For our Smoky Canyon mining operations, this means we have invested in developing new “cover” reclamation systems that provide protection for groundwater while restoring a healthy landscape for wildlife.

Innovations like this help us to mine phosphate ore responsibly and contribute to feeding our world.

Opinions and recommendations made by

or advertisers are not necessarily those of the publisher,

For over 65 years, Bayer’s P4 business, engaged in phosphate mining and phosphorus manufacturing, has been a central part of the Soda Springs community. Today it is a major pillar of the Southeast Idaho economy.

Helping to preserve our environment for people, plants, wildlife, and communities is a key focus of our work at Bayer. When it comes to phosphate mining, our aim is simple: To leave as few traces of mining as possible, ensuring the important ecological functions before mining are restored and working after mining. It’s a promise to our community that will last long after the last shovel of dirt is turned.

For more information about Bayer’s ongoing safety, health and community programs, visit us online at Bayer.com.

Over my 40+ years as a mining professional working in the coal, copper/precious metals sector, as well as in Idaho’s phosphate industry, I have firsthand experience with the ups and downs of the mining industry.

I began my career in the early ‘80s, where I was employed as a young engineer/production supervisor at the Bingham Canyon Copper Mine in Utah. Ten days after beginning work, they laid off 180 supervisors, and over my three years with the company, I moved from production to multiple engineering locations, including a summer in Alaska as an exploration geologist escaping one layoff after another.

Accompanying that period, Bingham Canyon was shut down, large investments were made, union demands were reduced, and the Utah Copper Division went from over 6,500 employees down to 2,200. During that time, I had the opportunity of moving my family to Arizona and stay in the copper business or come to Idaho in the phosphate industry. The decision to be here in Idaho was one of the best choices of my life. Although the phosphate industry was in much better shape than copper and precious metals, it was certainly anything but booming. During my first year with Monsanto one of our plant’s three furnaces were idled for nearly a year and our sister plant in Columbia

Tennessee was shut down after 50 years of operation. In contrast to that past, we live in a very different world today, long gone are the days of 60-cent copper and sub $400 gold.

As we reflect on our recent Idaho Mining Association (IMA) annual meeting, it is evident that we are experiencing extraordinary times. When Ben Davenport was hired as our executive director in 2016, we as an association were struggling with some challenging times of our own. In order to maintain our organization and keep the lights on, we were required to dip into our modest contingency fund just to manage our annual commitments. When Ben put together the first IMA annual meeting in 2017 we had less than 100 attendees. In contrast, this year’s meeting attracted over 117 vendors and 950 attendees. Our kudos and thanks go out to Ben, Alli, and all of the meeting committee members for their outstanding efforts in putting together this extraordinary event. With the high level of interest, it is especially evident that there is an increasing realization by industry, politicians, and society that the necessity of a viable and reliable minerals industry can support the demands of our modern evolving society and ensure our national security.

Our most recent annual meeting featured opening remarks by Governor Little, as well as details shared by Rich Nolan, the president of the National Mining Asso-

ciation. Nolan pointed out the importance of a viable domestic mining industry and associated reliable minerals supply, which is now part of the discussion on a national level with both political parties and is receiving the most bi-partisan support that he has observed in many years.

I am finishing this text while sitting in the Salt Lake City airport waiting for my flight. Just a few hours ago Donald Trump gave his acceptance speech and Republicans have prevailed in the Senate. I am certainly happy about that, and based on his first term, should bode well for some moderation with regard to ever-increasing regulations and government red tape. However, this extraordinary outcome should cause us, as the mining industry, great reflection and resolve. I believe we, as part of U.S. mining industry and here in Idaho, have demonstrated the ability to mine and coexist with the environment to a level that is equal to or better than anywhere in the world. Unfortunately, much of society, although may be beginning to realize the need for minerals and products we produce, still often have the attitude, “not in my backyard.” Minerals are where you find them and this is just one of the many reasons we need to continue to go the extra mile and put our best foot forward at all times. We can never relax or do just the minimum. Our right to operate is unfortunately a fragile gift. We need to always pursue self-improvement and

adopt the latest and best technology and practices.

Our conference provided abundant evidence as to the importance of our industry suppliers and educational institutions that will be vital in our industry’s quest for continuous improvement and best practices.

Being here in Idaho, we have so many things in our favor. Not only do we live in one of the most beautiful places on earth, but our people here largely are grounded and understand the importance of farm-

ers, loggers, and miners. This is where true wealth is created, and at the same time, like us, they want to make sure our majestic landscapes are protected for future generations. Fortunately, unlike many other states or locations, our government officials generally share similar attitudes.

As I reflect on my life’s career choice, I can say it has been extremely rewarding. I truly appreciate all the wonderful people I have met and worked with in this industry. When I think about those tough times

of the past, I am reminded that mining is a cyclical industry, however, a lot of the pain and anguish that companies experienced were due to not being diligent with the idea of continuous improvement. In many cases, they accepted the status quo and squandered opportunities when times were good, and in some cases, did not appreciate the fragile nature of their social right to operate.

I am hopeful and optimistic we will learn from the past; our future depends on it. s

The mining industry in 2024 remains a cornerstone for global development, driven by its essential role in producing minerals that contribute to nearly every industry and aspect of daily life. Mining provides the raw materials required to produce renewable energy infrastructure and technological advancements. Beyond economic contributions, mining also plays a key role in national security by providing access to strategic resources used in defense technology, energy storage, and critical infrastructure. As a country, investing in a stable and responsible mining industry would reduce our reliance on foreign imports, strengthen supply chains, and ensure access to the materials needed to advance technology and innovation. To this day, we still rely on imports for over 90 percent of the identified critical minerals listed by the USGS.

Idaho’s vast and unique geography offers up an undeniable opportunity to provide our nation with the minerals needed. All of Idaho’s minerals are deemed critical, strategic, and necessary. Projects across the state are leading the way in industry best practices and continue to exceed safety, environmental, and community engagement standards in Idaho. Because of this, Idaho is quickly becoming an attractive place to invest in for the mining

industry. It has been a pivotal year for our state, as we have seen significant growth in the exploration and development space with countless deposits renewed and discovered. We continue to see land managers in our phosphate district prioritize the permitting of new mines that will continue to help feed our nation and we are now looking forward to the Stibnite Gold Project receiving a Final Record of Decision after Perpetua Resources received their Draft Record of Decision in September. The industry is thrilled to finally see the evolution of this project come to life, and believe that it sets a great example for the potential for future efforts here in Idaho. Remember, we can mine here, and we can do it in a much safer and more environmentally responsible manner than many of our competing nations.

Back in Washington, D.C., the needle seems to be turning on long-awaited mining policy. This year, the Good Samaritan Remediation of Abandoned Hardrock Mines Act passed unanimously out of the U.S. Senate and awaits passage in the U.S. House of Representatives. This carefully crafted legislation has been a contribution from many stakeholders, and will represent over a decade of bipartisan work to improve responsible remediation efforts. When passed, this will be a big

win for the mining industry and conservationists alike, and reflects the endless dedication to land reclamation and stakeholder collaboration.

As I reflect on the past year, I believe that there is much to be excited for in our industry. Many times, it feels as though we are the only ones who recognize the good that the hard-working men and women in the industry provides, however, I have noticed a shift. 2024 underscored mining’s pivotal role in the global energy transition, national security, and domestic supply chain investment. There seems to be a fundamental shift towards balancing traditional extraction with always evolving environmental stewardship and resilience.

All this to say, members of the IMA and non-members alike deserve the credit for the inroads we have made. This certainly isn’t to say that it is time to relax our efforts, as there is still much to accomplish, but I am confident in the resolve of this industry to take on these hard discussions. I consider myself fortunate to be able to help in these efforts. I have and will continue to consider it to be one of the biggest honors of my life to be able to work for all of the hardworking miner’s here in the Gem State.

“Esto Perpetua.” s

Stay informed on up-to-the-minute industry news that might otherwise pass you by. Becoming a member of the Idaho Mining Association (IMA) gives you access to news and developments in the industry along with the opportunity to hear and learn from peers in the industry

Amplify industry's voice, support industry growth, and act as a watchdog for mining as a whole. As a member, you will be supporting the mission of the IMA and the work we do. Many of our members see the values of helping promote the future of mining.

