75 year

boom

Corporate Headquarters

South Randolphville Rd.

NJ 08854

South Jersey

Hurffville Rd.

NJ 08096

Long Island

Peconic Ave.

NY 11763

Mid-Hudson Valley

Route

NY 12542

New York City

Zerega Ave

NY 10462

Headquarters

PA

PA

Pittsburgh, PA

PA

PA

Lincoln Avenue

PA 19076

Wilkes-Barre, PA

Sathers Drive

PA

ALT Sales Corp.

Brecksville Rd.

OH 44286

Dawes Rigging & Crane Rental

555th Ave

Mound, WI 54739

Hyland Ave.

2 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com For

trust and c class-leadi National Cr > Stand-up s,National Cran onfidence of our ng features,and ane

trucks a models with capaci e boom trucks co r customers than wide range of av re available in: ties from 10 USt to 3 ntinue to earn th ks to their durab vailable accessori 3 USt e ility, es. > Swing seaat models with capaacities from 30 USt to 60 USt manitowocwww w .com

300

Piscataway,

732-752-3600

1330

Deptford,

856-227-6400

22

Medford,

631-207-2900

1440

9W Marlboro,

845-236-3000

1144

Bronx,

718-822-1180 Corporate

Harrisburg,

7201 Paxton Street Harrisburg,

17111 800-325-6455

8181 Noblestown Road McDonald,

15057 800-692-7600 Philadelphia,

135

Prospect,

800-220-4033

600

Pittston,

18640 866-667-6756

4945

Richfield,

330-659-2100

E8670

Elk

800-943-2277 2401

Kaukauna, WI 54130 800-236-8630 www.hoffmanequip.comwww.stephensonequipment.com

RIGGING CRED

The rigger is responsible for inspecting all rigging gear prior to use as well as protecting the rigging from sharp surfaces.

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) has released an updated standard on mobile and locomotive cranes that includes a clear definition of the role a qualified rigger plays in a lifting operation.

The standard now requires the presence of one qualified rigger any time a mobile crane more than 2,000 lbs. capacity is at work.

“Having a qualified rigger present on a job site during a lift is not just a good idea; it is also an OSHA and ASME requirement when mobile cranes are involved,” said Tony Fiscelli of Lifting Gear Hire (LGH).

ASME B30.5 Standard Sets Requirements for Mobile Crane Rigger Qualification EARNING

continued on page 10 4 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 51900 CRW TCC2500 Family CEG ad 12.8.20.indd 1 12/9/2020 2:00:38 PM oven worldrP ele-craw ed-class T MERICA! H WLER wlers MEERRIICCAA! NOORTTH R WLEER L#1T L#1T AM TELECRA LINE-UP W A E-UPN -C IN-U A ELLEE-CRAW etts 508 499 1950 02-658-1700 | 68m main boom|223 ft Massachus mont 8erVe TELESCOPIC CRAWLER 230 mt|250 t 4 cameras!Vision packageUltra-wide winch design Superior capacities with full attachment 105m max tip height348 ft , Uentuckyexington, KL www.woods ork 3oNew Y Pennsylvani .linkbelt.comSA | www w.comscr 315 676 2008 a 717-795-0700 5084991950 THE MARKET! INABLEAILAVA ACITY AHIGHEST CAP BUY • LEASE • RENT

Altaequipment.com

18405 115th Avenue

Orland Park, IL 60467 877-399-6430

420 Nolen Drive South Elgin, IL 60177 877-399-6430

2500 Westward Drive Spring Grove, IL 60081 815-581-1479

613 E Stevenson Road Ottawa, IL 61350 815-587-7610

1035 Wylie Drive Bloomington, IL 61705 888-693-2271

480 Blaine Street Gary, IN 46406 219-240-0268

empirecrane.com

7021 Performance Drive N. Syracuse, NY 13212 800-342-7575

9 Finderne Avenue, Ste 7 Bridgewater, NJ 08807 908-203-0400

12 Mear Road Holbrook, MA 02343 508-868-7734

coastlinecd.com

325 N. 5th Street, Bldg. A Sacramento, CA 95811 916-440-8090

Santa Ana, CA 714-265-6550

Las Vegas, NV 702-399-2700

Meridian, ID 208-888-3337

smequipment.com

14925 South Main St. Houston, TX 77035 713-721-7070

Dallas, TX 214-391-4000

Corpus Christi, TX 361-289-2782

Tulsa, OK 918-224-2000

exactcrane.com

Serving Ohio, Michigan, W. Pennsylvania, Kentucky

28985 Ambina Drive Solon, OH 44139 440-349-1999

6 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

TAC Distributor Ad 2021_CEG.indd 1 9/30/2021 11:06:04 AM 1 2 0 2 d t L s iutortrb no ad a T © TAC Distributor Ad 2021_CEG.indd 1 9/30/2021 11:06:04 AM www.tadano mricas.comae aCcireomnAada Ts nee2r4WG,2n4oirtopr oa6P 607,X7nTotsu,odH R0 3090)6188:+2eno h1(

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 7 HAYDEN-MURPHY EQUIPMENT COMPANY | www.hayden-murphy.com | Minneapolis, MN QUALITY PRODUCTS | SUPERIOR SUPPORT | COMPETITIVE PRICES A Manitowoc / Grove “Elite” Dealer 2016 Grove GHC75, 118’ plus 36’ 4 sec full-power telescopic boom, 2 hoists, six sheave hook, block, tier 4 final, 2,379 hours, stk#0001617 $550,000 2020 GRT880, 134’ plus 56’ 4 sec boom, block, ball, 2 hoist, tier 4 final stk#0001723, 53 hours $750,000 2017 GROVE GRT655, 114’ boom, 2 hoists, block, ball tier 4 final stk#001665, 1,113 hours $449,000 2014 RT765E-2, 110’ boom, block, ball, 2 hoists, tier 4 final, 3,875 hours, stk#0001567 $385,000 2019 TEREX CROSSOVER 8000, Mounted on 2019 Kenworth T800, Lift Capacity: 80 ton, 916 hours $525,000 2019 TEREX HC120, 150’ boom w/offset, triple drum, block, ball, 100 ton capacity stk#000497, 1,515 hours $749,000 2013 SHUTTLELIFT 5540F, 15 ton lift capacity, 41’ boom, 15’ jib, 4WD, LMI, Tier 3 stk#0001492, 2,231 hours Rental Rate $4,500/month 2014 GROVE YB5515-2, 20ton 2Sheave Hook Block, s/n: 322188, 1,613 hours Rental Rate $4,950/month 2019 MANITOU MHT10130, 28,860 LB capacity, fork positioner, side shift, 94” forks, cold weather package #0020090, 127 hours Rental Rate $10,000/month 2020 MANITOWOC MLC100-1, 700 hours, Lift Capacity:110 ton, s/n: 91001036 Call for Price 2005 MANITOWOC 10000, 13rd drum, 100T block, Very Good Undercarriage, 100ft Boom, 11,577 hours, s/n: 4295 $225,000 2006 MANITOWOC 10000, Block, Ball, 150ft Boom, 14,269 hours, stk#22341 $239,000

WESTERN PACIFIC CRANE & EQUIPMENT

www.wpcrane.com

8600 Calabash Ave. Fontana, CA 92335 562/286-6618

1500 Madruga Road Lathrop, CA 95330 855/927-2637

275 W. Larch Road Tracy, CA 95304 209/597-3824

3521 Alken Street

Bakersfield, CA 93308 855/927-2637

19602 60th Avenue NE Arlington, WA 98223 253/254-7950

91-210 Kalaeloa Blvd. Kapolei, HI 96707 808/682-7263

8912 NE Vancouver Way Portland, OR 97211 971/202-4002

6720 Arctic Blvd. Anchorage, AK 99518 855/342-7263

WPCE - CANADA 9538 195th Street Surrey, BC V4N 4G2 855/342-7263

HAYDEN-MURPHY

EQUIPMENT COMPANY

www.hayden-murphy.com

9301 E. Bloomington Freeway Minneapolis, MN 55420 952/884-2301 800/352-2757

RING POWER CRANE www.ringpowercrane.com

St. Augustine, FL 904/737-7730

Pompano Beach, FL 954/971-9440

Orlando, FL 407/855-6195

Tampa, FL 813/671-3700

Union City, GA 770/774-7300

Concord, NC 704/795-3636

Ladson, SC 843/818-1954

HOFFMAN EQUIPMENT CO. www.hoffmanequip.com

New Jersey

Corporate Headquarters 300 S. Randolphville Rd. Piscataway, NJ 08854 732/752-3600

South Jersey 1330 Hurffville Rd. Deptford, NJ 08096 856/227-6400

New York 1144 Zerega Ave. Bronx, NY 10462 718/822-1180

Mid-Hudson Valley 1440 Route 9W Marlboro, NY 12542 845/236-3000

Long Island 22 Peconic Ave. Medford, NY 11763 631/207-2900

Pennsylvania Philadelphia Metro Area 120 Gordon Dr. Lionville, PA 19341 610/363-9200

CLEVELAND CRANE & SHOVEL SALES INC.

