Since 1989 Since 1989 Since 1989 Nov-Dec 2022, Vol 33 No.6 Nov-Dec 2022, Vol 33 No.6 The use of adhesives Perforated metal in design The Abidjan Metro Project Accidents in construction sites The Lesotho Highlands Water Project

Newark, NJ 07105 U.S.A. / Tel: +01-973-465-5700 LubeXpert@lubriplate.com / www.lubriplate.com ECID TRADING INC. info@ecidtrading.com / www.ecidtrading.com Distributed By: LUBRIPLATE LTR-2 RED GREASE This rugged, extreme pressure lubricant can withstand higher operating temperatures than traditional lithium greases as well as most lithium complex greases. LUBRIPLATE LTR-2 is tacky, adhesive and very water resistant. The film strength and shear stability of this product is exceptional resulting in wear reduction and long lubricant life. Red in color. LITHIUM COMPLEX Provides Excellent Anti-Wear & Extreme Pressure Protection. Formulation for Heavy-Duty, High-Temperature Applications NLGI NO. 2 GRADE Super Multi-Purpose, Recommended For a Wide Range of Applications ® THE HEAVY-DUTY, TACKY, RED GREASE WITH... THE POWER TO PROTECT! ISO 460 BASE OIL

DEPUTY MANAGING EDITOR Francis Makari

EDITOR - in - CHIEF Dennis Ayemba

COUNTRY EDITORS

Uganda - Betty Nabakooza

Nigeria - Boladale Ademiju

South Africa - Jimmy Swira

WRITERS

WRITERS, Pascal Musungu, Anita Anyango, Patrick Mulyungi

WEB & GRAPHIC DESIGN

Gerald Oswald

Sales and Marketing Manager Faith Mburu

ADVERTISING

Kenya: William Mutama, Lilian Khavosa, Joyce Ndamaiyu, Wendy Kinya

Current Issue

In this issue we take a look at the Lesotho Highlands Water Project (LHWP) the largest bi-national infrastructure project beween Lesotho and South Africa.

South Africa: Thuli Nkosi, Winnie Sentabire, Angeline Ntobeng,

South Africa: Rachel Molapo, Winnie Sentabire, Angeline Ntobeng, Shephard Mthethwa, Jacqui Nyangabyaki

Uganda: Nobert Turiyo, Selina Salumah Namuli

Botswana: Dickson Manyudza, Gerald Mazikana

Ethiopia: Haimanot Tesfaye, Ruth Girma

Tanzania: Tom Kiage

Malawi: Anderson Fumulani

Ghana: Samuel Hinneh, Caleb Donne Hadjah

Zambia: Susan Kandeke

Zimbabwe: Chiedza Chimombe

Rwanda: Collison Lore

Nigeria: Seni Bello

China:Weng Jie

The editor accepts letters and manuscripts for publication from readers all over the world. Include your name and address as a sign of good faith although you may request your name to be withheld from publication. We reserve the right to edit any material submitted .

Send your letters to: info@constructionreviewonline.com

Construction Review is published eleven times a year and is circulated to members of relevant associations, governmental bodies and other personnel in the building and construction industry as well as suppliers of equipment, materials and services in Africa, the Middle and Far East. The editor welcomes articles and photographs for consideration. Material may not be reproduced without prior permission from the publisher. The publisher does not accept responsibility for the accuracy or authenticity of advertisements or contributions contained in the journal. Views expressed by contributors are not necessarily those of the publisher.

© All rights reserved.

C ov ER ST o R y: The Lesotho Highlands Water Project 6

Abidjan Metro project Côte d’Ivoire 10

Bagamoyo Port Project 12

Construction joints 14

Fabric and Container Shelters 17 Cement Render 18

Perforated Metal Exteriors in buildings 20

Noise pollution in construction 22

Application of satellite imagery in construction 24

Nirmal Fabricators - customer experience 26

Tackling accidents in construction projects 32 Adhesives in construction 34

Published by Group Africa Publishing Ltd

Head Office and for all enquiries: P.O. Box 10109 Nairobi 00100 Kenya, Tel: +254 722525326 +254-208000307

Email: info@groupafricapublishing. com

Uganda Agent

Projects Unusual Uganda Ltd. Jemba Plaza, Luwum St. Kampala, Uganda Tel: +256 776 883181 bettykatongole@yahoo.com

South Africa Agent

Mining and Construction News Network

14 Ballyclare Drive, Bryanston, Sandton +27 (0)011 875 4328, info@mcnnetwork.co.za

Ethiopia Agent Haymi Advertising Services

22 Mazoria, Genet Bldg 4th Flr P.O. Box 1316 - 1110 Addis Ababa

Tel: +251 118 955 855, Cell: +251 930 099 152

2 CR | May/June 2022 www.constructionreviewonline.com CON

MANAGING EDITOR Robert Barnes

Arnold Oduor Sales and Marketing Manager Ken Okore

ADVERTISING Kenya: William Mutama, Lilian Khavosa, Fred Okoth

REGULARS Corporate News 4 Events 5

Nov-Dec 2022, Vol 33 No.6 Nov-Dec 2022, Vol 33 No.6

Abidjan Metro

Abidjan Metro, also known as Metro d’Abidjan, is a 37km-long elevated rapid transit network being developed by French companies in coordination with the Ivory Coast Government

The use of perforated metal in construction

Perforated metal can be used on the exterior or interior of a building and can add an interesting visual element and improve acoustics. As perforated metal is becoming increasingly popular in modern design schemes, here are different ways to use it in a building design

Email: ethiopia@groupafricapublishing.com

Ghana Agent

Image Consortium

1st Floor, The Ecobank Building, Tesano. Tel: 233(0)30 223 2728 I 233(0)274807127 I +233(0)206299159 Fax: 233(0)24 882 8286 Email: ghana@groupafricapublishing.com, Calebhadjah@gmail.com

Kenya Agent

Northwest Ventures Ltd P.O. Box 16414 - 00100 G.P.O

Accidents on construction

Construction companies know that construction accidents are a common occurrence. Unfortunately, construction workers are the most likely employees to get injured while at work. Because of the high risk of injury, construction workers must be even more vigilant.

Nairobi, Kenya

Tel: +254 20 2679808

Email: kenya@constructionreviewonline.com, info@northwest.or.ke

Nigeria Agent

Rahma Associates B23/24, Aishetu Emoewa Plaza, 196, Iju Water Works Road, Ifako Ijaye Lga,Agege, Lagos. Tel: 234-1-7347860

Email: nigeria@constructionreviewonline.com

Rwanda Agent Kolline & Hemed Inc., B.P. 3328,

Kigali, Rwanda

E-mail: rwanda@constructionreviewonline.com

Zambia Agent Dayflex Limited, Dedan Kimathi Road, Lusaka, Zambia. Email: zambia@constructionreviewonline.com

Tanzania Agent: Group Africa Publishing Ltd tz@constructionreviewonline.com Dar-es-salaam

TENT Nov/Dec 2022 Volume 33 No.6

32

10

20

Mpact Recycling opens new operation in KwaZulu-Natal

10 NEO Load Haul Dumber (LHD)

10 NEO Load Haul Dumber (LHD)

The LF-10 NEO has a z-link design with the maximum tipping height in its class, of 2.5 m, which is perfect for truck loading all 30 ton trucks in the market. “The high break out forces, efficient boom and bucket motion times as well as the strong power to weight ratio makes the LF-10 NEO one of the best in class” says Ingo Rath, Product Line Manager Loaders at GHH in Germany. With a length of 9,6 m and width of 2,6 m the LF-10 NEO is very compact and versatile for excellent maneuverability in a mid-seam underground mining environment.

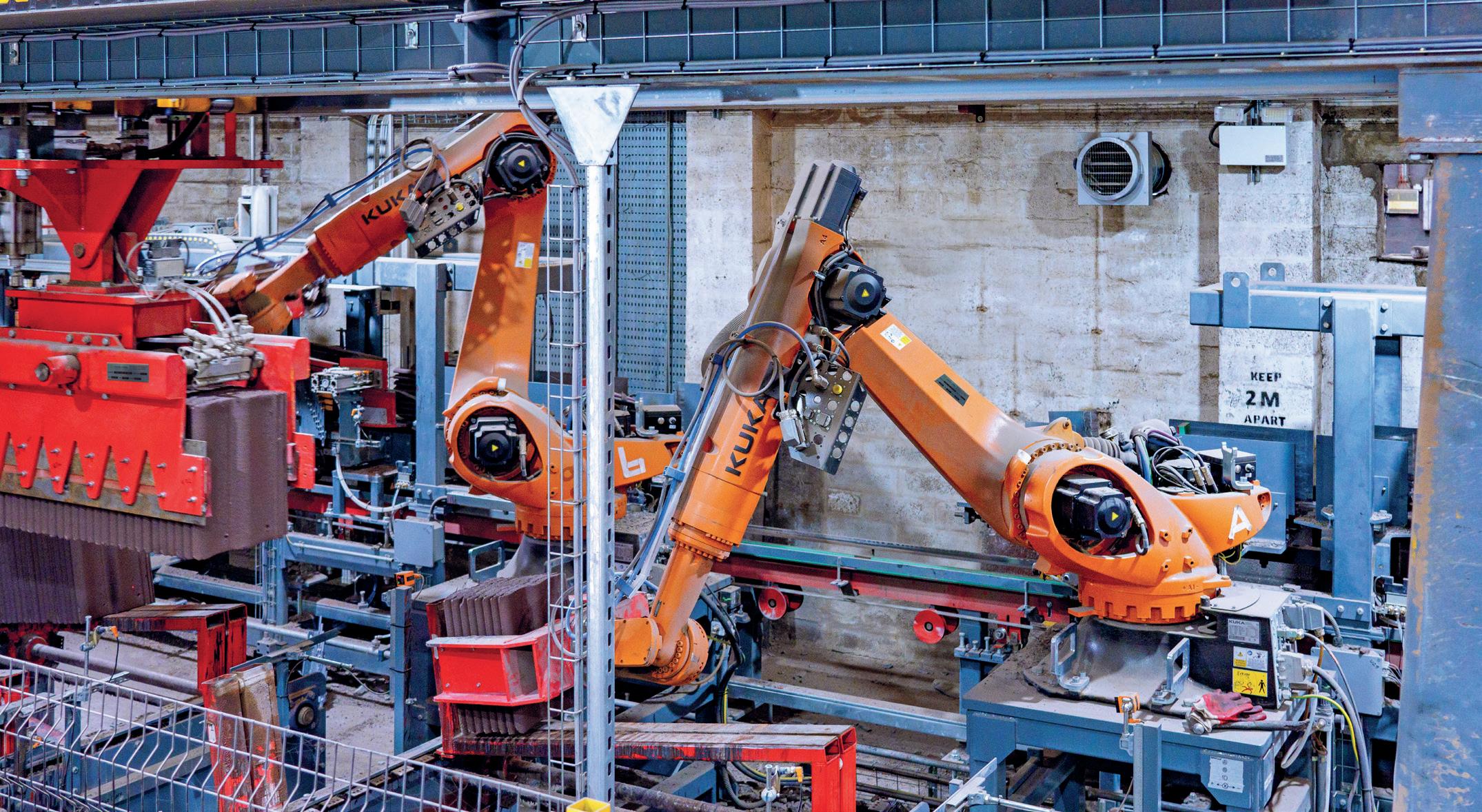

South Africa’s leading recycler, Mpact Recycling, has opened its recycling operation in Bridge City, KwaMashu in KwaZulu-Natal. The R150 million investment into this world-class infrastructure in the region will succeed in enabling the Mpact Group to service the Northern Coast corridor, and in turn, to uplift its surroundings communities.

