FACILITY CONDITIONS

BUILDING ENVELOPE IMPROVEMENTS

Roof Replacement on 1998 Addition Serving the Science and Media Center Wing

Roof Replacement on 1986 Pool Addition

Roof Replacement on 1998 Addition Serving the Cafeteria, Dance Studio, and Aux. Locker Rooms

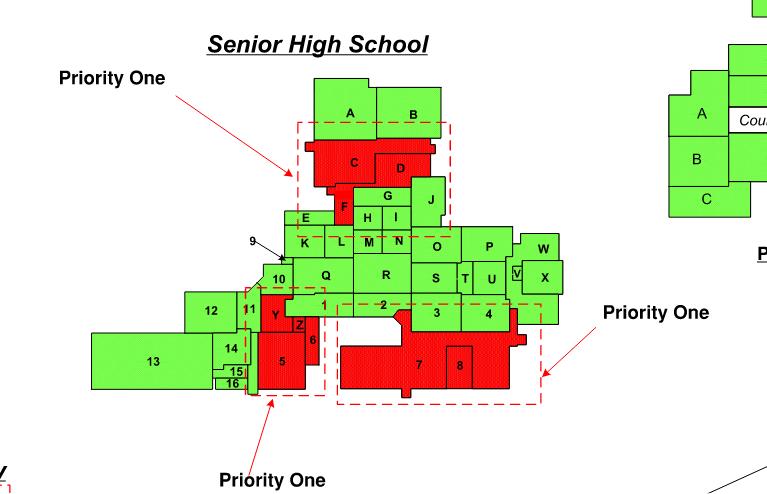

The roofs over the 1998 additions (main office, media center, science wing, cafeteria, and auxiliary locker rooms) and the 1986 pool addition (have all reached the end of their useful life and are showing signs of aging such as bridging / stretching at roof perimeters and multiple previous repairs. The roofs should be replaced in the next 1 to 3 years. (areas C, D, F, Y, Z, 5, 6, 7 and 8)

Roofing system replacement will improve energy performance by increasing system insulation values, reduce leaks, and will reduce operating and maintenance expenses.

BUILDING ENVELOPE IMPROVEMENTS

HS-BE-1 Roof Replacement on 1998 Addition Serving the Science and Media Center Wing

HS-BE-2 Roof Replacement on 1986 Pool Addition

HS-BE-3 Roof Replacement on 1998 Addition Serving the Cafeteria, Dance Studio, and Aux. Locker Rooms

• Removal of old roof systems & wet insulation / deteriorated wood blocking.

• Polyisocyanurate insulation layers. R-30 with a minimum positive slope of 1/8" per foot to ensure proper drainage.

• Recovery insulation board to accept new roof system & provide a stop gap against thermal bridging from insulation fasteners.

• Multiply modified built-up roof system with gravel surfacing. Provides a "severe hail" rating.

• Pre-finished sheet metal copings & counterflashing at all perimeters and projections to protect against damage and UV degradation.

•

HS-BE-1, 2, and 3 Benefits

• Extend life of building

• Reduce energy costs

• Reduce leaks

• Reduce operating and maintenance expenses

BUILDING ENVELOPE IMPROVEMENTS

Install through-Wall Flashing and Rope Weeps at Steel Lintels of the Original Building. Repair of Brick Cladding Including Tuckpointing and Replacement of Damaged Brick

Chisago Lakes High School is constructed with a brick veneer, precast concrete panel, and metal panel façade. The building has aluminum framed windows.

Cracked mortar joints between the brick units were typically observed around the steel lintels, building corners, and windows.

Through-wall flashing was present at some, but not all, windows and doors. Weep ropes were deteriorated in many of the areas where flashing was present.

A few locations of cracked, spalled, or broken bricks were noted. Efflorescence is present at many locations.

Some maintenance work is needed to improve the water penetration resistance of the brick, and new through-wall flashing may be needed in some areas to prevent water entry into the structure and prevent deterioration of steel lintels and other wall components.

High priority repairs include installing through-wall flashing and rope weeps at steel lintels of the original building. General maintenance of brick cladding, including tuckpointing and replacement of damaged brick, is currently needed. The above repairs should be conducted in the next 0-3 years.

BUILDING ENVELOPE IMPROVEMENTS

HS-BE-4 Install through-Wall Flashing and Rope Weeps at Steel Lintels of the Original Building. Repair of Brick Cladding Including Tuckpointing and Replacement of Damaged Brick

• Install through-wall flashing and rope weeps (600 LF)

• Tuckpoint and replacement of brick (2500 SF)

• Repair damaged brick (400 bricks)

•

HS-BE-4 Benefits

• Extend life of building

• Reduce leaks

• Reduce operating and maintenance expenses

BUILDING ENVELOPE IMPROVEMENTS

Precast Panels Showing Signs of Deterioration, Cracks, and/or Delamination Should be Repaired using Concrete Patch Materials. A Clear Water Repellent Should be Applied to all of the Exposed Precast Panels to Reduce Future Moisture Absorption.

Precast panels around the 1998 addition are showing signs of taking on moisture which is visible at the window opening locations as well as at areas in the west section of the addition. Rust staining exiting at cracks and efflorescence are prevalent at many locations at the west addition.

Deteriorated, cracked, and/or delaminated precast should be repaired using concrete patch materials. Apply a clear water repellent to the exposed precast panels to reduce future moisture absorption. Precast panels repairs should be conducted in the next 0-3 years.

BUILDING ENVELOPE IMPROVEMENTS

HS-BE-5 Precast Panels Showing Signs of Deterioration, Cracks, and/or Delamination Should be Repaired using Concrete Patch Materials. A Clear Water Repellent Should be Applied to all of the Exposed Precast Panels to Reduce Future Moisture Absorption.

• Removal of old roof systems & wet insulation / deteriorated wood blocking.

• Polyisocyanurate insulation layers. R-30 with a minimum positive slope of 1/8" per foot to ensure proper drainage.

• Recovery insulation board to accept new roof system & provide a stop gap against thermal bridging from insulation fasteners.

• Multiply modified built-up roof system with gravel surfacing. Provides a "severe hail" rating.

• Pre-finished sheet metal copings & counterflashings at all perimeters and projections to protect against damage and UV degradation.

•

HS-BE-5 Benefits

• Reduces staining

• Prevents damage to structure

• Reduces water absorption

BUILDING ENVELOPE IMPROVEMENTS

Clean Exposed Steel Lintels and Paint to Minimize Corrosion. Spray the Exterior at Downspouts to Remove Staining. Replace six (6) Exterior Doors and One (1) Garage Door at Loading Dock. Repair the Metal Panel that is Bowing on the PAC Addition.

Lintels above window openings are corroding and forming pack rust, which applies stress on the brick veneer and causes misalignment of the brick units. This condition warrants repair to prevent further damage to embedded steel and brick cladding, and to prevent water entry into and through the exterior walls. Paint peeling from the bottom exposed lintel is likely due to rust formation. The exposed steel should be cleaned and painted to minimize future corrosion/deterioration.

Water staining is present at downspout nozzles. Localized brick staining is occurring at water runoff locations. The cast stone does not have a large enough extension to prevent runoff from the sills to cascade down the brick wall. Clean surface of bricks at downspouts by means of power washing.

The hollow metal swing doors are corroded at the bottom of the door frames. The doors and center mullion are showing signs of wear.

We recommend replacing the indicated exterior doors, including the hardware and locks.

BUILDING ENVELOPE IMPROVEMENTS

HS-BE-6 Clean exposed steel lintels and paint to minimize corrosion. Spray the exterior at downspouts to remove staining. Replace six (6) exterior doors and one (1) garage door at loading dock. Repair the metal panel that is bowing on the PAC Addition.

•

• Install through-wall flashing

• Clean and paint steel lintels

• Sealant replacement at doors, windows, and control joints

HS-BE-6 Benefits

• Extend life of building

• Reduce leaks

• Reduce operating and maintenance expenses

BUILDING ENVELOPE IMPROVEMENTS

Replace the leaking windows and doors on the 1998 addition that includes the science wing and media center. This includes replacing 22 windows, and vestibules 50 and 33. This includes new flashing membranes around the entire perimeter of window opening and new window with sill receptors.

The windows located within the 1998 additions to the building are all store front window systems built with an aluminum frame and double pane glass. Entry vestibules #50 and #33 are part of this system and have significant water leakage. These systems appear to be the original installation, and no major work appears to have been done to these windows over the years.