www.craneandshovel.net

26781 Cannon Road Cleveland, OH 44146 440/439-4749

Toll Free: 800/362-8494 aforepaugh@ craneandshovel.net

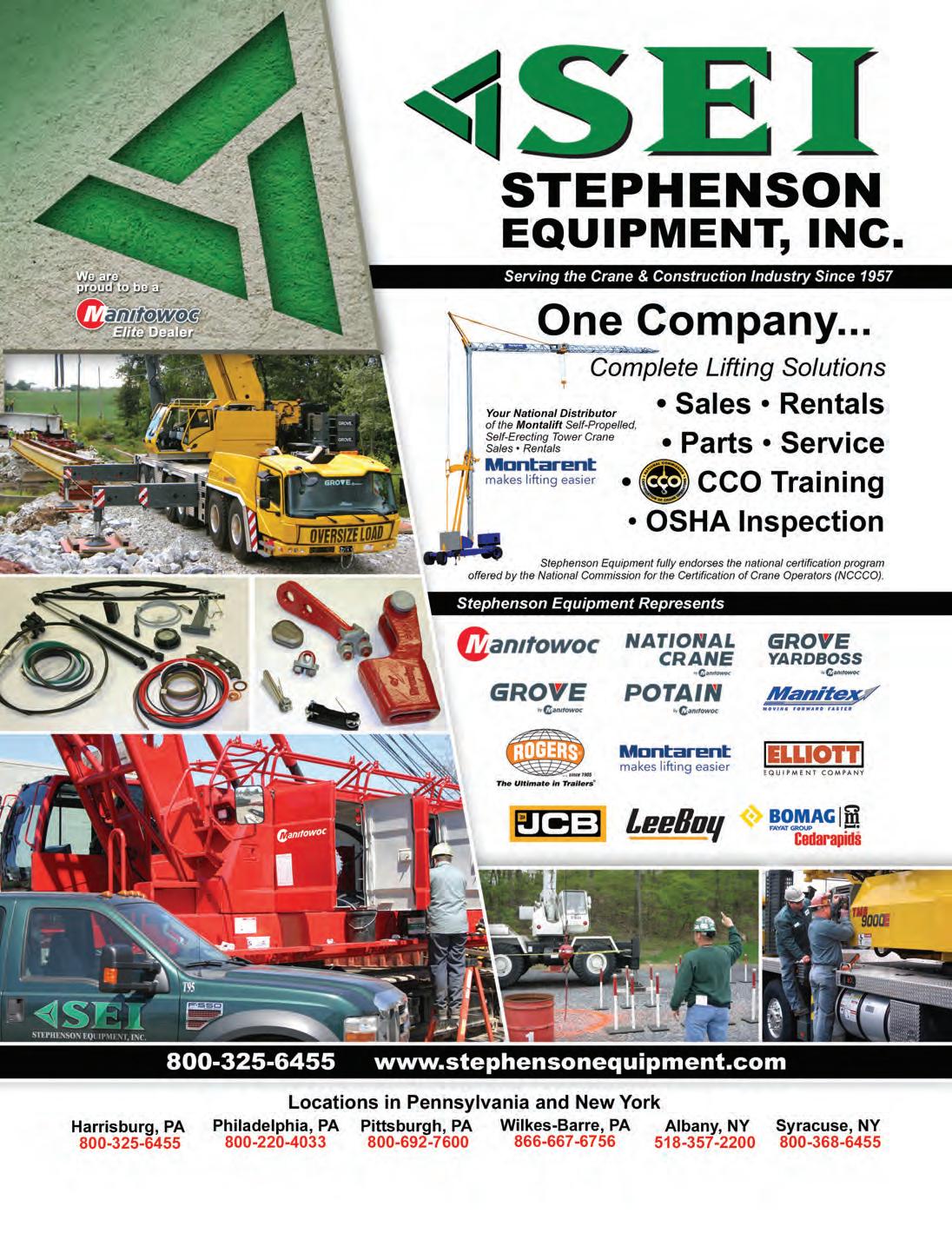

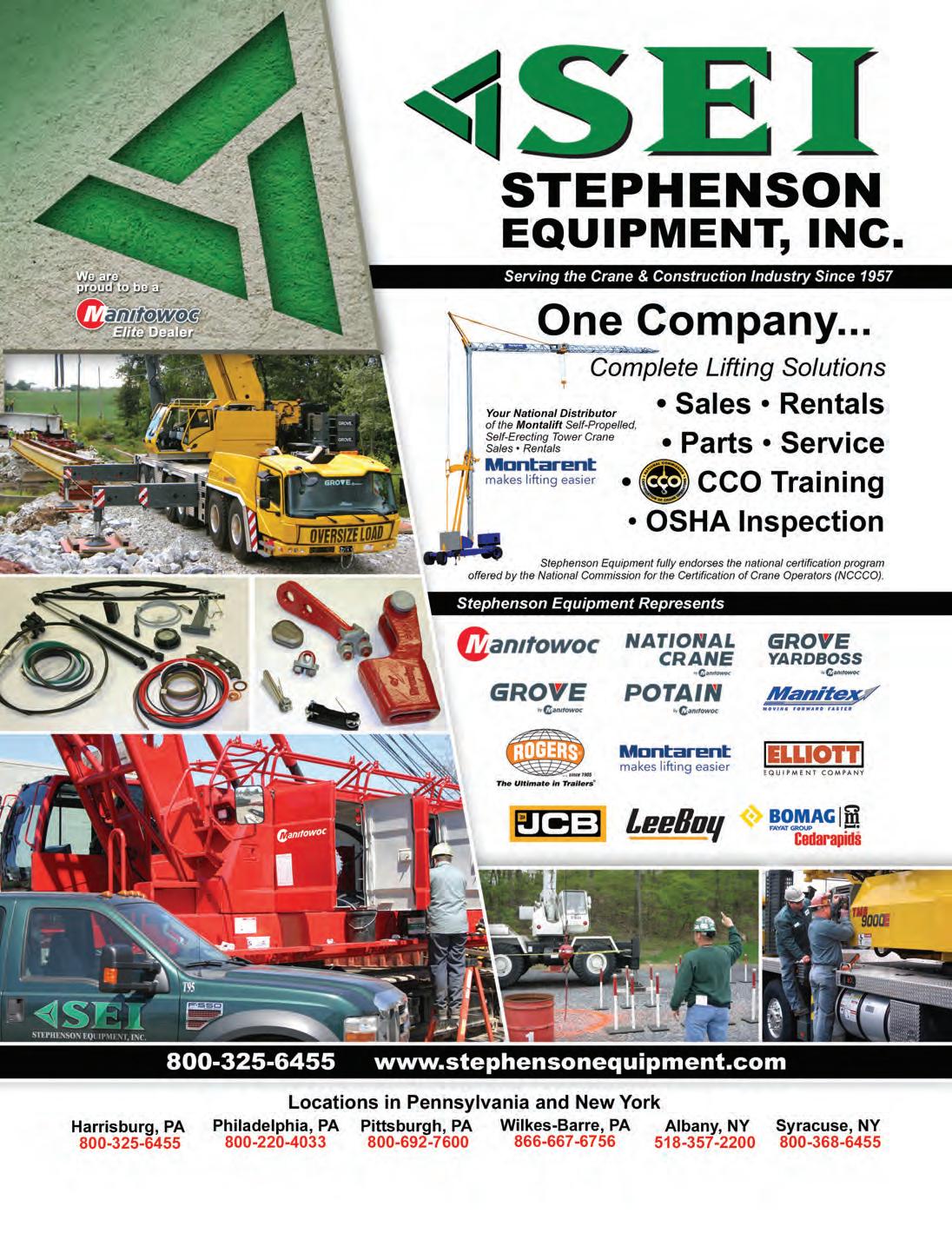

STEPHENSON EQUIPMENT, INC.

