4 minute read

Remote Fitness Check" helps Chinese customer

In the business world today, there are endless challenges from external and internal factors such as; shifting market trends, government policies, pressure to meet production capacity, daily operations, the list goes on.

Therefore, it is extremely important to have a long term and reliable business partner who can assist you to overcome the challenges together in keeping business sustainable and achieving success. The partnership of Heidelberg and Masterwork is an excellent example.

Advertisement

Masterwork Machinery Co. (MK), Heidelberg’s worldwide partner of choice for post-press packaging equipment was founded in 1995. MK has been focusing on both manufacturing and innovative R&D for die-cutting, hot-foil stamping and carton gluing equipment. The factory is based in Tianjin with a 90,000 sqm facility, employing approximately 900 staff and producing over 500 machines annually.

The ever-developing technology enables MK to provide comprehensive and professional solutions to customers in tobacco, pharmaceutical, cosmetic, food and electronic packaging industries.

In 2015, the strategic partnership between Heidelberg and MK in the post-press packaging market segment took off with immediate success, selling and installing 10 machines at customer sites in the first 6 months. The market has benefited from the partnership which offers high quality products with a very attractive price-performance ratio, produced by MK and sold and serviced by the Heidelberg global sales channel.

“Together and better” is the partners’ slogan for a winning team. In the first 18 months, the close collaboration of the two companies saw the development of the Easymatrix and Promatrix die-cutters as well as the Diana Smart folding carton gluing machines. Heidelberg also shared a substantial area of their DRUPA 2016 booth with MK, showing new products for the first time. Subsequently we have participated in many events such as Heidelberg’s Packaging Days and numerous local exhibitions.

Fighting the COVID-19 crisis, early in March 2020 with great work from the innovative R&D and production

The Easymatrix 106 C,

teams, MK successfully launched the Maskmatrix 200 automatic mask making machine.Capable of producing between 50-140 masks per minute, the Maskmatrix 200 was immediately successful with sales in many countries. During the same period, MK also donated 100,000 disposable masks to Heidelberg offices to ensure the employees of their business partners were protected.

MK, as the top packaging equipment manufacturer in China and second biggest manufacturer internationally, has further strengthened the partnership with Heidelberg by acquiring an 8.5% stake in Heidelberg, making it the largest private shareholder. We strongly believe that the partnership of the two manufacturers will benefit our customer’s needs for reliable, safe and affordable equipment.

Rapid change in the graphic arts industry has seen reduced run lengths per print job. A lot of short-run jobs of today’s commercial printers must be processed with very tight deadlines.

Most commercial printers have for many years utilized old Heidelberg Cylinder or Platten presses for cutting and creasing.

This is no longer an effective and costefficient way. With commercial printers also looking into producing packaging work the logical answer is the purchase of an Easymatrix Diecutter.

The Easymatrix 106 C, Heidelberg’s best-selling postpress packaging machine from MK, is a highly flexible die-cutting machine which accepts a wide range of substrates from 90 gsm – 2,000 gsm and up to 4mm corrugated board. It can process sheets between max. 750 x 1060 mm and min. 360 x 400 mm or – optional - 300 x 350 mm. Quick adjustment of feeder head, central adjustment on feed table, Quick-Lock and fine adjustments on both cutting and stripping station make the Easymatrix the ideal solution for short run jobs, while non-stop feeder and delivery allow non-stop operation for medium and long run production. Stripping functionality is an option which is often ordered by customers with a considerable share of folding carton production.

With its sturdy design the Easymatrix runs up to 7,700 sheets/hour production speed. Equipped with registration system it continuously delivers high production output without compromising quality. The optional suction belt on the feed table enables smooth transfer of thin substrate while the motorized pressure setting ensures precise cutting pressure for high quality production and longevity of tooling.