Connect and create relationships. The IMA provides a great networking opportunity for members who want to strengthen ties with clients or colleagues in their industry, hunt for jobs, or make long-term connections.

Lead the way in implementing industry best practices. Members of the IMA gain resources on what is happening in the industry to keep our practices safe and efficient and have a head start on implementing new practices as they are amended or changed.

Influence how decisions are made. Working together, our collective experience on the issues and in navigating the burdensome regulatory environment are valuable benefits all IMA members enjoy.

Make staying engaged easy. Companies who join the IMA participate in association events focused on forming valuable connections and trade shows, seminars, and workshops that provide valuable connections and education opportunities.

Companies that have produced or processed minerals in Idaho for at least one year.

Companies that have located minerals and are now in the process of contracting/permitting a mine to produce or process minerals.

Companies that were operating members of the IMA for at least 3 years, but are not currently producing minerals.

Companies that are engaged in the exploration for minerals in Idaho but are not currently producing or processing minerals.

Companies that provide products or services to the mining industry.

America's Gold and Silver

Bayer ITAFOS

Hecla Mining Company

J.R. Simplot Company

Idaho Strategic Resources | Integra Resources | Jervois Mining | Liberty Gold | Perpetua Resources | Revival Gold

Bunker Hill Mining | Electra Battery Minerals | Excellon Resources | Freeman Gold Corp | Gold Express Mines | Hercules Silver | Idaho Champion Gold Mines | Idaho Copper | Idaho Lime | IDEX Metals | McKinley Project | Phoenix Copper Limited | Scout Discoveries | Sunshine Silver Mines

Thompson Creek Mining | FMC, Solvay USA | Nutrien

ACZ Laboratories | AECOM | AFFCO, Air Sciences Inc | Albatross Environmental & Process Consulting | Arcadis | Arnold Machinery Company | AstraAlloy | Ball Ventures | Banlaw | Barker Rosholt & Simpson, LLP | Barrick Gold | Bar 7 LLC | Better In Our Back Yard | Bilbao & Co. | Boart Longyear | Bonneville Industrial Supply Co. | Brewer Exploration Inc. | Brooks and Nelson | Brown and Caldwell | CDM Smith | CGS Mule | Commercial Tire | Conrad & Bischoff | Consolidated Pipe and Supply/High Country | Cyanco | Degerstrom Venture Ecoanalysts, Inc | Dorsey | EM Strategies, Inc | Energy Labs | Environmental Resource Management | Environmental Technical Services | FlowTech Fueling | Formation Environmental LLC | Geobrugg | Geoengineers, Geosyntec Consultants | GHD | Gilmour & Company | Givens Pursely LLP | Granatus Septum | Great Ecology | Haley & Aldrich | Harmer Steel Products Co. | HDR Engineering, Inc | Holland and Hart | Idaho Power Company | Industrial Supply | IPS Pumping | Jadco Manufacturing | Jentech Drilling Supply | Kappes, Cassiday & Associates | KC Harvey | Kiewit Mining Group, Inc | Klepfer Mining Services | Lobby Idaho | Marten Law | Maul Foster & Alongi | Merger Mines | Modern Machinery | National Exploration | Newfields | Northwest Mining Supply | O’kane Consultants | O’keefe Drilling | Olympic Engineering Sales, Inc | Open Loop Energy, Inc. | Pace Analytical | Parsons Behle & Latimer | P&C Recruiting | Perkins Cole | Pioneer Tech | Premier Drilling | Rain for Rent | Ramboll | Ruen Drilling | S&G Electric Motor Repair | Savage Co | SBS Associates | Shimmick | Smith & Malek PLLC | Smith Power Products, Inc | Specialty Construction Supply | Stantec | Stinker Stations | Stoel Rives LLP | StrataGeoTech | SVL Analytical | TechStar | Tetra Tech | Tierra Group Intl. | True North Steel | Turner Mining | Valley Science and Engineering | Varin Wardell LLC | Wesco Explosives | Western Industrial Motor and Machine | Western States Equipment Company | Whiteman Lumber Company | Worldwide Rental Services | WSP

By Alli Stice, Idaho Mining Association Director of Strategic Communications

We kicked off this year with the 2024 Idaho legislative session where although we did not carry any bills, there were many policy discussions we engaged in. We hosted our annual Mining Day at the Capitol where legislators had a chance to sit down with local mining projects across the state to learn more about the projects and their benefits to the local communities. Later in the day, companies had an opportunity to present a project overview to the Senate Resources and Environment Committee. We finished the day off with our annual legislative dinner at the Idaho History Museum.

In May, I had the privilege of traveling to Washington, D.C. for the annual Women’s Mining Coalition Fly In. During the week, the group met with over 50 congressional offices from around the country, working to educate members of congress about the importance of a robust domestic mining industry. In June, IMA staff attended the Idaho Association of Commerce and Industry (IACI) Conference in Sun Valley. From there, we made our way through central Idaho where we hosted a legislative mine tour at the Thompson Creek Molybdenum Mine near Clayton, ID. From there, we found ourselves in Salmon, ID for a tour of the Revival Gold Beartrack Mine. It was a successful week traveling

the beautiful countryside in central Idaho!

During the August recess, the Idaho Mining Association Board of Directors met with three of our four congressional offices in Boise, ID. During these meetings we discussed new hope for mining policy and thanked our delegation for their continued support of the industry. Later that day, we hosted congressional offices, agency staff, and IMA members for an evening of networking.

Hosted by the National Mining Association (NMA), MinExpo happened this year in Las Vegas, NV. We had the great opportunity of participating in a kiosk pavilion along with our colleagues and friends from other state associations. It was a

great time to connect and network with members and other industry professionals from around the globe.

October 28th and 29th was our annual Idaho Mining Conference in Boise, ID. This year was a record-breaking year for us

with over 970 attendees, over 120 sponsors and vendors, and over 50 speakers. We nearly doubled in size from last year’s event, which we could not be more thrilled about. A big thank you to all of our sponsors and vendors, and to all who partici-

pate in our show. Save the date for the 2025 Idaho Mining Conference on October 27th and 28th.

As the 2024 General Election came to a close, we made our way up to north Idaho where we participated in the North

Idaho Legislative Tour. During our week, we coordinated a legislative tour of Lucky Friday with Hecla Mining Company. We also did two mine tours with our board of directors, one of Bunker Hill, and the other of Idaho Strategic Resources Golden

Chest Mine. The end of our year was celebrated at the American Exploration and Mining Association’s (AEMA) annual conference in Reno, NV. This is always a great week with industry professionals, sharing their expertise and continued dedication

to the mining industry. We want to extend a thank you to all of our members. Idaho is lucky to have you all contributing to the mining industry and our economy at large. s

TSX:LGD | OTCQX:LGDTF

By Dale Kerner, Perpetua Resources

Critical mass. In nuclear physics, it defines the minimum amount of fissionable material required to maintain a chain reaction. When you get some neutrons flying around bumping into neighboring nuclei, interesting things can happen. In social science, the term represents the threshold level of participants or resources that an activity needs to attain a certain level of success, which in turn opens the door to additional and diverse opportunities. This leads the contemplative mind to wonder; has the Idaho Mining Conference (IMC) achieved critical mass? Have the cooperative efforts of the Idaho Mining Associa-

tion (IMA), conference attendees, sponsors, vendors, speakers, and a growing contingent of students been successful in establishing an essential and sustainable annual touchpoint for Idaho’s mining community?

As my Uncle Wayne from ‘dah U.P.’ used to say, “You bet your sweet bippy.”

On October 28-29, 2024, mild autumn weather welcomed a record-setting 971 registrants to the Grove Centre in Boise, Idaho for the sixth-annual IMC. On Monday morning, registration opened at 7:30 a.m. and the Grove’s foyer was quickly filled with incoming patrons, booth-building vendors, and poster-toting univer-

sity students. Recurrent participants from IMC’s early days could be heard taking a moment to fondly recall the humble origins of the conference, as they nodded in appreciation at what was just a few years ago a quaint little get-together and has now become “a thing.” [Author’s note: We still love you, Riverside. It wasn’t you… it was us]. Setting nostalgia aside, they set their sights onto a full suite of events. There was much to hear, much to see, and oh, so many people to reconnect with.

