Curious to know who has won the awards? Stay tune to our announcement in November.

Innovation Print Award (IPA) is an annual competition that seek to recognise FUJIFILM Business Innovation’s customers creativity and innovation in print.

Push the creativity and technical boundaries of print with FUIFILM Business Innovation technologies – the only limit is your imagination!

https://reg.eventnook.com/event/ shift22labelpackagingconference andexcellenceaward/

The recent 2022 Asian Print Awards dinner ceremony was held on the 20th of October at the BITEC exhibition centre Bangkok during PackPrint International and the CorruTech exhibition.

Over 310 industry leaders gathered on the night to see first-hand which Printers in Asia had come up with the goods to win Gold, Silver and Bronze at the first live awards dinners since the COVID-19 Pandemic rocked the world. The Asian Print Awards have been at the forefront of recognising Print quality since 2002, and this year's winners were no exception to this rule.

The competition had over 1600 entries across 33 individual categories (the largest in the award's history), and on the night, 34 Gold Awards were presented (one category had two gold awards). Also, the benchmark Best of the Best Awards were presented by FUJIFILM (Best in Digital), Heidelberg (Best in Offset) and CGS ORIS (Best use of Colour).

Paul Callaghan, Chairman of Asian Print Awards, thanked the judges who presided over the event this year and the last time they will be judging in Australia, with the judging returning to its home in Singapore for the 2023 event. "This year, we have come back to some normality in our daily lives, and after walking the isles of the PackPrint International trade show and seeing people are once again doing business face to face, networking was such a wonderful feeling", Callaghan mentioned.

He continues, "Now that we are all in the same room again to see what the best quality printers have to offer, I'm happy to tell you that the judges have again seen some truly incredible work produced for this competition." "There seems to be no slowdown with the adaption of new technology to

help in the print shops of Asia", he concluded.

Also announced was the new partnership for the 2023 Asian Print Awards with the world's biggest trade show DRUPA, who has signed on as the title sponsor for the Awards (being held in Singapore, date to be announced). Also, next year, the Asian CorruTech exhibition is being held at BITEC, (alongside PackPrint International) has signed on as the title sponsor for the 2023 Asian Packaging Excellence Awards, which will further strengthen the drive for quality print and packaging production across the region.

The complete list of all winners is published on the following pages and also available at www. printinnovationasia.com for download with the photos of the evening.

A massive thank you to all the sponsors and people involved in putting this amazing event together!..

Scott Mackie - General Manager Graphic Communications Asia Pacific FUJIFILM Bisuniess Innovation

GOLD Company: Sirivatana Interprint Public Co Ltd Thailand

Job Title: ELLE Magazine Feb 2022 Press: Komori Ink: TOYO Ink Paper: Customer Supplied

SILVER Company: Cyberprint Group Country: Thailand

Job Title: Happiness Magazine #50 Press: Mitsubishi Dimond 3000 Pre-Press: PTT Group Ink: Soy Ink Paper: SCG

BRONZE Company: Phongwarin Printing Ltd Country: Thailand Job Title: Masala Life July 2022 Press: KBA 105 Pre-Press: In House Ink: DIC Graphics (Thailand) Co Ltd Paper: C.A.S Paper

GOLD Company: Sirivatana Interprint Public Company Limited Country: Thailand

Job Title: Forbes Thailand May 22 Press: Komori Web Ink: Toyo Ink Paper: Customer Supplied Ultimate Client: Post International Media Company Ltd

SILVER Company: ABP Pvt Ltd Country: India Job Title: B C Sen Jewellers Press: WIFAG Pre-Press: In House Ink: DIC Paper: UPM

GOLD

Company: Infinite Printing & Packaging Service Co. Ltd Country: Thailand

Job Title: Menu Lacol Press: Ricoh Pre-Press: Command In Design Co Ltd Paper: Antalis (Thailand) Ltd

SILVER Company: M.I.W. Group Company Limited Country: Thailand Job Title: Krua Muang Ve Menu Press: Iridesse Production Press

Silver Company: Cyberprint Group Country: Thailand Job Title: Chapter 2 cafe Press: HP Indigo 10000 Pre-Press: K Sirikarn Paper: SCG

BRONZE Company: Anaswara Offset (Private) Ltd Country: India

Job Title: Olive Kitchen Press: Konica Minolta – Accurio Press Pre-Press: Thought Factory Kochi Ink: Digital Toner Paper: Purnima Distributors Kochi

GOLD Company: Paperista Co. Ltd Country: Thailand Job Title: SAY I DO Mr Jirapong

SILVER Company: Pen’s Wedding Invitation House Country: Vietnam Job Title: “Close To You” Wedding Invitation Press: Iridesse Production Press

BRONZE Company: Grey Matter Co Ltd Country: Thailand Job Title: Pantone Wedding Invitation Press: Konica Pre-Press: In House Ink: Food Contact Toner Ink Paper: Thai Paper Co. Ltd + Ekkawin Co. Ltd

SILVER Company: K.P.P Packaging Pte Ltd Country: Singapore Job Title: Wedding favours Press: Heidelberg Pre-Press: In House Ink: Mukim Fine Papers Pte Ltd

GOLD Company: Siam Toppan Packaging Co. Ltd Country: Thailand Job Title: The Next Normal Store Press: Komori SILVER Company: Safe Power Printing & Box Mfg Co Ltd. (CGS Award for Best use of Colour) Country: Hong Kong

Job Title: Eternal Palace Game set Press: KBA Rapida 145 Pre-Press: In House Ink: Soy Ink

GOLD Company: Thung Hua Sinn Co Ltd Country: Thailand Job Title: King Fisher Press: Heidelberg

BRONZE Company: Sirivatana Interprint Public Company Limited Country: Thailand Job Title: PTT Oil Press: Komori Pre-Press: Kookiat Co Ltd Ink: Toyo Ink

GOLD

Company: Image Quality Lab Co. Ltd Country: Thailand

Job Title: The Portrait of Hua Lamphong Press: Iridesse Production Press Pre-Press: Yaowaphat Chantharakanok Paper: Digipro

SILVER Company: Ploy Printing Co Ltd Country: Thailand

Job Title: The Beauty of Death Press: Konica Minolta / Mimaki Pre-Press: In House Ink: Dy Toner/UV Ink Paper: Ekkawin Co. Ltd – Thai Paper Co. Ltd

GOLD

Company: Refine Printing Pte Ltd Country: Singapore

Job Title: Calendar 2022 World Cultural Heritage Press: Ryobi 926 Coater Pre-Press: Graffiti Creation Ink: UV Ink Paper: Graffiti Creation

SILVER

Company: Trinity Publishing Co. Ltd Country: Thailand Job Title: Mercedes Benz Calendar Press: Heidelberg CD 2000 Pre-Press: Imaging Hub Co. Ltd

GOLD

Company: Trio Trading Co. Ltd Printer: Parbpim Limited Company Country: Thailand

Job Title: We are ready to serve you Press: Heidelberg Pre-Press: Parbpim Limited Company Ink: Various. + Foil Paper: Trio Trading Co. Ltd

SILVER Company: Man Sang Envelope Manufacturing Co., Ltd Country: Hong Kong

Job Title: Create Every Possibility Press: Iridesse Production Press & Offset Pre-Press: In House

BRONZE

Company: Cyberprint Group Country: Thailand Job Title: Self Promotion Press: HP Indigo 10000 Pre-Press: In House Ink: HP Ink Paper: SCG

BRONZE

Company: PT Bintang Sempurna Country: Indonesia Job Title: Indonesia Tangguh Press: HP Indigo 7900 Pre-Press: Nirmana Exa Tricipta (NEXT) Ink: CYMK + Invisible Red Ink + Silver Ink Paper: Cover: Tyvex. Text: Tintoretto Gesso

BRONZE

Company: Allegro Print Pte Ltd Country: Singapore Job Title: Good Intentions Calendar Press: Heidelberg Pre-Press: In House Ink: Heidelberg Soy Ink Paper: RJ Paper Ho Yeong Liang

Company: 2B Printing Solutions Pte Ltd Country: Singapore Job Title: Year End Gift Set Press: HP Indigo 5600 Pre-Press: In House Ink: HP Ink CMYK + Orange/White and Fluorescent Pink Paper: Antalis / PT Digital Sarana Intimedia

GOLD

Company: Green Production (Overseas) group Country: Hong Kong

Job Title: 3D Paper Craft. Year of the Tiger Press: Konica Minolta C6100 + MGI Jet Varnish 3Ds iFoil Pre-Press: Sam Hui + Peter Lai Ink: Simitri HDE Colour + Digital Foil + Digital UV Paper: Acumen Mori Silk Paper (Japanese paper) Ultimate Client: DS Glitter Ltd

GOLD

Company: PRINTUSA (PVT) Ltd Country: Sri Lanka

Job Title: Unitea Green Tea Press: Heidelberg Pre-Press: In House Ink: CMYK + Special Colours + Foil

