Click on the either the Packaging Awards or the Print Awards logo for all the winners - photo's presentations - from this year's events

Click on the either the Packaging Awards or the Print Awards logo for all the winners - photo's presentations - from this year's events

At SHIFT 24 – the Asian Labels and Packaging Conference held on November 8 in Ho

Peter Woods, BOBST Southeast Asia Zone Business Director Labels, shared key insights and technologies shaping the narrow and mid-web label market.

BOBST, a global leader in packaging and label production equipment, is at the forefront of innovation in the label industry. With a presence in over 50 countries, 19 production facilities, and a workforce of more than 6,300, BOBST continues to lead through its commitment to innovation, quality, and customercentric solutions.

Label printers face numerous challenges that can impact profitability. Despite cost pressures and severe labor shortages, combined with the need to adapt to new market trends while maintaining high quality, growth opportunities exist for those prepared to embrace digitalization, automation and connectivity.

According to research by Smithers, the global label market is expected to reach $51.15 billion by 2028, with a compound annual growth rate (CAGR) of 3.3%. The Asian label market is expected to grow at a faster rate of 5.2% CAGR, reaching $19.26 billion by 2028. This growth is driven by a wide variety of applications, including labels, flexible packaging, and other formats.

On the technology front, a significant shift has emerged in digital label printing. In 2024, UV inkjet technology surpassed traditional LEP (liquid electrophotographic) and dry-toner units in annual sales for the first time. This shift reflects the increasing demand for versatile, high-quality digital solutions in label production.

The dynamic label market requires a high level of agility and flexibility to respond to the demands for quick turnaround, short run lengths, and excellent quality.

But with fewer young people entering the industry, there is a growing shortage of skilled operators. Without experienced staff to run the machines, the industry will be forced to rely on new technology to maintain standards.

One of the major pain points is ensuring the consistency of brand colors – not only over time but also between different printing technologies and types of applications. Meanwhile, the increasing emphasis on sustainability, including

waste reduction and the use of new eco materials, adds a significant dimension to an already complex situation.

The industry is addressing these issues from a product and process point of view. The main trend can be observed in digital printing with a shift towards automated inline processes with end-to-end or ‘Allin-One’ workflows. These advanced integrated solutions can produce readyto-ship labels in one pass with just a single person operating the whole production

Ho Chi Minh City, Vietnam –insights into the latest trends

line. In this space, BOBST’s DIGITAL MASTER series has become the bestselling All-in-One press, capturing 35% of the ‘hybrid’ market share.

Digitalizing flexo label production

Flexo printing remains the primary technology for label production in the short to medium term, accounting for nearly 40% of the market volume in 2023 according to Smithers. The technology is being optimized by incorporating higher levels of automation and digitalization to

improve efficiency and minimize waste, regardless of the operator’s skills or qualifications.

Traditional flexo presses requires a good level of technical knowledge, so with the number of experienced operators falling, companies must utilize more automated solutions to ensure output quality. BOBST offers highly automated inline flexo presses with innovative features such as DigiFlexo and DigiGap ensuring automatic register and pressure

“Through the press automation there is little margin for human error There is no need for the operator to adjust the register at speed variation, because the press automatically brings it in register, one color after the other and keeps the register during all stages of production. Waste at job changeover averages 30 meters, which is excellent.”

John Liao, Owner

JUIH TAY, Thailand

adjustment, automatic job change, and high-performance semi-rotary die-cutting with automatic die-plate change, amongst others.

oneECG for improved sustainability

There is a growing interest in oneECG, BOBST’s proprietary solution for extended color gamut printing. Through the digitalization of color information, converters can ensure highest color repeatability between jobs and between technologies, faster and more efficiently. oneECG for inline flexo not only improves productivity by 67%, but it reduces setup waste by up to 65%, as well as lowering energy consumption and ink waste.

BOBST oneECG also helps converters to streamline their operations. In combination with automatic job change, flexo machines like the BOBST MASTER M6 become not digital, but highly digitalized. Implementing oneECG in narrow-mid web flexo is particularly

effective for applications such as shrink sleeves and other flexible packaging. These are areas where job lengths are reducing but not to the point where digital technology is cost-effective.

The shift to All-in-One methodology, where labels are produced on one machine which incorporates digital and flexo printing along with embellishment, die-cutting and quality control, is accelerating. This trend is driven by the requirement from customers to deliver high quality faster, with low waste, at competitive costs.

The DIGITAL MASTER modular platform from BOBST gives converters the capability to produce a much wider variety of superior quality products. Complex applications, such as multilayer

faster turnaround which speeds up timeto-market. Combining multiple processes in one machine also reduces the need for additional equipment, such as offline embellishment machines, and operators,

labels or highly embellished labels, to name a few, can be much more effectively produced on these presses, which are configurable with multiple value-adding modules.

By removing wasted time between processes and reducing complexity in planning, DIGITAL MASTER enables

which lowers the overall production costs, simplifies the workflow and optimizes the factory floor.

The main benefits of digitalization and automation can be summed up as follows:

• Driving efficiencies and productivity

• Guaranteeing quality and consistency

• Mitigating staffing challenges

• Improving sustainability through waste reduction

• Enabling a connected workflow

BOBST’s mission is to develop increasingly automated, digitalized and

The Bobst team at SHIFT_24 in Ho Chi Minh City

connected solutions. The aim is to provide the highest ease-of-operation by leveraging a closed loop workflow infrastructure through BOBST Connect, the cloud-based platform that brings data and digital services together to enhance packaging productivity for customers.

BOBST Connect enables the connectivity between machines, the digitalization of processes, and the automation of workflows, all in real-time. Converters can view and analyze OEE trends, track job progress, and easily monitor trends over time. This information is crucial for optimizing productivity, improving machine performance, and eliminating waste.

Supporting the future of label production In addition to providing cutting-edge technology solutions, being a reliable partner with strong support capabilities is crucial in today’s market. BOBST’s 24/7 service and support structure ensures that customers receive the assistance they need whenever issues arise.

BOBST’s focus on automation, digitalization, sustainability, and customer support positions it well to meet future demands. By developing machines that are simple to use, environmentally friendly, and adaptable to market changes, BOBST reaffirms its commitment to leading the label industry into the future. With these advancements, label producers can look forward to more efficient, flexible, and sustainable production processes that cater to a wide range of applications and market needs.

So, don’t miss the opportunity to discover more: configure your press on https:// configurator.bobst.com

Rathna Packaging India is a leading name in the packaging industry, known for its high-quality and sustainable solutions.

With over 25 years of experience, the company has established itself as a trusted partner for customers across various sectors, including food, beverages, pharmaceuticals, and consumer goods. Rathna’s focus on customer satisfaction, and eco-friendly practices has made it one of India’s most reliable companies in flexible packaging.

