FACILITY CONDITIONS

BUILDING ENVELOPE IMPROVEMENTS

Roof Replacement at Office Area and Resource Center

The roofs over the main office and resource center (areas H and I) are reaching the end of their useful life and are showing signs of aging such as bridging / stretching at roof perimeters and multiple previous repairs. These roofs should be replaced in the next 3 to 5 years.

Roofing system replacement will improve energy performance by increasing system insulation values, reduce leaks, and will reduce operating and maintenance expenses.

BUILDING ENVELOPE IMPROVEMENTS

TF-BE-1 Roof Replacement at Office Area and Resource Center

• Removal of old roof systems & wet insulation / deteriorated wood blocking.

• Polyisocyanurate insulation layers. R-30 with a minimum positive slope of 1/8" per foot to ensure proper drainage.

• Recovery insulation board to accept new roof system & provide a stop gap against thermal bridging from insulation fasteners.

• Multiply modified built-up roof system with gravel surfacing. Provides a "severe hail" rating.

• Pre-finished sheet metal copings & counterflashings at all perimeters and projections to protect against damage and UV degradation.

•

TF-BE-1 Benefits

• Extend life of building

• Reduce energy costs

• Reduce leaks

• Reduce operating and maintenance expenses

BUILDING ENVELOPE IMPROVEMENTS

Install Through-Wall Fashing at Steel Lintels, Structural Steel Lintels Should be Thoroughly Cleaned of Corrosion and Painted with Quality Steel Coating, Repair or Replace Lintels that Show Major Damage. Replace Perimeter Sealant, Control Joints, Cast Stone Sill Joints at the Building Façade

Taylors Falls Elementary School is a single-story building constructed of mass brick masonry walls and corrugated metal panels. The windows and doors throughout the complex are aluminum-framed with insulated glass glazing. In general, the brick masonry façade appeared to be in fair condition for its age.

Through-wall flashing is present along the sills of the windows. Steel lintels and weep vents were present at doors and windows heads. There is no metal drip edge or through-wall flashing installed along the heads of the windows and doors. Some through-wall flashing was present at the eastern portion of the building with a drip edge exposed. The original building section windows do not appear to have through-wall flashing present at the lintels above window/door openings in the brick masonry.

Many steel lintels at the building were in fair to poor condition. Some lintels exhibited corrosion and expansive forces into the brick. Layers of pack rust have also formed. Structural steel lintels should be thoroughly cleaned of corrosion and painted with a quality exterior steel coating. If major section loss is present, then repair of the lintel or replacement may be warranted. This condition warrants repair to prevent further damage to embedded steel and brick cladding, and to prevent water entry into and through the exterior walls. Install through-wall flashing at existing steel lintels.

Exterior joint sealants at windows, doors, corners, and other areas of the façade were in poor condition. Weathering, splitting, debonding, and cracking of sealant was observed throughout the façade. Utilities pipe penetration sealants are deteriorated, or adhesive failure was observed. Based on observed conditions, it appears that the sealants on the building have reached or exceeded their useful life. Widespread sealant deterioration is present at the building. A building-wide sealant replacement project is recommended in the next 4-6 years.

BUILDING ENVELOPE IMPROVEMENTS

TF-BE-2 Steel lintels, Sheet Metal Flashing and Through-Wall Flashing

• Install through-wall flashing

• Clean and paint steel lintels

• Sealant replacement at doors, windows, and control joints

•

TF-BE-2 Benefits

• Extend life of building

• Reduce leaks

• Reduce operating and maintenance expenses

BUILDING ENVELOPE IMPROVEMENTS

Repair Brick Deterioration at the Localized Elevations Where Roof Runoff is Damaging Brick. Tuckpoint, Replace Damaged Brick, Repair the Shrunken Gasket in Window to Prevent Future Water Entry into the Wall System, and Replace the Concrete Surface Drains.

In general, the brick masonry façade appeared to be in good condition for its age. However, spalling was observed at isolated locations throughout the façade. In the courtyard some areas of the brick façade are in poor condition. Localized areas exhibit damage/deterioration of brick and mortar that appears to have resulted from freezing thaw circle A few locations were seen to have cracked, spalled, or broken bricks. Efflorescence is present at many locations at the original section of the building.

Other miscellaneous items include a cracked and broken concrete surface drain and a junction box that is missing a cover and is exposed to the elements.

