A CRANE OPERATOR’S COMFORT is crucial to a successful day at work. Discomfort to the point of tension is unhealthy, while relaxing to the point of drowsiness is a danger to the operator, crew and people on the ground. The notion of operator comfort during a long shift, whether that’s high up in a tower crane cab or closer to the ground in a mobile rig, is

gaining traction.

The National Safety Council (NSC), Itasca, Ill., reports that 69 percent of employees are tired on the job. This fatigue significantly increases the risk of workplace injuries and incidents, the nonprofit said.

Focused on high-risk industries where fatigue can have dire consequences, the report found that 100 percent of construction workers have at least one risk factor for fatigue. It also found that 46 percent of construction workers say they work during high-

risk hours, such as at night or early morning.

“Worker fatigue is often an overlooked hazard on the construction site,” found the NSC. “Fatigue, whether physical or mental, impairs a construction worker’s ability to safely and effectively perform their job duties.”

Fatigue also increases the risk of accidents and injuries, which can lead to unnecessary workers’ compensation costs and can greatly reduce productivity on a project.

continued on page 10

GROVE RT540E Hours: 478, Stk# 1716, S/N: 236997, 40 Ton Capacity, Single Hoist, Tier 4 Final Engine, Block, Ball, 102’ Boom, 45’ Jib

MANITOWOC MLC100-1 S/N: 91001040, 13 8t Ball, 150' Boom, Series 2 CWT, Cold Weather Package, Level Indicator, Camera Sys, RCL Warning Light, Free Fall on Front & Rear Drums, Bed Mounted 3rd Drum with Free Spool, Cummins QSB6.7 Tier 4 Final @ 300HP $Call

2014 GROVE RT765E-2 Hours: 4,581, Stk# 1603, S/N: 400023, 65 ton Capacity, 65 ton 5-Sheave Hook Block, 8.3ton Headache Ball with Hook, Graphic LMI & Anti-Two Block System, 4-Sheave Boom Nose, 36’-110’ Boom, 33’-56’ Jib, 2 Hoists, Tier 3 Engine $369,000

Stk# N000520, S/N: 235109, 90 ton Capacity, 5 Sheave 90 Ton Block; Ball; 142’ Boom, 33’-56’ Jib

WESTERN PACIFIC CRANE & EQUIPMENT

www.wpcrane.com

8600 Calabash Ave. Fontana, CA 92335 562/286-6618

1500 Madruga Road Lathrop, CA 95330 855/927-2637

275 W. Larch Road Tracy, CA 95304 209/597-3824

3521 Alken Street Bakersfield, CA 93308 855/927-2637

19602 60th Avenue NE

Arlington, WA 98223 253/254-7950

91-210 Kalaeloa Blvd. Kapolei, HI 96707 808/682-7263

8912 NE Vancouver Way Portland, OR 97211 971/202-4002

6720 Arctic Blvd.

Anchorage, AK 99518 855/342-7263

WPCE - CANADA 9538 195th Street

Surrey, BC V4N 4G2 855/342-7263

CLEVELAND CRANE & SHOVEL SALES INC.

