Print+Packaging INNOVATION Asia

SHAPING THE FUTURE OF THE PACKAGING WORLD

Whatever kind of packaging business you’re in, BOBST offers the connectivity, sustainability, digitalization, and automation you need to move your quality and productivity forward. Interested? Find your local BOBST representative at www.bobst.com/contact

The Asian Packaging Excellence Awards is the only regional Independent Packaging Print competition. Since 2001 we have been awarding Gold Silver and Bronze for packaging printers who have excelled in producing world class quality. The judges are non-supplier but are retired educators or production professionals and come from all over Asia/Europe/Australia.

* WE MUST have 5 consecutive samples for each job in ALL catergories

* ONLY 3 Jobs allowed for each catergory you enter

1. Narrow Web Flexo (up to 500mm width only)

1a Paper/Board

1.b Film

2. Mid Web Flexo (501mm to 914mm width only)

2a .Paper/Bpard

2b Film

3. Wide Web Flexo (915mm and over)

3a . Paper/Board

3b Film

4.Carton & Cups

5.Post Print for Corrugated

6.Pre Print for Corrugated

1. Flexo

2. Letterpress

3. Offset Labels

4. Gravure Labels

5. Combination Printing (Many different processes or embellishments)

6. Non Pressure Sensitive material

7.Digital Labels

7a. Up to 4 colours

7b. 4 to 5 colours

7c. 5 to 6 colours

7d. 7 Colours

1. Paper/Board

2. Metallised Paper/ Aluminium Foil Surface Print

3. Film

3a.. Surface Print

3b. Reversive Print

4.Speciality Gravure (Must provide written explanation)

OTHER

6 Mockup/Sample

7 Digital Packaging

8 Hybrid Printing

9 Offset Packaging

PLEASE READ: Asian Packaging Excellence Awards are open to all packaging compnaies across Asia. It is free to enter and winners will be presented Gold Silver Bronze awards live on stage in Bangkok 21st Sept 2023. If you do not attend we will not send awards to you. Job submitted must have been produced from November 2022 till September 2023. Judges decision is final and no other correspondance will be considered

SECTION A - This is seen by the Judges ONLY 3 JOBS PER CATERGORY PLEASE SELECT 5 FLEXO 5 LABELS 5 GRAVURE 5 MOCKUP

5 DIGITAL PACKAGING 5 HYBRID 5 OFFSET PACKAGING

Catergory Entered for this job (See catergories opposite page) _

Company Name_____________________________Contact Person________________________

Compnay Address________________________________________________________________

Country________________Contact Number _______________e-mail ______________________

Name of Entry_____________________________Printing Company_______________________

Your Name ________________________________Signature_____________________________

#

#

SECTION B - TAPE THIS TO THE BACK OF THE JOB ENRTY

Catergory Entered_____________Print Method_______________Number of colours__________

*Brand of Machine_________________________*Ink Supplier____________________________

*Plate Supplier__________________________*Tape Supplier____________________________

*Pre Press by_________________________________*Printed Quanity_____________________

*Paper/Board/Film/Label supplier____________________________________________________

*Web Width ___________________Other detials_______________________________________

If you would like to supply more information, please attach this to Section A above

Please send your entries to: Send your best work to:

ATT Asian Packaging Excellence Awards

c/o PRINT & MEDIA ASSOCIATION OF SINGAPORE

627A Aljunied Road, Biztech Centre, #04-07, Singapore, 389842

Telephone: +65 6336 4227

THE SHIFT 23 Conference will be held in Bangkok on the same day as the Asian Packaging Excellence Awards dinner presentation (September 21st) in Bangkok, during the Pack Print International and Corrutec Asia Exhibitions

The SHIFT 23 conference (now in its 21st year) is designed to give Packaging companies, no matter what area of production they are involved in, a view on the trends and technologies that effect business today.

Supported by the leading manufacturers and suppliers, the event offers you the chance to hear from world leading speakers on a whole range of industry topics. Also meet and network with other companies like yours at this intensive one-day event.

More detailed information will be available in the coming weeks so mark this date in your calendar, 21st September 2023, BITEC exhibition halls, Bangkok Thailand.

And if you enter the Asian Packaging Excellence Awards, we hope to see you on stage receiving your Awards for excellence in packaging.

2023

Issue 6 - 23

Print - Packaging INNOVATION

Asia Magazine

Published by Asian Print Awards Management Pte Ltd 65 Chulia Street #46-23 OCBC Centre 049513 Singapore

Print Innovation Asia Labels and Packaging Innovation Asia Asian Print Awards Packageing Excellence Awards Label and Packaging Conferences

Publisher Paul Callaghan paul@printinnovationasia.com

Editorial Elizabeth Liew elizabeth@printinnovationasia.com

Packaging Sales Elizabeth Liew elizabeth@printinnovationasia.com

We have all been the recipients of some of the many ways marketers communicate with their clients. Emails, paid adverts, social media, mobile, and content marketing can be quick to set up, affordable, and achieve good reach.

As such it is easy to see why digital marketing might be the first choice over print.

But digital marketing is not as effective as print, research has shown that while 71% of digital ads are viewable (at least half the ad is viewable and on the screen for at least a second), only 9% are actually viewed, or fixated upon. Display ads such as sponsored banners too are well known for generating relatively few clicks – good for brand building maybe but not so great for creating leads.

Not only is physical mail viewed, but 31% prompts a commercial action. .

It should also be why Print Service Providers (PSPs) look to sell the value of print with these four areas of opportunity:

1 Increasing customisation/ personalisation

Keypoint Intelligence reported that currently less than a quarter (24%) of total printed communications were being customised beyond the name and address while 60% of respondents expected the share of communications that contained more personalisation to

increase over the next three years in America.

Market demand is there. Forbes reports that investing in personalisation efforts can drive revenue growth of 10% to 30% while an overwhelming 70% of American consumers say they will shop exclusively with brands that personally understand them.

2 Adding Digital Print Enhancement

The vast majority of Keypoint Intelligence respondents were interested in enhancing their printing capabilities with a fifth colour for effects like clear coatings and special colours. These also included spot coatings, fluorescent/neon colors, white/clear ink, dimensional effects, raised textures, and metallic foils.

It is an opportunity that could be lucrative too. Research found brand owners in America expect to pay up to 33% more for coatings and textures, 33% more for special colours, such as white, metallic, or fluorescent and 31% more for secure print such as UV or infrared ink.

3 Using e-connectivity

Print buyers were interested in technology that enables the creation of QR codes, augmented reality, or NFC tags. Only 5% of Keypoint Intelligence respondents had no interest in purchasing these types of specialty products in the next two years.

With the pandemic giving QR codes a new lease of life it is now very common to scan them for additional information or to make payment. In

fact a survey research firm Appinio found eight in ten respondents are now used to scanning them, aided by the fact that scanning cameras are now integrated into most mobile phones and 95% of users found them a useful way to get detailed product information.

4 Establishing an online presence

93% of the print buyers Keypoint Intelligence surveyed were buying at least some of their print online with business cards, general office print, and posters, banners, and signage the most common applications being ordered. 84% of respondents that purchase some print online said that at least half of their print buying funds are spent online while nearly 70% who purchase print both online and offline expect their online spending budgets to increase over the next three years.

In a digital first world print buyers are being forced to reinvent themselves. This creates an opportunity for print based on demand for more complex personalisation and specialty printing techniques that ensure memorable print. High speed inkjet and toner technologies are continually evolving to offer enhanced production and application flexibility to deliver creative print, quickly and responsively.

It also allows PSPs to create different routes to selling supported by software solutions that enable ecommerce and web to print capabilities.

It is fantastic to see that, in such a fast paced environment of change, print remains the most reliable way to ensure communications are read, remembered, and crucially, acted upon.

Connect to Grow. That is your key to stay ahead in a demanding market. By connecting with MPSConnect, you ensure the best in reliability and productivity from your printing press. You will increase competitive advantages and maximize profits.

To improve productivity and profi tability, it’s critical to increase the understanding of your overall label print operation. With MPSConnect, you get real-time insights in the operator activities. You dive into the printing press and see exactly what’s happening.

With MPSConnect we see recurring annual cost savings of €50,000 - €100,000 and even more thanks to a more efficient workflow, time management and waste reduction.