The new operation allows for increased collection, sorting and baling of major waste streams such as paper, plastic, cardboard and the central collection of glass. Ultimately, this keeps perfectly recyclable products from going to landfill and into the recycling stream quicker.

The new operation boasts improved operational efficiency, increased volume throughput and a reduction on the reliance on grid-based energy supply. An initial solar installation of 130kW provides the facility with enough power to enable “grid-free” daytime operations. Over time, Mpact will consider expanding the solar installation and tying into the local supply grid for either resale or wheeling to its other KwaZulu-Natal operations.

The main warehouse, including a separate administration and operations centre, allowed Mpact Recycling to relocate its large sorting plant as well as two baling machines all under roof from its previous location. The improved design and process flow will reduce offloading and loading times for suppliers and collection vehicles, thereby improving capacity for collections with the existing fleet.

The standard bucket holds 4,6 m3 or 10 tons at 2500 mm width, making loading and unloading easier and more cost-effective. “GHH installs the water-cooled Mercedes OM936 diesel engine with 240 kW which is the best in the 10 ton loader size class”, says Rath. “The large fuel tank also allows for full shift operation with no worry for refuelling mid shift and losing valuable production time”. Exhaust gas emissions complies with EPA Tier 3 or EU Stage IIIA on the standard machine, while EU Stage V is also optionally available. The low fuel consumption, ease of maintainability and robust design as well as durability and reliability of the product all add to the low operating costs.

The LF-10 NEO has a great operators’ compartment which boasts excellent ergonomics, which is evident through the way the controls have been laid out and the general arrangement within the cabin.

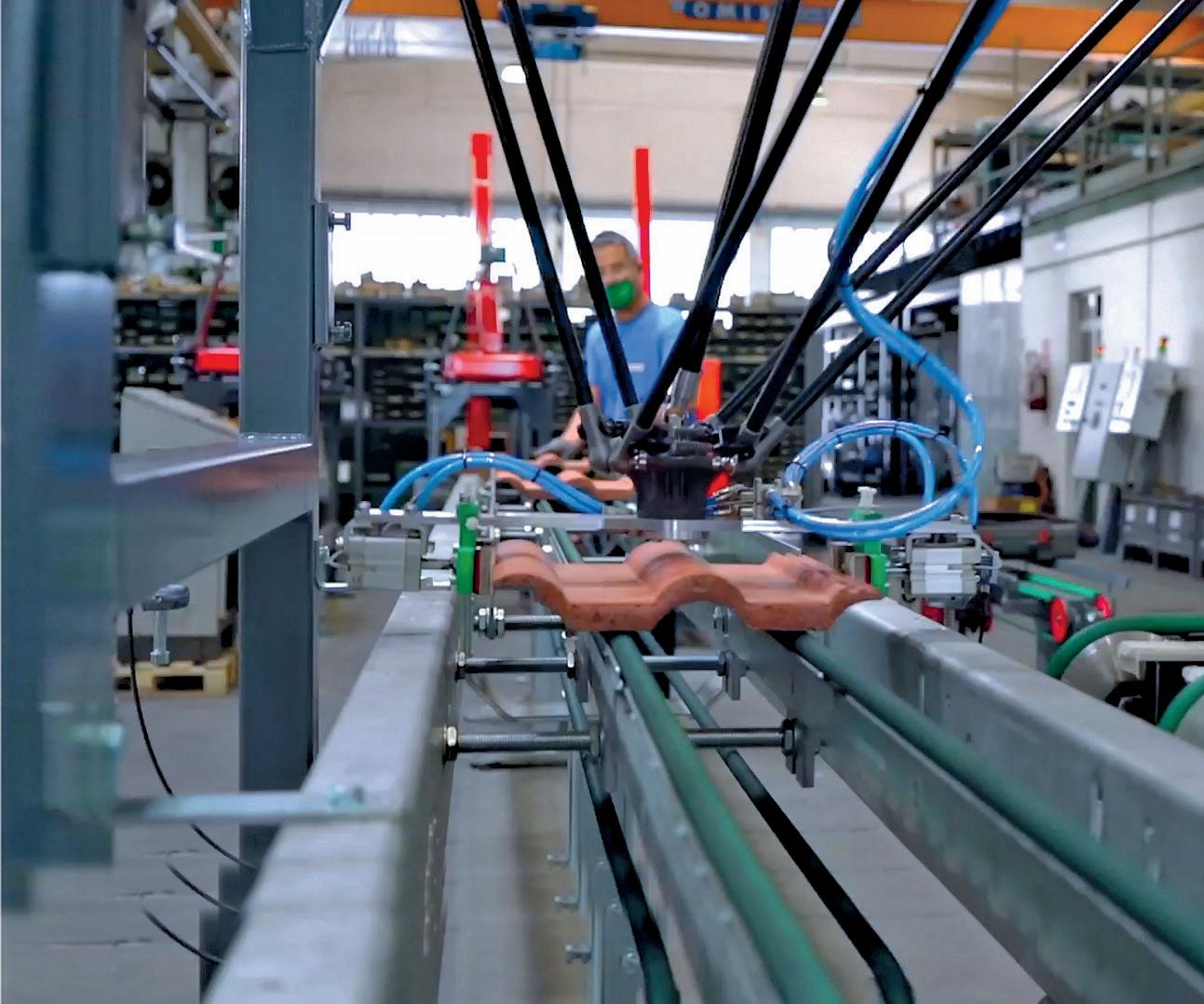

Combilift Boosts Equipment Uptime and Customer Service

Combilift, the largest global manufacturer of multi-directional forklifts and a leading provider of long-load handling solutions, is using Infor Coleman AIdriven parts recommendations, in combination with Infor CloudSuite Industrial, to boost equipment uptime and customer service while increasing employee satisfaction.

Within 60 days of the solution being deployed, Combilift expects a 30% increase in firsttime fixes, a 40% reduction in costs for service jobs, and a 30% increase in revenue per transaction.

Combilift – with global headquarters in Monaghan, Ireland, and North

American headquarters in Greensboro, N.C. – has 60,000 unique trucks in operation to meet its customers’ industry-specific needs. Managing this diverse set of trucks creates servicing complexities and requires expertise to accurately quote the right set of parts to ensure a first-time fix.

The company seized on the opportunity to leverage Infor Coleman AI, an integrated Infor platform technology service, with Infor CloudSuite Industrial, to further improve the customer and employee experience by having the AI system, utilizing three years of historical data, generate the right set of parts for service quotes. With Combilift continuing to grow rapidly, Coleman

AI not only improves the efficiency and accuracy of recommending the right set of parts, it also scales the service quote process, reducing stress on staff and ensuring first-time fixes for customers.

4 CR | November/December 2022 www.constructionreviewonline.com CORPORATE NEWS

The Building Performance Egypt Conference 30 –

GEO WEEK

Feb 13 to 15 2023

31 January 2023 Cairo

The Building Performance Egypt Conference is taking place on 30 – 31 January 2023 in Cairo, to create a platform for the key players in the Energy Efficiency, Sustainability and Retrofitting sectors in Egypt.

Egypt has a great opportunity to improve the efficiency of its energy resource utilization across all segments of economic activities. The objective of this Conference is to take stock of the past/ongoing energy efficiency initiatives and activities and to recommend a set of the principal strategic actions which could be undertaken by the Government of Egypt to promote and sustain energy efficiency improvements.

Governmental organisations were established earlier to be responsible for energy planning and efficient utilisation, information dissemination and capacity building as well as devising the necessary codes and standards.

Kenya

- Architectural Association of Kenya

- Institute of Quantity Surveyors of Kenya

- Institute of Engineers of Kenya

- Association of Consulting Engineers of - Kenya

- Association of Professional Societies of East Africa APSEA)

- Kenya Property developers Association

- Institution of Surveyors of Kenya

Geo Week, February 13-15, 2023 in Denver, is the learning and networking nexus of the geospatial and built worlds. Professionals from a wide variety of industries and disciplines convene to advance digital technologies in these sectors.

It combines 3 previous event brands (in AEC, 3D and Lidar) and important collocated user meetings (ASPRS, USIBD, MAPPS, WGIC and more to be announced).

The 2022 event had 2,121 registrants, and hosted 1,889 verified delegates from 48 nations. Geo Week 2023 will convene 2,500+ attendees from 6 continents. Use code SAVE100 for a $100 discount and/or FREE Expo. www. geo-week.com

Nigeria Build Expo 11- 13 July 2023

Nigeria Build Expo: 7th International Construction , Building Materials and Technologies Expo will take place between 11- 13 July 2023 at Land Mark Center Expo Center in Lagos , Nigeria.

About the rganisers. Elan Expo was founded in 1997 and now manages over 30 market-leading B2B events in up to 8 countries each year. Headquartered in Istanbul, Turkey, it is currently active in Nigeria, Azerbaijan, Kenya, Morocco, Iran, Iraq, Tanzania and Algeria.

