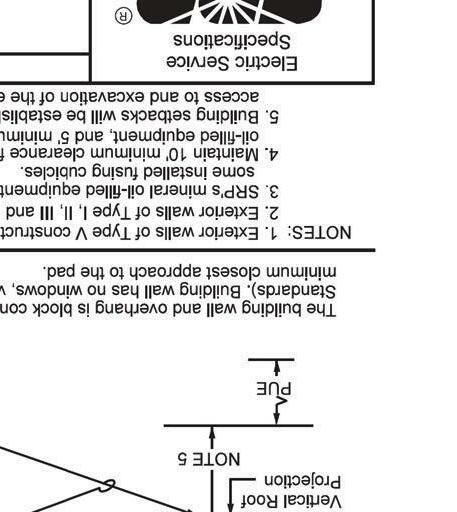

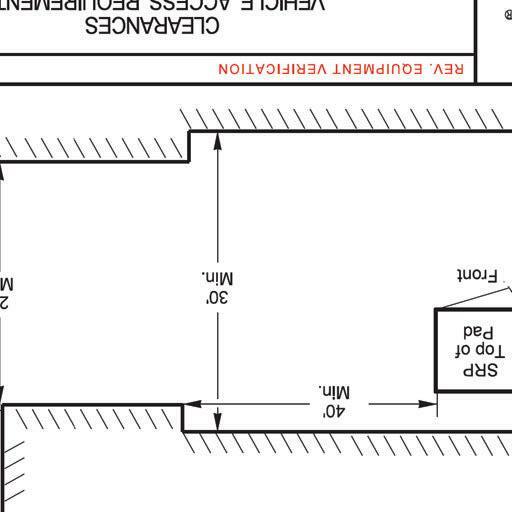

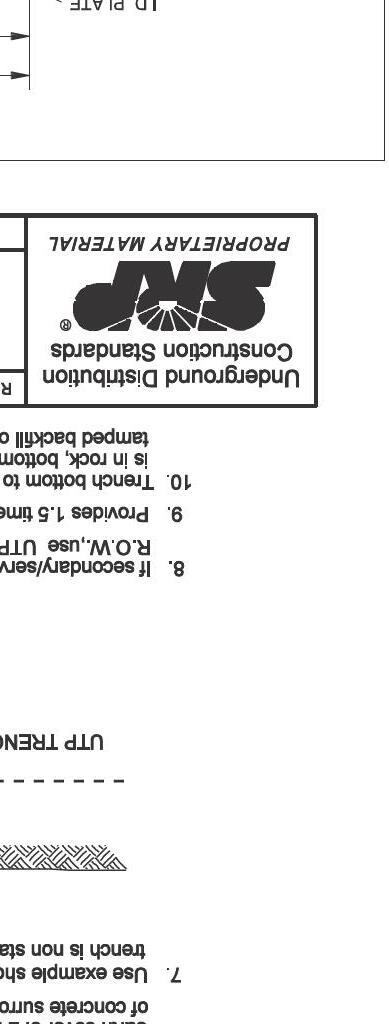

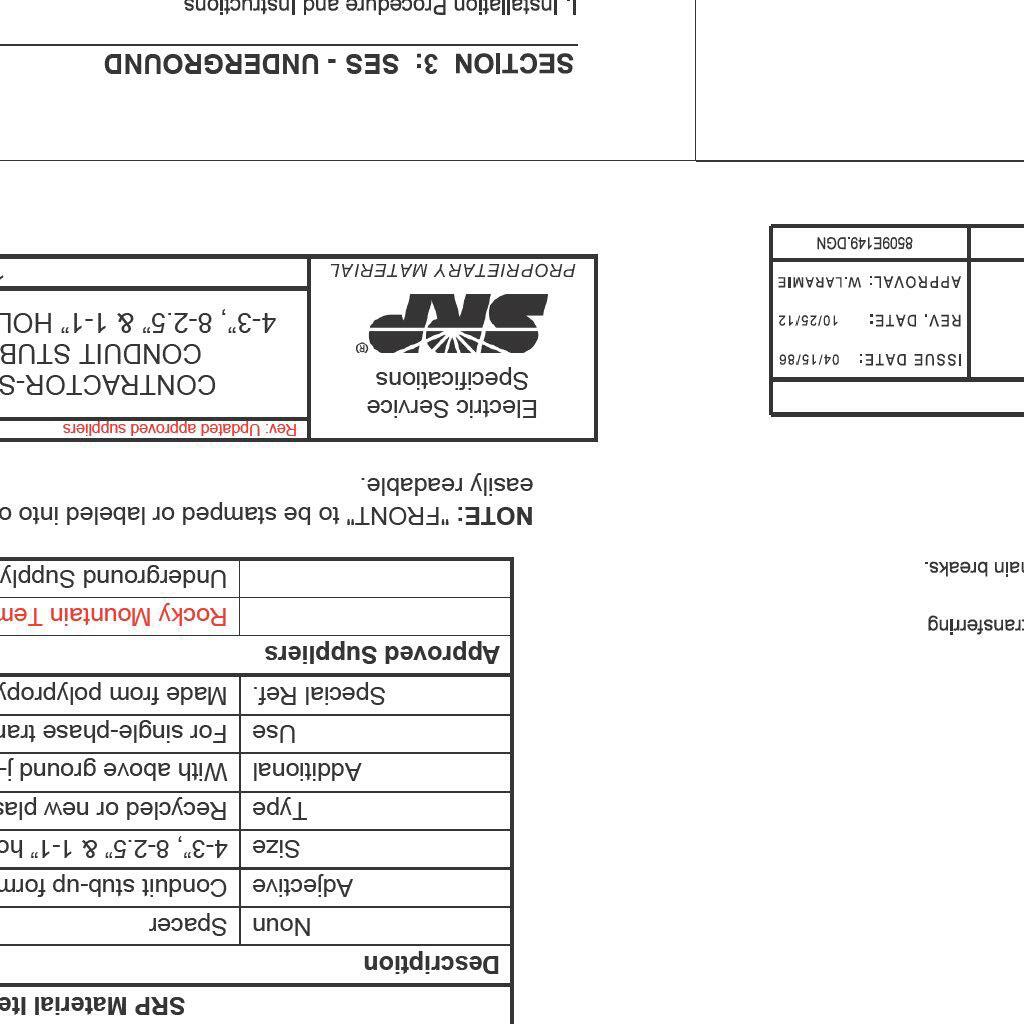

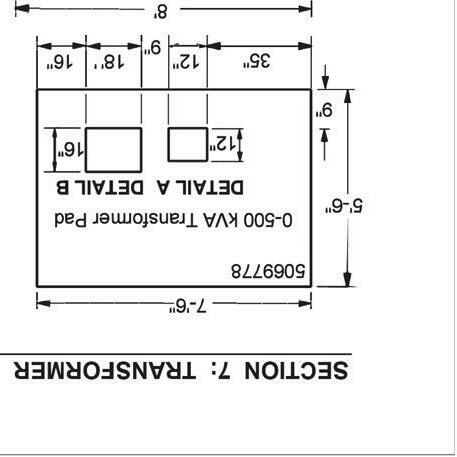

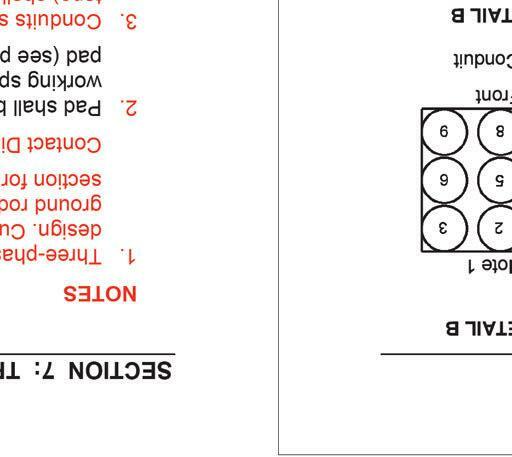

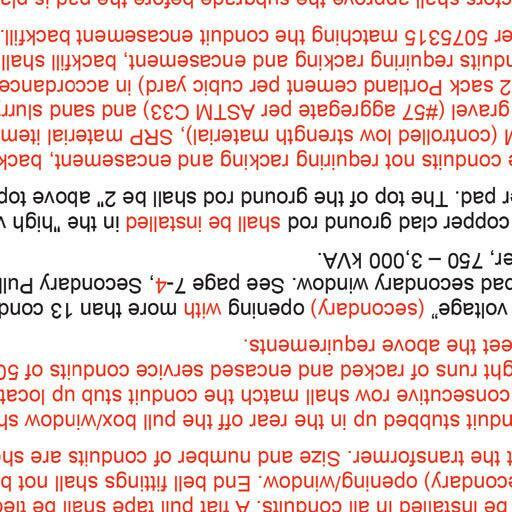

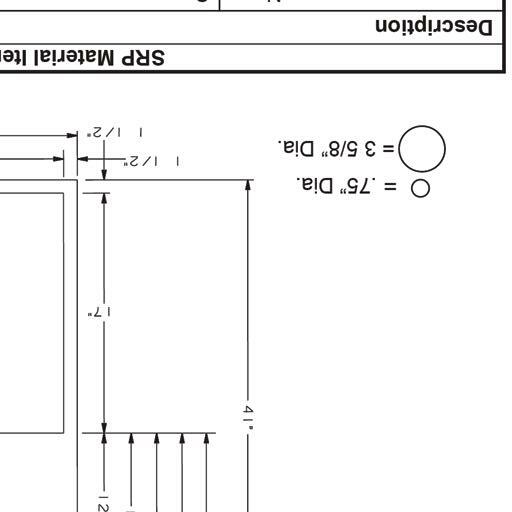

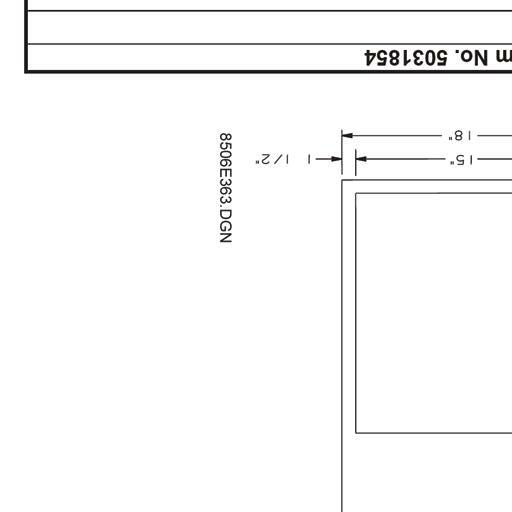

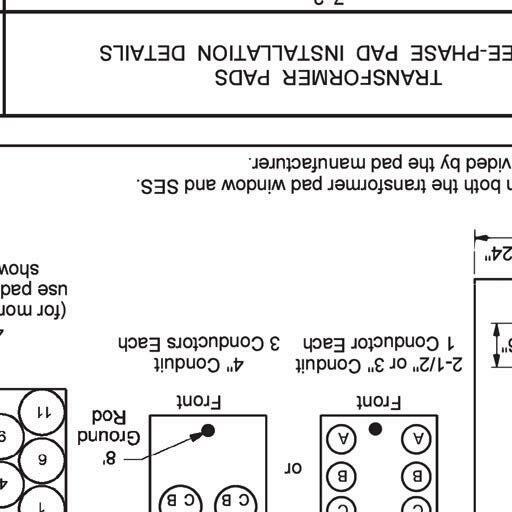

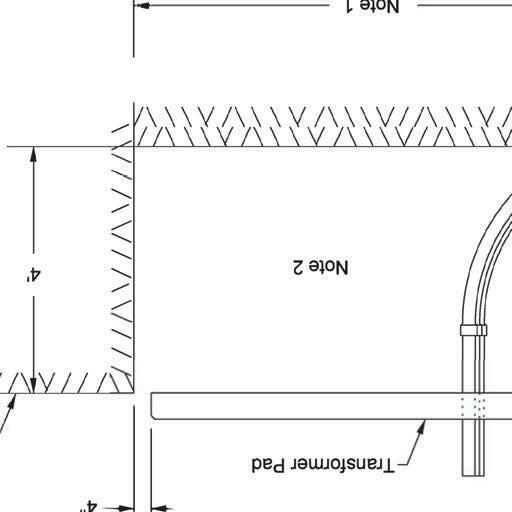

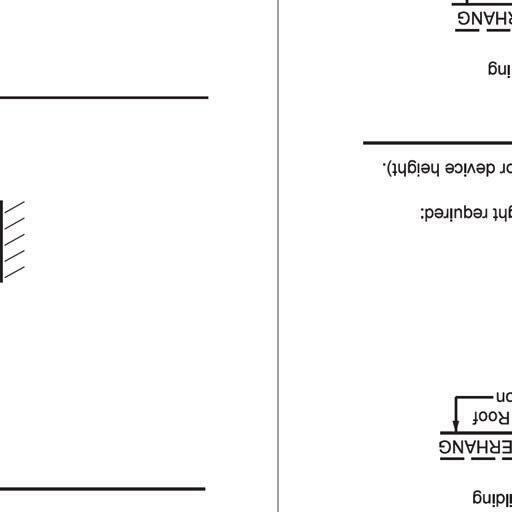

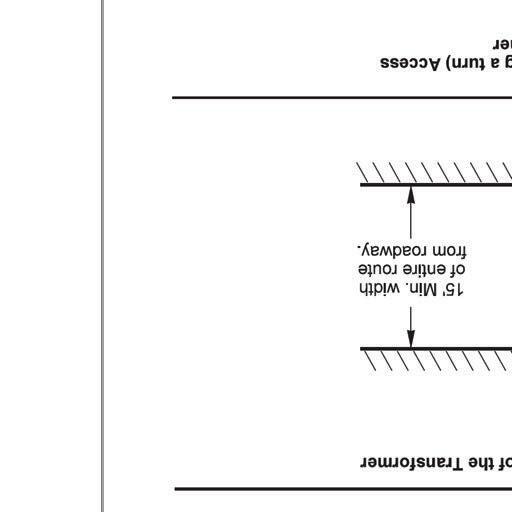

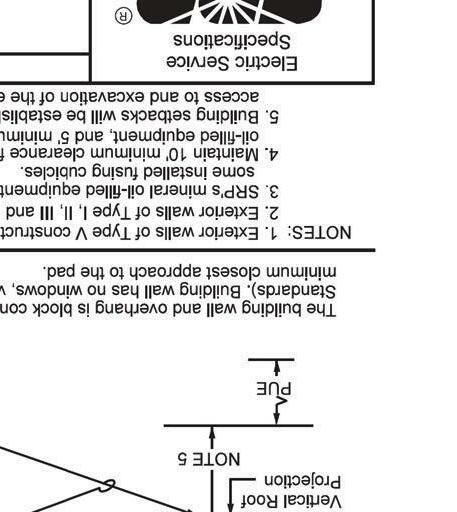

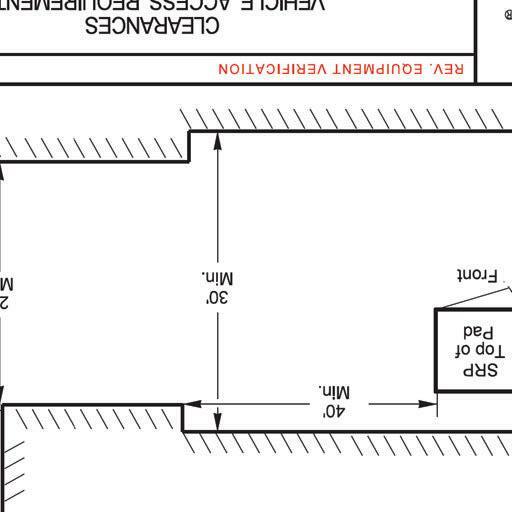

1. PROVIDE 4" HIGH CONCRETE PAD FOR EXTERIOR MOUNTED SERVICE ENTRANCE SECTION. PAD SHALL EXTEND 3' BEYOND THE LEADING EDGE OF THE NEW SES, AND EXTEND 6" ON