mps-printing.com/connect-to-grow

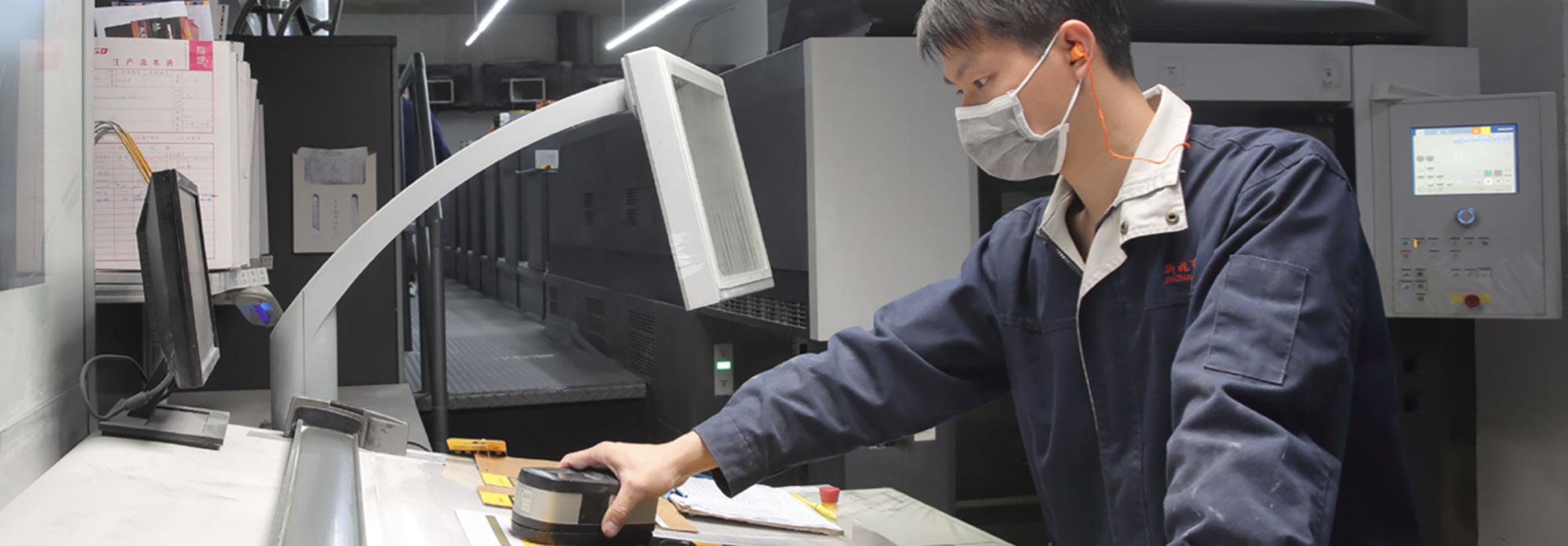

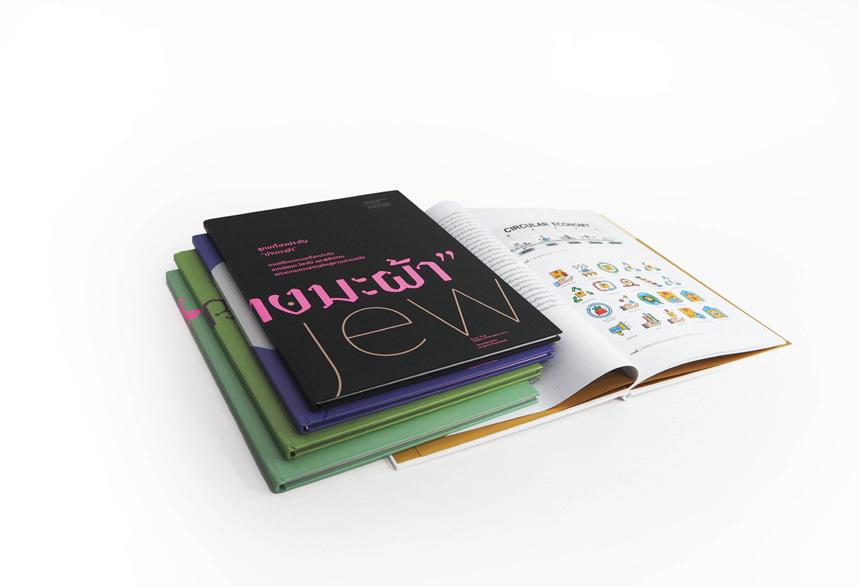

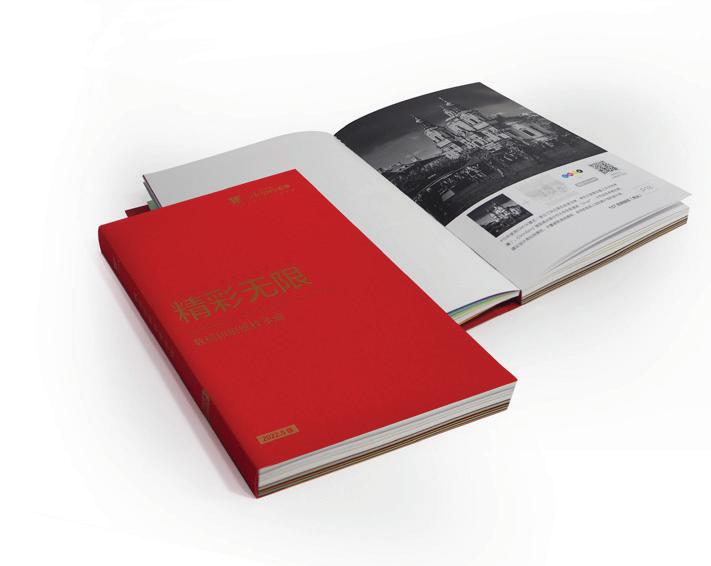

Ningbo SINSO Printing Co., Ltd. (hereinafter referred to: SINSO) is located in Ningbo, Zhejiang Province, was founded in 1998, mainly serving the world's top 500 customers and high-end brands, whose products include color box, gift box, paper card, paper holder and environmental protection packaging, functional packaging.

SINSO committed to continuously enhance the brand value for customers. SINSO has always taken the "Make innovation, Create the future" as its core strategy, attaching importance to invest high-tech equipment, apply innovative technology and the training and construction of talent teams.

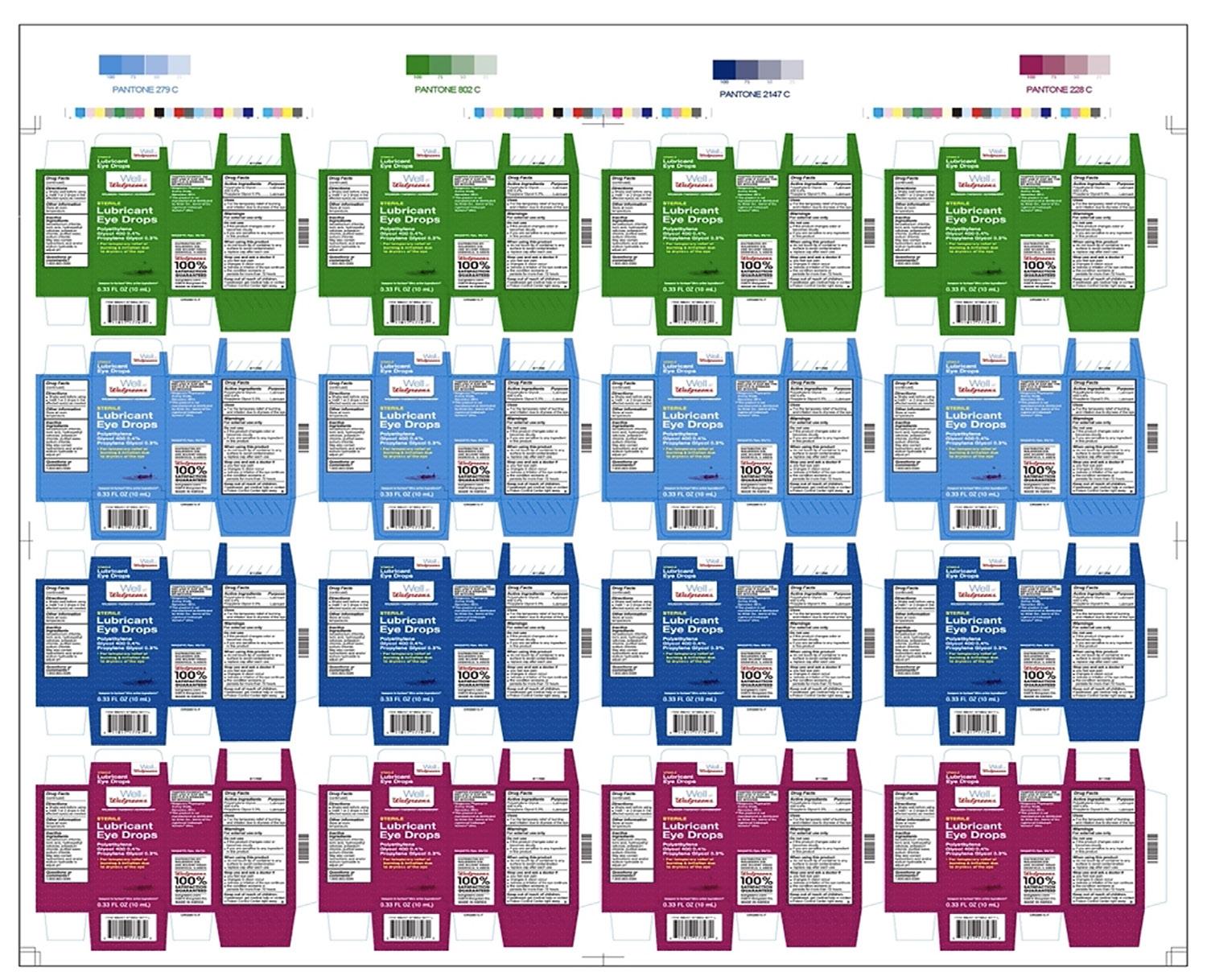

control system. As one of the first companies to eat crabs, SINSO mainly implements ECG printing for the following three goals.

1. Meet customer needs

With the concept of environmental protection and green sustainable

In recent years, SINSO has stood out in the supplier competition of the world's well-known retailers, precisely by virtue of the active application of new technologies and new processes. Mr. Yang Jianqing - General manager of SINSO, began to pay attention to Extended Color Gamut printing technology (hereinafter referred to as: ECG printing) many years ago, in that time there are few companies in the industry applied this technology.

In 2021, SINSO was determined to start to do ECG printing, they purchased a new 9-color printing press and CGS ORIS X GAMUT intelligent color separation system, and relevant measurement devices and process

development becoming more and more popular, SINSO’s customers also put forward the demand for this, hoping to be able to use recycled papers (manila board), but the color of recycled manila board cannot keep up with the white cardboard, and the replacement of paper leads to reduced printing quality.

If use ECG Printing on manila board not only makes up for the "gray" weakness of manila paper, but also

the color effect is more vivid, more realistic and more three-dimensional than the traditional printing (Because the color gamut of ECG printing is much bigger than than the color gamut of traditional printing). So, it is loved by brand owners.

2. Open up new markets

With the change of the overall environment, the transfer of the industrial chain, and the fierce competition in the market, traditional printing is facing changes. As a traditional printer, in addition to the continuous innovation and optimization of management, technological innovation is the core strategy of SINSO, and breaking through traditional printing has become the biggest goal of SINSO.

3. Enhance team capability

SINSO got the GMI Certification in 2012, in that time they already changed

the printing model to intelligent automatic from relying on the operator's experience. In the past ten years, the team has been adhering to the lean concept, constantly exploring the hidden functions of printing, looking for methods and technologies to continuously improve the printing color management ability, this lean thinking helps SINSO to dig deep into every link, the application of ECG gamut printing technology is also an opportunity for further improve the overall ability of the team.

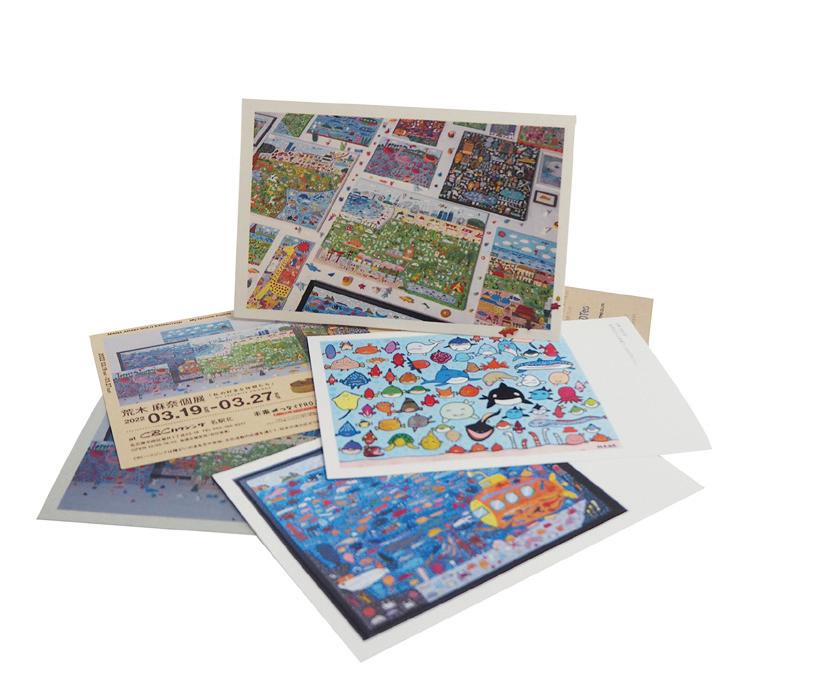

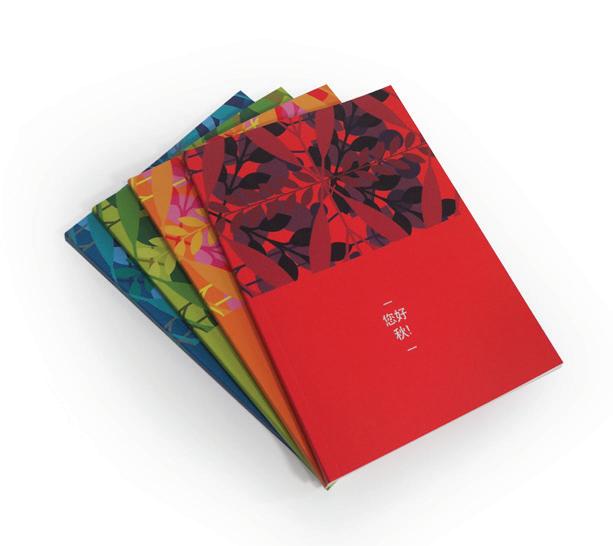

It is only less than 2 years for SINSO applying ECG Printing, but there are many customers are using the new technology, including pet products series packaging, children's toy picture books, intelligence card books, and various promotional materials. In the past two years, affected by the epidemic

and the transfer of the industrial chain, the business of many enterprises has declined significantly, but the business of SINSO not only has not declined but has risen against the trend.

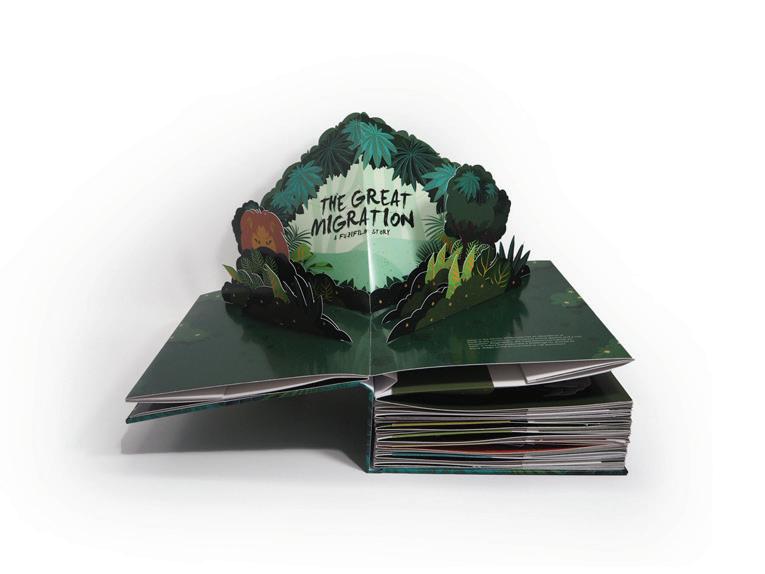

New technologies and new processes have enabled SINSO to develop well, so at this year's Hong Kong Printing and Packaging Exhibition and Gift Show, SINSO presented a "ECG printing application feast" for visitors.