Investigation of the windows shows multiple issues occurring with the current system is performing. Noted issues are water intrusion and gasket shrinkage. Further investigation noted that the windows were missing a sill receiver which is meant to take on water for the system and expel the water to the exterior.

The existing windows appear to have met the end of their useful life, and it is recommended to replace the windows in the next 0 to 3 years.

BUILDING ENVELOPE IMPROVEMENTS

HS-BE-7 Replace the leaking windows and doors on the 1998 addition that includes the science wing and media center. This includes replacing 22 windows, and vestibules 50 and 33. This includes new flashing membranes around the entire perimeter of window opening and new window with sill receptors.

• Demo 22 windows out of existing openings.

• Demo vestibules 33 and 50

• Clean all sealant from substrates.

• Install spray foam in all cavities where windows span from structural wall element to precastpanels.

• Install flashing membrane around entire perimeter of rough opening.

• Install new windows with sill receptor. Spray foam and sealant to be installed between window frame andsubstrate.

HS-BE-7 Benefits

• Eliminate water intrusion.

• Extend the life of the building

• Improve indoor environment

BUILDING ENVELOPE IMPROVEMENTS

Replace Sealant at Doors, Windows, and Control Joints

Sealant appeared generally in poor condition at window openings in brick masonry and precast cladding. Weathering, splitting, debonding, and cracking of sealant was observed throughout the façade. At previously repaired areas, new sealant at window frame edges and corners was smeared over old sealant and is failing. Debonding of sealantat window and door heads was noted at numerous locations. Sealant is missing or has fallen out at some utility penetrations in the facade

Exterior sealants deteriorate as a result of exposure to UV light, moisture, and temperature cycles. Sealants typically have a lifespan of 8-12 years depending on material, material quality, and application/configuration. Based on observed conditions, it appears that the sealants on the building have reached or exceeded their useful life.

Sealants are an important component of the exterior building envelope and in many cases are the first line of defense in preventing water entry into and through exterior walls. Deteriorated sealants greatly increase the potential for water entry.

Replace all window and door perimeter, control joint, and penetration sealant at the building façade, as well as any miscellaneous sealants present. These repairs should be completed in the next 0-3 years.

BUILDING ENVELOPE IMPROVEMENTS

HS-BE-8 Replace Sealant at Doors, Windows, and Control Joints

• Replace sealant (approximately 16,000 LF)

HS-BE-8 Benefits

• Extend life of building

• Reduces water infiltration

• Reduce operating and maintenance expenses

CONTROLS SYSTEM IMPROVEMENTS

Upgrade Building Controls and Convert Remaining Pneumatic to Direct Digital Controls (DDC)

The Chisago Lakes High School controls system is a combination of pneumatic controls and direct digital controls (DDC). Pneumatic control systems are less energy efficient and more difficult to maintain than modern DDC Systems. The controls system could use the following upgrades to bring the buildings controls system to the same standard as the rest of the District.

- Existing field mounted panels and wiring/conduit to remain

- Replacement of field devices

o Temperature sensors

o Static pressure transducers

o Humidity sensors

o Differential pressure transducers

- Safeties and limits to remain unless faulty in the field during checkout

- Discretionary replacement of valve assemblies and damper actuators

o All pneumatics to be removed and replaced

o Electronic damper actuators and valve assemblies are brand and age dependent

All JCI damper actuators replaced with Belimo

If Belimo actuators are current, they will remain and be reused

- If there are existing pneumatically operating fire/smoke damper actuators, they will remain and stay in operation

Benefits of the DDC controls upgrade include improved occupant temperature control, reduced energy consumption, reduced maintenance, improved equipment scheduling and troubleshooting, alarm monitoring, operational tracking and trending of mechanical equipment parameters.

CONTROLS SYSTEM IMPROVEMENTS

HS-MP-1 Upgrade Building Controls and Convert Remaining Pneumatic to Direct Digital Controls (DDC)

• Replace all the pneumatic components with DDC on HVAC equipment that is being re-used as well as the new equipment

• Replace the existing failing DDC controls with the new building automation system platform with remote access

• Provide DDC controllers and control panels

• Provide all programming required for this conversion

HS-MP-1 Benefits

• Easy to use, modernized system control updates

• Improved building monitoring and maintenance troubleshooting

• Improved occupant comfort

• Extended heating system life

• Reduced energy consumption

• Reduced maintenance

HEATING SYSTEM IMPROVEMENTS

Heating Improvements, Including Replacing 10 Unit Heaters in Tech Ed, Pool, Locker Rooms, etc., Add Individual Room Controls for Student Services

Nexus recommends the following upgrades:

- There are about ten (10) 1976/1986 suspended unit heaters located in the tech ed, pool, and locker room areas at the High School. Nexus recommends replacing these old heaters with new hot water suspended unit heaters that are more efficient. These spaces would be calculated to determine the heat loss of the space so the unit heater can be appropriately sized.

- Add individual control for the existing finned tube radiation (FTR) located in the exterior student services rooms as shown in the picture to the right. New thermostats and control valves would be installed so the temperature in these spaces can be controlled individually.

Replace Grooved Heating Piping Gaskets and Leaking Valves (Estimated 100)

- There are a number of grooved heating piping gaskets throughout the building that have failed and are leaking. Nexus recommends removing these gaskets and directly welding the pipes together as required by the district. Nexus has budgeted/estimated 100 of these gaskets to be welded.

Add New Hot Water Heating to Perimeter Rooms Including Band, Math Wing, and East Classrooms

- The band, math, and east classroom areas of the High School have no perimeter radiation as shown in the floor plan below. Nexus recommends adding new hot water radiant ceiling panels to these spaces to provide additional heating capacity for the cold seasons. New hot water piping would be extended to the new radiant ceiling panels from the nearest hot water mains. All associated valves and controls would be provided and installed as required.

Benefits of these heating system improvements include reduced maintenance, increased heating system life, and improved system operation.

HEATING SYSTEM IMPROVEMENTS

HS-MP-2, 3, 4 Miscellaneous Heating System Improvements

• Remove 1976/1986 suspended unit heaters located in the tech ed, pool, and locker room areas at the High School

• Install new hot water suspended unit heaters and associated piping

• Install new thermostats and control valves for FTR located in student services for individual room control

• Demo grooved heating piping gaskets and weld pipes together as required by the School District

• Install new radiant ceiling panels in band, math, and East classroom areas of the High School

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

HS-MP-2, 3, 4 Benefits

• Upgraded heating system

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

VENTILATION SYSTEM IMPROVEMENTS

Replace 1998 Roof Top Unit (RTU) Serving Fitness Room and Fan Coil Unit (FCU) Serving Tech/Staff Rooms, Remove Health Room RTU and Remove FCU-2, Outside and Relief Air Hoods. Add Ventilation from Adjacent AHUs to Cover Spaces from Removed Units.

There are several rooftop and fan-coil air handling units serving the Chisago Lakes High School that are becoming maintenance problems for the District. These units are as listed below.

• 1998 AAON RTU-1 that serves the fitness center (Wildcat Dance Studio). This rooftop air handling unit currently has R-22 DX cooling and gas heating. Nexus recommends replacing the rooftop air handling unit serving the fitness center (Wildcat Dance Studio) one for one with a new double wall rooftop air handling unit with hot water heating and DX dehumidification. The new rooftop air handling unit would come with code compliant filtration, hot water heating coils, DX dehumidification coils, access sections, and supply fans with variable speed drives (VSDs).

• 1998 Lennox RTU that serves the health room only. This rooftop air handling unit currently has R-22 DX cooling and no heating. Nexus recommends removing this unit entirely as it is no longer needed.

• 1998 FCU-1 and mated 2000 ACCU that serves two (2) spaces in the tech area. This fan coil air handling unit currently has R-22 DX cooling and hot water heating. Nexus recommends removing this fan coil unit and mated condensing unit entirely and extending new ductwork to ventilate these two (2) spaces from an adjacent air handling unit.

• 1998 FCU-2 that serves building storage room adjacent to the boiler room. This fan coil air handling unit currently has no cooling and hot water heating. This unit used to provide make-up air for a boiler that is no longer there. Nexus recommends removing this unit entirely as it is no longer needed and providing some ventilation air from adjacent air handling unit.

The benefits of this HVAC improvement include increased system life expectancy, improved DDC scheduling, improved ventilation, increased energy savings, improved occupant comfort, and an improved learning and working environment.

