CANADIAN CONCRETE PUMPERS

PUBLICATION MAIL AGREEMENT #40934510 2023 EDITION

The importance of monitoring temperature differentials in mass concrete

Canadian public projects built with sustainable solutions

Why built environment developers must prioritize resilience in every new project

Other shows may talk a big game, but only World of Concrete speaks concrete and masonry. We know that a solid foundation isn’t just part of the structures you build — it’s also the key to a more profitable business. That’s why you’ll find everything you need to strengthen your operation here, from new products, innovative solutions, and new technologies to help you capitalize on emerging opportunities.

We

EXHIBITS: JANUARY 17-19 2023 EDUCATION: JANUARY 16-19 LAS VEGAS CONVENTION CENTER

Speak Your Language: www.worldofconcrete.com

1-833-545-7867 #3 - 876 Leathead Road, Kelowna, BC V1X 2J8 www.pumppro.ca Suite 300, 6 Roslyn Road, Winnipeg, Manitoba, Canada R3L 0G5 Toll Free:1 866 831 4744 | Toll Free Fax: 1 866 711 5282 www delcommunications com We offer outstanding personal service and quality in the areas of: CREATIVE DESIGN | ADVERTISING SALES TRADE PUBLICATIONS | QUALIFIED SALES & EDITORIAL TEAM DEL Communications Inc and you, THE KEY TO SUCCESS .

4 Canadian Concrete Pumper 2023 2023 Published by: DEL Communications Inc. Suite 300, 6 Roslyn Road Winnipeg, MB R3L 0G5 Toll Free: 1.866.831.4744 President & CEO DAVID LANGSTAFF Editor SHAYNA WIWIERSKI shayna@delcommunications.com Advertising Sales Manager DAYNA OULION dayna@delcommunications.com Advertising Sales ROSS JAMES ANTHONY ROMEO GARY SEAMANS Contributing Writer CHRIS CALVIN DR. STAMATINA CHASIOTI THOMAS GUILLOT BRIAN J. HALL ALEXANDRA SKINNER Production services provided by: S.G. Bennett Marketing Services www.sgbennett.com Creative Director KATHLEEN CABLE ©Copyright 2022. CPAC. All rights reserved. The contents of this publication may not be reproduced by any means, in whole or in part, without the prior written consent of the publisher. While every effort has been made to ensure the accuracy of the information contained in and the reliability of the source, the publisher in no way guarantees nor warrants the information and is not responsible for errors, omissions or statements made by advertisers. Opinions and recommenda tions made by contributors or advertisers are not necessarily those of the publisher, its directors, officers or employees. Publications mail agreement #40934510 Return undeliverable Canadian addresses to: DEL Communications Inc. Suite 300, 6 Roslyn Road Winnipeg, MB R3L 0G5 PRINTED IN CANADA | 11/2022 CANADIAN concrete pumpers Message from the editor, Shayna Wiwierski ....................................................................... 6 Reducing carbon emissions at the project level ................................................................. 7 Canadian public projects built with sustainable solutions ............................................ 10 The Body of Knowledge for precast concrete (BOK) ....................................................... 12 Why built environment developers must prioritize resilience in every new project 16 Lehigh Hanson to become Heidelberg Materials .............................................................. 18 New certification requirements for B.C. concrete pump operators ........................... 19 The importance of monitoring temperature differentials in mass concrete ........... 22 Overcoming the complexities of waterproofing urban structures with Kryton’s Krystol® technology 24 Lightweights…. 26 Index to advertisers ................................................................................................................. 27

BUILT TO PERFORM BOOM PUMPS | LINE PUMPS | CONCRETE PUMP PARTS | SERVICE 1-844-397-8677 www.dyconcretepumps.com

Shayna Wiwierski

Ican’t believe that we are already at the end of the year.

There’s a saying that goes, “the days are long but the years are short” and that certainly rings true when it comes to construc tion. The construction season is short here in Canada, meaning that we only have a few months to work on projects every year. Of course, just because it’s cold doesn’t mean that the work stops, and when it comes to concrete, there are no shortage of projects here across the country… no matter which month it is.

In this issue of the Canadian Concrete Pumpers magazine, we take a look at projects that Heidelberg Materials, formerly Lehigh Hanson, is working on from coast to coast. This includes Ādisōke, the new Ottawa Public Library – Library and Archives Canada joint facility and the Métis Cultural Centre in Fort McMurray.

On page 16, the Global Cement and Concrete Association (GCCA) talks about the Roadmap to Net Zero 2050, which aims to decarbonise the cement and concrete industry by 2050. The GCCA launched the program last year and this year they introduced a se ries of Net Zero Accelerator initiatives to help national cement and concrete industries in developing countries decarbonise.

These are just a small taste of what we have in store for you in this issue of the Canadian Concrete Pumpers magazine. We hope you enjoy it and as always, we invite any feedback or story ideas you may have.

Enjoy!

Shayna Wiwierski shayna@delcommunications.com

6 Canadian Concrete Pumper 2023 MESSAGE FROM THE EDITOR

017898_Putz_CPAC Half Page Ad_7x4.8125.indd 1 5/10/19 10:56 AM

There is a well understood array of technologies, processes, and market policies needed to work synergistically across the construction value chain in order to make net-zero concrete possible.

Reducing carbon emissions at the project level

The toolbox to achieve deeper carbon reductions

By Dr. Stamatina Chasioti, Director of Codes and Standards, Cement Association of Canada

As the makers of the most-consumed material on the planet after water, Canada’s cement and concrete in dustry shares a responsibility to find solutions to the challenges of climate change, sustainable construc tion, and a circular economy. We have taken important steps to strengthen our commitment to reducing concrete’s carbon emissions by up to 40 per cent by 2030, and to net-zero by 2050.