EACH SIDE OF THE SES. 2.NEW UTILITY PAD-MOUNT TRANSFORMER COORDINATE EXACT LOCATION WITH SALT RIVER PROJECT. CONTRACTOR SHALL PROVIDE TRANSFORMER PAD AND GROUNDING PER SALT RIVER PROJECT INSTALLATION STANDARDS. 3.(3)-4"C WITH PULLSTRING FOR SECONDARY CABLES (CABLES FURNISHED AND INSTALLED BY SALT RIVER PROJECT). MINIMUM BURIAL DEPTH SHALL BE 36" BELOW FINISHED GRADE. 4.WEATHERPROOF JUNCTION BOX FOR CONNECTION OF GENERATOR BLOCK HEATER AND BATTERY CHARGER. VERIFY EXACT LOCATION AND REQUIREMENTS WITH GENERATOR SUPPLIER PRIOR TO ROUGH-IN. SEE ONE-LINE DIAGRAM FOR CIRCUIT DESIGNATION. 5.NEW DIESEL POWERED EMERGENCY GENERATOR. PROVIDE CONCRETE HOUSEKEEPING PAD PER MANUFACTURER'S REQUIREMENTS. SEE ONE-LINE DIAGRAM FOR ADDITIONAL INFORMATION. 6.ROUTE THRU LIGHTING CONTACTOR MOUNTED