Day one of IMC 2024 wasted no time in getting down to business with Idaho’s Governor Brad Little providing a welcome and opening remarks. After a warm-up

circuit through the vendor hall, participants had their pick of three parallel track technical sessions, or they could step out in the corridor and peruse a robust student poster session that featured 13 posters and students from Boise State University, Idaho State University, and the University of Idaho. This level of participation reflected the noticeably increased presence of Idaho’s institutions of higher learning at this year’s conference, which attracted an unprecedented number of university and college students, educators and administrators from all corners of the state. And while the comped student registration might have greased the skids, the driving force behind this trend is the growing awareness that Idaho’s mining industry has the potential to offer chal-

lenging, rewarding, and well-paying jobs to those with the initiative to engage with a community that welcomes them with open arms.

This focus on the next generation of Idaho’s mining workforce carried over to the Day One – Bridging the Gap Luncheon. Opening speaker and College of Western Idaho (CWI) Geoscience Professor Ander Sundell laid out CWI’s forthcoming Mining Technician Associate’s Degree, a program he conceived that, in just a few years, will meet a growing demand for middle-skill mine workers by offering a targeted curriculum that emphasizes health and safety, field-based experience, and acumen with high-tech monitoring and characterization tools. Complementary luncheon panel discussions led by Lindsey Schultz

(CEO of MRC Recruiting) and title sponsor University of Idaho’s Sheila Hennessy (director of strategic partnerships at U of I) further demonstrated to all in attendance that the call to action from Idaho’s mining industry is being heard; Idaho mines offer employment opportunities to Idaho students, and those who can help facilitate those connections are heeding the call.

Are the opportunities truly there for the next generation of Idaho’s mining workforce? Is there a diversity of projects and operations at stages ranging from discovery and exploration to development, operations, reclamation, etc.? Queue up Uncle Wayne’s homey affirmation again, because there most certainly are. In addition to the long-standing mining districts

• We keep the lights on 99.9% of the time, and business prices are 30% LOWER than the national average.

• Clean hydropower is our largest energy source and the foundation of our mission to safely provide reliable, affordable energy. Idaho Power is your trusted energy advisor:

• We offer personal service and energy efficiency incentives to help save you money.

and operators of Idaho’s panhandle and the southeastern phosphate district, this year’s IMC was bejeweled with presentations on a diverse and promising array of projects (some new, some familiar) that span the gamut from base to precious, and from critical to rare-earth. Integra Resources, Liberty Gold, Revival Gold, Idaho Copper, Hercules Metals, Perpetua Resources, Idaho Strategic Resources; as these company’s advance their projects through development and permitting, the demand for geologists and engineers of every stripe, regulatory agency technical specialists, equipment operators, metallurgists, ore techs, health and safety personnel, and environmental scientists will create enormous demand for skilled workers.

To meet this burgeoning demand, Idaho and the nation need to take a hard look at domestic policy around mineral resource development. As addressed by Ernest Scheyder’s IMC day two luncheon presentation referencing his award-winning book, The War Below, our desires to power the country and the globe with more sustainable sources of energy that are reliant upon a stunning requirement for mineral resources demands a reckoning. Do we seek out ways to reconcile mining operations in a nation dedicated to world-leading environmental regulations, or do we blithely review our net import dependence for so many minerals and turn a blind eye to how they are mined

elsewhere? Simply take a look at the list of nations from whom we are importing many of our mineral resources, ponder our present geopolitical stability, and you will quickly come to realize how tenuous those supply chains truly are, and how crucial it is that we expand responsible domestic mineral production capacity. It can be done. Miners and those who may be classically considered as mining industry detractors can find ways to work together to leverage the strengths of one another to the greater good of the environment, while maintaining operations in a world-class mining district. The Day two closing panel of the IMC, moderated by Alan Prouty (VP of environmental and regulatory affairs – J.R. Simplot Company) highlighted collaborative efforts in southeastern Idaho which have yielded environmental benefits in the Upper Blackfoot River drainage. In a discussion that included representatives from Freeport-McMoran (William E. Cobb – VP and chief sustainability officer), the Upper Blackfoot Confluence partnership (David Anderson – facilitator), and Trout Unlimited (Warren Collyer – national restoration director), successful restoration initiatives were discussed that rely upon the cooperation of operating mining companies and environmental groups. Through shared commitments to sustainable mining practices, funding of restoration projects, and electing productive over prohibitive stakeholder engagement, decades-old

impacts in the Blackfoot River drainage have been achieved, funded by continued operations and guided by good science, and ideally, this model could be expanded elsewhere.

After two action-packed days filled with engaging presentations, a Reverse Expo, countless swag grabs and the forging of new friendships, the IMC wound to a close on Tuesday, October 29, 2024 with an energetic reception, much soughtafter vendor and sponsor giveaways, and fond farewells. If this year’s event is any indication, much will happen between now and the 2025 IMC. New initiatives in the education sector will materialize and will benefit from increased industry interaction, progress will be made on a host of mining projects that will define the profile of Idaho’s mining industry for decades to come, intriguing innovations in the way we collect and process data will increase our capacity to identify and develop mineral resources, and (hopefully) the values of all stakeholders in Idaho’s mining industry will find new common ground. With comparable sponsor and vendor support, with Ben Davenport’s strength of leadership, the tireless coordination of the IMC Planning Committee (shout out to Alli Stice) and with the support of every one of you, the IMC will continue to be the catalyst for fomenting positive change.

Achievement of successful and sustainable growth fueling an increased diversity of opportunity. Critical mass. s

By Todd Glindeman and Kelly Collins, Brown and Caldwell

Idaho’s 2025 triennial review process is underway. This process, required by Section 303 of the Clean Water Act, requires states to modify and improve water quality standards at least once every three years. The Idaho Mining Association, led by executive vice president Ben Davenport, continues to be actively engaged in representing the mining industry’s interests as an active stakeholder.

Water quality aquatic life criteria for copper: Biotic Ligand Model Idaho Department of Environmental Quality (IDEQ) published guidance on

copper toxicity and the Biotic Ligand Model (BLM) to implement the copper criteria for aquatic life (22404 (idaho.gov)), replacing U.S. Environmental Protection Agency’s (EPA’s) 2007 hardness-based aquatic life freshwater quality criteria for copper (Copper Biotic Ligand Model | US EPA).

BLM uses 10 water quality parameters to calculate the bioavailability and toxicity of copper to aquatic life. Many water quality characteristics, including pH, alkalinity, dissolved organic carbon, and hardness, can affect the bioavailability, and thus the toxicity of a metal like copper.

Traditional copper criteria do not ac-

count for pH or natural organic matter effects, these criteria can be overly stringent or underproductive, or both, at different times (Tools to Estimate Missing BLM Parameters (epa.gov)).

EPA published three rules to address Tribal water quality.

• Water Quality Standards Regulatory Revisions to Protect Tribal Reserved Rights, proposed December 5, 2022, finalized May 2, 2024. This rule directs the state, to the extent supported by available data and information, to consider Tribal-reserved rights in setting water quality standards (WQS).

• Federal Baseline Water Quality Standards for Indian Reservations, proposed May 5, 2024. This proposed rule establishes uniform WQS to protect Tribalreserved rights to aquatic resources. EPA will consult with each Tribe on the baseline WQS to address location-specific water quality conditions and Tribal circumstances.

• Clean Water Act Section (CWA) 401 Water Quality Certification Improvement Rule, finalized September 2023. This rule states that Tribes have the responsibility to determine whether a discharge from another jurisdiction will violate its water quality requirements and should not be permitted. This rule affects permits is-

sued under CWA Section 402 (National Pollutant Discharge Elimination System [NPDES] permit) and CWA Section 404 (Dredge and Fill permit).

Clean Water Act lawsuits in Idaho

Two recently decided lawsuits show that the scope of the CWA is still in contention. In the first case, the Idaho Conservation League sued Shannon Poe for conducting suction dredge mining without an NPDES permit in the South Fork of

Court of Idaho and the U.S. Ninth Circuit Court of Appeals ruled against Mr. Poe, who petitioned the U.S. Supreme Court. In July 2024, the Supreme Court declined to hear Mr. Poe’s petition and left in place the lower court ruling that prohibits Mr. Poe from mining in the South Fork without obtaining required permits.