Through a partnership with the Government of Canada, we are supporting the development and implementation of a ‘Road map to Net-Zero-Carbon Concrete’. This roadmap will provide

our industry with the technologies, tools, and policies needed to achieve net-zero carbon concrete by 2050.

Canada’s cement industry was also the first industry-wide participant in the Government of Canada Net-Zero Challenge – a voluntary initiative that encourages businesses to devel op and implement credible and effective plans to transition their facilities and operations to net-zero emissions by 2050.

There are no “silver bullet” solutions

Cement represents only about seven per cent to 15 per cent

Canadian Concrete Pumper 2023 7

of concrete by volume, but it is responsible for over 80 per cent of the carbon footprint of concrete. A typical concrete mixture is made of sand, gravel, water, air, and industrial by-products that require very little energy to obtain and have a low environmental footprint. There is a well understood array of technologies, pro cesses, and market policies needed to work synergistically across the construction value chain in order to make net-zero concrete possible.

Factors affecting the sustainability targets for projects

Project delivery times, cost, specifications, regulations and proj ect management all play a critical role in the level of carbon re ductions that can be achieved. With construction project tenders beginning to prioritize sustainability targets, it is critical for project teams to sharpen their pencils to integrate CO2 reductions into all project designs, including design, cost and delivery times.

Tools to achieve deeper carbon reductions

• The project delivery methods

Integrated project delivery for small to larger projects aims to reduce the carbon footprint of a structure through collab oration between the owner, the engineer and/or architect, and the contractor. From the conception to the design and

•

up to 10 per

construction of the project, all project phases need to lock-in like a puzzle as decision-making throughout the project af fects quality, delivery time, and cost, as well as CO2 emissions.

The cementitious materials

The industry offers a wide range of cementitious materials across Canada. Supplementary cementitious materials (SCMs) reduce the carbon footprint by approximately the same per centage of the cement they replace. The use of Portland Lime stone Cement reduces the embodied CO2 of concrete by up to 10 per cent compared to the baseline Ordinary Portland cement.

• Performance-based codes, standards, and specifications

There is no “one size fits all”. Performance parameters are project-specific and there are various ways to satisfy them while also minimizing CO2 emissions. Codes and standards have been migrating to adopting performance tests in or der to facilitate faster adoption of existing and emerging low-carbon solutions. Use the CSA A23.1 “Concrete ma terials and methods of concrete construction” as a guide.

• Construction methods

Ready-mix concrete, prefabrication, modular construction,

8 Canadian Concrete Pumper 2023

The use of Portland Limestone Cement reduces the embodied CO2 of concrete by

cent compared to the baseline Ordinary Portland cement. Image courtesy of Lafarge.

and reuse of concrete components are options that need to be considered at the inception stage of a project. For example, steam-cured precast components may be used to facilitate the use of high-volume SCMs that are slow reacting. Post-ten sioning on site allows for significant concrete volume savings compared to pre-tensioning. Demolding and moving on to the next phase of pouring affects construction times; consid er only a construction load for the purpose of strength gain.

• Concrete curing

Material selection, outside temperature, and structure ge ometry can all affect progress times and demolding. It is rec ommended that the team considers wet curing, steam curing, continuous sprinkling, or wet fabric to accelerate curing times.

• Pouring throughout the year

In order to manage project cost, it is important that con struction doesn’t stop during cold winters and hot summers. Accelerators for concrete setting in cold weather and retard ers for hot weather concreting allow for time adjustments so that increased levels of SCMs can be used throughout the year. The chemical admixtures industry offers a wide range of solutions, such as pumping aids and viscosity modifiers.

• Lean design

Structural design is an iterative procedure and designers are

encouraged to explore various force-resisting systems that com fort with the National Building Code. The CSA A23.3 standard “Design of concrete structures” provides guidance for detailing reinforced concrete members. Concrete’s versatility can be used to effectively reduce volumes in a project. Use concrete where it’s needed. For example, bubble deck slabs in large spans are more cost-effective than regular slabs.

• Take durability into account

Allow 90 days to test the concrete’s permeability. Higher vol ume of slow-reacting SCMs may take longer times. Consider using higher strength concrete or have additional protection measures for the exposure. Use non-corrosive reinforcing bars. More durable structures extend the service life of the project.

Conclusion

•

It is critical to think of a project holistically during all phases from inception to completion to achieve a combined solution for carbon reduction, cost, and delivery times. Availability of ma terials, contractors, and permitted methods are subject to local limitations.

It is the interplay between specifications, construction practic es, timelines, cost, and embodied carbon that presents the big gest challenges and opportunities.

Canadian Concrete Pumper 2023 9

Robson Square in Vancouver.

Canadian public projects built with sustainable solutions

Sustainable projects have become top of mind for many new projects, especially ones that are government funded. These projects have certain sustainability targets and are often built to LEED certification with even more specific carbon-reduction goals, or to the new made-in-Canada framework called Zero Carbon Building (ZCB) standards. These programs and standards often focus on measures for operational and embodied carbon.

