By Michelle Stangler

Staff writer

LITTLE FALLS, Minn. — A vacation can include anything, but for farmers Sara Jane and Dave Brutscher, adding tours related to agriculture makes their trips more fun. The pair recently ventured to Italy, planning their travels around a farm show.

“Whenever we go away, we always try to connect with something associated with our farm and learn some things and learn about other cultures,” Dave said.

The Brutschers own DayStar Dairy near Little Falls where they milk 750 cows in a double-12 parallel parlor, managing the operation alongside their two sons, Paul and Jesse. Their vacation last fall lasted three weeks, a time that brought relaxation and curiosity together.

“There’s a purpose in this,” Dave said. “When we’re gone for three weeks, this is good for the farm.”

Dave said their two sons and many great employees know that when he returns, he is more refreshed and ready to help.

“It allows them to learn and gain independence,” he said.

The Brutschers’ travels took them through Tuscany, Cremona, Parma and other regions of Italy, blending history with their passion for dairy.

Sara Jane Brutscher looks at calves Dec. 2, 2024, on the Vi orio dairy farm near Pontevico, Italy. Brutscher said she enjoyed seeing the Italian calf programs because calves are part of her responsibili es on her farm in Minnesota. Turn to BRUTSCHERS | Page 4

“The dairy connection was secondary, but we have fun planning these vacations,” Dave said. “It’s like building a dairy. You work on all the pieces; and you get a blueprint of what you want to do. Then you put the pieces together and gure out how you’re going to build it.”

Dave said farmers worldwide share more similarities than differences.

“We don’t speak the same language, but we do when it comes to cows,” Dave said. “Wherever you go, you make connections, you make friends.”

style conscious,” Dave said. “They’re going to build a good cow. They’re really proud of their cows.”

One of the dairies they visited had well over a 90-pound tank average and high components.

“The Italian dairymen are very style conscious. They’re going to build a good cow. They’re really proud of their cows.”

DAVE BRUTSCHER, DAIRY FARMER

The couple visited two dairy farms — a 350-cow dairy and a 200-cow dairy —in the company of a translator. They had contacted their semen company in the U.S. to provide a contact for an Italian distributor.

“The Italian dairymen are very

Dave said there were multiple cows the farmers wanted to show them and share about the pedigrees.

The Brutschers learned new things while talking with the farmers about nutrition, breeding and herd management.

“We talked what their reproduction is like (since) they have some really hot summers in the valley,” Dave said.

Sara Jane said she enjoyed seeing their calf program.

6:30 a.m. Receiving Hours 10 a.m. Cattle, Hogs, Sheep and Goats Auction

THURSDAY 12 p.m. Hay Auction

“They had a Milk Taxi, which I’ve seen in a couple of places overseas,” she said.

At the other farm they learned about different feeding practices from a father and son duo which the Brutschers said were ecstatic to welcome American visitors. The major difference they said they noticed was in the processing of corn silage.

“Our nutritionists say we want this longer length stuff,” Dave said. “(There) it’s chopped like sawdust.”

Their trip also included a stop at the Cremona International Livestock Exhibition, a show similar to World Dairy Expo in Madison, Wisconsin.

“(There were) a lot of people having cheese or yogurt samples (and) almost every booth had charcuterie platters and were passing out wine,” Sara Jane said.

They had calf housing and all kinds of tractors and bedding throwers and anything farmers use in the U.S. Dave said. There was also a dairy exhibition and cattle on premise they could see as well.

While the trip was lled with memories, Dave said what made it most special is that they have been together for many years and still have fun together.

“We both are interested in history,” he said. “We are interested in farming. It’s nice to combine the two and meet dairy farmers in other countries.”

STAR

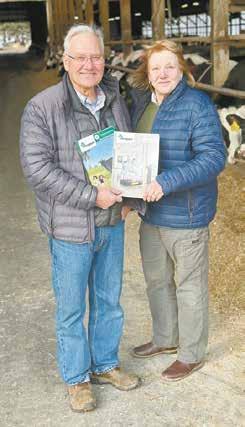

Dave and Sara Jane Brutscher hold magazines Feb. 27 on their farm DayStar Dairy near Li le Falls, Minnesota. The Italian semen company magazines were a souvenir the couple brought back from their 2024 vaca on to Italy.

• Calling on both established accounts and building

new accounts to market print and digital advertising

• Strong communication skills

• Basic computer knowledge

• Strong listening skills

• Work as part of a team including production and editorial members

The U.S. Department of Agriculture’s latest preliminary data shows January milk production hit 19.1 billion pounds, up 0.1% from January 2024, following a 0.5% decline in December. Output in the top 24 states totaled 18.3 billion, up 0.2%, after slipping 0.4% in December. December output was revised down 3 million pounds in the 50 states and was unchanged in the 24-state data.

January cow numbers, at 9.37 million, were up 10,000 head from December and 41,000 more than a year ago. The December count was revised up 4,000 head. The 24-state count, at 8.9 million, was up 9,000 from December, and 54,000 above a year ago. The December count was revised up 5,000 head.

January output per cow in the 50 states averaged 2,040 pounds, down 7 pounds or 0.3% from a year ago. The December average was revised down 1 pound. The 24-state January average, at 2,054 pounds, was down 8 pounds or 0.4%. The December average was revised down 2 pounds from last month’s report. Milk output for all of 2024 was reported at 226 billion pounds, down 0.2% from 2023. Revisions to 2023 production decreased the annual total by 53 million pounds. Revised 2024 production was up 14 million pounds from last month’s estimate. Annual milk production has increased 8.3% from 2015, said the USDA.

Cow numbers in 2024 totaled 9.34 million, down 42,000 from 2023. The average number of milk cows was revised up 3,000 head for 2024. The average has increased 0.2% from 2015. Production per cow averaged 24,178 pounds of milk, up 61 from 2023. That average has increased 8.1% from 2015, according to the USDA.

Lots of eyes were on California, which continues the battle with bird u. Variants in several states are keeping the war going. January output in the nation’s No. 1 milk producer was down a whopping 203 million pounds or 5.7% from a year ago. December output was revised down 43 million pounds, resulting in an 8.0% decline from a year ago, instead of the 6.8% reported.

Wisconsin’s January output was down 17 million pounds or 0.6% from a year ago, on 5,000 fewer cows, and output per cow was down 5 pounds.

Idaho’s output was up a hefty 88 million pounds or 6.4% from a year ago, thanks to 27,000 more cows and a 45-pound gain per cow. Idaho’s December output was revised up 35 million pounds, a 6.1% increase from December 2023, instead of the 3.5% originally reported.

Michigan was up 0.7% on 1,000 more cows and a 10-pound gain per cow.

Minnesota was off 0.2%, on a loss of 9,000 cows, though output per cow was up 35 pounds. New Mexico was down 1.2% on 3,000 fewer cows; output per cow was unchanged. New York was up 2.0% on a 40-pound increase per cow, while cow numbers were unchanged.

Oregon was up 2.0% on 1,000 more cows and a 20-pound gain per cow. Pennsylvania was up 0.8% on a 15-pound gain per cow. Cow numbers were unchanged.

South Dakota was up 6.5% on a 60-pound gain per cow and 7,000 more cows. Texas tied South Da-

kota for the biggest percentage gain this month, also up 6.5% but due to 40,000 more cows and a 5-pound gain per cow.

Vermont was unchanged though cow numbers were down 3,000 head. Output per cow was up 45 pounds. Washington State was down 2.9% on a 35 pound drop per cow and 3,000 fewer cows.

StoneX said both fat and protein content nationwide were well above a year ago, which puts component adjusted production up 2.2%.

The week ending Feb. 15 saw 53,500 dairy cows sent to slaughter, down 2,500 from the previous week, but 5,800 or 9.8% below a year ago. Year to date, 376,000 have been culled, down 20,700 head or 5.2% from a year ago.