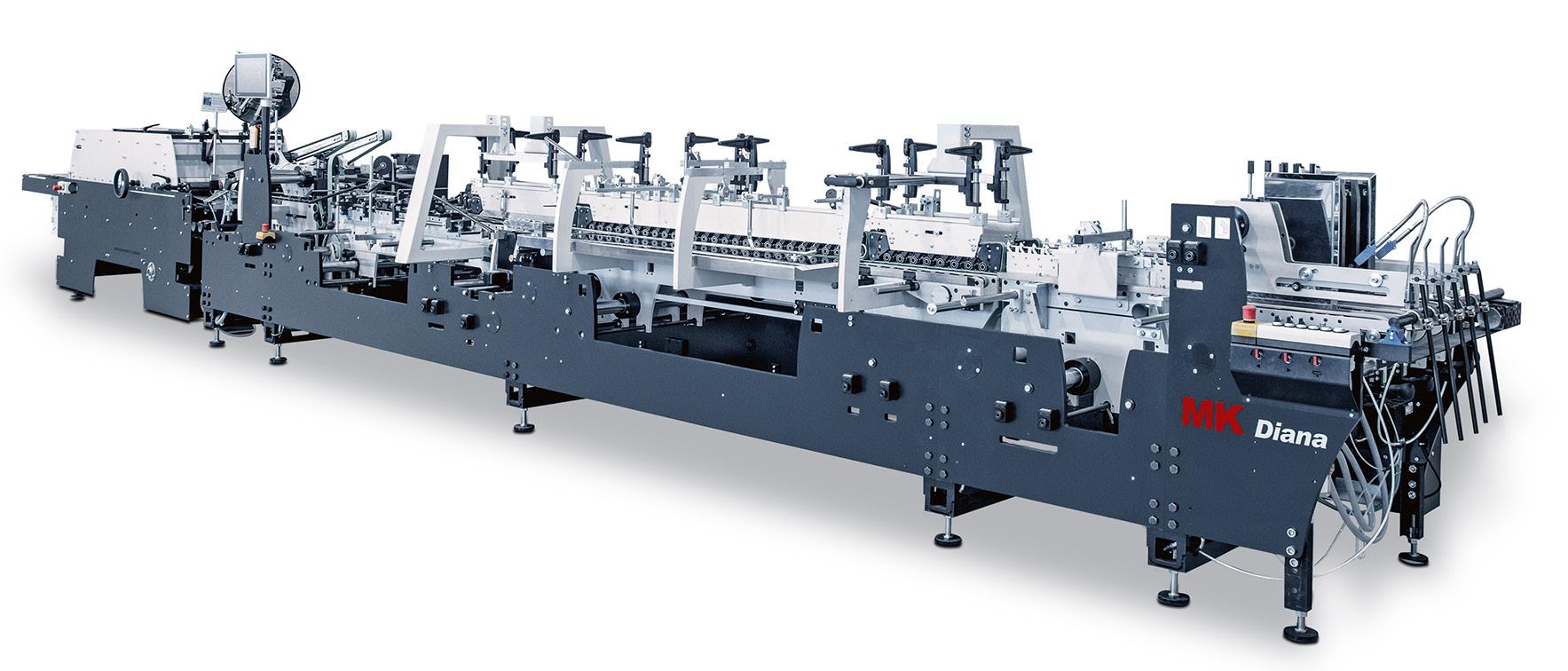

The Diana Go 85 with its working width between 70 to 850 mm, is a highly flexible folding carton gluing machine which allows processing of substrates between 200 gsm – 600 gsm into straight line or lock-bottom boxes.

Diana Go 85

With optional attachments, applications such as mailing envelopes, CD sleeves, double-wall cartons or straight-line cartons with a minimum blank width of 45mm are also possible. By means of the touch screen system that stores job data and setup parameters, make ready times are greatly reduced.

The Diana Go 85 is compact, less than 10 meters long. The strong side frame and feeder design ensures a stable maximum production speed of 250m/min or optional 300m/min. The Jagenberg-design folding section uses left before right folding principle hence leaving no room to lose control of the blank, even at high speed. Before the delivery, the variable speed pulley with lever ensures the final fold is accurate.

MK equipment sold by Heidelberg is GS-certified and built to last. The user-friendly operator interfaces of the Easymatrix 106 and the Diana Go 85 make both machines easy to handle.

High productivity can be achieved after a short operator training period which is provided by the proven Heidelberg service organization.