In the second case, EPA filed suit alleging that Ace Black Ranches in Bruneau, Idaho conducted work that altered the Bruneau River and surrounding wetlands without obtaining a CWA 404 permit. In

tion to dismiss the suit based on the U.S. Supreme Court ruling in Sackett v. EPA, which held that only wetlands with a continuous surface connection to a navigable water are jurisdictional. The case is pending.

Todd Glindeman is Brown and Caldwell’s (BC’s) mining market sector leader, and Kelly Collins, managing hydrogeology principal, specializes in regulatory compliance at BC. BC provides compliance and permitting, industrial water, and site investigation and remediation support services

By Peter J. Smith IV

The allure of untapped mineral resources on federal land has sparked a renewed interest in mining claims across Idaho. However, navigating the legal landscape of unpatented mining claims can be daunting for those unfamiliar with mining laws and regulations. As a mining lawyer specializing in federal land claims, I recommend the following due-diligence process to ensure your investment is secure and your rights are protected.

Unpatented mining claims on federal land fall under the purview of the Mining Law of 1872 and are administered by the Bureau of Land Management (BLM). These claims grant the holder the exclusive right to explore, develop, and extract valuable minerals, but they are subject to specific requirements and regulations to maintain fairness in resource allocation.

The due-diligence process

1. Claim documentation review: The duediligence process begins with an examination of all claim-related documents. This includes verifying that the location notice was properly filed with the BLM and recorded in the County within 90 days of the claim’s location.

2. Chain of title examination: Who owns a claim is a question answered by a review of the chain of title in the County records. This involves tracing the claim’s ownership from its original location to the present day by examining deeds, leases, options, and other relevant documents. This process verifies that the claim has been conveyed from one owner to the next and that there are no outstanding liens or encumbrances. I will also confirm that the affidavit of assessment work has been recorded each year in a timely manner.

3. Affidavit of assessment work: Idaho

law states that an affidavit of assessment work is evidence that the owner intends to maintain a claim. It should be recorded by November 1st each year. Though the failure to file the affidavit will not invalidate a claim, it may call into question whether the claim was properly maintained.

4. BLM records research and maintenance fees: While the BLM records are not determinative on claim ownership, it is essential to research BLM records related to each claim. These records provide insights into the claim’s history, ownership, and highlight any regulatory compliance issues that may need

to be addressed. The most important thing to check is whether the maintenance fees have been paid. If they have not, the claim is void.

The due-diligence process serves several critical purposes:

• Confirming validity: It ensures that the claim documents were filed and recorded correctly, adhering to federal and state legal requirements.

• Protecting your investment: By identifying potential legal issues early on, you can avoid costly disputes and protect your investment.

• Ownership: The chain of title review will tell you whether the person claiming to own the claim really does. If there are red flags, then you need to know them before investing money on the development of the minerals.

• Ensuring compliance: Thorough due diligence helps you understand whether there are potential issues, such as a failure to pay annual maintenance fees or record affidavits of assessment work, to prevent claim forfeiture.

Thorough due diligence is an investment in the long-term success of your mining venture. By examining the legal and technical aspects of each claim, you can mitigate risks, make informed decisions, and ensure a solid foundation for your mining operations.

Peter Smith IV practices in the areas of mining, business, and real estate. In 2015, he co-founded Smith + Malek, an Idahobased business firm that serves the western U.S. He currently serves as an at-large member of the Idaho State Bar Real Property Law Section, is the president of the North Idaho College Foundation, Inc., and is the vice-president of Schweitzer Alpine Racing School, Inc. Smith has applied his breadth of experience in litigation and transactional matters with renewed focus on mining law and is assisting mining companies with claims, leases, and permitting on private, state, and federal land. s

By Chris Paul, CEO & Director

The mythological hero, Hercules, is a story known to most of us.

The Greek and Roman tale has lasted through the ages, largely thanks to his epic feats and daring adventures that have influenced and inspired countless others throughout the centuries. Even today, the Hercules name is associated with strength, determination, resilience and power.

So, what better name for an exploration company and up-and-coming mineral project than Hercules? We like to think there isn’t one.

When our team first entered the toptier mining jurisdiction here in Idaho in 2021, the then Hercules Silver Corp. was determined to rediscover Idaho’s lost silver district. The more than 28,000 meters

of historical drilling in the 1960s through 1980s had left behind significant targets for this versatile mineral. But then, in 2022, during our exploratory drilling of those potential silver targets in Washington County – we struck gold! Actually, it was copper, and our primary objective immediately changed.

Now, we are pleased to reintroduce ourselves as Hercules Metals Corp., an exploration company that is focused on developing America’s newest porphyry copper belt.

Hercules Metals Corp. is diversifying its metals portfolio to include a large, zoned porphyry and a silver-lead-zinc system. Through our two years of aggressive exploratory drilling, we have discovered a series of stacked thrust sheets that hold

Hercules Metals Corp. is an exploration company that is focused on developing America’s newest porphyry copper belt.

rhyolite-hosted silver mineralization, and directly below that lies the massive Leviathan porphyry copper system.

It seems fitting that the Hercules Project holds one of the largest and most important discoveries of copper in our region, especially when the name itself is synonymous with power.

Copper is power.

It is the critical component in circuit boards for phones, computers, and power tools; it is used to make batteries for

Hercules Metals is continuing to identify and develop Washington County’s copper potential because of how crucial this particular development is to the betterment of not just our state, but the entire country.

electric cars, to run wind turbines and solar energy systems, and it is the base for electrical wiring in homes, appliances and telecommunication links.

Hercules Metals is continuing to identify and develop Washington County’s copper potential because of how crucial this particular development is to the betterment of not just our state, but the entire country. By having a domestic supply of copper, we will help create a more resilient energy system and eliminate our reliance on foreign entities. And while this quest for essential minerals is not easy, Hercules Metals is determined to wholeheartedly continue to tackle this undertaking

through rigorous exploration involving core and reverse circulation drilling, soil sampling, geophysics and field mapping.

We have also been working diligently with the U.S. Forest Service to expand our exploration targets to better understand the Leviathan system’s potential. Just this past summer, we were granted permission to drill-test two additional priority target areas, neither of which have been tested below the depth of shallow epithermal silver mineralization to the underlying Leviathan copper system. These will include up to 15 additional drill sites through the end of August 2025. We will work on an environmental assessment for the entire

Hercules Property to secure a longerterm drill program on these public lands. We want to know just how deep this rare deposit goes.

The story of Hercules is one of endurance and perseverance, a man who willingly embraced the most daunting of missions and bravely stood against all odds. Hercules Metals Corp. embodies those same qualities in its pursuit of mineral discovery. We know the best is yet to be uncovered, and we are determined to be an even stronger company and formidable ally in the continued exploration of the great state of Idaho. s

By Mark Barton, Virginia Gillerman, Scott Gifford, Idaho Geological Survey

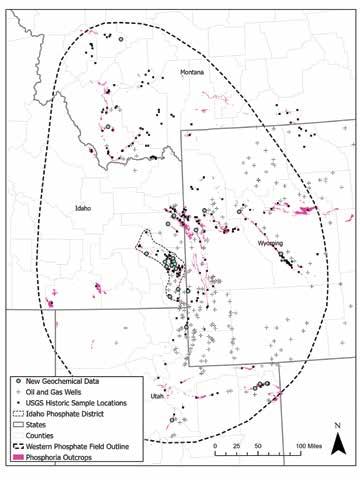

The Permian Phosphoria Formation, spanning parts of Idaho, Utah, Wyoming, and Montana, is one of the world’s largest sources of phosphate rock. This area, known as the Western Phosphate Field (WPF), has been mined for phosphorus – a key ingredient in fertilizers – since the early 1900s. Exploration

of the WPF began in the 1890s, as miners and scientists sought to unlock the region’s vast resource potential. Today, our project is building on this rich history, combining traditional exploration data with modern technology to better understand and utilize this critical resource.

The Phosphoria Formation is made up of thick layers of phosphorite, siltstone, carbonate rock, and chert, formed millions of years ago when the region was covered by shallow seas. The richest phosphate deposits are found in two key layers, known as the Meade Peak and Retort Members. In addition to phosphorus, these geological conditions also concentrated valuable minerals like rare earth elements (REEs), vanadium, chromium, and fluorine. While these minerals aren’t currently being mined, the large resource potential and existing mining infrastructure indicate that they could become a significant domestic source of critical materials in the future.