The higher fat and protein content of U.S. milk has resulted in plenty of butter and cheese and more butter in storage. USDA’s latest Cold Storage report shows Jan. 31 butter stocks totaled 270.3 million pounds, up a whopping 56 million or 26.1% from December, and up 22.7 million pounds or 9.2% from January 2024. December stocks were revised down 8.1 million pounds.

The American-type cheese inventory inched up to 777.6 million pounds, up 6.5 million or 0.8% from December’s level, but was down 62.2 million pounds or 7.4% from a year ago. The December total was revised 1.4 million pounds lower.

The “other” cheese category climbed to 573.0 million pounds, up 13.6 million pounds or 2.4% from the December level, but was down 21.9 million or 3.7% from a year ago. December’s level was revised up by 435,000 pounds.

The total cheese inventory hit 1.37 billion pounds, up 19.9 million pounds or 1.5% from December, but down 82.4 million pounds or 5.7% from a year ago as competitive U.S. prices attracted plenty of global buyers for our cheese.

StoneX said the report suggests that butter demand was better than thought for December and probably January as well. It adds; “This was the biggest cheese decline we’ve seen in January in at least two decades and would argue for Chicago Mercantile Exchange block close to $2.00 per pound, even though they averaged $1.88 for the month.”

New data from USDA’s Agricultural Marketing Service suggests the growing number of beef-on-dairy animals is contributing to higher cattle prices for producers and added value to feedlots and processors, according to CoBank livestock analyst Abbi Prins.

Speaking on the March 3 Dairy Radio Now broadcast, Prins said auction prices show that dairy beef crossbred cattle are more expensive, especially on the slaughter side, compared to native beef and traditional dairy cattle. She attributes that to a number of things, such as weight; she said, “Traditionally, dairy cattle are heavier than native beef cattle in a feedlot and dairy beef settle in between.”

Second are the attributes. “Because they have a dairy background, those animals can have a higher meat grade when they enter the processing plants, and they show a little more feed efciency compared to traditional dairy cattle,” Prins said. It’s also meant extra income for farm bottom lines as crossbred calves range $600-$800 per head at just a week of age, she said.

Prins says the trend for beef on dairy animals will continue because of the value it provides dairy producers but also for what it’s meant for feedlots and packers. She doesn’t see the beef herd getting rebuilt until 2027 or later because that’s dependent on weather and “We have really high calf prices right now, so once those things come into balance, we should see the herd starting to rebuild.”

“The U.S. beef cow herd is at historically low levels due to prolonged drought and poor grazing conditions,” CoBank said. “Tight supplies amid robust consumer demand for beef have pushed cattle prices to record highs.”

Checking Chicago, cash block Cheddar closed Friday and the month of February at $1.7750 per pound, down 12.50 cents on the week, lowest CME price in ve weeks, down 8.75 cents on the month, but still 22.50 cents above a year ago.

The barrels closed at $1.78, lowest in three weeks, 2 cents lower on the week, a penny lower on the month and 13 cents above a year ago. Block sales totaled 13 for the week and 41 for the month of February, down from 67 in January. Barrel sales totaled eight for the week and 28 for the month, down from 36 in January.

Midwest cheesemakers reported mixed results on demand, according to Dairy Market News. Most said weekly sales are steady to busy. Some retail and cut-and-wrap cheesemakers say orders are somewhat quiet. Per the norm, milk availability varies, although there were some extra loads on the market this week. Prices at mid-week were $2.50-under to Class III. Some contacts said milk availability seems to be closer to ush territory while others said milk offers have not increased.

Cheese markets are not bullish or bearish, said Dairy Market News, and near-term tones are questionable despite CME prices maintaining relative steadiness.

Demand for Class III milk from western cheese manufacturers is reportedly stronger as new processing capacities steadily become more heavily utilized. Milk volumes are sufcient and steady for supporting somewhat stronger output. Retail cheese demand is somewhat lighter to steady while moderate to steady from food service. Manufacturers and distributors indicate that demand from international buyers is mixed, according to DMN.

CME butter, after regaining almost 4 cents the previous week, dropped to $2.3350 per pound Wednesday, lowest since April 14, 2023. It regained a penny Thursday and stayed put Friday at $2.3450, down 7 cents on the week, 8.50 cents lower on the month and 41.25 cents below a year ago. There were 33 sales on the week and 136 for the month of February, up from 97 in January.

StoneX said export activity has increased as international buyers step in to a wildly discounted U.S. fat market. Central region butter makers reported some upticks in demand this week. As market prices continue to fall, retail customers are showing less reluctance to add to their orders. Delay times outside butter plants for cream trucks has declined, but the onslaught of cream has been heavy the past few weeks. Plant

THURSDAY, March 13th

Hay 10:00 a.m. • Cattle 11:00 a.m.

Dairy Cows

(3) Holstein cows. Fresh 40 to 47 days milking 78 to 140 lbs! 13 to 33 SCC. Reputation Consigner! Jeryl Martin, Ashland Brown Swiss cow bred 3month to Angus,Fancy 3 yr old! Red & White Holstein fresh 3 weeks already at 110 lbs. Fancy young cow!

(5) Holstein tie stall cows recently fresh. More info coming soon. (6) Holstein ties stall cows. Fresh 24 to 73 days. 1st and second lactation. 64 to 98 lbs.

Heifers

(7) Holstein heifers. 4 to 8 months bred to a good Holstein bull. Feeders

70 Angus strs & heifers. Weaned early December, 2x vacc. Corn silage and dry hay fed. Exceptional quality from a reputation seller!! Weller Farms.

(8) Holstein strs 650lbs. 2x Bovi, Inforce, Dewormed (20) Angus heifers. 700 lbs. 2x vacc. Fancy!! Glick, Viroqua (2) Angus beef hfrs bred Angus due April.

(2) Angus beef cows due April and July

We accept unadvertised drive-in cattle on sale morning!! If you call us in advance we’d love to advertise your cattle free of charge. Advance notice!

Thursday, March 20, 2025 Call now for advertising.

downtime due to weather or other situations subsided this week. Cream multiple lows have not been reported at the same levels this week, despite being well below 1.00 for most churn usage. The CME new crop rule may stanch some of the recent price declines, as butter produced before Dec. 1, 2024, will no longer be available to offer on the cash call, says DMN.

Cream also remains heavy in the West, and butter manufacturers say offers are at multiples comfortably lower than what has been customarily expected for the last week of February. Plants are busy working that affordable cream through the churns and building stock for later demand. Domestic demand is moderate to steady. International buying is steady to strong thanks to competitive U.S. prices.

Grade A nonfat dry milk closed Friday at $1.20 per pound, down 4 cents on the week, lowest CME price since Aug. 9, 2024, 14 cents lower than its Feb. 3 print and a quarter-cent above a year ago. Sales amounted to 19 loads for the week and 50 for the month, down from 60 in January.

StoneX said “Bearish news abounds.” Demand remains lackluster, and now discussions seem hopeless, especially that exports to Mexico will ever return to normal.

Dry whey closed the week and month at 51 cents per pound, down 3.50 cents on the week, lowest since July 17, 2024, but still 8.50 cents above a year ago. There were four sales for the week and 10 for the month, down from 16 in January.

Trump’s threatened tariffs look like they will indeed be implemented March 4, and the dairy industry is watching things closely because they will impact U.S. dairy exports.

HighGround Dairy’s Monday Morning Huddle said that the tariff exemption China has maintained on whey for the past four years on U.S. products expires Feb. 28, “which means U.S. whey imports into China will no longer be duty-free. The U.S. primarily ships feed-grade whey, which the Chinese use for pork production. This expiration and heightened trade tensions with the country have already signicantly impacted the U.S. whey market.”