www.stephensonequipment.com Philadelphia, PA 800/220-4033

Harrisburg, PA 800/325-6455

Wilkes-Barre, PA 866/667-6756

Pittsburgh, PA 800/692-7600 Syracuse, NY 800/368-6455

Albany, NY 518/357-2200

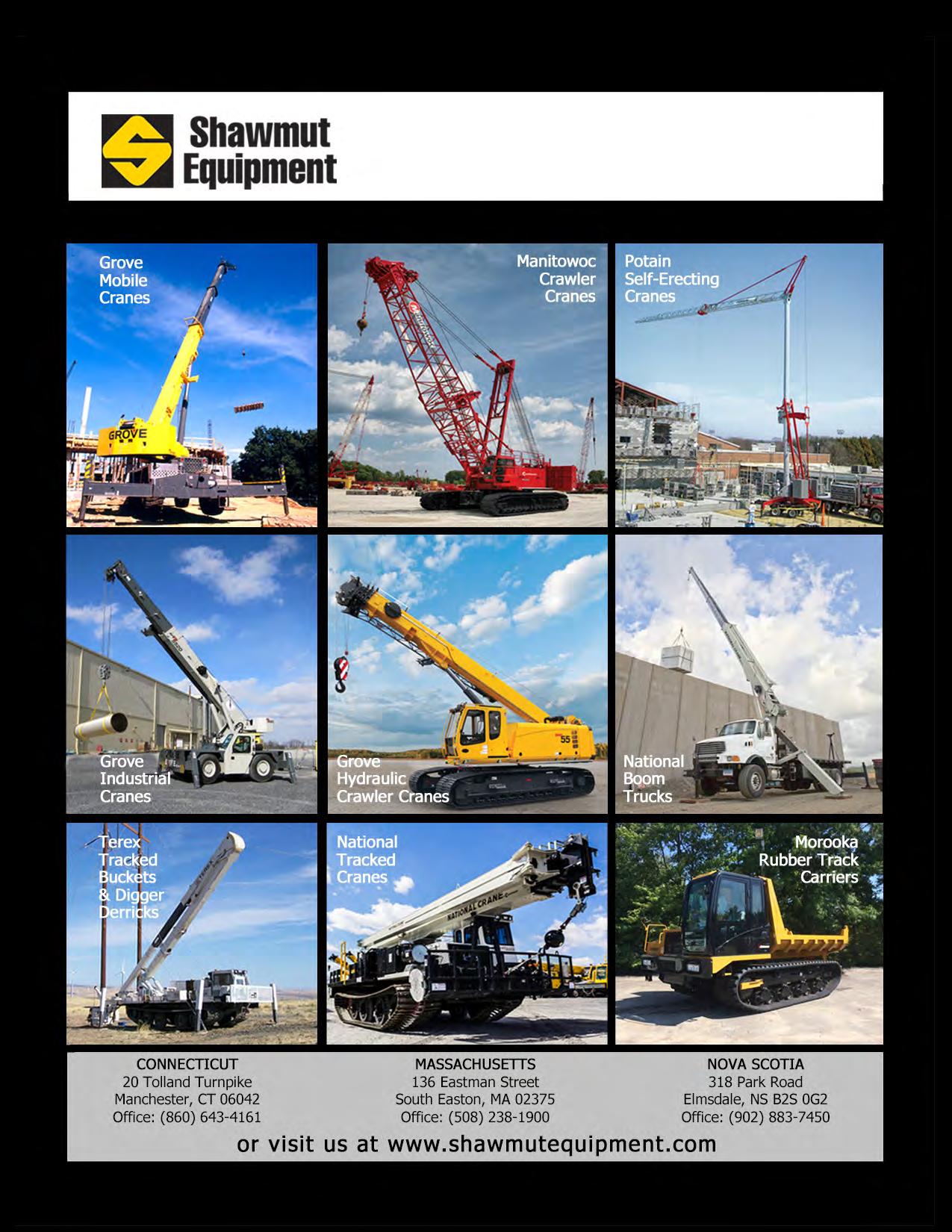

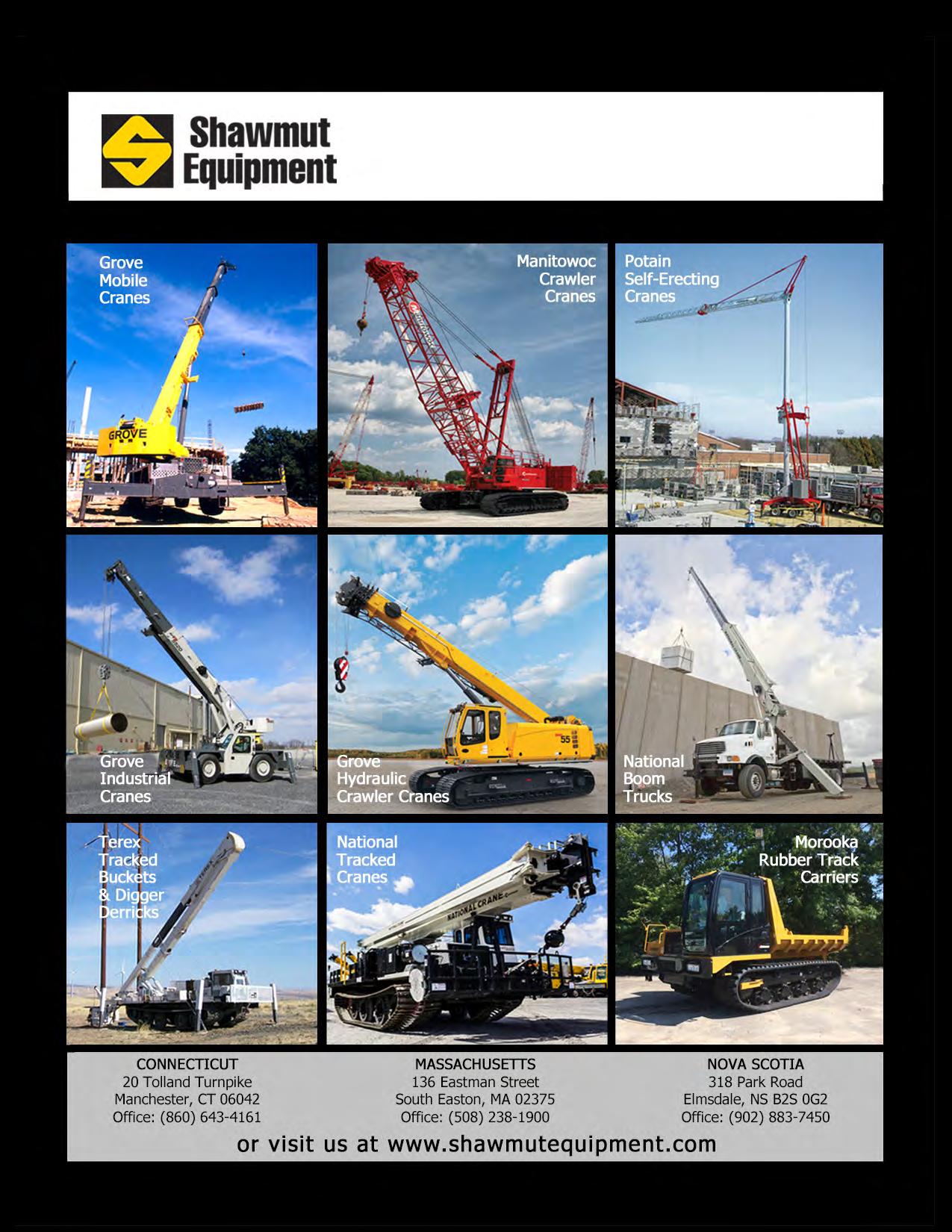

SHAWMUT EQUIPMENT COMPANY, INC. www.shawmutequipment.com

20 Tolland Turnpike Manchester, CT 06042 800/829-4161

136 Eastman St. South Easton, MA 02375 877/526-9213

SHAWMUT EQUIPMENT OF CANADA, INC.

318 Park Rd. Elmsdale, NS B2S 0G2 902/883-7450

8 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 9 Manitowoc productivit crawler cranes ar tyandvalueonthe e built to deliver u emostchallenging nsurpassed gjobsites Manitowoc > Cranes ra > Capacity > Optional boompo ty and value on the c delivers: nging from 80 USt enhancing VPC-MA long-reach booms, ints e most challenging to 2535 USt X® technology and fixed jibs, luffing jib g jobsites. MAX-ER® attachme bs and extended upp ents per boom po > Optional 3.5 m wide boom inserts for MLC300 and MLC650 .manitowwww oc.com

President of the Bridgeview, Ill., rigging gear rental company, Fiscelli said in prior ver sions of ASME B30.5, a qualified rigger was only required during assembly/disassembly or when personnel were present in a fall zone.

“The standard is not limited to large cranes on construction sites,” he said. “It applies just as much to the tree-trimming industry, for example, as it does to major construction out fits.”

Riggers Front, Center

The rigger’s responsibilities are numerous, said Larry Kime, the senior instructor of Crane Inspection and Certification Bureau (CICB), Orlando, Fla.

“From selecting the right hardware to attaching the load to the crane hook, riggers should be familiar with a variety of equipment used in a lift,” he said.

In addition to knowing load weight and center of gravity, responsibilities include inspecting all rigging gear prior to use and protecting the rigging from sharp surfaces.

He must follow the correct D/d ratios on wire rope and chain slings, or the diameter (D) around the object which the sling is bent, divided by the overall diameter (d) of the sling being used.

The rigger is responsible for equalizing loading on multiple legged slings; calculating sling angles; keeping personnel clear of the area; using proper hand signals; and maintaining load control.

He must understand the critical process of selecting the right hardware for each lift, said Kime.

“Riggers need to understand the limitations and applications for each type of hardware they select,” he added.

To properly execute a rigging job, it is essential for a rigger to have a good grasp of several mathematical concepts as well, said Kime.

That includes general concepts such as the ability to calculate the area of a triangle (1/2 x A x B) as well as a load weight based on a reference sheet that lists the pounds per cubic foot of typical materials and liquids.

Updated Requirements

The updated standard lays out the specifics of when and how a rigger is to be designated qualified.

According to B30.5, that’s after a written and practical exam that tests him in selection and use of hardware; standard hitches appli cations; estimation of load weight, center of gravity, angle and load movement; and inspection of equipment.

“However, passing these tests alone does not necessarily qualify the rigger,” said Fiscelli. “The final ‘qualified’ designation is given to the rigger by the employer, who must consider skills, knowl edge and prior experience before deciding whether the person is qualified to perform specific rigging tasks.”

from page 4

“Riggers need to understand the limitations and applications for each type of hardware they select.”

