“All

“All

By Amy Kyllo amy.k@star-pub.com

ROCHESTER, Minn. — Ensuring employees feel valued and understand the signicance of their work was an employee retention tip shared during a panel-style seminar entitled “Keys to Building and Retaining Your Team of Successful Employees.”

The seminar was held during the Form-A-Feed Dairy Conference Jan. 16-17 at the Mayo Civic Center in Rochester.

“If you care about people, they’ll care a lot more about what they’re doing,” said Andrew LeClair, one of the panelists. “Everybody’s the same, whether you’re the owner or whether you’re a milker. Whatever you’re doing, we’re all people.”

LeClair is a manager at Enchanted Dairy near Little Falls. There, they milk 2,000 cows in a rotary parlor with 20 employees. Another panelist was Hans Breitenmoser, who owns Breitenmoser Family Farm near Merrill, Wisconsin, where they milk 500 cows and have 16 employees. The nal panelist was Abe Sanchez, a manager at D&D Dairy near Rushford where they milk 1,000 cows and have 10 employees. The panel was moderated by Mario Solis Flores of Form-A-Feed Inc.

Good employees worthy of promotion are teachable, the panelists said. Breitenmoser said much on his farm is learnable, but employees must understand that their new role may mean a greater amount of responsibility.

“You never know who your rock star is going to be,” Breitenmoser said. “People have shown up and innocently wanted a milking job, and then 15 years later, they’re running day-to-day operations.”

LeClair agreed.

“It’s people that have a desire to learn, people that have a desire to do a good job and that want to know more,” he said. “Some people are that way, and some people are not.”

By Stacey Smart stacey.s@dairystar.com

OOSTBURG, Wis. —

When Scott Hesselink was in his early 20s, it appeared he was destined for a career in mechanics. He went to school for auto-body repair and favored working in a body shop over being a dairy farmer.

“I love cars and motorcycles and had an interest in other things,” Scott said.

However, he was back to the farm in a full-time manner by the time he was 25. Scott joined his dad, Mark, and his two brothers when his father offered him an opportunity to come home. Now, Scott is the sixth generation running Quonset Farms with his wife, Lisa.

Turn to HESSELINK | Page 6

STACEY SMART/DAIRY STAR

Sco� and Lisa Hesselink take a break in the farm office Jan. 9 at Quonset Farms near Oostburg, Wisconsin. Sco� is the sixth genera�on on his family’s farm where they milk 1,075 cows and farm about 1,500 acres.

beck’s farm near Sauk Centre, Minnesota. Wolbeck milks 65 cows. Some areas of Minnesota received over 10 inches of snow during the snowstorm.

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, SD, Nebraska) 605-864-7917 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Keya Sleister (Eastern IA, Southwest WI, IL) 563-608-5988 • keya.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute

nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy

By Emily Breth emily.b@star-pub.com

The number of dairy farms has been decreasing at a steady rate. But in 2024, the rate of decline slowed in Minnesota according to Nicole Neeser, DVM, division director of dairy and meat inspection with the Minnesota Department of Agriculture.

Neeser said MDA tracks dairy farm permit numbers as a part of their work inspecting dairy farms and ensuring all dairy farms are following pasteurized milk requirements.

“I think the Minnesota dairy industry will continue to see some farm numbers decline,” Neeser said. “Many of the farms we’re seeing go out of business are from retirement or farmers that are done with dairy farming and maybe moving on to a different kind of farming.”

Dairy numbers across the Midwest have ranged in the last years. In January, Minnesota ended with over 1,700 dairy farms, Iowa had a total of 854, South Dakota had 134, Nebraska had 78 and North Dakota had 23.

Currently, Minnesota’s dairy numbers are lower than past years and still decreasing. In the last six months, Minnesota saw a decrease in dairy farm numbers of close to 100. From October to December 2024, all counties in Minnesota had lost farms or remained the same.

However, this number includes seasonal farms, such as goat herds, that quit milking in the winter. As these herds start their kidding seasons and come back onto the market the dairy numbers will begin to increase. With this, Neeser said July offers the most accurate number of dairy farms.

Goat herds provide a positive outlook on dairy farm numbers Neeser said. More dairy goat herds are being added around Minnesota.

“I think the goat milk market continues to grow and that has an impact in terms of the number of farms there are,” Neeser said.

One of the biggest changes Neeser said she expects to see relates to the number of Grade B bovine dairy farms. The latest numbers as of Jan. 24 showed less than 20 dairy farms under this category. The reason this is happening Neeser said is because of market pressure, where pro-

cessing plants want to have a uniform milk source.

Here, dairy goats are keeping Grade B milk numbers up. Neeser said there are around 100 goat dairies in the Grade B category when they are all active.

The top dairy counties in Minnesota, as of December 2024, include Stearns with 328, Todd with 126 and Morrison with 118. The top dairy counties for Iowa are Dubuque with 98, Johnson County with 81 and Clayton with 74. Nebraska’s top counties were Cedar with 12, and Antelope, Jefferson, Lancaster and Wayne with ve each. The top counties in South Dakota included Minnehaha, Brookings and Grant.

Even with farm numbers decreasing, the dairy industry is keeping production levels similar. This is through the expanding of dairy farms, the building of new facilities with larger herds and the increased production of herds.

Each year dairy farmers are faced with challenges in order to keep dairying. Economics plays a major role in whether a dairy farm will survive and continue. Between cost of production and market prices, they have to remain protable even when prices are low.

“In general, we are seeing a decline (in farm numbers) but the decline has not been as steep as previous years,” Neeser said.

The optimal hoofcare program uses a mat and a automated pump for the application of

Central placement at the exit of the milking area ensures that cows pass over the mat regularly for automated hoof care.

• Skin care for healthy claws

• Ensures good adhesion to the claw

• pH-neutral

• Contains natural extracts (propolis)

• Optimised for the MS AutoHoofClean System • Environmentally friendly

Sanchez said employees are expected to be on time, respect the animals, do their best for the cows, and to be capable of learning and especially listening.

“Every farm, it’s different,” he said. “It doesn’t matter if you know a lot or how you used to do the work. You have to listen to your new boss … and respect the rules.”

When it comes to promoting, Sanchez said he works alongside his employees every day and sees those who have potential. When an opening for advancement comes, he offers it to them rst.

LeClair said he has seen that employees who appreciate step-by-step structure are those who transition into management roles better. He said this mindset helps them present and justify their decisions to those they work with.

Breitenmoser said it can be a juggling act to make sure employees are encouraged to

broaden their horizons through advancement while simultaneously nding a place for them to be able to grow.

“Looking back over the past 25 years … it was really just a matter of identifying people who wanted more responsibility, and then who were actually able to take more responsibility,” he said.

“There’s people who want more responsibility, sometimes because they understand that it comes with a bigger paycheck, but are incapable of handling any more responsibility.”

Breitenmoser’s farm has a raise schedule tied to quarterly reviews. Employees are evaluated on areas such as following protocols and getting along with coworkers. A manager communicates expectations with employees beforehand so they know what they need to work on to earn their raise.

“It formalizes things and gives people a path forward,” Breitenmoser said. “They can

look at their situation and say, ‘OK I know that at minimum, I’ll be making $1 more in a year from now, assuming I do all these things.’”

Though employees must meet the requirements across the categories, Breitenmoser said there is exibility. Breitenmoser uses a 3-strike system for ring so employees know where they stand.

LeClair said they use a at pay scale for positions. Cross training is how employees can make more money.

“Pay is something that will draw people in to a point,” LeClair said. “People lose motivation very quickly if their only motivation is pay. … A person that’s driven, a person that wants to be successful, a person that wants to do a good job, will do it for $13 or they’ll do it for $12 or they’ll do it for $15.”

Part of LeClair’s retention strategy is to become connected with his employees and

make sure they feel valued.