SILVER

Company: Hoang Ha Label Co Ltd (QLM Vietnam) Country: Vietnam

Job Title: SAMPAN Press: HP Indigo Pre-Press: In House Ink: HP Ink

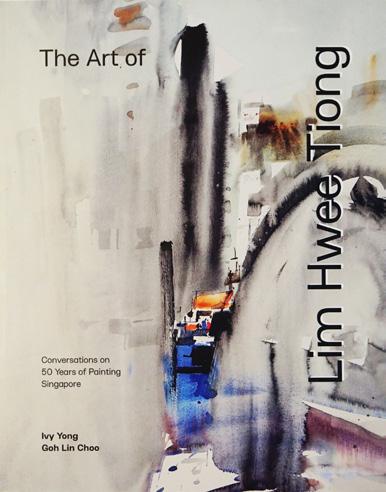

GOLD

Company: FUISLAND Offset Printing (S) Pte Ltd Country: Singapore Job Title: The Art of Lim Hwee Tiong Press: Ryobi MHI V-3000 Pre-Press: Candid Creation Publishing Ink: TK NE

Paper: OVOL Singapore Pte Ltd

SILVER

Company: Sirivatana Interprint Public Company Limited Country: Thailand

Job Title: The Ethics of Beauty Press: Komori Ink: Toyo Ink Paper: Hansol Paper Co Ltd (Offset) Multi Piece Products and Campaigns

GOLD

Company: Allegro Print Pte Ltd Country: Singapore

Job Title: Blood Sweat and Tears Press: Heidelberg Pre-Press: In House Ink: Heidelberg Soy Ink Paper: RJ Paper

SILVER Company: Percetakan Image Vest Sdn Bhd Country: Malaysia

Job Title: KL Wellness City Press: Mitsubishi Diamond 3000 Pre-Press: In House Paper: Antalis

BRONZE

Company: QLM Label Makers Sdn Bhd Country: Malaysia Job Title: Hammerhead Whisky Press: HP Indigo 6800 Pre-Press: In House Ink: HP ink + Gold and Black Stamping

Company: Phongwarin Printing Ltd Country: Thailand Job Title: Elegance Press: KBA 105 Pre-Press: In House Ink: DIC Graphics Paper: C.A.S Paper, Phainchai Co Ltd Client: ARIP Public Company Ltd

Gold

Company: Shoei Printing Co., Ltd Country: Japan

Job Title: General Catalogue “PLANETA” Material Sample Collection Press: Iridesse Production Press

Silver

Company: Sirivatana Interprint Public Company Limited Country: Thailand

Job Title: Trend Book (Vol 2) Press: Jet Press 750s Pre-Press: N/A Ink: Fuji Paper: T.Kuviboon Trading Co Ltd

GOLD

Company: Pan Pacific Printing Co Ltd. Country: Thailand

Job Title: IKANO Press: HP Latex 330 Pre-Press: IKEA Thailand Ink: HP Ink Paper: 3M

GOLD

Company: Mahachulalongkornrajavidyalaya Press Country: Thailand

Job Title: Samutprakan Land of Kings Press: Heidelberg Pre-Press: Luckkana Thaweesuk

SILVER

Company: Phongwarin Printing Ltd Country: Thailand

Job Title: Asian Jungle – African Bush Press: Komori / KBA 105 Pre-Press: In House Ink: DIC Graphics Co Ltd Paper: UMC Trading – Paper. Phianchai Co Ltd

GOLD

Company: Precetakan Image Vest Sdn Bhd Country: Malaysia

Job Title: Forest Hills Press: Mitsubishi Diamond 3000 Pre-Press: PWR Design Sdn Bhd/ Image Vest Sdn Bhd Ink: Tempo Tropica Paper: RJ Paper Sdn Bhd

Company: NPE Print Communications Pte Ltd Country: Singapore Job Title: Sail Book 2021 Press: Ryobi 920 Pre-Press: Redbean Paper: OVOL Singapore

GOLD Company: S.M.K Printing Co Ltd Country: Thailand

Job Title: Buphphesanniwas Press: Heidelberg Paper: C.A.S Paper Inks: Soy Ink

GOLD Company: PT Bintang Sempurna Country: Indonesia

Job Title: LPDP Calendar Press: HP Indigo 5900 Pre-Press: Nirmana Exa Tricipta (NEXT) Ink: CMYK + Orange + Violet Paper: Nettuno Bianco Artico + Sirlo PolarDown

SILVER Company: Darnsutha Press Co. Ltd Country: Thailand

Job Title: Rolls Royce Calendar 22 Press: HP Indigo 5900 Pre-Press: Rolls Royce UK Ink: HP Ink Paper: Shine Co Ltd Ultimate Client: Good Wood Motor Work Co Ltd

SILVER Company: Colourman Online Sdn Bhd Country: Malaysia Job Title: My Days Daily Calendar Press: Color 1000 Press

GOLD Company: Luck Advertising Co Ltd Country: Thailand

Job Title: Dentiste x Lisa Press: HP 5800 Pre-Press: Central Watson Paper: BPS

Ultimate Client: Central Waston

SILVER Company: Cyberprint Group Country: Thailand Job Title: Salmon Oil Press: Colmar UV Flatbed Pre-Press: The Best One Creation Ink: Led UV Ink Paper: SCG

GOLD Company: Fingerprint Pte Ltd Country: Hong Kong

Job Title: Memoir of Insect Funeral Press: Iridesse Production Press

SILVER Company: PT Bintang Sempurna Country: Indonesia Job Title: The Fighting Fish Press: HP Indigo 7900

Pre-Press: Nirmana Exa Tricipta (NEXT) Ink: CMYK + Fluorescent Yellow + Fluorescent Pink + White Ink Paper: Cover PU . Inside X Per Premium White

GOLD

Company: Wongtawan Co Ltd Country: Thailand

Job Title: Ink Waruntorn Box Set Press: Heidelberg CD 102 + manroland R704 + manroland R304

Pre-Press: Mr Supichan Rojanich Ink: PVC 4 Colour process ink + NEX-P 4 Colour Process ink Paper: KPP – Antalis (Thailand) Ltd + K Laser Technology (Thailand)

Ultimate Client: MUZIK MOVE Co Ltd

GOLD Company: K.P.P Packaging Pte Ltd. Country: Singapore Job Title: nor sken Press: Heidelberg Pre-Press: In House Paper: OVOL Singapore Pte Ltd

SILVER Company: NPE Print Communications Pte Ltd Country: Singapore Job Title: Starbucks Press: Heidelberg CD 102 Pre-Press: PMG Asia Pacific Paper: OVOL Singapore Pte Ltd

BRONZE Company: Precetakan Image Vest Sdn Bhd Country: Malaysia Job Title: BioWonders Press: Mitsubishi Diamond 3000 Pre-Press: In House Ink: ISI HDI Ink Paper: Hiew Paper Supplies Sdn Bhd

GOLD

Company: Image Quality Lab Co Ltd Country: Thailand Job Title: Out of Line 22 Press: Iridesse Production Press Pre-Press: Yaowaphat Chantarakanok Paper: Digipro

https://www.dropbox.com/scl/fo/rosq9ebw23bjjkeqibks3/h?dl=0&rlkey=uh8qd4q5dijkt9vw4bxibwl75

SILVER Company: Chanwanich Security Printing Co. Ltd Country: Thailand Job Title: Skin Agem 2022 Beauty Set Press: Heidelberg Pre-Press: In House Ink: DIC Corporation Paper: Suksawad Converting Centre Co Ltd

SILVER

Company: Cyberprint Group Country: Thailand

Job Title: Kanlungan Book Press: HP Indigo 5600 Pre-Press: Norman Design Ink: HP Indigo Electroink Paper: SCG + Ekawin

GOLD

Company: Refine Printing Pte Ltd Country: Singapore

Job Title: Top Thinkers – Bright Creatives Press: Iridesse Production Press Pre-Press: M.A.D School Ink: Digital Toner Paper: Sunway Paper (S) Pte Ltd

GOLD

Company: Art Book Coop. Online Country: Japan

Job Title: Art Book Zine products with Digital press technologies Press: Iridesse Production Press & JetPress 750S FBI Customer

GOLD (Special Application)

Company: Neolt Asia Pte Ltd Country: Singapore

Job Title: Metallica Beverages Press: Quantix Pre-Press: In House Ink: Quantix

GOLD (Board).