BUILDING ENVELOPE IMPROVEMENTS

TF-BE-3 Repoint Mortar Joints and Replace Cracked/Spalled Brick

• Replace brick (approximately 500)

• Repoint 2,000 square feet

• Replace the concrete surface drain and cover on junction box

•

TF-BE-3 Benefits

• Extend life of building

• Prevent moisture intrusion

• Reduce operating and maintenance expenses

BUILDING ENVELOPE IMPROVEMENTS

Replace Blue Metal Siding within Courtyard and Northside of Original Building Metal panel siding appears to be in fair to poor condition. No major dents or damage in the siding was noted during the inspection. Painting touchups have occurred on the siding at many locations. The metal siding is showing signs of aging. Consideration should be given to replacement of the metal siding.

BUILDING ENVELOPE IMPROVEMENTS

TF-BE-4 Replace Blue Metal Siding within Courtyard and Northside of Original Building

• Replace siding

•

TF-BE-4 Benefits

• Extend life of building

• Improve overall aesthetics

BUILDING ENVELOPE IMPROVEMENTS

Replace Two (2) Exterior Double Doors and Two (2) Single Exterior Doors

The hollow metal swing doors are corroded at the bottom of the door frames. The doors and center mullion are showing signs of wear.

We recommend replacing the indicated exterior doors, including the hardware and locks. Re-key all the door locks to comply with the District-wide Schlage standard.

BUILDING ENVELOPE IMPROVEMENTS

TF-BE-5

Replace Two (2) Exterior Double Doors and Two (2) Single Exterior Doors

• Replace exterior doors and frames including hardware and locks

• Re-key all locks to District-wide Schlage standard

•

TF-BE-5 Benefits

• Extend life of structure

• Reduce maintenance

• Increase security

MECHANICAL AND PLUMBING

Controls Upgrade

Controls Upgrade (Only if TF-ME-6 is NOT Accepted)

The Taylors Falls Elementary School building automation system is in good shape and all hardware and software are current.

The existing chiller is the only item that is in need of a controls upgrade. If the chiller replacement is NOT accepted in TF-ME-6 Nexus recommends upgrading the controls on the chiller. This upgrade would include new controls modules, programming, field labor, and mapping to the building’s BAS front end.

The benefits of this controls improvement include improved equipment scheduling, improved cooling system control, increased energy savings, improved occupant comfort, and an improved learning and working environment.

BUILDING ENVELOPE IMPROVEMENTS

TF-ME-1 Controls Upgrade (Only if TF-ME-6) is NOT Accepted

• Provide new controls for existing chiller

• Integrate new existing controls into updated platform

• Provide all programming required for this improvement

TF-ME-1 Benefits

• Easy to use, modernized system control updates

• Improved building monitoring and maintenance troubleshooting

• Improved occupant comfort

• Extended heating system life

• Reduced energy consumption

• Reduced maintenance

MECHANICAL AND PLUMBING

Add Suspended Unit Heaters to Gym Storage Rooms (Qty 2)

There are two (2) storage rooms located in the gym with external wall exposure but no source of heat. The lack of heat in the spaces results in them often being too cold resulting in comfort complaints. Additional temperature control zoning is required to improve occupant comfort.

Nexus proposes adding new hot water suspended unit heaters in each of the gym storage rooms. New hot water piping would be extended from the nearest existing hot water mains to the new suspended unit heaters. All associated valves and controls would be provided and installed as required.

Benefits of these heating system improvements include reduced maintenance and extended heating system life, and the ability to ventilate the spaces properly in all weather conditions.

MECHANICAL AND PLUMBING

TF-ME-2 Add Suspended Unit Heaters to Gym Storage Rooms (Qty 2)

• Add new suspended hot water unit heaters to each gym storage room

• Extend new hot water piping as required for these heating additions

• Provide all electrical and general construction work.

TF-ME-2 Benefits

• Reduced maintenance

• Improved occupant comfort

• Extended heating system life

MECHANICAL AND PLUMBING

Replace 1990 RTU-2 and 2004 RTU-5

There are several rooftop units serving the Taylors Falls Elementary School that are becoming maintenance problems for the District. These units are as listed below.

• 1990 Mammoth RTU-2 that serves a classroom and storage rooms. This rooftop air handling unit currently has a DX cooling coil and downstream hot water heating coils.

