Lots of people talk about safety. We live it. That’s why we go further to put safety at the heart of what we do. Go Further | Build Smarter

CIVIL AND CONSTRUCTION IRELAND

Email: info@civilandconstruction.ie

Civil and Construction Ireland 2023

Welcome to the latest issue of Civil and Construction magazine. Some of Ire land’s best known construction brands are amongst the founding members of a new industry body, MMC Ireland, established to represent those involved in the planning, design, procurement or delivery of offsite and other modern methods of construction in Ireland.

In response to delivery challenges, the Irish government has committed to enabling a more efficient and sustainable approach to the design, construction and operation of buildings. MMC will play a vital role in helping the State to meet ambitious targets set out under both the National Development Plan and the National Planning Framework, and increasing MMC adoption is critical to the post-pandemic recovery of Ireland’s built environment, economy and communi ties. MMC Ireland is a collaboration of industry talent and experience, working in partnership to gather insights and the team will work closely with stakeholders from the public sector, the private sector and from academia to ensure those insights feed into relevant policymaking. You can read the full article inside.

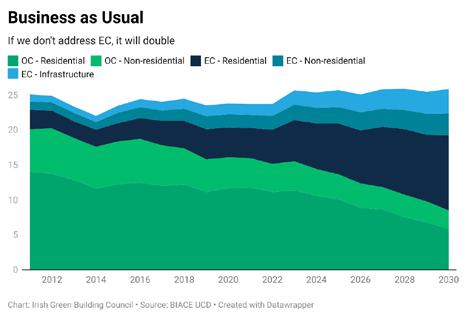

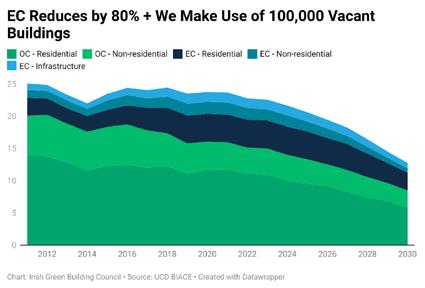

Recently the Irish Green Building Council (IGBC) launched its roadmap to decar bonise Ireland’s built environment across its whole life cycle. Backed by carbon modelling data, commissioned to the Building in a Climate Emergency (BIACE) Research Lab at UCD and developed in close cooperation with industry, “Buil ding a Net Zero Ireland” details a series of actions to accelerate the transfor mation of our built environment. Most of the policy and industry focus to date has been on addressing operational emissions from energy used to heat, cool, and light our buildings. Beyond climate action, the current energy crisis, and the growing number of people at risk of fuel poverty, highlight once again the urgency of improving energy efficiency and increasing the share of renewables. This article looks at how projections to 2030 show that the NZEB standard, the decarbonisation of the grid, and the national retrofit plan should lead to a signi ficant decrease in operational emissions.

Minister for Further and Higher Education, Research, Innovation and Science, Simon Harris, has recently announced that the government has approved publi cation of the Construction Safety Licensing Bill 2022. The Bill will modernise and reform the existing accreditation model and provide for a licensing model for construction and quarrying activities.

For all advertising and marketing queries, contact on email: info@civilandconstruction.ie

Sales & Marketing Director: Anthony Kelly

Graphic Design: Colin Brennan

Advertising Sales: darren@civilandconstruction.ie

Speaking at the Construction Industry Federation conference, Minister Harris said: “The Construction Safety Licensing Bill 2022, is a transformational piece of legislation designed to enhance the overall skills and knowledge, as well as to improve safety standards, for all those employed within the construction sector.

We have a lot of insightful articles in this issue along with news, appointments and a great new car review in the Lexus NX450h+ so flick forward for all of that great content. We would like to thank all our clients for there business throu ghout 2022 and wish you all continued success in 2023.

James Kelly EditorThe Irish homebuilding sector faces the challenges of rising demand, reducing costs and nding greater e ciencies. Modern Methods of Construction (MMC) can prepare it to deal with labour shortages and material costs while accelerating the pace of constructing new homes.

Enterprise Ireland has a range of grant and advisory supports focusing on productivity, digitalisation and innovation, to help the Construction Industry continue to innovate to build new homes. Through MMC, we can achieve the aims of the Government’s Housing For All plan.

Get the support you need to build homes smarter, leaner and faster at: enterprise-ireland.com/builttoinnovate or speak to one of our specialist construction advisers..

TBuiltToInnovate

An initiative of Enterprise Ireland under the Housing For All Plan.

he Irish homebuilding sector faces the challenges of rising demand, reducing costs and finding greater efficiencies. Modern Methods of Construction (MMC) can prepare it to deal with labour shortages and material costs while accelerating the pace of constructing new homes.

Enterprise Ireland has a range of grant and advisory supports focusing on productivity, digitalisation and

innovation, to help the Construction Industry continue to innovate to build new homes. Through MMC, we can achieve the aims of the Government’s Housing For All plan.

Get the support you need to build homes smarter, leaner and faster at: enterprise-ireland.com/ builttoinnovate or speak to one of our specialist construction advisers.

Smithstown Light Engineering has commenced construction and fitout of a new cGMP ISO8 cle anroom suite within its Suite II facility in Shannon, County Clare.

Townmore Construction’s Cleanroom Division has been appointed to deliver this fast track project on a Design & Build contract. This project has been designed with per formance, safety and sustainability in mind. Upon com pletion, the suite will be capable of being controlled to achieve ISO8 and will have a set-back facility in order to reduce energy usage and running costs when not in use. Other sustainability features include optimised HVAC de sign for negligible air loss and high efficiency LED lighting throughout.

Significantly, most specified products will be sourced from manufacturers based in Ireland and the UK, with the exception of the motors which come from Germany, to minimise the carbon footprint of the project. Speaking about the commencement of this critical project, Dr. Gerard Henn, CEO of Smithstown Light Engineering, said: “We look forward to working with the Townmo re team on this fast-track project. The new cGMP ISO8 cleanroom suite will further support our global medical

device client base with the ability to carry out secondary and ancillary process steps in a controlled environment. Providing clean, pack and label services and other closely controlled activities will complement our existing high precision machining and quality driven operations. Deve loping and managing a cleanroom suite allows us to keep pace with new technologies and solutions and furthers our drive to continually re-invest in our business and expand our horizons as we serve our customers with world-class standards.”

Engineering manager and head of Townmore Con struction’s Cleanroom Division, Finbarr Marrett, said: “We are delighted to be working with such a long establi shed partner as Smithstown Light Engineering on this cut ting edge project. It provides an important opportunity to use the design and delivery experience of our team, to deliver an innovative and sustainable facility in Shannon, and we look forward to a long standing relationship with Smithstown Light Engineering as both entities continue to grow and evolve.”

It is expected that Phase 01, comprising the new cleanro om suite, will be handed over and fully operational in Q1 of 2023.

Powered by the latest Stage V engines to give class-leading pushing capability combined with low fuel burn, Generation 8 dozers are engineered for efficiency. There’s a wide choice of blades, a unique tilting cab for easy servicing, and a new-look cab providing outstanding comfort and great views to blade and ripper.

Operators - need a little help? We offer Free Grade, Definition Grade or optional 3D Grade Assistance systems as well as optional factory fitted, GPS preparation for all popular systems.

It’s a Liebherr. Job done.

Grant, Ireland’s leading engineering company which specialises in the plumbing and heating industry, has announced the official opening of its new UK Head Office representing a capital investment of €13 million.

The opening of these facilities follows two years after Grant opened the doors of their €14 million state-of-theart expanded facilities featuring an R&D innovation cen tre in Birr, Co. Offaly. This latest investment is due to the continued growth and success of Grant within the sustai nable heating sector and will help pave the way for further growth.

At over 80,000 sq ft., Grants newest state-of-the-art faci lities based in Swindon, Wiltshire are three times the size of the previous premises in Devizes, Wiltshire and offer additional office spaces and significantly increased on-site storage capacity while also enabling further development of Grant UK’s Training Academy.