The Earth MRI Western Phosphate Field Study aims to explore this potential further. Funded by the Earth MRI initiative and led by the Idaho Geological Survey in partnership with Montana, Utah, and Wyoming, the study focuses on better understanding the phosphate deposits and their critical mineral content. The project involves three main components: (1) compiling existing geological, geochemical, and geophysical data, (2) collecting new geochemical data, and (3) mapping potential ore zones within the regional stratigraphic framework.

We’ve gathered and digitized detailed records from over 300 historic exploration sites, primarily from the US Geological Survey (USGS) exploration programs. This data includes information on rock types, their thickness, and their basic chemical composition. We’ve converted this data into digital LAS files that can be imported into 3D geological modeling programs.

Additionally, we’ve collected geophysical logs – including

Figure 2. The Meade Peak Member of the Phosphoria Formation is exposed in an abandoned mine. The Meade Peak Member, a black to brown phosphorite-, siltstone-, and carbonate-rich unit is bound by the browncolored Rex near the top, and the grass covered Wells Formation on the bottom left. This exposure is approximately 200 feet high.

gamma ray, photoelectric, and density logs – from 275 oil and gas wells that intersect the Phosphoria Formation across the WPF. One of our key tools is the gamma log, which measures natural radiation in rocks. The natural radiation corresponds well with the phosphate content in the Phosphoria. This tool allows us to discriminate key lithologies within the Phosphoria Formation. It is also used by the phosphate mining companies in their exploration programs and allows us to extend our 3D modeling across the study area. Combing the historic sampling data and well logs give us a more complete view of the Phosphoria both at the surface and subsurface.

Our project goes beyond revisiting historical data; we’re actively collecting new geologic and geochemical information to assess the potential of rare earth elements (REEs) and other critical minerals in the Phosphoria Formation. Previous research left significant gaps in geochemical data, and our new data collection program aims to fill these gaps. We’re sampling from various locations such as mines, roadcuts, and natural rock exposures. Collaborating with teams in Montana, Utah, and Wyoming, we’ve collected nearly 1500 samples from 37 sites. Our comprehensive sampling program aims to measure, describe, and collect rock samples representing every bed. Collecting high-quality samples

often requires significant trenching because of the soft, erosive nature of these rocks. Some of our best sites have over 200 continuous feet of rock, while others, especially on the margins of the study area, are much thinner. We are especially grateful to Itafos, Bayer, and Nutrien for providing access to their excellent mine exposures and core.

These samples are analyzed by the USGS to determine their chemical content, focusing on REEs and other minerals essential for modern technologies. Alongside this analysis, we’re capturing detailed photographs of each sample and creating visual representations of the study sites. By merging these new findings with historical data, we’re piecing together a comprehensive picture of the WPF.

Figure 4 presents a log of the geochemical data, illustrating the types of ore zones present. Phosphorite, mined from both the upper and lower ore zones, is widespread throughout the section. However, the distribution of critical minerals varies: Vanadium is concentrated in both the upper and lower ore zones, while rare earth elements (REEs) are more enriched in the phosphorites of the central waste zone.

Sequence stratigraphy is employed to define the ore zone stratigraphy. By analyzing well log data – such as gamma ray, re-

We’re sampling from various locations such as mines, roadcuts, and natural rock exposures. Collaborating with teams in Montana, Utah, and Wyoming, we’ve collected nearly 1500 samples from 37 sites.

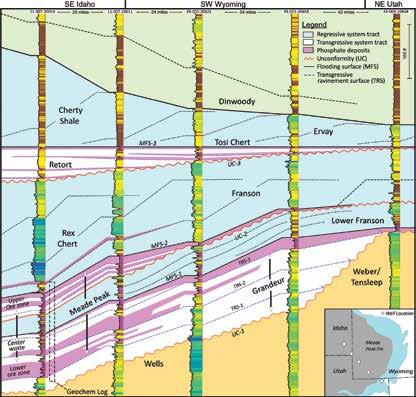

Above: Figure 5. Cross-section illustrating sequence stratigraphic relationships across the Phosphoria Fm that extends from the center of the Meade Peak basin in SW Idaho to its margin in NE Utah. Phosphate deposits that represent potential critical mineral ore zones are shown in pink.

Left: Figure 4. Geochemical log from the Meade Peak Member, Idaho. The log is 180-feet thick with the base on top of the Grandeur Formation and the top at the base of the Rex Chert Formation.

Columns from left to right are: mine stratigraphic subdivisions, rock type (phosphorite-pink, detritus-yellow, chert-green, blue-carbonate-blue, organic matter-grey), P2O5, Vanadium (V), and the Rare Earth Element Enrichment Factor (Ree EF) relative to NASC.

sistivity, and sonic logs – alongside lithologic logs from outcrops, geologists can identify key stratigraphic surfaces, including sequence boundaries, which indicate periods of erosion or non-deposition, and maximum flooding surfaces, which mark the peak of transgression. These surfaces assist in classifying sedimentary units into system tracts – regressive, lowstand, and transgressive – that represent various depositional environments with different potentials for sediment-hosted ore deposits. By correlating these stratigraphic surfaces and facies patterns across multiple wells and logs, geologists can build a 3D model of the sedimentary

basin and map the distribution of sediment-hosted ore bodies within it. This framework enhances the understanding of sedimentary processes and mineralization patterns, thereby aiding in the identification of the most promising areas for exploration and extraction. An example of a sequence stratigraphic interpretation of the ore zone stratigraphy for the Phosphoria Formation is shown in Figure 5. Phosphate deposits that have the potential to host critical minerals are best developed in the transgressive systems tracts.

Understanding the mineral content of the WPF is crucial for identifying resources vital to technology and industry. Our project will highlight the value of these minerals and offer insights for developing new genetic models of metal enrichment in marine chemocline systems that support efficient exploration and development of such deposits. s

By Virginia Gillerman, Mark Barton, Scott Gifford, Reed Lewis, Christopher Tate, Claudio Berti, Idaho Geological Survey (IGS)

The mineral industry in Idaho continued to follow trends from 2023 into 2024, driven by favorable precious metal prices, particularly for silver and gold, though criti-

cal commodities like cobalt and lithium experienced significant price declines. Mining activity in the state’s two worldclass districts, the Coeur d’Alene (Silver Valley) and Phosphate district (Figure 1), remained strong. North Idaho’s silver and gold operations, such as Hecla’s Lucky Friday mine and Americas Gold and Silver Corporation’s Galena mine, saw increased productivity, aided by innovations and exploration success. Meanwhile, Bayer, Itafos, and Simplot continued phosphate extraction in southeastern Idaho. However, the industry still faced challenges from lengthy permitting, legal issues, and public perception, all of which weighed on the pace of development.

In the Silver Valley, Hecla’s Lucky Friday mine operated at full capacity with lower costs due to their new UCB (underhand closed bench) mining method. The Galena mine, operated by Americas Gold and Silver, benefited from completion of the Sprott-financed rehabilitation work, a new hoist, and new stopes. The Bunker Hill Mining Corporation continued site cleanup and began constructing facilities needed to restart their historic Bunker Hill mine. Work included upgrading the underground ventilation, building a fine ore bin, and beginning the foundation for a new processing plant in Kellogg. Idaho Strategic Resources increased production at their Golden Chest gold mine in Murray. Their past drilling program was very successful, and the newly discovered H-vein is higher grade (Figure 2).

In the Phosphate district, Simplot, Bayer and Itafos were all operating and shipping phosphate ore to their respective plants. Bayer continued mining the south pit at their Blackfoot Bridge mine with concurrent reclamation (Figure 3). Bayer and the Bureau of Land Management

were actively revising the mine plan and Environmental Impact Statement for the Caldwell Canyon project, following a court decision that vacated the original plan in late 2023. Despite this setback, Bayer continued to advance critical engineering and construction efforts, including the installation of a new ore-handling system on private land near their plant. At the same time, Itafos made significant progress by securing a permit for its Husky/N Dry Ridge project in late 2023 and began actively mining N Dry Ridge this summer.

A promising development in late 2023 and into 2024 was Centerra Gold’s deci-

sion to initiate waste stripping for a high wall pushback at the Thompson Creek molybdenum mine in Custer County. This move aims to access the permitted Phase 8 ore. The mine had been placed under care and maintenance in 2014 due to low

molybdenum prices. However, by 2023, molybdenum prices had surged to nearly four times their 2013 levels, prompting Centerra to complete a pre-feasibility study for a phased mine restart. As of September 2024, the spot price of molyb-

denum was around $30 per pound.