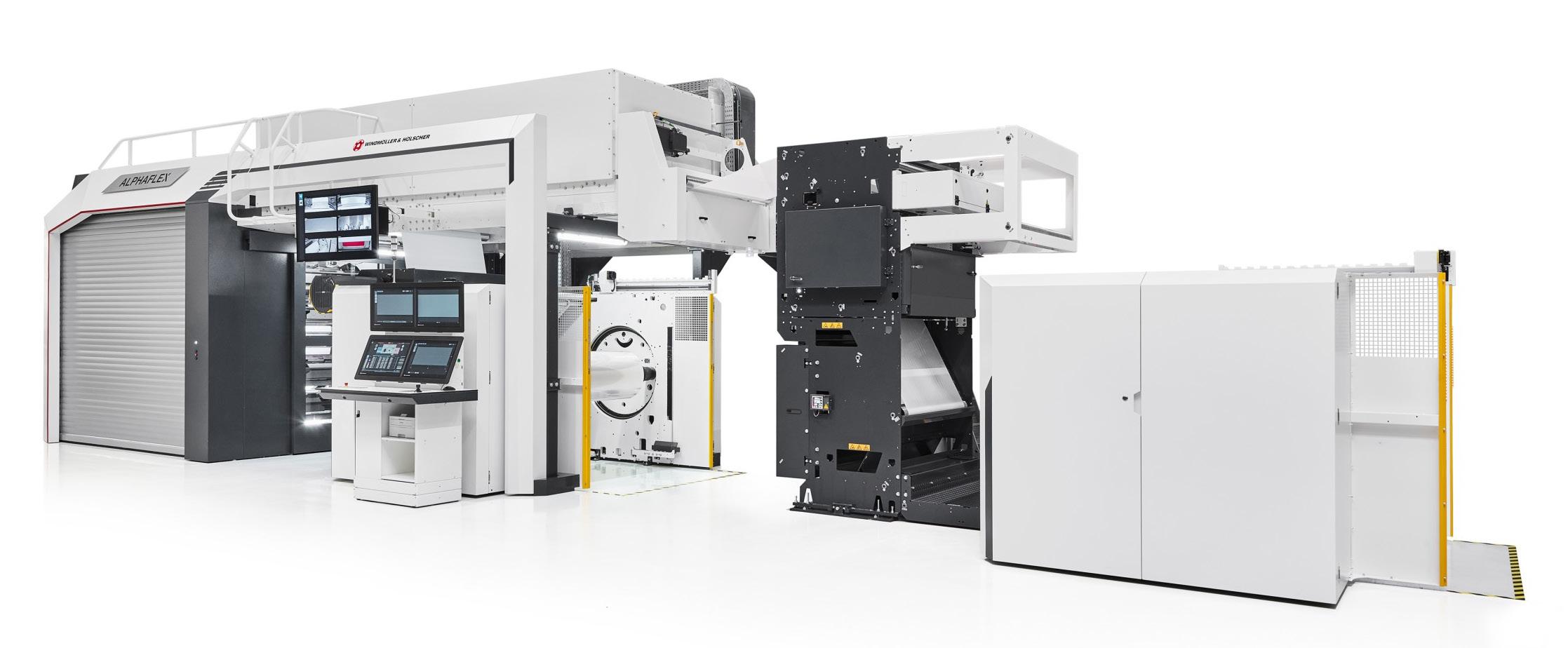

In a recent bold move to expand its production capabilities and strengthen its market position, Rathna Packaging has made a significant investment in advanced machinery from Windmöller & Hölscher. This expansion includes the installation of two W&H OPTIMEX II blown film lines and two ALPHAFLEX CI flexo presses. The four machines would be commissioned starting mid of 2025.

The OPTIMEX II blown film lines support a wide range of applications, making it ideal for producing highperformance films tailored to various industries.

The machine also comes equipped with advanced features like EASY2 Change assistance system, a game changing for blown film lines which supports the operator during every step of a product changeover and leads to never seen before repeatable performance. Compared to

an experienced operator, the number of necessary clicks for a product change is reduced by more than 70 % and the time needed is cut by more than a half, thanks to an intuitive HMI. With this innovative technology the operator maintains full transparency and control throughout a changeover, as the technology detects the bubble shape and frostline, ensuring reproducible high film quality.

On the printing side, the ALPHAFLEX CI flexo presses bring unmatched precision and quality production to the forefront. The new press offers better print stability and bounce free printing even for most difficult jobs at speeds of 400 m/min. Designed for printers of all scales, the ALPHAFLEX is engineered to meet the toughest industry challenges, including cost pressures, productivity

demands and sustainability goals. Both the presses include W&H’s fast, reliable and reproducible color matching solution called the EASY-COL. This module is fully integrated with ALPHAFLEX and gives guaranteed color matching results, considerably reducing the time and reruns needed for the process.

The ALPHAFLEX is the newest addition to W&H’s CI flexo portfolio, launched at Drupa 2024. These two presses will be among the very first installations in India, marking a significant milestone for both W&H and Rathna Packaging.

The machines are also integrated with W&H’s IoT platform called RUBY which is used to monitor data, automate and improve packaging production. This investment is a key enabler of Rathna’s ambitious expansion plans of scaling its operations while maintaining its reputation for quality and sustainability.

“We are proud of the fact that we have invested in the most advanced technologies from W&H. With these new technologies, we are prepared to deliver superior packaging solutions and continue our journey of growth. With the right planning and practices, we wish to plan another big expansion soon” Says Sudhakar Reddy, Managing Director, Rathna Packaging.

UPM Specialty Papers and Michelman have co-created three cutting edge solutions that are designed to allow brand owners to replace multi-material, non-recyclable packaging with paper-based alternatives that meet their requirements for food contact and recyclability.

“UPM's papers provide a perfect foundation for our water-based barrier and heat seal coatings. Working closely with them for many years has allowed our combined team to increase the performance threshold of fiber-based substrates while maintaining recyclability. These new solutions will allow the market to accelerate its transition to more sustainable packaging,” says Thierry Van Migem, Sales Director, EMEA, Michelman.

One of the most exciting results is a high barrier packaging material that combines UPM Solide™ Lucent base paper with three of Michelman’s waterbased coatings, delivering robust oxygen and moisture vapor barriers with heatsealability. This makes it ideal for

demanding products such as chocolate and even coffee.

A second innovation offers superior barrier properties ideal for frozen foods. The concept is based on a highly effective combination of either UPM Asendo™ or UPM Asendo™ Pro barrier papers and Michelman’s next generation heatsealable barrier coatings.

A third breakthrough solution has significantly boosted resistance to water vapor and grease. Michelman’s high performing VaporCoat® 2240 coating serves to enhance the existing barrier properties of UPM Asendo™ and UPM Asendo™ Pro papers, making the concept particularly suitable for inner liners in end-uses such as corrugated cardboard boxes.

All three structures have been tested for recyclability according to the PTS RH 021/97 Cat II method.

“We are very excited about the possibilities these three concepts can offer to brands and converters to replace multi-material packaging structures that are difficult to recycle. Collaborations such as these are crucial for innovating new, recyclable, fiber-based packaging solutions,” says Esa Saukkonen Manager, Packaging Portfolio Development, UPM R&D.