In other global news, Tuesday’s Global Dairy Trade Pulse saw 4.33 million pounds of product sold, up slightly from the Feb. 11 Pulse and 96.9% of the total on offer. Prices on both skim and whole milk powder were down from the last Pulse.

On a brighter note, the Feb. 24 Daily Dairy Report said, “The yogurt market could be poised for a

demand resurgence. Not only are sales increasing due to the growing use of GLP-1 weight loss drugs, but a new study shows that eating yogurt twice a week could reduce the risk of colon cancer. With colorectal cancer the third leading cause of cancer death in the U.S. in men and the fourth leading cause in women, that that can only bode well for yogurt consumption. Yogurt consumption in the U.S. reached an all-time high in 2024 at over 4.9 billion pounds, up 3.7% from 2023. According to Circana data, year-over-year unit sales of yogurt grew 2.8% last year, while unit sales of drinkable yogurt climbed 9.8%.”

In politics, the International Dairy Foods Association and the National Milk Producers Federation gave a thumbs up to the Trump administration’s updated response plan for highly pathogenic avian inuenza.

IDFA President and CEO Michael Dykes, D.V.M., said, “The International Dairy Foods Association is grateful to Agriculture Secretary Rollins for investing up to $100 million in new and ongoing research into animal vaccinations and therapeutic tools to manage highly pathogenic avian inuenza in our nation’s dairy herds and commercial poultry ocks. We continue to urge USDA and its federal partners to act quickly to develop and approve the use of safe, effective bovine vaccines to guard against current and future strains of avian inuenza affecting U.S. dairy. It is essential that the federal government work with our industry to ensure a vaccination strategy is feasible and costeffective for farmers while working with international trading partners to assure the use of vaccines does not limit or disrupt U.S. agricultural exports.”

NMPF President and CEO Gregg Doud said, “Dairy farmers and cooperatives appreciate USDA’s leadership in supporting American agriculture and safeguarding animal health as it deals with what soon will be a second year of H5N1 bird u disruptions in dairy cattle. Dairy farmers and all of agriculture take biosecurity seriously, and we thank USDA and the Trump administration for actions that will further those efforts.”

Round corn stalks $17.50. All prices by the bale. Check out our new website features! Get a detailed market report for every animal and every haybale sold on our Thursday sales. The dairy catalog is also posted with Market reports for your reference. Coming soon for Thorp as well.

By Michelle Stangler Contributing Writer

Editor’s note: Information for the article was provided by Dakota County Historical Society, trucker Bryan Pexa, two employees at the stockyards, Don Glassing and Tom Ostlie, along with independent research.

ST. PAUL, Minn. — Situated on a portion of 260 acres purchased in 1886, the South St. Paul Stockyards brought in more than 300 million head of livestock before closing their doors in 2008. When the land was rst purchased, 75 acres were plotted into town lots while the remaining 185 acres were designated for stockyard use. Despite

challenges, the stockyards grew, driven by the dedication of those who worked there as it led the way to shaping a city dependent on the livestock industry.

At its peak in the early 1900s, the stockyards saw record livestock receipts. In 1934, 1,475,890 cattle were sold as well as 840,413 calves.

A decade earlier in 1924, the stockyards saw 3,751,395 hogs. Two years later in 1926, 88,279 rail cars were used. In the midst of the war years in 1943 the stockyard sold 1,787,014 sheep.

For Don Glassing, the stockyards were a family tradition. His father worked at the Central Livestock Association Commission, and Glassing himself started there at age 16, dedicating 55 years to the industry. At 23, after three months of marriage, he was drafted into the military, serving two years in active duty, two years in the reserves and another two years on standby.

Turn to DAIRY HISTORY | Page 12

ON THE HIGHWAY, A TRACTOR TRAILER FLIES BY.

On the back door you see a picture of a Hotsy and a big QR code. You’ve just caught sight of the Hotsy Monster truck hauler on its way to or back from a Monster Jam event.

That QR code is your ticket to a free Hotsy 555SS or 795SS pressure washer. Scan it and it takes you to Hotsy.com/Monster to fill out a quick form. We’ll be choosing one lucky winner to receive a 555SS or 797SS. Want to get in the game? Head over to Hotsy.com/Monster.

One entry per person. Winner picked the first week of 2026!

“I still think of the stockyards,” Glassing said. “It was our livelihood for a lot of people that lived in South St. Paul.”

Tom Ostlie, a friend of Glassing, started working at the stockyards in 1972.

“The last few years, we became closer friends,” Ostlie said. “We still meet up.”

Dorner Equipment Green Bay • 920-655-3215

St. Joseph Equipment Lacrosse • 608-769-7796

Swiderski Equipment Wausau • 715-551-7893

Ritchie Equipment Cobb • 608-623-2331

Bryan Pexa, who spent 43 years trucking livestock, also said he recalls the stockyards fondly, though he is relieved not having to deal with heavy trafc.

“That’s one thing I don’t miss,” Pexa said. “Driving in trafc got worse over the years.”

“In whatever we may do in this matter, I want the hearty support of every businessman and citizen, and all these matters must be decided on their merits,” Stickney said.

Ostlie described the stockyards as a bustling hub.

“There were a lot of cattle, hogs, and sheep — large numbers,” Ostlie said. “It was a small city inside of a city. It was big in its time.”

Ostlie said there is an ever-present need for markets that support farmers, especially small producers.

“The larger producers always have different options, but small producers need good markets for their animals,” Ostlie said. “It continues to be a crucial part of livestock marketing.”

Historical documents from the 1970s highlight how livestock marketing became an issue when farmers produced more animals than their families needed.

The history of the South St. Paul Stockyards began May 3, 1886, with a meeting of local businessmen, western cattlemen and railroad ofcials. At the center of it all was A.B. Stickney, then president of the Minnesota and Northwestern Railroad, who recognized the need for a livestock market.

Stickney saw the need watching 75,000 western cattle pass through the St. Paul area enroute to Chicago. That same number of beef carcasses were moving back from Chicago.

Among those early conversations was one with Theodore Roosevelt before he served as president.

In response, Minnesota farmers centralized cooperative selling in 1921, forming the Central Cooperative Commission Company. Now known as the Central Livestock Association, it was the last commission rm operating in the stockyards before shifting most sales to its Zumbrota location.

The South St.Paul Stockyards faced many challenges that led to its closure. A drought in the 1930s led to increased sales, while World War II price controls created market confusion. Over time, industry trends changed, making it harder for large processing plants to operate efciently.

“There can be no possible disadvantage,” Roosevelt said. “It must be a great advantage to the producers. The great loss from shrinkage in the shipment of stock east is between St. Paul and Chicago. We would certainly gain on shrinkage, freight and absence of competition with inferior and southern cattle and still have the option of shipping to Chicago.”

Stickney knew community support was important and outlined the potential for a livestock market and meat packaging plant in St. Paul.

“The economy, the expenses, the costs of operating those big plants — it was difcult,” Glassing said. “So, they moved to smaller slaughter plants outside the city.”

Though the South St. Paul Stockyards are now gone, their legacy remains.

Nine years with Dairy Herd Improvement Association

Lonsdale, Minnesota

Tests for 39 farms

75,000 samples taken in 2024

What is a typical day in your life? I have a supervised herd to test every morning during the weekdays. I wake up between 2-5 a.m., depending on where I’m going. I try to double up on farms based on the timing of their milking schedule to make my morning worthwhile. Then, I pick up or drop off meters and samples for herds doing their own sampling.

My afternoons consist of getting samples numbered for upcoming herds, making phone calls and answering emails. Also, I ship off any samples through Spee-Dee Delivery Service Inc. Once that’s done, I go to my parents’ dairy farm and help them with chores. With a short break in between, it’s time to pick up my two kids from daycare. I test herds at night about two nights a week. I try to pick farms that get done earlier so I can spend time with my family.