“The people that I deal with and I talk to every single day are the people that I want to know everything about,” he said. “I want to know how your family is doing. I want to know if you’re struggling. I want to know if you’re happy, if you’re sad. … It takes a lot of time and effort, but if that person ever decides to leave, I want that to be the hardest decision that person makes.”

Breitenmoser utilizes monthly meetings with Mario Solis Flores on his farm to train his employees, rafe free swag from ag companies and give employees a place to voice frustrations.

“It allows people to vent,” Breitenmoser said. “It’s that safe space to get input from employees. … It’s a very formal thing that they know that once a month we’re going to have this meeting.”

These trainings are also an added value for employees.

“They understand that whatever they learn is theirs,” he said. “Nobody can take that away from them. So, if they decide to move on and go to work for somebody else, that’s information and education that they have.”

Breitenmoser said his favorite part of managing is watching his employees grow into a role and excel.

Sanchez said his advice to leaders is to keep working hard.

“Do your best and never give up,” he said. “Success doesn’t come alone. It is built step by step.”

LeClair agreed.

“It’s not all up to you to do everything,” he said. “Surrounding yourself with people that you can trust, that you can bounce ideas off of, that you can talk to about everything is extremely important. The more you isolate yourself, the more weight goes on your shoulders.”

“Scott was the least likely one to take over the farm,” Mark said.

The Hesselinks milk 1,075 cows three times a day in a double-15 parallel parlor and farm about 1,500 acres near Oostburg. The family also buys crops off the eld from several neighbors. Heifers are sent to a custom raiser when they are a couple of days old and return home pregnant.

“Our rst goal is producing the highest quality milk we can,” Lisa said. “Our parlor manager works hard to ensure that. Caring for our animals, our employees and our land is a priority.”

Quonset Farms is backed by nearly 180 years of history. When Scott’s ancestors arrived from the Netherlands in 1847, they purchased 40 acres where the current farm sits and another 40 acres to the west. The original deeds, signed by Presidents James Polk and Zachary Taylor, hang on the farm’s ofce wall.

The farm was named for the Quonset barn Scott’s grandpa bought after the farm’s original barn burnt down in 1941.

“It was World War II, and my grandpa could only get a Quonset barn at the time,” Scott said. “It has a round roof. My grandpa thought if he gave the farm a name like that, no matter who owned it, the name would stay.”

The Hesselinks use the Quonset barn to this day as a hospital barn. The Quonset roof has since been replaced with a regular truss roof and the barn remodeled and repurposed many times to t the family’s needs. It originally contained 20 stanchions.

“I can remember milking up to 120 cows in this barn,” Scott said.

The Hesselinks moved to freestall housing in the early 1970s and built their rst parlor in 1980 — a Trigon herringbone. In 2005, they gutted the parlor and put in new equipment to make the farm’s current double-15.

Today, Scott is the only brother farming after losing his brother and business partner, Ben Hesselink, to cancer May 23, 2022. Ben was 48.

“It’s amazing how some dates stick out in your head,” Scott said. “October 3, 2020, was the last day that Ben really did anything physi-

cal on the farm. We had started hauling manure, and he tried driving the truck for a couple of days, but he was in so much pain, he had to stop. He hadn’t been diagnosed yet. He had been complaining about back pain all summer. He had back pain before, but this was different.”

A blood test revealed Ben had multiple myeloma — a blood cancer that develops in plasma cells in the bone marrow. As he took over the work Ben had been doing, Scott’s role on the farm shifted from working primarily in the farm’s shop as head of maintenance doing repairs to managing crops and spending time in the ofce.

“We have a lot of really good employees who helped us through,” Lisa said.

Scott also had to take on more of a management role on the farm. Lisa shares this role with Scott, spending much of her time in the ofce. The pair has become the key decisionmakers at Quonset Farms, which is now a three-way partnership consisting of Ben’s trust, Scott, and Mark, who is 83 and continues to help on the farm.

The family has known its share of hardship. Scott also lost a sister in 2006 from multiple sclerosis.

“I’ve lost two children already,” Mark said. “But it’s OK. I know where they are, and they gave me four beautiful grandchildren.”

Ben left behind twin sons, Garret and Wyatt, who are now 13 years old.

“Ben would have liked to see his boys take over the farm, but he knew how many hours it takes to run a farm and that there are easier ways to make a living,” Scott said. “He didn’t want to push them into farming.”

The brothers started farming together in 1994 after Ben spent 3.5 years serving in the U.S. Army. In the late 90s, the brothers became partners in the operation with their dad and an older brother who was later removed from the partnership.

Scott said he and Ben were close, and that the two brothers, along with Lisa, did everything together.

The Hesselinks built their third freestall barn in 2015 and grew the herd to its current size. Expansion was driven by a need to support four families Scott said.

“My brothers wanted to expand more than I did,” he said. “I wanted to stay the same size and farm with no debt.”

In 2021, the Hesselinks’ faithful herd manager of 47 years retired, leaving another hole in the team.

“It was really challenging between the combination of Ben getting sick, losing him and nding a new herd manager,” Scott said. “The past four years were pretty challenging.”

The Hesselinks have 24 full-time and seven part-time or seasonal employees, including many long-term people that Scott said have become like family.

“Those are the people who keep us going,” Lisa said. “We have dedicated, high-skilled employees. We focus on how we treat people and try to make this a good place to work. That’s important to us.”

Lisa said they use a lot of technology on the farm, especially in the parlors, in their feeding program, and for monitoring cow health.

“Over the past several years on

the cow end of it, we started implementing new technologies and seeing the benets of those,” Scott said. “It has become easier to manage herd health.”

Improvements in cow health, milk production, and feed efciency are where the Hesselinks are seeing the biggest gains. By implementing smaXtec boluses for cow monitoring, sick cows are brought to their attention before showing physical symptoms.

“Cows are healthier for it,” Lisa said. “When it comes to calving, we know well in advance and are ready.”

The Hesselinks bed their cows with a paper byproduct.

“Cows love it,” Scott said. “It’s soft, like cotton, and cows are comfortable. If we wouldn’t use it for bedding, all that paper would be going to landlls.”

Like the longstanding Quonset barn the farm is named after, Quonset Farms is a picture of longevity. Despite adversity, the Hesselinks endure and are continually making updates as they press on into the future.

“It seems we’re always doing little things to improve,” Scott said. “We constantly try to do better.”

By Tiffany Klaphake tiffany.k@dairystar.com

FREEPORT, Minn. — When Tyler Roerick was in high school, he had zero intentions of returning to the home farm. After one year of college, that all changed.

“I relief milked for a few other farmers on weekends and, once in a while, during the week,” Tyler said. “It made me realize how nice it is to be your own boss and have that exible schedule, and yes, you have your daily chores, but there is a lot of other stuff that needs to get done in a day.”

At the time, Tyler was going to Alexandria Technical & Community College for carpentry, with intentions of being his own contractor.

After Tyler’s rst year of college, his uncle, Gerald Roerick, who farms with Tyler’s dad, Allen Roerick, announced he would like to retire from the dairy portion of the operation within the next few years. The brothers milked 80 cows near Freeport.

“Gerald wanted to sell the cows, but I wasn’t ready to retire yet and I didn’t want to do anything else,” Allen said. “Tyler had mentioned a few months prior that he was interested

became part owner of his family’s farm Feb. 1, 2024.

in coming back.”

After Tyler graduated from college in 2019, he did construction full time and helped on the farm when he could. As of Feb. 1, 2024, Tyler is ofcially part owner in the Roerick family farm.

“It just worked out that they were able to bring me into the farm when Gerald wanted out of the farm,” Ty-

ler said.

For now, Tyler owns 25% of the cows, youngstock, hay equipment, chopping equipment and about half of the tractors. Allen owns the other 75%, and the land is still owned 50/50 between Gerald and Allen.

Tyler is milking mornings and evenings. Since joining the farm, he switched to part-time at his construction job with Worms Lumber and Ready Mix Inc., based out of New Munich. On top of those two jobs, Tyler started his own custom bale wrapping business in 2020.

