Good. Safe. Klingspor.

Australian Catalogue

Klingspor products are marked with the oSa label

What does oSa mean?

In a host of applications, grinding and cutting require very high peripheral speeds from the rotating abrasive product. These products must therefore be particularly safe so as to stand up to the extreme mechanical and thermal stress.

Regrettably there are no globally binding safety requirements for abrasive products.

This is why responsible manufacturers of abrasive products from a number of European countries set up the Organisation for the Safety of Abrasives (oSa) in 2000 and thus setting a clear signal against inferior and dangerous products.

The user recognises these quality grade products from the oSa trade name. They signify to the manufacturer and trader a reduced liability risk, a market and competitive benefit and an image gain.

As a part of their in-house quality management system, the manufacturers see to it that the exact provisions are kept to and that only safe, high quality abrasive products are produced and marketed. The fact that the oSa – Organisation for the Safety of Abrasives - issues the worldwide protected oSa trademark to members is confirmation of this internal commitment.

The oSa label does not mean that the Organisation for the Safety of Abrasives or its institutions assume any liability of the designated products.

General information Contents 3 Product overview 5-7 Coated abrasives Applications guide 8-11 Rolls Rolls 12-15 Belts Short and long belt s 16-27 Sleeves 27-28 Wide belt s Wide belts 29-37 Fibre disc s Applications guide 38-41 Fibre discs 42-47 Strips/sheets/disc s Strips/sheets Strips/sheets, blocks, sponges 48-53 Discs Applications guide 54-55 Disc s 56-64 Quick Change Disc s Quick Change Disc s 65-67 Abrasive flap wheels Applications guide 68-73 Abrasive flap wheels, drums 74-77 Small abrasive flap wheels Applications guide 78-79 Small abrasive flap wheels 80-81 Non-woven products Applications guide 82-89 Non-woven rolls 90 Non-woven hand pads 91 Non-woven belt s 92 Non-woven discs 92-94 Non-woven quick change discs 94-96 Non-woven flap wheels and drums 97-99 Non-woven abrasive flap discs 99-100 Unitised wheels, clean and strip discs, power wheels 100-103

Abrasive flap discs Applications guide 104-109 Abrasive flap disc s 110-113 Cutting-off wheels Applications guide 114-123 Cutting-off wheels 0,8-1,2 mm 124-126 Small cutting-off wheels 127 Cutting-off wheels 1,6-1,9 mm 128 Cutting-off wheels 2,0-3,2 mm 129-132 Large cutting-off wheels 133-135 Grinding disc s Applications guide 136-137 Gr inding disc s 138-141 Diamond tools Applications guide 142-147 Diamond cutting blades 148-151, 154-158 Diamond cup gr inding wheels 152-153 Diamond dr ill bits & ot her diamond tools Diamond drill bits 159-16 Flex ible abrasives Fle xible abrasives 162-163 Carbide burrs Applications guide 164-167 Carbide burr s 168-171 Wire brushes Applications guide 172-179 Wire brushes 180-187 Retail range Applications guide 188-189 Retail range 190-201 Service Safety recommendations 202-203 Conditions of Sale 204-205 General information

Contents

The product groups at a glance

With this catalogue, Klingspor makes it quick and easy to select the products you need from our huge range of top quality abrasives. The clearly arranged categorisation into thirteen product groups will help you quickly find what you are looking for. State-of-the-art manufacturing techniques ensure that our coated abrasives fulfill the most demanding standards of surface finish, long life and stock removal.

Rolls

Klingspor rolls for hand sanding or use with handheld machines are available in a number of special grades designed for a wide variety of materials – from wood, to metal, to paint.

Belts

Klingspor abrasive belts are available in various sizes and grades to meet all grinding, sanding and finishing requirements for a wide range of materials and applications.

Fibre discs

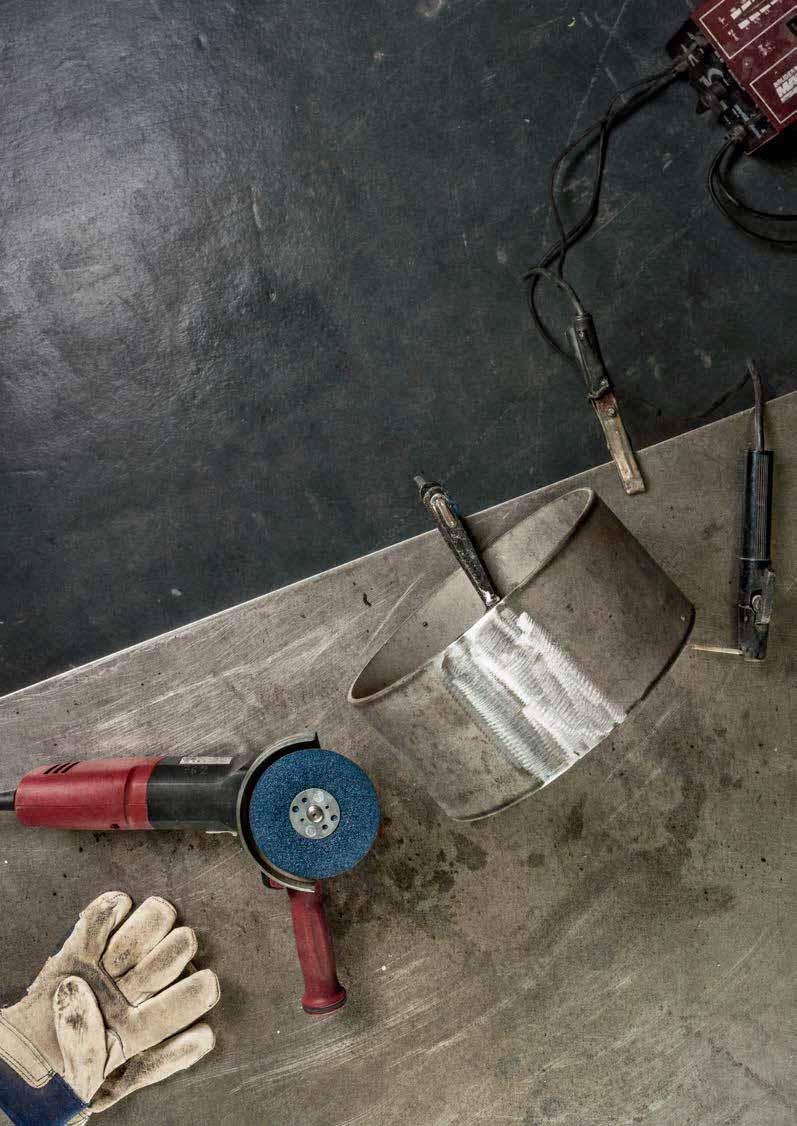

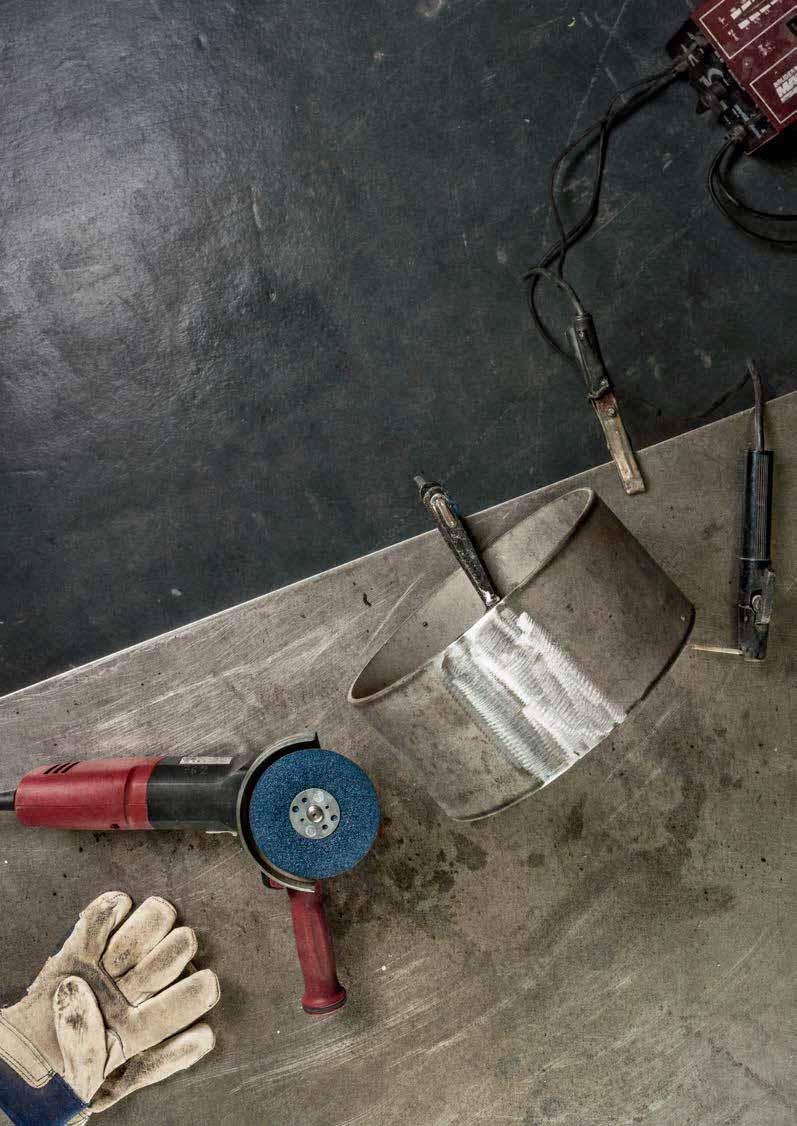

Klingspor fibre discs are exceptionally suited for rough grinding work, rust removal, deburring and working on welded seams.

Abrasive strips, sheets and discs

Klingspor strips, sheets and discs are available in various qualities and designs.

Abrasive flap wheels

The abrasive flap wheel is particularly suitable for finishing where flexibility is a must. It matches the contours of any workpiece perfectly. Klingspor has the right abrasive flap wheel for virtually every application and for nearly all types of material.

4

General information Product overview

Non-woven products

Klingspor offers a large variety of nonwoven products. From rolled goods, belts and wheels to abrasive angle grinder mop discs and abrasive spindle mop varieties.

Wire brushes

Klingspor wire brushes for use on the most diverse cleaning and surface preparation applications on steel and stainless steel.