What attracted you to this role? I started at a young age, keeping records of cows for my dad. As I got older, I enjoyed helping keep on top of cows that needed to be bred, dried off, etc.

I attended the University of Wisconsin-River Falls, where I majored in dairy science. I always knew I wanted to do something hands-on associated with dairy

cows, specically the management side. The opening for a Dairy Herd Improvement Association tester became available in my home county a couple of months from graduating. I gave it a shot, and here I am nine years later, still loving it.

How do you balance being a mom and working as a DHIA tester? Balancing can be tricky at times. The nights I work, I don’t get to see my kids sometimes because they are in bed when I get home. That’s why I try to work only two nights a week. Any more than that, I can really tell how much they miss me. When I am home, we spend a lot of time together playing, baking and going on walks.

What is a favorite memory you have of working this job? All the different people I have met. I have done a lot of relief work for other testers in different areas of the state, and meeting those farmers and learning about the way they run their farm has always been so interesting to me. No farm is ever really the same.

How did you adjust to the variable testing times of dairy farmers? It took me a little while to get adjusted to an abnormal sleep schedule. Those very early morning herds usually require some caffeine. The

Tracie Vikla holds up a milk sample Feb. 12 at Gar-Lin Dairy near Eyota, Minnesota. Vikla took 75,000 milk samples in 2024.

best thing you can do is know your limits and listen to your body.

What are three aspects of your job that you really enjoy? I really enjoy making my own schedule. That way, I can coordinate to get all my herds done when it works best for me. Typically, I like to schedule for me to come back for the next month before leaving a farm. I enjoy the people. The farmers and employees are some of the hardest working people. They all have dedication to the dairy industry and are constantly trying to improve to have the best quality product. Not as many people anymore can say that they work 365 days a year.

Turn to VIKLA | Page 14

I enjoy knowing the services I provide are going to benet the dairy. We provide them with so much information. Typically, with the SCC being an important indicator of udder health and milk quality. Also by monitoring milk components of butter fat and protein can help identify health and nutritional issues in cows.. We even provide pregnancy, Johne’s disease, leukosis and DNA mastitis culture testing.

Tell us about the most unique experience you’ve had in your role with DHIA. I have had my fair share of helping farmers corral animals back in. One time, I had just arrived at a farm on a foggy morning. As I was getting out of my car, the herd bull had gotten into the barn, and then he ran out of the sliding doors at me. He was not aggressive; he just looked at me and ran the other way.

Another time, I was traveling to southeast Minnesota to help with a larger herd when it had been snowing all night and the roads were slippery. They usually keep the roads cleared on U.S. Highway 52, but on that morning heading southbound, a semi started to lose control, and I ended up going into the ditch between the north and southbound lanes. I did a 360 and ended up on the northbound lane side. I needed a tow truck to pull me out, but I still made it to the farm to complete testing.

What is a lesson you have learned from the dairy farmers you test for? They are the most resilient people. The lowest milk price or loss of a favorite cow has not made it easy for them over the years.

I have also learned patience. Farming doesn’t go as planned, things break or there’s an unexpected down cow. Then, I end up being at that farm longer, but that’s the way it goes.

What has been one of the biggest challenges you have had to overcome in this role? The driving. It is not unusual for me to drive 200-300 miles each week. Farms are getting farther apart and farther from where I live.

How have you seen the benets of DHIA testing manifest themselves in the herds you work with? Having the farms know the SCC from month to month is a benet. If they have a cow go several months with a high SCC, she is put on the chronic cow list and a do not breed/breed to a beef sire list. The breeders heavily rely on our data to know the genomics of an animal. Also, nutritionists rely on the results of the components of fat and protein so they can adjust the ration.

For herds doing pregnancy testing on their cows, they are saving the step and cost of a vet. Also, by using Johne’s disease and leukosis testing, farmers can cull that disease out.

What issues and opportunities do you see in the future for the dairy industry as a whole? A lot of farmers are getting to the point where they want to retire and there is no one to take over. I see a lot of farms selling out in the next ve years. That is scary when so many businesses rely on these dairies.

More veterinarians don’t want to do large animals anymore because there are not enough farms to make it worthwhile. The farms left have a hard time getting a vet out if they have after-hour emergencies.

More farms are putting in robotic milking machines as it’s getting harder to nd reliable help. Farmers are resorting to putting these in to take milking off their chores.

What changes have you seen in the industry? Technology has been the biggest change. More farms are incorporating some type of technology, like using programs such as DairyComp or PCDart for management of their herd. Also, more farms are putting in robotic milking machines.

I have also seen farmers having the best components of fat and protein while still producing above-average milk production. The change in feed quality and the advanced sires being used have played a part, along with being able to do genomics and DHIA testing to quickly weed out the poorest cows.

What training did you receive? For about a week, you go with another tester to farms and learn the basics. The biggest thing is learning how to do everything for DairyComp. We are also required to do class work and take a test. We learn the proper way to mix and pour samples. Making sure we mix the samples before pouring them into a sample bottle is important because dairy cows have the most fat at the end of their milking. We learn to care for and wash the meters we use on farms; they get calibrated once a year.

Twice a year, we attend conferences to learn what is new and stay certied testers.

What is a common misconception about your job? That having a DHIA tester come is a requirement for dairy farmers by the state. We are hired to provide a service and to help give them information to make management decisions about their cows.

Tell us about yourself and your family. I have been married to my husband, Travis, for seven years. We have two children: Mary, who is almost 4 years old, and Marvin, who is 17 months. My husband is a full-time beekeeper with about 150 hives. We grow vegetables, melons and strawberries that we sell at the local farmers’ markets. Travis also farms corn and soybeans with his dad. Travis’ parents own a greenhouse business called Vikla Farm & Greenhouse. The time to start plants is right around the corner. My parents, Joe and Karen Korbel, have a 40cow dairy about two miles away from me. I help often with chores or milking along with my two brothers, Steve and Kevin.

By Stacey Smart stacey.s@dairystar.com

LUXEMBURG, Wis. — Megan Salentine is a fan of all things fair-related. From showing livestock with family and friends to emceeing the Kewaunee County Fair auction, the 21-year-old has made some of her favorite memories on the fairgrounds.

As the 2025 Wisconsin Fairest of the Fairs, Salentine will share her enthusiasm for these popular summertime events with fairgoers across the state.

“Fairs contribute so much to communities and to those who attend,” Salentine said. “I’ve been surrounded by the county fair my entire life. It was a holiday in our household, and I want to be able to share my love for that and show how important fairs are.”

Salentine was crowned Jan. 8 at the annual Wisconsin Association of Fairs convention in Wisconsin Dells. Representing the Kewaunee

County Fair, she was one of 33 vying for the title.

Salentine is the daughter of Josh and Jenny Salentine. The Salentines milk 300 cows and farm 600 acres near Luxemburg at Salentine Homestead Dairy, a fth-generation, century farm.

“On the farm is where my passion for everything dairy began,” Salentine said. “I love dairy, and I love promoting it. I enjoy connecting the producer to the consumer and explaining how a product gets to the grocery store from a hardworking family farm.”

Growing up, Salentine helped with milking cows, feeding calves and taking care of her and her siblings’ registered show herd. Salentine continues to help during college breaks and does the lawn cutting in the summertime.

“My dairy background has given me an incredible avenue to help share the message of fairs,” Salentine said. “I have gotten a front-row seat to see how hardworking and passionate dairy farmers are for their trade and craft in my county and community, and I am proud to be the one to help

BIDDING AVAILABLE THROUGH CATTLEUSA • www.equitycoop.com

Sheep and Goat Sale

First Sale April 1, 2025 1st Tuesday Of The Month

Regular Sales: Tuesdays @ 10:30 AM Fats, Bulls, Cows & Calves (Calves sell at 12:30 PM)

2nd & 4th Friday of each month @ 10:30 AM

nearly 60 years ago to choose an ambassador for the Wisconsin Association of Fairs. Representing 75 county, district and state fairs in Wisconsin, the association’s mission is to provide innovative programming and resources to its members, enhancing and supporting the vitality of the fair industry and community.

when she was in kindergarten. As she grew, Salentine immersed herself in everything the fair has to offer — from cake decorating, sewing and quilting to rubber stamping and leather crafting. She also showed swine and dairy with her siblings.