In China mainland, CGS ORIS and its partners have helped more than 10 printing and packaging companies implementing ECG printing, and the purpose of these printers to implement ECG printing is nothing more than the following two aspects:

1. Improve printing quality: RGB images are separated to ECG printing, color effect directly catches up with effect on the display, and also solve

which brings great challenges to printers. ECG printing can well meet the needs of such orders, so as to help printing enterprises to improve the comprehensive utilization rate of equipment, reduce the comprehensive production cost, so as to improve or ensure profit margins.

For the brand customers of SINSO, the most important thing they care is that ECG printing has a higher color reproduction, not only high saturation, but also better gradation and contrast, which can show a more real and fine color and image effect. Now the consistence of photos, screens and print in SINSO is the highest level in the industry.

The cooperation between SINSO and CGS ORIS is not the first time, the color management software used before is also CGS ORIS, both color match and stability can meet the high requirements of SINSO’s overseas customers, so the first thing that comes to mind is CGS ORIS when they were choosing ECG printing intelligent color separation software. The technical support of CGS ORIS in the early stage and the implementation of the landing service in the later stage, are both very good,

The function of X GAMUT is also very complete and intelligent, which help achieve the optimal combination of ink in color separation period, and it also has fine tone functions. For SINSO, they never worried about the problem of color shift, or difficult to print.

the traditional printing color distortion confusion. And then printers can obtain differentiated competitive advantages in the fierce competition now.

2. Spot color replacement: multi-spot color/small-batch jobs can greatly optimize the production workflow by ECG printing, and significantly reduce labor costs, time costs, quality costs and production costs. ECG printing help achieve high quality packaging without increasing costs.

At present, the overall packaging presents a trend of small batch and multiple styles, and the percentage of such orders continues to increase,

In addition, SINSO also values the rich experience of CGS ORIS and its partner Shenzhen ColorBlue Digital Co., LTD on printing standardization and ECG printing, which make sure the successful application of ECG printing in SINSO.

With the continuous promotion and application of ECG printing, this technology has become more and more mature in recent years, and some advanced printers and customers have begun to recognize the advantages and potential of ECG printing and have begun to pay attention to this new technology.

Although the overall market understanding of this technology is not very extensive, but with the popularity of ECG printing, more and more brand clients have applied ECG printing for their production/packaging printing.

"Make innovation, Create the future" is SINSO’s business philosophy, SINSO has always put the innovation and improvement of printing technology in the first place, and is more willing to make a small contribution to the practice of new technology in the industry, We believe that, under the leadership of General Yang, the development of SINSO will continue to leap to new levels.

Challenges

• Aging technology leading to frequent downtime and costly maintenance

•Tedious, time-intensive workflows

• A need to meet the increasing demand of high-quality transactional printing

• Outdated software solutions and - potential security vulnerabilities

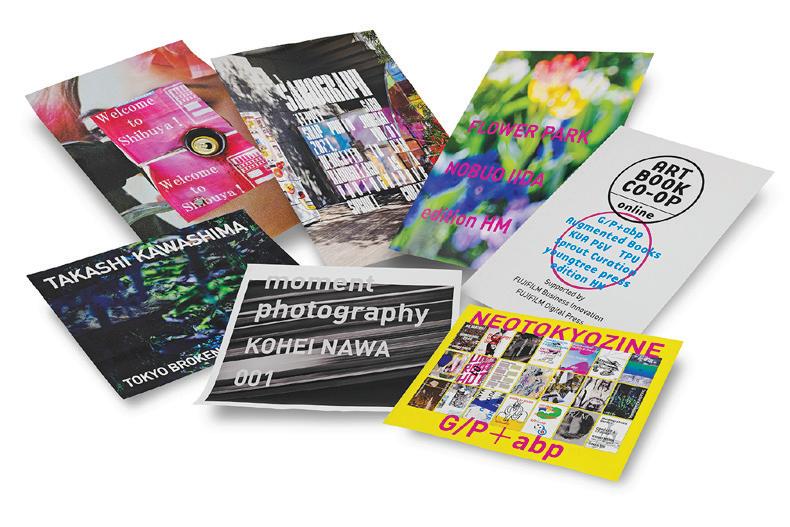

FUJIFILM Business Innovation Solutions

• FUJIFILM Revoria Press PC1120 6-colour print engine

• FUJIFILM Iridesse Production Press – 4-colour and 6-colour print engine

• Emtex Output Manager

Benefits & Results Revoria Press, Iridesse Production Press

• 60% improvement in productivity

• Increased print capacity

• Faster turnaround times

• Expanded print offerings and services

• High quality transactional output that exceeds the expectations of today's customers

Emtex Output Manager

• Improved productivity and business operations

• Legacy data streams transformed into usable formats

• Processes up to 10,000 pages per minute

• Single point of control for multiple printers

Toppan Security Systems is one of Asia’s leading security printers, with a rich history that dates to the early days of the Singapore Straits Settlement.

The company offers a wide range of traditional print services, including book printing, magazine production, and the core of their business, security printing solutions and digital statement printing – which incorporates an increasing slew of new technologies, such as software engineering, biometrics, the Internet-of-Things, and increased automation.

As the industry continues to evolve, Toppan Security Systems transforms with it – as a true market leader

that delivers new technology-based solutions, with the vision of becoming the industry’s top print security solution provider in Asia. With their extensive expertise and portfolio of in-house printing capabilities, Toppan Security Systems commands a strong market position and continues to be a trusted advisor to government agencies, businesses and financial institutions in Singapore and across the region.

Challenges

Toppan Security Systems has a legacy of embracing cutting-edge technologies, and wants to uphold this stellar reputation by continuing to provide solutions that keep their customers relevant and ahead of trends.

To meet the many challenges and opportunities confronting the industry, Toppan Security Systems sought to implement a strategy that would increase productivity and uptime, reduce the total cost of ownership, and meet increased demands for shorter print runs and faster turnaround times – all while enhancing the value that their solutions deliver.

As the transactional print industry changes, there is an increasing demand for exceptional print quality and fast turnaround times to meet compliance and strict service level agreements (SLAs) – and the company were finding it challenging to meet these demands with its existing portfolio.

What’s more, Toppan Security Systems wanted to go a step further, aspiring to expand their market and profitability by leveraging omni-channel opportunities and growing trends. In order to accomplish this, they would need print solutions that allow them to tap into these new possibilities.

In developing and executing their strategy, Toppan Security Systems looked to one of its most tenured and trusted partners, FUJIFILM Business Innovation. Toppan Security Systems and FUJIFILM Business Innovation share a 23-year relationship that is built on trust, professionalism and respect

Through this long-term connection, FUJIFILM Business Innovation developed an in-depth understanding

FUJIFILM Business Innovation Singapore's dedication and technical skillsets have resulted in better quality prints and support. Our business units are now able to produce small quantities flexibly, quickly and at a relatively lower cost. We have also benefitted from the reliability, commitment and technical expertise of FUJIFILM Business Innovation Singapore’s after-sales support team.

Crystine Cheong, Toppan Security Systems’ Data Printing Manager, shared her thoughts on their return on investment so far.

of Toppan Security Systems’ challenges and aspirations – and have the expertise to recommend optimal solutions for the business going forward.

The core of this strategy involved an upgrade to their existing transactional digital production printing capabilities, which included investments in the IridesseTM and Revoria Press PC1120 platforms and workflow automation solution – Emtex Output Manager.

On the recommendation of their trusted partner, Toppan Security Systems transformed the company’s printing capabilities with 120 pages per minute of high-speed printing that can consistently manage Toppan Security Systems' monthly production volume, including peak period print volume fluctuations.

In addition to consistent productivity and image quality, the new press

opens a world of possibilities with its automated functions and 6-colour print engine – including the capability to expand and bring to market new print applications for new clients and projects, going beyond transactional printing and into projects that need vivid, expressive and high-definition prints.

Together with their new print presses, Toppan Security Systems also integrated the Emtex Output Manager solution, which offers greater flexibility for migrating print jobs as it effortlessly converts files to optimised formats. This translates into more efficient and productive workflows that consistently meet established SLAs, which means consistently satisfied customers!

By converting a part of their aging continuous feed technology infrastructure to digital cutsheet, Toppan Security Systems has increased its capacity and productivity levels, while lowering their costs. In parallel, this approach also allows them to leverage new growth opportunities, while continuing to serve the needs of their existing customers.

Their investment in the FUJIFILM Revoria Press PC1120 is already paying huge dividends, with the company realising a 60% jump in productivity – which Toppan Security Systems credits to the faster print speed and

The combination of the FUJIFILM Revoria Press PC1120 and Emtex Output Manager solution has re-energised aspects of our traditional core business. With the new print capabilities, we can now offer a more diverse selection of print solutions to existing and potential customers. This has widened our customer base, enables us to engage in new business opportunities that are aligned to the industry trends, and has grown our brand's reputation as a cutting-edge security solution provider and innovator. –

Terence Ng - General Manager, Toppan Security Systems

increased capacity of the new presses. Toppan Security Systems’ growing pool of customers are impressed with the improved print quality of the FUJIFILM press, while employees and customers alike are excited about the expansive possibilities that digital technology offers.

Meanwhile, their management is happy with the lower investment costs and increased uptime of their new digital press – which means more jobs done, higher profits and more satisfied customers.

For over two decades, FUJIFILM Business Innovation has buoyed Toppan Security Systems’ business with its high product reliability, engineering skillsets and strong after-sales services and support. This support extends beyond printers and into key aspects of the client’s business.

For example, FUJIFILM Business Innovation partnered with Toppan Security Systems to conduct a business

development workshop targeted at their key clients, helping to strategise innovative ideas and concepts –leveraging the technologies Toppan Security Systems has to improve customer outreach and brand awareness.

This workshop is one of the many ways FUJIFILM Business Innovation supports partners with executable growth strategies for creating new business opportunities.

Furthermore, FUJIFILM Business Innovation’s Fogra certified Digital Print Partners (DPP) collaborate closely with the teams from Toppan Security Systems to adjust visuals for incredibly accurate colour and optimal print quality.

The DPPs further offer guidance on simplifying printing processes and achieving fast turnaround times, giving partners the confidence in the invested technology with FUJIFILM Business Innovation as a trusted provider.

Improvements to technology and shifts in printing trends signal a promising future for digital print solutions. New opportunities for innovation are emerging from the analogue to digital transitions that are happening in this era of development in business and society.

Digital printing solutions are being embraced in response to changing enduser behaviours and wider economic influences. Print runs are shortening and customisation is becoming more commonplace as cost- and timeefficiency remain front of mind for businesses. This comes along with an increased focus on waste minimisation and greener printing.

“Some print houses have responded to these trends by diversifying their equipment,” reflects Atte Lindström, Director, Technical Customer Service and Product Management at UPM Communication Papers. From his perspective, it does not have to be an either-or situation.

“Having both conventional and digital printing technologies under the same roof means the printer can efficiently cater to more diverse customer orders.” The flexibility of business models is a reaction to the reorganisation of a market. But it is also a catalyst for innovation. “Digitalisation opens up opportunities for smaller players to have greater accessibility to highquality products,” comments Atte. “As a committed graphical papers

provider, we must also ensure our product offering is fit-for-purpose in a constantly evolving market.”

The demand for print continues to diversify. Certain print assets are seeing an uptake post-COVID, and others are trending towards decline. Atte offers one example of this: “Printed statements, utility bills and other financial documents are increasingly moving online. This frees up capacity

within printing houses to broaden their offering to other graphic media.”

Meanwhile, the cost-effectiveness and steady ROI of direct mail keeps print firmly in the mix for omnichannel marketing strategies. This is one possible direction for where this freed up capacity can go, especially if the mail outs are strategically tailored and informed by data to minimise wastage and maximise effectiveness.