Most of Idaho’s smaller industrial mineral operations remained active, with aggregate producers staying especially busy supplying material for significant construction growth and roadwork. How-

ever, Emerald Creek Garnet in northern Idaho remained inactive. In the Boise area, Table Rock Sandstone, which operates the historic quarry above the city, was sold to a new owner in early 2022. The quarry, known for its high-quality silicified sand-

stone used in building projects and landscaping rock, is now focusing more on the dimension stone market, with several new projects underway in Boise.

Exploration activity for metals, while slower in 2024 due to challenging metal prices and financing, did see some key developments. Notably, Hercules Silver discovered a promising copper porphyry deposit in western Idaho near Cambridge, leading to increased interest and investment. The impressive results from the discovery hole HER-23-05 were confirmed by several subsequent drill holes in 2023. Following this success, Barrick Gold acquired a significant stake in the junior company, and exploration continued through the fall and winter of 2023 into 2024, generating considerable interest and prompting competitors to stake claims across the belt.

Hercules’ surface mapping and IP/ chargeability surveys continued in 2024, identifying new targets and structural trends by July. In June 2024, Hercules Silver rebranded as Hercules Metals Corporation to reflect its newly discovered copper deposit. Drilling to explore the copper zone, located beneath the TriassicJurassic unconformity, persisted throughout spring and summer 2024, despite some drilling challenges through faulted zones. A new permit was secured from the Forest Service to expand property access and widen roads for deep RC drilling. Additionally, Hercules acquired land in the Mineral District to the south.

Several other companies explored Idaho’s accreted terrains, including Scout Discoveries at the IXL property on Cuddy Mountain (just east of Hercules), NevGold, Zeus Mining, and Barrick. Scout also conducted drilling near Elk City at Robbers Gulch in spring 2024.

The long-awaited Final Environmental Impact Statement and Draft Record of Decision for Perpetua’s Stibnite Gold Project were released September 6, 2024. The document authorized the 2021 Modified Mine Plan for their mine in Valley County. This initiated the 45-day appeals process. The NEPA permitting application for the project was initially submitted in 2016, and calls for mining 4.5 million ounces of gold and 148 million pounds of antimony in addition to restoring the heavily impacted historic mining area. The U.S. Department of Defense awarded Perpetua millions of dollars to help jump-start a domestic antimony supply chain. The high-grade antimony-sulfide Stibnite is found in veins throughout the gold-mineralized rock (Figure 4).

Three advanced gold projects in Idaho are transitioning from exploration to permitting:

1. Revival Gold (Beartrack and Arnett Creek properties, Lemhi County):

In 2024, Revival Gold focused on surface mapping, sampling at underexplored areas, and geophysical work. The company is evaluating the economics, permitting needs, and baseline data to potentially restart a heap leach operation.

2. Integra Resources (DeLamar project, Owyhee County):

After releasing a new NI 43-101 technical report and mineral resource estimate in October 2023, Integra submitted a preliminary mine plan to the Bureau of Land Management (BLM) in late 2023. The BLM accepted the plan in June 2024, allowing the NEPA Environmental Impact Statement (EIS) process to begin. The project targets an oxide heap leach for 43 million tons of material, grading 0.3 g/t Au and 11 g/t Ag. Following its 2023 merger with

Millenium, Integra sold a 1.5 per cent net smelter royalty (NSR) to Wheaton Precious Metals Corporation for $10 million in February 2024. In July 2024, Integra merged with Florida Canyon Gold based in Nevada, and continued engineering and planning at DeLamar.

3. Liberty Gold (Black Pine project, Cassia County):

In July 2024, Liberty Gold launched a 20,000-meter reverse circulation drill program after securing an expanded exploration permit from the U.S. Forest Service. Liberty also pursued baseline studies and secured water rights for the project.

Despite high and stable precious metal prices during 2023-2024, cobalt and most

rare earth element prices slumped, negatively impacting projects in the Idaho Cobalt belt. Electra Battery Materials, which holds the Iron Creek Cu-Co project in Lemhi County, halted drilling to focus on completing a cobalt refinery in Ontario, Canada. The process uses “black mass” waste, and eventually, mine feed to produce cobalt sulfate and other products. Electra’s efforts were supported by grants from the Canadian government and a $20 million award from the U.S. Department of Defense under the Defense Production Act in August 2024. Additionally, Electra conducted surface exploration near Iron Creek and found new mineralized zones.

At Jervois Mining’s Idaho Cobalt Op-

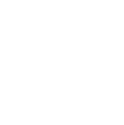

Figure 5. Location map showing regional geology of the Cuddy Mountain region, area of geologic mapping (blue outline) and proposed area for USGS Geophysical Survey (red outline).

eration, construction has been suspended since March 2023 due to the low metal price and financing challenges. However, in late 2023, the company resumed drilling at the Sunshine prospect, located just west of the main Blackbird horizons. A $15 million award from the U.S. Department of Defense helped fund this drilling work.

In support of the renewed interest in the Cuddy Mountain region, the Idaho Geological Survey is focusing new efforts in understanding the complex regional geology of the area as terrane correlations, geologic histories, and structure of the region in question are poorly constrained. The Idaho Geological Survey is conducting new geologic mapping in all or parts of seven 7.5’ quadrangles at a scale of 1:36,000 (Figure 5). To augment our geologic mapping objectives, we are collecting rock samples in the Cuddy Mountain region and submitting these samples to the USGS facility in Denver for geochemical characterization and to Boise State University for geochronology.

Field work is being conducted primarily by one geologist currently supported by a University of Idaho post-doc appointment, with assistance from two long-time IGS geologists as needed. IGS mapping strategy involves consolidating and verifying interpretations from six legacy thesis maps, one USGS open file report, and two private industry geologic maps from the region that range in age from 19691987. Field work started in the spring of 2024 and will continue through 2026. Additional analytical work involves geochronologic and isotopic studies to better characterize the terranes, and the age and style of mineralization within them.

This effort directly addresses the EarthMRI goal of inaugurating a government-

Figure 6. Oversized maps of mines in the Silver Valley being prepared for processing in IGS digital archives.

wide effort to strengthen and sustain the nation’s critical mineral supply chains as Mn, Zn, Sb, and Ba, which are listed by the USGS as critical minerals. IGS is also actively pursuing funding for a proposed regional geophysical survey over the larger region (Figure 5). Most of the Cuddy Mountain area is on federal and state land and open for mineral entry. This work will provide baseline science in support of all stakeholders for any future development in the Cuddy Mountain area.

For over 15 years, IGS, in conjunction with the Idaho Department of Lands and U.S. Geological Survey, has been involved with digital data preservation activities. These efforts have resulted in the scanning of historic mine maps, assays, geologic and mine reports, images, and drillhole maps, amounting to over 20,000 documents including digitized video files. All are available for download at no cost to the public. Data preservation efforts at IGS have resulted in millions of dollars of investment in the state of Idaho from the mining industry, particularly during exploration. Other users of IGS data preservation products include students, academics, historians, anthropologists, genealogists, hobby miners, gem collectors, and state and federal agencies.

Web map applications are the primary portal for discovering and obtaining data concerning Idaho mines, and oil and gas extraction and exploration activities. A new option on the web app allows users to filter for critical minerals, which are present at roughly one-third of the mines and prospects in Idaho. Additional LAS files are available for more oil and gas wells, and these too can now be filtered on the web app.

The IGS continued cataloging and processing an extensive collection of material donated by Don Adair, an exploration geologist who worked extensively in Idaho for decades. Processing of documents is currently underway for sites of interest to industry from Weiser to Cuprum, including the Almaden, Blue Dog, IXL, and Hercules properties. The Survey finished reviewing previously cataloged material for Idaho properties in the Pullman 1°x2° USGS quad. This marks the end of

a multi-year project to review material in each quadrangle. In another ambitious data preservation endeavor, IGS collected a donation of several thousand oversized maps of mines in the Silver Valley (Figure 6). Processing of these is expected to begin next year.