Recently, Heidelberg Materials, formerly known as Lehigh Han son, has supplied several lower carbon concrete solutions using mixture optimization tools for public projects in Canada. The company has been working with contractors and designers to be able to meet performance criteria for strength, durability and constructability, while developing smaller footprints, thanks to its EvoBuild Low Carbon Concrete. EvoBuild Concrete has envi ronmental product declarations (EPDs) that transparently reports the global warming potential (GWP) of the concrete, and often works to exceed the specifications of public projects with sus tainable goals intended to reduce greenhouse gas emissions.

An example of this is Ādisōke, the new Ottawa Public Library – Library and Archives Canada joint facility. PCL Construction, the general contractor, selected Heidelberg Materials, formerly known as Hanson Ready Mix in Ontario, to supply concrete mix tures with higher recycled content, and EcoCem®PLC for the ce ment, to lower the carbon footprint of the project and support the facility in meeting the standards of a net-zero carbon build

ing. In total, the new $334 million facility includes 20,000 cubic metres of concrete work.

Also in Ottawa, the West Memorial Building is a unique project that includes modernizing and conserving the West Memorial Building and the Supreme Court of Canada building. EllisDon Corporation is the construction management company and Hei delberg Materials was contracted to supply sustainable concrete solutions with a high recycled content and EcoCem®PLC for the lightweight floor toppings.

Out west in Fort McMurray, the Métis Cultural Centre, which is currently under construction, was designed as a net-zero car bon high-performance building. Inland Concrete, soon to be

10 Canadian Concrete Pumper 2023

Recently, Heidelberg Materials, formerly known as Lehigh Hanson, has supplied several lower carbon concrete solutions using mixture optimization tools for public projects in Canada.

come Heidelberg Materials, worked with Casman Construction to optimize lower carbon mixtures through tools available from EvoBuild Concrete. The use of EcoCem®PLUS, the lowest carbon cement in the region, helped to make some of the project goals.

“Across Canada we are seeing an increased focus on sustain able procurement and sustainable construction especially in publicly funded projects,” said Alex Car, Heidelberg Materials northeast region president and past chairman of the Cement As sociation of Canada.

Beginning in early 2023, Heidelberg Materials will be working on the Advanced Nuclear Materials Research Centre for Canadian

Nuclear Laboratories in Chalk River, Ont., located near Ottawa. The project is a joint venture consisting of Bird Construction Inc., Chandos Construction Inc., and M. Sullivan & Son Limited (CBS JV). Heidelberg Materials will be supplying EvoBuild concrete mixtures, incorporating EcoCem®PLC and other sustainable le vers for the optimized lower carbon concrete mixtures.

“Lehigh Hanson is proud to have the tools and technology that enable us to provide innovative and sustainable solutions for our customers and help us lead the industry in the journey to carbon neutral concrete,” said Car.

Canadian Concrete Pumper 2023 11

Heidelberg Materials was contracted to supply sustainable concrete solutions with a high recycled content and EcoCem®PLC for the lightweight floor toppings in the West Memorial Building in Ottawa. Photo courtesy of Heidelberg Materials.

Ādisōke, the new $334 million Ottawa Public Library – Library and Archives Canada joint facility includes 20,000 cubic metres of concrete work. Photo courtesy of Ādisōke.

The Body of Knowledge for precast concrete (BOK)

The Canadian Precast/Prestressed Concrete Institute (CPCI)

By Brian J Hall

By Brian J Hall

It is no secret among construction industry professionals that prefabricated and modular structures are the way of the future.

What is prefabrication and modular construction?

With rapid population growth, the construction industry is constantly challenged to adapt its technologies based on the market demand, such as the need for taller buildings, larger bridges, reduced on-site construction times, and enhanced building and bridge performance. Prefabrication and modular construction can solve most, if not all, of these demands.

Prefabrication is a construction method that involves fabricat ing and assembling building and bridge components off-site. It can refer to both flat elements (often known as prefabricat ed, panelized systems total precast or bridge components), or

modular volumetric units that typically include complete build ing spaces such as an apartment unit, hotel room, jail cell, etc. In either case, prefabrication construction also provides innovative solutions in which the entire building and/or bridge can be fab ricated off-site using prefabricated components.

12 Canadian Concrete Pumper 2023

The Putman Family YWCA in Hamilton, Ont. is the first Total Precast Concrete Passive House project in Canada. Photo credit: Kearns Mancini Architects.

Precast Concrete Education – BOK

From the Canadian Precast/Prestressed Concrete Institute’s (CPCI) Body of Knowledge (BOK), the institute delivers a wide range of educational programs. CPCI’s Lunch & Learn Presenta tions and Plant Tour Program involves educational presentations at client offices during lunch and plant tours throughout the year to showcase how precast concrete is manufactured under rigorous quality control. Twenty-two years ago, CPCI started a program called National Precast Day. Producer members across Canada open their precast concrete plants to demonstrate how precast components are manufactured and highlight the many benefits of building with precast concrete.

“In the last 22 years, National Precast Day has hosted over 50,000 students and AEC professionals,” says Brian J Hall, CPCI managing director.

CPCI’s Learn on Demand program is a continual series of ed ucational courses for architects, engineers, real estate develop ers, academics, students, government officials, and construction professionals who want to learn more about precast concrete products and services. Learn on Demand is available 24/7/365. Participants listen to a 45- to 50-minute presentation and answer questions about the course content. Upon completion, they re ceive a certificate of completion to qualify for professional devel opment hours and/or continuing education credits.

CPCI’s Precast Studio Program was started several years ago and CPCI now has four Precast Studios successfully operating in Canada at Dalhousie University, the University of British Colum bia – Okanagan Campus, the University of Manitoba, and Carle ton University. The Precast Studios provide a unique opportunity for students to gain hands-on experience, learn more about precast concrete, develop new technical skills, and work with local industry partners as part of their school program. It is also an opportunity for the precast industry to gain insights into the imaginations and goals of future leaders in the architecture and design industry.

