Every year, thousands of different inks are used by different industries around the world – especially inkjet) industrial printing, applying batch numbers and codes to products and packaging. But about the inks we use every day?

Since LEIBINGER produces both printers and the ink used in them, we are in a unique position to shed some light on this universal but often-overlooked substance. With the help of Dr. Thomas Paul, ink expert at LEIBINGER-Group, we have been digging into the secret world of industrial inks and uncovered a few interesting facts that you might not know.

1. Security UV ink has the same ingredient as washing powder UV-readable ink can be used as a security feature, when hidden marks or codes are added to prove a product is genuine. However, the colorant that shows up under UV light is commonly available; it is in fact a key ingredient in most laundry detergents since the blueish hue helps to counteract the gradual yellowing of clothes, thus keeping them apparently

whiter. As a security measure, ultraviolet ink is only effective if it cannot be easily recreated. More advanced security inks therefore combine different colours – for example a black ink that shows up as green under UV light – making them too technically difficult for most counterfeiters to produce.

2. The harder the PVC, the easier the printing

Over 40 million tonnes of PVC (polyvinyl chloride) are produced each year. In its pure form it is quite brittle so plasticizers are often added in order to make it more flexible. Rigid plastic pipes, for example, contain far less plasticizer than the more

flexible PVC is used for cable sheathing and the plastic wrap in food packaging.

But while ink adheres perfectly well onto PVC molecules, it won’t stick to plasticizer molecules. So printing on rigid pipes is straightforward, but printing onto food packaging and cables – where there is more plasticizer present – is challenging. The result is “set-off” – when the ink doesn’t stick and is readily transferred onto the item that is packed next to it. Our engineers have produced alternative ink formulations that adhere more readily to plasticizer molecules and have thus solved the problem.

3. Invisible ink is used to make product packaging more beautiful UV-readable ink is not just used for security – it’s also used to improve product aesthetics. If brands feel that a visible barcode or batch number would spoil the look of their high-end packaging, they can opt for ultra-violet ink instead. Many products in plain view carry coding information that is invisible to the naked eye but is highly useful for traceability purposes.

4. Green ink is harder to produce, but it’s worth the effort

Making the colour is easy. But how do you make ink that is environmentally friendly? To assess the environmental

especially in CIJ (continuous

But how much do you know

footprint of ink, we need to first look at its key components.

Around 80% of the ink consists of solvent, as the ink has to be ultra-fast drying in industrial and packaging coding applications. Most of the remaining material is the binding agent and the colorant that remains after the solvent has evaporated. Traditionally, both the solvent and the binding agent have been oil-based, which presents a significant challenge to ink manufacturers. But LEIBINGER is now able to produce an innovative ink that is around 85% biobased, dramatically reducing their impact on the world’s resources.

5. The perfect ink recipe requires a pinch of salt

In addition to the solvent, the colourant and the binding agent, there is another secret ingredient in CIJ ink that not everyone knows about: salt. This is because CIJ is a process that relies on giving each drop of ink an electrostatic charge so it can be deflected by electrostatic plates to form letters and codes on the substrate. This requires the addition of salts of some kind, which helps the ink to conduct electricity and therefore able to respond to the CIJ deflection process. As all good chefs know, the perfect recipe always includes a pinch of salt.

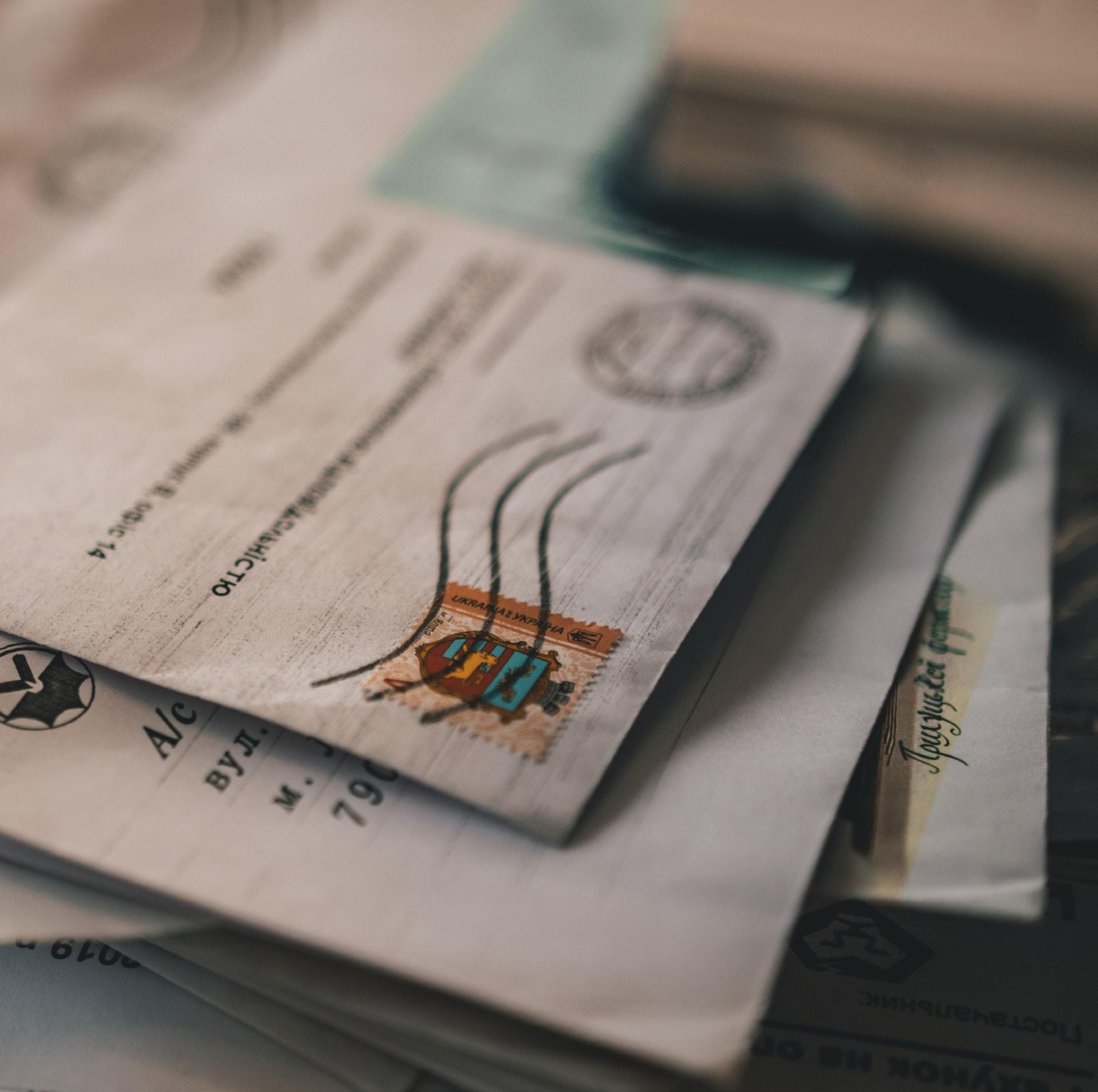

6. Every letter you receive contains ultra-violet ink

Machine readers – such as the millions of scanners that are used in postal sorting systems – work more effectively with UV ink. It is simply more legible than regular black and white printing. So, when a letter arrives at the sorting office, an OCR

scanner reads the written address and then applies a barcode in UV ink, which can be quickly and accurately read by subsequent scanners, thus speeding it through the postal system. If you’ve ever wondered why your mail often comes with a faint orange or pink barcode printed on it, now you know...

7. Ink properties reflect specific customer needs

Sometimes you may want the number or barcode that you print to stay visible forever. But our customers also often need inks that can be removed when required. So we need to create inks with varying levels of permanence or washability.

Take for example the expiration date on a recyclable glass bottle. When the bottle is refilled, a new expiration date needs to be applied in place of the old one – which is typically removed via a caustic solution of some kind in the bottle recycling plant. But because those bottles frequently get wet (whether in the ice bucket, or simply attracting condensation when they are straight from the fridge on a hot day) the ink must be permanent enough not to be erased by water alone. PET bottles present a different challenge. They are not refilled, but the expiration date must still be erased to prevent the ink adding a grey tinge to the recycled material.

However, some markings really are very

temporary. In car manufacturing, rolls of aluminium sheets are usually marked with a batch number. But once those sheets have been shaped into panels for the vehicle, the code must easily removable. Our customers require different levels of permanence depending on the needs of their products and the way customers use their products: it’s our job to produce inks that deliver it.

8. Many printer manufacturers cannot produce their own ink

Here at LEIBINGER, we’re well known as a manufacturer of industrial inkjet printers and industrial printer ink. That means we can help our customers print more accurately, more efficiently and

more sustainably because we understand how inks and printers work together.

This is in contrast to many other printer companies who have to buy in their ink from a third party. The ink manufacturer provides a “certificate of analysis” that proves the chemical constitution of the ink but, while this usually deliver perfectly good results, it’s not the same as actually testing different inks in different printers. That’s what we do every day at LEIBINGER and we like to think it makes a difference for our customers.

Whatever your print requirements, you need perfect combination of ink and print technology to get the best results. We have a range of machines that operate at different speeds, with different features and different price points that suit our customers’ production processes – and we combine this with an ink formulation that will give them best results on their substrate, whether that is metal, glass, cardboard or any other material. And because we produce both ink and printer, you know that it will be a combination that has been thoroughly tested by us to ensure optimum performance for you.

Simply consistent

Decrease waste and setup with predictable plates

Simply efficient

Increase on-press performance with a robust plate

Simply sustainable

Support sustainable inks and substrates all with the same plate

Simply better

Address your most demanding brand and quality requirements

From prepress to on-press, deliver the efficiencies and productivity needed from your plates to maximize your bottom line.

Discover how Expressprint optimised workflow productivity, as well as print and output quality, with Konica Minolta’s high chroma colour printing technology.

Express Print & Design Pte Ltd stands at the forefront of the commercial printing sector in Singapore, serving both corporate clients and individual consumers. Established in 2005, the company once boasted 14 physical locations at its peak. However, their evolution has been remarkable, transitioning entirely to an online platform by 2018.

This transformation was facilitated by their proprietary PriceCal software, a web-to-order solution simplifying price calculations for online print sales. The seamless functionality of the PriceCal software has led to a positive predicament for Expressprint. They are experiencing a notable and consistent rise in demand for specialized printing services such as books and variable data print. However, these orders typically entail smaller quantities, which may not be optimally cost-effective for their current production setup.

This success story aims to showcase how Konica Minolta's cutting-edge printing solutions have transformed Expressprint's operations by enhancing production efficiency, particularly in accommodating to on demand print requests, propelling productivity to unprecedented levels while elevating print quality to new standards.

The Challenge: Elevating Printing

Productivity and Colour Precision

Express Print & Design Pte Ltd encountered significant obstacles in meeting the demands of their burgeoning e-commerce portal, exacerbated by

customers' increasing expectations for swift turnaround times. This resulted in processing delays and compromised collateral quality, posing a threat to their customer satisfaction and competitive position.