“In 2019, we struggled making hay,” Tyler said. “I saw an opportunity to start (the custom bale wrapping business) and went with it. It was slow the rst year; then, 2023

was a drought, and then, last year, I couldn’t keep up with the business.”

Last summer was busy for Tyler as he and his wife, Katie, welcomed their rst child. Most of Tyler’s days would start at 4 in the morning with a drive to the farm where he would milk cows. Once morning chores were nished, he would drive to town and work at his construction job until it was time to milk cows again.

“There is something about being on the farm working that is different than being on a job site and working,” Tyler said.

In the summer, Tyler works four days a week with the construction job in order to have more time on the farm and for his custom bale wrapping business. When it was time to make hay, Tyler would take the week off from his job in town to make hay at his family’s farm and wrap bales for farmers in the area.

“Last year, I did 3,000 bales by the Fourth of July,” Tyler said. “That was more than I did all of the year before.”

Tyler’s brother, Carter, who is currently attending Ridgewater College, is set to graduate this spring with a degree in dairy management and has intentions of returning to the home farm. In the meantime, he helps throughout the summer and as often as he can when he is home from college.

“We have a group chat between us (Allen, Carter and Tyler),” Tyler said. “If one of us is running late or needs some help with something, we can gure it out pretty easily.”

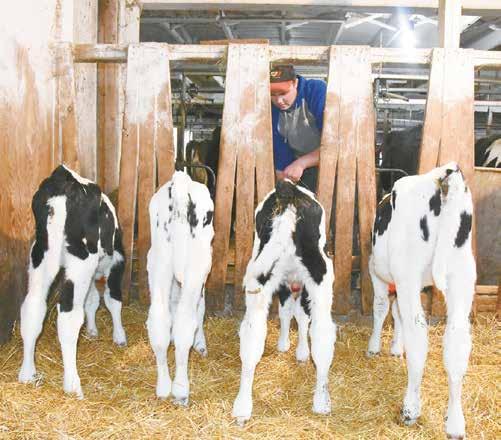

The three men help each other as needed, but each has their set of tasks around the farm. Tyler took over taking care of the calves and young-

stock; he helps with eld work and has his bale wrapping business. Carter takes care of the pre-fresh heifers and cow health. Allen and Gerald take care of the crops.

“I let the boys do some of the jobs I used to do, like treating fresh cows and the majority of the cow health stuff,” Allen said. “It’s nice that I can get a little more time off if I’m working on something else, I know that chores will always be taken care of.”

Tyler has a lot of tasks that he has to get done in day but said he feels good about his accomplishments.

“I own 25% of the cows, and that means a lot because, if you look what I have versus most 25-year-olds who I went to high school with, it’s a lot more in the long run,” Tyler said. “They go on trips and stuff, but my vacation is driving tractor.”

Over the years, the Roericks century farm in which Tyler is the fourth generation has seen many small changes to make things easier for the family members. Advancements such as making a heifer shed bigger so they can drive a skid loader through it and purchasing a feed cart for their tiestall barn have all benetted the dairy.

“I have done chores at other farms, and when you

come back home, you realize that the advancements and the money you stuck back into the farm can make farming that much easier,” Tyler said.

Throughout college and even today, Tyler assists other farmers when he can.

“I enjoy helping other people,” Tyler said. “It is helpful to see how other

farmers do things.”

Tyler said there are many aspects of farming he enjoys, especially being able to raise his family on the farm.

“The goal is to be full

Stop in for lunch and some amazing discounts!

time on the farm, and the hope is, with kids, to have them on the farm with me just like we were when we were little,” Tyler said.

The House Ways and Means Committee focused on expanding trade at Tuesday’s hearing. Former agricultural trade ambassador Gregg Doud, who is now the president and CEO of the National Milk Producers Federation, spoke about the importance of trade enforcement. Doud said 44% of U.S. dairy exports are shipped to our neighbors in Canada and Mexico. “Mexico has largely been a positive trading partner, Canada has not,” Doud said. “Unfortunately, Canada has a long history of attempting to undermine previously agreed-to market access, a trend that has continued under Unites States-Mexico-Canada Agreement. Through manipulative tariff rate quota policies and a systemic circumvention of USMCA’s dairy protein export disciplines, Canada has cheated U.S. exporters out of market access benets promised to them under the agreements and has tried to dispose of growing volumes of articially low-priced dairy protein into global markets.” Doud testied the 2026 USMCA review represents a critical opportunity for Canada to reform these practices.

Trade gap is “pathetic”

sponse to avian u and their ability to process farm loans, disaster relief and farm assistance.

Economic relief on the way

Speaking at the Ag Outlook Forum, Rollins said USDA plans to release the farm assistance payments by the congressional deadline of March 21. At the end of 2024, Congress passed $10 billion in ad hoc assistance within the overall disaster aid package.

an emergency funding bill for inclusion in the committee’s budget bill. This bill calls for a $1.5 million appropriation from the general fund for an agricultural emergency account to address avian u and other animal health diseases.

By Don Wick Columnist Ag Insider

Speaking at the U. S./ Department of Agriculture’s Agricultural Outlook Forum, Doud emphasized the need for a more aggressive U.S. trade policy, particularly in closing the agricultural trade gap with the European Union. “We import $3 billion in dairy from the European Union and we export $167 million to the European Union; that’s pathetic,” said Doud. “We export 15 times more cheese to Guatemala than we do the European Union. We export more cheese to New Zealand and they’re a major (dairy) exporter with 5 million people.” Doud, who is the former chief agricultural trade negotiator, said the U.S. agricultural trade decit with the EU today is $23.6 billion. He pointed to the $8 billion investment in U.S. dairy processing as evidence of the industry’s potential for growth.

Senate Dems challenge mass layoffs at USDA

Ranking member Amy Klobuchar and every Democratic member of the Senate Agriculture Committee are asking Agriculture Secretary Brooke Rollins for more information on the termination of numerous USDA employees. They want a breakdown by state, agency, job position and veteran status. The letter said these layoffs jeopardize the USDA re-

What are some of the DHIA tests you

Greer conrmed

The Trump administration’s new point person on trade was conrmed by the U.S. Senate with a 56-43 vote. Jamieson Greer is an attorney who specializes in international trade. He previously served as chief of staff to former U.S. Trade Representative Robert Lighthizer.

Time to look under the hood of government

With the national debt at more than $36 trillion, Minnesota Representative Brad Finstad says it’s more important than ever to get a balanced budget. The budget resolution passed this past week is a 40-page document that provides nancial targets for each committee. Finstad said the committees will now work on this process over the next few months. That includes conversations with their constituents. “What programs are working?” Finstad said. “What programs aren’t? Where can we tighten our belt? Where can we become more efcient? Where can we look under the hood of government and not only look at the engine but gure out if the fuel injectors work, is the exhaust hooked up, did we check the oil, is the dipstick showing oil in the engine? That’s really what the committee process will be about.”

Elanco and Medgene partnering on H5N1 vaccine for dairy cattle

A new avian inuenza vaccine for dairy cattle is moving one step closer to commercialization. Elanco Animal Health has an agreement with Medgene, based in Brookings, South Dakota, to bring this vaccine to market. The USDA has already approved Medgene’s vaccine technology platform in cattle, allowing the accelerated development of the H5N1 vaccine. Medgene has existing vaccine supplies to deploy for this purpose. The product is in the nal stages of review for conditional license approval.

Minnesota legislature working on ag emergency funding

The Minnesota House Agriculture Committee laid over

Other than the standard reports, we also receive pregnancy results.

Which is your favorite and why? The pregnancy report is very useful to keep our calving interval where we would like it.

How do you use them within your dairy? We use the production and SCC reports for culling decisions and use the fat, protein, and MUN reports to evaluate feed ration changes.

How long have you been using the DHIA pregnancy test? We have been using the milk pregnancy test for about two years.

What do you like about the DHIA Pregnancy Tests? It’s nice to be able to do the pregnancy test without any extra time or labor.