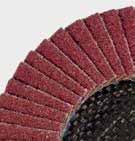

Abrasive flap discs

The performance of the Klingspor abrasive flap disc, with its fan-shaped radial arrangement of the cloth grinding flaps, far exceeds that of other abrasive products.

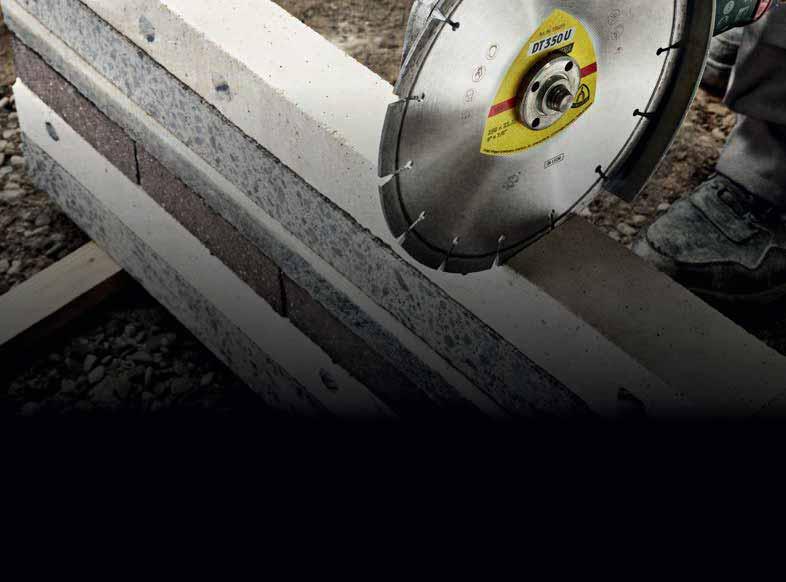

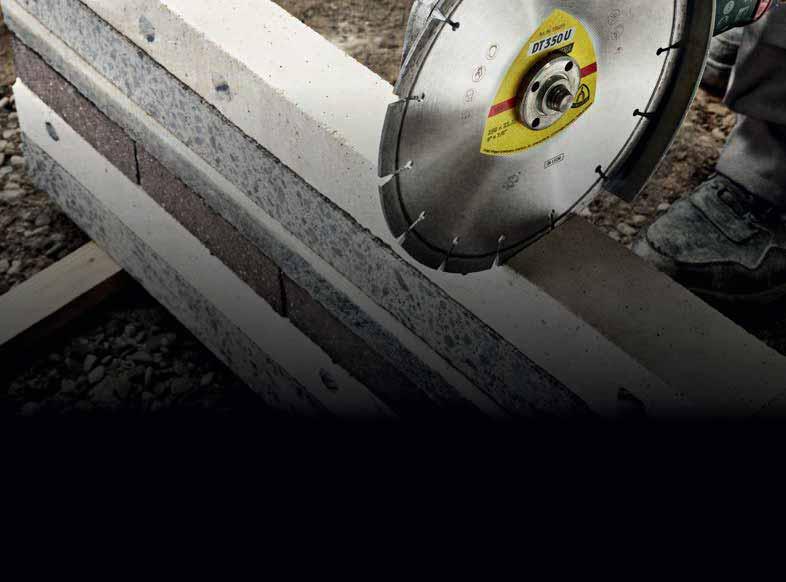

Kronenflex grinding discs and cutting-off wheels

Continuous innovation and the development of specialised products for all application areas enables Klingspor to offer a range of grinding discs and cutting-off wheels to satisfy every need.

Retail range

The complete range available with relevant grit ranges and assortments in customised packing units. Uniform packing design with precise product identification for quick access.

Flexible abrasives

Flexible abrasives which were developed by Klingspor for precision finishing and polishing work on all kinds of surfaces.

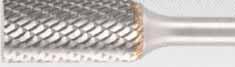

Carbide burrs

Klingspor carbide burrs are manufactured according to the highest quality standards and with utmost precision. The different cuts are adapted to meet the specific requirements of various materials and applications.

Diamond tools

Klingspor's comprehensive range of diamond tools makes it easy for any user to work faster and with greater precision and endurance. As they are made of carefully tested premium grade materials, the products included in each product line offer a wide range of possible applications and meet the highest safety standards.

5 General information

Product

General information

overview

6

Pad / stroke sanding machine

Hand tool belt grinder

Drilling machine

Back stand grinding machine Die grinder Cordless screwdriver

Centreless linishing machine

Portable

Satin finishing machine Hand sanding Hand block Handheld brush Orbital sander Random orbital

Through-feed grinding machine Floor standing grinder

Edge sanding machine Delta sander Contour linishing machine Wide belt linishing machine

belt sander

sander

General information Product overview

General information Product overview

7 General information

Joint cutter

Right angle die grinder

Variable speed angle grinder

Stationary cutting machine ≤ 5kW

Fillet weld grinder

Angle grinder

Angle grinder with brush

Chop saw

Joint router

Angle grinder with cup grinding wheel

Table saw

Petrol powered cutter

Flexible sha grinder

Petrol powered cutter with clamping device

Li ing beam with mottling points

Percussion drill

Stationary cutting machine > 5kW

Parquet sander Drill stand

Coated abrasives Applications guide

Coated abrasives are abrasive products that are made out of more or less flexible backing material upon which grit is anchored with a bonding agent. The product family “coated abrasives” includes abrasive belts, rolls, sheets, strips and discs. They comprise of the following four, optionally also five, components (please refer to the illustration on the right).

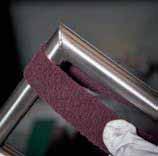

1. Backing

2. Base coat

3. Grit

4. Topsize coat

5. Optional: additional coating

Structure

1. Coated abrasive backing

The backing is coated with grit and transfers stock removal forces onto the workpiece. The following backings are primarily used in the manufacture of coated abrasives:

Paper Cotton cloth Polyester cloth

In addition, at Klingspor the following backings are used exclusively for individual products and/or for specific requirements/applications:

Fibre (is used exclusively for fibre discs on portable angle grinders) Film (is used exclusively for the products FP 73 W and FP 73 WK)

GX-blended cloth (special cotton/polyester blend for flexible yet highly tear resistant belts)

Tear resistance Flexibility JF-cloth J-cloth XF-cloth X-cloth Y-/Z-cloth Fibre Film A-paper B-paper C-paper D-paper E-paper F-paper GX-blended cloth G-paper

Paper and cloth backing classification in relation to tear resistance and flexibility

Coated abrasives Applications guide

Backing Description

Application examples

A – paper approx. 95 g/m² profile + surface finishing (hand)

B – paper approx. 105 g/m² profile + surface finishing (hand and machine)

C – paper approx. 110 g/m²

D – paper approx. 130 g/m²

E – paper approx. 250 g/m²

F – paper approx. 300 g/m²

G – paper approx. 400 g/m²

JF – cloth

GX – blended cloth

J – cloth

XF – cloth

X – cloth

Y – polyester

Z – polyester

light, highly flexible

surface finishing (hand and machine)

surface finishing (hand and machine)

surface grinding and sanding (machine)

surface grinding and sanding (machine)

surface grinding and sanding (machine)

high profiled workpieces (hand and machine)

light, flexible profiled workpieces (machine)

light, flexible profiled workpieces (hand and machine)

heavy, flexible hand tool belt grinder

heavy, firm

heavy, highly firm

surface and edge grinding and sanding (hand and machine)

surface and edge grinding and sanding (machine)

heavy, highly firm, can be segmented surface grinding (machine)

Film polyester film

finishing

Fibre vulcanised fibre grinding and finishing

2. Base coat

In the base coat step the grit is anchored. The basic bond is the connection between the grit and the backing. It is primarily formed using resin, this provides it with its consistent high quality properties. Glue is only added to a few abrasive papers that are used with hand operated machines and applications.

3. Grit

Grit is responsible for stock removal. When selecting the correct grit two properties are particularly important:

Bond

Toughness

All Klingspor grit types are produced synthetically. This ensures a consistently high quality product. Four different grit types are used with coated abrasives:

Silicon carbide

Aluminium oxide

Zirconia alumina

Ceramic aluminium oxide

Hardness

Zirconia alumina

Super alloys

Chipboard

Composite materials

Toughness

Grit classification in relation to bond, toughness and their primary applications

9 General information

Glass SiC Aluminium oxide Stone Plastics Varnishes

Steel Stainless steel Stainless steel

NF-metals WoodSteel

Ceramic aluminium oxide

Coated abrasives Applications guide

Silicon carbide (SiC) very hard / less tough crystalline

sharp-edged, brittle, highly friable / micro-wear

Aluminium oxide hard / tough crystalline, irregular

wedge-shaped, block grain, even wear

Zirconia alumina hard / very tough crystalline, even

wedge-shaped, block grain / micro-wear, self-sharpening

Ceramic aluminium oxide hard / very tough micro-crystalline

Grit type properties and their specific wear properties

sharp-edged, pointed grit / micro-wear, self-sharpening

Definition Description

Close coating The entire surface of the backing is coated with grit Semi-open coating Approx. 75% of the backing surface is coated with grit Open coating Approx. 50% of the backing surface is coated with grit

In addition, there are also so-called grit agglomerates. This is not an independent grit type, rather it is a grit agglomeration which is comprised of many individual aluminium-oxide or SIC-grits mixed with a resin bonding agent, which together form a large grit. Agglomerates are used almost exclusively on abrasive belts.

The advantage of agglomerates is that they provide an even finish from the first use to the last. Dull grit breaks off from the agglomerate and creates space for new, sharp grit. The objective is to attain an even finish through continual stock removal and an extremely long service life.

Coating

Moreover, the coated abrasives are coated with different grit coverage densities. The term “grit density” describes the grit coverage density distributed on the backing.

One differentiates between: close coating semi-open coating open coating

Open coated grit has a large space between the individual grits, such that the stock removal and the grinding dust can be extracted more easily from the grinding surface. This prevents premature clogging when working on long-chipping materials, such as wood.

The decision as to which grit density to use is primarily dependent upon how great the likelihood is that the grinding dust will clog the space between the grits.

10

Grain type Bond / toughness Structure Properties / wear properties

Coated abrasives Applications guide

Grit size chart

4. Size coat

The size coat supports the base coat in the anchoring of the grit on the backing and against forces which affect the grit during grinding. The cover bonds are produced exclusively from resin and also provide the product with its typical colour (exceptions are coated abrasives with additional coatings).