Speaking about the new facility, Stephen Grant, Founder, Grant Engineering said, “We launched our UK opera tion over 25 years ago and it has gone from strength to strength. As a company supplying award-winning heating products to homes throughout the globe, this investment reinforces our commitment to growth as we continue to expand and enhance the delivery of our sustainable hea ting technologies and services to customers.”

Dedicated to helping decarbonise home heating, Grant designs and manufactures a range of highly efficient and sustainable heating products including HVO biofuel com patible Vortex condensing boilers, Aerona3 R32 air to wa ter, air source heat pumps, solar thermal panels and inte grated pre-plumbed hot water cylinders. In recent years the company has diversified its offering to include heat emitters – Afinia aluminium radiators and Uflex underfloor heating.

For further information, please visit www.grant.eu

Some of Ireland’s best known construction brands are amongst the founding members of a new in dustry body, MMC Ireland, established to repre sent those involved in the planning, design, pro curement or delivery of offsite and other modern methods of construction in Ireland.

In response to delivery challenges, the Irish government has committed to enabling a more efficient and sustai nable approach to the design, construction and operation of buildings. MMC will play a vital role in helping the State to meet ambitious targets set out under both the National Development Plan and the National Planning Framework, and increasing MMC adoption is critical to the post-pan demic recovery of Ireland’s built environment, economy and communities.

MMC Ireland is a collaboration of industry talent and expe rience, working in partnership to gather insights and the team will work closely with stakeholders from the public sector, the private sector and from academia to ensure those insights feed into relevant policymaking. The gene sis of this organisation can be traced back to a gathering in 2019 where the chairman of both Tide Construction & Vision Modular Systems, John Fleming, inspired the indu stry with a vision of ‘Rebuilding Ireland through Modular Construction’.

Speaking about the establishment of MMC Ireland, co-founder Arthur O’Brien, Managing Director at C+W O’Brien Architects said: “Having been involved in the de sign of MMC projects for several years, I am acutely aware of the challenges project owners face and these challen ges are best tackled together. I have been humbled by the strength and knowledge base of the founding mem bers in recent months and by harnessing this strength and knowledge, we can drive this sector forward.”

The newly-elected Members’ Board is made up of:

• Declan Wallace of Evolusion Innovation

• Pat Kirwan of C+W O’Brien Architects

• Tony McLoughlin of Glenveagh Properties

• Eoin Waldron of Castle Modular

• Ger Fahey of Horizon Offsite Ltd

• Richard Walsh of O’Dwyer Steel

• Kevin Loftus of Cairn Homes plc.

Speaking at the announcement of the new MMC Ireland Board, Declan Wallace, CEO of Evolusion Innovation and newly-elected Board Member emphasised that: “The overarching objectives of the body are to develop and promote Ireland’s MMC sector in order to build knowled ge and awareness of the products and systems on offer in Ireland. Moreover, our members – through engagement with all stakeholders including relevant government de partments and building control authorities – are commit ted to ensuring a regulatory environment that addresses compliance, testing, certification, quality and other obsta cles to MMC adoption.”

Head of MMC Delivery at C+W O’Brien Architects and newly-elected Board Member, Pat Kirwan added “It has been proven that modern methods of construction can lead to more efficient and effective construction metho dologies, which help to reduce the carbon footprint of the built environment. Through the establishment of MMC Ireland, the construction industry now has a shared voice to develop a coordinated response to the many challen ges we face such as a severe housing crisis and climate change.”

In addition to the aforementioned Board members, foun ding members of MMC Ireland include Clancy, NorDan Vinduer, Peppard Investments Limited, John Sisk & Son Ltd, Xtratherm, Errigal, Arc Engineering Ltd, Vision-Bu ilt, John Paul Construction, CarlowBuild, Actavo, Fra mespace Solutions, ABM Design and Build Ltd, Procon Modular, LMC Group Ltd, Mac Zero Modular Buildings , Hines Ireland, HLM Architects, Saint-Gobain Ireland, Platt Reilly, CPAC Modular, Rothoblaas srl, PETRUF Consulting Structural Engineers, Steelframe (part of Montane Deve lopments) and Visor MMC.

Construction in Ireland, and indeed globally, is in transi tion at present. Innovation and collaboration will be key to building a more effective and sustainable sector. MMC Ireland as an industry representative body has the ability to collaborate with all key stakeholders and governmental bodies, including the recently established Construction Technology Centre and the MMC Innovation and Demon stration Park.

Further information about MMC Ireland is available at https://mmcireland.ie

This is the first Loxam Day that has been held in Ireland by the Rental business and it will happen once a year going forward! The weather hasn’t been great but there is a fantastic turnout. A lot of big customers have attended, and like us they enjoyed the complimentary tea/coffee and the food on offer. As Joe Gavin commented when we caught up with him “it’s a lot different being here for customers than looking at our website or machines on site. It’s a feel good factor as well.” After visiting Loxam I get where he’s coming from. Scrolling through a website doesn’t give you a feel for the enthusiasm the company has and the chance to look closely at new machinery, branding and the staff who seemed motivated and engaging.

So who are Loxam? Loxam are a European leader in the rental of equipment and tools for building, construction industry, landscaping & the private individual. Loxam is a French company with over 11,000 staff worldwide, turnover of €2.5 billion; it’s in 30 Countries on four continents. The big thing with Loxam is they are Number 1 in Europe and Number 4 in the World. They have the biggest amount of access equipment in the World. In Ireland, Loxam acquired Swan Plant Hire at the end of 2017. For the first few years they let it run to get a feel for it. Mr Joe Gavin, Managing Director, arrived in 2020. His remit was to convert the company into a Loxam Brand and develop the business countrywide at the time.

Mr Gavin explains “The plan going into the future is to expand the branch network firstly in the Northside of Dublin while also expanding across the Country. So we are looking at the likes of Cork, Limerick and Galway.

This year alone has been the first full year without Covid or stoppages due to Covid. We’ve seen in the first five months of the year really positive energy, lots of company’s doing well. The war in Ukraine started and things slowed, there was a bit of a lull and turndown in everything. Although, since the holidays finished in August we saw business ramp up again which is great. We hire all sorts of plant here, we go from 13 tonne rollers, diggers and dumpers down to consaws, hoovers and gardening equipment, whatever is needed.”

Knowing that everything is moving towards electric we ask if Loxam is taking into account this change to electric “We have our green range called LoxGreen, which is a big part of us. We have electric diggers, electric dumpers and electric equipment and it’s a growing area. Going into the future we see it going very well here and we will be ready for it.”

There is no doubt Loxam have big plans here in Ireland. Mr Gavin commented “Our aim is to be the largest and best equipment rental company in Ireland like we are in other countries. Loxam have invested heavily into new equipment last year, this year and plans to invest more next year. Clients are getting quality and we acknowledge we might not always be the cheapest but we are providing new equipment and high quality product.” It’s not just about equipment as Mr Gavin points out, “We look at health and safety as a major point, our CSR policies, and what we are doing to help the environment. We are also ISO certified in 9001 & 14001 and will be certified 45001 by the end of the year.

My colleague directly asks Mr Gavin how he aims to be the largest and best equipment rental company in Ireland and how will Loxam gets there. Mr Gavin comments “We are the best in Dublin, one of the biggest in the Dublin region. We will look at investments, acquisitions and natural growth throughout the country. Yet any acquisitions must make sense and be the right fit for the Loxam brand. Through our inward investment and our satisfied customers we will grow to be the biggest. Clients come back for good machines and you get a service that’s second to none. You get the service of the delivery of the machine, you know it’s a new machine and you won’t be calling for a service van to come out to repair it.”