Company: Cyberprint Group Country: Thailand

Job Title: Spectrum of Thai Coffee Press: HP Indigo 10000 Pre-Press: Kinnest Group Ink: HP Indigo Electroink

SILVER (Board)

Company: Hoang Ha Label Co Ltd (QLM Vietnam) Country: Vietnam

Job Title: Son Moisturising Cream Press: HP Indigo 5500 Pre-Press: In House Ink: HP Electroinks Paper: An Viet Phat

Company: Artech Printing & Graphix Pte Ltd) Country: Singapore Job Title: Dr Jart+ Product Carton Press: Iridesse Production Press

all the photos, click this link https://www.dropbox.com/scl/fo/rosq9ebw23bjjkeqibks3/h?dl=0&rlkey=uh8qd4q5dijkt9vw4bxibwl75

BRONZE (Board)

Company: Anaswara Offset Private Ltd Country: India

Job Title: BIPHA Yamini Cream Press: Konica Minolta – Accurio Press Pre-Press: Design Difference Kohi Ink: Digital Toner Paper: Padiyan Meena Associates Ultimate Client: BIPHA Drug Laboratories Pvt Ltd

GOLD

Company: Hoang Ha Label Co Ltd (QLM Vietnam) Country: Vietnam Job Title: Nouc Mam Diversity Press: HP Indigo 6800 Pre-Press: Supplied Ink: HP Electeoinks Paper: UPM Raflatac

SILVER Company: QLM Label Makers Sdn Bhd Country: Malaysia

Job Title: Cirillo 1850 Press: HP Indigo 6800 Pre-Press: In House Ink: HP ink Paper: AD

BRONZE Company: Mega Labels (Malaysia) Sdn Bhd Country: Malaysia Job Title: ME Alicafe French Press: Durst Pre-Press: In House Ink: Durst Ink Paper: Avery Dennison (Malaysia) Sdn Bhd

SILVER Company: Fastroll labels (M) Sdn Bhd Country: Malaysia Job Title: Jimeido Press: HP Indigo 6800 Pre-Press: In House Ink: HP ink Paper: Avery Dennison Materials Sdn Bhd

BRONZE Company: GMW Creative Prints Country: Malaysia Job Title: Space Monkey Windscreen Sticker Press: Iridesse Production Press

GOLD

Company: Marga Kirana Printing Country: Indonesia

Job Title: Michael Turning 7 Birthday Package (Halloween) Press: Iridesse Production Press

SILVER Company: Shirahashi Co., Ltd. Country: Japan

Job Title: Let’s support the athletes with “nonchan” at home! Press: Color 1000i Press - Versant 2100 - Iridesse Production Press

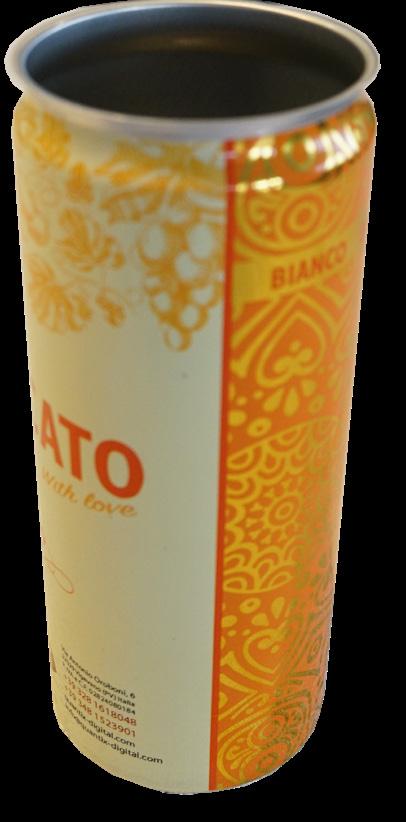

GOLD

Company: Chanwanich Security Printing Co. Ltd Country: Thailand

Job Title: Tang Tropical Fruit Press: Roland – CGS ORIS Pre-Press: In House Ink: N/A Paper: Suksawad Converting Centre Co. Ltd

SILVER Company: Sirivatana Interprint Public Company Limited Country: Thailand

Job Title: The Ethics of Beauty Press: Epson 9890 Pre-Press: N/A Paper: Hansol Paper Co Ltd Ultimate Client: Asia Pacific Offset Ltd

GOLD

Company: NPE Print Communications Pte Ltd Country: Singapore

Job Title: The Gift Press: Ryobi 920 Pre-Press: Currency Design House Ink: Soy Ink Paper: R.J Paper Pte Ltd and Sunway Paper (S) Pte Ltd Ultimate Client: Singapore Art Museum

SILVER Company: Neolt Asia Pte Ltd Country: Singapore

Job Title: Metallic Glass Press: MATAN Pre-Press: In House Ink: Secret Glass Substrate

SILVER Company: QLM Label Makers Sdn Bhd Country: Malaysia

Job Title: Labels (Various) Press: HP Pre-Press: In House Ink: HP Paper: AD

GOLD

Company: Holographic Label Sdn Bhd Country: Malaysia Job Title: Tax Stamp Holographic Press: Intermediate Sanki, Konica Minolta, Screen Print, Auto Screen Pre-Press: In House Ink: Invisible Ink, OCI Optical Changeable Ink Paper: Not disclosed

Security features: Un-copyable CertiEye marks (Super QR): Running Serial & Random Pin Number: Guilloche Design: Rochette Design: Line Width Modulation: Optical Changeable Ink (OCI): Filter image: Microtext: Invisible Ink: Sensitizing: Taggant Ink

GOLD TVG Thai Country: Thailand

Job Title: Phannapast Painting Reprint Press: Versant 180 Press Attn: Mr. Chaowut Cholchalathan (CEO) Email Address: jobchaowut@gmail.com

SILVER

Company: Green Production (Overseas) Group Country: Hong Kong

Job Title: 12 Joyful Chinese Zodiacs Press: Konica Minolta C6100 + MGI Jet Varnish 3Ds Foil Pre-Press: Terence lee Ink: Simitri HDE Colour by KM + Digital foil Paper: Acumen Paper – Mori Silk (Japanese)

GOLD

Company: Kwanginsa (South Korea) Country: South Korea

Job Title: Calendar Press: Heidelberg Pre-Press: In House Ink: Korea Special Ink – Nanobrick MTX Ink Paper: TARA Distribution & Moorim Paper

A new report has confirmed the increasing popularity of physical books over e-readers – especially on holiday where paper is the ideal companion.

So how was your holiday? Go anywhere nice? Lots of sun? Hopefully, you have managed to get a summer break and are now dealing with the barrage of questions about your holiday. But while it’s likely you will get plenty of enquiries about the destination and weather, you won’t get too many about your reading matter.

For many people, the chance to settle down with a book by the pool, on the beach, or on the campsite is one of the delights of a summer holiday. Hours of time to fill, uninterrupted by emails, calls, texts or alerts, is the ideal recipe for relaxation and the perfect time to catch up with some non-work-related reading.

But while what you read is frankly none of our business, did you lean back in the lounger with a physical book or an

e-reader? If you idly worked your way through a paper book then you’re in the global majority of readers that prefers paper to digital.

A new study by Stora Enso has found that 65% of people around the world prefer reading physical books, as

Connect to Grow. That is your key to stay ahead in a demanding market. By connecting with MPSConnect, you ensure the best in reliability and productivity from your printing press. You will increase competitive advantages and maximize profits.

To improve productivity and profi tability, it’s critical to increase the understanding of your overall label print operation. With MPSConnect, you get real-time insights in the operator activities. You dive into the printing press and see exactly what’s happening.

With MPSConnect we see recurring annual cost savings of €50,000 - €100,000 and even more thanks to a more efficient workflow, time management and waste reduction. mps-printing.com/connect-to-grow

mps-printing.com

opposed to 21% who prefer e-books –that’s over three times the amount of people.

Having surveyed 2,400 book readers of all ages in the UK, France, Germany and the US, the international paper makers discovered that the French showed the strongest preference for physical books, with most respondents saying they prefer to read to get quality time alone.

“These results confirmed our expectations that the market for physical books is set to stay strong,” said Jonathan Bakewell, VP, Head of Segment Office and Book Papers at Stora Enso. “People have begun rediscovering reading, partly prompted

by the pandemic, where many were tethered to their screens all day for work or school, then didn’t want to take them to the sofa when it was time to relax.”

It’s this disconnection that seems to be driving the continuing popularity of paper books, with the look and feel of the physical object adding to the reading experience. Some respondents in the Stora Enso survey even cited the smell of a physical book that could evoke pleasant memories.

But when you consider the beach or poolside environment, it’s clear that physical books have the edge over their digital cousin. Whether it’s the ease of reading under harsh sunlight, lack of concern about it getting covered in

sand, or not worrying about the battery life, paper books are the ideal holiday companion.

One of the other major advantages of print in the eyes of book readers is its sustainability and major contribution to the circular economy. Stora Enso reported that 42% of readers said they like to keep books when they finish reading them, while 26% loan or donate them. A further 26% sell their books and the remaining 5% recycle them.

The question was then posed about whether the respondents would pay more for carbon-neutral books, and an overwhelming majority said they would, with 61% saying they would be willing to pay on average 5.7% on top of the retail price. Given the paper industry’s excellent record for cutting carbon emissions and offsetting any remaining emissions, it stands head and shoulders above digital media when it comes to sustainability.