Elan Expo employees over 90 people who are passionate about the communities that they serve and skilled at creating the ideal circumstances for relationships to develop, knowledge to be gleaned and deals to be done by the departments of sales, marketing, B2B, visitor promotions, project, finance and advertising.

Uganda society of Architects Botswana

- Institute of Botswana Quantity Surveyors

Ethiopia

- Association of Ethiopian Architects

- Ethiopian Association of Civil Engineers

- Construction Contractors Association of Ethiopia

Association Partners

-Town and County Planners Association of Kenya (TCPAK)

South Africa

- ASAQS - SAICE

- South African Council for the Quantity Surveying Profession

- Khuthaza ( Women for Housing)

- Concrete Manufacturers Association

- Green Building council of SA

- South African Property Owners Association

- Master Builders South Africa

Uganda

Institute of Surveyors of Uganda

Uganda Institute of Professional Engineers (UIPE) &

Zimbabwe

- Zimbabwe Institute of Quantity Surveyors

- Zimbabwe Institute of Engineers

- The Construction Industry Federation of Zimbabwe (Cifoz)

Ghana

- Ghana Institute of Engineers

- Architects Registration Council

- Ghana Institute of Surveyors

- Ghana Green Builders Association

- Ghana Institute of Planners

- Association of Building and Civil Engineering Contractors of Ghana

Namibia

- Institute of Namibian Quantity Surveyors

- Association of Consulting Engineers of Namibia Tanzania

- Tanzania Institute of Quantity Surveyors

- Construction Regulation Board (CRB)

- Tanzania’s Registration Board of Architects and Quantity Surveyors (AQSRB)

Nigeria

- Association of Consulting Engineers Nigeria

- Association of Professional Women

Engineers Of Nigeria

- Council of Registered Builders of Nigeria

- The Nigerian Institute of Architects

- American Association of Petroleum Geologists Africa Region

- Nigeria Society of Engineers

- Nigeria Institute of Architects

- Building and Construction Skilled Artisans Association of Nigeria (BACSAAN)

Zambia

- Zambia Institute of Architects (ZIA)

- Association of Building and Civil Engineering Contractors (ABCEC).

www.constructionreviewonline.com November/December 2022 | CR 5 EVENT NEWS

Lesotho Highlands Water Project (LHWP) Updates,

Southern Africa

6 CR | November/December 2022 www.constructionreviewonline.com COVER STORY

Lesotho Highlands Water Project (LHWP) is the largest bi-national infrastructure project between Lesotho and South Africa. It involves the construction of an intricate network of tunnels and dams to divert water from the mountains of Lesotho to South Africa. It will provide water for South Africa and hydroelectricity for Lesotho.

Lesotho Highlands Water Commission (LHWC), previously known as the Joint Permanent Technical Commission, is a bi-national commission consisting of three delegates from each country. It is responsible for monitoring the project.

Lesotho Highlands Development Authority (LHDA) is responsible for the project’s overall implementation works such as dams, tunnels, power stations and infrastructure on Lesotho’s borders. It reports to LHWC.

Trans-Caledon Tunnel Authority (TCTA) in South Africa is responsible for tunnelling, delivery, integration and flow control of water into the Ash River outfall in South African territory.

The project is being undertaken in phases. Phase one was completed in 2004 and was intended to supply water from Lesotho to South Africa. About 4.8 billion m³ of water had been transferred by 2007. Feasibility studies for phase two began in October 2005 and were completed in May 2008.

Phase 2

The water transfer component of Phase 2 comprises an approximately 165-metre high concrete faced rockfill dam at Polihali, downstream of the confluence of the Khubelu and Senqu (Orange) Rivers, and an approximately 38 kilometre concrete-lined gravity tunnel connecting the Polihali reservoir to the Katse reservoir.

The completion of Phase 2 of LHWP will augment the transfer of water from Lesotho to South Africa, with extra 490 million m3/year from the current 780 million m3/year, to make it 1 260 million m3/year through the Integrated Vaal River System (IVRS).

The IVRS is the biggest system in the country, which comprises 14 dams with catchments in four provinces, namely the Free State, Northern Cape, Mpumalanga and North West. Purpose of the Lesotho Highlands Water Project

Phase 2 has faced numerous delays and is now scheduled for completion in 2028

Background of the Lesotho project

In the 1950s British High Commissioner to Lesotho Sir Evelyn Baring identified the LHWP as the most economical way of supplying water to South Africa. A feasibility study for the project was undertaken by the countries in 1978. A more detailed feasibility study was conducted by the Lahmeyer MacDonald Consortium between 1983 and 1986. The study found the project was economically viable and would allow hydroelectric power generation.

A treaty was signed by Lesotho and South Africa in October 1986 regarding the project design, construction, operation, maintenance and water transfer. South Africa agreed to pay the water transfer costs and Lesotho agreed to finance the hydroelectric power projects.

A detailed engineering and services analysis was undertaken for phase one, which involved phase 1A and phase 1B. Phase 1A required 2,800ha of rangeland and about 1,504ha of arable land and involved about 2,900 households being relocated. Phase 1B required 3,353ha of arable land and 3,434ha of rangeland and involved relocating 500 households.

Phase 1A

Phase 1A included construction of the 185m-high double curvature concrete arch Katse Dam in the central Maluti Mountains and the 72MW Muela hydropower station. The dam has a storage capacity of 1,950 million m³ and a spillway discharge of 6,252m³/s. Phase 1A also involved building a 45km transfer tunnel and a 37km delivery tunnel.

Phase 1B

Phase 1B involved construction of the 145m concrete-faced rock-fill Mohale Dam on the Senqunyane River.

www.constructionreviewonline.com November/December 2022 | CR 7 COVER STORY

8 CR | November/December 2022 www.constructionreviewonline.com Simply contact us to find your right solution! VORTEX HYDRA S.R.L. ITALY t. +39 0532 879411 f. +39 0532 866766 vh.sales@vortexhydra.com Vortex Hydra, your partner for innovating your production line. UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 PLANNING TO UPGRADE YOUR PLANT?

The dam has a storage capacity of 958 million m³ and a spillway discharge of 2,600m³/s.

A 32km interconnecting transfer tunnel between the Katse and Mohale reservoirs was also built. Phase 1B included construction of the 19m-high Matsoku Weir and a 6.4km transfer tunnel. Mohale Dam was inaugurated in 2004.

Other phases

During phase III the Tsoelike Dam will be constructed at the confluence of the Tsoelike and Senqu rivers, about 90km downstream from Mashai Dam. It will have a storage capacity of 2,223 million m³ and a pumping station. During phase IV the Ntoahae Dam and a pumping station will be built about 40km downstream from Tsoelike Dam on the Senqu River.

LHWP will have five dams and about 200km of tunnels and water transfer works constructed between the two countries. The project will transfer about 2,000 million m³ of water from Lesotho to South Africa every year.

Key players

The supervising engineer for construction of the Katse Dam and 45km transfer tunnel during phase 1A was Lesotho Highlands Consultants. The construction contractor was Highlands Water Ventures.

Construction of the Muela hydropower station and tunnelling was supervised by Lahmeyer MacDonald Consortium. Contractors for the tunnelling included Balfour Beatty, LTA, Spie Batignolle, Ed Züblin and Campenon Bernard. Electrical and mechanical work contractors included SDEM, Neyrpic and Deutsche Babcock. Equipment for Muela power station was provided by Kvaener Boving, Norelec and ABB Calor Emag Schaltanlagen.

The construction of Mohale Dam was supervised by Mohale Consultants Group. A joint venture of Concor Engineering, Hochtief and Impregilo (lead contractor) was formed for the project.

The mechanical and electrical works contract was awarded to an ATB joint venture. Lesotho Highlands Tunnel Partnership was the design and consultant supervisor for the transfer tunnel between Katse and Mohale. The contractors were Hochtief, Impregilo and Concor. The design and supervising consultant for Matsoku Weir and tunnel was Matsoku Diversion and Consult 4 partnership. The construction contractor was Matsoku Civil Contractors.

The phase two feasibility study contract was awarded to the C4-SEED joint venture. The venture consisted of companies from both countries: Consult4 of South Africa and Senqu Engineering Environment and Development Consultants of Lesotho.

Finance

The total cost of the four-phase project is expected to be $8bn. Phase 1A was expected to cost $2.5bn and phase 1B was expected to cost $1.5bn. The funds were issued by the World Bank, which also coordinates fund mobilisation from other financiers including the African Development Bank, the European Development Fund, Development Bank of South Africa, European commercial banks and several export credit agencies.

www.constructionreviewonline.com November/December 2022 | CR 9 COVER STORY

Abidjan Metro, 37.5km rapid transit

gineering. The South Korean partners withdrew from the project in October 2017.

Abidjan

Metro, also known as Metro d’Abidjan, is a 37kmlong elevated rapid transit network being developed by French companies in coordination with the Ivory Coast Government to address traffic congestion in the city of Abidjan.

The urban and suburban rail transport system will connect the Anyama and Port-Bouët suburbs of Abidjan.

Abidjan will become the third Af-

rican city with high-capacity urban metro upon commissioning of the system. The Abidjan metro will be able to carry more than 500,000 passengers a day. The project is expected to generate 2,000 jobs.

Ivory Coast initially signed an agreement with a French-South Korean consortium for the construction of the Abidjan metro on a build, operate, and transfer basis. The consortium included Bouygues, Keolis, Hyundai Rotem, and Dongsan En-

The government resumed the development of the metro in November 2017. In December 2019, a technical and financial offer submitted by Société des Transports Abidjanais sur Rail (STAR) consortium was approved by the government through a second addendum, clearing the way for construction works on line one of the metro project.

The consortium includes Alstom, Keolis, Colas Rail and Bouygues Travaux Publics. The construction of the metro is estimated to cost €1.36bn ($1.5bn). Expected to start by the end of 2020, the construction of line one is conditional on land availability and finalisation of the project financing.

Abidjan metro line and route details

The future Line 1 of the Abidjan metro network will be 37km-long and pass through 18 stations, linking seven municipalities in Abi-

10 CR | November/December 2022 www.constructionreviewonline.com

PROJECT

transit network in Abidjan, Côte d’Ivoire

Alstom will provide 20 trainsets of Metropolis trains comprising five cars each for the line. The trains will feature advanced communication-based train control (CBTC) system that will improve the train regularity and safety.