How does testing with DHIA bene t your dairy operation? We also use the individual somatic cell count scores. This helps us keep our SCC low so that we can receive quality premiums from our co-op.

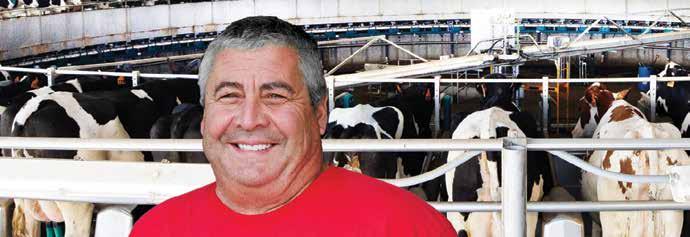

Tell us about your farm. We milk 95 cows and raise all of our replacements. The cows are housed in sand bedded freestalls and milked in a double 5 parlor. We also have a 40-cow beef herd and raise chickens for Pilgrims Pride. Our farm was started by my father and grandfather in 1937. Two of our children and most of the grandkids work on the farm.

A proposed increase in funding for farm business management Representative Nathan Nelson is sponsoring legislation that would boost funding for the Minnesota Agricultural Education Leadership Council from $4.5 million to $6 million in the 2026-2027 biennium. Funding would be prioritized for faculty with expertise in farm transition planning, rural mental health and growing specialty crops in urban areas. Northern Agricultural Center of Excellence Executive Director Keith Olander gave a presentation on the farm business management program. The House Agriculture Committee laid the bill over for consideration in its budget bill.

Milk production edges higher

Milk production in the 24 major dairy states totaled just over 18 billion pounds in January. That’s up 0.2% from one year ago. South Dakota milk production rose 6.5% with a 7,000-head increase in cow numbers. In Minnesota, January milk output is down a fraction of 1%. Cow numbers are down 9,000 head over the past year.

No cows needed

Lab-grown meat has made headlines in recent years, but the world’s rst lab-grown cow’s milk may soon be coming to market. A Boston company is producing what is called UnReal Milk. Rather than coming from a cow, this product is made from cell cultures. It reportedly replicates the taste, texture and nutrition of dairy milk and is billed as a lowercarbon, cruelty-free alternative.

Trivia challenge

National FFA Week began in 1948. That answers our last trivia question. For this week’s trivia, what is the home state for Agriculture Secretary Brooke Rollins? We’ll have the answer in our next edition of the Dairy Star. Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

By Sarah Middendorf sarah.m@star-pub.com

PAYNESVILLE, Minn. — Producers undecided about automation recently had the opportunity to learn the good and bad from dairy producers who had already made the switch.

During the “Milking Robots: Are they the future?” meeting Feb. 26 at Shady’s 55 Pub & Event Center in Paynesville, owners and employees of three dairy farms shared their experiences integrating robotic milking units.

“One big difference, when we were in the parlor (was) we used to push the cows,” said Stephen Roerick, one of the producer panelists. “Now (with the robots) we walk around the cows.”

Roerview Dairy, near Upsala, is owned and operated by Roger and Diane Roerick and their sons — Craig and his wife, Sarah, and Stephen and his wife, Amanda. They built their milking

barn in 2015 with three robotic milking units.

Merryville Farm LLC near Waverly, is owned by brothers Bill and Steve Uter. In 2020, they added four robots to the front of their existing freestall barn. Their barn is a guided ow. They milk their fresh cows, heifers and sick cows in a parlor.

Green Waves Farm near St. Micheal, Minnesota, is owned by David Berning and his dad, Mark. They built their barn in 2015 with four robotic milking units. In 2017, they decided to expand and now have eight robotic milking units. They have four rows of pens with the robots on one side of each pen. The design is the same on each side of the barn. They pre-train their heifers roughly 2-3 weeks prior to calving.

“The cow has to be comfortable standing in the robot, then she has to learn to go in on her own,” Berning said. “Then she has to learn to be nice while she’s in there. If we can accomplish the rst two before she calves, it’s not that big of a change for her when it comes time to start milking.”

Turn to ROBOT PANEL | Page 12

When looking at the robot information, Roerview Dairy watches milkings per cow, refusals, total visits, milking components and bunk management. Roerview Dairy and Merryville Farm have made a point to watch solids production per cow per day.

“We’ve really geared ourselves towards managing components,” Craig said. “We don’t get too worked up about the total pounds of milk we are producing out of the barn.”

When it comes to robotic milking unit maintenance, all three farms do as much of their own maintenance on the robots as they can, aside from scheduled maintenance.

“We try not to call out the technicians,” Stephen said. “A part on the back shelf will save you a lot of down time.”

Berning agreed.

“(Robot calls) are not that big of a deal, if you take care of your equipment; it should work the way it needs to,” Berning said. “Take care of your things and they will take care of you.”

Each farm has different management tactics for hoof care. Each farm has a foot bath, but they are located in different parts of the barn — either right out of the robot or on the opposite side of the robots.

Berning bought a used chute and trained himself how to trim hooves. They still have a scheduled hoof trimmer, but when they get a lame cow, he can x the problem right away. He also can use this for drying

ing Robots: are they the future?’

off certain cows.

“One challenge with robots that you might not think of is drying off cows can be a bit of a pain,” Berning said. “They’re not used to being touched by human hands.”

The panelists also talked about labor with robots.

Though their farms look different, they said robots do not take away all the labor for milking cows, they just change what is being done.

“Instead of milking cows for eight hours, we’re focusing on other areas to improve our cows,” Berning said. “It’s

not necessarily less labor, but it gives some exibility.”

Uter agreed.

“It’s your management style, whatever you put into it you’re going to get out of it,” Uter said.

During the panel, an audience member asked about milking rst lactation cows in the robots and how they handle them.

“Heifers are kind of like kids; they all have different personalities,” Stephen said.

Berning agreed.

He said, some heifers are two-person jobs. However, the

difference is employees are not going to be getting kicked like they maybe would in the parlor. Berning said he has noticed they have been able to milk more rst milking heifers with one person since pretraining their heifers.

“The benet (of pretraining) is for the transition of the cow and the people,” Berning said. “If we can have 90% of our heifers get milked with one person, I think that’s a big benet.”

When the Roericks put their robotic milking units in, they were told the transition

has different phases: three days, three weeks and three months. The rst three days are hard. After three weeks, the process goes pretty well. And after three months, producers understand why the system was put in.

Each panelist said they were glad they put in robots.

“The robots, whether they’re green, purple, blue or red, they’re going to milk cows,” Berning said. “We all do things a little differently. That’s kind of the cool thing about the dairy industry.”

Kayla (Herkenhoff)

Frieler

Family members: Matthew (husband), Emery, Brandt and Loretta (children) Freeport, Minnesota Stearns County

Current occupation: Product and marketing manager, Select Sires Inc.

Tell us about your role as a dairy princess. In 2016 and 2017, I was crowned a Stearns County Dairy Princess. I represented the dairy industry at various events, educating the public about dairy farming and promoting the benets of dairy products.

What is your background in the dairy industry? I grew up on my family’s dairy farm, where I helped with daily feeding, milking, animal health and care of 130 registered Holstein cows. The highlight of my summers growing up was exhibiting cattle in the show ring and gathering with 4-H friends in the cattle barn at our local county fair and the Minnesota State Fair. I also enjoyed competing in dairy judging through 4-H and FFA as well as at the collegiate level.

Why did you want to be a dairy princess? I have a passion for the dairy industry and wanted to share that passion with others. Growing up on a dairy farm, I developed a deep appreciation for the hard work and dedication that goes into dairy farming. I saw the role of a dairy princess as an opportunity to educate the public about the importance of the dairy industry and the many health benets from consuming dairy products.

Describe a fond memory of your time as a dairy princess. Some of my fondest memories as a dairy princess were participating in parades, school visits and community events. These experiences allowed me to connect with people of all ages and share my passion for the dairy industry. I particularly enjoyed seeing the excitement and curiosity in children's eyes when they learned about dairy farming and the importance of some of their favorite dairy products.