So next time you’re sitting on a beach or by the pool, take a look around. Chances are that most of your fellow holiday-makers will be engrossed in a paper book, being sustainable, one page at a time.

With every new format, consumer fad, market trend, and brand-owner‘s de mand, the packaging business gets more competitive and the pressure on printers increases. Premiumization, personalization, shorter runs, sustai nability, shorter lead time, lower costs — this is the world we operate in.

As everyone knows, your printing can‘t begin until the plates are moun ted. It‘s the starting point, and a pivotal aspect of every run. We work hand-inhand our customers to help printers, operators and plant managers to over come their challenges.

Print quality in flexo is improving conti nuously and is competing with stan dards of gravure print quality, the im portance of the right plate mounting solution is critical. The right solution and density are crucial in transferring the image to the substrate as accura tely as possible.

Futhermore, since brand owners have many changes in their design and want to minimize the time to market, the amount of job changes is increa sing. This puts a lot of pressure on the

tesa® Softprint plate mounting tapes are specially developed to provide the highest quality levels of both print qua lity and process efficiency. tesa® Soft print are made from high quality mate rials that ensure best performance in bonding, handling, and printing.

This performance can be reach not only with our adhesives but also be cause we do not apply stress to the foam during our manufacturing. When all foam cells are untouched and unda

mounting department and the press operators to get the maximum effi ciency out of their press with the lo west amount of downtime possible.

managed, the foam is better able to absorb bounce from the sleeves that can leave chatter, or gear marks. Fur ther more it will be more resilient. The foam will compress and return to the same thickness over and over and over, from the first impression to the last. This would result in beautiful prints from the fine screens to deep to deep solida areas, whether the job is a few thousand or a few million feet.

Self-adhesive

tesa® Twinlock layer

Stablization layer

Open cell polyurethane foam

Base sleeve

tesa® Twinlock

The unique concept of tesa® Twinlock is to provide sustainable and reusable plate mounting solutions for cost effi cient and consistenly high-quality print jobs. The basis for this technolo gy begins with the select of a base sleeve or cylinder from the customer‘s preferred supplier. We then add a po lyurethane (PU) foam layer to the top of the base sleeve. The PU foam is coated with an unique polymer that has the characterisitcs to remain per manently tacky. When proper clea ning and handling procedures are ob served, the tesa® Twinlock sleeves can be used for a very long period.

Our adhesive plate mounting sleeves provide exceptional print quality. Even after long press times, the sleeves produce accurate and reliable results. The consistent print quality is attribu ted to our open-cell foam structure. Through this foam structure, our slee

ves absorb bouncing effects to impro ve print quality. A second critical fctor that influences print quality is our strick diameter tolerances. We use la ser technology to measure our slee ves and ensure they meet customer exact requirements.

With tesa® Twinlock, we enable:

• High printing speeds

• Lasting print quality without the need for adjustments

• Excellent registration

The main advantage of this technolo gy is the reusability of the self-adhe sive sleeve. When best practices are observed, our reusable sleeves have the potential to be used fo a very long period of time. In most cases, our tesa® Twinlock sleeves only need to be recoated when physical damage occurs to the base sleeve or coating.

Flexo printers benefits from:

• Lower running cost

• Carbon footprint reduction

• Fast ROI when reusing the same repeats

• A more precise estimate of input production costs

Digitization and the latest innovative technologies can now give you the freedom and the guarantees to costeffectively and efficiently drive your business to new levels of capacity and capability. The range of possible applications is widening significantly and the options and choices are only limited by your imagination and ambition. The key is to find the right equipment supplier to make it happen!

We have all been part of the huge uptake in online ordering during the pandemic. The retail game has radically changed and everyone in the supply chain has to be ready and able. Differentiating and delivering products to satisfy the consumer’s ever changing tastes and preferences is a continuing challenge for everyone.

Market trends continue to evolve. Consumers are constantly online searching for ‘stand out’ high quality products and brand owners and designers are continually refreshing their brands. Equipment suppliers and printers and converters have to continually review and expand their capabilities and adopt the latest innovations and technologies to satisfy all the stakeholders and keep ahead of the competition.

If you are looking for innovation and the latest info on digital, Xeikon is your

‘go to’ digital guru. As a leading supplier of everything digital, having a chat with them is a good starting place for any company looking to the future. With over 40 years’ experience of digital innovation, Xeikon’s vision has always been to offer printers and converters a clear pathway to digital transformation.

One of the first things that Xeikon will tell you: ‘make sure you have an up to date and flexible, intelligent and innovative workflow’ that can drive and efficiently manage the zillions of small jobs that you will have to handle. Speed to market is essential so, apart from a clever and robust digital press with man/machine and machine/machine interfaces, you will also need powerful cloud connected software like Xeikon’s X-800 Digital Front End.

This has ‘ahead of the game’ capabilities for data management and security and full colour controls to drive multiple applications for the print and manufacturing of any kind of labels including high-end and security labels for track & trace against counterfeiting, interior décor applications such as wallpapers and textiles, also graphic arts applications such as books and bibles using the thinnest of papers, postcards with creative personalisation, calendars, posters, direct mail, point of sale – the list goes on and on…..

Xeikon is a technology agnostic company. They can advise you on the best way forward on your digital pathway to expand your business. They can advise you on how best to expand your portfolio of applications - whether to go with dry toner technology or inkjet technology for example. It’s not always known but different applications require different technologies to get the best results. Having the right finishing equipment will also equip you with flexible, high-end embellishment capability.

Xeikon’s portfolio is bang up to date:

- Cheetah dry toner technology with full accreditation for food safe applications

- Panther inkjet technology for high gloss, durable applications

- Sirius technology for graphic arts applications

- Idera technology for corrugated packaging – all driven by Xeikon’s X-800 digital front end.

Xeikon has carefully structured and developed its portfolio with the very latest technologies to offer printers and converters every opportunity to create the widest range of added value applications - all from one supplier.

If you’re thinking of widening your range of applications and wondering how to go about it – Get excited! Moving into full digital print production and manufacturing means you can expand your portfolio and radically change your business.

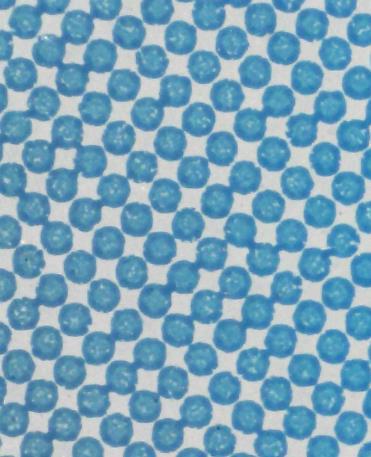

Expanding the ThermoFlexX Woodpecker family of high frequency surface screens, Nevis has been specifically developed for printing with white inks on film-based substrates.

XSYS is pleased to announce a new version of ThermoFlexX Woodpecker surface microstructure technology that enables higher imaging speeds of flat top dot flexographic plates for standard white inks. As a simple, open and effective screening solution, Woodpecker Nevis has the potential to save on costly white ink while providing more contrast and improved colors in flexible packaging printing. Already commercially available, it is the latest addition to the Woodpecker portfolio, which also includes the Sharp, Nano and Replay options for ThermoFlexX TFxX plate imagers.

“Woodpecker Nevis screening improves overall brilliance and makes it possible to save on white ink costs while also simplifying and speeding up the imaging process,” said Christophe Lievens, Global Sales Director XSYS

Prepress. “In combination with the ThermoFlexX Multiplate option, which allows multiple resolutions to be imaged on the same plate, it delivers a more cost-effective and competitive solution that will help printers optimize OEE and reduce waste.”

The objective of the Woodpecker surface screening solution is to control the ink more accurately, as it is transferred from the anilox to the plate and onto the substrate. The result is a smoother, higher opacity ink laydown, sharper line work, and cleaner screens, without any of the common printing defects often found in flexo printing, such as pin holing, trail edge voids, and halo effects, at full press speed.

Woodpecker surface microstructures are applied at the imaging stage and is an adaptable solution that works with

open RIPs. Furthermore, as the pattern is not embedded in the file, which normally increases its size greatly, much faster data exchange and computer processing times can be achieved. This significant reduction in workflow complexity also improves plate delivery times and ultimately speed to market for brand owners.

Developed to work seamlessly with the higher volume anilox rollers usually used for printing with standard white ink on film-based substrates in flexible packaging, Woodpecker Nevis consists of three surface patterns with different levels of coarseness for the broadest application reach.

While a higher volume anilox will increase quality and opacity, there is also the option to decrease the anilox volume which may consume less

expensive white ink without negatively impacting the opacity.

“Good coverage of white is essential in flexible packaging printing where it provides the foundation for strong colors and impactful graphics. However, white ink can represent as much as 50% of the total ink costs, so XSYS continues to develop new products that can help optimize the process, lower costs, and take out more waste.