www.craneandshovel.net

26781 Cannon Road

Cleveland, OH 44146

440/439-4749

Toll Free: 800/362-8494

aforepaugh@ craneandshovel.net

RING POWER CRANE

www.ringpowercrane.com

St. Augustine, FL 904/494-1219

Pompano Beach, FL 954/977-5010

Orlando, FL 407/855-6195

Tampa, FL 813/671-3700

Union City, GA 770/774-7300

Concord, NC 704/795-3636

Aiken, SC 843/818-1954

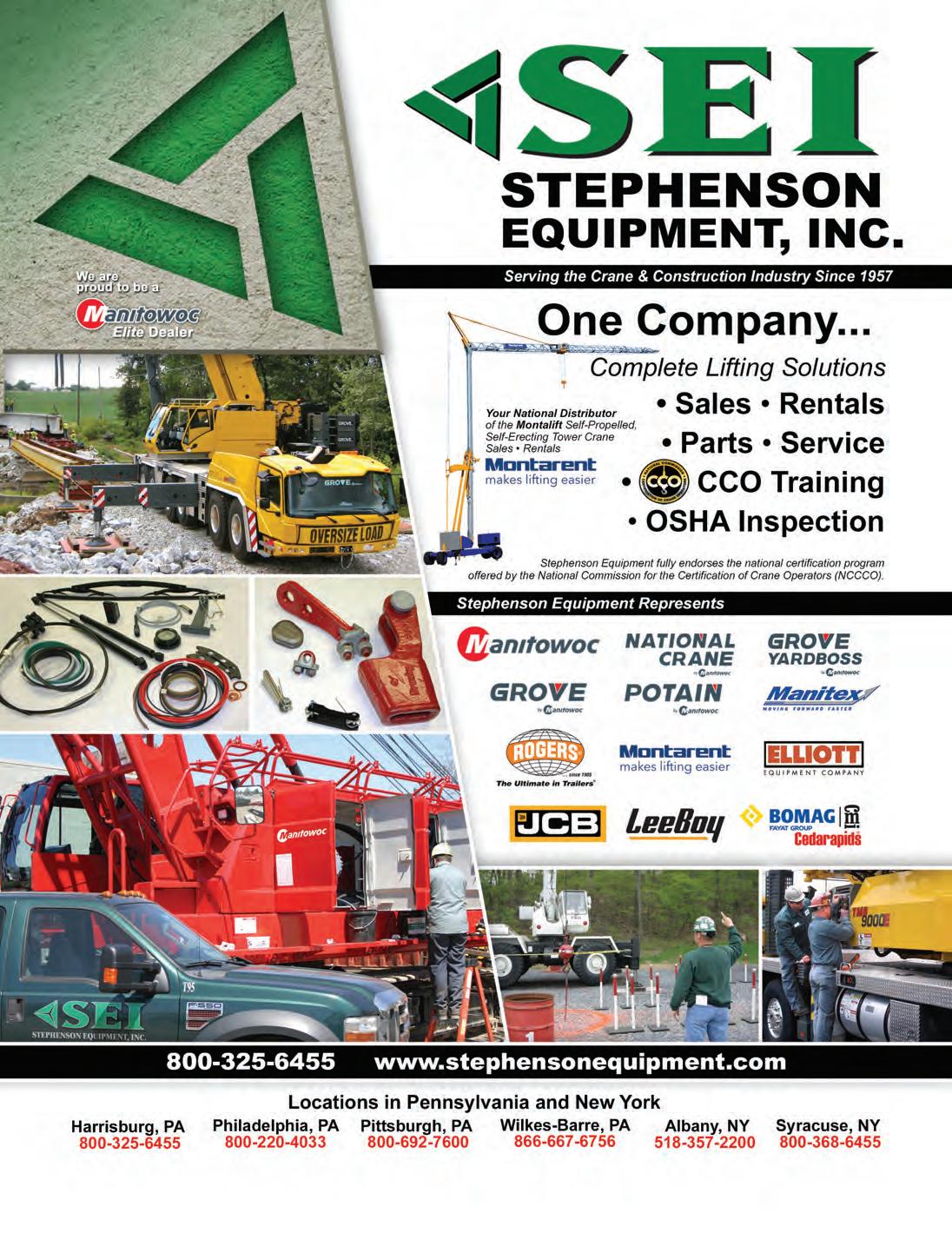

STEPHENSON EQUIPMENT, INC.

www.stephensonequipment.com

Philadelphia, PA 800/220-4033

Harrisburg, PA 800/325-6455

Wilkes-Barre, PA 866/667-6756

Pittsburgh, PA 800/692-7600

Syracuse, NY 800/368-6455

Albany, NY 518/357-2200

HOFFMAN EQUIPMENT CO.

www.hoffmanequip.com

New Jersey Corporate Headquarters 300 S. Randolphville Rd. Piscataway, NJ 08854 732/752-3600

South Jersey 1330 Hurffville Rd. Deptford, NJ 08096 856/227-6400

New York 1144 Zerega Ave. Bronx, NY 10462 718/822-1180

Mid-Hudson Valley 1440 Route 9W Marlboro, NY 12542 845/236-3000

Long Island 22 Peconic Ave. Medford, NY 11763 631/207-2900

Pennsylvania Philadelphia Metro Area 120 Gordon Dr. Lionville, PA 19341 610/363-9200

KIRBY-SMITH MACHINERY INC

www.kirby-smith.com

Oklahoma City, OK 405/495-7820

Tulsa, OK 918/438-1700

McAlester, OK 918/310-1550

Kansas City, KS 913/850-6300

St. Louis, MO 314/729-0125

Alta Equipment Company

www.altaequipment.com

Byron Center, MI (616) 878-7450

New Hudson, MI (248) 356-5200

Flint (Burton), MI (810) 744-4840

Traverse City, MI (231) 943-3700

Detroit, MI (313) 394-1811

Kelly Tractor Co.

Crane & Foundation Equipment

www.kellytractor.com

Clewiston, FL (863) 983-8177

Davie, FL (954) 581-8181

Ft. Myers (239) 693-9233

Mulberry, FL (863) 205-2537

Miami, FL (305) 592-5360

Orlando, FL (407) 568-8055

Rudd Equipment Company

www.ruddequipment.com

Louisville, KY (800) 283-7833

Corbin, KY (606) 528-9440

Prestonsburg, KY (606) 874-2104

Evansville, IN (812) 867-6661

Ft. Wayne, IN (260) 482-3681

Indianapolis, IN (317) 247-9125

St. Louis, MO (314) 487-8925

Clearfield, PA (814) 765-8500

Atlantic & Southern Equipment

www.atlanticandsouthern.com

Birmingham, AL (205) 951-6656

Theodore, AL (251) 443-5229

Lake City, GA (404) 361-1100

Central/Eastern, TN (888) 951-6656

Columbus Equipment Company

www.columbusequipment.com

Columbus (614) 443-6541

Toledo (419) 872-7101

Cincinnati (513) 771-3922

Richfield (330) 659-6681

Cadiz (740) 942-8871

Dayton (937) 879-3154

Massillon (330) 833-2420

Zanesville (740) 455-4036

Painesville (440) 352-0452

Piketon (740) 289-3757

General Equipment & Supplies

www.genequip.com

Shakopee, MN (952) 224-1500

Minot, ND (701) 852-0479

Fargo, ND (800) 437-2924

Bismarck, ND (701) 223-9700

Williston, ND (701) 572-0570

West Palm Beach, FL (561) 683-1231

Link-Belt Construction Equipment Mid-Atlantic

www.link-beltmidatlantic.com

Ashland, VA (800) 552-3837

Chesapeake, VA (800) 342-3248

Frederick, MD (833) 546-5235

NessCampbell Crane + Rigging

www.nesscampbell.com

Caldwell, ID (208) 366-9727

Portland, OR (503) 486-4150

Bothell, WA (206) 590-3420

Nixon-Egli Equipment Co.