This is a busy sector with competitors. We enquire as to what separates Loxam from the competition. Mr Gavin replies “We are number one in Europe, four in the world; we want to be number one in every Country we are in. We

are a certified great place to work. Loxam are also one of the main hire companies in Ireland to get this award. We are ISO9001 and 14001 certified quality management system in all branches. Loxam are looking for all stage 5 machines, we have to have the best to be the best and we are willing to invest. The easiest way to separate us from another company is to come in and look at us. We have the best fleet of hire equipment in Ireland.”

Mr Joe Gavin is on a mission to make Loxam Number 1 in Ireland and he has all the ingredients for success. We would encourage our readership to reach out to the Loxam team and if you get a chance drop into them and get a feel for the company. They pride themselves on quality machinery, inward investment, great staff and happy customers.

You can reach Loxam on 01-4507219.

Loxam Rental Southside Branch

Unit 4, Crossbeg Industrial Estate, Ballymount, Dublin 24, D24 CK07

Tel: 01 450 7219

Email: dublin.south@loxam.ie

Loxam Rental Northside Branch

Collinstown Business Park, Cloghran, Co. Dublin, K67 C5YC

Tel: 01 842 7868

Email: dublin.north@loxam.ie

This is the second generation Lexus NX with a plug-in hybrid drivetrain. Plug-in hybrid electric vehicles are perfect for people who want to try living with an electric vehicle (EV) without worrying about range anxiety. Howe ver, PHEVs are a transitional technology as consumers wean themselves off fossil fuels, wait for the EV charging infrastructure to develop, and ful ly adopt electrics as their future modes of transportation. The Lexus NX 450h+ joins the compact luxury PHEV SUV line-up and we give it a full overview here.

From the outside of the new NX it’s more of an evolution of the car it’s replacing than a radical rethink. Overall, it’s less angular, but still features the slim LED headlights and large spindle grille that make the mid-size SUV unmistakably a Lexus. Plus, there’s now a full-width tail-light, while the NX has grown by 20mm in overall length and has a 30mm lon ger wheelbase.

In its driving the NX 450h+ feels nimble and enjoyable to drive. On motorways, it provides a good ride quality and is quiet inside. Around town, where you’re likely to encounter speed bumps, the Lexus feels solid and secure due to its ro bust platform and vehicle architecture. It does an excellent job of isolating suspension, road, and tyre noise.

With four-wheel drive thanks to the electric motor on the rear axle, 0-100km/h takes only 6.3 seconds. In electric mode, the NX 450h+ is extremely quiet, with the motors providing enough power to get you off the line and accele rate with plenty of pace without the engine needing to chi me in. The CVT transmission does send the revs increasing on occasion, however, the transition from electric to petrol or vice-versa is superbly smooth. Plus, the Lexus is much more refined and comfortable than the Toyota RAV4 PHEV with which it shares its technology, and rides better on the road but doesn’t sacrifice body control.

Irish pricing for the Lexus NX starts at €61,100 for the NX 450h+ hybrid in Executive trim. This is pretty generously equipped, with 18-inch alloy wheels, LED headlights, key less entry and starting, a 9.8-inch touchscreen infotainment system, Apple Carplay / Android Auto, heated steering wheel and front seats, wireless phone charging, a powered tailgate and a suite of active safety features. This includes pre-crash system, blind-spot monitoring, road sign assist and adaptive cruise control.

For an extra €9,800 you can upgrade to the F Sport variant we tested here priced at €70,900. This adds 20-inch alloy wheels with run-flat tyres and a sportier body kit, privacy glass, Quad-LED headlights with adaptive main beam, LED front fog lights, a head-up display, a larger 14-inch touch screen, 8-way seat adjustment with driver seat memory, 360-degree exterior camera views, more leather trim and ventilated front seats.

The second-generation NX is offered with a Lexus First plug-in hybrid system, which offers a high degree of electric driving capability, acceleration and refinement. Plug-in hy

The NX is now in its second generation, having been reengineered and restyled to meet today’s needs.

Words: Anthony Kelly Pics: Webpress

Words: Anthony Kelly Pics: Webpress

brid NX couples an efficient 2.5-litre naturally aspirated petrol engine with a high-output electric motor, a large lithium-ion battery and a compact Power Control Unit (PCU). This allows the NX to deliver the electric driving ca pabilities required by many buyers. The 18.1kWh battery used in plug-in all-wheel-drive NX, which is cooled or hea ted for optimum output and lifespan, offers an all-electric combined range of up to 74km.

The plug-in hybrid version of the new NX adds refine ment and class-leading efficiency to an already appealing package. There are several significant improvements over the previous generation, such as more cabin space and a vastly improved infotainment system, while material and build quality throughout are as strong as ever.

Constructed by John Sisk & Son and provides a continuous flow of freight between Terminal 4-yard areas at Dublin Port. It was completed in November 2021.

The primary element of the project was a Red Bridge of 39 metres in length which formed part of a much larger piece of infrastructure enabling the movement of Ro Ro from the southern side of the Alexandra Road to the Northern side over live Railway and Road infrastructure set within the Dublin Port Facility. The engineering challenge was significant, designing and constructing a bridge which will be installed over a live railway line and critical road infrastructure.

The Red Bridge concept extended to all elements of the bridge including the top surface which was provided by way a pigmented pavement finish. The Contractors Design Challenge: The contractor designed element provided a significant challenge from both the structural design and construction viewpoints. The original concept for the façade was detailed in Glass Reinforced Concrete (GRC). The panels are five metres wide with the tallest panel being 4.9 metres in height. The geometry varies on each panel with up to four outer planes on some panels. There are eight sections to the façade on each side with the overall length of each side being 39 metres. The three centre panels on each side have 44 circular openings varying in diameter from 100mm to 600mm with each one containing an LED star light.

Darmody Architecture in conjunction with DBFL

Consulting Engineers were retained by Dublin Port Company Ltd (DPC) to design the most appropriate solution under the challenging conditions. The design response conceived a modern intervention which would achieve the functional aspects of the client brief and equally important was the generation of a visual gateway into the greater Dublin Port facilities.

It was inspired by the Poolbeg Lighthouse which robustly marks the entrance to Dublin Port and resonates fondly with all who connect with it.

Darmody Architecture liked the robust simplicity of the Poolbeg lighthouse and wanted to carry some of its characteristics into the bridge design. They had previously explored forms as part of the Port Centre project when creating the crane enclosure both in RC concrete and perforated metal Corten cladding. This experience led them to explore dynamic forms for the structural cladding which could incorporate starburst lighting as a communicator of the tidal currents. The concrete bridge beams provided an elegant, ribbed underbelly to the giant span which come to life at night with their light beam installation. The complete assemble communicates a fluid and dynamic structure which rests on just four columns on either side of the road. The shear robustness of the cladding elements designed by John

Sisk & Son and cast on site provided for a masterful piece of design and construction.

The challenges associated in constructing this façade were numerous given its difficult shape, geometry and location. The engineering involved in fixing the units to the bridge was complex and John Sisk & Son conducted detailed investigation into the viability of a reinforced concrete façade as an alternative to the GRC concept. The challenges included: Complex reinforcement design and arrangement · Size and weight (panels up to 16 tonnes each covering 25 square metres) · The large diameter circular openings · Casting of the units · Transport and handling of the units.

It was concluded that there were also numerous advantages to the reinforced concrete option for the project as opposed to GRC.

These included the provision of a robust connection detail, better impact resistance and low long-term maintenance

of the structure. John Sisk & Son engaged a Civil and Structural Engineering Consultant (BFP Consulting) to carry out the detailed design of the facade. The design was essentially a 150mm thick singly reinforced panel with two ribs. The ribs provided stiffness to the slim panel while also providing anchorage for the cast ins used in the permanent fixing to the bridge structure. The Client’s Engineer, and overall bridge designer (DBFL Consulting Engineers), made some structural changes including introducing a small deck cantilever and changes to the in-situ walls on both sides of the bridge that the façade is fixed to. The process was a collaborative approach by all stakeholders.