With Woodpecker Nevis, we are bringing to market a flexible and sustainable solution that can be adapted to each customer’s individual needs,” concluded Stephan Reis, Global Marketing Director. “We now offer high frequency surface screens for process colors and white, thereby covering the whole spectrum.”

The steady return of Manroland Sheetfed into the Indian packaging market in the last several years is bearing fruit as the company has considerably lifted its game in the past year. As the pandemic and the lockdowns ended, the company’s wholly-owned subsidiary in India, Manroland Sheetfed India became bolder and went beyond talking to its considerable installed footprint in the India monocarton industry.

This has paid off, as the industry returns to structured capacity building with several converters who have held off investments in the past two or three years purchasing highly automated 7-color plus coater automated B1 presses. The Manroland Evolution series are thus recognized by the Indian packaging converters as one of the modern automated options that

have to be evaluated when looking at capacity expansion.

Recently, Manroland Sheetfed Evolution 700 presses were purchased by two monocarton companies in the Delhi NCR-Sain Packaging and Galaxy Offset. The presses with full automate loading with interdeck and end-of-press UV cassettes besides the standard IR and hot air dryers. The Sain Packaging press will be installed at its plant north of the city in Sonipat, while Galaxy’s Evolution will come to its new plant built south of Manesar. The two Evolution presses will be shipped in the coming months and installed within the financial year that ends on 31 March 2022.

The return of Manroland Sheetfed to the ranks of global suppliers selling

new 7-color coater UV presses with automation into the Indian market a welcome and successful renewal of intensity by the third German offset sheetfed press manufacturer. It has been an uphill climb. But the reestablishment of the company with its persistence in the supplying spares, service, and technical support services has led to the multiple sales of new and used presses. Its active participation provides significant options for the fast-growing and maturing Indian carton industry.

The Indian and South Asian carton printers and converters are now relatively well versed in the technicalities and details of purchasing a sophisticated automated press. They are more than able to sort through the levels of features, options, and “innovations” - looking for high performance and reliability not only from the machines but also from the Indian subsidiaries and distributor of the five global manufacturers.

Engineering service and back office support are a given in this highly technical and competitive market, as are improved inputs and consumables. The carton manufacturers are looking for industrial strength reliability – they have put in place the infrastructure to use these presses to higher specification work and quality at rated speeds for performance, productivity, and return on investment. They are mindful of the benefits of automation to the skilled human resources and the talent in the press room, The press commissioned in this market in the current financial year are no less sophisticated or automated than those anywhere in the world.

Two new Evolution 700 plus coater UV presses to come in FY 2022-23

HP Inc. and ePac Flexible Packaging, have announced the purchase of 50 new HP Indigo digital presses to be deployed in existing and new sites around the world, as part of ePac's continued global expansion plan. It's the largest deal ever for HP Indigo.

ePac Flexible Packaging is a digitally based, flexible packaging company driven by its mission to help brands and businesses of all sizes remain competitive with a variety of flexible packaging solutions. ePac leverages the latest in digital print technology, providing its customers with a quick and easy way to purchase custom printed flexible packaging.

ePac has been a principal adopter of HP Indigo digital presses since the company’s inception in 2016 and has since upheld a strong and deeply rooted collaboration with HP. Over the past six years, the company’s fleet of HP Indigo digital presses has grown enormously, overseeing large-scale investments of HP Indigo 20000 and HP Indigo 25K digital presses.

The new wave of 50x HP Indigo digital presses, the largest single order in HP

Indigo’s history, will accelerate ePac’s record-breaking production capacity as it continues to disrupt the global flexible packaging market.

Focusing on global expansion, this new fleet will be distributed within 36 new and existing sites across 5 continents. These presses, which incorporate HP Indigo’s latest technologies, will also support ePac’s strategy to expand its share and business in existing markets

“As we recently announced, ePac aims to accelerate its growth and expand its global footprint. Our 50-press acquisition will enhance ePac’s record

breaking flexible packaging production on HP Indigo Digital Presses, further rooting our longstanding collaboration with HP. This transition will leverage ePac’s vast market experience together with HP’s unique digital printing technology,” said Virag Patel, COO, ePac.

“ePac Flexible Packaging is leading the global digital flexible packaging movement as it continues to replicate its HP Indigo-based business model in new locations around the world. ePac’s vision to utilize digital print to give a voice to small and medium brands and revitalize local communities exemplifies our joint values and demonstrates the power of digital to have a meaningful global impact,” said Haim Levit, GM of HP’s Industrial Print Business.

ePac Flexible Packaging’s latest investment in HP Indigo technology is an example of how HP is continuing to promote the advantages of digital printing and serving more brands and communities around the world.

The indoprint exhibition returned this year at Jiexpo, Jakarta. The leading print industry exhibition in Indonesia is organized every 2 years by Messe Dusseldorf Asia Pte Ltd in collaboration with Wakeni as the local event organizer.

Attended by 15,000 people from 15 countries, Heidelberg's booth was the biggest magnet for visitors to the exhibition featuring the latest Speedmaster CX 104-4 and Versafire EV machines. Occupying a strategic location, Heidelberg, with the theme "Your Key Partner in Commercial, Packaging & Label", presented the latest technology and innovative solutions to print entrepreneurs so that their business will increase.

This is a form of commitment and full dedication as a trusted key business partner so that customers can focus more on their business goals. As supporting activities for this exhibition Heidelberg also held press conferences, seminars, presentations and live demonstrations as well as exhibitions at the Heidelberg Indonesia Head office showroom featuring a line of post press packaging machines including the MK Easymatrix CS die cutter, Diana Go folder gluer and Polar cutter.

While enthusiastic visitors crowded at Heidelberg's booth, our seminar was also well attended by many visitors

including lecturers, members of printing associations and journalists. The two-day seminar program at the exhibition featured some exciting new topics. As a starter, on the first day we presented the topic 'Gallus solutions for labels with Flexo, Digital or Hybrid' and on the second day 'Your Key Partner in Commercial and Packaging' was the main topic of the seminar. On this occasion Heidelberg Indonesia introduced the world premiere of the new Gallus One label machine.

Heidelberg Indonesia's success at this exhibition was reflected in several achievements made during the exhibition, including the removal and installation of the machine in less than 3 days and the dismantling of the machine in 15 hours. This success was further enhanced with orders for

5 sheetfed machines, 10 post press machines, 2 CtP machines and 2 Gallus Flexo machines. There were also several deals made during the exhibition and dozens of prospects to follow up on.

This is certainly a significant benchmark, but the most important thing is to strengthen the market position with a clear differentiation with the main competitors in the print industry.

Heidelberg Indonesia President Director - Nick Trabold emphasized: "With our theme "Your Key Partner

in Commercial, Packaging & Label", we clearly convey and emphasize what we believe in: a reliable key consulting partner so that our customers can focus more on their business goals.

How to achieve, provide customer service and satisfaction and to guide our customers in making the right decisions while at the same time establishing strong partnerships to assist the internal side of print production and work optimization processes from PDF creation to finished printed goods".

Landa Digital Printing and Shenzhen Nine Stars Printing and Packaging Co., Ltd, a subsidiary of CR Sanjiu, has announce the installation of an S10 Nanographic Printing® Press at the Chinese packaging specialist, Nine Stars Printing and Packaging co,. Ltd at its Longgang (Shenzhen) facility.

The company is using its new Landa S10 press to widen its product offering to customers, while also streamlining production by replacing traditional analogue short to medium-run packaging jobs with a cost effective, profitable, and waste reducing digital printing process.

Nine Stars Printing believes that Nanography will revolutionize the Chinese packaging market. Mr. Liu, Wen Heng, General Manager of Nine Stars Printing comments: “We pride ourselves on adopting market leading technology, and the Landa S10 is one of the most exciting and transformative solutions to enter the market for generations.”

“We’re confident that the Landa S10 with its B1 digital format, high print speed and incredible color capabilities, will provide earlier adopters like us with a very valuable competitive advantage. Importantly, the Landa S10 will enable us to change our business model and offer a range of profitable new services – increasing our value to customers –

and ultimately, in close partnership with Landa, transition the Chinese printing industry to a more sustainable and future proofed technology.”

Established in 1989, Nine Stars Printing was ranked 49th in China’s top 100 printing companies of 2021. Supporting markets including pharmaceutical, electronics, personal care and food markets, the company provides a range of folding carton and label printing services from three production facilities in Longgang (Shenzhen), Shanghai and Benxi. The new Landa S10 was installed at the Longgang (Shenzhen) facility in

Engineered for the packaging and converting industries, the single-sided B1 (41 in. / 1,050 mm) format Landa S10 Nanographic Printing Press enables just-in-time mainstream efficiency for the production of folding carton and POP/POS. The Landa S10 press prints at a speed of 6,500 sheets per hour on standard offset papers and substrates in thickness from 4-32 pt. (0.06-0.8 mm). With a crossover point that can reach many tens’ thousands of boxes, the Landa S10 provides a perfect digital solution for the folding carton industry

Gil Oron, CEO, Landa Digital Printing comments: “China is such an exciting market for us, and we’re delighted to have Nine Stars Printing as another customer in the region. They are a very well-run business with an experienced and dynamic management team, and a clear vision for the future of the industry and Nanography’s role within it. We look forward to working with them over the coming weeks and months, and to further broadening our install base in this phenomenal region.”