www.nixonegli.com

Ontario, CA (909) 930-1822

Tracy, CA (209) 830-8600

Rexco Equipment Inc.

www.rexcoequipment.com

Burlington, IA (319) 419-6050

Cedar Rapids, IA (319) 393-2820

Davenport, IA (563) 381-1200

Des Moines, IA (515) 287-4910

Leetsdale, PA (412) 741-1731

Nitro, WV (304) 755-7788

Transport Equipment Sales

www.tes-inc.net

South Kearny, NJ (973) 589-4100

Triad Machinery

www.triadmachinery.com

Portland, OR (503) 254-5100

Eugene, OR (541) 342-7700

Bend/Prineville, OR (541) 447-5293

Seattle/Tacoma, WA (253) 722-5560

Spokane, WA (509) 534-1900

Mt. Vernon, WA (360) 488-3948

Wood’s CRW Corp

www.woodscrw.com

Carlisle, PA (717) 795-0700

Central Square, NY (315) 676-2008

Williston, VT (802) 658-1700

North Oxford, MA (508) 499-1950

The safety organization suggests employers develop a fatigue management plan to help reduce the risks of fatigue-related accidents.

“Employers should make workers aware of the dangers of working while fatigued,” it said. “Don’t overload workers with too much or put unrealistic expectations for the completion of tasks because workers will feel compelled to push themselves too hard to complete them.”

Employers also should monitor workers for signs of fatigue, ensure they’re taking adequate breaks throughout the day and make sure workers drink plenty of fluids.

On hot days dehydration can contribute to fatigue, so employers need to be mindful how shift work, overnight work and extended hours affect employees.

Crane trainer Ron Overton said one major distraction to crane operators is being sedentary for long periods of time. Shifts can stretch from eight to 12 hours, so an operator has a tendency to

cranes with a lifting capacity of more than 30 tons.

“Among the reasons for the exemption request was that the HOS rules create a challenge to find suitable parking when crane drivers go off duty for breaks,” said training organization J.J. Keller, Neenah, Wis.

SC&RA said that the exemption affects approximately 65,000 of the 85,000 trained and certified mobile crane operators in the United States.

The FMCSA published final changes to its HOS regulations and made the rule effective September 2020.

“The changes reflect some of the sentiments of SC&RA both in formal comments submitted last fall, and in a private meeting between SC&RA leadership and Jim Mullen,” then-acting FMCSA administrator said in early 2020.

The new rule allows more flexibility for the 30-minute restbreak rule by requiring a break after eight hours of consecutive driving. It allows the break to be satisfied by a driver using “onduty, not-driving” status, rather than “off-duty” status, according to SC&RA.

The rule allows drivers to divide their required 10 hours off duty into two periods: an 8/2 split or a 7/3 split.

“Neither period would count against the driver’s 14-hour driving window,” the association said.

It modifies the adverse driving conditions exception by extending by two hours the maximum window during which driving is permitted.

The rule lengthens certain shorthaul drivers’ maximum on-duty period from 12 to 14 hours. It also extends the distance limit within which the driver may operate from 100 air mi. to 150 air mi.

SC&RA member specialized transportation and crane and rigging companies find themselves addressing HOS challenges that can affect public safety as well as impact operational efficiency.

relax if he or she is sitting in a particular spot for a long period of time. Stretching, movement of arms and legs and standing up for a while helps, said Overton.

“Some companies say the operator has to get out of the cab, stand on the car body and stretch in order to make the brain work before they can get back into the cab,” he said.

He added since there is often downtime between lifts, operators are able to stop and walk around in between picks.

“Because they’re actually sitting in a chair, they can only sit there for so long and then they feel like they have to get moving again,” he said. “It causes the brain to reset and get back to an awareness of everything going on, as opposed to being kind of oblivious to the situation.”

The Specialized Carriers & Rigging Association (SC&RA) fought hard several years ago to convince the Federal Motor Carriers Safety Administration (FMCSA) to exempt crane operators from rest-break rules.

In 2020, the association was successful, and the federal hoursof-service (HOS) exemption for certain mobile crane operators was renewed until 2025.

The 30-minute rest-break exemption applies to operators of

“On average, crane operators spend only one to two hours of onduty time each trip driving a crane to and from a job site,” said the association. “However, operators have multiple periods of unscheduled breaks when they are basically ‘at rest’ or ‘on break.’”

During that time, they’re waiting for the scheduled lift, for the load to be rigged and for the load to arrive on the job site. They’re also waiting on jobsite delays extending the time on site, and then driving the roadways and dealing with traffic delays when returning to the yard.

Plus, mechanical breakdowns can happen, requiring a service technician and downtime waiting on repair, as well as weather delays.

SC&RA said the five-year exemption applies to all qualifying OS/OW motor carriers and drivers operating mobile cranes with a rated lifting capacity of greater than 30 tons.

Bathroom breaks for tower-crane operators are not required on all construction sites, but one major city is considering changing that situation.

Operators in Philadelphia often stay in their crane cabs all day where they eat and use the facilities in the same small space.

