By Irwin Rapoport

California's State Route 1 (better known as the Pacific Coast Highway) is an internationally renowned north-south arterial that draws millions of tourists annually and provides interregional, recreational, commuter and local travel through both urban and rural corridors.

But heavy rains over the past few years have caused landslides, the collapse of road sections along its edges and a weakening of the mountainsides above and below the road, which passes through many tourist meccas, including Monterey, Carmel and Big Sur.

The city of Los Angeles will break ground in December on a $740-million project that will turn wastewater into purified drinking water for the San Fernando Valley, according to the Los Angeles Times.

The project, slated for 2027 completion, will expand the local water supply in preparation for deepening droughts tied to climate

change. The project is designed to reduce the city’s reliance “on imported water that must travel hundreds of miles and is vulnerable to drought, earthquakes, climate change and other natural disasters,” the Los Angeles Department of Water & Power (LADWP) wrote.

“This is a big day for us and for the city of

Los Angeles,” LADWP CEO and Chief Engineer Janisse Quiñones said. “We’re committed to being a national and global leader in innovative water management by focusing on three key areas: the safety of drinking water, reliability of water infrastructure, and developing sustainable local water supplies. This Groundwater

Replenishment Project reflects our commitment to these objectives.”

Jacobs Inc is the main contractor and design builder, supported by Carollo Engineers of Walnut Creek, Calif.; Trussel Technologies Inc. of Pasadena, Calif.; and Hazen and Sawyer of Los Angeles.

Skanska announced on Nov. 12, 2024, the substantial completion of the new North First Avenue Bridge over the Burlington Northern Santa Fe (BNSF) railyard in the city of Barstow.

The $30.7 million project was awarded to Skanska by the San Bernardino County Transportation Authority and involved the replacement of the historic two-lane bridge built around 1930. Skanska’s replacement bridge was designed to improve traffic safety for commercial trucks, commuters, cyclists and pedestrians, while reenforcing the important connection through Barstow.

The bridge serves as the main connector for schools, neighborhoods, hospitals and other services in Barstow.

The 21-month project included the construction of a new seven-span post-tensioned concrete box girder bridge over 17 BNSF tracks; the realignment of North First Avenue; and the demolition of the existing 29-span steel truss and steel-timber girder bridge across the BNSF railyard. The project involved utility relocation, drainage improvements and lighting improvements.

“We’re excited to announce the completion of the new North First Avenue Bridge in Barstow,” said James Bailey, executive vice president of Skanska USA Civil’s West Coast operations. “For nearly a century, the Barstow Bridge served as an important connector for the city as well as the many others who travel across it every day. We are proud of the work we have done to rebuild this bridge that means so much to this community to make it safe, reliable and accessible.”

Construction began in January of 2023 and the team achieved substantial completion in October of 2024.

The bridge was first deemed structurally deficient in April 2012 during a Caltrans bridge inspection, according to the Victorville Daily Press. At that time, Caltrans said the superstructure, substructure and overall structure were deficient and the bridge was functionally obsolete.

The new concrete and steel bridge stretches about 1,180 ft., according to the Victorville Daily Press

The Placer County Board of Supervisors on Oct. 22, 2024, awarded a bid on the first phase of a $22 million wastewater pipeline extension design to alleviate North Auburn’s capacity constraints to alleviate capacity constraints in North Auburn, the Placer Sentinel reported.

The board chose a $10.79 million bid from contractor Steve P. Rados of Santa Ana, Calif., for a wastewater gravity trunkline from near Edgewood Road in Auburn to the Joeger Road Sewer Maintenance District 1 Regional Pump station.

Construction will start along Quartz Drive, Park Drive, Richardson Drive and Joeger Road in North Auburn, according to the Placer Sentinel.

The board also approved a $1.2 million contract with UNICO Engineering of Folsom, Calif., for construction management and related project services.

The construction start date is undetermined.

The Placer Sentinel said that UNICO will likely start administrative and planning work in the next few months, with construction beginning by the spring at the latest. Construction is expected to take 12-18 months to complete.

Funding for the first phase comes mostly through state and federal grants. That includes approximately $3.5 million from a Sacramento Area Council of Governments Green Means Go grant and $9 million of the county’s American Rescue Plan Act allocation funds.

The existing wastewater gravity trunkline was built in 1960 as part of the formation of Sewer Maintenance District 1 and is near capacity, according to the Placer Sentinel.

The project extension will be approximately 22,400 linear ft. and located within paved roadway and shoulder right of way, with the pipeline varying between 24 and 30 in. in diameter.

“The pipe will be installed using open trench construction within the existing paved roadway right-of-way,” according to the Placer County website. “Horizontal directional drilling will be used to cross under drainages and water supply canals that traverse the alignment. Construction will be in two phases.

“Pending availability of funds, Phase 1 will include installation of a 24-inch force main beginning at Quartz Drive and end at the Sewer Maintenance District 1 Regional Pump Station. Phase II will include construction of a 16-inch force main between Edgewood Road and Quartz Drive.”

Every machine delivers the power and reliability you need to take on any job in any working environment. Contact your nearest VCES location today.

PCH from page 1

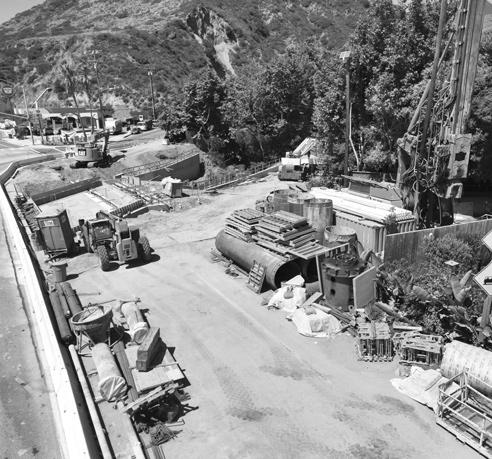

Crews from Security Paving Corp. are engaged in drainage improvements and the construction of a fish passage along a section of the PCH in Los Angeles and Malibu from south of the Temescal Canyon to the Ventura County line and in Ventura County from the Los Angeles County line to Tonga Street.

Within the project limits, the roadway consists of four lanes.

“The existing concrete culvert at PCH and Coral Canyon Road currently blocks the movement of the self-sustaining southern steelhead trout population formerly residing in Solstice Creek,” said Marc Bischoff, a public information officer with Caltrans District 7. “This prevents the trout from accessing spawning and rearing habitat in the creek upstream. The inability of the steelhead to move back and forth between the ocean and the creek subsequently resulted in the population becoming locally extinct.

“Recognizing the fact that the population of trout is in danger of extinction throughout all significant portions of its range [from Santa Barbara County south to the U.S.-Mexico border], the National Marine Fisheries Services in August 1997 declared this population an endangered species under the Endangered Species Act of 1973.”

The culvert at Solstice Canyon Creek will be replaced by a bridge, allowing trout to swim upstream. Twelve other damaged/defective culverts were assessed and require repair and rehabilitation or replacement.

“The assessment was based on inspection reports provided by the culvert inspection coordinator,” Bischoff said. “Damages to drainage culverts include joint separation, culver misalignment, concrete spall at reinforced concrete pipe joints, circumferential cracks and longitudinal cracks. Further deterioration to these drainage culverts is expected if they are not properly repaired and rehabilitated or replaced.”

The work also involves removing debris or flushing sediment inside the pipe; repairing the joint seal of pipes; relining culvert barrels; and replacing damaged sections of pipe, entire sections of culverts and the culvert at Solstice Creek

Equipment and materials used in the Pacific Coast Highway project.

with a bridge.

“The replacement of the Solstice Creek culvert with a bridge will provide access for the steelhead trout to the habitat upstream of the culvert,” Bischoff said.

“Various types of culvert deficiencies were discovered, including joint separation, misalignment, buckling, cracking of pipe barre and clogged sediment,” Bischoff said. “Repairs and rehabilitation are needed to restore functionality and to prevent further damage of drainage culverts. The performance measures for this project are 13 culverts rehabilitated or replaced.”

The project was designed by the Caltrans District 7 Design Division. Work began in May 2024 and is expected to be completed in the summer of 2029.

“The challenges we had in design included lane closure requirements on PCH and space constraints during construc-

tion as we had the ocean on one side and mountains on the other.” Bischoff said. “We had to have multiple stages of construction to keep lanes open for motorists and cyclists. For the bridge construction, we had to build the new bridge around the existing culvert and demo the old culvert and excavate after. We had challenges in design for fish passage and had to adjust for high stream velocities.”

The new infrastructure has an expected lifespan of 40 years, he said.

Two drainage systems are complete. The bridge at Solstice Creek is 50 percent complete. Thirteen more drainage systems remain to be completed.

The work sites are reasonably large, allowing equipment operators to move about freely and for materials to be stored on-site, Bischoff said. Access to the individual sites is fairly easy, so material and equipment can easily be brought in and out and construction workers can park nearby.

Crews are using large drill rigs and excavators, telehandlers, loaders and have a variety of pickup trucks to move crews from site to site, Bischoff said. CEG

(All photos courtesy of Caltrans.)

from page 1

The new facilities will be at the Donald C. Tillman Water Reclamation Plant in Van Nuys. Aside from an advanced water purification facility, electrical, maintenance and warehouse facilities will be built as well,

The Times reported that upon completion, the facilities will provide 20 million gallons of drinking water daily. That’s enough to supply about 250,000 people.

The advanced treatment process at Tillman includes membrane filtration, reverse osmosis and ultraviolet advanced oxidation, according to LADWP.

The drinking water produced will be piped to L.A. County’s Hansen Spreading Grounds. From there it will flow into basins and percolate into the San Fernando Groundwater Basin.

Later, the Los Angeles Department of Water and Power will pump the water from wells. Upon added testing and treatment, the water will be delivered to taps, the Times reported.

While Los Angeles has recycled wastewater for decades, the treated water was used for outdoor irrigation. And this project has been long in the making: Some of the infrastructure, including the pipeline and pump stations, was built in the 1990s.

(All photos courtesy of Jacobs Inc., with City of Los Angeles.)

While not all companies are created equal, some are more “not equal” than others.

Consider GBH Enterprises which, by offering its clientele a fleet of productive equipment — and a skilled operator for each machine — keeps the seemingly unending Southern California development humming along.

Slotted into the supplier chain as an “operator-maintained equipment rental company,” GBH has filled a gap within the Inland Empire section east of Los Angeles proper. It has done so by meeting the needs of its customers, keeping projects on track and on (or under) budget and offering reliable, productive equipment.

The ABCs of GBH

Established by Brad Hull in 1996, GBH Enterprises (the moniker stems from the couple Giovanna/Brad Hull) is a culmination of various jobs performed by Hull which piqued his interest in equipment.

“My dad got me my first job as an oiler helper for an engineering contractor,” he said. “It was nothing fancy — I used to fuel and grease heavy equipment. Later, after a few years running a business in which I power washed and cleaned other people'’ equipment, I finally bought my first piece of equipment, a skid-steer loader which I used for breaking concrete and performing small demolition projects.

“While doing those jobs, people would often ask if I had other excavators and backhoes. I kept saying no until I couldn’t say no anymore.”

GBH’s growth was slow but steady, with just Hull and his brother Kyle at the outset.

“I always had the plan to make this an operator-maintained equipment rental company,” he said. “So, as I added equipment — a half dozen skid-steers for the first 10 years in business — I got another friend to join us, who would tell his friend, and so on. Essentially, we grew by word of mouth. Today, in addition to a nice lineup of skid-steers and attachments, we also offer a full line of Link-Belt excavators — and an operator to accompany each.”

Successful entrepreneur though he is, Hull is fortunate to have established GBH in one of California’s most economically booming regions. The Inland Empire, which sits adjacent to coastal Southern California, centers around the cities of San Bernardino and Riverside, bordering Los Angeles County to the east.

Post-pandemic, it has fared far better than the rest of the state and saw more than 22,000 people move to the area in the last year. That has served GBH well, Hull said.

“Unlike many other areas, this region has really seen a lot of steady growth,” he said. “As a result, a lot of road reconstruction — which happens to be our specialty — is always taking place. Every major road contractor in this area uses us for the demolition facet of their jobs.”

An operator-maintained equipment rental company is one in which a customer comes to the company seeking not just a machine but also a skilled operator to run it on a particular project.

“These companies know that my people can do the job, do it well, and most likely do it faster than their own people,” Hull said. “Working with us relieves them of the headache of adding iron to their fleet and dealing with manpower allocation, while, at the same time, keeping projects on track. Over the years, they’ve come to depend on us for both our productivity and reliability.”

When it came time to build his larger equipment fleet, those customer demands helped drive Hull’s buying decision. He said that, after demonstration sessions, the choice was whittled down to two manufacturers: Link-Belt and another major company. From there, Hull said, the decision was fairly easy.

“After running both brand machines and having a perfect opportunity for comparison, my guys all said the Link-Belt was faster and smoother,” he said. “The fact that it was also more affordable didn’t hurt either. But what kind of sealed the deal for us was knowing that Bejac Corp. was the dealer. I knew they’d provide solid support after the sale and, in this business, uptime is key.”

GBH’s commitment to the Link-Belt line was steady, adding new machines as the market dictated. Today, it offers a full range to its customer base, including one 80X4, a pair of 145X4 Spin Ace units, a 355X4S and a new 245X4.

The company’s expertise was on display recently when it was called upon to provide earthmoving support for a project in nearby Chino, Calif. The customer, while one of the region’s leading asphalt paving specialists, opts not to own excavators, instead deferring to GBH for those needs.

“I’ve worked with All American Asphalt for a number of years and have been able to provide the machines they need when projects dictate it,” Hull said. “In this case, they were extending an existing road and there was a decent amount of earthwork involved. We provided a Link-Belt 145X4 Spin Ace which, positioned properly, loaded trucks faster than a traditional loader could have.”

A front-end loader needs to move laterally to grab a bucketful of dirt, raise and position itself to unload and then repeat the process to grab its next load. At the Chino site, by contrast, the Spin Ace swung left or right and quickly, efficiently loaded each truck.

Power Inn

4191 Power Inn Road, Suite D Sacramento, CA 95826 916-737-7777

PIRTEK

San Leandro

1997 Burroughs Ave San Leandro, CA 94577

510-568-5000

121 S. Maple Ave #4 South San Francisco, CA 94080

650-532-9200

“It’s a much more streamlined process, there’s no doubt,” Hull said.

Hull has grown his excavator fleet in line with the demands of his existing and projected client base. He has strengthened that lineup with a full array of attachments — shears, crunchers, specialty buckets, etc. While he has found success with the 145 X4, which fits most size and productivity demands, the 80X3 has shown itself to be a formidable option, too.

“This is actually the second 80X3, I’ve owned since upsizing,” he said. “Right now, we’re using it on an interior demo project. Using a hydraulic thumb, we’re able to break through the concrete, grab the rebar and pull it out using the thumb. The 80 has all the hydraulics needed to run a shear, a breaker, a rotational bucket, almost anything. It’s an extremely versatile unit for us.”

GBH bought the 80X3 with the offset boom option which, Hull said, has often paid dividends.

“The machine’s ability to rotate 130 degrees from left to right allows my guys to dig in tight areas such as directly up against building foundations and in places other machines can’t,” he said. “A little while back, it was tearing down block walls in Fontana one day, then, a day later, excavat-

ing for new footings to move the walls back 20 feet. That machine is becoming one of the more in-demand units in the fleet.”

Every machine in the GBH’s excavator lineup fills a specific need, whether in terms of size, adaptability, speed, etc. With that in mind, the true workhorse of the GBH inventory — the machine that literally and figuratively does the “heavy lifting” — would have to be its Link-Belt 355X4S. According to Hull, the combination of power that belies its sub-79,000 lb. weight and its zero-tail swing design make it indispensable.

“And the 355 is fast — probably 30 percent faster than any comparable machine,” he said. “If my guys, for some reason, have to operate a different brand machine, they say it feels like they’re working in slow motion. That unit was recently removing 16inch concrete slabs at John Wayne Airport runway in Orange County, an activity that can be a challenging lift for some machines. But, because the 355’s built-in lifting mode provides a hefty power boost just when it’s needed, those slabs were no problem.”

Given the success they’ve had and the development that continues around them, Hull said he sees no sign of slowing down.

“In fact, in the short-term, we're probably going to end up adding another 80X3 because it’s proven such a popular machine,” he said. “We’re getting more and more calls for it to the point where I’ve had to juggle jobs just to make it available. We’ve been very fortunate. We have a great group of people; we get the best performance imaginable from our equipment; and we enjoy an outstanding level of support from Bejac.”

(All photos courtesy of GBH Enterprises.)

Granite of Watsonville, Calif., announced that it signed a $34 million contract to implement seismic improvements to the Oakland International Airport Perimeter Dike.

The project will protect the airport runway from potential water intrusion by the adjacent San Francisco Bay. The dike is approximately 4.5 mi. long and traverses the airport’s shoreline between the cities of San Leandro and Alameda, according to DredgingToday.com.

The project will use 62,295 cu. yds. of a cement deep soil mixing construction solution (CDSM) to improve the dike’s seismic resilience over 4,200 linear ft.

Granite said that the technique will bolster the levee wall soils and reduce the risk of dike failure in case of a strong seismic event.

“The technical challenges and restricted access of this project will require meticulous logistical planning to ensure an efficient and safe workflow and zero impact on airport operations,” said Brent Fogg, Granite’s vice president of regional operations.

Keller North America, a geotechnical specialty contractor, has performed the CDSM

scope.

Aside from the dike work, other tasks include clearing and grubbing, constructing temporary work pads, installing wetlands protections, protecting existing fuel lines, and installing 2,100 cu. yds. of rip rap revetment and aggregate base surfacing to restore the existing perimeter road.

The project is expected to begin in the first three months of 2025 and be completed during 2026’s third quarter.

An earlier two-year $30 million project to bolster the dike was completed in 2022, according to DredgingToday.com.

During the project, the dike was increased in size by a foot to meet Federal Emergency Management (FEMA) certification standards and to meet projected impacts of midcentury sea level rises, iflyoak.com said.

The dike is largely comprised of sand, gravel and clay. Its original construction dates to the 1950s, according to www.portofoakland.com. Structural improvements to the dike occurred in the 1980s, as the structure requires maintenance and improvements approximately every 30 years.

1960 Highway 20 Colusa, CA 95932 (530) 458-2166

2173 Blossom Street Dos Palos, CA 93620-2313 (209) 392-2161 600 S. State Highway 59 Merced, CA 95341-6928 (209) 383-5888

1340 W. Charter Way Stockton, CA 95206 (209) 944-5500

Main St. Stratford, CA 93266 (559) 947-3301 1215 West Glenwood Ave Turlock, CA 95380-5703 (209) 634-1777

North Tehama St Willows, CA 95988 (530) 934-3382 3056 Colusa Highway Yuba City, CA 95993 (530) 923-7675