Packaging and printing technologies and solutions for today and tomorrow, this is the hallmark of PACKPRINT INTERNATIONAL 2023. As the exhibition for the industry by the industry, here's where you can conduct successful business transactions, secure deals and network with relevant brand names. For the second time, CorruTec ASIA - International Corrugated technology Exhibition for Asia - will be co-located with PACK PRINT INTERNATIONAL. Join us in presenting smart technologies and innovative solutions to the dynamic markets of Southeast Asia.

- The new press will allow ICC to achieve the goal of doubling output per labour hour and delivering product to customers in four to five weeks from order

- ICC was named 2021 High Performance Metal Decorator of The Year by Koenig & Bauer MetalPrint

- ICC’s goal is to be the primary source for highly decorated, specialty cans in the United States

In late September 2022, Independent Can Company, a leader in the printing and manufacturing of specialty metal packaging, celebrated the official commissioning of its new Koenig & Bauer MetalStar 3 press at an open house at its Belcamp, MD facility. ICC is now the only company operating a nine-colour metal decorating printing line in the Western Hemisphere.

The new nine-colour line allows one pass work for up to nine colours. This capability will be instrumental in helping ICC to achieve the goal of doubling output per labour hour and

delivering product to customers in four – five weeks from order.

“We have made historic investments to solidify our position in the market and this new press marks the latest,” says Richard Huether, President and CEO of Independent Can Company. “With the goal of being the primary source for highly decorated, specialty cans in the United States, our company has invested heavily in facility maximisation and the latest technology in can making and lithography.”

ICC is the largest user of MetalStar technology in North America. In addition to the new nine-colour line, the organisation also operates two sixcolour MetalStar 2 lines and a fourcolour MetalStar 2, in use at their plants in Maryland and Ohio.

For more than twenty years, ICC has been recognised for excellence in print quality by Can Maker Magazine, the International Metal Decorators & Packaging Association and most recently by Koenig & Bauer MetalPrint with the High Performance Metal Decorator of the Year 2021. This award was established to honour Koenig & Bauer MetalPrint customers who achieve outstanding, out-ofthe ordinary performance in metal decorating using Koenig & Bauer MetalPrint products.

Sam Pernice, Director of Sales & Service for Koenig & Bauer MetalPrint (US) commented on the historic nature of the order. “Independent Can Company is a true American success story which dates back to 1929,” he says. “Under the leadership of the Huether family, the company has grown and flourished for decades. This success has been achieved for a variety of reasons, not the least of which is their meticulous and professional approach when it comes to choosing their business partners.

Their decision to purchase a ninecolour MetalStar 3 is truly historic, as there is no other machine of this size

anywhere in the Western Hemisphere, giving them unmatched single pass capabilities.” Pernice concluded: “Their selection of the MetalStar 3 is the culmination of very careful planning and due diligence. We are honoured that they have chosen to place their confidence and trust in our hands once again.”

ICC is driven to remain competitive in a global market and being a domestic solution to the supply chain challenges for major brands. The company is more committed than ever to printing and manufacturing in the United States. With the largest portfolio of specialty can options, serving a wide range of markets, ICC is also keeping more than four hundred jobs in North America. Continuous improvement and reinvestment in technology benefits all of its customers and employees.

At the inauguration of the new Koenig & Bauer MetalStar 3, representatives from Koenig & Bauer MetalPrint and Independent Can Company celebrated. (Left to right) Sam Pernice, Koenig & Bauer Director of Sales & Service for the MetalPrint Division; Rick Huether, President and CEO of Independent Can Company; Ryan Huether, Chief Operating Officer of ICC; Doug Huether, Chairman Emeritus of ICC; Cathy Huether McClelland, family member and shareholder; Mac McClelland, shareholder of ICC; and Pekka Hobbeling, Managing Director of Koenig & Bauer MetalPrint

Floricolor is one of the leading producers of professional photography albums in the world. From its premises in Portugal, it serves customers in 27 countries around the globe, producing albums and other printed materials for some of the world’s leading portrait photographers.

Floricolor celebrated its investment in Fujifilm’s Revoria PC1120 press with an open house event. Inviting several Portuguese customers, Floricolor and Fujifilm demonstrated the full potential of the new Revoria press –working in tandem with the Jet Press 750S – with printed samples and live demonstrations.

“The open house presented an initial opportunity for us to showcase what the Revoria can achieve, as well as giving our customers a chance to provide feedback.” explains Tiago Yu, CEO, Floricolor. “They were all very impressed with the results and what can be achieved, so we knew exciting times lie ahead.

“Our main market used to be wedding albums, but in recent years we’ve seen the demand for this service decrease. Demand for wedding invitations, however, is still just as strong, so we saw an opportunity to compensate for this loss in wedding album production

by entering the wedding invitation space, something which has only been possible with the investment in the Revoria press. It also enables us to print large wedding album covers that we were previously not able to, helping us to expand our product offering and increase our revenue.

“With the Revoria PC1120, we have launched a new business venture named Studio 6. Under the Studio 6 brand, we print wedding invitations, thank you cards, business cards and special stationery for our customers. We use the PC1120, in combination with other finishing equipment, to offer our customers a range of unique products, using special colours such as gold and silver varnishes.

“In addition to the special colours, the PC1120 enables us to print on substrates of many thicknesses, sizes and types, including plastic – something that we could not achieve with any comparable press on the market.

The machine’s media handling is also particularly impressive.

“The designers have been very impressed with the results that can be achieved from the Revoria press, particularly the special colours, textures and different substrates. Typically, it would be difficult to achieve a small run order of special colours, but with the Revoria PC1120, we are now able to do just that. All of our customers have been amazed with the quality and turnaround times.

“There are many ongoing challenges in the market, but Fujifilm is always a reliable partner that has enabled us to overcome these challenges and help us to grow. We have immense confidence in them to help us deliver print of the highest standard and we are looking forward to continuing to develop this relationship in the future.”

Filipe Marques, Country Manager, Portugal at Fujifilm Europe comments: “We’re delighted to have an ongoing partnership with Floricolor that continues to grow. It’s been great to see how their business has developed, following their investment in both the Jet Press 750S and more recently, the Revoria PC1120. We are excited to see what is next for Floricolor and how we can continue to support them.”

in terms of productivity and quality. “The manufacturer achieved excellent results at a screen ruling of 150-175 lpi and a production speed of 130 tubes a minute.”

on plastic-based substrates, which are then applied to the tubes. As well as the additional production step, this adds complexity at the recycling stage, when labels and sleeves have to be separated from the tube.”

Asked what sets Numex Blocks apart from the competition, owner Nitin Patil replies: “We treat every job that comes in as if it’s the first job for that customer. They all deserve the same time and attention.”

This strategy has served the Mumbaibased trade shop well for over three decades of steady progress, crowned most recently with a Silver Award in the Miraclon-sponsored Global Flexo Innovation Awards (GFIA), awarded for a successful gravure-to-flexo process conversion involving ‘direct-to-tube’ printing of over 2,500 skincare SKUs.

As for the contribution of KODAK FLEXCEL NX Plates to the success of the job, Nitin believes the switch to direct-to-tube printing would have been impossible without them, both

Faith in flexo Numex invested in a KODAK FLEXCEL NX System in 2014. Subsequently, FLEXCEL NX Systems have also been installed at Numex’s sister companies — Nuflex Graphics in Pune, and NS Digital Flexo in Hyderabad. The quadruple investment – with a fifth system planned for later this year - is a clear sign of Nitin Patil’s faith in flexo and FLEXCEL NX Technology, especially for flexible packaging.

“The transition from gravure to flexo is happening across Asia, not just in India,” he says, adding that one factor in favor of flexo, and in particular FLEXCEL NX Plates, is its “ability to deliver high-quality results on thinner, more sustainable PE substrates — an area where gravure has limitations.”

The award-winning entry demonstrated precisely these advantages, as well as Numex’s trademark job-to-job attention to detail. A key objective of the job was to improve the sustainability performance of a substantial number of tube-packaged skincare products — over 2,500 SKUs in total. Says Nitin: “Gravure and other production processes typically involve printing

Numex’s customer, a packaging manufacturer, wanted to explore a ‘direct-to-tube’ workflow that would remove the variability in recycling and eliminate a manufacturing step, and for the purpose had invested in a special 13-color rotary form press. The next step was discussions between Numex, the manufacturer, and the brand owner to identify any potential challenges posed by the products themselves and the planned workflow, including achieving the right skin tone colors, the best way of refreshing the overall packaging, ensuring quick set-up and fast changeovers given the vast number of SKUs.