The Philadelphia Inquirer reported that the city council is

considering legislation that would require supervisors to give tower-crane operators breaks of at least 30 minutes every four hours. Supervisors also would have to allow operators to leave the crane for restroom breaks at any time.

While allowed, breaks are currently not required, and most operators stay in their crane for the majority of their shifts.

During breaks, supervisors would be allowed to assign another operator to continue working the crane, according to the bill, which was moved out of committee to be considered by the full council.

How the requirements would be enforced is the question, according to the Inquirer.

The local construction industry said requiring operators to climb up and down hundreds of steps multiple times per shift presents its own safety hazards. But Mark Squilla, the councilmember who helped introduce the legislation, said the bill came about from his visits to construction sites.

“I thought, ‘This sounds sort of draconian,’” Squilla said in an interview. “There’s no way they should have to stay up there where they’re eating and going to the bathroom.”

He added that after talking with workers the situation “sounded like something from the industrial days.”

Manny Citron, chief of staff in the Philadelphia Department of Labor, said during the hearing that the bill “will make straightforward and commonsense changes” to the section of the Philadelphia Code that regulates use and inspection of tower and mobile cranes.

“This administration believes that it is in the interest of safety to the operator, their coworkers on the job, and also the public at large that workers operating critical machinery such as tower cranes should have regular access to breaks,” Citron said.

“Additionally, we believe that all employees should have reasonable access to sanitary facilities.”

The Inquirer reported that Vaughan Buckley, chief executive officer of Volumetric Building Cos., said the association is “in full support of anything that enhances worker safety.”

Speaking on behalf of the Building Industry Association of Philadelphia, he said the group objects to the bill’s language requiring, instead of allowing, breaks.

On a 320-ft. tower crane, operators could have to climb as many as 500 steps to go up and another 500 to get down, Buckley said. At minimum, the legislation “would require them to ascend and descend six times on a 10-hour shift,” he said.

This, he continued represents a combined ascent and descent of 1,800 ft. and nearly 3,000 rungs of a ladder.

“The idea that such a requirement is an enhancement to operator safety is really challenged by the facts.”

Requiring operators to ascend and descend more often “exposes them to physical stressors” that could violate national safety protocols, Buckley said.

He added it also could endanger workers forced to leave their cranes in inclement weather. The requirement also “exposes the operators and the owners to a terrible choice,” he said. “They can either follow the law, or they can enhance operator safety. In some cases, it will not be possible to do both.”

Meantime, Councilman Squilla will continue his conversations with the building industry. He said if having workers go up and down several times becomes a problem, the city can revisit the requirements.

“I think we have an opportunity to help crane operators,” he said. CQ

Link-Belt Cranes has announced its all-new 300ton 300|AT all-terrain crane will debut at ConExpo-Con/AGG ‘23 in Las Vegas (March 14 to 18, 2023).

Following valuable voice of the customer data collection as well as engineering and manufacturing research, Link-Belt Cranes is debuting an entirely new crane platform with the 300|AT.

“We spoke extensively with our customer base and feel like we have delivered. They want a crane that travels down the road efficiently, goes together on a job site quickly, has a strong chart, and is reliable,” said Andrew Soper, product manager telescopic truck and all-terrain cranes.

The 300|AT is a five axle all-terrain crane built with transportability in mind meeting all North American transportation requirements. Its single

engine platform is HVO fuel ready and EPA OnHighway and CARB On-Road compliant.

“This crane represents Link-Belt’s long-term AT investment, which goes back to 2009 with construction of our own formed boom bay and subsequent ATC-3275 introduction,” said Soper.

The 300|AT is well equipped with a seven section 46 to 238 ft. pin and latch greaseless formed boom and optional two-piece 42 to 71 ft. on-board hydraulically offset fly and two 25 ft. lattice extensions. Maximum attachment will achieve a tip height of 369 ft. and an efficient modular counterweight configuration adds to the 300|AT’s versatility.

continued on page 21

The 300 | AT is a five axle all-terrain crane built with transportability in mind meeting all North American transportation requirements.

TMC Cranes LLC of Monroe, Ga., recently took ownership of a new 300-ton Link-Belt 348 Series 2 lattice crawler crane for precast tilt panel business in the southeastern United States.

“Since we took delivery of this 348 four months ago we have moved it 16 times,” said crane operator at TMC Cranes, Matthew DeLoach.

“We have an H5 [348 H5] we moved 41 times last year. We have the crew and experience to break these cranes down very quickly and get them on the road, we can breakdown a 348 with 150 ft. of boom in three hours with no helper crane.”

During a weeklong stretch of the

“Since we took delivery of this 348 four months ago we have moved it 16 times,” said crane operator at TMC Cranes, Matthew DeLoach.

initial four-month period, the 348 Series 2 lifted 38 precast panels for a new 48,765 sq. ft. Main Event bowling-themed entertainment complex in Lexington, Ky. Poured in place precast concrete sections weigh up to 125,000 lbs. and measuring 43 ft. tall by 26 ft. wide are lifted with the 348 Series 2. Structural steel is tied in with smaller mobile cranes and telehandlers.

“We set all the panels for this job in three days. The 348 Series 2 does well with pick and carry, I love the cameras on this crane — there are no blind spots with winching up and down or turning,” said DeLoach.

For more information, visit www.linkbelt.com.