2021MF5711Dw/FL3819ldr, 1021hrs,Dyna-4trans,3hyds, Cabsuspension,LikeNew!

NewSunflower5035-28 28'Fieldcultivator,5barspike harrow,Gaugewheels

“It was a lot of fun,” Salentine said. “My siblings and I do it together, and although the days were stressful and long, those were some of the fondest memories I have of all of us working together.”

The Wisconsin Fairest of the Fairs travels extensively throughout the state promoting the educational, agricultural, social, cultural, and commercial benets and opportunities available at Wisconsin’s fairs. Salentine will serve a 1-year term in which she will attend over 50 fairs and events throughout Wisconsin.

Salentine’s favorite event is the dairy futurity. She also enjoys her county fair’s auction.

“Our community is so well rounded and supportive of our youth in agriculture,” she said.

1994NewHolland8970 7150hrs,710/70R38rears,Front weights,Autosteer

NewSunflower5035-28 32'Fieldcultivator,5barspike harrow,Gaugewheels

2009AgcoDT240A 6222hrs,CVTtrans,Front3pt& PTO,Rearduals,Deluxecab

“I am excited to travel the state, see all the fairs, and meet exhibitors and fairgoers,” Salentine said. “I come from the northeast part of the state and haven’t gotten out of Kewaunee County much. I look forward to seeing what the rest of the state has to offer.”

One of Salentine’s favorite fair memories was celebrating the 100th anniversary of the Kewaunee County Fair while serving as Junior Fairest.

“It was a very special year celebrating the history and heritage that brought the county fair together while experiencing it in the Fairest role,” she said.

Early mornings on the wash racks and feeding animals before sunrise with her family of exhibitors are other fair memories Salentine said she cherishes.

NewMFVF1230&VW1230 planters-AvailableforSpring! PrecisionPlantingequippedvSet,vDrive,Deltaforce,20/20 NewLandoll7530-23'VTPlus 5-15degreeangle,Doublereel MSRP:$128,650(Lessdiscounts)

Salentine will also serve as the ofcial ambassador for the 2025 Wisconsin State Fair and will be present each day of the 11-day event taking place July 31-Aug 10. She will greet fairgoers and other guests, perform as the master of ceremonies for events, participate in various contests, and educate the community about fairs.

During her tenure, Salentine will work with the media, creating online content and engaging in conversations promoting the importance of Wisconsin fairs. In her travels, Salentine will highlight the uniqueness of each county fair and what it offers the state.

“I love the community we built as showmen,” she said. “I look back on those things fondly.”

Although she never showed animals at the state fair, Salentine and her family regularly made the trip down to West Allis every summer, where Salentine’s favorite thing was looking at the animal exhibits.

Salentine served as Junior Fairest of the Fair for Kewaunee County in 2017 alongside Isabella Haen who went on to become the 2018 Wisconsin Fairest of the Fairs.

No trip to the state fair would be complete for Salentine without also taking a ride on the sky glider and getting a cream puff.

“I love the food and the people,” she said. “At the state fair, you see the importance of agriculture and how important it is for our community at a higher level.”

“Isabella was one of my role models for this position, demonstrating the importance of fairs throughout Wisconsin,” Salentine said. “We are the only pair to have served together in the same year at the county level that went on to earn the Wisconsin Fairest of the Fairs title.”

In 2024, Salentine served as Fairest of the Fairs for Kewaunee County.

“The Kewaunee County community is really special, and this position helped me promote something I love so very much,” she said.

Salentine started taking projects to her county fair as a 4-H cloverbud

Salentine is a junior at St. Norbert College in DePere studying elementary education and English language arts. In the future, she hopes to teach in a lower elementary school classroom within a rural community.

“I want to continue giving back what my community has given to me and relay the importance of agriculture,” she said. “I want my students to know I grew up on a dairy farm and help them understand where their milk and cheese comes from.”

By Amy Kyllo amy.k@star-pub.com

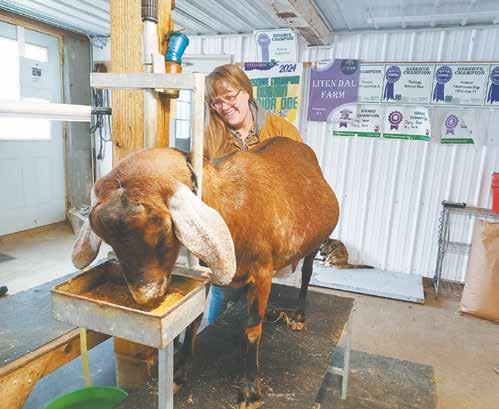

FOUNTAIN, Minn. — In the early mid-2000s, the Zoellner family got the rst of what they have since nicknamed their “gateway chickens.” For them, the fowl opened doors to a lifestyle of homesteading and self-sustainability that now includes dozens of dairy goats.

“I don’t care where you come from, (if you think) ‘I’m going to homestead,’ it’s a chicken — that’s the rst thing you get,” Kirsten Zoellner said. “We were just so blissfully happy.”

Kirsten and her husband, Joel, own Liten Dal Farm near Fountain. There, on almost 11 acres, they raise about 40-60 registered Nubian goats, milking 15-18 does each year. They also own Highland cattle that they can milk freestanding in the pasture as well as chickens

and other animals.

The Zoellners farm alongside their six children, homeschooling the youngest four. Evin, the oldest, is their farm manager. She will be attending the University of Minnesota’s College of Veterinary Medicine next fall. Another adult daughter, Lauren, works on their marketing.

The dairy goat herd was established around 2007 when they purchased their rst registered Nubian goat as a companion for the children’s pony.

The goats multiplied, tting the Zoellners’ desires to have their own milk supply for the large family they planned on having.

“We got into cheese making and all the other things that come with it,” Kirsten said. “It just snowballed.”

Today, the family markets their genetics and milk, and they show their goats. They sell breeding stock, from kids to aged does, annually, have exported breeding stock internationally, and have a waiting list for wethers. Increasingly,

Turn to LITEN DAL | Page 20

their micro dairy is becoming a major component of their business.

The Zoellners started doing linear appraisal in 2022. They breed for production, breed conformity, behavior, parasite resistance, fertility and kidding ease. Kirsten said health is their No. 1 priority. They test annually for disease, and each animal is tested once for genetic normalcy.

“If we can build animals that are going to work long-term for us and consistently put out the traits that we want, it’s going to reap so many more benets,” she said.

They have incorporated line breeding with their own bucks since 2022 and are beginning to utilize A.I. in their breeding program.

The Zoellners kid starting in midFebruary. They have cameras in their barn to aid in monitoring. Once kidded, the goats milk a 305-day lactation.

Kids are fed free choice cold milk in a lambar feeder. The Zoellners started using this last year and said they saw signicant increases to average daily weight gains and healthier kids with less parasite and disease problems.

Kirsten said infrastructure startup costs are part of the reason they have not become a larger, commercial goat dairy.

“We went the micro dairy route and just direct to customer because I have no interest in having 140 goats,” she said. “You add that many animals, and you exponentially have problems, and I think it’s very hard to manage what you want to do with the herd in the long term.”

Their milk customer base varies on the time of year and available supply. Normally, they have about 12 shares. Their customer base is diverse and in-

cludes older and younger adults, families and single people. Customers sign up for a share, sign a liability waiver and take the milk home in their own containers.