Sustainability is not a trend, but a revolution of all industries and business sectors. It is now driving our decisions and actions. Across industries, companies are looking for innovations that reduce their environmental footprint on an almost daily basis. With artificial intelligence, we can automate our process to become a sustainable and responsible company.

AI-driven design and optimisation

AI is revolutionising print design and optimisation. By analysing customer data and preferences, AI algorithms can create customised designs that not only appeal to the target audience, but also minimise waste. For example, AI can optimise the layout of printed pages to reduce paper consumption and ensure that every inch of paper is used effectively.

In addition, AI-driven design helps develop sustainable packaging solutions. By considering factors such as material consumption, transport efficiency and recyclability, we design packaging that is both environmentally friendly and costeffective.

Waste reduction and material efficiency

One of the biggest challenges in the printing and packaging industry is the generation of waste, especially in the form of misprints and excess material. AI-supported quality control systems detect and correct errors in real time, reducing misprints and material waste. This not only saves resources but also reduces production costs.

In addition, AI optimises material consumption by calculating the exact amount of ink, toner or other consumables needed for each print job. This ensures that materials are used efficiently and reduces the overall environmental impact of printing operations.

Sustainable ink and material selection

AI also helps in the selection of sustainable printing materials and inks. By analysing the environmental impact of different materials and ink options, AI algorithms can recommend greener choices. This includes selecting recycled paper, biodegradable inks and other sustainable options.

Proactive maintenance through artificial intelligence

Predictive maintenance systems are becoming more prevalent in the printing industry. These systems use data from sensors and machine learning algorithms to predict when printing equipment is likely to fail or need maintenance. By proactively responding to maintenance needs, companies can minimise downtime, reduce energy consumption and extend the life of their printing equipment.

Digital transformation and on-demand printing

The shift towards digital printing and ondemand production is a major trend in the printing industry. Artificial intelligence plays a crucial role in this transformation. It enables efficient, personalised production of printed products and goods. Short runs are becoming more cost-effective through digital printing and overproduction is being reduced.

The future of our industry is driven by sustainability and artificial intelligence

With AI-driven design, waste reduction, sustainable material selection, predictive maintenance and digital transformation, the industry is becoming greener and more efficient. Artificial intelligence is enabling the printing industry to meet the growing challenges posed by society and politics. Certainly, there are other solutions to shape and drive the turnaround. However, the algorithms of artificial intelligence are drivers of change and help us to accelerate the processes to the goal.

Your one stop for all flexo plate mounting solutions

With our extensive range of flexographic technology solutions, including unique plate mounting technologies, splicing and process tapes, we offer unparalleled expertise. Our dedicated team will help you find the perfect solution, providing onsite training to enhance your operational expertise. Witness the remarkable results: improved print quality, enhanced efficiencies, and a tangible reduction in waste and emissions. Choose tesa as your trusted flexo partner.

for extended continuous operation and enhanced productivity

FUJIFILM Business Innovation Asia

Pacific announces the launch of Revoria Press E1136P, an advanced monochrome production printer for on-demand printing, catering to professional and institutional environment. This latest addition to the Revoria Press E1 series, and now all models of the Revoria Press E1 series introduce innovative features as the new options, including the capability to connect two units for dual operation of the High Capacity Feeder and the Air Suction Feeder.

This advancement facilitates continuous mass printing, significantly enhancing productivity. Additionally, the optional Print Inspection System provides automated quality checks during the printing process, ensuring that defects on the printed materials are promptly detected. Sales of the Revoria Press E1136P and the new options for all models of the Revoria Press E1 series will commence on November 7 across the Asia Pacific region.

Since its release in 2021, the Revoria Press E1 series has garnered positive feedback from users, establishing itself as a trusted solution for on-demand print businesses across various sectors.

The Revoria Press E1 series is a versatile printing solution designed for a wide range of printing needs, particularly in commercial printing and production environments. This series is ideal for business seeking to enhance their printing capabilities with high-quality, high-speed production, and flexible finishing options.

The Revoria Press E1 series excels in producing high-quality marketing materials, manual, reports, and corporate documents for centralised in-house printing departments in corporations. It is also well-suited for high-volume printing jobs, including brochures, catalogues, and direct mail, making it a strong choice for commercial print providers. Furthermore, its capabilities extend to education and training materials, enabling schools and training organisation to create highquality materials.

Key features of the Revoria Press E1 series include:

The latest model, Revoria Press E1136P allows for the connection of two units of the High Capacity Feeder and the Air Suction Feeder, as well as the High Capacity Stackers. This new continuous paper feeding option reduces the

frequency of paper replenishment during large-volume printing, facilitating extended period of operation.

Print Inspection System: This advance system is compatible with all models in the Revoria Press E1 series. It automatically inspects printed materials in real-time, comparing scanned images against original RIP data to detect defects such as small as 0.3 mm. The system identifies issues such as dots, stains, pinholes, streaks, dog ears, registration misalignment, and variations in colour density. It also ensures the readability of printed barcodes and OCR fonts, confirming that the numbers are sequential and numbers on side 1 and side 2 match.

Quality Control Alert: The printer provides alerts for colour variation and front-to-back misalignment during printing process, enabling operators to maintain consistent print quality. By automatically identifying and reprinting defective materials, the system significantly reduces the operator’s workload and saves time, ultimately enhancing overall print process.

Landa press chosen for its 11K Speed Module that boosts productivity to 11,200 B1 sheets per hour

Landa Digital Printing and one of China’s leading online print companies, Grandprint CO. Ltd., today announce the order of a Landa S11P Nanographic Printing® Press. To be installed at Grandprint headquarters in Yongcheng, Henan, the new B1 digital press will be used to support its quick delivery online printing business and extreme productivity business model. Shifting jobs from offset to digital, the Landa press will enable the company to significantly increase productivity for jobs between 1 and 1000 prints, as well as the ability to add personalization – ideal for consumers, brands and SME’s looking for high quality print, amazing color and faster time to market with more engaging content.

Employing over 2000 people, Grandprint has more than 70 offset presses and an array of small format digital presses across the business. As a very large and progressive company, it introduced an online facility that enabled the business to enjoy almost 50% growth for over 10 years. The installation of a Landa S11P with seven colors, the 11K Speed Module and coating unit, is expected to support further business diversification by moving more offset jobs to digital, as well as open-up additional application possibilities to secure additional business success.

Cui Wenfeng,, chairman of Grandprint Co., Ltd., comments, “We are very excited to partner with Landa. We chose the S11P for several reasons, but color fidelity and the 11K Speed Module that boosts productivity to a continuous 11,200 sph, were critical factors for our business model. While we have a variety of printing technologies, without a doubt, the Landa S11P will play a significant role in improving customer experience and increasing productivity.”

“Nanography will enable us to better service our existing customer base, while also allowing us to explore new applications that could take us into entirely new areas of business,” confirmed Cui Wenfeng.