How did serving as a dairy princess impact who you are? Growing up on a farm, I’ve gained real life experiences that cultivated skills such as a strong work ethic, responsibility, problem-solving and initiative that have shaped me to who I am today. My family taught me that, by genuinely caring about our animals, they will in return take care of you. Being a dairy princess has helped me develop strong communication and public speaking skills, which have been invaluable in my professional career. The experience also deepened my passion for the dairy industry. It reinforced my commitment to advocate for the importance dairy farmers have in our local communities, economy and sustainable agriculture.

What would you say to someone who is considering being an ambassador for the industry? I believe it’s a rewarding experience that allows individuals to share their passion for the dairy industry with others. It provides an opportunity to educate the public about the signicance of dairy farming and the benets of dairy products. Being an

Kelsey Petit

Family members: Bob, Barb, Tyler and Emily Petit

Zumbrota, Minnesota

Goodhue County

Current occupation:

Goodhue County feedlot compliance coordinator

Tell us about your role as a dairy princess. Olmsted County Dairy Princess from 2010-2012.

What is your background in the dairy industry? I grew up on a 60-cow dairy south of Plainview. My responsibilities on the farm included feeding calves, separating and feeding dry cows and cleaning the barn, as well as assisting with vaccinating/separating heifers and cows. I also assisted in milking cows daily. Growing up, I was involved in different organizations including 4-H, FFA and dairy judging. I attended college at the University of Minnesota-Twin Cities, where I majored in ag education-communications with a minor in animal science. After college, I sold feed and worked at a large animal vet clinic.

Why did you want to be a dairy princess? I decided to become a dairy princess because I wanted to promote the dairy industry and all the dairy products to different types of consumers.

Describe a fond memory of your time as a dairy princess. A memory that sticks out is going to an event at the Ronald McDonald House that had many different agricultural groups involved. Everyone participated with all the families there and promoted agriculture.

How did serving as a dairy princess impact who you are? I am still supporting the nutritional value of dairy products daily and supporting the farmers who are involved in the agriculture since I still work in the agriculture industry.

What would you say to someone who is considering being an ambassador for the industry? Denitely give it a try. You’ll meet all sorts of wonderful people with all of the activities and events that you attend. You will also gain more knowledge about the industry.

How do you continue to promote the industry in your life? I am still working in the agriculture eld daily. I’m glad to be able to keep promoting the people and the land that give us wholesome, nutritious dairy products.

ambassador helps develop valuable skills such as communication, public speaking and leadership.

How do you continue to promote the industry in your life? I’m grateful for my time as an ambassador and have chosen career and lifestyle choices that continue to support and promote the dairy industry. My passion is to educate my children to incorporate dairy foods that are wholesome and delicious while ensuring they understand the impact local dairy farm families have in our world today.

Sarah (Paskewitz) Current Family: husband, Cody; son, Barrett Aldrich, Minnesota Todd County

Current occupation: Minnesota Department of Agriculture inspector

Tell us about your role as a dairy princess. I was a 2009-2011 junior ambassador, a county princess in 2012-2013 and a princess Kay nalist in 2013.

What is your background in the dairy industry? I grew up on my family’s dairy farm near Browerville. I helped most with calf chores. In college, I worked as an A.I. tech for Genex. I now work as an inspector with the department of agriculture.

Why did you want to be a dairy princess? I got to grow up watching my sister as a dairy princess and as a Princess Kay nalist. I saw the connections and impact she made and wanted to have my turn as well. I always found myself feeling most at home among my dairy judging and 4-H friends. The community I found in the dairy industry is something I am always proud to represent.

Describe a fond memory of your time as a dairy princess. During June Dairy Month, we would serve ice cream at local nursing homes. It was always fun to connect with residents who had farmed and hear their stories.

How did serving as a dairy princess impact who you are? Serving as a dairy princess taught me how to communicate with people in the industry and with those outside of it. I got to learn from those in the industry who do the work every day and relay the best our industry has to offer to peers and community members.

What would you say to someone who is considering being an ambassador for the industry? The dairy princess program has certainly helped shape who I am today. The communication and networking skills are so valuable regardless of where you hope life takes you.

How do you continue to promote the industry in your life? I have a unique opportunity to see all shapes and sizes of farms and dairy processors. I can share my experiences and insight with those I contact.

Jessica (Oelfke) Flygare

Family members: husband, Ben, daughter, Savannah, 8, and son, Bryce, 5 Green Isle, Minnesota

Sibley County

Current occupation: elementary teacher

Tell us about your role as a dairy princess. I was honored to serve as the Sibley County Dairy Princess in 2008 and 2009. In the spring of 2009, I was selected as a nalist for Princess Kay of the Milky Way. That same evening, at the Princess Kay coronation, I was also named Miss Congeniality.

What is your background in the dairy industry? I grew up on a dairy farm in Hamburg, Minnesota, with my parents, Jim and Jody, and my younger siblings, Janet, Jacob and Jennifer. Our family milked a herd of registered Jerseys. In my younger years, I was also the Minnesota Jersey Queen. Throughout my youth, I was actively involved in 4-H and FFA and exhibited in open class at county fairs, where I proudly showed animals from our herd.

Why did you want to be a dairy princess? I was incredibly proud of my farming roots and the livelihood my family depended on. Becoming a dairy princess was my way of sharing the vital role dairy farmers play in our food system. I wanted to thank my parents and the hardworking dairy community for their dedication. At the same time, I recognized how disconnected many people were from agriculture. I saw this as an opportunity to educate others about the importance of farming in our daily lives.

Describe a fond memory of your time as a dairy princess. One of my fondest memories of being a dairy princess was at the Minnesota State Fair, where I represented the Princess Kay program and had my head carved in butter. After watching that cooler from outside the glass for

Cynthia (Hamlett) Farmer

Family: Parents: Mark and Jennifer Hamlett, siblings, Sally, Vanessa, Henry, Louis and Natalie. Nevada, Iowa Story County

Current occupation: Iowa State policy manager, Center for Rural Affairs

Tell us about your role as a dairy princess. I served as the Fayette County Dairy Princess in 2016 and as the Iowa Holstein Princess Alternate in 2018.

What is your background in the dairy industry? Growing up on my family’s 60-cow dairy farm in southern Fayette County near Aurora, I spent more time than I can remember at the farm from the day I was brought home from the hospital. As soon as I was old enough to help, I quickly learned to feed the calves, milk the cows, and even drive the skid loader to pick up large square hay bales or the tractor to help plant and harvest the corn, soybeans and alfalfa hay we grow on rotation.

Outside of the farm, I participated in 4-H activities including Dairy Quiz Bowl, dairy judging and showing cattle at the county fair, and was a member of the FFA chapter competing in numerous Career Development Events. I was a member of the Iowa Junior Holstein Association and represented the Iowa Holstein breed at the national level through the Dairy Bowl Program and Dairy Jeopardy.

I furthered my education at Iowa State University studying dairy science and agricultural policy. I was heavily involved in the Dairy Science Club serving in numerous committee chair positions and as the president of the club in 2020. Following college graduation, I worked at Midwest Dairy and the Iowa State Dairy Association in a dual role as an Iowa farmer relations manager and the associate director of ISDA.

Why did you want to be a dairy princess? In 2008, I held my rst reign as dairy royalty. Alongside my older sister, I served as a Fayette County Little Miss Squirt, which prompted my

Rebecca Groos

Parents: Sean and Linda

Siblings: brother, Ethan, married to Gabriella, and together have one daughter, Charli; brother, Luke, and ancée, Jade; sister, Bethany Howard Lake, Minnesota Wright County

Current occupation: Events Coordinator with University of Minnesota Extension

Tell us about your role as a dairy princess. I was a Wright County Dairy Princess in 2011 and 2012 and competed in the May event in 2012.