Revoria

Revoria

The efficiency and versatility of digital printing solutions lend themselves to these changes. Innovation in printing and workflow technologies will play a key role in shaping the future of print. High-speed Inkjet printing is expected to thrive according to market forecast specialists Smithers, and continuing technological developments in Inkjet printing have already made it a competitive choice.

For papermakers, innovation in our own product is important to improve the quality of water-based Inkjet printing. “As a paper supplier we cannot anticipate and support this evolution on our own. Embracing partnerships

allows us to adapt and innovate our offering to suit more modern printing technologies,” explains Atte.

UPM Communication Papers recently piloted a new generation of digital printing papers that are specifically designed for high-speed inkjet printing technology. Developed in partnership with HP Inc, it is a demonstration of shared commitment between papermaking and printer technology to strengthen the future of graphic publication.

“For customers making the transition to digital printing methods, the new ColorPRO papers provide a

shared guarantee of both quality and efficiency.” The range will extend the selection of UPM papers for digital printing, adding to our existing portfolio for customers who want to remain flexible to constantly shifting demands.

An ongoing commitment to innovation and strategic collaboration can create opportunities for paper in an increasingly digitalised world. Of this, Atte remains encouraged: “By working collaboratively, UPM can continue to support the dynamic and diverse needs of the print community.”

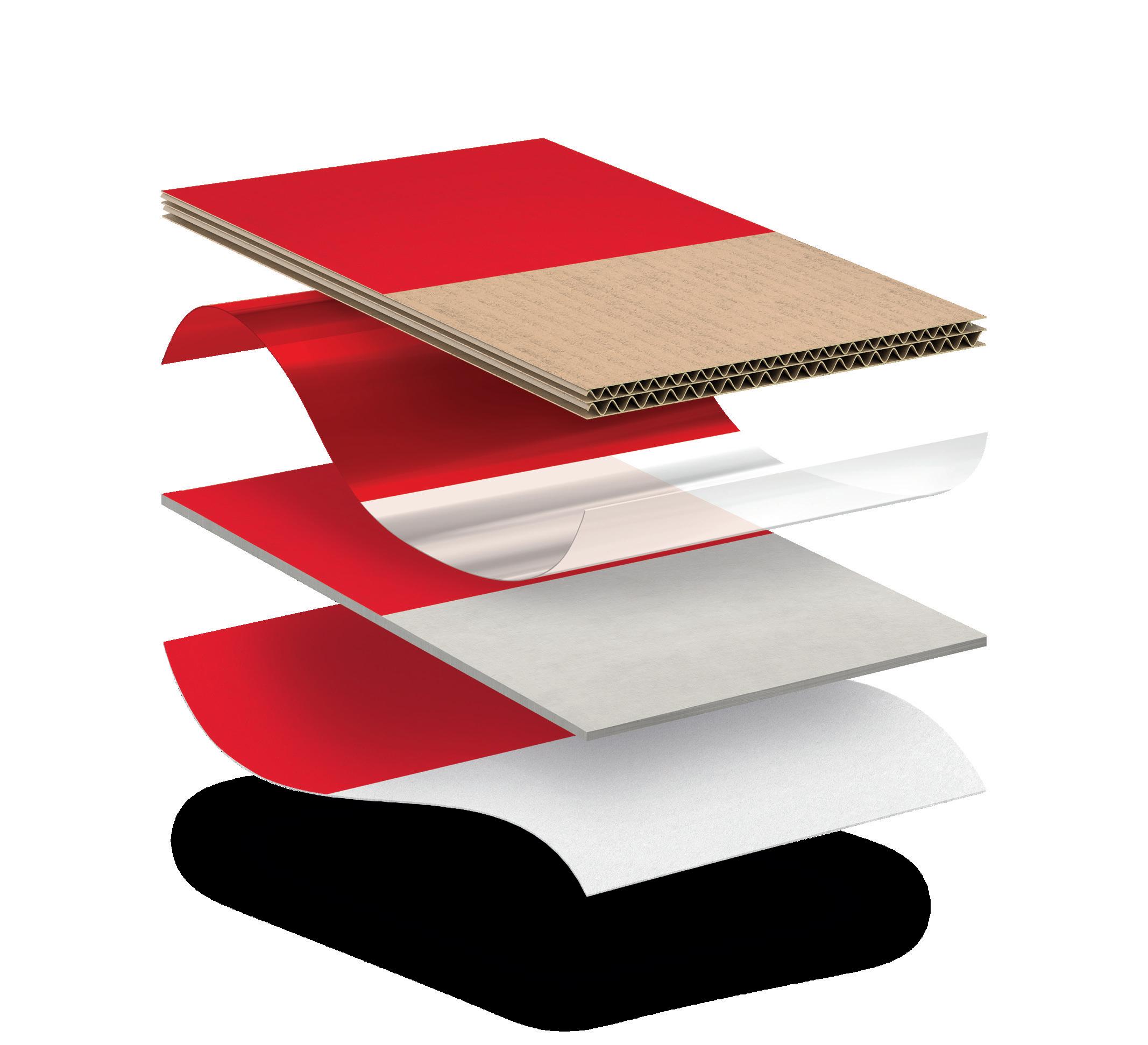

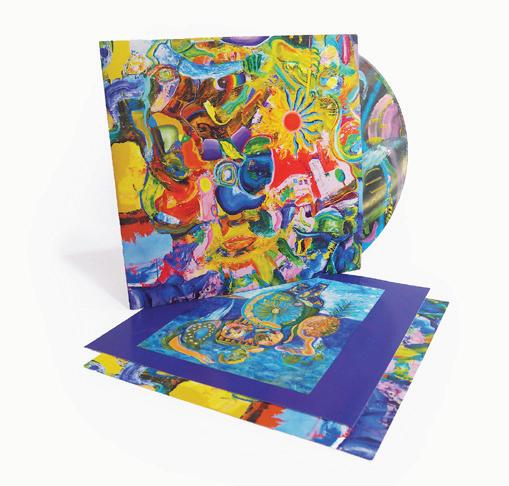

Packaging is an essential part of the customer journey. It is the customer’s first haptic contact with the product. At the point of purchase, it is even the first visual contact.

the customer’s mind by the packaging alone. Packaging is therefore a carrier for triggers. Some say packaging is a loud sales consultant.

If a package is plain and gives the logo enough space, the end consumer expects a luxury product. Of course, the material should then be chosen accordingly. High-quality materials reflect the product. A firm feel, i.e. high grammage, is then essential.

At the POP, we decide in less than a second whether to buy the product or not. The packaging plays a bigger role here than the product itself.

There is now even a marketing term for the process of unpacking: unboxing. There are thousands of videos of unboxing experiences on social media. Packaging has the potential to convert online and POP customers into brand fans. In other words, to reach the highest goal of a brand in the customer journey. Brand managers who have understood this can now replace entire cross-media campaigns with packaging marketing.

What aspects contribute to branding? The combination of psychology, material and design works.

Brands that are aware of their philosophy can visualise it with the

packaging alone. Depending on the material and design, characteristics can be imparted. The end consumer can tell from the packaging alone whether a product is sustainable, quality-conscious, cheap, organic, young or cheeky. In an ideal case, the famous imagination is triggered in

The icing on the cake is the finishing. Shiny elements such as gold or silver foil underline the high quality of a product. If, in addition to this aspect, the brand also wants to convey a responsible attitude towards our environment, it has the option of using resource-saving production methods and recyclable materials. The packaging industry today offers all possibilities, if you only look for them.

The outer packaging should be practical and appeal to the target group. In the

example of food or cosmetics, we are in the most demanding industries. Here, the packaging has to perform by far the best:

1. the packaging reveals what is inside.

2. the product is protected.

3. the packaging has a positive influence on the minimum shelf life.

4. today’s outer packaging should ideally be sustainable and yet attractively designed.

5. they should be practical and easy to stow away

6. the price range should be recognisable through design and material

7. there are plus points for upcycling possibilities

Today, target group analysis, but above all the needs of the target group, are integrated into the packaging. And for good reason: only those who know their target group exactly will get enough attention to be bought.

In a 2020 study by Trivium Packaging, 74% of respondents said they would be willing to pay more for sustainable packaging.

Brands communicate the trend topic of sustainability not only through colour, design and material, but also through function. A prime example is the children’s clothing brand Monday’s Child. The packaging of the clothing brand later serves as a doll’s house or other toys.

Upcycling is the king of sustainable packaging today. Brands such as Truefruits, Welch Marmalade and Thomy Mustard have been doing this since the beginning of the brand’s history.

Even if the change to the Thomy mustard jar initially seemed like an abolition of the drinking glass, the brand has demonstrated trend awareness. Because the mustard glasses can still be used as drinking glasses. Just in a more modern design and with more sustainable materials.

Another example is Bloom Everlasting Chocolate, the tasty gift that keeps on giving. Their outer packaging contains plant seeds from ingredients of the chocolates. The packaging can be placed in potting soil. As the cellulose decomposes, the seeds grow into chilli, mint and orange plants.

However, caution is also required when it comes to packaging design and the communication of sustainability. The end consumer is very well-read today and quickly recognises whether the product and packaging contain the same values. If a component is not sustainable, the brand is quickly accused of “greenwashing”. This often damages the brand more than honesty and well thought-out packaging marketing.

At the Leipzig University of Applied Sciences (HTWK), it was found that the packaging design influences the purchase decision by 60%. It is therefore a real attention booster.

As mentioned at the beginning, the product packaging is often the first visual and haptic contact with the customer. Perception begins at the point of sale, in the online shop and also in catalogues. It is one of the most important advertising media for the brand manager.

They convey brand messages as well as philosophies and product characteristics.

In 2018, Kerstin Erbe, as Managing Director of dm’s own drugstore brands, said: “Packaging is the central aspect because we don’t advertise.” The success of the drugstore’s own brands proves this statement. Brands differentiate themselves through packaging. With few concise messages on the packaging, the design is crucial for recognition. This is precisely why it is also important to create a long-lasting (i.e. sustainable) design.

If you stick to this advice, the packaging of the brand becomes the central element of brand management.

Simply consistent

Decrease waste and setup with predictable plates

Simply efficient

Increase on-press performance with a robust plate

Simply sustainable

Support sustainable inks and substrates all with the same plate

Simply better Address your most demanding brand and quality requirements

From prepress to on-press, deliver the efficiencies and productivity needed from your plates to maximize your bottom line.

Juan Señor, President of global media consultancy Innovation C onsulting, gives his ten pressing concerns for print.

1 Print dead? Just a fable

As new technologies arise, we love to conjure up and highlight fables, including the idea that print is dead. It’s not. The notion that one medium kills another is simply not true. If print were a platform, I’d say ‘Yes, it’s dead. RIP print,” because there’s no language there, no medium. But print as a medium has permanence. It’s eternal.

2 Print will find its place?

When films arrived many years ago, there was talk that theatre would die. But what we saw was a transition through disruption. We’ve seen this repeatedly throughout history – and for 25 years or more in digital. It also applies to print. We’ve transported this successful, text-based medium online, and once digital finally finds its own language, print will rediscover its future within that mix.

3 Displacement beats replacement

First comes disruption, then displacement. The web has managed to move into the newspaper space and newspapers have moved into the magazine space. The fact is, you can’t keep flogging the same, tired old horse and not reinvent your product.

Within the print space, the ‘play’ is to make it ever-more premium. Take Versace. It produces very few dresses in the £100,000 price bracket, yet these remain its flagship product. Print has to be reinvented as the premium choice, to have beautiful design, in a

larger format, and be a keepsake. And premium must be pricier.

5 Flat is the new up Everybody’s talking about the decline in print circulations. And yes, they will decline. Anybody who pretends they won’t is either naïve or nostalgic. But they’re not falling off a cliff edge. Eventually, circulations will flatten out at a stable, but still lucrative, level.

6 Less open , more lean back

The big, complicated, ever-evolving issue, particularly for newspapers, is frequency. Take FT Weekend. It’s a delicious, quality product that’s perfect for print. It arrives on a Friday and you spend the entire weekend reading it. You hear about the ‘lean-back experience’, but if you’re going to succeed, you have to provide something that’s genuinely ‘lean back’, like the FT Weekend.