VENTILATION SYSTEM IMPROVEMENTS

HS-MP-5 Replace 1998 Roof Top Unit (RTU) Serving Fitness Room and Fan Coil Unit (FCU) Serving Tech/Staff Rooms, Remove Health Room RTU and Remove FCU-2, Outside and Relief Air Hoods. Add Ventilation from Adjacent AHUs to Cover Spaces from Removed Units.

• Remove existing rooftop and fan-coil air handling units, piping, and controls

• Provide new double wall rooftop air handling unit with hot water heating and DX dehumidification for fitness center

• Extend new ductwork from adjacent air handling unit to serve the two (2) spaces in tech ed

• Extend new ductwork from adjacent air handling unit to serve the building storage room

• Provide variable speed drives for the supply and relief fans

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

HS-MP-5 Benefits

• Upgraded HVAC infrastructure

• Increased ventilation for improved indoor air quality

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

VENTILATION SYSTEM IMPROVEMENTS

Replace 1998 Energy Recovery RTUs (Qty 4)

There are four (4) 1998 rooftop energy recovery air handling units serving the Chisago Lakes High School that are still in good shape but should be considered for replacement in ten (10) years. These units provide outside air to downstream air handing units. These units are as listed below.

- ERU-1 provides outside air to units AHU-S1, AHU-S2, and AHU-S3.

- ERU-2 provides outside air to units AHU-7, AHU-8, AHU-9, and AHU-10.

- ERU-3 provides outside air to units AHU-15, AHU-16, AHU17, and AHU-18.

- ERU-4 provides outside air to units AHU-S5 and AHU-S8.

Nexus recommends replacing these rooftop air handling units in ten (10) years one for one with a new double wall rooftop air handling units with energy recovery. The new rooftop air handling units would come with code compliant filtration, access sections, and supply fans with variable speed drives (VSDs).

The benefits of this HVAC improvement include increased system life expectancy, improved DDC scheduling, improved ventilation, increased energy savings, improved occupant comfort, and an improved learning and working environment.

VENTILATION SYSTEM IMPROVEMENTS

HS-MP-6 Replace 1998 Energy Recovery RTUs (Qty 4)

• Remove existing rooftop energy recovery air handling and controls

• Provide new double wall rooftop energy recovery air handling units

• Provide variable speed drives for the supply and relief fans

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

HS-MP-6 Benefits

• Upgraded HVAC infrastructure

• Increased ventilation for improved indoor air quality

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

VENTILATION SYSTEM IMPROVEMENTS

Replace 1986 Air Handling Units (AHU) Serving the Boys Locker Room (AHU-11) and the Choir/Band Rooms (AHU-12); and Two Make Up Air Units Serving the Paint Booths. Replace Dust Collector. Add Dehumidification (Cooling) to Boys Locker Room and Choir/Band Room.

There are several air handling units (AHUs) serving the High School that are becoming maintenance problems for the District. Some of the air handling units also have no means of dehumidification.

The lack of dehumidification results in higher humidity levels and occupant discomfort. The areas are also unable to meet the American Society of Heating and Refrigeration Engineer’s (ASHRAE) Thermal Environmental Conditions for Human Occupancy Standard 55. This ASHRAE design standard specifies the combinations of personal and indoor thermal environmental requirements necessary to achieve an occupant comfort satisfaction rate of 80% or greater. These indoor environmental requirements include temperature, thermal radiation, humidity, and air speed.

These air handlings units are listed below.

• 1986 AHU-11 that serves the boys locker rooms. This air handling unit currently has hot water heating and no dehumidification. Nexus recommends replacing AHU-11 one for one and adding dehumidification.

• 1986 AHU-12 and mated 2004 ACCU that serves choir, band, and classrooms. This air handling unit currently has no heating and R22 DX dehumidification. Nexus recommends replacing AHU-12 one for one.

• 1986 AHU-4 and AHU-5 that serve the paint booth to provide make-up air. These air handling units currently have hot water heating and no dehumidification. Nexus recommends replacing AHU-4 and AHU-5 with a single new make-up air handling unit.

The existing wood dust collector at the High School is 1976 vintage. This antiquated unit does not adequately remove dust from the woodworking spaces due to age-related wear and tear and component failure. This compromises air quality when the woodworking spaces are in use.

Nexus recommends replacement of this dust collector unit with a new modern International Mechanical Code (IMC) compliant system. New dust collection ductwork would be installed where required and routed to each piece of equipment requiring dust collection if existing ducts cannot be re-used.

This upgrade will ensure adequate dust collection in the woodworking spaces, increasing indoor air quality and providing reliable unit operation.

Replace Thirteen AHUs Serving the 1976 Addition that Includes the North Wrestling Room, Three Locker Rooms, Gym, Classrooms, Lecture Hall, Wood Shop, Art and Ag Classrooms, Tech, and Student Services. Add Dehumidification to these Thirteen AHUs. There are multiple air handling units (AHUs) serving the High School that are becoming maintenance problems for the District. Some of the air handling units also have no means of dehumidification.

The lack of dehumidification results in higher humidity levels and occupant discomfort. The areas are also unable to meet the American Society of Heating and Refrigeration Engineer’s (ASHRAE) Thermal Environmental Conditions for Human Occupancy Standard 55. This ASHRAE design standard specifies the combinations of personal and indoor thermal environmental requirements necessary to achieve an occupant comfort satisfaction rate of 80% or greater. These indoor environmental requirements include temperature, thermal radiation, humidity, and air speed.

• 1976 AHU-1 that serves the North part of the wrestling room. This air handling unit currently has hot water heating and no dehumidification. Nexus recommends replacing AHU-1 one for one and adding DX dehumidification.

• 1976 AHU-2 that serves the North part of the girl’s locker room. This air handling unit currently has hot water heating and no dehumidification. Nexus recommends replacing AHU-2 one for one and adding DX dehumidification.

• 1976 AHU-4 that serves the South part of the girl’s locker room. This air handling unit currently has hot water heating and no dehumidification. Nexus recommends replacing AHU-4 one for one and adding DX dehumidification.

• 1976 AHU-5 that serves the 1974 Gym. This air handling unit currently has hot water heating and no dehumidification. Nexus recommends replacing AHU-4 one for one and adding DX dehumidification.

• 1976 AHU-7 and mated 2002 ACCU that serves classrooms. This air handling unit currently has hot water heating and R22 DX dehumidification. Nexus recommends replacing AHU-7 one for one.

• 1976 AHU-8 and mated 2002 ACCU that serves classrooms. This air handling unit currently has hot water heating and R22 DX dehumidification. Nexus recommends replacing AHU-8 one for one.

• 1976 AHU-9 and mated 2002 ACCU that serves classrooms. This air handling unit currently has hot water heating and R22 DX dehumidification. Nexus recommends replacing AHU-9 one for one.

• 1976 AHU-10 and mated 2002 ACCU that serves classrooms. This air handling unit currently has hot water heating and R22 DX dehumidification. Nexus recommends replacing AHU-10 one for one.

• 1976 AHU-15 and mated 2002 ACCU that serves student services. This air handling unit currently has no heating and R22 DX dehumidification. Nexus recommends replacing AHU-15 one for one and adding hot water heating.

• 1976 AHU-16 that serves the locker commons. This air handling unit currently has hot water heating and no dehumidification. Nexus recommends replacing AHU-16 one for one and adding DX dehumidification.

• 1976 AHU-17 and mated 2002 ACCU that serves the tech ed spaces. This air handling unit currently has hot water heating and R22 DX dehumidification. Nexus recommends replacing AHU-17 one for one.

• 1976 AHU-18 and mated 2002 ACCU that serves student services. This air handling unit currently has no heating and R22 DX dehumidification. Nexus recommends replacing AHU-18 one for one and adding hot water heating.

• 1976 AHU-19 that serves the wood shop. This air handling unit currently has hot water heating and no dehumidification. Nexus recommends replacing AHU-19 one for one and adding DX dehumidification.

The new air handling units would come with code compliant filtration, heating water coils, DX dehumidification coils, access sections, and supply fans with variable speed drives (VSDs).

The benefits of this HVAC improvement include increased system life expectancy, improved DDC scheduling, improved ventilation, increased energy savings, improved occupant comfort, and an improved learning and working environment.