5. Special coatings

Special coatings with grinding aids provide the grinding tool properties that positively affect the grinding process and extends the service life of the coated abrasive. Special coatings are applied as an additional layer.

Stearate coating

The stearate on a coated abrasive prevents the clogging and loading of the belt and is specifically suited for high quality varnish surface applications. Paints, varnishes and plastics can become so and sticky through the heat generated from grinding, this can result in the premature clogging and loading of the belt. The dust clogs the space between the grits and this can result in additional “negative bond“. This clogs the grits and the sharp edges are no longer effective. To prevent this from happening or to slow the process down, the coated abrasives can be coated with a non-stick material, so-called stearates.

Multibond

The multibond, like the stearate coating, is applied in an additional production step to the cover bond layer. This allows the cool grinding of stainless steel and high alloy steels, which in turn increases the stock removal rate and service life.

ACT – Advanced Coating Technology

Klingspor uses this technology to improve the properties of the coated abrasives. When working on metal, ACT provides significantly higher grit adhesion, e.g. for aggressive belt grinding of the edges of punched parts and castings. This significantly increases the life of the grinding belt. For belts that are used for wood and varnish sanding, ACT prevents the premature clogging of the coated abrasives and significantly increases the service life.

Antistatic

Electrode migration is the result of friction i.e. grinding between different materials, and in turn causes charge separation, which in the case of non-conductive materials, such as wood, results in the load differences not being balanced. In these cases, the coated abrasive is equipped with antistatic properties that ground the electrical charge through the coated abrasive and the machine. This prevents the grinding dust from adhering to the workpiece, belt and machine.

11 General information ANSI FEPA JIS P 2000 P 360 P 100 P 800 P 220 P 40 P 1200 P 280 P 60 P 500 P 150 P 30 P 16 P 1500 P 320 P 80 P 600 P 180 P 36 P 20 P 1000 P 240 P 50 P 400 P 120 P 24 P 12 2000 360 100 800 220 40 1200 280 60 500 150 30 16 1500 320 80 600 180 36 20 1000 240 50 400 120 24 12 360 100 220 40 280 60 500 150 30 16 320 80 180 36 20 240 50 400 120 24 12 600 Extra fine Fine Coarse Extra coarse Micro finishing Finishing Intermediate grinding Rough grinding

Rolls with paper backing

Coated abrasives

Abrasive paper

PS 30 D

Properties Applications:

Bonding agentResin

GrainAluminium oxide

CoatingSemi-open

BackingD-paper

Paint/Varnish/Filler J

Wood J

Metals K

Advantages: Sharp grit and high aggressiveness for use on wood, varnish, fillers - Flexible and tear resistant, easy folding - Product with good price-performance ratio

Other grits and sizes available on request.

12

Available grits: 16243036 40 50 6080100120150180220240 280 320 360400500600800100012001500200025003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 100 x 50000401 252415 100 x 50000601 252419 100 x 50000801 252420 100 x 500001201 252422 100 x 500001801 252424 115 x 50000401 174086 115 x 50000601 174088 115 x 50000801 174089 115 x 500001201 174091 115 x 500001801 174093

Rolls with paper backing

Coated abrasives

31 B

Advantages: Product with optimal price-performance ratio - Optimized wear properties for hand sanding and handheld machine sanding

PS 33 C

Advantages: Very high removal rate - Minimal clogging due to active abrasive substances - Longer service life - Good tear resistance and flexibility

Other grits and sizes available on request.

Rolls 13

Properties Applications: Bonding agentGlue GrainAluminium oxide CoatingSemi-open BackingB-paper Paint/Varnish/Filler J Wood J Metals K

Finishing paper PL

Available grits: 16243036 40506080100120150180220240280320 360 400 500600800100012001500200025003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 95 x 50000601 3281 95 x 50000801 3282 95 x 500001001 3191 95 x 500001201 3192

paper

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingSemi-open BackingC-paper Paint/Varnish/Filler J Wood J Plastic K

Available grits: 16243036 40 50 6080100120 150180220240280320360400500600800100012001500200025003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 100 x 50000801 248544 100 x 500001001 201722 100 x 500001201 300082 115 x 50000401 158947 115 x 50000601 155815 115 x 50000801 147575 115 x 500001001 147576 115 x 500001201 153398

Abrasive

Rolls with paper backing

Coated abrasives

33 B

Advantages: Very high removal rate - Minimal clogging due to active abrasive substances - Longer service life - Good tear resistance and flexibility

381 J

Standard product for wood and metal processing

Other

and sizes available on request.

14

paper

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingSemi-open BackingB-paper Paint/Varnish/Filler J Wood J Plastic K

Abrasive

PS

Available grits: 1624303640506080100120 150180220240280320 360 400500600 800100012001500200025003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 100 x 500001801 212055 100 x 500002401 160282 115 x 500001501 153177 115 x 500001801 149480 115 x 500002401 147055 115 x 500003201 148891 115 x 500004001 145520 Abrasive cloth

Properties Applications: Bonding agentGlue/resin GrainAluminium oxide CoatingClose BackingJ-cotton Wood J Metals J

Available grits: 16 24 30 3640506080100120150180220240 280 320 360 400 500600800100012001500200025003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 25 x 50000401 337941 25 x 50000601 337959 25 x 50000801 337951 25 x 500001201 337952 25 x 500001801 337953 25 x 500002401 337954

KL

Advantages:

grits

Rolls with cloth backing / Graphite coated canvas

Coated abrasives

Continuation of KL 381 J, Abrasive cloth

X

Properties

GrainGraphite

CoatingLamellar

BackingX-cloth

Thickness1,5 mm

Advantages: Reduces friction between the back side of the belt and the contact element - Reduces heat generation during the grinding process - Enables a smooth and constant grinding

No self-fastening support

All sizes and minimum purchasing quantities available on request

Other grits and sizes available on request.

Rolls 15 Width x Length in mm Grit Packing unit/pcs. Cat. number 50 x 50000401 337955 50 x 50000601 337958 50 x 50000801 337960 50 x 500001001 337957 50 x 500001201 337956 50 x 500001801 337961 50 x 500002401 337962 50 x 500003201 359015 50 x 500004001 364579

Graphite coated canvas CS 395

File belts

Coated abrasives

Abrasive cloth, multibond

CS 409 Y

Advantages: Aggressive abrasive behaviour - Cool grinding and increased grinding performance on stainless steel and high-alloy steels due to additional multibond - Very long service life also when used for grinding of non-ferrous metals

CS 411 X

Advantages: High aggressiveness and abrasive performance in rough grinding of steel and stainless steel - Very versatile in all areas of metalworking

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

16

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingClose BackingY-polyester Stainless steel J NF metals K

Available grits: 162430 3640 50 6080 100 120 150180220240280320360400500600800100012001500200025003000 Width x Length in mm Grit Belt joint Packing unit/pcs. Cat. number 10 x 33060F4G50 255422 20 x 52060F4G50 255432 Abrasive cloth

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingClose BackingX-cotton Stainless steel J Steel J Metals J

Available grits: 16 24 30 3640506080 100 120 150180220240280320360400500600800100012001500200025003000 Width x Length in mm Grit Belt joint Packing unit/pcs. Cat. number 10 x 33060F4G25 78849 12 x 33060F4G25 255423

File belts

Coated abrasives

Abrasive cloth, waterproof

CS 416 Y

Advantages: Very high aggressiveness and abrasive performance - Long service life also when used on materials that cause clogging

Other grits and sizes available on request.

Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Belts 17

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingSemi-open BackingY-polyester Stainless steel J Plastic J Leather J NF metals K

Available grits: 16 24 30 3640 50 6080100120 150180220240280320360400500600800100012001500200025003000 Width x Length in mm Grit Belt joint Packing unit/pcs. Cat. number 10 x 33040F4G50 318648 10 x 33060F4G50 307971 10 x 33080F4G25 307972 10 x 330120F4G25 318651 20 x 52040F4G50 318649 20 x 52060F4G50 307973 20 x 52080F4G50 307974 20 x 520120F4G50 318650

Short belts for hand held machines

Coated abrasives

LS 309 XH

Advantages: Special type for portable belt sanders - For universal use on wood, metal, paint and varnish - Large product mix of belts for all standard machines

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

18

Abrasive cloth

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingClose BackingX-cotton Wood J Metals J NF metals J Paint/Varnish/Filler K

Available grits: 16243036 40 50 6080100120150180 220 240 280320360400500600800100012001500200025003000 Width x Length in mm Grit Belt joint Packing unit/pcs. Cat. number 75 x 45740F510 329835 75 x 45760F510 329836 75 x 45780F510 329837 75 x 457120F510 329838 75 x 53340F510 321263 75 x 53360F510 321264 75 x 53380F510 321265 75 x 533100F510 321266 75 x 533120F510 321267 75 x 61040F510 321268 75 x 61060F510 321269 75 x 61080F510 321270 75 x 610100F510 321271 75 x 610120F510 321272 100 x 53340F510 329821 100 x 53360F510 329822 100 x 53380F510 329823 100 x 533120F510 329824 100 x 61040F510 321273 100 x 61060F510 321274 100 x 61080F510 321275 100 x 610100F510 321276 100 x 610120F510 321277

Belts with paper backing

Coated abrasives

Abrasive paper PS 21 F

Advantages: High aggressiveness and long service life due to self-sharpening zirconia aluminaSpecially developed for rough grinding through finish grinding of stainless steel surfaces

Abrasive paper, ANTISTATIC PS 24 F ACT

Advantages: For hard and tough surfaces - Finely sanded and varnish surfaces in the wood and furniture industry - Long service life due to ACT recipe and antistatic properties

Abrasive paper, ANTISTATIC PS 27 DW

Advantages: Special product for high-quality varnish surfaces, especially UV finishes - Substantially reduced clogging and longer service life due to additional special coating - Very fine surface scratch pattern

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Belts 19

Bonding

Grain

CoatingClose

Stainless steel J Metals J Steel J

Properties Applications:

agentResin

Zirconia alumin./ Al. oxide

BackingF-paper

Available grits: 16243036 40 50 6080100120 150 180220 240 280 320360 400 500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

All

Applications: Bonding agentResin GrainSiC CoatingClose BackingF-paper Paint/Varnish/Filler J Plastic J Wood K

Properties

Available grits: 16243036405060 80 100 120150180 220 240 280 320 360 400 500 600800 100012001500200025003000 All sizes and minimum purchasing quantities available on request