For more information on any of the ongoing projects or products and databases released by IGS, please visit the Survey’s webpage at www.idahogeology.org. s

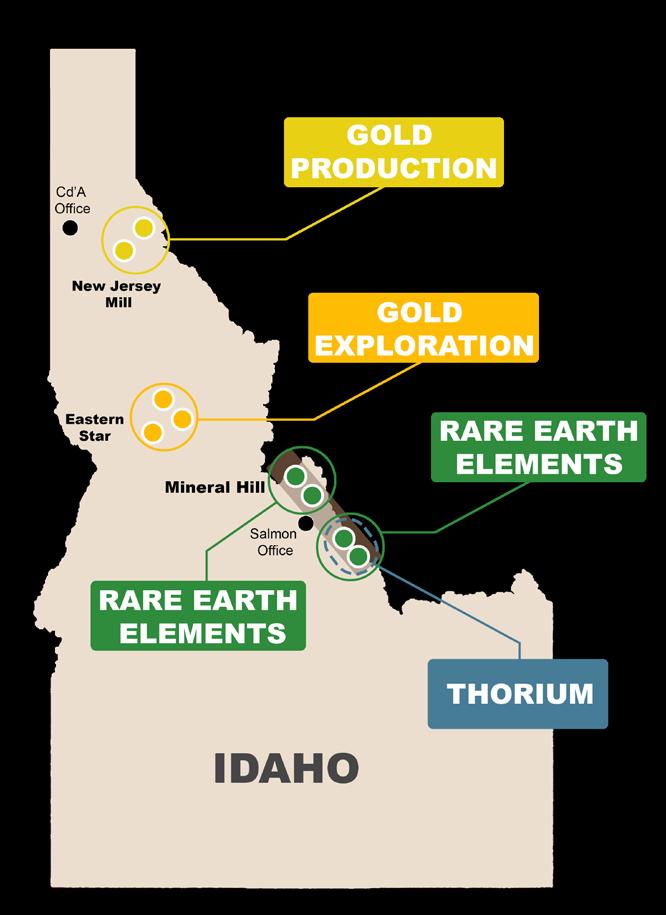

Idaho Strategic plans to expand its rare earth elements exploration efforts in 2025 to build on its successful exploration programs the prior two years.

Idaho Strategic Resources, Inc. (NYSE American: IDR) produces gold at its 100 percent owned Golden Chest Mine located in the historic Murray Gold Belt District adjacent to the worldrenowned Silver Valley Mining District. While the Golden Chest Mine sits on approximately 220 acres, Idaho Strategic owns and controls more than 7,000 acres of land (1,500 acres of private land and 5,800 acres of unpatented claims) comprising nearly all of the historic Murray Gold Belt District. Given Idaho Strategic’s profitability and in-house exploration and mine development expertise, the company has the potential to organically grow its operations to include multiple mines within the Murray Gold Belt District and elsewhere.

In addition to gold production and ongoing gold exploration, Idaho Strategic is the largest rare earth elements landholder in

the United States with approximately 18,000 acres of mineral claims spread across three separate projects: Lemhi Pass, Mineral Hill, and Diamond Creek. Idaho Strategic plans to expand its rare earth elements exploration efforts in 2025 to build on its successful exploration programs the prior two years. The company’s Lemhi Pass project has displayed a unique mix of rare earth elements that includes nearly 60 percent magnet rare earth elements enrichment in samples that range from one percent to greater than five percent total rare earth oxides (TREO).

At the company’s Mineral Hill project, exploration efforts have returned numerous repeatable rare earth elements grades in excess of 30 percent TREO. All three of Idaho Strategic’s rare earth elements projects are listed in the United States’ National Critical Minerals Inventory and are well documented in a number of

In addition to gold production and ongoing gold exploration, Idaho Strategic is the largest rare earth elements landholder in the United States with approximately 18,000 acres of mineral claims spread across three separate projects.

Given the company’s diverse and substantial mineral assets, combined with its focus on the long game, Idaho Strategic is replicating the successful business plans that were once the accepted norm in the mining industry.

United States Geological Survey reports. In addition to rare earth elements, the company’s Lemhi Pass project is also highly regarded as the United States’ largest source of thorium resources – a mineral that serves as a potentially safer and much more environmentally friendly fuel source for next-generation nuclear reactors.

Given the company’s diverse and substantial mineral assets, combined with its focus on the long game, Idaho Strategic is replicating the successful business plans that were once the accepted norm in the mining industry. This includes a focus on running a lean operation designed to maximize free cashflow to allow for organic expansion potential without the risk of falling victim to institutional pressures or an over-levered balance sheet. Idaho Strategic has a number of father-son, uncle-nephew, husbandwife, and various sets of brothers working together at the company, and nearly all of Idaho Strategic’s 55 employees live in the communities near its mining operations. The company enjoys the strategic value from both an environmental stewardship and mine safety perspective of employing local families – an advantage that is quickly acknowledged by outsiders while visiting the company’s operations and interacting with Idaho Strategic’s employees.

Overall, the company’s production-based exploration business plan has led to eight consecutive quarters of GAAP profitability while funding the discovery of numerous additional areas of potential mine production at the Golden Chest Mine, including both the high-grade H-Vein and the recently discovered Red Star Vein. And all while funding the construction of a paste backfill plant at the mine, which the company expects will serve as the future home of its planned flotation mill onsite.

Please visit idahostrategic.com to learn more.s

The concept of returning to old mining districts is not new to the mining industry as an exploration tool; however, an interesting project development template is emerging in Idaho.

The first discovery of gold in Idaho occurred in 1860 and mineral activities were prolific well into the early 1900s. Silver Valley, Orogrande, Simpson, Florence, Dixie, Salmon River Canyon, and many others were lucrative mining districts, some remain active today. Mineral patents were issued throughout these mineral districts. In many cases, districts were active into the early 1900s until U.S. Order L-208 was issued by the U.S. War Production Board on December 7, 1942 (Second World War), which shut down all gold mines in America. Many of these districts have had little or no interest or activity since that time.

Patented lands can be found through-

out these mining districts, which provides an interesting template for modern exploration and mine development.

A good example of a “New Look at an Old District” is the Simpson District which was mainly a placer mining area operated along the Salmon River near Riggins, Idaho. When placer gold resources ran out and prospectors started to search for the mother lode it resulted in numerous lode discoveries, including the present-day McKinley Mine.

The McKinley deposit was discovered in the late 1890s and was patented around 1910. Early mine development created nearly 2,000 feet of workings on five levels that all intercepted gold mineralized zones. The history of mining activities was not well documented, but it is reported that mining averaged 10 ounces per ton. Activities were suspended some time prior to or due to Order L-208. Evaluation of these deposits by prospectors

were limited following the Second World War.

The project is currently in early-stage development, managed by Klepfer Mining Services, LLC (KMS) for McKinley Mine Inc. There are approximately 70 acres of patented mining claims within the boundaries of a private land holding. McKinley Mine is considered a narrow vein gold system and recent sampling efforts have verified high-grade occurrences (+3 ounces per ton) in the existing workings.

What makes McKinley Mine standout? Patented lands and underground mining projects in Idaho provide for a higher level of certainty regarding project permitting and schedules. Permitting strategies can be developed to address air, water, and reclamation through the State of Idaho, rather than the more complex and lengthy federal permitting processes on public lands.

Many historic mining districts lie within

The McKinley deposit was discovered in the late 1890s and was patented around 1910. Early mine development created nearly 2,000 feet of workings on five levels that all

large tracts of public lands. This provides an opportunity to expand resource potential from private lands onto public lands. Staging mineral development from private patented claims to unpatented public lands can help launch a project while minimizing regulatory permitting.

Subsurface mineral activities on unpatented claims starting from private land, can generally be exempt from federal permitting programs.

These projects tend to have highergrade resource potential, and often the

mineral resources have not been fully exploited. Existing mine workings are generally available for exploration and used for initial mine development and production.

McKinley Mine has extensive workings that provide quick and cost-effective access for both exploration and eventual mine development. Qualities like these can allow projects to be brought into small-scale production sooner and at potentially lower capital costs.

Private investors are generally skepti-

cal of public land projects; however, developing private land first can generate cashflow quickly, create early investment returns, and support expanding resources on adjacent unpatented mining claims. This approach reduces uncertainty in future permitting delays.