7 Brand building? Use Print

It’s not great for clients to have their brands associated with fake news, so the leading industry voices are singing print’s praises. For brand finding, digital trumps print every time. But for brand building, when you’re relaunching an entire proposition, print wins.

8 The digital frenzy is absurd

As P&G’s Marc Pritchard has said, the misguided flip to digital spending isn’t working. This cycle needs to be rebalanced, because it’s evident that many millions of pounds aren’t performing. And they’re not performing because there’s this tremendous fraud. You may reach a million people, but you will reach a million people for a quarter of a second, as opposed to 100,000 for 10 or 20 seconds.

9 Print underpins campaigns

When it comes to awards, the traditional categories for print and publishing are getting reframed not because advertising interest in those categories is dying. We should be looking at the fact that many campaigns are now integrated and, in many cases, anchored in prestigious print work.

10 Take the fight to the duopoly

We’ve been playing defence for far too long. Google and Facebook have cornered £70bn of ad space globally, but their longevity is not guaranteed. Print has an important role to fill as the situation evolves, and if that means anchoring more campaigns in paper, so be it.

DEADLINE 5pm October 5th 2023

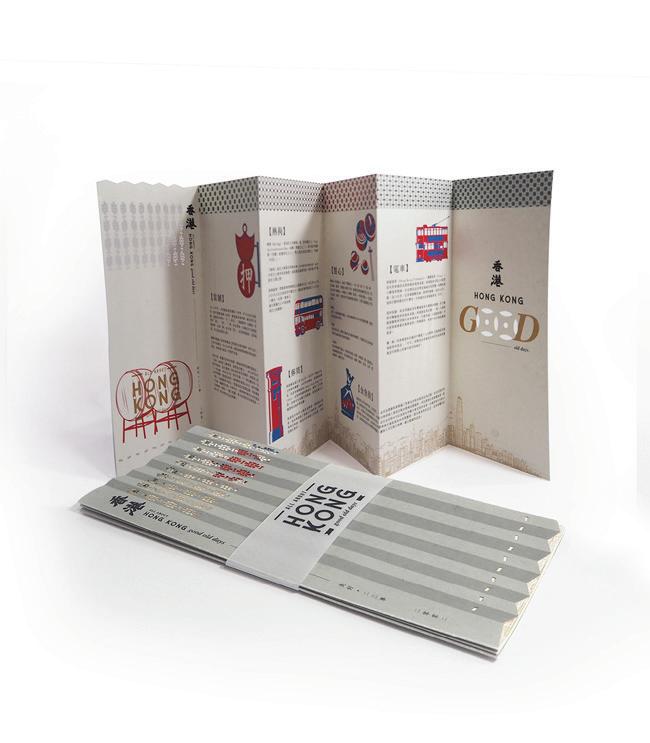

The annual Asian Print Awards was founded to recognise outstanding achievement in the print and packaging industries across Asia. With more than half the world’s population represented in this fast growing area, communication in the form of printed matter links Asia’s diverse cultures. It is imperative that such print achievements do not go unrecognised, especially among the population base that Asia enjoys.

The Awards are judged on a wholly quality-oriented set of criteria to ensure that fair play is enacted at all times.

The Independent Judging Panel comprises highly qualified personnel from within Asia and around the world. The independent judging panel has no knowledge of the actual entrants details. ALL ENTRIES ARE NUMBER-CODED. Entries must be commercially produced work.

The Asian Print Awards is the only regional print quality competition of its kind in Asia. Supported by leading industry-supply companies, any progressive quality print house should enter and prove that they are the best - by winning the Gold, Silver or Bronze award. Proving pride in quality awareness is what customers love to see. It’s not just empty words, you can prove it.

Categories 1-8 : Offset Printing Only

1. Calendars – any format

2. Sheetfed Magazines

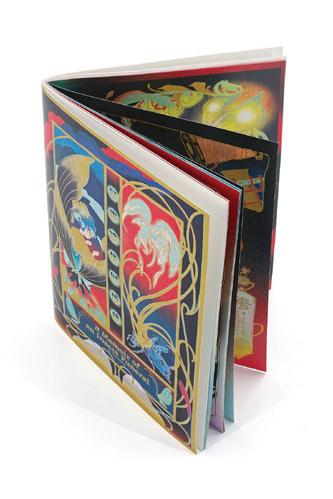

3. Book printing – less than 4 colours

4. Book printing – 4 or more colours

5. Limited Editions & Artwork Reproductions (under 1000 print run)

6. Web Offset – Coated stock 70gsm and above

7. Web Offset –LWC (light weight coated) 65gsm or less

8. Offset Packaging products

Categories 9 - 21 : Digital Printing Only

9. Book Printing

10. Calendars

11. Personalised photo books – any format.

12. Posters

13. Showcards & Point-of-Sale material

14. Digital Magazines

15. Gold, Silver and Special colours

16. Restaurant Menus

17. Limited Editions & Artwork reproductions (under 500 print run)

18. Digital Proofing (must supply the digital proof and the prinnted product)

19. Digital Packaging

20. Digital Labels

21 Digital - Outdoor Billboard

Categories 22-27 : Specialty Categories

22. Multi–Piece Productions and Campaigns

Any substrate or print process: Multi–piece Production must be 3 or more items such as folder, leaflets, ring binders, inserts, envelopes including their contents. Campaigns must be 3 or more items with a consistent theme produced during the year by the same printer for the same client.

23. Embellishment

Any substrate – any combination - for example: embossing – diecutting – foil stamping –laminatingcoating.

24. Innovation / Specialty Printing / New technology

The entry must exhibit any innovative and/ special application of machinery, process, substrate or finishing. A short description must be provided for the judges, detailing reasons for entry into this category.

25. Company Self Promotion

Any item printed to promote a product or company involved in the graphic arts industry. Self promotion cannot be entered into any other Category.

26. Judges Special Award (A job that catches all the Judges’ attention)

27. Design and layout. We look at the impact and visual effect.

Send your entries by 5th October - 5pm to: Asian Print Awards

c/o Print & Media Association of Singapore 627A Aljunied Road, Biztech Centre, #04-07

Singapore, 389842 Tel +61 422 869 728

Deadline for Entries Submission: 5th October 2023, 5pm

Remember to submit 2 copies of each job! Why? - Just in case one is damaged.

SECTION A (This will not be shown to judges). Please fill the form in capital letters.

Entered by (company name): ______________________________________________________________________________________

Contact Person: ________________________________________________ Email______________________________________________

Address: ___________________________________________________________________________________________________________

Telephone: __________________________________ Country____________________________________________________

Category entered: ___________________________________________________________ (Example Cat 4 Book printing)

Title of entry (ie: " Paul's Ice Cream" ): ________________________________________________________________________________

Printed by (Printers name): ________________________________________________________________________________________

Client name: _______________________________________________________________________________________________________

Designer Pre Press House: ___________________________________________________________________________________________

Brand of Printing Machine used: _____________________________________________________________________________________

Stock supplied by (Merchant’s name): ______________________________________________________________________________

Ink used to produce the entry : ____________________________________________________________________________

By signing here you accept the rules and conditions of the Asian Print Awards

Signature over printed name_____________________________ Name_____________________________________________________

SECTION B Production information to be shown to judges ( tape this securely to the back of your entries)

Category entered (Same as above): __________ Entry number (Administrative use only]

Title of entry (ie: " Paul's Ice Cream" )__________________________________________Print method: _______________________

Number of ink colours (4-6-8 etc) ________ Any Embellishment (foil stamping etc) __________________________________

Quantity produced (Print run copies): ___________ Other technical details (finishing processes etc) ________________________

The Awards Dinner will be held in October on the 9th November in Singapore Send all entries to - Asian Print Awards

c/o Print & Media Association of Singapore

627A Aljunied Road, Biztech Centre, #04-07 Singapore, 389842

email:Paul@printinnovationasia.com Tel. +61 422 869728

www.printinnovationasia.com

The 2023 Asian Print Awards Checklist!

1. Have you submitted your best work to be judged?

2. Have you checked the work to make sure its 1st class?

3. Check it one more time!

4. Are their 2 copies of each entry ?

5. Is it packed correctly for shipment with 2 copies of each entry ?

6. Have you left enough time for shipment5th October 2023 5pm is the Deadline

7. Check the address you have written - it should be Asian Print Awards

c/o Print & Media Association of Singapore

627A Aljunied Road, Biztech Centre, #04-07

Singapore, 389842

Tel +61 422 869 728

Good luck and may the regions BEST Printing Companies WIN!

Will be held in Singapore in November on the 9-10 - 2023.

Printers across the whole region are facing challenging times. International Print Congress aims to gather world class speakers to try and address all the issues that have an impact on Printing Companies today, with the view of giving them a roadmap as they try and navigate their business into the future.

What are some of the challenges and solutions we are facing today! The International Print Congress 2023 will address these in much more detail, but below is what most of us are seeing in our industry.

In recent years, the printing industry has undergone a profound transformation driven by advancements in digital technology. Traditional printing methods, such as offset printing, are now complemented by digital printing techniques that offer greater flexibility, efficiency, and cost-effectiveness. Digital printing allows for shorter print runs, customization, variable data printing, and faster turnaround times,

making it well-suited for on-demand production and personalized marketing materials.

Furthermore, the printing industry has embraced sustainability and environmental responsibility as key priorities. Manufacturers and print service providers have made significant strides in adopting eco-friendly practices, using renewable resources, and reducing waste. Many companies have also implemented energyefficient technologies and embraced recycling programs, minimizing their environmental footprint.

The printing industry's reach extends beyond traditional media, such as books, magazines, and newspapers. It encompasses a wide range of applications, including packaging materials, labels, promotional products, and large-format graphics. With advancements in digital printing technology, it has become easier to produce vibrant and high-quality prints

on diverse substrates, meeting the everchanging demands of businesses and consumers.

Additionally, the printing industry has embraced the digital era through the integration of augmented reality (AR), virtual reality (VR), and other interactive technologies. These innovative approaches enhance the printed material's impact by creating immersive experiences, bridging the gap between the physical and digital worlds.

As the world continues to evolve, the printing industry remains an integral part of our lives, enabling the dissemination of information, fostering creativity, and serving as a tangible medium for communication. With ongoing technological advancements and a commitment to sustainability, the industry is poised to embrace new opportunities and continue its significant contribution to global communication.

1 Embrace Digital Printing Technologies: Incorporating digital printing technologies alongside traditional offset printing can provide a more versatile and flexible service. Digital printing allows for shorter print runs, variable data printing, and quicker turnaround times. By investing in digital printing equipment, companies can expand their offerings and meet the growing demand for personalized and on-demand printing.

2 Offer Value-Added Services:

To differentiate themselves from online printing services, commercial printers can provide value-added services that enhance the customer experience. This can include graphic design, prepress services, customized packaging, and fulfillment. By offering a comprehensive solution, printers can become a trusted partner for clients, providing expertise and convenience beyond just printing.

3 Focus on Niche Markets: Identifying and targeting niche markets can help printers find areas where offset printing still holds value. For example, specialty packaging, high-quality art prints, or specialized marketing materials may require the capabilities and unique advantages of offset printing. By understanding the specific needs of these markets and tailoring their services accordingly, printers can establish a competitive edge.

4 Invest in Automation and Workflow Management: Streamlining production processes through automation and workflow management systems can improve efficiency, reduce costs, and enhance turnaround times. Automation

can include tasks like preflighting, color management, and file preparation, allowing printers to handle larger volumes of work effectively and minimize errors.

5 Develop Eco-Friendly Practices: To address environmental concerns, printers can adopt sustainable practices and promote eco-friendly options. This can involve using environmentally friendly inks, recycled paper, and implementing recycling and waste reduction programs. By showcasing their commitment to sustainability, printers can attract environmentally conscious clients and differentiate themselves in the market.

6 Enhance Online Presence and E-commerce: Establishing a strong online presence is crucial in today's digital landscape. Printing companies should invest in professional websites that showcase their services, provide easy online ordering and file uploading options, and highlight their expertise. Additionally, integrating e-commerce capabilities can enable customers to place orders conveniently, further expanding the reach of the business.

7 Collaborate with Clients and Stay Agile: Maintaining open communication and collaborating closely with clients can lead to innovative solutions and new business opportunities. By understanding their evolving needs, printers can adapt their services and develop customized solutions. Staying agile and responsive to changing market dynamics is essential to remain competitive.