VENTILATION SYSTEM IMPROVEMENTS

HS-MP-7.1, 7.2, 8.1, 8.2 Air Handling Unit and Air-Cooled Condensing Unit Replacements and DX Dehumidification Addition

• Remove existing air handling units, air-cooled condensing units, piping, and controls

• Provide new double wall indoor air handling units with hot water heating and DX dehumidification

• Provide new mated air-cooled condensing units and associated refrigerant piping

• Provide variable speed drives for the supply and relief fans

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

HS-MP-7.1, 7.2 ,8.1, 8.2 Benefits

• Upgraded HVAC infrastructure

• Increased ventilation for improved indoor air quality

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

COOLING SYSTEM IMPROVEMENTS

Replace (8) R-22 Air-Cooled Condensing Units and Associated Coils in Units Serving the Gym, Pool, Wrestling, Foyer, Stage, and Cafeteria

The are currently eight (8) air-cooled condensing units at the High School that are starting to corrode and deteriorate. These 20-year-old plus condensing units are still utilizing R-22 refrigerant which has become obsolete and far less efficient than today’s systems. These units are listed below.

• 1998 ACCU-5. This is a 32-ton condensing unit that is mated with air handling unit AHU-S5 that serves the foyer.

• 1998 ACCU-6. This is a 20-ton condensing unit that is mated with air handling unit AHU-S6 that serves the stage.

• 1998 ACCU-7. This is a 60-ton condensing unit that is mated with air handling unit AHU-S8 that serves cafeteria.

• 2002 ACCU-S1. This is a 40-ton condensing unit that is mated with air handling unit AHU-S1 that serves the science classrooms.

• 2002 ACCU-S2. This is a 50-ton condensing unit that is mated with air handling unit AHU-S2 that serves the media center and classrooms.

• 2003 ACCU-3. This is a 40-ton condensing unit that is mated with air handling unit AHU-3 that serves the South part of the wrestling room.

• 2005 ACCU-2. This is a 100-ton condensing unit that is mated with air handling unit AHU-S7 that serves the 1998 gym.

• 2005 ACCU that serves the pool air handling unit. This is a 55-ton condensing unit. The pool air handling unit also has six (6) supply fan motors located in the unit. Three (3) of these fan motors were replaced in 2022 and the remaining three (3) are original to the unit. The original motors have started to fail and should be replaced. Nexus recommends the replacement of the three (3) original fan motors in addition to the aircooled condensing upgrades noted below.

Nexus recommends replacing all eight (8) of these old inefficient aircooled condensing units and their mated DX cooling coils with new aircooled condensing units and associated DX cooling coils with American Society of Heating and Refrigeration Engineer’s (ASHRAE) code compliant refrigerant that is more energy efficient and environmentally friendly. New refrigerant piping would be installed as required for the new refrigerant.

Benefits of this cooling system upgrade include increased energy savings, reduced maintenance, improved system operation, and reduced environmental impact.

COOLING SYSTEM IMPROVEMENTS

HS-MP-9A Replace Eight (8) R-22 Condensing Units and Associated Coils in Units Serving the Gym, Pool, Wrestling, Foyer, Stage, and Cafeteria

• Provide new DX cooling coils with code compliant refrigerant

• Provide new air-cooled condensing units

• Provide new refrigerant piping to air handling units as required for new refrigerant

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

HS-MP-9A Benefits

• Upgraded HVAC infrastructure

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

COOLING SYSTEM IMPROVEMENTS

Replace the R-22 Cooling Systems with a New Chilled Water Plant that Serves the Entire High School

As a secondary cooling option in lieu of the DX additions noted above, Nexus recommends the addition of an air-cooled chiller to serve the High School.

This chiller would be sized to serve all the rooftop and indoor air handling units in the building with some capacity for any future addition of cooling. All existing DX air handing units would be converted to chilled water except for the 2018 RTU-1 and MAU-1 that serves manufacturing/Ag, the 2018 Carrier ACCU-4 that serves the auditorium, the 2019 AHU-4 and ACCU-4 that serves the tech area, and the 2021 Trane ACCU that serves the media center/classrooms. New chilled water piping mains would be installed throughout the building as required and would be sized for the potential future addition of cooling.

The benefits of this HVAC improvement include increased system life expectancy, improved DDC scheduling, improved ventilation, improved occupant comfort, and an improved learning and working environment.

COOLING SYSTEM IMPROVEMENTS

HS-MP-9B Replace the R-22 Cooling Systems with a New Chilled Water Plant that Serves the Entire High School

• Install new air-cooled chiller, pumps, and chilled water main distribution piping

• Install new chilled water-cooling coils for each air handling unit

• Install new chilled water piping to air handling units as required for cooling addition

• Provide propylene glycol, glycol fill station, and side-stream filter for the new chilled water system

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

HS-MP-9B Benefits

• Upgraded cooling infrastructure

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

VENTILATION SYSTEM IMPROVEMENTS

Replace Eight (8) Air Handling Units Serving the 1998 Additions and One (1) 2003 Serving the Girl’s Locker Room

There are eight (8) 1998 air handling units and one (1) 2003 AHU serving the Chisago Lakes High School that are still in good shape but should be considered for replacement in ten (10) years. These units are as listed below.

• 1998 AHU-1 that serves the science classrooms. This air handling unit currently has hot water heating and DX dehumidification.

• 1998 AHU-2 that serves the locker commons. This air handling unit currently has hot water heating and DX dehumidification.

• 1998 AHU-3 that serves the media center and classrooms. This air handling unit currently has hot water heating and DX dehumidification.

• 1998 AHU-4 that serves the auditorium. This air handling unit currently has hot water heating and DX dehumidification.

• 1998 AHU-5 that serves the foyer. This air handling unit currently has hot water heating and DX dehumidification.

• 1998 AHU-6 that serves the stage. This air handling unit currently has hot water heating and DX dehumidification.

• 1998 AHU-7 that serves competitive gym. This air handling unit currently has hot water heating and DX dehumidification.

• 1998 AHU-8 that serves the cafeteria. This air handling unit currently has hot water heating and DX dehumidification.

• 2003 AHU-3 that serves the South wrestling room. This air handling unit currently has hot water heating and R22 DX dehumidification.

The new air handling units would come with code compliant filtration, heating water coils, DX dehumidification coils, access sections, and supply fans with variable speed drives (VSDs).

The benefits of this HVAC improvement include increased system life expectancy, improved DDC scheduling, improved ventilation, increased energy savings, improved occupant comfort, and an improved learning and working environment.

VENTILATION SYSTEM IMPROVEMENTS

HS-MP-10 Replace Eight (8) Air Handling Units Serving the 1998 Additions and One (1) 2003 Serving the Girl’s Locker Room

• Remove existing air handling units, piping, and controls

• Provide new double wall indoor air handling units with hot water heating and DX dehumidification

• Provide variable speed drives for the supply and relief fans

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

HS-MP-10 Benefits

• Upgraded HVAC infrastructure

• Increased ventilation for improved indoor air quality

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

EXHAUST/VENTILATION SYSTEM IMPROVEMENTS

Add Overhead Exhaust Range Hoods to FACS and Ag Classrooms, Replace Exhaust Fans (Qty 50), Add Exhaust to Art Room and Laser Engraver, Add Thermal Equalizers to 1998 Gym

There are over 100 total inline and rooftop exhaust fans at the High School. Many of these exhaust fans have exceeded their recommended service life and are in need of replacement.

Nexus recommends replacing some of these fans when major work is taking place so the best pricing can be obtained from the contractors. Nexus has budgeted for the replacement of fifty (50) existing exhaust fans for the school. Nexus will work along with the District on the priority of which ones want to be replaced.

Fans will be a direct replacement to the original size/capacity but will have premium efficiency motors installed to increase energy savings. The fan size/capacity may be reduced if engineering can justify where over ventilation is occurring.

The benefits of this HVAC improvement will result in increased energy savings, improved flow and reduced maintenance for exhaust fans, and reduced leaks from seals.

- The existing range ovens in the FACS (Qty 6) and Ag (Qty 2) classrooms have no exhaust hoods. There are currently exhaust grilles located in the ceiling above which are inadequate and don’t meet code. Nexus recommends adding new overhead exhaust range hoods in FACS and Ag classrooms. The hoods would be ducted directly out to a new exhaust fan on the roof.

- The Art 2 room as shown in the picture below currently has no space exhaust which is not code compliant. ASHRAE 62.1 Ventilation and Acceptable Indoor Air Quality requires art classrooms to be exhausted at a rate of 0.7 CFM per square foot. Nexus recommends adding a new exhaust system for the art classroom consisting of new grilles, ductwork, and rooftop exhaust fan.