With an increase in demand and orders, Expressprint soon experienced a bottleneck in their processes, and workflow inefficiencies became apparent. Compounded by manual imposition processes, this led to prolonged prepress preparation and inaccuracies in print production. Expressprint found it challenging to keep pace with the escalating volume of booklet printing requests, hampering their ability to deliver on time and maintain quality standards consistently.

Quest for Vivid Colour Printing Excellence:

Expressprint recognised the need to enhance their colour printing capabilities to overcome the dull print colours that

persisted when producing marketing collaterals. With customers seeking vibrant and precisely rendered colours, Expressprint aimed to elevate their printing standards to match or exceed industry benchmarks, ensuring they maintain a competitive edge in the market.

Expressprint’s lean staffing meant they had a lack of highly skilled operators, impacting their ability to achieve vivid colour printing excellence. Without proficient personnel, maintaining colour precision and consistency became a challenge, hindering their efforts to meet customer expectations and industry standards.

Solutions: Optimising Print Workflows and High Chroma Colour Printing

Express Print & Design Pte Ltd embarked on a journey to address their pressing challenges after encountering

Konica Minolta's innovative solutions at the KL Print Exhibition in Kuala Lumpur. Recognising the potential of Konica Minolta's offerings, they reached out to request a demo session, seeking solutions to enhance their print workflows and achieve superior colour printing capabilities.

AccurioPress C83hc: Mastering High Chroma Colour Printing: Konica Minolta introduced Expressprint to the AccurioPress C83hc, a gamechanger in the realm of high chroma colour printing. With its unique ability to extend beyond standard CMYK and reproduce colours within the RGB spectrum, this machine offered Expressprint the capacity to deliver vivid, true-to-life colours, elevating their gamut print quality to new heights of excellence.

AccurioPro Flux: Streamlining for Optimal Printing Productivity

To further increase productivity and streamline their printing processes, Expressprint adopted Konica Minolta's AccurioPro Flux solution. This software facilitated seamless workflow management, providing operators with user-friendly tools to handle print jobs from start to finish efficiently. With enhanced flexibility and efficiency, Expressprint was empowered to meet customer demands with precision and reliability.

Results: Enhanced Printing Productivity and Wide Colour Gamut Printing

The integration of the AccurioPress C83hc and AccurioPro Flux brought about transformative results for Express Print & Design Pte Ltd, revolutionising their printing processes and expanding their colour capabilities.

Metrics of Success: A 300% Boost in Printing Productivity: Expressprint

experienced a remarkable surge in productivity, with digital print output increasing by an astounding 300%. This substantial improvement streamlined their workflow, allowing for faster turnaround times and more efficient handling of print jobs.

Financial Upswing: Revenue Growth by 80%: The adoption of Konica Minolta's solutions translated into tangible financial gains for Expressprint, as evidenced by an impressive 80% increase in revenue. This significant uptick in profitability can be attributed to higher operational efficiency, expanded product offerings, and enhanced customer satisfaction.

Expanding Horizons with Wide Colour Gamut Printing: With the wide colour gamut capabilities of the AccurioPress C83hc, Expressprint now boasts an extended range of colour options, enabling them to cater to diverse customer preferences and demands. This enhancement broadens their market appeal and solidifies their position as a provider of high-quality printing services.

Ease of Use for Smoother Operations: Expressprint benefited from userfriendly technologies introduced by Konica Minolta, facilitating seamless operations and maximising the potential of their printing machines. With intuitive interfaces and simplified prepress functions, operators were able to navigate tasks with efficiency, ensuring smooth workflow and optimal utilisation of resources for an overall increased productivity.

Market Impact: Satisfying Demand with Quality and Speed: Expressprint's ability to deliver superior print quality and meet customer expectations for prompt service has had a profound impact on the services offered to clients and customers. By enhancing both quality and speed,

they have bolstered customer satisfaction levels, attracting new clientele and strengthening relationships with existing customers.

Beyond the Machine: The Value of Support and Strategic Partnership

The collaboration between Express Print & Design Pte Ltd and Konica Minolta extends beyond the implementation of cutting-edge machinery. It encompasses a strategic partnership aimed at delivering ongoing support and fostering mutual growth and success.

After-Sales Support: Ensuring Continuous Excellence: Konica Minolta's commitment to customer satisfaction is exemplified through their reliable aftersales support. With dedicated service and maintenance offerings, they ensure that Expressprint's operations remain uninterrupted, maintaining a standard of excellence in print production.

Strengthening Bonds: The Konica Minolta and Expressprint Partnership: The successful collaboration between Konica Minolta and Expressprint serves as a cornerstone of success for both entities. Through collaborative efforts and mutual trust, they continue to navigate challenges, drive innovation, and achieve shared goals, setting the stage for sustained growth and prosperity.

Optimising Printing Workflow with Konica Minolta

Express Print & Design Pte Ltd's journey with Konica Minolta underscores the transformative potential of strategic partnerships in the printing industry. Through the adoption of innovative solutions such as the AccurioPress C83hc and AccurioPro Flux, Expressprint witnessed remarkable improvements in productivity, print quality, and revenue growth.

From the simple act of sharing a business card to the tactile experience of turning the pages of book, paper has the power to engage our senses and create meaningful connections.

What makes viewing a printed photo album more enjoyable than scrolling through a hundred photos on a screen? Each turn of the page reveals not just images, but a narrative woven through time. The weight of the album in your hands, the slightly glossy texture of the photographs, and the sound of pages turning create a multisensory experience that transcends the flat, digital alternative.

Paper makes you feel connected, from the simple act of sharing a business card, wedding invitations, or exchanging of your favourite novel. These seemingly insignificant pieces of paper carry with them a wealth of emotions and associations tied to the events they represent, preserving memories. A recent study conducted by Royal Mail Marketreach and WARC revealed that nearly two-thirds of individuals affirm that direct mail captures their complete attention. The personal touch of sending invitations or cards establishes a profound connection, underscoring the transformative power of paper.

Generation Z might allocate 35% of their daily time to online activities, 8.5 hours a day, but members of this generation exhibit a strong inclination towards traditional print books compared to eBooks. Last year, a mere 14% of sales in their age group were attributed to eBooks, according to BookRiot.

Characters, narratives, and themes within the written word serve as a mirror to our own experiences, allowing us to connect with the content on a deeply emotional level. The allure of reading on paper goes beyond the act of consuming information; it’s an immersive experience that engages the mind and stimulates the senses. The sensory elements of a physical book — textures, scents and the satisfying rustle of pages — are all part of the reading experience. Characters, narratives, and themes within the written word serve as a mirror to our own experiences, allowing us to connect with the content on a deeply emotional level.

As our lives become more entwined with technology, the value of paper as a medium for preserving memories and facilitating meaningful connections remains unparalleled. The tactile, multisensory experience it provides fosters a deep and lasting bond with the physical world, enriching our lives. In a world inundated with pixels and virtual experiences, the enduring allure of paper stands as a testament to the timeless power of the tangible.

Paper. Because it’s real.

• Autonomous printing in packaging production: Push to Stop takes automation to a whole new level • Enhanced competitiveness in commercial printing: Speedmaster XL 106 perfecting press operating at 21,000 sheets per hour boosts productivity by up to 15 percent • Sustainability: Up to 25 percent less paper waste • Postpress: New-generation Stahlfolder boosts productivity and StackStar C collaborative robot helps cushion effects of skills shortage

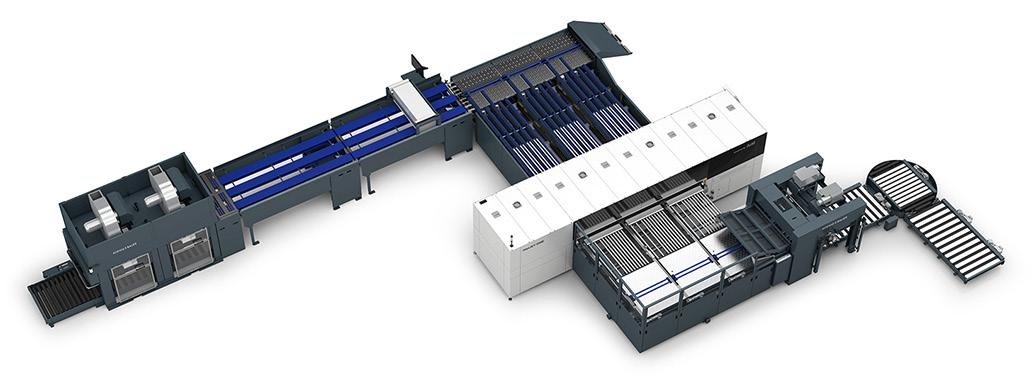

Heidelberg is using its new Peak Performance generation of the Speedmaster XL 106 to address the major challenges facing print shops – huge cost pressures, the manifest shortage of labor and skilled workers, and the growing sustainability requirements in printing. Manual work is a thing of the past – at drupa 2024, Heidelberg showcased sheetfed offset printing on a whole new industrial scale under the motto “Unfold your Potential”. Based on the new Peak Performance generation of the Speedmaster XL 106, the company exhibited a highly automated or autonomous end-to-end production workflow for commercial, packaging, and label printing respectively.

In commercial printing, 98 percent of manual interventions across the entire value chain – from job data through to

the finished brochure – can be eliminated compared to production that doesn’t utilize Push to Stop.

In packaging printing, numerous innovations on the Speedmaster XL 106 are resulting in up to 20 percent higher overall productivity while also reducing manpower requirements, paper waste, and energy consumption. This ultimately means lower costs per printed sheet, which is the decisive competitive factor for print shops. Along with its partners POLAR and MK Masterwork, Heidelberg is thus addressing the most pressing issues faced by industrial print shops worldwide – cost pressures, the skills shortage, sustainability, and digitalization. Autonomous printing in packaging production with Push to Stop Thanks to the new Peak Performance generation of the Speedmaster XL 106,

autonomous printing is now making its mark in packaging production. Heidelberg is achieving this with its new highly automated Push to Stop coating unit, which changes the coating plate, screen roller, and coating fully automatically. This unit reduces the overall makeready process by up to 30 percent.

Having been prepared while production is ongoing, makeready in the coating unit takes place on a fully autonomous basis. A further highlight when it comes to the production of sophisticated print motifs is the new AI-based Hycolor assistant in conjunction with another new product, the Hycolor XL inking unit and dampening system. Operating entirely autonomously, the assistant optimizes the presetting of the inking unit and dampening system before the first sheet enters the press, thus cutting the amount

of setup waste by up to 25 percent and reducing the time it takes to achieve the first OK sheet.

“Thanks to a combination of mechanical and AI-supported software innovations for the new Peak Performance generation of the Speedmaster XL 106, our packaging customers are benefiting from up to 20 percent higher net productivity. That’s a huge step toward boosting their competitiveness,” insists Christian Steinmassl, who is in charge of the Packaging segment at Heidelberg.

Competitiveness – 21,000 sheets per hour with sheet reversal now also achievable

The cost pressures in commercial and publishing printing are huge, and qualified staff are hard to find and hold onto. The Push to Stop philosophy on which the new Peak Performance generation of the Speedmaster XL 106 is based means production can, for the most part, take place without any operator intervention – now also at up to 21,000 sheets per hour in perfecting mode. The new fully integrated Prinect Inspection Control 4 has an efficient approach to quality assurance, checking both sides of the print sheet on perfecting presses for the first time ever.

Simply by using this solution, customers can make total savings of some 120,000 euros when it comes to paper waste, costs associated with complaints, and personnel expenses. Thanks to a combination of inline defective sheet ejection and delivery logistics, the system ensures that waste-free stacks are delivered to the postpress section without any operator interventions.

Productivity – postpress innovations result in 1:1 performance ratio What’s more, the new highly automated Peak Performance generation of Stahlfolder TH 82-P folding machines restores a 1:1 performance ratio between pressroom and postpress operations. In other words, a new Stahlfolder TH 82-P can handle the entire output of a newgeneration Speedmaster XL 106 at the postpress stage.

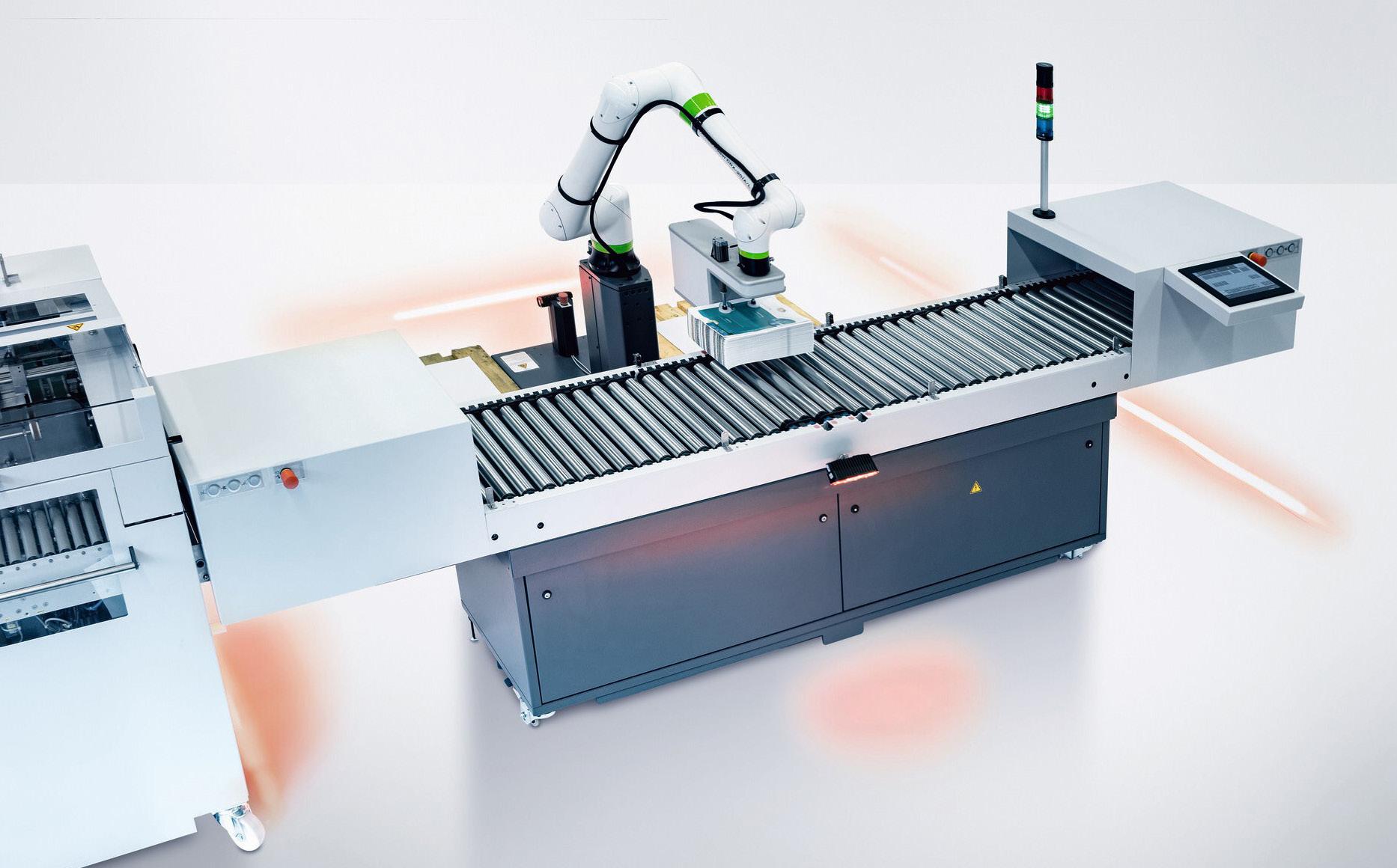

The new Stahlfolder TH 82-P generation offers Heidelberg customers a further improvement of around 15 percent in net output without increasing the speed of the machine. In addition to all this, the new collaborative StackStar C robot system relieves the strain on staff. This highly flexible robot automatically deposits product stacks in the postpress section. StackStar C is mobile and can be moved easily between different machines.

The new StackStar C is a collaborative robot system that safeguards productivity and relieves the strain on postpress staff.

It operates on a collaborative basis and, thanks to an innovative safety concept, ensures staff and the robot system can work together safely. This means no safety fencing is required. What’s more, quality control processes can be carried out during production without stopping the robot. Using two StackStar C units working in tandem makes it possible to double production capacity, and the different stacking patterns and pallet sizes can be selected intuitively at the control terminal.

“The enhanced automation and process efficiency we’re offering our commercial printing customers means they can boost their productivity while also using fewer resources. In this way, we’re helping them further improve their competitiveness in the future, too,” says Dr. Frank Schaum, who is in charge of the Print segment at Heidelberg.

Fully automatic reel splicer on CutStar brings another productivity boost The new fully automatic reel splicer on the CutStar sheeter achieves another productivity boost of over 12 percent. It results in a further substantial reduction in downtime and paper waste, too. This system also makes the Speedmaster XL 106 attractive to web offset businesses, who are increasingly facing shorter print runs.

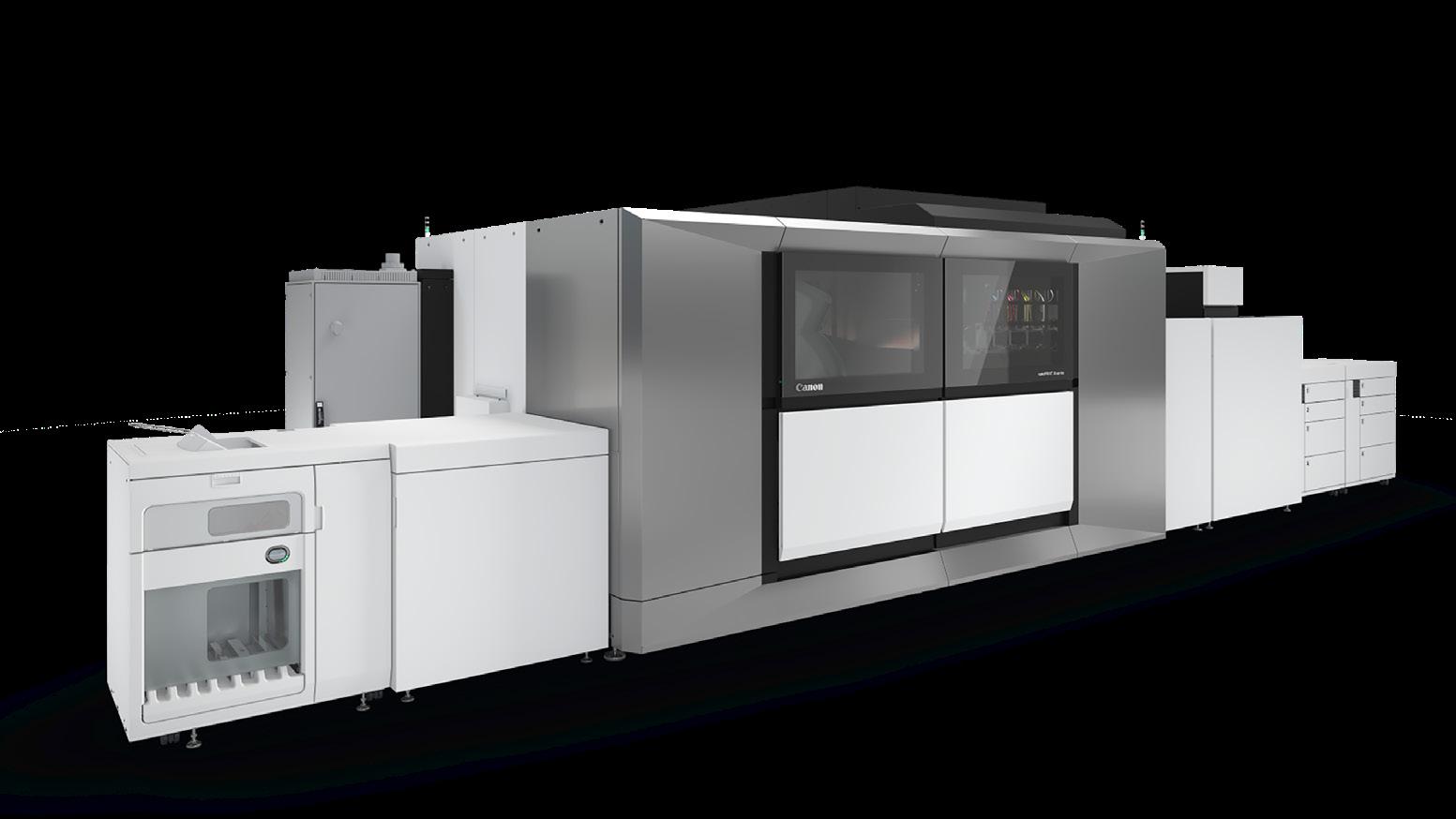

The varioPRINT iX-series revolutionises the commercial printing business experience. It combines stunning image quality and a wide media range with the high productivity and the attractive cost-efficiency of inkjet.

P R O D U C T I V I T Y . Q U A L I T Y .

V E R S A T I L I T Y .

As a global market leader in sheetfed inkjet, Canon offers more experience in this segment than others. Invest with confidence to expand profit and opportunity! Experience iX!

The family-owned company produces a vast range of printed products – from business cards, brochures, stationery and calendars to banners, signage & display, labels and packaging – for independent printers, franchise groups, print brokers and managers, advertising agencies and graphic designers. The investment is the culmination of two years’ inkjet research and testing by CMYKhub to find the platform that would best fit their mid-term plans and the needs of their customers.

Dayne Nankervis, CEO of CMYKhub, explains, “We were already a Canon CMYKhub, the largest wholesale printer in Australia, has made its first investment in inkjet production equipment by

customer as we have a number of their wide format Colorado devices, so had also followed their cutsheet inkjet developments and had the varioPRINT iX3200 on our list as a potential investment. We carefully considered a number of other inkjet printers as well, of course, but after rigorous testing that included factory and customer visits, it became clear that the iX3200 was the press for us.

We trust the technology and we see some great benefits – the print quality is exceptionally high with vibrant colours and it’s consistent on every substrate. As a

B3 printer, it also delivers an excellent level of productivity. And it’s also so easy to run and has an intuitive user interface. I can understand why it has such high uptime too, as it’s a simple machine designed extraordinarily well.

“We’ll start by running lighter weight, uncoated and document-based stocks through the iX3200 for letterheads, books and textbooks, and in time transition across more higher coverage products, such as leisure books, a sector that we want to break into. For CMYKhub, this purchase in the Canon varioPRINT is our first step into inkjet, but if it works well for our production environment, we could see a further investment in the future.”

Craig Nethercott, Managing Director, Canon Production Printing Oceania, comments, “I’m delighted that CMYKhub, Australia’s leading wholesale printer, has chosen the Canon varioPRINT iX3200 as its first investment in cutsheet inkjet technology. The press is a well tried and tested platform that hundreds of our customers rely on to profitably service the requirements of their customers and I’m confident that it will prove to be the perfect start to their inkjet journey and the catalyst for the next stage in their growth.”

Fink Group’s first investment in Fujifilm technology marks a significant milestone in its commitment to innovation, efficiency and sustainability

Fujifilm announces that Fink Group has recently made significant investments in both toner and inkjet Fujifilm digital print technology, with recent installations of the Jet Press 750S High Speed Model (HSM) and Revoria Press PC1120.

Founded in 1959, Fink Group has grown into a leading printing company based in Pfullingen, Germany. With 56 employees onsite and over 200 employees in Baden-Württemberg, the company is renowned for its diverse range of high quality printing services. Fink Group produces magazines, brochures, folding cartons, packaging for food, mailings, postcards, business cards and calendars. Additionally, they produce a weekly newspaper, handmade leather notebooks and vibrant calendars.

The Jet Press 750S HSM was installed in March 2024 and has already transformed Fink Group’s production capabilities. Known for its ultra-high print quality and remarkable efficiency, the Jet Press has set new benchmarks in digital printing. “The Jet Press has enabled us to produce shorter runs with superior quality compared to both digital and offset presses,” said Martin Fink, CEO

of Fink Group. “The prints are free from artefacts, stripes and cloudy colour fields, ensuring our products meet the highest standards.”

Fink Group’s investment in the Jet Press 750S HSM aligns with its longstanding commitment to sustainability. The waterbased inks used in the Jet Press are free from hazardous materials, promoting a safer work environment and more ecofriendly production. Additionally, the machine’s innovative design allows Fink Group to repurpose warm air from the printing process to heat other production areas, maximising energy efficiency.

“The water-based inks in the Jet Press 750S HSM are not only better for the environment, but they also ensure the safety of our employees,” Martin Fink added. “This investment reflects our dedication to sustainability and responsible production practices.”

Fink Group is dedicated to sustainable practices, sourcing materials locally within a 100km radius and aiming to produce compostable print products. This commitment is further reinforced using water-based inks in the Jet Press,

which are safer for the environment and employees.

Complementing the Jet Press 750S HSM, Fink Group’s investment in the Revoria Press PC1120 will enhance Fink Group’s flexibility with features like white, gold and silver printing capabilities, along with long banner and small format options. Together, these presses will streamline workflows and offer unparalleled print quality, enabling Fink Group to cater to diverse market demands.

The new printing solutions have also opened doors to new markets, attracting clients from various industries including fashion, automotive, photography, and art galleries. “The stunning print quality has helped us secure new customers with high expectations, such as media agencies and fashion designers,” noted Martin Fink. “The Jet Press allows us to deliver unparalleled detail and colour accuracy, setting us apart from competitors.”

As a family-owned business in its third generation, Fink Group continues to prioritise social responsibility and sustainability. “My grandfather established this business with a focus on weekly newspapers, my father expanded it to B2B, and now I am steering it towards sustainability and high quality printing,” said Martin Fink. “Our investments reflect our dedication to creating a healthier and more human business for future generations.”

Close and attentive support from Fujifilm ensured swift installation and integration of both machines. “The Fujifilm team worked seamlessly to ensure the installation was completed. I never thought that in such a small timeline Fujifilm could act so fast and do such an excellent job,” Fink added. “Their dedication and efficiency have been nothing short of amazing.”

Effortlessly convert images to CMYK + Pink without modifying the originals.

Since its establishment in 1946, Niwa Printing Co., Ltd. has worked with four major plate printing methods: letterpress, intaglio, offset, and screen printing, building technology specialized for cosmetic labels and packaging.

In October 2021, the company consolidated its factories in Shinagawa and Yokohama in a new plant in Isehara. They introduced the Lithrone G40 advance with coater (a six-color 40-inch sheetfed offset printing press), which can handle both multi-color and environmentally friendly printing. We asked President Tomohiro Horino, Plant Manager and Quality Assurance Department Manager Osamu Usui, Manufacturing Department Manager Shuzo Nishimori, and Offset Section Chief of Manufacturing Section 1 Ryota Kudo about the background and effects of this introduction.

Expectations for the versatile performance of the Lithrone G40 advance

To realize the dream of becoming a centennial company, Niwa Printing launched a project to build a new plant about five years ago. The newly completed Isehara Plant introduced new machines for all processes, selecting the Lithrone G40 advance with coater for the press and focusing on increasing demand

The Isehara Plant has established completely different entry criteria compared to previous plants. “Contamination such as hair has been completely eliminated, leading to a dramatic stabilization of quality,” says President Horino.

for color printing and reducing plastic in the future.

President Horino explains the reason for the selection: "The print quality of offset printing, which is our top process, greatly influences the quality of our production, which involves many secondary processes. Therefore, we introduced the Lithrone G40 advance, which provides superlative performance with regard to makeready time, register accuracy, and color reproducibility. As society moves away from plastic, we have been exploring surface processing alternatives to PET, PP, and matte finishes, reproducing them with screen printing. To improve productivity with offset printing, we decided to introduce new machines, and this was very effective. Our customers have already adopted this as a measure to reduce plastic."

Plant Manager Usui, who has been involved since the project's inception, added, "Previously, a four-color machine was sufficient for most jobs, but with the addition of special colors to process

There are many female employees who are active at the site, taking charge of color matching and other tasks.

colors, a six-or-more color press was desirable." He explained the background to selecting a six-color machine after detailed discussions with Komori, considering the changes in production needs.

Improved quality and productivity with multiple functions

The company handles many jobs requiring special colors and full-tone printing, and with conventional machines the printing speed was lowered due to consideration of register accuracy and drying.

Mr. Horino discusses the effects after introducing the Lithrone G40 advance: "The register accuracy is excellent, aligning almost right away. The more secondary processes like foil stamping and embossing increase, the more likely misalignment occurs, but the new machine makes it is easier to match register, and it smoothly handles secondary processes even with multi-imposition printing."

Additionally, the company adopted the extended delivery specification considering the drying (curing) of ink immediately after printing. Currently, even with the printing speed set at 1.5 times faster than before, register accuracy is maintained without drying defects. Furthermore, he says, "Printing defects leading to complaints, such as hickeys and ghosts, have significantly decreased. Equipping the press with inspection devices (PDC-SX, PQA-S) has provided operators with a sense of security."

Mr. Usui states, "For jobs that require only offset printing, the inspection devices have made it possible to omit the blank inspection process, so we proceed without any inspection and without complaints." He highlighted the simultaneous achievement of quality improvement and labor-saving.

Manufacturing Department Manager Nishimori praises the new machine: "We use many special colors and for changeover, we perform roller cleaning, fountain changing, and color changes. Our previous press took an hour with four colors, but the new machine completes the process with six colors and a coater in nearly the same time. Full-APC reduces plate-changing time by about half, significantly reducing makeready time.

For color adjustments, the number of times necessary from ink feeding to print start-up has significantly decreased due to preinking, and waste paper has been halved compared to before. There are fewer defects, and almost no surface irregularities within the sheet." He added, "Even when we raise the speed, there is no register error or color tone inconsistencies, enabling printing at a constant level from start to finish. It's a world-class machine."

Regarding feeder and delivery precision, he mentions, "Our company uses a wide variety of papers. We had difficulties with the previous machine, but the new press can print different papers, such as general paper, metallized paper, foam paper, black paper, PET, and film, and paper

The average age of the site staff is about 27.

thicknesses ranging from 0.1 to 0.5mm, with only air adjustment. Sheet alignment in the delivery is excellent, and work can be quickly moved to the next process, reducing the burden on the operator."

Offset Section Chief Kudo also explains, "Compared to the previous press, the new machine has more suction points for the first and second suctions, and the feeder has an exceptionally stable paper flow, almost eliminating issues like paper warping and double feeding. The number of air blowers has increased, making paper feeding smoother."

Addressing emerging challenges at the beginning of new plant operation with KGC support Immediately after the start of operation at the new plant, productivity temporarily declined due to a major replacement of employees following the relocation. However, about a year of improvement support from KGC (Komori Graphic Technology Center) was a catalyst for productivity improvement. President Horino says, "In addition to printing knowledge, by re-recognizing the importance of effective 5S activities and daily maintenance, operator awareness changed.

Printing quality improved, and productivity increased by about 1.3 times since the relocation." Offset Section Chief Kudo, who is the chief operator, also shares, "By learning maintenance and how to use PQA-S and PDC-SX, we have been able to maintain quality and gained confidence."

Finally, President Horino expresses his vision and thoughts for the future: "I believe packaging gives consumers dreams and hopes. We want to continue passing on our technology, producing craftsmen who can create printed products that evoke Kando when seen and touched. Printing technology worldwide is rapidly evolving. We feel the need to deliver printed products that provide 'the pleasure of paper felt with all the senses' as added value, creating an emotional impact globally."

Make the move to digital – and unbox your business with the flexibility to accommodate fast turns, versioning requests, last minute edits, and changing buying decisions.

With the new EFITM Nozomi 14000 LED digital press for corrugated packaging and POS, you can reduce process steps from weeks and days to hours and minutes. And personalize runs from one to infinity at higher margins and with lower costs – all in a single pass.

Let’s build your brilliant future. Together.

Scan to learn how corrugated converters and packaging printers are opening up new ways to say, “Yes!”

Print’s place among the top tier of advertising channels is under threat. The inexorable rise of digital media has been pushing print to the margins for some time. Is the continuing eclipsing of print a foregone conclusion or is there life in this cherished medium still?

Ulbe Jelluma, the director of Print Power, has recently given a thoughtful interview in which he explored the prospects for print in this digital age. Noting that less than five percent of advertising expenditure in Great Britain is allocated to print, he highlights the headwinds buffeting print’s position as a major advertising channel.

These include measurability (there are simply more data points available from online media) and the youthful specialists who create media plans, as “digital natives”, are steeped in the online realm and its metrics. Ulbe says: “This generation has less understanding of print’s role, making the qualitative element less relevant. Often, print is overlooked in media plans and many important facts are missed.”

Clients too are often Millennials or Generation Z, and it is easier to convince them to invest in a social media campaign as opposed to a magazine advert. And it’s true that measuring print and

online media with the same metrics for direct comparison purposes is not very viable, but there is no shortage of studies demonstrating the effectiveness of print as an advertising medium. Ulbe cites the 2024 ThinkBox study where print delivered the best profit return on investment over both 13 week and two year periods. And research by Ebiquity which also showed print’s effectiveness compared to other channels.

It seems that the compelling findings are being ignored though, and the downbeat prognosis for print’s advertising role feels about right.

However, Ulbe spotlighted a big consideration set to positively affect the adoption of print as an advertising medium. It’s the growing dissatisfaction with social media, especially as a source of reliable information. Fake news, AIcommodified content, and the drift towards sensationalism in pursuit of shares are breeding mistrust among consumers. Two recent American studies

(Pew Research and University of Florida) show these trends and their contribution to consumer scepticism.

In this febrile environment, there will be, Ulbe asserts, a return to trusted brands and quality journalists. Printed magazines and newspapers from reputable publishers will benefit from this flight from uncertainty.

There is another major factor that will drive increasing print use, and this is its proven superiority for information retention.

International research that substantiates this declaration includes 2024 research from America using EEG measurements which indicated deeper reading and learning from paper. As a result, some countries such as Sweden have returned to traditional textbooks and have prohibited mobile phones in classrooms.

So, there is hope for print, as the bullish assessments of drupa by leading vendors would also imply. Educational applications are poised to flourish, although the marketing arena, as Ulbe says, is not fully embracing the benefits of print advertising. The decision makers here have not yet absorbed and acted upon the persuasive data highlighting its unique value in enhancing comprehension, retention, and overall engagement that is out there.

This is where we all have a role to play – evangelising the special power of print among those leaders – many of whom, whether from agencies or brands, are your clients. We should all take any opportunity to help them to see that print can be the smart choice, and a magic ingredient to elevate a campaign to another level.

The countdown continues to 30 December 2024, when *most companies based in the EU or who supply goods to the EU must be compliant with the new EU Deforestation Regulation (EUDR).

The EU Deforestation Regulation (EUDR) is the latest set of EU rules that it hopes will influence global action on climate change by addressing deforestation on a global scale in accordance with the 2015 Paris Agreement and The European Green Deal aim of no net emissions of greenhouse gases by 2050, observes GlobalData, a leading data and analytics company.

The EUDR will impact companies that trade in the EU market in certain commodities as well as products derived from those commodities or who export them from the EU. They will need to demonstrate that their products are not linked to deforestation (such as products containing or made from wood), or to forest degradation through, for example,

the expansion of agricultural land. The regulation will require these companies and industries in producer countries to transition to a sustainable, deforestationfree supply chain and legal agricultural

value chain if they wish to trade in the EU.

The commodities being targeted by the EUDR include cattle, cocoa, coffee, palm oil, rubber, soya, and wood as well as some of their derived products, such as paper/ paperboard, leather, chocolate, tyres, and furniture. Therefore, companies trading with the EU across various sectors, including agriculture, food and beverages, cosmetics, and timber, among others, will be affected and must comply with the regulation.

Siddarth Sehgal, Consultant and Packaging Analyst at GlobalData comments: “Arguably, the EUDR is one of the EU’s most consequential and wide reaching sustainability actions, as the impact will not just be limited to EUbased companies. Non-EU-based firms exporting to the EU or with operations inside the EU will also need to comply with these regulations.

For example, a cocoa farmer in Colombia will have to meet the EUDR requirements if selling to a company that uses their

produce to make chocolate that is then sold in the EU. Therefore, any company, regardless of its location, that trades in the specified commodities and wants to do business in the EU will need to comply with the EUDR.”

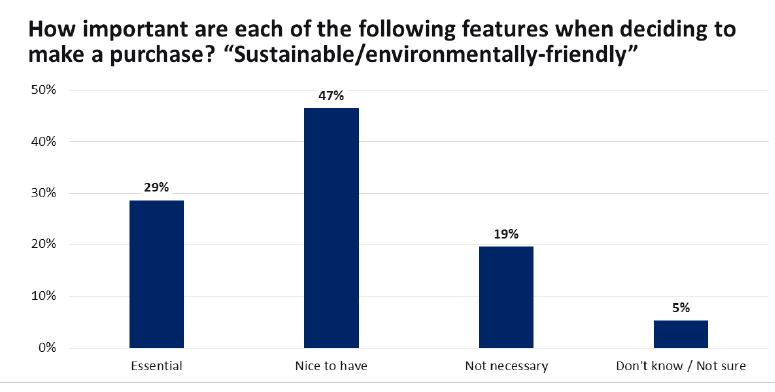

According to **Eurostat, the EU has a population of over 448.7 million people, which is one of the biggest consumer markets in the world. The aims of the EUDR will resonate with many of these consumers who continue to embrace environmental considerations when making a purchase, with over three quarters (76%) of consumers globally saying that “Sustainable/environmentallyfriendly” features are “Essential/Nice to have” when deciding to make a product purchase.

The EUDR primarily targets commodities and products linked to deforestation. While the regulation does not directly target packaging materials, it can indirectly affect certain types of packaging that are derived from the specified commodities. These would include paper and board packaging, derivatives of palm oil and rubber used for seals, gaskets and protective gloves used in the packaging process, and cattle which provide leather, will also be affected.

Paper and board packaging is a significant packaging pack type in Europe, with 129 billion pack units sold in 2023 across consumer packaged goods sectors (including food, beverages, household products, beauty, and pet care), which is expected to grow at a compound annual growth rate (CAGR) of 0.16% between 2022 and 2028, according to GlobalData.

These types of packaging are derived from wood, one of the commodities targeted by the regulation, and companies producing paper and cardboard packaging will need to ensure that the wood used in their products does not come from deforested areas.

To comply with the EUDR, companies must follow mandatory due diligence reporting of the goods and supply chain they wish to trade in. This must be submitted as part of a Due Diligence statement as part of the Corporate Sustainability Due Diligence Directive (CSDDD). This involves an exhaustive information collection to prove product traceability by providing GPS information on suppliers, buyers, and land plots, and showing that the goods are deforestation free by demonstrating that the product does not contain materials or ingredients from land deforested or degraded since 31 December 2020.

The EUDR outlines several measures to be taken in the case of non-compliance. This can result in fines totaling 4% of the company’s annual turnover within the EU. Companies also face the prospect of their products and/or income being confiscated. Companies facing noncompliance measures will have the details of the incidents published on the EU Commission website. This could result in further reputational damage. If they were found to be in breach of the EUDR, this could be particularly damaging to companies that promote themselves on ‘green’ values.

Sehgal added: “The EUDR has significant implications for companies trading in the EU, and time is running out for packaging suppliers to plan and implement their compliance strategies. One implication could be increased compliance costs for companies already managing global commodity price volatility, which if passed onto consumers, could prove inflationary in some EU countries.

The exact impact on consumers will depend on a variety of factors, including how companies choose to respond to the regulation and how the regulation is enforced. However, with recent news reports confirming that the world’s top climate scientists expect global heating to go well beyond the current 1.5C target, stopping and reversing deforestation remains an urgent priority for the planet.”

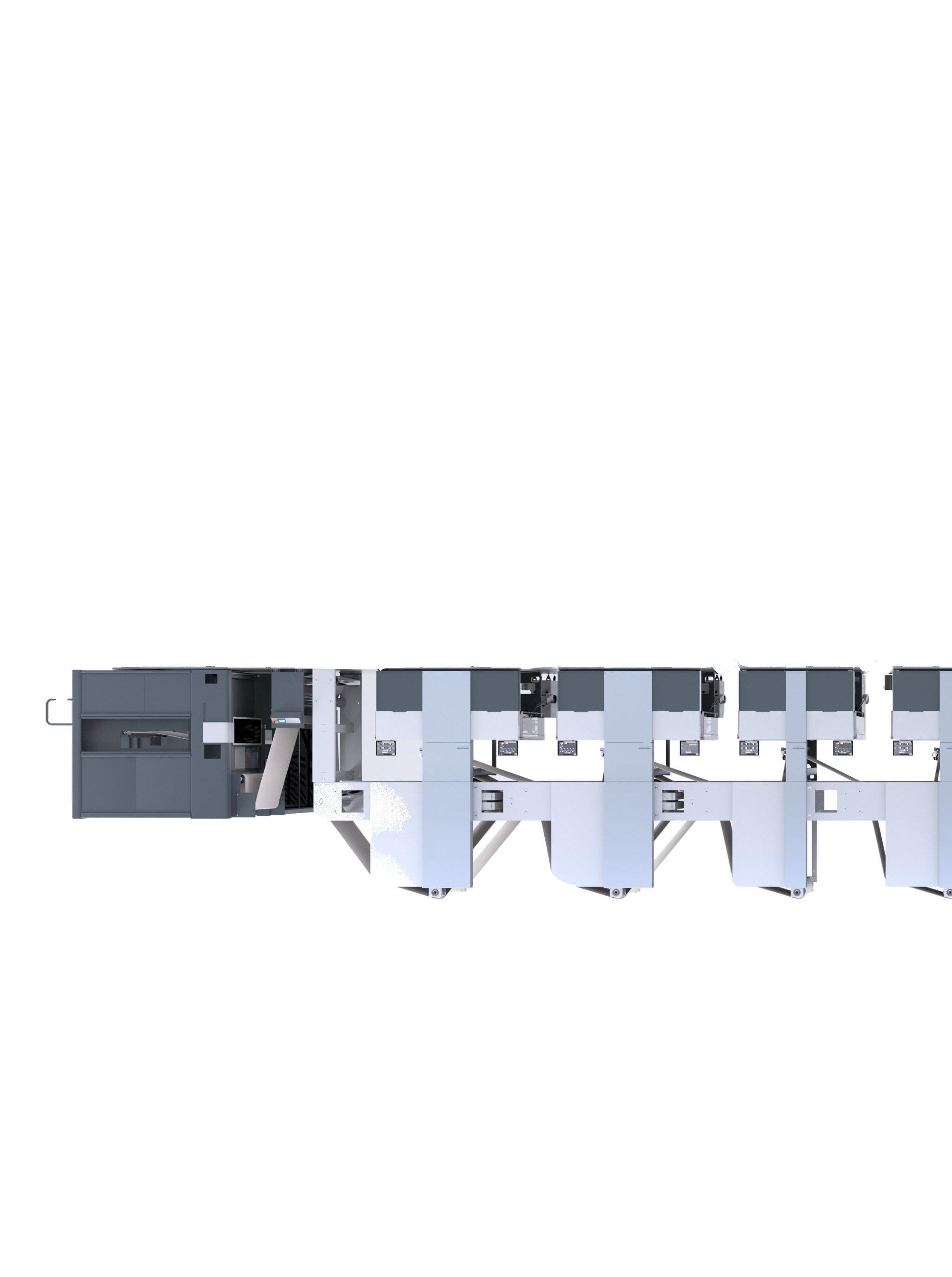

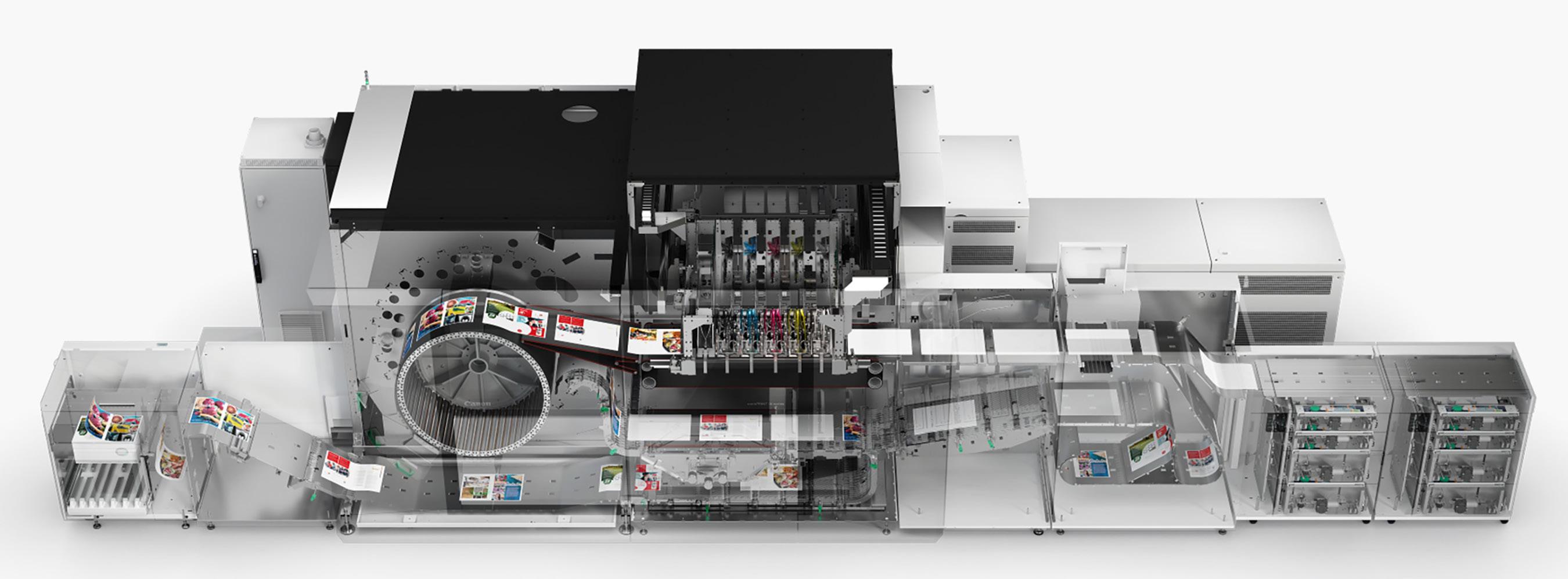

Sample configuration of a MetJET ONE line with optional features (feeder logistics, inspection unit, wide belt conveyors and double-box stacker)

Koenig & Bauer has successfully developed the first digital printing press that is integrated into a production line for metal decorating. As a leading supplier in the field of metal decorating, the Group subsidiary Koenig & Bauer MetalPrint thus enables a simple and flexible entry into the world of digital printing. The machine will start a field test at the beginning of 2025 in cooperation with Reynolds Services, Inc.

The basis of the MetJET ONE combines proven components from digital printing as well as sheet handling and system engineering for metal decoration: The sheet handling system is made by Koenig

& Bauer MetalPrint, an expert in this field, while the integrated inkjet technology is based on a multi-pass printing unit from Durst, one of the leading players in the digital printing industry.

“The MetJET ONE makes it as easy as possible for our customers to enter the world of digitally printed metal packaging,” explains Samuel Teufel, Product Manager at Koenig & Bauer MetalPrint. “The unique design enables us to create a customised solution that fits the flexibility and print quality requirements of our customers in the metal packaging industry.”

Thanks to the very attractive priceperformance ratio and outstanding print quality, the standards in metal decoration are being redefined. The modularity of the MetJET ONE enables flexible customisation and design of the entire production line to meet the demands of the packaging industry.

This means that the line can be equipped with the entire Koenig & Bauer MetalPrint portfolio in addition to the basic units. The MetalCoat coating machine, the inspection transport for checking the image (and overprint varnish) and the sheet management systems for reliable sheet ejection are just some of the possible features with which efficiency and profitability can be maximised on the MetJET ONE.

The field test, which will start early next year at RSI, is a crucial step in validating the machine's performance and reliability under real operating conditions.

“We are delighted to be working with Koenig & Bauer MetalPrint on the new MetJET ONE. We are convinced that this digital printing solution will enable us to realise customised prints in very short runs,” explains John Frangakis, CEO at Reynolds Services, Inc.

It’s that time again Start collecting your best printed work!

We are 23 this year

Recognising PRINT excellence across the Asian region

Deadline for submission - 24th September by 5pm Awards Dinner in Jakarta November 2024

5pm September 24th 2024

The annual Asian Print Awards was founded to recognise outstanding achievement in the print and packaging industries across Asia. With more than half the world’s population represented in this fast growing area, communication in the form of printed matter links Asia’s diverse cultures. It is imperative that such print achievements do not go unrecognised, especially among the population base that Asia enjoys.

The Awards are judged on a wholly quality-oriented set of criteria to ensure that fair play is enacted at all times.

The Independent Judging Panel comprises highly qualified personnel from within Asia and around the world. The independent judging panel has no knowledge of the actual entrants details. ALL ENTRIES ARE NUMBER-CODED. Entries must be commercially produced work.

The Asian Print Awards is the only regional print quality competition of its kind in Asia. Supported by leading industry-supply companies, any progressive quality print house should enter and prove that they are the best - by winning the Gold, Silver or Bronze award. Proving pride in quality awareness is what customers love to see. It’s not just empty words, you can prove it.

Categories 22-27 : Specialty Categories

23. Multi–Piece Productions and Campaigns

Any substrate or print process: Multi–piece Production must be 3 or more items such as folder, leaflets, ring binders, inserts, envelopes including their contents. Campaigns must be 3 or more items with a consistent theme produced during the year by the same printer for the same client.

5. Limited Editions & Artwork Reproductions (under

run) 6. Web Offset – Coated stock 70gsm and above

7. Web Offset –LWC (light weight coated) 65gsm or less 8.

-

:

24. Embellishment

Any substrate – any combination - for example: embossing – diecutting – foil stamping –laminatingcoating.

25. Innovation / Specialty Printing / New technology

The entry must exhibit any innovative and/ special application of machinery, process, substrate or finishing. A short description must be provided for the judges, detailing reasons for entry into this category.

26. Company Self Promotion

Any item printed to promote a product or company involved in the graphic arts industry. Self promotion cannot be entered into any other Category.

27. Judges Special Award (A job that catches all the Judges’ attention)

28. Design and layout. We look at the impact and visual effect.

29. Security applications

Send your entries by 24th September 2024 - by 5pm to: Asian Print Awards

c/o Print & Media Association of Singapore 627A Aljunied Road, Biztech Centre, #04-07 Singapore, 389842 Tel +61 422 869 728

INNOVATION PRINT AWARDS

Deadline for Entries Submission: 24th September 2024, 5pm

Remember to submit 2 copies of each job! Why? - Just in case one is damaged.

If you win an Award, YOU MUST attend the Award Dinner in Person. This is part of the competition rules!

SECTION A (This will not be shown to judges). Please fill the form in capital letters.

Entered by (company name): ______________________________________________________________________________________

Contact Person: ________________________________________________ Email______________________________________________

Address: ___________________________________________________________________________________________________________

Telephone: __________________________________ Country____________________________________________________

Category entered: ___________________________________________________________ (Example Cat 4 Book printing)

Title of entry (ie: " Paul's Ice Cream" ): ________________________________________________________________________________

Printed by (Printers name): ________________________________________________________________________________________

Client name: _______________________________________________________________________________________________________

Designer Pre Press House: ___________________________________________________________________________________________

Brand of Printing Machine used: _____________________________________________________________________________________

Stock supplied by (Merchant’s name): ______________________________________________________________________________

Ink used to produce the entry : ____________________________________________________________________________

By signing here you accept the rules and conditions of the Asian Print Awards

Signature over printed name_____________________________ Name_____________________________________________________

SECTION B Production information to be shown to judges ( tape this securely to the back of your entries)

Category entered (Same as above): __________ Entry number (Administrative use only]

Title of entry (ie: " Paul's Ice Cream" )__________________________________________Print method: _______________________

Number of ink colours (4-6-8 etc) ________ Any Embellishment (foil stamping etc) __________________________________

Quantity produced (Print run copies): ___________ Other technical details (finishing processes etc) ________________________

The Awards Dinner will be held in October in Jakarta Indonesia Send all entries to - Asian Print Awards c/o Print & Media Association of Singapore 627A Aljunied Road, Biztech Centre, #04-07 Singapore, 389842

email:Paul@printinnovationasia.com Tel. +61 422 869728 Additional entry forms can be downloaded online at www.printinnovationasia.com All entries are non-returnable unless a prepaid self addressed courier pack can be provided

https://issuu.com/cpublish/docs/2024_asian_print_ awards_flyer

https://issuu.com/cpublish/docs/2024_asian_print_ awards_flyer

https://issuu.com/cpublish/docs/2024_asian_print_ awards_flyer

https://issuu.com/cpublish/docs/2024_asian_print_ awards_flyer

An Intense one day program you must be part of

For the first time, the Asian Print Awards will hold an industry conference that will cover ALL areas of print production. If you put INK on PAPER then come and join us for this 1-day event, followed in the evening by the regional only printing competition, the Asian Print Awards.

The day’s events

Asian Print Awards Industry Conference

Morning ession from 10:00 am till 1:00 pm. (Lunch Break)

Afternoon session from 2:00 pm till 5:00 pm

Coffee and tea in the display area till 6:00 pm

Asian Print Awards 2024 Cocktails from 6:00 pm till 7:00 pm

Awards Gala Dinner 7:00 pm till late

Hear from companies and people who know what is needed to help your business grow. Also hear what technologies at drupa shape our industry. What you should look out for and be aware of as you drive your company forward.

To

Jarkata Indonesia 13th November

https://issuu.com/cpublish/docs/2024_asian_print_

https://issuu.com/cpublish/docs/2024_asian_print_

https://issuu.com/cpublish/docs/2024_asian_print_

Click on the logo to download the 2024 Entry Form

Since the end of November 2022, not a day goes by without a new report on the topic of "Artificial Intelligence" (AI) being published. Due to developments in the field of generative AI and the underlying language models, the application of AI is now open to everyone

With "Chat GPT," one can quickly write a text, or with "Midjourney," generate realistic images. What impact will AI have on the media and printing industry? Text by Knud Wassermann.

Quality and process optimization have been a topic in the printing industry for many years, and very often, Artificial Intelligence (AI), or better said "Machine Learning" (ML), is used specifically for individual tasks. Usually, such approaches are classified as weak AI solutions. Through image data acquisition and recognition, for example, quality is controlled across all process steps, and in case of deviation from reference data, software automatically compensates for it.

This happens on-the-fly without any manual intervention. This applies equally to analogue and digital printing machines. A lot has happened in recent years regarding process optimization, and overall equipment effectiveness (OEE) is continually being raised. The acronym OEE represents a business metric that measures the percentage of actual productive manufacturing time.

The average value for offset printing machines is currently slightly over 30% according to current numbers from Heidelberg. Individual printers that rely heavily on automation and optimization are already achieving peak values of more than 60% depending on the order mix. By integrating the machines into cloud-based solutions, order sequences, setup times, spoilage rates, process stability, and much more can be improved. But preventive maintenance concepts also help keep machine availability high. This requires

big data applications that are continually supplied with new data via the cloud.

AI, a data-driven algorithm

Generative AI is based on a data-driven algorithm. The internet provides an abundance of data, and this happens de facto on-the-fly via e-commerce or social media platforms. Databases operating in the background feed the algorithms very specifically until they have grown into powerful tools over time. Amazon, for example, created an algorithm years ago that predicts what customers will buy next.

With the Chatbot "Chat GPT" from OpenAI and image generators such as "Stable Diffusion" or "Midjourney," the

world of AI is accessible to everyone without having to program a single line themselves.

Sustainability largely ignored

It is astonishing how quickly the development and market penetration of individual AI solutions has taken place. OpenAI created Chat GPT in 2.5 years, it was launched on 30 November 2022, and within 5 days, 1 million users had registered. Two months later, there were already 100 million.

In comparison, Facebook took ten months. A problem with all generative AI solutions is the "data basis" on which AI is built: where does the data come from? With which data are the algorithms

Elevate your printing possibilities with Extended Colour Gamut (ECG) technology. Our MPS presses enable you to produce 97% of Pantone colours using ECG along with unparalleled image detail.

fed? How is diversity represented in AI solutions, for example? These are certainly not the only questions that remain unanswered. Where do the copyrights lie - with the company that developed the AI solution or with the user of the AI solution? Data protection issues must also be re-examined as AI applications are largely cloud-based, and the issue of sustainability has largely been ignored to date.

Who takes responsibility?

ChatGPT can certainly be used in professional environments, such as supporting online shop consultation, where chatbots are already in use today. But it can also be used in customer service and marketing, especially in creating product pages and formulating product description texts. By using AI, time-consuming manual tasks in these areas can be optimized. However, the responsibility for verifying and validating the generated information clearly lies with the user - in other words, blind trust in AI should not be placed.

KI und Robotik – ein Dream-Team

Mit »mindjourney« oder »DALL-E«, erhält man, vorausgesetzt man gibt die passenden «Prompts», also Schlagwörter,

ein, sehr schnell ein brauchbares Ergebnis. Je detailreicher die Prompts ausfallen, um so besser werden die Bilder. Die Plattform looka.com (www.looka.com) hilft bei der Erstellung von Logos und unterschiedlichsten Corporate DesignElementen. Das Ganze gibt es natürlich auch für den Video-Bereich und dann sind wir ganz schnell bei dem Thema »Deep Fake«. Der Begriff bringt es ziemlich gut auf den Punkt: es entstehen neue Bilder oder Videosequenzen, die nicht unbedingt etwas mit der Realität zu tun haben müssen.

Content from AI

Adobe recently demonstrated with generative AI models what will be possible in graphic design. "Generative AI is the next evolution of AI-driven creativity and productivity that makes the conversation between creators and computers more natural, intuitive, and powerful," emphasizes David Wadhwani, President of Adobe's Digital Media Business.

The company promises that with "Firefly," everyone can transform their own words into creative ideas, regardless of their personal knowledge. The first applications that will benefit from Firefly

integration are Express, Experience Manager, Photoshop, and Illustrator.

Adobe wants to address another issue that has not yet been clearly regulated by founding the Content Authenticity Initiative (CAI) to create a global standard for trusted attribution of digital content. Adobe assures that it is committed to open industry standards and wants to use the CAI's free open-source tools. The goal is to embed a universal "tag" in the file information.

This would enable image creators to exclude their content from being used to train AI image generators. The tag should be linked to the content wherever it is used, published, or saved. In addition, AIgenerated content will be appropriately marked and rewarded.

In addition to the weak AI solutions described at the beginning, which optimize targeted tasks in the entire production chain within the printing industry, generative AI solutions will significantly change the creative and design industry. New visual worlds, logos, or fonts can be created with just a few "prompts."

The market will ultimately decide which requirements can be met. For print service providers, the tools of the Firefly platform could open up possibilities for providing increased graphic design support to customers. More will probably be debated during drupa and this is why you should be there where you will touch the future.

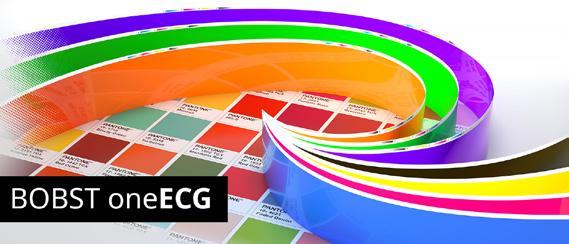

In packaging, accurate color reproduction can be critical to business success for converters and brand owners alike.

Consistent brand color across a single SKU, and even multiple types of packaging, signals product integrity and high quality. From Coke red and Cadbury’s purple to Heineken green, and the bright colors of M&M packets, color is intrinsically linked to brand identity.

Brand owners are also looking for faster time to market to respond to shifting consumer needs and new packaging trends. They seek agile suppliers that can react quickly to their requirements as they change, without compromising on color quality and consistency. In addition, sustainability targets must be met by reducing waste, by introducing new ecofriendly materials, and by optimizing production methods, without increasing costs.

All these demands put pressure on converters to deliver a streamlined and fully controlled process with high-quality results that closely match color targets. But it can be challenging to maintain color consistency and repeatability, keeping in mind the multitude of variances affecting the outcome, such as operator skill level, substrate quality, and global production facilities. The answer is to fully digitalize color matching and implement Extended Color Gamut (ECG) printing, an open

partnership system suited to solventbased, water-based, and Ebeam inks.

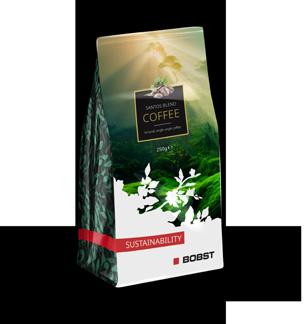

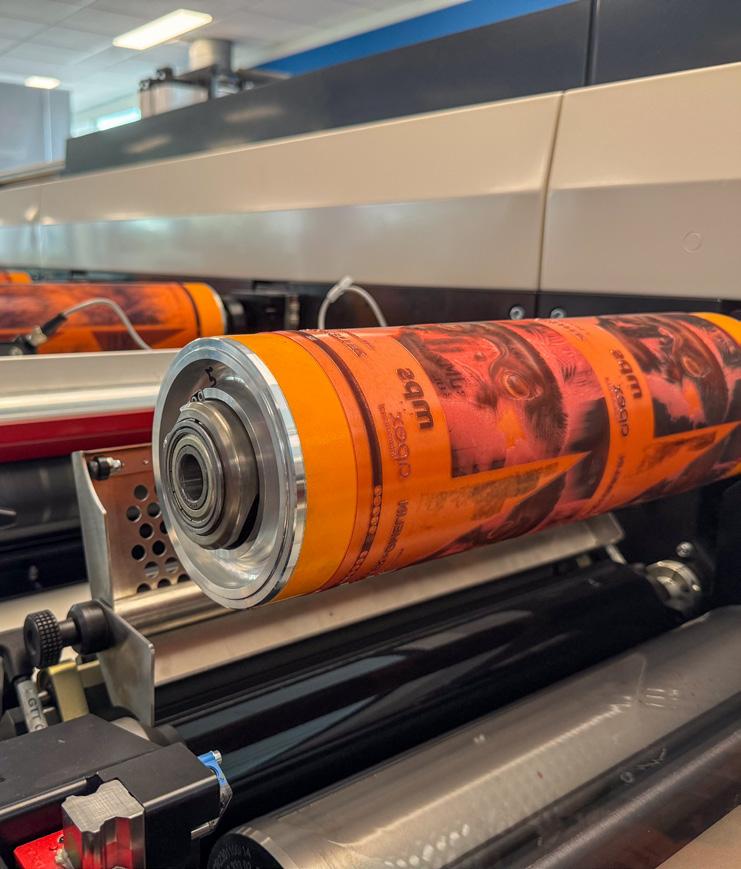

Extending the gamut with oneECG BOBST’s oneECG technology expands the traditional CMYK color model by adding up to three colors: orange, green, and violet to the standard cyan, magenta, yellow, and black set up on press. This extension gives converters access to a broader color gamut without relying on spot (Pantone) colors. As a result of this standardization, oneECG can achieve more vibrant and accurate color reproduction, especially in flexographic printing, while also minimizing waste and environmental impact.

With oneECG, color matching is taken out of the hands of operators to become a fully digital process, performed by a software system in prepress. Consequently, color Delta E (a measure of color difference) remains consistent, guaranteeing that print jobs meet the expectations of

storage as the inventory consists of only CMYK+OGV inks.

In oneECG printing, as much as 90% of job preparation is performed offline. This major shift in the workflow leads to an increase in press uptime, as start-up procedures and job changeovers can be performed much faster. It also reduces start-up waste of materials and ink by up to 35%, because the job comes to color in less time. Meanwhile, operators will have more time to take care of other tasks. These improvements boost productivity and align with brand owners’ green targets.

“oneECG offers converters a robust and innovative solution to eliminating color consistency issues. It also excels by enabling them to reach up to 95% of the

Pantone book with seven fixed colors, compared with only 65% when using the standard CMYK. This presents fantastic advantages in efficiency, sustainability and profitability, helping them to match brand owners’ expectations,” said Marco Carrara, Technology Sales Director, CI Flexo.