“They become like another … extension of the family,” Kirsten said. “They leave us Christmas cards and Christmas cookies. We leave them little gifts now and again.”

The Zoellners milk their goats twice a day with a milking system. Joel built their rst system in 2012. All milk is double ltered. The Zoellners do not have a bulk tank, so after milking, the milk is rapidly cooled in glass containers in a freezer for 90 minutes before being stored in a refrigerator.

“We’ve always told people … ‘We’re consuming this, too, and are giving it to our kids, so we’re making sure that everything is as high-standard as possible,’” Kirsten said.

The Zoellners said they have shown every species of farm animal through 4-H.

“(The goat community) is competitive, but the most cooperative and helpful, as well as being highly networked,” Kirsten said. “They want to work together and help each other.”

Kirsten shares their story via their farm’s social media. She said if she does not post for a few days, she gets texts wondering whether everything is OK.

“It’s people who don’t live on farms, they’re so curious about agriculture,” Kirsten said.

The Zoellners encourage visitors, although they require an appointment.

“If somebody has this genuine question about agriculture or wants to get into goats … we’re happy to talk,” Kirsten said.

As they look to the future, the Zoellners have the goal to convert their grain bin into a farm ofce and store. They are also planning other projects related to agriculture education, agritourism and direct-to-consumer sales. Overall, they hope to keep updating the farm, pay it off and give their children the opportunity to take over.

“The idea is that, when we’re ready to retire, we can pass off a farm that’s

Stjernholm sand separator now available through Midwest dealerships

A new partnership is bringing high-quality sand separation to the doorsteps of U.S. dairy farmers. Originating in Denmark, Stjernholm technology can now be found close to home through a full-circle approach that includes dealerships in Wisconsin and Minnesota working alongside a local distributor, Dairy Nutrient Reclamation. Providing three layers of quality to ensure a seamless experience, farmers will enjoy quick service with local boots on the ground.

The Stjernholm sand separating system provides quality sand bedding for maximum cow comfort, recycling at levels exceeding 90% retention. The tailor-made systems have the smallest footprint on the market. Currently, 12 systems are installed in the U.S. with 10 more to come this year.

Through this new partnership, you will have the backing of a trifecta of knowledge, service and experience accentuated by farmer-to-farmer interaction. Trillium Hill Farm is working with Dairy Nutrient Reclamation in showcasing its own Stjernholm system. See the system in action on a farm reclaiming 98-99% of its sand.

“We are here for the farmers,” said Mike Jones of Trillium Hill Farm. “Through this unique setup, we are engaged with customers from day one.”

fully functional and multifaceted,” Kirsten said.

The Zoellners nd working on their farm to be rewarding, and it has t their vision for raising their family.

“There’s just something that comes with that lifestyle,” Kirsten said. “It’s a slower pace. … You learn to appreciate more. ... You’re more connected to the world around you, to your neighbors, to your community.”

proven by farmers, for farmers

These Minnesota DHIA cows are top lifetime production cows in 2024 ranked by Dollar Value, which is one measure of high productivity. Cows making this list need to have both extreme longevity, high production, or both over multiple lactations.

Vorwerk Dairy’s 358 (ranked 126th) had the highest longevity among the top 200 cows with 13 lactations and 4,020 days in the herd since first calving.

Hyde-Park Holsteins’s 5346 (ranked 100th) had the highest Dollar Value of production per day ($27.64) among the top 200 cows and accumulated 19,635 pounds of solids in just 6 lactations.

Dollar value weights milk, butterfat, and protein pounds by their respective economic value. This year’s 2024 formula accounts is a significant change from previous years with an increased value of butterfat in current economic conditions: (0.0150 x milk pounds) + (3.38 x fat pounds) + (1.68 x protein pounds)

‘23 Bobcat S76, CAH, SJC, 1800 hours ‘22 Bobcat S76, SJC, 1600 hours

‘21 Bobcat S76, SJC, 1,500 hrs.

‘23 Bobcat S64, CAH, 3,400 hrs.

‘22 Bobcat S64, SJC, 4,100 hrs. ‘22 Bobcat S64, 4,100 hrs. ‘21 Bobcat S64, 2700 hours ‘21 Bobcat S64, Foot, 2,900 hrs.

‘20 Bobcat S64, CAH, SJC, 4650 hours

‘23 Bobcat T64, CAH, ONLY 13 Hours! ‘21 Bobcat T76, SJC, 600 hrs. ‘21 Bobcat T76, 1400 hours

‘21 Bobcat T76, 689 hrs.

Bobcat T76, 882 hrs.

Bobcat T770, 1,500 hrs.

Bobcat T770, SJC, 700 hours

Bobcat T770, SJC, 1000 hours

Bobcat T770, SJC, 300 hrs.

‘20 Bobcat T770, SJC, 900 hours PLANTING/TILLAGE

‘20 Kinze 3660, 16R30, bulk fill ‘23 Kinze 3605, 12R30, bulk fill, 410 acres ‘10

CAH, SJC, 1,500 hrs.

‘23 Bobcat TL619, CAH, 500 hrs.

‘18 Bobcat S650, 3,600 hrs.

‘17 Bobcat S650 CAH, 5400 hours

‘14 Bobcat S650, CH, highflow, 2,100 hrs. ‘20 Bobcat S570, CAH, 4,400 hrs.

‘20 Bobcat S570, 2,900 hrs. ‘18 Bobcat S570, CAH, SJC, 3200 hours ‘15 Bobcat S570, CAH, SJC, 2,000 hrs. ‘15 Bobcat T550, ACS, Open Station, 1,855 hrs. ‘08 Bobcat S185, 3,000 hrs. ‘06 Bobcat S300, CAH, 2 spd., 4,300 hrs.

‘02 Bobcat S300, 4,200 hrs.

‘04 Bobcat T300, CAH, 4,300 hrs.

‘91 Bobcat 440B ‘21 Gehl 325G, CAH, 800 hours ‘15 Gehl R190, 1,900 hrs.

‘14 Gehl V270, CAH, 400 hours

‘23 NH L320, 1,486 hrs.

‘23 NH L318, 1,400 hrs.

‘13 NH L215, C/H, IOS, 1,200 hrs.

‘21 Deere 325G, tracks, ISO 2 spd., 882 hrs. ‘17 Deere 324E, CAH, 5,200 hrs. ‘02 Caterpillar 262, 2300 hours ‘19 Kubota SSV65, CAH, 1000 hours ‘19 Kubota SSV65, CAH, 6000 hours

By Stacey Smart stacey.s@dairystar.com

PESHTIGO, Wis. — When doubling his land base three years ago, rst-generation farmer Aaron Pape was looking for the best utilization of land to drive a prot. He found that niche in grazing other peoples’ heifers.

“With custom grazing, I’m separated from the ups and downs of conventional cattle markets,” Pape said. “I set a price with my grazing clients, and that’s what I get paid. It’s very predictable, and the cash ow is great.”

Pape shared the successes and defeats of his journey during his presentation, “Custom Heifer Dos and Don’ts,” Jan. 23 at the GrassWorks Grazing Conference in Wisconsin Dells. Pape learned from trial and error and advice from others in the industry how to run a successful custom heifer-raising business that has become a money-maker for his farm.

Pape runs Pape Family Pastures with his wife, Erin, and children, Nora and Levi. Pape grazes 250-300 custom dairy heifers on about 200 acres across four different sites consisting of 31, 42, 51 and 85 acres. Each farm is within a 30-minute radius of where the Papes live.

Custom heifer grazing is one of four enterprises the Papes offer along with grassfed beef, organic pastured chick-

en and pastured pork. Pape also works off the farm as a business instructor at Northeast Wisconsin Technical College.

“We came to grazing because of the conservation benets and stayed for the farm economics,” Pape said.