The Metropolis trains can operate in both driver and driverless modes. The design supports customisation and provides improved passenger experience. The lightweight trains with improved power conversion efficiency will feature full electrical braking systems and LED lighting, consuming less energy. Predictive maintenance helps reduce costs related to maintenance and improve the availability of the trains.

The gangways and wide doors will facilitate optimal circulation between the rows of seats, while large windows and glass doors provide outside view. The train will also include spaces to enable easier movement of passengers with reduced mobility.

Passenger-friendly modern technologies include dynamic route maps, video surveillance, lighting solutions, on-board Wi-Fi, video displays, USB ports, and real-time passenger information.

The designed speed of Metropolis is 90km/h, while its operational speed will be 80km/h.

Project financing and benefits

France agreed to provide full funding to the metro project through concessional loans. The construction of the Abidjan metro line 1 will be 100% funded via the French Development Agency and the French Treasury.

The financing needs to be finalised with the French authorities.

djan district.

The overground metro will include the construction of 24 bridges, eight underpasses, a viaduct over the Ebrié lagoon and 34 footbridges for pedestrians. The train will pass through Abobo, Adjame, Plateau, Treichville, Marcory before reaching Port-Bouet.

The route will end with a connection between Port-Bouët and FélixHouphouët-Boigny International Airport to the south of the city. The total duration of the journey from Anyama centre to Aerocity will be 50 minutes.

The metro line one will contain two 1,435m standard gauge railway tracks. It will include electric traction, 21 rail and road bridges, landscaping and architectural systems, and protection from noise pollution. A 22ha railway depot will also be built at the Sagbe triangle.

The line will share the rights-of-way currently used by the Abidjan-Ouagadougou railway line for approximately 32.5km.

A new rail bridge will be constructed in parallel to the Felix Houphouet-Boigny (FHB) bridge, between the municipalities of Plateau and Treichville. The transit system will be connected to road and public transport networks such as SOTRA, STL and Citrans Aqualines.

Rolling stock of Abidjan metro

The project will resolve traffic congestion on trade routes during peak hours. It will also serve as an economical mode of transportation for the people residing in and around the capital.

Key players involved in the project

Bouygues Travaux Publics, a subsidiary of Bouygues Construction, is the head of the consortium and is responsible for the coordination and civil engineering.

Colas Rail will handle the electrification of the metro line and is also responsible for the track and ticketing, audio and video systems.

In addition to the Metropolis trainsets, Alstom will provide depot equipment, system integration, telecommunications and signalling.

Line one will be maintained and operated by Keolis. The Ivorian Society for the Construction of the Abidjan Metro (SICMA) is carrying out the network diversion works in preparation for the construction of the metro project.

www.constructionreviewonline.com November/December 2022 | CR 11 PROJECT

Construction of Bagamoyo Port Project back on

RecentlyPlasduce Mbossa, director general of the Tanzania Ports Authority (TPA), announced that the Bagamoyo port construction, will not have to wait any longer for investors to kick off.

While speaking to the board of directors of the East African Business Council (EABC) at the TPA's headquarters, Mr. Mbossa said investors would join them on the way. He reaffirmed that a number of multinational companies have expressed interest in developing and running the $10 billion Bagamoyo port project.

The Bagamoyo Port project is being implemented in Bagamoyo, Tanzania. It is expected to be one of the largest government infrastructure projects in the country. The Bagamoyo port and its affiliate industrial zone are meant to address congestion at the old port and support Tanzania to become East Africa’s leading shipping and logistics center.

Expected to be the largest port in East Africa, the US $10bn port is set to handle 20 million TEU by 2045; that is 25 times the amount of

cargo Dar es Salaam Port handles. The tri-government venture was initially between Tanzania, China, and Oman also involves the construction of a Special economic zone adjacent to the port.

190 industries including a manure processing industry were to be put up by the government of Oman around the port. When fully developed, the Bagamoyo Special Economic Zone was expected to attract about 700 industries.

Project background

In 2012, the Tanzanian government submitted its letter of approval for the Bagamoyo Special Economic Zone venture to China Merchants Port, agreeing to and accepting the investor's comprehensive project proposal.

By 2014 the project had still not started. It was however projected at the time the mega Bagamoyo port will take about 30 years to construct to reach its full potential at a cost of US$11bn, making it one of the largest in Africa.

The first phase of the new Bagamoyo project was to take three year. It would be able to han-

dle 20 million containers annually. The port would be able to handle twenty times more cargo than the port in the Tanzanian capital Dar es Salaam, the country's largest port. However not much has transpired to date

Construction works on US $10bn Bagamoyo Port project in Tanzania had stalled after China and Tanzania disagreed on terms of infrastructure investment. It is hoped that this mega project will see the light of day this time round after almost a decade.

First forward to 2021, the Bagamoyo Port project was revived. President Samia Suluhu Hassana made the announcement and said the government has begun talks with Chinese investors over the project.

“We have started talks with investors to revive the Bagamoyo Port project with the aim of opening it for the benefit of our nation,” said President Suluhu.

12 CR | November/December 2022 www.constructionreviewonline.com PROJECT

www.constructionreviewonline.com November/December 2022 | CR 13 1KVA - 4500 KVA G ENER AT O R S S A L E S INS TAL L AT ION & M AIN T ENANC E Y O U NEED, ANY TIME, ANYWHERE FULL RANGE: w w w.ryc e .c o. ke ryce@ryc e .c o ke 020 653 1786 +254 733 714 108 / +254 734 800 201 RYCE E A ST AFR I C A LTD KAMPALA ROAD INDUSTRIAL AREA Market leader in Generator sales, installations and back up support in Kenya. An Authorized Distributor for KOHLER (France) POWER GENERATORS over 25 years in the entire region of Kenya. Enterprise Road, Industrial Area, Nairobi - Kenya An ISO 9001:2015 Certified Company STAINLESS STEELS ENGINEERING STEELS CARBON STEELS CAST IRON COPPER ALLOYS LASER CUTTING WATERJET CUTTING CASTINGS GAS BURNERS MILD STEELS TOOL STEELS WEAR RESISTANT STEEL ALUMINIUM ENGINEERING NYLONS BRASS ALUMINIUM STAINLESS SHEETS STAINLESS TUBES MILD STEEL ENG. STEEL (+254) 0207 903903 , 0725 903903 sales ind@kensmetal co ke www kensmetal co ke SEAMLESS PIPES

Expansion joints in construction

An expansion joint is also known as a movement joint, which is an assembly consisting of separation in the wall a flexible material like a bond breaker or sealant. Bond breaker materials may comprise of sprays, liquids, rods, or tapes. They are required for breaking the bond between building sections for ensuring the sections can separate. The material being compressible, it can accommodate the movement of adjacent materials. For closing the joint opening and mitigating moisture from entering the joint, a flexible sealant is applied along with accommodating movement between wall sections. When performing a building envelope survey, all of these factors must be taken into account.

By temperature differentials, stress, and moisture infiltration, adjacent materials in a wall assembly are affected that causes movement between wall sections. Contraction and thermal expansion are the temperature movement of building materials and is very much common in areas that experience seasonal climate changes. When heated or cooled by ambient temperatures, a long masonry wall will contract or expand over its length and height. When heated, the individual masonry units will elongate, and when cooled it will get deformed. The changes in the height and length of the wall will create internal stress within the wall. Cracks will develop if the stress is not relieved. A temporary

change in length is elastic deformation, volume, or shape of a material under stress. Vertical loads like dead and live loads will create stress in building materials. The weight of the building or structure on itself. As they are permanent, the materials which comprise the building are considered to be dead weight. Live loads are rather moving or permanent than being permanent or fixed. For example, live loads are materials, people, office equipment and furniture or shelving which is not bolted down. Other loads that cause building materials to get deformed and deflect in volume, shape, and length are seismic activity, wind, and snow. A good example of this is the diving board. For example, let's just imagine that a person is standing on the edge of the diving board, the board itself is the dead load and the person is the live load. When the person is on the edge of the diving board, you can see the deflection in the board as it dips towards the pool. It gets deformed or bent due to the weight of the person. The deformation will be higher with the weight of the person and vice versa. The diving board will also experience variable deformation as the person walks up and down the board. When the person jumps up and down the deformation will get exaggerated. This will create stress.

By the expansion and contraction of the materials from the increase or decrease in moisture

content, moisture movement is caused. Materials like concrete, masonry block and wood get expanded because of saturated water and get the return to the original state after drying out. Think of these building materials as a dry sponge when they are installed first. Through rain events or leaks, when the materials are saturated they will grow and expand in size like a dry sponge that absorbs water. Like the same ways, when the material decreases in size when it dries out. Stress is created within the material by these variations and any abutting material.

The Importance of Expansion Joints on Concrete Bridge Decks

Expansion joints are vital to the life of a bridge itself and must be correctly installed and maintained in order to function properly. The two major causes of joint failure are improper installation and insufficient maintenance of the joint. Oftentimes, when dirt, dust or other types of debris build-up in and around these joints (caused by traffic and environmental conditions), the joints lose their ability to expand and contract with the structure, rendering them less effective. When this happens, the reduced flexibility will result in cracking or distortion/crushing of the joint material, compromising the entire bridge’s structural integrity.

14 CR | November/December 2022 www.constructionreviewonline.com EXPANSION JOINT

Bridge Deck Expansion Joints MUST:

protect concrete edges from damage caused by vehicle traffic,

act as a seal to prevent foreign objects/debris from entering the joint opening.

allow for expansion and contraction caused by thermal cycles, and allow for the natural creep and shrinkage of concrete.