BOBST oneECG deployed for CI flexo

BOBST has developed oneECG solutions for CI flexo, inline flexo and gravure printing, allowing presses to reproduce brand Pantone colors by digitalizing color matching. This makes the process stable, easy, repeatable, and consistent, as well as independent of human interpretation, while also guaranteeing process knowhow and support. For CI flexo, this innovation has been available for some time.

All BOBST CI flexo presses, new and existing, can run oneECG without additional upgrades or add-ons. Changing the color methodology is simply a decision made by the organization, but it requires a dedicated team effort and the understanding of customers to achieve successful outcomes. Crucially, the entire workflow, from prepress to tooling and press setup, must follow specific technical tolerances to ensure the process is reliable and repeatable, not just on a single press, but across multiple machines, sites, and regions.

Mastering process consistency is made possible by the high level of automation on BOBST’s CI flexo presses. Digital automation features include smartGPS (Graphic Positioning System), which

performs registration and impression setting procedures at the platemounting stage rather than on press. Advanced quality control measures, such as the Digital Inspection Table (DIT) for flexible packaging, can also be deployed.

Adding connectivity to the equation, BOBST Connect can offer automated visibility and full traceability of the entire production workflow. This digital platform provides data-driven insights, performance history, job comparison and statistics to support color consistency and efficiency over time.

It is important to note that the oneECG solution goes beyond implementing a new workflow and adjusting the mindset of the operators. BOBST also partners with other suppliers in the industry to help customers maximize color stability and repeatability, offering guidance and support when using oneECG or deciding to make the transition. At drupa 2024, a flexible packaging application, printed with water-based inks in seven colors plus white, showcased BOBST’s collaboration with Flexicon, XSYS, tesa, Petroplast and Follman to promote more sustainable printing with oneECG.

“oneECG is made possible through the four central pillars of BOBST’s vision: digitalization, automation, connectivity and sustainability. Considering the numerous benefits, it is evident that this technology represents the future of packaging production with consistent, high-quality printing. BOBST is at the forefront of innovation in all printing technologies, and we can support converters through every step when switching their production to oneECG,” concluded Marco Carrara.

For Litoplas in Columbia, the change to oneECG printing has made a vast difference, or as the company’s CCO, Luis Mora, describes it: “ECG has revolutionized our printing operations, resulting in better outcomes and a more efficient workflow.”

The customisation of print products still has the reputation as a lengthy and time-consuming process. Digital printing, new improved print technologies and the interconnection of systems make it possible to bring advertising close to the customer quickly and precisely.

Personalized print marketing has become a powerful tool for capturing audience attention and strengthening engagement. With the advent of modern technologies, marketing professionals have access to numerous tools for creating, managing, and analysing personalized print campaigns. An innovative addition to these approaches is Programmatic Printing. In this post, we take an in-depth look at tools, tips, and how Programmatic Printing can elevate personalization to a new level.

1. EFI Fiery Servers: Advanced Print Management

EFI Fiery Servers offer not only sophisticated print management solutions but also enable data collection on print jobs. Through detailed analysis of this data, companies can improve the efficiency of their print processes, reduce costs and enhance quality. EFI Fiery Servers provide a user-friendly interface, allowing marketing experts to monitor and control the print process accurately.

2. XMPie: Personalized Communication at its Best XMPie is a comprehensive personalised

communications platform. It enables companies to create highly personalised printed materials that contain not only the customer's name, but also information about their buying behaviour or preferences. By incorporating data-driven elements into print campaigns, companies can achieve higher engagement rates and improved conversion. XMPie's analytics capabilities provide insight into campaign performance so companies can optimise their strategies.

3. Pitney Bowes Clarity Solutions: Analytics across the entire Print Process

Pitney Bowes Clarity Solutions goes beyond personalization, offering comprehensive analytics for the entire print process. From print quality to shipping and delivery, this tool allows for a thorough evaluation of every aspect of a print campaign. This is crucial for identifying and addressing bottlenecks or inefficient processes, ultimately increasing the overall effectiveness of campaigns.

4. Programmatic Printing: The Future of Personalization

Programmatic Printing utilizes datadriven decisions to optimize print campaigns in real-time. It enables the automated adaptation of content based on customer behaviour, preferences and demographic data. By integrating Programmatic Printing into personalized print campaigns, companies can ensure that their content is always relevant and up to date. This approach helps strengthen customer engagement and maximize campaign effectiveness.

5. Implementation Tips: Set Clear Goals:

Define clear and measurable goals for your personalized print campaigns, whether it's increasing revenue, acquiring customers, or enhancing branding.

The quality of personalized content depends on the accuracy and relevance of customer data. Invest in efficient data management and keep information up to date.

Follow a Multichannel Approach:

Link personalized print campaigns with digital channels to provide a consistent brand experience. Ensure that the message is consistent across all channels.

Conduct A/B Testing:

Utilize A/B testing to compare and optimize the effectiveness of different personalized approaches. This helps identify the best strategies for continuous

improvement. Continuously Optimize:

Analyse data from your print campaigns continuously and adjust strategies accordingly. Continuous adaptation is crucial due to the ever-changing market and customer needs.

The world of personalized print marketing offers a wealth of opportunities

The right tools can make a significant difference. From advanced print management and analysis of the entire print process to the integration of

Printing, these tools provide comprehensive solutions. Through consistent implementation and analysis, companies can not only create impressive personalized print materials but also sustainably increase the success of their campaigns.

The UV Analyzer is a app-based UV radiation measuering device.

The measuring is quite easy. Put the strip on your substrate, irradiate it with UV and measure the strip with the stick. The app will show you the measured dose in mJ/cm². This dose value can be compared with your reference value to determine aging.

Scope of delivery:

UV Analyzer Stick and reference white, charging cable, lanyard, measuring strips

As with the variety of specifications faced on a daily basis for packaging, the preparation of artwork for labels and packaging differs from job to job.

Historically, prepress departments, either manually or with the help of automated workflow systems, have resolved several challenges. They include tasks such as:

- Preflighting: Assuring artwork file is ready to be printed.

- Colour management: Matching colour appearances as closely as possible from input to output and between devices, assuring colours will be printed as specified.

- Trapping: With traditional presses, assuring there are no gaps between type or images of different colours. Additionally, in flexo printing, consideration is given to keep aways or hold backs where required.

- Step and repeat: Determining the most efficient way to print jobs on press.

As these differ from converter to converter, the best way to illustrate how to consider file preparation would be to start from the beginning.

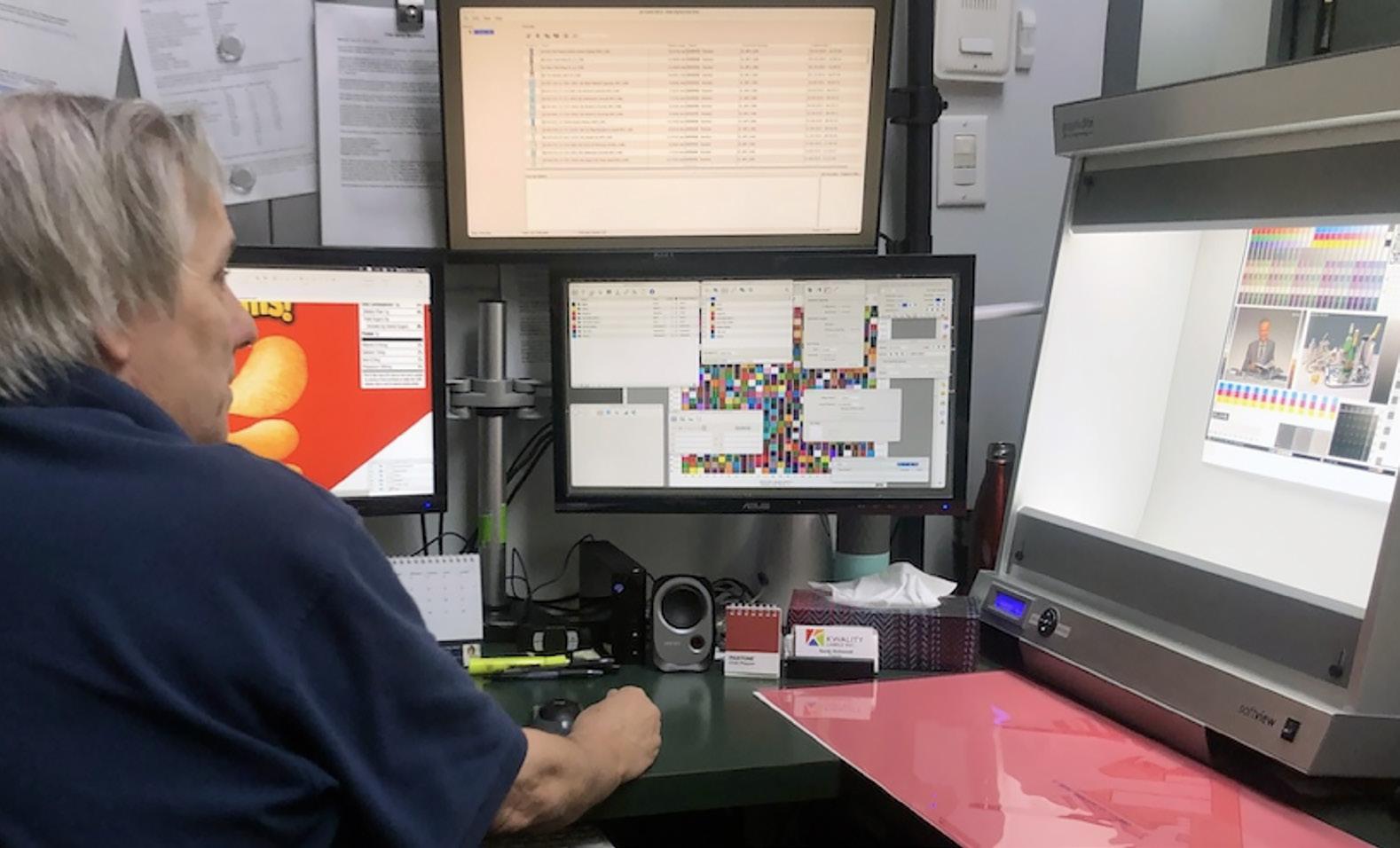

Kwality Labels, owned by Shanti Chadha and based in Richmond Hill, Ont., began more than 40 years ago as a narrow web commercial flexo label printer. They have since expanded capabilities to include custom digital label printing for both long and short print runs.

These include pressure sensitive, cut and stack, and double- sided labels, along with products like spirals. They offer a full range of products and services for their clients from industries like health, cosmetics, juice, and snack foods. Kwality Labels complies with several industry standards and has certifications such as G7, FTA FIRST, and IFS PACsecure, allowing them to achieve premium quality for everyone.

When Randy McDonnell joined Kwality Labels in 2019, they outsourced all prepress. After client approval, plates showed up and they ran the job. McDonnell, along with plant manager Joe Miller, were tasked with building a

prepress department from scratch using a PDF editor.