The Landa S11P Nanographic Printing® Press ordered by Grandprint, is the only proven field production B1 double-sided or single-sided digital press on the market for printing mainstream commercial, packaging and publishing applications. With unmatched offset speeds and digital versatility, the Landa S11P integrates seamlessly into any digital or analog production floor.

Taking productivity to a whole new level –crucial for Grandprint – the Landa S11P prints up to 11,200 (with 11K module) B1 sheets per hour while maintaining

the versatility of digital print. It also offers capabilities including variable data printing, collated signatures, instant job changeovers, unlimited spot colors per page and much more.

Sharon Cohen, Chief Business Officer, Landa Digital Printing comments: “Grandprint is one of the most progressive print businesses in the world. It adopts technologies that are industrial and robust in nature – ensuring ultimate reliability and productivity to deliver unique consumer value.

“We are considering this as the beginning of a very long-term partnership, with the expectation for additional presses in the near future. We look forward to supporting Grandprint over the coming months and years.”

Simply consistent

Decrease waste and setup with predictable plates

Simply efficient

Increase on-press performance with a robust plate

Simply sustainable

Support sustainable inks and substrates all with the same plate

Simply better

Address your most demanding brand and quality requirements

From prepress to on-press, deliver the efficiencies and productivity needed from your plates to maximize your bottom line.

While the sector continues to grow, brands are seeking cost savings and sustainability step changes; modern flexo can deliver both.

The growth trend in package printing is forecast to take the sector to over $695 billion by 2029, according to global data and research company Smithers, but while growth continues, economic challenges have made cost savings a big focus for brands. A recent survey by consultants L.E.K found that brand owners are looking to achieve sales growth and cost savings in tandem with progress on sustainability.

How does the industry continue to grow while making progress towards these important environmental goals?

A big part of the answer lies in innovation that can deliver maximum impact throughout the flexo print process. Modern flexo, a standardized, sustainable manufacturing process, allows packaging to be printed in a more sustainable and efficient manner than ever before.

While implementing modern flexo practices requires collaboration between printers and their key suppliers, the flexo plate sits at the center of the flexographic print process. The plate brings together substrates, inks, tape and anilox for a dramatic impact on press capability and results.

The unique FLEXCEL plate, a key enabler for sustainable printing, has been at the heart of a steady stream of flexographic innovation over the last decade, involving press, ink and anilox manufacturers and prepress providers.

The on-press performance benefits a FLEXCEL plate provides also reduce waste, increase resource utilization, and enable support for a wide range of ecofriendly materials, such as recyclable substrates and water-based inks, without impacting cost and actually improving the bottom line for printer/converters. It supports a double materiality approach to sustainability: addressing the impact on the environment and the financial impact for a business.

“The reassuring thing about how we’re focusing on sustainability is that it’s inextricably linked with efforts to help drive financial return on investment for our customers,” says Miraclon chief marketing officer Emma Weston. “Sustainability can’t be a separate part of the business agenda”.

Here’s how a modern flexo approach is helping printer/converters and prepress businesses all over the world make strides forward on improving sustainability while decreasing costs.

In Australia, flexographic printer Perfection halved the waste materials created when producing printed packaging for Arnotts biscuits. FLEXCEL NX Plates enabled them to achieve smoother ink laydown, more consistent printing and a better match to proof, resulting in 50% reduced waste, 50% faster setup time and no unscheduled stops for cleaning.

Overall, they achieved sustained production at 400 mpm – a level of performance previously unattainable. From the cost side, they were able to reduce overall expenses while boosting shelf sales – an all-round win-win, for Perfection and their client.

Uflex needed a more sustainable packaging option for short runs while maintaining visual consistency with their

previous gravure-printed packs. Using recycled polypropylene film, FLEXCEL NX Plates and PureFlexo™ Printing enabled Uflex to transition to 100% waterbased inks, reducing ink film weights to 0.9 gsm, while matching previous gravure press speeds with solvent inks.

Reprint production times were cut from three days to just four hours, resulting in

a 15% lower resource footprint overall. By minimizing rework and reducing substrate waste and ink usage, the overall costs of the project were lower.

Efficiency with more sustainable substrates

With a multitude of sustainable substrates in their business, Walki Poland struggled to get consistent results.

But thanks to the improved ink transfer and multi-form surface patterning of FLEXCEL NX Plates, they achieved more stable, repeatable results across all substrates – resulting in faster setups, lower energy costs and reduced consumables wastage. That means they’re now one step further towards their goal of a circular, resource-efficient, lowcarbon future.

In a significant upgrade to our real-time operator tool, we are thrilled to reintroduce VirtualCoach, now personified with a face and name - meet Emmy. This evolution marks a new chapter in how we support and enhance the efficiency of MPS press operations.

What’s New with Emmy?

Previously known for its advanced datadriven insights and artificial intelligence, VirtualCoach now brings a more personal touch to its robust capabilities. Emmy is designed to bridge the gap between management objectives and operator actions, offering a more relatable and engaging user experience.

Personalized Real-Time Guidance

Emmy builds on VirtualCoach’s legacy of real-time support with an enhanced interface that helps operators monitor the quality and efficiency of their tasks. What sets Emmy apart is her ability to provide personalized, actionable guidance tailored to each operator’s behavior - turning data into real-time, specific advice that improves both efficiency and performance.

Key Benefits of VirtualCoach, Emmy

· Aligning Management and Operator Goals:

Emmy ensures that management’s objectives, such as cost minimization, align seamlessly with operators’ day-today actions. Operators can now work smarter and more conveniently, while driving better press performance.

· Enhanced Operator Involvement:

By involving operators directly in the continuous improvement process, Emmy fosters a collaborative environment for operational excellence. For example, Emmy gives a notification when UV lamps could better be switched off. The operator only has to follow-up on this, which results in a direct cost reduction up to $30.000 per year for you as a company.

· Smart Maintenance Advice:

Emmy helps prevent and resolve issues before they become costly. She provides guidance on alarm messages, advising operators on whether to take direct action or alert the maintenance team.

This proactive support maximizes uptime and ensures the machine remains in peak condition.

· Real-Time Training

Emmy offers instant, on-the-job training, making it easier for operators to develop new skills and adopt best practices quickly. With personalized feedback updated every 5 seconds, operators can rapidly enhance their proficiency, making full use of machine automation features like job memory and auto-registration.

· Continuous Improvement through Personalized Feedback

Emmy’s feedback evolves with the operator’s performance, creating a dynamic, ongoing learning experience. This steep learning curve ensures operators quickly master the press and optimize machine performance.

The Future of Press Operation

As we look to the future, automation will continue to revolutionize press operations,

from job setup to fully automated printing processes. These advancements will lead to sustainable production, higher efficiency, and easier access to flexo press operation for everyone.

With VirtualCoach - and now Emmy

- MPS remains at the forefront of this trend, offering operators intuitive, realtime support to boost efficiency and accelerate skill development.

Achieve More with Connectivity

By leveraging all our Connectivity and Performance Services, you can increase your average production volume by 10% annually, reduce setup material waste by 2%, and save over $100,000. These results are not only achievable but common among our customers.

Ready to optimize your press operations and save money? Contact us today to learn how Emmy can help you reach your goals. Mpsconnect@mps-printing.com

Imagine you are sitting in your doctor's waiting room and your eyes fall on the magazines on the table in front of you: Do you reach for them? If the pages are coated with "Lock 3" from Varcotec, you can start reading without hesitation.

The innovative antimicrobial dispersion coating ensures perfect hygiene at all times. This also impressed the Japanese publisher Sinsei, who secured the exclusive rights for their home country directly at #drupa2024. "We are very proud to have Sinsei as our exclusive partner," said Joachim Frings, General Director Sales & Development at Varcotec, at the historic signing of the agreement on the AtéCé stand in Hall 13 at drupa. "'Lock 3' can help Japan to close hygiene gaps and break possible chains of infection, thus protecting Japan and its people, who are so proud of their traditions, from the invisible danger in the future".

Twelve years of searching for the right ingredient

The thought of harmful germs on menus, brochures on planes and trains, or magazines in waiting rooms has long preoccupied Joachim Frings. But his search for a durable, non-toxic antimicrobial coating for dry-printed surfaces had long been unsuccessful. In general, the printing industry seemed to have little interest in such a solution. Until Corona changed all that.

By chance, Frings came across the work of a research group at Regensburg University

Hospital who were investigating how they could reduce the risk of infection for patients with a special solution that used light-stimulated oxygen to kill hospital germs. "I was immediately excited because this new technology did not require any toxic or harmful chemicals and had already been used successfully in complex operations," recalls Frings. Countless experiments lead to the winning formula

Over the next few years, he experimented with different formulations to develop a water-soluble dispersion coating that was invisible, stable and reliably antimicrobial. After an extensive and sometimes difficult testing and certification process, Varcotec is now the manufacturer of the first working water-based antimicrobial dispersion coating that permanently disinfects dry paper and board surfaces. The effective variant of the oxygen molecule has been used routinely in medicine for more than 20 years to treat tumours and degenerative diseases, explains Frings. The development of resistance, as can be observed with antibiotics and conventional biocides, does not occur with this variant of oxygen and is not to be expected.

“Lock 3” is effective against bacteria, spores, viruses and fungi. As long as visible light is present and oxygen is supplied, there is a permanent disinfectant effect. The light activates the oxygen via a photocatalyst, which then destroys bacteria, viruses and fungi that come into contact with it. Even on dark days, the lighting in a waiting room is sufficient. In this way, “Lock 3” helps to effectively close hygiene gaps, reduce the risk of germ transmission and increase customer safety.

The benefits of “Lock 3” dispersion coating:

Does not require harmful UV radiation, only visible light

“Lock 3” shows reduction of microorganisms even under room light conditions (99.99%)

Resistance of micro-organisms to singlet oxygen is not known and not expected. Has controllable efficiency depending on light intensity

Works on dry surfaces

Does not contain toxic or mutagenic components

Does not release toxic chemicals into the environment

Does not produce odours or aerosols

“Lock 3” is suitable for all types of printed products.

The new nyloflex® eco series provides a unique and new approach of printing plates which are using renewable raw materials as part of the plate build up. Beside of being more sustainable, this Flexo plates comes with the advantage of a 20% faster plate processing capability, leading to time & energy savings.

The nyloflex® eco plates have been developed to enhance the quality standard in flexographic printing and lifting it to a sustainable future.

Contains renewable raw material

Proven, consistent quality in a more sustainable way

Suitable for bank- & LED exposure

Energy & Time saving

Stable & reliable plate processing

eco ACT for paper & board applications with water based inks

eco FAC for high performance corrugated post print to cope with all requirements

E-Print Solutions Sdn. Bhd is a Web to Print company based in Kuala Lumpur, Malaysia. Since its founding in 2010, the company has focused offering a wide range of products for both commercial and packaging segment with quick turnaround times and competitive pricing on web portal.

Their remarkably fast delivery speed allows their customers to pick up printed products at any of nine E-Print Solutions branches within 24 hours from placing orders, differentiates E-Print Solutions from the competition.

In addition to its headquarters in Kuala Lumpur, E-Print Solutions has factories in Bukit Serdang and nine pick-up branches across the country, employing a total of approximately

300 people. Since its establishment, the company has prioritized streamlining and improving manufacturing efficiency, achieving continuous business growth in the competitive Web to Print sector through the active adoption of the latest technologies.

The company installed multiple units of HEIDELBERG Suprasetter CtP’s, Speedmaster offset presses, and Polar high speed cutting machines

complimented with Polar Compucut –automatic cutting program generation. In March 2024, to further enhance productivity, E-Print Solutions installed the Speedmaster CX 92. This new CX 92 replaced the previously operating CD 102, with the deciding factors being improved automation technology, increased productivity, and reduced plate costs.

Increasing productivity while reducing production costs.

Compared to the CD 102, the Speedmaster CX 92 boasts a maximum printing speed of 16,500 sheets per hour, achieving an average productivity improvement of around 20%. The increase in productivity is significantly bolstered by various advanced automation that enhance efficiency.

Preset Plus Feeder and Preset Plus Delivery on the CX 92 automatically sets the feeder and delivery without human intervention while Prinect Easy Control further reduces make-ready time as well as stable color management during print production. Besides, the automation also relieves the stress in workforce.

The CX 92 produces 30 to 50 jobs per day, 3 million to 3.5 million good sheets per month, Prinect Press Center XL 3 plays important role to short make ready time. The Intellistart 3 simplifies the operating steps by 70% per job change. This means less labor intensive, quicker make ready even for short run, higher output thus higher efficiency. Additionally, the adoption of the 92 format has reduced plate costs by approximately 20%, a significant advantage in competitiveness.

Supported by HEIDELBERG s ervice team contributes to stable production.

In addition to the increased productivity from various features, the company's long-standing trust relationship with HEIDELBERG was a key factor in

the adoption, says company president Mr. Brian. "We have great confidence in Heidelberg's service team. The team always ensures smooth installations and quick response time to minimize downtime. We are very happy to work with a team that can cover the entire production process. They are well trained, high professionalism. With extensive experience, they complete excellent quality work. "

The goal is to achieve high efficiency in print production and Brian believes that advanced automation with integrated workflow in the entire production floor can help the company to achieve the

goal. "Currently, we are working on realizing the concept of Push to Stop for automated printing.

Furthermore, we are focusing on the implementation of MultiColor, a technology to cover spot colors with 7-color printing (CMYKOGV). We wish to strengthen our current smalllot production system of 100 sheets, hopefully, in future, 30 sheets, including postpress.

These initiatives are designed to enhance the range of choices, convenience, and value for our customers. We will continue to focus on new technologies to strengthen our business," Brian said.

List of Solutions:

Prinect Production Manager

Suprasetter 106 x 2

Speedmaster SX 52-5+L Anicolor IST UV

Speedmaster CS 92-5 LE UV

Speedmaster CX 92-4

Speedmaster CD 102-4 x 2

Polar N 115 Pro HD with Compucut x 3

Polar Jogger RA4 with counting scale x 2

“New Speedmaster CX 92 enables us to reduce plate costs by 20%, while increasing productivity by 20%”.

Brian Poon, Executive Director

PAPER. BECAUSE IT’S REAL.

Production printing, the process of producing large volumes of highquality printed materials, is undergoing significant transformation. Innovations in this field are driven by technological advancements, market demands, and the push for sustainable practices.

These developments are revolutionizing industries such as publishing, packaging, and commercial printing. Here are some key trends to watch in the world of production printing:

1. Digital Printing Advancements

Digital printing technology continues to evolve, offering many benefits over traditional offset printing. Key advancements include:

High-Speed Inkjet Printing: Modern high-speed inkjet printers deliver faster print speeds and superior image quality, making them ideal for large-scale production.

Enhanced Colour Management: Advanced colour management systems ensure consistent and accurate colour reproduction, meeting the stringent

demands of brand owners.

Variable Data Printing: Digital printing enables personalised and customised prints with variable data, catering to marketing campaigns and personalized products.

2. Sustainable Printing Solutions

Sustainability is a critical concern in production printing. Innovations in this area aim to reduce environmental impact and promote eco-friendly practices:

Recyclable and Biodegradable Materials: Use of sustainable substrates, such as recyclable and biodegradable papers and plastics, is increasing.

Eco-Friendly Inks: Water-based and vegetable-based inks are replacing traditional petroleum-based inks, reducing harmful emissions.

Energy-Efficient Equipment: New printing presses are designed to be more energy-efficient, lowering the carbon footprint of production facilities.

3. Integration of Automation and AI Automation and artificial intelligence (AI) are streamlining production printing processes, enhancing efficiency, and reducing labour costs:

Automated Workflow Systems: Integrated workflow solutions automate tasks such as file preparation, colour correction, and print scheduling, minimising manual intervention.

AI-Driven Quality Control: AI systems monitor print quality in real-time, detecting and correcting defects to ensure consistent output.

Predictive Maintenance: AI algorithms predict equipment failures before they occur, enabling proactive maintenance and reducing downtime.

4. Advanced Finishing Techniques

Innovations in finishing techniques are enhancing the final appearance and functionality of printed materials:

Digital Embellishments: Techniques such as digital foiling, embossing, and varnishing add tactile and visual appeal to printed products without the need for traditional dies and plates.

Hybrid Printing: Combining digital and traditional printing methods allows for creative effects and high-quality finishes.

Smart Packaging: Incorporating technologies like QR codes, NFC tags, and augmented reality into printed packaging provides interactive and engaging experiences for consumers.

5. On-Demand and Short-Run Printing

The demand for on-demand and shortrun printing is rising, driven by the need for flexibility and cost-efficiency:

Print-on-Demand Services: These services allow businesses to print materials as needed, reducing inventory costs and waste.

Short-Run Production: Advances in digital printing make it economically viable to produce small quantities of high-quality prints, catering to niche markets and limited-edition products.

Just-in-Time Production: Printing only what is needed, when it is needed, aligns with lean manufacturing principles and reduces excess inventory.

6. Integration with Digital Platforms

The integration of production printing with digital platforms is creating new opportunities for cross-media marketing and enhanced customer experiences:

Web-to-Print Solutions: Online platforms allow customers to design, customize, and order printed materials directly, streamlining the ordering process.

Cross-Media Campaigns: Integration with digital marketing channels enables coordinated campaigns across print, email, social media, and more.

Augmented Reality (AR): Printed materials with AR capabilities provide interactive and immersive experiences, bridging the gap between print and digital media.

The future of production printing is bright, characterised by rapid technological advancements and a strong focus on sustainability and efficiency. By embracing these innovations, businesses can stay ahead of the competition, meet evolving customer demands, and achieve higher levels of productivity and quality. As these trends continue to develop, production printing will remain a vital and dynamic industry, driving growth and innovation across various sectors.

The SigmaLine Compact sets another milestone in digital book block production. With a web speed of up to 200 m/min, it impresses with rapid changeover times for job and format changes. Changing the folding schemes – for example from 3-across to 4-across – takes less than 10 seconds. Digital printers can therefore produce more end products in the smallest of space (40 m²), with fewer staff and a lower waste rate.

mullermartini.com/sigmalinecompact

How do brands build trust in today’s highly distracting world? How can they be heard above the noise generated by so many communications channels?

While there may be some differences in how brands communicate with Gen Z, millennials, or baby boomers, there are two vital elements in building brand trust – meeting consumer expectations and adapting to their evolving behaviours.

But how can they be achieved?

Personalisation is one way. That is according to 62% of respondents in Marigold’s Relationship Marketing Trends: Brand Rankings Report who said their favourite brands treat them like individuals. Nearly one in eight (79%) are likely to interact with emails that are directly personalised to them.

One in five respondents in a study by Forbes Advisor and OnePoll, reported that personalised communication positively impacts their relationship with a brand. It fosters a more profound, personal connection, which is crucial for establishing trust. Gen Z and millennials were also found to prefer personalised product recommendations more than other generations.

In fact, four out of five millennials choose to buy products and services from brands they trust. For baby boomers, the figure drops to three out of five. For Gen Z consumers the Endelman Trust Barometer highlights that brands need to define their permission space, commit to it, and communicate actions within it clearly to continue to build trust.

Personalisation works most effectively when brands collect and analyse customer data to create relevant and timely interactions. By utilising behavioural data, brands can anticipate needs, preferences, and buying patterns, creating a seamless

experience. Timely recommendations or exclusive offers based on past purchases demonstrate an understanding of the consumer’s unique preferences.

Another way brands can build trust is with consistency – whether online, offline, or across various digital platforms. Marigold’s report highlights omnichannel experiences that deliver seamless interactions across platforms play a significant role in consumer loyalty. When brands maintain consistent messaging and deliver a unified experience, consumers gain greater confidence in the brand.

To effectively build trust across generations, brands should consider tailored strategies. Gen Z consumers, for example, are more likely to trust brands that are vocal about their values and transparent about their intentions. For millennials, who prioritise personalised experiences and ethical transparency, brands should focus on consistent and tailored interactions. Meanwhile, baby boomers, while more sceptical of digital-

first interactions, still show trust in brands that emphasise authenticity and consistency.

Understanding these nuanced expectations can help create the right approach for the target audience.

Brands that successfully integrate these factors can foster deeper consumer loyalty and stand out in a crowded market.

Digital print supports that approach by enabling the creation of carefully tailored and highly relevant messaging that can be produced in response to defined interactions such as new promotions, online shopping or key dates.

Through strategic personalisation, as well as consistent and transparent communication, brands can develop the kind of trust that transforms occasional customers into loyal advocates. Talk to us to explore ways digital production capabilities can help brands build that trust.

The varioPRINT iX-series revolutionises the commercial printing business experience. It combines stunning image quality and a wide media range with the high productivity and the attractive cost-efficiency of inkjet.

P R O D U C T I V I T Y . Q U A L I T Y .

V E R S A T I L I T Y .

As a global market leader in sheetfed inkjet, Canon offers more experience in this segment than others. Invest with confidence to expand profit and opportunity! Experience iX!

The Beijing Institute of Graphic Communication (BIGC) conducted an independent study comparing the carbon footprint of flexographic printing with that of gravure printing

The Beijing Institute of Graphic Communication (BICG), an independent body, carried out a study to better understand the differences in carbon footprint between gravure printing using solvent ink, and flexographic printing using water, solvent, and UV inks.

BIGC is the only undergraduate university in Asia that focuses on printing, publishing and media, and is a pioneer in publishing and printing higher education in China.

The independent study was conducted between 1 October and 4 December 2023 under the supervision of Lixin Mo, Professor, Doctor, teacher at the School of Printing and Packaging Engineering, BICG, and Director of the Beijing Printed Electronics Engineering Technology Research Center. The full report will be available in January 2025.

“Flexographic printing provides numerous advantages, including a more environmentally friendly approach compared to other printing technologies, compatibility with a wide range of

substrates, the ability to facilitate highspeed mass production, and flexibility in combining different printing methods,” Dr. Mo explained. “These benefits have led to its widespread use in the packaging printing markets of Europe and the United States.

According to statistics, flexographic products account for over 70% of the packaging printing market in the United States and approximately 50%in European countries. However, in China’s packaging printing market, gravure printing has dominated, occupying more than 90% of the market share.”

With that in mind, BICG conducted a survey and on-site research to investigate the current development status of

Study results showing the carbon footprint of gravure compared to three different flexographic configurations

flexographic and gravure printing enterprises in China’s packaging printing industry. This study aimed to analyze the comparative advantages, existing shortcomings, and development potential of flexographic printing technology, including their sustainability aspects.

The study concluded that there are significant sustainability benefits for printing and packaging companies in China to switch from gravure to flexography, or at a minimum, begin to introduce flexography into their operations.

“The most significant sustainability advantage,” Dr. Mo added, “came in the comparison of flexography using waterwash plates and water-based inks. We found emissions to be less than 4 CO2eq/ m2 for this configuration, compared to as much as a stunning 140 kg- CO2eq/m2 for gravure using solvent inks, a reduction of 136 kg-CO2eq/m2, or 35 times less emissions. While results from all sites were not this exaggerated, the best-case scenario for gravure resulted in emissions of 34 kg-CO2eq/m2 for gravure.”

A printer located in Anhui used both gravure and flexography printing technologies with solvent inks. An LCA (life cycle assessment) was conducted to compare the carbon footprints of these two printing methods when producing the same products. The comparison analyzed the environmental impact of the solvent-based gravure and flexography processes within a single printer facility.

The professor noted that even when using solvent inks, gravure emitted more than three times as much CO2eq/m2, test results achieved at one site where both technologies were in place.

“Based on our long experience in the packaging print industry in China, we realized that people in the industry have been waiting for a game changer in the market,”

“This neutral study from BICG clearly demonstrates that that game changer is here, and it is the fact data comparison study of a life cycle assessment (LCA) comparing flexography to gravure in China packaging printing industry. Government regulation has the highest power in China, and we expect to see strict regulations about CO2 emissions imposed in the coming months.

This study has the potential to accelerate implementation of those regulations. Both brand owners and converters should be thinking now about investment in flexography, even if it is costly. The risk of running afoul of these coming regulations is too high.”

Over the past few months and years, a number of popular magazines have revived their print versions, and entirely new titles have been launched. After a slump owing to the pandemic, there now appears to be room for new print magazines once again. But hybrid forms of catalogs and magazines, referred to as “megalogs,” are more and more often being used in sales communication.

Most notably, global fashion magazines, interior design magazines and even local newspapers are celebrating a comeback. One prominent example is “ELLE Australia”. Four years after its final edition, the fashion magazine is returning to the print market this year with two issues.

Four issues are already planned for 2025. Jane Huxley, CEO of Are Media, publisher of ELLE in Australia, sees two main reasons for this step: the sustained brand strength of magazines in economically difficult times and the response of consumers to the “digital flood” of information. Nicky Briger, General Manager Fashion and Beauty at Are Media, adds: “Print is seeing a resurgence globally, especially in the luxury and fashion space. So we’re thrilled

to be bringing back the much-loved magazine – something tangible to have, hold, read and leaf through.”

Print on the doormat

Fashion journalist Alexandra Zagalsky explains why the fashion industry in particular is increasingly turning its focus back to print: “Online shopping has become increasingly time-consuming, which confounds the click-to-buy convenience that we all initially fell for.

There’s too much choice. Search for a “black dress” on Net-a-Porter and over a thousand results come up.” And Lee Cooper, Creative Director of luxury knitwear brand WoolOvers, adds: “A beautiful book landing on your doormat is often more powerful than being inundated with emails, social advertising, and invasive SMS texts.”

Five years ago, legendary British music magazine “NME” discontinued its print edition in favor of an online-only concept, returning with a two-month print issue last year. “Print has always been a cornerstone of the NME brand,” emphasizes Holly Bishop, Chief Operating & Commercial Officer of NME Networks.

Totally new magazines are also coming out. According to consultancy

“Wessenden Marketing”, around 163 new titles were launched in Great Britain in 2021. Studies carried out by media consultant and journalism professor Samir Husni show a similar pattern in the US, where 122 new magazines popped up in 2021. In his opinion, “change is the only constant” also applies to the publishing market, and following this philosophy, there will continue to be room for new magazines in the future. If

a trend manifests itself, generally one or more magazines are launched that take up and cover the subject in all its facets.

Focus and success in niches

Though new publications of magazines are often geared to very different topics, most of them share commonalities: They’re generally niche-oriented, appear in small runs – for the most part only quarterly or semi-annually – and they rely on sales revenue and not ad revenue, which is reflected in their high retail price.

But according to Husni, this has a commercial benefit, as it enables the magazines “to focus much more on their audience and get away from the business of selling the audience to the advertiser.”

In many ways, print magazines are transforming into curated niche products with their business models.

Talking with German TV station “ndr. de”, media and communication specialist Stephan Weichert declares that many newspapers will disappear from the

market over the next ten years due to high printing costs and delivery aspects, but “the situation is different for magazines, which boast a different reading quality and delivery quality. Consumer magazines or special interest magazines, for example – they still work well in print.”

When asked how to develop a new magazine to still have a chance on today’s market, Weichert replies: “I think good pictures, good design, high-quality features and maybe some light reading still go down well. On the other hand, well-written long texts produced with high journalistic standards work too. The “Die Zeit” weekly newspaper, which still records good sales, is a good example of this.”

Programmatic printing

There’s now also a trend emerging towards hybrid forms of catalogs and magazines, commonly referred to as “megalogs.” But retail and mail order business especially strongly rely on this form of customer communication, as German mail order company “OTTO” emphasizes.

The all-encompassing mammoth catalog was discontinued, but OTTO still relies on light versions of catalogs tailored to segmented consumer preferences. Smart catalog marketing today doesn’t work without technology, asserts Dr. Nicolai Johannsen, VP Consumer Interactions, at OTTO. “With the help of data forecasts, we determine range preferences, the affinity for print and the likelihood to purchase of users and decide based on this whether and what print format is suitable for a customer.

The next step involves personalized ads, such as a postcard with custom product recommendations or tailored, seasonal catalogs. Instead of a scattergun approach, we use data-driven analyses and scoring models that assist us in deciding whether or not a print advertisement is used.”

And so there’s still hope that this tentative comeback becomes a strong, lasting one for the magazine market.

Wicked Brick, a British manufacturer of display solutions for collectible items, has invested in the Acuity Prime to support its development of premium-quality products for its customer base.

Founded in 2017, the company produces bespoke cases, stands and wall mounts for pop culture collectors worldwide. Their diverse range of products are designed to display collectables from LEGO to Funko Pops, Hot Toys and Pin Badges. Most recently, Wicked Brick has added Officially Licensed Warhammer display cases to their product range.

Recognising the importance of innovation and staying ahead of market trends, Wicked Brick continuously seeks ways to enhance its product offering. In light of this, last summer, the company invested in the Fujifilm Acuity Prime, a decision driven by its commitment to meet the evolving demands of its clientele.

Alex Ashley, Procurement Manager at Wicked Brick, comments: “Our customers expect nothing short of excellence, both in quality and turnaround time. With the Acuity Prime, we’ve not only elevated the quality of our products, we’ve streamlined our production process too, which has enabled us to deliver exceptional results in record time.”

Ashley adds: “We pride ourselves on being at the forefront of innovation and the Acuity Prime aligns perfectly with our vision. It has enabled us to meet the specific demands of our customers, as well as explore new avenues of creativity for our product designs.”

Wicked Brick attended a demo of the Acuity Prime at Fujifilm’s Broadstairs site, prior to the investment. During the demo, the team witnessed the machine’s ability to produce premium UV backgrounds, bases, and intricate designs on acrylic, which have since revolutionised the way the company crafts its products.

Following this demonstration, Wicked Brick facilitated the purchase of the Acuity Prime through Soyang Hardware, a supplier of leading edge wide- and superwide-format print production hardware solutions from many of the industry’s biggest and best-known printer brands.

Soyang’s expertise and through its sister company Soyang Europe (a leading manufacturer and distributor of digitally printable wide format and superwide for-

mat media and surface coverings) made them the ideal partner for this deal, ensuring a seamless and efficient transition. As an established UK-based partner for Fujifilm, Soyang’s involvement highlights their combined commitment to excellence in the printing industry.

Wicked Brick’s partnership with Fujifilm has been instrumental in its journey towards excellence. From sales consultation to installation and ongoing support, Fujifilm has demonstrated its unwavering commitment and expertise, facilitating a seamless installation of the Acuity Prime and ensuring its optimal performance.

Ashley comments: “Aside from the exceptional print quality, what truly sets the Acuity Prime apart is the outstanding support we’ve received from Fujifilm. Its team has been incredibly responsive and helpful throughout the entire process, reaffirming our confidence in both the product and the brand.”

With the Acuity Prime in operation, Wicked Brick looks forward to pushing the boundaries of its creativity and delivering the very best products and service to its customers.

Koenig & Bauer, a leading manufacturer of sheetfed offset presses for folding carton printing, invited existing and prospective customers from all over the world to an exclusive event under the banner ‘Post-press Solutions Experience’ that was held from 19 to 22 November

More than 150 guests from twelve countries were given the opportunity to learn more about the latest solutions for even greater profitability and efficiency at the post-press stages of folding carton production.

The objective of the event was to present innovations in the field of post-press technology and to share comprehensive insights into the future of folding carton production. It addressed both potential customers and current users who wish to further optimise their production processes and are therefore interested in learning about the latest trends in the industry.

End-to-end process chain for folding carton production

Having expanded its expertise in folding carton printing to cover the entire value

chain of post-press technologies, Koenig & Bauer is able to offer its customers solutions that go beyond traditional press engineering, such as 360-degree

Elevate your printing possibilities with Extended Colour Gamut (ECG) technology. Our MPS presses enable you to produce 97% of Pantone colours using ECG along with unparalleled image detail.

workflow solutions. As a trusted advisor, Koenig & Bauer supports its customers at all stages of folding carton production and presents alternatives to established products in the field of post-press. The combination of leading-edge press engineering and innovative post-press solutions enables users to stand out in an increasingly competitive market and to develop new business opportunities.

What’s more, Koenig & Bauer is a champion of digital networking and offers a manufacturer-independent ecosystem in the form of myKyana that optimises the complete production process and promotes seamless communication between machines. This digital platform ensures that all machines and processes communicate efficiently with each other – a key prerequisite for successfully mastering the ever-higher demands of customers and markets.

Live: practice-oriented presentations and machine demonstrations

A highly varied agenda allowed the international post-press experts to gather a wealth of information on current and future developments in folding carton production.

Ralf Sammeck, member of the executive board of Koenig & Bauer and CEO of Koenig & Bauer Sheetfed, used his keynote presentation to explain the postpress strategy and digital orientation of the company. He positioned Koenig &

Bauer as a leading partner in the field of folding carton production. Subsequent breakout sessions offered the participants additional, more detailed information on topics such as the service experience, performance management and expanding post-press options.

Practical demonstrations with live production runs and job changeovers presented a broad spectrum of innovative solutions with which Koenig & Bauer is shaping a forward-thinking and efficient future for folding carton production. The demonstrations covered the following machines and solutions in the Radebeul Customer Experience Centre:

- CutPRO Q 106 SB – Koenig & Bauer's performance benchmark in flat-bed die-cutting for maximum outputs in industrial folding carton production

- CutPRO X 106 – the game changer - Ipress 106 PRO SB – the new generation of the Ipress 106 flat-bed diecutter for even more efficiency - Omega Allpro 110 – the all-rounder for maximum productivity and versatility - myKyana – the digital ecosystem from Koenig & Bauer

Customers from different regions reported on their business development successes using sheetfed offset and postpress technologies from Koenig & Bauer. Thanks to innovative solutions geared to diversification and differentiation, they are in a better position to respond to the constantly changing demands of their customers. Koenig & Bauer offers not only the machines, but also tailored solutions covering the entire value chain of folding carton production.

to print MDO-PE

Highest quality with best register

Connected to RUBY to digitize the value chain ... and many more!

Windmöller & Hölscher KG

Lengerich / Germany

Phone + 49 5481 14 - 0 · info@wuh-group.com www.wh.group/int/en/

Best profitability at printing speeds up to 600 m/min. and fast job changes