Bonding

GrainSiC CoatingOpen BackingD-paper Paint/Varnish/Filler J Aluminium J Plastic K

Properties Applications:

agentResin

Available grits: 1624303640506080100120150 180 220 240280320 360 400 500 600 800100012001500200025003000

sizes and minimum purchasing quantities available

All

on request

Belts with paper / cloth backing

Coated abrasives

PS 29 F ACT

Advantages: High-quality universal belt for general woodworking, especially softwood - Reduced clogging and longer service life due to ACT recipe and antistatic properties

Advantages: High removal rate in metalworking and woodworking - Very good adaptation to radiuses and contours due to highly flexible cotton backing

All

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

20

Applications: Bonding agentResin GrainAluminium oxide CoatingOpen BackingF-paper Wood J

Abrasive paper, ANTISTATIC

Properties

Available grits: 16243036 40 50 6080100120150180 220 240 280320360400500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

All

Applications: Bonding agentResin GrainAluminium oxide CoatingClose BackingJF-cotton Metals J NF metals J Wood J

Abrasive cloth LS 309 JF Properties

Available grits: 16243036405060 80100120 150 180 220 240 280 320 360 400 500 600 800100012001500200025003000

sizes and minimum purchasing quantities

available on request

Belts with cloth backing

Coated abrasives

CS 310 X

Advantages: High-quality universal type for metalworking and woodworking - Good removal rate under high stress

CS 311 Y ACT

Advantages: Good removal rate for working on wood under high stress - Minimal clogging and long service life due to ACT recipe and antistatic properties

All sizes and minimum purchasing quantities available on request

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Belts 21

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingClose BackingX-cotton Stainless steel J Wood J Steel J NF metals J Plastic K

Abrasive cloth

Available grits: 16 24 30 3640 50 6080100120150180 220 240 280 320 360 400500600 800100012001500200025003000 Width x Length in mm Grit Belt joint Packing unit/pcs. Cat. number 50 x 91540F4G12 257198 50 x 91560F4G12 257199 50 x 91580F4G12 280156 50 x 915120F4G12 284570

Applications: Bonding agentResin GrainAluminium oxide CoatingOpen BackingY-polyester Wood J Metals K

Abrasive cloth ANTISTATIC

Properties

Available grits: 162430 3640 50 6080100120150180220 240280320360400500600800100012001500200025003000

Belts with cloth backing

Coated abrasives

Abrasive cloth

LS 312 JF

Advantages: Outstanding removal rate and service life due to active abrasive substances - Very good adaptation to radiuses and contours due to highly flexible cotton backing

Abrasive cloth, waterproof CS 320 Y Properties

Advantages: Outstanding abrasive performance on hard and difficult-to-machine materials - Ideal for high stress - Can be used wet or dry

Abrasive cloth, waterproof CS

321 X

Advantages: Outstanding abrasive performance on hard and difficult-to-machine materials - Ideal for wet grinding, but also suitable for dry grinding

All sizes and minimum purchasing quantities available on request

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

22

Applications: Bonding agentResin GrainAluminium oxide CoatingClose BackingJF-cotton Stainless steel J Metals J NF metals J Steel J Wood K

Properties

Available grits: 162430364050 6080100120150180 220 240 280 320 360 400 500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

All

Applications: Bonding agentResin GrainSiC CoatingClose BackingY-polyester Glass/Stone J Mineral based materials J Plastic J

Available grits: 16243036 40 50 6080100 120150180220240280320360400500600800100012001500200025003000

sizes and minimum purchasing quantities

on request

All

available

Bonding agentResin GrainSiC CoatingClose BackingX-cotton Glass/Stone J Mineral based materials J Plastic J

Properties Applications:

Available grits: 1624303640506080100 120 150 180 220 240 280 320 360 400500 600 800 100012001500200025003000

Belts with cloth backing

Coated abrasives

Abrasive cloth, waterproof CS 322 X

Properties Applications:

Bonding agentResin

GrainCork

BackingX-cotton

Glass/Stone J

Advantages: Special product for polishing glass with high quality cork/resin coating - Long life with consistent polishing effect - Waterproof

All sizes and minimum purchasing quantities available on request

Abrasive cloth, KULEX CS 326 Y

Properties Applications:

Bonding agentResin

Grain Al. oxide agglom.

BackingY-polyester

Stainless steel J Steel J

Advantages: Long-life abrasive belt for a satin surface scratch pattern, under medium to high grinding pressure - Extremely long life, with consistent surface roughness and finish - Suitable for wet grinding

All sizes and minimum purchasing quantities available on request

Abrasive cloth, multibond CS 409 Y

Properties Applications:

Bonding agentResin

GrainZirconia alumina

CoatingClose

Stainless steel J

metals K

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Belts 23

Available grits: 16243036405060 80 100 120 150 180 220 240 280 320 360 400 500600800100012001500200025003000

BackingY-polyester NF

Available grits: 162430 3640 50 6080 100 120 150180220240280320360400500600800100012001500200025003000 Width x Length in mm Grit Belt joint Packing unit/pcs. Cat. number 50 x 91540F4G12 280201 50 x 91560F4G12 280202 50 x 91580F4G12 280203 50 x 915120F4G12 280204

Advantages: Aggressive abrasive behaviour - Cool grinding and increased grinding performance on stainless steel and high-alloy steels due to additional multibond - Very long service life also when used for grinding of non-ferrous metals

Belts with cloth backing

Coated abrasives

411 X

Advantages: High aggressiveness and abrasive performance in rough grinding of steel and stainless steel - Very versatile in all areas of metalworking

412 Y

Advantages: High-quality universal type for wet and dry grinding of stainless steel, steel and other metal surfaces

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

24

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingClose BackingX-cotton Stainless steel J Steel J Metals J

Abrasive cloth CS

Available grits: 16 24 30 3640 50 6080 100 120 150180220240280320360400500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

All

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingClose BackingY-polyester Metals J NF metals J Stainless steel J Steel J Wood K

Abrasive cloth, waterproof CS

Available grits: 162430 3640 5060 80 100 120 150 180 220 240 280320360400500600800100012001500200025003000

sizes and minimum purchasing quantities available on

All

request

Belts with cloth backing

Coated abrasives

Abrasive cloth, waterproof CS

416 Y

Advantages: Very high aggressiveness and abrasive performance - Long service life also when used on materials that cause clogging

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Belts 25

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingSemi-open BackingY-polyester Stainless steel J Plastic J NF metals K

Available grits: 16 24 30 3640 50 6080100120 150180220240280320360400500600800100012001500200025003000 Width x Length in mm Grit Belt joint Packing unit/pcs. Cat. number 50 x 91540F4G12 280622 50 x 91560F4G12 280623 50 x 91580F4G12 280624 50 x 915120F4G12 280665 50 x 122040F4G12 281992 50 x 122060F4G12 281993 50 x 122080F4G12 281994 50 x 1220120F4G12 282065 75 x 200036F4G10 204858 75 x 200040F4G10 205377 75 x 200060F4G10 207651 100 x 91540F4G12 284572 100 x 91560F4G12 284573 100 x 91580F4G12 284575 100 x 915120F4G12 318652 150 x 200036F4G10 231336 150 x 200040F4G10 205474 150 x 200060F4G10 204213

Belts with cloth backing

Coated abrasives

Abrasive cloth, multibond CS 920

Y ACT

Properties Applications:

Bonding agentResin

GrainCeramic Al. oxide

CoatingClose

BackingY-polyester

Advantages: Special product with Advanced Coating-Technology (ACT) - Excellent grit adhesionHighly tear-restistant polyester backing and self sharpening ceramic grain for rough, and intermediate grinding of stainless steel and high alloyed steel at high loads - Higher service life and cool grinding due to special coating with active multibond

All

Abrasive cloth, waterproof CS 922

Y ACT

Properties Applications:

Bonding agentResin

GrainCeramic

CoatingSemi-open

BackingY-polyester

Advantages: Continuously aggressive grinding behaviour - Long service life due to self-sharpening ceramic grit - Very high grain adhesion thanks to Advanced Coating Technology and highly tearresistant polyester backing

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

26

High alloy steel

Stainless steel J

J

grits: 16 24 30 36 4050 60 80100120150180220240280320360400500600800100012001500200025003000

Available

sizes

purchasing

and minimum

quantities available on request

Al. oxide

steel

Steel J

Stainless

J

Available grits: 162430 3640506080100120 150180220240280320360400500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

All

NEW ! NEW !

Belts with cloth backing / Abrasive sleeves

Coated abrasives

931 JF

Abrasive cloth, multibond CS

Properties Applications:

Bonding agentResin

GrainCeramic Al. oxide

CoatingSemi-open

BackingJF-cotton

Stainless steel J

Titanium/Alloy J

Advantages: Special product with high flexible backing for the processing of stainless steel and high-alloyed steel - Continuously aggressive grinding properties with high lifetime due to semiopen coated self-sharpening ceramic grain - Very good adaptability to radiuses and edges through high flexible backing - The additional multibond provides a “cool grinding” in the processing of stainless steel and thus tempering colours are avoided

All sizes and minimum purchasing quantities available on request

Abrasive cloth, multibond CS

410 X

Properties Applications:

CoatingClose

BackingX-cotton

Advantages: Tear-resistent cloth with reinforced backing - Spiral shaped joint, cylindrical formCool grinding and no heat tinting due to additional multibond - Increased abrasive performance for use on stainless steel - High aggressiveness when used with rubber drum GK 555

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Belts 27

1624303640506080100120150180220 240 280320360 400 500600800100012001500200025003000

Available grits:

Bonding agentResin

GrainAluminium oxide

Stainless steel J NF metals K

Available grits: 16243036 40 50 6080 100 120 150180220240280320360400500600800100012001500200025003000 Diameter x Height in mm Grit Packing unit/pcs. Cat. number 19 x 254050 324115 19 x 256050 324116 19 x 258050 328370 19 x 2512050 328369 25 x 254050 324117 25 x 256050 324118 25 x 258050 328368 25 x 2512050 328367 38 x 254050 324119 38 x 256050 324121 38 x 258050 328366 38 x 2512050 328365

Rubber drums

Rubber drums GK 555

Advantages: Reusable rubber drum for cylindrical abrasive sleeves CS 310 X and CS 451 XMounting and dismounting by a light turn

28

Diameter x Width x Shaft in mm Max. operating speed Max. RPM Packing unit/pcs. Cat. number 19 x 25 x 630 m/s30000 rpm1 329898 25 x 25 x 630 m/s23000 rpm1 329897 38 x 25 x 630 m/s15000 rpm1 329899