In addition, CPCI recently launched the 2022-2023 Precast Concrete Wellness Bench Student Design Competition. The com petition, hosted by CPCI, is an excellent opportunity for students to learn about precast prestressed concrete design and con struction. This year’s theme is a Wellness Bench, where students will be challenged to utilize precast concrete in their design. The competition is open to all students enrolled in Architecture, Civil Engineering, or Civil Engineering Technology programs.

Lastly, CPCI is pleased to announce, in 2022, the launch of a 2030/2050 Net-Zero Roadmap Initiative, an essential step to de carbonizing our industry by 2050. The roadmap will align with the broader Canadian and international cement and concrete industry efforts by the Cement Association of Canada and the GCCA – Global Cement and Concrete Association and will also support international climate action industry efforts like the Paris Agreement and COP27 to limit the global average temperature rise to 1.5OC. The industry has established several working groups on benchmarking, production, design and construction, car

bonation, and communications. The Canadian precast concrete net-zero roadmap and action plan is expected to be published in 2022 and initiated in winter 2023.

For more information, contact CPCI at toll-free: 877 937 2724, email: info@cpci.ca, web: www.cpci.ca

Brian J Hall, B. B. A., MBA, is the managing director for the Cana dian Precast/Prestressed Concrete Institute and the vice-chair for the Royal Architectural Institute of Canada Foundation.

Canadian Concrete Pumper 2023 13

The West Calgary Ring Road North project in Calgary, Alta. features accelerated bridge construction with precast concrete girders in action. Photo credit: Lafarge Precast, Edmonton, Alta.

Why built environment developers must prioritize resilience in every new project

By Thomas Guillot, CEO of the Global Cement and Concrete Association (GCCA)

With the world facing an unprecedented climate crisis, communities across the globe are looking for ways to develop more resilient infrastructure to withstand its effects. However, for many, there are simply not the resources, nor the time, to adapt to changing environments. An IPCC report in February 2022 revealed that 40 per cent of the world’s population is projected to live in sub standard housing by 2030.

Social and economic risks like inadequate infrastructure, wrong choice of materials, and lack of government support can make communities more vulnerable to extreme weather. This vulnerability can lead to a ‘poverty disaster cycle’ developing, where it becomes impossible to improve the standard of living before another natural disaster damages the area.

More attention to eliminating catastrophic consequences caused by climate change is needed from every part of the construction process – from designers and architects to man ufacturers and policymakers. We must work together to ensure communities are resilient to prevent and prepare for the impact of disasters.

Strong foundations

Around 75 per cent of the infrastructure that will exist in 2050

has not been built yet, meaning there is a massive opportunity to put resilience at the heart of every new project. Concrete is already the world’s most used human-made material, but it should be at the front of the minds for designers, architects, and developers when it comes to improving resilience.

As an A1-rated (European Standards) material for fire-resis tance, projects using concrete can rely on fewer fire prevention methods. Concrete is itself non-combustible and inherently fire resistant, and remains the safest and most practical choice for buildings. For designers, the more complex it is to meet basic fire safety standards, the more likely there is to be an error in the process. Therefore, starting with a non-combustible material, like concrete, from the offset can mitigate these challenges and minimize risk.

The wider cement and concrete industry is taking steps to ensure the material improves resilient and sustainable commu nities around the world. Last year, the Global Cement and Con crete Association (GCCA) launched the Roadmap to Net Zero 2050, aiming to decarbonise the cement and concrete industry by 2050. Pillars of the roadmap include boosting the offering of low-carbon cement and concrete products and securing in creased government support for sustainable cement and con

16 Canadian Concrete Pumper 2023

crete. Through the roadmap, the aim is to ensure communities can access more sustainable and resilient materials faster and easier.

Another key aspect of the Net Zero Roadmap is to empower local industries with their decarbonisation process. That is why this year the GCCA launched a series of Net Zero Accelerator initiatives to help national cement and concrete industries in developing countries such as Egypt, Thailand, and Colombia decarbonise. Key actions include identifying the best routes to decarbonisation, such as investing in recycled concrete, and working with governments to find solutions for communities. The accelerator will be rolled out across more regions in the future.

A resilient future

The cement and concrete industry is full of innovative new solutions set to make it easier for designers, architects, and de velopers to improve resilience within communities. Innovations such as 3D printed and recycled concrete are growing in pop ularity, as this technology comes with great potential in being more cost-effective than traditional construction. It also offers a direct transfer of information from the 3D design model to con struction, which improves accuracy when designing a resilient infrastructure.

The industry is also collaborating with start-ups to further improve and accelerate innovation and create new affordable

technology for developing nations. The GCCA’s Innovandi arm is leading innovation in our sector – the Innovandi Global Ce ment and Concrete Research Network (GCCRN) brings together academia and industry to develop new methods for better ef ficiency in concrete production and in the design of concrete projects.

In 2021, we launched the Innovandi Open Challenge, pro viding an opportunity for start-ups from around the world to showcase their new decarbonisation technology and receive support from our member companies in the form of partner ships. The innovations being created, including in carbon cap ture, will help us decarbonise, providing designers, architects, and developers with a sustainable and strong material to use when creating resilient infrastructure.