Important Elements to Consider

cracking will occur. And inversely, when the expansion is restricted, distortion or crushing of the materials can occur. To prevent these types of failures, concrete bridge decks require joints fitted with materials that allow the structure to expand and contract without causing damage to the structural integrity. These are known as expansion joints, and there are many different types.

o compression seals

o strip seals

o reinforced elastomeric joints

o modular elastomeric joints

When using concrete as a building material, there are some very important things to consider. Of course, the strength and weight load of the concrete are important, but another vital component is the affect the environment has on the material. Thermal cycles within the geographical area must be taken into consideration. As seasons and weather change, the structure will expand and contract with the temperature. Sometimes, this is overlooked, and when these structures expand and contract, there can be serious issues with the expansion joint system.

he heating and cooling cycles of concrete bridge decks will cause expansion and contraction, respectively. If the contraction is greater than the tensile strength of the construction materials,

The 2 Types of Expansion Joints

Open joints – allow water and debris to move freely through the joint but are often subject to debris buildup, which can render them ineffective. These types of joints include:

o butt joints

o sliding plane joints

o finger joints

Closed joints - prevent debris and water from penetrating but must be designed specifically for the size and movement properties of the intended joint. These include the following types of joints:

o poured joints

o asphalt plug joints

Each of these joint types has a specific application method and set of parameters which must be followed to ensure the joint’s effectiveness. Proper sizing of the joint, along with an accurate assessment of the anticipated movement of the structure, must be considered when selecting the proper joint type for the intended project. Some other things to consider are substrate preparation, climatic factors, lane closure requirements, manufacturer requirements, physical properties and limitations of the joint material.

Many of the roads and bridges in the US have expansion joints which are structurally deficient. The main causes of failure range from tearing, separation of the seal from the substrate, snowplow damage, concrete deterioration, debris accumulation and improper alignment of deck sections. The majority of these failures can be attributed to improper installation or inadequate maintenance practices.

www.constructionreviewonline.com November/December 2022 | CR 15 EXPANSION JOINT

Benefits of fabric and container shelters in construction sites

Fabric and container shelters are forms of tents that are constructed using steel tubes and covered using fabric or container covers. These shelters are temporary and portable and can be moved when the need arises. The shelters protect the users from dust, direct sun lights, and also rain during rainy seasons.

Cost-effectiveness

Fabric and container shelters are very cheap to construct as compared to the construction of buildings. For instance, dome-shaped shelters come at a very small fraction of the construction of a building. In these case construction of a building is not even a viable option since they are constructed for temporary operations.

After the construction of the fabric shelters which can be used as a store for construction materials, the transportation costs of the materials to the site are minimized. In other cases where the shelters are to be used as a place of sleep for workers, the cost of transportation for the workers is also eliminated.

Quick to construct

In every activity or process, time is a very important factor that should be kept in order to increase production and reduce the time a project will take. For this concern Fabric and container, shelters take a few days or weeks to construct. This makes them available for use in the shortest time possible.

To construct fabric shelters, you only need to erect the steel tubes and then cover them with the fabric or container covers which can even take some hours as compared to many months or years which are required to construct a building.

They are portable

Fabric and container shelters are made of lightweight materials as opposed to solid bricks and mortar used in buildings and can be moved from one site to another. After the end of the project, these fabric shelters can be dismantled and kept in stores to be used later.

Are versatile

Fabric and container shelters have a wide variety of uses. They can be used in various industries such as construction, manufacturing, processing, maintenance, research, and institutions. In construction sites, these shelters can be used for different purposes. They can be used as offices, warehouses, or stores, lunch areas for workers, sleeping areas, and also as a room for machinery and equipment used on the site.

Durability

Fabric and container shelters can be made for temporary or permanent needs. These shelters are made from fabric material and steel which can last for many years. The skeletal frame of the shelter is made from prefabricated, heavy-duty steel which can last for decades.

Require a small space

Fabric and Container shelters are made of different sizes and shapes according to the need. These shelters can be set up in any available space on the construction site. This ensures that they do not occupy the space which is made for the construction of permanent buildings. They do not

need pillars, columns, beams, or posts to support themselves, therefore they can take the smallest space left for them.

Are flexible

Fabric and container shelters can be customized to meet unique requirements in terms of size, shape, and also purpose. These shelters can be outfitted to fit the user’s specific needs. In a construction site, the shelters can also be dismantled and repurposed when the need arises.

They provide security and

protection

In a construction site, fabric and container shelters can be used as a warehouse or store and provide enough security for the materials, machinery, equipment, and tools used on the site. They also provide protection to the people who are using them and the machines which can be damaged by conditions such as rain. They protect the users from dust, rain, harsh ultraviolet rays, direct sunlight, and falling materials in case of a storey building.

Low operation and maintenance cost

After installation of the fabric shelters, they do not need much maintenance and operating time and costs. These shelters are easy to clean and repair when required. They can last for very many years without the need for any repair or maintenance.

Provides a better working environment

In a construction site, fabric and container shelters will provide an environment free from dust, rain, and noise from machines. The shelters also provide bright natural light during the day time thus, no need to install electric lights in the shelters which save on the cost of electricity. According to researchers working under natural light helps improve the health and mood of the workers hence making them deliver well in their duties.

www.constructionreviewonline.com November/December 2022 | CR 17 SHELTERS

Tips when it comes to cement render

Many homeowners use quality materials in building their homes. Aside from using solid materials, they also use cement render to solidify how neat their house could be and protect it from the harsh elements outside. If a render gets dirty or peels, they can apply another after chipping it out. It's that simple.

However, the trick is using a reliable and tough cement render that can give your home an upgrade and a stylish and pleasing look. And in this post, you'll discover the best tips for using or applying rockcote cement render for your home's facade or interior walls:

1. Always Use A Sharp Blade And A Metal Float

When applying rockcote cement render to your walls, ensure that your tools are sharp. You could risk damaging the wall's surface and creating an uneven finish if you don't have a sharp blade. You should also use a metal float instead of a wooden one.

Metal floats are considered more effective at smoothing bumps or ridges than a less durable alternative. If you're unsure what type should be used, you can always ask your local hardware store for their opinion on the best way to proceed with your project.

2. You'll Get A Smoother Finish If You Don't Mess With It Too Much

While Rockcote cement render is a forgiving product, you should still avoid a few things to get the best results. One of these is reapplying to render too often. It can significantly help you achieve desired results if you don't do it.

Once your first application has dried, wait until it's fully cured before applying another coat. Ideally, let the first coat dry fully for at least 48 hours. If you keep applying fresh render over wet layers of the old coating, they'll tend to stick together and can form an unpleasant lumpy mess once they finally dry out.

In addition, don't apply too much at once, if possible. It can be tempting to plaster on lots of rockcote cement render, considering how easy it is to work with. However, note that your walls will be set in about 30 minutes, and you must wholly and evenly cover your surface area before letting it dry. And so, by applying bit by bit, without excess, you can achieve your goal with what you have. You wouldn’t want your walls to be unappealing even after maximizing a render to secure your walls.

3. Keep Your Arms Straight When Applying The Render

One of the most important things to remember when applying cement render is to keep your arm straight. This can help you

achieve a more precise rendering result, as compared to a messy job if you keep on waving the blade around without much care.

To ensure that you're keeping your arm straight, move it in one direction at a time. You can consistently move it back or front instead of moving your arms up and down and side to side. Think of it like you're an artist painting a house. A tip to note is to ensure that your reach doesn't exceed 12 inches or 30 cm., so you'll be able to achieve even application of Rockcote cement render over previously applied surfaces such as concrete blocks, etc.

4. Only Work On One End Of The Wall At A Time

Only work on one end or part of the wall at a time; that way, it doesn't dry out. Doing so can help ensure the consistency and uniformity of how each wall portion dries out.

Opting to apply render over large areas, instead of taking it bit by bit, can leave your wall with a big mess, as each part of the wall you didn’t complete will dry out. And in some cases, you may be forced to start all over again. And so, the best thing to do is, if you're not done with a section of the wall, don't move to the next just yet.

5. Always Wet The Sponge Before You Start Cleaning Up To Avoid Swirl Marks

Once you're done with the first layer, finishing comes next. For a sponge-textured finish, it would be best to use a damp sponge rather than a dry one to go over your work.

18 CR | November/December 2022 www.constructionreviewonline.com CEMENT

Note that you could risk creating swirl marks in your render if you use a dry sponge. And while a damp sponge can help make the job much easier and avoid unwanted paint marks, it's still essential to exercise extra care when doing this and not allow excess water to run down the finished wall.

Conclusion

Sometimes, you don't need to complete a house renovation for your home to have a polished look. You can apply rockcote cement render to improve the quality of the walls and protect them against harsh weather conditions. This would be part of an overall plan that relies on a renovation checklist to ensure that you have all the basics covered.

And hopefully, with the pro tips outlined above, you can be guided on how to apply and utilize such material and give your home a fresh and clean look.

www.constructionreviewonline.com November/December 2022 | CR 19 CEMENT

DavisandShirtliff.com

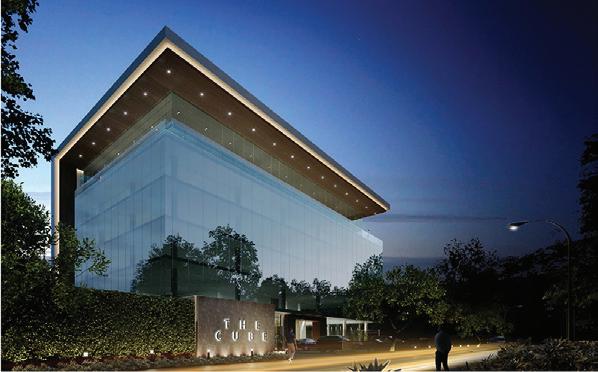

How Perforated Metal Enhances Building Design

Buildingdesign and aesthetics are one of the main concerns of architects and engineers. What a building looks like on the outside says much about what's inside. It is especially vital for commercial buildings, which must make a good impression on potential customers and clients.

Today, there are many ways to enhance the aesthetics, design, and functionality of a building, but one of the most effective is through the use of perforated metal. Perforated metal can be used on the exterior or interior of a building and can add an interesting visual element and improve acoustics. As perforated metal is becoming increasingly popular in modern design schemes, here are different ways to use it in a building design:

1. Perforated Staircase Design

Staircases are often one of the first things people notice when they enter a building. A boring, traditional staircase can be more interesting and exciting by using perforated metal. Perforated metal can be used on treads, risers, stringers, or

handrails to create an eye-catching design.

Additionally, perforated staircases are safer as they seal the space between treads and risers, preventing trips and falls. It makes it a vital part of a building used by children as there's no risk of them falling through the gaps. Perforated staircases are also cost-effective and more durable than glass or wood designs. If you're looking for where to buy this material, you need a reliable perforated metal sheet supplier, and you're good to go.