IN-GRADE JUNCTION BOX FOR CONNECTION TO EXTERIOR GATE. COORDINATE CONNECTION REQUIREMENTS WITH GATE MANUFACTURER. PROVIDE 3/4" CONDUIT TO MANUAL OVERRIDE SWITCH LOCATED IN KITCHEN. PROVIDE #8 WIRING TO PANEL INDICATED. 20.NOT USED 21.NOT USED 22.(2)-4" SCHEDULE 40 CONDUIT AND (1)-1" SCHEDULE 40 WITH TRACER WIRE TO FROM IT VAULT TO MDF FOR FUTURE. REFERENCE DETAILS ON SHEET E402. 23.PROVIDE IN-GRADE JUNCTION BOX FOR CONNECTION TO PROXIMITY CARD READER AND BEACON. COORDINATE CONNECTION REQUIREMENTS WITH MANUFACTURER. REFER TO DETAIL 18 & 19 ON SHEET A112. PROVIDE 1" CONDUIT TO TO GATE CONTROLLER. 24.4'x4' IT VAULT. VAULT TO BE FIBER OPTIC MANHOLE PER CITY OF MESA STANDARDS DETAIL M-66.01.1. COORDINATE EXACT LOCATION. 25.CONDUIT AND FIBER AT THIS LOCATION. 26.CONDUIT ONLY AT THIS LOCATION. 27.DIRECTIONAL BORE UNDER EXISTING STREET FOR INSTALLATION OF NEW UNDERGROUND CONDUITS. CONDUIT SHALL BE INSTALLED 5' BELOW GRADE UNDER STREET. UNDERGROUND CONDUIT SHALL BE RIGID STEEL CONDUIT OR HDPE AND UL LISTED FOR USE WITH DIRECTIONAL BORING EQUIPMENT. STEEL CONDUIT IN DIRECT CONTACT WITH THE EARTH SHALL RECEIVE A PROTECTIVE COVERING THAT IS MECHANICALLY APPLIED IN A FACTORY OR FIELD APPLIED USING 3M SCOTCHWRAP 50, 10 MILS THICK USED IN CONJUNCTION WITH 3M SCOTCHWRAP PRIMER APPLIED AS PER MANUFACTURER'S INSTRUCTIONS.. KEYED NOTES: 4 2 2 2 13 14 12 15 16 17 18 'LP3'-30 5 7 SA2 'LP2'-5 COVERED UTILITY TRANSFORMER 2 1 3 4 GEN. 5 DIESEL GENERATOR J 800A ATS 'LP2'-7 SH 6 7 22 22 800A 120/208V SES 'LP1'-1 6 7 'LP3'-2,4 6 7 SA SB SB SB SB 'LP1'-3 'LP7'-32,34 19 19 J 11 'LP6'-42 9 J 23 23 2 24 3 5 NEW M-66.07.1 NO. 9 ITD/ITS BOX 25 26 NEW M-66.01.1 ITD VAULT. EXACT LOCATION OF BOX TO BE DETERMINED BY HDA/ENGINEER DUE TO PROXIMITY TO SEWER STUB LOCATION. NEW (2) 3" ITD CONDUIT WITH ITD FIBER REMOVE EXISTING M-93.01 NO. 7 TRAFFIC SIGNAL BOX CONNECT EXISTING NORTH SOUTH TRAFFIC SIGNAL CONDUIT TO NEW ITD CONDUIT. REMOVE EXISTING M-93.01 NO. 7 TRAFFIC SIGNAL BOX CONNECT EXISTING NORTH SOUTH TRAFFIC SIGNAL CONDUIT TO NEW ITD CONDUIT. PULL NEW ITD FIBER (NOT CITY SUPPLIED) THROUGH EXISTING TRAFFIC SIGNAL CONDUIT NEW (2) 3" ITD CONDUIT WITH ITD FIBER NEW M-93.01 NO. 7 TRAFFIC SIGNAL BOX ABANDONED (2) 3" TRAFFIC SIGNAL NEW (2) 3" TRAFFIC SIGNAL CONDUIT NEW M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING (2) 3" TRAFFIC SIGNAL CONDUIT ABANDONED (2) 3" TRAFFIC SIGNAL PULL NEW ITD FIBER (NOT CITY SUPPLIED) FROM MEDIAN SOUTH OF POINT TWENTY TWO ON ELLSWORTH THROUGH EXISTING ITS CONDUIT PULL CITY PROVIDED 144 STRAND FIBER THROUGH EXISTING ITS CONDUIT FROM ELLSWORTH TO NEW ITS BOX NEW M-66.07.1 NO. 9 ITS BOX (SEE TRAFFIC SIGNAL PLANS) NEW METER & CONTROLLER (SEE TRAFFIC SIGNAL PLANS) NEW CONNECTION FROM ITS CONDUIT TO TRAFFIC SIGNAL (SEE TRAFFIC SIGNAL PLANS) EXISTING ITS FIBER 90'S NORTH TO THE MEDIAN DIRECTLY EAST OF PASTEUR SB SA T (2) 2" C. DSTRUCK CHARGE CONTRACTOR SHALL BE RESPONSIBLE FOR FIELD VERIFICATION OF ALL CONDUIT LOCATIONS, SIZES, PULLBOX LOCATIONS AND SIZES, AND CABLE/CONDUIT ENTRANCES AND EXITS. THE ELECTRICAL CONTRACTOR SHALL BE RESPONSIBLE FOR CONTACTING THE RESPECTIVE UTILITY COMPANY REPRESENTATIVES WITHIN (2) WEEKS OF AWARD OF CONTRACT AND FURNISH EACH REPRESENTATIVE (2) COMPLETE SETS OF CONSTRUCTION DOCUMENTS. VERIFY ALL TRENCH ROUTING, SERVICE LOCATIONS, ETC. WITH UTILITY COMPANY DESIGN CONSTRUCTION DRAWINGS AND SPECIFICATIONS PRIOR TO COMMENCING REQUIRED WORK. ALL UNDERGROUND NON-METALLIC CONDUITS SHALL BE PROVIDED WITH A #18 CU. TRACER WIRE SECURELY ATTACHED TO THE NON-METALLIC CONDUIT AT 8' O.C. IT SHALL HAVE 12" OF TRACER WIRE ACCESSIBLE ABOVE GRADE AT ANY ABOVE GRADE TERMINATION. ARIZONA STATE STATUTE REFERENCES 40-360.22,M.

SCALE: 1" = 20'-0" HDA A RCHITECTS, LLC. JJJ 4 ADDENDUM 4 7-17-2020 COORDINATION 9-23-2020 COORDINATION 11-02-2020 TRUCK CHARGER 06-14-2021 BACKFILL REQUIREMENTS RFI 163 RFI 148 RFI 138-R1 RFI 138 ETAI E402 A112 &19 Fuel Sta. Shut Off Location RFI 57 WestWall RFI 57 RFI 57 RFI 58 RFI 58-R1 7'-0"from FOC CD-20

UNDERGROUND CONDUITS

1 LOCATION, BELOW GRADE AND CLASS 1, DIVISIONS 2 LOCATION UP TO 18" A.F.G. WITHIN 20' HORIZONTALLY OF ANY EDGE OF ENCLOSURE.