The focus of the International Print Congress Day 1 is to look at all these issues with a line-up of world class presenters, be it technology, brand owners or tips and techniques that will help your business. The evening of day 1 will see the regions only Print Awards presentation dinner being held where the region’s best print production houses will be recognised for excellence in print, also another great opportunity to meet your colleagues from around the region.

Highlight for Day 2 will be the focus on technologies and delegates will be able to choose from several trips to see firsthand the latest technology available, visit print production sites and much more.

Apart from this the opportunity to network with companies like yours and to find common answers to many of the challenges we face.

They say “Knowledge is Power” the International Print Congress 2023 is a must for companies who want to grow and make sure that their business has this knowledge to succeed

SINGAPORE 9-10 NOVEMBER 2023

SAVE THE DATE AND STAY TUNED FOR MORE!

Join with us as we investigate the future of the printing industry across the region. Over two days we will hear from world leading presenters on what we can expect in the coming years, which will most certainly have an impact on the way we do business. You need to know how to keep your business moving ahead and be around for the next ten years. Knowledge is POWER.

• The keys to switch were Portal and Subscription

•

•

Printed materials are used to convey feelings (emotion) from one person to another. Sohokkai Corporation (Asahikawa, Hokkaido; President: Soshiro Tamura) celebrates its 70th anniversary in 2023. We offer a full range of services to our customers in Hokkaido and outside Hokkaido, mainly in Tokyo, including printed materials ranging from publications to general commercial and on-demand services, as well as digital tools such as website creation, data system construction, and network maintenance.

Sohokkai has been using Heidelberg‘s workflow software Prinect since

2003. With the introduction of the Speedmaster CD102 in 2015, the company began to fully integrate the prepress and printing processes. In 2020, they switched from a licensing agreement for some Prinect functions to a subscription agreement called Prinect Production Manager.

The keys to switch were Portal and Subscription

Regarding the reason for the switch to Prinect Production Manager, President Tamura said, “To be honest, we strongly felt that we wanted to improve the efficiency of our interface with our clients by introducing a system from

another company that would allow us to check proofs and give correction instructions in the browser.

On the other hand, what was a headache at the time was the cost of each additional purchase and upgrade of Prinect‘s online functionality. When we heard that the software subscription, Prinect Production Manager, included a portal to interface with our customers, and that there would be no cost for future upgrades because

it was a subscription, we made the decision to switch.” However, he says that even after actually connecting

DX and more efficient corporate

with customers through Portal, it took time to get things moving in a way that would contribute to Sohokkai‘s business. “It took about a year for the portal submission to actually start working.

Naturally, it is a tool to be used by customers, so we had to explain it to them first. The sales staff, who were reluctant at first, gained confidence when they saw that the portal was actually working and the customers were happy with it, and they started to introduce it to other customers aggressively.

Although there are variations among sales team, I believe that as such small successes accumulated, the superiority of the portal was gradually recognized both inside and outside the company. In addition, as a sales representative, we can now use the portal as one of the tools to differentiate ourselves from our competitors.

Going digital has also increased our sales efficiency, leading to a reduction in errors, wasted costs, and time.” He recalls the steady efforts made by the entire company, including the sales team.

“At the time, the day shift press utilization rate was low, and there was a need to change this, so we were working on various measures within

the company. There were many jobs that were submitted that day and printed that day, and submissions were concentrated in the evening.

This meant that there were many situations where the printing presses were down during the day. So we decided to increase the number of items that could be printed during the day shift. And to do that, we needed to improve the efficiency of the entire plant, and we started working on this because we knew we could use the automation of Prinect.” explains Aki, manager of the Prepress Section, about the initial challenges.

Regarding the results after the introduction of the system, he says, “By using the Prinect Production Manager‘s portal submission, we were able to speed up the timing to pre-press for printing during the day shift by a wide margin. If it is not a complicated imposition, it is submitted

after passing through the RIP with automatic imposition, so there is no need for plate-making work, and all that is left is checking, but some things can go without checking, so we have been able to reduce our workload by about 50 hours per month, especially for 20 regular items. Thanks to this, the number of holidays and overtime work, which used to be the norm, has been drastically reduced. ”

President Tamura commented, “We have heard that many useful functions of Prinect Production Manager can be used by printers at no extra cost. We would like to learn more about what it can do, and if there are any functions that can be useful to us, we would like to actively use them in the future. For example, we would like to immediately use the input of information about the papers that can be utilized throughout the production process, schedule assembly, which still involves a lot of analog work throughout the company, and pallet sheets, which could be done easily.

As a manager, the most important thing is visualization. If we cannot see what is important, we cannot make improvements and set goals for the future, so we would like to digitalize the prepress department, where it is particularly difficult to see the process. At the same time, we expect Heidelberg to come up with new proposals that will be useful for our business.” He also expressed his expectations for their potential they will unfold with Heidelberg.

Koseikan Co., Ltd. celebrated its 85th anniversary this year. The company formed a business alliance with the Tenmaya department store in 1969 and is currently a wholly-owned group company of Tenmaya.

Koseikan's main business is planning, design production, printing, and web production. Beginning in 2021, the company started the digital transformation of printing using KP-Connect Pro and achieved great results in improving production management efficiency and changing the consciousness of employees.

We asked Masao Uchida, President and Representative Director, Kaoru Iwai, Director and General Manager of the Management Department, Kazuhusa Yorizane, General Manager of the Management Team, Koichi Oda, General Manager of the Manufacturing Team, and Ikuko Yanagihara, Manager of the Process Control Group of the Management Team, about Koseikan's digital transformation of printing and its introduction of KP-Connect Pro.

introduction of KP-Connect Pro

Koseikan previously extracted data from the MIS, edited plans for each production machine on Excel, listed them, and output them on paper. Meetings of representatives of each site were held twice each day, at midday and in the evening. Then responses were provided to progress reports for each item from the person in charge at the site, but there was frequent back and forth about "Which is the latest information?"

This sort of confirmation also frequently took place among sales, design, and platemaking staff. Since job priorities often changed, operations that relied on people caused interruptions and waste due to information communication lags (timing delays), significantly reducing process management effectiveness.

In addition, the company's factory has three sheetfed offset presses (one from Komori and two from other manufacturers), one webfed offset press (from Komori), one POD system (from other manufacturer), three cutting machines (from other manufacturer), and one folder (from other manufacturer). Since machines from multiple manufacturers were in operation, centrally managing and visualizing the progress of each machine was thought to be difficult.

Director Iwai said, "When I visited an advanced company that always shared the status of the printing site with the sales department, I realized that our company was lagging behind. However, even though we tried to tackle digital transformation, it was not possible to achieve this," he said. During this time, he encountered KP-Connect Pro. "I was shocked to learn of the existence of KP-Connect Pro as a digital system capable of managing all processes in a printing factory in cooperation with MIS and decided to introduce KPConnect Pro," he said

The introduction of KP-Connect Pro made it possible to visualize the schedule and progress of all processes, resulting in many improvements.

The first was the reduction of one person in charge of scheduling printing.

100% sustainable

Best profitability at printing speeds up to 600 m/min. and fast job changes

Highest quality with best register

Connected to RUBY to digitize the value chain ... and many more!

Since the scheduler automatically calculates each job's load based on standard times, there is no longer a need for dedicated staff working on schedules, and the staffer is now working in another department which needed staff.

The second effect is the abolition of process meetings, eliminating the need to prepare meeting materials and reducing the time for responding to inquiries. Since KP-Connect Pro can always check the latest information on the schedule and progress, from handing over press-ready plates to finishing, the number of inquiries about progress has drastically fallen.

Two daily process meetings are no longer necessary, and staff can use their time effectively. The third effect is shortening the time for entering onsite daily work reports. Inputting daily reports on the iPad helps to reduce the amount of work that is necessary, including for daily reports on other

manufacturers' machines, and makes information real-time.

In addition, the company utilizes such visualized information in a variety of ways. General Manager Yorizane says of its effectiveness: "Being able to see each machine's load status makes it easier to distribute the workload, and we almost never outsource work. If there is no work in the morning due to the previous day's press-ready plate situation, it's now possible to stagger working hours, which can reduce unnecessary overtime work."

Process Control Group Manager Yanagihara, who is in charge of process management, says, "Being able to see the progress of each department has changed my awareness of the schedule." The sales/production and manufacturing sites were working at different bases, although there were issues with information sharing. However, since the conditions for receiving final data and the press-ready plates became visible, the consciousness of sales also changed and the delay in receiving final data disappeared.

The operation status of each machine obtained by KP-Connect Pro is also linked to MIS, and cost management is performed using the data.

In the latter half of 2021, the company called on its employees to "become an organization that can talk in numbers," and embarked on business transformation. A task force called

"margin improvement" was launched and business improvement was promoted. Director Iwai said, "Each team selects a general manager and one member to work on improving the profit margin across the company.

KP-Connect Pro data is used in each department for improving operational mechanisms and the workflow." The scope is wide-ranging, including elimination of waste and bottlenecks, reduction of wasteful overtime by improving productivity, and price negotiations for materials and outsourcing costs.

Employee awareness rises and Koseikan can talk in numbers

Regarding the investment effectiveness of KP-Connect Pro, Director Iwai said, "In addition to the cost reduction effect of indirect work of about 6 million yen or more annually, there are effects such as productivity improvement and reduction of overtime work due to visualization."

Only two years after its introduction, KP-Connect Pro has already become indispensable. "We communicate with prepress and postpress while looking at the data. Everyone thinks for themselves and works on their own work, so they have their own opinions, and the organizational culture is improving," says General Manager Oda.

Finally, President Uchida said, "We want to be a company that can provide customers with the maximum synergy of digital and analog, and that can grow with our feet firmly on the ground."

"Thanks to KP-Connect Pro, our company, which had suffered from a technological lag, is now able to proceed with digital transformation."