2. Perforated Facade Design

A facade is a building's face - it's the first thing people see when they look at a building. As such, it's best to ensure that the facade is well-designed and aesthetically pleasing. It can also hide nonaesthetic features such as air conditioning units, vents, pipes, and wires.

Perforated metal is often used in facades as it allows for ventilation while providing privacy and shade from the sun. It can also create

20 CR | November/December 2022 www.constructionreviewonline.com EXTERIOR

interesting patterns and designs to make your building stand out. The best part about using the perforated metal design is that it can prevent harsh weather from damaging your outdoor structural design while requiring minimal maintenance.

3. Infill Panels

Infill panels are used to fill in the space between the columns on a building's facade. They are usually made of glass, metal, or stone and can be used to add privacy, shade, or decoration.

Perforated metal infill panels are a popular choice as they offer many benefits. First, perforated metal is strong and can withstand high winds and impacts. It's also fire resistant, which is a crucial consideration for safety.

Additionally, perforated metal panels can be used to create interesting patterns and designs. You can also paint them to match the facade's color scheme. They are also perfect if you want to balance privacy and ventilation in your building. You can pick anti-rust designs to ensure they're easy to maintain and durable.

4. Outdoor Awnings

Awnings are a great way to provide shade and protection from the sun and rain. When using perforated metals on awnings, you still feel like being out in the open but protected from dry winds and UV rays. You can design the metal sheets to have smaller perforations to increase the shade they provide without sacrificing ventilation.

You can also use custom patterns on the perforated metals in your awnings.

It will help create eye-catching and unique patterns to add aesthetics to your outdoor space. You can add light patterns to the custom design and use them on your walkways, driveways, or other outdoor areas.

5. Perforated Metal Signage

Signages are a great way to tell people about your business, product, or service. They can be used indoors or outdoors and are usually made from perforated metals. So, you must get the design, color, font, and size right when designing your signage.

Perforated metal signage is perfect for indoor and outdoor use as it's durable and can withstand harsh weather conditions. You can use perforated metals to create 3D designs to make your signage stand out. They will help to add texture, color, and shape to create attentiongrabbing signs.

Another great thing about perforated metal signage is that it can be backlit to create a unique and eye-catching effect. It is perfect for businesses open late at night or in dimly lit areas. Therefore, perforated metals are the best option for creating a logo, architectural accents, or texts.

Conclusion

There are endless possibilities for using perforated metals in building designs. These are just a few examples of how you can use them to enhance the look and feel of your building. Perforated metals are functional, safe, and can be used in various ways to create interesting patterns and designs. When used correctly, they can add value to your property and make it more aesthetically pleasing.

www.constructionreviewonline.com November/December 2022 | CR 21 EXTERIOR

How To Reduce the Effects of Noise Pollution in Construction

Noise pollution is a problem that has been increasing in recent years as construction, and other industrial projects have taken off.

While the benefits of such projects are clear, the adverse effects of noise pollution on human health and the environment cannot be ignored.

Planning and Design

One of the best ways to reduce noise pollution is to plan and design projects with noise reduction in mind. This means considering the type of materials to be used, the project layout, and the soundproofing methods that will be employed.

For example, using acoustic barriers and soundabsorbing materials can go a long way toward reducing noise pollution.

In addition, moving the project away from residential areas can also help to reduce noise pollution. If this is not possible, working with residents to develop a noise mitigation plan can be beneficial.

This plan could include scheduling work during specific hours, providing advance notice of loud work, and offering compensation for any inconvenience caused.

Construction Methods

Another way to reduce noise pollution is to use construction methods that generate less noise. For example, mechanical means can be used instead rather than using explosives for demolition.

Mechanical means include a wrecking ball or excavator to knock down walls or hydraulic shears or saws to cut through metal.

In addition, using electric tools rather than gas-powered ones can help to reduce noise pollution. Electric tools are not only quieter, but they also produce less vibration, which can further help to reduce noise pollution.

Construction Management

Another way to reduce noise pollution is to employ effective construction management techniques. This includes ensuring that all workers know the need to reduce noise pollution and that they have the necessary equipment to do so.

In addition, enforcing strict work hours can help to reduce noise pollution by limiting the times when construction noise is most likely to occur.

Another vital aspect of construction management is developing a noise pollution control plan. This plan should identify the sources of noise pollution and detail the measures that will be taken to reduce it.

By taking these steps, construction managers can help to ensure that noise pollution is kept to a minimum.

Use of Heavy Machinery

Heavy machinery is one of the biggest causes of noise pollution in construction. While such machinery is necessary for many construction projects, it can also be a source of noise pollution.

As such, it is essential to use heavy machinery only when necessary and to take steps to reduce the noise it produces when it is in use.

There are several ways to reduce the noise produced by heavy machinery. One is to use quieter types of machinery, such as electric machines. In addition, using mufflers and soundproofing enclosures can also help to reduce the noise produced by construction machinery.

22 CR | November/December 2022 www.constructionreviewonline.com NOISE POLLUTION

Another way to reduce the noise produced by heavy machinery is to operate them only during certain times of the day. For example, avoiding construction noise during the night can help reduce noise pollution's effects on nearby residents.

Monitoring and Enforcement

In addition to taking steps to reduce noise pollution, it is also essential to monitor for it and enforce regulations when necessary. Regulations include having a system to measure noise levels and using this information to identify when construction noise is becoming a problem.

When noise pollution does become a problem, it is essential to take action to reduce it. This action may involve issuing warnings or citations to construction companies or even shutting down construction projects causing excessive noise pollution.

Noise-Reducing Equipment

One of the best ways to reduce noise pollution is to use noisereducing equipment, including using quieter types of machinery and soundproofing techniques. In addition, using soundabsorbing materials can also help to reduce noise pollution.

Another way to reduce noise pollution is to use noise-cancellation headphones or earplugs. These devices can help to reduce the amount of noise that workers are exposed to and can also be used by residents who live near construction sites.

Not only can this help to reduce noise pollution, but it can also help to protect workers' and residents' hearing.

Operational Procedures

Implementing operational procedures that minimize noise is another option. These procedures include limiting the use of construction equipment to certain times of day and avoiding construction activities during periods when the noise would be most disruptive.

In addition, avoiding construction activities near sensitive areas, such as schools and hospitals, can also help reduce noise pollution's effects.

Operational procedures can also be used to reduce the duration of construction projects. By minimizing the time that construction equipment is in use, it is possible to reduce the overall noise pollution produced.

Public Education

In addition to taking steps to reduce noise pollution, the public needs to learn about the issue. This education includes informing people about noise pollution's effects and tips on reducing its impact.

One way to educate the public about noise pollution is to provide information on construction projects in the area.

The information helps people to be aware of the potential for noise pollution and to take steps to reduce its impact. In addition, providing information on noisereduction measures can also help people to reduce the effects of noise pollution.

Another way to educate the public about noise pollution is to hold community meetings. These meetings can allow people to learn about the issue and share ideas on how to reduce its impact.

In addition to public education, enforcing regulations on noise pollution must also be done. Regulations include having a noise measurement system and taking action when noise exceeds certain limits.

Conclusion

Noise pollution is a serious issue, and it is vital to reduce its impact. By following the tips above, you can help to reduce the effects of noise pollution in your community.

In addition, by educating yourself and others about the issue, you can help to create more awareness of noise pollution and its effects, especially in construction sites.

www.constructionreviewonline.com November/December 2022 | CR 23 NOISE POLLUTION

Satellite Imagery Application In Construction And Architecture

Theplanet’s population is constantly growing, and consequently, the human influence on the environment is increasing. Because of it, the construction and architecture industries are facing an ever-increasing need for minimally invasive designs. Using high-quality satellite pictures of Earth helps create projects that are sustainable in the long run. Introducing remote sensing in AEC applications allows you to solve problems faster, more accurately, and more economically efficiently than conventional methods.

Satellite Imagery And AEC Industry

Any AEC industry branch can benefit from the use of live satellite imagery. Moreover, experts can use both images from public services like Google Maps and advanced tools like EOSDA LandViewer, depending on the scale of their projects.

Preconstruction Planning

Industry experts can utilize high-quality satellite imagery to survey the area and find potentially profitable sites early in the project development. Combined with AI, it enables georeferenced interpretation of each building’s geometric footprints. Based on satellite images, you can create detailed vector maps with the planned infrastructure: roads, green spaces, sidewalks, etc.

Construction Site Terrain Analysis

Sustainable construction involves considering the terrain and area features when creating plans, as they affect the placement of temporary objects, the

arrangement of places for the vehicles, and the safety of the site. Surveying the area to create a smart design with the Rapid Digital Elevation Model helps to meet construction schedules and reduce costs by 10-30%.

Infrastructure & Asset Management

Using live satellite images is a great way to monitor construction processes, allowing managers to monitor and evaluate the current situation remotely in realtime. The images’ high quality and scalability help reduce the number of on-site employees. Thus, experts can control each stage of work, identify risks to the environment, and reduce the impact on nature. It also makes it possible to evaluate global urban growth and competitors’ projects.

Green Space Monitoring

Green areas are integral parts of sustainable landscape design and construction. With the help of satellites, specialists can track the NDVI index, detect negative changes on time, and optimize land use. Besides, satellite technologies can also be used to improve existing residential areas and the quality of people’s lives.

How To Access Satellite Images

The advantages of using satellite technologies for various fields of human activity are undeniable. And if earlier it was not easy to get access to them, now our possibilities are much wider. The simplest and most accessible example of satellite images of Earth is Google Maps and similar mapping services. Thanks to

24 CR | November/December 2022 www.constructionreviewonline.com SATELLITE IMAGERY

them, satellite images are available to many users free of charge.

For enthusiasts, such pictures are pretty enough for simple landscape analysis. However, for professionals in the construction and architectural fields, the quality of such images and their detail may seem insufficient. Especially considering that they are updated relatively infrequently. This is where satellite imagery providers like EOS Data Analytics come into play.

Satellite Imagery Service – EOSDA Landviewer

EOSDA LandViewer is a tool that provides access to high-quality satellite imagery and makes it easy to analyze them. With it, users can work with extensive data and search for the information they need using more than ten indexes. You can access up to 10 average-quality images daily for free from satellites such as Sentinel-2 L2A, Landsat 8 OLI + TIRS, CBERS-4 MUX, and many more. You can also buy high and very high-quality images for business tasks that require maximum accuracy.