- The laser engraver located in the tech classroom currently has no exhaust system. The District has already received a quote to add new exhaust ductwork and exhaust fan for the laser engraver. Nexus recommends the addition of a new exhaust system for the laser engraver.

These exhaust upgrades will increase indoor air quality, improve occupant comfort, and reduce maintenance.

The existing 1998 gym currently suffers from temperature stratification due to the height of this space. Warmer air migrates to the ceiling making it difficult to achieve proper temperature control, especially in winter.

Nexus recommends the installation of thermal equalizer destratification fans in the 1998 gym (Qty 6) to ensure proper ventilation.

Benefits of these improvements include energy savings, improved temperature control and occupant comfort.

EXHAUST/VENTILATION SYSTEM IMPROVEMENTS

HS-MP-11 Add Overhead Exhaust Range Hoods to FACS and Ag Classrooms, Replace Exhaust Fans (Qty 50), Add Exhaust to Art Room and Laser Engraver, Add Thermal Equalizers to 1998 Gym

• Replace exhaust fans with new exhaust fans with associated ductwork

• Add new overhead exhaust hoods, associated ductwork, and exhaust fan in FACS and Ag classrooms

• Add new ceiling exhaust grilles, associated ductwork, and exhaust fan in Art 2

• Add new exhaust system for the tech ed laser engraver as per quote received from district

• Provide all roofing and sealing work as required

• Install thermal equalizers in 1998 gym

• Wire thermal equalizers to wall switch/controls

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

HS-MP-11 Benefits

• Upgraded exhaust system infrastructure

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved work environment

PLUMBING SYSTEM IMPROVEMENTS

Plumbing Upgrades Including Replacing Non-ADA Was Stations, Electric Water Coolers, and Drinking Fountains. Replace Science Room Faucets, Column Showers, Urinal and Flush Valves, and Sump Pumps

There are many plumbing devices that are starting to increase in maintenance/non-ADA compliant and should be replaced. See below for this equipment.

• Non-ADA Wash Fountain (Qty 3)

• Electric Water Coolers (Qty 16)

• Drinking Fountains (Qty 5)

• Science Room Faucets (Qty 90)

• Column Showers (Qty 8 Columns, Qty 40 Heads)

• Timer Flush Urinal Replacements in Toilet Rooms (Qty 11)

• Sump Pumps (Qty 2)

• Leaking Roof Drains (Qty 3)

Nexus recommends replacing these existing plumbing fixtures one for one with new ADA compliant fixtures. Plumbing piping would be modified as required for the new fixtures.

Replacing these plumbing fixtures would provide reduced water consumption, reduced maintenance, and extended life expectancy of the plumbing system.

PLUMBING SYSTEM IMPROVEMENTS

HS-MP-12,13 Plumbing Upgrades Including Replacing Non-ADA Wash Stations, Electric Water Coolers, and Drinking Fountains. Replace Science Room Faucets, Column Showers, Urinal and Flush Valves, Sump Pumps and Leaky Roof Drains

• Demo existing wash stations, electric water coolers, drinking fountains, sump pumps, column showers, urinals, and leaky roof drains

• Provide and install new ADA compliant fixtures one for one

• Modify existing plumbing piping as required for new fixtures

• Provide associated general and electrical construction work as required

HS-MP-12,13 Benefits

• Improved occupant comfort

• Improved plumbing fixture operation

• Increased equipment life

• Reduced maintenance

PLUMBING SYSTEM IMPROVEMENTS

Replace Sanitary Lines Under Boiler Room

The sanitary lines and drains in the boiler room are corroded and deteriorating. These sanitary lines are original to the building and should be replaced.

Nexus recommends sawcutting the existing sanitary lines out and demolishing them. New sanitary piping and floor drains would then be installed.

Replacing these sanitary lines would reduce maintenance and extend the life expectancy of the sanitary system.

PLUMBING SYSTEM IMPROVEMENTS

HS-MP-14 Replace Sanitary Lines Under Boiler Room

• Saw cut and remove existing sanitary lines as required

• Install new sanitary piping and floor drains

• Provide associated general construction work as required

HS-MP-14 Benefits

• Improved sanitary system

• Increased equipment life

• Reduced maintenance

FIRE PROTECTION SYSTEM IMPROVEMENTS

Extend Fire Protection Sprinkler System with New Water Service to Non-sprinkled areas

The existing Chisago Lakes High School has fire protection in all areas of the building except the areas as highlighted in yellow in the floor plan to the right. Therefore, these areas are not protected from property loss or life safety in the event of a fire. Installing fire protection sprinklers in buildings significantly enhances safety by automatically discharging water to suppress fires upon heat detection. According to the National Fire Protection Association (NFPA), buildings equipped with sprinklers see a lower rate of fire-related injuries and property damage compared to those without, highlighting their effectiveness.

Moreover, retrofitting buildings with these systems ensures compliance with modern safety standards and can lead to lower insurance premiums due to reduced risks of fire damage. Fire sprinkler systems also require minimal maintenance, ensuring durability and consistent performance over time, making them a reliable choice for enhancing safety.

Nexus proposes installing a fire protection sprinkler system for all the highlighted areas of the Chisago Lakes High School. Installation is a proactive measure to protect students, staff, and property.

CONDITIONS

FIRE PROTECTION SYSTEM IMPROVEMENTS

HS-MP-15 Extend Fire Protection Sprinkler System with New water Service to non-sprinkled areas

• Install new wet-pipe fire protection system to fully protect the entire building

• Provide all required general construction work

HS-MP-15 Benefits

• Reduced damage during a fire event

• Increased occupant safety

HVAC RETRO-COMMISSIONING

Retro-Commission HVAC Equipment

Building retro-commissioning is a systematic process that ensures all buildings perform as efficiently as possible according to the owner’s operational needs as well as adjustment of HVAC equipment’s operational parameters to meet current space use.

The Building Automation System (BAS) plays a crucial role in providing a comfortable, energyefficient environment for students, parents, and staff. Over time, damper and valve controls have gone out of proper adjustment, components fail, and controls sequences are modified and may not be programmed to provide an optimal balance between comfort, indoor air quality, and energy efficiency.

This Nexus Retro-commissioning Team will identify the root cause of HVAC equipment operational issues and will provide adjustments to the sequences and outdoor air setting to improve occupant comfort while reducing energy consumption where possible. The retrocommissioning process will also identify components that require adjustment or replacement.

Retro-commissioning activities include:

HVAC Equipment: Nexus will verify existing HVAC equipment operation and control sequences through observation. We will provide adjustment and tuning services to achieve optimal operation and improved occupant comfort. Documentation of the findings with corrections and recommendations for further improvements will be made.

Services include:

• Ventilation study to assure all spaces are ventilated per the current code requirements and the outdoor air setpoints will be adjusted up or down based on current space occupancy

• Test point commands vs actual controller output at each device for heating, cooling, and mixed air control

• Verify valve/damper operation on reheat coils and air handler coils

• Verify indicated vs actual (duct static, supply and return temperatures)

• Verify mixed-air operation (damper position and economizer operation)

Valves and Dampers: Nexus will test all existing rooftop (RTU) and indoor air handling unit (AHU) sequences along with the valve and damper operation to ensure control actuators are fully

operational. We observe valve/damper/actuator operation and check for any physical signs of valve/damper leakage or binding, which results in operational issues and increased energy consumption. We check discharge temperature with valves in the fully open and closed positions. In addition, we will provide unit pricing to replace any defective valves and/or actuators. Proper RTU and AHU operation provides improved occupant comfort at optimal energy efficiency.

Zone Reheat Valves: Nexus will test existing zone reheat valves for proper operation. We ensure command valves fully open and close and observe valve/actuator operation. We inspect valves for any physical signs of valve leakage or binding, check discharge temperature with valve in the fully open and closed positions and provide unit pricing to replace any defective valves and/or actuators.

Economizer: Nexus will update the control sequence for mixed-air dampers to their setpoints with economizer lockout setpoints.

Heating Water Pump Variable Speed Drives (VSDs): Nexus will lower the pressure setpoint to allow drives to modulate down to the slowest speed required to satisfy the most critical room temperature sensor.

Boilers: Nexus will optimize sequencing and staging of equipment and adjust the water reset schedules based on outside air temperature.