14.1" PVC COATED RGS WITH THREADED COUPLINGS FROM LEAK DETECTOR TO CONTROL AND MONITOR LOCATIONS IN TELE/ELEC ROOM. VERIFY EXACT LOCATION.

15.(3)-1-1/2" EMPTY CONDUIT STUBS WITH PULL CORD FROM ELECTRICAL ROOM INTO EDGE OF FUEL DISPENSING AREA, PROVIDE SEAL AND CAPS FOR FUTURE.

16.PROVIDE EMERGENCY SHUT-OFF SWITCH AND RESET BUTTON, RED MUSHROOM TYPE, WITH SIGN "EMERGENCY FUEL SHUT-OFF". LOCATE SWITCH ON WALL AT 42" A.F.G. WITHIN 75' OF FUEL DISPENSER. VERIFY LOCATION WITH FIRE MARSHAL PRIOR TO ROUGH-IN. SWITCH TO SHUNT TRIP ALL FUEL SYSTEM

1. PROVIDE 4" HIGH CONCRETE PAD FOR EXTERIOR MOUNTED SERVICE ENTRANCE SECTION. PAD SHALL EXTEND 3' BEYOND THE LEADING EDGE OF THE NEW SES, AND EXTEND 6" ON EACH SIDE OF THE SES. 2.NEW UTILITY PAD-MOUNT TRANSFORMER COORDINATE EXACT LOCATION WITH SALT RIVER PROJECT. CONTRACTOR SHALL PROVIDE TRANSFORMER PAD AND GROUNDING PER SALT RIVER PROJECT INSTALLATION STANDARDS. 3.(3)-4"C WITH PULLSTRING FOR SECONDARY CABLES (CABLES FURNISHED AND INSTALLED BY SALT RIVER PROJECT). MINIMUM BURIAL DEPTH SHALL BE 36" BELOW FINISHED GRADE. 4.WEATHERPROOF JUNCTION BOX FOR CONNECTION OF GENERATOR BLOCK HEATER AND BATTERY CHARGER. VERIFY EXACT LOCATION AND REQUIREMENTS WITH GENERATOR SUPPLIER PRIOR TO ROUGH-IN. SEE ONE-LINE DIAGRAM FOR CIRCUIT DESIGNATION. 5.NEW DIESEL POWERED EMERGENCY GENERATOR. PROVIDE CONCRETE HOUSEKEEPING PAD PER MANUFACTURER'S REQUIREMENTS. SEE ONE-LINE DIAGRAM FOR ADDITIONAL INFORMATION. 6.ROUTE THRU LIGHTING CONTACTOR MOUNTED ADJACENT TO PANEL. CONTACTOR SHALL BE PHOTOCELL ON TIMECLOCK OFF. PROVIDE WITH MANUAL OVERRIDE H-O-A SWITCH. 7.UTILIZE #10CU. CONDUCTORS THROUGHOUT THE ENTIRE LENGTH OF THE CIRCUIT. 8.NOT USED. 9.(3)-3"C WITH PULLSTRING FOR PRIMARY CABLES (CABLES FURNISHED AND INSTALLED BY SALT RIVER PROJECT). MINIMUM BURIAL DEPTH SHALL BE 48" BELOW FINISHED GRADE. 10.NOT USED. 11.WP JUNCTION BOX FOR IRRIGATION CONTROLLER MOUNTED 24" ABOVE FINISH GRADE. COORDINATE WITH LANDSCAPE ARCHITECT FOR EXACT LOCATION AND REQUIREMENTS. 12.WEATHERPROOF JUNCTION BOX FOR COMPLETE CONNECTION OF ABOVE GROUND DIESEL FUEL TANK AND DISPENSER. VERIFY LOCATION AND REQUIREMENTS PRIOR TO ROUGH-IN. 13.CLASS 1, DIVISION

POWER CIRCUITS. 17.ABOVE GROUND DIESEL FUEL TANK WITH DISPENSER. ELECTRICAL CONTRACTOR SHALL CONNECT ALL FUEL SYSTEM CONTROLS AND MONITOR AS DIRECTED BY FUEL SYSTEM SUPPLIER/INSTALLER. VERIFY PRIOR TO ROUGH-IN. 18.STUB UP AND CAP (2) 2" CONDUITS AND (1) 1" CONDUIT WITH PULL STRING TO DATA CLOSET ROOM FOR VOICED/DATA CABLES. 19.PROVIDE IN-GRADE JUNCTION BOX FOR CONNECTION TO EXTERIOR GATE. COORDINATE CONNECTION REQUIREMENTS WITH GATE MANUFACTURER. PROVIDE 3/4" CONDUIT TO MANUAL OVERRIDE SWITCH LOCATED IN KITCHEN. PROVIDE #8 WIRING TO PANEL INDICATED. 20.NOT USED 21.NOT USED 22.(2)-4" SCHEDULE 40 CONDUIT AND (1)-1" SCHEDULE 40 WITH TRACER WIRE TO FROM IT VAULT TO MDF FOR FUTURE. REFERENCE DETAILS ON SHEET E402. 23.PROVIDE IN-GRADE JUNCTION BOX FOR CONNECTION TO PROXIMITY CARD READER AND BEACON. COORDINATE CONNECTION REQUIREMENTS WITH MANUFACTURER. REFER TO DETAIL 18 & 19 ON SHEET A112. PROVIDE 1" CONDUIT TO TO GATE CONTROLLER. 24.4'x4' IT VAULT. VAULT TO BE FIBER OPTIC MANHOLE PER CITY OF MESA STANDARDS DETAIL M-66.01.1. COORDINATE EXACT LOCATION. 25.CONDUIT AND FIBER AT THIS LOCATION. 26.CONDUIT ONLY AT THIS LOCATION. 27.DIRECTIONAL BORE UNDER EXISTING STREET FOR INSTALLATION OF NEW UNDERGROUND CONDUITS. CONDUIT SHALL BE INSTALLED 5' BELOW GRADE UNDER STREET. UNDERGROUND CONDUIT SHALL BE RIGID STEEL CONDUIT OR HDPE AND UL LISTED FOR USE WITH DIRECTIONAL BORING EQUIPMENT. STEEL CONDUIT IN DIRECT CONTACT WITH THE EARTH SHALL RECEIVE PROTECTIVE COVERING THAT IS MECHANICALLY APPLIED IN A FACTORY OR FIELD APPLIED USING 3M SCOTCHWRAP 50, 10 MILS THICK USED IN CONJUNCTION WITH 3M SCOTCHWRAP PRIMER APPLIED AS PER MANUFACTURER'S INSTRUCTIONS.. KEYED NOTES: 13 14 12 15 16 17 18 'LP3'-30 7 SA2 'LP2'-5 COVERED PATIO UTILITY TRANSFORMER 3 4 GEN. 5 DIESEL GENERATOR 800A ATS 'LP2'-7 SH 7 22 22 800A 120/208V SES 'LP1'-1 6 'LP3'-2,4 6 7 SA SB SB SB SB 'LP1'-3 'LP7'-32,34 19 19 11 'LP6'-42 9 J J 23 23 2 24 NEW M-66.07.1 NO. ITD/ITS BOX 25 26 5 NEW M-66.01.1 ITD VAULT. EXACT LOCATION OF BOX TO BE DETERMINED BY HDA/ENGINEER DUE TO PROXIMITY TO SEWER STUB LOCATION. NEW (2) 3" ITD CONDUIT WITH ITD FIBER REMOVE EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX CONNECT EXISTING NORTH SOUTH TRAFFIC SIGNAL CONDUIT TO NEW ITD CONDUIT. REMOVE EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX CONNECT EXISTING NORTH SOUTH TRAFFIC SIGNAL CONDUIT TO NEW ITD CONDUIT. PULL NEW ITD FIBER (NOT CITY SUPPLIED) THROUGH EXISTING TRAFFIC SIGNAL CONDUIT NEW (2) 3" ITD CONDUIT WITH ITD FIBER NEW M-93.01 NO. TRAFFIC SIGNAL BOX ABANDONED (2) 3" TRAFFIC SIGNAL NEW (2) 3" TRAFFIC SIGNAL CONDUIT NEW M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX EXISTING (2) 3" TRAFFIC SIGNAL CONDUIT ABANDONED (2) 3" TRAFFIC SIGNAL PULL NEW ITD FIBER (NOT CITY SUPPLIED) FROM MEDIAN SOUTH OF POINT TWENTY TWO ON ELLSWORTH THROUGH EXISTING ITS CONDUIT PULL CITY PROVIDED 144 STRAND FIBER THROUGH EXISTING ITS CONDUIT FROM ELLSWORTH TO NEW ITS BOX NEW M-66.07.1 NO. ITS BOX (SEE TRAFFIC SIGNAL PLANS) NEW METER & CONTROLLER (SEE TRAFFIC SIGNAL PLANS) NEW CONNECTION FROM ITS CONDUIT TO TRAFFIC SIGNAL (SEE TRAFFIC SIGNAL PLANS) EXISTING ITS FIBER 90'S NORTH TO THE MEDIAN DIRECTLY EAST OF PASTEUR 6 SB SA T (2) 2" C. DSTRUCK CHARGE 8 CONTRACTOR SHALL BE RESPONSIBLE FOR FIELD VERIFICATION OF ALL CONDUIT LOCATIONS, SIZES, PULLBOX LOCATIONS AND SIZES, AND CABLE/CONDUIT ENTRANCES AND EXITS. THE ELECTRICAL CONTRACTOR SHALL BE RESPONSIBLE FOR CONTACTING THE RESPECTIVE UTILITY COMPANY REPRESENTATIVES WITHIN (2) WEEKS OF AWARD OF CONTRACT AND FURNISH EACH REPRESENTATIVE (2) COMPLETE SETS OF CONSTRUCTION DOCUMENTS. VERIFY ALL TRENCH ROUTING, SERVICE LOCATIONS, ETC. WITH UTILITY COMPANY DESIGN CONSTRUCTION DRAWINGS AND SPECIFICATIONS PRIOR TO COMMENCING REQUIRED WORK. ALL UNDERGROUND NON-METALLIC CONDUITS SHALL BE PROVIDED WITH A #18 CU. TRACER WIRE SECURELY ATTACHED TO THE NON-METALLIC CONDUIT AT 8' O.C. IT SHALL HAVE 12" OF TRACER WIRE ACCESSIBLE ABOVE GRADE AT ANY ABOVE GRADE TERMINATION. ARIZONA STATE STATUTE REFERENCES 40-360.22,M. UNDERGROUND CONDUITS SCALE: 1" = 20'-0" HDA A RCHITECTS, LLC. JJJ 4 ADDENDUM 4 7-17-2020 COORDINATION 9-23-2020 COORDINATION 11-02-2020 TRUCK CHARGER 06-14-2021 CD-20 Low Voltage Control and Communication Jbox For Fuel Island Keyed Notes 14,15,18 Gate Control Conduit 1” PVC to IDF Room Gate Control Conduit 1” PVC to IDF Room Card Reader 1” to Open Ceiling in Crew Office 2-4” and 1 1” in each trench for Fiber