What is your background in the dairy industry? I grew up as the sixth generation on a 175-cow registered Holstein dairy farm in Howard Lake. My primary responsibilities included milking cows and young calf care. I’d also assist with vet checks, sorting cattle, operating equipment and pitching in where needed. I’ve always shown cattle locally and at the state level, so my interest in registered dairy cattle genetics and working with quality show cattle started at a young age.

Why did you want to be a dairy princess? It’s a great platform to connect with the public and share knowledge about the dairy industry. We as dairy farmers need to be self-advocates for our industry and communicate the pride and passion we have for the great products produced. One of the best ways to combat misinformation regarding the dairy industry is to share personal stories about daily life on the farm, including the challenges, and create a comfortable space for conversation with consumers. People want to hear we provide the best care for our animals and continuously make decisions that positively impact the future of family farms.

many years, it felt like a dream, and it was surreal to nally sit inside and see my likeness created by Linda. The overwhelming pride I felt for my family, county and industry is a memory I will cherish forever.

How did serving as a dairy princess impact who you are? Serving as a dairy princess taught me to be condent and brave enough to stand up for what I believe in. I learned the power of advocacy and how to use my voice to make a difference. Public speaking and media engagements helped me realize I could have an impact, and this experience deepened my appreciation for agriculture. It also inspired me to continue nding ways to stay involved in the industry and educate others about our way of life. After my time as a dairy princess, I didn’t walk away from agriculture — I dove deeper into it. Today, my husband and I, as well as my brother and his wife, run a beef and crop farming operation. The skills, knowledge and passion I developed as a dairy princess are still with me, and I use them in our business.

What would you say to someone who is considering being an ambassador for the industry? This experience will leave a lasting impression on your heart and mind. You have the unique opportunity to truly make a difference in something you're passionate about; take the leap, because so many wonderful things can come from this. You’ll gain new friendships, expand your network and create memories that will last a lifetime. It’s a journey of personal growth and community impact.

How do you continue to promote the industry in your life? While my life has changed in many ways over the years, I still embrace every opportunity to advocate for the dairy industry. As a mother, I am eager to share with my children the importance of balanced and nutritious meals — especially those that include dairy — to help them grow strong and healthy. I also teach them how farmers care for the land, which in turn supports the animals and crops that provide for us.

As a teacher, I incorporate dairy nutrition and agriculture into my lessons. My students are always eager to learn more about farming, and I enjoy educating them about the role dairy plays in our food system. Being an advocate for the dairy industry is deeply ingrained in who I am, and I’m passionate about sharing its importance with future generations.

interest in one day becoming a dairy princess. As the years progressed, I looked up to each dairy princess crowned in our county. Not only did they have a crown, but they held many professional skills I was working toward during high school. Holding the title of dairy princess was something I looked forward to for years. I wanted to represent the dairy farmers in our county and expand on professional skills such as public speaking before heading off to college.

Describe a fond memory of your time as a dairy princess. I thoroughly enjoyed visiting and speaking to all second grade classrooms in Fayette County. It required a prepared presentation and a sense of exibility to think on my feet. Sharing my everyday life experiences with youngsters who had maybe never seen a cow in real life or realized that chocolate milk does not come from brown cows still puts a smile on my face today.

How did serving as a dairy princess impact who you are? As a young person looking to strengthen my professional skillset and build upon my leadership roles, serving in each of the dairy princess positions I held certainly shaped me into the person I am today. Specically, I think about the improvements in my public speaking and time management. Each position required condence to speak in front of anyone about the dairy industry, sometimes prepared and many times not, in addition to managing a busy schedule as a high school and college student. I credit much of my skillset today to my experiences while serving as dairy princess.

What would you say to someone who is considering being an ambassador for the industry? I would encourage them to get out of their comfort zone. Pushing yourself to do something you aren’t condent in is sometimes the best way to learn and grow. Remember that you know your story and experiences best. Sharing with others is the best way to spread the good word about the industry.

How do you continue to promote the industry in your life? This past fall, I started advising the Dairy Science Club at Iowa State University. Having had such a large involvement in the club during my collegiate career, it has been unique to support the students who want to learn and grow just as I did. It is fun to see the club evolve as the industry does over time as well. Although my job does not specically focus on the dairy industry now, I enjoy working on agriculture policy and ensuring dairy producers have a seat at the table.

Describe a fond memory of your time as a dairy princess. During spring break at the U of M, I spent a day in the Howard Lake-Waverly-Winsted middle school, reading books and sharing about the dairy community to students in several classrooms. The highlight of my day was reading to my sister’s class and doing my best to embarrass her a little. Overall, it was a great way for me to give back to my school and share information with impressionable students who, in turn, relay that to their families.

How did serving as a dairy princess impact who you are? Dairy farming, registered Holsteins and the dairy industry hold a special place in my heart and always will. Growing up in the dairy industry shaped who I am, the connections I’ve made and provided direction to my future. As a dairy princess, the crown provided an avenue to share my story and passion for the dairy community with those genuinely curious about what we do on the farm and our way of life. I’m a rm believer that advocating for agriculture, specically the dairy industry, doesn’t stop after the crown. Each year, sharing the honest work we as dairy farmers do becomes more important as we connect with consumers looking for transparency in the food products they buy.

What would you say to someone who is considering being an ambassador for the industry? It’s a great experience and one I fully recommend. Each county American Dairy Association gives young women a platform to hone public speaking skills and condence while effectively and concisely communicating messages to various audiences. I learned it’s important to meet your audience at their level and share information rather than “educate someone.” That can be seen as condescending, while sharing information allows an individual to reach their own conclusion.

How do you continue to promote the industry in your life? I currently serve on the Minnesota Holstein Association, am a dairy judging and dairy quiz bowl coach for Wright County 4-H and serve on the local Farm Bureau boards and the Farm Bureau Young Farmer & Rancher state committee. In my career with U of M Extension, I am part of the Ag Business Management team that puts on farm transition workshops statewide to help farm families manage and better ease into the transition from one generation to the next.

How many times a day do you milk, and what is your current herd average, butterfat and protein? We milk three times a day, and our herd average is 38,300 pounds of milk, with tests of 4.3% butter-

and 3.1% protein.

Describe your housing and milking facility. All cows are housed in a sand-bedded freestall barn. We have pens for lactating cows, dry cows, transition cows and hospital cows. Cows are milked in a double-9 parallel parlor that we retrotted into our original tiestall barn. All our youngstock four months and older are housed in three different freestall barns.

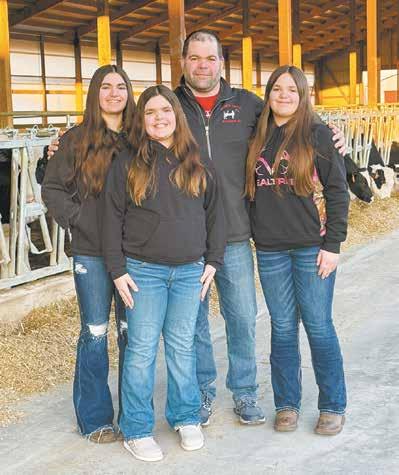

Who is part of your farm team, and what are their roles? My dad, Jerry, helps me on the farm along with my three daughters — Paige, Brianna and Jaclyn. In addition, we have seven employees, including ve full time and two part time.

What is your herd health program? We do a herd health check every two weeks. Cows receive a Bovi-Shield vaccine once a year and a J-VAC vaccine four times per year. Heifers receive both of those vaccines twice a year.

What does your dry cow and transition program consist of?

First-lactation animals go dry 55 days before calving, and older cows are dry for 50 days. Dry cows are housed in a separate pen in the freestall barn and fed a ration of corn silage and ryelage and a little distillers and mineral. Cows are moved into the pre-fresh pen three weeks before calving, whereas heifers are moved in one month prior to calving. Pre-fresh animals receive a ration of straw, corn silage, and pre-fresh protein and minerals. Animals are moved into the calving pen one or two days before freshening. After calving, fresh animals are moved into our hospital pen for a minimum of one week for cows and 10 days for heifers before being housed with the milking herd. We try not to overcrowd our transition animals.