After ve years of doing direct sales of beef, chicken and pork, Pape’s goals shifted to a desire to farm full time. To make that reality, scaling rapidly was a must. The Papes more than doubled their acreage in 2022, adding 95 acres of rental land.

Pape said custom grazing was a low capital expenditure expansion that allowed him to fully stock those additional farms with animals he did not have to purchase.

“It was a low nancial risk,” Pape said. “I had no cattle loans. We get paid monthly, and there are not a lot of hidden costs with good margins to be had.”

The Papes take in heifers under 14 months old, with most falling between 6-12 months of age. They also house a small group of post-weaned calves. Heifers are sent home before breeding.

“I do not currently have facilities for breeding animals,” Pape said. “I’m open to running bulls but haven’t had the right opportunity for that yet.”

Pape has two custom heifer clients. One is a 120-cow dairy, and the other is a connement custom heifer raiser. Pape said he enjoys the exibility of having a client who also custom raises heifers.

“I get as many heifers as I want, when I want,” Pape said. “He is the one who gave me my start and took a chance on me.”

Turn to PAPE | Page 24

Beta Glucans

Live Cell Boulardii Yeast

Yeast Culture

Bacillus (6 strains)

polyphenols

Methionine

MCM- (Manna-hydrolyzed Copra Meal)

MOS- Pre/Post biotic

Secure Covers

Silostop Gravel Bags

Sorbiam

Heifers get dropped off in one of the corrals and are fence trained for a day before being released to pasture. Pape uses poly wire on the interior corral fence to train animals.

“They’re going to knock that poly wire down repeatedly,” he said. “I stand it back up, and eventually they get the point.”

Within 24 hours, heifers are ready to go on pasture.

“Don’t make the rst paddock super tight,” Pape said. “Don’t push your luck.”

Pape said a single 32-inch-wire on interior fences is inadequate for maintaining control of heifers. He said heifers will test the wire when they get stressed. Therefore, he added a top wire, and now all interior fences contain 32inch and 42-inch wires. Pape said he recommends using a double poly wire in tall grass, making the fence line easy to see.

custom-raising heifers on grass.

“You need good working facilities,” he said. “Broken gates and baler twine are not going to cut it. These are animals that have never seen grass before, and you need a place to hold them securely.”

To ensure sufcient water for his herd, Pape uses a 100-gallon poly tank equipped with a mega ow valve that can pump 50 gallons per minute. The system contains brass ttings instead of plastic to prevent breakage by heifers.

“Water systems need to be bulletproof,” Pape said. “That is especially critical for us because we don’t go to the rental farms every day, and we can’t risk animals being out of water.”

Pape said communication between himself and his clients is the glue that holds everything together.

“You have to manage the grass so animals gain weight. Keeping grass vegetative as much as possible is important to get good gains.”

Paddock moves are every 1-3 days depending on location. At the home farm, heifers are moved daily, whereas moves at rental properties occur every other day. Over the weekend, Pape likes to set animals up for three days’ worth of grass. Pape also feeds supplemental grain at about 4 pounds per head per day.

AARON PAPE, FARMER

“We started at 2 pounds per day, but 4 pounds seems to be the sweet spot,” he said. “Heifers need energy to grow, so don’t be afraid to feed grain.”

“At the end of the day, this is a service business, and the client relationship is No. 1,” Pape said. “You have to work with people you can trust. This relationship requires a lot of trust from both parties.”

Pape frequently communicates with each client about everything from grass conditions to health issues.

“I send my clients pictures all the time,” he said. “I think people appreciate knowing their animals are being well tended to or learning about problems early on.”

Pape supplies the grain and passes that cost onto the client. Grain is fed in 55-gallon barrels cut in half and bolted together. He said they are easily moved from paddock to paddock. Pape provides his heifers with a luxurious amount of bunk space to make sure every animal can access feed. His benchmark is 24 inches per head.

Pape said feeding grain also allows him to stock more animals per acre. He feeds about 12% of a heifer’s dry matter needs through grain, enabling him to stock 12% more cattle.

“You have to manage the grass so animals gain weight,” Pape said. “Keeping grass vegetative as much as possible is important to get good gains.”

During his talk, Pape addressed the required infrastructure necessary for

Setting clear expectations and responsibilities is paramount to a good working relationship. Pape said rates are one key area to address along with payment frequency and terms. In Pape’s tiered payment structure, he charges more for larger animals and less for smaller ones. Deciding who pays for what, such as feed and drugs, should also be agreed upon. Pape said it is a good idea to have a written contract.

Although his rst grazing season produced poor results, guidance from a client helped turn things around for Pape.

“We’re open to feedback and criticism from our client farms, and that’s part of the reason we’re still in business,” Pape said. “We made changes, and our performance improved. Now, we’re having to turn people away because we don’t have enough land.”

By Danielle Nauman danielle.n@dairystar.com

WASHINGTON — For those stepping up to serve and protect the U.S., access to a cold glass of nature’s most perfect food — milk — is not currently a given.

Republican Rep. Derrick Van Orden, a retired Navy SEAL who represents Wisconsin’s 3rd Congressional District, introduced the “Strengthening our Servicemembers with Milk Act” alongside Republican Rep. Guy Reschenthaler of Pennsylvania in January. The legislation would direct the U.S. Secretary of Defense to provide uid or powdered milk to members of the armed forces at dining facilities on military installations.

“Right now, the military does not have to provide milk to our troops on military bases, and being from Wisconsin I nd that bizarre,” Van Orden said. “I’ve run into it several times personally. I served for 26 years and have been deployed around the world. I’ve lived and worked on ve continents. On several of the bases we just didn’t have milk available to us. To me, that is just silly.”

As a Wisconsin native, Van Orden said that lack concerned him on several levels, and he reached out to active duty servicemembers to see if access issues are still a problem. He learned that they are.

“Milk is quite possibly the most nutritious uid you can consume,” Van Orden said. “We have a younger population in the military, a number of them are still growing actually. They need strong bones; they need those essential minerals found in milk.”

Van Orden said for many servicemembers, a glass of milk can be a comfort in what can be stressful and dangerous situations.

“Even though I’ve lived it, it’s hard to imagine life without a simple glass of milk,” Van Orden said. “Imagine being overseas, serving your country and not being able to have that little bit of home?”

Van Orden said ensuring milk is available to service members is not a new concept.

“There is a contract from the 1960s that provides milk on submarines,” Van Orden said. “Submarines don’t like carrying uid milk because of space restraints; but they can make their own water and oxygen. With powdered milk — which can be as nutritious as uid milk — our sailors can have a nice, cold glass of milk 600 feet below the surface of the ocean. They rely on that milk as a source of vitamin D, which is a primary concern in that situation.”

This bill to ensure milk is available to military service members is a hallmark of the things important to Van Orden as he serves in the U.S. House of Representatives: support for Wisconsin agriculture and support for the troops.

“What we’re doing here in my ofce is trying to make sure that every single thing we can do to ensure our

dairy farmers have a level playing eld on the world stage (happens), and also that we can get our products out to our own people,” Van Orden said. “That is a primary focus of my ofce, taking care of our farmers.”

This is the second time Van Orden has introduced the legislation, but he said he is condent that this time it will make its way through both chambers of Congress and nd its way to the president’s desk to become law.

“This bill is very simple and it’s just the right thing to do,” Van Orden said. “I really can’t see anyone opposing it. It just ensures our servicemembers access to any kind of milk — powdered, avored, 1%, 2%, whole — you just have to have it available to them.”

In addition to this bill, Van Orden said he is happy to see a number of dairy-related bills being introduced.

“We’ve been able to tie a lot of them into the farm bill, which we are working diligently to get done,” Van Orden said. “It was disappointing the way the farm bill was held up in the last Congress. Was it a perfect bill? No, but it was a good bill. No legislation is ever going to be perfect.”

Van Orden said he did not feel there was a lot of focus on ag in the last Congress.