Utility Crane & Equipment, Inc. www.utilityce.com

8800 W Buckeye Road Tolleson, AZ 85353 866-832-4831

Richmond, CA 866-832-4831

Albuquerque, NM 505-342-9378

El Paso, TX 915-852-7201

Tucson, AZ 520-408-9378

Fontana, CA 909-419-8000

Versalift Midwest LLC inquiries@cannonequip.com

51761 Danview Technology Court Shelby Twp., MI 48315 586-991-0054

Coastline Equipment

Crane Division www.coastlinecd.com

325 N. 5th Street, Bldg. A Sacramento, CA 95811 916-440-8090

Santa Ana 714-265-6550

L & M Truck Sales, Inc. www.lmtrucks.com

4001 E. Boone Ave. Spokane, WA 99202 509-535-4175

Stephenson Equipment www.stephensonequipment.com

Hydraulic Machinery

consteqguide@craneworx.com

5024 N 56th Street Tampa, FL 33610 813-621-8002

Harrisburg, PA 800-325-6455

Philadelphia, PA 800-220-4033

Pittsburgh, PA 800-692-7600

Wilkes-Barre, PA 866-667-6756

Albany, NY 518-357-2200

Syracuse, NY 800-368-6455

Long Beach, CA 562-273-7013

Bakersfield, CA 661-399-3600

Oxnard, CA 805-485-2106

Santa Maria, CA 805-922-8329

Las Vegas, NV 702-399-2700

Elko, NV 775-777-7070

Meridian, ID 208-888-3337

Jerome, ID 208-324-2900

McCall, ID 208-634-3903

Nixon-Egli Equipment Co. www.nixonegli.com

2044 South Vineyard Avenue Ontario, CA 91761 909-930-1822

800 East Grantline Road Tracy, CA 95304 209-830-8600

Heaton Erecting, a provider of professional crane, rigging and transportation services to the Atlanta, Ga., construction market, has taken delivery of North America’s first Grove GMK6400-1.

The new flagship six-axle, 450 ton allterrain crane, which was supplied by Manitowoc dealer Ring Power Crane, expands Heaton’s growing fleet of Grove cranes at an opportune moment, with business booming as Atlanta continues to live up to its reputation of being one of the country’s fastest-growing cities.

“A lot of the work we do is building data centers, and the GMK6400-1 will be a great fit with that type of mechanical work,” said Billy Hancock Jr., vice president at Heaton Erecting.

“We’ll be installing 72 cooling units on the roof of one data center soon, as well as providing a hook for pipes, lights, and other components. This crane will also give us the ability to assist in the assembly and disassembly of tower cranes across Atlanta.”

The crane boasts a maximum tip height of 448 ft. (136.6 m) from within a smaller overall footprint — at 57.5 ft. (17.5 m) in length, 9.8 ft. (3 m) minimum width and a boom overhang of 5.9 ft. (1.8 m). This makes it an ideal fit for bridge construction, wind farm work, and other energy and infrastructure applications, according to the manufacturer.

Heaton ordered the crane with the optional, self-rigging MegaWingLift attachment, which can increase lift capacity on the 197 ft. (60 m) five-section main boom by up to 70 percent — from 84,000 lb. to 141,000 lb. at 40 ft. (11 m) working radius, for example.

The MegaWingLift attachment also will boost the lift capacity of the 82 to 259.2 ft. (25 to 79 m) luffing jib by up to 400 percent, positioning Heaton to take on jobs that would usually require a much larger crane.

And, as the successor to the GMK6400, the new model makes such tasks even easier through the addition of

Manitowoc’s Crane Control System (CCS).

“With the MegaWingLift, the luffing jib and the combinations that we’ll be using the most, the GMK 6400-1 will give us a huge advantage,” Hancock said. “Just look at how great its load chart is, even compared with seven-axle cranes.

“Another reason why it’s such a good fit for us is the Crane Control System. We have a large GMK fleet, so our operators and mechanics are very knowledgeable in using CCS for optimum results. So, whenever manpower is low, we can reposition operators and they’re immediately comfortable with it. We’re also expecting to reduce our assembly time even further so that we’re quickly in and out of the job site.”

One tool to enable this desired speedy setup is the MAXbase variable outrigger positioning system, which enables outriggers to be extended in a variety of symmetric or asymmetric lengths when obstacles prevent their full extension.

continued on page 20

Hurricane Ian struck Florida in late September. One of its enduring images was the collapsed Sanibel Causeway, which links Sanibel Island to Punta Rassa near Fort Myers on the mainland.

Just a few broken sections of roadway remained, breaking the surface of San Carlos Bay. Without the 3-mi. causeway, the island and its residents were cut off from access to relief supplies.

Just hours after Ian made landfall, ALL Crane Rental of Florida, a member of the ALL Family of Companies, was trucking cranes from Tampa to aid in relief efforts.

Ian made landfall Sept. 28. ALL Crane received the call Sept. 30 and had the cranes delivered later that same day.

“After we received the call on the 30th, it took most of the day to put a plan in place,” said Dennis Davis, sales representative of ALL Crane Rental of Florida.

“Precisely where the crane would be going, where we would be staging the equipment, where we’d be setting up the barge system. Given the debris and storm damage, it took some time to determine an acceptable location.”

The convoy of trucks and trailers carrying the cranes received a Highway Patrol escort. Normally, it’s a three-hour drive from Tampa to Fort Myers, but delivery took twice as long due to delays related to hurricane damage, even with the escort.

“We arrived in Fort Myers that night and immediately began setting up the cranes,” said Davis.