What is the composition of your ration, and how has that changed in recent years?

Our milking ration consists of 60% forage with a 55%:45% corn silage to haylage ratio. The ration also includes highmoisture corn and protein mix. I am also adding 1 pound of baled hay per animal currently because I have it after baling sixth-crop hay for the rst

Kollwelter and his daughters, Paige

and Brianna, gather next to one of their heifer barns Feb. 27 on their farm near Whitewater, Wisconsin. The Kollwelters milk 240 cows with a herd average of 38,300 pounds of milk, with tests of 4.3% bu erfat and 3.1% protein.

time this year. I have changed the protein content in recent years to get more butterfat. We changed the type of min-

erals and now feed more palm fat. We also started feeding a little dry corn through the summer this past year to help with foot health. Dry corn doesn’t go through the cows as fast as high-moisture corn does.

Tell us about the forages you plant and detail your harvest strategies. We plant haylage, corn silage, oatlage and ryelage. We are going to plant brown midrib corn for the rst time this year. In the past, we always planted conventional corn silage, but now we’re going to give BMR a whirl. We’re switching because the numbers and the experts are saying we should be able to get three more pounds of milk out of our cows. We harvest our forages as fast as we can. We cut it all down in one day and chop the next, and then we are done. Corn silage is harvested in two days. We don’t have a lot of acres, and we also have the equipment to get it done quickly. We have 180 acres of hay and 90 acres of new seeding. I turn the eld over after three years. Almost all our hay is used for haylage, and I take a fth crop every year. We cut hay on a 27-28-day interval.

“Udder ComfortTM works wonders for our fresh cows or mastitis flareups. For fresh cows, we apply it after each milking until edema is out,” says Peter Bartz of BA-HA Dairy, Glenbeulah, Wisconsin. He enjoys seeing the next generation growing the business for the future. He visited our booth at the 2024 World Dairy Expo with two granddaughters, who are the 4th generation on the farm. His daughter Chelsea loves crossbreds, and their 350 milking cows average 33,000M 4.2F 3.6P, with 77,000 SCC.

“Udder Comfort absolutely plays a role in our milk quality. We use it on any questionable cow. They come right back around, and it brings SCC down. Our treat time is cut. Edema is cut. It just works,” Peter explains.

“We tried other products, but did not get the results we wanted or were used to. That’s why we have continued using Udder Comfort for 20 years,” he shares.

As soon as we take the crop off, we irrigate the eld. Last year, we averaged over 10 tons per acre of dry matter on our hay ground. We consistently run around 60% moisture. Our feed is stored in bags on blacktop.

What is your average somatic cell count and how does that affect your production? Our cell count is 75,000. We only treat a couple cows per year for mastitis, which helps keep milk production higher. Our somatic cell count was around 150,000 until we changed milk processors. In the past, it was hard to get rid of a cow with a high somatic cell count if she was a high producer. When we switched processors, we had an incentive to lower our SCC because we got paid for doing so.

What change has created the biggest improvement in your herd average? Genetics. Every animal is genomic tested, and we have done more and more with genomics over the last ve years. The top 5% of our animals have 65%-70% of the calves born here through our embryo program. Any animal with a Total Performance Index under 3,100 receives an embryo. We are trying to have elite animals across the board based on TPI, which has also helped me earn a premium on the heifers I sell.

What technology do you use to monitor your herd? We don’t really use any technolo-

Cows eat a total mixed ra on Feb. 27 at JC-Kow Farms near Whitewater, Wisconsin. The

for the milking herd consists of 60% forage with a 55% to 45% corn silage to haylage ra o along with high-moisture corn, protein mix and baled hay.

gy in that area. Ten to 15 years ago, we used an activity monitoring system, but it didn’t pan out for us and didn’t deliver enough on the breeding side. I know these systems have come a long way since then, and I have contemplated going back, but we have good enough help here who are monitoring the cows with their own eyes.

What is your breeding program, and what role does genetics play in your production level? We are very into genomics, and we do a lot of embryo work. We work with Sunshine Genetics on a close basis for our embryo

program and herd health. We are focused on production and cow health. We want higher components and milk without having problems with cows. A healthier, more productive animal is what we strive for. This creates a big difference in quality milk as well as fat and protein. Our herd average was higher in the past, but now we focus on higher components and the health of the animals. We have a young herd, so that also brings our herd average a little lower. We use sexed semen or embryos along with a little bit of Angus on problem breeders. I use the highest genomic bulls available and have

attain your production and component level. Genetics, feed and cow comfort. We put up quality feed within the right windows. We have tweaked this over time to get what we want. Our focus on cow comfort includes sand bedding, rubber ooring, fans and sprinklers. Our barn is naturally ventilated, with fans over the stalls and sprinklers over the feed bunk.

had good success doing that. I pick 3-4 bulls every proof run, and whether she is our best or worst cow, she is getting bred to the same bull. I breed for TPI and production. I don’t breed for udders anymore. If she has high enough TPI, she’s going to have type too. The only physical or type characteristics I breed for are strength and feet and legs. To be in the top TPI, a cow has to have health and tness traits. I keep my best heifers and sell the rest, only keeping one out of four heifers that calve.

List three management strategies that have helped you

Tell us about your farm and your plans for the dairy in the next year. I am the third generation on the farm that was started by my grandpa in 1954. I came back in 2002 when we were milking 50 cows. We have a registered herd and never bought an animal to get to where we are today. From my dad to me, we have always used the best genetics. We ship our milk to Rolling Hills Dairy Producers Cooperative. We farm 650 acres, and everything is tiled below and has irrigation above. We also sell replacement heifers and sold 200 head this year. My plans for the next year are to get all the heifer barns full and keep trying to breed more elite genomic heifers. We have had as high as the No. 5 heifer in the breed and have a lot of calves coming out of her. I would also like to put more bulls into A.I. stud. We have put three into stud in the last year and a half. We are also hosting the Walworth County Dairy Breakfast June 14 to give people more knowledge of the dairy industry.

DECORAH, IA

Lang’s Dairy Equip. 563-382-8722

MONTICELLO, IA

United Dairy Syst. 319-465-5931

WEST UNION, IA United Dairy Syst. 563-422-5355

FREEPORT, MN Arnzen Construction 320-836-2284

Hartung Sales & Serv. 320-836-2697

LEWISTON, MN Lang’s Dairy Equip. 507-452-5532

MELROSE, MN Farm Systems 320-256-3276

MENAHGA, MN Dairyland Equip. 218-564-4958

MORA, MN Advanced Dairy 320-679-1029

PENNOCK, MN

WI Fuller’s Milker Center 800-887-4634

MARSHFIELD, WI Podevels Farm Serv. 715-384-6193 800-742-5748 MT. HOREB, WI The Scharine Group 800-872-3470

RICHLAND CENTER, WI Fuller’s Milker Center 800-887-4634 WHITEWATER, WI The Scharine Group 608-883-2880 WITHEE, WI Hoover Silo Repair 715-229-2527

Contact

to

IOWA

Prairie Land Ag Supply Inc.

Rock Valley, IA

712-476-9290

United Dairy Systems, Inc.

West Union, IA

563-422-5355

Monticello, IA

319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI 715-654-5252

Ederer Dairy Supply Plain, WI

608-546-3713

DeLaval Dairy Service Kaukauna, WI

866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI

608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH DAKOTA

Farm Systems Melrose, MN

320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

By Sarah Middendorf sarah.m@star-pub.com

HUTCHINSON, Minn.

Empowering women in the dairy industry one speech at a time is a focus for dairy farmer Katy Schultz.

Schultz was the keynote at the Women in Dairy: Farming with Family event hosted by the University of Minnesota Extension and Minnesota Dairy Initiative Feb. 13 near Hutchinson at Crow River Winery.