Wide belts with paper backing

Coated abrasives

Abrasive paper PS 21 F

Advantages: Aggressive abrasive behaviour due to self-sharpening zirconia alumina - Optimal recipe for rough grinding and finish grinding of stainless steel

Abrasive paper, ANTISTATIC PS 22 F ACT

All

Advantages: High removal rate, fine surface scratch pattern, especially suitable for hardwood, HPL panels and melamine and primer foil coatings - Reduced clogging and longer service life due to ACT recipe and antistatic properties

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Wide belts 29

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingClose BackingF-paper Stainless steel J Metals J Steel J

Available grits: 16243036 40 50 6080100120 150 180220 240 280 320360 400 500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingClose BackingF-paper Wood J Metals K NF metals K Paint/Varnish/Filler K Plastic K

Available grits: 1624303640506080100120150180220240280 320 360 400 500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

All

Wide belts with paper backing

Coated abrasives

Abrasive paper, ANTISTATIC PS 24 F ACT

Advantages: For hard and tough surfaces - Produces a brilliant, high gloss finish on stainless steel surfaces due to the very hard and sharp-edged silicon carbide grit - Long service life on varnish surfaces in the wood and furniture industry due to ACT recipe and antistatic properties

Abrasive paper, ANTISTATIC PS 27 DW

Advantages: Special product for high-quality varnish surfaces, especially UV finishes - Substantially reduced clogging and significantly longer service life due to additional stearate coating and antistatic properties

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

30

Properties Applications: Bonding agentResin GrainSiC CoatingClose BackingF-paper Stainless steel J Paint/Varnish/Filler J Plastic J Wood K

Available grits: 16243036405060 80 100 120150180 220 240 280 320 360 400 500 600800 100012001500200025003000

sizes and minimum purchasing quantities available on request

All

Properties Applications: Bonding agentResin GrainSiC CoatingOpen BackingD-paper Paint/Varnish/Filler J Aluminium J Plastic K

Available grits: 1624303640506080100120150 180 220 240280320 360 400 500 600 800100012001500200025003000

sizes and minimum purchasing quantities available on request

All

Wide belts with paper / cloth backing

Coated abrasives

PS 29 F ACT

Advantages: High-quality universal type for general woodworking - Large product mix - Reduced clogging and longer service life due to ACT recipe and antistatic properties

310 X

All

All

Advantages: Universal product with optimal price-performance ratio - Available in a wide grit range

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Wide belts 31

Applications: Bonding agentResin GrainAluminium oxide CoatingOpen BackingF-paper Wood J

Abrasive paper, ANTISTATIC

Properties

Available grits: 16243036 40 50 6080100120150180 220 240 280320360400500600800100012001500200025003000

sizes and minimum purchasing

on

quantities available

request

Applications: Bonding agentResin GrainAluminium oxide CoatingClose BackingX-cotton Metals J Steel J Stainless steel J Wood K Plastic K

Abrasive cloth CS

Properties

Available grits: 16 24 30 3640 50 6080100120150180 220 240 280 320 360 400500600 800100012001500200025003000

sizes

and minimum purchasing quantities available on request

Wide belts with cloth backing

Coated abrasives

Abrasive cloth ANTISTATIC CS

311 Y ACT

Properties

All

Abrasive cloth, waterproof CS 320

Y

Advantages: Specially developed for calibration grinding of wood - Reduced clogging and longer service life due to ACT recipe and antistatic properties

All

Properties

Advantages: Very hard and sharp silicon carbide grain for hard and tough workpiece surfacesHigh aggressiveness and abrasive performance - Especially suitable for wet grinding

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

32

Applications: Bonding agentResin GrainAluminium oxide CoatingOpen BackingY-polyester Wood J Metals K

Available grits: 162430 3640 50 6080100120150180220 240280320360400500600800100012001500200025003000

sizes and minimum purchasing quantities

available on request

Applications: Bonding agentResin GrainSiC CoatingClose BackingY-polyester Mineral based materials J Plastic J

Available grits: 16 24 3036 40 50 6080100 120150180220240280320360400500600800100012001500200025003000

sizes

purchasing

and minimum

quantities available on request

Wide belts with cloth backing

Coated abrasives

Abrasive cloth, waterproof CS 321

X

Properties Applications:

Bonding agentResin

GrainSiC

CoatingClose

Mineral based materials J

J Stainless steel J

Available grits:

Y

Abrasive cloth, KULEX CS 326

Bonding agentResin

Grain

Available grits:

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Wide belts 33

BackingX-cotton Plastic

1624303640506080100 120 150 180 220 240 280 320 360 400500 600 800 100012001500200025003000

Advantages: Produces a brilliant, glossy finish on stainless steel surfaces due to the very hard and sharp-edged silicon carbide grit - Very high aggressiveness and abrasive performance - Especially suitable for wet grinding

All sizes and minimum purchasing quantities available on request

oxide agglom.

Stainless steel J Steel J

Properties Applications:

Al.

BackingY-polyester

16243036405060 80 100 120 150 180 220 240 280 320 360 400 500600800100012001500200025003000

Advantages: Long-life abrasive belt for a satin surface scratch pattern, under medium to high grinding pressure - Extremely long life, with consistent surface roughness and finish - Suitable for wet grinding

All sizes and minimum purchasing quantities available on request

Wide belts with cloth backing

Coated abrasives

Abrasive cloth, multibond CS

409 Y

Properties Applications:

Bonding agentResin

GrainZirconia alumina

CoatingClose

BackingY-polyester

Advantages: Aggressive abrasive behaviour due to self-sharpening zirconia alumina - Prevents heat tinting on stainless steel - Cool grinding due to additional multibond - Minimal clogging when used on aluminium and aluminium alloys

All

Abrasive cloth CS

411 X

Properties Applications:

Bonding agentResin

GrainZirconia alumina CoatingClose

BackingX-cotton

Advantages: Aggressive abrasive behaviour - High-performance product for use on steel and stainless steel

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

34

Stainless steel J

Available grits: 162430 3640 50 6080 100 120 150180220240280320360400500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

Steel J Stainless steel J Metals J

Available grits: 16 24 30 3640 50 6080 100 120 150180220240280320360400500600800100012001500200025003000

All sizes and minimum purchasing quantities available on request

Wide belts with cloth backing

Coated abrasives

Abrasive cloth, waterproof CS 412 Y

Advantages: Universal product for rough and intermediate grinding of steel and non-ferrous metals

Abrasive cloth, waterproof CS 416 Y

All

Advantages: Very high aggressiveness and abrasive performance - Long service life also when used on materials that cause clogging

All sizes and minimum purchasing quantities available on request

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

Wide belts 35

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingClose BackingY-polyester Stainless steel J Metals J Steel J NF metals J Wood K

Available grits: 162430 3640 5060 80 100 120 150 180 220 240 280320360400500600800100012001500200025003000

sizes and minimum purchasing quantities available on request

Applications: Bonding agentResin GrainZirconia alumina CoatingSemi-open BackingY-polyester Stainless steel J Plastic J Leather J NF metals K

Properties

Available grits: 16 24 30 3640 50 6080100120 150180220240280320360400500600800100012001500200025003000

Wide belts with cloth backing

Coated abrasives

Abrasive cloth, multibond CS 920

Y ACT

Advantages: Special product with Advanced Coating-Technology (ACT) - Excellent grit adhesion - Highly tear-restistant polyester backing and self sharpening ceramic grain for rough, and intermediate grinding of stainless steel and high alloyed steel at high loads - Higher service life and cool grinding due to special coating with active multibond

Abrasive cloth, waterproof CS 922

Y ACT

Advantages: Continuously aggressive grinding behaviour - Long service life due to self-sharpening ceramic grit - Very high grain adhesion thanks to Advanced Coating Technology and highly tearresistant polyester backing

Other grits and sizes available on request. Please observe: Due to Manufacturing efficiencies, we reserve the right to over make or under make quantities of custom made belts.

NEW ! 36

Properties Applications: Bonding agentResin GrainCeramic Al. oxide CoatingClose BackingY-polyester Stainless steel J High alloy steel J

Available grits: 162430 36 4050 60 80100120150180220240280320360400500600800100012001500200025003000 All sizes and minimum purchasing quantities available on request

Applications: Bonding agentResin GrainCeramic Al. oxide CoatingClose BackingY-polyester Stainless steel J Steel J

Properties

Available grits: 162430 3640506080100120 150180220240280320360400500600800100012001500200025003000 All sizes and minimum purchasing quantities available on request

NEW !

Wide belts 37 Notes

Fibre discs

About the product

Klingspor fibre discs have high material removal rates and service life, producing an optimal finish. Suitable backing plates complete the product range.

Areas of use are steel, stainless steel, non-ferrous metal and cast iron. The comprehensive grit range makes it possible to select the right tool for every application. Even the most difficult of surfaces can be worked on easily with the fibre discs.

Klingspor fibre discs are outstanding for rough grinding and sanding, de-rusting metal parts, deburring and grinding welded seams. These discs are also suitable for precision finishing work on metals.

The state-of-the-art laser cutting technology allows special shapes for specific applications.

Quality and performance

Low clogging rate

Market leading service life

Even grinding finish

Cool grinding

Application Type Grain

Steel / NF metals

Steel / Stainless steel

Stainless steel

Applications Fibre Discs

Backing Coating Characteristics

CS 561 Aluminium oxide Fibre

FS 764 ACT Aluminium oxide Fibre

CS 565 Zirconia alumina Fibre

FS 964 ACT Ceramic aluminium oxide Fibre

CS 570 Zirconia alumina Fibre

FS 966 ACT Ceramic aluminium oxide Fibre

J = close K = semi-open I = open

J Abrasive fibre disc for working on steel and NF metals

J Abrasive fibre disc for processing steel and non-ferrous metals. High aggressiveness and long service life due to Advanced Coating Technology

J Abrasive fibre disc with high stock removal rate for rough grinding and deburring of steel and stainless steel

J

J

J

Premium fibre disc with micro-crystalline, self-sharpening ceramic grit delivering superior aggressiveness and removal on construction steel and high alloy steels. Outstanding grit adhesion and service life thanks to Advanced Coating Technology

High performance fibre disc with additional multibond for high stock removal rate and long service life for cool grinding on stainless steel and high alloy steel, especially for surface grinding

High performance fibre disc with very high stock removal rate and extremely long service life, with self-sharpening ceramic grain for the processing of high alloy steel, multibond for cool grinding. Improved grit adhesion due to Advanced Coating Technology

39 Fiberscheiben 39 Fibre discs

Fibre discs Applications guide

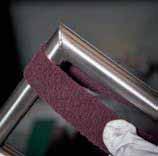

Technical information about the backing pad

Backing pad form

Benefit

Application

Medium hard, flat

Even grinding finish, good adaptation to the workpiece

Hard, ribbed

High material removal rates, high stability

Additional benefit of our ribbed backing pad: increased aggression, cool grinding

Finish grinding (grit 50 and finer), edge rounding, contour grinding, surface grinding

Rough grinding (up to grit 40 and coarser), chamfering, deburring work, welded seam work

The safe use of Klingspor abrasives

Klingspor fibre discs have been tested according to the guidelines of the oSa directives and are guaranteed to comply with European safety standard EN 13743

Compared to the smooth backing pad, the hard ribbed packing pad delivers stock removal that is up to 30% higher.