Larry

Kime

A written and practical exam tests the rigger in selection and use of hardware; standard hitches applications; estimation of load weight, center of gravity, angle and load movement; and inspection of equipment. 10 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

The employer also must obtain evidence of satisfactory comple tion of the rigger’s written and practical exams.

Though each rigger may have different credentials or experi ence, in general, a qualified rigger is a person who:

• Has a recognized degree, certificate or professional standing;

• Has extensive knowledge, training and experience; and

• Can successfully demonstrate the ability to solve problems related to rigging a load.

The person designated as the qualified rigger doesn’t have to be qualified to do every type of rigging job, though.

Fiscelli said most crucial is that he can properly rig the load for the job in question.

“Each load that requires rigging has unique properties that can range from simple to incredibly complex,” he said.

A rigger may have years of experience in rigging structural com ponents and other equipment to support specific construction activities.

However, this type of experience does not automatically qualify him to rig unstable or unusually heavy loads that may involve lift ing in tandem or require custom rigging equipment.

And, employers are required to ensure the designated qualified rigger can do the rigging work needed for the exact type of load and lifts for a particular job.

This includes being able to choose the proper equipment and rigging that will be used for that job.

“Rigger qualification is an employer designation based on the rigger’s experience as well as proof of successful completion of a written and practical exam,” said Fiscelli. “The exams may be administered by anyone, so long as they include the particular competencies outlined in the 2021 ASME B30.5 standard.”

Certification or Qualification?

When it comes to the designation, there’s a distinct difference between ‘qualified’ and ‘certified.’

“A qualified rigger may very well be a person with extensive hands-on experience but no formal training or certifications,” according to LGH.

Rigger certification is a different story. To be designated ‘certi fied,’ a rigger has to pass both a written and practical exam admin istered by an accredited certifying agency.

Currently, the national accreditation board of the American National Standards Institute (ANSI) only accredits NCCCO rigger certifications.

The NCCCO offers Rigger Level I and II and Lift Director certi fication programs.

“While there’s no OSHA or ANSI/ASME requirement for rigger certification, NCCCO Rigger I or II certification is a desired qualifi cation on contract bids,” said Fiscelli. “In some cases, certifications may also meet the requirements for an employer to designate a rigger as qualified. Specifically, the NCCCO Rigger II program ful fills the core competencies outlined in the ASME B30.5 standard for rigger qualification.”

CICB’s Kime noted that this standard applies across every indus try. All NCCCO rigging certifications are good for five years.

“CICB rigging certifications are typically valid for two to three years, depending on the program taken.”

This includes everything from boom trucks working on signs or trees, to mechanic’s service trucks making equipment repair.

“The standard is not limited to large cranes on construction sites,” said Kime.

There is currently no OSHA or ANSI/ASME requirement for rig ger certification, but since all candidates take the same test, it is a good yardstick to assess ability, he said.

The new standards cover cranes used in myriad users of construction cranes, from transportation contractors to arborists.

continued on page 12 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 11

Which Designation Makes Sense?

The important thing to note is that ‘qualification’ and ‘certifica tion’ do not have the same meanings. And, each has its advan tages, according to Fiscelli.

“The process to qualify riggers can be done with less prepara tion than is required for certification, and it fulfills OSHA and ASMI/ASME requirements,” he said.

However, the qualification process may not always fully evalu ate whether a rigger truly has the technical knowledge and handson skills needed to perform a specific task, he noted.

“Conversely, the certification process requires more preparation but covers testing on slings, knots, signaling, load control and other safety issues. As such, it generally acts as a good yardstick.”

The release of the 2021 ASME B30.5 standard is a welcome step toward safer rigging practices and mobile crane use, according to CICB’s Kime.

“International Crane & Construction Safety Solutions has found that fully 16.8 percent of crane accidents in construction are the result of faulty rigging practices,” he said.

The new requirement for qualified riggers is “a valuable com ponent in ensuring the safety of picks.”

Barb Fullman, president of Chester Spring, Pa.-based Total Equipment Training, agreed: “In construction, safety is the number one priority,” especially when lifting heavy objects and using heavy equipment.

“Using cranes and other equipment to lift and manipulate extremely heavy objects is the job of a qualified rigger,” she said. “Having a qualified rigger on site is essential to everyone’s safety.”

The Standard’s Scope

Kime noted that per ANSI, the B30.5 is one of ASME’s most

requested safety standards.

The volume is “widely respected and applied throughout the building and construction industry.”

It addresses crawler, locomotive and wheel-mounted cranes, as well as any variations thereof that retain the same fundamental characteristics and are powered by internal combustion engines or electric motors.

The new volume also includes an update to inspection require ments as well as updates for signalpersons.

The frequency of various types of crane inspections are outlined in this new volume, as are the critical difference between the words ‘should’ and ‘shall’ within the publication.

“There are occasions when it’s not just the crane operator who needs to operate the crane. ASME B30.5 explains those situations,” said Kime.

ASME B30.5 also specifies the qualifications required of a crane operator. “The responsibilities of a crane operator are surprisingly limited,” he added.

And, as there are a lot of roles and responsibilities on the job site the standard lists them and explains who should be assigned what.

“There is an umbrella of responsibilities that must be assigned under ASME B30.5,” he said.

The role of lift director is always filled on a mobile crane job site. ASME B30.5 explains their responsibilities.

The bottom line: In commercial applications requiring the movement of heavy loads and machinery, rigging is a key factor, said Fullman.

“The welfare of staff should be of the utmost importance when conducting a rigging operation,” she said. “Inappropriate load rig ging can cause unintended falls, leading to damage to property and exposing safety risks, injury, or even death to riggers and other nearby workers.”

The updated ASME B30.5 standard for mobile and locomotive cranes spells out the role of a qualified rigger on a lift, including selecting the right hardware.

CQ from page 11 12 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

AND SLIDE’‘JACK AND SLIDE’

J&B Heavy Haul Hoists Transformer Using Link-Belt 175|AT

J&B Heavy Haul of Oklahoma City, Okla., purchased a Link-Belt Cranes 175-ton (150-t) 175|AT all terrain crane for its trucking and heavy haul business.

Primarily, J&B Heavy Haul services the civil, power, petro chemical and manufacturing mar kets. The company already has well over 1,000 hours on its new 175|AT, utilizing it for its taxi rental fleet that services a 250-mi. range from Oklahoma City.

J&B Heavy Haul recently com pleted a 140,000-lb. transformer lift in Bentonville, Ark., with its 175|AT using a self-propelled modular transport (SPMT). Due to the tight nature of power stations, J&B has been able to utilize a transport trailer, lift the heavy transformer onto an SPMT with the 175AT, and then utilize a “jack and slide” method for positioning the transformer over a concrete pad and into its final position.

“Primarily, we like doing the transformer stuff but this 175 gets around town really well, and its chart without all the counter weight is really good. That’s what we like about it,” said Tra Neal, fleet manager of J&B Heavy Haul.

On a separate transformer lift in Hennessey, Okla., J&B Heavy Haul lifted a 70,000 lb. trans former at a 40 ft. radius for a sub station where a transformer had blown and needed repairs.

Versatility

“We rent this 175 down from time to time; you can send it out without any additional trucks and cover a lot of work. With just the weight on the deck it will out lift a lot of bigger cranes, mostly because of the weight of the big ger cranes’ boom,” said Neal.

“We lift a lot of heavy stuff at close radius and you can get 80,000 easily right off the back of the 175AT. That helps us a lot with the trucking stuff because we can usually get close, we just need to pick it up and load out.”

For more information, visit www.linkbelt.com.

Primarily,

J&B Heavy Haul services the civil, power, petrochemical and manufacturing markets. The company already has more than 1,000 hours on its new 175|AT, utilizing it for its taxi rental fleet that services a 250-mi. range from Oklahoma City. ‘JACK

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 13

RED SEA RESOLVE

Mammoet Assists With Ambitious Saudi Development Project

Once at the location, the segment is placed onto bear ings on crossheads of piers and the floating MTC 15 returns for the next section to repeat the process.

AUDI ARABIA’S RED SEA PROJECT is the world’s most ambitious and exciting tourism and hospitality project — a luxury destination created around one of the world’s last hidden natural treasures.

Led by the Red Sea Development Company (TRSDC), the project is located on Saudi Arabia’s west coast, between the cities of Umluj and Al-Wajh, and sits over pristine lands and waters, including a vast archipelago of more than 90 islands. Its main island —a dolphin shaped Shurayrah Island — will be the gateway to The Red Sea Project, setting the standard for

groundbreaking architecture and sustainable design. Shurayrah Bridge will become one of the main access points for guests onto the island.

TRSDC has appointed Archirodon, a marine contracting specialist to design and build the iconic bridge to the Shurayrah island. The bridge will stretch a total of .7 mi. and will connect the island to the mainland. A precast yard for bridge sections has been established near the coast to mini mize travel distances with concrete sourced from on-site batching plants.