The size and geometry of the panels led the contractor to cast the 16 panels on site. The casting beds were constructed adjacent to the bridge and a match-cast system was adopted to minimise casting anomalies. The panels were cast face down with a closing shutter used to form the back and ribs. The reinforcement was primarily 8mm in diameter and was bent on site due to

the complex nature of the panels.

Roadstone supplied a self-compacting concrete (SCC) that could fully encapsulate the slender formwork and achieve the high-quality finishes as specified. Through careful planning between the design team, contractor and the producer a design mix and placement methodology were agreed upon. An SCC concrete to a slump-flow class of SF2 was seen as the best option to achieve full encapsulation of the formwork and the desired quality of finish. The units were then poured in a hit and miss format. The central span of the bridge structure itself had in-situ reinforced concrete walls constructed to enable the façade panels to be fixed in position. These walls had a series of sleeves at rib positions to enable the panels to be bolted through using stainless steel fixings. The walls also had a series of openings at the three centre panel locations to enable access for maintenance of the lighting system.

Once all 16 panels were cast and cured, the process of lifting them out and placing them on the bridge began.

The slim design and shape of the panels gave rise to a difficult handling process. The units were first jacked vertically on 4 corners of a steel H-frame 100mm from the bed prior to being lifted out and set into a bespoke cradle.

The cradle was then stood vertically using two cranes before being used to lift the unit into position on the bridge during a weekend road and rail closure. The external faces of the panels were then coated with a red flexible coating system before each of the 88-star lights were installed in the cast in recesses. The façade is further lit with four projectors that change in intensity depending on the tide levels in the port.

In summary, the façade on the Terminal 4 Alexandra Road Bridge is testament to how an architectural design that posed many technical and engineering challenges can be realised through collaboration with all stakeholders.

As one of Ireland’s longest established companies, Jones Engineering has a proud history of innovative and sustainable growth. Here they discuss the evolution of their Responsible Business Framework and how it reflects their vision for the future.

Jones have recently finalised their internal Responsible Business Framework, which formally defines their goals and vision for a more sustainable and inclusive future. The framework builds a structured foundation around their established legacy and includes areas such as measurable carbon reduction goals, active community engagement and strong investments in team development. The framework has been aligned to the UN Sustainable Development Goals (SDG’s) with a particular focus on the seven main goals which Jones believe they can have the greatest

influence and impact on.

It is public knowledge that Jones have spent decades working on some of the most cutting-edge renewable energy projects such as Anaerobic Digestion Plants, Wind Farms, Battery Storage Systems and Power Plants. Their website is covered with exemplar examples of cross industry projects such as the design and build of Taggart Windfarm, the country’s first Renewable Electricity Support Scheme (RESS) wind farm to be connected, and the St. James’s Hospital Energy Performance Contract

As one of Ireland’s longest established companies, we have a proud history of innovative and sustainable growth. We have spent decades working on some of the most cuttingedge renewable energy projects. With our newly formalised Responsible Business Framework, we aim to deliver on our promises of securing a sustainable and brighter future for our clients, our staff and our community.

joneseng.com

which delivered €26 million in guaranteed energy and operational savings and reduced the hospital’s carbon footprint by approximately 118,380 tonnes.

However, what may be less commonly known, is just how active and engaged they are with their global and local communities as well as the development of their team members. From Senior Management down they strive to make a difference by fostering the next generation of talent, sponsoring organisations within the community, and supporting charities through company and employee efforts. Recently Jamie Bermingham, Jones Engineering Apprentice, was awarded the winners medal at the World Skills Ireland Plumbing and Heating Final in the RDS demonstrating his exemplary skills and training. While the innovative Jones BIM Team collected the Digital BIM Initiative Award at this year’s Irish Building and Design Awards.

Not every achievement is measured in accolades and some “wins” are more personal. For example, when Amy joined Jones in 2018 as a HR Intern, she never expected that two years down the road she would be able to pivot to her dream role. In her own words Amy said “Whilst I loved my job and the team, quantity surveying had tweaked my interest from a young age, but I pushed it to the back of my head as I didn’t feel confident to pursue such a male-dominated career. When I discussed the possibilities with my manager, she was very supportive and encouraged me to pursue my interests in Quantity Surveying. I have recently made the transition from

office to site and started my master’s degree in Quantity Surveying. Jones have helped me every step of the way from supporting me for college to the transition from office to site to get some hands-on experience. Although it is a big change, the support and guidance from Jones Engineering, in particular the HR and QS Teams has been outstanding.”

The CSO estimates that only 5.5% of the workforce across all construction related sectors are women. At Jones Engineering the figure of 8.4% is marginally higher than the norm, something they are proud of while still recognising the need for continuous improvement. With their newly formalised Responsible Business Framework, it seems inevitable that they will deliver on their promises, securing a sustainable and brighter future for their clients, their staff and their community.

Jones have already grown sustainably in both size and reputation, becoming a business with a turnover of €970m+ and resources of over 4,200 people worldwide. Their core value is the delivery of engineering through people, and the breadth of their team is unrivalled. Recruiting, nurturing and developing the best talent has been a cornerstone of the group’s development.

If this sounds like a company you would like to “engineer your career” with then why not check out their Current Opportunities today: https://joneseng. com/careers/current-opportunities/

With news that tech firms are rethinking their real-estate strategies in light of hiring free zes and changing work practices, cities that have invested heavily in commercial real estate – Dublin and Belfast, for example - may be about to see high levels of vacancy. This article considers a po tential response to changing occupancy patterns in cities. The CIOB has consistently called for flexibility in buildings to reflect changing patterns of interaction with the built environment. In 2020 we questioned the long-term logic of continuing to devote large swathes of urban space to offices in the midst of a paradigm shift in working habits. With a recent survey showing that on average people are attending the office 1.5 days a week, our scepticism looks well founded.

Our work on Permitted Development Rights (PDR) – ri ghts to change a building’s use without the need to apply for planning permission - has allowed us to develop the Institute’s thinking on adaptability. One of the main mes sages from our PDR work is that retrospectively converting commercial space to residential use is often simply not appropriate given the way buildings are constructed. In deed, research on the PDR regime has found that, due to the nature of the buildings being converted, it consistent ly produces substandard housing.

A longer term, more sustainable solution would look at interventions earlier in the building process, rather than retrofitting office blocks that are simply not suitable as housing. ‘Seed Planning’ is a planning and design approa

ch which gives minimum specification of how form relates to function, thereby allowing a building to fulfil multiple uses over the course of its life, without sacrificing quality. Part of the CIOB’s new sustainability policy agenda will focus on the adaptability of buildings, partly to avoid the embodied carbon associated with demolition, but also to reflect the changing habits of occupation in cities. With the news that tech firms are reassessing their commercial footprint in cities, our proposal to apply a spatially sensiti ve adaptability score to buildings when granting planning permission is timely. Hypothetically, if an adaptability re quirement did apply to new buildings in cities, and unoc cupied commercial real estate could easily be adapted to residential use, this would create a viable stream of quality housing supply in areas of high demand, well served by existing infrastructure.

We propose to reduce future demand for new con struction through design that supports adaptability, repair,

and maintenance. The indicators of the EU Framework for Sustainable Buildings provide a model within which the adaptability of a building could be assessed. The most si gnificant environmental impacts of constructing a building relate to its structure and facade. If the useful life of the building, and therefore also its structure, can be exten ded, there can be significant environmental benefits while also accommodating the changing needs of occupants. To ensure that new buildings reflect changing patterns of occupation, an assessment of whether a building can be adapted to a different use without sacrificing quality – an ‘adaptability score’ - could be germane to the decision of whether to grant planning permission. A building’s adap tability score can provide a semi-quantitative assessment of the extent to which the design of a building could fa cilitate future adaptation to changing occupier needs and market conditions. It can therefore provide a proxy for the capacity of a building to continue fulfilling its function and to extend the useful service life into the future. While an

adaptability requirement may be overly onerous on smal ler developments in peripheral locations, it could be criti cal to the evolution of cities.