• 2004 AAON RTU-5 that serves the West classrooms and health office. This air handling unit currently has a chilled water cooling coil and hot water heating coil.

Nexus recommends replacing the two (2) rooftop units one to one with new double wall rooftop air handling units with hot water heating and chilled water dehumidification. The new rooftop air handling units would come with code compliant filtration, hot water heating coils, chilled water dehumidification coils, access sections, and supply fans with variable speed drives (VSDs).

The benefits of this HVAC improvement include increased system life expectancy, improved DDC scheduling, improved ventilation, increased energy savings, improved occupant comfort, and an improved learning and working environment.

MECHANICAL AND PLUMBING

TF-ME-3 Replace 1990 RTU-2 and 2004 RTU-5

• Remove existing rooftop units, piping, and controls

• Provide new double wall rooftop air handling units with hot water heating and chilled water dehumidification

• Extended new hot water and chilled water piping to air handling units as required

• Provide variable speed drives for the supply and relief fans

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

TF-ME-3 Benefits

• Upgraded HVAC infrastructure

• Increased ventilation for improved indoor air quality

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

MECHANICAL AND PLUMBING

Replace 2004 RTU-3, RTU-6, and Kitchen MAU

There are several rooftop units serving the Taylors Falls Elementary School that are becoming maintenance problems for the district. These units are as listed below.

• 2004 AAON RTU-3 that serves the Kid’s Club and small group classrooms. This air handling unit currently has a chilled water cooling coil and hot water heating coil.

• 2004 AAON RTU-6 that serves the cafeteria. This air handling unit currently has a chilled water cooling coil and hot water heating coil.

• 2004 Kitchen McQuay MAU that serves the kitchen hood. This air handling unit currently has a chilled water cooling coil and hot water heating coil.

MECHANICAL AND PLUMBING

TF-ME-4 Replace 2004 RTU-3, RTU-6, and Kitchen MAU

• Remove existing rooftop units, piping, and controls

• Provide new double wall rooftop air handling units with hot water heating and chilled water dehumidification

• Extended new hot water and chilled water piping to air handling units as required

• Provide variable speed drives for the supply and relief fans

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

TF-ME-4 Benefits

• Upgraded HVAC infrastructure

• Increased ventilation for improved indoor air quality

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

MECHANICAL AND PLUMBING

Replace Four (4) Fan Coil Air Handling Units with New Rooftop Energy Recovery Units

There are several fan coil air handling units serving the Taylors Falls Elementary School that are becoming maintenance problems for the District. These units are as listed below.

• 2004 MagicAire Classroom Fan Coil Units (Qty 4)

MECHANICAL AND PLUMBING

TF-ME-5

Replace Four (4) Fan Coil Air Handling Units with New Rooftop Energy Recovery Units

• Remove existing fan coil units, piping, and controls

• Provide new double wall rooftop air handling units with hot water heating and chilled water dehumidification

• Extended new hot water and chilled water piping to air handling units as required

• Provide variable speed drives for the supply and relief fans

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

TF-ME-5 Benefits

• Upgraded HVAC infrastructure

• Increased ventilation for improved indoor air quality

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

MECHANICAL AND PLUMBING

Replace 2004 R-22 Chiller

There is currently a 2004 vintage AAON air-cooled chiller serving Taylors Falls Elementary School. This existing unit has increased in maintenance and is experiencing corrosion, leaking, and mechanical component failure such as fans, belts, and motors.

Nexus recommends replacing the existing chiller with a new air-cooled chiller plant that is sized to accommodate the entire building. The new air-cooled chiller would be provided with variable frequency drives (VFDs) to provide maximum efficiency at part-load conditions when the chiller runs most of the time. A sound attenuating package will be included for noise reduction. The new chiller would be tied into the DDC control system.

The benefits of these chilled water system upgrades include improved equipment scheduling, improved ventilation, increased energy savings, improved occupant comfort, and an improved learning and working environment.