Successful demonstration of this template can be applied numerous times and gain investor interest. Identifying quality resources and building a highly experienced team to tackle the challenges are the key to success. s

By Mckinsey Lyon, VP of External Affairs

At Perpetua Resources, we have a bold vision for the future of mining – and it’s a future that’s rooted in our past.

The Stibnite Mining District, which is home to our site, saw over 100 years of mining. Our site supplied the antimony and tungsten that sustained the war effort during the Second World War.

Stibnite’s history is something we’re very proud of, however, there’s another side of the coin: a full century of mostly unregulated mining left behind serious environmental challenges that continue to impact the site to this day.

When you look at Stibnite, you see problems. Millions of tons of legacy waste and tailings sit unconstrained, leaching arsenic and antimony into the water. The East Fork South Fork of the Salmon River flows directly into an abandoned mining

pit, which has blocked fish migration to miles of prime spawning habitat for more than 80 years. And throughout the site, habitat conditions are degraded and in desperate need of repair.

We knew all of this from the outset. Rather than running from it, we used the site’s legacy to propel our future. From the beginning, our motto has been “restore the site.”

We have an opportunity to rewrite the legacies of the past, and we believe that the future of responsible American mining lies in places like Stibnite.

The Stibnite Gold Project is a first-ofits-kind mining project that doesn’t simply return the site to reclamation standard – it restores it.

Our project will remove and safely store millions of tons of legacy mine waste and

tailings that are polluting the river. We will reconnect fish to miles of their spawning grounds for the first time in over 80 years. And we will leave Stibnite better than we found it.

The Stibnite Gold Project is a win-winwin. Our project will restore the environment; it will produce one of the highestgrade and lowest-cost U.S. sources of gold and the only domestically mined source of the critical mineral antimony, which we need for national defense and clean energy. And it will benefit Idaho’s communities for a generation to come.

That’s the beauty of the Stibnite Gold Project: it is all of the above. The gold and antimony resources we have in Idaho are nothing short of incredible, and we are proud to propose a project that will mine those resources responsibly and ethically

right here in the Gem State.

In terms of our permitting timeline, we have reached the final countdown.

In September 2024, we received our Final Environmental Impact Statement and Draft Record of Decision authorizing our mine plan after 14 years of community engagement and scientific study, and our Final Record of Decision is scheduled to be handed down at the end of 2024.

From the very beginning, we’ve used our history to path-find our future. Perpetua has worked incredibly hard to bring this vision to life, and we have never been closer to making it a reality.

The Stibnite Gold Project comes with a deep, ingrained sense of responsibility: responsibility to the land, to the community, and to the place we are so fortunate to call home.

Responsible, modern mining can address the mining legacies of the past, and we are ready to move forward. We are proud to be a company that, at our core, is committed to doing this right. s

Restore an abandoned mine site

Produce American-made critical minerals

Create a more secure future.

Idaho now has its very own Fort Knox, only substantially larger.

After three years of planning and construction, Money Metals has opened its state-of-the-art 37,000-square-foot vaulting and fulfillment facility in Eagle, Idaho. Nestled into the base of the Boise Foothills, Money Metals’ high-security gold and silver storage compound cost $28 million to construct, has the capacity to hold upwards of $100 billion in gold and silver, and can be further expanded to 60,000 square feet.

Built on a 3.2-acre lot adjacent to city and county police and emergency services, the new depository offers an extremely secure location for individuals, businesses, family offices, governments, and financial institutions across the globe to store highvalue precious metals assets. Embedded into the facility are advanced security measures, around-the-clock monitoring, secure access controls, a security team composed of armed former law enforcement and military personnel, and third-party audits and insurance to ensure the highest standards of integrity and protection.

Money Metals’ Class 3 vault is the largest in North America,

Money Metals has opened its state-of-the-art 37,000-squarefoot vaulting and fulfillment facility in Eagle, Idaho.

providing nearly 9,000 square feet in ultra-secure storage space, more than twice the capacity as the United States Bullion Depository at Fort Knox, Kentucky (Class 3 is the highest possible vault rating possible in accordance with Underwriter’s Laboratory [UL] standards).

The opening of this new depository for storage of gold and silver in the Gem State has already attracted attention from industry players across the U.S. and internationally, not only because of its size but also because most depositories are located in the major financial centers of the northeast United States.

“We’ve seen growing demand for storage of precious metals in a location that is independent of, and removed from, Wall Street, the federal government, and the big banking centers,” said Stefan Gleason, president and CEO of Money Metals. “Idaho is perceived as a safer location than the northeast U.S. for a variety of reasons, including the fact that it is a generally pro-freedom state with less intrusive government, a heavily armed citizenry, and lower levels of crime.”

Since its founding in 2010, Money Metals has expanded dramatically over time, establishing itself as one of the leading pre-

Money Metals offers low-cost storage options for bullion coins, rounds, ingots, and bars with comprehensive protection against theft, loss, and damage – and robust insurance backed by Lloyd’s of London. Storage through Money Metals Depository is generally more cost-effective and secure than bank safety deposit boxes, other storage facilities, and personal home safes.

cious metals dealers in the U.S. and conducting nearly $5 billion in transactions to date. A family-owned business, Money Metals began as a tiny operation with a single employee located in the historic Eagle Hotel and has since grown into an internationally recognized precious metals dealer with 100 employees. Money Metals currently delivers as many as 40,000 gold and silver orders each month and has already served nearly 750,000 customers in North America.

“Because we’ve made the process to buy, sell, and/or store precious metals so seamlessly, Money Metals is now able to handle the transactions, storage, and other needs of hundreds of thousands of customers each year,” said Gleason. “The need for this massive new depository is a testament to the significant and growing demand for physical gold and silver coming from Americans who seek refuge from the deliberate federal policy of currency debasement.”

With its extensive product inventory, fast shipping, superior customer service, and high-volume sales, Money Metals has been named Best Overall Online Precious Metals Dealer by Investopedia multiple times and has maintained an A+ rating by the Better Business Bureau (BBB). Money Metals offers low-cost storage options for bullion coins, rounds, ingots, and bars with comprehensive protection against theft, loss, and damage – and robust insurance backed by Lloyd’s of London. Storage through Money Metals Depository is generally more cost-effective and secure than bank safety deposit boxes, other storage facilities, and personal home safes.

The vision behind this massive facility was also driven by the observation that most of the legacy depositories are poorly run, plagued by slow processing times, high costs, and limited customer service.

“We realized there was a big opportunity to do things better and capture market share,” Gleason said. “We’re able to offer an array of services to precious metals investors in a seamless manner, all under one roof.”

The new depository is expected to impact the community positively by creating additional employment opportunities and bringing prestige to the area.

“While our focus is national in scope, we already serve thousands of Idaho and Treasure Valley gold and silver investors seeking a secure and high-class operation with which to do business,” Gleason said.

Looking ahead, Gleason noted that they see lots of growth coming in the precious metals market, as well as general awareness of how gold and silver are useful as financial insurance.

In addition to buying, selling, and securely shipping or storing precious metals, Money Metals offers monthly purchase plans and assists with Individual Retirement Accounts (IRAs), allowing investors to include physical precious metals in their retirement portfolios. Meanwhile, Money Metals is a leading news and education hub in the precious metals space. The company also offers collateralized loans and leads sound money public policy efforts across the United States.

The construction project involved key partners who contributed to the project’s success. Wright Brothers Construction Company served as the general contractor while Zions Bank provided financing. Other notable vendors and industry specialists involved in the project include Erstad Architects, Integrated Security Resources, The Land Group, Musgrove Engineering, Global Risk Evaluations, American Special Risk, American Vault Corporation, and Lloyd’s of London. s

Market forces continue to demand that the mining industry learn to do more with less. Fuel is a mining operations largest variable cost, however; very little focus is placed on the fueling process or even tracking where the fuel is going. FlowTech works with its customers to develop a customized and comprehensive plan to improve the fueling process from delivery, to bulk storage, to equipment refueling, to inventory tracking and reconciliation. Fueling process improvement offers mining operations a unique opportunity to easily eliminate fuel waste while maximizing efficiency.

Established in 2001, FlowTech Fueling is the leader in fueling process improvement. Our patented Fuel Overfill Prevention Systems, large-scale Mobile Fueling Depots, and FlowTran Fuel Management Systems are designed to meet the challenges of harsh mining environments. With several decades of mining ex-