A spatial criterion could be used to implement adaptabi lity scoring in the assessment of a planning application. New buildings in central urban locations could be requi red to achieve a high adaptability score. This would be in keeping with national planning policy In Ireland, Northern Ireland, Scotland, Wales, and England, which prioritise dense, mixed-use development. In addition, an adapta bility requirement would offset the need to repeatedly reproduce the most significant environmental impacts of the construction process. Furthermore, by providing an adaptability score, developers, local planning authorities

and communities will be presented with clear options to take a longer view on the design aspects and decisions that may influence a building’s service life, and its impact on the community. They would be invited to engage in the increasingly marginalised art of long term planning. Changing commuting and work patterns are still bedding in, and their long-term impact on cities remains unclear. Nevertheless, from a thought leadership perspective, if the built environment sector wants to continue to meet the needs of its occupants, the possibility that we are wit nessing the beginning of a long-term change in how cities are occupied must be acknowledged. That means having a conversation about embedding adaptability into the construction process to ensure that our sector, as well as our buildings, can adapt to this change.

The Irish homebuilding sector faces the challenges of rising demand, reducing costs and nding greater e ciencies. Modern Methods of Construction (MMC) can prepare it to deal with labour shortages and material costs while accelerating the pace of constructing new homes.

Enterprise Ireland has a range of grant and advisory supports focusing on productivity, digitalisation and innovation, to help the Construction Industry continue to innovate to build new homes. Through MMC, we can achieve the aims of the Government’s Housing For All plan.

Get the support you need to build homes smarter, leaner and faster at: enterprise-ireland.com/builttoinnovate or speak to one of our specialist construction advisers..

BuiltToInnovate

An initiative of Enterprise Ireland under the Housing For All Plan.

Haldane Fisher Newry has won the overall Octabuild Award for Excellence 2022 at the first-ever all-island Octabuild Builders Merchant Excellence Awards. The company also won the Northern Ireland Regional Award.

The Octabuild Builders Merchant Excellence Awards ceremony was held on Thursday 13th October at a gala event in the Round Room at the Mansion House in Dublin. It was attended by over 300 guests including shortlisted merchants and representatives of the builders merchant trade from across the country. The event was hosted by the eight Octabuild members, Dulux, Etex, Glennon Brothers, Grant Engineering, Gyproc, Irish Cement, Kingspan Insulation and Wavin.

Guest of honour at the awards was Michael McGrath TD, Minister for Public Expenditure and Reform. Congratulating all the winners the Minister said: “I would like to congratulate all the finalists and winners at this year’s awards, particularly Haldane Fisher Newry who won the overall Octabuild Award for Excellence 2022. This is the first year the awards were held on an all-island basis and I want to commend the organisers and Octabuild Chairperson, Ray Molyneaux for such a great event. These are a unique set of awards designed to promote excellence within the Irish builders merchants industry and highlight the

importance of the industry to the wider construction and building sector.”

Since these prestigious awards were first introduced in 1986, this is the first year they have been held on an allisland basis. Previously awards were held in Ireland and Northern Ireland on alternate years. This year builders merchants competed for four Regional Awards, five Individual Category Awards and a Rising Star Award, which acknowledged up-and-coming talent in the industry.

Octabuild Chairperson, Ray Molyneaux said: “It’s important for Octabuild that the Awards highlight to the building and construction industry the excellence of Irish builders merchants amidst its ever-changing landscape. Congratulations to all finalists and winners from all over the country who represented absolute excellence in the industry.”

Commenting on the quality of the entries, Chair of the independent Judging Panel, Liam O’Gorman, said: “It is evident that the industry has evolved hugely and that merchants have led the way in embracing this changed landscape. These merchants have transformed their processes, systems and operations to reflect this new way of doing business.”

In total eleven awards were presented at the awards ceremony as well as the Octabuild Lifetime achievement Award, which was presented to Brian Wogan, Dunleer Hardware, Dunleer, Co Louth.

In addition to the two awards won by Haldane Fisher, Newry other winners were:

Connacht/Donegal/Monaghan/Cavan Regional Award

• Joyce’s Hardware & Home, Galway

Leinster Regional Award

• Rooney’s Homevalue, Kells, Co Meath

• Morris Builders Providers Ltd, Waterford

• Chadwicks Coolock Dublin

Excellence in Customer Service

• Nioclás Ó Conchubhair Teo Homevalue, Connemara, Co Galway

Excellence in Sales and Marketing

• Ganly’s Longford

Excellence in Sustainable Business

• Brooks Timber & Building Supplies Ltd, Galway

Excellence in Community Outreach

• Chadwicks Thomas Street, Dublin

Rising Star Award

• Rooney’s Homevalue, Kells, Co Meath

Haldane Fisher, Newry was founded in 1946 in County Down and is the main headquarters of the Haldane Group.

According to the independent judging panel it is an incredibly impressive store kept in pristine condition. It has highly developed management systems and acts as a feeder depot for other Haldane Group branches. The staff are knowledgeable and well-motivated with the firm having cultivated a Buddy system to mentor new employees.

Overall, the judges were really impressed with the store, its systems, customer service initiatives, strong health and safety ethos, community involvement, staff training, sustainability initiatives and new website sales platform, all led by a team of 160 employees adhering to high standards of workmanship.

Octabuild was established in 1984 and is unique among representative groups in the building and construction industry. The objective of the group is to promote the

benefits of high quality, Irish manufactured products. Each Octabuild company is committed to excellence in providing an efficient and reliable service to builders merchants.

Between them, the Octabuild companies make a significant contribution to the Irish building and construction industry. Their manufacturing plants are spread throughout the country providing significant employment (1,800+ employed directly) and contributing substantially to the economic well being of their local communities. Their combined product portfolio represents an impressive range of high quality Irish manufactured brands. The companies between them make 20,000+ quality products available every day.

Pictured

Pictured at The Octabuild Builders Merchant Excellen ce Awards 2022 is Octabuild Chairperson, Ray Moly neaux with Octabuild Award for Excellence winner, Haldane Fisher, Newry. (L-R) Mark Nicholson, Chris Bagnall, Ray Molyneaux, Gary Cranney, Brian McCau ley, Patrick Craven, Sean Cleary.

To be eligible for this apprenticeship, an applicant

• Be employed by a solas employer •Be at least 16 years of age •Have a minimum of 3 month’s site experience •Have a minimum of grade D in 5 subjects at Junior Certificate, or equivalent, to include Maths and English •Have evidence of CEFRL level B2 minimum if English is not a first language •Hold a current, valid Safe Pass registration card

On Friday, 7th October the Irish Green Building Council (IGBC) launched its roadmap to decarbonise Ireland’s built environment across its whole life cycle.

Backed by carbon modelling data, commissioned to the Building in a Climate Emergency (BIACE) Research Lab at UCD and developed in close cooperation with industry, “Building a Net Zero Ireland” details a series of actions to accelerate the transformation of our built environment.

Most of the policy and industry focus to date has been on addressing operational emissions from energy used to heat, cool, and light our buildings. Beyond climate action, the current energy crisis, and the growing number of peo ple at risk of fuel poverty, highlight once again the urgency of improving energy efficiency and increasing the share of renewables. However, there are emissions associated with all life stages of a building, from raw materials extraction to construction materials production, and buildings con struction and demolition. These so called “embodied car bon” emissions are often poorly documented.

As data on the emissions associated with construction and the built environment in Ireland was limited, a report was commissioned to the Building in a Climate Emergency (BIACE) Research Lab at UCD to gain a better understan ding of the scale of the challenge. For the first time ever, it shows that our sector accounts for 37% of Ireland’s emis sions, the same as agriculture. This is made up of about

23% operational emissions, with a further 14% associated with embodied carbon emissions from the production of construction materials, transport of materials, and con struction process itself.