1 LOCATION, BELOW GRADE AND CLASS 1, DIVISIONS 2 LOCATION UP TO 18" A.F.G. WITHIN 20' HORIZONTALLY OF ANY EDGE OF ENCLOSURE.

14.1" PVC COATED RGS WITH THREADED COUPLINGS FROM LEAK DETECTOR TO CONTROL AND MONITOR LOCATIONS IN TELE/ELEC ROOM. VERIFY EXACT LOCATION.

15.(3)-1-1/2" EMPTY CONDUIT STUBS WITH PULL CORD FROM ELECTRICAL ROOM INTO EDGE OF FUEL DISPENSING AREA, PROVIDE SEAL AND CAPS FOR FUTURE.

16.PROVIDE EMERGENCY SHUT-OFF SWITCH AND RESET BUTTON, RED MUSHROOM TYPE, WITH SIGN "EMERGENCY FUEL SHUT-OFF". LOCATE SWITCH ON WALL AT 42" A.F.G. WITHIN 75' OF FUEL DISPENSER. VERIFY LOCATION WITH FIRE MARSHAL PRIOR TO ROUGH-IN. SWITCH TO SHUNT TRIP ALL FUEL SYSTEM

1. PROVIDE 4" HIGH CONCRETE PAD FOR EXTERIOR MOUNTED SERVICE ENTRANCE SECTION. PAD SHALL EXTEND 3' BEYOND THE LEADING EDGE OF THE NEW SES, AND EXTEND 6" ON EACH SIDE OF THE SES. 2.NEW UTILITY PAD-MOUNT TRANSFORMER COORDINATE EXACT LOCATION WITH SALT RIVER PROJECT. CONTRACTOR SHALL PROVIDE TRANSFORMER PAD AND GROUNDING PER SALT RIVER PROJECT INSTALLATION STANDARDS. 3.(3)-4"C WITH PULLSTRING FOR SECONDARY CABLES (CABLES FURNISHED AND INSTALLED BY SALT RIVER PROJECT). MINIMUM BURIAL DEPTH SHALL BE 36" BELOW FINISHED GRADE. 4.WEATHERPROOF JUNCTION BOX FOR CONNECTION OF GENERATOR BLOCK HEATER AND BATTERY CHARGER. VERIFY EXACT LOCATION AND REQUIREMENTS WITH GENERATOR SUPPLIER PRIOR TO ROUGH-IN. SEE ONE-LINE DIAGRAM FOR CIRCUIT DESIGNATION. 5.NEW DIESEL POWERED EMERGENCY GENERATOR. PROVIDE CONCRETE HOUSEKEEPING PAD PER MANUFACTURER'S REQUIREMENTS. SEE ONE-LINE DIAGRAM FOR ADDITIONAL INFORMATION. 6.ROUTE THRU LIGHTING CONTACTOR MOUNTED ADJACENT TO PANEL. CONTACTOR SHALL BE PHOTOCELL ON TIMECLOCK OFF. PROVIDE WITH MANUAL OVERRIDE H-O-A SWITCH. 7.UTILIZE #10CU. CONDUCTORS THROUGHOUT THE ENTIRE LENGTH OF THE CIRCUIT. 8.NOT USED. 9.(3)-3"C WITH PULLSTRING FOR PRIMARY CABLES (CABLES FURNISHED AND INSTALLED BY SALT RIVER PROJECT). MINIMUM BURIAL DEPTH SHALL BE 48" BELOW FINISHED GRADE. 10.NOT USED. 11.WP JUNCTION BOX FOR IRRIGATION CONTROLLER MOUNTED 24" ABOVE FINISH GRADE. COORDINATE WITH LANDSCAPE ARCHITECT FOR EXACT LOCATION AND REQUIREMENTS. 12.WEATHERPROOF JUNCTION BOX FOR COMPLETE CONNECTION OF ABOVE GROUND DIESEL FUEL TANK AND DISPENSER. VERIFY LOCATION AND REQUIREMENTS PRIOR TO ROUGH-IN. 13.CLASS 1, DIVISION