Recommended applications:

The hard ribbed backing pad ST 358 A supports the selfsharpening effect on fibre discs with zirconia alumina (CS 565, CS 570) and ceramic grit (FS 964, FS 966), yielding a higher stock removal rate and longer service life.

Wear

Use

Only

Do

40

Wear safety goggles or glasses to protect the eyes

Wear safety gloves to protect hands

a dust maskObserve safety instructions

ear protectors

permitted with a backing pad

not use for wet grinding

Do not use if damaged

glatter Stützteller 0% 20% 40% 60% 80% 100% 120% 140% ribbed backing pad flat backing pad Removal

The right backing pad Product

ST 358

ST 358 A

Fibre discs Applications guide Hole pattern for fibre discs

10 = round hole30 = star-shaped hole Additional special cutting shapes are available on request. Please ask for more information.

50 = X-LOCK

Minimum order quantities for made to order items

We reserve the right to over-deliver or under-deliver made to order items.

Conventional abrasives Abrasives with ACT technology Grain pullout

ACT-Advanced Coating Technology

Provides a significantly higher grit adhesion, when working on metal with fibre discs. This significantly increases the life.

Fibre discs

41

Advanced Coating Technology Stock removal

Time

Disc diameter Minimum order quantities up to 235 mm 1,000 pieces

Fibre discs

Coated abrasives

Abrasive fibre disc CS 561

Advantages: For universal use - Largest selection of diameters, grit sizes and hole patterns

Backing pads see page 46-47 / Dispenser see page 47

42

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingClose Steel J NF metals J Metals J Plastic K Stainless steel K Wood K

Available grits: 1624303640506080100120150180220240 280 320 360400500600800100012001500200025003000 Diameter x Hole in mm GritHole pattern Packing unit/pcs. Cat. number 100 x 1616 R 10 25 65708 100 x 1624 R 10 25 65713 100 x 1636 R 10 25 65718 100 x 1660 R 10 25 65730 100 x 1680 R 10 25 65735 100 x 16120 R 10 25 65743 115 x 2224 a 30 25 10978 115 x 2236 a 30 25 10980 115 x 2260 a 30 25 10983 115 x 2280 a 30 25 10984 115 x 22120 a 30 25 10986 125 x 2216 a 30 25 11009 125 x 2224 a 30 25 11010 125 x 2236 a 30 25 11012 125 x 2250 a 30 25 11014 125 x 2260 a 30 25 11015 125 x 2280 a 30 25 11016 125 x 22120 a 30 25 11018 180 x 2224 R 10 25 66451 180 x 2236 R 10 25 66459 180 x 2216 a 30 25 11057 180 x 2224 a 30 25 11058 180 x 2236 a 30 25 11060 180 x 2260 a 30 25 11063 180 x 2280 a 30 25 11064 180 x 22100 a 30 25 11065 180 x 22120 a 30 25 11066

Fibre discs

Coated abrasives

Abrasive fibre disc CS 565

Advantages: Self-sharpening effect - High aggressiveness on steel and stainless steel - Ideal for rough grinding work - Excellent price-performance ratio

Backing pads see page 46-47 / Dispenser see page 47

43

Fibre discs

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingClose Stainless steel J Steel J Metals J

Available grits: 16 24 30 3640506080100 120150180220240280320360400500600800100012001500200025003000 Diameter x Hole in mm GritHole pattern Packing unit/pcs. Cat. number 100 x 1624 R 10 25 100711 100 x 1636 R 10 25 23680 100 x 1660 R 10 25 84604 100 x 1680 R 10 25 188678 115 x 2224 a 30 25 95335 115 x 2236 a 30 25 6686 115 x 2240 a 30 25 242801 115 x 2260 a 30 25 6687 115 x 2280 a 30 25 6688 125 x 2224 a 30 25 97643 125 x 2236 a 30 25 6620 125 x 2250 a 30 25 93054 125 x 2260 a 30 25 6721 125 x 2280 a 30 25 23005 180 x 2224 a 30 25 95993 180 x 2236 a 30 25 65703 180 x 2260 a 30 25 6690 180 x 2280 a 30 25 6691

Fibre discs Coated abrasives

Abrasive fibre disc, multibond CS 570

Advantages: Self-sharpening effect - High aggressiveness, especially suitable for stainless steelIncrease in performance due to low temperatures - Multibond prevents heat tinting - Especially suitable for use on aluminium

Backing pads see page 46-47 / Dispenser see page 47

44

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingClose Stainless steel J Aluminium J NF metals K

Available grits: 16 24 30 3640506080100120 150180220240280320360400500600800100012001500200025003000 Diameter x Hole in mm GritHole pattern Packing unit/pcs. Cat. number 100 x 1636 R 10 25 204823 100 x 1660 R 10 25 204825 100 x 1680 R 10 25 204826 100 x 16120 R 10 25 204828 115 x 2236 a 30 25 204086 115 x 2260 a 30 25 204088 115 x 2280 a 30 25 204089 115 x 22120 a 30 25 204091 125 x 2224 a 30 25 204092 125 x 2236 a 30 25 204093 125 x 2260 a 30 25 204095 125 x 2280 a 30 25 204096 125 x 22100 a 30 25 204097 125 x 22120 a 30 25 204098 180 x 2224 a 30 25 204099 180 x 2236 a 30 25 204100 180 x 2260 a 30 25 204102 180 x 2280 a 30 25 204103 180 x 22120 a 30 25 204105

Fibre discs

Coated abrasives

Abrasive fibre disc

FS 964 ACT

Advantages: Premium product with excellent performance for working on steel - Micro-crystalline self-sharpening effect - High aggressiveness thanks to self-sharpening, aggressive ceramic grains throughout the service life - Outstanding grit adhesion - Advanced coating technology (ACT) for extraordinary grain adhesion and extended service life

Abrasive fibre disc, multibond FS

966 ACT

Advantages: Micro-crystalline self-sharpening effect - High aggressiveness throughout the service life - Outstanding grit adhesion - Long service life, especially suitable for heavy duty applicationsIncrease in performance due to low temperatures - Multibond prevents heat tinting

Backing pads see page 46-47 / Dispenser see page 47

45

Fibre discs

Properties Applications: Bonding agentResin GrainCeramic Al. oxide CoatingClose Steel J Stainless steel J

Available grits: 16 24 30 3640506080 100 120 150180220240280320360400500600800100012001500200025003000 Diameter x Hole in mm GritHole pattern Packing unit/pcs. Cat. number 125 x 2224 a 30 25 330484 125 x 2236 a 30 25 330485 125 x 2260 a 30 25 330487 125 x 2280 a 30 25 330490 125 x 22120 a 30 25 330491 180 x 2224 a 30 25 330489 180 x 2236 a 30 25 330492 180 x 2260 a 30 25 330495

Properties Applications: Bonding agentResin GrainCeramic Al. oxide CoatingClose Stainless steel J

Available grits: 16 24 30 3640506080 100 120 150180220240280320360400500600800100012001500200025003000 Diameter x Hole in mm GritHole pattern Packing unit/pcs. Cat. number 100 x 1636 R 10 25 318725 100 x 1660 R 10 25 318726 100 x 1680 R 10 25 318727 100 x 16120 R 10 25 324236

Fibre discs / Backing pads

Coated abrasives

Continuation of FS 966 ACT, Abrasive fibre disc, multibond

Backing pad, plain/flexible ST 358

Advantages: Medium-hard backing pad allows good adaptation to the workpiece - For universal use, especially for surface and finish grinding (grit 50 and finer) - High temperature resistance

46 Diameter x Hole in mm GritHole pattern Packing unit/pcs. Cat. number 115 x 2236 a 30 25 316490 115 x 2260 a 30 25 316492 115 x 2280 a 30 25 316493 125 x 2224 a 30 25 318305 125 x 2236 a 30 25 316494 125 x 2260 a 30 25 316496 125 x 2280 a 30 25 316497 125 x 22120 a 30 25 324239 180 x 2236 a 30 25 316498 180 x 2260 a 30 25 316501 180 x 2280 a 30 25 316502

Diameter in mm Thread/Shaft Suitable for Max. operating speed Max. RPM Packing unit/pcs. Cat. number 100thread M10Diameter 100 x 1680 m/s15300 rpm1 305190 100thread M14Diameter 100 x 2280 m/s15300 rpm1 2774 115thread M14Diameter 115 x 2280 m/s13300 rpm1 14838 125thread M14Diameter 125 x 2280 m/s12200 rpm1 14835 180thread M14Diameter 180 x 2280 m/s8500 rpm1 14840

Backing pads / Dispenser

Backing pad, ribbed/hard ST 358 A

Advantages: For rough grinding - Cool grinding - Increased aggressiveness due to hard, ribbed abrasive surface - High temperature resistance and stability

Dispenser for fibre discs

FS 555

Advantages: Easy stocking and removal of up to 100 fiber discs with diameter of 115 to 180 mmOrderly and accessible storage at the workplace Fibre discs not included

47

Fibre discs

Diameter in mm Thread/Shaft Suitable for Max. operating speed Max. RPM Packing unit/pcs. Cat. number 100thread M10Diameter 100 x 1680 m/s15300 rpm1 329045 115thread M14Diameter 115 x 2280 m/s13300 rpm1 126346 125thread M14Diameter 125 x 2280 m/s12200 rpm1 126347 180thread M14Diameter 180 x 2280 m/s8500 rpm1 126348

Width x Length x Height in mm Packing unit/pcs. Cat. number 170 x 140 x 1961 316463

Sheets with paper backing

Coated abrasives

Abrasive paper, waterproof PS

11 C

Advantages: Special product for auto repair and painting - For hard and tough surfaces - Good adaptation and high stability - Wet and dry sanding

Abrasive paper, waterproof PS

11 A

Advantages: Special product for auto repair and painting - For hard and tough surfaces - Good adaptation and high stability - Wet and dry sanding

Other grits and sizes available on request.