Projections to 2030 show that the NZEB standard, the decarbonisation of the grid, and the national retrofit plan should lead to a significant decrease in operational emis sions. However, these savings could be fully negated if the National Development Plan, Housing for all, and the national retrofit plan fail to consider embodied carbon emissions.

This is not the type of news we want to hear and decar bonising our buildings will be challenging, but the sooner we start, the better chance we have to reach our climate targets. This also presents an opportunity to improve our quality of life, while developing a sustainable and resilient industry.

The modelling is clear. An absolute priority in reaching our 2030 targets is to deliver on our retrofit goals. 3,200 homes were retrofitted to a BER B2 in 2020. Although this number increased in 2021, we are still very far from the 50,000 homes per year required to reach our 2030 targets. Not only 500,000 homes must be retrofitted to a BER B2 by 2030, but they must deliver as per design. The road map includes several recommendations to accelerate the renovation rate and address the performance gap. When it comes to energy renovation, there is no silver bullet, but additional financial and technical support for homeowners and small landlords is needed.

While free energy upgrades are available for homeowners who receive certain welfare payments, the programme must be reformed to ensure low-income households li ving in low BER homes are eligible – regardless of home ownership status and/or welfare payment eligibility. This is urgent as a significant part of the population cannot currently access the financial support, they need for ener gy renovation. For the “able-to-pay” market, the intro duction of low interest loans must be accelerated, and we must ensure the rates are truly low (i.e., below 2%).

Another significant challenge is that homeowners and small landlords who want to retrofit often do not know what to do and where to start. Energy renovation must not only be made more affordable, it must also become more accessible. A way to address this and to better support phased renovation is to introduce Building Renovation Passports (BPRs). BRPs are masterplans for retrofit and in clude a record of works. They ensure that any renovation

works are planned and implemented in a holistic and te chnically sound manner, hence preventing “lock-ins” and facilitating a step-by-step approach to deep renovation. If the building owner don’t have the money to do all the work now, they can do it bit by bit, in a way that works to an end goal of a zero carbon and comfortable building.

Another reason to focus on energy renovation is that it allows us to address both operational and embodied car bon emissions: the embodied carbon of a deep retrofit has approximately 25% the carbon intensity of a new bu ild. With 400,000 homes to be delivered by 2031, it is time to consider how our existing building stock can be better used and to link these policies with energy renova tion objectives. Taking this approach would also allow us to tackle Ireland’s fastest source of carbon emissions, tran sport, as people living in central locations are usually less reliant on private cars. But this approach is not only good for the environment, it is also good for people and the economy. It represents a unique opportunity to make our village, town, and city centres more vibrant, to enhance air quality, and to restore the cultural and aesthetic value of these areas.

Better using our existing stock does not mean that we should stop building new homes or infrastructures which provide significant environmental, societal, or economic benefits. It means that when we do build, buildings must not only be highly energy efficient and deliver as per de sign; the construction process itself must also be low car bon.

As often said, “what is not measured, cannot be impro ved”. A key recommendation of the “Building a Net Zero Ireland” roadmap is hence to start measuring Whole Life Carbon (WLC) as soon as possible. The European fra mework for sustainable buildings, Level(s) already provi des guidance for measuring the WLC of buildings consi stently. Implementing it now, would allow us to build up a truer picture of the emissions of our sector and to build capacity within the industry.

A growing number of European countries and cities have already regulated embodied carbon. The European Union, through the proposed revision of the Energy Performan ce of Buildings Directive (EPBD) and its Taxonomy for su stainable activities, is also moving in that direction. The later means that addressing WLC will be more and more needed to access lower-cost finance. The other advanta ge of WLC assessment is that it sends a clear signal to construction product manufacturers that they need to me asure and disclose the environmental impact of the pro duction process, through the production of Environmental Product Declarations (EPDs). This is a first step in reducing the carbon intensity of construction products. Anecdotal evidence gathered from our Green Building Councils’ col leagues in France and the Netherlands (where WLC is al ready regulated) shows that mandating measurement has led to innovation in low carbon construction materials. This is key as materials and products can represent more than 80% of the embodied carbon of construction.

A reduction in carbon intensity per sq. metres can initially be achieved by leaner design, i.e., using commonly avai lable materials, but using less by optimising building form factor, efficient structural design, and material use. Howe ver, significant inno vation will be needed to rapidly decarbonise the materials themsel ves and/or develop alternative low carbon materials. In particular, the reduction in car bon intensity in con struction that is nee ded in the next decade means that transitio ning to more biobased materials and more cir cular business models will be needed.

Although this transition will require reviewing building regulations and the additional sup port for the develop ment of a low carbon

supply chain, everyone in the industry can act now, and you do not have to do it alone.

Over the last few years, the IGBC has developed tools and training for building professionals to help them in ad dressing WLC. For instance, we run life cycle assessment (LCA) training on a regular basis and recently launched the Carbon Designer Tool for Ireland. Developed with the support from the EPA and the LDA, this free tool allows building professionals to estimate the carbon impact of their project at an early stage of the building design, i.e., when many of the big, most impactful decisions are made. Through our Environmental Product Declaration (EPD) Campaign, we are encouraging specifiers of construction products to ask for EPDs and to favour products with EPD where possible to help drive the demand for better envi ronmental data from manufacturers. Irish product manu facturers can also avail of support from Enterprise Ireland to produce EPDs and decarbonise their production pro cess.

Finally, to facilitate the implementation of the “Building a Net Zero Ireland” roadmap, the document also includes simple steps that building owners, investors, developers, product manufacturers and suppliers, planners, design professionals, contractors and facility managers can take right now to accelerate their decarbonisation journey.

“Building a Net Zero Ireland” was developed in close co operation with over 200 key stakeholders from across the supply chain as part of the #BuildingLife campaign. The roadmap and carbon modelling report are available at www.igbc.ie.

Scoil Naomh Pádraig National School, constructed by Vision Contracting in 17 months during the Covid-19 pandemic in Kanturk, Co Cork, is a much-needed state-of-the-art education facility that the local community has been fighting to get for many years.

In August 2020, Vision Contracting was contracted under a ‘Public Works Contract for Building Works Designed by the Employer’ by the Office of Public Works (OPW) to build Scoil Naomh Pádraig National School, Kanturk, a 16-classroom school with three special education teacher rooms on a 2.4-hectare greenfield site at Mill Road, Kanturk, Co Cork.

The school was developed to facilitate the amalgamation of two local national schools; St Colman’s Boys National School and the Convent of Mercy National School.

The brief for the two-storey primary school, designed by OPW Architectural Services, called for a school building with a total internal floor area of 3,253 sq metres, containing 16 classrooms, general-purpose hall, library, support accommodation, a three-room special needs (ASD) unit and all ancillary and services works.

External ancillary works included 37 on-site car parking spaces, three disabled parking spaces, vehicular access roads, a set-down area, pedestrian access pathways, ball courts, play areas, bin store, bicycle shelters, and gas storage tanks, as well as a new connection to existing foul drainage system, surface water drainage system with stormwater attenuation connected to the existing surface water network at the entrance to Market Place in the town. The contract also included the provision of signage and landscaping as part of the overall site development works on the circa-2.4-hectare campus.

Vision Contracting started work on site on 30 August 2020. The contractor appointed a widely experienced in-house project management team to ensure that the work would progress smoothly and disruption as a result of Covid-19 restrictions would be minimised.

Vision Contracting Project Director Aidan Drummond explains, “We assigned the team for the project at a very early stage so we could commence immediately as soon as the tender letter of acceptance was issued and signed. We were keen to get started on site as early as possible to get bulk earthworks, and site preparation progressed as rapidly as possible in case of an early onset of harsh or wet winter weather. As it turned out, we had a difficult winter, but the rapid start helped to offset some of the worst of the weather-related impacts. We also had an established Covid-19 Standard Operating Procedure (SOP) in place before we opened the site, which all our teams were well drilled on.”

