1 minute read

STRUCTURAL INSULATED PANELS (SIPS

INTRODUCTION

SIPS are a high performance building system for both residential and light commercial construction. Structural Insulated Panels (SIPS) are structural frames made from a sandwich of two layers of structure, and one layer of insulation. The outer layers tend to be OSB, with the insulation layer being premium carbon treated expanded polystyrene (EPS). The edges of the panels are formed so that they can be easily fitted together over a connection plate. The wall panels vary in thickness from 100mm to around 172mm and are usually around 1200mm wide and 3000mm high. Roof panels are much larger, at around 6500mm, and are self-supporting, which means there is no need for trusses, making the roof space a useable area.

Advertisement

The panels are manufactured under factory conditions, and can be prefabricated to almost any design.

The panels are strong, and highly insulated, with no need for a cavity. The walls can achieve U-values as low as 0.14 W/Km2, using just a standard panel without extra insulation. They allow for extremely fast and efficient construction times on site, whilst being a cost effective option.

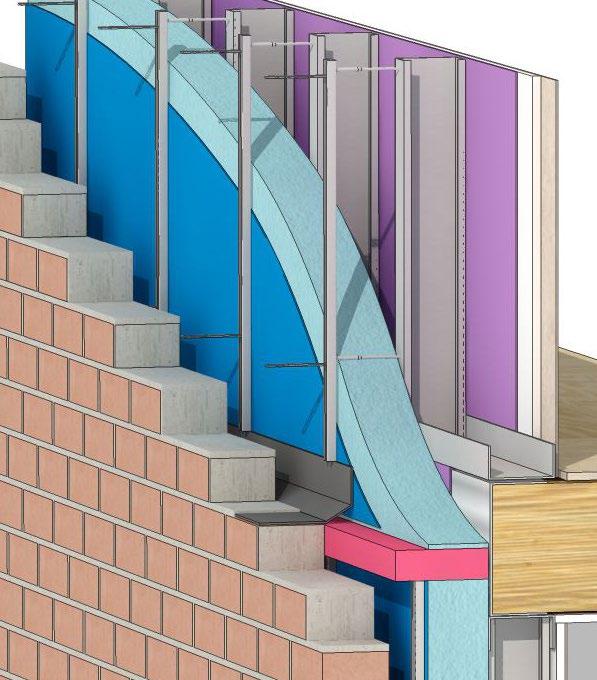

The SIPS can be finished with external claddings such as brick, render, timber cladding and so on. The roofing panels can be finished with slates, tiles and metal roofing.

Typical construction consists of a standard foundation system, with a sole plate installed above dpc level to provide a suitable base for the panel to be fitted to with angle brackets to secure in place. Openings are factory formed, with the door or window installed on site. Joist hangers are secured to the panels to support the first floor joists. Roof panels can be fixed to a wall plate on top of the first floor panels, or roof trusses can also be used.

Figure 6.1 - Example of SIP construction