A brighter future

As the climate crisis becomes more severe, the resilience of communities will become increasingly vital. Industries involved with the built environment must work together and ensure communities have the tools and resources to adapt accord ingly. As a material, cement and concrete can ensure resilient construction, and as an industry, we welcome partnerships with designers, architects, and developers who share the same mindset. By embracing sustainable innovations, we also hope to create more accessible forms of cement and concrete that can be used to further bolster communities.

Canadian Concrete Pumper 2023 17

018203_Putz ACPA Parts and Service_7x4.8125.indd 1 6/20/19 9:44 AM

Lehigh Hanson to become Heidelberg Materials

Lehigh Hanson, Inc. is pleased to announce the transformation of its global parent company, Heidel bergCement, to Heidelberg Mate rials, a new brand with a global reach and a focus on sustainability, digitalization, and leadership in the building materials industry. As the North American subsidi ary of HeidelbergCement, Lehigh Hanson will begin the process to become Heidel berg Materials in early 2023.

Lehigh Hanson’s evolution to Heidel berg Materials reflects its much broader

and innovative approach to serving its customers and becoming the industry leader in sustainability and digital solu tions. The new name will unify its many legacy brands and nearly 9,000 employ ees in North America to better serve its customers, engage the local communi ties, and drive the sustainable and circular economy.

“This is a major step change for our company, both globally and here in North America,” said Chris Ward, president and CEO of Lehigh Hanson and member

of the managing board of Heidelberg Materials. “I am thrilled to lead this trans formation in North America and take the next steps in our global journey to grow our business beyond cement and aggre gates and become the most sustainable company in the sector.”

The change to Heidelberg Materials will launch in North America beginning in the first quarter of 2023, and ultimately will be rolled out in the different geogra phies and operational areas during the remainder of the year and beyond.

18 Canadian Concrete Pumper 2023

T: 204-434-6873 F: 204-434-6833 Box 853, Grunthal, Manitoba R0A 0R0 “Providing professional concrete pumping for even the toughest jobs”

New

requirements for

By Alexandra Skinner

Since 2012, there have been 351 injury claims at job sites around the province involving concrete pump trucks. In 2015, ongoing health and safety concerns around this equipment prompted construction safety asso ciations to request changes to B.C.’s Occupational Health and Safety Regulation (OHSR).

“Concrete pumps are large, complex pieces of equipment that operate under high pressure, delivering materials that

are dense, heavy, and potentially dangerous,” explains Jaret Swanson, manager of consultation and education services at WorkSafeBC.

Concrete placing requires workers to be in the area of the pump and the discharge end of the placing boom — making it a high-risk activity that could cause serious injury or death to workers in the vicinity if the equipment is not handled cor rectly.

Canadian Concrete Pumper 2023 19

As of January 1, 2024, all concrete pump operators must hold a valid certification when operating this equipment.

certification

concrete pump

Learn how to register for your Certified Concrete Pump Operator (CCPO) Certification

B.C.

operators

New cer tification requirement

Although the Workers Compensation Act requires workers to be trained to ensure their safety and the safety of others in the workplace, prior to the regulatory changes, there were no spe cific competency requirements for concrete pump operators.

In July 2021, WorkSafeBC’s Board of Directors approved changes Part 20 of the Occupational Health and Safety Regu lation, making certification mandatory for all concrete pump operators working in British Columbia. The purpose of the amendments is to improve worker safety by requiring concrete pump operators to hold a certificate granted by an authority designated by WorkSafeBC.

These amendments took effect on December 1, 2021. How ever, the amendment provided operators two years to obtain certification. Therefore, as of January 1, 2024, all concrete pump operators must hold a valid certification when operating this equipment.

The Certified Concrete Pump Operator Program (CCPO)

The Certified Concrete Pump Operator (CCPO) certification is

a professional accreditation delivered by the BC Construction Safety Alliance (BCCSA), which is currently the only authority issuing certifications to concrete pump operators in the prov ince.

Certification requires operators to demonstrate both theo retical knowledge of concrete pump operations through a writ ten multiple-choice exam, and an on-site assessment by way of a practical exam that requires the operator to demonstrate competency in the field.

Pump operators who hold this certification are known as Certified Concrete Pump Operators (CCPOs).

“Those who hold CCPO Certification have demonstrated theoretical knowledge of concrete pump operations, and they have shown they can apply this knowledge in the field,” says Swanson.

Once an operator has passed their exams, they will receive a certification identification card, which they must always have on hand when operating equipment. The card will be re-issued every five years upon completion of recertification require ments.

20 Canadian Concrete Pumper 2023

Please support the advertisers who make this publication possible.

“The certification program was created by industry and safety professionals to ensure operators understand what equipment does, how to inspect the equipment, how to doc ument those inspections — and of course how to keep every one working with pump trucks safe,” explains Swanson.

Benefits for employers

Concrete pumps are an increasingly important tool in mod ern concrete. Like other skilled trades, concrete pump opera tors now have a certification they can be proud to carry, and which employers can use to verify the competence of any pumpers coming on their worksite. Employers who employ CCPOs can benefit

WorkSafeBC is supporting workers and employers

WorkSafeBC prevention officers have been visiting work sites to raise awareness about the new regulation and certifi cation requirements to ensure that all employers — from large companies to single-owner operators — are aware of the reg ulatory changes, and know how to get certified.

Once the requirement goes into effect on January 1, 2024, prevention officers will inspect worksites and ask pump truck operators to provide proof of their certification documenta tion.

It is important that all employers, owners, workers, and con tractors who work with concrete pumps review the revised regulatory requirements to ensure their work practices are compliant.