-- Masao Uchida, President and Representative Director

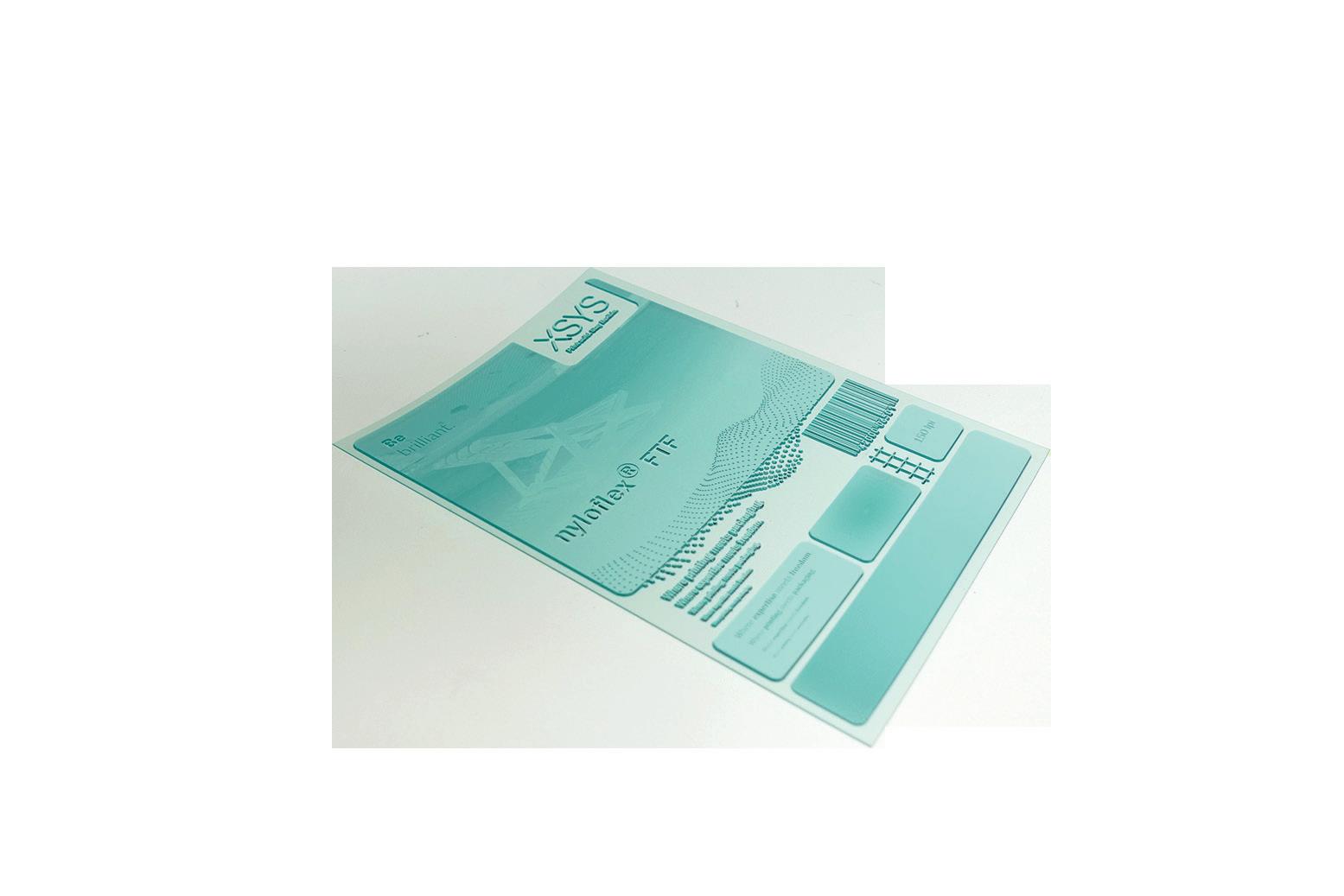

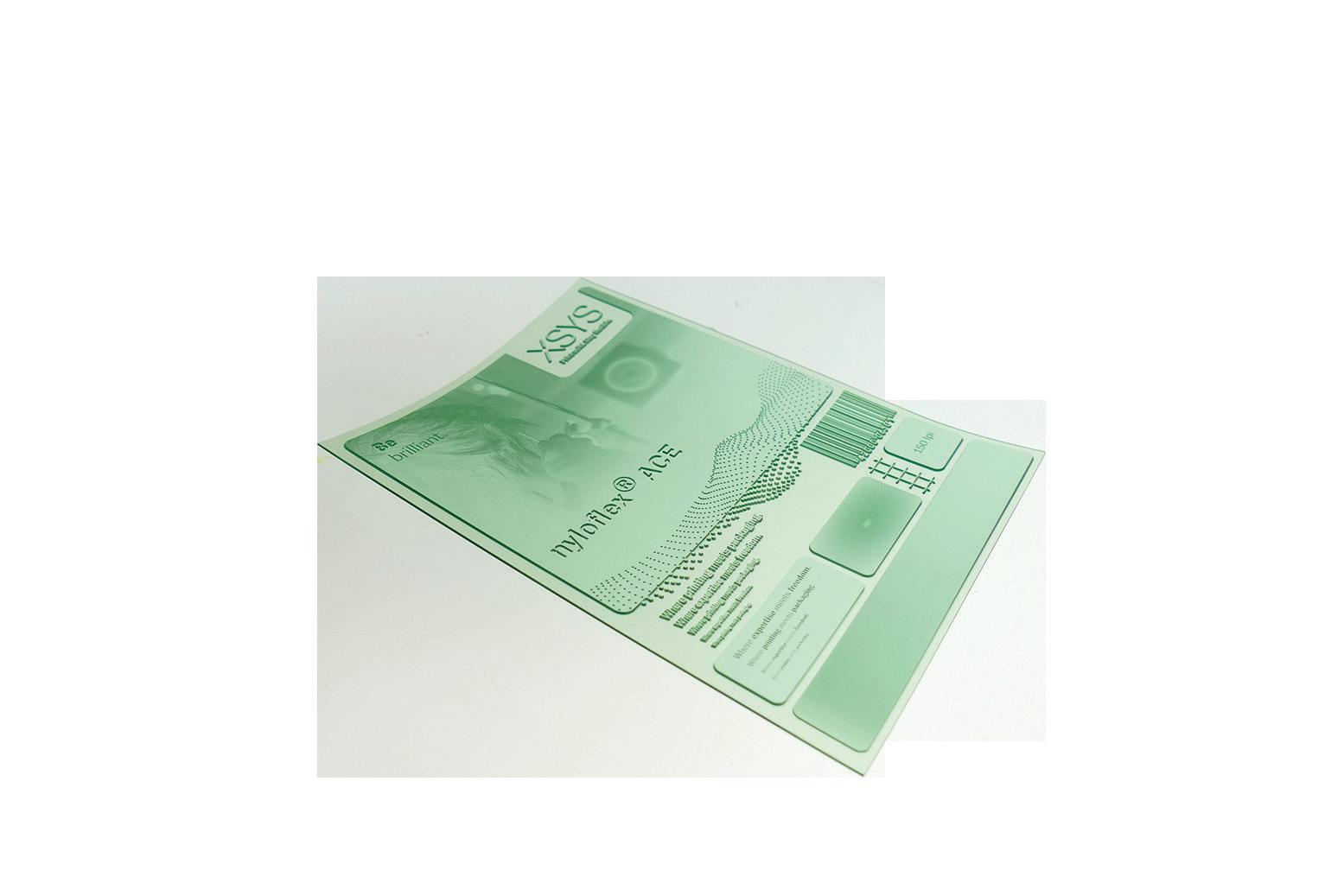

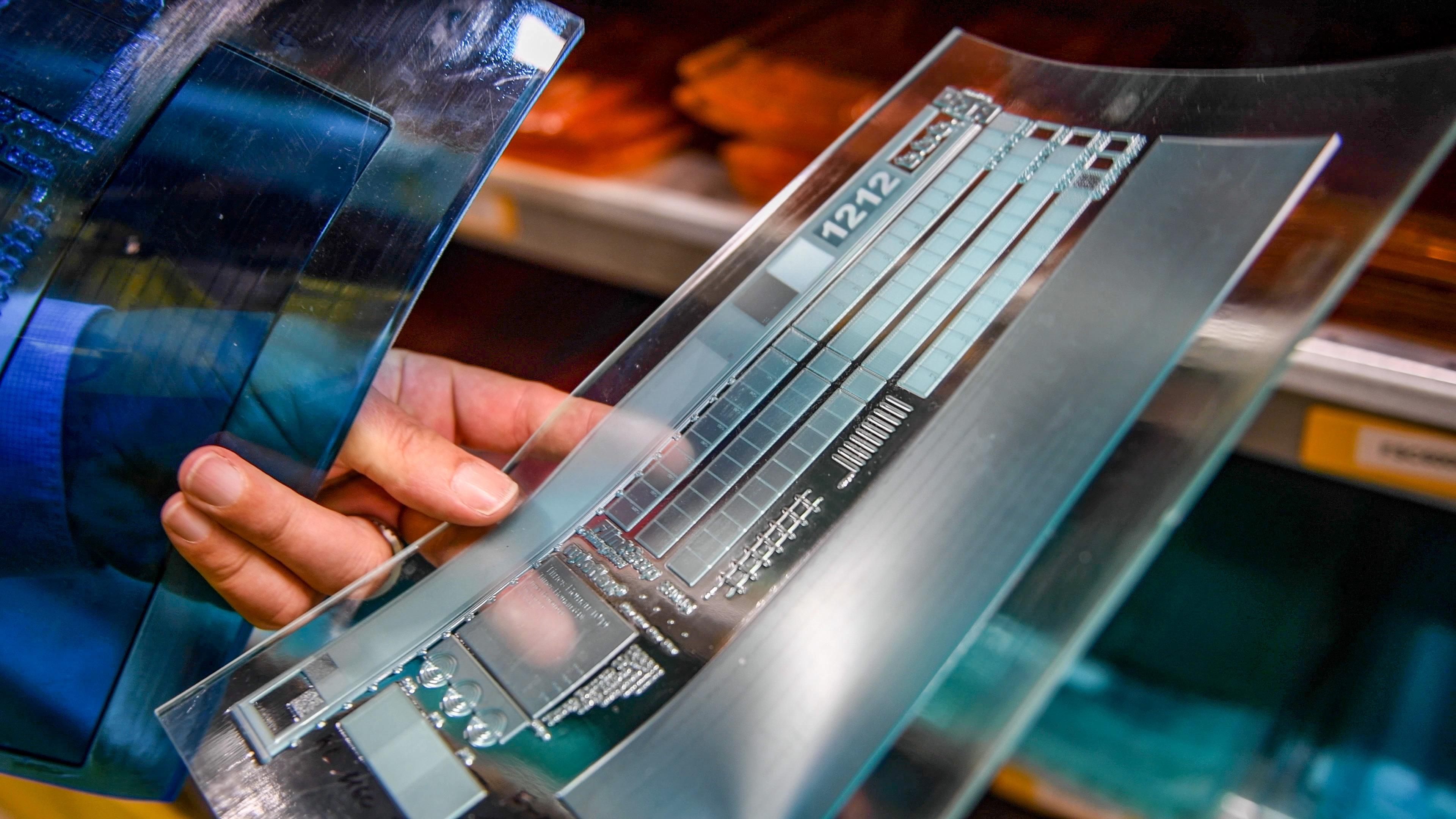

Hard photopolymer flexo plate with inherent flat top dots LED optimized plate formulation

Developed for the high end flexible packaging market Smooth plate surface is able to hold all customized surface screening patterns (e.g. Pixel+ and Woodpecker

+ Highest ink transfer and excellent highlights out of the box

+ Robust and consistent on press, simple to process, already includes flat top dots and a surface screening pattern

+ Optimal for short (quick to color) and long clean print runs (anti ink-filling)

+ Known in the market as THE digital plate for high quality Flexible Packaging Print

+ Excellent print results even under challenging printing conditions

+ Very good for long clean print jobs (anti-ink filling)