MECHANICAL AND PLUMBING

TF-ME-6 Replace 2004 R-22 Chiller

• Remove existing air-cooled chiller, piping, and controls

• Provide new air-cooled chiller

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

TF-ME-6 Benefits

• Upgraded chilled water system infrastructure

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

MECHANICAL AND PLUMBING

Add Dehumidification to Gym AHUs

The Gym is currently served by two (2) 2020 vintage Daikin air handling units. These air handling have no means of dehumidification which results in higher humidity levels and occupant discomfort in the Gym. The Gym is also unable to meet the American Society of Heating and Refrigeration Engineer’s (ASHRAE) Thermal Environmental Conditions for Human Occupancy Standard 55. This ASHRAE design standard specifies the combinations of personal and indoor thermal environmental requirements necessary to achieve an occupant comfort satisfaction rate of 80% or greater. These indoor environmental requirements include temperature, thermal radiation, humidity, and air speed.

Nexus recommends adding new chilled water dehumidification coils to both air handling units to allow for dehumidification of the code required ventilation air to the Gym. Chilled water piping would be extended to each air handling unit as required.

The benefits of these chilled water system upgrades include improved equipment scheduling, improved ventilation, increased energy savings, improved occupant comfort, and an improved learning and working environment.

MECHANICAL AND PLUMBING

TF-ME-7 Add Dehumidification to Gym AHU

• Provide new chilled water dehumidification coils to gym air handling units (Qty 2)

• Extended new chilled water piping to air handling units as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

TF-ME-7 Benefits

• Upgraded chilled water system infrastructure

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved learning/work environment

MECHANICAL AND PLUMBING

Replace Eight (8) Rooftop and Inline Exhaust Fans, Replace Exhaust and Add Transfer Air to Lower-Level Locker Room, and Re-Route Water Heater Venting for Removal of Chimney, Add Demand Recirculation Pumps for Eight (8) Sinks with Hot Water Issues

There are several rooftop and inline exhaust fans serving the building that have exceeded their recommended service life and are in need of replacement.

Nexus recommends replacing some of these fans when major work is taking place so the best pricing can be obtained from the contractors. Nexus has budgeted for the replacement of eight (8) existing exhaust fans for the school. Nexus will work along with the district on the priority of which ones want to be replaced.

Nexus also recommends adding two (2) demand domestic hot water recirculation pumps for the classroom sinks that have trouble getting hot water in an appropriate amount of time. There are eight (8) classrooms with current hot water issues. These classrooms include rooms 109, 108, Quiet Room, Staff Restroom, 110, 111, 106, and 118.

Nexus also recommends replacing the inline exhaust fan serving the lowerlevel locker room and adding transfer air to better ventilate the space.

Fans will be a direct replacement to the original size/capacity but will have premium efficiency motors installed to increase energy savings. The fan size/capacity may be reduced if engineering can justify where over ventilation is occurring.

The existing water heating venting is routed right up through the chimney. As part of this improvement, we would reroute that venting so the chimney can be removed.

The benefits of this HVAC improvement will result in increased energy savings, improved flow and reduced maintenance for exhaust fans, and reduced leaks from seals.

MECHANICAL AND PLUMBING

TF-ME-8 Replace Eight (8) Rooftop and Inline Exhaust Fans, Replace Exhaust and Add Transfer Air to Lower-Level Locker Room, and Re-Route Water Heater Venting for Removal of Chimney, Add Demand Recirculation Pumps for Eight (8) Sinks with Hot Water Issues

• Replace rooftop and inline exhaust fans with new exhaust fans with associated ductwork

• Replace Lower-Level Locker Room inline exhaust fan with new exhaust fan and add transfer air

• Re-route water heating venting for chimney removal

• Provide all roofing and sealing work as required

• Provide DDC controls, sequencing, and programming

• Provide all associated general construction and electrical work as required

TF-ME-8 Benefits

• Upgraded exhaust system infrastructure

• Improved temperature control

• Improved occupant comfort

• Reduced maintenance

• Improved work environment

MECHANICAL AND PLUMBING

Replace Galvanized Plumbing

Some domestic water piping located in the 1951, 1962, and 1970 portions of the building is old, galvanized steel. Over time, galvanized pipes are susceptible to corrosion and rust, which can lead to a buildup of mineral deposits within the piping. This corrosion process not only reduces water flow but also compromises water quality, potentially introducing harmful contaminants into the water used by students and staff. The deterioration of these pipes can lead to frequent leaks and occasional bursts, disrupting school operations and requiring costly repairs and maintenance.