“The tubes were of standard PE coextruded construction, which is challenging to print on,” says Nitin. “In addition, most jobs were eight colors and each SKU featured different design features — for example, matte coatings to add a premium ‘look and feel’, spot varnishes, and graphics with demanding gradients that faded almost to zero.

All these coatings and varnishes were done using FLEXCEL NX Plates. So we put a lot of work into establishing

Gravure-to-flexo conversion “enabled by the productivity and quality offered by KODAK FLEXCEL NX Technology”Nitin Patil

how best to render, and even improve, colors and textures.”

“Great colors, wonderful imagery” The hard work paid dividends, with the GFIA judges praising the successful streamlining of the production process and its enhancement of the products’ sustainability, as well as the “excellent print quality, great colors and wonderful imagery”.

Productivity and quality were precisely what Numex wanted from its investment in the FLEXCEL NX System. Recalls Nitin: “By 2014, and largely thanks to FLEXCEL NX Technology, brands recognized that flexo produced high-quality results and that it was also a more cost-effective and productive solution that would remove expenditure from the supply chain — a key consideration.”

He lists a host of benefits that FLEXCEL NX Technology delivers, including accurate imaging, speed to register and color for faster set-up, durability and significantly greater productivity: “Imaging, processing and drying times are all faster — the overall production

time for a plate is 30-35 minutes less than with other technologies.”

Over 60% of Numex’s production — both flexible packaging and labels — now goes on FLEXCEL NX Plates, he says, and singles out the multiple advanced plate surface patterning features from Miraclon for delivering “optimum ink densities, whatever the substrate. It controls the ink flow like a mini anilox! We can confidently handle fine halftones in jobs using 175-200pli screen rulings, and smooth vignettes are also achievable.”

Nitin further comments positively on the support provided by Miraclon since becoming a FLEXCEL NX user. “They do a fantastic job of giving us end-to-end support, of both hardware and software, from calibration and workflow optimization to contributing to our gravure-to-flexo discussions with customers, which really helps the industry grow.”

A bright future with flexo

Looking to the future, Numex has plans to cement its position as a leading flexofocused trade shop, including working more closely with customers in the early

stages of projects. “That way we believe we can help brands shorten lead times even further.” Key to this is keeping abreast of the latest technology, because that will ensure we keep growing, and growth is a must if we’re to have a better tomorrow.”

In line with this strategy is Numex’s investment in the new FLEXCEL NX Central Software. Developed by Miraclon specifically to support customers in their drive for efficiency, waste reduction and labor savings, the software is tailored to the FLEXCEL NX System and enables customers to automate plate production while still employing multiple advanced plate surface patterning features.

Concludes Nitin: “With FLEXCEL NX Central Software we’re able to execute the plate layout function much faster than doing it manually, which simplifies ganging of jobs. We have easily been able to save as much as 50% of our time with the automatic plate layout function, as there is no thinking or planning involved – we just add the files into FLEXCEL NX Central and it prepares the plate layout automatically.”

The important role of print in reporting, documenting, and providing a permanent record of significant historical events was evident following the sad passing of Queen Elizabeth II.

Great Britain’s collective grief and reverence for a monarch that had reigned for seventy years was underlined by the huge interest in printed media that commemorated and celebrated her life.

Sales for many newspapers increased dramatically demonstrating how we still connect with the authenticity, credibility, and enduring presence of print.

The Daily Express sold 75% more copies the day after Her Majesty’s death.

On Twitter Karl Holbook, executive editor of the Express, said the demand showed the ‘deep affection’ people still have for print.

A spokesperson for the Guardian said that the newspaper’s sales more than doubled on September 10.

As well as special editions on the morning following the Queen’s death, there were a number of substantial commemorative supplements.

Magazines also produced editions that celebrated the life of the Queen. Special tribute issues included those from Grazia and Yours. These special editions will be retained through the years, held and treasured in the way that no online content ever can be.

Among the reasons we turn to print at significant moments is the power of trust it holds.

This is something Print Power recently highlighted following the results of the “Press and the various drivers of Trust” study by ACPM & Dentsu in France.

It found that in a world of fake news, deep fakes and alternative facts, the net trust score for offline media, including print, is three times higher than online media.

It also reported printed newspapers and magazines were among the communications channels that gave the highest trust levels to consumers because they offer credibility, proximity, and transparency.

Consumers are increasingly looking for trusted environments, and that extends to trusted media channels too.

Printed newspapers and magazines deliver this.

They remain consistently reliable sources that we turn to in significantly important times. The tangible power of print lends gravitas that online communications cannot deliver.

Printing on tube laminates using UV inkjet poses several application-specific challenges. The tubes, which are bent and crushed during squeezing, require a flexible ink film. By Dieter Finna

Seen in this light, it is not an easy task that the well-known laminate printers entrusted product development at Gallus Ferd. Rüesch AG with. The printing press manufacturer was able to adopt some of the solutions for the complex task from the results of another development project. On folding cartons, where the solids extend beyond the ink edges, there are comparable requirements for the flexibility of UV inkjet inks as for tube laminates.

The challenge lies in preventing the UV inkjet film from cracking under mechanical stress. For a long time, the only way to avoid cracking of the brittle ink film was to avoid solids that

extended beyond the folds by necessity in the packaging design.

Development of a flexible UV inkjet ink

For this reason, Gallus launched the "Flexible UV Inkjet Ink" project for folding carton printing along with a wellknown brand manufacturer at the start of 2019. The complex development project took three years to complete, including all the development steps, suitability tests and six months of ink qualification. For product qualification, the brand manufacturer printed more than 900 km of board on a Gallus Labelfire 340 and produced around 8 million blanks.

The requirement criteria in printing were for the ink film to be fully cured at a printing speed of 70 m/min and for a scratch-resistant, flexible ink film. In the packer test, blanks printed over the entire surface had to be able to be processed at 1,000 packs/minute without ink cracking. In addition, the UV inkjet printing ink had to pass the sensory test programme in the tobacco sector and fulfil all the requirements in the Regulatory Compliance & Toxical Assessment.

This included the composition of the UV inkjet ink according to Swiss Ordinance requirements, the REACH conformity test for chemicals, the requirements of the RoHS Directive

2011/65EU and the EUPIA exclusion list for defined raw materials as well as proof of freedom from substances with carcinogenic, mutagenic or reprotoxic effects.

The UV inkjet ink system developed in the project with the product name „UVF01“ passed the tests and has been released for commercial production in the brand manufacturer's folding box production since the beginning of this year. This provided the prerequisites for transferring the results of flexible UV inkjet inks from folding carton printing to the solution approach for tube laminates.

Modifications of the printing press system

Modifications to the Gallus Labelfire 340 were necessary to use the UVF01 ink system. These related to the drying technology and web guide. The latter had to be designed for the shortest possible web paths for the costintensive substrate.

Gallus has broken new ground in radiation curing. In the Gallus Labelfire version for the new flexible UV ink system, UV-LED curing systems replace the mercury vapour lamps previously used. The advantage of UV-LED technology is that the energy penetrates the ink layers more effectively thanks to the high intensity of the UV-A beams, resulting in more uniform curing. Due to the high intensity of the UV-LEDs, the use of boosters to intensify drying can be dispensed with.

This means that the temperaturesensitive tube laminate can be processed without heat effects. As an

additional measure, inert gas is used for fast and complete curing of the ink film wherein cross-linking of the ink film in the inert chambers takes place in the absence of oxygen, which has been replaced by nitrogen in the sealed environment.

The oxygen content in the inert chambers is continually monitored by sensors and kept below 500 ppm. The increase in curing performance achieved, as well as the reactivity of the photo initiators result in complete curing of the ink film at a printing speed of 70 m/min. An added benefit is that a very good adhesion of the ink to the substrate is achieved without the use of primers.

The machine layout of the modular Gallus Labelfire "Tube Edition" was designed to keep the web path in the machine as short as possible. Therefore only a single rewinder is used instead of the double rewinder. When selecting the flexographic printing units, the company opted for the Gallus ECS series.

The main advantage of these printing units is that they have an ultra-short web path of just 1.1 metres from printing nip to printing nip, which significantly reduces waste during makeready and production. Given the high material costs of tube laminates, this is a major factor contributing to high profitability in the printing process.

For example, the web path between unwinding and rewinding on the "Tube-Edition" is only around 25 m, compared to around 80 m on a comparable press for tube laminate

The press layout of the Gallus Labelfire "Tube-Edition" shows the centrally located UV inkjet digital printing unit DPU with an upstream and a downstream flexographic printing unit. (Source: Gallus Ferd. Rüesch AG)

printing. What's more, the servodriven Gallus ECS printing units allow for maximum substrate flexibility when using different thicknesses of laminates.