“Having qualified and certified concrete pump operators will help reduce the risk of incidents, injuries, and fatalities so that everyone on site goes home safely at the end of the day,” Swanson says.

Canadian Concrete Pumper 2023 21 www.delcommunications.com YOUR KEY TO ONLINE & PRINT PUBLISHING SUCCESS. We offer outstanding creative and sales services: • E-newsletters • Online directories • Websites • Full print publications (including magazines, directories, newsletters)

1. Reduced

2. Fewer

3. Assurance

4. Less

5. Improved

6. Enhanced

through:

risk

accidents, injuries & fatalities

of operator’s abilities

property damage

safety records

public image

The importance of monitoring temperature differentials in mass concrete

What is mass concrete?

According to the American Concrete Institute (ACI), mass concrete is “any volume of concrete with dimensions large enough to require that measures be taken to cope with generation of heat from the hydration of the cement and attendant volume change to min imize cracking”. Some examples of mass concrete include dams, large bridge piers and columns, mat slabs, and foundations. Likewise, smaller structures may also be categorized as mass concrete depending on several factors, such as type and quan tity of cement, volume to surface ratio of the concrete, weather conditions, concrete placing temperatures, degree of restraints to volume changes, and the effect of thermal cracking on func tion, durability, and appearance.

Why is it important to monitor mass concrete tempera ture?

In order to ensure that mass concrete properly cures to reach adequate strength, it must be poured when the ambient temperature is between 50 to 60 °F (10 to 16 °C). If the tem perature is too low, the chemical reactions that strengthen the concrete slow down significantly and, at a certain point, come to a complete stop. If the temperature is too high, it will cause the concrete to have high early strength development, but consequently gain less strength in the later stages, resulting in lower overall durability of the structure. Generally, a concrete temperature is limited to 70°C (160°F) during hydration. If the temperature of the concrete during hydration is too high, it will cause the concrete to have high early strength development

22 Canadian Concrete Pumper 2023

but consequently gain less strength in the later stage, result ing in lower durability of the structure overall. Furthermore, it has been observed that such temperatures interfere with the formation of ettringite in the initial stage and subsequently its formation in the later stages is promoted, which causes an ex pansive reaction and subsequent cracking.

How do temperature differentials affect mass concrete?

As concrete hydrates and hardens, it generates heat. When constructing mass concrete structures, significant tensile stresses and strains are likely to develop due to the difference between the structure’s core temperature and surface tempera ture. This difference is known as the temperature differential.

The likelihood of thermal cracking increases as the inner core of the mass concrete continues to heat (hydration) while the outer surface of the concrete cools (heat dissipation). This is ex acerbated by extreme cold weather, which quickly cools the outer surface of the concrete, but does not reach the inner core.

Without monitoring temperature differentials in mass con crete, contractors and project managers could run into serious problems such as cracking, reduced service life, project delays and non-compliance. These problems can make it hard to have a sustainable concrete construction.

Why is monitoring temperature differentials in mass con crete so important in winter?

In addition to slowing down the curing process, cold weather also causes the water in concrete to freeze and expand, crack ing and weakening the concrete. In some cases, the concrete may even be rendered useless. However, it can still be success fully poured and placed during the winter if the right precau tions are taken to heat it properly.

ally measured using thermocouples or data loggers. Unfortu nately, using these tools to collect data and subsequently ana lyze the data on a computer becomes quite time-consuming, which negatively impacts a project’s schedule.

Fortunately, contractors and engineers can take advantage of advanced technology that monitor concrete temperatures and strength. One such technology is Giatec’s SmartRock®, an easy-to-install wireless sensor with innovative dual-tempera ture functionality. This trusted sensor, used on over 9,000 proj ects worldwide, is installed on the rebar before a mass concrete pour and enables the measurement of concrete temperatures in two locations simultaneously.

SmartRock offers precise real-time temperature readings for mass concrete pours at the surface and centre of the slab. These readings are sent in real-time to the SmartRock app on the user’s mobile device, allowing users to access SmartRock data anytime, anywhere, on site or off

On construction sites, temperature differentials are tradition

Canadian Concrete Pumper 2023 23

What is the best way to monitor temperature differen tials?

Giatec’s SmartRock® is an easy-to-install wireless sensor with innovative dual-temperature functionality.

SmartRock offers precise real-time temperature readings for mass concrete pours at the surface and centre of the slab.

Overcoming the complexities of waterproofing urban structures with Kryton’s Krystol® technology

With more people continuing to populate urban areas, there has been less room for builders and contractors to work with during construction.

It’s a problem that has particularly impacted those wanting to waterproof their concrete structures. After all, traditional waterproofing methods typically involve external membranes, which require trenches to be dug around a struc ture before installation. It’s a process that takes up space, further limiting a building’s footprint. It’s also one that can be less effec tive under certain concrete conditions. For instance, with shot crete applications, concrete is funnelled through a nozzle with a heavy force behind it that is capable of tearing right through

membranes, leaving a project vulnerable to water ingress.

Under these limitations, it’s clear that highly dense cities need an alternative solution. Recognizing this, Westbank Corp. went ahead with their plans to use shotcrete to develop the area of 700 West 8th in the Fairview neighbourhood of Vancouver. They knew that shotcrete would optimize the amount of building space they would have to work with when constructing their project’s two-storey parkade. And they knew there was another way to prevent their project’s proximity to sea level from becom ing a water ingress concern. All it required was a shift in water proofing methodology.