Nexus recommends the replacement of the galvanized domestic water piping with insulated copper piping. Copper plumbing offers superior durability and resistance to corrosion compared to galvanized steel and does not suffer from the same accumulation of mineral deposits that can impede water flow and quality. Furthermore, copper pipes are less prone to leaks and bursts, ensuring a more reliable water supply. Importantly, copper systems do not carry the risk of leaching harmful substances like lead, providing a safer environment for students and staff and aligning with health and safety standards in educational facilities.

Benefits of this work would be reduced maintenance, improved water quality, and improved domestic hot water system.

MECHANICAL AND PLUMBING

TF-ME-9 Replace Galvanized Plumbing

• Remove existing galvanized domestic water piping and components in 1951, 1962, and 1970 portions of the building

• Install new insulated copper domestic water piping

• Provide associated general and electrical construction work as required

TF-ME-9 Benefits

• Reduced potential for elevated lead and galvanized contaminants in water supply

• Improved drinking water quality

• Improved plumbing fixture operation

• Increased equipment life

• Reduced maintenance

MECHANICAL AND PLUMBING

Retro-Commissioning of HVAC Equipment

Building retro-commissioning is a systematic process that ensures all buildings perform as efficiently as possible according to the owner’s operational needs as well as adjustment of HVAC equipment’s operational parameters to meet current space use.

The Building Automation System (BAS) plays a crucial role in providing a comfortable, energy-efficient environment for students, parents, and staff. Over time, damper and valve controls have gone out of proper adjustment, components fail, and controls sequences are modified and may not be programmed to provide an optimal balance between comfort, indoor air quality, and energy efficiency.

This Nexus Retro-commissioning Team will identify the root cause of HVAC equipment operational issues and will provide adjustments to the sequences and outdoor air setting to improve occupant comfort while reducing energy consumption where possible. The retro-commissioning process will also identify components that require adjustment or replacement.

Retro-commissioning activities include:

HVAC Equipment: Nexus will verify existing HVAC equipment operation and control sequences through observation. We will provide adjustment and tuning services to achieve optimal operation and improved occupant comfort. Documentation of the findings with corrections and recommendations for further improvements will be made.

Services include:

• Ventilation study to assure all spaces are ventilated per the current code requirements and the outdoor air setpoints will be adjusted up or down based on current space occupancy

• Test point commands vs actual controller output at each device for heating, cooling, and mixed air control

• Verify valve/damper operation on reheat coils and air handler coils

• Verify indicated vs actual (duct static, supply and return temperatures)

• Verify mixed-air operation (damper position and economizer operation)

Valves and Dampers: Nexus will test all existing rooftop (RTU) and indoor air handling unit (AHU) sequences along with the valve and damper operation to ensure control actuators are fully operational. We observe valve/damper/actuator operation and check for any physical signs of valve/damper leakage or binding, which results in operational issues and increased energy consumption. We check discharge temperature with valves in the fully open and closed positions. In addition, we will provide unit pricing to replace any defective valves and/or actuators. Proper RTU and AHU operation provides improved occupant comfort at optimal energy efficiency.

Zone Reheat Valves: Nexus will test existing zone reheat valves for proper operation. We ensure command valves fully open and close and observe valve/actuator operation. We inspect valves for any physical signs of valve leakage or binding, check discharge temperature with valve in the fully open and closed positions and provide unit pricing to replace any defective valves and/or actuators.

Economizer: Nexus will update the control sequence for mixed-air dampers to their setpoints with economizer lockout setpoints.

Heating Water Pump Variable Speed Drives (VSDs): Nexus will lower the pressure setpoint to allow drives to modulate down to the slowest speed required to satisfy the most critical room temperature sensor.

CONDITIONS

Boilers: Nexus will optimize sequencing and staging of equipment and adjust the water reset schedules based on outside air temperature.

The action steps noted above are part of the Nexus retro-commissioning process. The benefits of this process include improved temperature control and occupant comfort, reduced energy consumption, reduced maintenance, and extended HVAC equipment life.

MECHANICAL AND PLUMBING

TF-ME-10 Retro-Commissioning of HVAC Equipment

• Provide retro-commissioning of all existing HVAC systems

• Provide adjustments to existing sequences to improve HVAC system operation

• Verify operation of all dampers, actuators, valves, and terminal HVAC devices

TF-ME-10 Benefits

• Improved temperature control and occupant comfort

• Reduced energy consumption

• Reduced maintenance

• Extended HVAC equipment life

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

Upgrade Electrical Power Distribution Including Switchgear, Panels, and Generator

There are five panels that are original to the 1962 building are now more than 60 years old and are at the end of their useful life. The panels were manufactured by States, which is no longer in existence. Parts for this equipment are no longer available.