The press layout of the Gallus Labelfire "Tube Edition" features the centrally arranged UV inkjet digital printing unit DEU, with an upstream and a downstream flexographic printing unit. The arrangement combines high print quality in digital printing with the cost benefits of flexographic printing, even for motifs with high ink coverage. The upstream printing unit is used to apply spot colours, cold foil or a primer (if required), while the downstream unit is used to apply the protective coating over the entire surface. At the user's request, the digital production system can also be supplemented with an additional cold foil unit.

UV-LED curing systems are used for printing tube laminates. (Source: Gallus Ferd. Rüesch AG)

Qualifying comparison of digitally and conventionally printed tubes

Once the press concept and the ink series were available, the next step in the project was a practical comparison of digitally and conventionally printed tubes. This allowed an evaluation to be made as to whether, or to what extent differences between the designs were recognisable based on defined quality criteria.

To this end, Permapack AG contributed its printing expertise in laminate printing to the project producing the conventionally printed tube samples. These were printed on a Gallus RCS 330 as a benchmark for digital printing and joint assessment with Gallus. The

the "1-very good" range. "During the tests, we found that the adhesion and flexibility of the new flexible UV inkjet ink showed good values.

The digitally printed tube material could be processed in the same way as conventionally printed material," Günther Forster, Prepress Manager, Business Unit Printing Product Manager Cosmetics at Permapack AG, in describing the analysis of the test results. Only the digitally printed PP laminate, which is only used to a very limited extent on the market, showed a deviation in the aging test. With PP laminates, printing conditions and inkjet inks still need to be modified somewhat.

metres are cheaper to produce than purely conventionally printed tubes. With a standard tube of 200 ml, this corresponds roughly to a quantity of 53,000 tubes and is considered an average run length in tube printing.

This project provided all of the evidence that qualifies the flexible UV inkjet ink for use in tube printing. This means that the Gallus Labelfire "Tube Edition" and the UVF01 inkjet series are now ready for use in industrial laminate printing.

The family-owned company, founded in 1958 and headquartered in Rorschach,

digital benchmark samples were printed on a Gallus Labelfire 340 running in industrial use and equipped with the "UVF01" inkjet series and modified dryer technology. The designs for the benchmark and the different tube laminates were selected according to typical market requirements.

"During the tests, we found that the adhesion and flexibility of the new flexible UV inkjet ink showed good values. The digitally printed tube material could be processed in the same way as conventionally printed material," Günther Forster, Prepress Manager, Business Unit Printing Product Manager Cosmetics at Permapack AG, describes the evaluation of the test results.

The test results with the UVF01 inkjet ink showed excellent results across all fastness requirements for the tube laminates PBL and ABL, which are predominantly used in the market, as well as on paper laminate. The evaluations exclusively show results in

The Gallus Labelfire "Tube-Edition" together with the flexible UVF01 inkjet ink presents itself as a pioneering alternative to purely conventional tube printing. Thanks to the high native resolution of 1200x1200 dpi, digital printing can score points in terms of print quality by outperforming the motifs usually printed in 54 screens in flexographic printing.

Besides print quality, the economic efficiency of a production system is the decisive criterion for its industrial use. Here the machine system meets a market situation in which run lengths in the tube market are declining. Since short to medium run lengths are a strength of digital printing, it can also demonstrate its strengths here.

A break-even analysis of the costs of the print samples from the print comparison shows that the digitally conventionally printed runs up to a run length of approx. 5,000 running

Switzerland, is divided into the divisions "Labels & Flexible Packaging" and "Construction, Industry, Retail". Labels and packaging are printed in the in-house print division, with a growing share of laminate films for tube production. The target markets are the non-food, food and cosmetics sectors. Collaboration with Gallus in the print sector dates back to the company's early days and continues to find expression in innovative products.

To this end, Permapack's printing experts make use of the technical possibilities offered by the company's modern machinery and create highly unusual designs and products. The European Tube Manufacturers Association (etma) named Permapack's paper tube "Tube of the year 2021" in the sustainability category.

Packaging providers are under considerable pressure to provide alternative and eco-friendly packaging solutions from manufacturers, retailers, and consumers themselves, thus driving the shift towards circular economy, says GlobalData, a leading data and analytics company.

Manish Dixit, Practice Head at GlobalData, comments: “Packaging companies are adopting intelligent and sustainable packaging solutions

to minimize their carbon footprint. It is noted that seven deals among the top 10 investment deals in Q2 2022 fall under the ‘sustainability & ethics’ theme, reflecting the interest of global investors. Even the global consumer brands like Cola-Cola, PepsiCo, Unilever, Danone, and Nestle have committed to provide 100% recycled plastic in their packaging and introduced reusable or recyclable packaging.”

Prathyusha Paruchuri, Senior Disruptive Tech Analyst at GlobalData, comments: “Both regulators and non-governmental institutions are encouraging the packaging sector shift towards a circular economy to maximize efficiency and minimize resource wastage. With the importance of sustainability to the packaging sector becoming explicit, many packaging firms are being regenerative by design and enhancing their buy-build-and partnership strategy in circular economy space to avoid falling behind with their peers, competitors, and clients.”

GlobalData's latest report, “Digital Innovation Case Studies in Packaging,” highlights the implementation of

The packaging sector is still recovering from the impact of the COVID-19 pandemic, along with the paradigm shift towards online shopping, tighter regulatory norms for packaging waste, and the increasing consumer demand for sustainable packaging solutions.

emerging technologies with real-world use cases and assesses the return on investment.

LivingPackets creates sustainable packaging solution

LivingPackets, which provides eco-friendly packing solutions for e-commerce deliveries, collaborated with NXP Semiconductors to develop and launch IoT-based sustainable “THE BOX” to ship packages with zero waste with end-to-end visibility of a package's path in the supply chain.

Dell develops solution to track and trace recycled plastic

Dell intended to create a circular economy to prevent plastics from entering the ocean by recycling and repurposing them in its supply chain. Thus, it partnered with VMware, a

of recycled material and to ensure the long-term sustainability of its supply chain.

Harpak-ULMA introduces smart packaging solutions

Harpak-ULMA, a packaging equipment manufacturer, along with Rockwell Automation, a provider of digital transformation and industrial automation, used IoTand augmented reality for smart packaging solutions. These digital solutions are integrated with real-time analytics to improve to enhance operational efficiency and boost employee productivity.

Paruchuri concludes: “Sustainability has become so vital that plastic packaging firms face difficulty to access capital as investors tighten their policies around non-sustainable packaging. The end-to-end technology adoption by packaging companies into their supply chain is resulting in operational improvements, supplier reliability, and customer engagement. Global providers are speeding up innovations such as the development of advanced materials, products with embedded technology, and custom solutions to promote reusable, biodegradable, and sustainable packaging.”

You don’t need to be the biggest. But you do need the right tools at the ready to adapt to the new normal.

XMPie’s Web-to-print solution, StoreFlow, is an essential ingredient for success, especially through hard economic times, offering a plethora of revenue opportunities for Print Providers:

• Move Online: Launch a digital presence with a workflow that reduces physical human interaction.

• Fast Turnaround: Stay agile and pivot to new products or services whenever circumstances change.

• Diversification: Sell anything from hats and shirts to static print items, fully personalized items, and complete marketing campaigns.

• Adaptability at Scale: Move away from unscalable manual order fulfilment processes. Your print buyers’ needs, feature requests, and integration capabilities will continually change.

• Automate: Don’t waste staff talent on manual, repetitive chores. Concentrate on higher-value creative tasks instead like complex design work, improving customer relationships, and selling profitable services like omnichannel communications.

The XMPie platform offers so much more than print ordering. With its advanced personalization capabilities, fast variable content rendering, multichannel capabilities, and integration options, you can position yourself well above the competition.

It is not the strongest of the species that survives, nor the most intelligent that survives. It is the one that is most adaptable to change.

Scan this QRCode to learn more

a mainstream application in all sectors of the print industry, particularly the recognition we’ve now attained in packaging because of the productivity, economics and sustainability of our solution.”

Scodix Ultra 6000 is the 400th Scodix Press sold, demonstrating the company’s mainstream appeal and accelerating growth in the packaging sector

Scodix, the world’s leading provider of digital finishing and embellishment solutions for the graphic arts industry, has announced a milestone today as it celebrates the sale of its 400th Digital Enhancement Press to Curtis Packaging in Connecticut, USA.

Curtis Packaging invested in the latest evolution of the Scodix Ultra 6000 Press, now powered by SHD. Developed for embellishment for the packaging industry with its B1/41-inch format, the Ultra 6000 system also allows thicker substrates and incorporates industrial pallet feeders and stackers. Scodix SHD (Smart High Definition) algorithmcontrolled digital printing achieves high accuracy and quality precision of complicated detailing for foiling, spot embellishments and micro fonts.

The milestone sale exemplifies the cross sector and mainstream appeal Scodix sees, with installs in every sector of the print industry and now a significant increase in business from the packaging sector, particularly over the last two years with the launch of the Ultra 5000 and 6000 Presses.