“I am hopeful we can change that and bring ag into the foreground,” he said. “We need to focus on our American agriculture industry. If you become dependent on somebody else to feed your country, you’ll nd yourself in a tight spot rather quickly. You have to feed your own people.”

Stearns County is seeking candidates associated with the dairy industry. The Stearns County Dairy Advisory Committee meets on a quarterly basis to recommend and advise local and state governments. They discuss and highlight industry issues and opportunities, with the goal of improving Stearns County and the dairy industry as a whole. Responsibilities of members include providing input on educational engagement for dairy farmers, understanding local governments interactions with local dairy farmers, and interpreting benefits and possible hurdles. The committee is composed of dairy producers and dairy allied industry professionals that reside in Stearns County.

If you are a dairy industry professional interested in being considered for said appointment, please complete the online application located on the S tearns County website (https:// stearnscounty.civicweb.net/Portal/ BoardApplication/). Otherwise, please direct all further information to the Auditor Email (Auditor. Email@stearnscountymn.gov) or by mail to the Stearns County Auditor-Treasurer’s Office (Attn: Sierra Lorbeski, 705 Courthouse Sq., Rm. 148, S t. Cloud, MN, 56303). ALL APPLICATIONS MUST BE RECEIVED BY 4:30PM ON FRIDAY, MARCH 21ST, 2025.

I am ready to shift from the deep-frozen grip of winter to our next weather adventure. By the new month on the calendar, it looks like I need to start thinking of new menu ideas to prepare for the transition as well. With Lent starting this week, that means I can start making more homemade noodles as an entire meal. Mark loves to recall how his mother had bowls of fresh noodles and browned butter waiting on the table. It is one of his favorite meals. Over the years, our kids have loved noodles as well as Aluski. I know the bacon bits kind of throw it off for a Lenten meal, but you could substitute chicken broth for the avoring instead of using bacon.

And what meal is complete without a sweet dessert? Here are two family favorites from Jill and my sister, Nancy.

Homemade Noodles

2 eggs

4 tablespoons milk

1 teaspoon salt

2 cups sifted our, more as needed Mix eggs, milk and salt together. Add our and stir until dough is stiff; extra our can be added if necessary. Separate dough into two balls. Sprinkle our on work surface and roll out dough to desired thickness; let rest 20 minutes. Using pizza cutter, cut dough into strips. Continue to dry or cook noodles in a pot of boiling salt water for 5-10 minutes.

Mark loves homemade noodles served with browned butter. Just melt 4 tablespoons butter and brown slightly. Pour over noodles with extra salt and pepper. Aluski

Rev. Tim Wenzel

Dumplings:

6 large eggs

1 cup milk

4 1/2 cups our

3 teaspoons salt

Food columnist, Natalie Schmitt

Base:

1 pound melted butter

2 bags shredded cabbage or 1 head cabbage, shredded 2 large onions, diced 1/2 pound bacon, fried and chopped

For the dumplings, mix eggs, salt and milk. Add our until it forms a thick dough. Add more our if needed but no more than 1/2 cup. Drop by teaspoon (or less batter) into boiling water. Cook dumplings until they oat, plus an extra 2 minutes. Rinse in cold water; set aside.

In a large slow cooker or Dutch oven, mix melted butter, cabbage, onion and bacon. Add cooked dumplings. Turn slow cooker to low for 3 hours or cook until done.

I generally make a double batch and use my roasting oven at 350 degrees for an hour.

Tuna Noodle Casserole

1/2 cup water

1 tablespoon chicken bouillon

1 package frozen peas

1 cup chopped onion

1 cup sliced mushrooms

1/4 cup chopped celery

1 garlic clove, minced

1/2 teaspoon dill weed

1/2 teaspoon salt

Dash pepper

4 teaspoons corn starch

1 1/2 cups milk

1/2 cup Velveeta cheese, cubed 1/4 cup mayonnaise or Miracle Whip

2 1/2 cups medium noodles, cooked and drained

12 ounces tuna (4 small cans), drained 1/3 cup dry breadcrumbs

Butter

Cook noodles rst. While they are cooking, bring water and bouillon to a boil in a large saucepan; stir to dissolve. Add next eight ingredients; bring to a boil. Reduce heat; cover and simmer 5 minutes. Dissolve corn starch in milk. Add to vegetable mixture, stirring constantly. Bring to a boil; boil 2 minutes or until thickened. Remove from heat; stir in cheese and Miracle Whip until blended. Fold in noodles and tuna. Pour into a greased 2 ½-quart baking dish. Brown breadcrumbs in butter. Sprinkle on top of casserole. Bake uncovered at 350 degrees for 25-30 minutes. Yields 4-6 servings.

Blueberry Oven Pancake

Jill Gablenz

3/4 cup fresh or frozen blueberries

1 1/2 teaspoons sugar

3 tablespoons buttered

4 eggs

1/2 cup our

1/4 teaspoon salt

1/2 cup milk

1 tablespoon powdered sugar

Maple or blueberry syrup

Preheat oven to 425 degrees. Rinse berries; drain. Sprinkle with sugar; set aside. Spray 10-inch oven-proof skillet or glass pie plate with non-stick cooking spray. Don’t skip this step. Melt 1 tablespoon butter in skillet or pie plate by placing in warming oven for a bit. Swirl butter around pan. Melt remaining 2 tablespoons butter for mixture.

In a medium mixing bowl, beat eggs and then add our, salt and milk. Stir or whisk until mostly smooth (there can be a few lumps). Stir in reserved 2 tablespoons melted butter. Gently fold in blueberries; pour into greased/buttered skillet or pie plate. Bake at 425 degrees for 20-25 minutes. Watch it after the rst 20 minutes as speed will depend on how fast your oven bakes. Make sure you don’t miss the moment you take it out of the oven. The pannenkoeken will be nice and high but quickly deates, like a soufe. Dust with powdered sugar, cut into wedges and serve immediately with warm syrup. Sprinkle extra blueberries on the slices for an added treat.

Raspberry Bundt Cake

Nancy Dowell

1 plain white cake mix

10 ounces frozen red raspberries thawed or 1 ¼ cups crushed fresh berries and juice

1 small box red raspberry gelatin

4 eggs

2/3 cup salad oil

Mix all ingredients and beat 2 minutes. Bake in greased bundt pan at 325 degrees for 50 minutes or until done. Drizzle with powdered sugar glaze when cool.

As their four children pursue dairy careers off the family farm, Natalie and Mark Schmitt started an adventure of milking registered Holsteins just because they like good cows on their farm north of Rice, Minnesota.

3-5

1 ounce packet brown gravy

Add roast to slow cooker. Add ranch packet and brown gravy packet to the top of the roast. Add butter, peppers and pepper juice; cover and cook on low for 8-10 hours or high for 6-7 hours. Shred and serve in hoagie buns or with your favorite side, such as mashed potatoes.

1/2

Toppings: Shredded cheese Nacho chips

Mix soups, enchilada sauce and milk in large soup pot; add cooked chicken. Simmer for 15 minutes or until heated through. Top with shredded cheese and crushed nacho chips.

1

Mix all ingredients. Roll into balls and then dip in sugar. Bake at 375 degrees for 8-10 minutes, or until done. Do not overbake.

your tires and Secure Covers with us

“The Hanson Silo Bunker empowers us to control shrink loss. With our piles, we used to see lots of spoilage. But now we see very little, if any at all.”

Sako Vandermeer - White, South Dakota

• Engineered for strength and long-term durability

• DRY CAST formulation creates low porosity and slump

• Computerized batching for uniformity

• Robotic mold system provides consistency

• Quality nished for smooth edges and sure footing

• Manufactured in a controlled environment (Steam Beds) for faster curing

• Delivered, professionally leveled and installed

• Strength Compression Tests to exceed quality standards

• Modular design for easy installation