The action steps noted above are part of the Nexus retro-commissioning process. The benefits of this process include improved temperature control and occupant comfort, reduced energy consumption, reduced maintenance, and extended HVAC equipment life.

HVAC SYSTEM RETRO-COMMISSIONING

HS-MP-16 Retro-Commission HVAC Equipment

• Provide retro-commissioning of all existing HVAC systems

• Provide adjustments to existing sequences to improve HVAC system operation

• Verify operation of all dampers, actuators, valves, and terminal HVAC devices

HS-MP-16 Benefits

• Improved temperature control and occupant comfort

• Reduced energy consumption

• Reduced maintenance

• Extended HVAC equipment life

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

Electrical power distribution upgrades including switchgear, panels and backup generator for critical loads including boiler, boiler pumps, emergency lighting, coolers and freezers (450 kw)

Switchboard and panels

The switchboard and panels that are original to the 1974 building are now 50 years old and are at the end of their useful life. The original manufacturer of these panels no longer exists, and replacement circuit breakers are not available.

Panelboards that were installed for the 1986 and 1998 additions appear to be in good condition. However, there is electrical equipment in the pool chemical room (installed in 1986) that should be replaced due to rusted enclosures.

It is recommended that the 1974 electrical panels and switchboard be replaced. New panels will provide a safer electrical system since new equipment will be in compliance with current manufacturing standards for electrical equipment and will reduce maintenance costs.

Equipment in the pool pump room shows signs of corrosion due to the environment. Corroded controllers should be replaced.

Equipment recommended to be replaced includes one switchboard, one distribution panel, and 19 panelboards. In addition, it is recommended that three motor controllers in the pool chemical room be replaced.

Emergency/Standby Generator

There currently is no emergency or backup generator. It is desired to have a generator that will provide backup power for life safety equipment, IT equipment, coolers and freezers, and boilers and pumps associated with the heating system. A generator would prevent damage to the building in the event of a power loss and the building freezing. With the life safety and IT equipment on the generator, communications with building occupants can be maintained in the event of a power loss in an emergency situation.

Increase the size of the generator from 450kw to 1,750kw to cover full building load including cooling (cost represents the increased cost between the two generators)

Installing a generator with full building backup will allow the school to function, even when utility power is lost. Increasing the size of the generator from 450 kW to 1,750 kW will also allow the building to be cooled.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-1.1 Electrical Power Distribution Upgrades Including Switchgear and Panels in the 1958 Building

• Replace original 1974 electrical panels

• Replace two Switchboards

• Replace 18 Panelboards

• Install new generator – 450 kW

• Install new automatic transfer switches, feeders, and electrical distribution

HS-ES-1.2 Increase the size of the generator from 450 kw to 1,750 kw to cover full building load including cooling (cost represents the increased cost between the two generators)

• Install new generator sized for entire building load including cooling – 1,750 kW

• Install new automatic transfer switches, feeders, and electrical distribution

HS-ES-1.1, 1.2 Benefits

• Protection of and Improved Reliability of Electrical Infrastructure

• Reduced energy consumption

• Reduced maintenance

• Extended HVAC equipment life

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

LED lighting upgrade. Retrofit kits for fixtures in good condition, replacement for unique or outdated fixtures.

Light Fixture Upgrades

The existing lighting in classrooms, gymnasiums, and common areas is primarily fluorescent lamps throughout. The fixtures appear to be in fair condition; however, LED lamp technology is more energy efficient.

Replacing the light fixtures with LED light fixtures will reduce energy use and maintenance costs. LED light fixtures have a life span of more than 50,000 hours and do not require lamp replacements, which reduces maintenance costs.

It is recommended that all light fixtures be replaced with new LED light fixtures.

Lighting Control Upgrades

With LED light fixtures, dimming becomes a more viable standard. Dimmable lighting allows the users of the space to adjust the light levels as needed to enhance learning for students. Implementing dimming and occupancy sensors not only improves the functionality of the space, it reduces energy use.

It is recommended that dimming and occupancy sensor lighting controls be implemented to enhance the functionality of the lighting and to reduce energy use.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-2 LED Lighting Upgrade. Retrofit Kits for Fixtures in Good Condition, Replacement for Unique or Outdated Fixtures.

• Replace light fixtures throughout the building with LED light fixtures

• Controls to provide dimming capabilities

• Automatic shutoff of lighting

HS-ES-2 Benefits

• Reduce energy costs

• Reduce maintenance costs

• Enhance safety

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

Replace existing fire alarm system with a voice evacuation system

The existing fire alarm system is a Notifier system and is outdated. Current building codes require a voice evacuation fire alarm system in schools. The existing system is not capable of supporting a voice evacuation system. It is recommended that the entire fire alarm system be replaced throughout with a voice evacuation system to provide a code compliant system and better safety for staff and students.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-3 Replace existing fire alarm system with a voice evacuation system

• Replace existing fire alarm panel and amp

• NAC panels

• Remote annunciators

• Smoke/heat and dust detectors

• Pull stations

• Monitor modules

• A/V Devices, speakers

HS-ES-3 Benefits

• Protection and improved reliability

• Improved safety

• Enhance security

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

Replace existing paging system and add audio enhancement to the remaining classrooms that is tied into the new paging system, replace common area speakers

The existing paging system is outdated and needs to be replaced. Newer systems have better intelligibility and easier to use, making them more functional. Continual issues with the existing system also have continual maintenance costs to keep it operational.

Audio Enhancement systems for classrooms implement speakers and microphones in classrooms that enhance the learning experience for students. These systems have become the standard for new classrooms. Audio enhancement systems for classrooms have become beneficial for teachers and students to enhance the audio in the room making it easier for students to listen and understand the teacher. There are audio enhancement systems in seven classrooms. Audio enhancement should be implemented in the remaining classrooms.

It is recommended that the paging system be replaced throughout the building and audio enhancement be implemented in classrooms. The paging and audio enhancement systems can utilize the same speakers for both functions to help manage costs of replacement and implementation.

CONDITIONS

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-4 Replace existing paging system and add audio enhancement to the remaining classrooms that is tied into the new paging system, replace common area speakers

• Replace Paging system

• Add audio enhancement to 51 classrooms

• Add 5 corridor paging zones

• Add 192 common area speakers

• Server

HS-ES-4 Benefits

• Better zone paging

• Improved scheduling of notification bells

• Improved safety

• Enhanced learning environment

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

Add 10 new security cameras to existing system, upgrade cable serving telephone system and install vape sensors to locker rooms and restrooms. There are several security system concerns that require attention. There is currently no visitor entry call system at the main entrance. Typically, there would be a pushbutton intercom with a camera that visitors activate to call the main office to be let into the building. This allows for a security checkpoint when visitors need to enter the building. Security cameras are approximately 5-6 years old. Although they still have 3-4 years left of their useful life, there are areas that need better camera coverage for better security.

Correcting these items will provide better security for staff and students.

Vape Sensors

With the increase in vaping among students, implementing vape sensors in restrooms and locker rooms helps to prevent vaping. It is recommended that vape sensors be installed in these problem areas.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-5 Add 10 New Security Cameras to Existing System, Upgrade Cable Serving Telephone System and Install Vape Sensors to Locker Rooms and Restrooms

• Add 10 security cameras

• Add vape sensors to locker rooms and restrooms (qty 18)

• Upgrade cable serving telephone system

HS-ES-5 Benefits

• Protection and improved reliability

• Improved safety

• Enhance security

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

Install Additional Outlets in Classrooms

The older areas of the building were not designed for the current need for outlets. For example, the older ag classrooms have 4 outlets each. Other classrooms have 10. Students need the outlets to keep the computers charged for the day. Adding more outlets will eliminate the need for extension cords used throughout the rooms.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-6 Install Additional Outlets in Classrooms

• Add additional outlets where needed to average 6 per room

HS-ES-6 Benefits

• Improved charging stations

• Improved safety

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

The Ward and main gym sound systems are more than 25 years old. Replace both sound systems.

The existing sound systems in both the Ward gym and the main gymnasium are approximately 25 years old. This equipment has passed its useful life. It is recommended that this system be replaced.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-7 The Ward and main gym sound systems are more than 25 years old. Replace both sound systems.