POWER CIRCUITS. 17.ABOVE GROUND DIESEL FUEL TANK WITH DISPENSER. ELECTRICAL CONTRACTOR SHALL CONNECT ALL FUEL SYSTEM CONTROLS AND MONITOR AS DIRECTED BY FUEL SYSTEM SUPPLIER/INSTALLER. VERIFY PRIOR TO ROUGH-IN. 18.STUB UP AND CAP (2) 2" CONDUITS AND (1) 1" CONDUIT WITH PULL STRING TO DATA CLOSET ROOM FOR VOICED/DATA CABLES. 19.PROVIDE IN-GRADE JUNCTION BOX FOR CONNECTION TO EXTERIOR GATE. COORDINATE CONNECTION REQUIREMENTS WITH GATE MANUFACTURER. PROVIDE 3/4" CONDUIT TO MANUAL OVERRIDE SWITCH LOCATED IN KITCHEN. PROVIDE #8 WIRING TO PANEL INDICATED. 20.NOT USED 21.NOT USED 22.(2)-4" SCHEDULE 40 CONDUIT AND (1)-1" SCHEDULE 40 WITH TRACER WIRE TO FROM IT VAULT TO MDF FOR FUTURE. REFERENCE DETAILS ON SHEET E402. 23.PROVIDE IN-GRADE JUNCTION BOX FOR CONNECTION TO PROXIMITY CARD READER AND BEACON. COORDINATE CONNECTION REQUIREMENTS WITH MANUFACTURER. REFER TO DETAIL 18 & 19 ON SHEET A112. PROVIDE 1" CONDUIT TO TO GATE CONTROLLER. 24.4'x4' IT VAULT. VAULT TO BE FIBER OPTIC MANHOLE PER CITY OF MESA STANDARDS DETAIL M-66.01.1. COORDINATE EXACT LOCATION. 25.CONDUIT AND FIBER AT THIS LOCATION. 26.CONDUIT ONLY AT THIS LOCATION. 27.DIRECTIONAL BORE UNDER EXISTING STREET FOR INSTALLATION OF NEW UNDERGROUND CONDUITS. CONDUIT SHALL BE INSTALLED 5' BELOW GRADE UNDER STREET. UNDERGROUND CONDUIT SHALL BE RIGID STEEL CONDUIT OR HDPE AND UL LISTED FOR USE WITH DIRECTIONAL BORING EQUIPMENT. STEEL CONDUIT IN DIRECT CONTACT WITH THE EARTH SHALL RECEIVE PROTECTIVE COVERING THAT IS MECHANICALLY APPLIED IN A FACTORY OR FIELD APPLIED USING 3M SCOTCHWRAP 50, 10 MILS THICK USED IN CONJUNCTION WITH 3M SCOTCHWRAP PRIMER APPLIED AS PER MANUFACTURER'S INSTRUCTIONS.. KEYED NOTES: 13 14 12 15 16 17 18 'LP3'-30 7 SA2 'LP2'-5 COVERED PATIO UTILITY TRANSFORMER 3 4 GEN. 5 DIESEL GENERATOR 800A ATS 'LP2'-7 SH 7 22 22 800A 120/208V SES 'LP1'-1 6 'LP3'-2,4 6 7 SA SB SB SB SB 'LP1'-3 'LP7'-32,34 19 19 11 'LP6'-42 9 J J 23 23 2 24 NEW M-66.07.1 NO. ITD/ITS BOX 25 26 5 NEW M-66.01.1 ITD VAULT. EXACT LOCATION OF BOX TO BE DETERMINED BY HDA/ENGINEER DUE TO PROXIMITY TO SEWER STUB LOCATION. NEW (2) 3" ITD CONDUIT WITH ITD FIBER REMOVE EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX CONNECT EXISTING NORTH SOUTH TRAFFIC SIGNAL CONDUIT TO NEW ITD CONDUIT. REMOVE EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX CONNECT EXISTING NORTH SOUTH TRAFFIC SIGNAL CONDUIT TO NEW ITD CONDUIT. PULL NEW ITD FIBER (NOT CITY SUPPLIED) THROUGH EXISTING TRAFFIC SIGNAL CONDUIT NEW (2) 3" ITD CONDUIT WITH ITD FIBER NEW M-93.01 NO. TRAFFIC SIGNAL BOX ABANDONED (2) 3" TRAFFIC SIGNAL NEW (2) 3" TRAFFIC SIGNAL CONDUIT NEW M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX EXISTING (2) 3" TRAFFIC SIGNAL CONDUIT ABANDONED (2) 3" TRAFFIC SIGNAL PULL NEW ITD FIBER (NOT CITY SUPPLIED) FROM MEDIAN SOUTH OF POINT TWENTY TWO ON ELLSWORTH THROUGH EXISTING ITS CONDUIT PULL CITY PROVIDED 144 STRAND FIBER THROUGH EXISTING ITS CONDUIT FROM ELLSWORTH TO NEW ITS BOX NEW M-66.07.1 NO. ITS BOX (SEE TRAFFIC SIGNAL PLANS) NEW METER & CONTROLLER (SEE TRAFFIC SIGNAL PLANS) NEW CONNECTION FROM ITS CONDUIT TO TRAFFIC SIGNAL (SEE TRAFFIC SIGNAL PLANS) EXISTING ITS FIBER 90'S NORTH TO THE MEDIAN DIRECTLY EAST OF PASTEUR 6 SB SA T (2) 2" C. DSTRUCK CHARGE 8 CONTRACTOR SHALL BE RESPONSIBLE FOR FIELD VERIFICATION OF ALL CONDUIT LOCATIONS, SIZES, PULLBOX LOCATIONS AND SIZES, AND CABLE/CONDUIT ENTRANCES AND EXITS. THE ELECTRICAL CONTRACTOR SHALL BE RESPONSIBLE FOR CONTACTING THE RESPECTIVE UTILITY COMPANY REPRESENTATIVES WITHIN (2) WEEKS OF AWARD OF CONTRACT AND FURNISH EACH REPRESENTATIVE (2) COMPLETE SETS OF CONSTRUCTION DOCUMENTS. VERIFY ALL TRENCH ROUTING, SERVICE LOCATIONS, ETC. WITH UTILITY COMPANY DESIGN CONSTRUCTION DRAWINGS AND SPECIFICATIONS PRIOR TO COMMENCING REQUIRED WORK. ALL UNDERGROUND NON-METALLIC CONDUITS SHALL BE PROVIDED WITH A #18 CU. TRACER WIRE SECURELY ATTACHED TO THE NON-METALLIC CONDUIT AT 8' O.C. IT SHALL HAVE 12" OF TRACER WIRE ACCESSIBLE ABOVE GRADE AT ANY ABOVE GRADE TERMINATION. ARIZONA STATE STATUTE REFERENCES 40-360.22,M. UNDERGROUND CONDUITS SCALE: 1" = 20'-0" HDA A RCHITECTS, LLC. JJJ 4 ADDENDUM 4 7-17-2020 COORDINATION 9-23-2020 COORDINATION 11-02-2020 TRUCK CHARGER 06-14-2021 CD-20 LP1-3 LP1-3 LP1-3 LP1-3 LP1-5 LP1-5 LP1-1 Fuel Island Circuits: Panel LP3 Circuits 12-14 Unleaded Fuel Pump Circuits 26,28 Diesel Fuel Pump Circuit 38: Fuel Island Controls Circuit 40 Fuel Island Monitoring Equipmen 6 36 Added Gate Motor Circuits LP7-32,34,36

1 LOCATION, BELOW GRADE AND CLASS 1, DIVISIONS 2 LOCATION UP TO 18" A.F.G. WITHIN 20' HORIZONTALLY OF ANY EDGE OF ENCLOSURE.

14.1" PVC COATED RGS WITH THREADED COUPLINGS FROM LEAK DETECTOR TO CONTROL AND MONITOR LOCATIONS IN TELE/ELEC ROOM. VERIFY EXACT LOCATION.

15.(3)-1-1/2" EMPTY CONDUIT STUBS WITH PULL CORD FROM ELECTRICAL ROOM INTO EDGE OF FUEL DISPENSING AREA, PROVIDE SEAL AND CAPS FOR FUTURE.

16.PROVIDE EMERGENCY SHUT-OFF SWITCH AND RESET BUTTON, RED MUSHROOM TYPE, WITH SIGN "EMERGENCY FUEL SHUT-OFF". LOCATE SWITCH ON WALL AT 42" A.F.G. WITHIN 75' OF FUEL DISPENSER. VERIFY LOCATION WITH FIRE MARSHAL PRIOR TO ROUGH-IN. SWITCH TO SHUNT TRIP ALL FUEL SYSTEM