Instead of trying to waterproof the outside of their structure

24 Canadian Concrete Pumper 2023

Well-known in the area for their award-winning Smart Concrete® solutions, Kryton would make it possible to transform Westbank’s concrete parkade into a waterproof barrier.

with external membranes, they’d waterproof it from the inside. To do that, they turned to Kryton International Inc. Well-known in the area for their award-winning Smart Concrete® solutions, including their waterproofing admixture, Krystol Internal Mem brane™ (KIM®), Kryton would make it possible to transform West bank’s concrete parkade into a waterproof barrier.

Using Krystol® technology, Kryton’s KIM admixture would im bue Westbank’s shotcrete mix directly with waterproof qualities. All that was necessary was for the applicators to add KIM into the mix, permeating the entirety of the concrete with the ability to chemically react to the presence of water. Consequently, any sign of water would ensure the concrete made with this shot crete mix would react to it and unhydrated cement particles to form interlocking crystals. These crystals would then fill up mi cro-cracks and capillary pores in the concrete, blocking any path ways for water and waterborne contaminants and allowing the concrete to self-seal.

It was a waterproofing solution that didn’t require trenches and couldn’t be torn by shotcrete, allowing Westbank to maxi mize their building footprint and ensure that its waterproofing remained intact.

That also allowed Westbank to give other areas of concern more attention such as the surrounding details and construction joints of the building’s parkade. Without the right protection, they would remain a weak point for water ingress despite the

concrete’s own waterproofing. That led Westbank to using not only Kryton’s KIM admixture, but also the company’s Krystol® Wa terstop System, ensuring both the concrete and its details and joints would remain permanently watertight.

All of which made Kryton’s waterproofing highly appealing to maximize the building footprint while still giving it quality water tight protection. But like any good builder knows, it’s important to have built-in redundancy in the rare case that something does go wrong.

It’s why Westbank and their construction team were keen to back up their waterproofing protection with Kryton’s warranty service, the Krystol Assurance Program™ (KAP). It would give them an extra edge on their waterproofing, with manufacturing consultation, training, and inspection knowledge. At the same time, it would cover the cost of material and labour should any leaks occur within the next 10 years.

In the end, however, Westbank hadn’t needed to worry about leaks. With the use of Kryton’s KIM, Krystol Waterstop System, and KAP, Westbank’s shotcrete parkade was a success and remains standing to this day, showing how the complexities of urban construction don’t need to extend to its waterproofing. It led the project’s contractor, ICON Pacific Construction Corp., to go on to use the same shotcrete and waterproofing system for many other successful projects, including 60 West Cordova, 6th and Fir, and the Avra.

Canadian Concrete Pumper 2023 25

Westbank Corp. went ahead with their plans to use shotcrete to develop the area of 700 West 8th in the Fairview neighbourhood of Vancouver.

Kryton’s waterproofing maximized the building’s footprint while still giving it quality watertight protection.

Lightweights…

By Chris Calvin

When you mention lightweights to many people, they have all kinds of reactions to the term “light weight concrete”. Some are good and some are bad, especially when it comes to pumping differ ent variations of lightweights, including all the special handling of it.

In the past, I could pump some mixes, and for others it was a disaster. Even if everything was done correctly, it was always a role of dice for me pumping it.

After a motorcycle accident in 2014, in mid-2015, I began in my garage experimenting with different ingredients to make light weight concrete. It was more to pass the time while I was healing from my accident.

Since I used to own concrete pumps and my large line was two-inches, I had to learn mix designs. However, I preferred to pump all the concrete through 1.5-inch lines and back, which was something no one would even attempt at the time.