With EOSDA LandViewer, you get access to satellite imagery of any region you are interested in. You can compare images of the same area at different times to track changes and visualize the results as a timelapse animation. In addition to the default indexes, you can create your own ones that combine various spectral bands explicitly needed for your project.

Satellite Imagery Benefits For The Architecture Sector

Satellite technology is developing rapidly, and we will have more opportunities to use it shortly. Currently, imaging satellites have somewhat limited capabilities regarding image quality and re-imaging the same areas. Despite minor drawbacks, they can be used to regularly monitor small objects (up to several meters in length), which means they are applicable in architecture, construction, real estate, and so on.

Live satellite view can be utilized at any stage of project development. Using satellite technologies in preconstruction planning makes it possible to discover more promising regions and create vector maps for developing future infrastructure. Since sustainable building involves the creation of urban green spaces to reduce human impact on the environment, satellites help monitor the health of plants through various indexes. Also, insurance agencies and banks can use images from space to assess risks and their prospects. Historical data allows them to track the dynamics of changes in the object’s value.

Thus, satellite image usage, in combination with other technologies such as AI, allows complex terrain analysis, risk and benefit assessments, prospective area identification, and sustainable project development based on historical and current data. As the number of satellites in orbit increases and image quality and resolution improve, we will have even more opportunities for developing the AEC industry in the coming years.

www.constructionreviewonline.com November/December 2022 | CR 25 SATELLITE IMAGERY

TOP TANK SOLUTION. AN IMMERSIBLE NEW e-SVI.

Xylem we believe in products that do their job when expected; that are efficient, easy to commission, operate and service.

At

The new immersible multistage e-SVI series is the efficient top tank solution that provides uncompromised performance and reliability. xylem.com

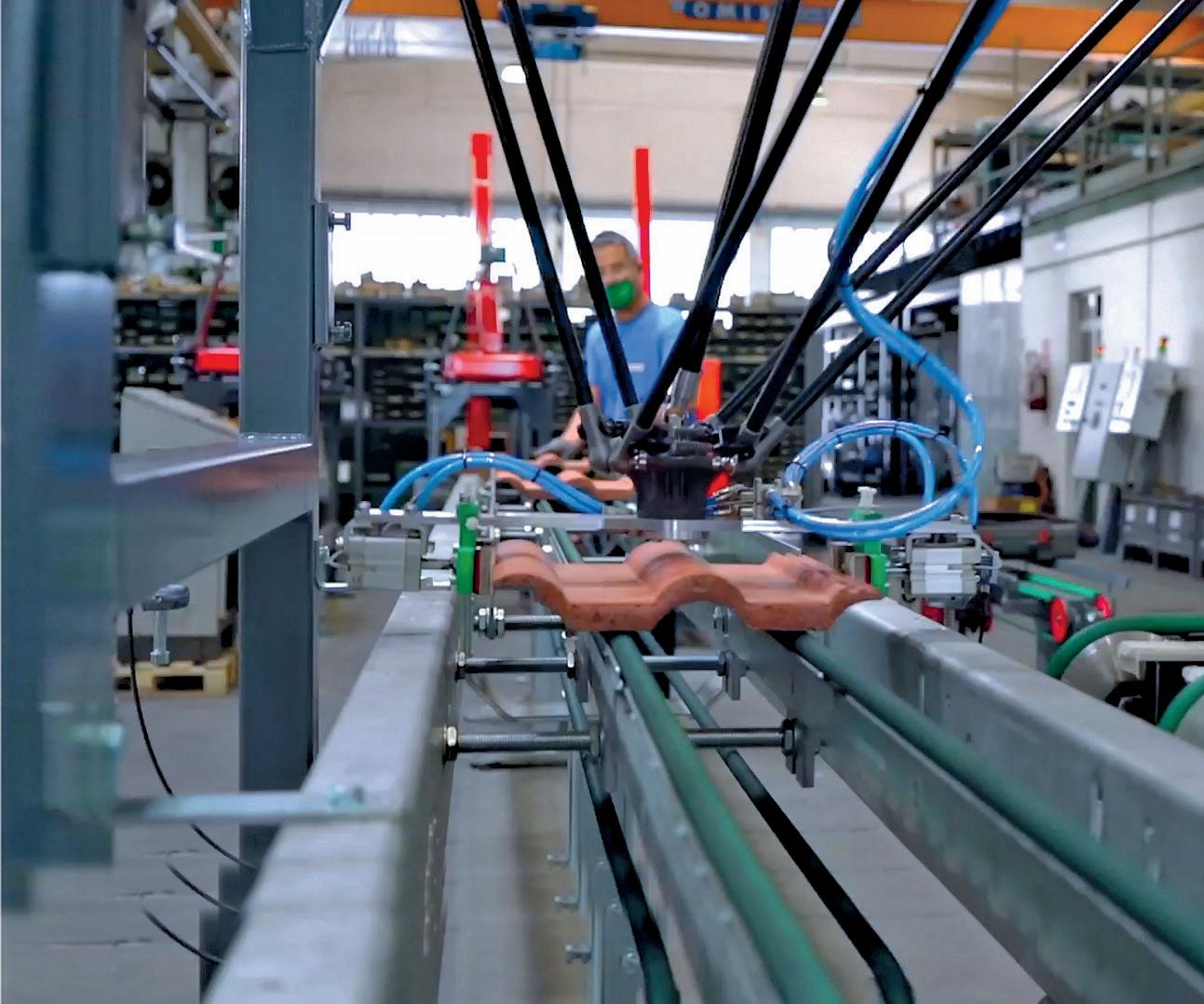

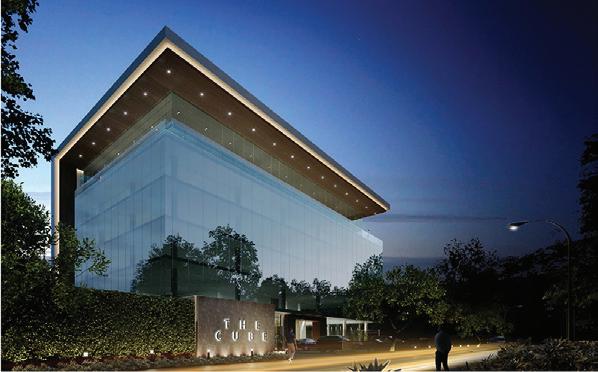

The Riverside Cube: Grade A Office Development Customer experience is at the core of Nirmal Fabricators as it turns 25

With 25 years of experience under its belt and several bespoke products to its name, Nirmal Fabricators has evolved to become the com pany of choice in the engineering and construction sectors.

And as the company’s founder and chief executive Nirmal Singh explains, superior services and quality products have helped the company maintain its position in the sector which more than ever faces stiff competition both locally and globally.

“We provide real value to all our clients by achieving the best in the industry results and the highest level of professionalism in every service, project, and structure we deliver. The individualized care and unwavering attention that we bring to all our projects are deciding factors in why our clients continuously choose us,” says Nirmal.

“We aim to provide only the highest quality services and product while remaining competitive to our clients. We have consistently constrained ourselves to high work ethics, workmanship, laws, regulations, and fair play

in all our projects to ensure that each of our products propel us to new levels in customer confidence, our experience, and our own sense of pride and satisfaction.”

With a state of the art workshop in Industrial Area, and backed by qualified staff Nirmal Fabricators continue to churn out a range of excellent products to the market.