First, a 120-ton Liebherr LTM 1100-4.2 all-terrain crane helped to assemble a temporary barge system. In the absence of the causeway, the barge would be used to carry rescue vehicles, other emergency equipment, and supplies to the island. Next, a 265-ton Liebherr LTM 1220-5.2 was erected to help load the barge.

ALL Crane also supplied a Terex RT 555, a 55-ton rough terrain crane, in the early days to provide assistance with moving material. The barge was then carried by tugboat to Sanibel Island. (A separate drive-off dock had been erected on the island’s shore to receive and dispatch the deliveries.)

Construction of the temporary barge was completed Oct. 1, and relief work began immediately following. The ALL team remained at the site for two weeks.

But this obviously is a story about more than delivering

cranes to a hurricane-ravaged part of the state. It’s about the resilience of that state and its people.

“One of our operators arrived at the site and told me, ‘You can see all the pictures in the world, but you can’t even fathom the devastation until you see it with your own eyes,’” said Cody Johnson, general manager of ALL Crane Rental of Florida.

“A resident pointed to an 18-foot-tall building and said he saw a storm surge go right over it,” said Davis. “I saw a 400,000pound shrimp boat that had been thrown on top of an SUV. It’s hard to imagine the type of force required to send something that heavy that far inland. What these residents have lost is unfathomable.”

“Our guys went willingly into the unknown,” said Johnson. “It says a lot about their character.”

ALL Crane dispatched three operators to the cleanup zone — one to run the crane, the other two to act as riggers. The team worked 18-hour shifts for two weeks straight with no off days. An encampment of mobile trailers was set up near the work site — bunkhouses, portable restrooms and a food trailer. Visiting tradesman slept on cots among strangers, now united by a common mission.

For more information, visit www.allcrane.com.

Just hours after Ian made landfall, ALL Crane Rental of Florida, a member of the ALL Family of Companies, was trucking cranes from Tampa to aid in relief efforts.

ALL supplied cranes to assemble and load a temporary barge system. In the absence of the causeway, the barge would be used to carry rescue vehicles, other emergency equipment and supplies to the island.

ALL supplied cranes to assemble and load a temporary barge system. In the absence of the causeway, the barge would be used to carry rescue vehicles, other emergency equipment and supplies to the island.

`ê~åÉëI=`êÉïë=cêçã=^ii=^áÇ=áå=eìêêáÅ~åÉ=f~å=aáë~ëíÉê

Combining National Crane's largest capacity boom truck, the NBT60XL, with LineWise's TLL-2000-Series 3 Triple Line Lifter, capable of handling 230kV power lines, significantly expands the work scope of electric utility contractors.

The Triple Line Lifter 2000 Series 3 is an insulated crane attachment used to support up to three energized lines. Constructed of high-strength steel, the maximum capacity for the TLL-2000 is 2,000 lbs. per phase, or 6,000 lbs. overall.

The 60-ton National Crane boom truck and attachment allow utility contractors to perform repairs or maintenance to live transmission wires without disrupting power, thus avoiding substantial downtime and lost productivity to end energy users.

NBT60XL's agile roading and impressive load charts allow it to seamlessly control the attachment from ground level installation to maximum height. The TLL-2000 unit can hydraulically articulate from a horizontal to a vertical configuration, and the spacing between insulators can be adjusted from 12 to 24 ft. to capture the outer conductors with a convenient handheld radio remote control.

“National Crane and LineWise are superior leaders in their fields, and recent validation testing with the TLL-2000 triple line lifter and our 60-ton boom truck showcased the duo’s capabilities. We look forward to seeing the products at work with our end customers,” said Mike Heinrich, vice president of sales for National Crane.

A specifically designed boom tip adapter, hydraulic power unit (HPU), and transportation skid are standard with every TLL-2000.

The separate ground-level hydraulic power unit powers the TLL-2000. Insulated hoses run from the power unit to the line lifter. The TLL can be powered by the boom truck’s hydraulics if preferred. With

either option, the end-user achieves more reliable, responsive control, the manufacturer said.

The transport skid, with dedicated slots for the triple line lifter, wire holders, insulators and pins, fits compactly on a flatbed or low-boy trailer. Unique to the National Crane NBT60XL, the attachment can be installed directly from ground level in less than one hour without needing supplemental lifting equipment, saving additional costs and time.

The TLL-2000 and TLL-1300 can be ordered in the United States and Canada through LineWise or their distribution network. To maximize the utilization of the crane and attachment, National Crane application engineers assist each customer in developing boom truck design options and configurations. Once delivered,

LineWise

service managers provide onsite training.

Twenty National Crane model variations are compatible with Triple Line Lifter attachments. The total utility offer from National Crane also includes personnel platforms, radio remote controls for crane functions, and boom-mounted hose reels. Additionally, through Manitowoc Lift Solutions, customers can request factory-fit boom-mounted augers, pole grabs, or any other custom-application needs. (When using the Triple Line Lifter product on a National Crane, ensure all work is performed in accordance with National Crane and LineWise operational procedures and OSHA regulations regarding work on electric utilities.)

For more information, visit www.manitowoc.com.

field The National Crane NBT60XL matched with the LineWise TLL-2000 Series 3 Triple Line Lifter expands the scope of work for electric utility contractors.The Specialized Carriers & Rigging Association’s 2023 Specialized Transportation Symposium will be held Feb. 28 to March 2, at the Rosen Centre Hotel, in Orlando, Fla.

The annual event for the specialized transportation industry, STS 2023 will bring 500-plus heavy haul professionals across the OS/OW spectrum and offer a wealth of opportunities to learn from respected experts sharing the latest ideas, products and solutions.

Larry Minor, associate administrator for Policy, Federal Motor Carrier Safety Administration, will be one of the featured speakers. Minor will address several areas of interest to SC&RA members including mandating transponders; exemptions to electronic logging devices for equipment made prior to 2000; and the CSA and DataQ programs.

Always high on the list of attendee benefits at STS is the chance to network with top operations managers, safety directors, safety managers, pilot car professionals, permitting officials and law enforcement, as well as one-on-one access to state and federal officials from MAASTO (Mid America Association of State Transportation Officials), NASTO (Northeast Association of State Transportation Officials), SASHTO (Southern Association of State Highway and Transportation Officials) and WASHTO (Western Association of State Highway and Transportation Officials). Attendees may make appointments with their respective state DOT officials for a one-on-one session.

STS also exposes attendees to numerous opportunities designed

continued from page 17

The system works in conjunction with Boom Configurator mode to achieve longer working radii and higher main boom capacities in less-than-ideal environments.

to give them the insight needed to position their companies for what’s ahead in safety, permitting and overall best practices. Moreover, the event serves as a meeting place for SC&RA’s Pilot Car, Transportation Safety, Education, and Training, and Permit Policy Committees.

In addition to an assortment of educational sessions (featuring 20-plus speakers), attendees will enjoy different networking events, including two evening receptions and an exhibit center featuring 55 exhibitors.

The educational sessions at a glance include: 2022 SC&RA Job of the Year Winners; Let’s Talk — An Industry Conversation; Recruiting and Retaining the Specialized Transportation Workforce; Challenges in Availability of Law Enforcement Escorts; The LifeAltering Power of Grit; Changing Dynamics of Permitted Routes; What You Need to Know About Insurance; and a live roadside inspection demonstration.

“From engaging key state officials in person to productive conversations about workforce retention to the modern evolution of permitting and what it means to the industry both today and tomorrow, this year’s event will offer a variety of well-considered options designed to help people transform their specialized transportation business’ short-term challenges and build the connections and strategies they need for long-term success,” said Chris Smith, SC&RA vice president, Transportation.

For more information, visit scranet.org/symposium2023.

Easy Rider

Heaton’s mobile crane fleet includes GMK5250L, GMK5240, and GMK5150L allterrains as well as TMS9000E and TMS800 truck cranes and a National Crane NBT45 boom truck.

“Over the years, we’ve transitioned to become more of a taxi fleet relying on our all-terrain cranes, and now that every job seems to require more and more capacity it’s always best to have the largest-possible roadable crane,” Hancock added.

“We can legally drive this with the boom trailing behind in a three-axle dolly, but without the need for another crane assisting assembly on the job site.”

The crane is a smooth drive in transport mode, featuring a 577 hp (430 kW) Tier IV Final/Stage V Mercedes-Benz OM473LA engine, 12speed ZF transmission and MEGATRAK suspension with automatic leveling system. At the job site, the MegaDrive 12x8x12 hybrid driveline, with axles 4 and 5 being driven hydrostatically, assumes control to optimize the ease of precise positioning.

The delivery of the GMK6400-1 was timed with on-site training provided by Manitowoc engineers to Heaton

Erecting and Ring Power. Ring Power started its relationship with Heaton in 2009 and the two companies have since forged a close relationship.

“We are very excited about the impact the new GroveGMK6400-1 will make in our territory,” said Andrew Kurz, vice president of sales – utility, crane and truck divisions at Ring Power. “Our team is extremely fortunate and proud to partner with Heaton and Manitowoc to bring this impressive crane to our market.”

Hancock echoed Ring Power’s sentiment.

“Being able to build such strong relationships with our partners and customers is what keeps us in our unique position after 56 years in the industry,” Hancock concluded. “I’ve always been very impressed with Ring Power, especially their support on the service side.

“They recently sold us our GMK5250L, which we bought to take some of the workload off our GMK5240. It didn’t though — it just brought in more work, which was great. So, we’re extremely excited to see what our newest Grove has to offer.”

The GMK6400-1 is available for order worldwide.

For more information, visit www.manitowoc.com.

“Our team is extremely fortunate and proud to partner with Heaton and Manitowoc to bring this impressive crane to our market.”

Andrew Kurz

Ring Power Crane

Bechtel, a leading engineering, construction and project management company, awarded Manitowoc as one of its top suppliers at the company’s 2022 Global Supplier Awards.

The annual event recognizes business partners that have supported Bechtel’s projects across the globe.

“This award recognizes the outstanding contributions of our dedicated employees in the U.S. and around the world,” said Aaron Ravenscroft, Manitowoc president and CEO.

“Manitowoc has established itself as a global leader of cranes and lifting solutions, in part, due to the productive and enduring partnerships it has with companies such as Bechtel. We look forward to continuing to work closely with Bechtel in the future.”

Manitowoc was selected for the award based on its overall performance, ability to deliver quality services, and meeting or exceeding expectations in aspects of safety, performance, technical expertise and environmental compliance.

“Strong supplier relationships are essential to our work and the resilience of our supply chain. At Bechtel, we are proud to partner with companies that share our values and our mission,” said Tarek Amine, Bechtel chief supply chain officer.