It is recommended that the 1962 electrical panels be replaced. New panels will provide a safer electrical system since new equipment will be in compliance with current manufacturing standards for electrical equipment and will reduce maintenance costs.

Equipment recommended to be replaced includes one switchboard and 5 panelboards.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

TF-ES-1 Upgrade Electrical Power Distribution Including Switchgear, Panels, and Generator

• Replace five original 1962 electrical panels and one switchboard

TF-ES-1 Benefits

• Protection of and Improved Reliability of Electrical Infrastructure

• Reduced energy consumption

• Reduced maintenance

• Extended HVAC equipment life

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

Install New Generator to Control Primary Systems such as Boiler, Boiler Pumps, Emergency Lighting, Coolers and Freezers (230kW)

Currently, there is no backup power generator installed. There are frequent power outages at this location. This poses a risk for building security and life safety. In addition, costs may be incurred due to loss of heat in the building causing it to freeze up and loss of food that is stored in the coolers and freezers. In addition, there is a 40-horsepower fire pump, which should be backed up by a generator for a code compliant installation.

It is recommended that a generator be installed to provide backup power for these necessary items.

Increase the Size of the Generator from 230kw to 700kw to Cover Full Building Load including Cooling (cost represents the increased cost between the two generators)

Alternately, with frequent power outages, installing a generator with full building backup will allow the school to function, even when utility power is lost.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

TF-ES-2.1, 2.2 Install New Generator

• Install new natural gas generator

• Install new automatic transfer switches, feeders, and electrical distribution

TF-ES-2.1, 2.2 Benefits

• Protection of and Improved Reliability of Electrical Infrastructure

• Improved safety

• Option to handle the entire building load to prevent school shutdowns

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

LED Lighting Upgrade for Areas with Fluorescent. Retrofit Kits for Fixtures in Good Condition, Replacement for Unique or Outdated Fixtures. Including Emergency and Exit Lights. Add Lighting Controls to Corridors and Gym.

Light Fixture Upgrades

The existing lighting in classrooms, gymnasiums, and common areas is primarily fluorescent lamps throughout. The fixtures appear to be in fair condition; however, LED lamp technology is more energy efficient.

Retrofitting the light fixtures by replacing the fluorescent lamps with LED lamps will reduce overall energy use. In addition, the LED lamps have a life of 50,000 hours compared to only 36,000 hours for a fluorescent lamp, which will reduce maintenance costs.

In specific areas, such as corridors, it is recommended to replace the entire fixture to match newer LED fixtures installed in a recent renovation project.

Lighting controls that automatically shut off lights based on occupancy reduce energy use and are required to comply with current energy codes. There are no occupancy sensors in the corridors. It is recommended that occupancy sensors are installed in corridors to provide automatic shutoff of lighting.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

TF-ES-3 LED Lighting Upgrade for Areas with Fluorescent. Retrofit Kits for Fixtures in Good Condition, Replacement for Unique or Outdated Fixtures. Includes Emergency and Exit Lights. Add Lighting Controls to Corridors and Gym.

• Replace light fixtures throughout the building with LED light fixtures

• Add light fixtures on building exterior

• Controls to provide dimming capabilities

• Automatic shutoff of lighting

TF-ES-3 Benefits

• Reduce energy costs

• Reduce maintenance costs

• Enhance outside security

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

Install New Burglar Alarm System with 10 Motion Sensors and 2 Keypads.

A burglar alarm system is also needed to enhance the security of the building. It is recommended that a burglar alarm system be installed.

ELECTRICAL, TECHNOLOGY, AND SAFETY SYSTEMS

TF-ES-4 Install New Burglar Alarm System with 10 Motion Sensors and 2 Keypads.

• Add a burglar alarm systems

• Add 10 motion sensors and 2 keypads

TF-ES-4 Benefits

• Enhance security

.