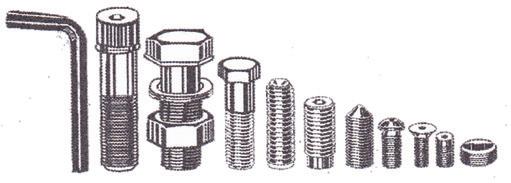

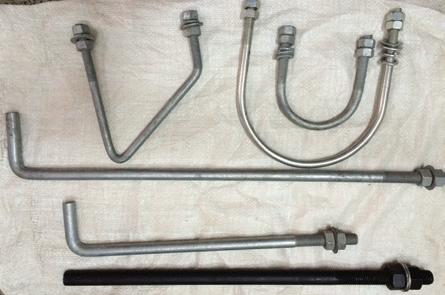

Products and Services

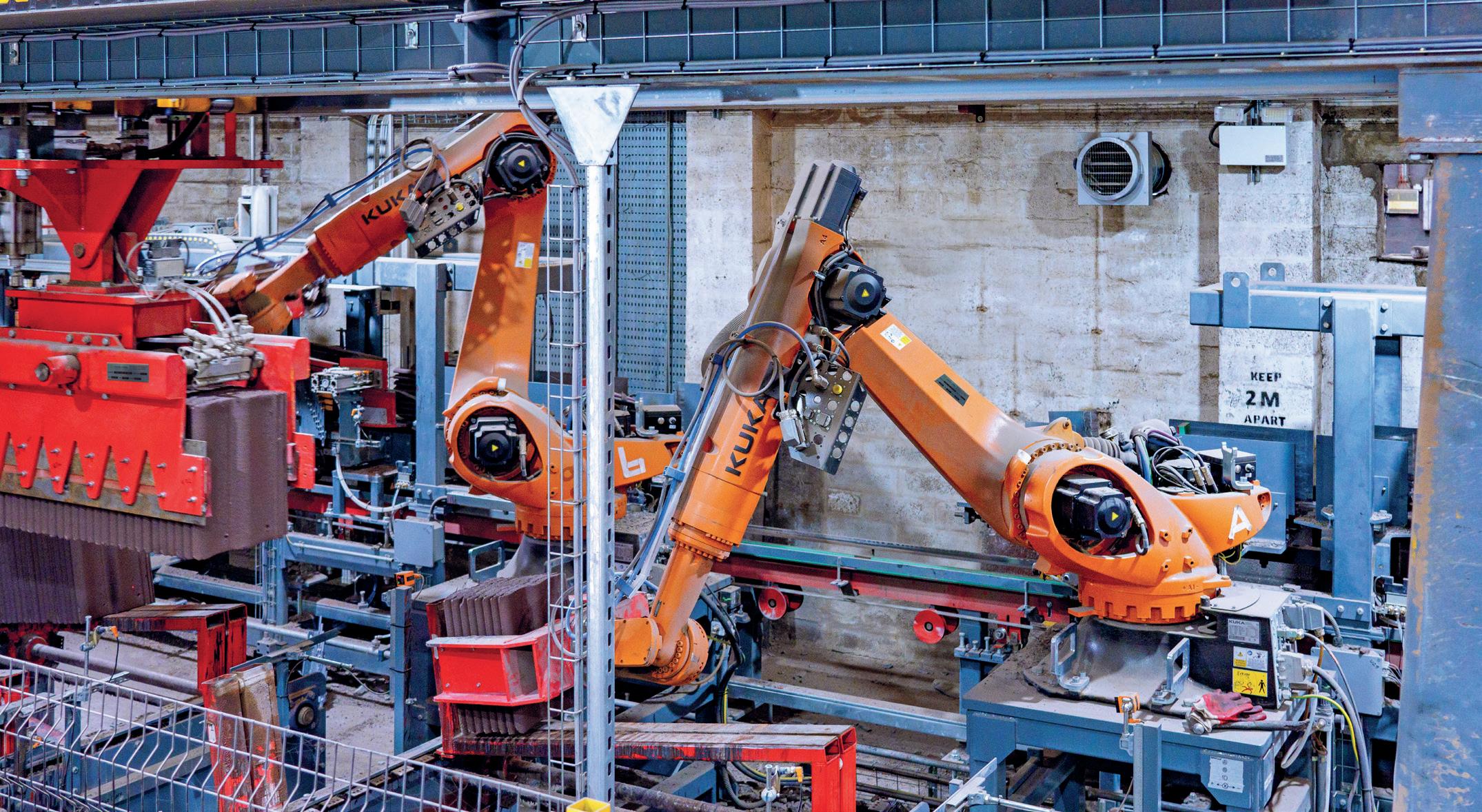

Overhead Cranes

Nirmal Fabricators Ltd Electric Over-Head Crane is used to lift loads in various environments, such as factories, warehouses, stockyards etc. The company offers a range of Over-Head Cranes suited for customer requirements and needs. Every crane is custom designed for every client starting from analysing the site to the lifting requirements. Nirmal offers Single girder cranes, double girder cranes, Gantry, Semi-Gantry cranes and Jib cranes with lifting capacity from 250kg up to 200 Tonne.

The company manufactures crane girders with high quality steel in their

The Electric Single Girder Crane is a light small lifting crane, equipped with electric hoists as the lifting mechanism. The lifting capacity of the single girder crane ranges from 250kg to 20MT in different configurations. Beam ⁄ Box type main girders (dependent on spans). These cranes can be freed either with an Electrically Operated Trolley (EOT) or a

www.constructionreviewonline.com PROFILE

The Electric Double Girder Crane in SWLs ranging from 1000kg to more than 200MT. These cranes incorporate fully customised open winch type crabs. Nirmal can supply fully customised Double Girder Cranes as per the client requirements for different duty cycles and for diverse range of applications. Double Girder Cranes can be given for a very large range of spans‚ a large of heights of lift as well as a large range of speeds. With the double girder structure, the crane has sufficient strength, rigidity and stability.

Gantry

Available in a double or single girder version, gantry cranes are a varied option for many worksites. We carry both double and single girder gantry cranes for East Africa. The single girder ranges from 1 to 50 MT capacity, while the double girder version ranges from 5 to 160 MT. Pictured is a double box girder gantry with the hoist crab unit running on rails attached to the top flange. Support columns are attached to the bridge structure to enable the crane to run along ground tracks. Catering for spans up to 40 meters.

Semi Gantry

These versatile cranes are used mainly for activities in steel yards‚ pre-cast segment yards and other outdoor applications. These are

self-propelled cranes running on rails installed at the ground level and do not require any supporting structures. These cranes can be supplied in Single Girder or Double Girder options depending on requirements of SWLs‚ speeds‚ heights of lift and other characteristics.

Jib cranes assist the staff and multiply human efforts‚ handling loads up to 6300kg precisely and effortlessly. Jib cranes are useful especially for loading or unloading of workpieces on machine tools. These are also useful for loading or unloading of trucks. They can also become an inseparable part of a standalone workstation and machine assembly area.

Goods Hoist

Goods Hoist is a heavy duty well engineered lift specifically designed to hoist heavy goods between levels. They are popular in warehouses, distribution centers and factories. The company offers a range of hoists with rated loads from 500kg upwards.

“Our focus is on giving a well-manufactured goods hoist that ensures maximum safety and functional efficiency,” explains Nirmal.

He continues, “As a leading supplier in the related markets, we provide excellent after sales services, catering for the needs of our customers throughout the region. We have an experienced engineering team in designing standard equipment or custom-made solutions for local markets.”

www.constructionreviewonline.com November/December 2022 | CR 27 PROFILE

EVENTS NEWS

quence fault, available with hook suspended or fixed mounted trolley design as per requirement, all motors are provided with D.C. disc brakes and are available with twin speed motion on request.

PROFILE

30 CR | November/December 2022 www.constructionreviewonline.com +254-724-356-515 +254-733-674-042 info@blantyresteel.co.ke 45 Enterprise Road. GoDown No 6. Opposite Karatasi Industries Ltd. Gabion boxes 2x1x1 Geo-Textile, 200g, 300gs and 400g available in 2 meters by 50 meters roll Also available are gabion mattresses 2m x 1 x 0.5m, 2m x 1m x 0.3 and 1m x 1m x 1m Kenya Institute of Supplies Management Headquarters - Nairobi The Edge - Leadership Centre, at College of Insurance - Nairobi Moi Educational Centre, High School - Nairobi CONGRATULATIONS NIRMAL FABRICATORS LTD ON YOUR SILVER JUBILEE ANNIVERSARY. WE ARE PROUD TO BE ASSOCIATED WITH YOU Milicon’s is a leading Building and Civil Engineering Company in Kenya registered under NCA 1 offering quality and timely comprehensive solutions and services in Building and Civil Engineering fields to the complete satisfaction of Clients, Consultants and its End Users, with continuous investment and technology up-gradation, contributing to globalization Proposed SASDF Plaza Proposed Convention Centre - Kenya School of Government, Embu Campus East End Plaza, Bukani Road, Nairobi Kenya | P.O. Box 4546 - 00506 TEL: +254-20-6008584, 0705-167161 Email: info@milicons.com Website: www.milicons.com COINA Award Certificate COINA Award Trophy CONGRATULATIONS NIRMAL FABRICATORS LTD ON YOUR SILVER JUBILEE ANNIVERSARY WE ARE PROUD TO BE ASSOCIATED WITH YOU

Steel Fabrication

Nirmal is one of the leading manufacturers of high quality Steel Fabrication in the Industry.

“Our facilities are equipped with latest technologies that deliver the highest quality end products. Our team comprises of highly skilled fitters, welders, structural fabricators, electricians, and managers who can expertly streamline even the most complex project from concept to delivery.”

Projects include; Metal Doors & Gates, hand Railing & Protection Rails, warehousing & Stores Showrooms, office building, factory building, storage racks, car parking sheds, multi-scaffolding systems among others.

Body Fabrication

Nirmal is among the most renowned fabrication service providers in Kenya and engaged in truck body fabrication, bus body fabrication, pick-up body fabrication, all other Commercial Vehicle Body Fabrication and repairing of your existing vehicle. For the best possible convenience of our clients, we take all types of fabrication jobs.

“We are continuously moving towards our success with our innovative skills and resourcefulness. There is a clear endorsement of the quality of products and services given by us. Our company has been continuously receiving a new direction and new approach towards new horizons, equipped with latest machines and apparatus for Engineering and Fabrication services,” explains Nirmal.

The company also offers various types of repairing and maintenance services to our clients across the country.

“We pride ourselves on offering the broadest list of services of any company in our industry. Whether you are looking for a service to your Grilles Rolling Shutter, Roller Shutter, Punched Roller Shutter, Perforated Lath Roller Shutter, Micro Perforated Roller Shutter and Truck Body Repairing, Bus Body Repairing, Pickup Body Repairing and all other Commercial Vehicle repairing, we can assist you,” Nirmal concludes.

Sprintex: A Leader in High Tech Quality, Efficient Refurbishment Electric Machines

SPRINTEX Engineering Services Ltd, is an established professional electrical motor rewinding and repairs workshop, with vast and knowledgeable experience in overhauling and rewinding of all types of electric motors both AC/DC motors, generators, transformers, Semi Hemertic Compressors, Stepper motors, Servo Motors, Lift motors and Welding machines. We offer high tech quality, efficient and quick turnaround services ensuring that our clients down time is minimised in refurbishment of the electric machines.

Engineering in Kenya Magazine Issue 009 33

+254 733 247 584, +254 721 692 342 info@sprintexengineering.com md@sprintexengineering.com Contact Sprintex Engineering Services Ltd P. O. Box 60889-00200 Nairobi, Kenya Sprintex Engineering Services Ltd www.sprintexengineering.com

Managing Director Eng. George Okoth explains to a customer conditions of bearings and sensors. Confirmation of the bearing journals for the right tolerance on the slipring rotor. 1600 kW slipring motor after comprehensive refurbishment. 930 kW Slip Ring motor, Completely Rewound Rotor winding using imported bar winding materials to class H insulation. 3 Megawatts turbine generator rotor after servicing ready to be installed in the main stator. We are dedicated to offering professional services, on-site inspection. We also provide technical solutions to our esteemed clients.

Sprintex

George Okoth Managing Director Sprintex Engineering Services

Eng.

Limited

CONGRATULATIONS NIRMAL FABRICATORS LTD ON YOUR SILVER JUBILEE. WE ARE PROUD TO BE ASSOCIATED WITH YOU

Preventing accidents

Construction accidents can happen unpredictably even when all workers are properly trained. Sometimes mishaps are completely unavoidable. In some cases, the maintenance company may not properly inspect equipment leading to mistakes. There is also the risk of tools malfunctioning due to defects. Additionally, workers sometimes have fatigue and become sloppier in execution.

Construction companies know that construction accidents are a common occurrence. Unfortunately, construction workers are the most likely employees to get injured while at work. Because of the high risk of injury, construction workers must be even more vigilant. Here are ways that construction accidents can be prevented:

Be Openly Communicative