48

Properties Applications: Bonding agentResin GrainSiC CoatingClose BackingC-paper Paint/Varnish/Filler J Plastic J Glass/Stone K Metals K

Available grits: 162430364050 6080100120150180220240280320360400 500 600 800 1000 12001500200025003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 230 x 2806050 320719 230 x 2808050 320667 230 x 28010050 320668 230 x 28012050 320669 230 x 28015050 320670 230 x 28018050 320671

Properties Applications: Bonding agentResin GrainSiC CoatingClose BackingA-paper Paint/Varnish/Filler J Plastic J Glass/Stone K Metals K

Available grits: 1624303640506080100120150180 2202402803203604005006008001000120015002000 25003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 230 x 28022050 320672 230 x 28024050 320673 230 x 28028050 320674 230 x 28032050 320675 230 x 28036050 320676 230 x 28040050 320677 230 x 28060050 320678

Sheets with paper backing

Coated abrasives

Continuation of PS 11 A, Abrasive paper, waterproof

Other grits and sizes available on request.

Advantages: High removal rate - For diverse applications

Strips / Sheets / Discs 49 Width x Length in mm Grit Packing unit/pcs. Cat. number 230 x 28080050 320679 230 x 280100050 320680 230 x 280120050 320681 230 x 280150050 320682 230 x 280200050 320683

Bonding agentResin GrainAluminium oxide CoatingSemi-open BackingC-paper Paint/Varnish/Filler J Wood J Plastic K

Abrasive paper PS 33 C

Properties Applications:

Available grits: 16243036 40 50 6080100120 150180220240280320360400500600800100012001500200025003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 230 x 2804050 320684 230 x 2806050 320685 230 x 2808050 320686 230 x 28010050 320687 230 x 28012050 320688

Sheets with paper backing

Coated abrasives

Abrasive paper

PS 33 B

Advantages: High removal rate - For diverse applications

Abrasive paper, self-fastening PS

33 CK

Advantages: High removal rate - For diverse applications

Other grits and sizes available on request.

50

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingSemi-open BackingB-paper Paint/Varnish/Filler J Wood J Plastic K

Available grits: 1624303640506080100120 150180220240280320 360 400500600 800100012001500200025003000 Width x Length in mm Grit Packing unit/pcs. Cat. number 230 x 28015050 320689 230 x 28018050 320690 230 x 28022050 327156 230 x 28024050 320691 230 x 28028050 327157 230 x 28032050 320692 230 x 28040050 320693 230 x 28060050 320694

Properties Applications: Bonding agentResin GrainAluminium oxide

BackingC-paper Paint/Varnish/Filler

Wood J Plastic K

Available grits: 16243036 40 50 6080100120 150180220240280320360400500600800100012001500200025003000 Width x Length in mm Grit Hole pattern Packing unit/pcs. Cat. number 115 x 23080 j GL 15 100 146968 115 x 230120 j GL 15 100 147182

CoatingSemi-open

J

Strips with paper backing, self-fastening

Coated abrasives

Abrasive paper, self-fastening PS

33 BK

Properties

Bonding agentResin

GrainAluminium oxide

CoatingSemi-open

BackingB-paper

Applications:

Paint/Varnish/Filler J

Wood J

Plastic K

Advantages: High removal rate - For diverse applications

Other grits and sizes available on request.

Strips / Sheets / Discs

51

Available grits: 1624303640506080100120 150180220240280320 360 400500600 800100012001500200025003000 Width x Length in mm Grit Hole pattern Packing unit/pcs. Cat. number 115 x 230180 j GL 15 100 147183 115 x 230240 j GL 15 100 147184 115 x 230320 j GL 15 100 147185

Abrasive block

Abrasive block, flexible, coated on 4 sides

SK 500

Advantages: Can be used flat and upright (four usable sides) - For flat and profiled surfaces due to flexible foam core - Robust, washable and reusable

Abrasive block, flexible, coated on 4 sides

SK 700 A

Advantages: Can be used flat and upright (four usable sides) - The angled edge (approx. 45°) makes it an exceptional choice for narrow, tapering workpiece contours - Excellent contouring and pressure distribution thanks to flexible foam core - Robust, washable and reusable

Other grits and sizes available on request.

52

Properties Applications: GrainAluminium oxide CoatingClose Paint/Varnish/Filler J Wood J Plastic K Metals K

Available grits: 162430364050 6080100120 150 180220 240 280 320360400500600800100012001500200025003000 Width x Length x Height in mm GritDensityGrit colorFoam color Packing unit/pcs. Cat. number 70 x 100 x 2580hardbrowngrey100 225165 70 x 100 x 25120hardbrowngrey100 225166

Properties Applications: GrainAluminium oxide CoatingClose Paint/Varnish/Filler J Wood J Plastic K Metals K

Available grits: 162430364050 6080100120 150180220240280320360400500600800100012001500200025003000 Width x Length x Height in mm GritDensityGrit colorFoam color Packing unit/pcs. Cat. number 89 x 125 x 2560hardbrowngrey100 337846 89 x 125 x 2580hardbrowngrey100 337847 89 x 125 x 25120hardbrowngrey100 331019

Abrasive sponge

Abrasive sponge, flexible, coated on 2 sides, tear-resistant

SW 501 TR

Properties Applications: GrainAluminium oxide CoatingClose Paint/Varnish/Filler J

Wood J

Plastic K

Metals K

Advantages: Satin surface scratch pattern - For low and high profiled surfaces (two usable sides)Crease and break-resistant - Washable and reusable - Extremely tear-resistant - Solvent free bonding with grit size dependent colouring Available

Other grits and sizes available on request.

53

Strips / Sheets / Discs

1624303640506080 100120150180220 240280320360400500600800100012001500200025003000 Width x Length x Height in mm GritDensityGrit colorFoam color Packing unit/pcs. Cat. number 96 x 123 x 12,5100softlight brownyellow100 351573 96 x 123 x 12,5120softgreenyellow100 353264 96 x 123 x 12,5150softredyellow100 353263 96 x 123 x 12,5180softblueyellow100 351574 96 x 123 x 12,5220softbrownyellow100 353262

grits:

Discs Applications guide

Hole patterns for discs

Klingspor offers a wide range of products with hole patterns for dust extraction. You will find the available hole patterns marked in the table below. The chart on the following product pages shows the most popular types of machines and the required hole pattern.

Other hole patterns available on request.

Minimum order quantities for made to order

itemsMaximum disc diameter

We reserve the right to over-deliver or under-deliver made to order items.

54

Ø

Minimum order quantities

400 up to

5,000 pieces

310 X

2,500

321 X

1,000

411

500

200

Type

[mm]

AN

50 mm

CS

up to 90 mm

pieces CS

up to 125 mm

pieces CS

XK up to 200 mm

pieces FP 73 WK up to 400 mm

pieces

PS 11 C up to 600 mm 100 pieces

PS 19 EK over 600 mm 25 pieces

PS 21 FK

77 CK FP 77 K Ø 670 mm Ø 770 mm Ø 1,100 mm PS 21 FK PS 61 FK PS 11 C PS 22 K PS 19 EK PS 33 BK/CK FP 73 WK PS 73 BWK/CWK AN 400 CS 411 XK CS 310 X CS 321 X PS 77 CK FP 77 K

PS 22 F ACT PS 22 K PS 33 BK/CK PS 61 FK PS 73 BWK/CWK PS

Shape 0 no

different dimensions

different dimensions

different dimensions GLS 2 Ø 150mm 8 holes Ø 10mm on hole circle Ø 65mm GLS 15 Triangular Ø 96mm 6 holes Ø 8mm on hole circle Ø 52mm GLS 5 Ø 125mm 8 holes Ø 10mm on hole circle Ø 65mm GLS 3 Ø 150mm 6 holes Ø 10mm on hole circle Ø 80mm GLS 4 Ø 115mm 8 holes Ø 10mm on hole circle Ø 65mm GLS 24 98 × 148mm 7 holes Ø 10 m GLS 47 Ø 150mm 8 holes Ø 9mm on hole circle Ø 120mm, 6 holes Ø 9mm on hole circle Ø 80mm + 1 centre hole Ø 17mm GLS 51 Ø 150mm 8 holes Ø 10mm on hole circle Ø 120mm, 8 holes Ø 8mm on hole circle Ø 65mm + 1 centre hole Ø 10mm GLS 74 Ø 150mm 8 holes Ø 9,5mm on hole circle Ø 119mm, 16 holes Ø 6mm on hole circle Ø 119mm 8 holes Ø 7mm on hole circle Ø 95mm 8 holes Ø 8,5mm on hole circle Ø 65mm 8 holes Ø 6mm on hole circle Ø 39mm + 1 centre hole Ø 10mm GLS 52 Ø 225mm 10 holes Ø 12mm on hole circle Ø 105mm

1 Ø 150mm 8 holes

on

+ 1

27 Ø 125mm 8 holes Ø 10mm on hole

Ø

+ 1

Ø

hole

Shape 10 round hole

Shape 30 star-shaped hole

GLS

Ø 10mm

hole circle Ø 120mm

centre hole Ø 17mm GLS

circle

90mm

centre hole

10mm

Discs Applications guide

Orbital and delta sanders

Please contact Klingspor if you cannot find the machine used by you on this list. We will be pleased to assist you further. If the product you require is not in stock, we will manufacture it for you subject to a minimum order quantity.