“Each recipient of a Bechtel Global Supplier Award is a business that has provided outstanding materials and service to our projects around the world and is critical to our ability to innovate and deliver for our customers.”

For more information, visit www.manitowoc.com.

continued from page 12

Maximum counterweight is 162,000 lbs. with four overflow truckloads, and for improved mobility and efficiency for a variety of jobsite scenarios the 300|AT can be set up with two overflow loads and 74,000 lbs. of counterweight.

Another improvement to the 300|AT’s mobility is the option of transporting the 300|AT with its upper 8,000 lbs. counterweight tray and still stay below 160,000 lbs. gross vehicle weight [23,000 lbs. per axle].

The 8 ft. heavy lift fly provides robust capacities and line separation for two load line operation in applications like precast wall panels. Time tested and proven features such as greaseless sheaves and Teflon wear pads cut maintenance and service costs. Additional standard boom features include wireless wind speed indicator, single-hand operation rope guard, and three work lights on the boom base section.

The 300|AT also will feature SmartFly. Link-Belt’s simple, intuitive SmartFly system ensures proper fly erection and stowage sequence while minimizing work at height. Link-Belt fly erection procedures have been embraced in the market on most all of Link-Belt’s telescopic product line for their ease of assembly and one person operation, according to the manufacturer.

A single 554 hp Cummins X15 diesel engine with ZF Traxon automated manual transmission delivers best-in-class power on the 300|AT. The transmission features improved shifting performance and offers integrated intarder braking with paddle shift controls for easy stop-and-go at highway speeds. The 300|AT also features an innovative new power transmission system for efficiently powering upper hydraulic functions. It offers a 24 volt electrical system with an optimized, modern CANBUS communications.

Customers will recognize the purpose-built two-person carrier cab from the 175|AT on the new 300|AT. The interior features amenities such as automatic climate control, blue tooth radio, cell phone charging and LED lighting. An air ride seat with lumbar support provides optimum comfort while driving.

The operator’s cab is a legacy success story, tailored for all-terrain operations. Pulse 2.0 with its 10 in. touch display is at the heart of this crane with features and controls that are intuitive, adaptable and in easy arm’s reach. The view from the seat is unimpeded in any kind of weather with large sweeping wipers in the front and top, and strategically-placed vents for quick defrost.

Another new feature to Link-Belt’s all-terrain lineup is the improved flexibility of V-CALC, an infinitely variable outrigger positioning that allows for setup in tight jobsite conditions where outriggers require being unevenly extended (0, 40, 70 and 100 percent extension). All capacities are printed in crane rating manual and automatic swing function kick-out works to maintain forward and backward stability.

Standard carrier features that operators are accustomed to include: four points of access to the flat carrier deck, a comprehensive camera “Site Vision” package, and the premiere lighting package on the market for nighttime operations.

Other standout features of the 300|AT include:

• Wireless rigging remote (carrier function, upper function, fly erection)

• Tire pressure and temperature monitoring system

• SmartStack counterweight detection system

• Tie offs at all dedicated anchor points for multiple work positions

• Flat carrier deck

For more information, visit www.linkbelt.com.

Courtesy of Historical Construction Equipment Association

Working to preserve the history of the construction equipment that shaped our world . . .

The Historical Construction Equipment Association (HCEA) is a 501(c)3 non-profit organization dedicated to preserving for public education the history of the construction, dredging and surface mining equipment industries.

Altaequipment.com

18405 115th Avenue Orland Park, IL 60467 877-399-6430

420 Nolen Drive South Elgin, IL 60177 877-399-6430

2500 Westward Drive Spring Grove, IL 60081 815-581-1479

613 E Stevenson Road Ottawa, IL 61350 815-587-7610

1035 Wylie Drive Bloomington, IL 61705 888-693-2271

480 Blaine Street Gary, IN 46406 219-240-0268

empirecrane.com

7021 Performance Drive N. Syracuse, NY 13212 800-342-7575

9 Finderne Avenue, Ste 7 Bridgewater, NJ 08807 908-203-0400

12 Mear Road Holbrook, MA 02343 508-868-7734

coastlinecd.com

325 N. 5th Street, Bldg. A Sacramento, CA 95811 916-440-8090

Santa Ana, CA 714-265-6550

Las Vegas, NV 702-399-2700

Meridian, ID 208-888-3337

smequipment.com

14925 South Main St. Houston, TX 77035 713-721-7070

Dallas, TX 214-391-4000

Corpus Christi, TX 361-289-2782

Tulsa, OK 918-224-2000

exactcrane.com

Serving Ohio, Michigan, W. Pennsylvania, Kentucky

28985 Ambina Drive Solon, OH 44139 440-349-1999

Piscataway, NJ 732-752-3600

South Jersey Deptford, NJ 856-227-6400

Long Island Medford, NY 631-207-2900

Mid-Hudson Valley Marlboro, NY 845-236-3000

New York City Bronx, NY 718-822-1180

Corporate Headquarters Harrisburg, PA Harrisburg, PA 800-325-6455

Pittsburgh, PA McDonald, PA 800-692-7600

Philadelphia, PA Prospect, PA 800-220-4033

Wilkes-Barre, PA Pittston, PA 866-667-6756

ALT Sales Corp. Richfield, OH 330-659-2100

Dawes Rigging & Crane Rental Elk Mound, WI 800-943-2277

Kaukauna, WI 800-236-8630