S 14 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

engineering team

To handle the transportation and instal lation of 60 pre-cast bridge-beam and edge-beam segments onto piers Archirodon reached out to Mammoet.

Initially, the customer was looking at installing the bridge sections by SPMTs on a barge with the help of SPMT’s suspension cylinders to lift and then lower the pre-cast segments on the bridge bearings.

However, having studied the project in more detail, Mammoet’s engineering team proposed an alternative installation method by using Mammoet’s mobile floating crane concept: MTC 15 crane positioned on a barge, thereby creating a 551 ton capacity containerized floating sheer leg with an outreach of 98 ft. This installation method would provide significant time savings to the client as it will allow them to build the bridge faster by installing one section a day instead of one in two days, and provide more flexibility and accuracy to the opera tion.

The MTC 15 comes in standard shipping containers and can be easily shipped to any port, then assembled and erected in a matter of days. Archirodon’s 210-class barge with a suitable deck load was avail able at the site, this minimized the costs associated with mobilization of a new barge, and reduced the environmental harm by using readily available local resources.

The MTC 15 was shipped to the Port of Yanbu, where it was swiftly assembled on the barge and then sailed to the project site in Umluj, where its boom was then raised, ready to lift the 441 ton bridge sections.

The Process

At the pre-cast yard, Mammoet’s SBL1100 hydraulic gantry, a four-point lift ing system, lifts a section and safely places

it onto SPMTs for the transport to a new temporary jetty. At the jetty, the MTC-15 crane on the barge then lifts the segment from the trailers, places the segment on the bow while on hook and then floats off to the installation area. Once at the location the segment is skillfully placed onto bear ings on crossheads of piers and the floating crane returns for the next section to repeat the process.

“The combination of creative engineer ing with a flexible innovative equipment enables Mammoet to offer this unique tai lor-made solution for the customer that saved significant time. Moreover, the decreased handling time made this method of operation safer and eliminated the need to build an additional temporary infrastruc ture. Our collaboration with the client opti mized the overall project schedule and ulti mately kept the customer’s budget,” said Abdul Rouf, manager sales Mammoet Saudi Arabia.

Jacques Stoof, Mammoet’s global direc tor market development and innovation, said: “We always work closely with the cus tomers to listen and understand their

requirements to be able to offer the most efficient solutions. MTC 15 on a barge or a containerized floating sheer leg is a testa ment to that as it provides a simple yet effective way to lift heavy loads, both inland and in coastal waters and can be perfectly suitable to any civil project, on any local river or a lake.”

Sustainability is at the heart of The Red Sea Project, from design and architecture through to construction, operations and destination management. All transport and installation works are performed during the daylight hours in order to protect a sensi tive marine habitat. The MTC 15 also has been constructed by reapplying parts from previous cranes, reducing its environmen tal footprint. Using sand or water on-site for ballast reduces environmental impacts fur ther.

Upon completion in 2030, the Red Sea Project will comprise 50 hotels, with up to 8,000 hotel rooms and around 1,300 resi dential properties across the 22 islands and six inland sites.

For more information, visit www.mam moet.com.

SPMTs transporting the segment to the jetty.

The

proposed using Mammoet's mobile floating crane con cept: an MTC 15 crane positioned on a barge, thereby creating a 551-ton capacity containerized floating sheer leg with an outreach of 98 ft. For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 15

Utility Crane & Equipment, Inc.

www.utilityce.com

8800 W Buckeye Road

Tolleson, AZ 85353 866-832-4831

Richmond, CA 866-832-4831

Albuquerque, NM 505-342-9378

El Paso, TX 915-852-7201

Tucson, AZ 520-408-9378

Fontana, CA 909-419-8000

Versalift Midwest LLC

inquiries@cannonequip.com

51761 Danview Technology Court

Shelby Twp., MI 48315 586-991-0054

Coastline Equipment

Crane Division

www.coastlinecd.com

325 N. 5th Street, Bldg. A Sacramento, CA 95811 916-440-8090

Santa Ana

714-265-6550

Long Beach, CA 562-273-7013

L & M Truck Sales, Inc.

www.lmtrucks.com

4001 E. Boone Ave. Spokane, WA 99202 509-535-4175

Bakersfield, CA 661-399-3600

Oxnard, CA 805-485-2106

Santa Maria, CA 805-922-8329

Las Vegas, NV 702-399-2700

Hydraulic Machinery consteqguide@craneworx.com

5024 N 56th Street

Tampa, FL 33610 813-621-8002

Stephenson Equipment

www.stephensonequipment.com

Harrisburg, PA 800-325-6455

Philadelphia, PA 800-220-4033

Pittsburgh, PA 800-692-7600

Wilkes-Barre, PA 866-667-6756

Albany, NY 518-357-2200 Syracuse, NY 800-368-6455

Elko, NV 775-777-7070

Meridian, ID 208-888-3337

Jerome, ID 208-324-2900

McCall, ID 208-634-3903

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 1617 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

VOICE OF THE CUSTOMER

GROVE DEBUTS NEW TRUCK CRANE

Manitowoc has expanded its Grove truck crane offering with the new four-axle TTS9000-2, boasting all-wheel steering and an impres sively long boom on a lightweight carrier.

Much of the improved design comes from Manitowoc’s Voice of the Customer process, which uses consumer insights to improve engineering work and product development.

The 115-ton capacity truck crane fea tures an automated steering system that helps operators navigate challenging driv ing conditions, whether on congested urban job sites or small backcountry roads.

“We listened to the input of customers who were passionate about the need for rear steering capability and worked with Manitowoc’s Lift Solutions engineers and other teams to leverage our successful TMS9000-2 platform and make this new crane a reality,” said JJ Grace, Grove’s prod uct manager of truck-mounted cranes.

“Once again, our commitment to the Voice of the Customer process resulted in the development of an innovative new model that will greatly benefit both Manitowoc and our customers,” he said.

Each of the all-wheel steering modes can be activated by the operator at the click of a button on the right-hand console. For instance, with crab steering selected, all tires point in the same direction when the steering wheel is turned, allowing the crane to travel diagonally. Another option is a coordinated mode where the driver turns the front wheels in the direction of travel and the rear wheels turn in the opposite direction. This reduces the truck crane’s turning

radius and makes tight turns much easier.

“One of the model’s biggest advantages is that the operator doesn’t have to manu ally adjust the rear wheels, as this feature has traditionally been engaged on similar machines,” Grace said. “By incorporating automated controls, our system is designed to be intuitive for operators of all levels. This new model is a great option for cus tomers looking for advanced steering options in a compact package, in conjunc tion with the best truck crane features on the market.

“During development, we worked close ly with a customer who services wineries and utilities in Northern California. He rou tinely has to overcome some very steep inclines in addition to extremely tight switchbacks, which were nearly impossible with his front-steer truck crane,” he said.

“When he put the TTS9000-2 into rearsteer mode, it glided up gravel roads with grades over 19 percent. On another wind ing road, where he’d previously needed to perform a six-point turn, he was now able to make the bend without having to back up.”

Improved Drivability

The TTS9000-2’s drivability is improved due to the crane’s compact dimensions and light roading weight afforded by its remov able counterweight feature.

“We see this model as a great option for customers who need a truck crane that can wear a lot of different hats,” Grace added. “Our customers can reach more job sites by taking the crane along with a small support truck for the extra counterweight. It’s a

The 115-ton capacity truck crane features an automated steering system that helps operators navigate challenging driving conditions, whether on congested urban job sites or small backcountry roads.

setup that has worked well for many of our TMS9000-2 customers.”

Even without a jib extension, reach is impressive, due to the TTS9000-2’s MEGAFORM, six-section boom shape that also increases capacity over conventional designs. Extending from 36 to 169 ft., it makes optimum use of the TWIN-LOCK pinning system that not only eliminates weight from inside the extended boom but automatically locks the sections together.

Faster, Simpler Setup

The outriggers of the TTS9000-2 also benefit from recent Grove design improve ments that aim to make jobsite setup sim pler and faster.

The rear outrigger box, for example, is now 5 in. higher to improve the departure angle to 18 degrees. Also, the front outrig ger jacks have been mounted 3.5 in. higher to improve ground clearance, while allow ing for an extra 3 in. of outrigger stroke. Additionally, the outrigger pad size has been increased from 20 to 24 in. to provide even greater stability.

“Our outrigger improvements will play a big part in making this crane even more user-friendly, and elevating the overall ownership experience,” Grace said. “That was also a change made in response to customer suggestions and will serve to enhance their trust and confidence in our machines even further.”

The TTS9000-2 is now available for order throughout the Americas.

For more information, visit www.mani towoc.com.

18 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 19 CONTACT LINK-BELT MID-ATLANTIC TODAY! Ashland, VA • 800-552-3837 Chesapeake, VA • 800-342-3248 Frederick, MD • 833-546-5235 SERVING VIRGINIA, MARYLAND, DISTRICT OF COLUMBIA, DELAWARE www.link-beltmidatlantic.comFind us on: Link-Belt Cranes Lexington, Kentucky, USA | www.linkbelt.com The Link-Belt TCC is the future of how tough jobs get done! Low overhead clearance Unprecedented pick and carry capacities Link-Belt's vision package Cummins Tier 4F diesel engine Fast set up & move 55-ton |50 mt Telescopic Crawler Crane 4160 CEG Mid Atlantic TCC family ad 2.10.22.indd 1 2/17/2022 1:15:49 PM

4 + 4 = 1?