• Replace speakers and headend (Qty 2)

HS-ES-7 Benefits

• Improved sound

• Improved functionality

ELECTRICAL, TECHNOLOGY AND SAFETY SYSTEMS

Enhance security with upgraded burglar alarm including controller, keypads and sensors

There is an existing burglar alarm intrusion detection system, but it is not currently functional. This system needs to be updated so it functions properly.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-8 Enhance security with upgraded burglar alarm including controller, keypads and sensors

• Install new burglar alarm

• Install 64 motion sensors

• Install 2 keypads

HS-ES-8 Benefits

• Enhanced security

• Improved safety

ELECTRICAL, TECHNOLOGY AND SAFETY SYSTEMS

In the auditorium, replace the existing sound system, the speaker power amplifiers, and add an additional amplifier with 3 panels. Update portable wireless intercom to an FCC compliant system. Replace assisted listening transmitter with a combination Wi-Fi/FM system.

Auditorium Speakers

The auditorium is currently serviced by an aging main speaker system, consisting of two horn-loaded loudspeakers and two large horns and is original. 3D speaker simulation modeling of the space should be undertaken to determine the best coverage and help predict intelligibility.

The existing system be removed and replaced with a left/right array, allowing for multiple speaker patterns to cover the front and mid-section of the seating areas. As the catwalk area is easily accessible with structural iron in locations that allow for straightforward rigging, delay speakers could be added to provide better coverage in the rear seating area. Replacing these speakers and their associated amplifiers should be the top priority item for any updating of this space.

Audio Amplifiers

Power amplifiers for the speaker system are aging and should be replaced. An additional amplifier is recommended to be added into the “Effects” speaker system that has output panels around the space (stage, seating and balcony areas).

Production Intercom System

An older, portable wireless intercom system is currently in use, but no frequency information was visible. This system may be subject to FCC changes. It is recommended that the system be updated with a more robust, frequency compliant system that can be expanded in the future.

ADA Compliance

An older FM assisted listening transmitter is mounted in the equipment rack, but there wasn’t a clear count on the number of beltpacks/receivers for this system. It is recommended that a combination WiFi/FM system be installed to increase the usability of the system. Signage placards should be installed to alert guests on how to connect to the system.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

HS-ES-9 In the auditorium, replace the existing sound system, the speaker power amplifiers, and add an additional amplifier with 3 panels. Update portable wireless intercom to an FCC compliant system. Replace assisted listening transmitter with a combination Wi-Fi/FM system.

• Replace auditorium speakers

• Replace power amplifier

• Replace wireless intercom system

• Replace assisted listening transmitter

HS-ES-9 Benefits

• Enhanced sound in auditorium

• Improved wireless intercoms

• Improved hearing accessibility

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

A new auditorium audio console and breakout boxes should be installed that route through a dedicated audio network switch and a digital signal processing unit. Update the wireless microphones.

Audio System Inputs and Infrastructure

Currently, all system inputs are routed to two patch panels in the control booth. This makes it straightforward to update and expand the capabilities of the audio system. The front of house mix position is in the control booth as well. This location presents difficulties in understanding the sound in the auditorium. The current audio mixer provides a control option via iPad that helps alleviate some of the difficulties, but having a wired position for the mixer in the auditorium would be beneficial. The mixer itself is primarily setup for analog inputs and outputs. This presents difficulty in expansion and routing.

The system would greatly benefit from a new console and breakout boxes which route through a dedicated audio network switch and digital signal processing unit. Two breakout I/O devices would be dedicated to on-stage use, while the other would be rack mounted to allow reuse of some of the existing analog infrastructure. In this case, the processor can also do double-duty as a control processor for AV presentations. Updating the console would also assist in teaching students a more modern workflow on audio mixers.

Wireless microphone systems

Four single wireless microphone systems are mounted in the rack with frequency bands not identified.

Updating the wireless microphone system with a common antenna and network audio outputs is recommended. This will also provide FCC frequency compliance well into the foreseeable future. The number of required wireless units would need to be discussed.

Microphone input, video inputs, intercom and effects speaker patch plates from the original construction are found at stage left, stage right, both sides of the audience seating area, in the booth and on the stage lip. It is likely the raceway and locations can be repurposed for the needed remote breakout box network audio connections.

HS-ES-10 A new auditorium audio console and breakout boxes should be installed that route through a dedicated audio network switch and a digital signal processing unit. Update the wireless microphones.

• Install new console and breakout boxes with dedicated audio network switch and digital signal processing unit

• Two breakout I/O devices on-stage

• Install rack mounted breakout devices

• Update wireless microphones

HS-ES-10 Benefits

• Processor can be used as a control for AV presentations

• Students learn modern workflow on audio mixers

• FCC compliant microphones

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

The auditorium video system should be upgraded to a new HD switcher, PTZ cameras, camera control system and a streaming appliance. Upgrade the existing projector and backstage monitors. Two new control panels should be installed: control booth and backstage left.

Video Systems

The auditorium is currently utilizing portable video cameras, typically operated from the balcony railing. These cameras provide SD, composite video down to the video switcher in the control booth. The video switcher has four camera inputs, no control or image adjustments. The auditorium and students would benefit from updating this system to an HD switcher, PTZ cameras, camera control system and streaming appliance.

The existing projection screen should be evaluated for surface integrity, size and aspect ratio. The existing projector should be replaced with a brighter, higher resolution and 16:9 or 16:10 format system.

Back Of House Audio Visual

There are currently five video monitors located throughout the backstage areas. These are in male & female dressing rooms, the common area, backstage and green room. Composite video signal is delivered to these, being routed out of the control booth video system. It is recommended that this system is updated to deliver HD content via network video and can be controlled/routed through the video production system.

Speakers in the auditorium lobby and backstage areas are serviced by existing analog mixer/amps. These devices have no remote-control capabilities. Control and a new amplifier for these areas would be integrated into audio DSP, video and control systems.

Control Systems

The auditorium has no existing control systems. It is recommended that two control panels being installed, connecting to the new AV system network. One device should be in the control booth and the other should be located backstage left. These devices would provide quick system preset recall for the sound and video systems.

HS-ES-11 The auditorium video system should be upgraded to a new HD switcher, PTZ cameras, camera control system and a streaming appliance. Upgrade the existing projector and backstage monitors. Two new control panels should be installed: control booth and backstage left.

• Install new HD switcher

• Install PTZ cameras

• Install a new camera control system

• Streaming device

• Upgrade projector

• Upgrade backstage monitor

• New control panels

HS-ES-11 Benefits

• Updated video system

• Ability to deliver HD content thru network video

• Better control for sound and video systems

INTERIOR FINISHES AND ADA

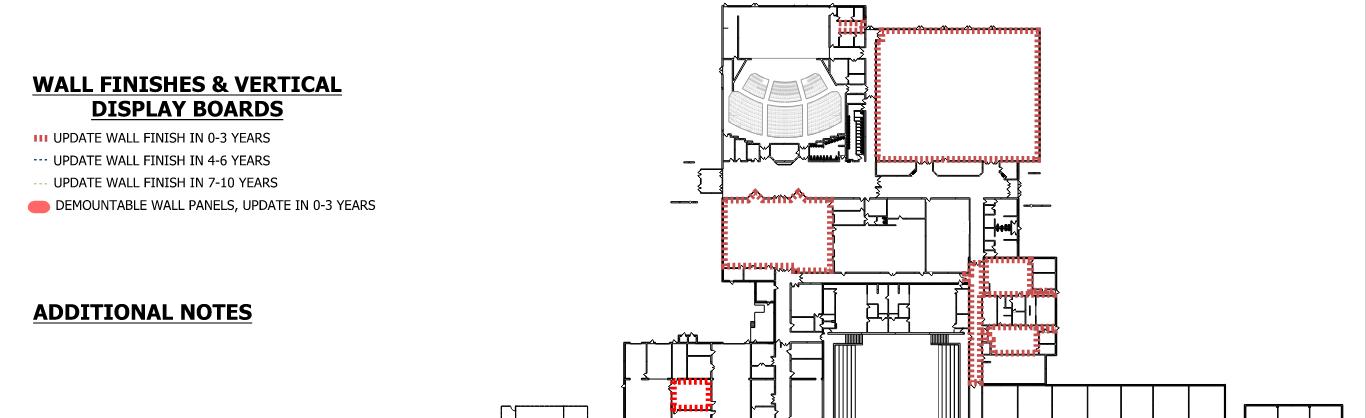

High priority doors: Replace 10 sets of double doors and 72 single interior doors through out the building. Replace the hardware on 23 interior doors. Replace coiling shutter at lecture hall. Re-key all door locks to comply with district wide Schlage standard.