He continues: “Our core team included a highly experienced internal team of project manager, site engineers and a civils team, who all, fortunately, became available due to the timely completion of another similar size project.”

The initial challenge was to clear the 2.4-hectare greenfield site.

“As it was an extremely overgrown greenfield site, we procured a local contractor with suitable equipment to remove the excess vegetation and trees,” Aidan Drummond continues. “While Vision Contracting has a long-standing relationship with many of our subcontractors, we also try to subcontract locally where possible. We find that this approach helps to create community goodwill and brings the advantages associated with having detailed local knowledge and familiarity with nearby facilities and resources, which invariably results in added value. The local contractor we procured had a suitably licenced waste facility, and they undertook the bulk of the earthworks, stripping and stockpiling the topsoil on site for re-use later on. This approach helped us minimise the environmental impact of the project on the local community and was one of a number of sustainability measures we were able to implement.”

As it was a greenfield site, there were no services available when Vison Contracting took possession.

“We bored a temporary water well for freshwater, which we decommissioned prior to the completion of the project, and we installed a temporary waste holding tank for the duration of the project for the site toilets and canteens,” Drummond adds. “This was serviced on a regular basis by a waste-licenced contractor. The tank was then decommissioned and removed from the site on completion of the project.”

A 60 KVA diesel generator supplied the site electricity for the first four months until ESB Networks supplied a temporary connection from its network.

As the Letter of Acceptance was issued on 18 August 2020, Vision Contracting planned to get as much of the substructure and groundworks completed as soon as possible before the onset of the wet and dark winter months.

“It was a sloping site with a steep gradient which required extensive earthwork cutting and filling,” Aidan Drummond notes. “These activities slowed and impacted the foundations’ progress. The design included stepped floors to deal with the sloping site topography, and consequently, the ground floor substructure required extensive reinforced concrete retaining walls and precast floor slabs to bring the building out of the ground.” The timing of the commencement date was not ideal, as this meant that Vision Contracting had no choice but to follow on with fair-faced blockwork in November 2020. “The timing made the masonry works extremely difficult due to the wet weather in November and December 2020,” he adds. “All masonry works needed to be protected and covered at all times until the mortar cured. The winter of 2020/2021 was extremely wet and resulted in some soaked masonry concrete blocks despite our best temporary works measures. This resulted in efflorescence, which is the surface growth of watersoluble salt crystals as water dried out from the face of the walls. But the team got stuck in, and although it took much grinding and cleaning effort, it was removed

satisfactorily once the building was weathered and dry.”

The continuing impact of Covid-19 was another challenge that needed to be taken into consideration. As the project started in September, the Vision Contracting team and supply chain were well-versed in the company’s Covid-19 SOP.

“We followed the industry Covid-19 SOP on the site with social distancing throughout the project. But Covid-19 also dramatically impacted our supply chain and materials availability. Materials shortages and delivery backlogs caused critical delays, and increased costs were being notified almost on a weekly basis. We adapted and worked as best as we could to minimise the impact of the pandemic on the project. This was greatly helped by the collaborative approach taken by the entire project team.”

The completed Scoil Naomh Pádraig comprises a traditional concrete RC frame with masonry infill. The brief had specified an airtightness of < 3m3/hr/m2, and the Vision Contracting team achieved an improved airtightness of 2.73 m3/hr/m2.

For glazing elements, the specialist subcontractor installed an AMS XT66 window system with unique patented architectural design features combined and market-leading thermal performance with a u-value of 1.37W/(m²K).

External ancillary works included 37 on-site car parking spaces, three disabled parking spaces, vehicular access roads, a set-down area, and pedestrian access pathways.

The structure was topped off with an EQC standing seam roof system with 320mm insulation.

The building is fitted with JA Solar - JAM60S10-320-340 PV panels with a rated output of 25.16 kWpH. All extraction fans in the school run on timers, and all lighting is provided by dimmable LEDs controlled by PIRs. The works programme started on 31 August 2020, with the project completed on 28 February 2022, only running two months behind schedule despite the significant Covid delay impacts and the particularly adverse winter weather.

At the official opening of the Scoil Naomh Pádraig in September 2022, school principal Eilís Finnegan told local newspaper, The Corkman, “It is fabulous to be in a building that is bright and spacious with beautiful rooms and furniture. We’re coming from the legacy of an oldfashioned building, where we depended on Scoil Mhuire for a hall. Now we have a fine large hall here.”

Speaking about how the overall project went and how it sits in Vision Contracting’s portfolio, Aidan Drummond comments, “Scoil Naomh Pádraig was a great project for Vision Contracting and our team of subcontractors. We enjoyed an excellent collaborative relationship with the design team, the wider project team and all of the stakeholders. This proved invaluable when dealing with multiple external adverse factors, such as Covid 19, Brexit and materials supply challenges, that impacted the project’s progress. Despite all of these challenges, we were only a few weeks over schedule with the work, and the local community in Kanturk now has a state-ofthe-art, well-finished modern education facility to meet its education needs in the years ahead.”

Vision Contracting Project Director Aidan Drummond.

Vision Contracting Project Director Aidan Drummond.

With an ever-expanding innovative product portfolio, including award-winning HVO biofuel compatible condensing boilers, innovative heat pump technology and the latest high-quality offering in heat emitters, Grant is the number one choice for heating.

Since 1978, Grant has truly made its mark on the heating

industry with continuous investment in research and development, demonstrating its commitment to providing sustainable heating solutions for the future.

Grant’s Integrated Heating Packages deliver maximum efficiencies for new build properties, and help save time on achieving relevant compliance as required under Part L of the Building Regulations. Each bespoke heating

Our complete integrated heating packages provide everything needed to build a highly efficient, warm and comfortable home.

Tailored to suit the homeowners’requirements, each Grant heating package is correctly sized and specified, free of charge, to achieve compliance, maximise efficiencies and provide long-term savings.

Packages feature the Grant Aerona3 air to water, air source heat pump, Grant hot water cylinders, Grant Afinia aluminium radiators and the Grant Uflex underfloor heating system. Smart controls are also available.

Trust Grant on the journey to warmth and comfort by sending house plans to heatpump@grantengineering.ie

package features a range of award-winning heating technologies from the Grant portfolio including a main heat source, hot water storage unit and heat emitters.

A popular choice for new build properties is the highly efficient Grant Aerona3 R32 air to water air source heat pump range. The manufacturer has experienced significantly increased interest in this range across Ireland as the demand for renewable solutions continues to rise. The range is available in outputs of 6kW, 10kW, 13kW and 17kW and operates using an air to water system which utilises heat captured from the air in ‘wet’ heating system radiators or underfloor heating. Models within the A+++ Aerona3 air source heat pump range help to significantly reduce carbon emissions.

Highly efficient hot water storage is also a key feature within a Grant integrated heating package, with options now extended to include Grant’s latest hot water storage unit – the Grant Integrated Unit. If this unit isn’t suitable for the new build property, a Grant pre-plumbed and prewired cylinder will be specified. During the specification of the most appropriate hot water storage system for the new build property, Grant’s specialist team will also calculate the correct cylinder capacity to suit the exact requirements of the property and to ensure no energy is wasted.

Heat emitters are also specified by the Grant team based on the unique needs of the property to ensure optimum efficiency. These may include the Grant Uflex underfloor heating system and / or Grant Afinia aluminium radiators. The Grant Uflex underfloor heating system and Afinia radiators can help new build properties achieve NZEB

standards and compliance with Part L of the building regulations, especially when paired with the Grant Aerona3 R32 air to water air source heat pump. This combination of technologies improves the overall efficiency of a new build property as both the Aerona3 R32 heat pump and the heat emitter systems can run at lower temperatures, therefore enabling savings to be made on annual heating bills. Each of these heat emitter technologies included in Grant’s integrated heating packages can be controlled using Grant smart controls.