1. PROVIDE 4" HIGH CONCRETE PAD FOR EXTERIOR MOUNTED SERVICE ENTRANCE SECTION. PAD SHALL EXTEND 3' BEYOND THE LEADING EDGE OF THE NEW SES, AND EXTEND 6" ON EACH SIDE OF THE SES. 2.NEW UTILITY PAD-MOUNT TRANSFORMER COORDINATE EXACT LOCATION WITH SALT RIVER PROJECT. CONTRACTOR SHALL PROVIDE TRANSFORMER PAD AND GROUNDING PER SALT RIVER PROJECT INSTALLATION STANDARDS. 3.(3)-4"C WITH PULLSTRING FOR SECONDARY CABLES (CABLES FURNISHED AND INSTALLED BY SALT RIVER PROJECT). MINIMUM BURIAL DEPTH SHALL BE 36" BELOW FINISHED GRADE. 4.WEATHERPROOF JUNCTION BOX FOR CONNECTION OF GENERATOR BLOCK HEATER AND BATTERY CHARGER. VERIFY EXACT LOCATION AND REQUIREMENTS WITH GENERATOR SUPPLIER PRIOR TO ROUGH-IN. SEE ONE-LINE DIAGRAM FOR CIRCUIT DESIGNATION. 5.NEW DIESEL POWERED EMERGENCY GENERATOR. PROVIDE CONCRETE HOUSEKEEPING PAD PER MANUFACTURER'S REQUIREMENTS. SEE ONE-LINE DIAGRAM FOR ADDITIONAL INFORMATION. 6.ROUTE THRU LIGHTING CONTACTOR MOUNTED ADJACENT TO PANEL. CONTACTOR SHALL BE PHOTOCELL ON TIMECLOCK OFF. PROVIDE WITH MANUAL OVERRIDE H-O-A SWITCH. 7.UTILIZE #10CU. CONDUCTORS THROUGHOUT THE ENTIRE LENGTH OF THE CIRCUIT. 8.NOT USED. 9.(3)-3"C WITH PULLSTRING FOR PRIMARY CABLES (CABLES FURNISHED AND INSTALLED BY SALT RIVER PROJECT). MINIMUM BURIAL DEPTH SHALL BE 48" BELOW FINISHED GRADE. 10.NOT USED. 11.WP JUNCTION BOX FOR IRRIGATION CONTROLLER MOUNTED 24" ABOVE FINISH GRADE. COORDINATE WITH LANDSCAPE ARCHITECT FOR EXACT LOCATION AND REQUIREMENTS. 12.WEATHERPROOF JUNCTION BOX FOR COMPLETE CONNECTION OF ABOVE GROUND DIESEL FUEL TANK AND DISPENSER. VERIFY LOCATION AND REQUIREMENTS PRIOR TO ROUGH-IN. 13.CLASS 1, DIVISION

POWER CIRCUITS. 17.ABOVE GROUND DIESEL FUEL TANK WITH DISPENSER. ELECTRICAL CONTRACTOR SHALL CONNECT ALL FUEL SYSTEM CONTROLS AND MONITOR AS DIRECTED BY FUEL SYSTEM SUPPLIER/INSTALLER. VERIFY PRIOR TO ROUGH-IN. 18.STUB UP AND CAP (2) 2" CONDUITS AND (1) 1" CONDUIT WITH PULL STRING TO DATA CLOSET ROOM FOR VOICED/DATA CABLES. 19.PROVIDE IN-GRADE JUNCTION BOX FOR CONNECTION TO EXTERIOR GATE. COORDINATE CONNECTION REQUIREMENTS WITH GATE MANUFACTURER. PROVIDE 3/4" CONDUIT TO MANUAL OVERRIDE SWITCH LOCATED IN KITCHEN. PROVIDE #8 WIRING TO PANEL INDICATED. 20.NOT USED 21.NOT USED 22.(2)-4" SCHEDULE 40 CONDUIT AND (1)-1" SCHEDULE 40 WITH TRACER WIRE TO FROM IT VAULT TO MDF FOR FUTURE. REFERENCE DETAILS ON SHEET E402. 23.PROVIDE IN-GRADE JUNCTION BOX FOR CONNECTION TO PROXIMITY CARD READER AND BEACON. COORDINATE CONNECTION REQUIREMENTS WITH MANUFACTURER. REFER TO DETAIL 18 & 19 ON SHEET A112. PROVIDE 1" CONDUIT TO TO GATE CONTROLLER. 24.4'x4' IT VAULT. VAULT TO BE FIBER OPTIC MANHOLE PER CITY OF MESA STANDARDS DETAIL M-66.01.1. COORDINATE EXACT LOCATION. 25.CONDUIT AND FIBER AT THIS LOCATION. 26.CONDUIT ONLY AT THIS LOCATION. 27.DIRECTIONAL BORE UNDER EXISTING STREET FOR INSTALLATION OF NEW UNDERGROUND CONDUITS. CONDUIT SHALL BE INSTALLED 5' BELOW GRADE UNDER STREET. UNDERGROUND CONDUIT SHALL BE RIGID STEEL CONDUIT OR HDPE AND UL LISTED FOR USE WITH DIRECTIONAL BORING EQUIPMENT. STEEL CONDUIT IN DIRECT CONTACT WITH THE EARTH SHALL RECEIVE PROTECTIVE COVERING THAT IS MECHANICALLY APPLIED IN A FACTORY OR FIELD APPLIED USING 3M SCOTCHWRAP 50, 10 MILS THICK USED IN CONJUNCTION WITH 3M SCOTCHWRAP PRIMER APPLIED AS PER MANUFACTURER'S INSTRUCTIONS.. KEYED NOTES: 13 14 12 15 16 17 18 'LP3'-30 7 SA2 'LP2'-5 COVERED PATIO UTILITY TRANSFORMER 3 4 GEN. 5 DIESEL GENERATOR 800A ATS 'LP2'-7 SH 7 22 22 800A 120/208V SES 'LP1'-1 6 'LP3'-2,4 6 7 SA SB SB SB SB 'LP1'-3 'LP7'-32,34 19 19 11 'LP6'-42 9 J J 23 23 2 24 NEW M-66.07.1 NO. ITD/ITS BOX 25 26 5 NEW M-66.01.1 ITD VAULT. EXACT LOCATION OF BOX TO BE DETERMINED BY HDA/ENGINEER DUE TO PROXIMITY TO SEWER STUB LOCATION. NEW (2) 3" ITD CONDUIT WITH ITD FIBER REMOVE EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX CONNECT EXISTING NORTH SOUTH TRAFFIC SIGNAL CONDUIT TO NEW ITD CONDUIT. REMOVE EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX CONNECT EXISTING NORTH SOUTH TRAFFIC SIGNAL CONDUIT TO NEW ITD CONDUIT. PULL NEW ITD FIBER (NOT CITY SUPPLIED) THROUGH EXISTING TRAFFIC SIGNAL CONDUIT NEW (2) 3" ITD CONDUIT WITH ITD FIBER NEW M-93.01 NO. TRAFFIC SIGNAL BOX ABANDONED (2) 3" TRAFFIC SIGNAL NEW (2) 3" TRAFFIC SIGNAL CONDUIT NEW M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING M-93.01 NO. 7 TRAFFIC SIGNAL BOX EXISTING M-93.01 NO. TRAFFIC SIGNAL BOX EXISTING (2) 3" TRAFFIC SIGNAL CONDUIT ABANDONED (2) 3" TRAFFIC SIGNAL PULL NEW ITD FIBER (NOT CITY SUPPLIED) FROM MEDIAN SOUTH OF POINT TWENTY TWO ON ELLSWORTH THROUGH EXISTING ITS CONDUIT PULL CITY PROVIDED 144 STRAND FIBER THROUGH EXISTING ITS CONDUIT FROM ELLSWORTH TO NEW ITS BOX NEW M-66.07.1 NO. ITS BOX (SEE TRAFFIC SIGNAL PLANS) NEW METER & CONTROLLER (SEE TRAFFIC SIGNAL PLANS) NEW CONNECTION FROM ITS CONDUIT TO TRAFFIC SIGNAL (SEE TRAFFIC SIGNAL PLANS) EXISTING ITS FIBER 90'S NORTH TO THE MEDIAN DIRECTLY EAST OF PASTEUR 6 SB SA T (2) 2" C. DSTRUCK CHARGE 8 CONTRACTOR SHALL BE RESPONSIBLE FOR FIELD VERIFICATION OF ALL CONDUIT LOCATIONS, SIZES, PULLBOX LOCATIONS AND SIZES, AND CABLE/CONDUIT ENTRANCES AND EXITS. THE ELECTRICAL CONTRACTOR SHALL BE RESPONSIBLE FOR CONTACTING THE RESPECTIVE UTILITY COMPANY REPRESENTATIVES WITHIN (2) WEEKS OF AWARD OF CONTRACT AND FURNISH EACH REPRESENTATIVE (2) COMPLETE SETS OF CONSTRUCTION DOCUMENTS. VERIFY ALL TRENCH ROUTING, SERVICE LOCATIONS, ETC. WITH UTILITY COMPANY DESIGN CONSTRUCTION DRAWINGS AND SPECIFICATIONS PRIOR TO COMMENCING REQUIRED WORK. ALL UNDERGROUND NON-METALLIC CONDUITS SHALL BE PROVIDED WITH A #18 CU. TRACER WIRE SECURELY ATTACHED TO THE NON-METALLIC CONDUIT AT 8' O.C. IT SHALL HAVE 12" OF TRACER WIRE ACCESSIBLE ABOVE GRADE AT ANY ABOVE GRADE TERMINATION. ARIZONA STATE STATUTE REFERENCES 40-360.22,M. UNDERGROUND CONDUITS SCALE: 1" = 20'-0" HDA A RCHITECTS, LLC. JJJ 4 ADDENDUM 4 7-17-2020 COORDINATION 9-23-2020 COORDINATION 11-02-2020 TRUCK CHARGER 06-14-2021 CD-20 EV Charger - 2-2” PVC Conduits 6’ off East App Bay Wa 1-2” PVC Conduit 2-2” PVC Conduits to SES