Four Cranes, Four ALL Branches Lead to One Perfectly Executed Quad Lift

From the Georgia branch came a 600-ton Liebherr LTM 1500-8.1 and 550-ton Grove GMK7550, Florida supplied a second GMK7550 and Louisiana con tributed a 550-ton Liebherr LTM 1450-5.1.

F

our southern branches of the ALL Family of Companies banded together to accomplish a massive lift for construction of a new hangar at an international airport in northern Florida.

Steel box beams formed large trusses, the heaviest of which weighed in at 610,000 lbs. This truss, which measured 20 ft. high and 400 ft. long, needed to be lifted and set as a single piece. And, by the way, the massive framework would need to be raised to a height of 80 ft.

In this case, a journey of 80 ft. began with one phone call … then a second and a third.

ALL Crane Rental of Alabama, a member of the ALL Family of Companies, was awarded the contract to provide lift equipment. Due to the weight and length of the truss, four heavyweight all ter rain (AT) cranes, all with capacities of 550 tons and above, were needed to execute the lift, each rigged to the truss at the same time and lifting in perfect unison.

The Alabama branch sourced the cranes from three of its sister yards from the ALL national footprint in three other southern states: ALL Crane Rental of Florida, located in Tampa; All Crane Rental of Georgia, located in Austell; and ALL Crane Rental of Louisiana, located in Geismar.

From the Georgia branch came a 600-ton Liebherr LTM 1500-8.1 and 550-ton Grove GMK7550, Florida supplied a second GMK7550 and Louisiana contributed a 550-ton Liebherr LTM 1450-5.1.

Scott Swearengin, sales representative of ALL Crane Rental of Alabama, acted as point man for the project and also programmed the 3-D lift plan for the four cranes. Although executing the lift took just one hour, planning began a full six months prior.

“To reserve four large cranes like that, we needed to get on the radar of our sister branches as early as possible,” said Swearengin. “On Florida’s Gulf Coast, weather can always become an issue, so scheduling a job is even more sensitive. You’ve got to be able to turn on a dime.”

The 3-D lift planning took time as well, as Swearengin first had to program each crane individually then bring all four together. Any adjustment in the overall plan required an update to the com puter, so the 3-D plan was revisited multiple times in the months

and weeks leading up to lift day.

ALL has its own trucking division, so delivering the four massive cranes to the airport from three separate yards across three differ ent states did not present the scheduling issues that might have arisen from using third-party trucking.

“In all, 40 truckloads descended on the job site from the three sister branches,” said Swearengin. “We started assembly roughly five days before the lift so everything would be ready.”

On lift day, Swearengin’s team was in constant radio contact with crane operators conducting the 610,000-lb. quad lift. Each operator reported his crane’s load, with instructions relayed back from the team on whether to speed or slow its individual portion of the lift.

“Executing a lift like this is all about the skill of the operators,” said Swearengin.

Once lifted into position, the four cranes held the truss aloft as thousands of bolts were installed to secure it.

The four-crane package was needed only to lift this particular truss. The two GMK7550 ATs remained on site for several days after to execute dual picks for the remaining steel needed to frame the hangar.

For more information, visit www.allcrane.com.

20 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

The Alabama branch sourced the cranes from three of its sister yards from the ALL national footprint in three other southern states: ALL Crane Rental of Florida, located in Tampa; All Crane Rental of Georgia, located in Austell; and ALL Crane Rental of Louisiana, located in Geismar.

4 + 4 = 1?

BKB Finds Perfect Lifting Solution Through RMS RentalsTEAM TRIUMPH

Brittney Yares is a fast learner and an extremely ambitious person. Those two traits are why her company Brittney Kate Builds (BKB) has grown from a weekend project with a friend to a booming and respected company. BKB completes large housing complexes throughout the Minneapolis suburbs.

“Six years ago, I framed a basement with

a friend and thought it was a great accom plishment and super fun,” recalled Yares.

“So I kept doing it. I did some more base ments, then houses, then townhomes, and eventually giant complexes.

Her passion has fueled the company’s growth, and recently BKB worked on its largest project to date, a two-phase, 150unit housing complex in Minneapolis’

northwest suburbs.

To tackle the job, BKB enlisted the help of RMS Rentals and Territory Manager, Crane Specialist Scott Solberg to add a Potain T80 self-erecting crane at the job site.

“We knew we needed the crane so we could reach the most area and lift anything we needed to,” explained Yares. “Over four months we had it on site, we were able to reach anywhere we needed — front, back, side, courtyard — and we only moved the crane once.

It also was the first time BKB had called on RMS Rentals and Solberg. The team was an integral partner during the process.

“Our training was with RMS Rentals,” Yares said. “We trained in the yard until we were comfortable and then took the tests we needed to. They set the crane up and tore it down. Scott and everyone at RMS were awesome.”

The addition of the crane was a definite upgrade from the alternative process, Yares said.

“I don’t know how we could have done it without a crane,” said Yares. “We would probably have to hire a mobile crane, and even then the boom would have probably started hitting the fourth floor of the build ing. It would have been a huge challenge.

“The T80 definitely contributed to the speed and convenience of this project.”

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 21

RMS Rentals Territory Manager, Crane Specialist Scott Solberg (C) visits with Brittney Kate Builds (BKB) CEO/Owner Brittney Yares (R) and Chief Assistant Chelsey Daubenspeck about the Potain T80 crane.

BKB recently worked on its largest project to date, a two-phase, 150-unit housing complex in Minneapolis' northwest suburbs that required the use of a Potion T80 crane.

Manitowoc Introduces CONNECT Digital Solution

M M

anitowoc continues its expansion and investment in support services with the launch of CONNECT, a new digital plat form that will launch at bauma 2022.

CONNECT enables remote monitoring through an app-based system that gives owners and operators the ability to view real-time crane information, receive alerts, exchange data and more with further func tionality to be added in the future.

The versatile CONNECT platform, with its wide-ranging capabilities, will advance fleet management, boost sustainability, streamline service and maintenance for users, and improve connectivity to cranes with the easy-to-use platform working across smartphones, tablets and laptops.

Dirk Wolfsteller, vice president of Aftermarket for Grove in Europe, said, “The launch of CONNECT kickstarts a new digi tal era of owning and operating Manitowoc cranes.

“In a matter of seconds, users can access a range of features or data related to their cranes through the app-based platform. They can analyze performance, check serv ice gauges, diagnose faults, and more. It allows unprecedented insight into their cranes, transforming performance, sustain ability, and ultimately profitability linked to their investments.”

The new platform will be phased in, ini tially on Potain tower cranes and Grove allterrain cranes. The company plans to add other product lines and brands in due course.

CONNECT delivers an optimized user experience, assisting with set-up, simplify ing maintenance, providing driver assis tance systems and more. Owners get realtime access to services and information with just a couple of taps on a screen.

Grove CONNECT

For Grove, CONNECT will initially be available on GMK all-terrain cranes pro duced from 2023. It will be offered on all new models and available to retrofit on cranes equipped with the CCS control sys tem.

Benefits include optimized troubleshoot ing due to the real-time availability of crane information. This allows remote technicians to quickly understand the status of the crane, with any error codes displayed through the app. The remote service team can then run root cause analysis and pro pose potential solutions without the delay of travel or on-site physical assistance.

Business Intelligence is improved too. With simplified and expanded insight into fleet usage, crane owners can adjust their operations to make optimum use of resources or strengthen preventative main

tenance programs. A further benefit is the ability to help customers meet their broader sustainability goals.

CONNECT’s functionality means that onsite trips to check cranes are reduced as more of this will happen remotely. Improved data access also means that any necessary visits are optimized. Finally, there is much less need for printed documenta tion as this can be accessed more easily in digital format.

Patrick Stelter, product manager of allterrain cranes at Manitowoc, said, “Grove crane owners can harness the power of data through CONNECT to better under stand performance and maximize the return on their investment.

“For so many of our clients, their overall business goals are tied to issues like sus tainability, digitalization, and connectivity. With CONNECT they can now advance those goals and reap the benefits.”

Potain CONNECT

For Potain tower cranes, CONNECT will be offered as an option on new top-slew ing and self-erecting cranes. In addition, it can be retrofitted on all CCS-equipped cranes. With extensive capabilities available through CONNECT, Potain will discontinue production of its older CraneSTAR Diag tool.

The user-friendly CONNECT solution offers seamless integration between remote diagnostics, advanced analytics and fleet management to help owners significantly increase fleet utilization while increasing

uptime. On the job site, technicians and others can use local Wifi to link to the crane via CONNECT. This allows them to easily see the operating system and review performance data.

In the future, Manitowoc plans to enable CONNECT to be embedded into the BIM (Building Information Management) model for a project and allow the creation of dig ital twins of the crane. This functionality will deliver better optimization, site plan ning, monitoring and materials flow on the job site, boosting building speed and qual ity.

As with Grove GMK cranes, Potain own ers with CONNECT will enjoy increased utilization through better preventative maintenance. Customers’ sustainability goals are improved too, due to the extend ed service life of cranes that should come through better management.

Xavier Claeys, director of digital innova tion of tower cranes at Manitowoc, said, “CONNECT advances how contractors and rental companies will use tower cranes on job sites.

“The platform improves the user experi ence immediately and opens a world of exciting possibilities in the future. For example, customers can compare expected use versus actual use, with the potential to reframe how pricing and operational mod els are run. This insight simply wasn’t avail able before, but we expect it to positively transform how customers approach crane ownership. We’re excited to showcase the new technology at bauma 2022.”

22 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

The CONNECT platform, with its wide-ranging capabilities, will advance fleet management, boost sus tainability, streamline service and maintenance for users and improve connectivity to cranes with the easy-to-use platform working across smartphones, tablets and laptops.

WE’RE NUMBER ONE

Mass. Firm Takes Delivery of First Tadano AC 4.110-1 in North America

Harry Leo III of H.A. Leo Crane LLC in Webster, Mass., recently took delivery of a new 2022 Tadano AC 4.110-1, 120-ton all terrain crane from Empire Crane Company.

This is the first Tadano AC 4.110-1 to be delivered in North America.

Leo Crane is a third generation com pany that offers rigging, lifting and haul ing throughout New England. The 100 to 120 ton class is the ideal size for the category of work and customers H.A. Leo Crane serves. In order to reduce downtime and increase efficiency, they felt it was best to purchase a new unit.

“I grew up in an old school work environment and always believed the less things that can go wrong the better. This Tadano is rock solid,” said Leo.

The Tadano AC 4.110-1 features the following:

• 37.4 ft. to 196.9 ft. main boom

• 12.1 ft. to 104.7 ft. jib

• 67,020 lbs. counterweight

• Mercedes-Benz engine

• 223 ft. max radius

• 12.5 ft. tail swing radius, even at the full counterweight

H.A. Leo Crane also owns a 100 ton Krupp, 120 ton Grove and a 250 ton Tadano. Their love of their 250 ton Tadano had a major influence in their purchasing decision.

“We can get to the job site quicker, set up in tighter spaces, and the capacity is

Harry Leo III (R), owner of H.A. Leo Crane, and his father, Tony, picked up the crane at the Port in New Jersey.

The AC 4.110-1’s first job was performing work on a cell tower on an extremely tight job site in Cranston, R.I.

“This crane was tailor made for jobs like this because of the extremely tight set up area, narrow access road and very tall tower,” Leo said.

They used the full 196.9 ft. of main boom and the small footprint with uneven outriggers. Their heaviest pick was 2,500 lbs. at a radius of 85 ft.

Paul Lonergan, Empire Crane owner and president said, “For guys like Harry, it’s like Tadano engineered this crane just for them. The size, the mobility, the ease of use and simplicity is perfect for the jobs they perform everyday.”

Empire crane has a team of Tadano fac tory trained technicians and stocks many Tadano parts and filters needed to support their customers.

“From ordering the crane to taking delivery of it 6 months later, it has been a pleasure to work with both Paul and Luke [Lonergan of Empire Crane]; they are genuine people,” Leo said.

For more information about Empire Crane, visit. www.EmpireCrane.com.

For more information on H.A. Leo Crane Service, visit www.haleocrane.com.

For more information on Tadano, visit https://tadanoamericas.com/uscan/en/

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 23

unmatched,” Leo said.

H.A. Leo Crane used the full 196.9 ft. of main boom and the small footprint with uneven outriggers. Its heaviest pick was 2,500 lbs. at a radius of 85 ft.

D

ebutigital

Although CCO candidates began taking exams utilizing computers nearly 15 years ago, CCO recently announced its technolo gy initiative to move all written exams to the computer.

This initiative not only uses the latest and greatest testing and security technology, but it has several key benefits for candi dates and employers. Benefits include:

• Immediate score reporting once exams are complete* (*A preliminary score will be available immediately. Results are subject to review and approval following standard testing protocols)

• Extended test availability windows to include outside of normal work hours

• A greatly expanded network of areas where the test can be taken

• Increased ease of scheduling or rescheduling exams

CCO remains committed to offering its candidates options that best suit their schedules and needs. To support candi dates accustomed to testing in a group environment (often exams hosted by

employers or following a training course), CCO will introduce a new test administra tion modality known as Event Online Testing (EOT). To support candidates wanting to test on their own schedule, CCO will introduce an alternative test administration modality known as Online Proctored Testing (OPT).

“Both EOT and OPT leverage technolo gy and current best practices in test deliv ery to improve the candidate experience through increased flexibility in scheduling and faster exam scoring, while also ensur ing higher levels of test security” said Joel Oliva, CCO senior director of innovation.

“We expect that both EOT and OPT will be available in limited applications before the end of this year and will be available to all CCO candidates in early 2023,” he added. “It is CCO’s vision to see the new modalities replace current delivery meth ods testing by the conclusion of 2023.”

Event Online Testing (EOT)

EOT is CCO’s solution to the group test

CCO to Move Written Exam Delivery Into Digital Age

ing setting as a replacement for paper/pen cil testing. In many instances, candidates are brought together at a single location to go through training and then complete test ing. EOT supports this approach, but instead of candidates testing using paper exam booklets and scantron bubble forms, they will test on computers.

EOT administrations will be conducted at CCO authorized test centers. These can be established at dedicated facilities (such as an employer’s office or training facility) or set up at temporary locations such as hotels or other off-site locations. Just as they do today, candidates will apply online to test at an EOT and receive notification of approval for testing.

Each candidate will need a dedicated computer for the test administration. However, because of the flexibility of this modality, a candidate may be scheduled to utilize a computer in the morning, and a different candidate may use the same device in the afternoon.

Any supplemental material, such as load charts, reference material or calculators, will be provided within the exam onscreen. On test day, the candidates will be checked in by a proctor who is physically present. The candidate will take all exams they are scheduled for in succession.

While candidates who currently test in a group setting (via paper/pencil) must wait up to 12 business days to receive exam results, a major benefit to moving to EOT is that all candidates who complete exams will receive their scores immediately at the conclusion of their tests.

Exam security will be maintained by the physically present proctor. In addition, exam administrations also will be recorded. Every candidate will be recorded from start to finish via webcam, microphone and screen record. All recordings are stored and will be reviewed for test irregularities.

24 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

CCO

plans to eliminate both brick and mortar computer and paper/pencil test modalities by the end of 2023.

Photo courtesy of NCCCO twitter page

Online Proctored Testing (OPT)

While EOT meets the traditional training/testing model, OPT offers the highest degree of candidate flexibility. OPT is CCO’s solution to the individual testing setting which will be a replace ment for computer-based testing (at PSI test centers).

OPT can be done at home or almost any private room with an internet connection. Testing is available 24/7/365 from anywhere around the world, and once approved for testing, candidates can book an OPT session in as little as 15 minutes. This will be partic ularly convenient for scheduling around work obligations and inclement weather, or even testing at night or on the weekend. Even more, candidates can cancel/reschedule their exam up until the exam start time with no additional fee.

OPT candidates will receive their exam scores immediately at the conclusion of their tests.

OPT incorporates additional exam security measures allowing for this more flexible testing option. In this mode the online proc tor will monitor the candidate in real time via webcam, micro phone and screen share, with the assistance of artificial intelligence (AI). All recordings are stored and will be reviewed for testing irregularities.

The online proctor will lead each candidate through a check-in process that is anticipated to take about a half hour. They will check the candidate’s ID, ensure the computer meets minimum requirements and is set up properly, and ensure that the computer is not running any inappropriate software. Additionally, the online proctor will have the candidate perform a 360-degree room scan using the computer’s camera to show that the candidate is in the

room alone and that there is nothing that could be used during the exam to offer an unfair advantage.

Testing On Computers

While CCO has offered its exams through PSI computer labs since 2008, these new modalities will move all CCO candidates to testing on computers. Technical requirements for EOT and OPT can be found at www.nccco.org/techreq.

In addition to testing on computers, all test resources also will be provided digitally. This includes load charts, calculators, digital whiteboard and digital scratch paper. All physical paper is being eliminated from CCO test administrations.

CCO is committed to ensuring all its candidates have a positive test experience and are prepared for test day. Materials are current ly in development to assist candidates with the new processes, including videos of what to expect and an exam demo so that can didates can have the opportunity to practice taking an exam in the computerized environment.

Phase Out of Current Testing Methods

CCO plans to eliminate both brick and mortar computer and paper/pencil test modalities by the end of 2023. The new modal ities offer significant advantages, particularly related to candidate flexibility and test security. Beginning in 2024, these legacy modal ities will be eliminated as standard operating procedure. CCO does plan to maintain them for extenuating circumstances if online test ing is not an option. More information will be available in 2023.

For more information, email candidate@nccco.org.

CCO PLANS TO ELIMINATE BOTH BRICK AND MORTAR COMPUTER AND PAPER/PENCIL TEST MODALITIES BY THE END OF 2023.

THOMAS CANTWELL TO HEAD FOUNDATION SELECTS

Thomas (T.J.) Cantwell has been named executive director of the NCCCO Foundation. He will take over from current chief executive, Graham Brent, on Aug. 1. As previously announced, Brent will retire from the Foundation at the end of July.