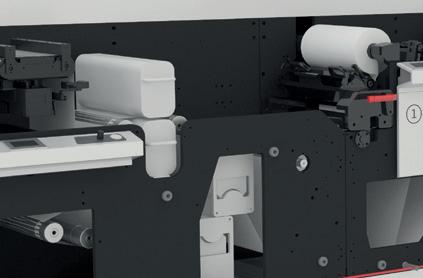

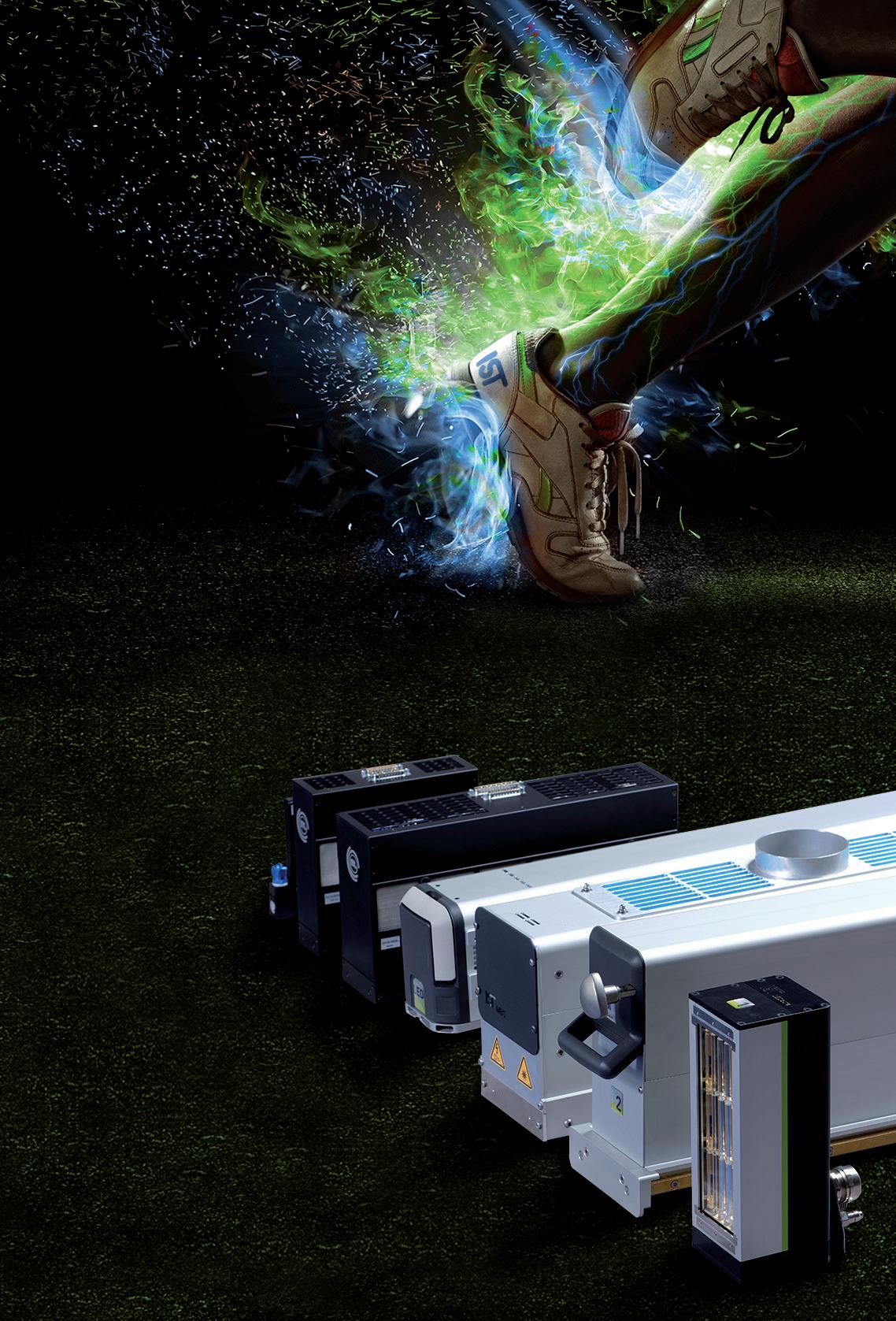

As the industry prepares for the return of Labelexpo Europe 2023 on September 11–14, BOBST lifts the veil on some of the technologies that will greet visitors on its booth at the Brussels Expo.

Under the motto “Simplifying label production”, BOBST will be demonstrating its leading innovation in labels and flexible packaging production with two main production lines in focus. The company is spearheading digitalization, automation, connectivity and sustainability in packaging production with a portfolio that includes flexo, digital and All-inOne presses for the widest variety of applications.

“Innovation in the label industry is shown at its best at Labelexpo,” says Matteo Cardinotti, General Manager and Global Head of BOBST Narrow Mid-Web. “New manufacturing technologies continue to support opportunities that simply were not available before, and we will see more of that at the 2023 edition. BOBST wants to welcome visitors on the booth

to show them how we have the best solutions to the challenges they face in today’s market and for the future, and how we can help create new business opportunities.”

The BOBST DIGITAL MASTER 340 All-in-One modular and upgradable label press, equipped with the latest UV inkjet technology, will be running live at 100 m/min. Visitors will be able to see how BOBST’s ACCUCHECK system, which comes as standard on this machine, performs 100% inline quality control at full speed. The full configuration will also include flexo modules and a highly automated diecutting unit to showcase true end-toend label production.

As converters face manpower shortages and demands for more sustainable solutions, BOBST will highlight

unique automation features that can alleviate these issues. The high-end BOBST MASTER M6 flexo press will demonstrate how oneECG technology for extended color gamut printing and V-Flower printing units enable fast, automatic changeovers of the printing cylinders without stopping the press and with only very minimal waste.

“Labelexpo has always been a major milestone for BOBST, and for converters. For this edition, together with our partners, we will continue to shape the future of label production. We will take you across all the steps required to make labels better and more sustainable than ever,” concludes Cardinotti.

Earlier this year we looked at the shift to more and more work with new substrates in flexography – in How flexographic printing can unlock new packaging potential. Here we focus on three industry perspectives in a series of short interviews…

Innovation with flexographic printing in India: Anand Patel Rising regulation and costs pressures… Anand Patel, Director at Pentaflex, on what’s driving packaging innovation in India and using flexographic printing to deliver on changing brand needs

From your point of view, what’s the main issue driving substrate innovation in India? There was a time when we didn’t talk about different types of substrates with customers at all. But that’s changing. Companies and brands are looking really hard at sustainability.

There’s a sense of urgency because many governments, including in India, are becoming more and more proactive. But India is still fundamentally a volume

driven market, and price is of utmost importance. That’s something that can hinder innovation.

Q. Where have you seen the biggest shifts in substrate use?

Frozen food is maybe the best example. It doesn’t require heavy packaging because it’s stored in a cooler environment. The shelf-life doesn’t come from the packaging itself; it comes from the environment that it’s stored in. So we’ve seen a huge shift there:

I’d say 90% of our frozen food clients are now using only surface printed polyethylene – nothing else. And of course, surface-printed PE is effectively 100% recyclable. That’s one sector where we’ve seen a huge shift. The challenge we have is that for some products – such as a bag of chips, for example, no other packaging is going to offer the same shelf life at the same price point as the traditional laminate structure people are using right now.

Q What are the big challenges in your opinion?

In India, concepts like biodegradability, compostability and recyclability are still very new. Trying to find a way to implement these ideas is going to take time. Waste collection and recyclability are the big challenges here. Just changing the packaging is not going to help unless it is segregated at the user level, collected and recycled. What’s missing at the moment is the financial incentive for the waste to be collected, segregated and recycled properly.

Tracking trends in packaging printing: Laurel Brunner

Laurel Brunner, Managing Director at Digital Dots, on shifts in the flexographic printing industry to single-material packaging and process digitization

Q What’s the biggest change that’s happening right now in the world of packaging?

For me, the move to replace plastics with paper is the big thing. Recycling is obviously important, and the whole awareness of the damage that plastics do is something most big brands are very sensitive about, so they’re trying to move away from that. Products that are traditionally made as complex laminates can now be made with single materials. They still do the job they’re supposed to do, but they use paper – which is recyclable. It’s an interesting area, but it’s still early days.

Q Are there any other trends you’re following?

The other trend that’s important to consider, I think, is flexographic printing with ECG, extending the core CMYK

From my perspective, I’d say the machine consistency needs to be much more precise. Previously, the substrates we used had very wide operating windows, with a lot of variability – whether it’s the plates, the impression, the inks or how your dryers work. You could run your machines all day, limit to limit. Many of the new substrates don’t have those same operating margins, so our machine setup needs to be very precise. It’s usually the shrink wraps, and the Cryovac® low density polyethylenes –those tend to be more challenging in my experience.

Q How are you addressing those challenges?

ink set without having to buy special inks. That’s a big trend because it saves money and it saves waste. But also from a producer point of view, it makes sense because it costs less.

Q Is there a technological development that really stands out for you?

In terms of technology change, the most active area is substrates. Then, I’d say process digitization throughout the packaging supply chain, so that brands and users are more closely connected than ever before. Brands don’t just use the package to communicate information, and consumers don’t expect just to see the package. Everyone expects more.

Q What do you think are the main challenges facing the industry over the next few years?

In general, the challenges are going to be in supply chains and logistics management. One of the biggest problems flexographic printers and brands face is how to manage that supply chain. Do you continue to take the risk of having long, drawn-out supply chains – or do you start looking at shorter supply chains where you have more control and more reliability? The problem with that is often higher costs. I think you’ll see a lot of innovation in using AI and digital technologies to manage supply chains better.

Overcoming substrate challenges with flexographic printing: Rodney Pennings

Rodney Pennings, Director of Sales at PCMC, a global converter equipment manufacturer, on the narrower operating window some substrates have and the flexographic printing advantages in bringing down production costs

Q What are the main challenges for flexographic printers of working with some of the newer substrates on the market?

We’re building a lot of artificial intelligence into our equipment these days, especially around impression and register settings. We actually have algorithms that can look at how the machine is running and tell you when you’re running out of standard. That has two benefits: it helps operators learn more quickly, and allows them to build up from a lower skill set from the start.

Q How can flexographic printing help with that?

Well, the cost is a major benefit. We all know that offset used to have the advantage of higher print qualities. But because of advances in plate technology, and advances in the press performance, like deck stability and precision designs, the quality of print available on a flexographic printing machine is now nearly at the level of, if not the same as, offset.

So when the quality is the same – well, that’s where the economics of flexo really come into their own. That’s causing a lot of people to make the switch.

Q Where do you see the big cost advantages?

For most printers, 50-60% of their ink buy is white ink. So if you can lay it down more evenly, or find ways to use less of it, that’s a win. With Miraclon’s FLEXCEL NX plates, you get a nice, even surface coverage that allows you to get good results with less ink. And if you’re using less ink, it’s going to cost the end customer less to run.

Anand Patel Rodney Pennings Laurel BrunnerKoenig & Bauer Banknote Solutions announced the creation of a new strategic partnership with GIETZ in the domain of OVD application for banknotes. The objectives of this new relationship are defined in a Joint Development Agreement, under which both parties commit to leveraging their respective competencies and technologies to improve and develop OVD application platforms for banknote printers.

The fusion of technologies, expertise, and research in this domain creates a unique opportunity for both organisations to explore and discover new ways to create value for our trusted customers while maintaining the highest standards in OVD application, synonymous with the banknote printing industry.

Hansjörg Gietz, owner and Managing Director of GIETZ, expressed his excitement about this new partnership: "We strongly believe that this partnership will further improve the solutions available for applying holograms onto banknotes and our customers will benefit significantly from the new synergies created.”

Eric Boissonnas, CEO at Koenig & Bauer Banknote Solutions, added to this positive statement by saying; “We extremely proud to welcome GIETZ into our trusted partner family and together we look forward to bringing innovation and new services to our customers.

This partnership reflects the significant level of evolution in the OVD and foil-technology feature space that will require new application solutions to enrich their value contribution to

banknotes. By pooling our expertise and technology, we can ensure that our customers enjoy the application platforms necessary to exploit the very latest developments in OVD technology.”

The new partnership between Koenig & Bauer Banknote Solutions and GIETZ will result in:

- Joint development of an upgraded application machine NotaFoil based on the GIETZ FSA 1060 Foil Commander NOTA technology with Koenig & Bauer Banknote Solutions proprietary inspection, drying, and modular multi-pile delivery systems.

- Koenig & Bauer Banknote Solutions entrusting the joint design and development of an upgrade and

service package for installed OptiNota H machines to GIETZ.

- Common development and distribution of a high speed application platform.to meet future needs.

The technologies developed under this new partnership agreement will be distributed globally by Koenig & Bauer Banknote Solutions (excluding Japan). Thomas Hendle, Head of Sales and Managing Director at Koenig & Bauer Banknote Solutions, declared: "We are partnering with GIETZ to maximise value creation for our customers. OVD application is a core component in our process offering and by exploring new approaches and technologies together, we can support our customers to achieve success.”

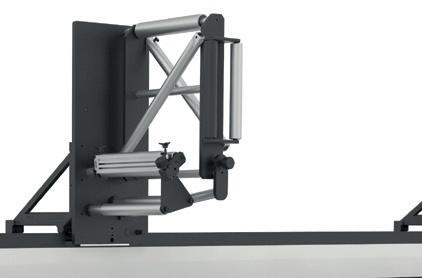

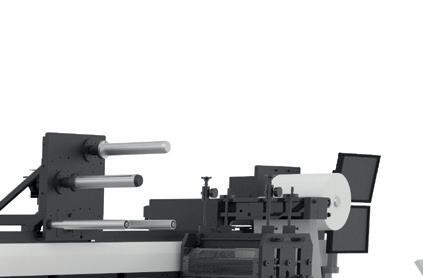

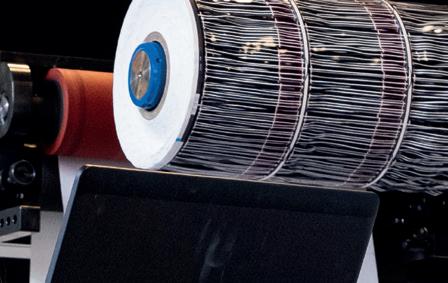

confirms the sale of a new 530mm, 10-color MPS EF next generation fully automated flexographic press to Meyers, the fourth MPS machine added to their production facility. The MPS EF next generation press brings narrow web flexo printing to the 21st century with 24/7 data collection and feedback. By embracing the full potential of IoT, the EF helps MPS customers optimize production by identifying possible bottle necks and automatically suggesting areas for improvement.