INTERIOR FINISHES AND ADA

Ceiling Replacement

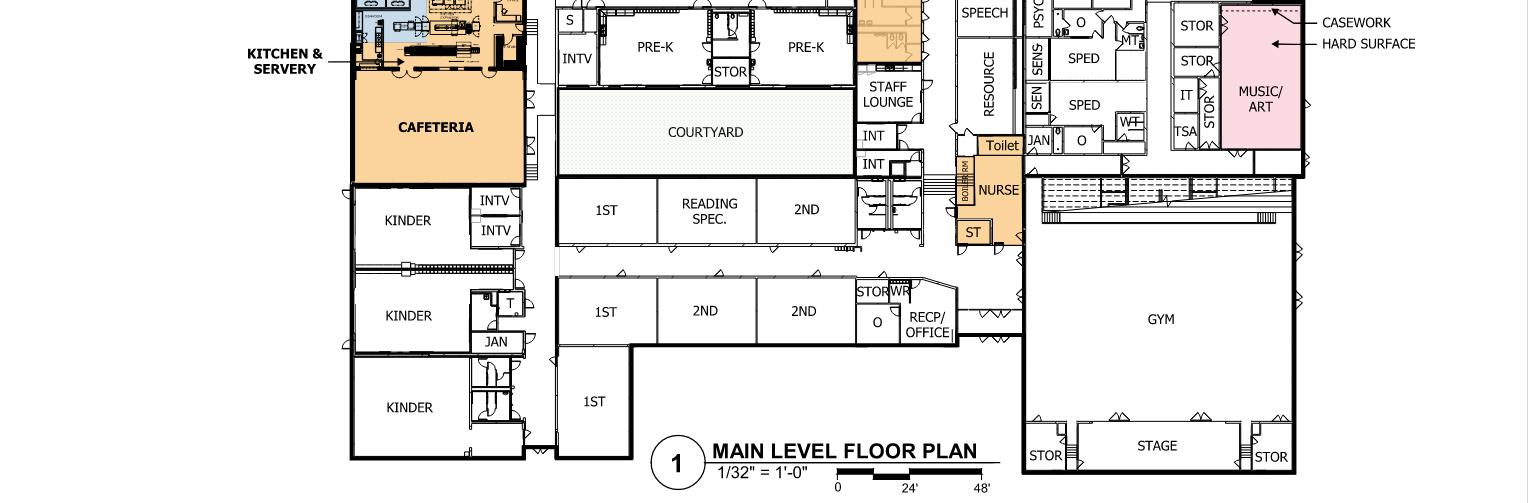

Taylor Falls elementary has been maintained well, however, there are a few high priority interior finishes needs that should be addressed in the next 0-6 years. We have reviewed the ceilings and exposed structures to determine what has reached the end of useful life, shows stains, or is beginning to sag. The flooring from worn carpet to old VCT in corridors has been prioritized. Other areas include casework, ADA needs, and interior doors. Prioritization is based on immediate needs (0-3 years), priority 2 is from 4 to 6 years. Low priority would be those items that can be addressed in 7 to 10 years. The floor plans on the following pages indicate areas that need to be addressed based on the prioritization.

High Priority Ceilings:

High priority areas include the music room/ art room and adjacent rooms, the corridor from the kitchen past the SPED rooms, the cafeteria and the kitchen and a few smaller areas.

Low Priority Ceilings:

Low priority ceilings include the kid’s club/ intervention/ third grade classrooms, the corridor outside of the cafeteria, and the large kindergarten room. Other areas include the 1st and 2nd grade classrooms, the nurse’s office, and the reading specialist room.

Ceilings

INTERIOR FINISHES AND ADA

TF-IA-1 High Priority Ceilings

• Replace ceiling as noted on the plans within the next 0-6 years

• Replace gyp board ceilings adjacent to stage

TF-IA-6 Low Priority Ceilings

• Replace remaining ACT ceilings in older classrooms

• Replace corridor ceiling outside of cafeteria

TF-IA-1 & 6 Benefits

• Extending the life of the interior materials

• Reduce maintenance cost

• Improves facility aesthetics

INTERIOR FINISHES AND ADA

High Priority Flooring

The wood floor in the gym, including the stage, is at the end of its useful life and needs to be replaced. Replace the old VCT in the corridors east of the gym with new rubber tiles as part of a district wide standardization. The flooring in the kitchen and cafeteria, along with rooms 116 and 118. Replace VCT flooring with a flooring material that requires less maintenance, such as an LVT.

Low Priority Flooring

The resilient flooring in the classrooms for the 1st, 2nd and 3rd grades should be replaced in the next 10 years.