Cantwell is currently administrator (exec utive director) of the Physical Therapy Compact Commission headquartered in Alexandria, Va. He brings to the Foundation more than 20 years of non-profit manage ment experience.

“T.J. was selected from an exceptionally strong field of candidates,” said NCCCO Foundation President Garry Higdem, who chaired the executive search committee. “We are confident that his passion for edu cation, workforce development and veter ans transition issues, along with his exten sive national non-profit management back ground, will serve the Foundation well in its pursuit of its stated safety and education goals.”

“T.J. is exactly the experienced and high ly self-motivated individual we were look

ing for,” said Brent. “And his demonstrated expertise in developing industry outreach and forging strategic alliances with national organizations will be extremely valuable in furthering the Foundation’s mission in its advocacy for safety education and access by youth, military personnel, and under served communities to the crane and rig ging and associated industries.”

It also was clear, Brent noted, that Cantwell’s experience with non-profit organizations engaged in activities as diverse as building materials supply, trans portation and disaster relief had impressed upon him the value in following safety pro cedures and adopting best workplace prac tices.

An executive transition program that would ensure a smooth and seamless exec utive transition to new leadership had already been put in place and would unfold over the coming weeks, Brent added.

For more information, visit www.nccco foundation.org.

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 25

T.J

Cantwell

Antique Cranes Star at Modern Events

Working to preserve the history of the construction equipment that shaped our world . . .

The Historical Construction Equipment Association (HCEA) is a 501(c)3 non-profit organization dedicated to preserving for public education the history of the construction, dredging and surface mining equipment industries.

What sets this 1957 Bantam C35, owned by the HCEA’s Heartland Chapter, apart is what Bantam called its “all-vision” cab. It was standard on the CR35 self-propelled version, but the C35 literature in the HCEA Archives doesn’t even list it as an option for the crawler or truck models. (HCEA 2021 International Convention & Old Equipment Exposition, Concordia, Kansas.)

A late 1930s Byers Bearcat Junior half-swing shovel is owned by Lakeside Sand & Gravel. (HCEA 2021 International Convention & Old Equipment Exposition, Concordia, Kansas.)

A 1945 Bucyrus-Erie

15-B backhoe and 1942 Manitowoc 3500 dragline are both owned by the National Construction Equipment Museum.

(HCEA 2019 International Convention & Old Equipment Exposition, National Construction Equipment Museum, Bowling Green, Ohio.)

Look again, this isn’t a conventional Bantam backhoe. This 1962 C-350 is equipped with an optional hydraulic tilt cylinder for the bucket, a feature offered by many cable backhoe manufacturers in the late 1950s and 1960s. The owner is Scott Kacite of Michigan.

(HCEA 2019 International Convention & Old Equipment Exposition, National Construction Equipment Museum, Bowling Green, Ohio.)

26 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Courtesy of Historical Construction Equipment Association

HCEA photo A 1958 American Hoist & Derrick 399 dragline is owned Jim Hornbostel (HCEA 2021 International Convention & Old Equipment Exposition, Concordia, Kansas.)

HCEA photo

HCEA photo

HCEA photo

HCEA photo

NEW CRANE PARTS

All Model Cranes, Draglines, Clamshells & Backhoes

American; LinkBelt; Manitowoc; Terex; Kobelco; Sumitomo; Liebherr; Bucyrus Erie - Northwest; Lima; Insley; Bantam; Marion; P&H; Hopto; Hy-Hoe; Lorain; Michigan; Koehring; Bay City; Gradall; Unit: John Deere; Hein-Werner

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 27

&

28 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com Rent

Roll! y s Y pa lo estributor a o t has you w kltcowlinbe . . m , USAentuckyLexington, K Thenlinenser o a w w www.linkbelt.com| toalofourLinkBeltCraneques l y tions. Find us on: Link Belt Cranes

Alta Equipment Company

www.altaequipment.com

Byron Center, MI (616) 878-7450

New Hudson, MI (248) 356-5200

Flint (Burton), MI (810) 744-4840

Traverse City, MI (231) 943-3700

Detroit, MI (313) 394-1811

Kelly Tractor Co. Crane & Foundation Equipment

www.kellytractor.com

Clewiston, FL (863) 983-8177

Davie, FL (954) 581-8181

Ft. Myers (239) 693-9233

Mulberry, FL (863) 205-2537

Miami, FL (305) 592-5360

Orlando, FL (407) 568-8055

Atlantic & Southern Equipment

www.atlanticandsouthern.com

Birmingham, AL (205) 951-6656

Theodore, AL (251) 443-5229

Lake City, GA (404) 361-1100

Central/Eastern, TN (888) 951-6656

West Palm Beach, FL (561) 683-1231

Rudd Equipment Company

www.ruddequipment.com

Louisville, KY (800) 283-7833

Corbin, KY (606) 528-9440

Prestonsburg, KY (606) 874-2104

Evansville, IN (812) 867-6661

Ft. Wayne, IN (260) 482-3681

Indianapolis, IN (317) 247-9125

St. Louis, MO (314) 487-8925

Clearfield, PA (814) 765-8500

Leetsdale, PA (412) 741-1731

Nitro, WV (304) 755-7788

Columbus Equipment Company

www.columbusequipment.com

Columbus (614) 443-6541

Toledo (419) 872-7101

Cincinnati (513) 771-3922

Richfield (330) 659-6681

Cadiz (740) 942-8871

Dayton (937) 879-3154

Massillon (330) 833-2420

Zanesville (740) 455-4036

Painesville (440) 352-0452

Piketon (740) 289-3757

Link-Belt Construction Equipment Mid-Atlantic www.link-beltmidatlantic.com

Ashland, VA (800) 552-3837

Chesapeake, VA (800) 342-3248 Frederick, MD (833) 546-5235

Oklahoma Territory Construction Equipment

www.oklahomaterritoryequipment.com

Oklahoma City, OK (405) 917-9191 • (866) 339-6827 Tulsa, OK (918) 835-7200 • (866) 334-6827

Transport Equipment Sales www.tes-inc.net

South Kearny, NJ (973) 589-4100

Triad Machinery

www.triadmachinery.com

Portland, OR (503) 254-5100

Eugene, OR (541) 342-7700

Bend/Prineville, OR (541) 447-5293

Seattle/Tacoma, WA (253) 722-5560

Spokane, WA (509) 534-1900

Mt. Vernon, WA (360) 488-3948

Wood’s CRW Corp

www.woodscrw.com

Carlisle, PA (717) 795-0700

General Equipment & Supplies

www.genequip.com

Shakopee, MN (952) 224-1500

Minot, ND (701) 852-0479

Fargo, ND (800) 437-2924

Bismarck, ND (701) 223-9700

Williston, ND (701) 572-0570

Rexco Equipment Inc. www.rexcoequipment.com Burlington, IA (319) 419-6050

Cedar Rapids, IA (319) 393-2820 Davenport, IA (563) 381-1200 Des Moines, IA (515) 287-4910

Central Square, NY (315) 676-2008

Williston, VT (802) 658-1700

North Oxford, MA (508) 499-1950

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 29

30 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 31 “We Have What You Need – Call Today ” 562.273.7013 HQ: Long Beach, CA sales@coastlinecd.com www.coastlinecd.com SALES RENTAL PARTS & SERVICE CRANE FILTERS CRANE SEAL KITS WORLD WIDE CRANE PARTS IN STOCK PROVIDING PARTS FOR: 2016 TADANO GR 900XL 90 TON #66261 $495,000 New Units In Stock as66fo 2017 TADANO GR 750XL 75 TON # 72043 $435,000 - New GR800XL’s In Stock - Call bm46bw 2019 TADANO MANTIS GTC 1200 130 TON #85818 $960,000 - New GTC 1300 In Stock bh62qk 2018 TADANO GR 1600XL 160 TON #75890 $995,000 - In The Yard - New Unit Available at66rq 2022 MANITEX 40124SHL 40 TON - #99538 Pete 567 - 13 Speed - Unit Avail - Call Today bn40te 2018 TADANO GR 1200XL 120 TON #71341 $635,000 New Units In Stock - Call as17vx 2022 ELLIOTT M43R - Stk# 100770 43FT Work Platform - Basket Winch - In Stock bp27bm 2021 MANITEX 1970C 19 TON #97517 Freightliner M2106 - Auto Trans - In Stock bm03va 2019 TADANO GR 550XL 55 TON #78051 $405,000 - New Units In Stock - Call Today ax71ha 2018 SKYJACK ZB2044 20K Capacity #79464 $210,000 New Units In Stock - Call bp27bn 2022 MANITEX 3051T 30 TON - Stk# 99622 Pete 567 13 Speed - In Stock - CALL bn55sr 2019 TADANO GR 350XL 35 TON #78049 $325,000 New Units In Stock - Call bp62bu 2023 MANITEX 30100C 30 TON #100737 Kenworth T440 Auto Trans - In Stock Call bo25cr 2019 TADANO GR 150XL 15 Ton Industrial #85977 $260,000 Unit In Stock - Call Today az28by

32 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com