The interior doors in the original building and 1986 addition are reaching the end of their useful life. Twenty three doors need only the hardware updated in the next 3 years. There are also a number of doors that need to be replaced along with the hardware. All of the door locks need to be re-keyed to comply with the District-wide Schlage standard. The coiling shutter outside of the lecture hall is damaged and needs to be replaced. Refer to the following floor plan for information on what doors need replacement along with hardware changes.

Low priority doors: Replace doors in science wing, administration, and social studies area in the next 7 to 10 years.

The district should plan on replacing the doors in the 2000 addition within the next 10 years.

CHISAGO

Doors & Hardware

INTERIOR FINISHES AND ADA

HS-IA-1 High Priority Door Replacement, Hardware and Locks. Re-Key all Door Locks to Comply with District-Wide Schlage Standard

• Replace locks on all doors to comply with district standard

• Replace 10 double doors and hardware

• Replace 72 single doors and hardware

• Replace 23 hardware only

HS-IA-3 Low Priority Door Replacement, Hardware and Locks.

• Replace 41 single doors and hardware

HS-IA-1 and 3 Benefits

• Improved building aesthetics

• Improved acoustics

• Improved security

• Improved functionality of building

INTERIOR FINISHES AND ADA

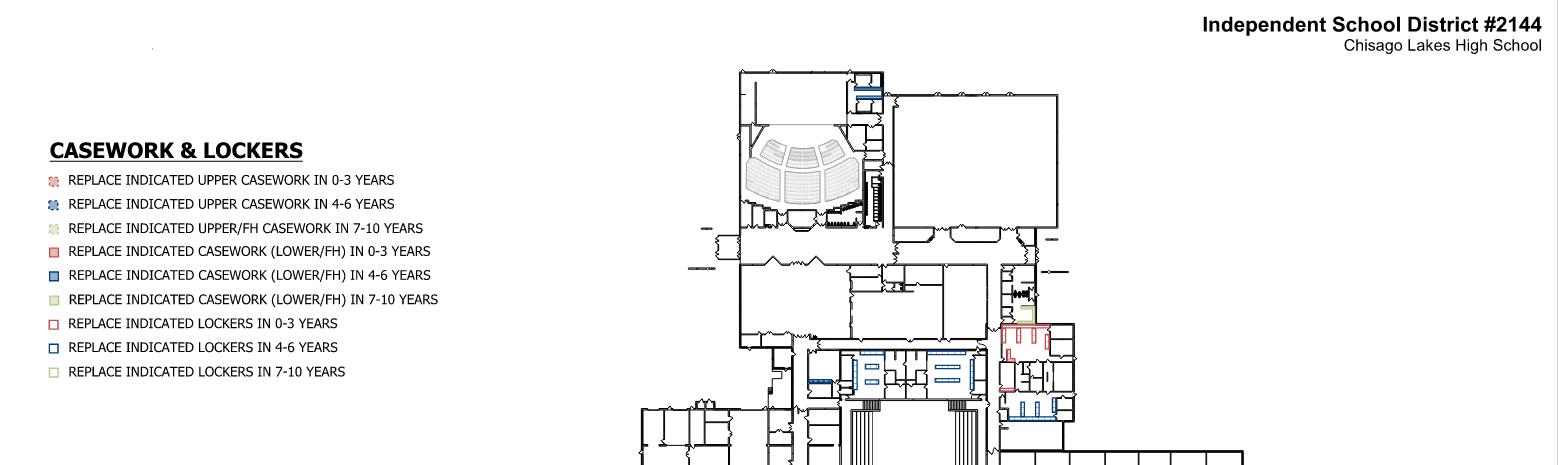

Upgrade restrooms (14) and locker rooms (5) with new finishes

The interior finishes in the restrooms in the original building and the 1986 addition need updating. There are alos a few in the 2000 addition that do not comply with ADA. The boys and girls gym locker rooms do not have accessible benches, showers and toilets. There are 14 restrooms that also have a lack of accessible features. Smaller restrooms that include the PAC green rooms, the coaches in the boys locker room, the shop tech room, the main maintenance office are included, along with larger restrooms such as the ones located near the media center corridor. (The cost of locker replacements is in HS-IA-7).

CHISAGO

INTERIOR FINISHES AND ADA

HS-IA-2 Upgrade restrooms (14) and locker rooms (5) with new finishes

• Update finishes in restrooms

• Replace restroom partitions

HS-IA-2 Benefits

• Improved building aesthetics

• Extending the life of the interior materials

• Improved functionality of building

INTERIOR FINISHES AND ADA

In the Ward gym replace the existing wire glass windows on the east corridor. Remove bleachers on one side of gym and replace the bleachers on the other side. Replace the handrail on the staircases.

The Ward gym is in need of a few upgrades. The wire glass windows on the east corridor should be replaced due to safety and to improve visibility. The bleachers are damaged and do not meet ADA. Only one side of the bleachers needs replacement, while the other just needs to be removed. Replace the handrails on the staircase.

HS-IA-4 Ward gym windows, bleachers and handrails

• Replace wood floor in wood gym

• Replace VCT in corridors with rubber tiles

• Replace VCT and resilient flooring with LVT in areas marked on the plans

• Replace worn carpet

• Install carpet in music room

HS-IA-4 Benefits

• Extending the life of the interior materials

• Reduce maintenance cost

• Improves facility aesthetics

INTERIOR FINISHES AND ADA

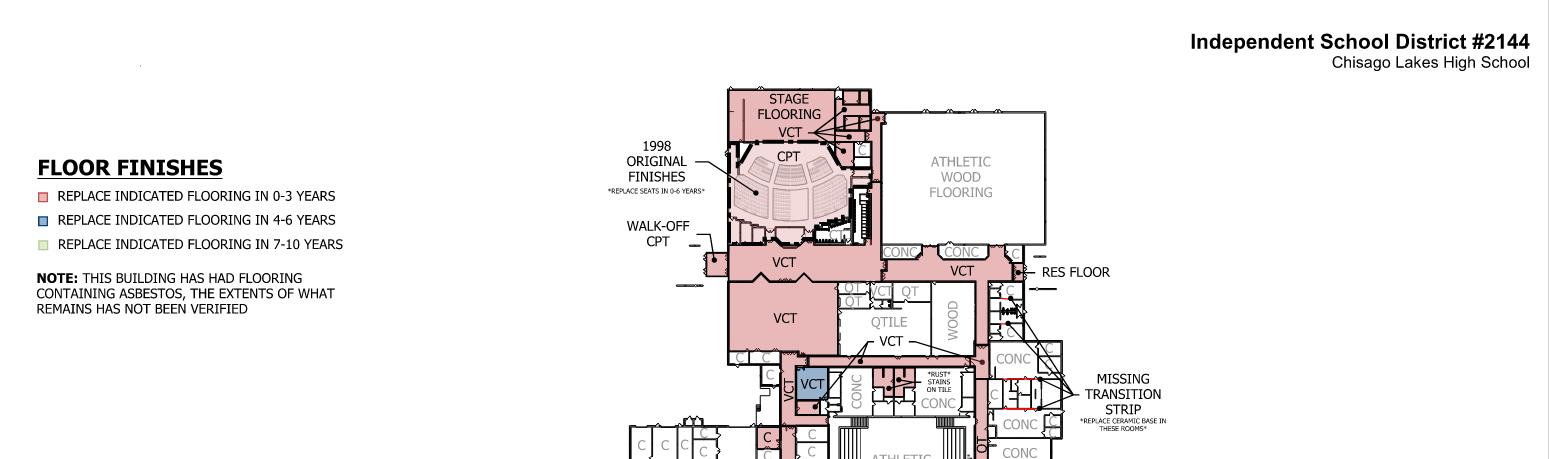

High Priority Flooring

The majority of the carpet and VCT should be replaced in the next three years. The VCT in high use areas such as the corridors and cafeteria, should be replaced with new rubber tiles as part of District-wide standardization. Replace VCT flooring with a flooring material that requires less maintenance, such as an LVT. The original 1976 kitchen tile in the commons area and tech classrooms should be replaced with a combination of carpet and LVT. The needs in the Performing Arts Center are addressed HS-IA-12.

Low Priority Flooring

A few classrooms have recently been recarpeted but may need replacement in the next 10 years. At that point consideration should be given to replacement.

CHISAGO