Schultz is part owner and herd manager at Tri-Fecta Farms near Fox Lake, Wisconsin, where they milk 400 cows and farm around 2,000 acres. Along with keeping track of herd numbers, Schultz also manages the hired employees, whom she calls her farm family.

“My favorite part of being the herd manager is working with the people,” Schultz said. “I love being able to help empower people.”

During her presentation, Schultz talked with attendees about core values and what is going to add fulllment to the “bucket” of their lives.

“You’re not going to ll

all of that bucket at the farm,” Schultz said. “You’re not going to ll all of that bucket in your marriage. You’re not going to ll all of that bucket from your kids. When your buckets aren’t lled, you try and ll it with other things that maybe aren’t as healthy.”

Schultz said being able to do things outside of the farm to ll her bucket is important. For Schultz, public speaking, such as the Women in Dairy event, helps ll her bucket.

Understanding the core values of those on the farm Schulz said can help each team member have a better mindset. She said when her family and employees see they are being valued, everything goes up — production, animal health and quality of life.

“When I invested more in everyone else, I was fullled,” Schultz said.

When someone is getting frustrated, Schultz said it is important to think about three questions to help the situation: do they need to be heard, do they need a hug, and do they want help?

“Being able to have grace and respect has gone a really long way for us,” Schultz said.

Schultz also talked about the communication on the

farm. She said everybody in the day-to-day operation should get a voice.

“Our farm ... looks like it did when I grew up, but it doesn’t feel like it anymore,” Schultz said.

Every day they have a meeting at 9 a.m. that lasts nine minutes. This allows everybody to talk about what they need help with for the day. Asking questions beyond the farm can go a long way as well, Schultz said.

“People are my passion,” Schultz said. “I will do whatever it takes to see them succeed.”

At Tri-Fecta Farms, they also have biannual business meetings. During these meetings, both owners and their spouses have a voice in the business. It is each owner’s responsibility to bring concerns from their spouse.

“We had to gure out a way to strengthen the marriages at the same time to make sure their voices were heard,” Schultz said.

When the agenda is sent out, there is a spot specied for each in-law. Schultz said she wants to know the in-laws’ thoughts and concerns.

Ultimate EZ™ Electric Milker is 100% portable, operates using 110V or power tool batteries, includes bottles, stainlesssteel buckets and many accessories.

Schultz’ dairy farming story goes back to 1989, when a neighboring farm came up for sale. Her parents decided to buy it and start dairy farming. Before this purchase, they were raising steers and crop farming.

When her parents were building the dairy farm, they contemplated its design not knowing if any of their kids would come back to the farm, Schultz said.

“I am unbelievably grateful to my parents for making sure that we had a successful and viable business,” Schultz said. “Our parents gave us an opportunity to buy a successful business. We didn’t want to be given anything else. They gave us an opportunity of a lifetime.”

Schultz’s parents had requirements for those that wanted to come back to the farm. These included having an

education beyond high school, working for someone else for a time and obtaining a skill nobody else had.

Schultz said her parents wanted to make sure that if something happened and the business did not make it, they had something else to do.

“When you have a skill set that no one else has, you add value to the farm and you feel valued (in return),” she said.

Schultz’s skillset is working with people and making sure they are empowered and feel valued.

Being able to empower those around her is important Schultz said, and has made an impact on her family business.

“When you are improving small little things … it gives you an opportunity to be able to look at your business a little differently,” Schultz said.

By Tiffany Klaphake tiffany.k@dairystar.com

PAYNESVILLE, Minn.

Johann “CJ” Spangenberg has been dairy farming since he was 16 years old. During his tenure, he has worked on many farms in various countries with different milking systems.

“Animals have always been my passion,” CJ said. “I have never wanted to be a vet, but I have always wanted to be a farmer.”

Now, CJ and his wife, Yvette, are buying equity in a dairy farm near Paynesville.

The farm is home to 280 cows — Holsteins, Brown Swiss and crossbreds — that are milked with four DeLaval robotic milking units.

“The owners are retired bachelors, so we are their transition plan,” CJ said. “I have been dairying for a long time but never with robots.”

The Spangenbergs’ succession plan allows the couple to receive equity each year, and eventually, the farm will belong to them.

TIFFANY KLAPHAKE/DAIRY STAR

Yve e and Johann “CJ” Spangenberg stand together Feb. 12 at the farm they operate near Paynesville, Minnesota. The Spangenbergs milk 280 cows with four robo c milking units.

The barn, which was built in 2019, houses newborn calves, milk cows and dry cows, all under one roof. The owners of the farm had housed and milked the herd in a tiestall barn. Spangenberg said the transition to the robotic barn has had its challenges.

“We are here now to help them … so they can retire

Brian & Eileen Hoefler

Hoefler Dairy • New Vienna, IA

Purchased December 2017

properly,” CJ said.

The Spangenbergs have completed their rst year at the farm and said they have learned a lot. Over the past year, they have increased the herd from 235 cows to 280, adjusted the breeding strategy so the cows t better in the robots and changing the ration to encourage the cows to enter

the robots on their own. They also have had to learn the ins and outs of the robotic milking units.

“The technology was the biggest learning curve,” CJ said. “At the large dairies, you feed a (total mixed ration). Here, it is a (partial mixed ration) with some of the feed being fed with the robot. I know

there are different philosophies as to what is the best way to manage a robot dairy, and we are still learning them.”

Yvette agreed.

“The robot community is amazing,” she said. “We visited with a lot of farmers, and a lot of them came here. We were all brainstorming different ideas on how to do things. We take a little bit from here and there to nd what works best for us. It’s actually quite exciting to be a part of this community.”

The Spangenbergs, who are originally from South Africa, have worked at several types of dairy farms before settling in Stearns County. Prior to managing this farm, they managed a large dairy farm in southern Minnesota.

“Ever since we got married, we decided we wanted to own a robotic dairy farm,” Yvette said. “We tried establishing one in South Africa. We still go back every two years to see family.”

The couple came to the U.S. in 1998 to learn about dairy farming. Then, they returned to South Africa in 2000. They subsequently traveled to New Zealand and Canada to work and learn about types of dairy farms.

for straw, sawdust etc.

FEATURES:

• 3-in-1 – The BOBMAN bedding machines scrape the slats, sweep the stalls and spread an even layer of bedding all in only one pass!

• Reduces the time taken to clean out the stalls or the milking cubicles

• Can help to reduce somatic cell count & prevent mastitis

• Time and labor saving

• Save on the amount of bedding materials used

• Clean and dry cow resting surface

“Cleaning freestalls was a dreaded chore before, but now with the BOBMAN everyone wants to do them. It has helped us to save time, reduce labor, and have cleaner stalls. The support from Wille’s has been excellent as well.”

In 2012, while the Spangenbergs were working on a research farm in Canada, the same dairy farmer they worked for in southern Minnesota originally asked if they would work for him again, and they agreed. Eventually, that farm came under new ownership. When CJ and Yvette heard about a farm for sale in Stearns County, they saw their opportunity.

“It is tremendous hard work,” CJ said. “It is much different than a large dairy. ... Here, it is just us, so we are the manager, laborer and everything in between. Luckily, I am not scared of hard work and don’t like sitting still.”

The day-to-day tasks are carried out by CJ and Yvette, their daughter, Karlijn, and neighbors, as needed. Karlijn is in 4-H, where she participates in dairy bowl, dairy judging and shows. The couple’s son, Zac, joined the military after high school. Yvette does the calf chores and CJ does the herd health.

“Everything comes natural to us,

and we share most of the responsibilities,” Yvette said.

CJ agreed.

“We complement each other well by making sure all the chores get done,” he said. “It gets to be a lot of getting up early and going home late, but everything gets done.”

After adjusting the herd size, breeding program and rations, the Spangenbergs are seeing progress with the cows.

“Every day things are getting better,” CJ said. “Each day, more cows come to the boxes themselves. There is a lot of information and data, and we are still learning how to process it.”

It has been a long road for the Spangenbergs to operating their own robotic farm.