55 Strips

Discs

/ Sheets /

Manufacturer Type Size in mm Hole pattern AEG powertools Delta DSE 260 105 × 105 × 105 GLS 17 FS 2 D 98 × 148 GLS 24 EX 400 EXE 400 EX 450 EXE 460-125, EX 125 E, EX 125 ES 125 GLS 5 EXE 450 convertible to 125 GLS 5 EXE 450 150 GLS 2 (7) EXE 460 - 150, ROS 150 E, EX 150 E 150 GLS 3 EX/E 450 150 GLS 7 Atlas Copco LST 21 R350, LST 22 R350, LST 22 R325, LST 20 R350 90 GLS 41 VS 11 D 98 × 148 GLS 24 LST 30 H90-11 115 plain LST 20 R525, LST 20 R550 125 plain LST 21 R525, LST 21 R550, LST 22 R525 LST 22 R550 125 GLS 5 TXE 150 convertible to 125 GLS 5 LST 20 R625, LST 20 R650, LST 30 H090-15, LST 30 S090-15 150 plain ROS 150 E, LST 21 R625, LST 21 R650, LST 22 R625, LST 22 R650, LST31 H90-15, LST31 S90-15, LST32 H090-15 LST32 S090-15 LST 22 R625-9, G2438-6.5N Pro, G2438-6.5I Pro, G2438-6.3I Pro, G2438-6.10I Pro, G2438-6.5C Pro, G2438-6.3N Pro G2438-6.3C Pro G2438-6.10N Pro, G2438-6.10C Pro, G2438-10 self-fastening 6 Pro, LST 22 R650-9 150 GLS 3 TXE 150 150 GLS 7 Black & Decker VP510 96 × 96 × 96 GLS 15 KA 510 94 × 94 × 94 GLS 15 KA 165 GT (mouse) GLS 25 KA 230 E GLS 34 BD190, BD190 E, BD190S, BD190D, XTA90EK, KS 191 EK, KA 198, KA 190, KA 190 E, KA 190 S, KA 198GT, KA220, KA220G, KA191EK 125 GLS 5 Bosch Delta GDA 280 E, Delta PDA 100, PDA 10-92, Delta PDA 120 E, Delta PDA 240 E, PDA 180, PDA 180 E 96 × 96 × 96 GLS 15 PEX 11 A, PEX 115, PEX 11 AE 115 GLS 4 PEX 300 A/AE, GEX 125-150 AVE Professional, PEX 400 AE, PEX 12 A PEX 12 AE PEX 125 A-1, PEX 125 AE, PEX 270 A/AE, GEX 125 A, GEX 125 AC, GEX 125-1 AE, PEX 220 A 125 GLS 5 PEX 15 AE, GEX 150 AE, GEX 150 AC/E, GEX 150 Turbo, PEX 420 AE 150 GLS 3 DeWalt ES 55 E , DW423, D26453 125 GLS 5 ES 56 E, ES 56 EK, DW443, D 26410 150 GLS 3 Einhell DE-G 200 E 94 × 94 × 94 GLS 15 EX 115 115 GLS 4 EX-G 125 E, BES 125, EX-G 125, BT-RS 420 E, BES 125 E, BRS 380 E 125 GLS 5 Fein LL 107 VEA 115 plain MSf 636-1, M 10000-5, XS 712 125 GLS 5 MSf 636-1 150 GLS 26 MSf 649-2 a/b, M 10000-6 150 GLS 2 (7) ROT 14-200 E 150 GLS 2 X 1107 VE 150 GLS 3 ROT 14-200 E 200 GLS 9 Felisatti TP 521/AS, TP 521/E, TP 522 AS/CE, RGF 150/600 E 150 GLS 3

Manufacturer Type Size in mm Hole pattern Festool RO 90 DX FEQ-Plus 90 GLS 41 DS 400, DTS 400 98 × 148 GLS 24 DX 93 94 × 94 × 94 GLS 16 ES 125, ES 125 E, ES 125 E-PLUS, ES 125 PLUS 125 GLS 5 ES 125 EQ-Plus; ES 125 EQ, ES 125 Q-Plus, ES 125 Q, ETS 125, LEX 2 125/3, LEX 1 125/7, LEX 3 125/3, LEX 3 125/5 125 GLS 27 RO 125 FEQ-Plus 125 GLS 27 ET 2 E 150 GLS 2 ET 2 E - Plus, RO 150, RO 150 E, RO 2 E-Plus, LEX 3 150/3 , LEX 150, ETS 150/3, ETS 150/5, WTS 150/7 E, WTS 150/7 E-Plus, ETS 150/5 EQ, ETS 150/S EQ-E, ETS 150/5 EQ-Plus 150 GLS 1 Multi-Jetstream (8+8+1) 150 GLS 51 LHS 225 EQ-Plus 225 GLS 38 Flex OD 100-2, ODE 100-2 98 × 148 GLS 24 XS 712, XS 713 125 GLS 5 X 1107 VE, XS 1107 VE 150 GLS 3 ORE 125-2 125 GLS 27 GE 5, GE 5 R, GE 7, GSE 5 R, WST 700VV, WST 700 VV Plus 225 GLS 52 GE 7 225 GLS 55 GE 7, WST 700 VV Plus 285 GLS 60 Hilti WFE 150, WFE 380, WFE 450 E 150 GLS 3 Hitachi FSV 13 Y, TSV 13 Y, SV 13 YA 125 GLS 5 SAY 150 A 150 GLS 3 HOLZ HER 2445 150 GLS 7 (1) Kress CDS 6425, CDS 6420, CDS 6422 E 105 GLS 17 CPS 6115-1, 6115 E 115 GLS 4 CPS 6125-1, CPS 6125 E, CPS 6125 E SET, HEX 1385 E, HEX 6385 E, 300 EXE 125 GLS 5 900 MPS, 900 HEX /2 150 GLS 3 Mafell UT 150 E, UX 150 E 150 GLS 1, 3, 47 Makita BO 4561, BO 4565 96 × 96 × 96 GLS 15 BO 5000, BO 5010, BO 5041, BO 5031 K, BO 5021, BO 5021 K, BO 5041 K 125 GLS 5 BO 6030, BO 6040 J 150 GLS 1 Metabo DS E 130 DS E 170 DS E 180 96 × 96 × 96 GLS 15 DSE 300, DSE 300 Intec, DSE 280 INTEC 94 × 94 × 94 GLS 15 SXE 400 80 GLS 13 SX E 125, FSX 200 INTEC, SXE 425 TURBOTEC SX E 425 SXE 325 INTEC 125 GLS 5 SX E 425 XL, SX E 450 Duo, SXE 450 TURBOTEC, 150 GLS 3 Milwaukee PDS 13, FS 2 D 98 × 148 GLS 24 PRS 125 E 125 GLS 5 ROS 150 E 150 GLS 3 Peugeot PAE 115 115 GLS 4 PRX 150 E 150 GLS 3 Pro Tool ESP 150 E 150 GLS 3 Ryobi ERO 2412V, CRO 180M, ROS 300 A CRO 180 MHG 125 GLS 5 SKIL 7110 AA 7115 AA 96 × 96 × 96 GLS 15 7415 115 GLS 4 7400, 7425, 7430, 7435, 7440 AA, 7460 AA, 7470 MA 125 GLS 5 Stayer RO 150 E, LRT 150 150 GLS 3 Wegoma LRE 84 H RTE84H 125 GLS 5 RX 91 C, RT188N, RTE46L, RTE146L 150 GLS 3

Discs with paper backing, self-fastening

Coated abrasives

Abrasive paper, self-fastening

PS 21 FK

Advantages: Aggressive abrasive behavior due to self-sharpening zirconia alumina - Optimal recipe for rough grinding and finish grinding of stainless steel - Long service life

Other grits and sizes available on request.

56

Properties Applications: Bonding agentResin GrainZirconia alumina CoatingClose BackingF-paper Steel J Stainless steel J Metals J

Available grits: 16243036 40 50 6080100120150180 220 240 280 320 360 400 500600800100012001500200025003000 Diameter in mm Grit Hole pattern Packing unit/pcs. Cat. number 12540 Q 0 50 246857 12560 Q 0 50 237780 12580 Q 0 50 237781 125120 Q 0 50 237782 125240 Q 0 50 237785 125320 Q 0 50 237786 15040 Q 0 50 230312 15060 Q 0 50 230313 15080 Q 0 50 230314 150120 Q 0 50 246488 150150 Q 0 50 239244 150180 Q 0 50 252774 150240 Q 0 50 251509 18080 Q 0 50 256056

Discs with paper backing, self-fastening

Coated abrasives

Abrasive paper, self-fastening

PS 22 K

Advantages: Universal abrasive disc for metalworking and woodworking - Uniform surface scratch pattern - Available in many grit sizes and dimensions

Other grits and sizes available on request.

Strips

Sheets

Discs 57

/

/

Properties Applications: Bonding agentResin GrainAluminium oxide CoatingSemi-open BackingE-paper Wood J Metals J Stainless steel K Paint/Varnish/Filler K Plastic K

Available grits: 16 24 3036 40 50 6080100120150180220240 280 320 360 400 500600800100012001500200025003000 Diameter in mm Grit Hole pattern Packing unit/pcs. Cat. number 12540 Q 0 50 2294 12560 Q 0 50 2295 12580 Q 0 50 6774 125120 Q 0 50 6775 125180 Q 0 50 62107 125240 Q 0 50 91922 125320 Q 0 50 93284 125400 Q 0 50 130114 12540 W GLS 5 50 89486 12560 W GLS 5 50 89488 12580 W GLS 5 50 89489 125100 W GLS 5 50 89491 125120 W GLS 5 50 89493 125150 W GLS 5 50 89494 125180 W GLS 5 50 89495 125240 W GLS 5 50 92753 12540 Z GLS 27 50 260795 12560 Z GLS 27 50 260796 12580 Z GLS 27 50 260797 125120 Z GLS 27 50 260799 125180 Z GLS 27 50 260801 15040 Q 0 50 20207 15060 Q 0 50 6649 15080 Q 0 50 6936 150120 Q 0 50 6937 150150 Q 0 50 71140 150180 Q 0 50 4022 150240 Q 0 50 91605 150320 Q 0 50 91721 18040 Q 0 50 2476 18060 Q 0 50 2477 18080 Q 0 50 6914 180120 Q 0 50 6915 30580 Q 0 50 201390

Discs with paper backing, self-fastening

Coated abrasives

Abrasive paper, self-fastening

PS 33 CK

Properties Applications:

Bonding agentResin

GrainAluminium oxide

CoatingSemi-open

BackingC-paper

Paint/Varnish/Filler J Wood J Plastic K

Advantages: High removal rate - For diverse applications Available grits:

Abrasive paper, self-fastening

PS 33 CK

Properties Applications:

Bonding agentResin

GrainAluminium oxide

CoatingSemi-open

BackingC-paper

Paint/Varnish/Filler J Wood J Plastic K

Advantages: High removal rate - For diverse applications Available grits:

Other grits and sizes available on request.