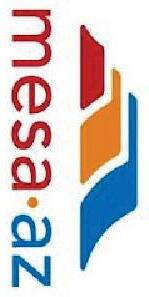

CD-02

C CC C C SD SD SD C F F F FE F FE F F F F F FE F F FE F FE F F F F F D D 'LP3'-3 OS RP P F D D 7 7 7 7 7 7 7 7 7 2 2 2 2 3 4 10 5 TYP. KKK K KK K K K SF 5 TYP 'LP1'-33 P LP133 3 'LP2'-15 LP 5 15 LP2 7 8 7 FE LTG CKT 'LP3'-3 P3 LTG CKT 'LP3'-1 3 'LP3'-1 LP3'1 L 2 A P3'-11 11 9 2 F J F E AE M A F M M M J 13 13 3 13 1 13 3 13 1 13 9 2 4 9 4 4 9 4 9 31 31 3 29 9 29 3 AE E AAA AE AE AE AE A A A A AE G H H A A C C C C A 'LP3'-9 P OS S RP OS O RP R 'LP3'-13 35 5 LD 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 'ELP1'-7 'EL -7 7 LP1' P17 7 D D OS 1 1 1 3 3 3 3 3 4 10 10 0 35 3 35 3 FE A OS 7 A A OS 7 A AE A A AE C C C C C C C C C C C C C J OS O RP P LD D LD D LD D 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 2 2 3 3 4 10 0 'LP1'-37 1 7 37 7 37 3 LD L LD D C C C C C C C D D D D 7 7 7 7 SD D SD D H H 5 C C G 5 G H H 5 5 G H H 5 AE A A G G OS A A A A A A A RP OS 'LP7'-15 P 15 15 OS RP P 'LP7'-17 DD D D D 'LP'1-21 P'12 39 39 4 10 A A H 33 3 SF S SF SF SF SF DD D D D D OS OS OS O OS OS S LD LD G AE 13 1 13 OS O OS O OS 9 'LP1'-29 L'LP1'-31 LP9 9 'LP3'-5 3 5 9 NL C 5 5 5 SF CE SFE SF S E SFE E SFE S 9 G E E G G G G OS G OS S 9 K K K K K K 15 15 5 OS 15 15 1 15 15 1 15 SFE E 15 1 15 15 5 15 1 15 15 17 1 17 1 17 17 17 7 17 7 SF 'LP2'-13 'LP2'-15 7 8 7 8 2 2 2 2 2 3 1 15 1 15 5 15 5 E 3 3 15 1 'LP2'-15 2 L - 'LPP2 1 LP 'G G E E E 'LP3'-19 'LP2'-17 3 3 X1 X1 X X1 1 X1 1 X1 X X1 X X1 1 X1 X MOUNT @ 12' A.F.F. F. @12'AF MOUNT @ 12' A.F.F.12'AFF X1 X1 SF F L L 15 15 OS OS S OS OS RP RP RP R RP P LD D LD LD D LD D E 2 2 F F J F M F M M M J 11 1 11 11 1 11 1 11 1 11 1 4 9 4 4 9 4 9 39 39 3 27 7 27 13 1 11 'LP1'-27 L'LP1'-39 LPF 1.FIXTURE TO BE OPERATE AS A NIGHT LIGHT (PER IBC 1006.1) AND AS EMERGENCY LIGHT PER IBC 1006.3 AND 1006.4 RESPECTIVELY. CONTRACTOR SHALL WIRE LAMPS SO THAT THEY ARE UNSWITCHED AND CONSTANTLY ON DURING NORMAL OPERATION (NIGHT LIGHT) AND TURN ON AT A REDUCED LUMEN OUTPUT DURING A POWER LOSS (EMERGENCY POWER). 2.PROVIDE AN UNSWITCHED HOT AT THE FIXTURE. FIXTURE SHALL OPERATE AS AN EMERGENCY LIGHT PER IBC 1006.3 AND 1006.4 RESPECTIVELY. FIXTURE IS WIRED TO GENERATOR. EMERGENCY BATTERY PACK FOR SECONDARY BACKUP ONLY. 3.PROVIDE AN UNSWITCHED HOT TO THE EXIT. FIXTURE SHALL BE INSTALLED AND OPERATE IN ACCORDANCE WITH THE LATEST EDITION OF NFPA-101, SECTION 7.10. 4.PROVIDE OUTLET BOX THAT IS LISTED AND MARKED BY THE MANUFACTURER AS SUITABLE FOR USE WITH CEILING FANS PER NEC 314-27(D). FOR CEILING FANS WEIGHING MORE THAN 35LB., THE REQUIRED MARKING ON THE BOX SHALL INCLUDE THE MAXIMUM WEIGHT TO BE SUPPORTED. 5.REFER TO ARCHITECTURAL DETAILS FOR MOUNTING HEIGHT OF EXTERIOR WALL FIXTURES. 6.PROVIDE AN UNSWITCHED HOT AT THE FIXTURE. FIXTURE SHALL OPERATE AS AN EMERGENCY LIGHT PER IBC 1006.3 AND 1006.4 RESPECTIVELY. 7.ROUTE THRU LIGHTING CONTACTOR MOUNTED ADJACENT TO PANEL. CONTACTOR SHALL BE PHOTOCELL ON TIMECLOCK OFF. PROVIDE WITH MANUAL OVERRIDE H-O-A SWITCH. 8.UTILIZE #10CU. CONDUCTORS THROUGHOUT THE ENTIRE LENGTH OF THE CIRCUIT. 9.CEILING FAN. CASABLANCA 'UTOPIAN' 52" MODEL: 54038 (BUSHED NICKEL) WITH 52" BURNT WALNUT BLADES. DOWNROD LENGTH AS REQUIRED SO FAN BLADES ARE AT +9'-6" A.F.F. PROVIDE WITH U.L. LISTED FAN BOX AND SUPPORTER PER N.E.C. 422-18. 10.CEILING FAN. CASABLANCA 'UTOPIAN' 52" MODEL: 54035 (BUSHED NICKEL) WITH 52" ANTIQUE HALIPAX ALL-WEATHER BLADES. DOWNROD LENGTH AS REQUIRED SO FAN BLADES ARE AT +9'-6" A.F.F. PROVIDE WITH U.L. LISTED FAN BOX AND SUPPORTER PER N.E.C. 422-18.

HDA A RCHITECTS, LLC. Last S aved: 5 -21-2 0 09 :21am Drawing file: T:\Projects\2019\19-101 CITY OF MESA FS 221\Drawings\Electrical\19101-E201 Plot Date: 5-11-21 08:49am Drawing scale: 1:1 By: shyrod JJJ 3 ADDENDUM 3 6-17-2020 4 ADDENDUM 4 7-17-2020 SCALE: 1/8" = 1'-0 SCALE: 1/8 = 1'-0 2 QC ADDENDUMCOMMENTS 5-12-2020 RFI 157 RFI 157 X1 X RFI 157 'LP L RFI 157 C C C C C C C C 5 15 5 15 5 1 15 15 5 15 15 15 AE A OS RP RP P 'LP3'-15 P3 15 15 15 15 4 'LP1'-36 LP 3 1 2 RFI 141 1 RFI 123-R1 RFI 123 F 1 F F 1 F 1 F 29 F 1 F 1 F 1 1 1 F 1 F 1 1 29 1 3 3 3 F 3 RFI 166 RFI 113 3 3 3 F 3 3 3 3 3 F 3 3 3 3 3 E 3 3 3 3 3 F 3 2 Typ. CD-15

KEYED NOTES:

KEYED NOTES: