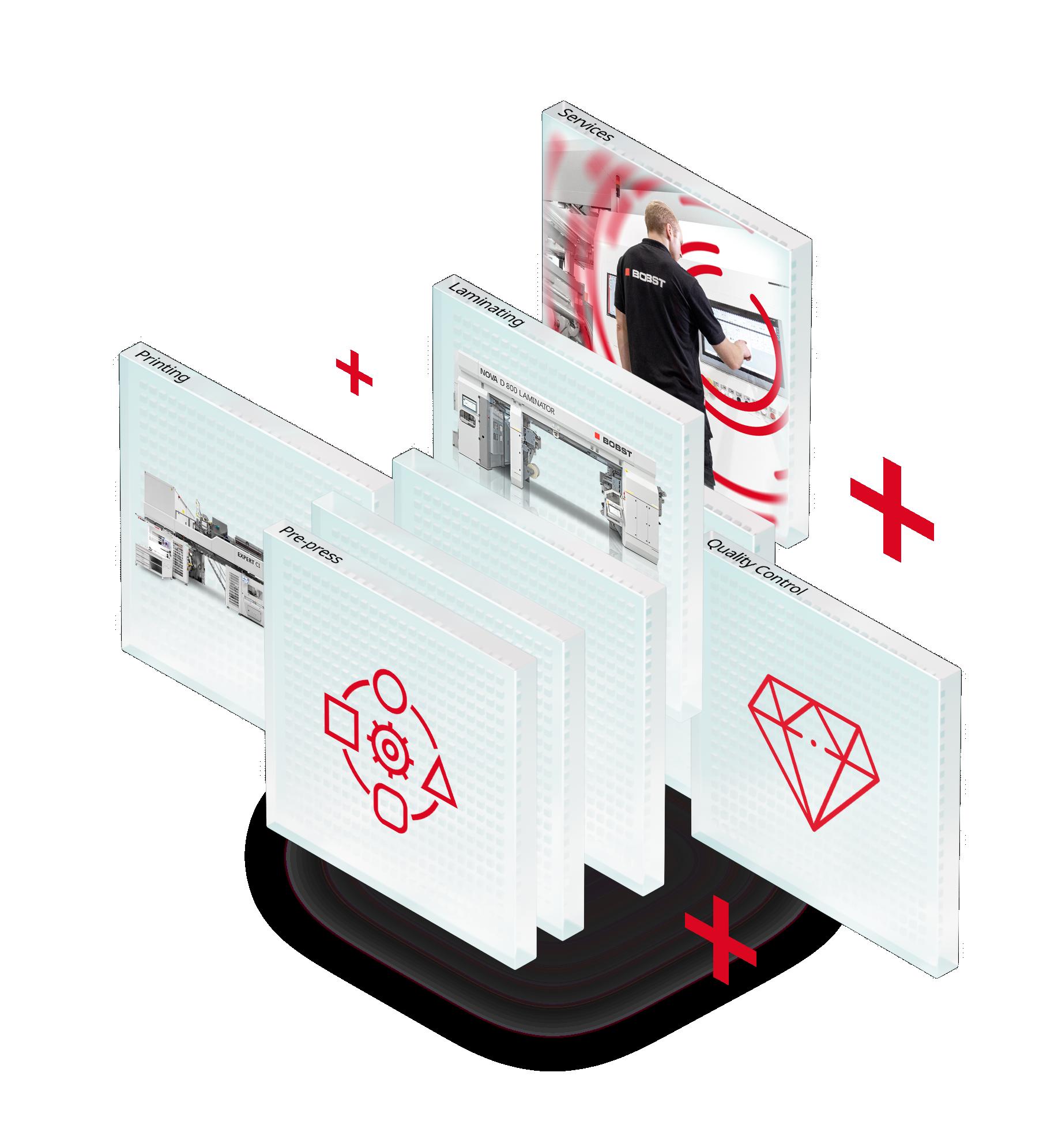

One complete solution from BOBST connects, integrates and orchestrates your flexible packaging workflow. With the help of BOBST Connect, it enables you to manage pre-press, printing, converting and quality control seamlessly while maximizing sustainability and empowering continuous optimization. Interested? Find your local BOBST representative at www.bobst.com/contact

The annual Asian Print Awards was founded to recognise outstanding achievement in the print and packaging industries across Asia. With more than half the world’s population represented in this fast growing area, communication in the form of printed matter links Asia’s diverse cultures. It is imperative that such print achievements do not go unrecognised, especially among the population base that Asia enjoys.

The Awards are judged on a wholly quality-oriented set of criteria to ensure that fair play is enacted at all times.

The Independent Judging Panel comprises highly qualified personnel from within Asia and around the world. The independent judging panel has no knowledge of the actual entrants details. ALL ENTRIES ARE NUMBER-CODED. Entries must be commercially produced work.

The Asian Print Awards is the only regional print quality competition of its kind in Asia. Supported by leading industry-supply companies, any progressive quality print house should enter and prove that they are the best - by winning the Gold, Silver or Bronze award. Proving pride in quality awareness is what customers love to see. It’s not just empty words, you can prove it.

20. Digital Labels

21 Digital - Outdoor Billboard

Categories 22-27 : Specialty Categories

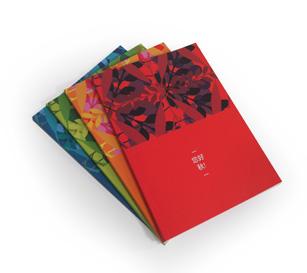

22. Multi–Piece Productions and Campaigns

Any substrate or print process: Multi–piece Production must be 3 or more items such as folder, leaflets, ring binders, inserts, envelopes including their contents. Campaigns must be 3 or more items with a consistent theme produced during the year by the same printer for the same client.

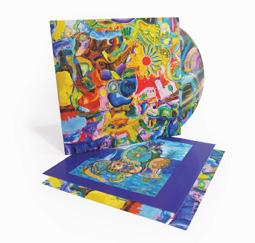

23. Embellishment

7.

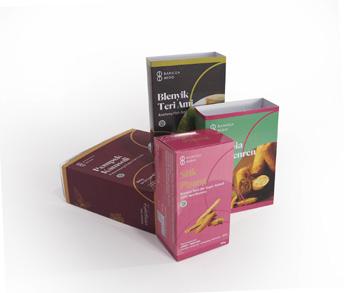

8. Offset Packaging products

Categories 9 - 21 : Digital Printing Only

65gsm or less

Any substrate – any combination - for example: embossing – diecutting – foil stamping –laminatingcoating.

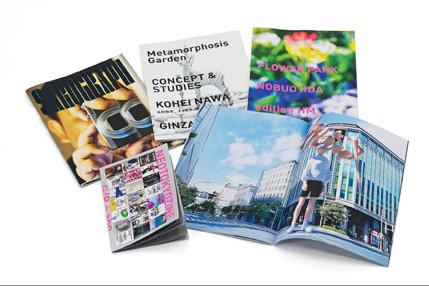

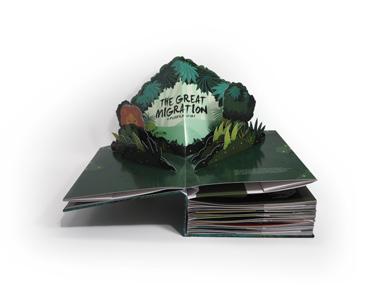

24. Innovation / Specialty Printing / New technology

The entry must exhibit any innovative and/ special application of machinery, process, substrate or finishing. A short description must be provided for the judges, detailing reasons for entry into this category.

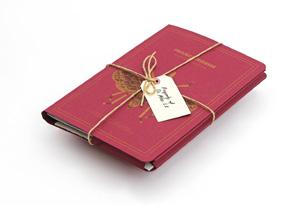

25. Company Self Promotion

Any item printed to promote a product or company involved in the graphic arts industry. Self promotion cannot be entered into any other Category.

26. Judges Special Award (A job that catches all the Judges’ attention)

27. Design and layout. We look at the impact and visual effect.

Send your entries by 5th October - 5pm to: Asian Print Awards

c/o Print & Media Association of Singapore

18. Digital Proofing (must supply the digital proof and the prinnted product)

19. Digital Packaging

627A Aljunied Road, Biztech Centre, #04-07 Singapore, 389842 Tel +61 422 869 728

Deadline for Entries Submission: 5th October 2023, 5pm

Remember to submit 2 copies of each job! Why? - Just in case one is damaged.

SECTION A (This will not be shown to judges). Please fill the form in capital letters.

Entered by (company name): ______________________________________________________________________________________

Contact Person: ________________________________________________ Email______________________________________________

Address: ___________________________________________________________________________________________________________

Telephone: __________________________________ Country____________________________________________________

Category entered: ___________________________________________________________ (Example Cat 4 Book printing)

Title of entry (ie: " Paul's Ice Cream" ): ________________________________________________________________________________

Printed by (Printers name): ________________________________________________________________________________________

Client name: _______________________________________________________________________________________________________

Designer Pre Press House: ___________________________________________________________________________________________

Brand of Printing Machine used: _____________________________________________________________________________________

Stock supplied by (Merchant’s name): ______________________________________________________________________________

Ink used to produce the entry : ____________________________________________________________________________

By signing here you accept the rules and conditions of the Asian Print Awards

Signature over printed name_____________________________ Name_____________________________________________________

SECTION B Production information to be shown to judges ( tape this securely to the back of your entries)

Category entered (Same as above): __________ Entry number (Administrative use only]

Title of entry (ie: " Paul's Ice Cream" )__________________________________________Print method: _______________________

Number of ink colours (4-6-8 etc) ________ Any Embellishment (foil stamping etc) __________________________________

Quantity produced (Print run copies): ___________ Other technical details (finishing processes etc) ________________________

The Awards Dinner will be held in October on the 9th November in Singapore

Send all entries to - Asian Print Awards c/o Print & Media Association of Singapore

627A Aljunied Road, Biztech Centre, #04-07 Singapore, 389842

email:Paul@printinnovationasia.com Tel. +61 422 869728

The 2023 Asian Print Awards Checklist!

1. Have you submitted your best work to be judged?

2. Have you checked the work to make sure its 1st class?

3. Check it one more time!

4. Are their 2 copies of each entry ?

5. Is it packed correctly for shipment with 2 copies of each entry ?

6. Have you left enough time for shipment5th October 2023 5pm is the Deadline

7. Check the address you have written - it should be

Asian Print Awards

c/o Print & Media Association of Singapore

627A Aljunied Road, Biztech Centre, #04-07

Singapore, 389842

Tel +61 422 869 728

Good luck and may the regions BEST Printing Companies WIN!

AWARDS: 2023

Issue 8 - 23

Print - Packaging INNOVATION

Asia Magazine

Published by Asian Print Awards Management Pte Ltd 65 Chulia Street #46-23 OCBC Centre 049513 Singapore

Print Innovation Asia

Labels and Packaging Innovation Asia Asian Print Awards

Packageing Excellence Awards Label and Packaging Conferences

Publisher Paul Callaghan paul@printinnovationasia.com

Editorial Elizabeth Liew elizabeth@printinnovationasia.com

Packaging Sales Elizabeth Liew elizabeth@printinnovationasia.com

Conventional plastic cups are highly convenient but not eco-friendly at all. They contribute to plastic waste in landfills, as most are not recyclable.

Industrial designers Chelsea Briganti and Leigh Ann Tucker believed there had to be a better way to consume cold beverages on the go. They developed edible cups in a variety of flavors as an eco-friendly alternative to disposable plastic cups.

Conventional plastic cups are highly convenient but not eco-friendly at all. They contribute to plastic waste in landfills, as most are not recyclable. It is estimated that 2.5 billion disposable cups are thrown away each year.

Industrial designers Chelsea Briganti and Leigh Ann Tucker who met while attending Parsons New School for Design in New York believed there had to be a better way to consume cold beverages on the go. They developed edible cups in a variety of flavors as an eco-friendly alternative to disposable plastic cups.

Their invention was spurred by their love for Jell-O, a gelatin-based dessert. The designers entered a competition for Jell-O in 2010 and were inspired by the decorative history of Jell-O as a molded dessert. As industrial designers, the two women wanted

to make something more functional, however, and set their minds on developing colorful, translucent cups that can either be eaten after use or composted. They finally chose the seaweed-based gelatin-substitute agar for it’s structural nature, taste and vegan-friendliness. Agar is tasteless and odorless and can be flavored in a variety of ways.

The first taste they made for their cups was citrus because it goes with many summer drinks but currently, one of their best-selling cups in New York and Los Angeles is flavored with matcha green tea. Other flavors include tart cherry and Madagascar vanilla. The designers Briganti and Tucker use natural sweeteners, organic ingredients and flavored color derived from fruits and vegetables. The cups have been reported to taste like fruit-rolls albeit less sweet.

When vodka-maker Absolut inquired about ordering 60,000 agar cups for use at an outdoor concert, the designers realized that this project could turn into a business. Briganti and Tucker formed a partnership to move forward

and raised more than 10,000 USD through a 2011 Kickstarter campaign. Because of the taste and fun colors, the two designers named their 100 percent biodegradable product Loliware. After raising more money, the two designers are now selling their edible cups and are contemplating expanding their product line: One potential is making a bottle out of agar.

Their efforts have won them a lot of recognition. In March, they won the 2015 NEXT Accelerator Natural Products Pitch Slam at Natural Products Expo West, which came with products and services valued at 27,500 USD.

While the designer-duo focuses on cups for cold beverages, the fast-food chain KFC had introduced edible coffee cups in collaboration with Seattle’s Best Coffee earlier this year. The cups were made of a cookie shell and lined with a layer of white chocolate. The outside of the cup is wrapped in sugar paper. The cups were developed by scientists at the experimental UK food development company, the Robin Collective.

Connect to Grow. That is your key to stay ahead in a demanding market. By connecting with MPSConnect, you ensure the best in reliability and productivity from your printing press. You will increase competitive advantages and maximize profits.

To improve productivity and profi tability, it’s critical to increase the understanding of your overall label print operation. With MPSConnect, you get real-time insights in the operator activities. You dive into the printing press and see exactly what’s happening.

With MPSConnect we see recurring annual cost savings of €50,000 - €100,000 and even more thanks to a more efficient workflow, time management and waste reduction.

mps-printing.com/connect-to-grow

The Washington Post coined the phrase "news is the first rough draft of history" in the 1940s. Well, if newsprint provides the first draft, it is the magazine that captures the spirit and solidifies it in our social psyche. Eight decades later, in the wake of a global pandemic, the midst of a humanitarian and energy crisis stemming from the Russia-Ukraine war, and a worsening climate emergency, people are hungry for significance to be given to the “first draft” that is unfolding on our newsfeeds - and they want it to be accurate and credible.

In an increasingly chaotic, distorted and censored digital media landscape, it falls increasingly on the credible print media to defend the integrity of the written word.

While the migration from print to digital continues, reach does not equate to relevance or accuracy. Indeed, there

is a newfound appreciation, most notably among younger audiences, for the high-quality commentary and reporting that paper publications have always been trusted to deliver.

A gaze into the future: Where next for the paper industry in a time of turmoil? Sign up for the webinar 20 April 2023

However, the worrying reality is that press freedom is in decline globally. Publishers increasingly face the risk of censorship of journalistic content shared online, exacerbated by the spread of misinformation on social media platforms. For journalists themselves, there are more safety risks while on the job, and they are increasingly being targeted online with threats of violence or digital abuse.

The digitisation of press not only exposes the people who bring us news of current events, but the very information itself: without a paper trail to corroborate the internet’s version of events, we risk leaving history open to being completely rewritten.

There is a reassurance in knowing that the papers and magazines that grace today’s newsstand will always read the same, whether they are picked up that morning, in a community centre a month later, or an an official archive ten

An epoch is defined as a particular period of history, considered remarkable or noteworthy. So, I think it’s fair to say we are living through that right now. But who defines an epoch, and who writes the history?

supply industries is to embrace this evolution in the media mix and play to our strength: quality and the values of journalism.

The quality of the paper itself plays no small part in this: the connection our minds make between holding something physical and a sense of “realness” remains strong in contrast to the digital devices that feed us with endless streams of content. The tactile experience of handling paper brings an interactive quality to reading that adds value, and some studies suggest that we remember words read on a physical paper much better than something we have read on a screen.

Digital has brought immediacy to news gathering and has provided citizens with the opportunity to share their experiences and views with the world, benign or malign, unfiltered. What is real, what is fake, what is news or propaganda, is imperceptible.

That is why I believe that we need print, now more than ever, to satisfy the growing need for trustworthy reporting and analysis in a rapidly changing media landscape. It speaks to the very foundations that underpin democratic society. There is no-one else who can be relied upon to analyse, write and consolidate a fair and balanced "first draft" of this epoch.

When considering where your operational profits are being generated what is your main focus? Margins on jobs? Order volumes? Application diversity?

Increasingly ink and toner choice is being explored by Print Service Providers (PSPs) for its ability to enhance profitability. That is the finding of the global Taktiful/WhatTheyThink 2023Specialty Digital Ink and Toner Embellishment Study.

It reported that 41% of survey respondents who own digital ink and toner embellishment technologies said that the main reason they added specialty ink and toner capabilities was to generate more profit.

It also found 27% said that specialty ink and toner jobs were ‘always’ more profitable than regular CMYK jobs, and 36% said they ‘usually’ are. A further 55% were satisfied with the profits they made from these jobs, while 40% were satisfied with the sales of these jobs.

With 75% of respondents stating clients are interested in specialty ink and toner capabilities there is a lot of opportunity to capitalise on.

NAPCO Research’s study, Adding Value to Digital Print, found print providers are levering Digital Print Enhancement to improve profitability. The survey of both print providers and marketers/brand owners found many printers are looking for new value added print applications to help boost their profit margins and differentiate their offerings.

At the same time marketers value providers that offer ways to enhance print. Of the 600 brand owners/ marketer respondents that influence commercial printing taking the survey, 52% said it was highly important that their print providers offer unique ideas to enhance the print they purchase.

The right technology innovation can transform printed materials from commodity, price sensitive offerings to higher value products that command a premium.

Brands are prepared to pay premiums. Up to 33% for speciality colours such

as white, metallic and fluorescent and 31% for security ink.

Digital printing simplifies processes and reduces production costs for special effects while offering a wide array of value added options.

For example the fifth colour station on a digital colour sheetfed press can offer neon pink, neon yellow, white, clear, gold and silver toners as well as invisible red toners.

Neon pink and neon yellow toners enable colours to pop, gold and silver elevates any application from catalogues, posters and flyers to direct mail, brochures, and invitations, and invisible red supports security features. White can be used as a base layer for high quality graphics on coloured and transparent media and clear can be used to add patterns or enhance photos.

All of which enable PSPs to expand their creativity while also boosting their profitability.

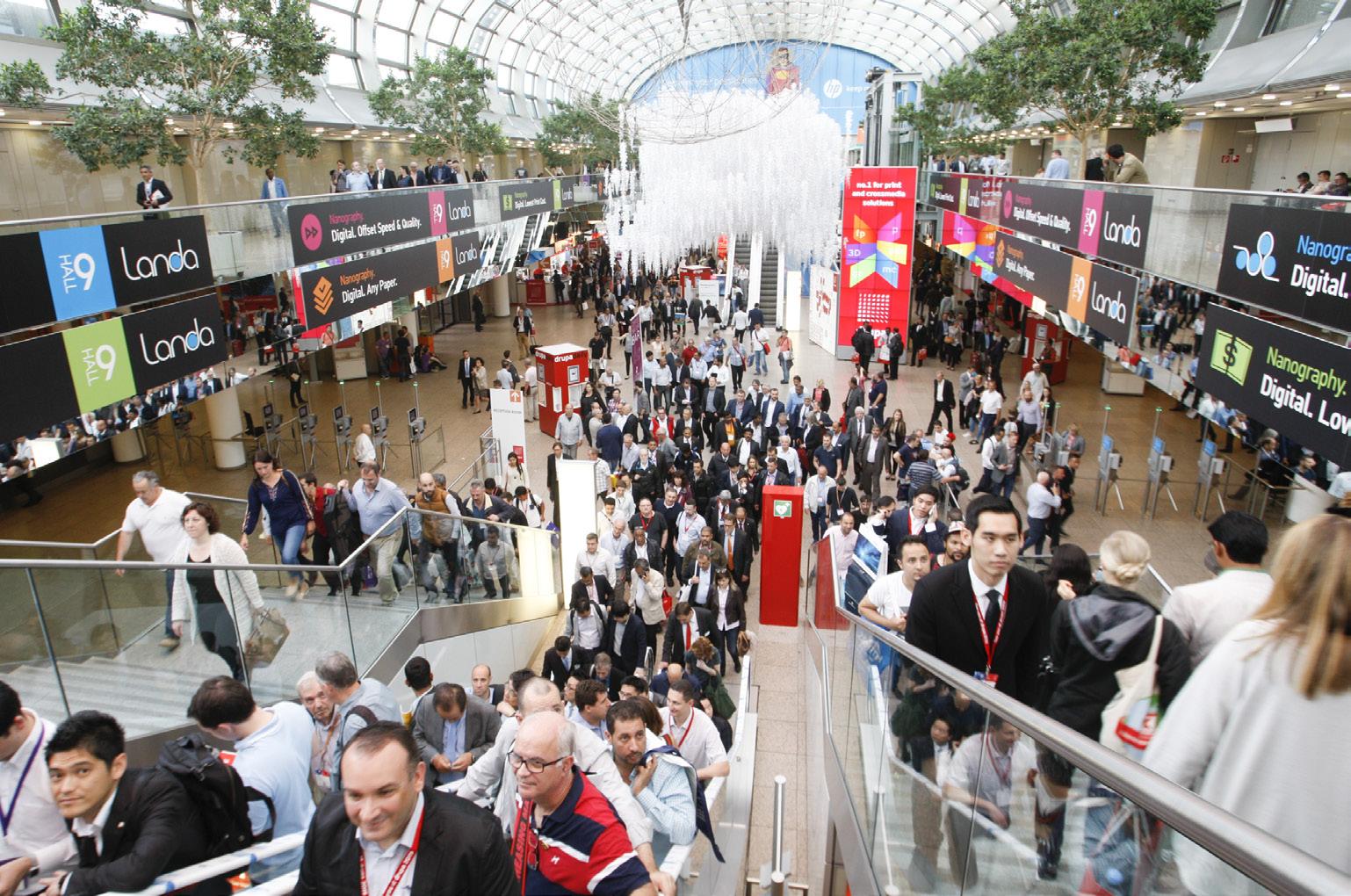

Traditional customer touchpoints are being challenged, even replaced, as the mix of engagement activities becomes more complex and sophisticated. So here are a few personal insights into ways to captivate and inspire customers in this evolving, dynamic situation.

Having spent over 20 years in the graphics industry, attending numerous

tradeshows and events across the globe, not one occasion passes by without me being asked “how long will we attend tradeshows?” or “are tradeshows still relevant?”. These questions, often raised by financial controllers looking out for potential savings, are not surprising and are also raised by many tradeshow visitors themselves.

The answer is neither yes nor no, as that would be just too simple. What is important is to put things into perspective and to understand that we live in a more complicated world – especially in the graphics industry where, for example, ongoing digitalization creates opportunities but also fear or uncertainty.

The rise of digital communication, which started in the late 90’s, helped customers to access product information instantly at their fingertips, via websites and all kinds of e-newsletters. Later, around 2010, many manufacturers went further by opening eye-catching, content-rich demo-centers to host and engage clients in various ways, in person or digitally. Webinars, amplified during the COVID time, became as popular as e-newsletters.

This happened as traditional media, especially newspapers, declined and journalists and influencers grew to rely on the web to access and share information. They also started organizing actual events with properly integrated online components including social media, which is still something of a buzzword in the graphics industry.

The resulting traffic and customer engagement has been incredible. Emailcampaigns to customers and prospects are more efficient and automated, even traditional direct mailing is more effective with better targeting. To complement this, industry-associations continue to organize local events and user-communities run even more sophisticated global events, all with digital outreach. Lastly, the traditional

Over the last 20 years, the way to engage with customers across the entire sales-cycle has evolved beyond recognition. New technologies have enabled things that simply were not possible before and this process continues.

tradeshows, predicted by many to die out by the time COVID was over, have adapted and are thriving and that is so true for drupe, which takes place again soon.

So how can we connect the dots and navigate around this complex, dynamic environment?

One could claim everything nowadays is in such flux, even chaos, that it’s actually impossible to fathom. Well, from far away yes maybe - like our universe - it could look daunting. But when you break it down and look closer, it all comes down to customer touch-points which each have their reason to exist, their purpose. They are all aligned to and orbit around the customer purchase-cycle. Let’s take a look.

Starting off, when you are simply an observer, today you can surf the web and easily find all manner of useful, rich content. You can subscribe to numerous newsletters and collect enough subject-matter to make your own reference-collection. You can attend a few webinars, even sign-up for an online immersive experience, to

learn something new, something that triggers your mind further. Then, when you become more serious, attending an industry or association event and meeting your peers will make a lot more “real” sense.

This could also be the time when you’ve decided to check out a specific configuration for real, like wanting to sit in the car you previously configured on the web. You could visit a democenter, see the solution for the first time in action. But let’s say they seduced you but didn’t quite convince you – it was

so VIP, but you still want to be sure you haven’t missed anything. This is where an industry tradeshow fits the bill, it can and will help you make the most important, reliable decisions.

In one single location, you can see and feel everything that could make your dream a tangible reality. You can compare things that are either not on the web at all or identify their real differences when everyone online often looks the same. You can read between the lines, can see what is not documented, you can connect your

own dots and, for a while, sit in the future.

This helps explain why, ever since the middle-ages from around 13001400, numerous industries organized very large tradeshows in easy-to-reach locations, from Antwerp to Lyon to Hannover to Samarkand and many other places. Some of these were a “must attend” in order to stay ahead, to understand before others what should be offered on the shelves.

These traditions have survived and all the industries you can name perpetuate this ritual, for a very simple reason –human interaction. As humans, we simply need it, to evolve and prosper. Without it, humanity would be long gone! In this context tradeshows, although they are still narrowly called tradeshows, are in reality much more.

In every industry from automotive to aerospace to travel to textile to food to home furnishing and of course to printing & packaging – there is a fundamental imperative to interact in order to understand market trends, connect the dots and so to touch the future.

This is why drupa truly is the pulse of the print & packaging industry, the place where all manufacturers exhibit and benefit, whether as a large player or a smaller one. It helps them to set timelines on internal productdevelopment and for their industry announcements. It helps them to motivate their employees towards an ambitious target. It enables customers to meet and to exchange views and ideas. Every visitor gets to see so many things not available anywhere else. In a word, it’s kind of magical.

I know it may sound old-fashioned to be promoting tradeshows in this digital world, especially knowing there are some who’d consider scrapping them for a purely digital future. But drupa is the Olympics of our industry and is evolving at the same speed of the entire industry it serves. Every drupa is different and the way it engages with visitors is always transforming.

The customer experience provided by exhibitors is evolving from “touching the metal” to understanding industry

trends; from measuring speeds to discussing new business opportunities and to assessing more sustainable solutions. It is aimed more than ever at highlighting things you do not do today but which you should be doing tomorrow, in order to succeed and prosper, things which may indeed take you by surprise!

So drupa is not just a tradeshow anymore. It’s the “rendezvous point”

for millions of people, living for and thanks to the print & packaging industry, who seek unparalleled insights and opportunities to stay ahead of the game. That’s what makes drupa the “must attend” event for anyone involved in the printing industry whether printer, supplier or software provider.

THANK YOU FOR YOUR PARTICIPATION

* Stay Tuned for Winners’ Announcement in October 2023.

In part 2 of our chat with FUJIFILM Business Innovation Asia Pacific President, Masatsugu Naito, we discussed the role of digital transformation in changing the business landscape, and the importance of innovative leadership in setting a vision for future resilience.

Q: Similar to many other terms, the popularity of digital transformation emerged after the COVID-19 pandemic, and FUJIFILM Business Innovation now has a range of new products and services available in this field. Do you believe that disruption is a key factor in driving the need for digital transformation? How do you see the work of building resilience in this area?

Masatsugu Naito: The demand for digital transformation has been on the rise, particularly in the aftermath of the COVID-19 pandemic. It’s fair to say that digital transformation will permanently shape the future of business operations.

Our competency lies in creating comprehensive solutions that meet our customers’ complex needs. We take the time to understand their structural

concerns by looking at pain points that exist across their entire process. From there, we develop an end-to-end solution that improves the experience for all involved in this process rather than individual segments.

This is done by looking at the needs of our customers and using our solutions as well as our trusted partners’ technology to meet them. I believe our value has always been about identifying the lack of integration between different operations, then bridging those gaps in an innovative way.

Q: That makes a lot of sense. We integrate our distinctive expertise with cutting-edge technology from our trusted partners, and in this way we create value for our customers that’s more holistic. Delivering an end-to-end solution gives customers a clearer picture of our unique proposition, as you say.

Discover our latest innovation

Find out more

Harness the capability of specialty colours by utilising 6 colours in a single pass to push creative boundaries on various media.

Maximise business efficiency with AI-powered technologies that support pre-production enhancements.

Unlock new revenue streams with infinite colour possibilities and diverse print applications.

Revoria PressTM PC1120

Revoria PressTM PC1120

operation, but really bringing their business to the next level so that they’re equipped to face upcoming challenges and opportunities in the new normal. This is what we mean by building resilience.

Q: Do you see any upcoming trends in business that you think will shape the landscape?

Masatsugu Naito: In the past, the main objective of companies was to generate returns for their investors. However, with the emergence of this new individualised lifestyle trend, the focus is shifting more to becoming a sustainable company that can adapt to the evolving needs of customers, rather than solely prioritising the interests of shareholders. Take the Fujifilm Instax product as an example. Instant film continues to be relevant

by answering the customer’s desire to capture memories in this way and it has continued to be an essential part of their lifestyle over the years. Similarly, to achieve success, enterprises should start thinking of how to innovatively satisfy consumer needs that are also in flux, rather than just focusing on investors.

Q: You’ve had extensive experience running businesses in various countries, where changes in the process have been a significant factor in achieving success. These changes are commonly referred to as innovation. What guidance would you provide to business leaders aiming to promote innovation within their organization?

Masatsugu Naito: Establishing a company culture that embraces innovation requires business leaders to create a vision for change. To realise this vision, leaders need to establish human connections with employees to reassure them to try new things and not be intimidated by change. To promote innovation within the organisation you need a more engaged and driven workforce that is willing to step outside their comfort zone, to think creatively and experiment.

"Continue to embrace change and view the change as an opportunity for growth and improvement. Build the capacity for agility on an organizational level while keeping a measured approach".

We recently had the opportunity to discuss the state of the Thai printing industry with Kitti Pornpipatwong, Graphic Communication Head FUJI Film Business innovation Thailand, as also ask about the relationship with CGS ORIS and what is the view of colour management in the country. Below is the interview in full.

Q - How is the market situation in Thailand, are things back to normal now after the years we had to live and work with COVID-19.

KP - The feedback from the market is that It's still recovering from the COVID-19 pandemic. As you know Thailand’s majority of GDP is driven directly from our global export business as well other big industries like travel and tourism. As of now the export business is not going well and still has some way to go to get back to pre-pandemic levels, however but travel business is rapidly recovering at an amazing pace, which is a good part of the industry rebound, ultimately its all connected one way or another, more tourism means ultimately more local demand for print, both commercial offset and now digital.

We call all agree that the printing industry is also a supporting function to many industries. The one thing holding back a lot of business is the uncertainty of a politic situationwhich currently we don’t know what to expect next. This one issue has directly affected investment in purchasing for many customers both local and more so internationally. We need to carefully look for a clear picture of political stability to drive economic growth, not just in our industry but every industry across Thailand.

Q - What is the growing market segment, is it commercial print, digital print, packaging, wide format etc

KP - Label and packaging dominate the market with revenues of around 250 billion Thailand baht (THB) and

the rest are commercial printing etc. For digital printing, we still have double digit growth in total from toner base and inkjet products. For signage and display, according to market input, is almost identical to before pandemic, but for equipment sales and new product isn’t back yet, the reason is that a lot of the trade houses have a lot of available capacity to serve current demand. I think this year will be getting better in total and it might hit a new number of revenue contribution on both domestic consumption and export as well. It is looking very promising for this industry.

Q - Are people investing inDigital technology, and if yes are they also investing in Colour Management.

KP- For the digital printing sector, I think the normal solution would be a CMS solution. The reason why I say this is because of the customers behaviour which has totally changed. With turnaround time pressures, dynamics of the print applications needed, just in time approach with low/less stock. All these reasons (and many more) make digital printing the best fulfillment option in the print market today. Then print provider must deal with the expectation of identical or almost identical print output. Color management solution and our only true partner CGS ORIS is the key to address this challenge.

Doesn't matter if its commercial printing or quick print, we have to offer the best in class color management solution not only for consistency and accuracy but also for brand reputation, especially color needs be consistent across difference output technologies. That's why we definitely need it and are happy that we have the strength of CGS ORIS to show our customers.

We recently organized the first ever workshop for commercial print market. We got massive feedback about our digital innovation technology and many solutions that customer in this space never knew about before. One solution which had customer interest and is a must in commercial print is color management. We had Managing Director Sales CGS ORIS, Mr.Christoph Thommessen join our show and explain why we exactly need this color solution. That’s a helpful and strong commitment as our business partner together with CGS ORIS.

Q - What areas are FUJIFILM BI looking at moving ahead in and how has the merger with FF effected the business in Thailand, does this present more opportunities with more products.

KP- As you know Thailand is the biggest exporter and the leader in Southeast Asia in printing industry. I’d like to share the strong synergy of graphic communication business under Fujifilm Holding. To algin with the market growth in SEA, we strongly aim to be your Brand of Choice in printing business that why we decide to integrate Fujifilm Business Innovation Graphic Communication & Fujifilm Graphic Communication to be the “One”.

Our mission is to be your print business innovation partner and to provide the “True” value provider. From analogue to digital print, fully end to end integration with sophisticate innovation technology to bring customers business to the next level. Our commitment and focus are commercial printing, Label and Packaging with our strongest R&D team. Our market insight is to develop new technology to help streamline business processes & breakthrough the challenges our customers face in a changing print enviroment, not just selling boxes and moving up but we want to become real business partners with them.

I know that the Thai Printing industry is truly resilient, we have shown over time that we can take hits and bounce back even stronger, we have, and I feel will continue to be recognised as an exporter of the highest quality print available in the world. We have also shown this with Thai companies winning many awards in global print competitions, and especially at the Asian Print Awards, we see many Thai companies taking to top awards purely based on print quality excellence, and to close this interview, I know colour management is in this equationhelping them win year after year.

In the rapidly changing media landscape, print publishing continues to thrive. The coexistence of print and digital media constantly takes new forms and offers media owners new sources of revenues. One thing is clear: print adds value and we provide the right choice of paper for varying purposes.

Follow us on LinkedIn

In today’s world, we are constantly bombarded with all kinds of information in all possible formats, shapes, colours and sounds. Our brains receive thousands of messages every day and are constantly switching from one topic to another.

At work, we are handling video conferencing, instant messaging, emails, phone calls and face-to-face meetings while also keeping an eye on our phone in case something urgent comes up and needs an immediate response. In a matter of years, generations have shifted from watching movies to YouTube videos to TikTok clips to Instagram adverts in their leisure time.

In this hectic environment of endless choices, brands aiming to last and be profitable must find ways to stand out from the crowd. Revolutionized by the internet, marketing has become a crucial element of any business plan, with companies dedicating significant resources to it.

However, not all types of marketing can fulfil a company’s objectives. Today, customers are more market-aware, more demanding and less brand-loyal, meaning that companies must be very smart with their marketing approach and design an effective marketing strategy that will truly reflect their values and products, differentiate from competitors and ultimately, and most importantly, drive sales.

By “effective marketing” we don’t mean that we must favour digital (or modern) marketing – quick to implement – and forget about offline (or traditional) marketing. Instead, effective marketing means defining a powerful strategy with original, creative and thoughtful ideas

that will make an impact on our target audience, supported by consistent, coherent and clever messages and followed by a well-defined and timely action plan.

Now we know what’s needed to achieve effective marketing, let’s talk about implementing it. Great marketing

ideas often die because companies fail to implement them properly. On the other hand, good marketing ideas can become an incredible success when they are flawlessly implement-ed.

For reasons that vary depending on the company’s type or products, nowadays many brands solely focus on digital

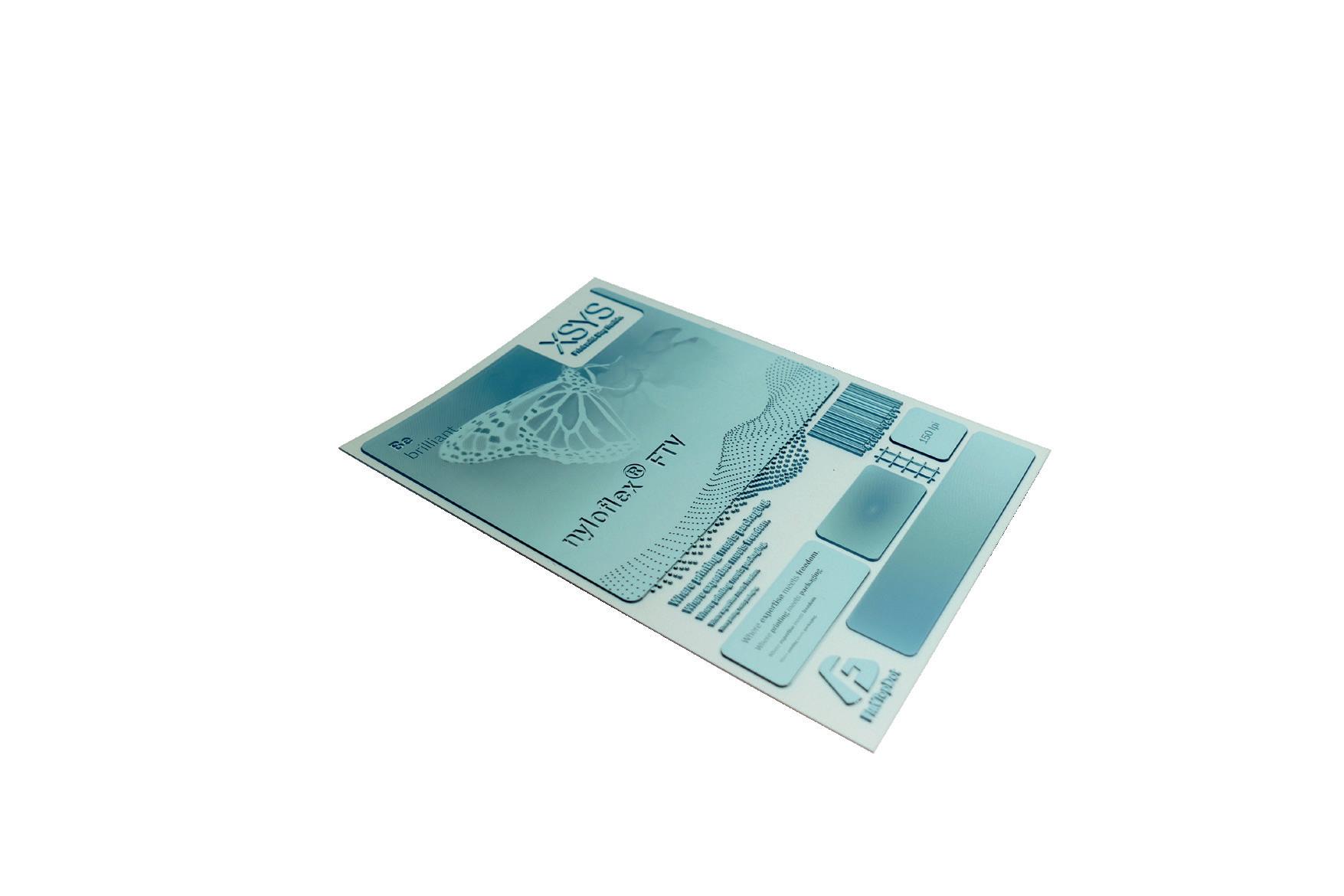

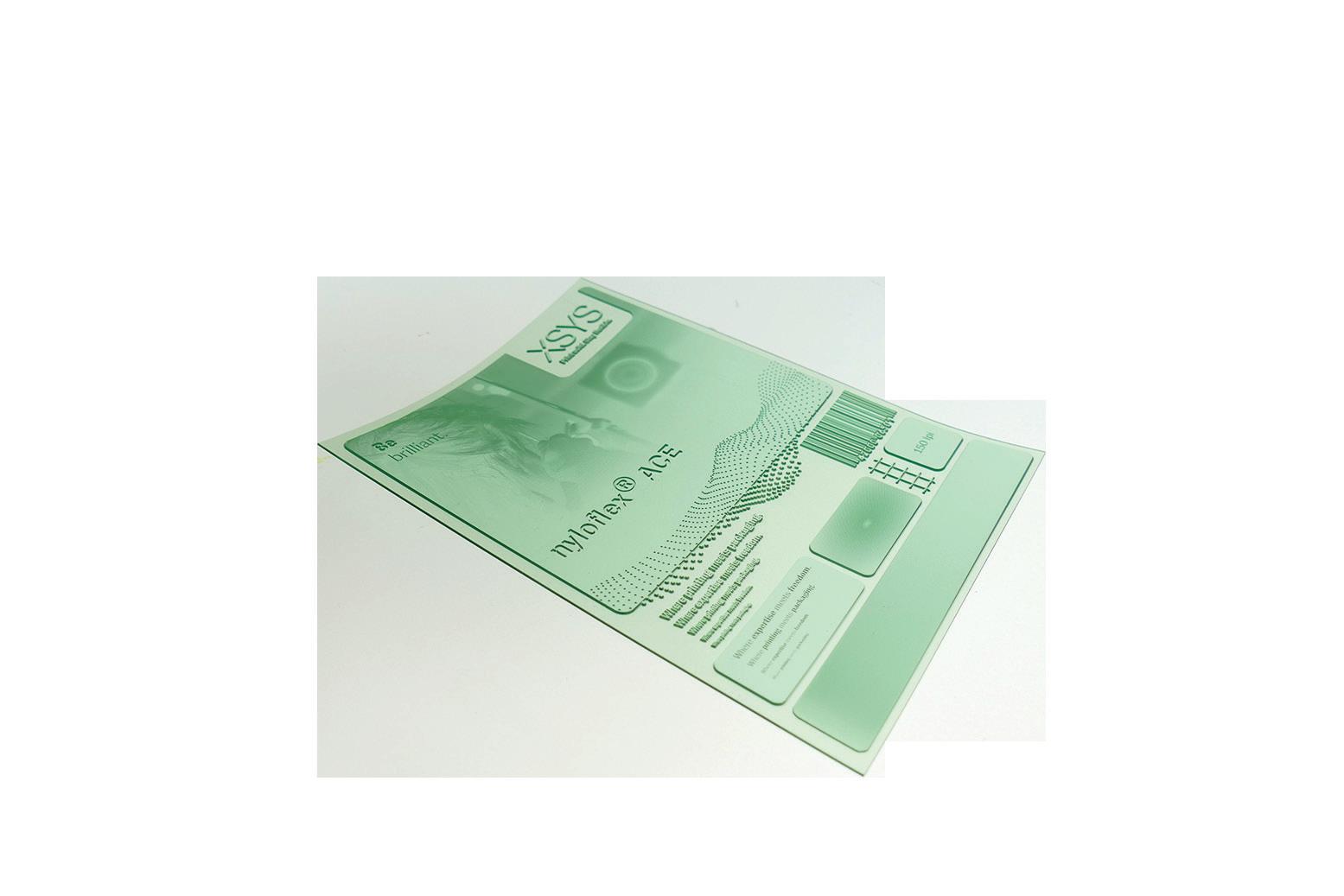

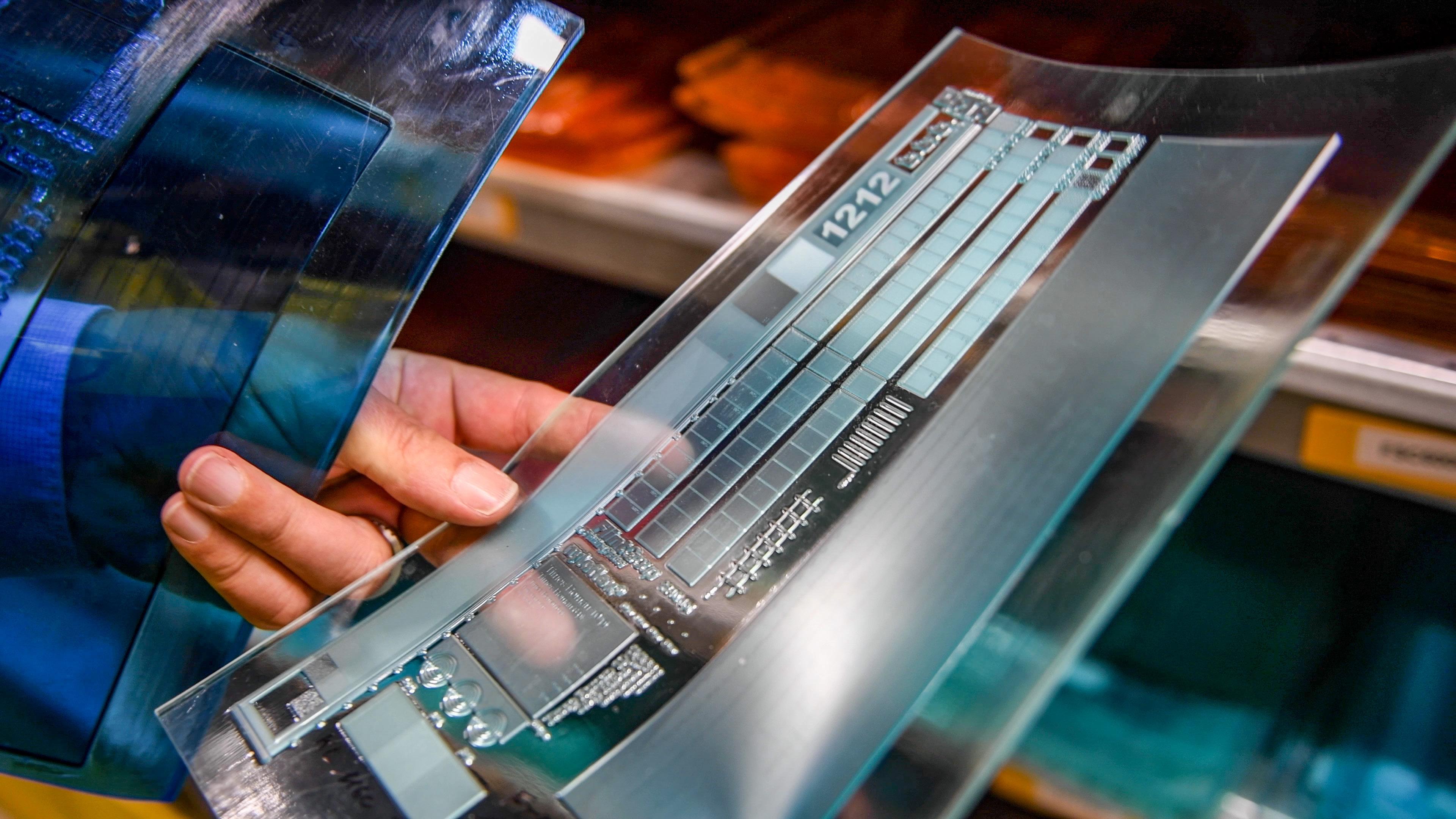

XSYS

remains one of the largest suppliers for the global flexographic printing industry, offering flexographic and prepress solutions and expert professional services while helping the industry move forward with increasing innovation, improved productivity and a reduced environmental footprint.

marketing. They invest from modest budgets to millions of dollars in Google and YouTube ads, Instagram videos, TikTok clips, web banners, SEO and SEM, hiring influencers to pro-mote their products, etc. To survive, these brands need a constant market presence online, contin-uously delivering new content and being ever more creative and compelling. If they don’t, it’s just a matter of time before these brands fade and die.

At first, digital marketing may seem fun, modern and less costly than printed marketing. However, there’s a high risk involved in advertising your brand exclusively through digital marketing: due to the huge volume of content available on the Internet and the usually short attention span of online customers, your brand will be competing with millions of other brands and can be quickly forgotten and replaced by one more active, more pervasive, or trendier than yours.

We always tell our customers that online marketing is like a fireplace: the moment you start burn-ing fewer logs than your competitors, your fire will eventually go out. Branding your product online is a constant battle to burn more and more logs!

So, even though online marketing is a must and can bring significant benefits, we must not ignore the enormous influence of offline marketing in helping shape consumer behaviour and the ampli-fied benefits of mixing both types of marketing.

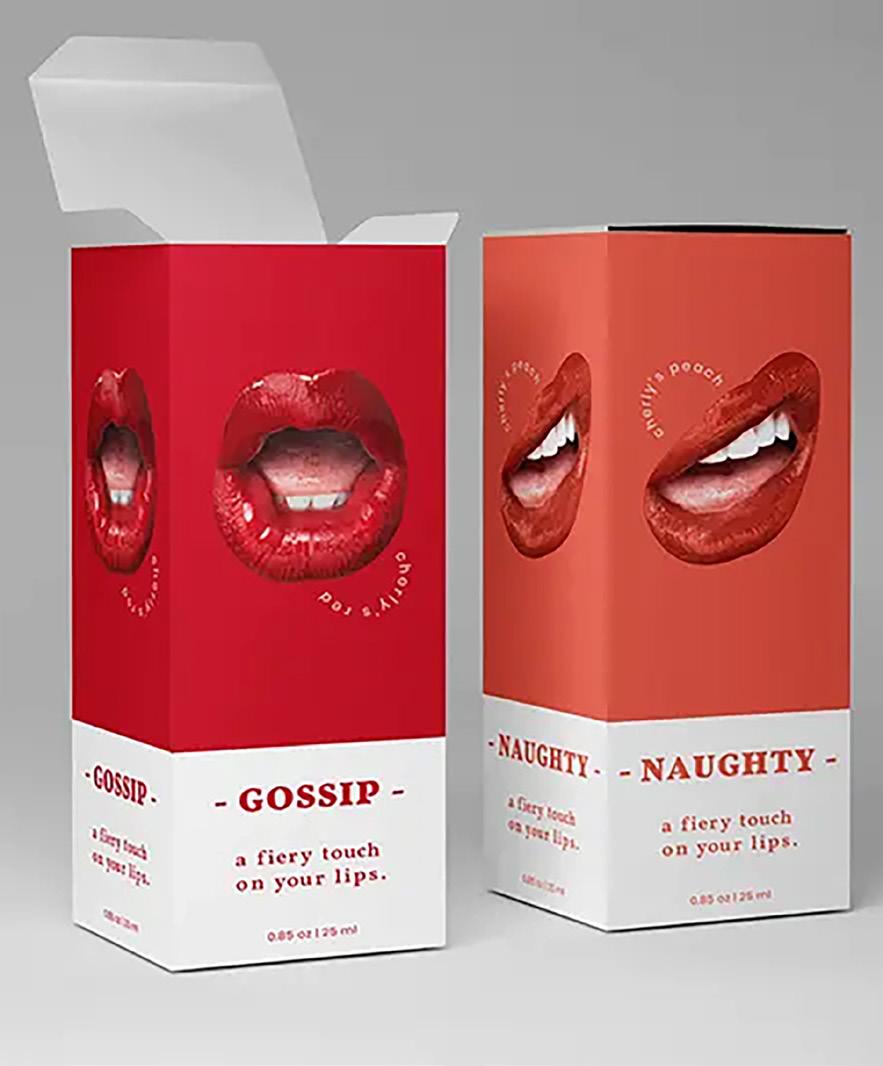

While digital marketing reaches the sight and hearing of customers, brands must use a combination of printed, physical and offline marketing to reach all five senses: smell, vision, taste, hearing and touch.

Because of the vast amounts of information we receive every day, our brains can only retain what makes a strong impression on us by creating a memorable experience. Of course, emotions play a very important role in making an experience memorable. The more senses are involved in that experience or event, the more impactful it will be.

Sensory marketing is a form of marketing that targets customers’ senses to create an emotional connection with a product or brand. It utilises a variety of sensory stimuli to influence consumer behaviour. By engaging multiple senses, sensory marketing can help brands create a lasting impres-sion on consumers. Sensory marketing can also be used to influence consumer behaviour. For ex-ample, research has shown that certain scents can increase sales, while certain colours can influence consumer perceptions of a product's quality.

Printed marketing materials help achieve sensory marketing Overall, sensory marketing has become an increasingly important tool for

brands looking to create memorable customer experiences and drive sales. On many occasions, sensory marketing can only be achieved with the help of printed materials, such as a magazine advert that includes a sample of a hand lotion or a perfume, or a high-level financial services company that sends its prospect cus-tomers a copy of their new corporate brochure printed on a special substrate that reflects wealth and prestige.

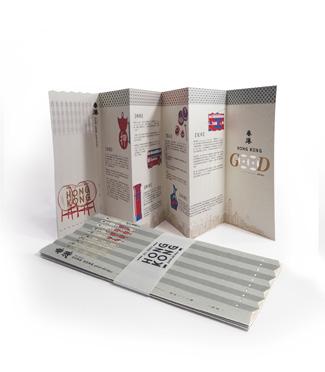

Printed materials such as brochures, catalogues and flyers are physical items that remain in poten-tial customers’ hands, making them easier to revisit and recall, read at their leisure and even share with others. For instance, when a company is exhibiting at a tradeshow,

distributing printed prod-uct brochures or postcards (instead of a PDF or an email) inviting customers to join a company event can make the difference between a potential customer forgetting about the brand or re-membering it long after the tradeshow has ended.

Printed marketing materials can be very cost-effective, as they can be produced digitally at an af-fordable cost and strategically placed in locations where the target audience is most likely to be. A typical example: a real estate company placing flyers about a new housing development in local cafes or grocery stores to reach their target audience.

Printed marketing can also help build brand recognition by using distinctive substrates, designs, fonts, and colour schemes that people associate with the company. This strategy can be highly ef-fective in creating a loyal customer base more likely to remember the company, its products and services in the future.

Finally, printed marketing can help a company establish credibility and trust in the eyes of potential customers. Companies that invest in quality printed marketing give the impression that they are serious about their business and are generally seen as more trustworthy than those relying solely on digital marketing. This, in turn, can lead to increased confidence from potential customers and greater brand recognition as well.

In conclusion, despite the rise of digital marketing, offline marketing remains an essential part of any effective marketing strategy as very often it involves “touching” the customers’ five senses. Brands that decide to include printed marketing in their marketing mix to provide a tangible means of accessing information are a step ahead in establishing credibility and trust among their target audience.

Drupa is the perfect example of a five-sense marketing activity heavily supported by offline market-ing. This is the place where new technologies are presented in a way that is impacting the consum-er’s five senses creating a memorable and meaningful experience. Only online is not enough!

Parkside Flexibles pioneers sustainable, flexible packaging innovation and development. With over 180 employees across two locations in the UK and Malaysia, working closely with supply chain partners to ensure all expectations are met and surpassed, with accreditations to service the packaging industry.

Today, Parkside offers a wide range of sustainable, flexible laminate specifications for various pack formats and lidding films to meet the needs of consumer-packaged goods categories.

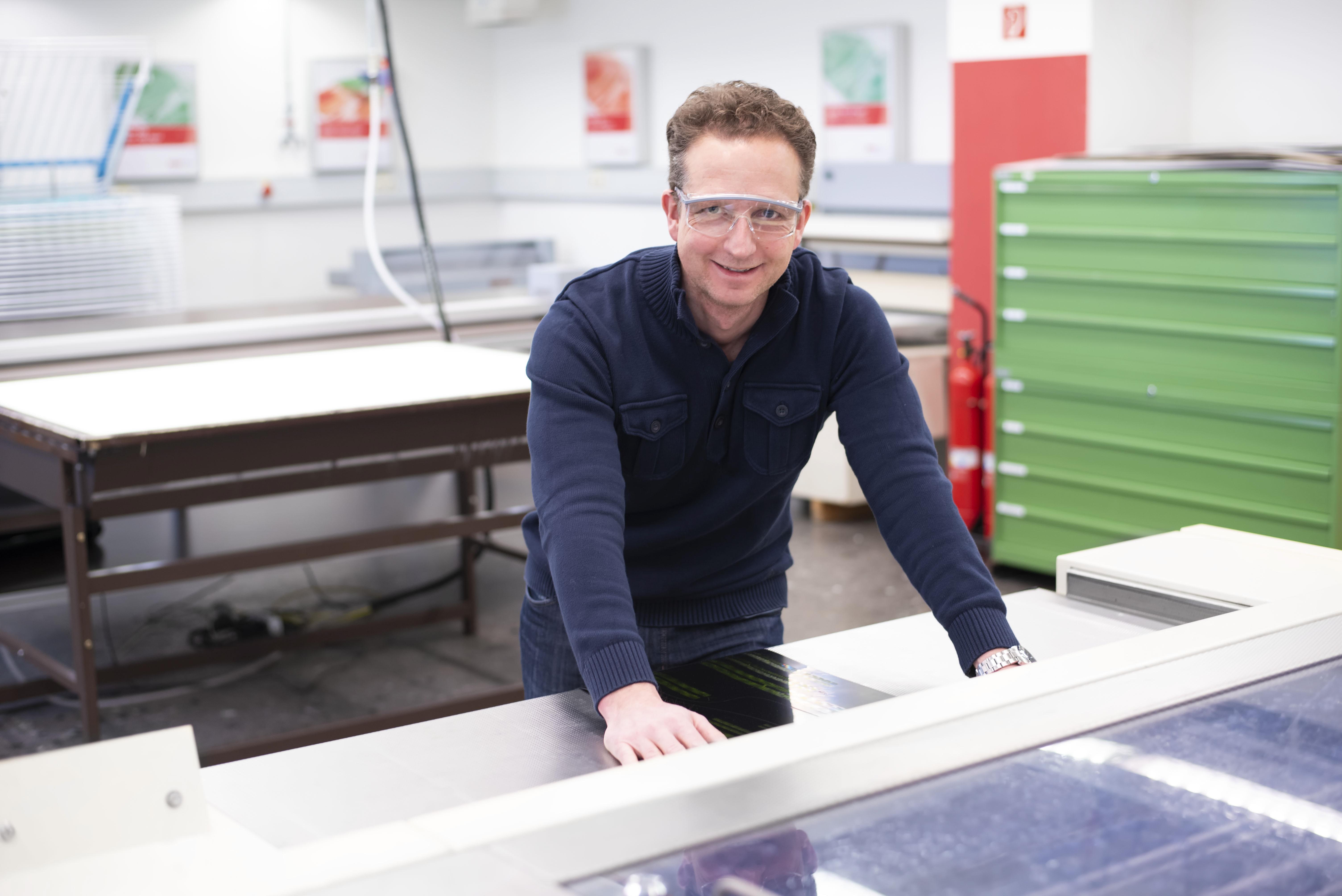

Parkside Flexibles Malaysia partnered with tesa tape, DIC, Miraclon, Tye Cine, and Kimberly-Clark to conduct a handson training workshop. As part of the workshop, teams from the companies got together for a full-day, joint exercise that involved a mix of flexographic theory and on-press experience. tesa tape, DIC, and Miraclon conducted the activity with a combination of theory sessions and discussion about the best practices of adhesive tapes, inks, and flexo plates, respectively, followed by a fingerprint test on Parkside Flexible's W&H Primaflex press. The sessions saw participation from Southeast Asia, Japan, Australia, Korea, India, and the UK.

Typically, training exercises of this nature are conducted to troubleshoot existing on-press issues. However, this unique coming together of experts and partners addressed training and education needs while bringing a fresh perspective to flexo training in the region.

Mark McMain - Operations Team Manager from Parkside Flexibles Malaysia, says, "As a leading flexible packaging supplier in the region, we keep pushing the envelope of what's possible with Flexo. To provide sustainable packaging, we use a range of substrates, including compostable,

which are often more challenging to print.

As Malaysia's only company producing compostable packaging, we continue implementing more sustainable packaging for our brand clients. With support from our strong industry partners, it is essential to have opportunities like this to exchange information and grow together. It shows our commitment and allows us to put theory into practice, not just get certifications or green credentials. Today's print jobs are export-oriented, but we look to increase awareness with our Asian brand clients to drive sustainable packaging."

Stephanie Lee, Regional Key Account Manager from tesa tape, adds, "Once we brainstormed the idea to have the joint training exercise, Parkside Flexibles was highly positive and quick and immediately went ahead with a fingerprint trial as part of the activity. Each print site is unique, as are the parameters and variables that influence print conditions, so training is vital to grow together and to come upon the right solution that works for each printer site.

It helps motivate all involved partners to learn and understand Flexo better and truly move Flexo forward. We are dedicated to improving the adhesive technologies to transform the plate mounting process. We aim to constantly

improve our solutions and promote sustainability in the dynamic world of flexible packaging. Working together, we are creating a better future for the industry."

As the pre-press supplier for Parkside Flexibles, Tye Cine brings a depth of knowledge in pre-press and color management. Their participation highlighted the importance of file preparation and utilizing the correct tools to enable accurate graphic reproduction and on-press efficiencies. Joanne Chiew says, "Flexo offers much shorter turnaround times today using the latest plate-making technologies.

Digital proofing and getting approvals on these proofs is critical to reduce turnaround time and on-press variability. With Miraclon's Flexcel NX technology geared to expand the possibilities of pre-press design innovation and sustainability, we can now offer an achievable print-by-numbers approach that meets the requirements of brand owners. Alignment with the brand owners early on also helps to set the right expectations for the digital output file and print results."

DIC Inks was the ink partner for the exercise and a regular supplier to Parkside Flexibles. Lim Ka Min –Senior Technical Consultant from DIC, says, "Flexography is continuously evolving. There are more complex designs to meet the ever-expanding

requirements of brand owners and their consumers. Advanced inks that achieve high densities and deliver stellar print results now address Flexo printers' challenges."

Ms. Azlin - Technical Packaging Engineer from Kimberly Clark, says: "I am happy with such a multitude of training from Flexo industry partners — this type of training brings the flexographic capability to a higher level, supporting brand owners' challenging design packaging requirement.”

It is uncommon to have formal flexo education in the Asia Pacific region. The lack of standardized press operations across the region has led to lower press efficiencies and high resource waste, impacting press profitability for wide web, mid-web, and narrow web flexo printers.

The joint training exercise, which brought together industry experts from the package printing value chain, was an initiative to exchange knowledge and best practices. Such activities can support flexible packaging printers and the growth of Flexo. It can also aid in adopting Flexo by transitioning more jobs from competitive print processes. It is viewed as highly challenging but has been proven possible and effective following simplified process control measures with the latest and best technologies available.

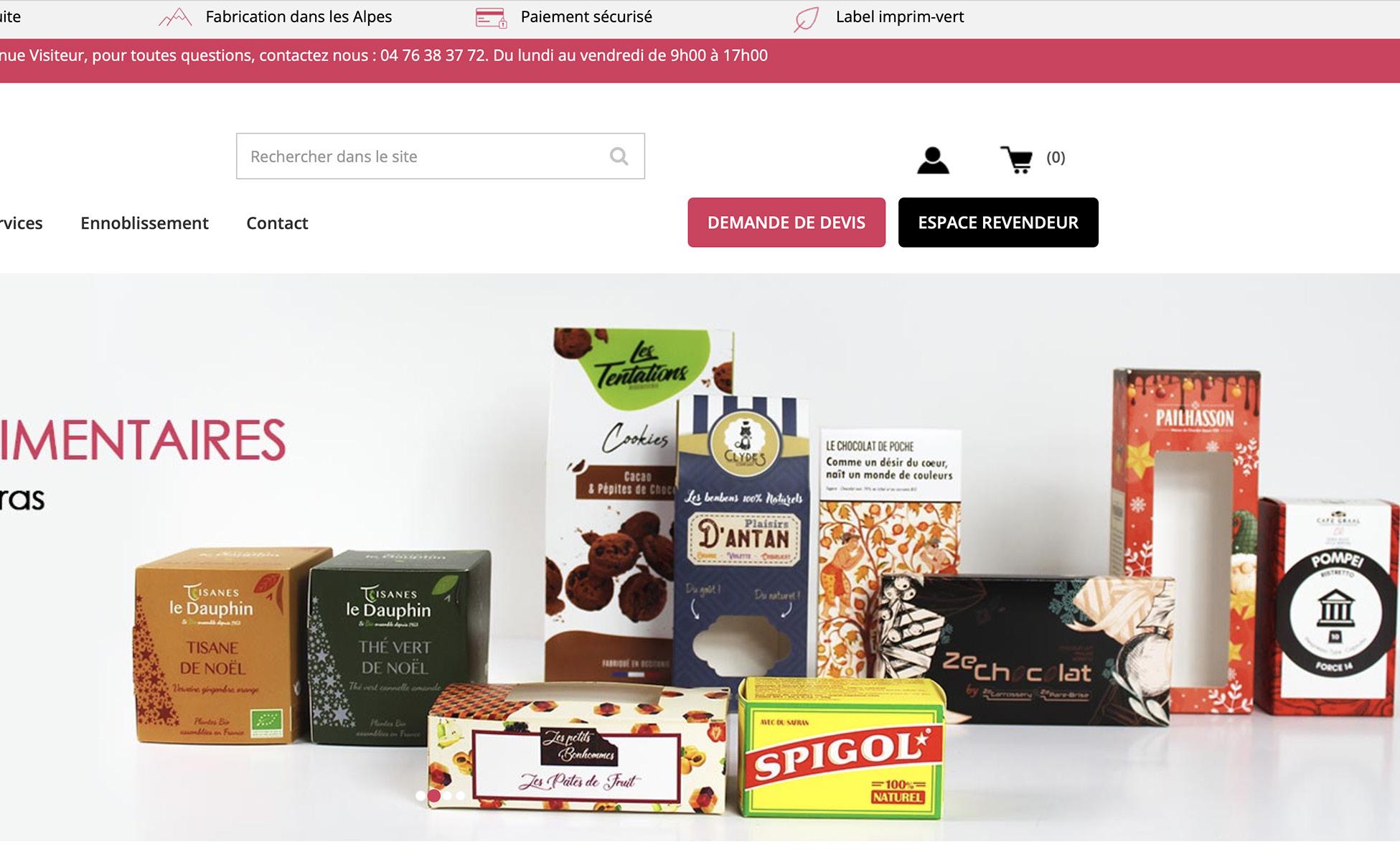

As producers of packaging, we are accustomed to explaining to our clients that the packaging that is most easily recycled is the one we haven't produced and they haven't brought to the market! One might say we are schizophrenic. Or rather, it is an urgent and absolute necessity to align ourselves with values, both personal and applied to our company, even if it means shocking others.

And yet, if we want to envision a sustainable and harmonious future, we must change our attitudes and discourse, offer new solutions that embody the challenges of tomorrow, disrupt deeply rooted habits, approach growth differently, and recognize that there is not just one way of doing things.

Digital technologies, which commercial printing and the label industry have embraced for a long time, will inevitably contribute, whether we are convinced or reluctant, to providing new perspectives in service of projects and needs. Behind digitalization lies not only the printing aspect, which is often seen in opposition to conventional approaches like offset or flexography, but also a world of finishing, including embellishments - varnish, foil stamping, etc -, as well as cutting, automated workflow management, and enhanced prepress control that bridges the gap between clients and production.

To embrace and perhaps anticipate these technologies, the key is to evolve

the mindset, adopt a holistic approach, reconsider the relationship with clients and the market, and thus transform the company culture, allowing new capabilities to permeate and impact all levels of society.

For the past 7 years, our goal hasn't been to prospect for selling packaging. We have been evangelizing the market. We are raising awareness among brands and stakeholders, urging them to step out of their comfort zones, embrace technological innovation, and consider that there are alternative paths, which may appear impenetrable at first but complement each other to achieve results that meet expectations.

For 7 years, we have been pounding the pavement, advocating a different and intriguing message, which involves no longer operating like previous generations: embracing the constraints of cardboard manufacturers - such as minimum quantities, combining multiple references, tooling costs that exclude new market entrants, etc. - and making them our own. By denouncing these archaic concepts, though still coherent with the constraints of conventional technologies, a light shine on the path of all brands and project holders who embrace this paradigm shift: "Now, my constraints and desires take precedence!"

Digital Synergies

Web-to-print, continuously evolving in its approach to the market, anticipating needs, and delivering highly refined

“If we want to envision a sustainable and harmonious future, we must change our attitudes and discourse”

customer experiences, has directly benefited from the new capabilities offered by digital advancements. It certainly would not have revolutionized the market without this contribution. However, we must not forget that Web-to-Print and Digital Technologies mutually leverage and feed off each other to progress and gain market share, forming a virtuous spiral.

"The waste that is recycled best is the one that we haven't produced." This adage, whose perspicacity cannot be questioned nowadays, applies to all areas, particularly the packaging world.

“To embrace digital technologies, the key is approach, reconsider the relationship with transform the company culture”

In turn, Web-to-Pack benefits from the capabilities provided by digital means dedicated to the packaging and Point-Of-Sales industry. This, in turn, justifies the development of new equipment and solutions by manufacturers. The combination of Digital and Web-to-Pack undoubtedly contributes to democratizing access to simplified packaging solutions that were previously reserved for experts with minimum volumes.

It now allows any brand or project holder to launch, test the market, make mistakes, backtrack, and avoid imposing heavy commitments.

is to evolve the mindset, adopt a holistic clients and the market, and thus

All these factors contribute to the rapid growth of the market share captured by Web-to-Pack, without impeding the

traditional business conducted on a personal basis. Moreover, the increasing number of new product launches, special and limited editions, and the incredible trend of offering numerous

variations of the same product - to cater to individual consumers' preferred flavor, color, etc. - all contribute to the explosion of demands that require online solutions coupled with digital production technologies. And if these numerous packages are produced locally, directly within the workshops connected to the web-to-pack platform, the loop is closed.

We are witnessing the development of more or less advanced and transparent web-to-pack offerings, indicating that these solutions seem like El Dorados. However, let us not be mistaken; the production of packaging, even with digital equipment, requires wellcontrolled processes and technical know-how that are acquired over time, sometimes through setbacks.

Some platforms simply act as intermediaries, selling products produced by local or exotic manufacturers, while others make the radical choice of controlling their processes and production in-house, despite the constraints and difficulties this entails. However, they retain all the added value within their own company.

As with any epic journey, we are witnessing the creation, consolidation, disappearance, and rapid growth of companies until the market structure solidifies. In the meantime, ingenuity and creativity know no bounds, naturally pushing the boundaries. Therefore, drupa 2024 becomes an essential event where new technologies, developments, and perhaps revolutions will be presented to serve markets, anticipating unspoken desires that are either unknown or unconscious for brands.

Technological developments occur both continuously and in bursts. drupa 2024 will be the perfect opportunity to confront the complementarity of conventional and digital means, combined with Artificial Intelligence, which should be harnessed and used to our advantage, just like innovative solutions that enable the continuous reduction of Musculoskeletal Disorders and other occupational diseases that permanently affect our operators.

The remarkable ability of human beings to invent and reinvent themselves gives us hope for a promising future, albeit

“Let us not be mistaken; the production of packaging, even with digital equipment, requires well-controlled processes and technical know-how that are acquired over time, sometimes through setbacks”

different from what we know today. Ultimately, one question remains: Do we wish for something better tomorrow, or can we become better ourselves? That is quite a program.

About the author

Fred CORBO created and launched Smilepack.fr, the first fully integrated Web-to-Pack platform, in 2017. Concurrently, he oversaw the installation of one of the initial HP Indigo 30000 printers dedicated to cardboard substrates for folding box production.

As the CEO and owner of FP Mercure Packaging, Fred possesses a clear vision of the packaging market's evolution, closely intertwined with digital process equipment. With over 20 years of expertise and experience in pharmaceutical and semiconductor production worldwide, he has embraced a disruptive approach that combines innovation and tradition while focusing on the market's new needs and trends.

Being a pioneer in digital packaging, Fred remains committed to shaking up the market by leveraging advancements in digital technologies to benefit customers and meet the demands of a rapidly evolving industry

“drupa 2024 will be the perfect opportunity to confront the complementarity of conventional and digital means, combined with Artificial Intelligence”

Join with us as we investigate the future of the printing industry across the region. Over two days we will hear from world leading presenters on what we can expect in the coming years, which will most certainly have an impact on the way we do business. You need to know how to keep your business moving ahead and be around for the next ten years. Knowledge is POWER.

Gomundang Printing INC (CEO Jang Sun-yoon and Jang Si-young), which started printing in Dalseogu, Daegu in 1962, is a leading printing company in Korea that

is continuously growing with the aim of becoming a leader in 21C global printing and packaging service solutions. It is one of the few global printing companies in Korea that operates a printing business in Vietnam after China, aiming to grow into a sustainable global company. Gomundang produces packages and labels for global companies such as LG and Samsung, as well as various food, beverage, and tobacco manufacturers.

It has various quality certifications such as Single PPM, ISO9001/14001, 6 Sigma activity, and G7 (CMS), and is making great efforts to improve quality management and productivity.

Gomundang operates printing plants in three locations in Daegu, Hwaseong, and Asan in Korea, and in Vietnam, especially with a long-term vision, is to build a future-oriented smart

factory in Asan, Chungcheongnam-do. Heidelberg-MK is the most important partner in Post press Packaging in completing this work.

Mr. Lee Chun-gi, director of the Asan plant of Gomundang Printing, said, „Before Heidelberg and MK formed a partnership, we knew the MK company and its products well. This is because MK is one of the best companies in China in post press Packaging, and it has been used well since the time when Gomundang was operating a Chinese factory.

Since our company knows and trusts the advantages of MK machines, when building a new post press Packaging process in Korea, we invested in MK products without hesitation from Heidelberg Korea when they started selling MK machines,” he explained the background of investing MK machines from Heidelberg Korea.

To build a smart factory to produce packages and labels in Asan in 2022, Gomundang Printing installed MK Di-

ana Eye 55, MK Promatrix106 CSB, and MK Duopress106 FF. All these machines are the first machines in Korea to have fully automatic logistics installed to enable automatic pallet feed and delivery. The inspector, Diana Eye 55, is a representative MK product that is equipped with two RGB line scancameras consisting of one light dome and one low-angle light and checks the deviation and consistency of foil, metalized board, hologram, spot vanish effect, print quality and colour, The backside camera for inspection for highest requirement.

MK is operating their own software program company needed for

inspectors, responding quickly to changes in the market and focusing on user convenience. In particular, Gomundang instal-led special options for inspecting cigarette packages. In addition, this inspection machine is equipped with an auto feeder, lifting device, and viewing table exclusively for cigarettes. The delivery section is characterized by installing a curved conveyor belt so that workers can easily remove defective products.

Promatrix 106 CSB, die-cutter is a professional die-cutter model with stripping and blanking functions to maintain the high quality of demanding packages, with a maximum speed of 7,500 sheets/h and a cutting pressure of 260t. In particular, the Promatrix 106 CSB supplied to Gomundang has a logistic system that automatically supplies and discharges pallets to the feed and delivery sections combined with automatic non-stop pile exchange that can minimize worker’s labour.

In the field of packaging of cosmetics, food, and to-bacco, there is a very high demand for foil stamping processes, and gold foil work is one of the essential tasks. The Duopress 106 FF, installed in Gomundang as the first Duopress in Korea, is a hot foil stamping machine and designed to produce accurate registration when stamping foil and embossing at once.

The 20 independently controlled heating zones concentrate energy and keep temperatures individually and stably at the most important points, providing the best results even if you do complex tasks. Set up and monitor 20 heating zones is done at the

control station. Software for foil feed systems developed by MK Masterwork can calculate complex foil usage, minimizing the use of foil to save cost.

The foil tension is adjusted by a servo drive motor, and the waste foil can be easily treated by applying a foil rewinder. In the case of the Duopress 106FF supplied this time, it is a model that can perform two hot foil operations in one path or hot foil stamping and diecutting at the same time.

Therefore, it can have various effects at once and can perform high-quality foil operations, resulting in excellent effects with high productivity. The machine is also designed to enable fully automatic logistics, and like other MK equipment, it is certified by GS European Safety, ensuring excellent stability is guaranteed.

Gomundang Printing is currently working with MK to push for another project. Gomundang Printing continues to strive to increase its market share in packaging sector through futureoriented investments, especially to expand its tobacco package business. In this regard, it is expected that the developmental partnership bet-ween Gomundang and MK will continue.

„MK has excellent technology in the post press field of packages and I think it will be highly evaluated in Korea, “said Lee Chun-gi, director of Gomundang. „I believe that if Heidelberg provides the application know-how for users to handle a variety of jobs, Korean printing companies will like MK machines as much as we do, “he said.

The customisation of print products still has the reputation as a lengthy and time-consuming process. Digital printing, new improved print technologies and the interconnection of systems make it possible to bring advertising close to the customer quickly and precisely.

NFC takes the digitisation and personalisation of print products to a new level. For a long time, the NFC sign on the mobile phone was just a reason for the battery to run out faster and we quickly looked to switch it off. Today we know that it opens up new possibilities and makes our lives easier. A highlight project at PRINT & DIGITAL CONVENTION 2023 shows how Near Field Communication (NFC) is revolutionising the direct marketing industry. The brand partners f:mp., grunewald, NFC21, locr and Wonderlandmovies joined forces in a best practice and proved with their personalised invitation card how surprising, exciting and captivating print can be.

The invitation to PRINT & DIGITAL CONVENTION 2023 was part of the event's highlight guide this year. The highlight guide presents particularly unusual print projects from the real world.

The printed invitation mailing 2023 had it all: namely an NFC chip that led to a personalised website.

On the URL, the invitees found an individual teaser video and all information about the congress. The self-mailer itself was given a personal touch with an individual map showing

how to get to Düsseldorf, including a precisely calculated journey time.

Now you could say: What can NFC do that QR code can't?

The advantages of NFC over the QR code

Learning something new again? The print and media industry seems to be overtaxing the end consumer. After all, the QR code has not even reached everyone yet. Yet the advantages of NFC technology over QR are obvious:

- The connection to the website is established more quickly.

- International transmission standard according to ISO norm.

- No special app necessary / NFC is integrated in the mobile phone.

- NFC increases counterfeit protection because each chip has a unique ID.

- Invisible integration in designs (no line of sight to the smartphone necessary).

- The data on the chip can be changed at any time.

In addition, NFC technology is becoming more widespread. The ease of use via the mobile phone - the one thing we always carry on our bodies - is making more and more everyday services rely on the technology.

NFC works with three different modes

1. Card emulation mode:

We know this mode mainly from cashless payment or unlocking doors. Either a card or our smartphone interacts with the NFC receiver. Basically, you no longer have to carry around many cards, but have everything integrated into your mobile phone.

2. Reader/writer mode:

This mode was used for the self-mailer of the invitation. The NFC chip is read by a smartphone and a URL is displayed. So-called "smart posters" are also becoming increasingly popular here. From the poster directly to the purchase - this is ideal for all online offers of goods.

3. peer-to-peer mode:

We know this mode especially when we have a new mobile phone. With this mode, we transfer data from one device to another. The mode describes the communication and data exchange between two devices.

Digitisation and print - more and more possibilities

What this example shows: The print industry is also getting more and more opportunities to realign itself and offer digitised products.

At drupa 2024 we will have a lot to discover - we can hardly wait to learn about more digitisation possibilities.

Hard photopolymer flexo plate with inherent flat top dots LED optimized plate formulation

Developed for the high end flexible packaging market Smooth plate surface is able to hold all customized surface screening patterns (e.g. Pixel+ and Woodpecker

+ Highest ink transfer and excellent highlights out of the box

+ Robust and consistent on press, simple to process, already includes flat top dots and a surface screening pattern

+ Optimal for short (quick to color) and long clean print runs (anti ink-filling)

+ Known in the market as THE digital plate for high quality Flexible Packaging Print

+ Excellent print results even under challenging printing conditions

+ Very good for long clean print jobs (anti-ink filling)

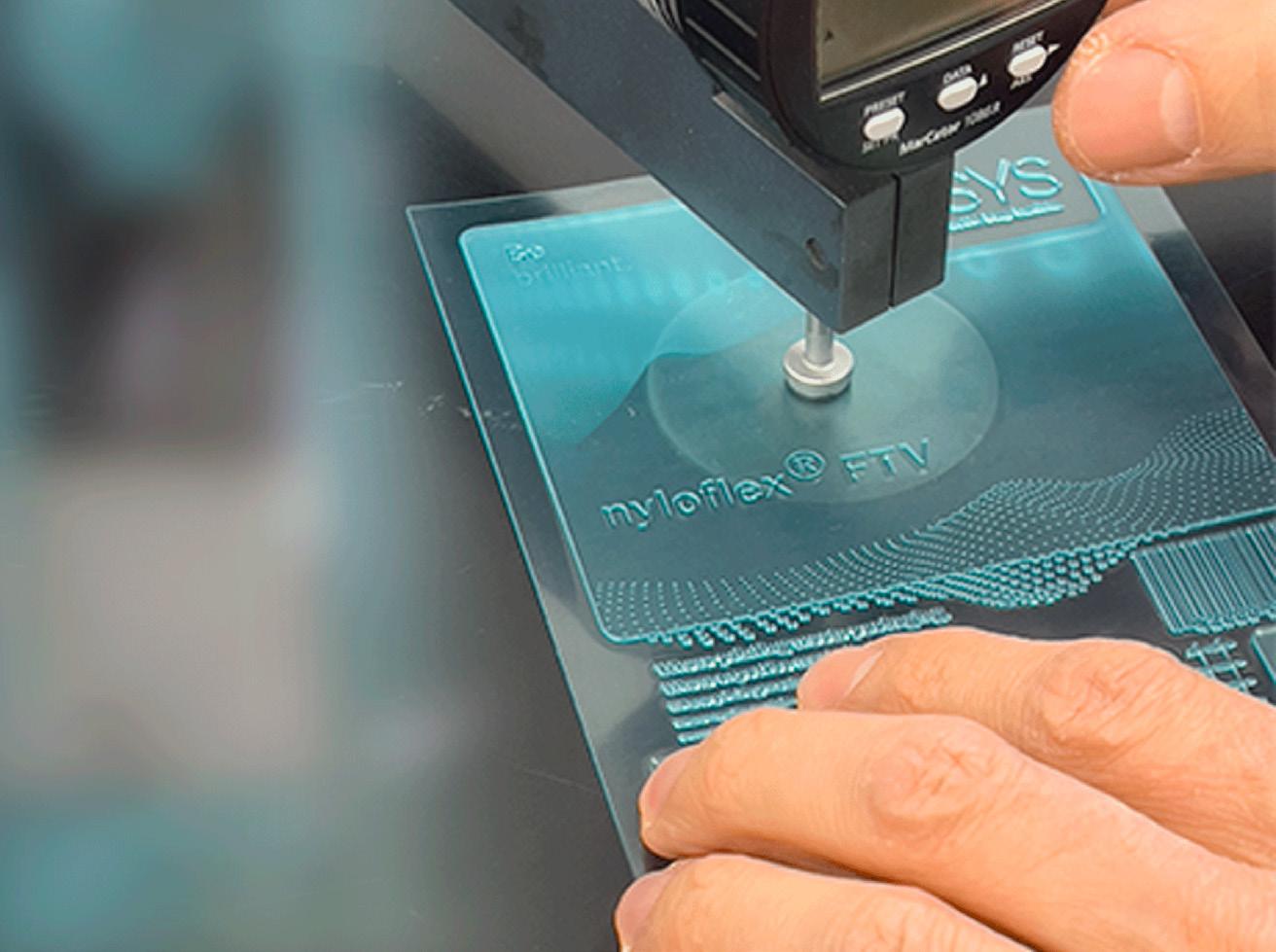

To stay competitive, producers of printed packaging are constantly challenged to ensure they can differentiate their product offerings. The exacting demands of brands are ever changing, and must be met while boosting capacity and maximizing profitability.

The many elements and processes involved in flexographic printing make it highly technical, and the lack of standardization can drive complexity. Removing some of the unnecessary day-to-day complexities in the production process gives printers room to focus on differentiation, increase capacity and improve profitability.

“Taking the complexity from standard daily operations allows printers to focus on what they really need to – being different, delivering value to clients, and growing their business.”

“By simplifying complex tasks, printers can reclaim time,” explains Emma Weston, Chief Marketing Officer at Miraclon. “And time is what makes money. If talented teams are wasting their time troubleshooting and looking for workarounds, it reduces profitability. Taking the complexity from standard daily operations allows printers to focus on what they really need to – being

different, delivering value to clients, and growing their business.”

Thanks to major advancements over the past 15-plus years, flexographers have become adept at meeting the exacting graphic reproduction demands made by brands.

But those demands don’t stand still; they change over time and the need for compelling shelf impact doesn’t exist in a vacuum. Output from the press needs to be at the same, high standard – on repeat. That means that a core component of the printing process – the printing plate –needs to be highly predictable. Any plate remakes due to errors, imager guesswork

Are you still looking for multi-talent that meets all your requirement? There are no challenges in commercial, label, and packaging printing that a Speedmaster CX 75 cannot handle, and no customer requirements it cannot meet. heidelberg.com/sg

and time-consuming troubleshooting have a negative compound effect.

The same is true in reverse. Consistent quality in output, and efficiency in platemaking and press set-up through more predictable, simplified processes compound to create more cost-effective print. And with growing sustainability demands, driven by brand requirements and changing regulation, printed packaging also needs to generate less waste while supporting sustainable inks and substrates. Predictable, consistent plate performance is key to meeting all of these challenges.

“If you know how the plate is going to perform every single time you put it on press and can anticipate exactly how to set your press up, you’ll know how much uptime you’re going to have and how fast you can run your press,” says Weston.

“That’s going to drive efficiencies. And if you don’t have to stop the press to correct, to clean, or to compensate, that drives efficiencies further. It also reduces waste, so everything you do to simplify your process also contributes to your sustainability efforts.”

Start with simplified platemaking

Simplifying these process challenges starts

with the plate. The plate affects the entire flexo process and by bringing together substrates, inks and anilox rollers, the plate technology has the power to define press capability and results.

The KODAK FLEXCEL NX Solution, for example, is a fully integrated technology solution, made up of a plate, imaging system, software that enhances print performance, and focused technical support, all of which work together to simplify the flexo process.

It delivers maximum control throughout flexo print production, eliminating the complexities outlined here. It was designed and engineered specifically to overcome limitations and challenges traditionally associated with flexo through a highly controlled process. This seeds predictability at the very start of the platemaking journey, and the benefits fan out from there.

“From Italy to Chile, flexographers have seen how platemaking technology can simplify their whole process.”

“The flexo process can have many variables, but the FLEXCEL NX System either eliminates them or makes managing

them really simple,” says Shyam Sundar partner at NS Digital Flexo based in Hyderabad, India. “We’re totally confident we can provide customers with consistent, repeatable results. It also makes it easier to solve any print issues that arise.”

NS Digital is not alone. From Italy to Chile, flexographers have seen how platemaking technology can simplify their whole process, from the impact it has on reducing press setup time and coming up to color faster, to enabling lower volumes of ink usage and reducing press downtime. “In a simplified packaging print process, people can be freed up to apply their talents to the high value tasks that will makes a business stand out and help drive growth.”

Plenty of workers across industries have built their careers around managing and overcoming the complexities of their profession. But simplifying the flexo process doesn’t reduce the importance of this skillset, which many flexographers have developed through working with the complexities of print production.

“Those people can become the most valuable in driving complexity out of a process, because they truly understand it,” says Weston.

In a simplified packaging print process, people can be freed up to apply their talents to the high value tasks that make a business stand out and help drive growth.

The right printing plate won’t just deliver high quality graphic reproduction. The right plate helps enable a simplified production process, which feeds predictability, efficiency and sustainability. The key for flexographic packaging printers lies in spotting the steps where complexity lies, from platemaking all the way to the printed package; and then identifying whether they have the technology to simplify it.

“Flexographic printers have proven they can deliver a quality product – across the gamut of packaging types and substrate materials – but now they need to do so while becoming more profitable, running the process with fewer skills, and maximizing the use of assets they already have on the production floor,” says Weston. “Success today is about running a consistent, predictable, highly efficient print process. Those complexities have to go.”

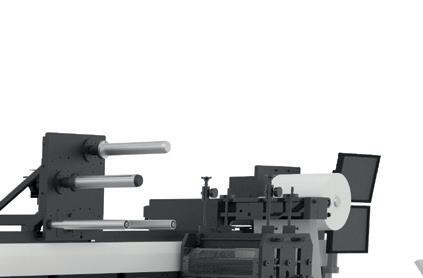

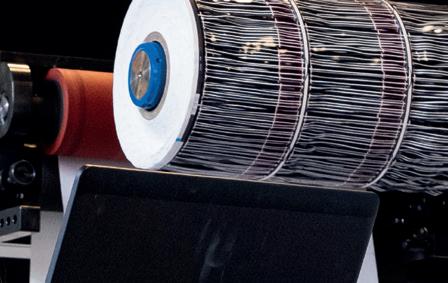

PT Indopoly Swakarsa Industry Tbk. has purchased two EXPERT K5 2450mm, one for their production site in Indonesia and the other for Indopoly’s subsidiary, Suzhou Kunlene Film Industries Co. Ltd. based in China. Both machines will be installed by the end of 2023.

PT Indopoly Swakarsa Industry Tbk. purchases two EXPERT K5 metallizers The two machines are identical and incorporate a number of BOBST innovations including the unique AlOx GEN II and AluBond processes. The machines also include a high rate source, post plasma unit, 700mm diameter coating drum which is the largest in the industry, and the Hawkeye in-line optical density deposition control and defect monitoring system.

The AlOx GEN II process builds on the foundations of the BOBST AlOx process which has been hugely successful in the market since its launch nearly 15 years ago, primarily for PET films. With the current market trend for sustainable, transparent films with high barrier in mind, AlOx GEN II was launched at the end of 2019 and was developed primarily for the BOPP market.

The process gives better barrier performance at a reduced optical density and transparency straight off the machine, resulting in a high barrier AlOx BOPP offering a solution to sustainability requirements; in combination with the right BOPP film substrate, it shows great potential for a fully recyclable transparent barrier PP mono-material packaging solution.

BOBST AluBond® is also ideal for BOPP films and has established itself in the market as the standard metallizing process for polyolefin-based PP substrates. In addition to providing excellent adhesion levels and improved dyne level retention on all substrates, when AluBond® is applied to BOPP films, it provides enhancement of oxygen (OTR) and water vapour (WVTR) barrier performance.

Commenting on the purchases, Jeffrey Halim, Vice President Director from PT Indopoly Swakarsa Industry Tbk. said “This is the first time we have bought metallizers from BOBST but with their AluBond and AlOx processes, they were able to meet our

requirements for high barrier films with good dyne level retention. The two machines will be installed at our production sites by the end of the year and we hope this is the start of a new relationship with BOBST”

PT Indopoly Swakarsa Industry Tbk. was established in 1995. A manufacturer of premium BOPP and BOPET films for the flexible packaging industry under the brand name, ILENE. With a consolidated production capacity of 100,000 ton films per year and over 25 years of experience in the flexible packaging field, the Company has valuable technical know-how as well as market expertise, in serving more than 250 prominent customers worldwide.

Driving Digital

• HEIDELBERG and Gallus utilize Labelexpo to bolster their commitment to “smart, connected printing” with trio of new products

• Labelexpo presentation addresses shortage of skilled labor and ways to boost productivity

• Gallus One digital press – designed to remove the TCO barrier for the adoption of reel-to-reel digital labels

• HEIDELBERG showcases complete production workflow for in-mold label production, with the highest performance on the market

Heidelberg and its subsidiary Gallus will be showcasing a range of unique digital solutions at Labelexpo Europe 2023 (Stand 11C30). The systems support increased automation of the entire print ecosystem, with the aim of facilitating “smart, connected printing” to address shortage of skilled labor, increase productivity, and reduce waste.

For HEIDELBERG, digital label printing is a very attractive market to grow in the digital printing segment, as it has a growth rate of around 6 percent per year and is, therefore, increasingly turning to digital solutions. The latest innovations from HEIDELBERG and Gallus underscore their commitment to boosting this digital transformation.

“The new solutions that HEIDELBERG and Gallus have developed together address the most important challenges that stakeholders market-wide are facing every day, such as the shortage of skilled labor and the demand for more productivity,” comments Dr. Ludwin Monz, CEO, HEIDELBERG.

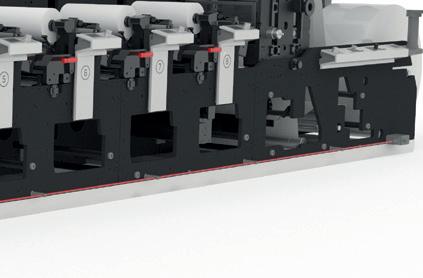

Gallus One digital press removes TCO barrier for digital label printing Labelexpo will mark the European trade show debut of the new Gallus One digital label press. Launched in August 2022, the Gallus One was specifically designed to remove the total cost of ownership (TCO) barrier for the adoption of reel-toreel digital labels with the highest level of automation and cloud-based technologies, thus bringing digital label printing into the wider area. In doing so, Gallus One provides brands, for the first time, with access to costeffective and sustainable, high-quality digital labels.

Further optimizing the TCO benefits, Gallus recently launched the new Gallus One with Converting. This new solution brings everything inline, featuring a digital printer with an inline flexo station, a semi-rotary die cutter that can change a job within one minute and process up to 70 m per minute, and vision inspection systems to ensure the highest level of quality and minimize waste.

The trade show will also see Gallus highlight the newly available digital printing unit (DPU) for the Gallus ECS 340 flexo press. Launched this summer as part of the inaugural Gallus Experience Days, the DPU transforms a traditional Gallus ECS 340 into a Gallus Labelfire 340 hybrid press – but crucially, without the additional platform investment.

This means that customers are now able to access all the flexibility and versatility of digital printing, but with the reliability and precision of conventional printing and further processing technology.

The trade show will also provide a platform to showcase the new HEIDELBERG Customer Portal (HCP), which was recently unveiled at the opening of the Gallus Group’s landmark new industry facility – the Gallus Experience Center – and which automates almost every customer touchpoint.