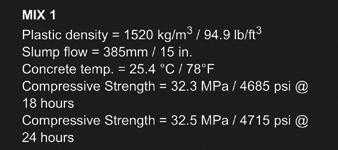

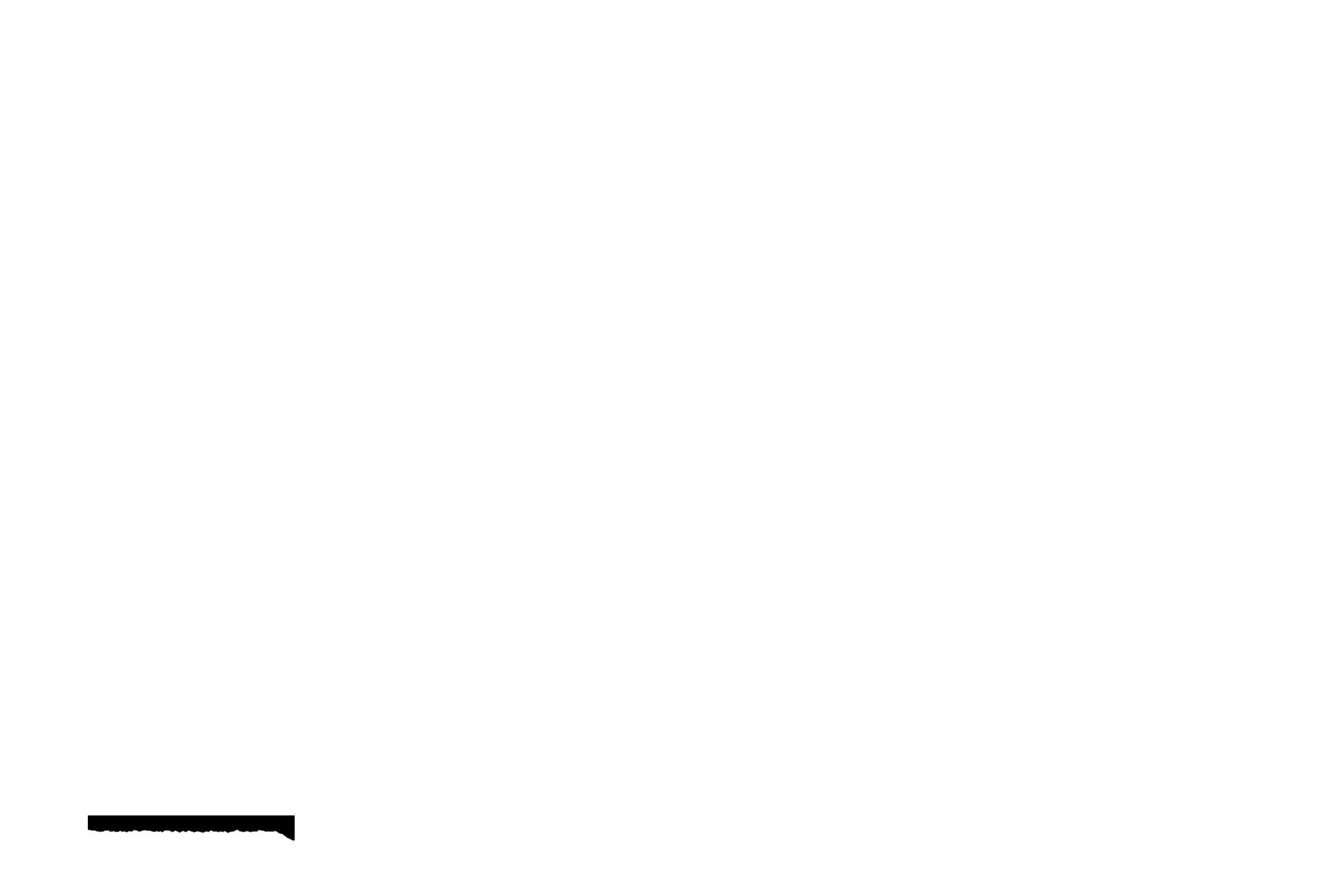

Making the concrete extremely lightweight was actually very easy, but making it so that it had decent compressive strength was not as easy. With a lot of trial and error, Matt Boehler and myself found the right combination of ingredients to achieve compres sive strength up to and including 60 mpa, while reducing the weight by 1,000 kgs per cubic metre. Our lightweights are like nothing else anywhere in the world.

Fast forward to today……

Since then we have multiple patents on our lightweights. We are active in three countries and that list continues to grow. We have lightweight concrete, shotcrete, SCC mixes, and flowable grouts.

We are in the 1,200 to 1,500 kgs per cubic metre range plastic, and 30 to 50 MPA range, depending on the mix design and what

is required for the mix performance. Plus, every single mix design will pump with ease. Adding to that, our lightweights reduce CO2 emissions by a minimum of 20 per cent across the board. There is a very long list of benefits that come with our technology.

Another leap forward is we have been working with CorTuf UHPC, located in Manassas, Virginia, to make the world’s first UHPC Lightweight.

CorTuf, in my opinion, is the most advanced and stable UHPC in the world. CorTuf can constantly achieve 150 MPA and above. Plus, it can be made in an RM truck. It truly is an excellent UHPC. They have many YouTube videos showcasing what CorTuf can achieve, and we have been present on many locations while CorTuf is showing what it can do.

To date, we have achieved 124/125 mpa with a 27 per cent weight reduction, which could be brought into construction today. However, back in the beginning, we decided that we will wait until we achieve 151 MPA/22,000 PSI, then we will have a true UHPC LW.

We believe that we will bridge this gap of 25 mpa on our next round of mix designs. Then after that milestone has been reached, all the independent third-party testing by CTL has to be complet ed. Once it is completed and passed, then there will be another material that designers, architects, and engineers can utilize to make our world an even better place with materials that will last for centuries instead of decades.

Lightweight concrete is a global game changer today. Imagine what it could do tomorrow.

26 Canadian Concrete Pumper 2023

Canadian Concrete Pumper 2023 27 Index to advertisers DY Concrete Pumps Inc. . ...........................................................................................5 ICC Distribution Group, Llc .................................................................................. OBC Pump Pro .......................................................................................................................3 Putzmeister America, Inc. 6, 14 & 15, 17 Southeast Concrete Pumping Ltd. ........................................................................ 18 World of Concrete Informa Markets ................................................................... IFC T: 204-434-6873 F: 204-434-6833 Box 853, Grunthal, Manitoba R0A 0R0 “Providing professional concrete pumping for even the toughest jobs”

PavixCCC100 is patented dual crystalline waterproofing product that has been proven to penetrate into the surface of green or cured concrete to fill and seal pores and capillary voids, and cracks up to 1/16” creating a permanent protective zone within the concrete substrate. Once concrete is treated, this proven technology will prevent water from penetrating through the protective zone and causing associated damage, such as freeze-thaw cracking, reinforcing steel corrosion, and chloride ion penetration. One application of the PavixCCC100 crystalline penetrating sealer will waterproof and seal the surface, as the hygroscopic crystals continuously seek out the vapor within the substrate.

FIELDS OF APPLICATION: • Airport Runways • Aircraft Parking • Tunnels • Parking Lots • Sea Ports • Airport Taxiways • Bridges • Concrete Roads • Highways • Buildings • Walkways and more! ICC CANADA 4101 106th STREET, DES MOINES, IOWA 50322 250-801-8046 www.canadaicc.com

By Brian J Hall

By Brian J Hall