Grant is committed to helping architects, specifiers and those working in the building and construction trade save time and hassle on new build projects and developments, giving them more time to develop their skills and competency levels. With this in mind, those in the heating trade can register to Grant’s popular eLearning Academy. The Grant eLearning Academy was launched last year and features on-demand and instructor led courses that provide a hybrid solution to help those in the trade expand their knowledge of Grant products and gain valuable CPD points.

One course of particular interest to architects is a The Royal Institute of the Architects of Ireland (RIAI) approved CPD approved course focused on the Grant Aerona3 R32 air to water, air source heat pump.

Visit www.grant.eu for more information on Grant’s range of innovative heating solutions. Follow Grant on Facebook and Twitter @GrantIRL or Instagram @Grant_ IRL or LinkedIn @grantengineeringulc.

GRESB

Investors and asset managers rely on GRESB assessments and results to provide a minimum standard for ESG and property portfolio performance.

GRESB assesses a wide variety of performance metrics. These metrics and their results are used for enhanced communication among stakeholders and to improve the material performance of portfolios.

GRESB is a globally recognised standard for ESG data and insights. It allows members to compare assets, improve engagement among stakeholders, and improve ESG performance.

• GRESB data is used by investors to monitor ESGrelated risks and opportunities.

• Asset managers including REITS, real estate owners and fund managers use ESG data to monitor portfolio performance and to engage with investors.

• Partners provide ESG services and solutions to improve and meet ESG and GRESB standards.

GRESB assessment takes place on a yearly cycle. Participants conduct self-assessments and peer review results to set an industry standard. The benchmarks created by GRESB assessments are:

• Real Estate Benchmark

• Real Estate Development Benchmark

• Infrastructure Fund Benchmark

• Infrastructure Asset Benchmark

Real estate owners, funds and asset managers who are members of GRESB can take part in the Real estate Assessment.

Members must pay a yearly fee to take part in the GRESB assessment cycle. Information regarding fees and the payment schedule can be found by contacting GRESB directly.

The assessment provides relevant, validated and peerreviewed data for real estate owners, managers and investors. In 2021 the real estate assessment represented $5.7 trillion in assets.

Assessment indicators are guided by what investors and the industry deem to be material issues in the sustainability performance of real estate. Real estate owners need to utilise online resources provided by GRESB.

• On March 1st- Real estate and infrastructure assessments reference guides are released.

• On April 1st- the GRESB portal is open to participants. Real estate owners must submit indicator responses and provide information regarding their portfolio and assets under management. The portal closes on July 1st.

• On October 3rd results are released for both participants and investors.

The GRESB real estate assessment generates two benchmarks:

• The GRESB Real Estate Benchmark, which considers management and performance factors

• The GRESB Development Benchmark, which considers management and development factors

The management component - This looks at the policies, management and stakeholder engagement of entities. The performance component - Performance indicators include energy consumption, GHG emissions, water consumption and waste.

The development component - This is suitable for entities undergoing major construction and renovations and looks at attempts to address ESG performance and issues.

Taking part in the real estate assessment allows members to identify areas of risk and opportunity, improve investor engagement and gain a clear picture of ESG performance.

Proptech Ireland is Ireland’s construction and real estate ESG technologies resource hub. Confused about how and where to start on your ESG journey? Contact us https://prop-tech.ie

Ireland’s construction and real estate ESG technologies resource hub

GRESB is an investor-led organisation that sets a global standard for ESG performance in the property market.

GRESB performance metrics are used by investors to manage risk, spot new opportunities and meet long term goals

ESG performance data is gathered throughout a yearly assessment cycle.

Real estate owners and managers use GRESB to improve ESG performance, communicate with potential investors and to benchmark performance against peers.

Partners use GRESB data to provide services and solutions to managers and investors.

Participating members self-assess assets and submit results to GRESB. Information is validated and scored through a secure and innovative system developed by GRESB.

Peer benchmarking considers region, country and investment type variations when providing final results.

PARTICIPATING COMPANIES ARE ENCOURAGED TO REVIEW ASSESSMENT RESOURCES.

This includes core assessment documents, a resource library and online assessment training

THE GRESB ASSESSMENT PORTAL IS OPEN ON APRIL 1ST.

Participants must fill in the ‘entity and reporting characteristics’ to identify the reporting entities.

Review the assessment indicators and submit the final assessment with all required responses by July 1st at 23:59 PDT.

PRELIMINARY RESULTS ARE AVAILABLE ON SEPTEMBER 1ST.

During the review period, companies will be able to submit a review request.

FINAL RESULTS ARE AVAILABLE ON OCTOBER 1ST.

The two primary reports the GRESB Scorecard and Benchmark Report will be released to investors and participant members.

Understanding how to provide these sources, sy stems and applications is seen as key in meeting the future needs of both commercial and dome stic heating.

Expertise is vital to renewables success and so Pipelife are delighted to offer a range of courses that have been spe cifically designed to provide experienced heating, plum bing, installation and building professionals with a real understanding of the potential for renewable energy sour ces, installation and their application. Relevant, practical, industry-leading training courses delivered at our state-ofthe-art Academy in Cork or Dublin by fully qualified pro fessionals in a relaxed, informal environment.

The courses are free to attend and will be led by mem bers of our Technical Team who have a wealth of practical knowledge and installation practices, and feature a detai led tour of the Pipelife manufacturing facility where visi tors are given the opportunity to see first-hand where our products are designed and manufactured.

The free courses will be available to installers, service en gineers, plumbers, merchants, architects, local authorities and BER Assessors. By offering a valuable insight into each of our heating technologies, those who attend our courses will be equipped with the best product knowle dge and installation techniques, ensuring that our custo mers are fully satisfied. We are also a registered training provider with Engineers Ireland.

Heat Pump Training -

Intended for domestic heating and renewable installers who wish to know more about our Air to Water heat pump range. Training covers both the Hitachi Yutaki S Split Com bi and Midea Monobloc Heat pumps. This course covers its construction, principles of operation, electrical wiring, controller settings, sizing, selection of the correct unit(s) to suit the property concerned, installation considerations, requirements and commissioning the complete system.

Intended for domestic heating installers of boilers or Air to Water Heat Pumps either with Underfloor Heating experience or those wishing to know more about Pipelife underfloor heating systems. This training course covers the basic principles of underfloor heating and the system design considerations, as well as full details of the Pipe life systems, their installation, filling, pressure testing and commissioning. Also included are full details of the Pipeli fe UFH control system, the options, operation, installation and set-up.

CPD training for Architects, Engineers, Energy Asses sors, etc

Continuous Personal Development (CPD) is training we provide here and off site for architects, engineers, energy assessors and similar minded professionals. These certi fied courses are available in many technologies, give in sight and knowledge on current and new products and areas for which are relevant to attendees.

Our course titles are -

• Underfloor Heating Systems Design & Control

• An Introduction to Air to Water Heat Pumps – Split Combi Unit

• An Introduction to Air to Water Heat Pumps – Mono bloc

For off-site training contact ireland@pipelife.com for booking details.

To book your training day with Pipelife please contact us at Ireland@pipelife.com, contact us on 021 4884700 or visit our website www.pipelife.ie/training

We currently offer 3 CPD courses which enable installers, engineers, architects, local authorities and BER assessors, throughout the island of Ireland with the opportunity to earn one CPD point for their professional development and gain better knowledge of our heat pump technology and in particular the appropriate sizing specific to Pipelife heat emitters.

Those interested in attending Pipelife’s new Underfloor and Heat Pump technology courses, can access the cour se in three ways. This includes in-person training where a Pipelife trainer will attend your place of work to deliver the course, or delegates can attend one of Pipelife’s training academies at our premises in Cork or Dublin. This varied approach ensures continued professional development accessible for all.

This new Engineers Ireland approved course from Pipe life has been developed by the manufacturers specialist training team to further educate engineers throughout Ireland on Pipelife’s range of innovative heating techno logies and how these technologies work together effecti vely to maximise efficiencies and long-term carbon and cost savings.